Page 1

Document No:B650004 Rev.C

Foxconn LIF 223 Socket

User Guide

P/N: PL223*3-164*-01F

Approved by: Michael Lai Checked by: Gallen Hseih Prepared by: Peter Sun

Confidential

ICS/DQA

2006/03/20 Page:1

Page 2

Contents

Contents

Contents

• Application

• Socket Outline Dimension

• Socket Pick & Place Design

• Recommended Soldering Condition

• Socket Actuation Introduce

• Unpacking Guide

• How to Reserve Socket

Confidential

ICS/DQA

2006/03/20 Page:2

Page 3

Application

Application

Application

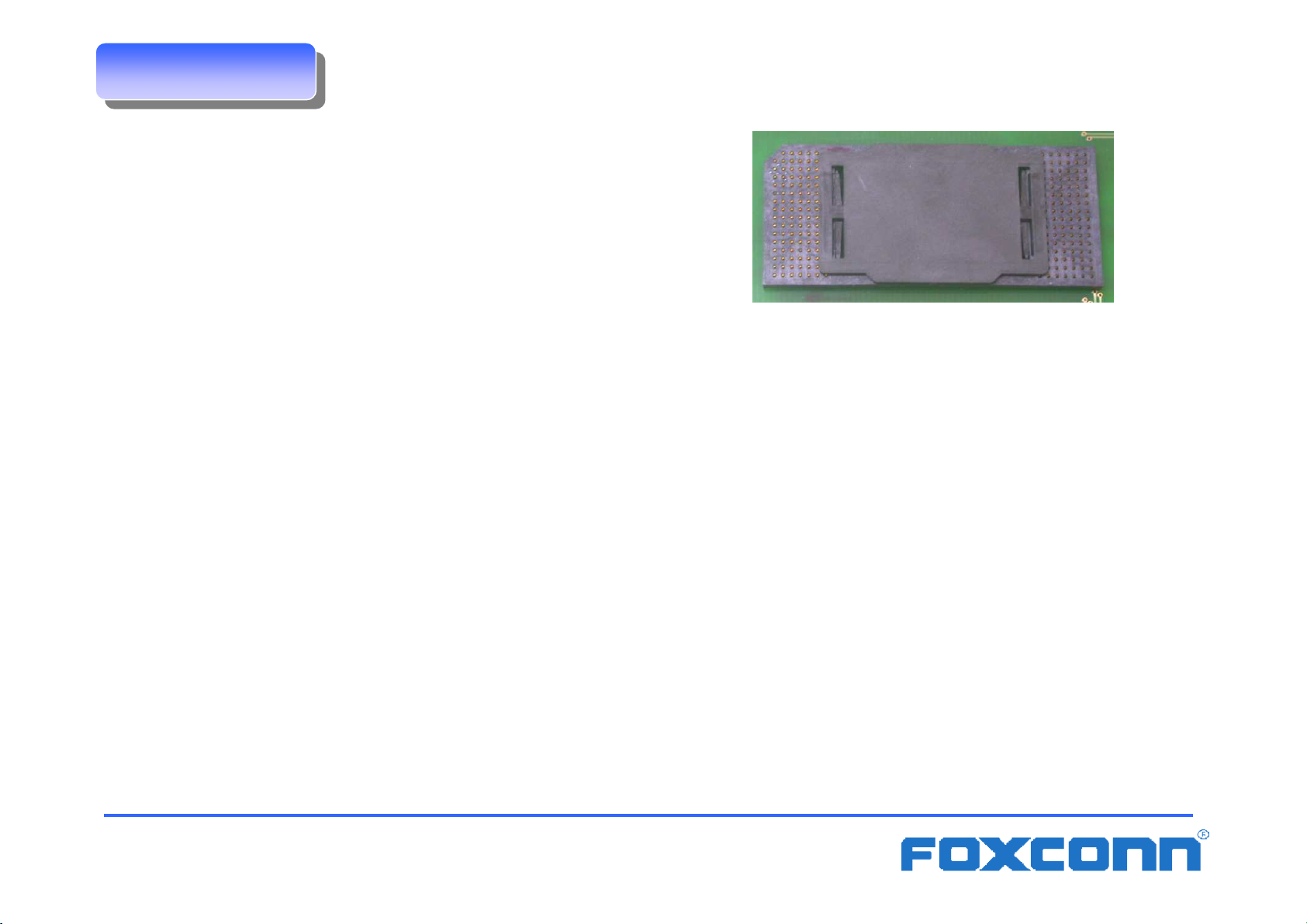

Introduction

• Name : LIF 223 Socket

• Pin count : 223 Positions

• Socket envelop: 50.34mmx21.94mmx2.24mm

• Interface:

Carrier side : Low insertion force with 2 point contact for

m PGA pin on the package

PCB side : ∅∅∅∅0.76mm solder ball

Solder ball coplanarity 0.20mm max

Confidential

ICS/DQA

2006/03/20 Page:3

Page 4

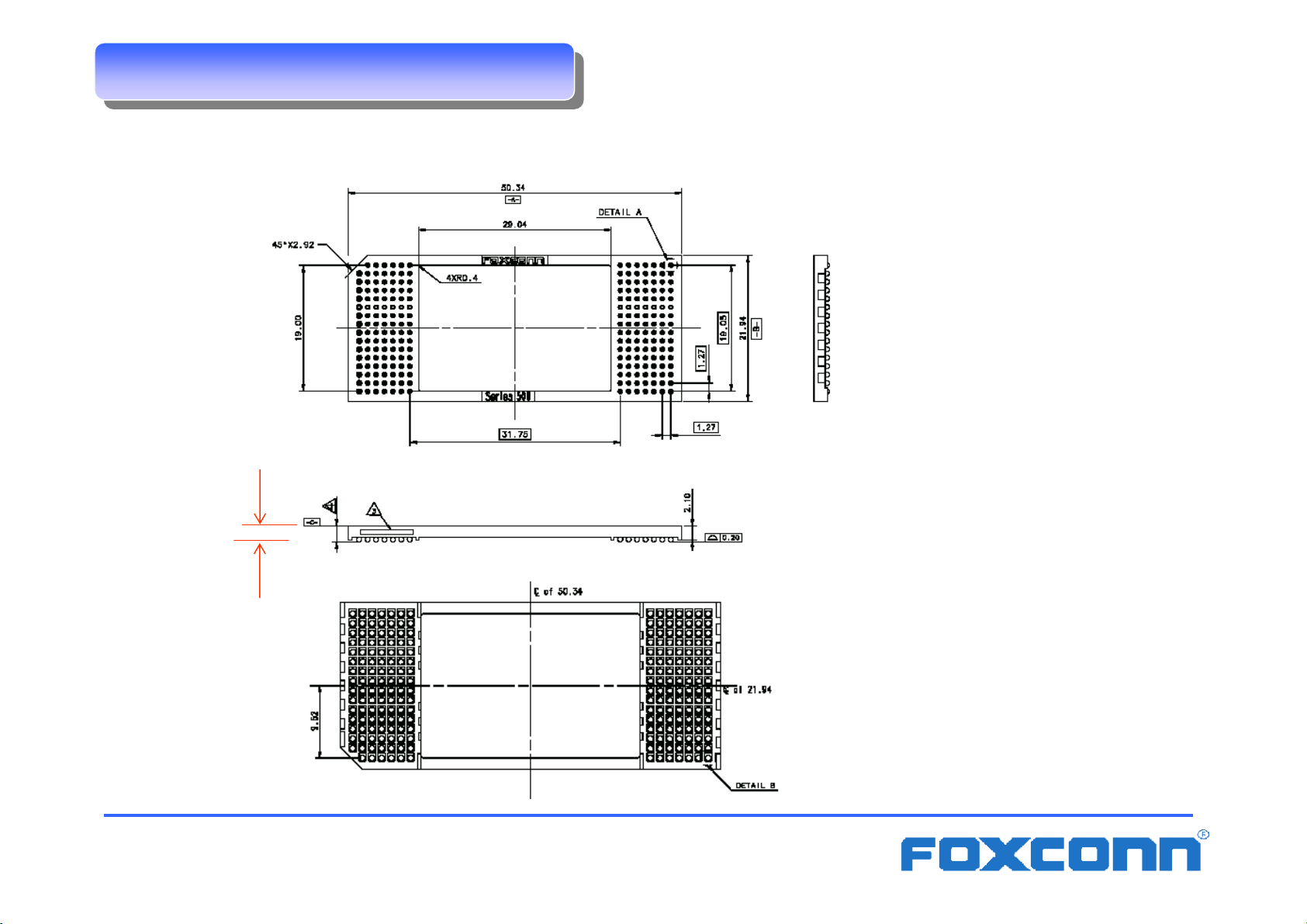

Socket outline dimension

Socket outline dimension

Socket outline dimension

The outline dimensions of LIF223 socket are shown as below.

Dim H

Confidential

ICS/DQA

Dim H: 2.235+/- 0.127mm after

soldering process

2006/03/20 Page:4

Page 5

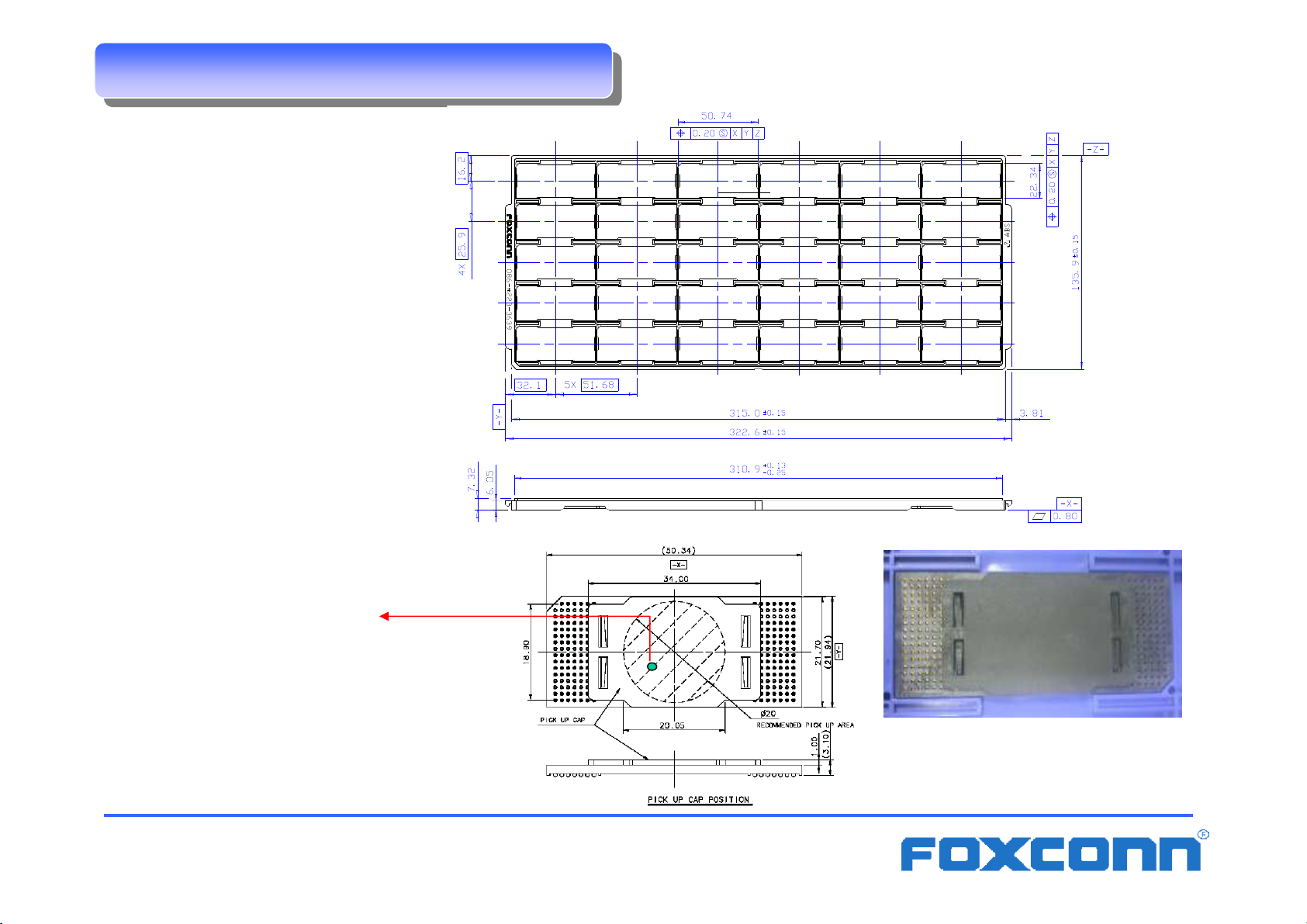

Socket Pick & Place Design

Socket Pick & Place Design

Socket Pick & Place Design

Foxconn’s packaging tray

dimension:

Center of Gravity

(Recommended Pick-up Location)

Confidential

ICS/DQA

Relation between socket

and tray pocket

2006/03/20 Page:5

Page 6

Recommended Soldering Condition

Recommended Soldering Condition

Recommended Soldering Condition

Defining the location of tested point

In order to ensure the quality of all the solder balls after reflow process,the

profile of the point at lowest temperature and highest temperature must be

controlled.The point at lowest temperature and highest temperature were

defined as the following figure.

The test point of solder ball

Confidential

ICS/DQA

Thermocouple

2006/03/20 Page:6

Page 7

Recommended Soldering Condition

Recommended Soldering Condition

Recommended Soldering Condition

Solder Ball Temperature Profile

Recommend profile of lead-free type is showed as below.

230~250oPeak temp.

o

218

C

Slope < 3

150oC

o

C/sec

Soak time

60 - 90 sec

_continued

_continued

_continued

Time above

liquidous

40 – 120 sec

Slope < 3oC/sec

Solder paste:Tamura (lead free type)

Stencil thickness:0.14~0.15mm

Stencil diameter:0.55~0.65mm

Confidential

ICS/DQA

2006/03/20 Page:7

Page 8

Socket actuation Introduce

Socket actuation Introduce

Socket actuation Introduce

Insert Carrier on Socket

1.Remove the cap with two fingers by vertical force.

vertical removal force

Confidential

ICS/DQA

2006/03/20 Page:8

Page 9

Socket actuation Introduce

Socket actuation Introduce

Socket actuation Introduce

_continued

_continued

_continued

2.1 Make sure pin 1 indicator is on your bottom-left side.

2.2 Aim at the socket and place the carrier carefully into the socket by purely vertical motion,

Press the Carrier lightly by fingers to make sure there is no gap between Carrier and

socket.

2.3 Visually inspect if the Carrier is seated well into the socket. If not, take out the CPU with

purely vertical motion and repeat the step to re-load the CPU.

Note

:a. The red mark on Carrier should be match with the mark on socket before carrier insertion as

below figure.

b. The alignment wall of Carrier should be match with the alignment hole of socket before carrier

insertion as below figure.

Pin 1

indicator

of socket

Pin 1

Alignment wall

of Carrier

Alignment edge

of socket

Chamfer

of Carrier

Confidential

ICS/DQA

2006/03/20 Page:9

Page 10

Socket actuation Introduce

Socket actuation Introduce

Socket actuation Introduce

3.Push down the carrier with two hands by vertical down force.

_continued

_continued

_continued

vertical down force

Confidential

ICS/DQA

2006/03/20 Page:10

Page 11

Socket actuation Introduce

Socket actuation Introduce

Socket actuation Introduce

Remove Carrier from Socket

1. Hold the four corners of the carrier with two hands. Remove the Carrier by vertical up force.

_continued

_continued

_continued

vertical up force

Confidential

ICS/DQA

2006/03/20 Page:11

Page 12

Unpacking Guide

Unpacking Guide

Unpacking Guide

1. Place the box and make sure the logo ‘Foxconn’ is in the right direction.

2. Use a knife the open the box.

3. Take out the packing foams.

4. Hold the sockets with two hands carefully.

5. Lift up and put the socket on the table.

Confidential

ICS/DQA

2006/03/20 Page:12

Page 13

Unpacking Guide

Unpacking Guide

Unpacking Guide

6. Locate the opening of the vacuum bag.

7. Tear the bag gently without shaking the tray.

8. Remove the vacuum bag.

9. Customer application.

_continued

_continued

_continued

Confidential

ICS/DQA

2006/03/20 Page:13

Page 14

How to reserve Socket

How to reserve Socket

How to reserve Socket

If the vacuum package is opened, we suggest the following method to reserve

the remain socket if sockets cannot used up.

1. Put the remain socket on the hard tray and put back the hard tray into the

vacuum package.

2. Keep the package in the following condition.

Humidity <60% RH , Temperature under 22~50。C (Same as

chipset’s reserved condition is preferred. )

3. The reserved time limit is six months.

4. After customer reused the remain socket, the socket does not need to

bake.

5. Put the remain socket on the hard tray and put back the hard tray into the

vacuum package.

Confidential

ICS/DQA

2006/03/20 Page:14

Loading...

Loading...