FORUM DSI User Manual

Smart Solutions. Powerful Products.

DSI® Forged Steel

Carbon, Stainless and Alloy

Gate, Globe and Check Valves

Manufacturer of Quality Valve

Products Around the Globe

At Forum™ Energy Technologies we are committed to improving our clients’ operational and financial performance by supplying the most comprehensive range of valve products in the industry through our family of trusted valve brands.

For years, DSI® Forged Steel Valves have been satisfying the needs of Petroleum Refineries, Chemical Processing Plants, Power Generating Plants, and other processing facilities throughout the world.

Our Forged Steel Valves are designed, engineered and manufactured in strict conformance to API, ASTM, ASME, ANSI and other recognized standards. DSI® Forged Steel Valves are not only characterized by outstanding performance, reliability and quality, they’re also known for their standard features normally optional

in other brands.

Low Fugitive Emission Service

DSI® standard Forged Steel Gate, Globe and Check Valves are designed and manufactured to ensure leakage of less than 100 ppm (parts per million) of volatile organic compounds (VOC).

Standard Features of

DSI® Forged Steel Valves

•All DSI® forged carbon steel valves maintain a .22% maximum carbon content and are normalized to further refine the grain and homogenize the microstructure.

•All valves meet NACE conformance.

•DSI® forged steel valves come standard with a Stellite® #6 seating surface. The Stellite® #6 is applied by an automatic GTAW process, maintaining a minimum thickness of 0.05 inches.

•Valves are furnished with non-asbestos Grafoil® packing. The top and bottom wiper rings are braided graphite, while the center rings are die-formed Grafoil® containing an inorganic passivating inhibitor for corrosion and oxidation resistance.

•The DSI® bolted bonnet and bolted cap valves not utilizing a ring joint connection are fitted with a 316 Stainless Steel spiral wound Grafoil® filled gasket.

•All flanged DSI® forged steel valves through Class 2500 are integrally forged to avoid the potential leak path that exist when welding flanges onto valve bodies.

•Welded bonnet valves are initially joined by threading the body-bonnet joint together, then welding by automatic GMAW. All welds are inspected after welding assuring quality control.

•DSI® forged steel valves contain no copper bearing alloys.

•Every DSI® forged steel valve is manufactured with a two-piece self-aligning gland flange assembly which ensures even compression of the stuffing box during assembly and repacking.

Contents

DSI® Forged Steel Gate, Globe and Check Valves

Company Profile and Features ......................................... |

2 |

Globe Valves ....................................................... |

13 -19 |

Product Range, Testing, Modifications & Accessories ................ |

3 |

Check Valves ...................................................... |

20-28 |

Figure Numbers, Trim Chart ............................................ |

4 |

Pressure Temperature Charts .......................................... |

29 |

Gate Valves .......................................................... |

5 -12 |

Flow Coefficients (Cv) and Cracking Pressure Charts ............... |

30 |

2

Product Range, Testing & Modifications

DSI® offers NDE Testing and a variety of product modifications, saving our customers time and resources by eliminating the need for multiple purchase orders, time and transportation costs.

A single warranty then applies to each modified product, with each product inspected for quality and conformance to our customer’s specifications and industry standards.

DSI® Forged Steel Valve Families

DSI® offers a broad range of standard commodity forged, flanged and take-off style Gate, Globe and Check valves.

Size Range: 1/2" thru 2" Class Range: 150 -4500

Style: Bolted, welded or union bonnet connection of either inside screw or outside screw and yoke design.

Materials: A105N, LF2, LF3, F316, F304, F316L, F5, F9, F11, and F22

Standard

Production Valves

Available Modifications for DSI® Forged Steel Valves |

|

• Packing and Gasket Changes |

Flanged End |

• End Connection Modifications |

Production Valves |

• Trim Changes |

|

• Cryogenic Gas Columns |

|

• Teflon® Disc Inserts |

|

• Oxygen & Chlorine Cleaning & Packaging |

|

• Customer Specified Coatings |

|

• API Performance Testing |

|

NDE Testing Available |

|

• Dye Penetrant Test |

Take-off |

• Magnetic Particle Test |

Type Valves |

• PMI (Positive Material Identification) |

|

• Ultrasonic Testing |

|

Manufactured in Strict Conformance With the Following Industry Standards:

Industry Standard |

Specification |

|

|

|

|

API 602 |

Compact steel gate, globe and check valves |

|

|

|

|

API 598 |

Valve Inspection and Test |

|

|

|

|

ANSI /ASME B16.34 |

Steel valve, flanged and butt-welding end |

|

|

|

|

ANSI /ASME B16.5 |

Steel pipe flanges and flanged fittings |

|

|

|

|

ANSI /ASME B16.10 |

Face-to-face and end-to-end dimensions of ferrous valves |

|

|

|

|

ANSI /ASME B16.11 |

Forged steel fittings, socket welding and threaded |

|

|

|

|

ANSI /ASME B1.20.1 |

Pipe threads, general purpose |

|

|

|

|

ANSI /ASME B31.3 |

Chemical plant and petroleum refinery piping |

|

|

|

|

MSS SP -25 |

Standard marking system for valves, fittings, flanges and unions |

|

|

|

|

MSS-SP-6 |

Standard finishes for contact faces of pipe, flanges and connecting end flanges of valves and fittings |

|

|

|

|

NACE MR0175 / ISO 15156 |

Petroleum and natural gas industries, materials for use in H2S-containing |

|

environments in oil and gas production |

||

|

||

|

|

|

NACE MR0103 |

Materials resistant to sulfide stress cracking in corrosive petroleum refining environments |

|

|

|

Note: All information is subject to change without notice.

3

Figure Numbers and Trim Chart

Specifying DSI® Forged Steel Valve Figure Numbers

Example: 4121T-A8-18 This number represents a Class 800, Gate Valve Type, Threaded (Standard) End-Port, BB-OS&Y Design Style, TFE Packing, A105N Body Material, Stellite® Seats for Trim and NACE conformance.

4 |

1 |

2 |

1 |

T |

– |

A |

|

8 |

– |

18 |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Class |

Type |

End-Port |

Body/ |

Special |

|

Body Material |

Trim |

|

|

Other |

||

Bonnet Style |

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

1 |

1 |

1 |

BW |

|

A |

O |

1 |

25 |

|

|

18 |

150 |

Gate |

SW-Std. |

BB-OS&Y/BC |

Buttweld |

|

A105N |

F53 |

410 |

F321 |

|

|

NACE |

2 |

2 |

2 |

2 |

Ends |

|

B |

P |

2 |

26 |

|

|

20 |

300 |

Globe |

Thrd-Std. |

UB-OS&Y/ |

CT |

|

F5 |

F304L |

F304 |

F347 |

|

|

Oxygen |

3 |

3 |

3 |

UC |

Ext. Couplet |

|

C |

Q |

5 |

27 |

|

|

Clean |

600 |

Lift Check |

Flgd-Std. |

3 |

EB |

|

F11 |

I800 |

Full Stellite® |

F91 |

|

|

22 |

4 |

4 |

4 |

WB-OS&Y/ |

Ext. |

|

D |

R |

8 |

28 |

|

|

Cryogenic |

800 |

Swing Check |

F. Thrd x |

WC |

Bonnet |

|

F316 |

F51 |

Stellite® Seats |

Alloy 20 |

|

|

24 |

6 |

5 |

M. Thrd |

4 |

FB |

|

E |

S |

9 |

29 |

|

|

Bellows |

1500 |

Ball Check |

5 |

PS-OS&Y/ |

Full Port |

|

F316/F316L |

Monel® |

Monel® |

F316L |

|

|

26 |

7 |

6 |

F. Thrd x |

PSC |

FF |

|

F |

T |

10 |

30 |

|

|

Alkylation |

2500 |

Vert. Ball |

M. SW |

5 |

Flat |

|

LF2 |

F91 |

F316 |

F44 |

|

|

|

8 |

Check |

6 |

UB-IS |

Faced Ends |

|

G |

U |

11 |

31 |

|

|

|

4500 |

7 |

SW-Full |

6 |

R |

|

F9 |

A20 |

Monel® HFS |

I825 HFS |

|

|

|

|

Needle / |

7 |

WB-IS |

RTJ Ends |

|

H |

V |

12 |

32 |

|

|

|

|

Globe |

Thrd-Full |

7 |

S |

|

F22 |

F317 |

F316 HFS |

I825 |

|

|

|

|

8 |

8 |

RTJ-BB/BC |

Parallel Slide |

|

J |

W |

15 |

33 |

|

|

|

|

Stop Check |

Flgd-Full |

8 |

SC |

|

F347 |

I625 |

F304 HFS |

I625 |

|

|

|

|

Globe |

9 |

WB-PS |

Special Class |

|

K |

X |

16 |

34 |

|

|

|

|

|

IREB-Std |

|

T |

|

LF3 |

I825 |

F316L HFS |

F316H |

|

|

|

|

|

0 |

|

TFE Packing |

|

L |

Y |

17 |

35 |

|

|

|

|

|

F. SW x F. Thrd |

|

Y |

|

F304 |

F55 |

F321 HFS |

I800 |

|

|

|

|

|

|

|

Y-Pattern |

|

M |

Z |

19 |

36 |

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

F321 |

F44 |

F347 HFS |

F347H |

|

|

|

|

|

|

|

|

|

N |

|

20 |

51 |

|

|

|

|

|

|

|

|

|

F317L |

|

F317 |

Duplex SS |

|

|

|

|

|

|

|

|

|

|

|

21 |

53 |

|

|

|

|

|

|

|

|

|

|

|

F91 HFS |

Hastelloy® C |

|

|

|

|

|

|

|

|

|

|

|

22 |

54 |

|

|

|

|

|

|

|

|

|

|

|

F304L |

F304H |

|

|

|

|

|

|

|

|

|

|

|

24 |

55 |

|

|

|

|

|

|

|

|

|

|

|

F317L |

F55 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

API Trim

Trim No. |

Material |

Seat / Disc |

Stem |

Notes |

|

1 |

410 |

410 |

410 |

410 |

|

2 |

304 |

304 |

304 |

304 |

|

3 |

F310 |

310 |

310 |

310 |

|

4 |

Hard 410 |

410 |

410 |

410 |

Seats 750 BHN min. |

5 |

Hardfaced |

Hardfaced |

Hardfaced |

410 |

|

5A |

Hardfaced |

Ni-Cr |

Ni-Cr |

410 |

|

6 |

410 and Cu-Ni |

Cu-Ni |

Cu-Ni |

410 |

|

7 |

410 and Hard 410 |

410 |

410 |

410 |

Seats 750 BHN min. |

8 |

410 and Hardfaced |

Hardfaced |

410 |

410 |

|

8A |

410 and Hardfaced |

Ni-Cr |

410 |

410 |

|

9 |

Monel® |

Monel® |

Monel® |

Monel® |

|

10 |

316 |

316 |

316 |

316 |

|

11 |

Monel® and Hardfaced |

Hardfaced |

Monel® |

Monel® |

|

12 |

316 and Hardfaced |

Hardfaced |

316 |

316 |

|

13 |

Alloy 20 |

Alloy 20 |

Alloy 20 |

Alloy 20 |

|

14 |

Alloy 20 and Hardfaced |

Hardfaced |

Alloy 20 |

Alloy 20 |

|

15 |

304 and Hardfaced |

Hardfaced |

Hardfaced |

304 |

|

16 |

316 and Hardfaced |

Hardfaced |

Hardfaced |

316 |

|

4

Footnotes: |

|

BB • Bolted Bonnet |

BC • Bolted Cover |

WB • Welded Bonnet |

WC • Welded Cover |

UB • Union Bonnet |

UC • Union Cover |

PS • Full Penetration |

IS • Inside Screw |

OS&Y • Outside Screw & Yoke |

|

IREB • Integrally Reinforced Extended Body (male couplet x female threaded)

Note: All information is subject to change without notice.

DSI® Forged Steel Gate Valves

Class 150, 300, 600, 800, 1500 & 2500

Parts & Materials, Availability

No. |

Description |

ASTM A105N |

ASTM A350 |

|

|

ASTM A182 |

|

|

LF2 |

F316/L |

|

F5 |

F9 |

F11 |

|||

|

|

|

|

|||||

1 |

Body |

A105N |

LF2 |

F316/L |

|

F5 |

F9 |

F11 |

2 |

Seat Ring* |

410 + HF |

316 + HF |

316 + HF |

|

410 + HF |

410 + HF |

410 + HF |

3 |

Wedge* |

410 |

316 |

316 |

|

410 |

410 |

410 |

4 |

Stem* |

410 |

316 |

316 |

|

410 |

410 |

410 |

5 |

Gasket |

|

|

316 + Graphite (SPW) |

|

|

||

6 |

Bonnet |

A105N |

LF2 |

F316 /L |

|

F5 |

F9 |

F11 |

7 |

Bonnet Bolt |

B7M |

L7M |

B8 |

|

B16 |

B16 |

B16 |

8 |

Packing |

|

|

Graphite |

|

|

||

9 |

Gland* |

410 |

316 |

316 |

|

410 |

410 |

410 |

10 |

Gland Flange |

A105N |

LF2 |

316 |

|

A105N |

A105N |

A105N |

11 |

Gland Nut |

2HM |

7M |

Gr. 8 |

|

2HM |

2HM |

2HM |

12 |

Gland Bolt |

B7M |

L7M |

B8 |

|

B7M |

B7M |

B7M |

13 |

Yoke Sleeve (Nut) |

|

|

|

416 |

|

|

|

14 |

Handwheel |

|

|

Carbon Steel |

|

|

||

15 |

Handwheel Nut |

Carbon Steel |

Carbon Steel |

Gr. 8 |

|

Carbon Steel |

Carbon Steel |

Carbon Steel |

16 |

Name Plate |

Aluminum |

Aluminum |

Stainless Steel |

|

Aluminum |

Aluminum |

Aluminum |

Additional Materials

No. |

Description |

|

|

ASTM A182 |

|

|

|

F321 |

F347 |

F51 |

F22 |

F91 |

|||

|

|

||||||

1 |

Body |

F321 |

F347 |

F51 |

F22 |

F91 |

|

2 |

Seat Ring* |

321+ HF |

347+ HF |

S31803 |

410 + HF |

410 + HF |

|

3 |

Wedge* |

321 |

347 |

F51 |

410 |

410 |

|

4 |

Stem* |

321 |

347 |

S31803 |

410 |

410 |

|

5 |

Gasket |

316 + Graphite |

347+ Graphite |

N06625+Graphite |

316 + Graphite |

316 + Graphite |

|

(SPW) |

(SPW) |

(SPW) |

(SPW) |

(SPW) |

|||

|

|

||||||

|

|

|

|

|

|

|

|

6 |

Bonnet |

F321 |

F347 |

F51 |

F22 |

F91 |

|

7 |

Bonnet Bolt |

B8 |

B8 |

B8 |

B16 |

B16 |

|

8 |

Packing |

|

|

Graphite |

|

|

|

9 |

Gland* |

321 |

347 |

S31803 |

410 |

410 |

|

10 |

Gland Flange |

321 |

347 |

S31803 |

A105N |

A105N |

|

11 |

Gland Nut |

Gr. 8 |

Gr. 8 |

Gr. 8 |

2HM |

2HM |

|

12 |

Gland Bolt |

B8 |

B8 |

B8 |

B7M |

B7M |

|

13 |

Yoke Sleeve (Nut) |

AISI 416 |

416 |

416 |

416 |

416 |

|

14 |

Handwheel |

|

|

Carbon Steel |

|

|

|

15 |

Handwheel Nut |

Gr. 8 |

Gr. 8 |

Gr. 8 |

Carbon Steel |

Carbon Steel |

|

16 |

Name Plate |

Stainless Steel |

Stainless Steel |

Stainless Steel |

Aluminum |

Aluminum |

*Material may vary based on trim. Additional materials available upon request.

Note: All information is subject to change without notice.

5

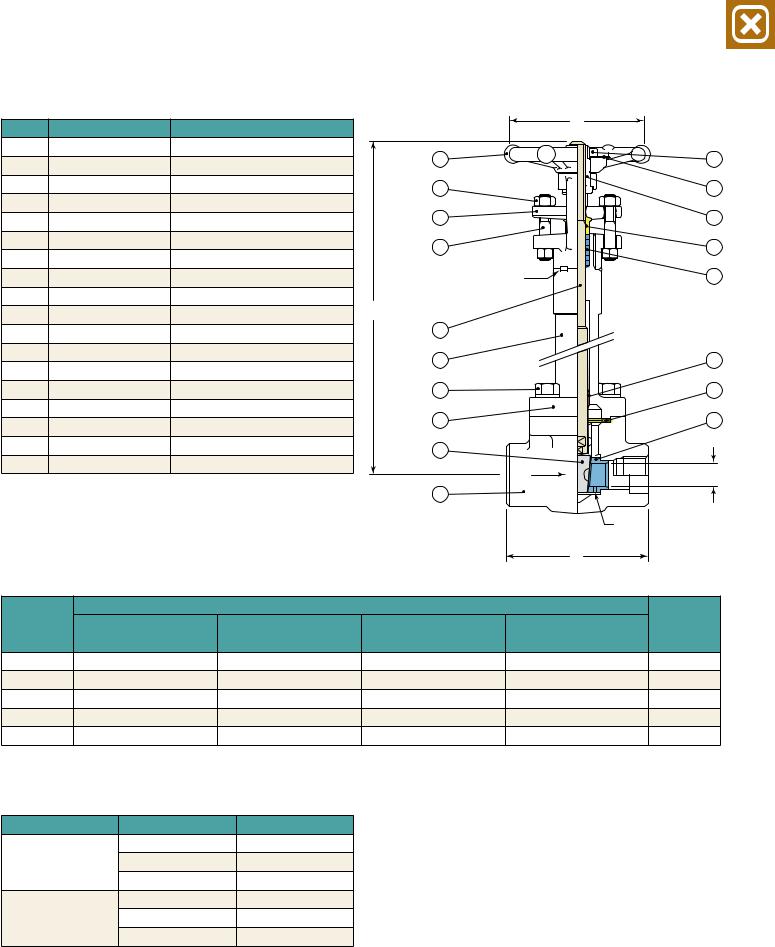

DSI® Forged Steel Gate Valve

API 602 • Bolted & Welded Bonnet

Parts & Materials

No. |

Description |

Material |

|

|

|

1 |

Body |

A105N |

|

|

|

2 |

Seat Ring* |

410 + HF |

|

|

|

3 |

Wedge* |

410 |

|

|

|

4 |

Stem* |

410 |

|

|

|

5 |

Gasket |

316 +Graphite (SPW) |

|

|

|

6 |

Bonnet |

A105N |

|

|

|

7 |

Bonnet Bolt |

B7M |

|

|

|

8 |

Packing |

Graphite |

|

|

|

9 |

Gland* |

410 |

|

|

|

10 |

Gland Flange |

A105N |

|

|

|

11 |

Gland Nut |

2HM |

|

|

|

12 |

Gland Stud |

B7M |

|

|

|

13 |

Yoke Sleeve / Stem Nut |

416 |

|

|

|

14 |

Handwheel |

Carbon Steel |

|

|

|

15 |

Handwheel Nut |

Carbon Steel |

|

|

|

16 |

Name Plate |

Aluminum |

|

|

|

*Material may vary based on trim.

Dimensional Data and Weight

Class 800, Reduced Port

|

|

Dimensions (in.), Reduced Port |

|

|||

Valve |

|

|

|

|

|

|

|

B |

C |

D |

|

||

Size |

A |

Center |

Weight |

|||

Handwheel |

Port |

|||||

(in.) |

End to End |

to Top |

(lbs.) |

|||

Diameter |

Diameter |

|||||

|

|

(open) |

|

|||

|

|

|

|

|

||

|

|

|

|

|

|

|

1/4 |

3.15 |

5.71 |

3.15 |

0.31 |

3.97 |

|

1/2 |

3.15 |

5.71 |

3.15 |

0.39 |

3.75 |

|

3/4 |

3.54 |

6.08 |

3.15 |

0.55 |

4.63 |

|

1 |

4.33 |

7.31 |

3.94 |

0.71 |

7.94 |

|

|

|

|

|

|

|

|

11/4 |

5.00 |

8.58 |

4.72 |

0.94 |

11.24 |

|

11/2 |

5.00 |

9.77 |

5.00 |

1.16 |

15.43 |

|

2 |

5.12 |

10.63 |

5.12 |

1.44 |

20.06 |

|

|

|

|

|

|

|

|

Class 1500, Reduced Port

|

|

Dimensions (in.), Reduced Port |

|

|||

Valve |

|

|

|

|

|

|

|

B |

C |

D |

|

||

Size |

A |

Center |

Weight |

|||

Handwheel |

Port |

|||||

(in.) |

End to End |

to Top |

(lbs.) |

|||

Diameter |

Diameter |

|||||

|

|

(open) |

|

|||

|

|

|

|

|

||

|

|

|

|

|

|

|

1/2 |

3.54 |

6.02 |

3.07 |

0.39 |

5.50 |

|

3/4 |

4.33 |

7.13 |

3.94 |

0.55 |

8.36 |

|

1 |

4.72 |

8.65 |

4.72 |

0.71 |

11.88 |

|

|

|

|

|

|

|

|

11/4 |

5.12 |

9.60 |

5.51 |

0.94 |

17.60 |

|

11/2 |

5.12 |

10.79 |

5.51 |

1.14 |

22.44 |

|

2 |

5.91 |

11.97 |

6.69 |

1.42 |

33.00 |

|

|

|

|

|

|

|

|

Note: All information is subject to change without notice.

|

C |

14 |

15 |

11 |

16 |

10 |

13 |

12 |

9 |

B |

|

6 |

8 |

4 |

7 |

1 |

5 |

|

D |

|

FLOW |

3 |

2 |

|

A |

Class 800, Full Port

|

|

Dimensions (in.), Full Port |

|

|||

Valve |

|

|

|

|

|

|

|

B |

C |

D |

|

||

Size |

A |

Center |

Weight |

|||

Handwheel |

Port |

|||||

(in.) |

End to End |

to Top |

(lbs.) |

|||

Diameter |

Diameter |

|||||

|

|

(open) |

|

|||

|

|

|

|

|

||

|

|

|

|

|

|

|

1/4 |

|

|

— |

|

|

|

1/2 |

3.54 |

6.08 |

3.07 |

0.55 |

4.85 |

|

3/4 |

4.33 |

7.30 |

3.94 |

0.71 |

8.16 |

|

1 |

5.00 |

8.58 |

4.65 |

0.94 |

11.90 |

|

|

|

|

|

|

|

|

11/4 |

5.00 |

10.08 |

5.51 |

1.16 |

16.31 |

|

11/2 |

5.12 |

10.90 |

5.51 |

1.44 |

21.16 |

|

2 |

5.91 |

12.88 |

6.69 |

1.89 |

31.31 |

|

|

|

|

|

|

|

|

Class 1500, Full Port

|

|

Dimensions (in.), Full Port |

|

|||

Valve |

|

|

|

|

|

|

|

B |

C |

D |

|

||

Size |

A |

Center |

Weight |

|||

Handwheel |

Port |

|||||

(in.) |

End to End |

to Top |

(lbs.) |

|||

Diameter |

Diameter |

|||||

|

|

(open) |

|

|||

|

|

|

|

|

||

|

|

|

|

|

|

|

1/2 |

3.54 |

7.80 |

3.94 |

0.55 |

8.38 |

|

3/4 |

4.33 |

9.55 |

4.72 |

0.71 |

11.90 |

|

1 |

4.72 |

11.06 |

5.51 |

0.94 |

17.64 |

|

|

|

|

|

|

|

|

11/4 |

5.12 |

12.25 |

6.69 |

1.14 |

22.49 |

|

11/2 |

5.12 |

14.33 |

6.69 |

1.44 |

33.00 |

|

2 |

5.91 |

14.93 |

6.69 |

1.57 |

33.07 |

|

|

|

|

|

|

|

|

6

DSI® Forged Steel Gate Valve

API 602 • Bolted & Welded Bonnet

Dimensional Data, Weight and Figure Numbers

Class 2500, Full Port

Valve |

|

Dimensions (in.), Full Port |

|

Weight |

||

|

|

|

|

|||

A |

B |

C |

D |

|||

Size (in.) |

(lbs.\ |

|||||

End to End |

Center to Top (open) |

Handwheel Diameter |

Port Diameter |

|||

|

|

|||||

|

|

|

|

|

|

|

1/2 |

4.33 |

6.89 |

3.94 |

0.39 |

7.72 |

|

3/4 |

4.72 |

8.31 |

4.72 |

0.55 |

12.13 |

|

1 |

5.12 |

9.55 |

5.51 |

0.71 |

16.53 |

|

|

|

|

|

|

|

|

11/4 |

5.12 |

10.98 |

6.69 |

0.94 |

22.05 |

|

11/2 |

8.27 |

12.17 |

6.69 |

1.14 |

35.27 |

|

2 |

9.45 |

14.01 |

10.24 |

1.44 |

39.68 |

|

|

|

|

|

|

|

|

Figure Numbers

Port |

Bonnet |

Class 800 |

Class 1500 |

Class 2500 |

Ends |

|

|

|

|

|

|

|

|

4121 |

6121 |

— |

Threaded |

|

|

|

|

|

|

|

Bolted |

4111 |

6111 |

— |

Socketweld |

|

|

|

|

|

|

Reduced |

|

4101 |

6101 |

— |

Thrd x SW |

|

|

|

|

|

|

|

4123 |

6123 |

— |

Threaded |

|

|

|

||||

|

|

|

|

|

|

|

Welded |

4113 |

6113 |

— |

Socketweld |

|

|

|

|

|

|

|

|

4103 |

6103 |

— |

Thrd x SW |

|

|

|

|

|

|

|

|

4171 |

6171 |

— |

Threaded |

|

|

|

|

|

|

|

Bolted |

4161 |

6161 |

— |

Socketweld |

|

|

|

|

|

|

Full |

|

4101FB |

6101FB |

— |

Thrd x SW |

|

|

|

|

|

|

|

4173 |

6173 |

7173 |

Threaded |

|

|

|

||||

|

|

|

|

|

|

|

Welded |

4163 |

6163 |

7163 |

Socketweld |

|

|

|

|

|

|

|

|

4103FB |

6103FB |

7103 |

Thrd x SW |

|

|

|

|

|

|

For years Industry professionals have specified DSI® valve products for their most demanding projects, and consistently DSI® delivers the highest performance fluid control products available anywhere.

Note: All information is subject to change without notice.

7

DSI® Forged Steel Gate Valve

Cryogenic, API 602 • Bolted & Welded Bonnet

Parts & Materials

No. |

Description |

Material |

|

C |

|

||

|

|

|

|||||

1 |

|

Body |

F316 |

16 |

|

17 |

|

2 |

|

Seat Ring* |

316 + HF |

|

|||

|

|

|

|

||||

3 |

|

Wedge* |

316 |

13 |

|

18 |

|

|

|

|

|

|

|||

4 |

|

Stem* |

316 |

|

|

|

|

5 |

|

Gasket |

316 + Graphite (SPW) |

12 |

|

15 |

|

|

|

|

|

||||

6 |

|

Bonnet |

F316 |

14 |

|

11 |

|

7 |

|

Yoke |

F316 |

|

|||

|

|

|

|

||||

8 |

|

Stem Bushing |

F316 |

Tack Weld |

|

10 |

|

9 |

|

Bonnet Bolt |

B8 |

|

|

|

|

10 |

|

Packing |

Graphite |

B |

|

|

|

|

|

|

|

||||

11 |

|

Gland* |

316 |

4 |

|

|

|

12 |

|

Gland Flange |

316 |

7 |

|

8 |

|

13 |

|

Gland Nut |

Gr. 8 |

|

|||

|

|

|

|

||||

14 |

|

Gland Stud |

B8 |

9 |

|

5 |

|

15 |

Yoke Sleeve / Stem Nut |

416 |

6 |

|

2 |

||

16 |

|

Handwheel |

Carbon Steel |

|

|||

|

|

|

|

||||

17 |

Handwheel Nut |

Gr. 8 |

3 |

|

|

||

|

|

|

|

|

|

||

18 |

|

Name Plate |

Stainless Steel |

|

|

D |

|

*Material may vary based on trim. |

|

|

FLOW |

||||

|

1 |

|

|||||

|

|

|

|

|

|

||

|

|

|

|

|

|

Bleed |

|

|

|

|

|

|

|

Hole |

|

Dimensional Data, Weight and Figure Numbers |

|

A |

|

||||

Class 800, Reduced Port |

|

|

|

|

|||

Valve |

|

Dimensions (in.), Reduced Port |

|

Weight |

|||

A |

B |

C |

D |

||||

Size (in.) |

(lbs.\ |

||||||

End to End |

Center to Top (open) |

Handwheel Diameter |

Port Diameter |

||||

|

|

|

|||||

|

1/2 |

3.15 |

15.20 |

3.94 |

0.39 |

9.90 |

|

|

3/4 |

3.54 |

15.61 |

3.94 |

0.55 |

11.22 |

|

|

1 |

4.33 |

16.68 |

4.72 |

0.71 |

20.90 |

|

11/2 |

5.00 |

19.25 |

6.69 |

1.16 |

25.96 |

||

|

2 |

5.12 |

20.19 |

7.87 |

1.44 |

33.00 |

|

Figure Numbers |

|

|

|

|

|||

|

Bonnet |

Class 800 |

Ends |

|

|

|

|

|

|

4121 D12-22* |

Threaded |

|

|

|

|

|

Bolted |

4111 D12-22* |

Socketweld |

|

|

|

|

|

|

4101 D12-22* |

Thrd x SW |

|

|

|

|

|

|

4123 D12-22 |

Threaded |

|

|

|

|

|

Welded |

4113 D12-22 |

Socketweld |

|

|

|

|

|

|

4103 D12-22 |

Thrd x SW |

|

|

|

|

* Figure number may vary by body & trim material.

Note: All information is subject to change without notice.

8

DSI® Forged Steel Gate Valve

API 602 • Extended Body • Bolted & Welded Bonnet

Parts & Materials

No. |

Description |

Material |

|

C |

|

|

|

||||

1 |

Body |

A105N |

14 |

15 |

|

2 |

Seat Ring* |

410 + HF |

|||

|

|

||||

3 |

Wedge* |

410 |

11 |

16 |

|

4 |

Stem* |

410 |

|

||

10 |

|

||||

6 |

Bonnet |

A105N |

13 |

||

|

|||||

8 |

Packing |

Graphite |

12 |

|

|

9 |

Gland* |

410 |

B |

9 |

|

10 |

Gland Flange |

A105N |

6 |

|

|

|

8 |

||||

11 |

Gland Nut |

2HM |

4 |

||

|

|||||

|

|

||||

12 |

Gland Stud |

B7M |

1 |

3 |

|

|

|

|

|||

13 |

Yoke Sleeve / Stem Nut |

416 |

|

|

|

14 |

Handwheel |

Carbon Steel |

|

|

|

15 |

Handwheel Nut |

Carbon Steel |

|

D |

|

16 |

Name Plate |

Aluminum |

|

|

|

*Material may vary based on trim. |

|

|

2 |

||

|

|

|

|

||

|

|

|

|

E |

|

A

Dimensional Data, Weight and Figure Numbers

Class 800, Reduced Port

Valve |

|

Dimensions (in.), Reduced Port |

|

|

Weight |

||

|

|

|

|

|

|

||

A |

B |

C |

|

D |

E |

||

Size (in.) |

|

(lbs.\ |

|||||

End to End |

Center to Top (open) |

Handwheel Diameter |

|

Port Diameter |

Center to End |

||

|

|

|

|||||

|

|

|

|

|

|

|

|

1/2 |

5.57 |

5.92 |

3.15 |

|

0.39 |

4.00 |

5.29 |

3/4 |

5.77 |

6.08 |

3.15 |

|

0.55 |

4.00 |

5.95 |

1 |

6.54 |

7.31 |

3.94 |

|

0.71 |

4.37 |

9.04 |

|

|

|

|

|

|

|

|

11/2 |

7.50 |

9.77 |

5.51 |

|

1.14 |

5.00 |

18.96 |

2 |

8.50 |

10.75 |

5.51 |

|

1.61 |

5.98 |

26.46 |

|

|

|

|

|

|

|

|

Figure Numbers

Bonnet |

Class 800 |

Class 1500 |

Ends |

|

|

|

|

|

|

Bolted |

4151 |

6151 |

Male SW x FPT |

|

|

|

|

||

4141 |

6141 |

MPT x FPT |

||

|

||||

|

|

|

|

|

Welded |

4153 |

6153 |

Male SW x FPT |

|

|

|

|

||

4143 |

6143 |

MPT x FPT |

||

|

||||

|

|

|

|

Note: All information is subject to change without notice.

9

DSI® Forged Steel Gate Valve

API 602 • Integrally Reinforced Extended Body • Bolted & Welded Bonnet

Parts & Materials

No. |

Description |

Material |

|

C |

|

|

|

||||

1 |

Body |

A105N |

|

|

|

2 |

Seat Ring* |

410 + HF |

14 |

15 |

|

3 |

Wedge* |

410 |

11 |

16 |

|

|

|

|

|||

4 |

Stem* |

410 |

|

||

10 |

|

||||

6 |

Bonnet |

A105N |

13 |

||

|

|||||

|

|

|

|

||

8 |

Packing |

Graphite |

12 |

|

|

9 |

Gland* |

410 |

B |

9 |

|

10 |

Gland Flange |

A105N |

6 |

|

|

|

8 |

||||

11 |

Gland Nut |

2HM |

4 |

||

|

|||||

12 |

Gland Stud |

B7M |

1 |

3 |

|

13 |

Yoke Sleeve / Stem Nut |

416 |

|||

|

|

||||

14 |

Handwheel |

Carbon Steel |

|

|

|

15 |

Handwheel Nut |

Carbon Steel |

|

|

|

16 |

Name Plate |

Aluminum |

|

|

|

*Material may vary based on trim. |

|

|

D |

||

|

|

|

E |

2 |

|

|

|

|

|

A |

|

Dimensional Data, Weight and Figure Numbers

Class 800, Reduced Port

Valve |

|

Dimensions (in.), Reduced Port |

|

|

Weight |

||

|

|

|

|

|

|

||

A |

B |

C |

|

D |

E |

||

Size (in.) |

|

(lbs.\ |

|||||

End to End |

Center to Top (open) |

Handwheel Diameter |

|

Port Diameter |

Center to End |

||

|

|

|

|||||

|

|

|

|

|

|

|

|

1/2 |

8.15 |

5.90 |

3.15 |

|

0.39 |

6.57 |

5.95 |

3/4 |

8.60 |

6.08 |

3.15 |

|

0.55 |

6.83 |

7.28 |

1 |

9.63 |

7.31 |

3.94 |

|

0.71 |

7.48 |

11.46 |

|

|

|

|

|

|

|

|

11/2 |

10.37 |

10.32 |

5.51 |

|

1.42 |

7.87 |

21.83 |

2 |

10.59 |

10.71 |

5.51 |

|

1.73 |

8.03 |

31.98 |

|

|

|

|

|

|

|

|

Class 1500, Reduced Port

Valve Size |

|

Dimensions (in.), Reduced Port |

|

|

Weight |

||

|

|

|

|

|

|

||

A |

B |

C |

|

D |

E |

||

(in.) |

|

(lbs.\ |

|||||

End to End |

Center to Top (open) |

Handwheel Diameter |

|

Port Diameter |

Center to End |

||

|

|

|

|||||

|

|

|

|

|

|

|

|

1/2 |

8.60 |

5.98 |

3.15 |

|

0.39 |

6.83 |

8.36 |

3/4 |

9.63 |

7.05 |

3.94 |

|

0.55 |

7.48 |

12.54 |

1 |

10.37 |

11.34 |

5.51 |

|

0.71 |

8.00 |

22.88 |

|

|

|

|

|

|

|

|

11/2 |

10.53 |

11.95 |

5.51 |

|

1.16 |

8.00 |

33.88 |

2 |

12.80 |

12.60 |

10.24 |

|

1.44 |

9.85 |

48.00 |

|

|

|

|

|

|

|

|

Figure Numbers

Bonnet |

Class 800 |

Class 1500 |

Ends |

|

|

|

|

Bolted |

4191 |

6191 |

IREB X FPT |

|

|

|

|

Welded |

4193 |

6193 |

IREB X FPT |

|

|

|

|

Note: All information is subject to change without notice.

10

Loading...

Loading...