Page 1

T e c h n i c a l M a n u a l

Duet Condensing

Unit/Cooler

Page 2

If not disposed of properly all refrigerators have components that can be harmful to the environment. All old refrigerators must be

disposed of by appropriately registered and licensed waste contractors, and in accordance with UK laws and regulations.

DISPOSAL REQUIREMENTS

2

CONTENTS

Page

Table of Contents 2

Duet Package Refrigeration System 2

Duet Specifications 3

Cooler Specifications 4

Condensing Unit Technical Data 5

FKS Cooler Dimensions 6

FTG Cooler Dimensions 7

Liquid and Suction Line Pipe Size 7

Control Panel 8

Microprocessor Controls - Duet HV, GP Series 8

Thermostat Function 8

Display 8

Microprocessor Controls - Duet C, F, M, and L Series 9

Thermostat Function 9

Display 10

Controller Parameter Settings 10-11

Electrical System Description 11

Duet Package Wiring Schematic 12

Duet Installation Guidelines 13

ENVIRONMENTAL MANAGEMENT POLICY.

PRODUCT SUPPORT AND INSTALLATION CONTRACTORS

Foster Refrigerator recognises that its activities, products and services can have an adverse impact upon the environment. The organisation is committed to implementing systems and controls to manage, reduce and eliminate its adverse environmental impacts wherever possible, and has formulated

an Environmental Policy outlining our core aims. A copy of the Environmental Policy is available to all contractors and suppliers upon request.

The organisation is committed to working with suppliers and contractors where their activities have the potential to impact upon the environment. To

achieve the aims stated in the Environmental Policy we require that all suppliers and contractors operate in compliance with the law and are committed

to best practice in environmental management.

Product Support and Installation contractors are required to:

1. Ensure that wherever possible waste is removed from the client’s site, where arrangements are in place all waste should be retumed to Foster

Refrigerator’s premises. In certain circumstances waste may be disposed of on the clients site; if permission is given, if the client has arrangements in

place for the type of waste.

2. If arranging for the disposal of your waste, handle, store and dispose of it in such a way as to prevent its escape into the environment, harm to human health, and to ensure the compliance with the environmental law. Guidance is available from the Environment Agency on how to comply with the

waste management ‘duty of care’.

3. The following waste must be stored of separately from other wastes, as they are hazardous to the environment: refrigerants, polyurethane foam,

oils.

4. When arranging for disposal of waste, ensure a waste transfer note or consignment note is completed as appropriate. Ensure that all waste is correctly described on the waste note and include the appropriate six-digit code from the European Waste Catalogue. Your waste contractor or Foster

can provide further information if necessary.

5. Ensure that all waste is removed by a registered waste carrier, a carrier in possession of a waste management licence, or a carrier holding an appropriate exemption. Ensure the person receiving the waste at its ultimate destination is in receipt of a waste management licence or valid exemption.

6. Handle and store refrigerants in such a way as to prevent their emission to atmosphere, and ensure they are disposed of safely and in accordance

with environmental law.

7. Make arrangements to ensure all staff who handle refrigerants do so at a level of competence consistent with the City Guilds 2078 Handling Refrigerants qualification or equivalent qualification.

Page 3

Duet Specifications

3

Duet Package Refrigeration System

The Duet Package Refrigeration System Comprises of:

Air Cooled Condensing Unit (standard items)

• Compressor

• Air cooled condenser

• Liquid receiver

• High/Low pressure switches

• Liquid line sight glass

• Filter Drier

• Liquid/Suction line shut off valves

• Crankcase heater (except DCU1-1H, DCU2-1H, DCU1-1L as option)

• Low ambient kit (only DCU5-3L, DCU6-3L others as option)

• Mounting Channels (DCU6-3H, DCU 7-3H, DCU 5-3L only)

• R404a refrigerant

• White unit cover

Cooler

• FTG Range with and without electric defrost heaters

• FKS Range with and without defrost heaters

Control Panel

• Microprocessor Controller c/w function indicators

• Ten metre sensing probes

• Component contactors

• Component circuit breakers

Not included

• Interconnecting pipework

• Pipe installation

• Mechanical fasteners (screws, pipe clamps etc.)

• Refrigerant

• Mains supply wiring

• Lockable isolator switch

• White enclosure

• Remote alarm contacts

Ancillaries (supplied loose)

• Expansion valve

• Liquid line solenoid valve

• Drain line heater (where applicable)

• Cooler fixing nylon bolts c/w nuts and washers

Options

• Wall brackets

• Oil separator (except DCU1-1H, DCU2-1H, DCU1-1L)

• Low ambient kit (except DCU5-3L, DCU6-3L this fitted as standard)

• 220-1-60hz in lieu of 230-1-50hz

• 220-3-60hz in lieu of 400-3-50hz

Page 4

Duet Installation Guide Notes

1. GENERAL

Installation should be carried out by competent persons adopting

codes of good refrigeration practices as detailed in BS.EN 378-1:2000

Refrigerating Systems and Heat Pumps - Safety and environmental

requirements. Particular care should be taken installing horizontal and

vertical pipe runs incorporating correct bends, traps etc.

2. CONDENSING UNIT

Although the Condensing Unit is rated to operate in an ambient

temperature up to 43°C it is still important to consider the location

of the Unit during installation. Solar Gain from direct sunlight can

raise the temperature inside the unit housing beyond the operating

specification of the unit resulting in loss of performance and possible

damage to equipment.

Equally protection from very low ambient conditions should be addressed

Basically consider protection components such as oil separators, head

pressure control, additional solenoid valves, crankcase heaters etc for

adverse operating conditions.

The Condensing Unit can be positioned at low level ensuring that it is

raised off the ground and mounted on wall fixing brackets. There should

be at least 600mm clearance in front of the unit to allow for adequate

air to the condenser plus access for servicing through the top therefore

at least 600mm clearance should be allowed.

3. PIPE RUNS

The nominal design pipe run for the system is 50 metres however care

should be taken to consider any vertical rise where the condensing unit

is situated above the coldroom. The introduction of “P” traps in the

suction line to aid oil return to the compressor should be considered

also the requirement of an oil separator, especially low temperature

applications. Where the vertical rise is 5 metres and above the use of

an oil separator should be considered, especially on low temperature

applications, plus the position of the oil “P” trap and the size of the

suction line to maximise oil return to the compressor.

4

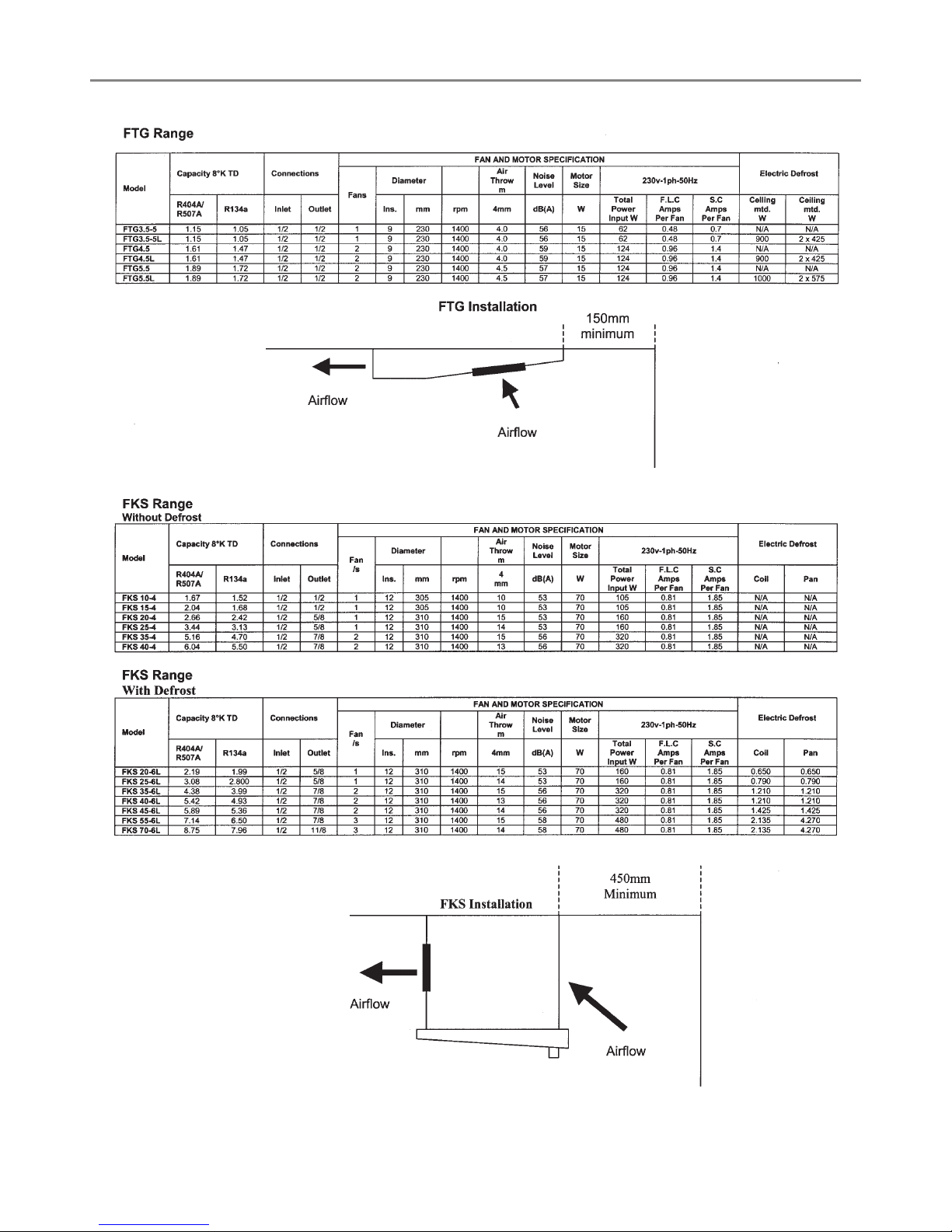

Cooler Specification

Page 5

CONDENSING UNIT TECHNICAL DATA

Receiver** HP LP *Max Max Cond Air ***Unit Net Dimensions Liquid Suction

Model

Nom

Refrigerant

Gas

Capacity Setting Setting

Electrical supply

*Abs

*Nom Run

Start

Fuse Fan Motor

Volume

Absorbed Noise

kgs

Ht x w x d Line Line

hp

Charge

Its Bar Bar Volts Phase Hz

Kw

Amps Amps

Amps

Rating x mm

m3/hr

Watts Level dBa

Weight

mm mm mm

NOTE:

* Based on 40°C condensing temperature.

** Based on 80% liquid capacity at 40°C condensing temperature.

*** Based on 3 metres from front of unit, 1.5 metres from floor level.

DCU1-1H 0.5 R 404a 1.00 1.6 28 0.2 230 1 50 0.5 3.2 6.3 19 13 1 x 250 750 1 x 90 59 39 368 x 660 x 330 10 12

DCU2-1H 0.75 R 404a 1.00 1.6 28 0.2 230 1 50 0.7 3.7 7.8 31 20 1 x 250 750 1 x 90 60 43 368 x 660 x 330 10 16

DCU3-1H 1 R 404a 1.60 2.5 28 0.2 230 1 50 1.1 5.1 11.3 32 20 1 x 300 1400 1 x 90 60 61 458 x 880 x 400 10 16

DCU4-3H 1.8 R 404a 2.00 2.5 28 0.2 400 3 50 1.7 3.6 6.6 18 16 1 x 330 1500 1 x 120 62 62 458 x 880 x 400 10 16

DCU5-3H 2.3 R 404a 2.00 2.5 28 0.2 400 3 50 2.1 4.4 8.1 25 20 1 x 330 1500 1 x 120 63 64 458 x 880 x 400 10 22

DCU6-3H 3 R 404a 6.00 6.5 28 0.2 400 3 50 3.2 6.2 9.7 27 20 1 x 400 3100 1 x 160 64 102 595 x 1075 x 532 10 22

DCU1-1L 0.75 R 404a 1.50 1.6 28 0.2 230 1 50 0.8 3.8 7 28 16 1 x 250 750 1 x 90 60 46 368 x 660 x 330 10 16

DCU2-1L 1.8 R 404a 1.60 2.5 28 0.2 230 1 50 1.4 8.6 16 40 20 1 x 300 1400 1 x 90 60 60 458 x 880 x 400 10 22

DCU3-3L 2.3 R 404a 1.60 2.5 28 0.2 400 3 50 1.8 4.5 6.2 25 16 1 x 300 1400 1 x 90 61 65 458 x 880 x 400 10 22

DCU4-3L 3 R 404a 2.00 2.5 28 0.2 400 3 50 1.8 4.8 5.8 30 20 1 x 350 1500 1 x 120 61 73 458 x 880 x 400 10 22

DCU5-3L 4 R 404a 6.00 6.5 28 0.2 400 3 50 3.8 7.9 12.7 71 25 1 x 400 3100 1 x 160 68 120 595 x 1075 x 532 10 28

DCU6-3L 7.5 R 404a 10.00 12 28 0.2 400 3 50 5.8 12 24.8 80 25 1 x 450 3100 1 x 160 72 187 654 x 1575 x 642 12 35

5

Condensing Unit Wall Brackets

The wall brackets are supplied in two sizes. The first bracket part number 00-876220-01, size 900 x 430 is used on models :- DCU1-1 H, DCU 2-1 H, DCU 3-1 H, DCU 4-3H, DCU 5-3H,

DCU 6-3H, DCU 1-1L, DCU 2-1L, DCU 3-3L, DCU 4-3L.

The second bracket part number 00-876221-01, size 1200 x 600 is used on models ;- DCU 5-3L, DCU6-3L.

The brackets should be fitted approximately 150mm from each end of the unit at a height determined by site conditions.

Important

Allow adequate space around the unit for air circulation and easy removal of panels for service requirements

Page 6

Electrical System Description

The Duets are to be wired in accordance with the latest revision of the respective wiring diagram:

SEE DETAIL FOR REMOTE ALARM CONNECTION

Par. No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26

DUET ‘C’, ‘F’, ‘M’, ‘L’ AND ‘IC’ SERIES

Units Deg Deg Deg Min Min % Sec Hrs Deg Min Min Min Flag Flag Min Deg Flag Deg Deg Min Flag Deg Deg Deg Flag 01

Mnemonic SPL SPh hYS coF con cdc crS drE dLi dto drP diS dtY doP Fct FrS Fid ALo Ahi AdL Ain oS1 oS2 oS3 SiM Adr

Min. Limit -50 SPL 01 00 00 00 00 01 01 00 00 -01 FAn con -01 -50 00 -50 SPh -01 01 -20 -20 -20 00 1

ELE 00 01 00 02

Max. Limit 150 150 20 10 10 10 120 99 70 120 10 30 GAS Acc 10 50 02 SPL 50 120 03 20 20 20 200 255

C 0 8 02 00 00 06 00 06 20 15 05 05 ELE con -1 01 00 -3 8 60 01 00 00 00 00 01

F -5 8 02 00 00 06 00 06 20 15 05 05 ELE con -1 01 00 -10 8 60 01 00 00 00 00 01

M -3 8 02 00 00 06 00 06 20 15 05 05 ELE con -1 01 00 -8 8 60 01 00 00 00 00 01

L -23 -15 03 00 00 06 00 03 30 30 05 05 ELE con -1 5 00 -25 -10 60 01 00 00 00 00 01

IC -28 -18 03 00 00 06 00 03 30 30 05 05 ELE con -1 5 00 -30 -15 60 01 00 00 00 00 01

CONTROL PANEL/WIRING DIAGRAMS

FKS Cooler Dimensions

6

Page 7

FTG Cooler Dimensions

LIQUID AND SUCTION LINE PIPE SIZE

Model 32°C Ambient

Liquid Line Pipe Size Suction Line Pipe Size

Horizontal (Vertical)

Duet 20m 50m 20m (V) 50m (V)

1-1 H/M 3/8” 3/8” 1/2” 1/2” 5/8” 1/2”

2-1 H/M 3/8” 3/8” 5/8” 1/2” 5/8” 1/2”

3-1 H/M 3/8” 3/8” 5/8” 1/2” 5/8” 1/2”

4-3 H/M 3/8” 3/8” 7/8” 3/4” 7/8” 3/4”

5-3 H/M 3/8” 3/8” 7/8” 3/4” 11/8” 7/8”

6-3 H/M 3/8” 3/8” 11/8” 7/8” 11/8” 7/8”

1-1 L 3/8” 3/8” 5/8” 1/2” 3/4” 5/8”

2-1 L 3/8” 3/8” 3/4” 5/8” 7/8” 3/4”

3-3 L 3/8” 3/8” 7/8” 3/4” 7/8” 3/4”

4-3 L 3/8” 3/8” 7/8” 3/4” 11/8” 7/8”

5-3 L 3/8” 3/8” 11/8” 7/8” 13/8” 11/8”

6-3 L 1/2” 1/2” 13/8” 11/8” 13/8” 11/8”

Note: These are guidelines only. Exact pipe sizing to be carried out for each application.

“H” models include HV and GP range

“M” models include C, F and M range

“L” models

The exact pipe size should be determined by application.

Recommended maximum vertical change 5 metres. The suction lines have been selected to achieve a pressure drop of 2psi or less whilst maintaining refrigerant velocity in the horizontal

plane of 3.5m/s (700ft/min) and in the vertical plane of 7.0m/s (1500ft/min) to achieve oil return.

Model 43°C Ambient

Liquid Line Pipe Size Suction Line Pipe Size

Horizontal (Vertical)

Duet 20m 50m 20m (V) 50m (V)

1-1 H/M 3/8” 3/8” 1/2” 1/2” 5/8” 1/2”

2-1 H/M 3/8” 3/8” 5/8” 1/2” 5/8” 1/2”

3-1 H/M 3/8” 3/8” 5/8” 1/2” 5/8” 1/2”

4-3 H/M 3/8” 3/8” 7/8” 3/4” 7/8” 3/4”

5-3 H/M 3/8” 3/8” 7/8” 3/4” 11/8” 7/8”

6-3 H/M 3/8” 3/8” 11/8” 7/8” 11/8” 7/8”

1-1 L 3/8” 3/8” 5/8” 1/2” 3/4” 5/8”

2-1 L 3/8” 3/8” 3/4” 5/8” 7/8” 3/4”

3-3 L 3/8” 3/8” 7/8” 3/4” 7/8” 3/4”

4-3 L 3/8” 3/8” 7/8” 3/4” 11/8” 7/8”

5-3 L 3/8” 3/8” 11/8” 7/8” 13/8” 11/8”

6-3 L 1/2” 1/2” 13/8” 11/8” 13/8” 11/8”

7

LIQUID AND SUCTION VALVE HEXAGONAL WRENCH SIZE

3/8” valve = 5mm

1/2” valve = 5mm

5/8” valve = 5mm

7/8” valve = 10mm

Page 8

MICROPROCESSOR CONTROLS

Thermostat Function

SPL Min set point (°C)

Maximum allowable low alarm setting (°C)

SPh Maximum set point (°C)

Maximum allowable high alarm setting (°C)

hyS Temperature hysteresis (°K)

coF Compressor minimum off time (mins)

con Compressor minimum on time (mins)

cdc Cooler duty cycle. Compressor on duration during a ten minute

crS Compressor start delay (secs)

drE Time between defrosts (hrs)

dLi Defrost termination temperature (°C)

dto Defrost termination time (mins). Unused if set to zero

Defrost Function

Duet ‘M’ and ‘L’ Series

All controller parameters are factory set for optimum storage conditions.

The parameters should only be adjusted by persons familiar with the

unit operation and controller functions. Certain parameters however

may be adjusted within limits, to suit certain storage needs.

1

2

Check Set Point — Low point of temperature band

Press button 1

Increase Set Point

Press and hold button 1

Press button 3 until required temperature is displayed

Decrease set point

Press and hold button 1

Press button 4 until required temperature is displayed

Manual Defrost

Press and hold button 2

Press button 4 a timed defrost will follow

Indicators

LED 5 Compressor on

LED 6 Evaporator fan on

LED 7 Defrost on

PF1 or PF2: Indicates a probe failure — call engineer

Adjustment Parameters

Freezer: Set Point -21°C

Meat: Set Point -2°C

Control Panel

The control panel contains a microprocessor temperature controller indicator automatically controlling the required process to maintain the correct

storage temperature within the coldroom and initiate and control defrost and evaporator fan functions.

The controllers are pre-set prior to leaving the factory but should it be necessary to make an adjustment the following procedures should be

followed.

MICROPROCESSOR CONTROLS

Duet ‘H’ Series

All controller parameters are factory set for optimum storage conditions. The parameters should only be adjusted by persons familiar with the unit

operation and controller functions. Certain parameters however may be adjusted within limits, to suit certain storage needs.

DUET HIGH TEMPERATURE UNITS WITH LDU 15 CONTROLLER – 00-555357

Temperature Controller

When the controller is switched on a single line appears on the display for 3 seconds to indicate the autotest period.

After this period the air temperature measured by the T1 probe is displayed.

It is strongly advised that before adjusting any Service Parameters a thorough understanding of the following instructions should be obtained.

LDU 15 CONTROLLER

lae

aux

Check temperature set point.

Check set point by pressing the “set” button

To increase set point press “set” +

To decrease set point press “set” +

Factory Temperature Set Point +3°C.

Exit from set up occurs after 10 seconds if no button is pressed.

Controller Set Up.

The parameters are accessed by pressing the following keys in succession + “set” + and keeping them pressed for 3 seconds.

Access to the parameters has been achieved with the first parameter SCL being displayed.

To pass from one parameter to the next press either the or key

To display the value press. “set”

To change the value press “set” + to increase, or “set” + to decrease.

Exit from set up by pressing “aux” or is automatic after 30 seconds if no buttons are pressed.

set aux

8

Page 9

MICROPROCESSOR CONTROLS

Thermostat Function

SPL Min set point (°C)

Maximum allowable low alarm setting (°C)

SPh Maximum set point (°C)

Maximum allowable high alarm setting (°C)

hyS Temperature hysteresis (°K)

coF Compressor minimum off time (mins)

con Compressor minimum on time (mins)

cdc Cooler duty cycle. Compressor on duration during a ten minute

cycle e,g. cdc = 04, 4 min on time, 6 min off time (active only

under probe fault conditions, PF1)

crS Compressor start delay (secs)

drE Time between defrosts (hrs)

dLi Defrost termination temperature (°C)

dto Defrost termination time (mins). Unused if set to zero

Defrost Function

Alarm Function

ALo Low temperature alarm setting (°C)

Ahi High temperature alarm setting (°C)

AdL Alarm delay (min)

00 = Instantaneous audible alarm

01.120 = Duration of delay (min)

— 01 = Alarm is disabled

Ain Determines which probe is monitored for alarm functions

1 = Air probe (prode 1)

2 = Evaporator probe (probe 2)

3 = Food probe (probe 3)

Thermal Mass Simulation

oS1 Air probe offset (°K)

oS2 Evaporator probe offset (°K)

oS3 Food probe offset (°K) — where fitted

SiM Controls the thermal mass volume simulated by the controller

and displayed on the fascia. The greater the value the greater

the resulting display slow down. The controlling function

remains to operate directly on air temperature.

00 = Instantaneous air temperature display

01.200 = Thermal mass simulation

Adr Controller peripheral number — only used where controllers

are networked

drP

Drain down time (mins)

diS Display during defrost

00 = Temperature display

— 01 = DEF is displayed during defrost and until air

temperature falls below the value setpoint —

hysteresis.

1.30 (mins) = dEF is displayed during defrost and until the

set

time has elapsed after defrosting or until air

temperature falls below the value setpoint +

hysteresis.

dtY Defrost type

FAn = Off cycle defrost

ELE = Electric heater defrost

GAS = Hot gas defrost

doP Defrost optimisation

con = At regular intervals of drE (hrs)

Acc = Defr ost t imer only r uns w hile evaporator

temperature is below 0°C, defrosting occurs when drE time

has elapsed e.g. if compressor cycle time is 5 min run and 5

min stop and drE = 4, defrosting will take place every 8 hours

Evaporator Fan Control

Fct Evaporator fan control during cooling

— 01 = Continuous operation

00 = Cycle on/off with compressor

1.10 (mins) = Start with compressor, set time delay stop

after compressor

Frs Fan delay temperature following defrost (°C)

Fid Evaporator fan operation during defrost

00 = off until fan delay temperature

FrS (°C)

is reached

01 = On while evaporator temperature is below

value

FrS (°C)

02 = On during defrost

Duet ‘M’ and ‘L’ Series

All controller parameters are factory set for optimum storage conditions.

The parameters should only be adjusted by persons familiar with the

unit operation and controller functions. Certain parameters however

may be adjusted within limits, to suit certain storage needs.

1

5

6

3

4

7

2

Check Set Point — Low point of temperature band

Press button 1

Increase Set Point

Press and hold button 1

Press button 3 until required temperature is displayed

Decrease set point

Press and hold button 1

Press button 4 until required temperature is displayed

Manual Defrost

Press and hold button 2

Press button 4 a timed defrost will follow

Indicators

LED 5 Compressor on

LED 6 Evaporator fan on

LED 7 Defrost on

PF1 or PF2: Indicates a probe failure — call engineer

Adjustment Parameters

Freezer: Set Point -21°C

Meat: Set Point -2°C

9

CDC 122

Page 10

Controller Parameter Settings

Display

When the unit is switched on the display shows “- - -” for a period of

five seconds, during which the controller performs a self check. The

display then shows the air temperature measured by probe 1.

The coil temperature, measured by probe 2 may be viewed by pressing

[ ].

Access to the control parameters is achieved by pressing in sequence

[ ]

+

[ ]

+

[ ]

and holding in keys for a period of 4

seconds.

It is possible to scroll through the parameters by pressing —

[

]

or

[ ]

.

The value of a selected parameter is checked by pressing -

[ ]

and

may be altered by pressing at the same time

[ ]

+

[ ]

or

[ ]

.

Exit from setup occurs after 10 seconds if no key is pressed.

If an alarm condition is entered the alarm buzzer will sound and

‘ALM’

will flash on the display. The alarm may be acknowledge by

pressing

any key causing the buzzer to cease and the display will alternate

between ‘ALM’ and air temperature while the alarm condition

persists.

Display Parameter LDU151E-B Duet High Temp

Default Values Used in Panels F,H,L.

SCL Readout Scale 2°C 2°C

SPL Minimum Temperature Set Point 05 0

SPH Maximum Temperature Set Point 01 8

SP Effective Temperature Set Point 03 2

HYS Hysteresis 3 +3

CRT Compressor Rest Time (minutes) 10 2

CDC Compressor Regulation with T1 Fail 20 7

DFR Defrosting Frequency (/24 hours) 4 4

DTO Defrosting Duration (minutes) 20 15

DDY Defrost Display Control 1 1

ATL Low Alarm Differential -5 -5

ATH High Alarm Differential 5 10

ATD Temperature Alarm Delay (minutes) 60 90

ACC Condenser Clean Interval 05 0

OAU Auxiliary Output Mode of Operation 30 ALR

BAU Auxiliary Button Mode of Operation 05 NON

OS1 T1 Offset 00 00

SIM Display Slowdown 00 00

ADR Address 01 01

ALARMS AND WARNINGS

HI High Temperature Alarm

LO Low Temperature Alarm

E1 T1 Probe Failure

DF Defrosting in Progress

CLN Condenser

LDU 151E-BG Electrical Connections

DUET ‘HV’ AND ‘GP’ SERIES

DATA

PWR

AUX

T1

1 2 3 4 5 6 7 8 9 10 11

FTG Cooler Dimensions

LIQUID AND SUCTION LINE PIPE SIZE

Model 32°C Ambient

Liquid Line Pipe Size Suction Line Pipe Size

Horizontal (Vertical)

Duet 20m 50m 20m (V) 50m (V)

1-1 H/M 3/8” 3/8” 1/2” 1/2” 5/8” 1/2”

2-1 H/M 3/8” 3/8” 5/8” 1/2” 5/8” 1/2”

3-1 H/M 3/8” 3/8” 5/8” 1/2” 5/8” 1/2”

4-3 H/M 3/8” 3/8” 7/8” 3/4” 7/8” 3/4”

5-3 H/M 3/8” 3/8” 7/8” 3/4” 11/8” 7/8”

6-3 H/M 3/8” 3/8” 11/8” 7/8” 11/8” 7/8”

1-1 L 3/8” 3/8” 5/8” 1/2” 3/4” 5/8”

2-1 L 3/8” 3/8” 3/4” 5/8” 7/8” 3/4”

3-3 L 3/8” 3/8” 7/8” 3/4” 7/8” 3/4”

4-3 L 3/8” 3/8” 7/8” 3/4” 11/8” 7/8”

5-3 L 3/8” 3/8” 11/8” 7/8” 13/8” 11/8”

6-3 L 1/2” 1/2” 13/8” 11/8” 13/8” 11/8”

Note: These are guidelines only. Exact pipe sizing to be carried out for each application.

“H” models include HV and GP range

“M” models include C, F and M range

“L” models

The exact pipe size should be determined by application.

Recommended maximum vertical change 5 metres. The suction lines have been selected to achieve a pressure drop of 2psi or less whilst maintaining refrigerant velocity in the horizontal

10

LIQUID AND SUCTION VALVE HEXAGONAL WRENCH SIZE

3/8” valve = 5mm

1/2” valve = 5mm

5/8” valve = 5mm

7/8” valve = 10mm

Page 11

Electrical System Description

The Duets are to be wired in accordance with the latest revision of the respective wiring diagram:

SEE DETAIL FOR REMOTE ALARM CONNECTION

Cooler minimum set

Cooler maximum set

Cooler hysteresis

Cooler min. off time

Cooler min. on time

Cooler duty cycle

Cooler re-start

Defrost repetition time

Defrost limit temperature

Defost time out

Dripping time

Display in defrost

Defrost type

Defrost optimisation

Evaporator fan control

Fan re-start after defrost

Ventilation in defrost

Low alarm threshold

High alarm threshold

Temperature alarm delay

Thermostat probe offset

Evaporator probe offset

Displayed probe offset

Thermal mass simulation

Peripheral number

Par. No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26

DUET ‘C’, ‘F’, ‘M’, ‘L’ AND ‘IC’ SERIES

*00 = OFF

01 = Te < FrS

02 = Always ON

Units Deg Deg Deg Min Min % Sec Hrs Deg Min Min Min Flag Flag Min Deg Flag Deg Deg Min Flag Deg Deg Deg Flag 01

Mnemonic SPL SPh hYS coF con cdc crS drE dLi dto drP diS dtY doP Fct FrS Fid ALo Ahi AdL Ain oS1 oS2 oS3 SiM Adr

*

Min. Limit -50 SPL 01 00 00 00 00 01 01 00 00 -01 FAn con -01 -50 00 -50 SPh -01 01 -20 -20 -20 00 1

ELE 00 01 00 02

Max. Limit 150 150 20 10 10 10 120 99 70 120 10 30 GAS Acc 10 50 02 SPL 50 120 03 20 20 20 200 255

C 0 8 02 00 00 06 00 06 20 15 05 05 ELE con -1 01 00 -3 8 60 01 00 00 00 00 01

F -5 8 02 00 00 06 00 06 20 15 05 05 ELE con -1 01 00 -10 8 60 01 00 00 00 00 01

M -3 8 02 00 00 06 00 06 20 15 05 05 ELE con -1 01 00 -8 8 60 01 00 00 00 00 01

L -23 -15 03 00 00 06 00 03 30 30 05 05 ELE con -1 5 00 -25 -10 60 01 00 00 00 00 01

IC -28 -18 03 00 00 06 00 03 30 30 05 05 ELE con -1 5 00 -30 -15 60 01 00 00 00 00 01

CONTROL PANEL/WIRING DIAGRAMS

Alarm probe selection

11

Page 12

Duet Package Wiring Schematic

Fig 1.

Fig 2.

Fig 3.

Supply In: 400v—50—3

Control Panel

HP/LP Condenser Fan Pressure Switch

1mm2 3 core

Crankcase Heater – 1mm2 3 core

(Optional)

In ter conn ecti ng Cabl es for thr ee ph ase su pp ly

Condensing Unit

Unit Cooler

Evaporator Fan — 1mm2 3 core

Defrost Heaters (if fitted) – 1mm2 5 core

Drain Line Heater – 1mm2 3 core

Wiring Diagram 00-838106-00

(See page 11 for model reference)

Compressor/Fan – 2.5mm2 5 core

Supply In: 400v—50—3 + N

Control Panel

HP/LP Condenser Fan Pressure Switch

1mm2 3 core

Crankcase Htr. – 1mm2 3 core

(Optional)

In ter conn ecti ng Cabl es for thr ee ph ase su pp ly

Condensing Unit

Unit Cooler

Liq. Line Solenoid — 1mm2 3 core

Evaporator Fan — 1mm2 3 core

Defrost Heater (if fitted) – 1mm

2

5 core

Drain Line Heater – 1mm2 3 core

Wiring Diagram 00-838359-00

00-838362-00

(See page 11 for model reference)

Compressor/Fan – 2.5mm2 5 core

Supply In: 230v—50—1 + N

Control Panel

HP/LP Switch — 1mm2 3 core

(Optional Condenser Fan Pressure Switch)

Crankcase Heater – 1mm2 3 core

(Optional)

Int ercon necti ng Cabl es fo r sing le phas e supp ly

Condensing Unit

Unit Cooler

Evaporator Fan — 1mm2 3 core

Defrost Heaters (if fitted) – 1.5mm

2

3 core

Drain Line Heater – 1mm2 3 core

Wiring Diagram 00-838099-00 (off cycle

defrost)

00-838101-00, 00-838102-

00

Compressor/Fan – 2.5mm2 5 core

Liquid Line Solenoid — 1mm2 3 core

Liquid Line Solenoid — 1mm2 3 core

12

Page 13

Duet Installation Guide Notes

1. GENERAL

Installation should be carried out by competent persons adopting

codes of good refrigeration practices as detailed in BS.EN 378-1:2000

Refrigerating Systems and Heat Pumps - Safety and environmental

requirements. Particular care should be taken installing horizontal and

vertical pipe runs incorporating correct bends, traps etc.

2. CONDENSING UNIT

Although the Condensing Unit is rated to operate in an ambient

temperature up to 43°C it is still important to consider the location

of the Unit during installation. Solar Gain from direct sunlight can

raise the temperature inside the unit housing beyond the operating

specification of the unit resulting in loss of performance and possible

damage to equipment.

Equally protection from very low ambient conditions should be addressed

Basically consider protection components such as oil separators, head

pressure control, additional solenoid valves, crankcase heaters etc for

adverse operating conditions.

The Condensing Unit can be positioned at low level ensuring that it is

raised off the ground and mounted on wall fixing brackets. There should

be at least 600mm clearance in front of the unit to allow for adequate

air to the condenser plus access for servicing through the top therefore

at least 600mm clearance should be allowed.

3. PIPE RUNS

The nominal design pipe run for the system is 50 metres however care

should be taken to consider any vertical rise where the condensing unit

is situated above the coldroom. The introduction of “P” traps in the

suction line to aid oil return to the compressor should be considered

also the requirement of an oil separator, especially low temperature

applications. Where the vertical rise is 5 metres and above the use of

an oil separator should be considered, especially on low temperature

applications, plus the position of the oil “P” trap and the size of the

suction line to maximise oil return to the compressor.

4. EVAPORATORS / COOLERS

FTG Range - Ceiling Mounted

These are used for small coldroom applications and are available for

both high and low temperature conditions. The low temperature models

have defrost heaters mounted under the coil block with access via the

drain pan. It will not be necessary to allow space at the side of the

Cooler for heater removal.

Positioning the Cooler should allow the discharged air from the finned

face to circulate around the coldroom. The rear of the Cooler can be

positioned close to the coldroom wall leaving sufficient space to remove

the drain pan. If the opposing wall is less than 600mm from the finned

face of the Cooler a curved air “deflector plate” should be used.

Fit the 1” BSP Drain Connector to the drain pan and connect the drain

line to it.

FKS Range.

These ceiling mounted Coolers are designed for medium/large

coldrooms for both high and low temperature applications.

The cooling air is discharged through the fan motors therefore it should

be positioned within the coldroom allowing at least 450mm clearance

between the rear finned face and the wall for air return to the Cooler.

If the opposing wall is less than 1.5m from the fan motors a curved air

“deflector plate” should be considered depending on model.

5. CONTROL PANEL

The Control panel is supplied with a main’s isolator switch, function

contactors, circuit breaker and a microproces sor temperature

controller complete with 10m long temperature sensing probes. The

air temperature sensing probe should be positioned in the return air

to the finned evaporator coil and the defrost termination temperature

sensing probes (when required) inserted at least 25mm into the finned

coil at the top.

See separate wiring diagrams for the various Condensing Unit /

13

Page 14

Foster Refrigerator

Oldmedow Road, King’s Lynn,

Norfolk PE30 4JU

England

Tel: 01553 691122

Fax: 01553 691447

Website: www.fosterrefrigerator.co.uk

E-mail: sales@foster-uk.com

a Division of ITW (UK) Ltd.

DUET/TM/05/05

T e c h n i c a l M a n u a l

Loading...

Loading...