Page 1

Display Case

FHG 2L & FHG 3L

Page 2

Foster Refrigerator Environmental Management Policy

Product Support and Installation Contractors

Foster Refrigerator recognises that its activities, products and services can have an adverse impact upon the

environment.

The organisation is committed to implementing systems and controls to manage, reduce and eliminate its adverse

environmental impacts wherever possible, and has formulated an Environmental Policy outlining our core aims. A

copy of the Environmental Policy is available to all contractors and suppliers upon request.

The organisation is committed to working with suppliers and contractors where their activities have the potential to

impact upon the environment. To achieve the aims stated in the Environmental Policy we require that all suppliers

and contractors operate in compliance with the law and are committed to best practice in environmental

management.

Product Support and Installation contractors are required to:

1. Ensure that wherever possible waste is removed from the client’s site, where arrangements are in place all

waste should be returned to Foster Refrigerator’s premises. In certain circumstances waste may be disposed

of on the clients site; if permission is given, if the client has arrangements in place for the type of waste.

2. If arranging for the disposal of your waste, handle, store and dispose of it in such a way as to prevent its

escape into the environment, harm to human health, and to ensure the compliance with the environmental law.

Guidance is available from the Environment Agency on how to comply with the waste management ‘duty of

care’.

3. The following waste must be stored of separately from other wastes, as they are hazardous to the environment:

refrigerants, polyurethane foam, oils.

4. When arranging for disposal of waste, ensure a waste transfer note or consignment note is completed as

appropriate. Ensure that all waste is correctly described on the waste note and include the appropriate six-digit

code from the European Waste Catalogue. Your waste contractor or Foster can provide further information if

necessary.

5. Ensure that all waste is removed by a registered waste carrier, a carrier in possession of a waste management

licence, or a carrier holding an appropriate exemption. Ensure the person receiving the waste at its ultimate

destination is in receipt of a waste management licence or valid exemption.

6. Handle and store refrigerants in such a way as to prevent their emission to atmosphere, and ensure they are

disposed of safely and in accordance with environmental law.

7. Make arrangements to ensure all staff who handle refrigerants do so at a level of competence consistent with

the City Guilds 2078 Handling Refrigerants qualification or equivalent qualification.

8. Ensure all liquid substances are securely stored to prevent leaks and spill, and are not disposed of to storm

drains, foul drain, surface water to soil.

Contents Page

Introduction

Technical Specification.

Temperature Controller

Controller Display and Symbols.

Setting the set point

Programming the controller.

Accessing the type “F” parameters

Accessing the type “C” parameters

Modifying the parameters

Procedure for setting the default parameter values

Classification of Parameters

Parameter Settings

Parameter Definitions

Spare Parts List

Wiring Diagrams

2

2

3

3 to 4

4

4

4

4 to 5

5

5

6

6 to 7

8 to 13

13

14 to 17

1

Page 3

Introduction

The display case are manufactured in two formats FHG 2L, 2 doors, and the FHG 3L, three doors.

There are also Multiplex options that are a combination of two FHG 2L cases to make a FHG 4L or a combination

of the FHG 2L and FHG 3L to make a FHG 5L.

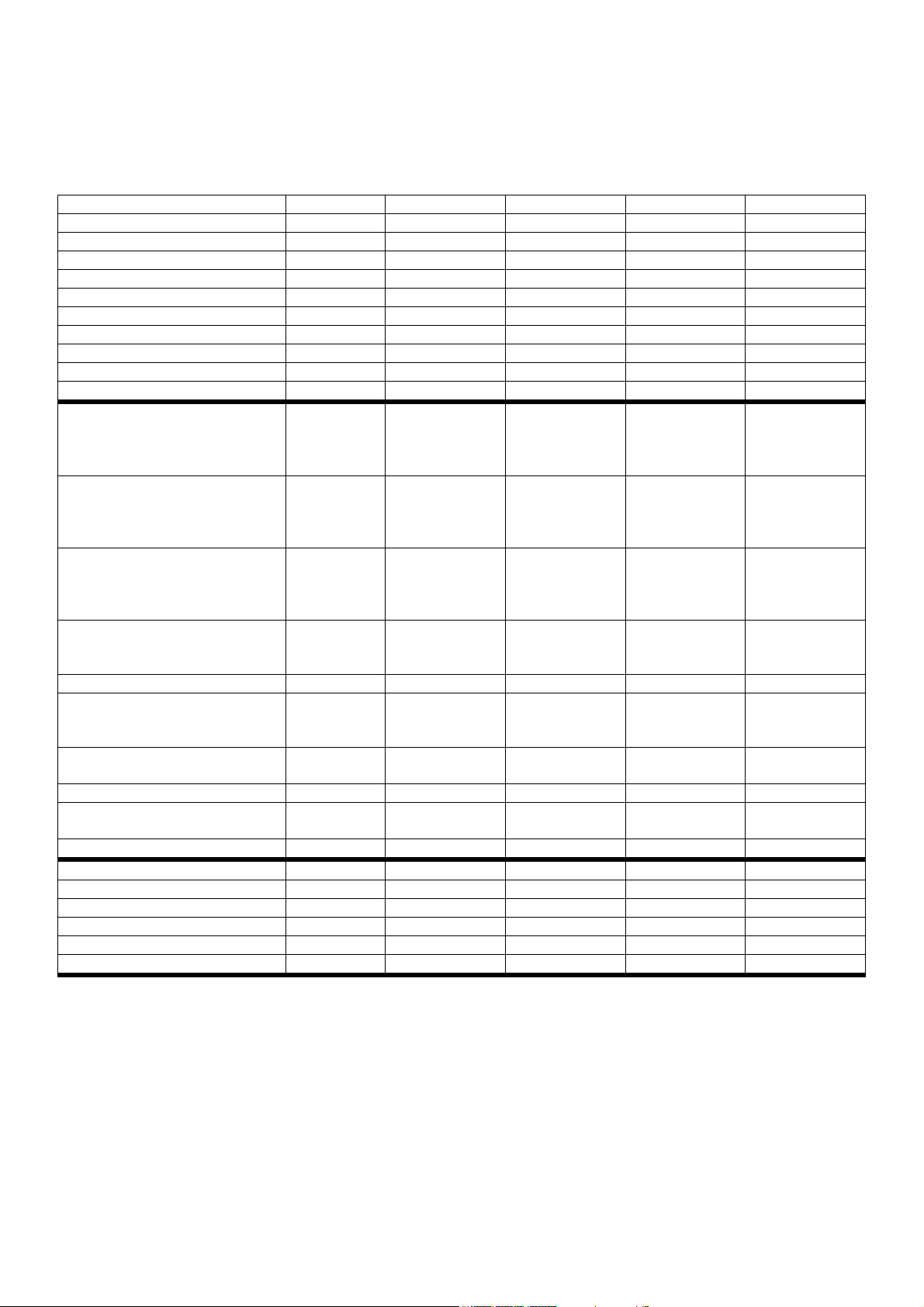

Technical Specification.

Model 2 Door 3 Door 4 Door 5 Door

External Dimensions (m) Height (m) 2100 2100 2100 2100

Width (m) 1684 2463 3254 4035

Depth (m) 900 900 900 900

Internal Dimensions (m) Height (m) 1354 1354 1354 1354

Width (m) 1564 2343 3128 3907

Depth (m) 550 550 550 550

No. of Shelves 12 18 24 30

Shelf capacity (each) Kg 40 40 40 40

Door System Schott Schott Schott Schott

Refrigeration System

Compressor

Refrigerant

Vaporisation

Defrost Type

Electrical supply 230/1/50 400/3/50 230/1/50 X 2

Electrical Supply Capacity 16A 16A 16A 16A

Controller

Heat loads & Consumption

Lighting Watts 140 210 280 350

Door frame heaters Watts 266 380 522 646

Fan motors Watts 132 198 264 330

Compressor consumption Watts 2760

Compressor Duty Watts 2660

Compressor Current A 5.1

Up to Aug

2004

From Aug

2004

Hitachi

FL200 DL

400v 3 phase

Hitachi

DS 183651

230v 1 phase

Hitachi

FL300DL

400 3 Phase

R404A

2500 grms

Hot Gas Hot Gas Hot Gas Hot Gas

Hot Gas and

Electric (1 kW)

Carel

PB00F0HB10

R404A

3500 grms

Hot Gas and

Electric

( 1.5 kW)

Carel

PB00F0HB10

Hitachi FL200

DL

400v 3 phase

(x 2)

Hitachi

DS 183651

230v 1 phase

(x 2)

R404A

2500 grms

(x 2)

Hot Gas and

Electric

(2.1kW)

Carel

PB00F0HB10

Hitachi

FL300DL

400 3 Phase

(x 2)

R404A

2500 grms +

3500 grms

Hot Gas and

Electric

(2.5 kW)

400/3/50 +

230/50/1

Carel

PB00F0HB10

2

Page 4

Temperature controller

It is strongly advised that before adjusting any Service Parameters a thorough understanding of the

following instructions should be obtained.

Carel PB00F0HB10

15

4

3

13

9

10

11

12

14

2

1

16 17 18 19

6

5

8

7

Controller Display and Symbols.

NOTE: When the buttons are pressed a brief audible signal is emitted; this signal can not be disabled.

1. HACCP: Pressing this button displays a sub menu used to access the HACCP parameters (not used by

Foster)

2. ON/OFF: When pressed for more than 5 seconds switches the controller on/off. When OFF the controller

display alternates between “OFF” and the air temperature as read by the air probe.

3. PRG/MUTE: Mutes the audible alarm and deactivates the alarm relay.

: If pressed for more than 1 second the during the reception of the automatic network address

assignment request package, starts the address assignment procedure (not used by Foster).

: If pressed for more than 5 seconds, allows access to the menu for setting the “F” (frequent)

parameters.

: If pressed for more than 5 seconds together with, allows access for setting the “C”

(configuration) Parameters.

: If pressed for more than 5 seconds when switching the instrument ON, activates the procedure for

setting the default parameter values.

: If pressed for more 5 seconds together with, resets any active alarm with manual reset (the message

‘rES ‘ indicates that the alarm has been reset); any delays relating to the alarms are re-activated.

4. UP/CC: If pressed for more than 5 seconds, activates/deactivates the continuous cycle operation (the

message ‘ccE’ and ‘ccE’ indicate, respectively, the start and end of the continuous cycle request).

: If pressed together with, for more than 5 seconds, starts the report printing procedure (provided the

printer interface is connected to the controller).

: If pressed for more than 5 seconds together with, resets any active alarm with manual reset (the

message ‘rES ‘ indicates that the alarm has been reset); any delays relating to the alarms are reactivated.

5. Light: If pressed for more than 1-second activates/deactivates auxiliary output 2.

6. AUX: If pressed for more than 1-second activates/ deactivates auxiliary output 1.

7. DOWN/DEF: If pressed for mare than 5 seconds, activates/deactivates a manual defrost (the message

‘dFb’ and dFE’ indicate, respectively, the start and end of defrost).

8. SET: If pressed for more than 1 second displays and/or sets the set point.

: If pressed for more than 5 seconds together with , accesses the menu for setting the type ”C”

(configuration) parameters.

: If pressed together with for more than 5 seconds, starts the report printing procedure (provided the

printer interface is connected to the controller).

3

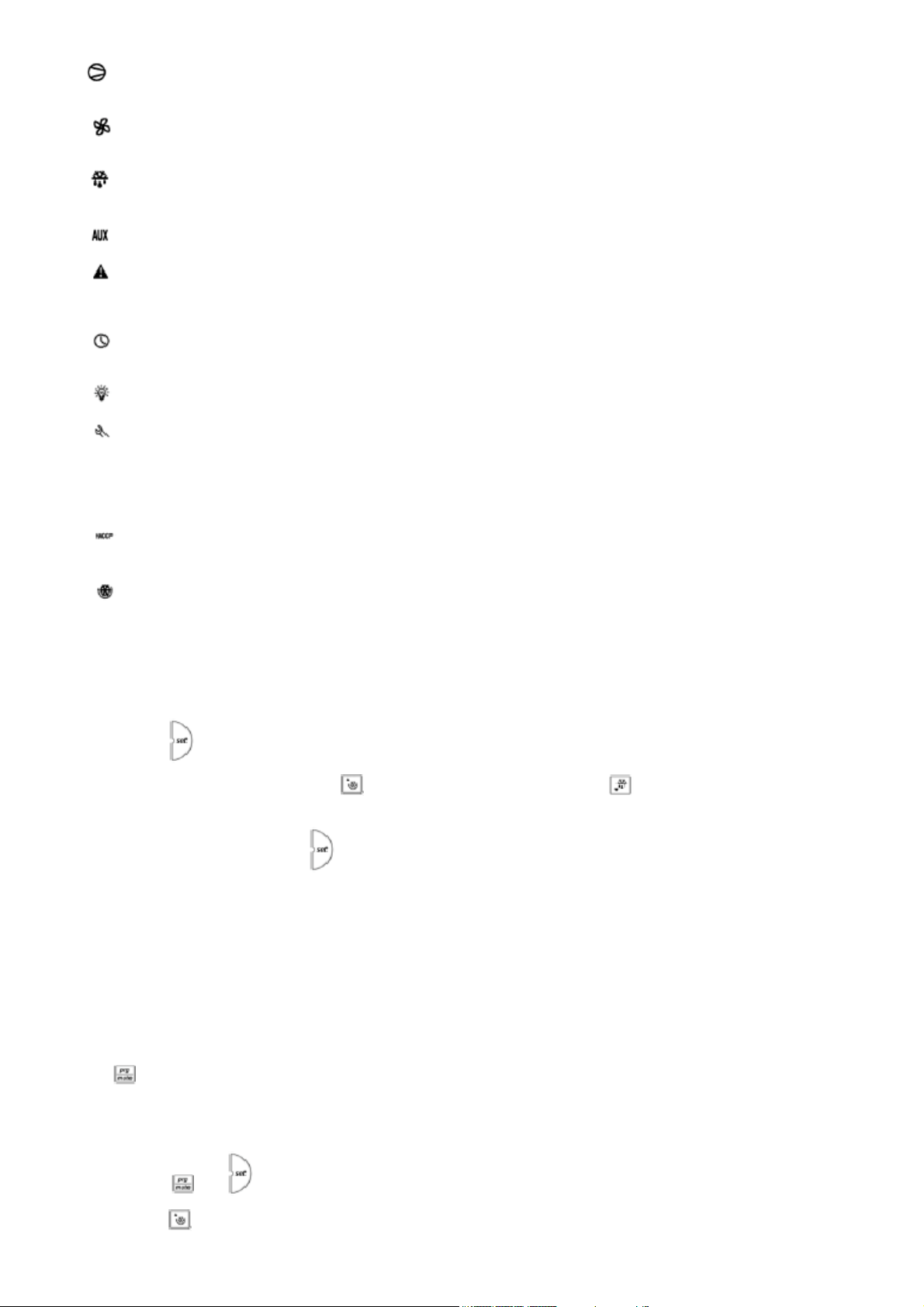

Page 5

Compressor: Illuminated when the compressor is running. Flashes when the activation of the compressor

9.

is delayed by safety times.

10. FAN: Illuminated when the fan starts. Flashes when the activation of the fan is prevented due to external

disabling or procedures in progress.

11. DEFROST: Illuminated when defrost is activated. Flashes when the activation of the defrost is prevented

due to external disabling or procedures in progress.

12. AUX: Illuminated when the auxiliary output (1 and/or 2) selected as AUX is activated.

13. ALARM: Illuminated following the activation of the external digital input alarm. Flashes in the event of

alarms during normal operation (e.g. high /low temperature) or in the event of alarms from an external

digital input, immediate or delayed.

14. CLOCK: Illuminated if at least one timed defrost has been set. On start up comes ON for a few seconds to

indicate that the Real Time Clock is active.

15. LIGHT: Illuminated when the auxiliary output (1 and /or 2) is selected as the LIGHT is activated.

16. SERVICE: Flashes in the event of a malfunction, for example EPROM errors or probe faults.

17. DISPLAY: Displays the temperature in the range –50 to +150°C. the temperature is displayed to the tenth

of a degree between –19.9 and + 19.9°C. the display of the tenths can be disabled by setting the related

parameter.

18. HACCP: Illuminated if the HACCP function is enabled. Flashes when there are hew HACCP alarms stored

(HA and/or HF alarm shown on the display).

19. CONTINUOUS CYCLE:Illuminated when the CONTINUOUS CYCLE function is activated. Flashes if the

activation of the function is prevented due to external disabling or procedures in progress (e.g. minimum

compressor OFF time).

Setting the set point.

To display the set point proceed as follows:

1. Press for more than 1 second to display the set point.

2. To increase the set point press or to decrease the set point press until the desired value is

reached.

3. To confirm the value press .

Programming the controller.

The parameters can be modified using the front keypad.

The operating parameters are divided into two families: Frequent parameters (type “F”) and configuration

parameters (type “C”).

Access to the configuration parameters is protected by a password that prevents unwanted modification or access

by unauthorised persons.

Accessing the type “F” parameters.

Press for more than 5 seconds (if an alarm is active, the buzzer is muted), the display shows the code of the

first modifiable type “F” parameter.

Accessing the type “C” parameters.

1. Press and together for more than 5 seconds; the display will show the number “00”.

2. Press until the display shows “22” ( the code allows access to the parameters)

4

Page 6

3. Confirm by pressing .

4. The display shows the code of the first modifiable type “C” parameter.

Modifying the parameters.

After having accessed the parameters, either type “C” or type “F”, proceed as follows.

1. Press or until the parameter to be modified is reached, when scrolling through an icon appears on

the display indicating the category the parameters belong to.

2. Alternatively, press to display a menu that is used to quickly access the group of parameters to be

modified.

3. Scroll through the menu using the or buttons, the display shows the codes of the various

categories of the parameters, accompanied by the display of the corresponding icon (if present).

4. Once having reached the desired category, press to move directly to the first parameter in the

category.

(If there are no visible parameters in the selected category pressing will have no effect.)

5. At this point continue to scroll through the parameters until reaching the parameter to be modified, or return

to the “Categories” menu by pressing for one second.

6. Press to display the associated value.

7. Increase or decrease the value by pressing or buttons respectively, until the desired value has

been reached.

8. By pressing this will temporarily save the new value and return to displaying the parameter code.

9. Repeat the operations point 1 or point 2.

10. If the parameter has sub-parameters, press to display the first sub-parameter.

11. Press or to display all of the sub-parameters.

12. Press to display the associated value.

13. Increase or decrease the value by pressing or buttons respectively, until the desired value has

been reached.

14. By pressing this will temporarily save the new value and return to displaying the sub-parameter code.

15. Press to return to displaying the parent parameter.

Procedure for setting the default parameter values

To set the default parameter setting proceed as follows.

1. Switch the instrument off.

2. Press and hold the button

3. Whilst holding the button switch the instrument on again until the message ”_std_” is shown on the

display.

Note: the standard default values are set for parameters “C” and “F”, on completion it is necessary to change the

respective parameters as detailed in the parameter settings table on page 6 and 7.

5

Page 7

Classification of Parameters

The parameters, as well as being divided into type, are also grouped into logical categories identified by the initial

letters or symbols of such parameters. The following table lists the categorise and the corresponding letters.

Parameter Category Text Icon

/

r

c

d

A

F

H Configuration

H HACCP

RTC

Parameter Settings

The highlighted section indicate the Foster settings

No Code Parameter

1 /2 Measurement stability - 4 4 4

2 /3 Probe display reaction - 0 0 0

3 /4 Virtual probe - 0 0 0

4 /5 Select °C or °F flag 0 0 0

5 /6 Decimal point flag 0 0 0

6 /tI Display on internal terminal - 1 1 1

7 /tE Display on external terminal - 0 0 0

8 /P Select type of probe - 0 0 0

9 /A2 Configuration of probe 2 - 2 2 2

10 /A3 Configuration of probe 3 - 0 0 0

11 /A4 Configuration of probe 4 - 0 0 0

12 /C1 Calibration of probe 1 °C/°F 0.0 0.0 0.0

13 /C2 Calibration of probe 2 °C/°F 0.0 0.0 0.0

14 /C3 Calibration of probe 3 °C/°F 0.0 0.0 0.0

15 /C4 Calibration of probe 4 °C/°F 0.0 0.0 0.0

16 St Temperature set point °C/°F 0.0 0.0 0.0

17 rd Controller differential °C/°F 2.0 4.0 4.0

18 r1 Minimum SET allowed °C/°F -50 -26 -26

19 r2 Maximum SET allowed °C/°F 60 -15 -15

20 r3 Operating mode flag 0 0 0

21 r4 Automatic night time set point variation °C/°F 3.0 3.0 3.0

22 r5 Enable temperature monitoring flag 0 0 0

23 rt Temperature monitoring interval hours - - 24 rH Maximum temperature read °C/°F - - 25 rL Minimum temperature read °C/°F - - -

26 c0 Compressor and fan start delay at start up min 0 0 0

27 c1 Minimum time between successive starts min 0 1 1

28 c2 Minimum compressor OFF time min 0 0 0

29 c3 Minimum compressor ON time min 0 0 0

30 c4 Duty Setting min 0 80 80

31 cc Continuous cycle duration hours 0 0 0

32 c6 Alarm bypass after continuous cycle hours 2 2 2

33 c7 Maximum pump down (PD) time min 0 0 0

34 c8 Compressor start delay after opening PD valve sec 5 5 5

Temperature probe parameters ‘Pro’

Temperature control parameters ‘CtL’

Compressor safety time and activation parameters ‘CMP’

Defrost parameters ‘dEF’

Alarm parameters ‘ALM

Fan parameters ‘Fan’

General configuration parameters (addresses, enabling, etc….) ‘CnF’

HACCP parameters ‘HcP’

RTC parameters ‘rtc’

Unit of

Measure

6

Default FHG2l FHG3L

Page 8

35 c9 Enable autostart with PD operation flag 0 0 0

36 c10 Select Pd by time or pressure flag 0 0 0

37 c11 Delayed compressor delay sec 4 4 4

38 d0 Type of defrost flag 0 1 1

39 dI Interval between defrosts hours 8 6 6

40 dt1 End defrost temperature, evaporator. °C/°F 4.0 20.0 20.0

41 dt2 End defrost temperature, aux. evaporator °C/°F 4.0 4.0 4.0

42 dp1 Maximum defrost duration, evaporator min 30 20 20

43 dp2 Maximum defrost duration, aux. Evaporator min 30 30 30

44 d3 Defrost start delay min 0 0 0

45 d4 Enable defrost at start up flag 0 0 0

46 d5 Defrost delay at start up min 0 0 0

47 d6 Display off during defrost - 1 1 1

48 dd Dripping time after defrost min 2 1 1

49 d8 Bypass alarm after defrost hours 1 1 1

50 d9 Defrost priority over compressor protection flag 0 0 0

51 d/1 Display defrost probe °C/°F - - 52 d/2 Display defrost probe °C/°F - - 53 dC Base time for defrost flag 0 0 0

54 d10 Compressor running time hours 0 0 0

55 d11 Running time temperature threshold °C/°F 1.0 1.0 1.0

56 d12 Advanced defrost - 0 0 0

57 dn Nominal defrost time - 65 65 65

58 dH Proportional factor for variation in ‘dI’ - 50 50 50

59 A0 Alarm and fan differential °C/°F 2.0 4.0 4.0

60 A1 Type of threshold for ‘AL’ and ‘AH’ flag 0 0 0

61 AL Low temperature alarm threshold °C/°F 0.0 0.0 0.0

62 AH High temperature alarm threshold °C/°F 0.0 0.0 0.0

63 Ad Low and high temperature alarm delay min 120 120 120

64 A4 Configuration of digital input 1 - 0 0 0

65 A5 Configuration of digital input 2 - 0 0 0

66 A6 Stop compressor from external alarm min 0 0 0

67 A7 External alarm detection delay min 0 0 0

68 A8 Enable alarms ‘Ed1’ and Ed2’ flag 0 0 0

69 Ado Door switch light management mode flag 0 0 0

70 Ac High condenser temperature alarm °C/°F 70.0 70.0 70.0

71 AE High condenser alarm temperature differential °C/°F 5.0 5.0 5.0

72 Acd High condenser temperature alarm delay min 0 0 0

73 AF Off time with light sensor sec 0 0 0

74 F0 Fan management flag 0 0 0

75 F1 Fan start temperature °C/°F 5.0 5.0 5.0

76 F2 Fan off with compressor off flag 1 0 0

77 F3 Fans in defrost flag 1 1 1

78 Fd Fans off after dripping min 1 1 1

79 H0 Serial address - 1 30 30

80 H1 Function of relay 4 flag 1 2 2

81 H2 Disable key / infra red flag 1 1 1

82 H3 Remote control enabling code - 0 0 0

83 H4 Disable buzzer flag 0 0 0

84 H5 Function of relay 5 - 3 3 3

85 H6 Lock out buttons - 0 0 0

86 H7 Select PD by time or pressure flag 0 0 0

87 HPr Print profile - 0 0 0

Note: The total number of parameters is 105. For ease of set up Foster only use the ones listed. The

remaining are not used and adjustment is not recommended.

7

Page 9

Parameter Definitions

/2 Measurement stability.

Defines the coefficient used to stabilise the temperature reading.

/3 Probe display rate

Sets the rate at which the temperature display is updated.

/4 Probe average (Virtual probe)

Used to choose whether to control the temperature based solely on the room probe reading, or

alternatively whether to refer to the average of the room probe S1 and probe 2(S2, see parameter /A2).

/5 Select °C or °F

Defines the unit of measure in degrees centigrade or Fahrenheit.

/6 Decimal point

Used to enable or disable the displaying of the temperature with the resolution to the tenth of a degree

between –20 and +20.

/tI Probe displayed by instrument

Select the probe to be displayed by the instrument.

Warning: Control is always based on the virtual control probe.

/tE Probe displayed on external terminal

Selects the probe to be displayed on the remote terminal.

/P Select type of probe

Used to select the type of probe for temperature measurement.

Default. /P = standard NTC probe with range –50 to +90°C.

/A2 Configuration of probe 2

Used to configure the operating mode of probe 2.

Default: /A2 =2 = Defrost probe.

/A3 Configuration of probe 3

Used to configure the operating mode of probe 3.

Default: /A3 = 0 = Probe 3 absent.

/A4 Configuration of probe 43

Used to configure the operating mode of probe 43.

Default: /A4 = 0 = Probe 4 absent.

/C1 Calibration or offset probe 1

/C2 Calibration or offset probe 2

/C3 Calibration or offset probe 3

/C4 Calibration or offset probe 4

These parameters are used to correct the temperature by the probes using an offset.

Example: To decrease the temperature measured by probe 1 by 2.3 degrees, set /C1 = -2.3.

St Set point

Establishes the controller set point.

Default: St = 0.0

rd Control delta

Establishes the value of the differential, or hysteresis, used to control the temperature.

Default: rd = 2.0. Foster setting: rd = 4.0

r1 Minimum allowed set point

Determine the set point minimum value.

Default: r1 = -50. Foster setting: r1 = -26.

r2 Maximum allowed set point.

Determine the set point maximum value.

Default: r2 = +60. Foster setting: r2= -15.

8

Page 10

r3 Operating mode

The controller can work as a thermostat and defrost controller (r3 = 0), or as a simple thermostat in direct

operation (r3 = 1), or as a simple thermostat in Reverse- cycle operation (r3 = 2).

Default setting: r3 = 0.

r4 Automatic variation of the set point in night time operation.

Default: 3.0. Not used by Foster

r5 Enables minimum and maximum temperature monitoring.

rt Effective interval for monitoring the maximum and minimum temperature.

rH Maximum temperature measured in the interval rt.

rL Minimum temperature measured in the interval rt.

These parameters are used for recording the temperature. Not used by Foster.

c0 Compressor and fan start delay (if fan relay present) on start up.

When the controller is switched on the compressor and evaporator fans start after a delay (in minutes)

equal to the value set for this parameter.

Default: c0 = 0.

c1 Minimum time between two successive starts of the compressor.

Sets the minimum time (in minutes) that must elapse between two starts of the compressor irrespective of

the temperature and the set point. Setting this parameter limits the number of starts per hour.

Default: c1 = 0. Foster setting c1 = 1.

c2 Minimum compressor OFF time.

Sets the minimum time (in minutes) that the compressor must remain OFF. The compressor is not started

again until the minimum time selected (c2) has elapsed from when it last stopped.

Default: c2 = 0. No minimum OFF time is set.

c3 Minimum compressor ON time.

Sets the minimum running time for the compressor.

Default: c3 = 0. No minimum running time selected.

c4 Duty setting

If the virtual control probe fault alarm occurs (indicating a probe fault) the compressor unable to operate

based on temperature will run on a timed bases equal to the value set in c4 with a fixed OFF time of 15

minutes.

Default: c4 = 0 minutes. Foster setting c4 = 80 minutes.

cc Continuous cycle duration.

The time (in hours) that the compressor operates continuously to lower the temperature, even below the

set point

Default: cc = 0 = the continuous cycle is disabled.

c6 Alarm bypass after continuous cycle.

The time in hours that the temperature alarm is deactivated after a continuous cycle.

Default: c6 =2 hours.

c7 Maximum pump down time.

Not used by Foster.

c8 Compressor start delay after opening PD valve.

Not used by Foster.

Default: c8 = 5

c9 Enable autostart function with PD operation.

Not used by Foster

Default: c9 = 0

c10 Select pump down by pressure or time.

Not used by Foster

Default: c10 = 0

9

Page 11

c11 Delayed compressor delay

Not used by Foster

Default: c11 = 4

d0 Type of Defrost

Sets the type of defrost required.

Default: d0 = 0. Foster setting d0 = 1. Hot gas defrost terminated by evaporator probe or in the event of

probe failure by time (see dP1).

dI Interval between defrosts.

The defrosts are performed periodically at an interval equal to the value of ‘dI’ in hours.

The interval is cyclical and is maintained if the controller is turned OFF, when the controller is turned back

ON a defrost will occur if the interval was exceeded.

Default: dI = 8. Foster setting dI = 6.

dt1 End defrost temperature, evaporator probe.

The evaporator probe termination temperature, in the event of a probe failure the defrost will be terminated

by time (see dP1).

Default dt1 = 4.0. Foster setting dt1 = 20.0.

dt2 End defrost temperature, auxiliary evaporator.

Not used by Foster.

Default: dt2 = 4.0.

dP1 Maximum defrost duration, Evaporator.

Maximum time, in minutes, for defrost in the event of evaporator probe failure.

Default: dP1 = 30. Foster setting dP1 = 20.

dP2 Maximum defrost duration, auxiliary evaporator.

Not used by Foster

Default: dP2 = 30.

d3 Defrost start delay

Not used by Foster.

Default: d3 = 0.

d4 Enable defrost at start up.

Activates a defrost when the defrost is switched on.

0 = no defrost performed when the instrument is switched on

Default: d4 = 0.

d5 Defrost delay at start up.

Not used by Foster.

Default: d5 = 0.

d6 Display during defrost.

1 = The last temperature read prior to the start of the defrost remains on the display. The display returns to

displaying the temperature when the set point is achieved.

Default: d6 = 1.

dd Dripping time after defrost.

The time, in minutes, that the evaporator fans are delayed after defrost to allow for the evaporator to drip.

Default: d6 = 2. Foster setting d6 = 1.

d8 Bypass alarms after defrost.

The time, in hours, that the high temperature alarms is disabled for after the end of the defrost cycle

Default: d8 = 1.

d9 Defrost priority over compressor protection.

Not used by Foster

Default: d9 = 0

10

Page 12

d/1 Display defrost probe.

Displays the value measured by the defrost probe.

Once d/1 has been selected press the button to display the temperature measured by the defrost

probe.

d/2 Display defrost probe 2 reading.

Not used by Foster.

dC Base time for defrost.

Not used by Foster

Default: dC = 0.

d10 Compressor running time.

Not used by Foster

Default: d10 = 0.

d11 Running time temperature threshold.

Not used by Foster

Default: d11 = 1.0.

d12 Advanced defrost.

Not used by Foster

Default: d12 = 0.

dn Nominal defrost time.

Indicates the average duration of the defrost in normal operating conditions expressed as a percentage in

accordance with dP1.

Default: dn = 65. Example dn at 65% of dP1 20 minutes = 13 minutes nominal defrost duration.

dH Proportional factor for variation in ‘dI’.

Default: dH = 50.

A0 Alarm and fan differential.

Default: A0 = 2.0. Foster setting A0 = 4.0.

A1 Type of threshold for ‘AL’ and ‘AH’.

Used to select if the values of parameters ‘AL and ‘AH’ are absolute threshold or relative to the value of the

set point.

Default: A1 = 0 = ‘AL’ and ‘AH’ are relative thresholds.

AL Low temperature alarm threshold.

Not used by Foster.

Default: AL = 0 = alarm disabled.

AH High temperature alarm threshold.

Not used by Foster.

Default: AH = 0 = alarm disabled.

Ad Low and high temperature alarm delay.

Indicates the time in minutes that the alarm from when the alarm was signalled.

Default: Ad = 120.

A4 Configuration of digital input 1.

Not used by foster.

Default: A4 = 0.

A5 Configuration of digital input 2.

Not used by foster.

Default: A5 = 0.

A6 Stop compressor from external alarm.

Not used by Foster

11

Page 13

Default: A6 = 0.

A7 External alarm detection delay.

Not used by foster

Default: A7 = 0.

A8 Enables alarm ‘Ed1’ and ‘Ed2’.

Not used by Foster.

Default: A8 = 0 = alarms ‘Ed1’ and ‘Ed2’ disabled.

Ado Door switch light management mode.

Not used by Foster.

Default: Ado = 0.

Ac High condenser temperature alarm.

Not used by Foster.

Default: Ac = 70.0.

AE High condenser alarm temperature differential.

Not used by Foster.

Default: AE = 5.0.

Acd High Condenser temperature alarm delay.

Not used by Foster.

Default: Acd = 0.

AF Off time with light sensor.

Not used by Foster.

Default: AF = 0.

F0 Fan management.

F0 = Fan runs all of the time, for fans during defrost see ‘F3’.

Default: F0 = 0.

F1 Fan start temperature.

Used in conjunction with ‘F0’ when ‘F0’ = 1.

Default: F0 = 5.0. Fans remain ON while the evaporator is 5 degrees colder than the room temperature.

F2 Fans off with compressor off.

Used in conjunction with ‘F0’.

Default: F2 = 1. Foster setting F2 = 0 fans are always ON (F0 =0).

F3 Fans in defrost.

Used to determine if the fans operate or not during defrost.

Default: F3 = 1. Fans do not operate during defrost.

Fd Fans off after dripping.

Fans can be stopped for a further period, in minutes, after defrost beyond what has been set in ‘dd’.

Default: Fd = 1 = 1 additional minute dripping time.

H0 Serial address.

Used to assign an address to the instrument so that it responds to when connected to a supervisory or

telemaintenance system.

Default: H0 = 1. Foster setting H0 = 30.

H1 Function of relay 4.

Auxiliary output used to power the doorframe lighting and frame heater.

Default: H1 = 1. Foster setting H1 = 2.

H2 Disable keypad / infra red.

Can be used to inhibit some functions relating to the use of the keypad.

Default: H2 = 1 = all enabled.

H3 Remote control enabling code.

Assigns an access code to the remote control if fitted.

Not used by Foster.

12

Page 14

Default: H3 = 0.

H4 Disable buzzer.

H4 = 0 buzzer enabled. H4 = 1 buzzer disabled.

Default: H4 = 0.

H5 Function of relay 5.

Not used by Foster.

Default: H5 = 3.

H6 Lock out Buttons.

Not used by Foster.

Default: H6 = 0.

H7 Select Keypad.

Used to select the type of keypad on the controller.

Default: H7 = 0. Use the standard controller.

HPr Print Profile.

Not used by Foster.

Default: HPr = 0 = printing report disabled.

Note: Although there are further parameters in the controller these are not used by Foster and should be

left with the standard default settings.

Spare Parts List

Item Description Part Number FHG2L FHG3L

Compressor

Compressor

Compressor Scroll Compressor FL300DL 400/3/50 00-555451

Condenser coil Condenser Set LUVE STVF370 00-555448

Cond Fan Motor MOTOR 11W/S

Cond Fan Blade Blade 254-26-5A 16240059

Cond Fan Shroud SHROUD CF-27 16240060

Condenser coil Condenser Coil BC6013/115 00-555474

Condenser Fan Motor 5136 Grid Mount 16W 15470027

Drier DML 053S 00-555389

Liquid Receiver VLR 122637 3/8 Sweat 15482010

HP Switch Set at 28 BAR 00-555386

LP Switch Set at 4PSI 00-555387

Sight Glass 3/8" SGN-105 15483015

Solenoid Valve EVR6 32F1212 15451215

Vaporiser Tray Heater Copper Coil TBA

Vaporiser Tray Container White Part 758 140 81 Fish 00-554948

Defrost Klixon Thermal Cutout 1/2" Autoreset 15243602

Defrost Heaters Heater Rod PGC 94 (2 off per coil) 15843181

Evaporator Coil BC6013/114 FHG2L 00-555475

Evaporator Coil BC6013/114 FHG3L 00-555476

Fan Motor 5133 Ring 10W 200mm 00-599687

Expansion Valve Body TES2-NL68Z34300/68 15450386

Expansion Valve Valve Exp Solder Adaptor 68-2 15450910

Orifice NO 03 68-209300/68-20 15451105

Orifice NO 02 68-2092/68-2072 15451104

Control Panel FHG2L Three Phase Complete 01-233868-01

Control Panel FHG2L Single Phase Complete 01-233867-01

Control Panel FHG3L Three Phase Complete 01-233869-01

Controller Carel PB00F0HA10 16240051

Interface RS 482 IROPZ48500 16240053

Probes NTC 030WP00 IP68 3 metre 16240052

Isolator KG10BT214/04E 20AMP 4 pole 16240211

16 AMP Contactor KN S1010-C240- 300 15841105

R1/ R2 Relay Omron G7L-1A-T 30Amp 1 Pole 15490420

Scroll Compressor FL200DL 400/3/50

Used up to August 2004

Scroll Compressor DS183651 230/1/50

Used from August 2004

00-555449

00-555450

16240058

X

X

X

X

X

X

X

X

X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X

X

X X

X X

X X

X

X

X

X

X

X X

X X

X X

X X

X

X X

13

Page 15

MCB Siemens 5SY6316 –8 TP 16 Amp 3 Pole 16240209

Wiring diagrams

The drawings numbers for the display cases are as follows:

FHG2L - 2 door unit single phase 00-233867-02

FHG2L - 2 door unit three phase 00-233868-02

FHG3L - 3 door unit three phase 00-233869-02

X X

14

Page 16

15

Page 17

FHG2L - 2 door unit single phase 00-233867-02

Page 18

FHG2L - 2 door unit three phase 00-233868-02

Page 19

FHG3L - 3 door unit three phase 00-233869-02

1

Page 20

Foster European Operations

France

Foster Refrigerator France SA

Tel: (33) 01 34 30 22 22. Fax: (33) 01 30 37 68 74.

Email: commercial@fosterfrance.com

Germany

Foster Refrigerator Gmbh,

Tel: (49) 2333 839375. Fax (49) 2333 839377.

Email: info@foster-gmbh.de

Foster Refrigerator

Oldmedow Road

Kings Lynn

Norfolk

PE30 4JU

Tel: 01553 691122

Fax: 01553 691447

Website: www.fosterrefrigerator.co.uk

Email: sales@foster-uk.com

a Division of ‘ITW (UK) Ltd’

DISPCASE/SM/10/04

Loading...

Loading...