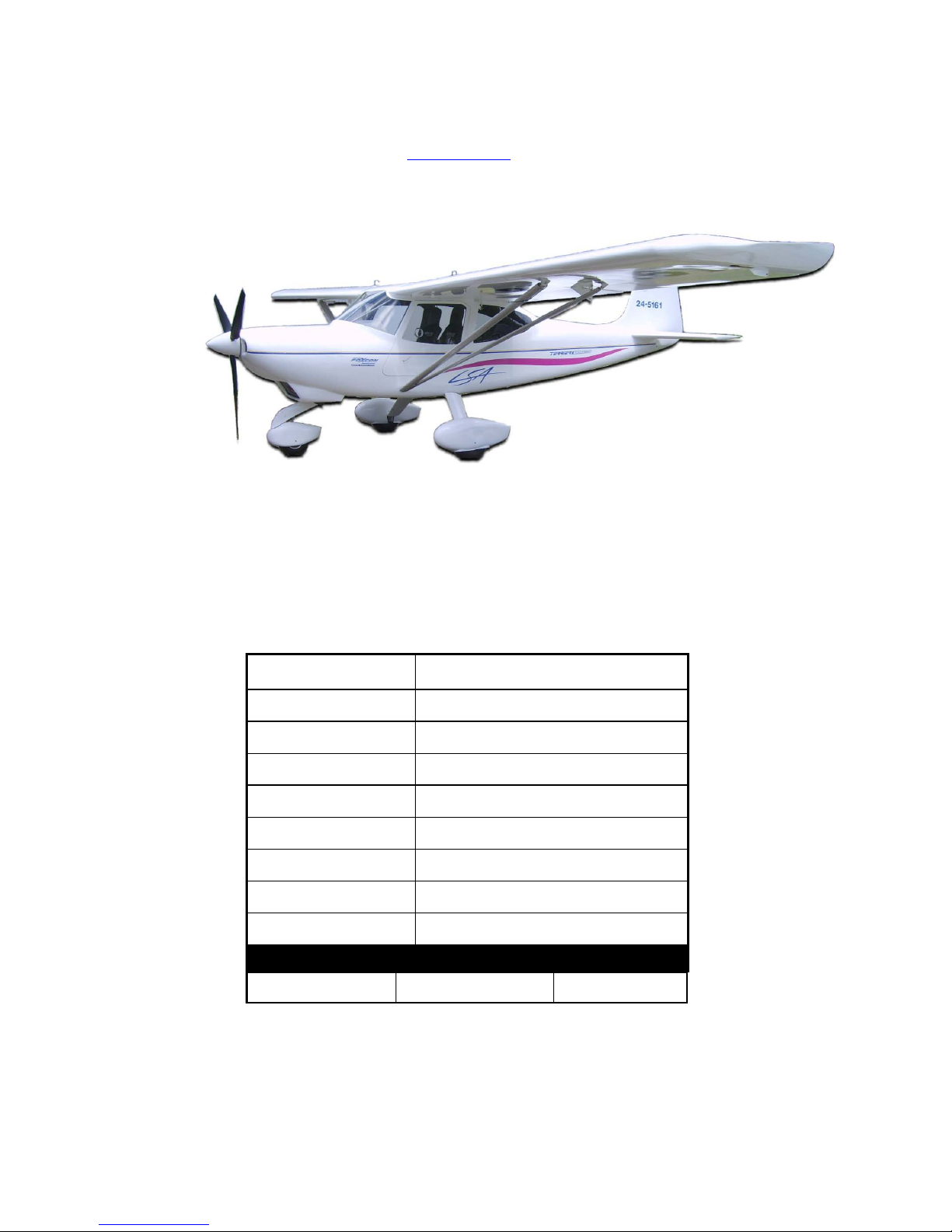

Foxcon terrier T200 Maintenance Manual

Terrier T200 LSA Maintenance Manual Rev No.: 0.1 1 Mar 2008 Page 1 of 13

FOXCON

Aviation & Research Pty Ltd

291 Gormley’s Road Seaforth Mackay QLD 4741

Ph/Fax: 07 4959 0252 Mobile: 0418 747 751

www.Foxcon.com

Aviation@Foxcon.com

Maintenance Manual

Terrier T200 LSA

Aircraft Registration

Number:

21-5161

Aircraft Serial Number:

#040701

Power plant:

Subaru EA-81

Power plant Serial No:

544848

Propeller:

Bolly BOS3

Date of First Flight:

05.03.08

Current Owner:

Address:

Empty Weight Moment Date Weighed

323kg

698.26

25.02.08

Terrier T200 LSA Maintenance Manual Rev No.: 0.1 1 Mar 2008 Page 2 of 13

Table of Contents

1.1 General

1.1.1 Equipment list

1.1.2 Sources to purchase parts

1.1.3 List of disposable replacement parts

1.1.4 Engine Specifications

1.1.5 Weight and balance information

1.1.6 Tire inflation pressures

1.1.7 Approved oils and capacities

1.1.8 Recommended fastener torque values

1.1.9 General safety information

1.1.10 Instruc ti ons f or report i ng possible saf ety of flight concerns found during inspection/maintenance

1.2. Inspections

1.2.1 Inspection– 6 month/50-h

1.2.2 Inspection– Annual/100-h

1.3 Structures

1.3.1 Wing

1.3.2 Empennage

1.3.3 Landing Gear

1.3.4 Control surfaces

1.4 Engine

1.5 Fuel System

1.6 Propeller

1.7 Utility Systems

1.8 Instruments and Avionics

1.9 Electrical System

1.10 Structural Repair

1.11 Painting and Coatings

1.12 Forms and Checklists

LSA05 Feedback Form

LSA04 Inspection Procedure Checklist – 6 month/50-h

LSA03 Inspection Procedure Checklist – Annual/100-h

2.0 Line Maintenance, Repairs and Alterations

3.0 Heavy Maintenance, Repairs and Alterations

4.0 Overhaul

5.0 Major Repairs and Alterations

6.0 Task-Specific Training

7.0 Safety Directives

8.0 Definitions

9.0 Abbreviations

10.0 Revision History

11.0 List of Valid Pages

12.0 Appendix

Terrier T200 LSA Maintenance Manual Rev No.: 0.1 1 Mar 2008 Page 3 of 13

1.1 General

The purpose of this manual is to provide guidance to owners and mechanics who wish to undertake maintenance, repairs, and alterations

on the Terrier 200 light sport aircraft. If in any doubt, please contact the manufacturer.

1.1.1 Equipment list

• Metric socket & spanner set

• UNF socket & spanner set

• Spark plug spanner

• # 1 & #2 Philips head screwdriver

1.1.2 Sources to purchase parts

• Foxcon Aviation & Research Pty Ltd

• Automotive supply store

1.1.3 List of disposable replacement parts

• Reduction drive belt

1.1.4 Engine Specifications

• Subaru E81 – 100hp

• Type - Liquid cooled horizontally opposed 4 cyl OHC

• Firing Order – 1-3-2-4

• Capacity – 1781cc

1.1.5 Weight and balance information

• Empty Weight -__________

1.1.6 Tire inflation pressures

• Nose wheel tyre - 103kPa / 15psi

• Main tyres - 103kPa / 15psi

1.1.7 Approved oils and capacities

• Refer to engine manual

1.1.8 Recommended fastener torque values

• Refer to engine manual

1.1.9 General safety information

• Always handle the aircraft with care. Do not allow anyone to help move the aircraft by pushing on any control surface (flaps,

ailerons, tail -elevators) the hinges are NOT designed to take these stresses.

• To push the tail down, lift the prop hub or push down on the rear fuselage near the horizontal stabilizer.

• Remember to follow all safety precautions pertaining to aircraft, especially around the propeller area.

• The following maintenance program outlines the minimum maintenance that must be followed to keep the aircraft in good

flying condition. The suggested time interval of 50 hours does not in any way eliminate the need for routine maintenance before

and after each flight. Maintenance is part of the pilot's responsibilities: the pilot should be certain that the aircraft is airworthy at all

times, especially when flying.

• The recommended 50 and 100-hour maintenance checks are designed to cover areas that are not normally checked in the

quicker pre-flight inspection, and this guide is offered only as an indication of the required maintenance. It is the owner’s

responsibility to determine what should be performed, and ensure that it is done.

• A qualified individual should perform aircraft servicing and maintenance

NOTE: If anything unusual is discovered at any time, during pre-flight or at a scheduled inspect ion, contact your normal maintainer

for the proper maintenance procedure. Do not attempt to maintain or repair the aircraft without proper qualifications.

Do NOT fly an un-airworthy aircraft.

1.1.10 Instructions for reporting possible safety of flight concerns found during inspection/maintenance

• Please complete the Feedback Form (LSA05) and send to Foxcon Aviation & Research Pty Ltd.

Terrier T200 LSA Maintenance Manual Rev No.: 0.1 1 Mar 2008 Page 4 of 13

1.2. Inspections

1.2.1 Inspection– 6 month/50-h (whichever comes first)

Check the general condition of the TERRIER and in particular the following:

GENERAL: Verify that no cables are chafed, check for proper anchorage and connection of all items (fuel and coolant hoses, oil lines and

electrical wiring, etc), check tension of alternator belt. Verify that all fasteners and pins have the required "safety" wire or s pl i t pins.

CONTROLS: Check for rust on steel parts (clean and repaint as required). Lubricate all moving parts (hinges, control attachments, bearings,

etc.). Verify that all controls operate smoothly and that they are firmly attached.

LANDING GEAR & WHEELS: Inspect nose steering stops and steering tension (use a cheap set of fish scales hooked to the wheel - 7 Kg

pull to move), and inspect the main wheel braking system and lines. Check for correct (15 lbs) tyre pressure, then look for tyre wear or flat

spots (wheel it along while watching the bit of tyre you can see).

BATTERY: (IGNORE IF A SEALED UNIT) Check fluid level, especially in hot weather. Maintain the level at the top mark by adding distilled

water as required (read instructions located on battery). DO NOT OVERFILL as spillage may corrode the airframe.

BATTERY: (All types) Clean around terminals, looking for corrosion and grease lightly with Vaseline.

WOOD PROPELLER: Wood propellers are inexpensive and dampen vibrations efficiently, but maintenance is required to keep the propeller

in proper condition. The prop may need periodic re-varnishing.

ALL PROPELLERS: Check the tips and leading edges for damage. Look for nicks and cracks. Inspect spinner, bolts (tight and secured).

Wiping the propeller with an oily cloth will result in cleaning off grass and bug stains. DO NOT OPERATE AIRPLANE IN RAIN since the

propeller will get damaged.

ENGINE COMPARTMENT: Thoroughly check and inspect the engine compartment, including the reduction drive belt tension, exhaust

system, fuel system, oil system, and coolant system. Is the radiator clogged with insects? Hosing from the rear can help here. Clean

(replace if required) the carburettor air filter. The engine and compartment should be kept free of any accumulation of oil, grease, and dirt to

prevent a fire hazard. See the Engine Manual for more information on routine maintenance and inspections.

ENGINE: Refer to Engine Manual. Check for plastic lines or rubber hoses in direct contact with a rough or sharp surface or with wear due to

the constant vibration emitted by the engine. It is important that all electrical wires and hoses (fuel, water, oil) be in a secured position clear

of contact with the engine casting, cowl, exhaust, or any "sharp" edge. Go over each item separately, replacing what is damaged or worn,

and securing each item using adequate insulation to prevent premature wear.

EXHAUST: Check for cracks, cowl clearance, missing springs. Where flexible pipe is used, replace pipe at the first sign of a crack.

ENGINE COWLING: Check for looseness, rear pins, are the throwover latches still well attached to cowl, look for any damage or cracks.

Make sure everything is properly secured.

FUEL: Remove, clean and re-install gascolator. Inspect for any leaks and loose fittings in the lines and tanks, and check the smooth

operation of shut-off valves. Clean (or replace) any installed filt ers.

Use checklist LSA04 & record all maintenance performed in log book.

Loading...

Loading...