Page 1

FortiGate-7060E System Guide

7000

Page 2

FORTINET DOCUMENTLIBRARY

http://docs.fortinet.com

FORTINETVIDEOGUIDE

http://video.fortinet.com

FORTINETBLOG

https://blog.fortinet.com

CUSTOMERSERVICE&SUPPORT

https://support.fortinet.com

http://cookbook.fortinet.com/how-to-work-with-fortinet-support/

FORTIGATECOOKBOOK

http://cookbook.fortinet.com

FORTINETTRAININGSERVICES

http://www.fortinet.com/training

FORTIGUARDCENTER

http://www.fortiguard.com

FORTICAST

http://forticast.fortinet.com

ENDUSER LICENSE AGREEMENT

http://www.fortinet.com/doc/legal/EULA.pdf

FORTINET PRIVACY POLICY

https://www.fortinet.com/corporate/about-us/privacy.html

FEEDBACK

Email: techdocs@fortinet.com

Monday, March 26, 2018

FortiGate-7060E System Guide

01-540-411632-20180326

Page 3

TABLEOFCONTENTS

FortiGate-7060E Chassis 5

FortiGate-7060E front panel 5

FIM modules 6

FPM-7620E FPMmodules 6

FortiGate-7060E back panel 7

Registering your FortiGate-7060E chassis 7

FortiGate-7060E chassis schematic 8

Chassis hardware information 9

Shipping components 9

Optional accessories and replacement parts 9

Physical description of the FortiGate-7060E chassis 10

Cooling fans, cooling air flow, and minimum clearance 11

Cooling air flow and required minimum air flow clearance 12

Optional air filters 13

AC Power Supply Units (PSUs) and supplying AC power to the chassis 13

Hot Swapping an AC PSU 13

DC Power Supply Units (PSUs) and supplying DC power to the chassis 14

Crimping guidelines 15

Connecting a FortiGate-7060E PSU to DC power 16

Hot Swapping a DC PSU 17

Connecting the FortiGate-7060E chassis to ground 17

Turning on FortiGate-7060E chassis power 18

FortiGate-7060E hardware assembly and rack mounting 19

Installing accessories 20

Mounting the FortiGate-7060E chassis in a four-post rack 21

Mounting the FortiGate-7060E chassis in a two-post rack 22

Air flow 22

Inserting FIM and FPM-7000 series modules 23

Recommended slot locations for interface modules 23

FortiGate-7060E Management Modules 24

Management module failure 25

Management Module LEDs 25

About management module alarm levels 28

Using the console ports 28

Page 4

Connecting to the FortiOS CLI of the FIM module in slot 1 29

Connecting to the FortiOS CLI of the FIM module in slot 2 30

Connecting to the SMC SDI CLI of the FPMmodule in slot 3 30

Changing the management module admin account password 30

Connecting to the management module using an IPMItool 31

FortiGate-7060E chassis slots IPMB addresses 31

Rebooting a chassis module from the SMC SDI CLI 32

Comlog 32

System event log (SEL) 34

Sensor data record (SDR) 34

Common management module CLI operations 35

Cautions and Warnings 39

Environmental Specifications 39

Safety 40

Regulatory Notices 42

Federal Communication Commission (FCC) – USA 42

Industry Canada Equipment Standard for Digital Equipment (ICES) – Canada 42

European Conformity (CE) - EU 42

Voluntary Control Council for Interference (VCCI) – Japan 43

Product Safety Electrical Appliance & Material (PSE) – Japan 43

Bureau of Standards Metrology and Inspection (BSMI) – Taiwan 43

China 43

Page 5

FortiGate-7060E front panel FortiGate-7060E Chassis

ESD

socket

FPM-7620E

slot 3

FPM-7620E

slot 4

FIM-7910E

slots 1 and 2

FPM-7620E

slot 5

FPM-7620E

slot 6

Management Module 2Management Module 1

Power

Supply 6

(empty)

Power

Supply 5

(empty)

Power

Supply 1

Power

Supply 4

Power

Supply 2

Power

Supply 3

FortiGate-7060E Chassis

The FortiGate-7060E is a 8U 19-inch rackmount 6-slot chassis with a 80Gbps fabric and 1Gbps base backplane

designed by Fortinet. The fabric backplane provides network data communication and the base backplane

provides management and synch communication among the chassis slots.

FortiGate-7060E front panel

The chassis is managed by two redundant management modules. Each module includes an Ethernet connection

as well as two switchable console ports that provide console connections to the modules in the chassis slots. The

active management module controls chassis cooling and power management and provides an interface for

managing the modules installed in the chassis.

FortiGate-7060E front panel, (showing AC PSUs, example module configuration)

5 FortiGate-7060E System Guide

Fortinet Technologies Inc.

Page 6

FortiGate-7060E Chassis FortiGate-7060E front panel

Do not operate the FortiGate-7060E chassis with open slots on the front or back panel.

For optimum cooling performance and safety, each chassis slot must contain an FIM

or FPM module or an FIM or FPM blank panel (also called a dummy card). For the

same reason, all cooling fan trays, power supplies or power supply slot covers must be

installed while the chassis is operating.

Power is provided to the chassis using four hot swappable 3+1 redundant 100-240 VAC, 50-60 Hz AC or -48V DC

power supply units (PSUs). At least three PSUs (power supplies 1 to 3) must be connected to power. Power

supply 4 is a backup power supply. You can add a 5th or 6th power supply for 3+2 and 3+3 redundancy.

The standard configuration of the FortiGate-7060E includes two FIM (interface) modules in chassis slots 1 and 2

and up to four FPM (processing) modules in chassis slots 3 to 6.

FIM modules

FIM modules are hot swappable interface modules that provide data and management interfaces, base

backplane switching and fabric backplane session-aware load balancing for the chassis. The FIM modules

include an integrated switch fabric and DP2 processors to load balance millions of data sessions over the chassis

fabric backplane to FPM processor modules. The following FIM modules are available:

l The FIM-7901E includes thirty-two front panel 10GigE SFP+ fabric channel interfaces (A1 to A32). These interfaces

are connected to 10Gbps networks. These interfaces can also be configured to operate as Gigabit Ethernet

interfaces using SFP transceivers.

l The FIM-7904E includes eight front panel 40GigE QSFP+ fabric channel interfaces (B1 to B8). These interfaces are

connected to 40Gbps networks. Using 40GBASE-SR4 multimode QSFP+ transceivers, each QSFP+ interface can

also be split into four 10GBASE-SR interfaces and connected to 10Gbps networks.

l The FIM-7910E (shown in FIM modules on page 6) includes four front panel 100GigE CFP2 fabric channel

interfaces (C1 to C4). These interfaces can be connected to 100Gbps networks. Using 100GBASE-SR10 multimode

CFP2 transceivers, each CFP2 interface can also be split into ten 10GBASE-SR interfaces and connected to

10Gbps networks.

l The FIM-7920E includes four front panel 100GigE QSFP28 fabric channel interfaces (C1 to C4). These interfaces

can be connected to 100Gbps networks. Using a 100GBASE-SR4 QSFP28 or 40GBASE-SR4 QSFP+ transceiver,

each QSFP28 interface can also be split into four 10GBASE-SR interfaces and connected to 10Gbps networks.

If you are installing different FIM modules in the FortiGate-7060E chassis, for optimal

configuration you should install the module with the lower model number in slot 1 and

the module with the higher number in slot 2. For example, if your chassis includes a

FIM-7901E and a FIM-7904E, install the FIM-7901E in chassis slot 1 and the FIM7904E in chassis slot 2. Also, for example, if your chassis includes a FIM-7904E and a

FIM-7920E, install the FIM-7904E in chassis slot 1 and the FIM-7920E in chassis slot

2. This applies to any combination of two different interface modules.

FPM-7620E FPMmodules

The FPM-7620E modules are hot swappable processor modules that provide FortiOS firewalling and security

services. The FPM modules function as workers, processing sessions load balanced to them by the FIM modules.

FPM modules include multiple NP6 network processors and CP9 content processors to accelerate traffic.

FortiGate-7060E System Guide

Fortinet Technologies Inc.

6

Page 7

FortiGate-7060E back panel FortiGate-7060E Chassis

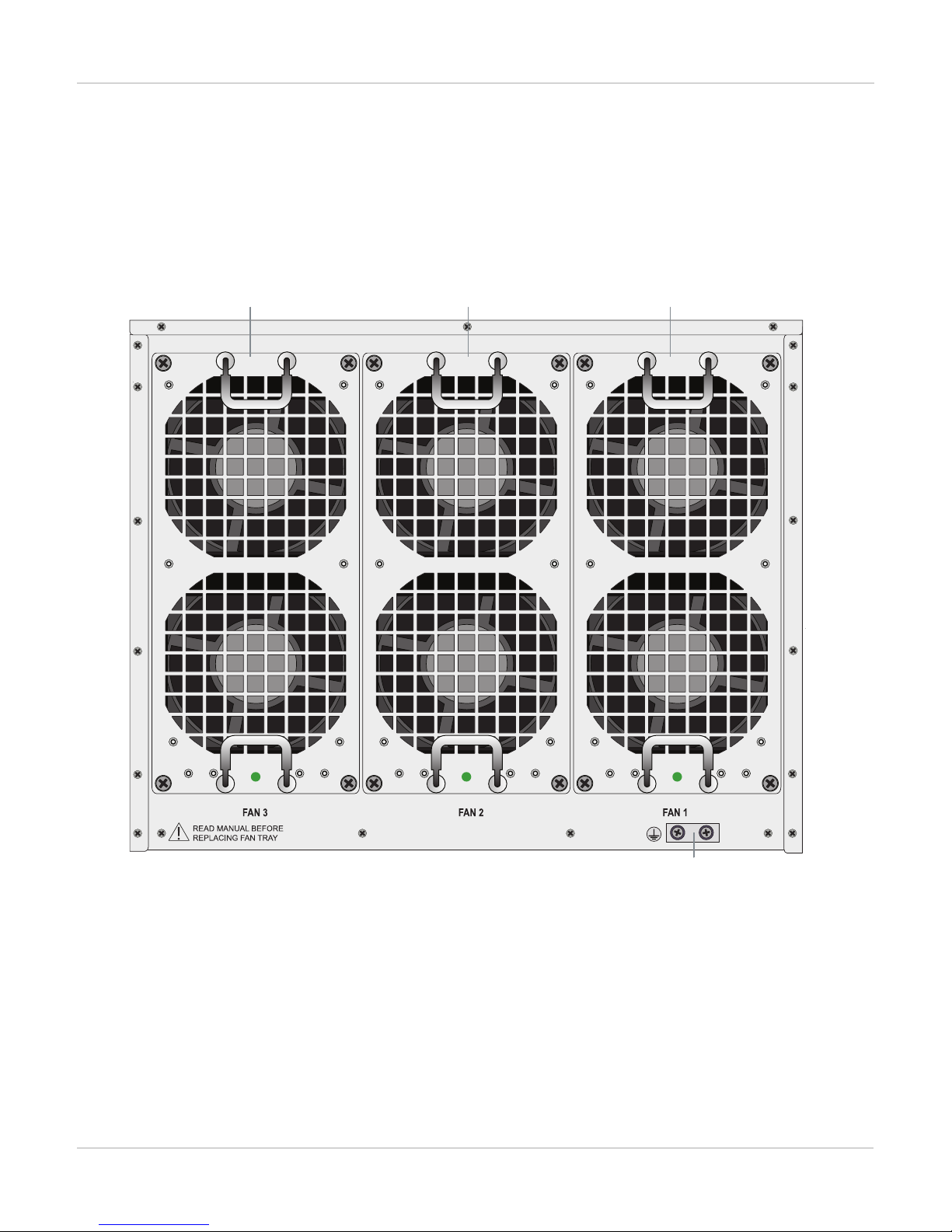

Fan Tray 1Fan Tray 2Fan Tray 3

Chassis

Ground

Connector

FortiGate-7060E back panel

The FortiGate-7060E back panel provides access to three hot swappable cooling fan trays and the chassis ground

connector that must be connected to ground.

FortiGate-7060E back panel

Registering your FortiGate-7060E chassis

FortiGate-7000 series products are registered according to the chassis serial number. You need to register your

chassis to receive Fortinet customer services such as product updates and customer support. You must also

register your product for FortiGuard services. Register your product by visiting https://support.fortinet.com. To

7 FortiGate-7060E System Guide

Fortinet Technologies Inc.

Page 8

FortiGate-7060E Chassis FortiGate-7060E chassis schematic

IPMB

SERIAL

IPMB

SERIAL

IPMB

SERIAL

IPMB

SERIAL

NP6

CP9

NP6

CP9

SMC SDI

ISF

DP2

ISF

DP2

IPMB

SERIAL

1G

SMC SDISMC SDI

MGMT2 (active by default, IPMB 0x20)MGMT1 (inactive by default, IPMB 0x22)

FPM Module

FIM Module

FIM Module

FPM Module

FPM3 IPMB 0x86

IPMB

SERIAL

NP6

CP9

SMC SDI

FPM Module

FPM5 IPMB 0x8A

FPM4 IPMB 0x88

FIM1 IPMB 0x82

FIM2 IPMB 0x84

PMB 0x82

SMC SDI

PMB 0x84

SMC SDI

PMB 0x88

SMC SDI

IPMB

SERIAL

NP6

CP9

FPM Module

FPM6 IPMB 0x8C

SMC SDI

Data

Interfaces

MGMT

1-4

M1 M2

Data

Interfaces

MGMT

1-4

M1 M2

Fabric Backplane

1G

1G

1G

1G

1G

1G

80G

80G

80G

80G

80G

80G

80G

80G

80G

80G

80G

80G

80G

80G

80G

80G

40G

40G

Base Backplane

register, enter your contact information and the serial numbers of the Fortinet products that you or your

organization have purchased.

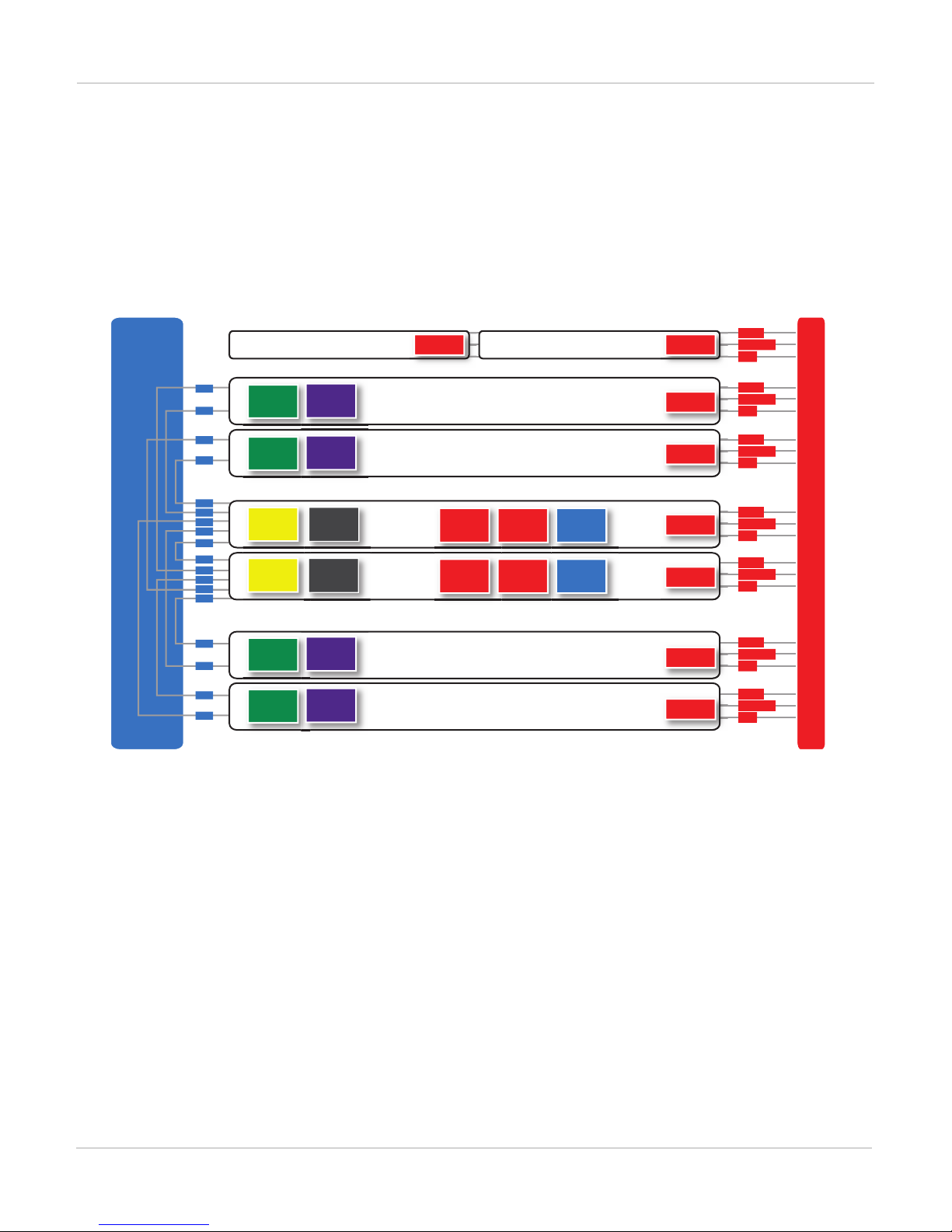

FortiGate-7060E chassis schematic

The FortiGate-7060E chassis schematic below shows the communication channels between chassis components

including the management modules (MGMT), the FIM modules (called FIM1 and FIM2) and the FPM modules

(FPM3, FPM4, FPM5, and FPM6).

By default MGMT2 is the active management module and MGMT1 is inactive. The active management module

always has the IPMB address 0x20 and the inactive management module always has the IPMB address 0x22.

The active management module communicates with all modules in the chassis over the base backplane. Each

module, including the management modules has a Shelf Management Controller (SMC). These SMCs support

Intelligent Platform Management Bus (IPMB) communication between the active management module and the

FIM and FPM modules for storing and sharing sensor data that the management module uses to control chassis

cooling and power distribution. The base backplane also supports serial communications to allow console access

from the management module to all modules, and 1Gbps Ethernet communication for management and

heartbeat communication betweenmodules.

FortiGate-7060E System Guide

Fortinet Technologies Inc.

FIM1 and FIM2 (IPMB addresses 0x82 and 0x84) are the FIM modules in slots 1 and 2. The interfaces of these

modules connect the chassis to data networks and can be used for Ethernet management access to chassis

components. The FIM modules include DP2 processors that distribute sessions over the Integrated Switch Fabric

(ISF) to the NP6 processors in the FPMmodules. Data sessions are communicated to the FPM modules over the

80Gbps chassis fabric backplane.

8

Page 9

Chassis hardware information FortiGate-7060E Chassis

FPM03, FPM04, FPM05, and FPM06 (IPMB addresses 0x86, 0x88, 0x8A, and 0x8C) are the FPM processor

modules in slots 3 to 6. These worker modules process sessions distributed to them by the FIMmodules.

FPMmodules include NP6 processors to offload sessions from the FPM CPU and CP9 processors that accelerate

content processing.

Chassis hardware information

This section introduces FortiGate-7060E hardware components and accessories including power requirements

and FIMand FPM modules that can be installed in the chassis.

Shipping components

The FortiGate-7060E chassis ships pre-assembled with the following components:

l The 8U FortiGate-7060E chassis

l Two FIM modules

l Up to four FPM modules

l Two management modules in the front of the chassis. (Management modules are not field replacable. If a

management module fails you must RMA the chassis. The chassis will continue to operate with one or no operating

management modules.)

l Four Power Supply Units (PSUs) installed in the front of the chassis

l Three cooling fan trays installed in the back of the chassis

l One protective front panel installed in the chassis to protect internal chassis components. This panel must be

removed before installing FIM and FPM modules.

l Four power cords with C15 power connectors

l Four power cord management clamps

l One set of 4-post rack mounting components

l One set of 2-post rack mounting components

l One pair of cable management side brackets

l Two front mounting brackets

l Twenty M4x6 flat-head screws

l Six M4x8 large head pan-head screws

l Six rubber feet

l Two console cables

l One RJ-45 Ethernet cable

Optional accessories and replacement parts

The following optional accessories can be ordered separately:

SKU Description

FG-7060E-FAN FortiGate-7060E fan tray.

9 FortiGate-7060E System Guide

Fortinet Technologies Inc.

Page 10

FortiGate-7060E Chassis Chassis hardware information

SKU Description

FG-7060E-PS-AC 1500W AC power supply units (PSUs) for the FortiGate-7060E.

FG-7060E-PS-DC 1500W DC power supply units (PSUs) for the FortiGate-7060E.

FG-7060E-CHASSIS

FortiGate-7060E chassis including 2x management module, 3x fan trays, and 4x AC or

DC PSUs.

You can also order the following:

l Additional FIM and FPM modules

l Transceivers

l DC PSUs

l Air Filter kit

l FPM and FIM single slot cover trays to be installed in empty chassis slots

The following optional accessories can be ordered separately:

l Additional FIM and FPM modules

l Transceivers

l DC PSUs

l Additional AC PSUs

l Additional FAN trays

l Air Filter kit

l FPM and FIM blank panels to be installed in empty chassis slots

Physical description of the FortiGate-7060E chassis

The FortiGate-7060E chassis is a 8U chassis that can be installed in a standard 19-inch rack. The following table

describes the physical characteristics of the FortiGate-7060E chassis.

Dimensions (H x W x D) 14.0 x 17.3 x 25.6 in (352.7 x 440 x 650 mm)

Chassis weight completely assembled with

FIM and FPM modules installed

207.2 lbs (94.1 kg)

Operating Temperature 32 to 104°F (0 to 40°C)

Storage Temperature -31 to 158°F (-35 to 70°C)

Relative Humidity 10% to 90% non-condensing

Noise Level

63db

AC Input Current and Voltage Range 10-12 A, 100 to 240 VAC (50 to 60 Hz)

DC Input Rating Average: 12.5A@48V for eachPSU, max 44A

FortiGate-7060E System Guide

Fortinet Technologies Inc.

10

Page 11

Cooling fans, cooling air flow, and minimum clearance FortiGate-7060E Chassis

Reten ti on

Screw

Fan

LED

Reten ti on

Screw

Reten ti on

Screw

Reten ti on

Screw

Outle t

Grill

Outle t

Grill

Power Support Rating max. 3277W

Supplied Power Supply Units (PSUs) 4 (for 3+1 redundancy)

Max Power Supply Units (PSUs) 6 (for 3+3 redundancy)

Max Power Consumption 3277W

Average Power Consumption 2330W

Heat Dissipation 11799KJ/hr (11184BTU/hr)

Cooling fans, cooling air flow, and minimum clearance

The FortiGate-7060E chassis contains three hot swappable cooling fan trays installed in the back of the chassis.

Each fan tray includes two fans that operate together. When the fan tray LED is green both fans are operating

normally. If the LED turns red or goes off, one or both of the fans is not working and the fan tray should be

replaced.

Cooling Fan Tray

11 FortiGate-7060E System Guide

Fortinet Technologies Inc.

Page 12

FortiGate-7060E Chassis Cooling fans, cooling air flow, and minimum clearance

Cool air

Intake

Left and R ig ht

Side Coo l A ir

Intakes

50 mm

Clearanc e

(Optiona l)

Front

FortiGat e- 70 60E chassis ( si de Vie w)

Fan

Trays

100 m m

650 m m

Warm Air

Exhaust

Back

100 m m

During normal chassis operation, all three fan trays are active and the fan speed is controlled by the active

management module. Fan trays are hot swappable. You can replace a failed fan tray while the chassis is

operating. To replace a fan tray, unscrew the four retention screws and use the handles to pull the fan tray out of

the chassis.

Install a replacement fan tray by sliding it into place in the empty slot and tightening the retention screws. As you

slide the new fan into place it will power up and the fan tray LED will light.

The other fan trays will continue to operate and cool the chassis as a fan tray is being removed and replaced.

However an open fan tray slot will result in less air flow through the chassis so do not delay installing the

replacement fan tray.

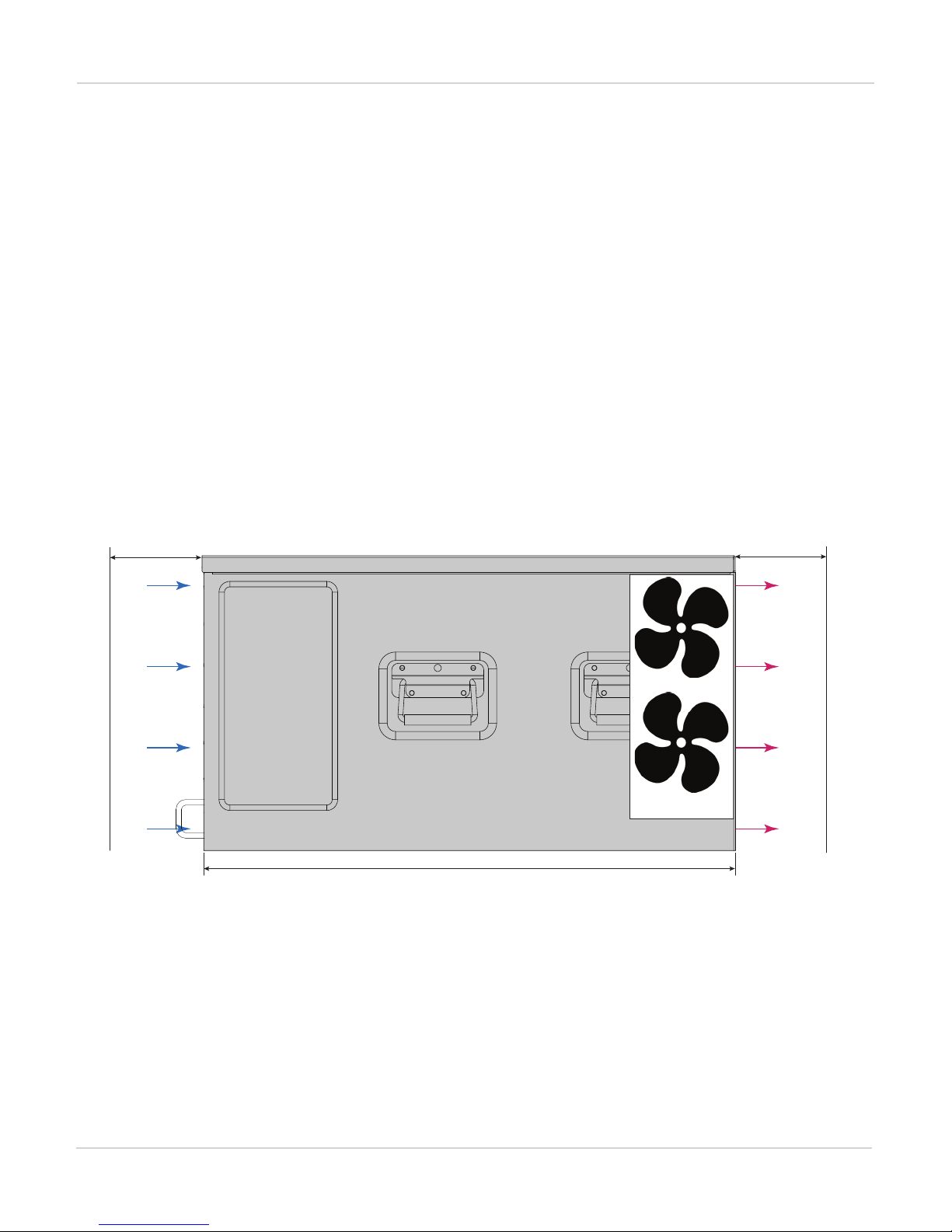

Cooling air flow and required minimum air flow clearance

When installing the chassis, make sure there is enough clearance for effective cooling air flow. The following

diagram shows the cooling air flow through the chassis and the locations of fan trays. Make sure the cooling air

intake and warm air exhaust openings are not blocked by cables or rack construction because this could result in

cooling performance reduction and possible overheating and component damage.

FortiGate-7060E cooling air flow and minimum air flow clearance

Most cool air enters the chassis through the chassis front panel and all warm air exhausts out the back. For

optimal cooling allow 100 mm of clearance at the front and back of the chassis and 50 mm of clearance at the

sides. Under these conditions 80% of cooling air comes from the front panel air intake and 20% from the left and

right side panels and 100% exits out the back. Side clearance is optional and chassis cooling will be sufficient if

no side clearance is available.

FortiGate-7060E System Guide

Fortinet Technologies Inc.

12

Page 13

Optional air filters FortiGate-7060E Chassis

Latch

PSU

LED

C16

Power

Connect or

Optional air filters

You can purchase an optional NEBScompliant air filter kit that includes a front filter that fits over the front of the

chassis and two filters for the side cool air intakes. These filters are not required for normal operation but can be

added if you require air filtration.

The air filters should be inspected regularly. If dirty or damaged, the filters should be disposed of and replaced.

The air filters can be fragile and should be handled carefully.

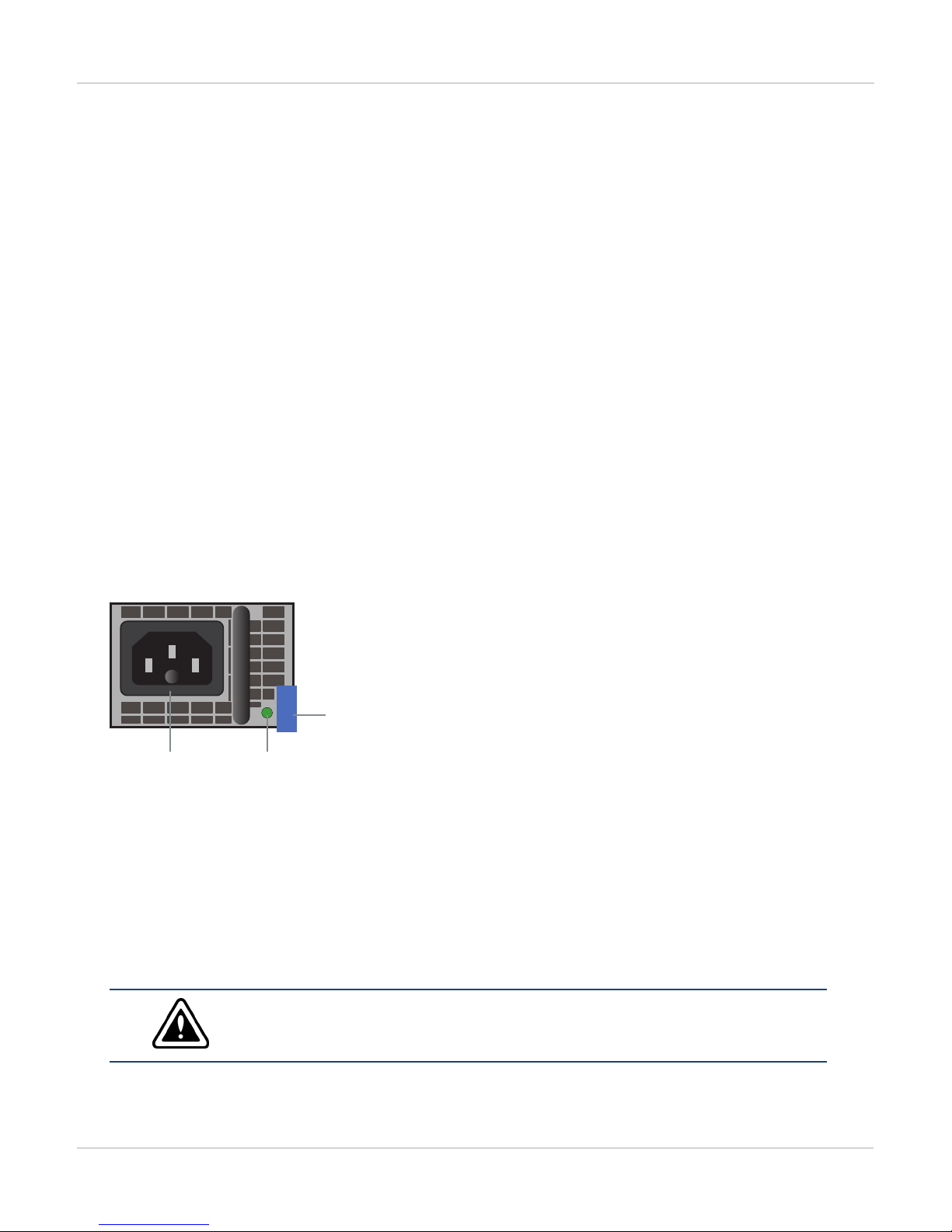

AC Power Supply Units (PSUs) and supplying AC power to the chassis

The AC version of the FortiGate-7060E chassis front panel includes four hot swappable DC PSUs. At least three

PSUs (1, 2, and 3) must be connected to power. Power supplies 4 to 6 are backup power supplies that provide

3+1 , 3+2, and 3+3 redundancy. See FortiGate-7060E front panel on page 5 for locations of the PSUs.

All PSUs should be connected to AC power. To improve redundancy you can connect each power supply to a

separate power source.

Use a C15 Power cable, supplied with the chassis, to connect power to each PSU C16 power connector. C15/C16

power connectors are used for high temperature environments and are rated up to 120°C.

AC PSU showing C16 power connector

The PSU LED indicates whether the PSUis operating correctly and connected to power. If this LEDis not lit check

to make sure the PSU is connected to power. If the power connection is good then the PSU has failed and should

be replaced.

Hot Swapping an AC PSU

Follow these steps to safely hot swap an AC PSU.

You can hot swap a PSU without powering down the FortiGate-7060E as long as three

PSUs are connected to power and operating normally. If you need to hot swap one of

three operating PSUs you must power down the chassis first.

13 FortiGate-7060E System Guide

Fortinet Technologies Inc.

Page 14

FortiGate-7060E Chassis DC Power Supply Units (PSUs) and supplying DC power to the chassis

1.

Attach an ESD wrist strap to your wrist and to an ESD socket or to a bare metal surface on the chassis or frame.

2.

Turn off the power being supplied to the power supply and disconnect the power cord.

3.

Press the latch towards the handle until the PSU is detached then pull it out of the chassis.

4.

Insert a replacement PSU into the chassis and slide it in until it locks into place.

5.

Connect the PSUpower terminals as described above.

6.

Turn on power to the PSU.

7.

Verify that the PSU status LED is solid green meaning that the PSU is powered up and operating normally.

DC Power Supply Units (PSUs) and supplying DC power to the chassis

The DC version of the FortiGate-7060E chassis front panel comes with four hot swappable 48-72V to 12V 125A

DC PSUs. Each PSU has a Internal 60A/170VDC fast blow fuse on the DC line input.

At least three PSUs (power supplies 1, 2, and 3) must be connected to power. The fourth power supply is a

backup power supply and provides 3+1 redundancy. You can add a 5th power supply to provide a second backup

power supply and 3+2 redundancy. You can add a 6th power supply to provide a third backup power supply and

3+3 redundancy. See FortiGate-7060E front panel on page 5 for locations of the PSUs. The diagram shows AC

PSUs, with a DC version of the chassis the AC PSUs are replaced with DC PSUs.

Each PSU is designed to be installed in a Telecom data center or similar location that has available -48VDC

power fed from a listed 40A circuit breaker. To improve redundancy you can connect each power supply to a

separate power circuit.

DC power cables are intended to be used only for in-rack wiring, must be routed away from sharp edges, and

must be adequately fixed to prevent excessive strain on the wires and terminals.

DC terminals accept UL approved ring terminals for 8/M4 stud with ext ring diameter < 9.8 mm. DC cables must

be a minimum of 8 AWG.

The following table lists some key power data for each PSU.

Max Inrush Current 50A

Max Inrush Current Duration 200ms

Input Voltage -40V to -72V

Input Current Average: 12.5A@48V for each PSU, Max: 44A

FortiGate-7060E System Guide

Fortinet Technologies Inc.

14

Page 15

DC Power Supply Units (PSUs) and supplying DC power to the chassis FortiGate-7060E Chassis

Latch

LED

+ (Red)

Power

Connector

- (Black)

Power

Connector

DC PSU (power connector cover removed)

PSU LED States

State Description

Off DC power not connected.

Flashing

Green

Green Normal Operation with DC power connected.

Amber

Flashing

Amber

The PSUis in standby mode, not supplying power to the chassis.

Input voltage outside of normal operating range, PSU fan not operating, or output voltage outside of

normal operating range.

Warning that power input or output is close to outside of normal operating range. PSU should be

replaced.

Crimping guidelines

To connect the PSUs to data center power you should use 8 AWG or larger wires depending on the wire length

and the power requirements of your chassis. The ends of these wires must be fitted with UL approved ring

terminals for 8/M4 studs with ext ring diameter < 9.8 mm. Use the following information to crimp and prepare

these wires.

Do not crimp energized wires.

Follow these crimping guidelines:

l Strip the insulation from cable. Be careful not to nick cable strands which may later result in stands breaking.

l Cable end should be clean: wire brush or clean with emery cloth if necessary. Insert cable into connector until it

stops. The insertion length must approximate the stripped length of cable.

15 FortiGate-7060E System Guide

Fortinet Technologies Inc.

Page 16

FortiGate-7060E Chassis DC Power Supply Units (PSUs) and supplying DC power to the chassis

DC Power

Source

-48VDC

RTN

+ RTN

(red)

-48VDC

(black)

l Insert connector in die and compress between the markings beginning near the tongue of the connector. Using the

wrong installing die may result in a defective connection.

l After crimping, remove all sharp edges, flash or burrs.

Connecting a FortiGate-7060E PSU to DC power

The following procedure describes how to connect a PSU to DC power. Repeat this procedure to connect each

PSU.

You need the following equipment to connect the primary FortiGate-7060E PSUs to DC power:

l An electrostatic discharge (ESD) preventive wrist strap with connection cord.

l One black 8 AWG stranded wire with attached UL approved ring terminal for 8/M4 studs with ext ring diameter < 9.8

mm.

l One red 8 AWG stranded wire with attached UL approved ring terminal for 8/M4 studs with ext ring diameter < 9.8

mm.

To connect a PSU to DC power

1.

Attach the ESD wrist strap to your wrist and to an ESD socket or to a bare metal surface on the chassis or frame.

2.

Make sure that the PSU and power cords are not energized.

3.

Snap the clear plastic cover off of the PSUpower terminals.

4.

Remove the first set of nuts and lock washers from the connectors on the PSU.

5.

Connect the black -48V power wire from your DC power source to the connector on the PSU labeled - using the

ring terminal.

6.

Connect the red RTN power wire from you RTN power source to the connector on the PSU labeled + using the ring

terminal.

7.

Use the previously removed nuts and lock washers to secure the connectors. Do not apply torque of more than 3.8

Nm (33.62 lbf.in).

8.

Snap the clear plastic cover over the PSU power terminals.

9.

Make sure the power wires are secured using tie wraps if required.

10.

If required, label the black wire -48V.

11.

If required, label the red wire RTN.

12.

Turn on power to the PSU.

13.

Verify that the PSU status LED is solid green meaning that the PSU is powered up and operating normally.

FortiGate-7060E System Guide

Fortinet Technologies Inc.

16

Page 17

Connecting the FortiGate-7060E chassis to ground FortiGate-7060E Chassis

Data Center

ground

connector

(Central office

ground system)

Chassis

Ground

Connector

Hot Swapping a DC PSU

Follow these steps to safely hot swap a DC PSU.

You can hot swap a PSU without powering down the FortiGate-7060E as long as three

PSUs are connected to power and operating normally. If you need to hot swap one of

two operating PSUs you must power down the chassis first.

1.

Attach an ESD wrist strap to your wrist and to an ESD socket or to a bare metal surface on the chassis or frame.

2.

Turn off the power being supplied to the PSU.

3.

Snap off the terminal cover and remove the wires from the PSU terminals.

4.

Press the latch towards the handle until the PSU is detached then pull it out of the chassis.

5.

Insert a replacement PSU into the chassis and slide it in until it locks into place.

6.

Connect the PSUpower terminals as described above.

7.

Turn on power to the PSU.

8.

Verify that the PSU status LED is solid green meaning that the PSU is powered up and operating normally.

Connecting the FortiGate-7060E chassis to ground

The FortiGate-7060E chassis includes a ground terminal on the rear the bottom of the FortiGate-7060E back

panel. The ground terminal provides two connectors to be used with a double-holed lug such as Thomas & Betts

PN 54850BE. This connector must be connected to a local ground connection.

You need the following equipment to connect the FortiGate-7060E chassis to ground:

l An electrostatic discharge (ESD) preventive wrist strap with connection cord.

l One green 6 AWG stranded wire with listed closed loop double-hole lug suitable for minimum 6 AWG copper wire,

such as Thomas & Betts PN 54850BE.

To connect the FortiGate-7060E chassis to ground

1.

Attach the ESD wrist strap to your wrist and to an ESD socket or to a bare metal surface on the chassis or frame.

2.

Make sure that the chassis and ground wire are not energized.

3.

Connect the green ground wire from the local ground to the ground connector on the FortiGate-7060E chassis.

4.

Secure the ground wire to the chassis.

5.

Optionally label the wire GND.

17 FortiGate-7060E System Guide

Fortinet Technologies Inc.

Page 18

FortiGate-7060E Chassis Turning on FortiGate-7060E chassis power

Turning on FortiGate-7060E chassis power

Connect AC or DC power to PSUs 1, 2, 3, and 4. Once the FortiGate-7060E chassis is connected to power the

chassis powers up. If the chassis is operating correctly, the LEDs on the PSUs and fans should be lit. As well, the

LEDs on the FortiGate-7060E management module should be lit.

When the chassis first starts up you should also hear the cooling fans operating.

In addition, if any modules have been installed in the chassis they should power on and their front panel LEDs

should indicate that they are starting up and operating normally.

FortiGate-7060E System Guide

Fortinet Technologies Inc.

18

Page 19

Turning on FortiGate-7060E chassis power FortiGate-7060E hardware assembly and rack mounting

FortiGate-7060E hardware assembly and rack mounting

The FortiGate-7060E chassis must be mounted in a standard 19-inch rack and requires 8Uof vertical space in the

rack. This chapter describes how to attach accessories to the FortiGate-7060E chassis, how to install the chassis

in a 4-post or 2-post rack, and how to install FIM and FPM modules in the chassis front panel slots.

If you install the FortiGate-7060E chassis in a closed or multi-unit rack assembly, the operating ambient

temperature of the rack environment may be greater than room ambient temperature. Make sure the operating

ambient temperature does not exceed the manufacturer's maximum rated ambient temperature.

The FortiGate-7060E chassis should not be operated as a free-standing appliance.

It is recommended that you mount the FortiGate-7060E chassis near the bottom of the rack to avoid making the

rack top-heavy and potentially falling over. If you are going to mount the chassis higher make sure the rack is well

anchored. Since the chassis is over 100 lbs use a lift to raise the chassis into position before mounting it.

Install accessories before mounting the chassis in a rack. Install the modules after the

chassis is rack mounted.

19 FortiGate-7060E System Guide

Fortinet Technologies Inc.

Page 20

FortiGate-7060E hardware assembly and rack mounting Installing accessories

Front Mounting

Brack et

Front Cable

Manag ement

Brack et

Left Cable

Manag ement

Brack et

Right Cable

Manag ement

Brack et

M4x 8 la rge he ad

pan hea d scre ws

M4x 8 la rge he ad

pan hea d scre ws

M4x 8 fl at-hea d

scr ews

M4x 8 fl at-hea d

scr ews

Front Mounting

Brack et

Power Cord

Clamp s

Installing accessories

These accessories are optional and not required for all configurations. If you have them, before mounting the

chassis in a rack you should install the left and right front mounting brackets and the cable management brackets

as shown in the following illustration.

Installing FortiGate-7060E accessories

You can also install power cord clamps into the front of the chassis beside each PSU. Install the clamps by

inserting them into the holes adjacent each supply at the back of the chassis. Use the clamps to secure the AC

power cords so they are not accidentally disconnected.

FortiGate-7060E System Guide

Fortinet Technologies Inc.

20

Page 21

Mounting the FortiGate-7060E chassis in a four-post rack FortiGate-7060E hardware assembly and rack mounting

Secur e the Chassis

to th e Rack Mount Tray

Rac k Mo unt

Scr ews not

pro vide d

M4x 6 pa n-head screw

wit h M4 washe r

Rac k Mo unt

Scr ews not

pro vide d

Attac h the Left

Tray to th e Left

Rack Po sts

Attac h the Right

Tray to th e Right

Rack Po sts

Rac k Mo unt

Scr ews not

pro vide d

Mounting the FortiGate-7060E chassis in a four-post rack

The FortiGate-7060E package includes a set of extendable brackets that you can use to mount the chassis in a 4post rack. Install the brackets to create a 4-post rack mount tray that the chassis will slide on to. Attach each side

of the tray to the 4-post rack using the front and back brackets as shown below. Make sure you install the tray with

enough space above it for the chassis. The length of the tray sides adjusts to match your rack.

Once the 4-post rack mount tray has been installed, slide the chassis onto the tray and secure it to the rack mount

tray as shown in the diagram.

Mounting the chassis in a four-post Rack

21 FortiGate-7060E System Guide

Fortinet Technologies Inc.

Page 22

FortiGate-7060E hardware assembly and rack mounting Mounting the FortiGate-7060E chassis in a two-post rack

Left Mid Mount Tray

(Atta ch to the Rack

First )

M4x 6 fl at hea d

scr ews

M4x 6 fl at hea d

scr ews

Right Mid Moun t Tray

(Atta ch to the Rack Fir st)

Left Mid Mount Ear

(Atta ch to the

Chass is)

Right Mid

Mount Ear

(Atta ch to the

Chass is)

Mounting the FortiGate-7060E chassis in a two-post rack

The FortiGate-7060E package includes two mid-mount trays and two mid-mount ears that you can use to mount

the chassis in a 2-post rack. As shown in the diagram, first attach the mid-mount trays to the rack making sure to

leave enough space above the trays for the chassis. Then attach the mid-mount ears to the chassis also as shown

in the diagram. Finally line up the mid-mount trays with the mid-mount ears so that the chassis is supported in the

rack. Then use screws to attach the mid-mount ears and the chassis to the rack.

Mounting the chassis in a 2-post rack

Air flow

For rack installation, make sure that the amount of air flow required for safe operation of the FortiGate-7060E

chassis is not compromised. Make sure that the chassis ventilation openings at the front and back are not blocked

by cables or other components. The recommended minimum clearance at the front of the chassis is 100 mm and

the recommended clearance from the rear of the chassis is 100 mm. This results in a total footprint of 850 mm

from front to back. See FortiGate-7060E Chassis on page 5 for more details.

FortiGate-7060E System Guide

Fortinet Technologies Inc.

22

Page 23

Inserting FIM and FPM-7000 series modules FortiGate-7060E hardware assembly and rack mounting

Inserting FIM and FPM-7000 series modules

All FortiGate-7060E chassis are shipped with a protective front panel installed in the chassis to protect internal

chassis components. This panel must be removed before you install FIM and FPM modules.

Insert FIM modules into chassis slots 1 and 2. Insert FPM modules into chassis slots 3, 4, 5, and 6.

Do not operate the FortiGate-7060E chassis with open slots on the front or back panel.

For optimum cooling performance and safety, each chassis slot must contain an FIM

or FPM module or an FIM or FPM blank panel (also called a dummy card). For the

same reason, all cooling fan trays, power supplies or power supply slot covers must be

installed while the chassis is operating.

To insert FIM and FPM modules, see the guide supplied with the module.

You must carefully slide the module all the way into the chassis slot, close the handles

to seat the module into the slot, and tighten the retention screws to make sure the

module is fully engaged with the backplane and secured. You must also make sure

that the sliding latches are fully closed by gently pushing them down. The handles

must be closed, the retention screws tightened and the latches fully closed for the

module to get power and start up. If the module is not receiving power all LEDs remain

off.

All FIM and FPM-7000 series modules must be protected from static discharge and

physical shock. Only handle or work with these boards at a static-free workstation.

Always wear a grounded electrostatic discharge (ESD) preventive wrist strap when

handling these boards.

Recommended slot locations for interface modules

If you are installing different FIM modules in the FortiGate-7060E chassis, for optimal configuration you should

install the module with the lower model number in slot 1 and the module with the higher number in slot 2.

For example:

l if your chassis includes a FIM-7901E and a FIM-7904E, install the FIM-7901E in chassis slot 1 and the FIM-7904E

in chassis slot 2.

l If your chassis includes a FIM-7904E and a FIM-7920E, install the FIM-7904E in chassis slot 1 and the FIM-7920E

in chassis slot 2.

This applies to any combination of two different interface modules.

23 FortiGate-7060E System Guide

Fortinet Technologies Inc.

Page 24

FortiGate-7060E Management Modules Inserting FIM and FPM-7000 series modules

Status, Alarm,

Temp, Power

LEDs

Fan and PSU

(power supply)

LEDs

MGMT Ethernet

Interface

Console 1

Connection

LEDs

H8S Mode

LED

H8S Mode

Select Button

Console 2

Connection

LEDs

Retention

Screw

Retention

Screw

Console 1 RJ-45

RS-232

Serial Interface

Console 1 Connection

Change Button

Console 2 Connection

Change Button

Console 2 RJ-45

RS-232

Serial Interface

FortiGate-7060E Management Modules

The FortiGate-7060E chassis includes two management modules (shelf managers), located at the top of the

chassis front panel. The management modules are factory installed and configured and is not field replaceable.

The management modules operate in an active-passive redundant configuration. By default, when the system

starts up the management module in slot MGT2 is active and the management module in slot MGT1 is passive.

The active management module always has IPMB address 0x20 and the passive management module always

has IPMB address 0x22.

If the passive management module fails, the chassis just keeps operating with the active management module. If

the active management module fails, the passive management module becomes active.

The active management module synchronizes the following data to the passive management module:

l Chassis state and chassis policy

l LAN parameters for each LAN channel, including, the IP address, gateway IP address, channel enable status, local

interface/non-local interface setting, and the session support flag.

l The console connect feature status (enable or disable).

FortiGate-7060E management module front panel

The active management module communicates with module SMCs in the chassis, each of which is responsible

for local management of one or more Field Replaceable Units (FRUs), including FIM and FPM modules, fan

trays, and power supplies. Management communication within a chassis occurs over the Intelligent Platform

Management Bus (IPMB).

The active management module includes LED indicators that report on the status of many of the chassis

components, including fan trays and power supplies. You can also use the management module console ports to

connect to the management module CLI and to the CLI of the modules in chassis slots 1 to 6.

The active management module controls chassis power allocation, monitors chassis operating parameters,

monitors and controls chassis cooling, and generates alarms if the chassis encounters problems. All FIM and

FortiGate-7060E System Guide

Fortinet Technologies Inc.

24

Page 25

Management module failure FortiGate-7060E Management Modules

FPM modules installed in the chassis communicate with the active management module through the module's

IPMC. FIM and FPM module power on/off requires authorization from the active management module and the

active management module controls the power supplied by the chassis power systems to the modules.

Each module in the chassis includes its own module Shelf Manager Controller (SMC) Serial Debug Interface

(SDI)or SMC SDI console that communicates with the management module SMC SDI. You can connect a serial

cable to the active management module console ports to connect to the management module SMC SDI and to

connect to each module's SMC SDI console. You can also interact with the SMC SDI consoles using an Intelligent

Platform Management Interface (IPMI) tool.

Management module failure

If one or both of the management modules fails you should RMA the chassis. The chassis and the modules in it

will continue to operate with one or no functioning management modules until you can replace the chassis. If

there is no functioning management module the chassis fans operate at maximum speed and the FIM and FPM

modules in the chassis switch to standalone mode and manage their own power.

Management Module LEDs

The following table describes the management Module LED indicators:

FortiGate-7060E Management Module LEDs

LED State Description

Status Off The management module is powered off or not initialized.

Solid Red

Blinking Red The active management module cannot communicate with

Solid Green

Blinking Green The management module is passive.

The management module is not operating normally either

because it is starting up or because it has failed.

the passive management module.

The management module has started up and is operating

normally.

25 FortiGate-7060E System Guide

Fortinet Technologies Inc.

Page 26

FortiGate-7060E Management Modules Management Module LEDs

LED State Description

Off No alarms

Red One or more analog sensors in the chassis or on a module in

the chassis (other than PSUs) have surpassed a critical or

non-recoverable (NR) threshold causing an alarm. When a

critical threshold has been reached, it means that a condition

has been detected that has surpassed an operating

tolerance. For example, a temperature has increased above

Alarm

the allowed operating temperature range.

One or more analog sensors in the chassis or on a module in

the chassis (excluding PSUs) has surpassed a major or critical

(CR)threshold. Any sensor, including sensors on PSUs, has

Amber

generated an alert. Sensor alert criteria is defined per sensor.

For analog sensors, alerts usually mean passing an upper

critical (UC) or lower critical (LC) threshold. For other sensors,

an alert could mean a flag bit is indicating an anomaly.

Temp Solid Green All temperature sensors indicated acceptable operating

temperatures.

At least one temperature sensor is detecting a high

temperature outside of the normal operating range. In this

Blinking Green

case an upper non-critical (UNC) temperature. The

management module increases fan speed to increase cooling

and reduce the temperature.

Blinking Red At least one temperature sensor is detecting a temperature

outside of the acceptable operating range. In this case an

upper critical (UC) temperature. The management module

increases fan speed to the maximum level. This also

indicates possible problems with the cooling system and

could mean that the ambient temperature is too high. Also

causes a major or critical (CR) alarm.

At least one temperature sensor is detecting a temperature

outside of the allowed operating range. In this case an upper

non-recoverable (UNR) temperature. The management

Solid Red

module increases fan speed to the maximum level. The

temperature is high enough to potentially cause physical

damage. Also causes a critical or non-recoverable (NR)

alarm.

FortiGate-7060E System Guide

Fortinet Technologies Inc.

26

Page 27

Management Module LEDs FortiGate-7060E Management Modules

LED State Description

Power Solid Green Normal operation.

Chassis 12V disabled. This means that the administrator has

entered commands into the management module CLI to

Blinking Green

power off the PSU main 12V outputs. All fans, FIM and FPM

modules are completely powered off but the management

module is still running.

Red Chassis 12V enabled but not OK. This means the

management module has enabled the main 12V outputs for

all chassis components, but the power OK (PWOK) signal of

at least one PSU has not been sent. When a PSU is powering

up, it would be normal for this LED to be red for a second

(before PSU outputs are stabilized), but if LED remains red, it

indicates a problem (such as a failed PSU). Management

module or FIM or FPM module voltage sensors would most

likely also trigger alarms if this happens since the PSUs may

not be delivering enough power.

FAN (LEDs for each of

three fan trays)

PSU (LEDs for each of

four PSUs)

Fan tachometer sensors disabled. This could happen if the

Off

administrator disabled them from the management module

CLI.

Green The fan tray is operating normally.

The fan tray is not working. Chassis cooling may be sufficient

Blinking Red

but redundancy is lost and the fan tray that is not working

should be replaced.

Red A fan tachometer sensor in this fan tray has registered an

alert because a critical or non-recoverable (NR) threshold has

been crossed.

Off The PSU is not installed in the chassis.

Green The PSUis present and operating normally.

Blinking Red

The PSU module is installed but no power is being delivered

(not plugged in).

Red The PSU's sensors have detected an alert condition. The

PSU's analog sensors crossed critical or non-recoverable (NR)

thresholds, or the PSU Status Failure bit has been set.

27 FortiGate-7060E System Guide

Fortinet Technologies Inc.

Page 28

FortiGate-7060E Management Modules About management module alarm levels

LED State Description

This console port is not connected or is connected to the

management module SMM CLI.

Console 1 and 2

Off

Green This console port is connected to this module host console in

this chassis slot.

Amber This console port is connected to this module's SMC console.

About management module alarm levels

Minor, major and critical alarms are defined based on both IPMI, ATCA, and Telco standards for naming alarms.

l A minor alarm (also called an IPMI non-critical (NC) alarm) indicates that a temperature or a power level was

detected by a sensor that is outside of the normal operating range but is not considered a problem. In the case of a

minor temperature alarm the system could respond by increasing fan speed. A non-critical threshold can be an

upper non-critical (UNC) threshold (for example, a high temperature or a high power level ) or a lower non-critical

(UNC) threshold (for example, a low power level).

l A major alarm (also called an IPMI critical or critical recoverable (CR) alarm) indicates a temperature or power level

was detected by a sensor that is far enough outside of the normal operating range to require attention from the

operator. It could also mean that the system itself cannot correct the alarm. For example, the cooling system

cannot provide enough cooling to reduce the temperature. It could also mean that conditions are close to being

outside of the allowed operating range. For example, the temperature is close to exceeding the allowed operating

temperature. A critical threshold can also be an upper critical (UC) threshold (for example, a high temperature or a

high power level ) or a lower critical (LC) threshold (for example, a low power level).

l A critical alarm (also called an IPMI non-recoverable (NR) alarm) indicates a temperature or power level was

detected by a sensor that is outside of the allowed operating range and could potentially cause physical damage.

You can use the management module CLI to get details about alarm sensors, thresholds, and the events that

trigger alarms.

Using the console ports

The active management module includes two console ports named Console 1 and Console 2 that can be used to

connect to any serial console in the chassis. This includes the management module CLI, the FortiOS CLIs (also

called host CLIs) of the FIM and FPM modules in chassis slots 1 to 6 and all of the SMC SDI consoles in the

chassis.

Each module, including the management modules, includes an SMC SDI console.

These consoles are used for low level programming of the module using an IPMItool

and are disabled by default. You can enable serial access to individual module SMC

SDI consoles from the management module SMC SDI CLI using the command

serial set sdi enable <slot>. During normal operation you may want to

access the management module SMC SDI CLI, you shouldn't normally require access

to individual module SMC SDI consoles.

FortiGate-7060E System Guide

Fortinet Technologies Inc.

28

Page 29

Connecting to the FortiOS CLI of the FIM module in slot 1 FortiGate-7060E Management Modules

By default when the chassis first starts up Console 1 is connected to the FortiOS CLIof the FIM module in slot 1

and Console 2 is disconnected.

The default settings for connecting to each console port are: Baud Rate (bps) 9600, Data bits 8, Parity None,

Stop bits 1, and Flow Control None.

The FIM and FPMmodules use the standard FortiOS CLI. The SMC SDI CLIs are described in this chapter.

You can use the console connection change buttons to select the CLI that each console port is connected to.

l Press the button to cycle through the FIM and FPM module FortiOS CLIs and disconnect this console.

l Press and hold the button to connect to the management module SMC SDI CLI. You can also cycle through each

module's SMC SDI CLI if they are enabled.

The console's LEDs indicate what it is connected to. If no LEDis lit the console is either connected to the

management module SMC SDI console or disconnected. Both console ports cannot be connected to the same

CLI at the same time. If a console button press would cause a conflict that module is skipped. If one of the

console ports is disconnected then the other console port can connect to any CLI.

If you connect a PC to one of the management module console ports with a serial cable and open a terminal

session you begin by pressing Ctrl-T to enable console switching mode, then you can do the following:

l Press Ctrl-T multiple times to cycle through the FIM and FPM module FortiOS CLIs (the new destination is

displayed in the terminal window). If you press Ctrl-T after connecting to the FPM module in slot 6 the console is

disconnected. Press Ctrl-T again to start over again at slot 1.

l Press Ctrl-R multiple times to cycel through the FIM and FPM module SMC SDI CLIs if they are enabled (the new

destination is displayed in the terminal window). After cycling through all of the enabled SMC SDI CLIs the next

press of Ctrl-R disconnects the console port.

Once the console port is connected to the CLI that you want to use, press Enter to enable the CLI and login. The

default admininstrator account for accessing the FortiOS CLIs is admin with no password. The default

administrator account for the SMC SDI CLIs is admin/admin.

When your session is complete you can press Ctrl-T until the prompt shows you have disconnected from the

console.

Connecting to the FortiOS CLI of the FIM module in slot 1

Use the following steps to connect to the FortiOS CLIof the FIM module in slot 1:

1.

Connect the console cable supplied with your chassis to Console 1 and to your PC or other device RS-232 console

port.

2.

Start a terminal emulation program on the management computer. Use these settings:

Baud Rate (bps) 9600, Data bits 8, Parity None, Stop bits 1, and Flow Control None.

3.

Press Ctrl-T to enter console switch mode.

4.

Repeat pressing Ctrl-T until you have connected to slot 1. Example prompt:

<Switching to Console: FIM01 (9600)>

5.

Login with an administrator name and password.

The default is admin with no password.

For security reasons, it is strongly recommended that you change the password.

6.

When your session is complete, enter the exit command to log out.

29 FortiGate-7060E System Guide

Fortinet Technologies Inc.

Page 30

FortiGate-7060E Management Modules Connecting to the FortiOS CLI of the FIM module in slot 2

Connecting to the FortiOS CLI of the FIM module in slot 2

Use the following steps to connect to the FortiOS CLIof the FIM module in slot 2:

1.

Connect the console cable supplied with your chassis to Console 1 and to your PC or other device RS-232 console

port.

2.

Start a terminal emulation program on the management computer. Use these settings:

Baud Rate (bps) 9600, Data bits 8, Parity None, Stop bits 1, and Flow Control None.

3.

Press Ctrl-T to enter console switch mode.

4.

Repeat pressing Ctrl-T until you have connected to slot 2. Example prompt:

<Switching to Console: FIM02 (9600)>

5.

Login with an administrator name and password.

The default is admin with no password.

For security reasons, it is strongly recommended that you change the password.

6.

When your session is complete, enter the exit command to log out.

Connecting to the SMC SDI CLI of the FPMmodule in slot 3

Use the following steps to connect to the management module SMC SDI CLI:

1.

Connect the console cable supplied with your chassis to Console 1 and to your PC or other device RS-232 console

port.

2.

Start a terminal emulation program on the management computer. Use these settings:

Baud Rate (bps) 9600, Data bits 8, Parity None, Stop bits 1, and Flow Control None.

3.

Press Ctrl-T to enter console switch mode.

4.

Press Ctrl-Rto switch to the management module SMC SDI CLI switching mode.

5.

Repeat pressing Ctrl-R until you have connected to slot 3. Example prompt:

<Switching to Console: FIM03-MC (9600)>

6.

Login with an administrator name and password.

The default administrator name and password are admin/admin.

For security reasons, it is strongly recommended that you change the password.

7.

You can begin entering commands at the admin@FPM03-MC # prompt.

8.

When your session is complete, enter the exit command to log out.

Changing the management module admin account password

Use the following procedure to change the management module admin account password.

1.

Enter the following command to show all users and their user IDs.

user list

The output should show that the admin user has a user ID of 2.

2.

Use the command user set password <user-id> [<password>] to add a password for the admin

account. For example:

user set password 2 <password>

FortiGate-7060E System Guide

Fortinet Technologies Inc.

30

Page 31

Connecting to the management module using an IPMItool FortiGate-7060E Management Modules

3.

Enter and confirm a new password for the admin account.

The password should be between 5 and 20 characters long and should include a combination of upper and lower

case letters and numbers.

You can change the admin account password at any time.

Connecting to the management module using an IPMItool

You can install a remote IPMItool on a management computer and then use this IPMItool to start an IPMI

session with the management module. You can use one of the console ports or the MGMTport to connect with

the IPMItool.

The IPMIcommands are the same as the CLI commands described in this chapter but they have to be prefixed

as shown in the following example that changes the MGMT interface IP address to 172.20.120.30 over a serial

connection:

sudo ipmitool -I serial-terminal -D /dev/ttyS1:9600 -U <username> -P <password> lan set 4

ipaddr 172.20.120.30

Here is the same command over an Ethernet connection:

sudo ipmitool -I lanplus -H 10.160.19.30 -k gkey -U <username> -P <password> lan set 4

ipaddr 172.20.120.30

Use the following IPMI commands to change the management module password:

First from a console port connection:

sudo ipmitool -I serial-terminal -D /dev/ttyS1:9600 -U <username> -P <password> user set

password 2 <password>

And from an Ethernet connection:

sudo ipmitool -I lanplus -H 10.160.19.30 -k gkey -U <username> -P <password> user set

password 2 <password>

To perform an operation on a module according to its chassis slot include the -t <slot> parameter in the IPMI

command. For example, to list the sensors on the FIMmodule in chassis slot 2 (0x82), use the following IPMI

command:

sudo ipmitool -I lanplus -H 10.160.19.30 -k gkey -U <username> -P <password0> -t 0x82

sensor

FortiGate-7060E chassis slots IPMB addresses

The following table lists the IPMB addresses of the FortiGate-7060E chassis slots.

Chassis slot number Name IPMB Address (FRUID)

Management module 1 MGMT1 if active 0x20, if passive (the default)0x22

Management module 2 MGMT2 if active (the default) 0x20, if passive0x22

5 FPM5 0x8A

31 FortiGate-7060E System Guide

Fortinet Technologies Inc.

Page 32

FortiGate-7060E Management Modules Rebooting a chassis module from the SMC SDI CLI

Chassis slot number Name IPMB Address (FRUID)

3 FPM3 0x86

1 FIM1 0x82

2 FIM2 0x84

4 FPM4 0x88

6 FPM6 0x8C

You can use the IPMB address or chassis slot number to reference a chassis slot when entering commands in the

management module CLI. For example, enter either of the following commands to display sensor readings for

the FIM module in slot 2:

sensor 0x84

sensor 2

When command syntax descriptions in this chapter include the <slot> variable you can replace it with a slot

number (1 to 6) or an IPMB address number (0x82 to 0x8C)

Rebooting a chassis module from the SMC SDI CLI

A common use of the SMC SDI CLIis being able to remotely reboot a FIM or FPMmodule.

From any SMC SDI CLI use the following command to reboot the module in slot 3:

mc reset 3 warm

Use the following command to power off the module in slot 4:

fru deactivate 4

Use the following command to power on the FIM module in slot 2 (IPMI address 0x84):

fru activate 0x84

Use the following IPMI command to reset the module SMC to reboot the module in slot 3:

sudo ipmitool -I lanplus -H 10.160.19.30 -k gkey -U admin -P admin -t 0x86 mc reset warm

Use the following IPMI command to power off the module in slot 4:

sudo ipmitool -I lanplus -H 10.160.19.30 -k gkey -U admin -P admin -t 0x88 picmg

deactivate 0

Use the following IPMI command to power on the FIM module in slot 2 (IPMI address 0x84):

sudo ipmitool -I lanplus -H 10.160.19.30 -k gkey -U admin -P admin -t 0x84 picmg activate

0

Comlog

All module SMCs include a comlog system for writing and saving console log messages. When enabled, the

comlog saves log messages in a local comlog file. Log messages include all local host console messages

including BIOS boot up messages. In the comlog these messages include the following headers:

FortiGate-7060E System Guide

Fortinet Technologies Inc.

32

Page 33

Comlog FortiGate-7060E Management Modules

Header Cause

\n--- COMLOG SYSTEM BOOT: YYYY/MM/DD hh:mm:ss ---\n The module is starting up after being powered on

or reset.

\n--- COMLOG DISABLED: YYYY/MM/DD hh:mm:ss ---\n Logging is disabled.

\n--- COMLOG ENABLED: YYYY/MM/DD hh:mm:ss ---\n Logging is enabled

\n--- COMLOG TIME: YYYY/MM/DD hh:mm:ss ---\n

This message is written every hour when the

module is powered on and logging is enabled.

The following comlog-related CLI commands are available:

Description SMC CLI Commands IPMI commands

Display comlog information.

Available on the passive

module.

comlog getinfo

Status Disabled

COM Speed 9600

Storage Size 0x00400000

Log Start 0x00000000

Log End 0x00000C37

Log Size 3127 Bytes

Display a module's comlog.

Available on the passive

module.

Clear a module's comlog. Either

by resetting the a comlog start

comlog getinfo <slot>

comlog print <slot>

comlog clear [reset_loc]

[chip_erase]

fortinetoem comlog getinfo

fortinetoem comlog print

fortinetoem comlog clear

location in flash (reset_loc) or

erasing all of the flash storage

(chip_erase). Available on the

passive module.

Disable a module's comlog.

Available on the passive

module.

Enable comlog. Available on

the passive module.

Set comlog baud rate.

<speed> can be 9600, 19200,

38400,57600, 115200, or

expressed as level 1 to 4.

Available on the passive

module.

33 FortiGate-7060E System Guide

comlog disable

fortinetoem comlog clear

comlog enable fortinetoem comlog clear

comlog setbaud <speed>

fortinetoem comlog setbaud

<speed>

Fortinet Technologies Inc.

Page 34

FortiGate-7060E Management Modules System event log (SEL)

System event log (SEL)

The SMC in each module generates system event log (SEL) messages that record system events as they occur.

All SEL messages are stored by individual FIM and FPM module SMCs. They are also all collected and stored by

the management module SMC. From the management module you can use the following commands from the

active or passive management module to view and clear SEL messages.

Operation SMC CLI Commands IPMI Commands

Display the local SEL for a

module.

Clear the local SEL.

Get SEL information. N/A

Get SEL time

Set SEL time

sel <slot> sel list

sel elist

-v sel list

sel clear sel clear

sel info

time get sel time get

time set <yyyy/mm/dd

hh:mm:ss>

sel time set

Sensor data record (SDR)

The sensor data record (SDR) contains static information about the sensors in each chassis module. Information

includes the Sensor ID string, sensor type, sensor event/reading type, entity id, entity instance, sensor unit,

reading linearization parameters, sensor thresholds, and so on. The following commands display information

stored in the SDR.

Operation SMC CLI Commands IPMICommands

Display current local sensor values

and sensor SDRs or sensor

thresholds for a module. Available

on the passive module.

Set Sensor thresholds N/A

FortiGate-7060E System Guide

Fortinet Technologies Inc.

sensor <slot>

sensor_thresholds <slot>

sensor

sensor hexlist

sdr list

sdr elist

-v sdr list

(-v required when using the Windows

command prompt)

sensor thres help

(use this command to display online

help for setting sensor thresholds)

34

Page 35

Common management module CLI operations FortiGate-7060E Management Modules

Common management module CLI operations

The following table lists many of the operations you can perform from the management module CLI and the

commands you use to perform them. Only a subset of these commands are available on the passive

management module as indicated below. Also, the <slot> option is not available on the passive module.

Action SMC CLI Commands IPMI Commands

Log into the CLI. Ctrl-R N/A

Log out of the CLI.

Available on the

passive module.

exit (followed by Ctrl-R) N/A

Display all commands.

Available on the

passive module.

Display information

about all SMC

firmware in the

chassis.

Display SMC device

ID, Build

Date/Number, SMC

firmware information,

address info, entity

map for the device in

the slot. Available on

the passive module.

Switching active

management module.

The active

management module

becomes passive and

the passive becomes

active. Available on

the passive module.

help help

info mc info

info <slot>

smm_switch

N/A

N/A

Display status, power

budget and hot swap

state for all modules.

Available on the

passive module.

List the IPMI channels.

35 FortiGate-7060E System Guide

status

channel list

N/A

channel info [<channelnumber>]

Fortinet Technologies Inc.

Page 36

FortiGate-7060E Management Modules Common management module CLI operations

Action SMC CLI Commands IPMI Commands

Change the SDI

verbosity level. <level>

can be:

0: Alerts + Errors

1: Alerts + Errors +

Verbose + Low-Level

Errors

2: Alerts + Errors +

Verbose + Low-Level

Errors + PI traffic

3: Alerts + Errors +

Verbose + Low-Level

Errors + PI traffic +

IPMB traffic + LAN

Interface traffic

4: Same as 3

Display the

management module

time. Available on the

passive module.

Set the management

module time. Available

on the passive

module.

verbose <level>

N/A

time get sel time get

time set <yyy/mm/dd hh:mm:ss> sel time set <yyy/mm/dd

hh:mm:ss>

Synchronize all

module SMC times.

List management

module user accounts.

Available on the

passive module.

Disable a user

account. Available on

the passive module.

Enable a user account.

Available on the

passive module.

Set a user account

user name. Available

on the passive

module.

time sync

N/A

user list user list [<channel number>]

user disable <user-id> user disable <user-id>

user enable <user-id> user enable <user-id>

user set name <user-id> <name> user set name <user-id> <name>

FortiGate-7060E System Guide

Fortinet Technologies Inc.

36

Page 37

Common management module CLI operations FortiGate-7060E Management Modules

Action SMC CLI Commands IPMI Commands

Set a user account

password. Available on

user set password <user-id>

<password>

the passive module.

Set the privilege level

that a user account

has for a specified

session-based

IPMI<channel>. If a

<channel> is not

specified the privilege

user priv <user-id> {callback

| user | operator |

administrator | no_access}

[<channel>]

level is set for all IPMI

channels. Available on

the passive module.

View a summary of

N/A

users.

User test command. N/A

Display the

serial print

management module

serial interface

settings. Available on

the passive module.

user set password <user-id>

<password>

user priv <user id> <privilege

level> [<channel number>]

user summary

user test

N/A

Set the SDI baud rate.

Available on the

passive module.

Set the sniff baud rate

when the console is

disabled. Available on

the passive module.

Enable a console

connection from the

management module

to another module.

Disable the console

connection between

the management

module and another

module. Available on

the passive module.

Cold or warm reset a

module.

serial set sdi baud <speed>

serial set sdi default_sniff_

baud <speed>

serial set sdi enable <slot>

serial set sdi disable <slot>

mc reset <slot> cold

mc reset <slot> warm

N/A

N/A

N/A

N/A

mc reset cold

mc reset warm

37 FortiGate-7060E System Guide

Fortinet Technologies Inc.

Page 38

FortiGate-7060E Management Modules Common management module CLI operations

Action SMC CLI Commands IPMI Commands

Run a module self

N/A

test.

Power on a module.

Power off a module.

fru activate <slot> [<fruid>] picmg activate

fru deactivate <slot>

[<fruid>]

Reset a module.

Power cycle the

fru reset <slot> [<fruid>] picmg reset

N/A

chassis

Get chassis sttatus N/A

Display the LAN

lan print <channel>

configuration.

Available on the

passive module.

lan set <channel> ipaddr <ip>

[<netmask>]

lan set <channel> macaddr

<mac>

Set LAN configuration.

The kgkey and

krkey options are

used for RCMP+.

lan set <channel> defgw ipaddr

<ip>

lan set <channel> defgw

macaddr <mac>

lan set <channel> kgkey

<value>

lan set <channel> krkey

<value>

mc selftest

picmg deactivate

chassis power cycle

chassis status

lan set help

(use this command to display online help

for LAN settings)

Enable or disable all

LAN interfaces.

Set fan levels. Change

or switch the active fan

set.

lan enable

lan disable

fan_min_level <0-30>

fan_max_level <0-30>

fan_set_switch

Change LED settings. N/A picmg led set help

Display HPM.1 status. N/A

Run an HPM.1

N/A

upgrade.

FortiGate-7060E System Guide

Fortinet Technologies Inc.

fortinetoem param set 0 1

fortinetoem param set 0 0

N/A

(use this command to display online help

for LED settings)

hpm check

hpm upgrade <.img> hpm upgrade

<.img> all activate

38

Page 39

Environmental Specifications Cautions and Warnings

Cautions and Warnings

Environmental Specifications

Rack Mount Instructions - The following or similar rack-mount instructions are included with the installation

instructions:

Instructions de montage en rack - Les instructions de montage en rack suivantes ou similaires sont incluses

avec les instructions d'installation:

Elevated Operating Ambient - If installed in a closed or multi-unit rack assembly, the operating ambient

temperature of the rack environment may be greater than room ambient. Therefore, consideration should be

given to installing the equipment in an environment compatible with the maximum ambient temperature (Tma)

specified by the manufacturer.

Température ambiante élevée – S'il est installé dans un rack fermé ou à unités multiples, la température

ambiante de fonctionnement de l'environnement du rack peut être supérieure à la température ambiante de la

pièce. Par conséquent, il est important d’installer le matériel dans un environnement respectant la température

ambiante maximale (Tma) stipulée par le fabricant.

Reduced Air Flow - Installation of the equipment in a rack should be such that the amount of air flow required

for safe operation of the equipment is not compromised.

Ventilation réduite – Installation de l'équipement dans un rack doit être telle que la quantité de flux d'air

nécessaire au bon fonctionnement de l'équipement n'est pas compromise.

Mechanical Loading - Mounting of the equipment in the rack should be such that a hazardous condition is not

achieved due to uneven mechanical loading.

Chargement Mécanique – Montage de l'équipement dans le rack doit être telle qu'une situation dangereuse

n'est pas lié à un chargement mécanique inégal.

Circuit Overloading - Consideration should be given to the connection of the equipment to the supply circuit

and the effect that overloading of the circuits might have on overcurrent protection and supply wiring. Appropriate

consideration of equipment nameplate ratings should be used when addressing this concern.

Surtension – Il convient de prendre l’ensemble des précautions nécessaires lors du branchement de

l’équipement au circuit d’alimentation et être particulièrement attentif aux effets de la suralimentation sur le

dispositif assurant une protection contre les courts-circuits et le câblage. Ainsi, il est recommandé de tenir

compte du numéro d’identification de l’équipement.

Reliable Earthing - Reliable earthing of rack-mounted equipment should be maintained. Particular attention

should be given to supply connections other than direct connections to the branch circuit (e.g. use of power

strips).

39 FortiGate-7060E System Guide

Fortinet Technologies Inc.

Page 40

Cautions and Warnings Safety

Fiabilité de la mise à la terre – Fiabilité de la mise à la terre de l'équipement monté en rack doit être

maintenue. Une attention particulière devrait être accordée aux connexions d'alimentation autres que les

connexions directes au circuit de dérivation (par exemple de l'utilisation de bandes de puissance).

Blade Carriers, Cards and Modems must be Listed Accessories or Switch, Processor, Carrier and similar blades or

cards should be UL Listed or Equivalent.

Serveur-blades, cartes et modems doivent être des accessoires listés ou commutateurs, processeurs, serveurs et

similaire blades ou cartes doivent être listé UL ou équivalent.

Refer to specific Product Model Data Sheet for Environmental Specifications (Operating Temperature, Storage

Temperature, Humidity, and Altitude).

Référez à la Fiche Technique de ce produit pour les caractéristiques environnementales (Température de

fonctionnement, température de stockage, humidité et l'altitude).

Safety

Moving parts — Hazardous moving parts. Keep away from moving fan blades.

Pièces mobiles – Pièces mobiles dangereuses. Se tenir éloigné des lames mobiles du ventilateur.

Warning: Equipment intended for installation in Restricted Access Location.

Avertissement: Le matériel est conçu pour être installé dans un endroit où l’accès est restreint.

Warning: A readily accessible disconnect device shall be incorporated in the building installation wiring.

Avertissement: Un dispositif de déconnexion facilement accessible doit être incorporé dans l'installation

électrique du bâtiment.