Page 1

F130, F200, F300

installation and operating instructions

Modular Ice Cubers

GB

Operating instructions

operating instructions

Foster European Operations

Foster Refrigerator

Oldmedow Road, King’s Lynn,

Norfolk, PE30 4JU

England

Tel: 01553 691122

Fax: 01553 691447

Website: www.fosterrefrigerator.co.uk

Email: sales@foster-uk.com

a Division of ITW (UK) Ltd.

France

Foster Refrigerator France SA

Tel: (33) 01 34 30 22 22 Fax: (33) 01 30 37 68 74 Email: info@fosterfrance.com

Germany

Foster Refrigerator Germany

Tel: (0781) 96 93 00 Fax: (0781) 96 93 019 Email: info@fosterrefrigerator.de

MODULARICECUBERS/OP/INS/0305

F

Notice d’installation

D

Bedienungsanleitung

NL

Gebruiksaanwijzing

Page 2

10) Connect the

3/4" Feeding pipe

(supplied) to the

machine and to the

cold drinking water

supply line. It is

advisable to install a

shut-off valve (not

supplied) to the

water feed pipe. If

the feed water

contains impurities,

the installation of a

filter system is

recommended. If the

water is particularly hard, i.e.

rich in minerals and their derivatives, the

application of a suitable water filter is

recommended, preventing any scale

deposits blocking the water circuit of the

machine (Fig.18).

11) Fit the flexible drain pipes to the

icemaker and the storage bin ensuring

there is adequate fall on the pipes to avoid

the drain water backing up. For a perfect

water outlet from the machine a minimum

incline of 3% of the pipes is advisable.

Check also that the pipes are not throttled

or siphoned. It is advisable that the pipes

discharge in an open vented drain (Fig.18).

Warning!

It is expressly forbidden for the users of

the equipment to carry out the following

operation or those marked by the symbol, Such operations must be performed

exclusively by qualified personnel.

1. Electrical connections

2. Water mains connections

3. Machine installation

4. Machine test run

5. Repairing machine components and parts

6. Disassembly of machine and/or

components

7. Adjustment and setting procedures

8. Machine cleaning and maintenance relative

to the following parts and components:

Electrical, Electronic, Mechanical,

Cooling System

Models 200 KG, 300 KG,

The icemaking machines

are approved by VDE, GS

and the relative symbols

are put on the packing,

serial plate and body of

the machine (Fig.10).

Note

Before installing the machine make

sure that:

a) the room temperature must not fall

below 10˚c (50˚F) or above (100˚F).

b) the water conductivity value must not

be below 10 µs/cm.

c) the main water temperature must not

fall below 5˚C (40˚F) or above

35˚C (95˚ F).

english

GB

2

OUR PRODUCTS ARE GOVERNED BY EC

LOW VOLTAGE DIRECTIVE 73/23/EEC EMC - 89/336/EEC AND THE COVER OF

THE MANUAL IS MARKED ACCORDINGLY.

preface

general specifications

installation

1

3) Clean the inside of machine and storage bin by

means of a warm water and sodium-bicarbonate

dampened sponge; rinse with plain water and dry

thoroughly.

4) Locate the icemaker and

the storage bin in the final

place, making sure that the

two are perfectly level, in

order to obtain an even

distribution of the water all

over the evaporator and a

uniform filling of the cube

plate (Fig.13).

The storage bin is equipped

with adjustable feet, which

allow for easy levelling and

sufficient height for cleaning

under the machine.

5) Unlock the sensor and the baffle by removing

the transit packaging 1and tape 2, which have

been applied to avoid any damage during

transportation (Fig.16 & Fig.17).

6) The icemaker has been designed for coupling

with another icemaker, which can be installed on

the top of the first one. For this installation, a kit

can be supplied upon request. It contains all

necessary assembling instructions.

7) Do not put the machine in a dusty

environment as this could cause a fast build up of

dust etc, therefore effecting the efficient working

of the condenser (only for air-cooled models).

8) Never keep food, bottles or other things in the

bin in order to avoid the stored ice becoming

tainted.

9) Connect machine to the water supply first and

then to a suitable electricity supply.

2) Match the icemaker to

its storage bin, fixing them

with the two screws

supplied with the machine

(Fig.20).

Before bringing the icemaker into action

perform the following operations:

e) machine is

away from

sources of heat

and in a

sufficiently

ventilated area.

A distance of at

least 20cm must

be allowed

between the

sides, back and

the walls of the

machines

(Fig.12, Fig.14).

12) Connect the

machine to the

electricity supply

after having

checked that the

voltage corresponds

to that on the plate

on the rear panel of

the machine (Fig.5).

13) Air deflector installation. (Fig.24) The

deflector has to be installed in order to

prevent the re-circulation of hot air to the

condenser.

The maximum voltage variation should not

exceed ± 6% of that stated on the rating

plate. A fused isolator must be included in

the electrical circuit to the machine, with its

own bipolar main switch at least 3 mm. of

contacts opening. The machine should be

connected to a suitable power supply with

earth terminal.

d) the main water pressure

must not fall below

1bar. (14 PSI) or above

5 bar. (70 PSI). If

pressure is above 5 bar.

a pressure regulator

should be fitted to

the water supply to the

machine (Fig.11)

f) the machine will

not work with

demineralized

water.

Fig 10.

Fig 11.

Fig 12.

Fig 14.

Fig 1.

Fig 20.

Fig 13.

Fig 16.

Fig 17.

Fig 18.

Fig 5.

Fig 24.

1) Check that ice cuber has

not been damaged during

transportation (Fig.1)

11

DISPOSAL REQUIREMENTS

If not disposed of properly all refrigerators have components that can

be harmful to the environment. All old refrigerators must be disposed

of by appropriately registered and licensed waste contractors, and in

accordance with National laws and regulations.

Page 3

The following operations must be carried

out by qualified personnel.

Starting the Machine

Before starting the ice machine perform the

following:

a) Remove the cover and the side.

b) Check that the compressor moves freely

on the rubber mounts and that the

condenser fan blade turns freely.

c) Verify that the water supply valve is

open; then connect the machine

electrical plug to the socket and switch

on the main switch; the machine starts

working automatically.

d) Check that the sensor prevents the

water from overflowing into the storage

bin, controlled by the water level sensor.

(After 3 minutes from start up the water

solenoid valve is activated again for a

few seconds till the water reaches the

maximum water level to reduce any

possibility of slush ice formation).

e) Check if the water pumps works

regularly (30 seconds delay from start up).

f) Check that the water flows evenly over

the evaporator and that there are no

leaks in the water-piping system.

g) Verify any irregular vibrations.

i) Check an ice production cycle ensuring

that the cube plate is conveyed into the

storage bin and that all operations are

performed correctly.

j) Verify the working of the machine-

stopping microswitch by keeping the

splash-guard deflector plate open for

over 30 seconds.

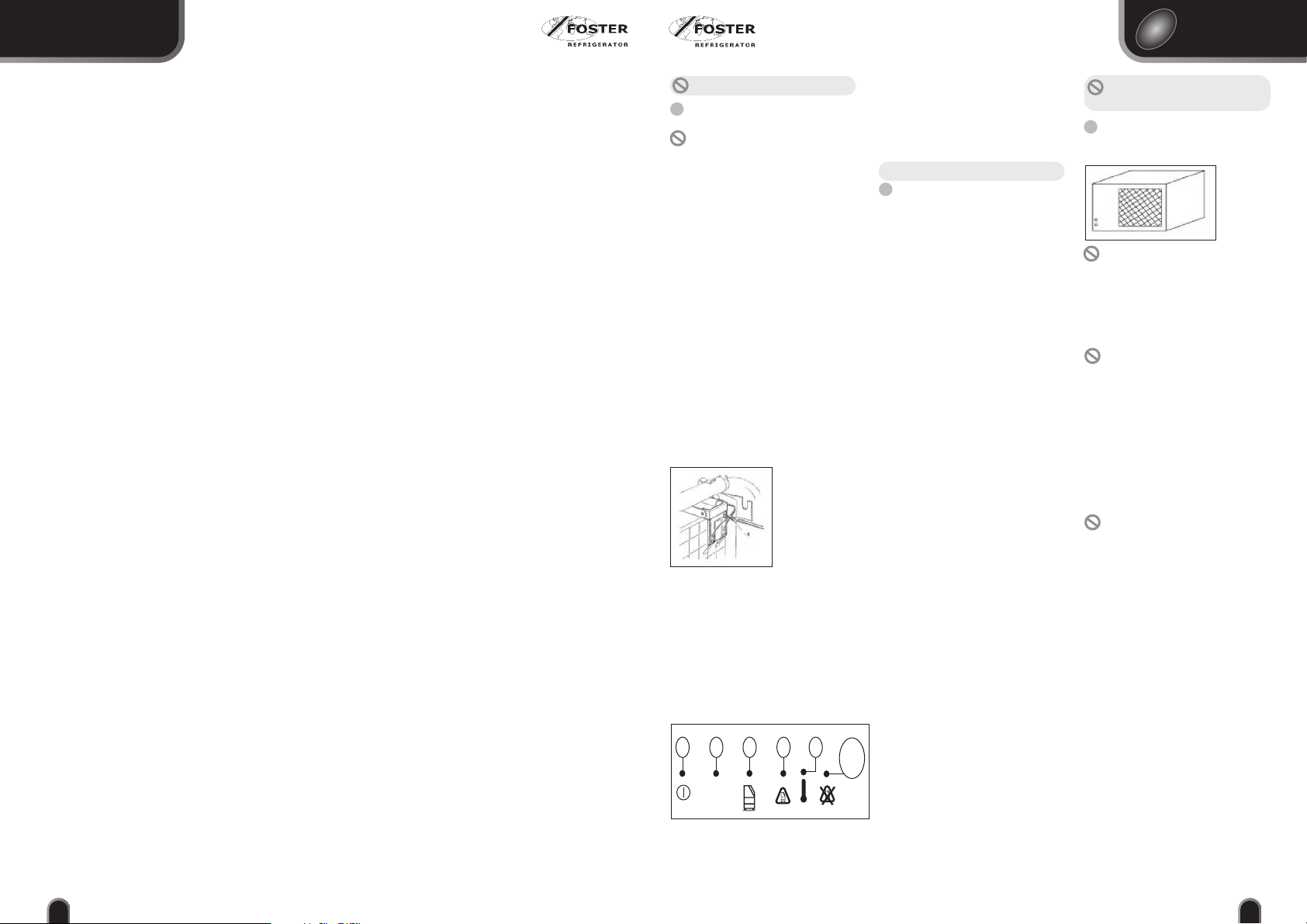

k) The LED panel, located behind the front

cover, is equipped with 5 'LEDs' with

the symbols corresponding to the

following functions:

Attention

The machine is equipped with a maximum

pressure switch with manual reset (located

at the rear of the machine).

LED 1 illuminated : alarm due to a raised

condensation pressure, the machine stops.

l) Replace the panels previously removed .

The ice cubes are produced within a special

hive-like vertical copper evaporator.

A circulation pump produces a continuous

water flow on the front grid; gradually, a

portion of the water turns into ice on the

inner walls of the small cells and forms

cubes, the height of which is controlled by

a special adjustable sensor. Such a sensor is

made up of two metal reeds, which are fed

by a low-voltage circuit, (insulated between

themselves), and kept at a certain distance

(adjustable through a screw) from the

evaporator. As the ice is produced, the

water film flowing on the ice itself

approaches the two reeds and finally

touches them, thus closing the electronic

circuits which operates simultaneously:

- The sending of warm gas to the

evaporator, by opening a solenoid valve,

and the consequent disjunction of the

partially joined cube plate from the

evaporator.

- The opening of the water-discharge

valve in order to remove any possible

residual impurity.

Once it has been disjuncted, the cube plate

slides away from the evaporator and moves

the front baffle (which is hinged in its upper

portion) toward the outside and with simple

gravity, falls into the container,

The front baffle, while rotating back and

forth, opens and closes the contacts to an

elecrtronic card, which, in turn restores the

normal ice-production cycle.

When the bin is full, the last ice-cube plate

keeps the baffle open and stops the switch

contacts from closing. Thus the electronic

card, connected to the switch, stops the

machine within 30 seconds.

The removal of the ice from the collecting

bin allows the baffle to restore its normal

position, and therefore the process is

started again.

A complete cycle takes from 15 to 30 mins

depending on water and room temperature.

If the machine stops because of irregular

working, the LED No. 2 will illuminate.

Wait at least 3 hours from the alarm

beginning, before pressing reset.

If the machine continues to malfunction call

a service technician.

Unfavorable electrical power supply to the

machine can cause a drop in voltage

causing the machine to stop working.

h) To adjust the

cube size, adjust the

screw No. 1

(Fig.19) which

determines the

distance between

the sensor reeds

and the evaporator.

The distance

(factory set) is about

4 mm for a

normal ice cube.

service information

3

functionning

3

english

GB

LED No. 1

Alarm high pressure

LED No. 2

Alarm.

LED No. 3

Bin full/Washing.

LED No. 4

Operation.

LED No. 5

Electrical power

supply.

BUTTON B

Reset/Washing.

Note:

Observe safety practice: disconnect the

machine from electricity supply before

cleaning and maintenance operations.

Cleaning of the Air Condenser

The gradual accumulation of dust in the

condenser causes a significant reduction

in the refrigerating action of the machine

and consequently in its ice production. It

is recommended to inspect frequently the

condenser at the back of the machine

and to clean in either with a nonmetallic brush, or better with a vacuum

cleaner (Fig.23).

Cleaning of the Water Inlet Filter

Close the shut-off valve of the water

supply. Unscrew the water connection to

the machine and take out the water inlet

filter. Rinse the filtering part under

running water, when clean reassemble.

Cleaning of the Cabinet Exterior

Clean using a clean cloth and warm

water.

Cleaning of the Ice Storage Bin

Remove the ice from the storage bin.

Clean the interior with a sponge wetted

in warm water with a little sodium

bicarbonate: rinse with clean water and

dry thoroughly.

Cleaning of the Water Circuit

Attention

The machine is equipped with a new

semi-automatic washing device that

enables the effective cleaning of the

entire water system.

The washing of the entire water system

should be carried out by a service

technician.

The washing frequency depends upon

the hardness of the water.

It is advised that the washing operation is

carried our at least twice a year.

cleaning and

maintenance

5

4

Fig 19.

Fig 23.

54321

HIGH

PRESS

B

❆

10

100%

100%

100%

Page 4

4) Placer l'ensemble tête de

production et bac de

stockage à sa position

définitive en s'assurant qu'il

est parfaitement de niveau

(utiliser un niveau à bulle)

pour garantir une

distribution uniforme de

l'eau sur l'évaporateur et un

démoulage régulier des

glaçons de la plaque

(Fig 13)

Des vérins réglables en

hauteur sont fournis avec le bac de stockage pour

faciliter cette mise de niveau ainsi que le

nettoyage éventuel du sol.

10) Raccorder le

tuyau d'alimentation

d'eau fourni (3/4)

entre la machine et

le réseau d'eau

potable. Nous

conseillons de poser

un robinet d'arrêt

(non fourni) pour

des motifs pratique

et de sécurité. Il est

possible de poser un

filtre sur le réseau

pour retenir toutes

les impuretés. En

cas d'eau

particulièrement

dure, c'est à dire riche en minéraux et

calcaire, il est recommandé de prévoir un

adoucisseur d'eau (TH mini 15) pour éviter

l'entartrage prématuré de l'appareil

(Fig 18)

11) Mettre en place sur la tête de

production et le bac de stockage les

évacuation au moyen des deux tubes

flexibles fournis. Pour une évacuation

optimale, prévoir une pente minimale de

3% en prenant soin de ne pas provoquer

d'étranglement ou siphon. Il convient de

raccorder la tuyauterie dans un siphon

ouvert. (Fig 18)

Modèles 200 Kg et

300 Kg

Les fabriques de glaçons

agréés VDE et GS portent

ce marquage sur

l'emballage, sur la plaque

signalétique et sur la

carrosserie des appareils.

Lors du choix du local où sera installée

la machine, s'assurer que:

a) La température ne descende pas au

dessous de 10˚C et ne dépasse pas 40˚C

b) La conductibilité de l'eau ne doit pas

être inférieure à 10 µs/cm;

c) La température de l'eau n'est pas

inférieure à 5˚C et ne dépasse pas 35˚C

français

F

4

Nos appareils sont soumis à la directive

Basse Tension 73/23/CEE-EMC89/336/CEE.

Le marquage CE est également porté sur

les notices

Préface

Informations générales

Installation

1

1) Contrôler que l'appareil

n'ait pas été endommagé

durant le transport (Fig 1)

3) Nettoyer l'intérieur du bac avec une éponge

préalablement trempée dans de l'eau tiède

additionnée d'une faible quantité de bicarbonate

de soude; rincer à l'eau claire et sécher

soigneusement.

5) Débloquer le capteur et le déflecteur en ôtant

les fixations 1 et 2 prévues pour éviter les

dommages en cours de transport. (Fig 16 &

Fig 17)

6) La tête de production est pré-équipée pour

recevoir éventuellement une seconde tête de

production en partie supérieure. Dans ce cas un

kit d'installation est disponible en option avec les

instructions de montage.

7) Ne jamais installer la machine dans des locaux

poussiéreux. Le condenseur serait rapidement

obstrué risquant l'endommagement de l'appareil.

8) Pour éviter que la glace n'absorbe de

mauvaises odeurs ou saveurs, ne jamais rien

stocker d'autre dans le bac (bouteille,

aliments etc...)

9) Effectuer les raccordements en eau avant tout

branchement électrique.

2) Assembler la tête de

production au bac de

stockage au moyen des 2

vis fournies (Fig 20)

Effectuer les opérations suivantes avant la

mise en service.

e) La machine est

éloignée de

toute source de

chaleur et se

trouve dans un

endroit bien

aéré. Prévoir un

espace de 20cm

au minimum sur

les 2 côtés et à

l'arrière. (Fig 12,

Fig 14)

12) Avant de

brancher la machine

s'assurer que le

voltage du secteur

correspond bien à

celui indiqué sur la

plaque signalétique

posée à l'arrière de

l'appareil. (Fig 5)

13) Installation du déflecteur d'air (livré en

standard) (Fig 24)

Le déflecteur doit être installé comme

indiqué pour empêcher le recyclage de l'air

chaud au travers du condenseur.

La tolérance maximale admise aux variations de

tension est de ± 6 % par rapport à la valeur

nominale.

Prévoir une ligne électrique pour la machine

avec son propre interrupteur général bipolaire à

ouverture des contacts de 3mm minimum.

Prévoir également une protection fusible ou

automatique et une prise de courant avec mise

à la terre. Le tout doit être dimensionné en

fonction de la puissance indiquée sur la plaque

signalétique de l'appareil.

f) La machine ne

fonctionne pas

sur un réseau

d'eau

déminéralisée.

Fig 10.

Fig 11.

Fig 12.

Fig 14.

Fig 1.

Fig 20.

Fig 13.

Fig 16.

Fig 17.

Fig 18.

Fig 5.

Fig 24.

Attention

Les opérations suivantes ainsi que celles

mises en évidence par le symbole en

marge sont strictement réservées à du

personnel technique agréé.

d) La pression de l'eau n'est

pas inférieure à 1 bar

(14 PSI) et ne dépasse

pas 5 bars (70 PSI). En

cas de pression

supérieure, prévoir la

mise en place d'un

réducteur de pression sur

l'alimentation d'eau en

amont de la machine

(Fig 11)

1. Raccordements électriques

2. Raccordement en eau

3. Installation de l'appareil

4. Essais

5. Interventions de réparation sur tous les

composants et organes de l'appareil

6. Démontage de l'appareil ou de ses

composants

7. Interventions sur la régulation ou le

calibrage

8. Nettoyage et entretien des composants

électriques, électroniques, mécaniques

ou frigorifiques.

De hiervolgende handelingen mogen alleen

worden uitgevoerd

door gekwalificeerd personeel, dat is

aangewezen door onze distributeur.

Let op!

De machine is voorzien van een

overdrukbeveiliging, een schakelaar die

handmatig moet worden gedeblokkeerd. 1) de

rode “led” brandt: alarm wegens hoge

ondensatiedruk, de machine komt tot stilstand.

2) Druk op de rode drukknop achter op de

machine om de machine weer op te starten.

BELANGRIJK: als de machine na handmatige

herinschakeling bij herhaling wordt

uitgeschakeld, moet u contact opnemen met

de onderhoudsdienst.

De ijsblokjes worden gevormd in een

speciale verticale koperen verdamper die de

vorm heeft van een honingraat. Een

circulatiepomp zorgt voor een voortdurende

stroom water aan de voorkant en geleidelijk

wordt een deel van het water als ijs afgezet

op de binnenwanden van de kleine cellen

van de verdamper, waarbij ijsblokjes

ontstaan die de door middel van een

regelbare sensor ingestelde hoogte

bereiken. Die sensor bestaat uit twee

onderling geïsoleerde metalen lamellen die

onder laagspanning staan en op een

bepaalde afstand van de verdamper worden

gehouden. Deze afstand wordt met een

afstelmechanisme (stelschroef) ingesteld.

Terwijl het ijs wordt gevormd, nadert het

laagje water dat over het ijs stroomt

geleidelijk de beide lamellen totdat die

worden aangeraakt en een elektronisch

circuit wordt kortgesloten, dat tegelijkertijd

zorgt voor:

- uitstroom van heet gas uit de ver

damper door opening van een

electroventiel, waardoor de plaat met

de gedeeltelijk aan elkaar vastzittende

ijsblokjes langzaam wordt losgemaakt

uit de verdamper.

- opening van de uitlaatklep waardoor

het resterende water kan weglopen met

eventueel aanwezige

restverontreiniging.

Wanneer de plaat met de ijsblokjes is

losgekomen uit de verdamper, beweegt de

frontale deflector die scharniert aan zijn

bovenkant, naar buiten, en valt door de

zwaartekracht in de bewaarunit. De

centrale deflector opent bij zijn beweging

eerst naar voren en daarna naar achteren

de contacten van een magnetische

microschakeling, die verbonden is met een

elektronische chip. Deze start de gewone

cyclus voor het maken van de ijsblokjes

opnieuw. Wanneer de bewaarunit vol is,

houdt de laatste plaat met ijsblokjes de

deflector open, en dus blijven ook de

contacten van de microschakeling open. In

deze toestand zorgt de met de

microschakeling verbonden chip ervoor dat

de machine na 30 seconden wordt

uitgeschakeld. Wanneer er ijs uit de

bewaarunit wordt gehaald, keert de

deflector terug in de normale positie, en

begint dus de ijsmachine weer te werken.

De tijd voor een volledige cyclus kan

variëren van circa 15 tot circa 30 minuten,

al naar gelang de temperatuur van het

water en die van de omgeving. In geval van

stilstand van de machine door een storing

gaat LED nr. 2 branden. Wacht in dit geval

tenminste 3 uur vanaf het begin van de

cyclus voor u op reset drukt. Als de cyclus

weer tot stilstand komt, dient u contact op

te nemen met de onderhoudsdienst.

Als de stroomtoevoer te wensen over laat,

kan tijdelijke spanningsval optreden.

h) om de hoogte van de

ijsblokjes af te stellen

kunt u draaien aan

schroef 1 (zie

figuur 19) die de

afstand van de lamellen

van de sensor regelt,

vanuit de

verdamper. De afstand is

in de fabriek ingesteld op

circa 3,5 mm voor een

gewoon ijsblokje.

onderhoudsvoorschriften

(“service”)

3

werking

9

nederlands

N

LED No. 1

Alarm, hoge druk

LED No. 2

Alarm

LED No. 3

Bewaarunit vol/wash

LED No. 4

Functionering

LED No. 5

Netvoeding

RODE DRUKKNOP B

Reset/Wash.

N.B.:

Reiniging en onderhoud, van elke aard

ook, mogen pas worden uitgevoerd

wanneer de stroomtoevoer van de

machine is uitgeschakeld.

Reiniging van het luchtfilter van de

condensor

Ophoping van stof in het filter van de

condensor zorgt ervoor dat het

koelrendement van het apparaat

geleidelijk afneemt en daarmee ook de

ijsproductie terugloopt. Het verdient

daarom aanbeveling de condensor, die

zich achterin de ijsmachine bevindt,

regelmatig te controleren (tenminste elke

30 dagen) en hem schoon te maken met

een niet metalen borstel, of nog liever,

met de stofzuiger (figuur 23).

Reiniging van het waterfilter

Sluit de veiligheidskraan, draai de

verbindingsslang los, verwijder het filter

en maak het filterelement schoon onder

de kraan en monteer het dan weer op

zijn plaats.

Reiniging van de ombouw

Maak deze schoon met een niet te nat

doekje met schoon lauw water.

Reiniging van de bewaarunit

Verwijder het ijs uit de bewaarunit. Maak

de unit van binnen schoon met een

spons met lauw water waaraan u een

beetje natriumbicarbonaat

(zuiveringszout) heeft toegevoegd; met

schoon water nawassen en zorgvuldig

droogmaken.

Reiniging van de waterleidingen

De machine is uitgevoerd met een nieuw

semi- automatisch reinigingssysteem

waarmee het watersysteem in zijn

geheel wordt gereinigd. De reinigingen

dienen te worden uitgevoerd door een

vakman van de onderhoudsdienst.

De frequentie waarmee de reinigingen

dienen te worden uitgevoerd hangt af van

de hardheid van het water. Aangeraden

wordt de reiniging ten minste een maal per

jaar uit te voeren.

reiniging en

onderhoud

5

4

Fig 19.

Fig 23.

54321

HIGH

PRESS

B

❆

Inbedrijfstelling

Alvorens de ijsmachine in werking te stellen

moeten de volgende handelingen worden uitgevoerd:

a) neem het deksel van de machine en

verwijder de zijpanelen.

b) controlleer of de compressor vrij kan

bewegen op de rubbertjes die zijn

aangebracht op de verankeringen, en of

de kleppen van de electroventilatoren vrij

kunnen draaien.

c) controleer of de waterkraan openstaat; nu

kan de stekker van de machine in het

stopcontact worden gestoken en de

schakelaar van de elektrische leiding

worden bediend; de machine treedt dan

automatisch in werking.

d) Let erop dat de waterlevelsensor werkt,

die er voor zorgt dat er geen water in de

bunker loopt.

e) controleer of de sensor de watertoevoer

naar het bakje op circa 40-45 mm stopzet.

f) controleer of de waterpomp naar behoren

werkt (met 30” vertraging).

g) ga na of er abnormale trillingen

waarneembaar zijn.

i) laat de machine een hele cyclus

doorlopen, erop lettend of de ijsplaat

wordt afgevoerd naar de bewaarunit en

alle bewerkingen van de cyclus normaal

verlopen.

j) controleer de werking van het

microuitschakelingsmechanisme van de

machine door het

deflector-sproeischerm voor langer dan

30 seconden naar boven te bewegen.

k) het bedienings- en controlepaneel aan

de voorzijde van het apparaat is

voorzien van 5 “LEDs” naast de

symbolen die de volgende functies

aangeven:

MODALITES DE MISE AU REBUT

Certains composants des réfrigérateurs peuvent présenter un danger

pour l'environnement. Aussi est-il indispensable que ces produits

soient mis au rebut dans une décharge habilitée à ces fins selon la

législation en vigueur.

100%

100%

100%

Page 5

Les opérations suivantes doivent

uniquement être pratiquées par du

personnel techniquement agréé.

Précaution

L' appareil est équipé d'un pressostat haute

pression à réarmement manuel.

1) Voyant rouge allumé: alarme d'une

pression de condensation trop élevée;

l'appareil s'arrête

2) Appuyer sur la bouton rouge à l'arrière

de l'appareil pour le réarmer.

IMPORTANT! Au cas oú l'appareil s'arrête

toujours après plusieurs réarmement, faire

appel à un installateur agréé.

La formation des glaçons est produite dans

un évaporateur vertical spécial en cuivre et

en forme de ruche. Une pompe assure un

flux continu d'eau sur le réticule frontal et

graduellement une partie de l'eau se

transforme en glaçon sur les parois internes

des alvéoles et forme des cubes de

dimensions prévues par un capteur réglable.

Le capteur se compose de 2 lamelles

métalliques alimentées par un circuit basse

tension isolées entre elles et maintenues à

distance de l'évaporateur grâce à un

réglage par vis. Au fur et à mesure que la

glace se forme, le voile d'eau qui s'écoule

sur la glace s'approche des lamelles jusqu'à

les toucher et à fermer le circuit électrique.

Cela provoque:

- l'enclenchement de l'électrovanne et

l'envoi du gaz chaud dans l'évaporateur

et en conséquence la séparation gradu

elle de la plaque des glaçons,

partiellement unis à l'évaporateur.

- L'ouverture de la vanne d'évacuation

d'eau qui élimine les résidus éventuels

d'impuretés.

Après sa séparation, la plaque d'injection

déplace vers l'extérieur le déflecteur frontal

articulé sur la partie supérieure et les

glaçons tombent dans le bac de stockage

par gravité. Le déflecteur central, dans son

mouvement de rotation en avant puis en

arrière active les contacts d'un microswitch

relié à une carte électronique qui rétablit un

nouveau cycle de production. Lorsque le

bac est plein, la dernière plaque maintient

le déflecteur ouvert et empêche le

redémarrage de la production avec une

temporisation de 30 secondes. L'extraction

de glaçons du bac permet au déflecteur de

revenir sur sa position normale et autorise le

redémarrage de l'appareil. La durée du cycle

complet peut varier de 15 à 30 minutes

environ en fonction de la température de

l'eau et de l'environnement. En cas d'arrêt

de l'appareil par suite d'une irrégularité

dans le fonctionnement la LED s'allume.

Attendre au moins 3 heures entre le début

de l'alarme et la remise en marche en

actionnant le bouton "reset".

En cas de persistance du défaut, faire appel

à un installateur agréé.

En cas de conditions d'alimentation

électrique défavorable, l'appareil peut

provoquer des chutes de tension

transitoires.

h) Pour régler la

hauteur des glaçons,

intervenir sur la vis 1

(Fig 19) qui

détermine la distance

des lamelles du

capteur en face de

l'évaporateur. La

distance réglée

d'usine est de 3,5

mm pour un glaçon

de taille correcte.

INFORMATIONS

TECHNIQUES

3

Fonctionnement

5

français

F

LED No. 1

Alarme haute pression

LED No. 2

Alarme

LED No. 3

Stockage plein/lavage

LED No. 4

Fonctionnement

LED No. 5

Secteur

Touche B

Reset/Lavage

Précaution

Toutes les opérations de nettoyage et de

maintenance doivent être effectuées

après avoir désactivé l'alimentation

électrique de l'appareil.

Nettoyage du filtre condenseur à air

L'accumulation progressive de la

poussière dans le filtre condenseur

provoque peu à peu une réduction du

rendement frigorifique de l'appareil et

donc de la production de glace. Nous

conseillons de vérifier fréquemment (une

fois par mois) le condenseur situé à

l'arrière de la tête de production et de le

nettoyer avec une brosse non métallique

ou avec un aspirateur.(Fig 23)

Nettoyage du filtre d'arrivée d'eau

Fermer la vanne d'arrêt d'eau; dévisser le

tube d'alimentation, enlever le filtre et

nettoyer l'élément filtrant avec un jet

d'eau, puis remonter.

Nettoyage de la carrosserie

Nettoyer avec un chiffon légèrement

imbibé d'eau chaude

Nettoyage du bac de stockage

Extraire la glace du bac. Nettoyer

l'intérieur avec une éponge trempée dans

de l'eau tiède additionnée d'une faible

quantité de bicarbonate de soude; rincer

à l'eau claire puis sécher soigneusement.

Nettoyage du circuit hydraulique

Attention!

La machine est équipée d'un nouveau

dispositif de lavage semi automatique qui

permet un détartrage complet du

système.

L'opération de détartrage doit être

réalisée par un technicien agréé. La

fréquence des détartrages dépend de la

dureté de l'eau. Nous recommandons

d'effectuer un détartrage deux fois par

an au minimum.

Nettoyage et

maintenance

5

4

Fig 19.

Fig 23.

54321

HIGH

PRESS

B

❆

Mise en service

Effectuer les opérations suivantes avant la

première mise en marche.

a) Enlever le couvercle et les panneaux

latéraux

b) Contrôler que le compresseur puisse

osciller sur ses patins caoutchoutés; que

les rotors des moteurs ventilateurs

tournent librement

c) Contrôler que le robinet d'eau est

ouvert puis relier la fiche d'alimentation

électrique. Activer l'interrupteur

générale de la ligne électrique. La

fabrique de glaçons démarre

automatiquement.

d) Vérifier que le flotteur coupe l'arrivée

d'eau avant qu'elle ne coule dans le bac

de stockage.

(Après 3 minutes de fonctionnement,

l'électrovanne s'enclenche de nouveau

pendant quelques secondes jusqu'à ce

que l'eau atteigne le niveau maximum

et réduire les risques de formation de

neige fondue).

e) Contrôler que le flotteur arrête l'eau du

bac à 40-45mm

f) S'assurer que la pompe à eau

fonctionne régulièrement (retard de

30 secondes)

g) Vérifier qu'il n'y ait aucune vibration

anormale

i) Contrôler un cycle de production de

glace complet jusqu'au démoulage et la

chute des glaçons dans le bac de

stockage.

j) Vérifier le fonctionnement du

microswitch de coupure en maintenant

soulevé le déflecteur anti-éclaboussures

pendant plus de 30 secondes

k) Le panneau frontal est équipé de 5 LED

et de symboles indiquant les fonctions

4) De combinatie van

ijsmachine en bewaarunit

op haar definitieve plaats

brengen en erop letten dat

ze goed waterpas staat, dit

om ervoor te zorgen dat het

water homogeen over de

verdamper wordt verdeeld

en dat de plaat met

ijsblokjes op regelmatige

wijze naar beneden kan

vallen (figuur 13). De

bewaarunit wordt geleverd

met in hoogte regelbare voetjes, die het mogelijk

maken om de machine goed waterpas te stellen

en de onderliggende vloer zo nodig gemakkelijk

te reinigen.

10) Sluit de

meegeleverde 3/4”

slang aan op de

machine en op de

(koude) drinkwaterleiding. Wij adviseren om

praktische redenen,

maar ook ten behoeve

van de veiligheid van

de installatie, om

tussen de leiding en de

machine een

veiligheidskraan te

installeren, die niet

door ons wordt

geleverd. Als het

drinkwater van slechte

kwaliteit is, kan een waterfilter worden

aanbevolen. In geval van bijzonder hard

drinkwater (water dat rijk aan zouten en

mineralen is), is het wenselijk een

waterontharder te installeren. Hiermee

vermijdt u dat er kalkafzetting in de interne

leidingen van de machine plaats vindt (zie

figuur 18). Informeert u zich hierover bij uw

waterleidingbedrijf

11) Verbindt de twee bijgeleverde buigzame

slangen met de aansluitingen voor de afvoer

van de machine en de container. Voor een

probleemloze afvoer van het water moeten

de leidingen een minimaal afschot van 3%

hebben. Controleer hierbij ook dat de

slangen geen knikken, bobbels of deuken

vertonen. Het verdient aanbeveling om de

afvoer via een open sifon te laten

plaatsvinden (figuur 18).

Models 200 KG, 300 KG

De ijsmachines met Italiaans

VDE, GS keurmerk zijn op de

verpakking, het registratieplaatje en op de

machine zelf voorzien van de

symbolen die zijn aangegeven

in figuur 10.

Let op!

Bij de keuze van de plaats waar de

machine moet worden geïnstalleerd is

het belangrijk erop te letten dat:

a) de temperatuur van de ruimte niet

lager wordt dan 10°C (50° F) en niet

hoger dan 40°C (100° F).

b) De geleiding van het water mag niet

minder bedragen dan 10 µs/cm

c) de watertemperatuur niet lager is dan

5°C (40° F) en niet hoger dan 35°C (95° F).

nederlands

N

8

ONZE PRODUCTEN VOLDOEN AAN DE

RICHTLIJN LAAGSPANNINGSAPPARATUUR

73/23/EEC - EMC - 89/336/EEC EN HEBBEN

DAAROM OOK HET CE- MERK OP DE

OMSLAG VAN HET INSTRUCTIEBOEKJE

Inleiding

algemene informatie

Installeren

1

1) Controleren of het

apparaat bij het transport

niet is beschadigd (zie

figuur 1).

3) De machine van binnen reinigen met een spons

met lauw water waaraan u een beetje

natriumbicarbonaat (zuiveringszout) heeft

toegevoegd; met schoon water nawassen en

zorgvuldig droogmaken.

5) Deblokkeer de sensor en de deflector door de

beschermers 1 en 2 te verwijderen. Deze dienen

uitsluitend om beschadiging bij het transport te

voorkomen (figuur 16 en 17)

6) De ijsmachine kan eventueel gekoppeld

worden aan een tweede machine die boven de

eerste kan worden geïnstalleerd. Daarvoor kan op

aanvraag een kit worden geleverd met een aparte

montagehandleiding.

7) De machine dient niet in een stoffige ruimte te

worden geïnstalleerd, daar in dat geval de

condensator van de koeleenheid snel verstopt

kan raken (dit geldt alleen voor luchtgekoelde

machines).

8) Om te voorkomen dat het ijs vervelende

luchtjes absorbeert, adviseren wij dringend in de

bunker geen levensmiddelen, flessen en

dergelijke te bewaren

9) Sluit eerst de waterleiding aan en pas daarna

de stroomvoorziening.

2) De ijsmachine bevestigen

aan de zgn. bewaarunit

(ook deposit genoemd)

door middel van de twee

bijgeleverde schroeven

(figuur 20).

Alvorens de ijsmachine in werking te stellen,

dient u de volgende handelingen te verrichten:

e) de machine zich

niet in de

nabijheid

bevindt van

warmtebronnen

en op een goed

geventileerde

plaats komt te

staan. Zorg hier

bij voor

tenminste

20 cm ruimte

aan weerszijden

van de machine

(figuur 12 en 14).

12)Controleer

alvorens de elektrische

aansluitingen tot

stand te brengen of

het voltage

overeenkomt met

het op het

identificatieplaatje van

de machine

aangegeven voltage

(figuur 5).

13) Installatie van de bijgeleverde deflector:

(figuur 24). De deflector moet zoals

aangegeven worden geïnstalleerd, om

hercirculatie van de warme lucht in de

condensator te vermijden.

De maximaal toegestane stroomafwijking

bedraagt ± 6% van de nominale waarde. Zorg

voor een elektrische aansluiting met een eigen

algemene bipolaire schakelaar en een opening

van tenminste 3 mm voor de stekkerpinnen.

Deze aansluiting dient geaard te zijn en over

een eigen stop te beschikken. Een en ander

moeten zijn afgestemd op het vermogen dat

staat aangegeven op het identificatieplaatje.

f) De machine werkt niet wanneer

gedemineraliseerd water wordt gebruikt

Fig 10.

Fig 11.

Fig 12.

Fig 1.

Fig 20.

Fig 13.

Fig 16.

Fig 17.

Fig 18.

Fig 5.

Fig 24.

Opgelet!

De handelingen die hieronder opgesomd zijn en handelingen die gemarkeerd zijn met dit symbool mogen

onder geen beding door de gebruiker

van de machine worden uitgevoerd

d) de waterdruk niet

minder bedraagt dan 1

atmosfeer (14 PSI) en

niet meer dan 5

atmosfeer (70 PSI). Als

de waterdruk hoger dan

5 atmosfeer is, dient een

drukverminderaar te

worden geïnstalleerd in

de toevoerleiding van de

machine (figuur 11).

1. Elektrische aansluitingen

2. Wateraansluitingen

3. Installatie van de machine

4. Testen van de machine

5. Reparatiewerkzaamheden aan alle componenten

en organen van de machine

6. Demontage van de machine en/of van zijn

componenten

7. Instellingen en afstellingen

8. Onderhoud en reiniging van de volgende

onderdelen:

En componenten van het apparaat:

Elektrisch, Elektronisch, mechanisch,

Koelelementen, Hydraulisch

VERWERKINGSVOORSCHRIFTEN

Koelkasten bevatten onderdelen die, wanneer ze niet op de juiste manier

worden verwerkt, schadelijk kunnen zijn voor het milieu. Alle oude koelkasten

moeten door erkende en geregistreerde afvalverwerkingsbedrijven worden

verwerkt - dit in overeenstemming met wetten en bepalingen geldig in Nederland.

100%

100%

100%

Page 6

4) Den Eiswürfelbereiter an

den definitiven Standort

bringen. Der Vorratsbehälter

ist mit höhenverstellbaren

Füßen ausgestattet, um das

Ausrichten des Gerätes und

die Reinigung unter dem

Gerät zu erleichtern. Der

Eiswürfelbereiter muss gerade stehen, damit sich das

Wasser gleichmäßig in der

Verdampferplatte verteilt.

Sorgen Sie daher dafür, dass

das Gerät gerade steht und prüfen Sie dies mit

einer Wasserwaage (Abb. 13).

10) Den mitgelieferten

Wasserzuleitungsschlauch (3/4 Zoll)

anschließen. Es ist ratsam, die

Wasserzuleitung mit einem Absperrventil zu

versehen. Bei unreinem oder hartem Wasser

sollte ein geeigneter Filter in der

Wasserzuleitung montiert werden (Abb. 18).

11) Montieren Sie die mitgelieferten

Abflussschläuche am Abfluss und am

Vorratsbehälter. Sorgen Sie für ein

Mindestgefälle von 3%, damit das Wasser

einwandfrei abfließt. Den Schlauch nicht

knicken. Das Wasser muss in einen offenen

Siphon abfließen.

Modelle F200 und F300

Die Geräte sind GS- und VDEgeprüft. Diese Symbole finden

Sie auf der Verpackung, am

Typenschild und am Gerät.

Die nachstehenden Arbeitsvorgänge dürfen nur von einem Fachmann durchgeführt werden.

Achtung!

Die Maschine ist mit einem Überdruckschalter mit manueller Rücksetzung ausgestattet.

1) Rote Kontrollleuchte ein: Alarmzustand

wegen hohem Kondensationsdruck. Die

Maschine hält an. 2) Mit der roten Taste an

der Rückseite die Maschine wieder in

Betrieb setzen. WICHTIG: Sollte die

Maschine wiederholt nach einem manuellen

Resetvorgang anhalten, den Kundendienst

anfordern.

Die Bildung der Eiswürfel erfolgt in einem

vertikalen Spezialverdampfer aus Kupfer mit

Wabenstruktur. Eine Umlaufpumpe sorgt für

einen andauernden Wasserstrom auf das

frontseitig angebrachte Gitter. Nach und

nach bildet sich aus einem Teil des Wassers

Eis an den Innenwänden der kleinen Zellen,

wodurch Würfel entstehen, deren Höhe

durch den einstellbaren Sensor vorgegeben

ist. Der Sensor besteht aus zwei getrennten

mit einer Stellschraube vom Verdampfer

entfernt gehaltenen Metalllamellen, die

durch eine Niederspannungsschaltung

versorgt werden. Durch die allmähliche

Eisbildung nähert sich der über das Eis

laufende Wasserschleier den zwei Lamellen,

bis er sie berührt und einen elektronischen

Kreislauf schließt, der gleichzeitig folgende

Vorgänge aktiviert:

- Zuströmung des warmen

Verdampfungsgases durch Öffnung

eines Magnetventils, was die schrittweise Ablösung der Würfel von der

Platte bewirkt.

- Öffnung des Wasserablassventils zum

Abschwemmen eventuell zurückge

bliebener Verunreinigungen.

Die Eiswürfelplatte bewegt nach dem

Ablösen das an der Oberseite mit Scharnier

befestigte, vordere Leitblech nach außen

und fällt durch Schwerkraft in den Behälter.

Das mittlere Leitblech öffnet und schließt

durch die zuerst nach vorne, dann nach

hinten gerichtete Drehbewegung die

Kontakte eines an eine elektronische

Steuerung angeschlossenen, magnetischen

Mikroschalters, der den normalen

Eisproduktionszyklus wieder startet. Wenn

der Behälter voll ist, hält die letzte Eisplatte

das Leitblech und somit die

Mikroschalterkontakte offen. Unter diesen

Bedingungen stoppt die an den

Mikroschalter angeschlossene elektronische

Steuerung nach 30 Sekunden die Maschine.

Die Herausnahme der Eiswürfel aus dem

Behälter ermöglicht dem Leitblech die

Rückkehr in die Ausgangsposition und

somit die erneute Inbetriebsetzung der

Eismaschine. Die Dauer eines kompletten

Zyklus kann, abhängig von der Wasser- und

Raumtemperatur, 15 bis 30 Minuten

betragen. Bei einem Maschinenstillstand

wegen einer Betriebsstörung erleuchtet LED

2. Man sollte mindestens 3 Stunden nach

Beginn warten, bevor Resettaste gedrückt

wird. Sollte die Maschine wiederholt

anhalten, den Kundendienst rufen.

Unter ungünstigen Versorgungsbedingungen

kann das Gerät vorübergehend

Spannungsabfälle auslösen

Allgemeines

Bei der Wahl des Raums, in dem die

Maschine aufgestellt wird, ist folgendes

zu beachten:

a) Die Raumtemperatur muss zwischen

10°C und 40°C liegen.

b) Die Wasserreinheit darf nicht unter

10 µs/cm liegen.

c) Die Wassertemperatur muss zwischen

5°C und 35°C liegen.

deutsch

D

6

UNSERE PRODUKTE ENTSPRECHEN DEN

RICHTLINIEN 73/23/EWG (NIEDERSPANNUNG)

UND 89/336/EWG (EMV). DAS DECKBLATT

DER GEBRAUCHSANLEITUNG IST DESHALB

MIT DER CE-KENNZEICHNUNG VERSEHEN.

Hinweis

Installation

1

1) Sicherstellen, dass das

Gerät keine

Transportschäden erlitten

hat (Abb. 1)

3) Das Innere der Maschine mit einem Schwamm

und lauwarmem Wasser reinigen. Mit frischem

Wasser nachwischen und sorgfältig trockenreiben.

5) Die Transportsicherungen vom Sensor und vom

Leitblech entfernen (Abb. 16-17).

6) Die Eiswürfelmaschine ist für den Anschluss

einer zweiten Eismaschine vorgerüstet, die über

der ersten installiert wird. Für diese Anwendung

kann auf Wunsch ein Montagesatz, inklusive

Montageanleitung geliefert werden.

7) Die Maschine nicht in staubigen Räumen

aufstellen, da es zu einer raschen Verstopfung

des Kondensators im Kühlaggregat kommen

kann (nur bei luftgekühlten Maschinen).

8) Damit das Eis keinen schlechten Geruch oder

Geschmack aufnimmt, dürfen andere Waren

(Lebensmitteln, Flaschen, u.s.w.) nicht im

Vorratsbehälter gelagert werden.

9) Erst nach dem Wasseranschluss den

Stromanschluss vornehmen.

2) Den Eiswürfelbereiter an

den eigenen Vorratsbehälter

anschließen. Die

Verbindung mit den zwei

mitgelieferten Schrauben

(Abb. 20) sichern.

Vor Inbetriebnahme des Eiswürfelbereiters

folgende Arbeitsgänge ausführen:

e) Die Maschine

muss fern von

Hitzequellen

und an einer

gut belüfteten

Stelle stehen.

Einen Freiraum

von mindestens

20 cm an den

Seiten und an

der Rückwand

lassen

(Abb. 12 – 14).

12)Vor dem

elektrischen

Anschluss der

Maschine

sicherstellen, dass

die Netzspannung

mit der am

Kennschild an der

Maschinenrückseite

angegebenen

Spannung übereinstimmt (Abb. 5).

13) Montage des mitgelieferten Leitblechs

(Abb. 24): Das Leitblech muss wie dargestellt

montiert werden, um die Heißluftrückführung

in den Kondensator zu verhindern.

Die maximal zulässige Toleranz für

Spannungsschwankungen beträgt +/-6% des

Nennwerts. Eine Stromversorgungsleitung zur

Maschine herstellen, die einen eigenen

zweipoligen Hauptschalter und eine

Kontaktöffnung von mindestens 3 mm hat.

Diese ist außerdem mit einer Sicherung oder

einem Sicherungsautomaten sowie mit einer

geerdeten Steckdose zu versehen.

h) Zur Einstellung der

Würfelhöhe die

Schraube 1 (Abb. 19)

betätigen, die den

Abstand der

Sensorlamellen zum

Verdampfer

bestimmt. Die werkseitig eingestellte

Entfernung für einen

Normalwürfel beträgt

ca. 4 mm.

f) Die Maschine

funktioniert

nicht mit

entmineralisiertem Wasser.

Inbetriebnahme

3

Betrieb

7

deutsch

D

LED 1

Alarm Hochdruck

LED 2

Alarm

LED 3

Behälter voll/Spülen

LED 4

Betrieb

LED 5

Netz

TASTE B ROT

Reset/Spülen

Hinweis:

Alle Reinigungs- und Wartungsarbeiten

dürfen erst nach Ausstecken des Geräts

vorgenommen werden.

Reinigung der Filters am

Luftkondensator

Der sich mit der Zeit im Kondensatorfilter

ansammelnde Staub führt nach und nach

zu einem Abfall der Kühlleistung des

Geräts und somit der

Eiswürfelproduktion. In der Regel sollte

man häufig (mindestens alle 30 Tage) den

im rückwärtigen Bereich der

Eiswürfelmaschine installierten

Kondensator inspizieren und mit einer

Bürste (keine Metallborsten) oder am

besten mit einem Staubsauger reinigen

(Abb. 23).

Reinigung der Filters am

Wassereinlauf

Den Wassersperrhahn zudrehen, das

Anschlussrohr abschrauben, den Filter

herausnehmen und das Filterelement mit

einem Wasserstrahl reinigen. Danach

wieder einsetzen.

Reinigung des Gehäuses

Zum Reinigen einen mit lauwarmem

Wasser angefeuchteten Lappen

verwenden.

Reinigung des Behälters

Das Eis aus dem Behälter nehmen. Das

Innere mit einem Schwamm auswaschen,

der in lauwarmes, Wasser mit einer

geringen Zugabe von Natron getaucht

wird. Mit sauberem Wasser nachwischen

und sorgfältig trockenreiben.

Reinigung des Wasserkreislaufs

Die Maschine ist mit einer neuen

halbautomatischen Waschvorrichtung

ausgestattet, die eine korrekte Reinigung

des gesamten Wassersystems ermöglicht.

Diese Arbeit muss von einem

Servicetechniker verrichtet werden. Die

Häufigkeit der Reinigungen hängt von

der Wasserhärte ab. Es werden jedoch

halbjährliche Abstände empfohlen.

Reinigung und

Wartung

5

4

Abb. 10.

Abb 11.

Abb. 12.

Abb. 14.

Abb. 1.

Abb. 20.

Abb. 13.

Abb. 16.

Abb. 17.

Abb. 18.

Abb. 5.

Abb. 24.

Abb. 19.

Abb. 23.

54321

HIGH

PRESS

B

❆

Achtung!

Alle mit diesem Symbol gekennzeichneten

sowie die nachstehenden Arbeiten dürfen nur

von einem Fachmann durchgeführt werden.

d) Der Wasserdruck muss

zwischen 1 bar und 5 bar

liegen. Bei einem

Wasserdruck über 5 bar

muss ein Druckreduzierer

installiert werden.

Vor der Inbetriebnahme:

a) Den Deckel und die Seitenpaneele

entfernen.

b) Sicherstellen, dass der Kompressor frei

auf den Gummiteilen der

Verankerungsbügel schwingen kann

und dass die Elektroventilatoren

ungehindert drehen.

c) Kontrollieren, ob der Wasserhahn

aufgedreht ist. Dann den Netzstecker

der Maschine an der Steckdose

anschließen und den Ein-/Ausschalter

einschalten. Die Maschine setzt sich

automatisch in Betrieb.

d) Sicherstellen, dass das Wasser nicht in

den Vorratsbehälter läuft. Dies wird

durch einen Wasserfühler verhindert.

Das Magnetventil öffnet sich wieder

nach ca. 3 Minuten, bis der

Wasserbehälter voll wird, um eine

optimale Eisqualität zu gewährleisten.

e) Sicherstellen, dass die Wasserpumpe

einwandfrei funktioniert (ca. 30

Sekunden Verzögerungszeit nach dem

Einschalten).

f) Prüfen, ob sich das Wasser gleichmäßig

in der Verdampferplatte verteilt.

g) Sich vergewissern, dass keine anormalen

Schwingungen erzeugt werden.

i) Anhand eines Probelaufs prüfen, ob die

Eisplatte in den Behälter abgeladen wird

und die einzelnen Schritte des Zyklus

ordnungsgemäß ablaufen.

j) Die Funktionstüchtigkeit des

stoppauslösenden Mikroschalters

prüfen, indem das Spritzschutzleitblech

über 30 Sekunden lang gehoben wird.

k) Auf der Bedienblende an der

Vorderseite befinden sich 5 LED’s neben

den Symbolen für folgende Funktionen:

1. Stromanschluss

2. Wasseranschluss

3. Installation

4. Inbetriebnahme

5. Reparaturen

6. Ausbau und Austausch von Teilen

7. Einstellen

8. Wartung

Allgemeines

Entsorgung

Alle Kühlgeräte und deren Teile müssen fachgerecht

entsorgt werden.

100%

100%

100%

Loading...

Loading...