Page 1

F200 & F300

Modular Ice Cuber

&

FMIC 180 & 260

Electronic Modular Ice Cuber

Foster Refrigerator

Oldmedow Road, King’s Lynn,

Norfolk PE30 4JU

England

Tel: 01553 691122

Fax: 01553 691447

Website: www.fosterrefrigerator.co.uk

E-mail: sales@foster-uk.com

a Division of ITW (UK) Ltd.

F/FMIC/SM/03/03

By Appointment to

Her Majesty Queen Elizabeth II

Suppliers of Commercial Refrigeration

Foster Refrigerator (UK) Ltd King’s Lynn

Service Manual

Service Manual

Page 2

F200 & F300 Modular Ice Cuber

CONTENTS - F200 & F300

1. SPECIFICATION 4

1.1 Capacities 4

1.2 Installation Notes 4

1.3 Stacking Installation 4

INSTALLATION INSTRUCTIONS 5

2. START UP CYCLE 6

2.1 Start Up Cycle 6

2.2 Freezing Cycle 6

3. HARVEST CYCLE 6-7

4. OPERATION 7

4.1 Refrigeration During Freezing 7

4.2 Water System During Freezing 7

4.3 Ice Harvest Cycle 7

4.4 Water System During Ice Harvest Cycle 7

4.5 Control Sequence 7-8

Page

5. ALARM CONDITIONS 8

6. P.C. BOARD SET UP 8

6.1 Water Error 8

6.2 Too High Condensing Temperature 8

7. COMPONENT DESCRIPTION 9

7.1 Front Console Panel 9

7.2 P.C. Board 9

7.3 Compressor Contactor 9

7.4 Ice Thickness Sensor 9

7.5 Magnetic Switch 9

7.6 Hot Gas Valve 9

7.7 Condenser Temperature Sensor 9

7.8 High Pressure Control 9

7.9 Water Regulating Valve (water cooled models only) 9-10

7.10 Water Distribution System 10

7.11 Water Drain Solenoid Valve 10

7.12 Thermostatic Expansion Valve 10

7.13 Water Pump 10

7.14 Water Inlet Solenoid Valve (male fitting) 10

7.15 Water Level Sensor 10

8. WIRING DIAGRAM 10

9. SERVICES DIAGNOSTICS 11

10. MAINTENANCE, CLEANING AND SANITATION 12

10.1 Icemaker 12

10.2 Ice Storage Bin 12

10.3 Cabinet Exterior 12

10.4 Cleaning Ice Maker 12

2

Page 3

FMIC 180 & 260 Electronic Modular Ice Cuber

CONTENTS - FMIC 180 & 260

1. SPECIFICATIONS 13

2. FOR THE INSTALLER 14

2.1 Important operating requirements 14

2.2 Select location 14

2.3 Ice machine 14

2.4 Final check list 14

3. FOR THE PLUMBER 15

3.1 Conform to all applicable codes 15

3.2 Water Inlet 15

3.3 Drains 15

4. FOR THE ELECTRICIAN 15

4.1 Electricial Connections 15

5. START-UP 15

5.1 Start-up 15-16

6. OPERATION 16

6.1 Refrigeration during freeze 16-17

6.2 Water system 17

6.3 Refrigeration system during harvest 17

6.4 Water system 17

6.5 Control sequence 17-18

Page

7. SERVICE SPECIFICATIONS 18

7.1 Component 18

7.2 Operating characteristics 18

7.3 Freeze cycle 18

7.4 Harvest cycle 18

8. COMPONENT DESCRIPTION 18-19

9. REMOVAL AND REPLACEMENT PROCEDURES 20-21

WIRING DIAGRAMS - FMIC 180 & FMIC 260 22

10. SERVICE DIAGNOSIS 23

11. MAINTENANCE AND CLEANING INSTRUCTIONS 23

11.1 Ice maker 23-24

11.2 Ice storage bin 24

11.3 Cabinet exterior 24

11.4 Cleaning (Ice maker) 24

12. ASSEMBLY INSTRUCTIONS OF CONVEYOR KITS FOR 24-25

ICE MACHINES TO BE FITTED ON STORAGE BIN

13. WIRING DIAGRAM CONCERNING THE CONNECTION 25

OF UPPER ICE MAKER MICRO TO CONVEYOR KIT MICRO

14. GUIDELINES FOR ICEMAKER BIN LIDS 25

3

Page 4

F200 & F300 Modular Ice Cuber

1. Specification

1.1 Capacities

F200F200

F200

F200F200

Output (kg/ 24 hours) 215 320

Bin Storage Capacity (kgs) 150/ 210 150/210

Cubes Per Cycle (kgs) 2.3 2.3

Standard Cube Size 24mm x 24mm x 26mm 24mm x 24mm x 26mm

Cycle Time (minutes) 16 11

Amps start/run 29/5.5 31/8.5

Watts Consumption 1000 1600

Machine Weight net / gross (kgs) 70/85 73/88

Refrigerant R404A R404A

Refrigerant Charge 500 grms 850 grms

Discharge Pressure Freeze Cycle Max 17 bar/ Min 15 bar Max 18 bar/ Min 16 bar

High Pressure Cut Out 30 bar 30bar

High Pressure Safety Switch Cut in 20 bar/ Cut Out 33 bar Cut in 20 bar/ Cut Out 33 bar

Suction Pressure Freeze Cycle Start 3.6 bar/ End 2.3 bar Start 3.6 bar/ 2.5 bar

Compressor Amps Freeze Mode Start 4.2 amps/ End 3.4 amps Start 7.0 amps/ End 5.2 amps

Voltage 230/50/1 230/50/1

Reservoir Water Level 40mm to 45mm 40mm to 45mm

Water inlet Connection 3/4 gas 3/4 gas

1.2 Installation Notes.

Allow 15cm minimum space at the sides and back for ventilation.

Bin Installation

The F200 and 300 fit the New SB150 Bin.

The F200 and F300 can be fitted to the New SB210 Bin but a KN311 Lid is required.

The F200 and F300 can be fitted to the Old SB150 Bin but a SB150 frame is required, as the F200 and F300 are smaller than the Old SB150

Bin.

The F200 and the F300 can be fitted to the Old SB210 Bin provided the KN310 lid is fitted first. However it is necessary to re-drill the lid to

secure the machine to it.

1.3 Stacking Installation.

To stack a Modular Cuber onto the present one, first remove the top panel from the lower machine.

Add a bead of food grade silicone sealer to the top edges of the lower units freezing compartment.

Lift the top machine onto the bottom machine, (the use of a mechanical lift is recommended).

Align the two machines, and using the two screws supplied in the hardware package supplied with the top machine, fasten the two together

through the fixing holes on either side of the machines.

Fit the Stacking Kit KS into the bottom machine as per the instructions supplied with the kit.

Using food grade silicone sealer, seal the edges between the freezing compartments of the top and bottom machine so as to avoid any

possible leakage of water through the join.

F300F300

F300

F300F300

Fig.4

Fig.5 Fig.6

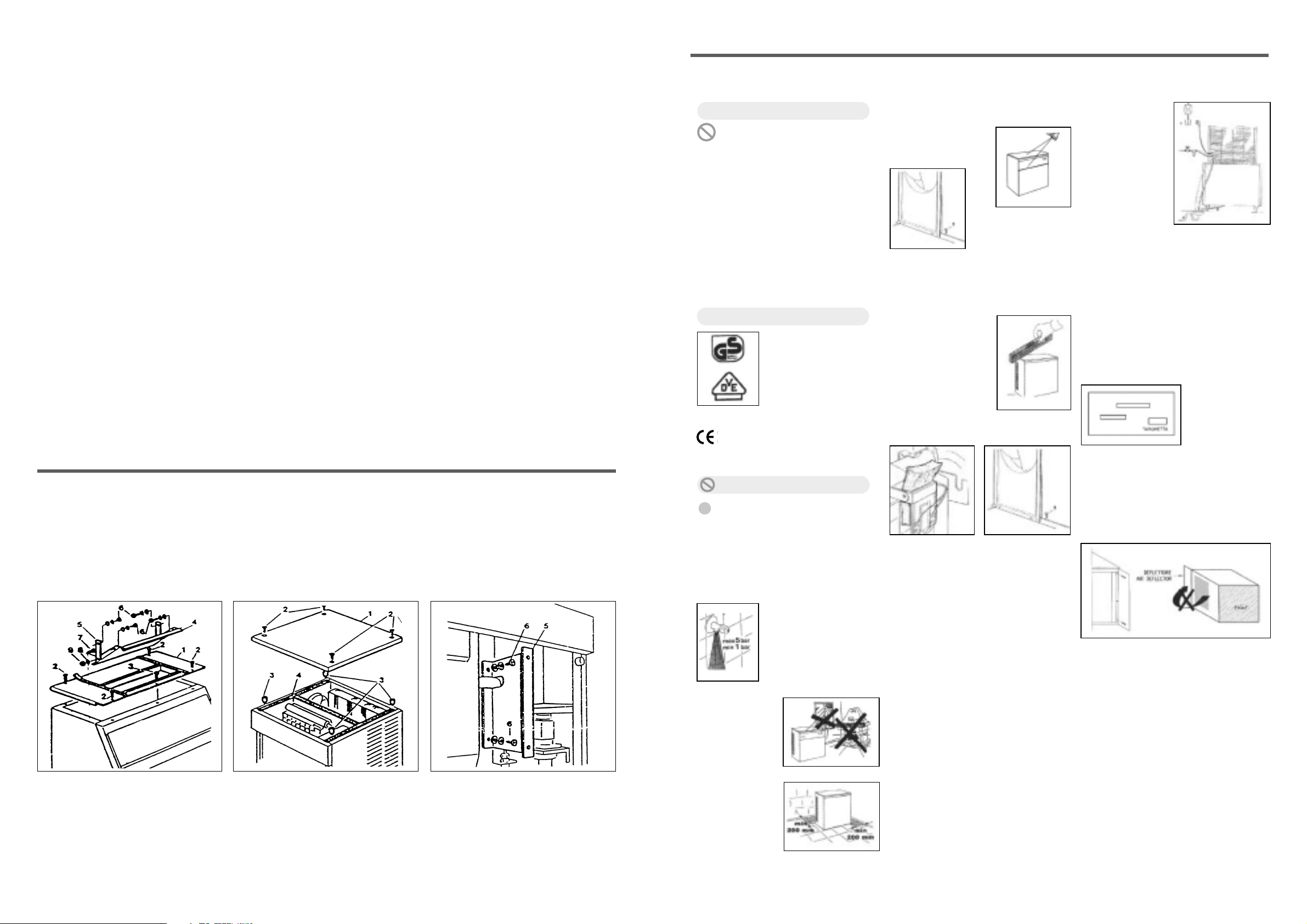

13. Wiring Diagram Concerning The Connection Of Upper Ice Maker Micro

To Conveyor Kit Micro

1. Detach the light blue (No.13) cable of the upper ice maker; this cable is connected to the NC contact (usually closed) of the micro.

Connect it to the light blue (No.14) cable which is joined to the NO contact (usually opened) of the conveyor kit micro.

2. Connect the brown (No.16) cable which comes from the COM (common) contact of the conveyor kit micro to the NC contact (usually

closed) of the upper ice maker micro.

14. Guidelines for Icemaker Bin Lids

FMIC 180 HEAD

FMIC 260 HEAD

FMIF 220 HEAD

FMIF 550 HEAD

SB 150 BIN

SB 210 BIN

SB 150 BIN

SB 210 BIN

SB 150 BIN

SB 210 BIN

SB 210 BIN

NO BIN LID

KN 310 BIN LID

NO BIN LID

KN 310 BIN LID

NKF 200 BIN LID

NKF 310 BIN LID

NKF 310 BIN LID

4

25

Page 5

5. Check and tighten all bolts and screws.

6. Check for water leaks and make corrections.

7. Check the bin control to test shut-off.

Holding the evaporator deflector in open Position for more that 30secs, should cause the ice maker to shut-off at the end of harvest cycle.

Once the evaporator deflector is released in its closed position, the ice maker will restart.

8. Check cube size, adjust if required through setting screw of ice thickness control sensor.

9. With unit out of operation, clean the condenser using vacuum, cleaner, whisk broom or brush.

Instruct customer to clean condenser frequently DO NOT USE A WIRE BRUSH.

11.2 Ice Storage Bin

The interior liner of the bin is in contact with a food product, ice, and should be cleaned regularly. Once a week clean with soap and water,

and after that a hot water rinse and dry thoroughly. Commercial food grade sanitisers are available, and may be used.

11.3 Cabinet Exterior

Wipe clean unit and bin cabinet exterior with a clean cloth or disposable paper wipers, soaked in warm water with mild detergent solution.

11.4 Cleaning - Ice Maker

WARNING - Ice Machine Cleaner contains Phosphoric and Hydroxyacetic acids. These compounds are corrosive and may cause

burns. If swallowed, DO NOT induce vomiting. Give large amounts of water or milk. Call physician immediately. In case of

external contact, flush with water.

KEEP OUT OF THE REACH OF CHILDREN.

1. Empty bin of ice.

2. Remove front panel.

3. Switch the Master switch power line and Unit Toggle switch OFF

4. Remove evaporator cover deflectors by lifting-up and pulling-up.

5. Switch the Master switch power line ON. Pour 200grs of Ice Machine Cleaner into the reservoir and put the unit toggle switch to

WASH position. Run unit for 15 minutes.

6. Using correct brush clean the interior of each evaporator egg-crate using the cleaning solution from the water reservoir.

7. Switch to OFF, remove the drain plug from the water reservoir to flush cleaning solution out of the reservoir. Replace the plug and allow

fresh water through float valve to fill-up the reservoir to thoroughly rinse it.

8. Repeat the reservoir flushing out two or three times.

9. Switch the toggle switch to ICE position.

10. Replace the evaporator cover deflector and front panel.

11. Check the next batch of cubes to be sure all the cleaner has gone (no sour taste).

CAUTION: DO NOT use ice cubes produced from the cleaning solution. Be sure none remains in the bin.

12. Pour hot water into the storage bin to melt the cubes, and to also clean the bin drain.

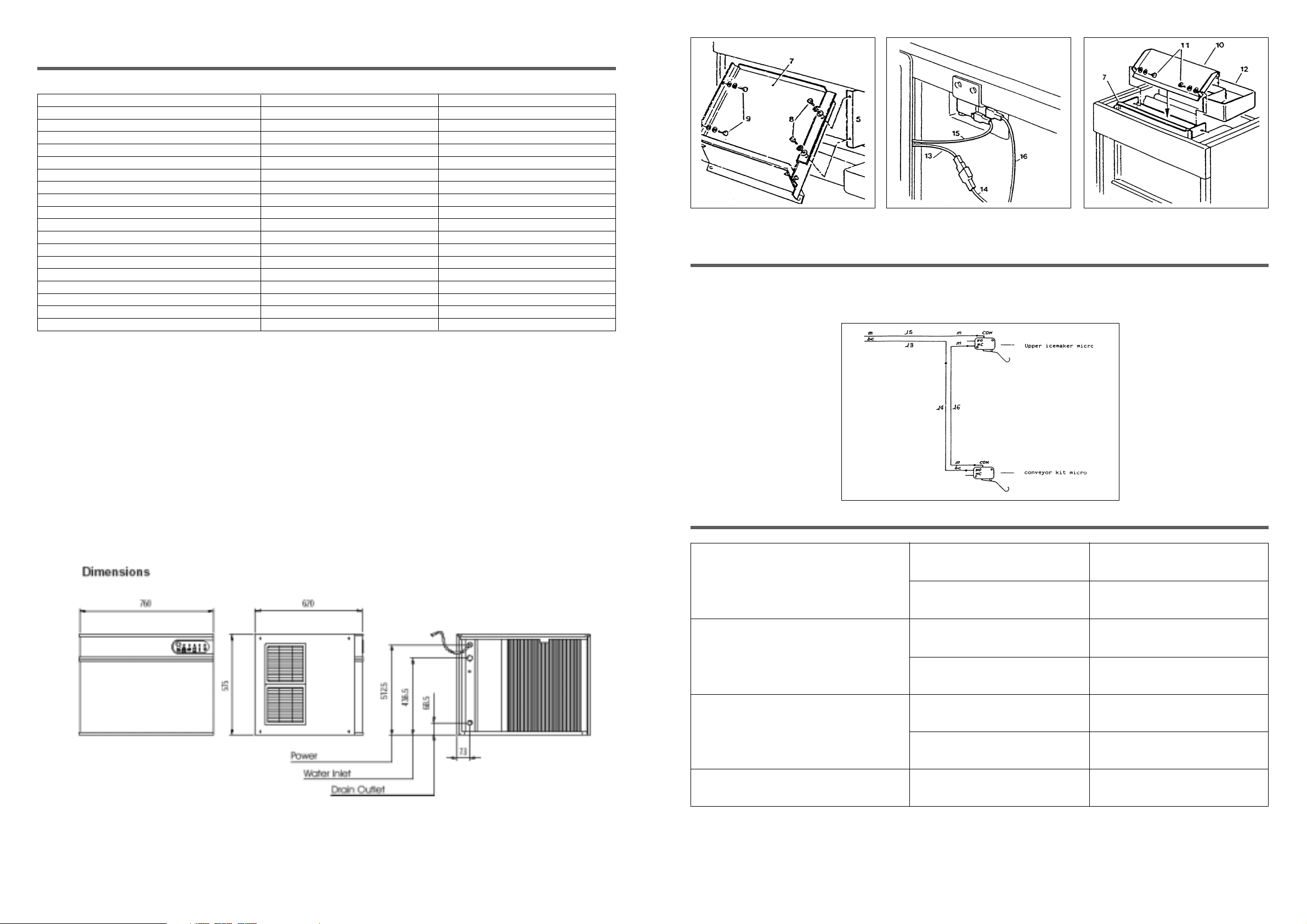

12. Assembly Instructions of Conveyor Kits for Ice Machines

to be fitted on Storage Bin

1. Fit the cover kit on the storage bin of 300kg (as indicated in Fig. 1) and put the lower ice maker on the bin as indicated in the instruction

manual.

2. Remove the cover and the 4 bushes (No.3) of the lower ice maker (Fig. 2), then apply the support gaskets No.4.

3. Remove the front and the 2 lateral panels of the lower ice maker and fit the conveyor support No.5 (Fig. 3).

4. Fit the conveyor kit (No.7 - Fig. 4).

5. Apply the upper ice maker after having removed the front and the 2 lateral panels and fix it to the lower ice maker through 2 screws on

the lateral edges.

6. Hook the shoot conveyor (No.10 - Fig. 6) at the edge of the upper ice maker water pan and fix it to the vertical conveyor No.7, previously

fitted on the lower ice maker (as indicated on Fig. 6).

7. Connect the upper ice maker micro to the conveyor kit as explained on Fig. 5 and on the enclosed wiring diagram.

8. Place back the panels previously removed.

Fig.1

Fig.2 Fig.3

Installation Instructions

preface

Warning!

It is expressly forbidden for the users of

the equipment to carry out the following

operation or those marked by the symbol, Such operations must be performed

exclusively by qualified personnel.

1. Electrical connections

2. Water mains connections

3. Machine installation

4. Machine test run

5. Repairing machine components and parts

6. Disassembly of machine and/or

components

7. Adjustment and setting procedures

8. Machine cleaning and maintenance relative

to the following parts and components:

Electrical, Electronic, Mechanical,

Cooling System

general specifications

Models 200 KG, 300 KG,

The icemaking machines

are approved by VDE, GS

and the relative symbols

are put on the packing,

serial plate and body of

the machine (Fig.10).

Fig 10.

OUR PRODUCTS ARE GOVERNED BY EC

LOW VOLTAGE DIRECTIVE 73/23/EEC EMC - 89/336/EEC AND THE COVER OF

THE MANUAL IS MARKED ACCORDINGLY.

installation

Note

1

Before installing the machine make

sure that:

a) the room temperature must not fall

below 10˚c (50˚F) or above (100˚F).

b) the water conductivity value must not

be below 10 µs/cm.

c) the main water temperature must not

fall below 5˚C (40˚F) or above

35˚C (95˚ F).

d) the main water pressure

must not fall below

1bar. (14 PSI) or above

5 bar. (70 PSI). If

pressure is above 5 bar.

a pressure regulator

should be fitted to

the water supply to the

Fig 11.

e) machine is

away from

sources of heat

and in a

sufficiently

ventilated area.

A distance of at

least 20cm must

be allowed

between the

sides, back and

the walls of the

machines

(Fig.12, Fig.14).

f) the machine will

not work with

demineralized

water.

machine (Fig.11)

Fig 12.

Fig 14.

Before bringing the icemaker into action

perform the following operations:

1) Check that ice cuber has

not been damaged during

transportation (Fig.1)

Fig 1.

2) Match the icemaker to

its storage bin, fixing them

with the two screws

Fig 20.

3) Clean the inside of machine and storage bin by

means of a warm water and sodium-bicarbonate

dampened sponge; rinse with plain water and dry

thoroughly.

4) Locate the icemaker and

the storage bin in the final

place, making sure that the

two are perfectly level, in

order to obtain an even

distribution of the water all

over the evaporator and a

uniform filling of the cube

plate (Fig.13).

The storage bin is equipped

with adjustable feet, which

allow for easy levelling and

sufficient height for cleaning

under the machine.

Fig 16.

5) Unlock the sensor and the baffle by removing

the transit packaging 1and tape 2, which have

been applied to avoid any damage during

transportation (Fig.16 & Fig.17).

6) The icemaker has been designed for coupling

with another icemaker, which can be installed on

the top of the first one. For this installation, a kit

can be supplied upon request. It contains all

necessary assembling instructions.

7) Do not put the machine in a dusty

environment as this could cause a fast build up of

dust etc, therefore effecting the efficient working

of the condenser (only for air-cooled models).

8) Never keep food, bottles or other things in the

bin in order to avoid the stored ice becoming

tainted.

9) Connect machine to the water supply first and

then to a suitable electricity supply.

supplied with the machine

(Fig.20).

Fig 13.

Fig 17.

10) Connect the

3/4" Feeding pipe

(supplied) to the

machine and to the

cold drinking water

supply line. It is

advisable to install a

shut-off valve (not

supplied) to the

water feed pipe. If

the feed water

contains impurities,

the installation of a

filter system is

recommended. If the

water is particularly hard, i.e.

rich in minerals and their derivatives, the

application of a suitable water filter is

recommended, preventing any scale

deposits blocking the water circuit of the

machine (Fig.18).

11) Fit the flexible drain pipes to the

icemaker and the storage bin ensuring

there is adequate fall on the pipes to avoid

the drain water backing up. For a perfect

water outlet from the machine a minimum

incline of 3% of the pipes is advisable.

Check also that the pipes are not throttled

or siphoned. It is advisable that the pipes

discharge in an open vented drain (Fig.18).

12) Connect the

machine to the

electricity supply

after having

checked that the

voltage corresponds

to that on the plate

Fig 5.

The maximum voltage variation should not

exceed ± 6% of that stated on the rating

plate. A fused isolator must be included in

the electrical circuit to the machine, with its

own bipolar main switch at least 3 mm. of

contacts opening. The machine should be

connected to a suitable power supply with

earth terminal.

Fig 24.

13) Air deflector installation. (Fig.24) The

deflector has to be installed in order to

prevent the re-circulation of hot air to the

condenser.

on the rear panel of

the machine (Fig.5).

Fig 18.

24

2

5

Page 6

2. Start Up.

10. Service Diagnosis

2.1 Start–up Cycle.

Open the water valve and switch on the power to the machine.

The machine enters the Start-Up mode with the energising of the PC Board with the green LED (Power On) illuminated.

It is necessary to remove the front cover of the machine to see all of the LED’s.

The Green LED of Machine In Operation is also energised, blinking fast for 40 seconds prior to the start up of the machine.

Power On.‘Green’. Bin Full/ Washing. ‘Amber’. High Pressure. ‘Red’.

Machine in Operation ‘Green’. Alarm ‘Red’. Reset / Washing. ‘Push Button’.

During the start up cycle the following components in operation are.

Hot Gas Valve.

•

Water drain valve.

•

Water pump.

•

2.2 Freezing Cycle.

After the Start Up cycle the machine enters directly into the Freezing cycle with the following components in operation:

Water Inlet Valve

•

Compressor

•

Fan Motor (running continuous for the first three minutes).

•

The LED’s energised are:

Machine Power On.

•

Machine in Operation (constant).

•

Water is coming into the water reservoir through the Water Inlet Solenoid Valve until it reaches the maximum level controlled by the Water

Level Sensor.

After 30 seconds the Water Pump starts up.

3 minutes after the start of the freeze cycle the Water Inlet Solenoid Valve is activated for a few seconds until the water reaches the

maximum level, this is to reduce the possibility of slush ice formation.

In the meantime the condenser sensor starts to transmit the current to the PC Board keeping in operation the Fan Motor in ON-OFF mode

or continuously according to the condenser temperature.

Note: Do not remove the evaporator deflector, as it will cause the switching off of the machine at ‘FULL STORAGE BIN’.

The machine remains in the freezing cycle with the ice becoming thicker until the two metal fingers of the Ice Thickness Sensor (energised

at low voltage) are covered by the water cascading over the front surface of the ice plate.

If the contact between the two metal fingers remains established (by the water) for more than 10 seconds power is transmitted back to the

PC Board and the machine enters into the Harvest Cycle mode depending on:

Fan motor in ON-OFF Mode during the previous freezing cycle.

•

If the Condenser Sensor detects a rise in temperature to 38°C (due to high Ambient) the length of the freezing cycle is extended by 30

seconds before entering the harvest mode.

Fan motor running CONTINUOUSLY during the previous freezing cycle.

•

Goes straight into the harvest mode.

The first freezing time will range between 15 and 20 minutes. Freeze time will be longer if the ambient temperature is above 25°C and

shorter if it is below 25°C. The Average cycle time is about 22 minutes.

3. Harvest Cycle

During the harvest cycle the components in operation are:

Hot Gas Valve.

•

Water Drain/Purge Valve.

•

Water Pump for the first 40 seconds.

•

Compressor.

•

And both of:

Power On LED.

•

Machine In Operation LED.

•

30 seconds from the start of the harvest cycle, the Water Inlet Solenoid valve is

energised for ten seconds to allow fresh water into the sump whilst the pump is in

operation.

The Fan Motor remains in OFF mode unless the condenser probe detects a rise in

temperature above 38°C (Same as per the freezing cycle).

When the Ice Plate falls down from the evaporator, the magnetic switch is activated

sending a signal back to the PC Board to start a new freeze cycle.

Check the cubes from the first harvest to determine if any adjustments are required:

If any adjustments are needed either turn IN or OUT the screw shown as 1 in the

illustration.

The screw position (factory set at 6mm) determines the distance between the sensor

fingers and the front of the evaporator therefore setting the ice cube thickness.

NOTE: This type of machines produces an “Ice Plate” that breaks when it falls into the storage bin. Setting the ice thickness

sensor to have single ice cubes may cause the machine to malfunction.

The table below is intended as a quick reference to aid the Service Agent to determine the cause of a particular type of malfunction, as well

as the recommended repair. It is not intended to be an exclusive list.

Reference to other portions of this manual including wiring diagrams, installation, and operation are recommended to better determine the

cause of a problem.

Symptom Possible cause Correction

Machine does not run at all. Master switch open. Test and replace.

Machine does not run. Bin full of ice None

Machine does not run. The harvest cycle time is too long causing Press the ‘reset’ push button to resume

Machine runs, compressor does not. Toggle switch open in ICE position. Test and replace.

Machine runs, makes no ice. No water in reservoir Check water supply and float valve.

Machine runs, makes ice, does not try to Ice thickness control open Check sensor fingers are not covered with scale

harvest sediment.

Machine runs, makes and harvests ice, Low refrigerant charge. Check system, repair leak weigh in charge.

but very slowly.

Low ice capacity. High discharge pressure due to not- Evacuate and weigh in charge.

Machine makes irregular ice. Low water supply. Check float valve not maintaining proper

Machine runs, makes ice, but does not Hot gas valve coil open. Test and replace hot gas valve.

harvest.. Hot gas valve will not open. Test and replace hot gas valve.

Hi-pressure safety switch open W.C. Test and replace.

E.C. board inoperative. Remove board and check.

No power to unit. Check electrical source.

N.C. contacts of control switch open. Check and replace.

Magnetic switch inoperative. Check and replace.

Interface P.C. Board inoperative. Check and replace.

safety device to trip-off unit operation and check freezing and harvest time.

Compressor contactor open. Test and replace.

Compressor relay open. Test and replace.

Compressor winding open. Test and replace.

Water, but not pumping. Check power to pump, replace pump.

Water pumping but does not cool. Check refrigeration system pressure, check

Built-in transformer for ice thickness control Check and replace P.C. Board.

open.

Built-in relay on P.C. Board open. Check and replace P.C. Board.

condensable or overcharge.

Inefficient compressor. Replace.

Condenser dirty. Clean.

Low water pressure (water-cooled). Check and repair.

High air temperature (air cooled) Check temperature of air entering condenser.

Water pump not running. Check and repair or replace.

Plugged water distributor. Clean machine.

TXV super heat wrong. Adjust or replace.

Refrigerant charge low. Adjust - check or leak. Recharge.

system for leak, check condenser

condenser for clog, or poor air circulation,

check compressor. Test and replace relay, must

be energised to freeze.

water level in reservoir.

11. Maintenance and Cleaning Instructions

A FOSTER Ice System represent a sizable investment of time and money in any company’s business. In order to receive the best return for

that investment, in MUST receive periodic maintenance.

It is the USER’S RESPONSIBILITY, and less costly in the long run, to avoid possible down time by keeping it clean, adjusting it as needed

and by replacing worn parts before they can cause failure. The following is a list of recommended maintenance that will help keep your

machine running with a minimum of problems.

Maintenance and Cleaning should be scheduled at a MINIMUM of twice per year.

11.1 Ice Maker

THE FOLLOWING MAINTENANCE SHOULD BE SCHEDULED AT LEAST TWICE A YEAR ON THIS ICE MAKER. CALL YOUR

AUTHORISED SERVICE AGENCY

1. Check and clean or service any optional water treatment devices, if any are installed.

2. Clean water strainer.

3. Check that the cabinet is level, in the side-to-side and front-to-back directions.

4. Clean the water system, evaporator plate and sump assembly, using a solution of Ice Machine Cleaner. Refer to CLEANING - Ice

maker.

NOTE: Cleaning requirements vary according to local water conditions and individual user operation. Continuous checking of

the clarity of ice cubes and visual inspection of the water system parts, evaporator plates and the sump assembly before and after

cleaning will indicate frequency and procedure to be followed in local areas.

6

23

Page 7

Wiring Diagrams

180 + 260 Wiring Diagram

Air Cooled 220 V. 50 Hz 1 ph

Colour of the Cables

m– Brown

bc– Light blue

gv– Yellow green

b – White

n–Black

r–Red

Magnetic Switch

H – N.C. Microswitch /

L – Electronic card

M – Fan motor

N – Motor pump

O – Water drain valve

P – Hot gas valve

Check the second and third cube harvest. Ensure that they are the correct size and make adjustments to the Ice Sensors Fingers as

necessary. In certain areas where there are extreme water problems it may be necessary to fit a filter or purifying equipment.

NOTE. If the water is too soft (demineralized) the Ice Thickness Sensor may not be able to sense the water on its fingers, thereby

not switching the unit onto the harvest cycle. In the event of this occurring a safety system built into the PC Board will automatically

switch the unit into the harvest mode if the freezing period goes beyond 30 or 40 minutes.

NOTE. To ensure a correct operation of the machine the water must have a minimum electrical conductivity level of 20 us.

Open the bottom end of the plastic ice deflector for 30 seconds to check the operation of the magnetic switch. The machine will switch OFF

and the Amber LED will glow to indicate machine OFF at full storage bin. Releasing the deflector will restart the machine in the freezing

mode commencing with the 3-minute delay.

Replace all panels and screws previously removed.

4. Operation

180 + 260 Wiring Diagram

Water Cooled 220 V. 50 Hz 1 ph

A – Power

B – Terminal block

C – Contactor

D – Compressor

E – Toggle switch

F – Pressostat

G – Ice sensor

Colour of the Cables

m– Brown

bc– Light blue

gv– Yellow green

b–White

n–Black

r–Red

Magnetic Switch

H – N.C. Microswitch /

L – Electronic card

M – Fan motor

N – Motor pump

O – Water drain valve

P – Hot gas valve

A – Power

B – Terminal block

C – Contactor

D – Compressor

E – Toggle switch

F – Pressostat

G – Ice sensor

REFRIGERATION SYSTEM SCHEMATIC

4.1 Refrigeration during freezing.

This ice machine employs either air (standard) or water (optional) as a condensing media, the refrigeration system for either one is as

follows:

The refrigerant metering is by thermostatic expansion valve.

4.2 Water System during freezing.

A combination of the water inlet solenoid valve and water level sensor is used to control the level of the water in the reservoir/sump.

30 seconds from the start of the freeze cycle the water pump starts, forcing water to the top of the evaporator where it is distributed through

the water tube and then cascades over the surface of the evaporator by gravity. Some of the water will turn to ice with the remainder

returning to the water reservoir for redistribution over the evaporator.

4.3 Ice harvest cycle.

When the ice reaches the desired size, as determined by the fingers of the ice thickness sensor, the hot gas bypass valve is energised

allowing the hot gas to warm the evaporator resulting in the ice cube block falling into the storage bin below.

4.4 Water system during ice harvest cycle.

During the harvest cycle, the electric water drain valve is energised opening the drain line. All of the water remaining in the reservoir at the

end of the freezing cycle is pumped, out to drain, through the water solenoid valve during the last 40 seconds of the defrost cycle eliminating

any possible build-up and accumulation of mineral concentration and other impurities in the reservoir.

The water inlet valve is energised for the last 10 seconds whilst the pump is running to allow fresh water to rinse the reservoir.

When the ice cube block is released from the evaporator it causes the deflector to swing open sufficiently to reset the contactor of the

magnetic switch which, via the PC Board, de-energises the water drain valve initiating a new freezing cycle.

The harvest/defrost cycle lasts between 1 and 2 minutes.

4.5 Control sequence.

At the start of the freezing cycle the contacts of the magnetic switch, mechanically operated by deflector cover, are closed via the PC Board,

thereby closing the circuit to the main contactor coil and consequently the compressor, fan motor and after 30 seconds the water pump.

As the ice reaches the thickness required the film of water flowing over it makes contact with the ice thickness sensor fingers (energised at

low voltage). If contact is maintained for more than 10 seconds a relay on the PC Board is energised controlling simultaneously the hot gas

valve and the water drain valve.

NOTE: In the event of failure of the ice thickness sensor, the PC Board automatically turns the unit into the defrost cycle when the

freezing cycle reaches 30 or 40 minutes depending on the operation of the fan motor during the freezing cycle.

At this point the unit initiates the defrost cycle. The hot gas circulating into the evaporator serpentine causes a slight melting of the ice cube

22

7

Page 8

block releasing it from the mould. Once released the ice block drops into the storage bin below and breaks into individual cubes, in the

process it moves the deflector plate forwards. The defector has on its side a magnetic switch that when it moves forward it opens and closes

the contacts. This motion deactivates the relay contacts that control the hot gas and water drain valve allowing the unit to start a new

freezing cycle.

When the ice bin is full of ice, the last batch of ice released from the evaporator cannot continue into the bin and so it stops the deflector from

returning to its position. With the magnetic switch contacts remaining open for more than 30 seconds the entire unit stops with the glowing

of the Amber bin full LED.

The machine will restart when the deflector returns to its normal position provided the machine has been of for more than 3 minutes, if not

the start will be delayed for 3 minutes with the blinking of the green Machine In Operation LED.

5. Alarm Conditions

Power On.‘Green’. Bin Full/ Washing. ‘Amber’. High Pressure. ‘Red’.

Machine in Operation ‘Green’. Alarm ‘Red’. Reset / Washing. ‘Push Button’.

The two Red LED’s are glowing constantly.

Condenser Sensor faulty.

The two Red LED’s are blinking slowly.

Water Error. The water level inside the reservoir is to low after 3 minutes from start of the water inlet valve being activated.

The two Red LED’s are blinking fast.

Reset Mode. Charging water through the Water Solenoid Valve after tripping OFF on Water Error.

The Red Alarm LED is glowing continuously.

Harvest cycle longer than 3 minutes 30 seconds.

The Red Alarm LED is blinking slowly.

Too High Condensing Temperature: The Condenser Sensor detected a temperature above 65°C.

The Red Alarm LED is blinking fast.

Reset Mode: Condenser Sensor sensing condenser temperature below 50°C, fan motor in operation for 3 minutes then back on to Start Up

Cycle Mode.

Red High Pressure LED is glowing continuously.

Too High Discharge Pressure, exceeding 33 bar (460 PSI).

Red High Pressure LED is blinking fast.

RESET MODE: After pushing the Red Reset Button of the Pressure Control (located at the rear of the machine) firstly the fan motor runs for

3 minutes then back on to the Start Up Cycle Mode.

The PC Board also checks the maximum time of the freeze cycle that may change according to the operation of the fan motor during the

freezing cycle (relative to room temperature).

Fan motor in ON/OFF Mode: Maximum Freeze Cycle length equal to 30 minutes.

Fan motor ON All of the time: Maximum Freeze Cycle length equal to 40 minutes.

Whenever the machine remains in the Freezing Cycle for the Maximum time ( 30 or 40 minutes) the PC Board moves the unit directly into

the Harvest Cycle.

6. PC Board Set Up

The PC Board can be set up for Manual Reset Mode with the Jumper In Place.

Manual Reset Mode. (Jumper in place)

To Restart the Machine it is necessary to Push the Reset Button.

The PC Board can be set up for Automatic Reset Mode with the Jumper Out Of Place.

Automatic Reset Mode. (Jumper out of place)

The Automatic Reset Mode is activated only for the following ALARM CONDITIONS.

WATER ERROR

•

TOO HIGH CONDENSING TEMPERATURE

•

TOO LONG HARVEST CYCLE.

•

6.1 Water Error

The machine remains in OFF mode for 30 minutes then it tries to re-fill with water.

Fills with water: Machine remains in operation.

Fails to fill with water: Machine again in the OFF mode for a further 30 minutes.

6.2 Too High Condensing Temperature

As soon as the temperature registered by the Condenser Sensor is above 50°C, the PC Board starts up firstly the condenser fan motor for

3 minutes then the entire machine through the normal Start UP Cycle Mode.

After the 3 minutes 30 seconds of the Harvest Cycle, the PC Board moves the machine into a new Freezing Cycle.

CAUTION: If the factory seal is broken on the replacement drier, exposing it to the atmosphere for more than a few minutes, the

drier will absorb moisture from the atmosphere and lose substantial ability for moisture removal.

To replace the drier:

1. Remove the factory seals from the replacement drier and install the drier in the refrigerant lines with the arrow positioned in the direction

of the refrigerant flow.

2. Solder the drier into the lines, two places, taking precautions NOT TO OVERHEAT the drier body, during installation soldering.

3. Purge the system and check for leaks.

4. Thoroughly evacuate the system to remove moisture and non- condensables.

5. Charge the system with refrigerant, by weight. SEE NAMEPLATE.

6. Replace and attach front and left side panel.

9.10 Removal and Replacement of the Evaporator Plate Assembly

1. Remove front and top panels.

2. Store refrigerant charge in liquid receiver and isolate parts to be opened from the rest of the system.

3. Disconnect water distributor tube above the evaporator plate and remove it.

4. Unsnap and remove evaporator cover deflector.

5. Loosen and remove all screws securing the evaporator frame to the chassis.

6. Unsolder and remove the refrigerant lines at the top of the evaporator plate to be replaced.

7. Remove nuts at top and left and right side of the evaporator to remove top and side trimming that make-up the frame of the evaporator

plate. The evaporator plate is now free.

To replace the evaporator plate, reverse the removal procedures. See nameplate. Weight in proper charge of R22/R404A.

9.11 Water Regulating Valve - Water Cooled

1. Shut off water.

2. Remove front and right side panel.

3. Unscrew water inlet fitting connection at the water regulator valve to condenser bracket.

4. Purge system of refrigerant.

5. Unscrew fitting connection at outlet of valve.

6. Unsweat valve connection from ‘T’ joint on system liquid line.

7. Remove valve from machine.

Reverse to reassemble.

9.12 Thermostatic Expansion Valve

1. Remove front, top and right side panels.

2. Purge system of refrigerant.

3. Unsweat valve at inlet, equaliser, and outlet.

4. Remove insulation from valve bulb, remove mounting straps and valve from cabinet.

5. Place new valve bulb in same place as old valve, secure with straps, and reinsulate.

Reverse to reassemble.

NOTE: Always install a replacement drier, any time the sealed refrigeration system is opened. Do not replace the drier until all

other repair or replacement has been completed.

Thoroughly evacuate the system to remove moisture and non-condensables.

9.13 Fan Motor or Blade - Left and Right Side

1. Remove left or right side service panels.

2. Remove screws and fan motor shroud.

3. Unplug fan motor to be removed.

4. Remove fan motor bracket from upper tie rod of unit chassis.

5. Remove fan blade from motor. Note location on motor shaft, and hub position.

6. To also replace fan motor, remove it from bracket.

Reverse to reassemble.

NOTE: When replacing a refrigeration component, the exact refrigerant charge must be WEIGHED or metered into a completely

evacuated system, because the FMIC is a CRITICALLY charged system.

8

21

Page 9

9. Removal and Replacement Procedures

7. Component Description

WARNING Be sure the electrical power supply circuit breaker and the inlet water supply are OFF, BEFORE starting any of the

following REMOVAL AND REPLACEMENT procedures as a precaution to prevent possible personal injury or damage to equipment.

9.1 Water Pump

1. Remove front panel.

2. Remove front interior metal strip.

3. Unplug pump.

4. Remove one screw holding pump bracket to reservoir right side.

5. Pull pump forward and lift up.

6. Remove discharge hose from pump outlet.

Reverse to replace.

9.2 Reservoir

1. Close water valve on water supply line.

2. Perform above steps and remove water pump.

3. Remove reservoir drain plug and flush reservoir out.

4. Remove the float valve from the reservoir.

5. Remove screws securing reservoir.

6. Liff-up and pull forward to remove reservoir.

Reverse to replace.

9.3 Distributor/Water Tube

1. Remove front panel.

2. Locate water distributor at the top of the evaporator.

3. Pull distributor forward to unsnap it from its holding clamps.

4. Remove hose clamp and water hose.

Reverse to replace.

9.4 Outlet Water Valve

1. Remove front and right side panel.

2. Unplug water valve.

3. Remove clamp securing outlet tube to valve.

4. Remove hose clamp and hose from inlet fitting.

5. Remove two screws and nuts securing valve to its metal bracket and remove valve.

Reverse to replace.

9.5 Compressor

1. Remove top panel (if possible), front panel, leff side service panel and left fan motor shroud.

2. Store refrigerant charge in liquid receiver.

3. Disconnect electrical lines from compressor.

4. Isolate parts to be opened from the rest of the system.

5. Remove compressor mounting bolts.

Reverse to reassemble.

NOTE: Always install a replacement drier any time the sealed refrigeration system is opened. Do not replace the drier until all

other repair or replacement has been completed.

9.6 Condenser - Air Cooled

1. Remove both side panels and remove screws of condenser bracket.

2. Store most of refrigerant charge in liquid receiver.

3. Isolate parts to be opened from the rest of the system.

4. Cut or unsweat liquid and discharge lines.

5. Unbolt and remove condenser from unit rear side.

Reverse to reassemble.

9.7 Condenser - Water Cooled

1. Shut-off water.

2. Remove front and left side panels.

3. Store most of refrigerant charge in liquid receiver.

4. Isolate parts to be opened from the rest of the system.

5. Unsweat water and refrigerant lines.

6. Unbolt and remove condenser.

Reverse to reassemble.

9.8 Hot Gas Valve

1. Remove front, right side panel and right fan motor shroud.

2. Unplug hot gas valve.

3. Purge system of refrigerant.

4. Cut or unsweat valve, remove from machine.

5. To replace, heat sinking the valve is CRITICAL. Wrap the replacement valve in wet rags, and sweat into place. Leave rags on until joints

cool.

Reverse steps 3-1 to reassemble.

9.9 Removal and Replacement of the Drier

To remove the drier:

1. Remove front and left side panel.

2. Remove screws and remove left side fan motor shroud.

3. Store most of the refrigerant charge in liquid receiver.

4. Unsolder refrigeration lines at both ends of the drier and remove the drier.

7.1 Front Console Panel

Power On.‘Green’. Bin Full/ Washing. ‘Amber’. High Pressure. ‘Red’.

Machine in Operation ‘Green’. Alarm ‘Red’. Reset / Washing. ‘Push Button’.

7.2 P. C. Board.

Located in the control box, this board is the brain of the system as it governs the ice machine cyclematic through sensors, relays and

switches. It consists of two separated printed circuits one at high and the other at low voltage integrated with a fuse, four connectors for the

sensors/ switches. (Condenser sensor – BLACK-, Magnetic switch- GREEN-, ice thickness sensor- RED-, water level Sensor- BLUE), two

jumpers (one J1 for factory use only – and the second J2 for the selection between manual or automatic reset mode). One outlet connector

(front LED display- BLACK ), one serial port connector (BLACK) and four plug in terminals for input and output power. With J2 closed the

P.C. Board is set up for Manual reset mode. When J2 is open the P.C. Board is set up for Automatic Reset mode.

The P.C. Board includes a electronic safety timer that turns on the unit automatically to the defrost cycle when the freeze cycle is longer than

30 or 40 minutes and trips off the unit when the defrost cycle is longer than 3 minutes and 30 seconds (red alarm LED on).

A trimmer, located close to the transformer, can be used to change the current received from the Ice Thickness Sensor in relationship to the

Electrical Conductivity of the water.

7.3 Compressor Contactor.

Located in the control box, the compressor contactor function is to carry the compressor line current. The contactor is wired to receive power

from the P.C. Board.

7.4 Ice Thickness Sensor.

Located in the front upper right side of the evaporator, the sensor is constructed of two metal reeds through which passes current at a low

voltage. The two metal reeds, which are individually insulated, are set, through a setting screw, to maintain a minimum clearance from the

evaporator (3 to 6mm). Once ice is formed in the moulds plus sufficient to bridge the minimum clearance between the two sensor reeds and

the evaporator, the water flowing over the evaporator makes contact between the two sensors. If contact is made for 10m seconds the P.C.

Board receives the signal and starts the defrost cycle.

7.5 Magnetic Switch.

Located in the plastic deflector plate, in front of the evaporator, the switch sends a pulse to the P.C. Board which switches the machine back

into the freezing cycle.

7.6 Hot Gas Valve

The Hot Gas Solenoid Valve functions only during the Harvest Cycle, to divert the Hot Discharge Gas from the Compressor, bypassing the

Condenser and Expansion Valve, for a direct flow to the Evaporator to release the ice cubes from the moulds.

The Hot Gas Solenoid Valve is comprised of two parts, the Body and Plunger and the Coil Assembly. Installed in the discharge line from the

compressor, the energised coil lifts the valve stem within the body to cause the hot gas to be diverted when the ice Thickness Sensor signals

the P.C. Board to start the Harvest Cycle.

7.7 Condenser Temperature Sensor.

The condenser temperature sensor probe (located in contact with the condenser coil) detects the condenser temperature variations and

signals them to the P.C Board at low voltage.

In the air cooled versions, in relation to the different current received, the microprocessor of the P. C. Board supplies, through a TRIAC, the

power at high voltage to the condenser fan motor to cool the condenser and reduce the temperature.

If the condenser temperature rises and reaches 65°C (150 °F) the current passed to the micro processor is such to cause an immediate and

total stopping of the operation with the blinking of the Red Alarm LED.

7.8 High Pressure Control.

The High Pressure Control, safety control, is factory set to cut out at 30 bar and cut in at 22 bar. The control functions as a precautionary

device to shut OFF electrical power to the machine should a loss of water occur, to water-cooled machines condenser, or the failure of the

920

Page 10

Condenser Fan Motor on the air-cooled versions. The high Pressure Control is manual reset with the reset button at the on the rear of the

machine and a monitoring Red LED on the Front Console Panel.

7.9 Water Regulating Valve (water-cooled models only).

The water Regulating Valve function is to maintain a constant Compressor head pressure by regulating the amount of water flowing through

the condenser, on water-cooled models. The valve operates through the refrigeration system high-pressure side. Rotating the adjusting

screw, located at the top of the valve, will Increase or Decrease the water flow through the water-cooled condenser, which in turn will

Decrease or Increase the Compressor operating head pressure.

7.10 Water Distribution System.

The Water Distribution System functions to evenly supply water to all of the cells of the evaporator plate. The water is pumped from the water

reservoir to the distributor, above the evaporator, through the holes and flows over the ice moulds. Gravity returns the unfrozen water to the

reservoir for recirculation.

7.11 Water Drain Solenoid Valve.

The Water Drain Solenoid Valve functions in conjunction with the water pump to flush-out the reservoir assembly at the beginning (first 40

seconds) of every harvest cycle. This action cleans-up and rinses the reservoir during each harvest cycle preventing dangerous water

mineral concentration.

7.12 Thermostatic Expansion Valve.

The Thermostatic Expansion Valve regulates the flow of refrigerant to the evaporator and reduces the pressure of the liquid refrigerant from

condensing pressure to evaporating pressure.

7.13 Water Pump.

The water pump primes the water from the reservoir to the distributor tube and through the holes (in the distributor) it cascades over the

evaporator moulds by gravity to be frozen into clear ice cubes. The water pump remains OFF during the first 30 seconds of the freezing

cycle whilst it continues to run for the first 40 seconds of the defrost/ harvest cycle to drain the remaining water in the reservoir.

7.14 Water Inlet Solenoid Valve (male fitting).

The P.C. Board energises the Water Inlet Solenoid Valve during the beginning of the freezing cycle until the water reaches the maximum

level in the reservoir (controlled by the Water Level Sensor).

After 3 minutes, from the start of the freezing cycle, the Water Inlet Valve is energised again for a short period to re-fill the reservoir to the

maximum level to minimise the possibility of slush ice forming.

A flow control is fitted in the feed pipe to reduce the pressure of the water.

7.15 Water Level Sensor.

The Water Level Sensor, located in the upper right side of the reservoir, works in conjunction with the P.C. Board in order to control the water

level at the beginning of the freeze cycle by receiving a low power current through the water. When the current reaches the P.C. Board the

water inlet solenoid valve is de-energised.

If the P.C. Board doesn’t receive any signal from the Water Level Sensor within the first 3 minutes of the freeze cycle the P.C. Board trips

OFF the operation of the machine with the switching ON of the two Red LED’s blinking slowly.

8. Wiring Diagram - F200 & F300

F200 - F300 Wiring Diagram

220V 50Hz 1ph

M = brown

bc = light blue

gv = yellow green

b=white

n = black

r=red

a = orange

A - Input terminal board

B - Compressor contactor

C - Compressor

D - Ice sensor

E - End defrosting switch

F - Water level sensor

G - Condenser temperature probe

H - Led card

I - P.C. Board

J - HI pressure switch

K - Manual/Automatic reset jumper

L - Water pump

M - Water inlet valve

N - Water drain/purge valve

O - Hot gas valve

P - Fan Motor

(only AIR cooled unit)

Q - Fan Motor

(only WATER cooled unit)

RC - Compressor relay

CS - Start capacitor

CM - Run capacitor

8.3 Compressor Contactor

Located in the control box, the compressor contactor functions is to carry the compressor line current. The contactor is wired to receive

power from the ICE/OFF/WASH switch through the P.C. Board.

8.4 Ice Thickness Sensor

Located in the front upper right side off the evaporator, the sensor is made with two metal reeds in which passes power at low voltage. The

two metal reeds, which are individually insulated, are set, through a setting screw, to maintain a minimum clearance from the evaporator

(7mm) Once ice is formed into each mould and is thick enough to fill-up that minimum clearance existing between the two sensor reeds, and

the evaporator, the water that cascades over the ice has gradually increased to make contact between the two sensor reeds.

Contact remains there for about 6 seconds the P.C. Board receives the signals to put the ice machine on defrost.

8.5 N.C. Microswitch/Magnetic Switch

Signalling the ice cubes release. Located in the upper left side corner of the evaporator, this low voltage switch - single pole/single throw mechanically operated by the evaporator deflector actuator, signals to the P.C. Board the end of the defrost cycle and to re-start a new

freezing cycle. The swinging motion, to which the ice deflector is subject to when the ice cubes drop into the bin below, causes the deflector

actuator to press (open the contact) and the release (close the contact) microswitch plunger. This OFF and ON situation of the N.C. contact

is enough to signal to the P.C. Board that the timed defrost cycle is over. On later models the sequence is controlled by a magnetic switch

attached to the bottom right hand side of the deflector.

If the bin is full of ice, the evaporator deflector will be left in the open position by the last batch of released cubes. This means that the

deflector actuator will keep the N.C. microswitch plunger pressed,or the magnet and switch separated, as long as the deflector remains in

open position.

If the N.C. contact are open for more that 30 seconds, the switch signals to the built-in time delay of the P.C. Board to turn the unit OFF

NOTE: In case the Interface P.C. Board does not receive the second pulse from the microswitch/magnetic switch, after 30 to 32

seconds from the first pulse, it will send a signal to the main Board, to switch the unit from defrost to freezing cycle.

It is possible to vary the maximum waiting time for starting a new freezing cycle after the pulse sent by the first switch, by

adjusting a ‘trimmer’. The waiting time variation ranges from 22 to 45 seconds.

8.6 Hot Gas Solenoid Valve

The Hot Gas Solenoid Valve functions only during the Harvest Cycle, to divert the hot discharge gas from the Compressor, bypassing the

Condenser and thermostatic expansion valve, for direct flow to the Evaporator Platen Assembly to release ice cubes from the ice cube

moulds.

The Hot Gas Solenoid Valve is comprised of two parts - the Body/Plunger and the Coil assemblies. Installed in the discharge line of the

Compressor, the energised solenoid coil liffs the valve stem within the valve body to cause the hot discharge gas to be diverted when the ice

Thickness sensor has signalled to the P.C. Board to start the Harvest Cycle.

8.7 High Pressure Fan Control - Air Cooled Models

A reverse acting automatic reset, high pressure control is electrically connected to the two condenser fan motors and by a capillary tube to

the liquid line.

Its function is to maintain the head pressure during the freezing cycle between the preset values and the head pressure during the harvest

cycle ensuring sufficient heat to release the cubes from the cube moulds.

The control contacts are set to open at 13 bar cutting off the electrical power supply to the fan motors and to close at 15 bar.

8.8 High Pressure Control - Water Cooled Models

The High Pressure Control, a safety control, is factory set to cut-out, at 20 bar and cut-in at 13 bar. The control functions as a precautionary

device to shut OFF electrical power to the Ice maker, should a loss of water occur to the water cooled Condenser. In addition to being a

manually reset Control, there is an adjusting screw for raising or lowering the CUT-IN pressure.

8.9 Water Regulator Valve - Water Cooled Models

The Water Regulator Valve functions maintain a constant Compressor head pressure, by regulating the amount of incoming water flowing

through the Condenser, on water-cooled models. The valve operates through the refrigerant system high side pressure.

Rotating the adjusting screw located on top of the valve, can INCREASE or DECREASE the water flow through the water-cooled Condenser,

which in turn, will DECREASE or INCREASE the Compressor operating head pressure.

8.10 Water Distribution System

The Water Distribution System functions is to evenly supply water to all cells of the evaporator plate. The water pump pumps water from the

sump to the tee.

From there water is channelled through the vertical tygon tube to the water distributors, above the evaporator plate, and from the holes in the

distributor tube water flows to the cells on one side of the evaporator plate.

Gravity flow returns the unfrozen excess portion of water to the sump reservoir for recirculation.

8.11 Water Outlet Solenoid Valve

The Water Outlet Solenoid Valve functions in conjunction with the water pump to flush-out the sump assembly at every harvest cycle.

This action cleans-up and rinses the sump during each harvest cycle preventing dangerous water mineral concentration.

8.12 Thermostatic Expansion Valve - TXV

The Thermostatic Expansion Valve regulates the flow of refrigerant to the evaporator and reduces the pressure of the liquid refrigerant from

condensing pressure to evaporating pressure.

10

19

Page 11

At this point, the unit initiates the defrost cycle. The hot gas circulating into the evaporator serpentine causes a slight melting of the ice cubes

which get released from their moulds. Once entirely released the ice cubes drop simultaneously into the ice storage bin below; in doing so

they move apart from the evaporator bottom end of the plastic deflector. This plastic deflector has on its upper left corner a metal actuator

which, on account of the deflector’s swinging motion, caused by the ice dropping in the bin, pushes the microswitch plunger to open and

close the N.C. contacts. This will, in turn, de-activate the relay contacts that control the hot gas and water drain valve which get de-energised

allowing the unit to start a new freezing cycle. On later models the sequence is controlled by a magnetic switch attached to the bottom right

hand side of the deflector.

When the ice bin is full of ice, the last batch of ice cubes released from the evaporator accumulates to keep the bottom end of the plastic

deflector in open position; with the N.C. microswitch/magnetic switch contact open for longer than 30sec the entire unit stops.

7. Service Specification

In servicing a machine, it is offen useful to compare individual units operating characteristics to those of a normally operating machine. The

data that follows gives those characteristics; however, be aware that these values are for a NEW, CLEAN machine. USE THESE NUMBERS

AS A GUIDELINE ONLY.

COMPONENT R22 - R404A Machines

Reservoir level 30-35 mm

Cube Size Control Ice Sensor

distance from evaporator 7mm

High Pressure Safety Switch

Water-cooled C/IN 13 bar - C/OUT 20 bar

Fan Pressure Control

Air-cooled only C/IN 15 bar - C/OUT 13 bar

7.1 Operating Characteristics

On air-cooled models during the freezing cycle the discharge pressure is maintained between 13 and 15 bar by means of fan pressure

control and at the same time, the suction pressure will also decline reaching its lowestpoint just before harvest. Compressor amps experience

a similar drop.

On water-cooled models the discharge pressure is constantly maintained during the freeze cycle by the water regulating valve at 13 bar.

However, suction pressure and compressor amps, will still decline as the machine freezes ice.

7.2 Freeze Cycle

Suction Pressure at the beginning of the Freeze Cycle 2.8/2.5 bar 3.5 bar

Average Discharge Pressure A/C 14 bar 15.5 bar

Average Discharge Pressure W/C 13 bar 17 bar

Suction Pressure at the end of the Freeze Cycle 1.5/1.3 bar 1.7 bar

Freeze Time 20/25 Minutes 20/25 Minutes

Amps. drawn at the beginning of the Freeze Cycle FMIC 180 5.5 5.0

Freeze Cycle FMIC 260 Beginning 7.6 8.0

Amps. drawn at the end of the Freeze Cycle FMIC 180 4.4 4.0

Freeze Cycle FMIC 260 End 4.6 5.5

Suction Pressure at the end of the Freeze Cycle 1.5 1.7

7.3 Harvest Cycle

Average Discharge Pressure 9 bar 13/15 bar

Average Suction Pressure 7.5 bar 7.5 bar

The values listed are representative of values seen at a wide range of air and water temperatures and are for a normal cube size. When

comparing these figures to field data, allow a variation from each end of the range given.

Refrigerant charge R22 Machines R404A Machines

Model FMIC180 FMIC260 FMIC180 FMIC260

Air cooled l000gr l500gr 1200gr 1700gr

Water cooled 650gr 700gr 1200gr 900gr

Refrigerant metering device

Expansion valve

NOTE: Always check nameplate on individual ice machine for special refrigerant charge before charging the refrigeration system.

Such refrigerant charge is the average charge for the Modular Cubers. However, it is important to check nameplate for each

machine.

R22 Machines R404A Machines

R22 Machines R404A Machines

9. Service Diagnosis.

The table below is intended as a quick reference to aid the service engineer to determine the cause of a particular malfunction as well as the

recommended repair. It is not intended to be an exclusive list.

Reference to other portions of the manual inclusive of wiring diagrams, installation and operating instructions are recommended to better

determine the cause of a problem.

Symptom Possible cause Correction

Warning RED LED ON See Page 20. See Page 20.

No Warning RED LED ON P.C. Board inoperative Remove board and check.

No power to machine Check electrical source.

Bin Full Amber LED ON Bin Full of Ice. None.

Magnetic Switch inoperative Check and replace.

Machine Runs but compressor not running. P.C. Board compressor relay open. Test and Replace.

Compressor Contactor open. Test and Replace.

Compressor relay open. Test and Replace.

Compressor Winding open. Test and Replace.

Machine runs, makes ice, Ice thickness control open. Check sensor fingers to determine if covered

does not try to harvest. with scale or sediment.

Water Too soft Water electrical conductivity must be higher

than 20 uS.

Machine will not run with demineralized water.

Built in relay on P.C. Board open. Check and replace P.C. Board.

Machine runs makes ice and Low Refrigerant Charge. Check system for correct refrigerant charge.

harvests ice but very slowly. Check system for leak.

Low ice capacity High discharge pressure due to under Reclaim refrigerant and recharge with the

condensing or refrigerant overcharge. correct amount.

Inefficient Compressor. Replace compressor.

Dirty condenser. Clean Condenser.

Low water flow (water cooled only). Check and repair.

High air temperature (Air-cooled only). Check temperature of air entering condenser.

Machine makes irregular ice. Water distributor blocked. Clean water distributor.

Expansion valve superheat wrong. Adjust or replace.

Low refrigerant charge. Check for leak, reclaim refrigerant and

recharge with correct amount.

8. Component Description

8.1 Toggle Switch - ICE/OFF/WASH

Is a double pole-double throw switch. In OFF position keeps the electric circuit open through the P.C. Board built-in ON-OFF switch. In ICE

position the unit electric circuit is closed for normal operation of electric component.

In WASH position opens the electric circuit to the compressor contactor and fan motors and closes the circuit for the water pump.

8.2 Electronic Control Board

Located in the control box, this board is the brain of the system as it governs the ice machine cyclematic through sensors, relays and

switches. The sensor is the ice thickness control which signals to the P.C. Board to energise the built-in relay that controls the Hot Gas Valve

and Water Drain Valve. The other contactor to which the P.C. Board supply power is on the compressor line.

The switches are: the Toggle ICE/OFF/WASH switch and the N.C. microswitch/magnetic switch actuated by the evaporator deflector that

signals to the P.C. Board that ice has been defrosted and released, so that the relay controlling the defrost can be disconnected.

The P.C. Board is equipped with an electronic safety timer that turns-on automatically the unit to defrost cycle when the freezing cycle is

longer than 40 minutes and trips-off the complete unit when defrost cycle is longer then 4 minutes.

18

11

Page 12

10. Maintenance, Cleaning and Sanitation Instructions.

The Foster Modular Ice Cuber represents a sizeable investment of time and money in any company’s business.

In order to receive the best return for the investment periodic maintenance is essential.

It is the USER’S RESPONSIBILITY to see that the machine is maintained and the following is a list of recommended instruction to keep the

machine running with a minimum of problems.

Maintenance and Cleaning should be scheduled at the minimum twice per year while sanitation at least once per month.

10.1 Icemaker

THE FOLLOWING MAINTENANCE SHOULD BE SCHEDULED FOR AT LEAST TWO TIMES PER YEAR ON THE ICE MAKER AND

SHOULD BE CARRIED OUT BY YOUR AUTHORISED SERVICE AGENT.

Check and clean or service any optional water treatment devices, if installed.

Clean water strainer.

Check that the cabinet is level, checking from front to back and side to side.

Clean/ Sanitise the water system, evaporator plate and water reservoir using a solution of Citric Acid. (refer to Cleaning Icemaker).

Note: Cleaning/ Sanitising requirements vary according to local water conditions and individual user operation.

Continuous checks of the clarity of the ice cubes and visual inspection of the water systems parts, evaporator plate and the

reservoir before and after cleaning will indicate frequency and procedure to be followed.

Check and tighten all bolts and screws.

Check for water leaks and secure as necessary.

Check the bin control to test shut off. Holding the evaporator deflector in the open position for more than 30 seconds should cause the ice

machine to hut off. Once the deflector has been returned to the closed position the ice making process will restart.

Check cube size, make adjustments to the ice thickness sensor as necessary.

Switch the machine OFF clean the condenser using a vacuum cleaner, brush between the fins using a soft brush. DO NOT USE A WIRE

BRUSH. Instruct the user to clean condenser frequently.

10.2 Ice Storage Bin

The interior of the ice storage bin is in contact with food products, ICE, and should be cleaned and sanitised regularly. Once a week sanitise

it with a commercial food grade sanitiser in compliance with the manufacturer instruction.

10.3 Cabinet Exterior.

Wipe clean the machine and ice bin exterior with a clean cloth or tissue soaked in a mild solution of soapy water.

10.4 Cleaning Ice Maker

Empty the bin of ice.

Remove the front panel.

Wait till the end of the defrost/harvest cycle then push and hold the RESET BUTTON for 6 to 8 seconds. The machine will stop with the

blinking of the Amber LED (slow blink)

Pour 100gr of citric acid directly into the reservoir then push the RESET BUTTON again for a short while. The water pump starts to operate

with the fast blinking of the Amber LED, the water inlet valve will be energised till the reservoir is full.

After 15 minutes push the RESET BUTTON for a short while. The P.C.Board will put the machine in automatic rinsing mode with the Amber

LED blinking (blinking twice and then repeat).

NOTE: Rinsing mode consists of:

(a) Energising the water drain valve and the water pump for 40 seconds to empty the reservoir.

(b) De-energise the water drain valve and the water pump for 1 minute.

(c) Energise the water inlet valve till the reservoir is full.

(d) Energise the water pump for 1 minutes.

The above sequence is repeated 7 time so as to be sure that all traces of citric acid have been removed.

At the end of the 7th rinsing cycle the P.C>Board stops the operation of the machine and the Amber LED will be blinking slowly.

Push and hold the reset button for 6 to 8 seconds the machine will restart in the freezing mode.

Replace the evaporator deflector and front panel.

Check the next batch of ice to be sure all of the cleaner has gone (no sour taste).

Caution- DO NOT use ice cubes produced from the cleaning solution. Ensure none remain in the storage bin.

Pour hot water into the storage bin to melt any cubes that may remain and to also clean the bin drain.

The thermostatic expansion valve meters how much liquid refrigerant is to be allowed into the evaporator section of the refrigeration system.

This is determined by the temperature of the TXV sensing bulb, located on the suction line manifold, at the outlet of the evaporator.

If the bulb senses a warm suction line, more refrigerant is allowed into the evaporator, (common at the beginning of the freeze cycle) and

when the temperature begins to fall, less refrigerant is allowed through. This is why the suction side gauge pressure will decline throughout

the freeze cycle. At the evaporator, the liquid refrigerant released from high pressure, boils off in the low pressure environment and absorbs

heat, thus cooling the evaporator surface and anything near it, such as water.

The low pressure refrigerant vapour then is forced through the heat exchanger where any excess liquid refrigerant boils-off, allowing only

refrigerant vapour to enter the compressor suction tube, where it is recompressed into high pressure, high temperature gas again and the

cycle repeats.

6.2 Water System

A fixed charge of water had been brought into the machine during the harvest or defrost cycle through the float valve.

A pump, running continuously, forces the water to the top of the evaporator, where it is distributed through a water tube and then cascades

down the evaporator surface by gravity. As it flows across the refrigerated evaporators, some of the water will be chilled enough to change

form, turn to ice, and stay frozen onto the evaporator. Most of the water returns to the reservoir, to be sucked back into the pump, and

repumped over the evaporators.

6.3 Refrigeration System During Harvest

The refrigeration system performs the harvest of ice by use of a hot gas bypass valve. When the time comes to de-ice the evaporators, the

hot gas valve is energised, and the high temperature, high pressure gas bypasses the condenser, and is allowed directly into the evaporator.

The high pressure gas is cooled by the cold evaporator so it condenses into a liquid, giving up its heat as it does so. This heat warms the

evaporator and the ice frozen onto the evaporator surface melts, releasing the frozen cubes. Ice then falls by gravity into the storage bin.

The liquid refrigerant goes through the suction line into the heat exchanger where it boils-off so that only refrigerant vapour is drawn into the

suction tube of the compressor.

6.4 Water System

During the harvest cycle, the electric water drain valve is energised thereby opening the drain line.

All water remaining in the reservoir at the end of freezing cycle is pumped-out, to the waste, through the water solenoid and drain line during

the entire defrost cycle eliminating any possible build-up and accumulation of minerals concentration and impurities in the water reservoir.

As the pump stops, the incoming water, passing through the float valve, has still sufficient time, before beginning the next freezing cycle, to

properly fill up the sump/reservoir, so that there would not be any cavitation problem when the water pump resumes its operation, granting

thereby a beffer ice formation inside the cooling cells.

When the released ice cubes drop into the bin, they open-up for a fraction of a second the bottom end of the plastic deflector.

The deflectors swinging motion is enough to reset the contact of the N.C. microswitch/magnetic switch which - via electronic control board

- de-energises the water drain valve allowing the unit to initiate a new freezing cycle.

NOTE: If the interface P.C. Board does not receive the pulse from the second microswitch/magnetic switch, after 30-32 seconds

from the first pulse it will send the signal to the main Board, to switch the unit from defrost to freezing cycle.

The harvest cycle lasts about 1 1/2 to 2 minutes.

6.5 Control Sequence

At the start of the freezing cycle, the N.C. contacts of the microswitch/magnetic switch mechanically operated by the actuator plate of the

deflector cover are closed,- via electronic control board, - closing the circuit to the main contact or coil and consequently to the compressor,

fan motors and to the water pump motors.

Then, as the ice thickness reaches the value that corresponds to the full cube size, the film of water that constantly cascades over the slab

of ice formed on the evaporator, arrives to establish a contact between the two fingers (energised at low voltage) of the ice sensor control,

located on the front upper right side of the evaporator. If the contact between the two fingers of the ice sensor remains established - by the

film of water - for more than 10 seconds, a small relay on the electronic board energises, controlling simultaneously both the hot gas valve

and the water drain valve.

NOTE: In case of failure of the ice level sensor the P.C. Board automatically turns the unit to the defrost cycle if the freezing cycle

is longer than 40 minutes.

12

17

Page 13

Check operation of the freezing cycle:

a) Compressor is operating.

b) Water pump is operating as seen by water moving through the tygon tube up to

the water distributor at the top of evaporator plate, where water is uniformly

dispensed and cascades down over the egg-crate evaporator and drains back

into the Sump Assembly for recirculation.

4. Remove the evaporator deflector cover temporarily and feel inside the ice cube mould of the egg-crate evaporator, this should feel cold

to the touch, shortly after ice will begin to form.

First freezing cycle will range between 20 and 25 minutes. Longer for temperature above 25°C and shorter when temperature is below 25°C

Average complete cycle time is about 25 minutes.

5. Make sure of correct operation of float valve and water pump.

6. Check for any irregular noise source and if any, eliminate it.

7. Replace plastic cover deflector before harvest cycle.

8. Observe first ice cube harvest.

a) Check operation of N.C. microswitch/magnetic switch on models controlling the

ice maker operation by keeping open the bottom end of the plastic deflector for

more than 30 seconds.

b) Check size of ice cubes; if an adjustment is required thread down or out screw

N. 1 as shown in the illustration.

This screw position determines the distance between the sensor reeds and the

egg-crate evaporator thus keeping the ice cube at a proper thickness.

9. Observe second and third cube harvest.

Check if size and shape combination is correct.

In areas where extreme water problem conditions exist, filtering or purifying equipment

is recommended.

NOTE: If water used is too soft, ‘demineralised’ the ice thickness sensor might

not be able to sense the water on its reeds, thereby it will not switch the unit on

harvest cycle.

A safety system built in the E.C. board switches the unit on harvest cycle whenever

the freezing period gets longer than 40min.

10. Replace all cabinet panels and screws previously removed.

11. Thoroughly explain to owner/user the significant specifications of the ice maker start-up, reset and operation, going through the procedures

in the operating instructions.

Answer all questions about the ice maker by the owner and inform the owner himself of the name and telephone number of the

authorised service agency serving him.

6. Operation

FMIC 180 & 260 Electronic Modular Ice Cuber

1. Specification

FMIC180

1 20mm — WATER OUTLET

2 20mm — WATER OUTLET –

WATER COOLED ONLY

33/4in GAS WATER INLET

4 CORD SET

Accessories:

KSC 18 — Cube stacking kit

Dimensions:

HEIGHT 530mm (20

WIDTH 800mm (31

DEPTH 600mm (253/8in)

WEIGHT 77kg

FMIC 180 Machine Specifications - R22 Machines

Model Cond. unit Finish Comp. Water reg.

FMIC 180

Model electr. amps amps Watts per 24hr wires fuse

FMIC 180A

FMIC 180W 5.5 28 810 20

Cubes per Harvest: 204 Full

* Subject to variations according to different water and ambient temperature conditions. (Amb. 32°C – Water 15°C)

Air

Water 1920*

Basic Start cons. kWh No. of Amps

220-240/50/1

Stainless Steel

Electric

power

6 30 980 24

1

FMIC260

7

/8in)

1

/2in)

It/24hr

300

3 x 2.5mm215

FMIC 180 Machine Specification

R404A Machines

Cond unit Finish Comp consumption

Air cooled Stainless steel 11/

Basic Start

Electr. Amps amps Watts

230/50/1 6 30 A 1100 26.4 16 A

4

16 litre per hr

Elec Power

Cons. kWh

per 24hr

Water

Fuse

Amps

6.1 Refrigeration During Freeze

This ice machine employs either air or water as a condensing media, the refrigeration system for either is as follows:

At the hermetic compressor, Refrigerant is compressed into a high temperature, high pressure gas.

This gas contains the heat removed from the evaporator, as well as compressor motor heat. The gas moves through the discharge line

into the condenser, air or water-cooled. If air-cooled, the discharge pressure will change with the heat load and the ambient air temperature.

If water-cooled, the discharge pressure is controlled by the amount of water flowing through the condenser - which is determined by the

water regulating valve.

After the gas is cooled in the condenser, giving up much of its heat, the gas condenses into a high pressure liquid. This liquid travels through

the liquid line to the metering device, a thermostatic expansion valve.

REFRIGERATION SYSTEM SCHEMATIC

1 20mm — WATER OUTLET

2 20mm — WATER OUTLET –

WATER COOLED ONLY

33/4in GAS WATER INLET

4 CORD SET

Accessories:

KSC 25 — Cube stacking kit

Dimensions:

HEIGHT 680mm (263/4in)

WIDTH 800mm (311/2in)

DEPTH 600mm (253/8in)

WEIGHT 100kg

FMIC 260 Machine Specifications - R22 Machines

Model Cond. unit Finish Comp. Water reg.

FMIC 260

Model electr. amps amps Watts per 24hr wires fuse

FMIC 260AS

FMIC 260W 6.5 48 1230 35

Cubes per Harvest: 289 Full