Page 1

Model FC10 Flow Conditioner

Precision Mass Flow Measurement

An ON

I

CON Brand

Irregular flow

profiles

Proper flow profile

FLOW

for Gas Applications

• Reduces the need for long straight pipe

runs

• Precision, laser-cut design

• 316 stainless steel material

• Creates proper gas flow profile from

irregular flow profiles

• Negligible pressure drop

• Use with insertion style flow meters

• Available in 10 sizes for schedule 40

pipes: 1.5”, 2”, 2.5”, 3”, 4”, 5”, 6”, 8”, 10”,

and 12”

• Install upstream from the flow meter

probe between 150 lb. flanges

• Easy installation in the center of the

pipe via flange matching pipe outer

diameter (OD)

FC10

Flow Conditioner

for use with Insertion

Style Flow Meters

Flow conditioners installed upstream

of ow meters reduce the need for

long, straight pipe runs.

Installation Solutions for Limited Pipe Runs

Flow meter accuracy is often dependent on achieving a uniform flow

profile near the center of the pipe. Distortion and swirl are disturbances

in flow that can be remedied either by extending the length of space

between the cause of the disturbance and the sensing element

(increasing straight pipe runs) or by adding a flow conditioner to correct

the disturbance directly.

FOX THERMAL

399 RESERVATION ROAD

MARINA, CA 93933

PHONE: 831-384-4300

FAX: 831-337-5786

sales@foxthermal.com

www.foxthermal.com

In certain circumstances, the extra space needed to accommodate flow

meters requiring more straight pipe runs upstream or downstream of

the flow meter’s flow sensor isn’t available. In these cases, it’s necessary

to find solutions to these space limitations.

Insertion thermal mass flow meters are easy to install and require

minimal straight pipe runs. In the past, the only option to reducing

straight pipe runs for very tight spaces was to order inline flow meters

with flow conditioners. In order to give customers more flexibility,

Fox Thermal has developed the FC10 flow conditioner for use with

insertion style flow meters.

Each flow meter is calibrated with the flow conditioner to ensure the

highest accuracy.

FC10 Rev. A

Page 2

SPECIFICATIONS

Flow meter

(customer supplied)

Sizing

The FC10 was designed to be used in a variety of pipe

sizes. FC10s are available in 10 sizes for schedule 40 pipes:

1.5”, 2”, 2.5”, 3”, 4”, 5”, 6”, 8”, 10”, and 12”. For pipe sizes

outside of this range, an inline ow meter is recommended.

NOTE: For pressure drop data, please visit the Fox website.

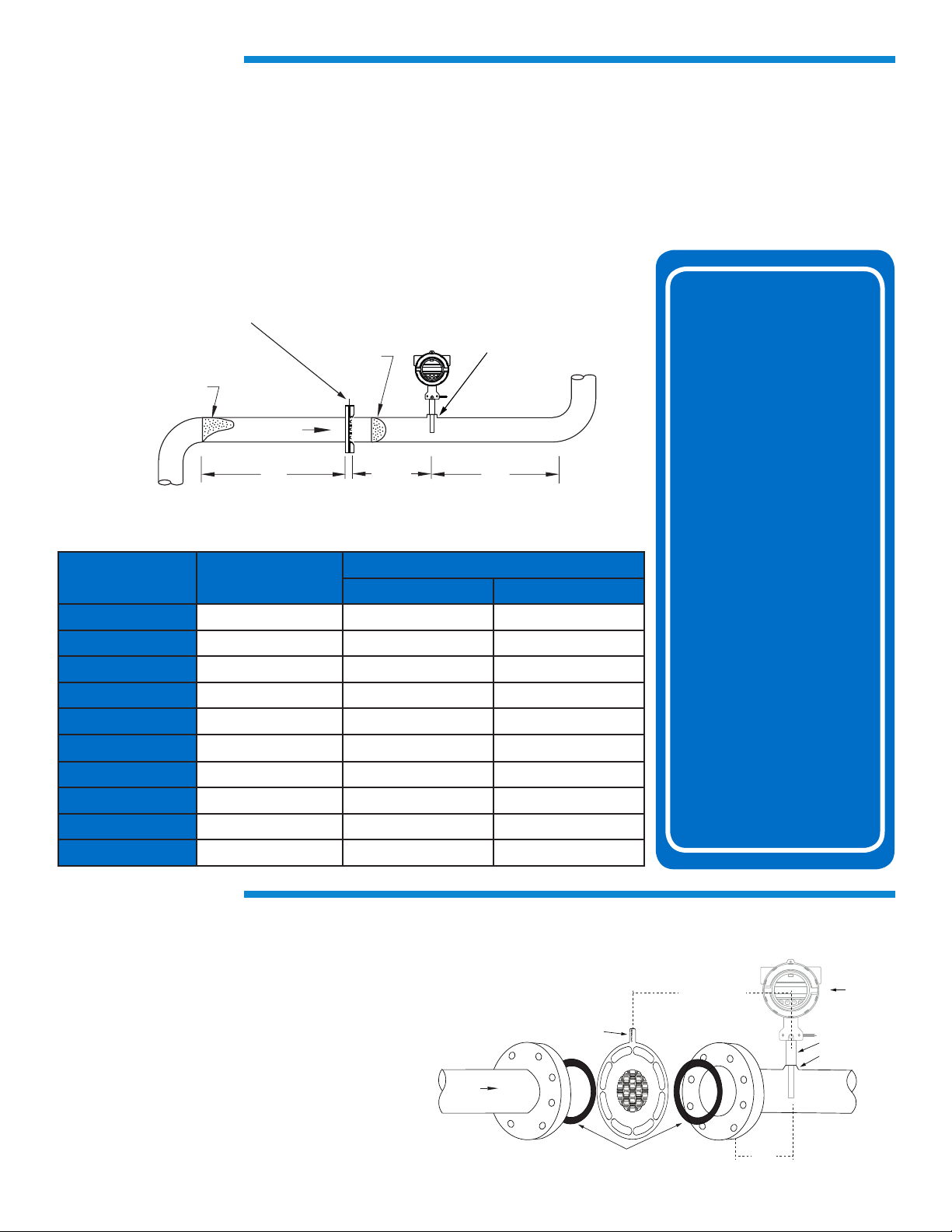

Figure 1.1: Straight Pipe Run Requirements

FC10 Flow Conditioner

installed between two flanges

Irregular Flow

Profile

FLOW

Table 1.1: Straight Pipe Run Requirements

Proper

Flow

Profile

“X”

F1

F2 F3 F4

Lateral Placement

To determine where to install the FC10 flow conditioner,

the pipe size is important. FC10s require 5D upstream.

The flow meter’s sensor should also have 5D before any

downstream disturbances. The distance between the FC10

flow conditioner and the flow meter’s sensor is dependent

on the pipe size and is listed in Table 1.1 and illustrated in

Figure 1.1 below.

TECH TIP

Branch Outlet

(installed by customer)

5D5D

Compare Upstream &

Downstream Straight

Run Requirements for

Common Flow Meter

Technologies

DP METERS

20 Upstream

10 Downstream

Schedule 40

Pipe Size

“X”

Inch (mm)

Min. Up/Downstream

Pipe Diameters Inch (mm)

1.5 6 (152) 5D 8 (203)

2 6 (152) 5D 10 (254)

2.5 9 (229) 5D 15 (381)

3 9 (229) 5D 15 (381)

4 9 (229) 5D 20 (508)

5 10 (254) 5D 25 (635)

6 12 (305) 5D 30 (762)

8 16 (406) 5D 40 (1016)

10 20 (508) 5D 50 (1270)

12 24 (610) 5D 60 (1524)

INSTALLATION

FC10 Orientation

Every FC10 has “UPSTREAM” etched into the

orientation marker at the top of the flow conditioner.

This marker should be pointing parallel to the probe

with the “UPSTREAM” etching pointing toward the

upstream portion of the pipe.

The FC10 is installed between two 150lb flanges and

gaskets (supplied by customer) should be placed on

both sides of the flow conditioner to ensure a tight

seal.

Please refer to document #107679 for further

installation instructions.

VORTEX METERS

35 Upstream

5 Downstream

TURBINE METERS

20 Upstream

5 Downstream

ULTRASONIC

METERS

10 - 20 Upstream

10 - 20 Downstream

Figure 1.2: Orientation of FC10 Flow Conditioner

Orientation marker

FLO

FC10 Orientation marker

with “UPSTREAM” etching

(supplied by customer)

Gaskets

must be parallel to

flow meter probe

(see table previous page)

F1

F2 F3 F4

Probe

Branch Outlet

“X”

Loading...

Loading...