Page 1

FortiADC 1000F

QuickStart Guide

Page 2

Register for Support

Register your Fortinet product to receive:

• Technical Support

• New product features

• Protection from new threats

Vous devez enregistrer le produit pour recevoir:

• Support technique

• Nouvelles fonctionnalitées du produit

• Protection contre de nouvelles menaces

La reistrazione ti permette di usufruire di:

• Supporto Tecnico

• Nuove funzionalita

• Proteezione dalle ultime minaccce

Debe registrar el producto para recibir:

• Apoyo técnico

• Nuevas funcionalidades del producto

• Protección contra ataques

登録のお願い

本日、フォーティネット製品の登録をしてください。

登録すると次のメリットがあります。

テクニカルサポート • 新機能の追加 • 新しい脅威への防御

QuickStart Guide

September 25, 2017

2nd Edition

Copyright© 2017 Fortinet, Inc. All rights reserved. Fortinet®, FortiGate®,

FortiCare® and FortiGuard®, and certain other marks are registered trademarks

of Fortinet, Inc., in the U.S. and other jurisdictions, and other Fortinet names

herein may also be registered and/or common law trademarks of Fortinet.

All other product or company names may be trademarks of their respective

owners. Performance and other metrics contained herein were attained in

internal lab tests under ideal conditions, and actual performance and other

results may vary. Network variables, different network environments and other

conditions may affect performance results. Nothing herein represents any

binding commitment by Fortinet, and Fortinet disclaims all warranties, whether

express or implied, except to the extent Fortinet enters a binding written

contract, signed by Fortinet’s General Counsel, with a purchaser that expressly

warrants that the identied product will perform according to certain expresslyidentied performance metrics and, in such event, only the specic performance

metrics expressly identied in such binding written contract shall be binding on

Fortinet. For absolute clarity, any such warranty will be limited to performance

in the same ideal conditions as in Fortinet’s internal lab tests. In no event

does Fortinet make any commitment related to future deliverables, features or

development, and circumstances may change such that any forward-looking

statements herein are not accurate. Fortinet disclaims in full any covenants,

representations, and guarantees pursuant hereto, whether express or implied.

Fortinet reserves the right to change, modify, transfer, or otherwise revise this

publication without notice, and the most current version of the publication shall

be applicable.

请马上注册

您的飞塔产品

您在注册以后才能得到技术支持、新产品特点信息、最新威胁防护

https://support.fortinet.com

Toll free: 1 866 648 4638

Phone: 1 408 486 7899

Fax: 1 408 235 7737

Email: register@fortinet.com

Page 3

Box Includes Before You Begin

Write down details that you may need from your network administrator or ISP.

FortiADC 1000F

2 Power cables

Console cable

1 screw pack for sliding rails and

rack mount bracket

FortiADC 1000F

QuickStart Guide

QuickStart Guide

Ethernet cable

5 Rubber feet

DSL PPPoE

Username

Password

Cable Modem DHCP

It is normal to not require a hostname but your ISP may require it.

Hostname

T1/E1, Static broadband, Cable, or DSL with a static

IP

IP Address

Default Gateway

Subnet Mask

Primary/Secondary DNS

2 Sliding rail handles

2 Sliding rails

2

3

Page 4

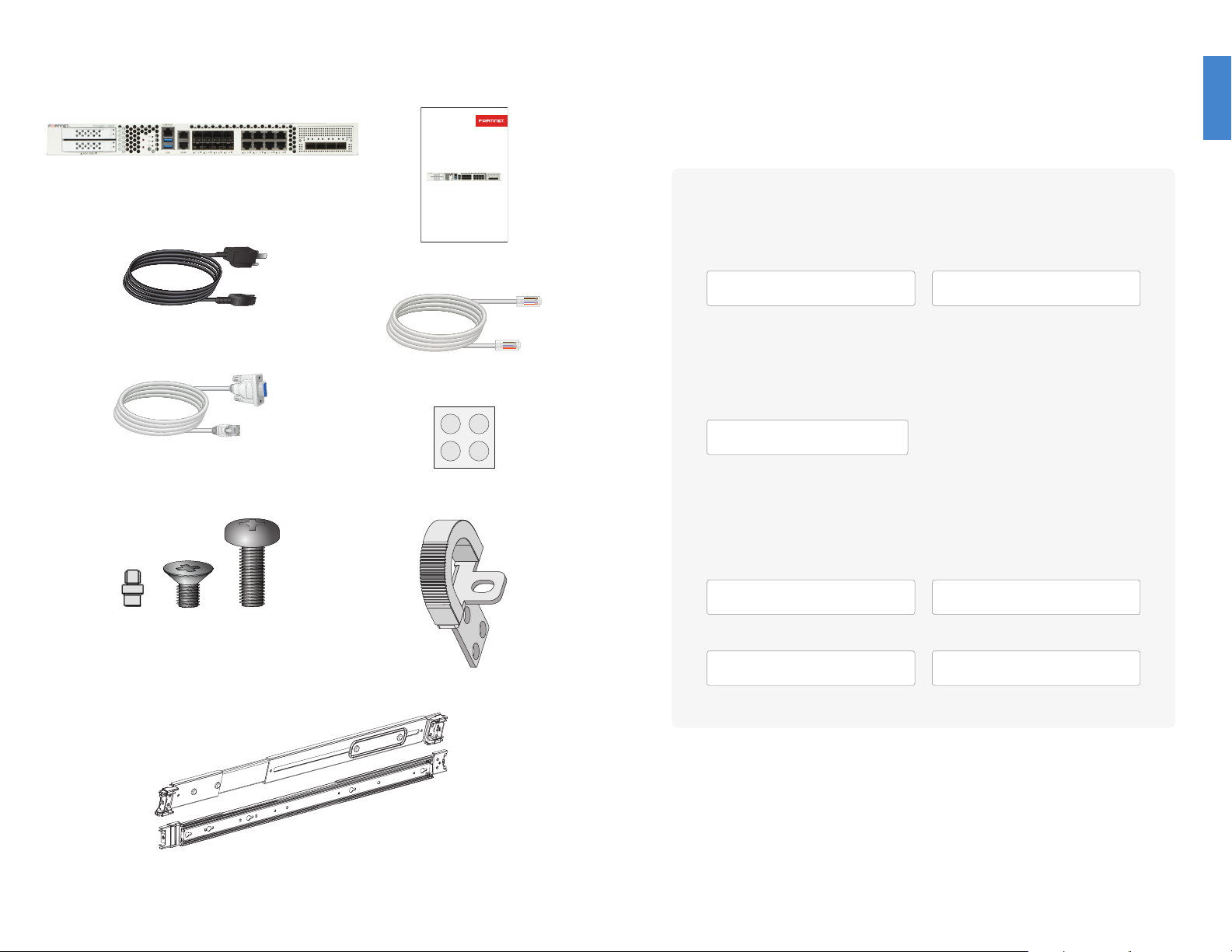

1

Basic Connections FortiADC Setup Options

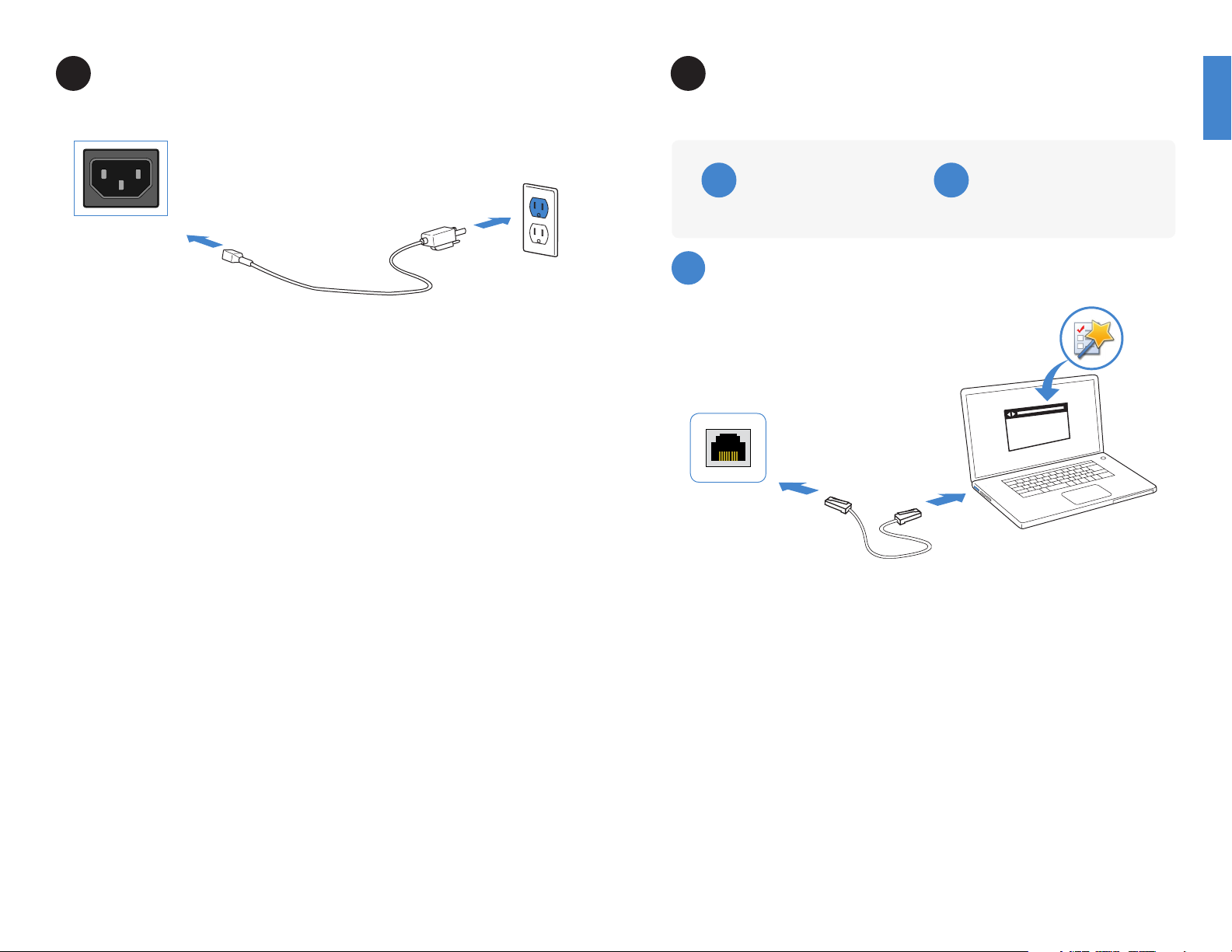

2

Power Connection

Plug the provided power cable into the rear of the appliance, and then into a grounded

electrical outlet or a separate power source such as an uninterruptible power supply

(UPS) or a power distribution unit (PDU).

Web Browser

A

With Ethernet cable (p.5)

A

Web Browser with Ethernet cable

MGMT1

Terminal Emulation

B

With console cable (p.6 )

https://

To connect to the Web UI

Requires: Microsoft Internet Explorer 9 or higher, the latest version of Mozilla Firefox,

Apple Safari 6, or Google Chrome.

1. Use the Ethernet cable to connect MGMT port of the FortiADC unit to the

management computer.

2. Congure your computer to match the appliance management port default subnet.

For example, from the Windows 7 Control Panel, go to Network and Sharing Center.

Click the Local Area Connection link, and then click the Properties button. Select

Internet Protocol Version 4 (TCP/IPv4) and then click its Properties button. Select

Use the following IP address, and then enter the following settings:

IP address: 192.168.1.2

Netmask: 255.255.255.0

3. To connect to the web UI, start a web browser and go to http://192.168.1.99.

4. Type admin in the Name eld, leave the Password eld blank, and then click Login.

544 5

Page 5

B

Terminal Emulation with Console

Cable

3

General Installation

The FortiADC unit can be mounted in any standard 19 inch rack unit with the provided

rail mount kit.

Serial Port

Console Port

To Connect to the CLI

Requires: Terminal emulator such as PuTTY, Tera Term, or a terminal server.

1. Connect the appliance console port to the management computer using the provided

console cable.

2. Start a terminal emulation program on the management computer. Select the COM

port and use the following settings:

Baud Rate: 9600

Data bits: 8

Parity: None

Stop bits: 1

Flow Control: None

3. Press Enter on your keyboard to connect to the CLI.

4. Login using username “admin” and no password. You can now proceed with

conguring your device.

Please read the “Cautions and Warnings” prior to installing your device.

To install the FortiADC unit into a rack:

1. Ensure that the FortiADC unit is placed on a stable surface prior to rack-mount

installation.

2. Assemble the rails and install the system in the rack following the safety instructions

and the rack installation instructions in Rail Installation (p. 8).

3. Verify that the spacing around the FortiADC unit conforms to requirements and that

the unit is level.

4. Connect the provided power cables to the system.

5. Plug the other end of the power cables into separate power sources, such as

uninterruptible power supplies (UPS) or power distribution units (PDU).

6. Insert one end of the provided Ethernet cable into one of the Ethernet ports on the

FortiADC unit. Insert the other end to a router or switch that is connected to the

Internet.

7. Press the power button on the system to turn on the device.

Do not place heavy objects on the unit.

Get started by typing “?” for a list of available commands.

Begin typing a command and type “?” for a list of available ways to complete.

For example “cong ?” shows the lowest level of conguration options.

76

Page 6

4

Rail Installation

To install the FortiADC unit using the rail mount kit:

1. To remove the chassis (inner) member, pull the slide open, and then press the trigger

down as shown on the drawing, and pull the chassis (inner) member out.

Press the trigger

down to release

Pull chassis (inner)

member out

Release safety lock

before mounting

Push the safety lock forward to secure

4. To mount the chassis into the cabinet, rst ensure that the ball retainer is in the fully

open position. Then, insert the chassis (inner) member into the cabinet member.

When you push the chassis back into the cabinet, press the trigger down to release

the slide from the locked position.

2. Use the standoffs to mount the chassis (inner) member to the chassis.

3. To attach the cabinet (outer) member to the rail, rst ensure that the safety lock is in

the unlocked position. Then, insert the stag into the upper and lower square holes on

the EIA rail from the back of the rail.

Finally, push the safety lock forward to secure the bracket.

88 9

Retainer is in fully open position

Press trigger down to unlock slides

Page 7

Caution: SFP

SFP Cage Sockets

Transmit Optical Bore

transceivers are

static sensitive

devices. Use

an ESD wrist

strap or similar

grounding device

when handling

transceivers.

Do not install

or remove SFP

transceivers while

ber-optic cables

are still attached.

This can cause

damage to the

cables, cable

connectors,

and the optical

interfaces. It may

also prevent the

transceiver from

latching correctly

into the socket

connector.

Note: Installing

and removing

SFP transceivers

can shorten their

useful life. Do not

install or remove

transceivers more

than is necessary.

SFP Transceivers

Receive Optical Bore

To install the SFP transceivers

1. Ensure that you are properly grounded.

2. Remove the caps from the SFP cage sockets on the

front panel of the unit.

3. Position the SFP transceiver in front of the cage socket

opening and ensure that the transceiver is correctly

oriented. When the transceiver is correctly oriented, the

extraction lever will be level with the socket latch.

Note: SFP cage socket orientation may vary. Ensure that

the SFP transceiver module is correctly oriented each

time that you are inserting a transceiver.

4. Hold the sides of the SFP transceiver and slide it into the

cage socket until it clicks into place.

5. Press the transceiver rmly into the cage socket with

your thumb.

6. Verify that the transceiver is latched correctly by grasping

the sides of the transceiver and trying to pull it out

without lowering the extraction lever.

If the transceiver cannot be removed, it is installed and

latched correctly.

If the transceiver can be removed, reinsert it and press

harder with your thumb.

If necessary, repeat this process until the transceiver is

securely latched into the cage socket.

To remove the SFP transceivers

1. Ensure that you are properly grounded.

2. If applicable, disconnect the ber-optic cable from the

transceiver connector and install a clean dust plug in the

transceiver’s optical bores.

3. Pull the extraction lever out and down to eject the

transceiver. If you are unable to use your nger to open

the lever, use a small at-head screwdriver or other

similar tool to open the lever.

4. Hold the sides of the transceiver and carefully pull it away

from the cage socket.

Caution: Do not

force the SFP

transceivers into

the cage slots.

If the transceiver

does not easily

slide in and click

into place, it may

not be aligned

correctly or may

be upside down.

If this happens,

remove the SFP

transceiver, realign

it or rotate it and

slide it in again.

Note: Follow

proper beroptic handling

procedures when

installing and

removing

SFP transceivers

to ensure the

devices remain

clean and are not

damaged.

5. Replace the cap on the SFP cage socket and place the

removed SFP transceiver into an antistatic bag.

1010 11

Page 8

2x HDD Bay

Hot-swappable HDD bays for Log Disk usage

* Default conguration is 1x HDD. HDD2 is reserved for

users need RAID for data reliability.

Console

Optional connection to the management

computer. Provides access to the CLI.

NMI Button

Reserved for software application

Not in use

Device Guide

8x RJ45 Ports 9-16

Gigabit Ethernet RJ-45 ports for connections to

your network

Reset Button

Reboot the system

2 x USB Ports

Reserved for future use

MGMT

Dedicated Gigabit Ethernet Management

Port for system management

1212 13

8x SFP Ports 1-8

Gigabit Ethernet SFP ports for connections

to your network

4x SFP+ Ports 17-20

10G Ethernet SFP+ ports for connections to

your network

Page 9

Power Supply Warning Buzz Reset Button

To disable power supply warning buzz

ESD Anchor

For user connection to their ESD wrist band

Device Guide

Power Switch

To turn the power ON/OFF

Grounding Screws

Provides extra grounding

1414 15

Power Connections

100 – 127VAC 7.1A, 200 – 240VAC 3.4A, 47 – 63Hz

redundant power supply

Page 10

HDD1/2 POWER (Top)

Green: HDD is installed and powered ON

HDD1/2 Status (Bottom)

Flashing Amber: HDD in use

Power

Green: The unit is ON

Off: The unit is OFF

Status

Off: System is normal

Green: Minor system alarm

Red: System failure

HDD Status

Flashing Amber: HDD in use

Device Guide

PORT 9 – 16 Link/Activity (Left)

Flashing Amber: Transmitting & receiving data

Off: Port is not in use

PORT 9 – 16 Speed (Right)

Amber: Port is connected at 1Gbps

Green: Port is connected at 100Mbps

Off: Port is connected at 10Mbps or no link

MGMT Link/Activity (Left)

Flashing Amber: Transmitting & receiving data

Off: Port is not in use

MGMT Speed (Right)

Amber: Port is connected at 1Gbps

Green: Port is connected at 100Mbps

Off: Port is connected at 10Mbps or no link established

1616 17

PORT 1 – 8 Link/Activity (Left)

Flashing Amber: Transmitting & receiving data

Off: Port is not in use

PORT 1 – 8 Speed (Right)

Amber: Port is connected at 1Gbps

Off: No link established

PORT 17 – 20 Speed (Left)

Green: Port is connected at 1Gbps or 10Gbps

Off: No link established

PORT 17 – 20 Link/Activity (Right)

Flashing Amber: Transmitting & receiving data

Off: Port is not in use

Page 11

SSL Accelerator Alarm (Top)

Off: Accelerator is operating normally

Red: Accelerator failure

SSL Accelerator Power (Bottom)

Green: Accelerator is up and running

Device Guide

Power Supply Status

Green: Power supply is operating normally

Red: Power supply is not connected to power or failure

1818 19

Page 12

Cautions and Warnings

Environmental specications

Ambient operating temperature: 0C to 40C

Rack Mount Instructions - The following or similar rack-mount instructions are included with the installation instructions:

Instructions de montage en rack - Les instructions de montage en rack suivantes ou similaires sont incluses avec les instructions d’installation:

Elevated Operating Ambient - If installed in a closed or multi-unit rack assembly, the operating ambient temperature of the rack environment may

be greater than room ambient. Therefore, consideration should be given to installing the equipment in an environment compatible with the maximum

ambient temperature (Tma) specified by the manufacturer.

Température ambiante élevée – S’il est installé dans un rack fermé ou à unités multiples, la température ambiante de fonctionnement de

l’environnement du rack peut être supérieure à la température ambiante de la pièce. Par conséquent, il est important d’installer le matériel dans un

environnement respectant la température ambiante maximale (Tma) stipulée par le fabricant.

Reduced Air Flow - Installation of the equipment in a rack should be such that the amount of air flow required for safe operation of the equipment is

not compromised.

Ventilation réduite – Installation de l’équipement dans un rack doit être telle que la quantité de flux d’air nécessaire au bon fonctionnement de

l’équipement n’est pas compromise.

Mechanical Loading - Mounting of the equipment in the rack should be such that a hazardous condition is not achieved due to uneven mechanical

loading.

Chargement Mécanique – Montage de l’équipement dans le rack doit être telle qu’une situation dangereuse n’est pas lié à un chargement mécanique

inégal.

Circuit Overloading - Consideration should be given to the connection of the equipment to the supply circuit and the effect that overloading of the

circuits might have on overcurrent protection and supply wiring. Appropriate consideration of equipment nameplate ratings should be used when

addressing this concern.

Surtension – Il convient de prendre l’ensemble des précautions nécessaires lors du branchement de l’équipement au circuit d’alimentation et être

particulièrement attentif aux effets de la suralimentation sur le dispositif assurant une protection contre les courts-circuits et le câblage. Ainsi, il est

recommandé de tenir compte du numéro d’identification de l’équipement.

Reliable Earthing - Reliable earthing of rack-mounted equipment should be maintained. Particular attention should be given to supply connections

other than direct connections to the branch circuit (e.g. use of power strips).

Fiabilité de la mise à la terre– Fiabilité de la mise à la terre de l’équipement monté en rack doit être maintenue. Une attention particulière devrait

être accordée aux connexions d’alimentation autres que les connexions directes au circuit de dérivation (par exemple de l’utilisation de bandes de

puissance).

Refer to specific Product Model Data Sheet for Environmental Specifications (Operating Temperature, Storage Temperature, Humidity, and Altitude)

Référez à la Fiche Technique de ce produit pour les caractéristiques environnementales (Température de fonctionnement, température de stockage,

humidité et l’altitude).

Safety

Moving parts — Hazardous moving parts. Keep away from moving fan blades.

Pièces mobiles – Pièces mobiles dangereuses. Se tenir éloigné des lames mobiles du ventilateur.

Warning: Equipment intended for installation in Restricted Access Location.

Avertissement: Le matériel est conçu pour être installé dans un endroit où l’accès est restreint.

Battery – Risk of explosion if the battery is replaced by an incorrect type. Do not dispose of batteries in a fire. They may explode. Dispose of used

batteries according to your local regulations. IMPORTANT: Switzerland: Annex 4.10 of SR814.013 applies to batteries.

Batterie – Risque d’explosion si la batterie est remplacée par un type incorrect. Ne jetez pas les batteries au feu. Ils peuvent exploser. Jetez les piles

usagées conformément aux réglementations locales. IMPORTANT: Suisse: l’annexe 4.10 de SR814.013 s’appliquent aux batteries.

警告

本電池如果更換不正確會有爆炸的危險

請依製造商說明書處理用過之電池

Caution: Disconnect power supply cords before servicing.

Attention: Débranchez les cordons de la source d’alimentation avant tout entretien.

Caution: Slide/rail mounted equipment is not to be used as a shelf or a work space.

Attention: Un équipement monté sur bâti ne doit pas être utilisé sur une étagère ou dans un espace de travail.

Regulatory Notices

Federal Communication Commission (FCC) – USA

This device complies with Part 15 of FCC Rules. Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received; including interference that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy, and if it is not installed and used in accordance with the instruction manual, it may cause

harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference, in which case the

user will be required to correct the interference at his own expense.

WARNING: Any changes or modifications to this product not expressly approved by the party responsible for compliance could void the user’s

authority to operate the equipment.

Industry Canada Equipment Standard for Digital Equipment (ICES) – Canada

CAN ICES-3 (A) / NMB-3 (A)

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital apparatus set out in the Radio Interference Regula¬tions

of the Canadian Department of Communications.

Cet appareil numérique n’émet pas de bruits radioélectriques dépassant les limites applicables aux appareils numériques de la classe A prescrites

dans le Règlement sur le brouillage radioélectrique édicte par le ministère des Communications du Canada.

European Conformity (CE) - EU

This is a Class A product. In a domestic environment, this product may cause radio interference, in which case the user may be required to take

adequate measures.

Voluntary Control Council for Interference (VCCI) – Japan

この装置は、クラスA情報技術装置です。 この装置を 家庭環境で使用すると電波妨害を引き起こすことがあります。 この場合には使用者が適切な対策を講ず

るよう要求されることがあります。VCCI-A

Product Safety Electrical Appliance & Material (PSE) – Japan

日本では電気用品安全法(PSE)の規定により、同梱している電源コードは本製品の専用電源コードとして利用し、他の製品に使用しないでください。

Bureau of Standards Metrology and Inspection (BSMI) – Taiwan

這是甲類的資訊產品,在居住的環境中使用時,可能會造成射頻干擾,在這種情況下,使用者會被要求採取某些適當的對策。

The presence conditions of the restricted substance (BSMI RoHS table) are available at the link below:

https://www.fortinet.com/bsmi

China

此为A级产品,在生活环境中,该产品可能会造成无线电干扰。这种情况下,可能需要用户对其采取切实可行的措施。

Page 13

Fortinet Customer Service & Support

Create a support account, register and manage your products,

download updates, rmware images and release notes, and create

technical support tickets.

https://support.fortinet.com

Fortinet Document Library

Up-to-date versions of Fortinet publications for the entire family of

Fortinet products.

http://docs.fortinet.com

Training Services

Course descriptions, availability, schedules, and location of training

programs in your area.

http://www.fortinet.com/support/training.html

Technical Discussion Forums

Communicate with other customers and Fortinet partners about

Fortinet products, services, and conguration issues.

https://support.fortinet.com/forum

FortiGuard Threat Research and Response

Up-to-date information on vulnerabilities and threats, includes a virus

scanner, IP signature look-up, and web ltering tools.

http://www.fortiguard.com

Fortinet Product License Agreement / EULA

and Warranty Terms

https://www.fortinet.com/content/dam/fortinet/assets/legal/EULA.pdf

Fortinet.com

Loading...

Loading...