Page 1

FortiGate-5140B

Chassis Guide

This FortiGate-5140B Chassis Guide describes FortiGate-5140B hardware features as well as how to install a

FortiGate-5140B chassis.

The most recent versions of this and all FortiGate-5000 series documents are available from the FortiGate-5000 page of

the Fortinet Technical Documentation web site (http://docs.fortinet.com).

Access to Fortinet customer services, such as firmware updates, support, and FortiGuard services, requires product

registration. You can register your FortiGate-5140B at http://support.fortinet.com.

FortiGate-5140B Chassis Guide

01-500-156415-20151104

Page 2

Warnings and cautions

Warnings and cautions

Only trained and qualified personnel should be allowed to install or maintain

FortiGate-5000 series equipment. Read and comply with all warnings, cautions and

notices in this document.

• Risk of Explosion if Battery is replaced by an Incorrect Type. Dispose of Used

Batteries According to the Instructions.

• Turning off all power switches may not turn off all power to the FortiGate-5000 series

equipment. Some circuitry in the FortiGate-5000 series equipment may continue to

operate even though all power switches are off.

• FortiGate-5000 equipment must be protected by a readily accessible disconnect

device or circuit breaker that can be used for product power down emergencies.

• Many FortiGate-5000 components are hot swappable and can be installed or

removed while the power is on. But some of the procedures in this document may

require power to be turned off and completely disconnected. Follow all instructions in

the procedures in this document that describe disconnecting FortiGate-5000 series

equipment from power sources, telecommunications links and networks before

installing, or removing FortiGate-5000 series components, or performing other

maintenance tasks. Failure to follow the instructions in this document can result in

personal injury or equipment damage.

• Install FortiGate-5000 series chassis at the lower positions of a rack to avoid making

the rack top-heavy and unstable.

• Do not insert metal objects or tools into open chassis slots.

• Electrostatic discharge (ESD) can damage FortiGate-5000 series equipment. Only

perform the procedures described in this document from an ESD workstation. If no

such station is available, you can provide some ESD protection by wearing an

anti-static wrist strap and attaching it to an available ESD connector such as the ESD

sockets provided on FortiGate-5000 series chassis.

• Make sure all FortiGate-5000 series components have reliable grounding. Fortinet

recommends direct connections to the building ground.

• If you install a FortiGate-5000 series component in a closed or multi-unit rack

assembly, the operating ambient temperature of the rack environment may be greater

than room ambient. Make sure the operating ambient temperature does not exceed

Fortinet’s maximum rated ambient temperature.

• Installing FortiGate-5000 series equipment in a rack should be such that the amount

of airflow required for safe operation of the equipment is not compromised. See

“Cooling fans, cooling air flow, and minimum clearance” on page 25 for details.

• FortiGate-5000 series chassis should be installed by a qualified electrician.

• FortiGate-5000 series equipment shall be installed and connected to an electrical

supply source in accordance with the applicable codes and regulations for the

location in which it is installed. Particular attention shall be paid to use of correct wire

type and size to comply with the applicable codes and regulations for the installation /

location. Connection of the supply wiring to the terminal block on the equipment may

be accomplished using Listed wire compression lugs, for example, Pressure Terminal

Connector made by Ideal Industries Inc. or equivalent which is suitable for AWG-10.

Particular attention shall be given to use of the appropriate compression tool specified

by the compression lug manufacturer, if one is specified.

• FortiGate-5000 series equipment shall be located in a restricted access location

where only crafts personnel are allowed access.

Page 3

• WARNING: The intra-building ports, Gigabit Ethernet, RJ-45 10/100/1000 Base-T

Ethernet, and RS-232 Serial ports of any FortiGate, FortiSwitch, and FortiController

5000 Series Boards, including Shelf-Manager of the equipment or subassembly is

suitable for connection to intrabuilding or unexposed wiring or cabling only. The intrabuilding port(s) of the equipment or subassembly MUST NOT be metallically

connected to interfaces that connect to the OSP or its wiring. These interfaces are

designed for use as intra-building interfaces only (Type 2 or Type 4 ports as described

in GR-1089-CORE, Issue 6) and require isolation from the exposed OSP cabling. The

addition of Primary Protectors is not sufficient protection in order to connect these

interfaces metallically to OSP wiring.

• FortiGate-5000 series chassis shall be installed and connected to the common

bonding network.

• FortiGate-5000 series chassis are suitable for installation in the Central Office and

NEC.

• The battery returns of FortiGate-5000 series chassis shall be connected as DC-I.

• All bare grounding connection points to FortiGate-5000 series chassis shall be

cleaned and coated with an anti-oxidant solution before connections are made.

• All surfaces on FortiGate-5000 series chassis that are un-plated shall be brought to a

bright finish and treated with and anti-oxidant solution before connections is made.

• All non-conductive surfaces on FortiGate-5000 series chassis shall be removed from

all threads and connection points to ensure electrical continuity.

• Unambiguous reference to service documentation for instructions for replacement of

fuses replaceable only by service personnel.

• The FortiGate-5140B chassis is capable of operating -40 VDC to -60 VDC at a

maximum current level 100 A.

• Caution: Double pole fusing.

Page 4

Warnings and cautions

Page 5

FortiGate-5140B

Contents

Warnings and cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

FortiGate-5140B chassis 9

Chassis Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

FortiGate-5140B front panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

FortiGate-5140B chassis back panel. . . . . . . . . . . . . . . . . . . . . . . . . . 12

Chassis hardware information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Shipping components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Supported FortiGate, FortiSwitch and FortiController ATCA boards . . . . . . . 13

Power requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Physical description of the FortiGate-5140B chassis . . . . . . . . . . . . . . . 14

FortiGate-5140B shelf managers. . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Using the shelf manager CLI . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Shelf Manager fan and power control . . . . . . . . . . . . . . . . . . . . . . . 16

FortiGate-5140B shelf alarm module . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Shelf alarm panel telco alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Air filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Cooling fans, cooling air flow, and minimum clearance . . . . . . . . . . . . . . . . 19

Power connection and configuration 21

FortiGate-5140B chassis power level requirements . . . . . . . . . . . . . . . . . . 21

Connecting the FortiGate-5140B chassis to DC power and ground . . . . . . . . . . 22

Connecting a FortiGate-5140B PEM to DC power. . . . . . . . . . . . . . . . . . . 23

Connecting the FortiGate-5140B chassis to ground . . . . . . . . . . . . . . . . . . 25

Supplying power using the FortiGate-5053B power supply shelf and PSU-5000B power

supplies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Selecting the power supplies and power supply shelves that you need for your

FortiGate-5140B chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Connecting a FortiGate-5140B chassis to the FortiGate-5053B power supply shelf .

28

Turning on FortiGate-5140B chassis power . . . . . . . . . . . . . . . . . . . . . . 30

FortiGate-5140B hardware procedures 31

Mounting the FortiGate-5140B chassis . . . . . . . . . . . . . . . . . . . . . . . . 31

Air flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Inserting 5000 series boards and RTM modules into a FortiGate-5140B chassis . . . 32

Using FortiController-5103B boards for session-aware load balancing . . . . . . . . 32

Using FortiSwitch-5003B boards for backplane communication . . . . . . . . . . . 33

Using FortiSwitch-5203B boards for content clustering . . . . . . . . . . . . . . . . 33

FortiGate-5140B Chassis Guide

01-500-156415-20151104 5

http://docs.fortinet.com/

Page 6

Contents

Using the shelf manager CLI 34

Connecting to the shelf manager CLI using a serial port and setting up passwords . 35

Connecting to the shelf manager CLI . . . . . . . . . . . . . . . . . . . . . . . 35

Changing the shelf manager root account password . . . . . . . . . . . . . . . 36

Resetting a lost shelf manager password . . . . . . . . . . . . . . . . . . . . . 36

The shelf manager command line interface agent (CLIA) . . . . . . . . . . . . . 37

Using CLIA interactive mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

IPMB addresses, logical and physical slot numbers, and FRU ids . . . . . . . . . . 38

Basic shelf manager CLI Commands . . . . . . . . . . . . . . . . . . . . . . . . . 39

Change IP address of the primary Shelf Manager . . . . . . . . . . . . . . . . . 39

Display the shelf manager firmware version . . . . . . . . . . . . . . . . . . . . 39

List all FRUs in the chassis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

List all sensors on a FRU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

List only sensors that are outside of established thresholds . . . . . . . . . . . 39

Display sensor data for a FRU . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Display the FRU information for a FRU . . . . . . . . . . . . . . . . . . . . . . 40

Change the speed for a fan tray . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Display the contents of the system event log (sel) . . . . . . . . . . . . . . . . . 40

Clear the system event log (sel) . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Changing the shelf manager IP address and default gateway . . . . . . . . . . . . . 40

Sensor types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Shelf manager CLI commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

activate/deactivate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

clia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

exit/quit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

fru . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

fruinfo. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

getlanconfig . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

getthreshold/threshold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

minfanlevel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

sel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

sensordata . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

setthreshold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

shmstatus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

showunhealthy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

switchover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

terminate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

user. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Generating SNMP traps for shelf manager system events. . . . . . . . . . . . . . . 63

SNMP trap details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

FortiGate-5140B Chassis Guide

6 01-500-156415-20151104

http://docs.fortinet.com/

Page 7

Contents

Removing and inserting a fan tray . . . . . . . . . . . . . . . . . . . . . . . . . 69

Setting up SNMP polling for the shelf manager . . . . . . . . . . . . . . . . . . . . 70

Using the shelf manager system event log (SEL). . . . . . . . . . . . . . . . . . . . 71

Before you begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Chassis Design Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Alarm LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Reading the SEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Clearing SEL logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Example IPMC log output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Example FRU log output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Example sensor log output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Sample sections of SEL Output . . . . . . . . . . . . . . . . . . . . . . . . . . 85

For more information 87

Training Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Technical Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Comments on Fortinet technical documentation . . . . . . . . . . . . . . . . . . . 87

Customer service and support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Fortinet products End User License Agreement . . . . . . . . . . . . . . . . . . . . 87

FortiGate-5140B Chassis Guide

01-500-156415-20151104 7

http://docs.fortinet.com/

Page 8

Contents

FortiGate-5140B Chassis Guide

8 01-500-156415-20151104

http://docs.fortinet.com/

Page 9

FortiGate-5140B

FortiGate-5140B chassis

This chapter describes the FortiGate-5140B chassis and includes the following sections:

• Chassis Overview

• FortiGate-5140B front panel

• FortiGate-5140B chassis back panel

• Chassis hardware information

• FortiGate-5140B shelf managers

• FortiGate-5140B shelf alarm module

• Air filter

• Cooling fans, cooling air flow, and minimum clearance

Chassis Overview

You can install up to 14 FortiGate-5000 series boards in the 14 slots of the

FortiGate-5140B ATCA chassis. The FortiGate-5140B is a 13U 19-inch rackmount ATCA

chassis that contains two redundant hot swappable DC power entry Modules (PEMs).

The PEMs connect to -48V DC power and supply 300 W to each chassis slot. The

FortiGate-5140B chassis also includes four hot swappable front pluggable cooling fan

trays that provide 300W of cooling power per slot and a front replaceable air filter with

redundant pressure sensor. If all 14 slots contain FortiGate-5001B boards, the

FortiGate-5140B chassis provides a total of 112 FortiGate 10-gigabit ethernet interfaces.

If all 14 slots contain FortiGate-5101C boards, the FortiGate-5140B chassis provides a

total of 56 FortiGate 10-gigabit ethernet interfaces. If all 14 slots contain FortiGate-5001C

boards, the FortiGate-5140B chassis provides a total of 28 FortiGate 10-gigabit ethernet

interfaces. If all 14 slots contain FortiGate-5001D boards, the FortiGate-5140B chassis

provides a total of 28 40-gigabit ethernet interfaces.

You can also install FortiSwitch-5003B boards in FortiGate-5140B chassis slots 1 and 2

to provide base backplane communications using the dual star 1-gigabit base backplane

interface. Base backplane communications can be used for HA heartbeat and other

control communications and for data communications. FortiSwitch-5003B boards also

provide fabric backplane communication using the FortiGate-5140B fabric backplane

channels. The fabric backplane is a dual-star 10-Gigabit switch fabric.

For both base and fabric backplane communications you can install a single

FortiSwitch-5003B board in slot 1 and add a second board to slot 2 for redundancy.

These boards provide backplane switching for data communication between FortiGate5000 series boards and for HA clustering.

The FortiGate-5140B chassis supports the following load balancing solutions:

• FortiController-5103B boards can be installed in slots 1 and 2 to provide

session-aware load balancing (SLBC) for FortiGate-5001B, 5101C, or 5001C boards

in the chassis.

• FortiSwitch-5003B boards can be installed in slots 1 and 2 to form a Enhanced Load

Balancing Cluster (ELBC) to load balance traffic to multiple FortiGate-5001B, 5101C

or 5001C boards installed in the chassis

• FortiSwitch-5203B boards can be installed in slots 1 and 2 to support content

clustering to load balance traffic to multiple FortiGate-5001B boards installed in the

chassis.

FortiGate-5140B Chassis Guide

01-500-156415-20151104 9

http://docs.fortinet.com/

Page 10

FortiGate-5140B front panel FortiGate-5140B chassis

FortiGate-5001B

boards

slots 4, 6, 8, 10,

12, and 14

Cooling

fans

(behind the

cooling fan

bay cover)

FortiGate-5001B

boards

slots 3, 5, 7, 9,

11, and 13

FortiSwitch-5003B

boards

slots 1 and 2

ES D

socket

Slot

numbers

HandleHandle

Air lter

(behind the

air intake

bezel)

• FortiSwitch-5902D boards can be installed in slots 1 and 2 to support content

clustering to load balance traffic to multiple FortiGate-5001D boards installed in the

chassis.

Finally, you can add other Fortinet 5000 series boards to a FortiGate-5140B chassis,

including the 5000 series FortiMail and FortiManager boards.

Some of the boards installed in a FortiGate-5140B chassis can be operating in a

FortiGate HA cluster and some can be operating as standalone FortiGate units. You can

also operate multiple HA clusters and standalone FortiGate units in a single

FortiGate-5140B chassis.

The FortiGate-5140B chassis requires -48V DC power. If DC power is not available you

can install a FortiGate-5053B power supply shelf and PSU-5000B power supplies

(purchased separately).

FortiGate-5140B front panel

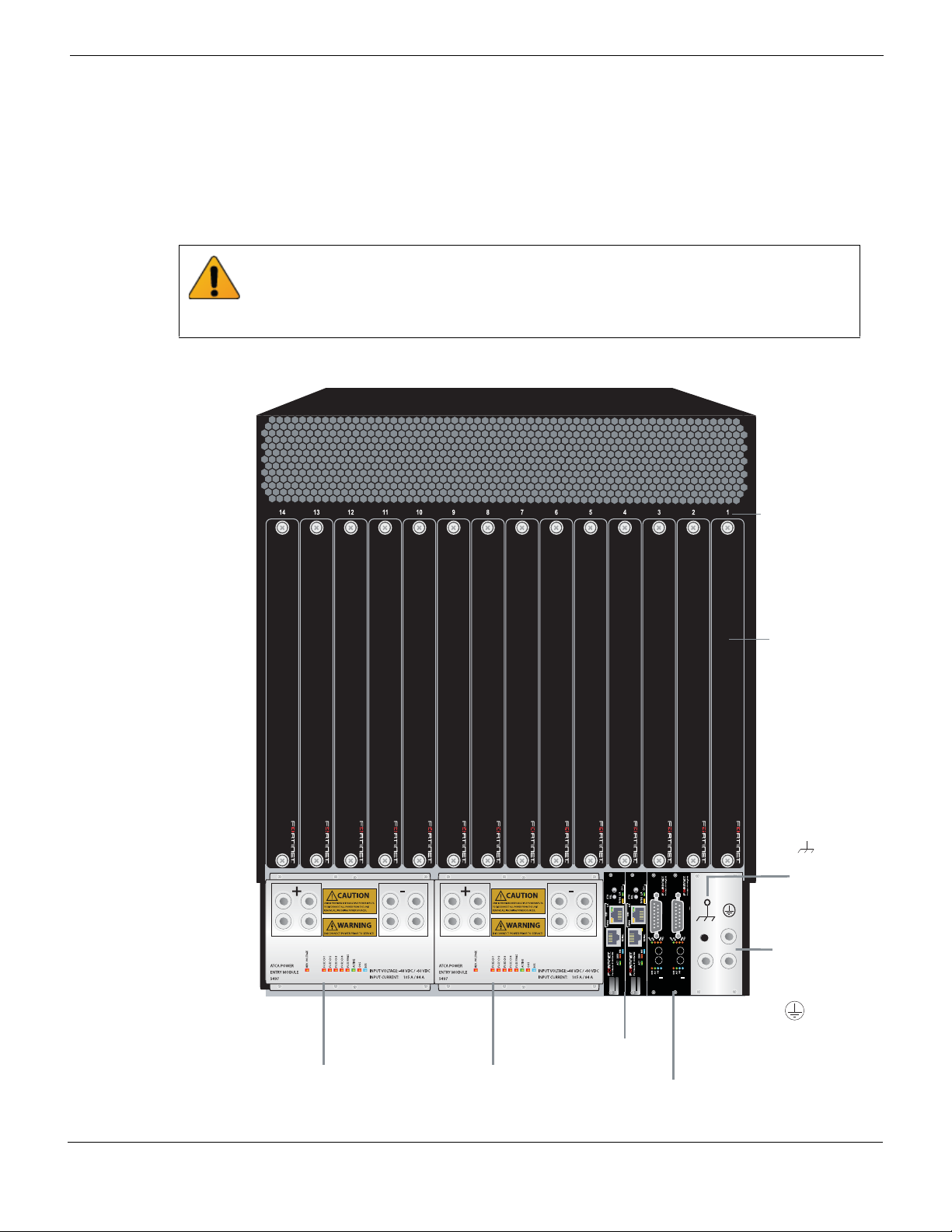

Figure 1 shows the front of a FortiGate-5140B chassis. Two FortiSwitch-5003B boards

are installed in slots 1 and 2 and 12 FortiGate-5001B boards are installed in slots 3 to 14.

Figure 1: FortiGate-5140B front panel with FortiGate-5001B and FortiSwitch-5003B

boards installed (cable tray not shown)

The following components are visible on the front of the FortiGate-5140B chassis:

FortiGate-5140B Chassis Guide

10 01-500-156415-20151104

http://docs.fortinet.com/

Page 11

FortiGate-5140B chassis FortiGate-5140B front panel

• The location of the four hot-swappable front replaceable cooling fans (behind the

cooling fan bay cover)

• The location of the front-replaceable air filter (behind the air intake bezel).

• The Electrostatic discharge (ESD) socket, used for connecting an ESD wrist band

when working with the chassis

• Chassis handles.

Do not operate the FortiGate-5140B chassis with open slots on the front panel. For

optimum cooling performance and safety, the chassis slots must contain a

FortiGate-5000 series board or an air baffle slot filler. For the same reason, all cooling

fan trays and the air filter should be installed while operating the chassis. As well both

PEMs must be installed in the back of the chassis.

Figure 2: FortiGate-5140B chassis back panel (cable tray not shown)

RTM

slot numbers

RTM

air bafe

slot covers

ES D

socket

Chassis

ground

connector

(green)

RTN

(red)

-48/-60 VDC

nom (black)

RTN

(red)

-48/-60 VDC

nom (black)

Shelf

Power

Entry Module B

Power

Entry Module A

Managers

Shelf Alarm

Modules

FortiGate-5140B Chassis Guide

01-500-156415-20151104 11

http://docs.fortinet.com/

Page 12

FortiGate-5140B chassis back panel FortiGate-5140B chassis

FortiGate-5140B chassis back panel

Figure 2 shows the back of a FortiGate-5140B chassis.

The FortiGate-5140B chassis back panel includes two redundant -48V to - 60 VDC

power entry modules (PEMs). Fortinet ships the FortiGate-5140B chassis with both

installed. The PEMs provide redundant DC power connections for the FortiGate-5140B

chassis and distribute DC power to all chassis slots and components.

If you require redundant power you should connect both PEMs to DC power. If redundant

power is not required, you can connect one of them. Each PEM includes two power

terminals, one for connecting to -48V/-60 VDC (labelled -) and one for connecting to RTN

(labelled +). To connect power to the PEMs see, “Power connection and configuration”

on page 21.

The back panel also contains 14 RTM slots numbered to correspond to the front panel

slots. The RTM slots are available for FortiGate-5000 RTM modules. When the chassis is

shipped, these slots are covered by RTM air baffle slot covers.

The FortiGate-5140B Shelf Managers and the Shelf Alarm Modules (SAMs) are also

visible. The factory installed primary shelf manager provides power allocation, cooling,

alarms, and shelf status for the FortiGate-5140B chassis. The factory installed primary

and secondary Shelf Alarm Modules display alarms and provide telco alarm interfaces.

You can also install a secondary shelf manager as a backup for the primary one. For more

information about these components, see “FortiGate-5140B shelf managers” on page 14

and “FortiGate-5140B shelf alarm module” on page 16.

The back panel includes the FortiGate-5140B chassis ground connector which must be

connected to ground. The chassis also includes an ESD socket on the back panel.

Chassis hardware information

This section introduces FortiGate-5140B hardware components and accessories

including power requirements and FortiGate-5000 series boards that can be installed in

the chassis.

Shipping components

The FortiGate-5140B chassis ships pre-assembled with the following components (see

Figure 1 on page 10 and Figure 2 on page 11 for the location of the components in the

chassis):

• The 13U FortiGate-5140B chassis

• One shelf manager installed in the back of the chassis

• Two shelf alarm modules (SAMs) installed in the back of the chassis

• Two Power Entry Modules (PEMs) installed in the back of the chassis

• One air filter installed behind the air intake bezel at the bottom of the chassis

• Four cooling fans installed in the fan bays at the top of the chassis

• 13 front panel air baffle slot covers installed in the front panel slots

• 14 RTM air baffle slot covers installed in the RTM slots

• Four 3-ft. power cables with AWG-6 stranded wires and double-hole lugs: Black for

-48VDC and red for RTN. These cables should only be used to connect the

FortiGate-5140B PEMs to a FortiGate-5053B power convertor shelf if purchased with

your FortiGate-5140B chassis

FortiGate-5140B Chassis Guide

12 01-500-156415-20151104

http://docs.fortinet.com/

Page 13

FortiGate-5140B chassis Chassis hardware information

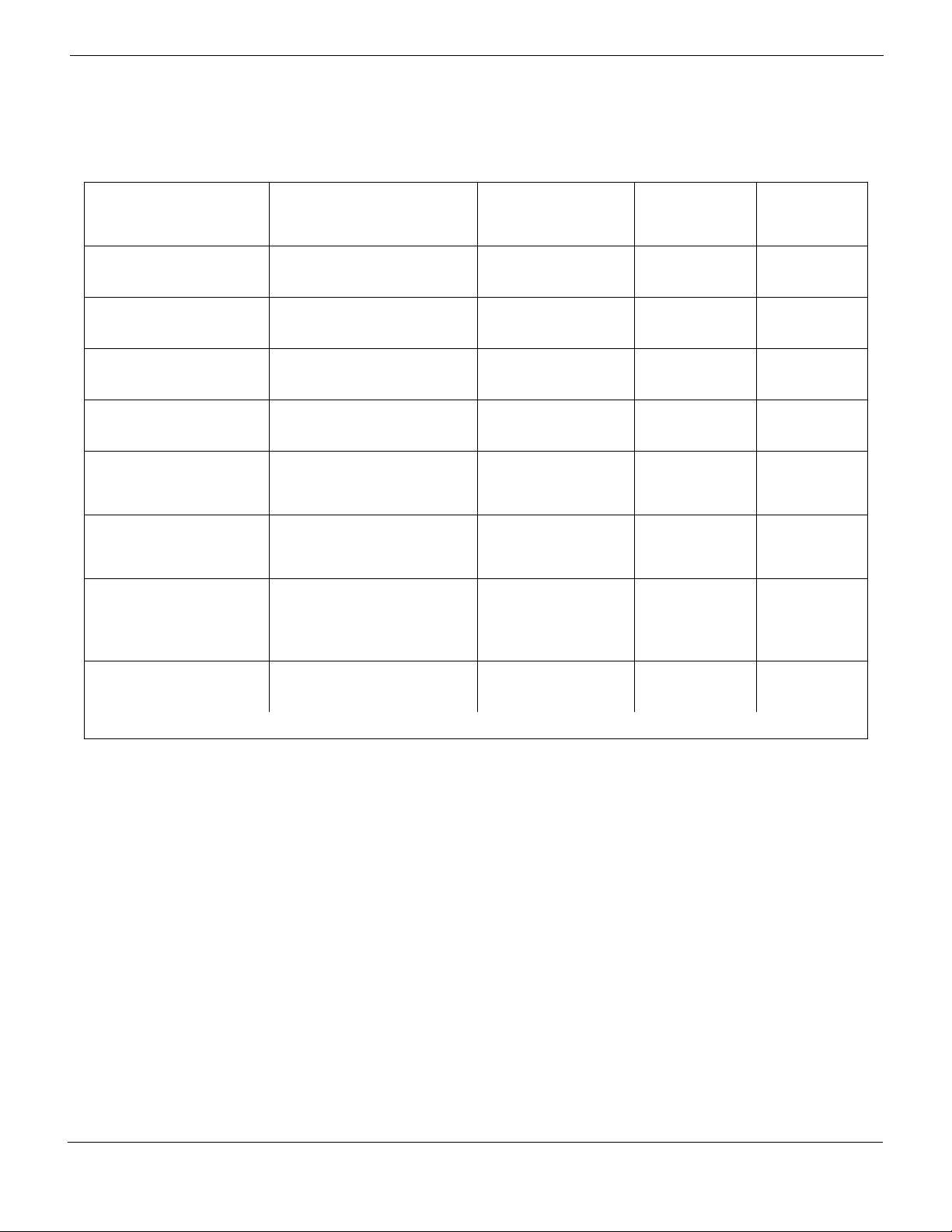

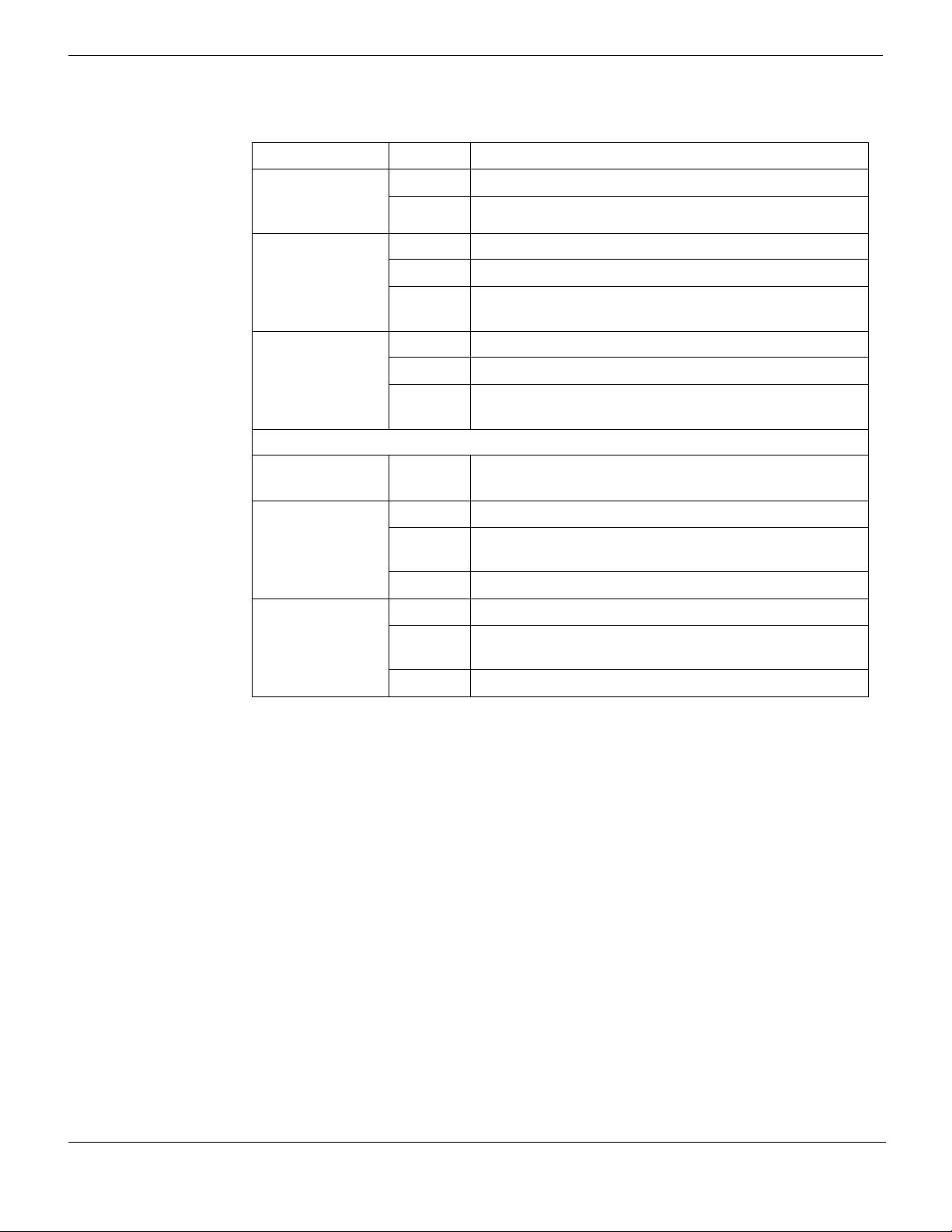

Supported FortiGate, FortiSwitch and FortiController ATCA boards

You can install the following FortiGate-5000 series boards in a FortiGate-5140B chassis

to provide security services. This includes the following:

ATCA board Interfaces Function

FortiGate-5001B Front Panel: 10 Gbps

Fabric: 10 Gbps

FortiGate-5001C Front Panel: 10 Gbps

Fabric: 10 Gbps

FortiGate-5101C Front Panel: 10 Gbps

Fabric: 10 Gbps

FortiGate-5001D Front Panel: 10 Gbps

Fabric: 40 Gbps

FortiSwitch-5203B Front Panel: 10 Gbps

Fabric: 10 Gbps

FortiController-5902B Front Panel: 10 Gbps

Fabric: 10 Gbps

FortiSwitch-5003B Front Panel: 10 Gbps

Fabric: 10 Gbps

FortiController-5103B Front Panel: 10 Gbps

Fabric: 10 Gbps

*Approximate values, see product datasheets for actual numbers.

FortiOS network

security

FortiOS network

security

FortiOS network

security

FortiOS network

security

Content clustering

with

FortiGate-5001Bs

Content clustering

with

FortiGate-5001Ds

Backplane switching,

FGCP HA, and

extended load

balancing (ELBC)

Session-aware load

balancing

Power Used

(WDC)*

Max: 225

Ave: 187

Max: 225

Ave: 187

Max: 226

Ave: 189

Max: 225

Ave: 187

Max: 250

Ave: 210

Max: 270

Ave: 223

Max: 180

Ave: 150

Max: 255

Ave: 213

Heat

Dissipation

(BTU/hr)*

768

768

774

768

853

919

614

754

The following older Fortinet ATCA boards can also be installed in the FortiGate-5140B

chassis:

• FortiGate-5001A

• FortiCarrier-5001A

• FortiGate-5005FA2

• FortiGate-5001FA2

• FortiGate-5001

• FortiGate RTM-XB2

• FortiGate RTM-XD2

• FortiSwitch-5003A

• FortiSwitch-5003

• FortiMail-5001A and 5002

• FortiManager-5001A

Power requirements

The FortiGate-5140B chassis is designed to be installed in a data center or similar

location that has available -48VDC power fed from a 100A listed circuit breaker (also

called battery power or main DC power). Fortinet expects that most FortiGate-5140B

customers will be installing their chassis in a data center or similar location that is already

equipped with a -48VDC power system fed from a 100A listed circuit breaker that

provides power to existing networking or telecom equipment. The FortiGate-5140B

chassis is designed to be connected directly to this DC power system.

FortiGate-5140B Chassis Guide

01-500-156415-20151104 13

http://docs.fortinet.com/

Page 14

FortiGate-5140B shelf managers FortiGate-5140B chassis

If DC power is not available you can use one or more FortiGate-5053B power converter

shelves equipped with PSU-5000B power supplies to convert AC to DC to supply DC

power to the FortiGate-5140B chassis from an AC source.

Physical description of the FortiGate-5140B chassis

The FortiGate-5140B chassis is a 13U chassis that can be installed in a standard 19-inch

rack. Ta bl e 1 describes the physical characteristics of the FortiGate-5140B chassis.

Table 1: FortiGate-5140B chassis physical description

Dimensions 22.63 x 19 x 22.6 in. (57.5 x 48.3 x 57.4 cm) (H x W x D)

Shipping weight completely

assembled with packaging

Chassis weight completely

assembled with shelf

manager and air baffles (13

front and 14 RTM)

PEM DC terminal torque No more than 3.8 Nm (33.62 lbf.in)

Operating environment

110 lbs (50 kg)

84 lbs (38 kg)

Temperature (long term): 41 to 104°F (+5 to 40°C)

Temperature (short term): 23 to 131°F (-5 to 45°C)

Power consumption

Power input 2x redundant -48 Vdc/-60Vdc, 100A-84A per PEM

Overcurrent Protection

Cooling Capacity

Protected Earth Test EN60950-1, test current 25 A, resistance <100 mOhm

Hipot Test EN60950-1, 1000 V

FortiGate-5140B shelf managers

The FortiGate-5140B chassis includes one or two redundant hot-swappable shelf

managers, located in the dedicated shelf manager slots at the bottom right side of the

back panel. The primary shelf manager is installed on the left the secondary shelf

manager (if present) is installed on the right. The secondary shelf manager is optional.

Relative humidity: 5 to 85% (Non-condensing)

Maximum: 530 W (Power consumed by an empty

chassis with four fans, one shelf manager, two shelf

alarm modules and two PEMs installed and operating

with the fans running at full speed.)

Each PEM includes 5 power channels. Each channel

includes its own 100 A fuse.

Front Boards: 300 W per board

RTM: 35 W per module

FortiGate-5140B Chassis Guide

14 01-500-156415-20151104

http://docs.fortinet.com/

Page 15

FortiGate-5140B chassis FortiGate-5140B shelf managers

Retention

Screw

Ethernet CH0 network

activity LEDs

Ethernet CH1 network

activity LEDs

RS-232

Serial

CH0 and 1

100base-T

Ethernet

Active (Green)Hot Swap

Actuator

Ethernet

Channel Selector

Retention

Screw

Out of Service (Red)

Hot Swap (Blue)

The shelf managers support redundant operation with automatic switchover. If both shelf

managers are operating normally, one acts as the active shelf manager and the other as

the standby. Usually the primary shelf manager would be the active shelf manager and

the secondary shelf manager would be the standby. The shelf managers monitor each

other and either can trigger a switchover if necessary. The active shelf manager performs

all shelf manager functions. If the active shelf manager fails or is removed, the standby

shelf manager takes over all shelf manager functions. If one shelf manager fails or is

removed the other will operate independently and the chassis will continue to function

normally.

The shelf managers control chassis power allocation, monitor chassis operating

parameters, monitor and control chassis cooling, and can signal alarms if the chassis

encounters problems. All FortiGate-5000 boards installed in the chassis communicate

with the shelf managers.

The shelf managers are factory installed. In most cases users do not have to install or

configure the shelf managers.

Each shelf manager has two ethernet interfaces (CH0 and CH1). Both channels connect

to the chassis backplane.

• When the Ethernet channel selector button is pushed in (recessed) CH0 connects to

the backplane.

• When the Ethernet channel selector button is pulled out you can use the front panel

Ethernet connector to connect to CH0.

Each shelf manager also has an RS-232 serial port for connecting to the shelf manager

console CLI.

The shelf managers detect alarm conditions and communicate alarm signals to the

FortiGate-5140B shelf alarm module.

The shelf managers are hot swappable. You remove a shelf manager by loosening the

retention screw that positions the hot swap actuator. This disengages the hot swap

switch and puts the shelf manager into hot swap mode. The hot swap LED starts blinking

blue. When the hot swap LED turns solid blue you can completely loosen both retention

screws and remove the shelf manager from the chassis.

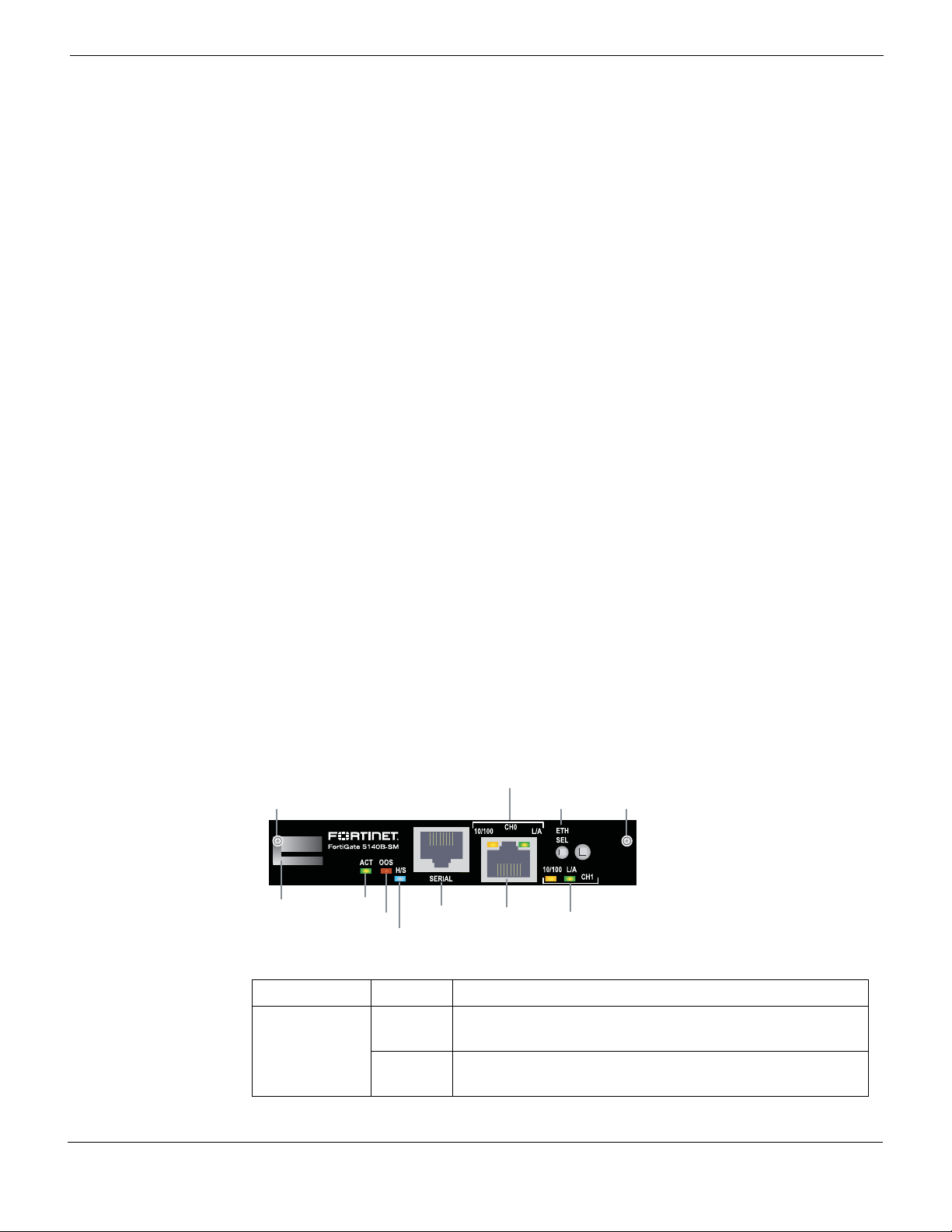

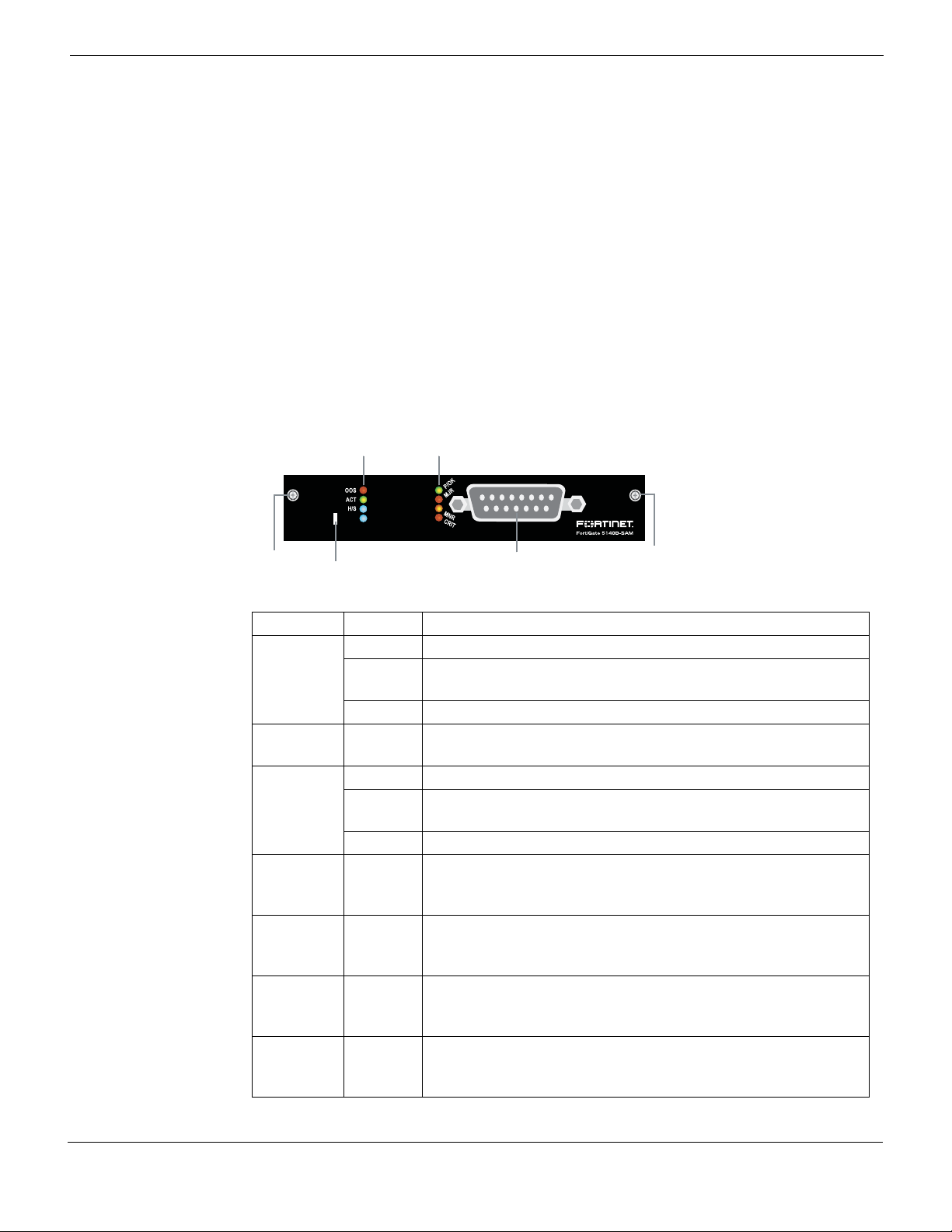

Figure 3: FortiGate-5140B shelf manager front panel

Table 2: FortiGate-5140B shelf manager LEDs

LED State Description

Solid

Indicates that this is the active shelf manager.

Green

FortiGate-5140B Chassis Guide

01-500-156415-20151104 15

http://docs.fortinet.com/

ACT (Active)

Blinking

Green

Indicates that this is the standby shelf manager.

Page 16

FortiGate-5140B shelf alarm module FortiGate-5140B chassis

Table 2: FortiGate-5140B shelf manager LEDs

LED State Description

OOS (Out of

Service)

H/S (Hot

Swap)

10/100 (CH0

and CH1)

L/A

(Link/Activity

for CH0 and

CH1)

Off Normal Operation.

Red Shelf manager software reboot or other failure.

Off Normal operation.

Blinking

Blue

Blue The shelf manager can be removed from the chassis.

Amber 10/100 Mbit link for Ethernet CH0 or CH1.

Green Link/activity for Ethernet CH0 or CH1.

Using the shelf manager CLI

You can use the shelf manager command line interface (CLI) to communicate with the

intelligent management controllers of the chassis, with boards in the chassis, and with

the shelf manager itself. The CLI is an IPMI-based set of commands that can be

accessed directly or through a higher-level management application or a script. Using the

CLI, you can access information about the current state of the chassis including current

board population, current sensor values, threshold settings, recent events, and overall

chassis health.

To get started using the shelf manager CLI, see “Using the shelf manager CLI” on

page 34.

The shelf manager is shutting down in preparation for

being removed from the chassis.

Shelf Manager fan and power control

The FortiGate-5140B shelf managers monitor the internal temperature of the

FortiGate-5140B chassis and adjust the operating speed of the cooling fans as required.

When the chassis is first powered on all cooling fans run at full speed. Once the shelf

manager is up and running, the shelf manager reduces cooling fan speeds to maintain an

optimum temperature in the chassis. If shelf managers are not installed or not operating

correctly the FortiGate-5140B chassis cooling fans always operate at full speed.

FortiGate-5140B shelf alarm module

The FortiGate-5140B chassis includes two redundant hot-swappable shelf alarm

modules (SAMs) each of which provide LED indicators of FortiGate-5140B alarms, a telco

alarm connector, and an alarm LED reset buttons. The LED alarm indicators include

critical, major, and minor alarms.

FortiGate-5140B Chassis Guide

16 01-500-156415-20151104

http://docs.fortinet.com/

Page 17

FortiGate-5140B chassis FortiGate-5140B shelf alarm module

Retention

Screw

Reset

Retention

Screw

Telco Alarm

Interface

Out of Service (Red)

Active (Green)

Hot Swap (Blue)

Power OK (Green)

Major Alarm (Red)

Minor Alarm (Amber)

Critical Alarm (Red)

The shelf alarm modules support redundant operation with automatic switchover. If both

shelf alarm modules are operating normally, one acts as the active shelf alarm module

and the other as the standby. Usually the primary shelf alarm module would be active and

the secondary module would be the standby. The shelf alarm modules monitor each

other and either can trigger a switchover if necessary. By default the shelf alarm module

on the left is the active one. The active shelf alarm module performs all shelf alarm

functions. If the active shelf alarm module fails or is removed, the standby shelf alarm

module takes over all functions.

The Telco Alarm Interface is a standard DB-15 male Telco Form-c connector. The external

dry relay Telco alarm interface (48VDC) provides Telco form-c relay connections for minor,

major and critical power faults. The cable required to connect to the alarm interface is not

supplied by Fortinet. To monitor alarms you should connect to the telco alarm interface of

the active shelf alarm panel, which by default is the one on the left.

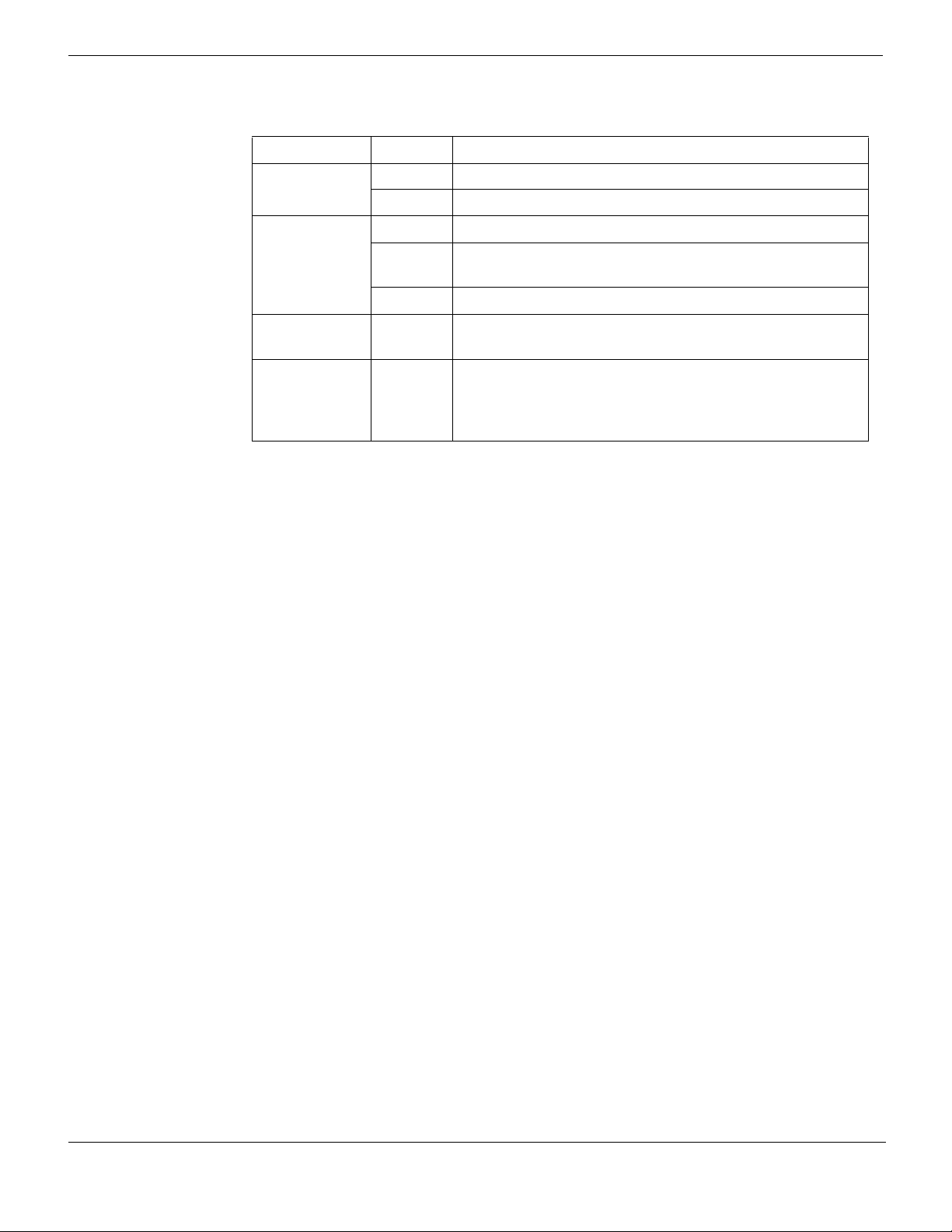

Figure 4: FortiGate-5140B shelf alarm module front panel

Table 3: FortiGate-5140B shelf alarm module LEDs

LED State Description

Off Normal operation.

OOS (Out

of Service)

Blinking

Red

Lost connection to the shelf manager or no IPBM bus.

Red Incorrect hardware address or FRU data corruption.

ACT

Green Normal operation.

(Active)

Off Normal operation.

H/S (Hot

Swap)

Blinking

Blue

The shelf manager is shutting down in preparation for being

removed from the chassis.

Blue The shelf alarm module can be removed from the chassis.

POK

Green Input power to the chassis is within limits.

(Power

OK)

MJR

Red Major alarm detected in chassis.

(Major

Alarm)

MNR

Amber Minor alarm detected in chassis.

(Minor

Alarm)

CRIT

Red Critical alarm detected in chassis.

(Major

Alarm)

FortiGate-5140B Chassis Guide

01-500-156415-20151104 17

http://docs.fortinet.com/

Page 18

FortiGate-5140B shelf alarm module FortiGate-5140B chassis

Eth port0

Eth port1

Eth port0

Eth port1

ShMC port1

ShMC port2

ShMC port1

ShMC port2

Base Hub A

ShMC

IPMC IPMC IPMC IPMC

ShMC

Shelf

Manager

(active)

Shelf

Manager

(backup)

Base Hub B ATCA board

Redundant IPMB-0 on Backplane

ATCA board

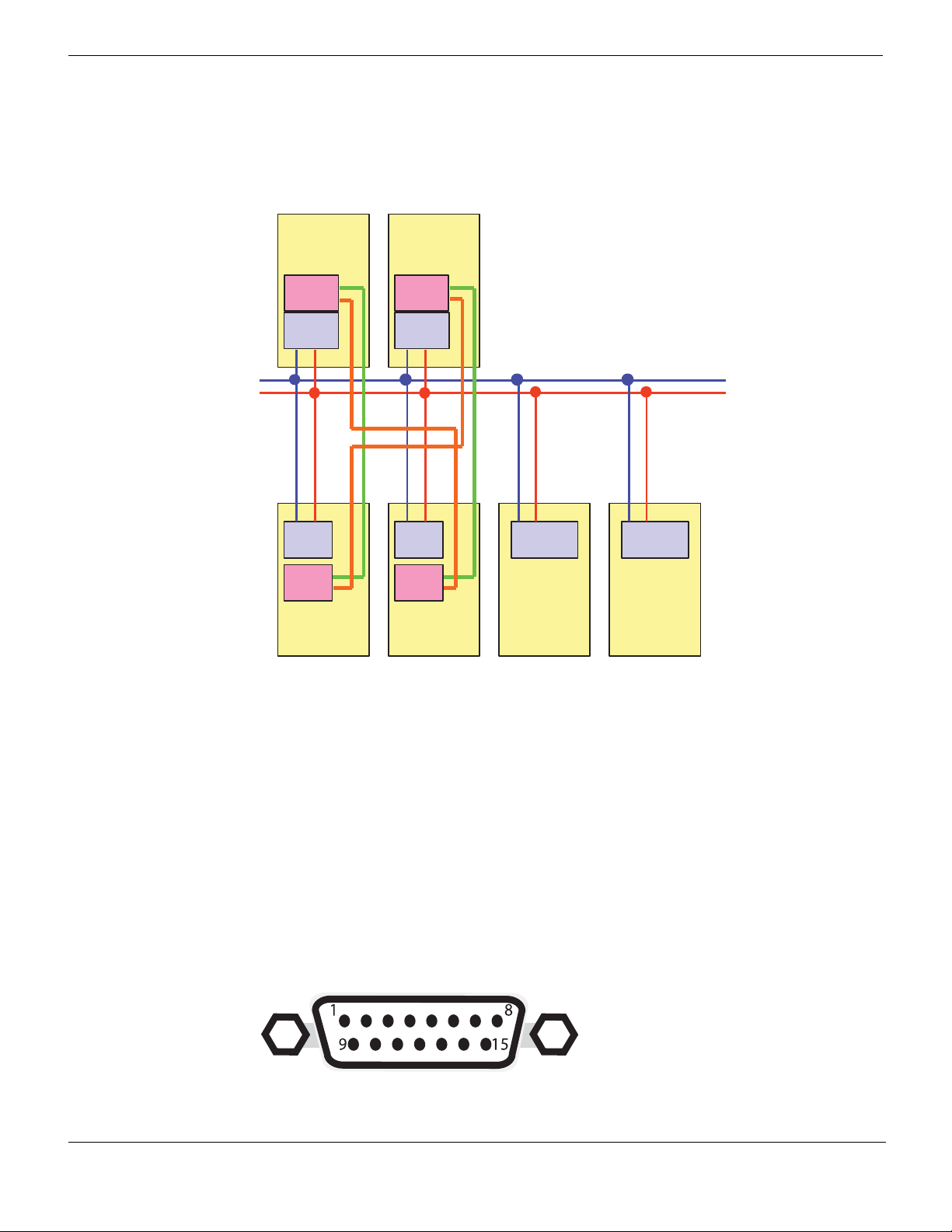

Figure 5 shows the connections between the primary and secondary shelf managers and

the shelf alarm panel.

Figure 5: Ethernet connections between shelf managers and the base backplane

interfaces

Shelf alarm panel telco alarms

The shelf alarm panel telco alarm interface relay circuits are capable of carrying 60 VDC

or 1 A with a max. rating of 30 VA. The shelf alarm panel accepts timed pulse inputs for

clearing minor and major alarm states. Reset is accomplished by asserting a voltage

18 01-500-156415-20151104

differential from 3.3 V to 48 V for between 200 and 300 ms. The acceptance voltage

range is from 0 to 48 VDC continuous (handles up to 60 VDC at a 50% duty cycle). The

current drawn by a reset input does not exceed 12 mA.

The alarm LED reset button activates the alarm cutoff (ACO) state for major, minor, and

user-defined alarms. You cannot reset critical alarms with the alarm LED reset button.

When the ACO state is activated, active alarm LEDs blink and all of the alarm relays are

deactivated. The alarm reset button activates the ACO state but does not clear the alarm

completely.

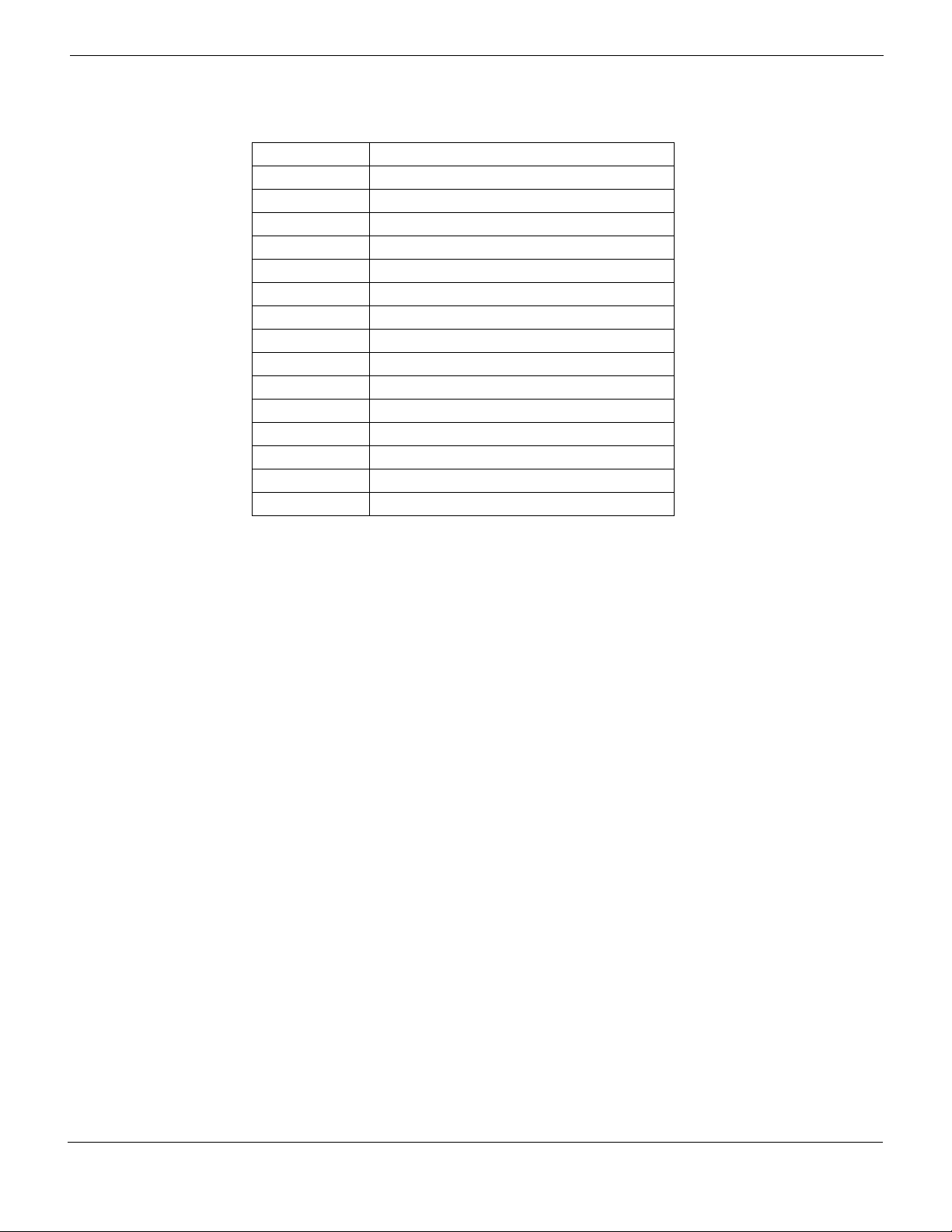

Figure 6: The telco alarm connector (DB-15 male)

FortiGate-5140B Chassis Guide

http://docs.fortinet.com/

Page 19

FortiGate-5140B chassis Air filter

Table 4: Telco alarm connector pin assignment

Pin Description

1 MinorReset+

2 MinorReset-

3MajorReset+

4MajorReset-

5 CriticalAlarm - NO

6Critical Alarm NC

7Critical Alarm COM

8 Minor Alarm NO

9 Minor Alarm NCt

10 Minor Alarm COM

11 Major Alarm NO

12 Major Alarm NC

13 Major Alarm COM

14 Power NO

15 Power COM

Air filter

The FortiGate-5140B chassis includes a front replaceable air filter that removes dust from

intake air and provides static pressure to achieve uniform airflow. The filter must be

installed for the chassis to operate normally. If the air filter is not locked into place the

redundant air filter presence sensors cause an alarm.

Air filters should be inspected regularly. If dirty or damaged, the filter should be disposed

of and replaced. The air filter can be fragile and should be handled carefully.

To service the air filter you must remove the air intake bezel at the bottom of the front of

the chassis. See Figure 1 on page 10 for the location of the air intake bezel and air filter.

The bezel is held in place by four torq screws which must be loosened before the bezel

can be removed. The air filter can be removed using the lower flange as a handle. Gently

push the filter and tilt it down to remove it.

Care should be taken when inserting an new air filter to prevent damage to the sensors.

To insert a new filter, slide it along the guide rails at each side of the shelf until the filter

contacts springs at the back of the chassis. Then tilt the filter up until it locks into place

under the card cage. Pull the filter forward to make sure it is locked into place.

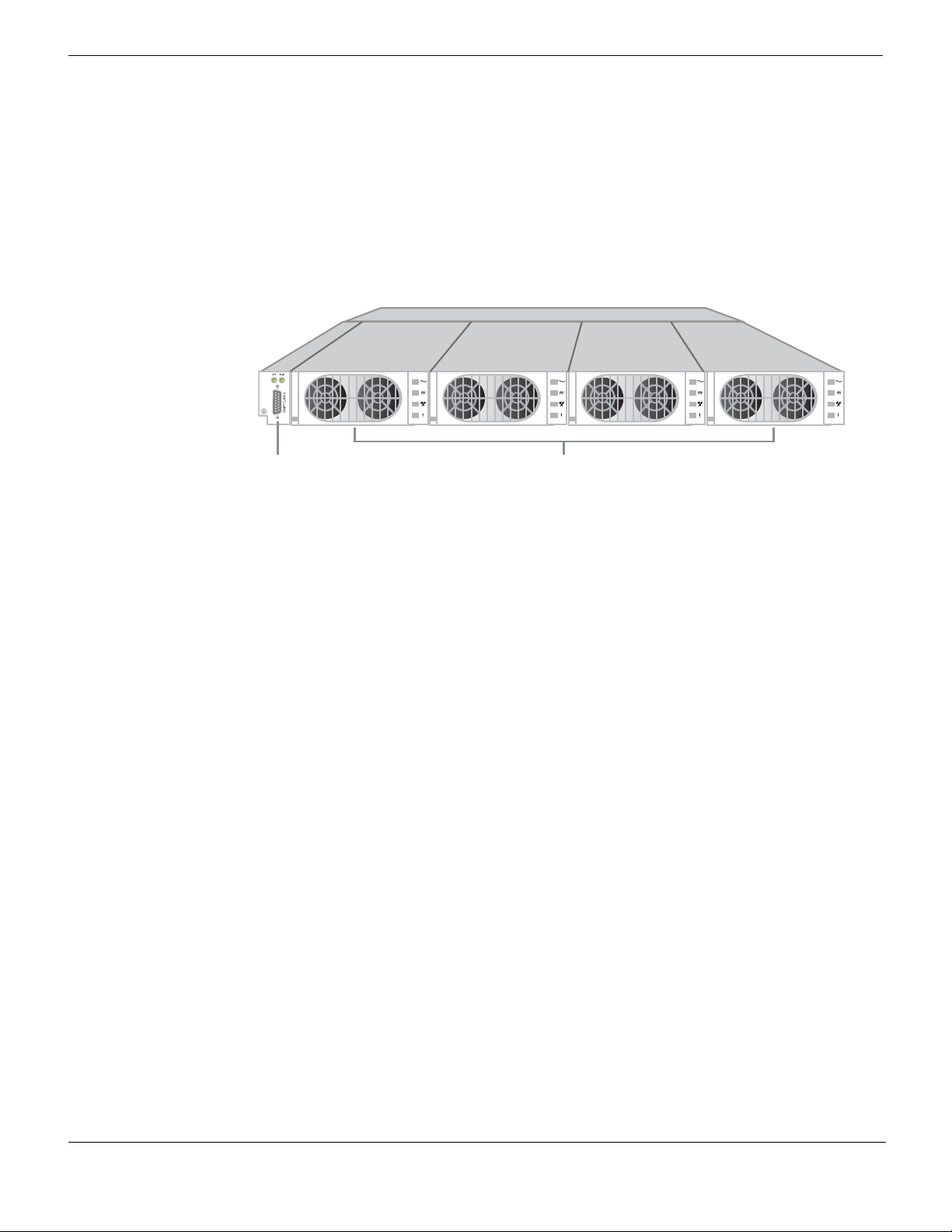

Cooling fans, cooling air flow, and minimum clearance

The FortiGate-5140B chassis contains four identical hot-swappable cooling fans installed

in the fan cabinet at the top of the chassis. See Figure 1 on page 10 for the location of the

cooling fans. Two fans are installed at the top of the cabinet and two at the bottom. The

fans at the bottom of the cabinet are not directly under the fans at the top, but are located

further towards the back of the cabinet. To be able to reach the bottom fans long handles

are attached to them so that you don’t have to insert your hand into the chassis to access

them.

FortiGate-5140B Chassis Guide

01-500-156415-20151104 19

http://docs.fortinet.com/

Page 20

Cooling fans, cooling air flow, and minimum clearance FortiGate-5140B chassis

100 mm

600 mm

600 mmCool air

Intake

Warm air

Exhaust

60 mm

40 mm

Front

Back

Air Filter

(normal operation)

Air Filter

(Tilted down to

remove or insert)

Fan

Fan

To service the fans, open the latches on either side of the fan cabinet and open the cover

by pulling it down. Access the top fans by pulling them out. Access the bottom fans by

pulling them out by their handles.

You do not need to press a hot swap switch to remove a fan. Just pull it out of the fan

cabinet. The shelf manager regulates the fan speed by adjusting the DC voltage supplied

to the fan trays.

Table 5: FortiGate-5140B fan tray LEDs

LED Description

HS (Hot Swap) Normally off. Blinking blue indicates that the fan is starting up.

OOS (Out of

Service)

Normally off. Blinking red indicates the fan is out of service and

should be replaced.

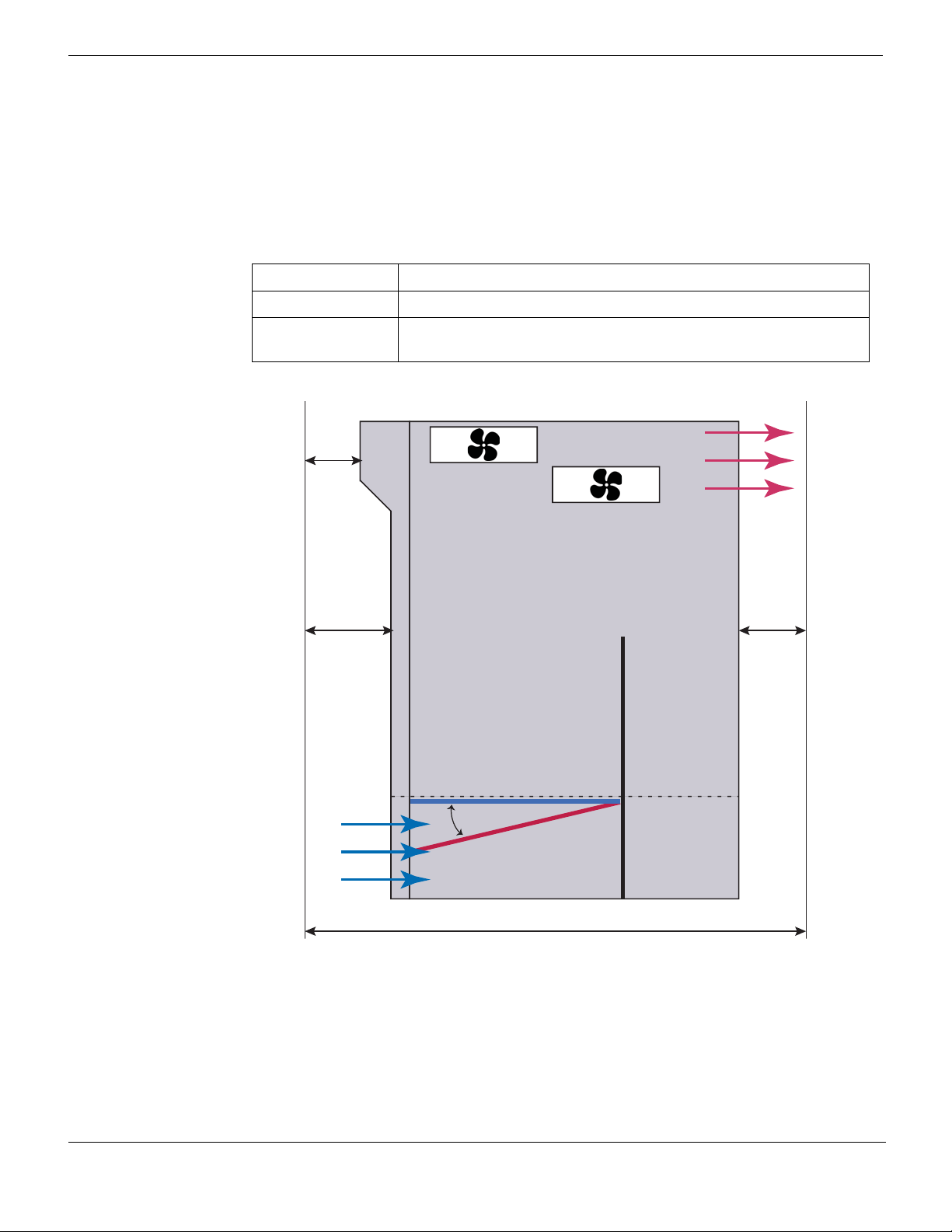

Figure 7: Cooling air flow and required minimum air flow clearance

When installing the chassis, make sure there is enough clearance for effective cooling air

flow. See Figure 7 on page 20 for the minimum clearance requirements. The diagram also

shows the cooling air flow through the chassis and the location of the air filter and cooling

fans. Make sure the cooling air intake and warm air exhaust openings are not blocked by

cables or rack construction because this could result in cooling performance reduction

and possible overheating and component damage.

20 01-500-156415-20151104

FortiGate-5140B Chassis Guide

http://docs.fortinet.com/

Page 21

FortiGate-5140B

Power connection and configuration

This chapter describes how to connect DC power to a FortiGate-5140B chassis.

The FortiGate-5140B chassis is designed to be installed in a data center or similar

location that has available -48VDC power fed from a 100A listed circuit breaker (also

called battery power or main DC power). Fortinet expects that most FortiGate-5140B

customers will be installing their chassis in a data center or similar location that is already

equipped with a -48VDC power system fed from a 100A listed circuit breaker that

provides power to existing networking or telecom equipment. The FortiGate-5140B

chassis is designed to be connected directly to this DC power system.

If DC power is not available at the location in which the FortiGate-5140B chassis is to be

installed you can use the FortiGate-5053B power converter shelf to convert AC to DC to

supply DC power to the FortiGate-5140B chassis.

Fortinet supplies four 3-ft. power cables with AWG-6 stranded wires and double-hole

lugs: Black for -48VDC and red for RTN. These cables should only be used to connect

the FortiGate-5140B PEMs to a FortiGate-5053B power convertor shelf if purchased with

your FortiGate-5140B chassis. The double-hole lugs to be connected to the

FortiGate-5140B PEMs include rubber boots that should be installed before energizing

the power system. If the power cable length needs to be longer than 3 ft., higher gauge

wires should be considered.

If you are connecting your chassis to a local DC power source, use cables that meet your

local wiring codes. To connect the wires to the FortiGate-5140B PEMs use 3/4-inch

double-hole lugs with insulating boot suitable the DC cables used, such as Thomas &

Betts PN 256-30695-1225.

Green AWG-6 wires are recommended for ground connections (not supplied with the

chassis).

This chapter describes:

• FortiGate-5140B chassis power level requirements

• Connecting the FortiGate-5140B chassis to DC power and ground

• Connecting a FortiGate-5140B PEM to DC power

• Connecting the FortiGate-5140B chassis to ground

• Supplying power using the FortiGate-5053B power supply shelf and PSU-5000B

power supplies

• Turning on FortiGate-5140B chassis power

FortiGate-5140B chassis power level requirements

This section provides some basic information for determining the power requirements of

your FortiGate-5140B chassis. This section provides guidelines only. Actual requirements

may vary depending on your installation requirements. Contact Fortinet Support if you

need more information.

FortiGate-5140B Chassis Guide

01-500-156415-20151104 21

http://docs.fortinet.com/

Page 22

Connecting the FortiGate-5140B chassis to DC power and ground Power connection and configuration

The base FortiGate-5140B chassis (empty, with four fans, one shelf manager, two shelf

alarm modules and two PEMs installed and operating with the fans running at full speed)

requires a maximum of 530 W. Each chassis slot can supply up to 300 W. You can use

these numbers to estimate the power requirement for a chassis configuration.

Example: power for a chassis with 5 boards

For example, the power requirement for a FortiGate-5140B chassis with FortiGate,

FortiSwitch, or FortiController boards in five slots would be:

530W + (300W * 5) = 2030W

Example: power for a fully-loaded chassis (14 boards)

The power requirement for a fully loaded FortiGate-5140B chassis with boards in all 14

slots would be:

530W + (300W * 14) = 4730W

Connecting the FortiGate-5140B chassis to DC power and ground

Connect the FortiGate-5140B chassis to DC power using the redundant -48V to - 60 VDC

power entry modules (PEMs) at the bottom of the chassis back panel. The specified

voltage range of the PEMs is -40 VDC to -72 VDC. The chassis ships with both PEMs

installed. The PEMs provide redundant DC power connections for the FortiGate-5140B

chassis and distribute DC power to all chassis slots and components.

The PEM includes a Reverse Voltage LED that lights if you have reversed the polarity

when connecting power.

Each FortiGate-5140B PEM includes four -48V/-60 VDC (labeled as - and connected

together internally) and four return connectors (labeled as + and connected together

internally). Each PEM supplies 5 power channels. Each channel includes a separate 30A

fuse to power a group of 3 to 4 chassis slots or a 20A fuse for fans and Shelf Managers.

All terminals should be connected single -48VDC power source with a 100A listed circuit

breaker.

To connect the FortiGate-5140B PEMs to DC power you must use power connectors and

wires that comply with the local electrical wiring code and the requirements of the facility

in which you are installing the FortiGate-5140B chassis.

The PEMs are hot-swappable, which means you can remove and replace a defective

PEM while the system is operating (assuming that the FortiGate-5140B system has both

PEMs connected for redundancy). It is not necessary to notify the software or reset the

system power to remove a PEM. You can add, remove, or replace a second PEM without

interrupting FortiGate-5140B operation.

FortiGate-5140B Chassis Guide

22 01-500-156415-20151104

http://docs.fortinet.com/

Page 23

Power connection and configuration Connecting a FortiGate-5140B PEM to DC power

DC Power Source

-48VDC

connector

RTN (+)

red to power

source RTN

DC Power Source

RTN connector

-48V/-60 VDC

black to power

source -48VDC

Reverse Voltage LED

Fuse LEDs

Active OOS H/S

Crimping guidelines

To connect the PEMs to datacenter power you should use AWG-6 or larger wires

depending on the length and the power requirements of your chassis. The ends of these

wires must be fitted with 3/4-inch double-hole lugs with insulating boot suitable the DC

cables used, such as Thomas & Betts PN 256-30695-1225. Use the following information

to crimp and prepare these wires.

Do not crimp energized wires.

Before crimping, slide rubber boot along each wire. Follow these crimping guidelines:

• Strip the insulation from cable. Be careful not to nick cable strands which may later

result in stands breaking

• Cable end should be clean: wire brush or clean with emery cloth if necessary. Insert

cable into connector until it stops. The insertion length must approximate the stripped

length of cable

• Insert connector in die and compress between the markings beginning near the

tongue of the connector. Using the wrong installing die may result in a defective

connection.

• After crimping, remove all sharp edges, flash or burrs.

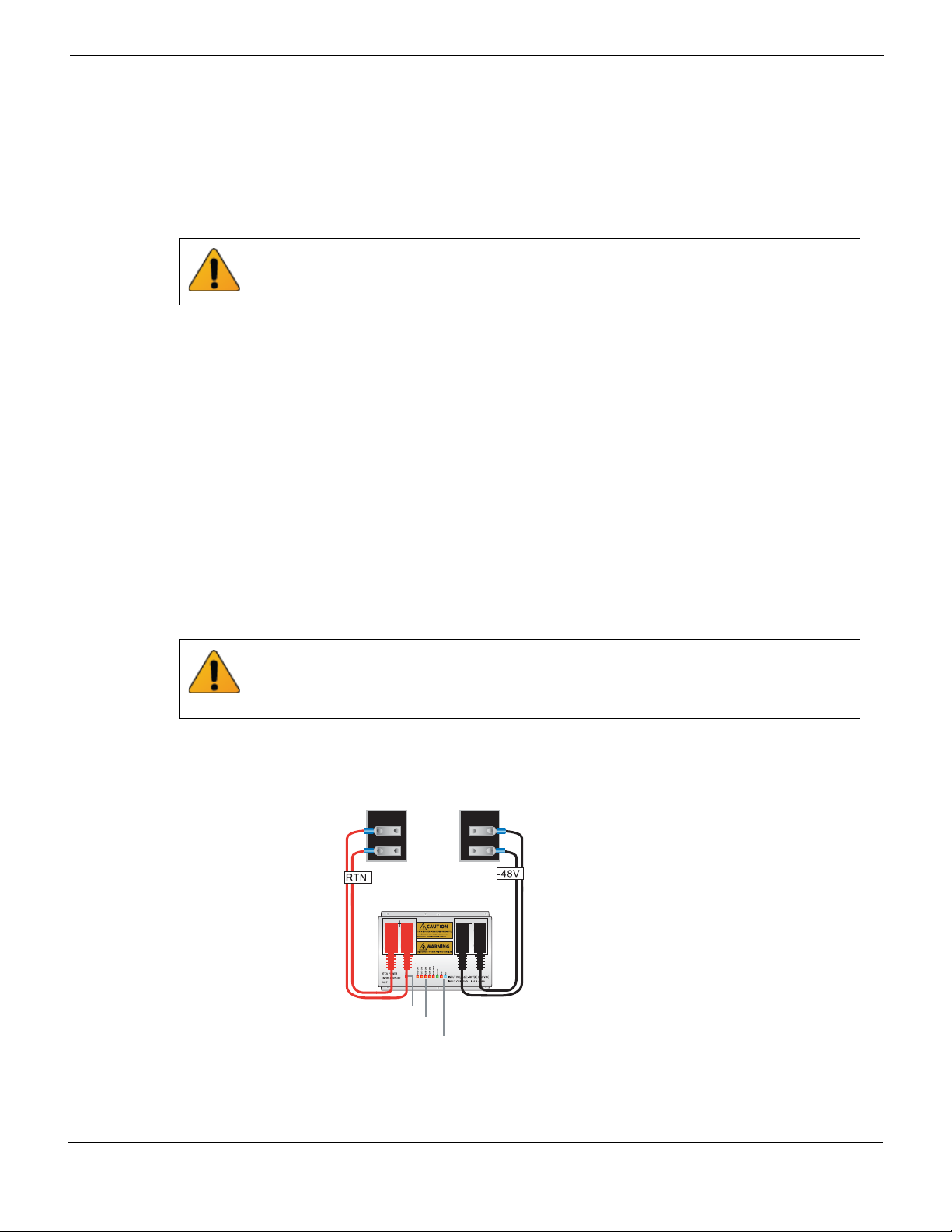

Connecting a FortiGate-5140B PEM to DC power

The following procedure describes how to connect power to a PEM. You can repeat this

procedure for both PEMs.

Two DC cable sets are required for each PEM connection (and all 4 terminals on each

polarity should be used). If for any reason any of the PEM terminals are not used the

unused terminals need to be covered with insulated material (or wrapped with electrical

tape) as the exposed terminals are a shock hazard.

Figure 8: Connecting a FortiGate-5140B PEM to DC power

FortiGate-5140B Chassis Guide

01-500-156415-20151104 23

http://docs.fortinet.com/

Page 24

Connecting a FortiGate-5140B PEM to DC power Power connection and configuration

Table 6: FortiGate-5140B PEM LEDs

LED State Description

REV. VOLTAGE

(Reverse

Voltage)

Off Normal operation

Solid Red Input voltage polarity reversed.

Off Normal operation.

FUSE CH1-4

(Fuses for power

channels 1 to 4)

Solid Red Fuse blown or absent.

Blinking

Input power lost

Red

FUSE FANS

(Fuses for the

cooling fan

power channel)

Off Normal operation.

Solid Red Fuse blown or absent.

Blinking

Input power lost.

Red

If all five fuse LEDs are simultaneously blinking input power to the PEM has been lost.

ACTIVE

Solid

Green

Normal operation.

Off Normal Operation.

OOS (Out of

Service)

Blinking

Red

Lost connection to shelf manager or IPMB bus.

Solid Red Incorrect hardware address or FRU data corruption.

Off Normal operation.

H/S (Hot Swap)

Blinking

Blue

The PEM is shutting down in preparation for being

removed from the chassis.

Blue The PEM can be removed from the chassis.

You need the following equipment to connect a FortiGate-5140B PEM to DC power:

• An electrostatic discharge (ESD) preventive wrist strap with connection cord.

• Two black AWG-6 stranded wires labelled -48V with attached 3/4-inch listed closed

loop double-hole lugs with insulating boot suitable for the DC cables used, such as

Thomas & Betts PN 256-30695-1225.

• Two red AWG-6 stranded wires labelled RTN with attached 3/4-inch listed closed loop

double-hole lugs with insulating boot suitable for he DC cables used, such as Thomas

& Betts PN 256-30695-1225.

To connect a FortiGate-5140B PEM to DC power

1 Attach the ESD wrist strap to your wrist and to an ESD socket or to a bare metal

surface on the chassis or frame.

2 Make sure that the PEM and power cord are not energized.

3 Remove the first set of nuts and lock washers from both connectors on the PEM.

4 Connect two black -48V power wires from the DC power source to the connectors on

the FortiGate-5140B PEM labeled - (the connectors on the right side of the PEM)

using the double-hole lugs (see Figure 8).

Install each double-hole lug vertically. Do not apply torque of more than 3.8 Nm (33.62

lbf.in).

FortiGate-5140B Chassis Guide

24 01-500-156415-20151104

http://docs.fortinet.com/

Page 25

Power connection and configuration Connecting the FortiGate-5140B chassis to ground

Data Center

ground

connector

(Central ofce

ground sys tem)

Chassis

Ground

Connector

(green)

5 Connect two red RTN power wires from your location’s RTN terminal to the

connectors on the FortiGate-5140B PEM labeled + (the connectors on the left side of

the PEM) using the double-hole lug (see Figure 8).

Install each double-hole lug vertically. Do not apply torque of more than 3.8 Nm (33.62

lbf.in).

6 Install previously removed nuts and washers to secure the connectors.

7 Cover the connectors with rubber boots.

8 Make sure the power wires are secured using tie wraps if required.

9 If required, label the black wires -48V.

10 If required, label the red wires RTN.

Connecting the FortiGate-5140B chassis to ground

The FortiGate-5140B chassis includes a ground terminal on the lower right side of the

FortiGate-5140B back panel (see Figure 2 on page 11). The ground terminal provides two

connectors to be used with a double-holed lug such as Thomas & Betts PN 256-30695-

1225. This connector must be connected to a local ground connection.

You need the following equipment to connect the FortiGate-5140B chassis to ground:

• An electrostatic discharge (ESD) preventive wrist strap with connection cord.

• One green AWG-6 stranded wire with listed closed loop double-hole lug with

insulating boot suitable for minimum 6 AWG copper wire, such as Thomas & Betts PN

256-30695-1225.

Figure 9: Connecting a FortiGate-5140B chassis to ground

To connect the FortiGate-5140B chassis to ground

1 Attach the ESD wrist strap to your wrist and to an ESD socket or to a bare metal

surface on the chassis or frame.

2 Make sure that the chassis and ground wire are not energized.

3 Connect the green ground wire from the local ground to the ground connector on the

FortiGate-5140B chassis (see Figure 9).

4 Secure the ground wire to the chassis.

5 Optionally label the wire GND.

FortiGate-5140B Chassis Guide

01-500-156415-20151104 25

http://docs.fortinet.com/

Page 26

Supplying power using the FortiGate-5053B power supply shelf and PSU-5000B power supplies Power connection and

PS U-5000B hot swappable

Power Supplies (4)

Edge

Controller

Supplying power using the FortiGate-5053B power supply shelf and PSU-5000B power supplies

If DC power is not available at your location, you can use the FortiGate-5053B and

FortiGate-5053B-LC 1U 19-inch rack mount power supply shelves with PSU-5000B hot

swappable power supplies to convert AC power to DC power. These components are not

supplied with the FortiGate-5140B chassis and must be purchased separately.

Figure 10: FortiGate-5053B power supply shelf with four PSU-5000B power supplies

As already stated, Fortinet supplies four 3-ft. power cables with AWG-6 stranded wires

and double-hole lugs: Black for -48VDC and red for RTN. These cables should only be

used to connect the FortiGate-5140B PEMs to a FortiGate-5053B power supply shelf if

purchased with your FortiGate-5140B chassis. The double-hole lugs to be connected to

the FortiGate-5140B PEMs include rubber boots that should be installed before

energizing the power system. If the power cable length needs to be longer than 3 ft.,

higher gauge wires should be used.

The FortiGate-5053B power supply shelf can include up to four PSU-5000B power

supplies. The power supply shelf can be connected to high line AC input (186-240VAC) or

low line AC input (100-185VAC).

• When connected to high-line AC input, a single power supply can provide 2725W of

DC power and a fully populated FortiGate-5053B power supply shelf can provide up

to 10.9KW of DC power and 8175W of DC power with 3+1 redundancy with an output

voltage of 54 VDC.

• When connected to low-line AC input a single power supply can provide 1200W of DC

power and a fully populated FortiGate-5053B power supply shelf can provide up to

4800W of DC power and 3600W of DC power with 3+1 redundancy with an output

voltage of 54 VDC.

The FortiGate-5053B power supply shelf edge controller controls and manages the

power supplies, provides for redundancy, and provides a control and alarm

communication interface for the power supply shelf.

For a more information about the FortiGate-5053B power supply shelf see the FortiGate-

5053B Power Supply Shelf Guide.

To supply power to a FortiGate-5140B chassis you must connect one FortiGate-5053B

power supply shelf to one FortiGate-5140B PEM.

You can install extra PSU-5000B power supplies in a single FortiGate-5053B power

supply shelf to provide power redundancy. If a PSU-5000B fails or is removed a backup

PSU-5000B will continue to supply power.

For a completely redundant power supply you can connect a second FortiGate-5053B

power supply shelf to the second FortiGate-5140B PEM.

FortiGate-5140B Chassis Guide

26 01-500-156415-20151104

http://docs.fortinet.com/

Page 27

Power connection and configuration Supplying power using the FortiGate-5053B power supply shelf and PSU-5000B power

Selecting the power supplies and power supply shelves that you need for your FortiGate-5140B chassis

This section provides some basic information for determining the power requirements of

your FortiGate-5140B chassis. Using these power requirements you can decide how

many PSU-5000B power supplies and FortiGate-5053Bpower supply shelves you need

to provide that power. This section provides guidelines only. Actual requirements may

vary depending on your installation requirements. Contact Fortinet Support if you need

more information.

The base FortiGate-5140B chassis (empty, with four fans, one shelf manager, two shelf

alarm modules and two PEMs installed and operating with the fans running at full speed)

requires a maximum of 530 W. Each chassis slot can supply up to 300 W. You can use

these numbers to estimate the power requirement for a chassis configuration.

Example: power for a chassis with 5 boards

For example, the power requirement for a FortiGate-5140B chassis with FortiGate,

FortiSwitch, or FortiController boards in five slots would be:

530 W + (300 W * 5) = 2030 W

If you are using high-line AC power, one PSU-5000B produces 2725W. Powering a

chassis with 5 boards would require one FortiGate-5053B power supply shelf connected

to one PEM. The power supply shelf would include one PSU-5000B unit. You can add a

second power supply for redundancy. If you want completely redundant power for the

chassis you can connect a second FortiGate-5053B unit to the other FortiGate-5140B

PEM and include one or two power supplies.

If you are using low-line AC power, one PSU-5000B produces 1200W. Powering a

chassis with 5 boards would require one FortiGate-5053B power supply shelf connected

to one PEM. The power supply shelf would include two PSU-5000B units. You can add a

third power supply for redundancy. If you want completely redundant power for the

chassis you can connect a second FortiGate-5053B unit to the other FortiGate-5140B

PEM and include two or three power supplies.

Example: power for a fully-loaded chassis (14 boards)

The power requirement for a fully loaded FortiGate-5140B chassis with boards in all 14

slots would be:

530 W + (300 W * 14) = 4730 W

If you are using high-line AC power, one PSU-5000B produces 2725W. Powering a

chassis with 14 boards would require one FortiGate-5053B power supply shelf

connected to one PEM. The power supply shelf would include two PSU-5000B units and

produce a total of 3450W. You can add a third power supply for redundancy. If you want

completely redundant power for the chassis you can connect a second FortiGate-5053B

unit to the other FortiGate-5140B PEM and include two or three power supplies.

If you are using low-line AC power, one PSU-5000B produces 1200W. Powering a

chassis with 14 boards would require one FortiGate-5053B power supply shelf

connected to one PEM. The power supply shelf would include four PSU-5000B units. If

you want redundant power for the chassis you can add a second FortiGate-5053B unit

connected to the other FortiGate-5140B PEM and include four power supplies.

FortiGate-5140B Chassis Guide

01-500-156415-20151104 27

http://docs.fortinet.com/

Page 28

Supplying power using the FortiGate-5053B power supply shelf and PSU-5000B power supplies Power connection and

Connecting a FortiGate-5140B chassis to the FortiGate-5053B power supply shelf

To use a FortiGate-5053B power supply shelf with the FortiGate-5140B chassis you need

to make DC power connections between A FortiGate-5140B PEM and the

FortiGate-5053B power supply shelf. You also need to the connect the FortiGate-5140B

chassis and the FortiGate-5053B power supply shelf to ground.

If your configuration requires a FortiGate-5053B-LC unit you must also connect it to the

FortiGate-5140B PEM.

Connecting a FortiGate-5140B chassis to a single FortiGate-5053B power supply shelf

The following procedure describes how to connect power to one FortiGate-5140B PEM

using the FortiGate-5053B power supply shelf. You can repeat this procedure to connect

the other PEM to a second FortiGate-5053B power supply shelf.

You need the following equipment:

• An electrostatic discharge (ESD) preventive wrist strap with connection cord.

• Two black AWG-6 stranded wires labelled -48V with attached Listed closed loop

double-hole lugs with insulating boot suitable for minimum AWG-6 copper wire

(supplied by Fortinet), such as Thomas & Betts PN 256-30695-1225

• Two red AWG-6 stranded wires labelled RTN with attached Listed closed loop doublehole lugs with insulating boot suitable for minimum AWG-6 copper wire, such as

Thomas & Betts PN 256-30695-1225.

• A FortiGate-5053B power supply shelf containing the required number of PSU-5000B

power supplies and mounted in a rack near the FortiGate-5140B chassis.

To connect a FortiGate-5140B power input connector to a FortiGate-5053B power

supply shelf

The FortiGate-5053B power converter shelf should not be connected to AC power until

specified in the following procedure.

1 Attach the ESD wrist strap to your wrist and to an ESD socket or to a bare metal

surface on the chassis or frame.

2 Make sure that the PEM, power supply shelf and DC power cable are not energized.

3 Remove the first set of nuts and lock washers from both connectors on the back of

the FortiGate-5053B power supply shelf.

4 Connect two black -48V power wires to the connectors labelled NEG on the back of

the FortiGate-5053B power supply shelf using the double-hole lug (see Figure 11).

Install each double-hole lug either horizontally or vertically. Do not apply torque of

more than 3.8 Nm (33.62 lbf.in).

5 Connect two black -48V power wires to the connectors labelled POS on the back of

the FortiGate-5053B power supply shelf using the double-hole lug (see Figure 11).

Install each double-hole lug either horizontally or vertically. Do not apply torque of

more than 3.8 Nm (33.62 lbf.in).

6 Install previously removed nuts and washers to secure the connectors.

7 Cover the connectors with the connector covers on the back of the power supply

shelf.

FortiGate-5140B Chassis Guide

28 01-500-156415-20151104

http://docs.fortinet.com/

Page 29

Power connection and configuration Supplying power using the FortiGate-5053B power supply shelf and PSU-5000B power

8 Select a PEM to connect power to and remove the first set of nuts and lock washers

from its connectors.

9 Connect the two black -48V power wires from the power supply shelf to the

connectors on the FortiGate-5140B PEM labeled - (the connectors on the right side of

the PEM) using the double-hole lug (see Figure 11).

Install each double-hole lug vertically. Do not apply torque of more than 3.8 Nm (33.62

lbf.in).

10 Connect two red RTN power wires from the power supply shelf to the connectors on

the FortiGate-5140B PEM labeled + (the connectors on the left side of the PEM) using

the double-hole lug (see Figure 11).

Install each double-hole lug vertically. Do not apply torque of more than 3.8 Nm (33.62

lbf.in).

11 Install previously removed nuts and washers to secure the connectors.

12 Cover the connectors with rubber boots.

Two DC cable sets are required for each PEM connection (and all 4 terminals on each

polarity should be used). If for any reason any of the PEM terminals are not used the

unused terminals need to be covered with insulated material (or wrapped with electrical

tape) as the exposed terminals are a shock hazard.

Figure 11: Connecting a FortiGate-5140B PEM to a FortiGate-5053B power supply

shelf

Red + to

FortiGate-5053B

POS

-48V/-60 VDC

- black to

FortiGate-5053B

NEG

13 Make sure the power wires are secured to the chassis using tie wraps if required.

14 If required, label the black wires -48V.

15 If required, label the red wires RTN.

16 Connect the FortiGate-5053B power supply shelf to AC power.

Only connect the power supplies that are installed in the FortiGate-5053B to AC

power. For example, if your FortiGate-5053 includes two power supplies, the power

supplies will be installed in slots 1 and 2. In this case you should only connect AC

connectors 1 and 2 to AC power. If your power supply shelf contains four power

supples, connect all four AC in connectors to AC power.

FortiGate-5140B Chassis Guide

01-500-156415-20151104 29

http://docs.fortinet.com/

Page 30

Turning on FortiGate-5140B chassis power Power connection and configuration

Data Center

ground

connector

(Central ofce

ground sys tem)

Shelf ground

connector

Connecting the FortiGate-5053B power supply shelf to ground

The FortiGate-5053B and LC power supply shelves both include ground terminals on the

center of the back panel (see Figure 12 on page 30). The ground terminal provides two

connectors to be used with a double-holed lug such as Thomas & Betts PN 256-30695-

1225. This connector must be connected to ground.

You need the following equipment to connect the FortiGate-5053B unit to ground:

• An electrostatic discharge (ESD) preventive wrist strap with connection cord.

• One green AWG-6 stranded wire with listed closed loop double-hole lug with

insulating boot suitable for minimum AWG-6 copper wire, such as Thomas & Betts PN

256-30695-1225.

Figure 12: Connecting a FortiGate-5053B power supply shelf to ground

To connect the FortiGate-5053B power supply shelf to ground

1 Attach the ESD wrist strap to your wrist and to an ESD socket or to a bare metal

surface on the chassis or frame.

2 Make sure that the shelf and ground wire are not energized.

3 Connect the green ground wire from the location’s ground terminal to the ground

connector on the power supply shelf (see Figure 12).

4 Secure the ground wire as required.

5 Optionally label the wire GND.

Turning on FortiGate-5140B chassis power

If you are using a power supply shelf, connect the power supply shelf to AC power and

verify that it is operating correctly.

If you are using local DC power, turn on the power to the chassis according to the

requirements of your local DC power system.

Once the FortiGate-5140B chassis is connected to DC power the chassis powers up. If

the chassis is operating correctly, the LEDs on the connected PEM(s) and fans should be

lit. As well, the LEDs on the FortiGate-5140B shelf manager and shelf alarm modules

should be lit (see Figure 3 on page 15).

When the chassis first starts up you should also hear the cooling fans operating.

In addition, if any FortiGate-5000 series boards have been installed in the chassis they

should power on and their front panel LEDs should indicate that they are starting up and

operating normally.

30 01-500-156415-20151104

FortiGate-5140B Chassis Guide

http://docs.fortinet.com/

Page 31

FortiGate-5140B

FortiGate-5140B hardware procedures

This chapter assumes the chassis has been mounted and connected to a power source

as detailed in “Power connection and configuration” on page 21.

This chapter discusses:

• Mounting the FortiGate-5140B chassis

• Inserting 5000 series boards and RTM modules into a FortiGate-5140B chassis

• Using FortiController-5103B boards for session-aware load balancing

• Using FortiSwitch-5003B boards for backplane communication

• Using FortiSwitch-5203B boards for content clustering

Mounting the FortiGate-5140B chassis

Mount the FortiGate chassis before installing the FortiGate-5000 series modules.

The FortiGate-5140B chassis must be mounted in a standard 19-inch rack. The chassis

requires 13U of vertical space in the rack.

If you install the FortiGate-5140B chassis in a closed or multi-unit rack assembly, the

operating ambient temperature of the rack environment may be greater than room

ambient temperature. Make sure the operating ambient temperature does not exceed the

manufacturer's maximum rated ambient temperature.

The FortiGate-5140B chassis should not be operated as a free-standing appliance.

Install the FortiGate-5140B chassis at the lower positions in the rack to avoid making the

rack top-heavy and potentially falling over.

Air flow

For rack installation, make sure that the amount of air flow required for safe operation of

the FortiGate-5140B chassis is not compromised. Make sure that the chassis ventilation

openings at the top rear and the bottom front are not blocked by cables or other

components. The recommended minimum clearance at the front of the chassis is

100 mm and the recommended clearance from the rear of the chassis is 60 mm. This

results in a total footprint of 600 mm from front to back. See “Cooling fans, cooling air

flow, and minimum clearance” on page 19 for more details.

FortiGate-5140B Chassis Guide

01-500-156415-20151104 31

http://docs.fortinet.com/

Page 32

Inserting 5000 series boards and RTM modules into a FortiGate-5140B chassis FortiGate-5140B hardware procedures

Inserting 5000 series boards and RTM modules into a FortiGate-5140B chassis

You can insert FortiGate and FortiSwitch-5000 series boards into the front of the

FortiGate-5140B chassis and RTM modules into the back of the chassis. Arrange the

boards and modules in slots as required for your configuration. FortiGate-5000 series

boards can be installed in any FortiGate-5140B front panel slots. FortiSwitch boards can

only be installed in switch slots 1 and 2. FortiGate-5000 series RTM modules can be

installed in any FortiGate-5140B RTM slot.

All FortiGate-5140B chassis are shipped with air baffle filler panels/cards on all but one

front slot that include a warning message to read the FortiGate-5000 documentation

before installing your product. The temporary slot fillers must be removed and all slots

filled; either with FortiGate-5000 series boards or with air baffle slot fillers. Air baffle slot

fillers are similar to blank FortiGate-5000 boards and are required for proper cooling air

flow.

FortiGate-5000 series and FortiSwitch-5000 series modules must be protected from

static discharge and physical shock. Only handle or work with FortiGate-5000 series and

FortiSwitch-5000 series modules at a static-free workstation. Always wear a grounded

electrostatic discharge (ESD) preventive wrist strap when handling FortiGate-5000

series or FortiSwitch-5000 series modules.

Do not operate the FortiGate-5140B chassis with open slots on the front panel or rear

panel. For optimum cooling performance and safety, front panel slots must contain a

FortiGate-5000 series module or an air baffle slot filler and rear panel slots must either

be covered or must contain a rear transition module or slot filler.

To avoid damaging components, you should install RTM modules (such as the

FortiGate-RTM-XD2 module) first before you install the corresponding FortiGate front

panel board. If you have already installed a FortiGate board, you should remove it before

installing the RTM module.

To install FortiGate-5000 boards or RTM modules, see the documentation supplied with

the board or module. You can find copies of all FortiGate-5000 series documentation on

the FortiGate-5000 Series documentation web page.

Using FortiController-5103B boards for session-aware load balancing

FortiController-5103B boards installed in a FortiGate-5140B chassis in slot 1 or slot 2

provide session-aware load balancing for all of the FortiGate-5001B series boards

installed in the chassis. A FortiController-5103B board forms a session-aware load

balanced cluster with up to 12 FortiGate-5001B boards and uses FortiASIC DP

processors to load balance millions of sessions to the cluster, providing 10 Gbps of traffic

to each cluster member. Performance of the cluster shows linear improvement if more

FortiGate-5001B boards are added.

To install FortiSwitch-5000 series boards, see the documentation supplied with the

board. You can find copies of all FortiGate-5000 series documentation on the FortiGate-

5000 Series documentation web page.

FortiGate-5140B Chassis Guide

32 01-500-156415-20151104

http://docs.fortinet.com/

Page 33

FortiGate-5140B hardware procedures Using FortiSwitch-5003B boards for backplane communication

Using FortiSwitch-5003B boards for backplane communication

FortiSwitch-5003B boards installed in a FortiGate-5140B chassis in slot 1 or slot 2

provide fabric backplane switching for all of the FortiGate-5000 series boards installed in

the chassis. Fabric backplane switching is most often used for data communication

between FortiGate-5000 series boards in a chassis. The fabric backplane is a dual-star

10-Gigabit switch fabric.

FortiSwitch-5003B boards installed in a FortiGate-5140B chassis in slot 1 or slot 2

provide base backplane switching for all of the FortiGate-5000 series boards installed in

the chassis. Base backplane switching is usually used for HA heartbeat communication

between FortiGate-5000 series boards in HA clusters.

To install FortiSwitch-5000 series boards, see the documentation supplied with the

board. You can find copies of all FortiGate-5000 series documentation on the FortiGate-

5000 Series documentation web page.

For complete information about using the FortiSwitch-5003B for backplane

communications (including the FortiSwitch-5003B CLI reference), see the related