Page 1

FD 8804CC Cross-Cut

FD 8804SC Strip-Cut

Industrial Conveyor Shredders

7/2013

OPERATOR/

MAINTENANCE MANUAL

FIRST EDITION

Page 2

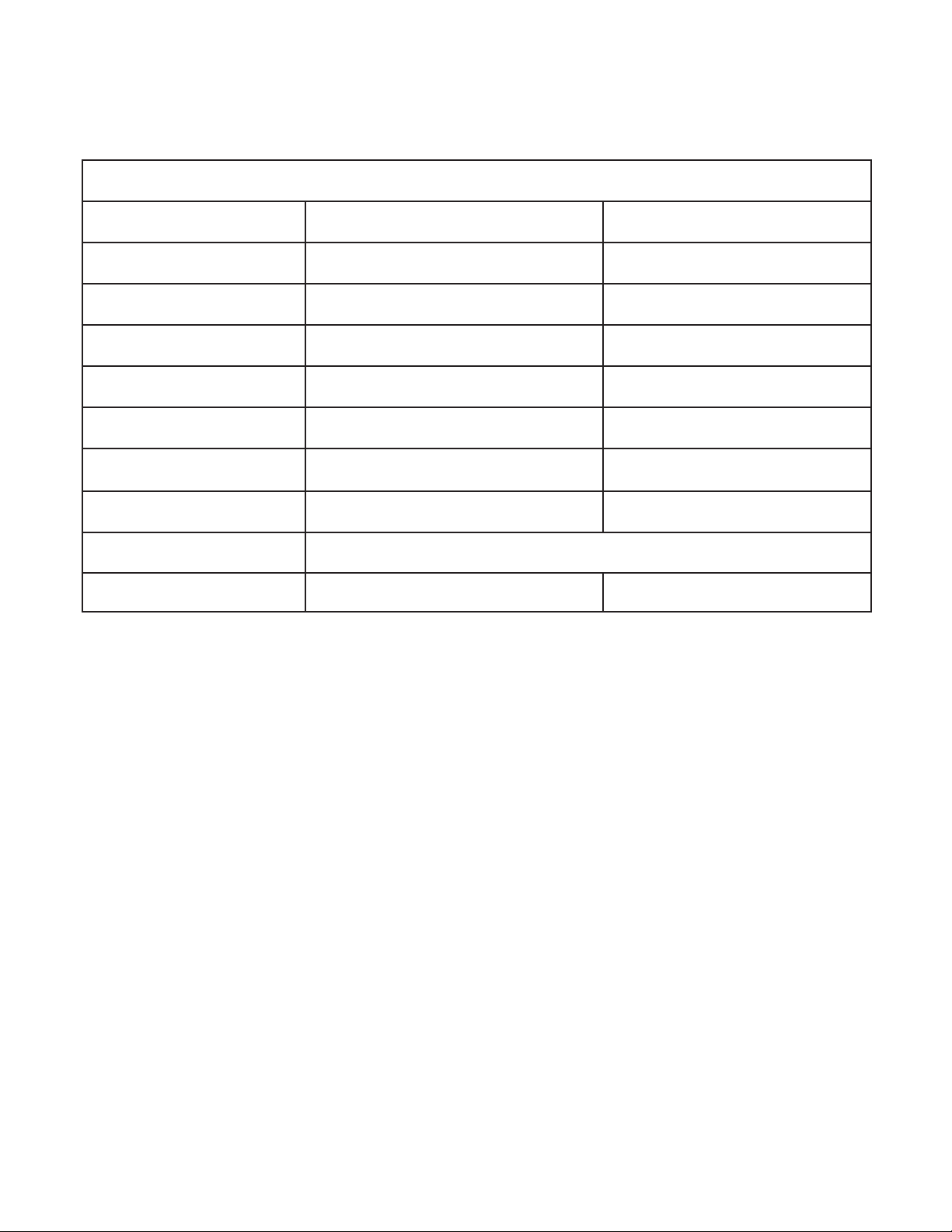

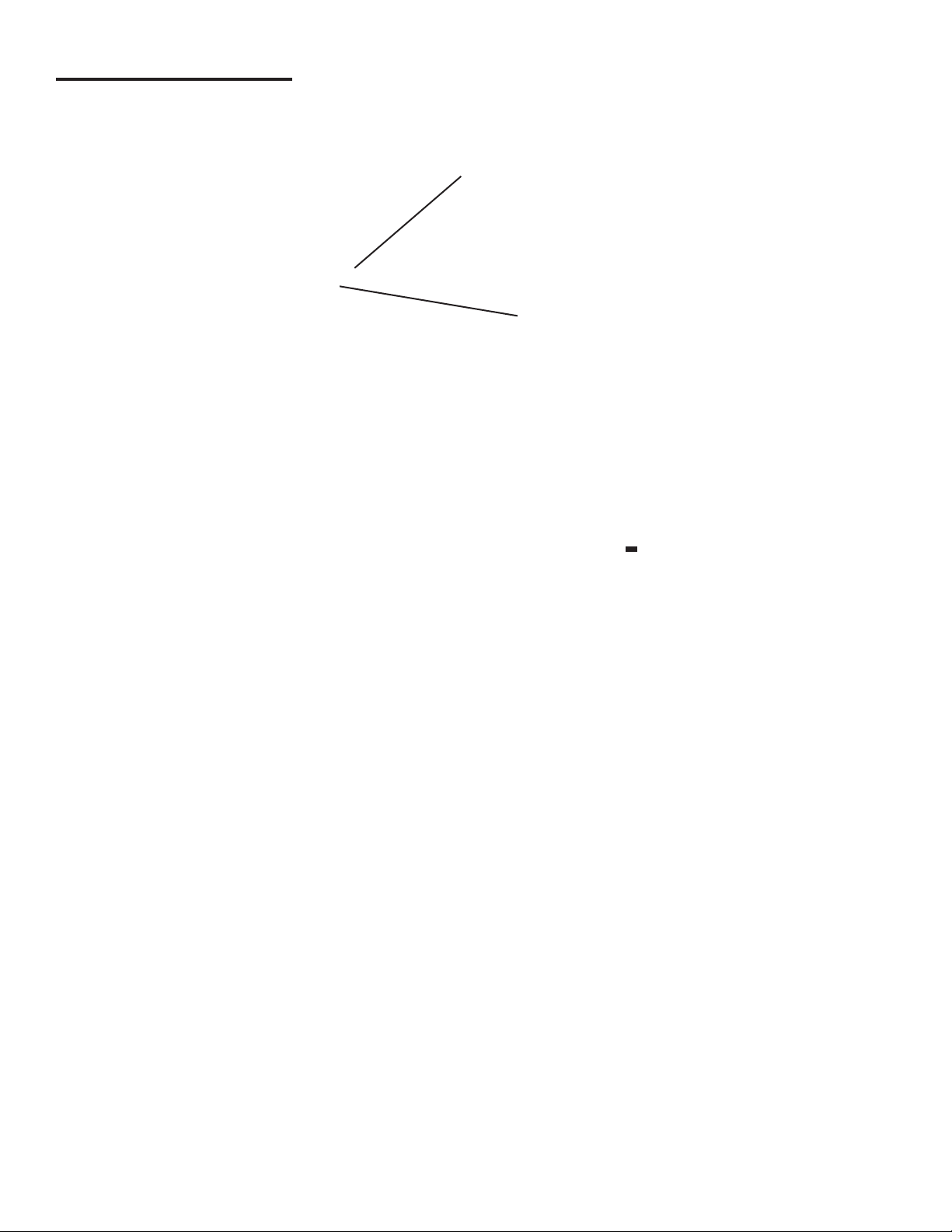

MACHINE SPECIFICATIONS

Model Type FD 8804CC FD 8804SC

Serial #:

Shred Size: 1/4” x 2” 1/2”

Sheet Capacity: 75 - 90 105 - 125

Speed: Up to 40 fpm Up to 50 fpm

Throat Width: 16” 16”

Waste Bin Capacity: 36 gallons 49 gallons

Motor: 8HP 8HP

Power: 3-Phase, 220V, 50/60Hz, both models

Weight: 661 lbs. 661 lbs.

The serial number is specied on the nameplate of the shredder. Guarantee claims and inquiries cannot be

processed if you do not quote the serial number.

Enter this number into the nameplate shown here immediately after receipt of the shredder.

Page 3

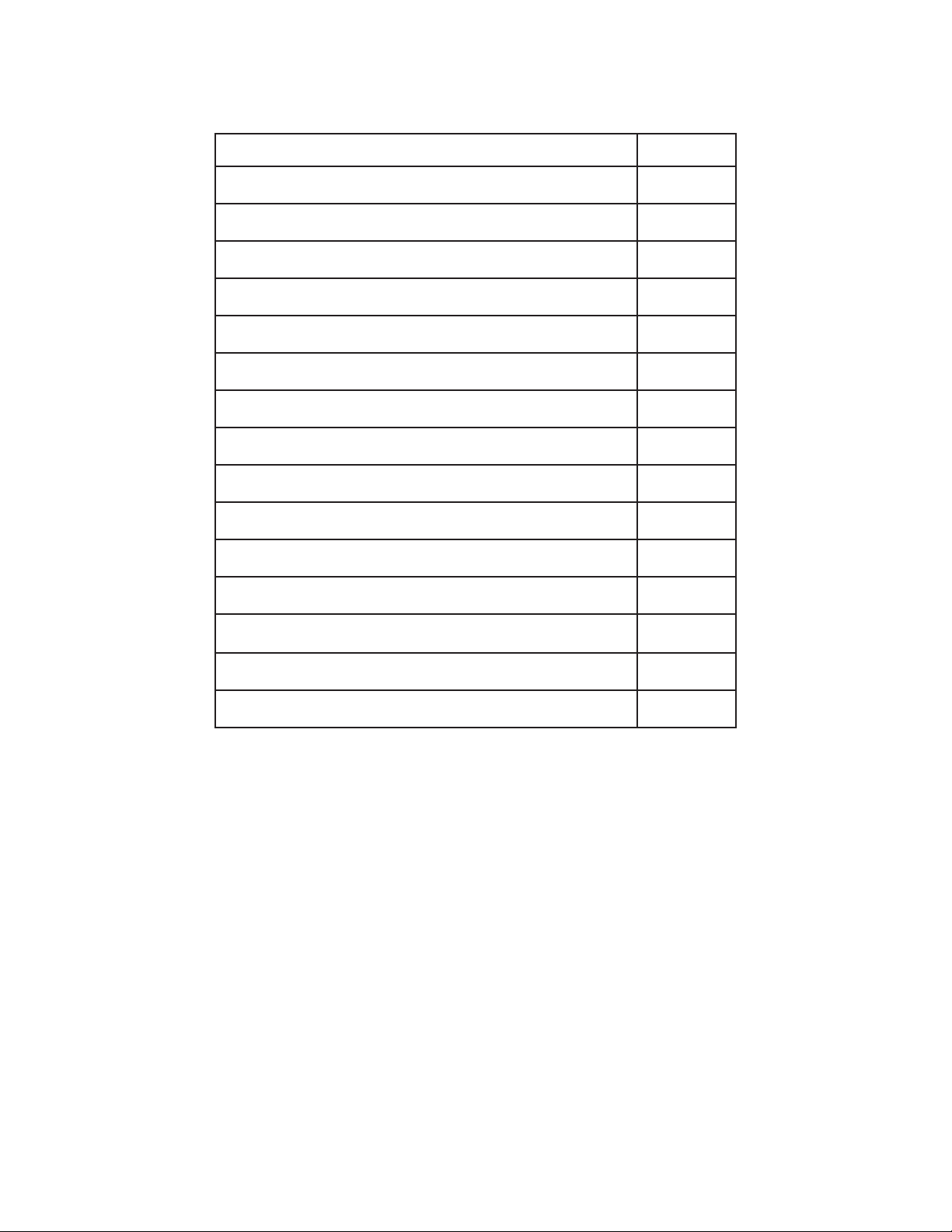

TABLE OF CONTENTS

TOPIC PAGE

Safety Precautions 1-2

Checking Safety Devices 3

Overview 4

Machine Characteristics 5

Cutting Data, Speed, Dimensions, Weight 5

Motor Specications, Power Requirements 5

Installation 5

Start-up: Main Switch and Control Panel 6

Operation, Overloading 7

Maintenance: Emptying Waste Bin 8

Maintenance: Removing Side Covers 8

Maintenance: Conveyor Belt Maintance 8-9

Maintenance: Lubricating Shredder Mechanisms 10

Maintenance: Exterior Cleaning 10

Parts Lists 11-20

Page 4

Safety Precautions

“Work safety” symbol

This symbol marks all work safety notes in this manual which can endanger the health

or life of operators. Please pay attention to this symbol and exercise particular care in

such cases. Please also forward all work safety notes to other users.

Apart from the instructions in this manual, you should also follow generally

applicable safety and accident prevention regulation.

“Attention” notes

This icon marks information in this manual which requires particular attention including

guidelines, regulations, instructions and correct working procedures intended to prevent

damage to the machine and/or other equipment.

Notes on work safety

The FD 8804 shredder has been inspected for safety. However, improper operation and misuse risk the

following:

• the health or life of the operator

• the machine and other valuable equipment

• the efcient operation of the shredder.

The FD 8804 employs state-of-the-art technology and is safe to operate. However, this machine can become

hazardous if used incorrectly, by untrained staff or for purposes other than those for which it is designed.

• Material with a tendency to curl, e.g. tapes, cords, etc. should not be processed.

• Keep long hair, loose clothes, ties, scarves, etc. away from paper feed opening.

• Only one person should operate the shredder at a time.

• Always follow local safety and accident prevention regulations when operating the shredder.

• No pedestals or other raised surfaces may be placed in the vicinity of the machine if they alter the

safety clearances.

• All connecting cables must be laid in such a way that they cannot be tripped over.

• Mechanical wearing parts must be inspected once a year.

1

Page 5

The FD 8804 shredder is intended only

for shredding large volumes of archive les, bound EDP lists and the contents of waste paper bins. The

hardened, solid-steel cutting rollers are unaffected by loose-leaf binders, paper clips and staples contained in

these materials.

Any other use beyond the scope described here is regarded as not being in accordance with the instructions.

The manufacturer will not be held liable for damage resulting from incorrect use; the user alone is responsible.

Users must also follow the assembly, dismantling, re-assembly, operation and maintenance procedures

specied by the manufacturer. The operation, maintenance and repair of the machine must be performed only

by trained personnel who are aware of the potential dangers.

The relevant accident prevention regulations as well as other generally recognized rules concerning safety

engineering and occupational safety must be observed.

• Each person responsible for assembling, dismantling and reassembling and maintenance (inspection,

servicing, repair) of the shredder must have read and fully understood the entire operating manual, in

particular the "Safety" section.

• The shredder may only be operated, serviced and repaired by authorized, trained personnel.

• The shut-down procedures specied in this manual must be followed during all assembly, dismantling

and re-assembling, cleaning, and maintenance work. This type of work must be performed only when

the machine is idle.

• The drive of the FD 8804 must be secured against unintentional switching-on before performing

work on the machine. Set the main switch to "Off" and unplug machine from wall outlet.

• After repair, check all protective devices to be sure they have been re-installed before operation.

• Do not perform any work which may impair your safety while operating the machine.

• Immediately report any changes which impair your safety to the person responsible. Shut the machine

down until such damage has been resolved.

• Before operating the shredder, ensure that it is in perfect working condition.

• Ensure that the workplace around the FD 8804 is always clean and safe.

• The user must not make any conversions or changes on his own initiative which impair the safety of

the FD 8804. Protective devices must not be removed or rendered inoperative.

for shredding paper, paperboard and cardboard. It is designed

• All work which is not directly connected to the normal operation of the machine must always be

performed when the machine is idle.

• Doors and aps must not be opened until the machine is motionless. Observe safety labels!

• Test the safety features after installing or repairing electrical components.

2

Page 6

Checking the safety devices

Check the safety devices:

• at the start of each work shift (when operation is sporadic)

• at least once a week in continuous operation

• after each maintenance or repair

Check the safety devices for:

• specied condition • specied location

• safe attachment • specied function

Correct defects before you operate the shredder.

1. Immediately shut down the shredder if defects occur during operation and make sure the defects are

corrected.

2. Do not modify or remove protective devices. Do not switch off protective devices. For safety reasons,

modications of the machine are not allowed.

Danger: Defective safety devices can cause serious accidents. If safety devices are not

working properly, the shredder should immediately be put out of operation.

Never reach into the cutting system while it is operating; you risk serious injury!

Only when all safety devices are operating correctly can the shredder be used again.

Operate the shredder only when these devices have been checked and are in order.

1. Check the Safety Bar push button (A) in front of the feeding table:

The shredder must switch off immediately when you press the Safety Bar button and the Emergency

stop light must go on.

2. Check the Stop button (B) on the right of the

control panel:

The shredder must switch off immediately

when the button is pushed.

3. Check the Safety Switch inside the Cutting

Block Access Door at the top of the shredder (C).

Press the door handle release. Handle will rotate

up. Pull up on handle.

The shredder must switch off immediately

when the door is opened.

B

C

A

3

Page 7

General Overview

Feed Table

Safety Bar

Front View with Waste Bin

Breaker Panel

Control Panel and

Cutting Block Access Door

Right Side View with Electricity

Control Box Access Door

4

Page 8

Machine characteristics

Machine designation: conveyor-belt paper shredder

Machine type: FD 8804CC, FD 8804SC

Total machine weight: 661 lbs.

Technical equipment: large feeding table, inlet conveyor belt

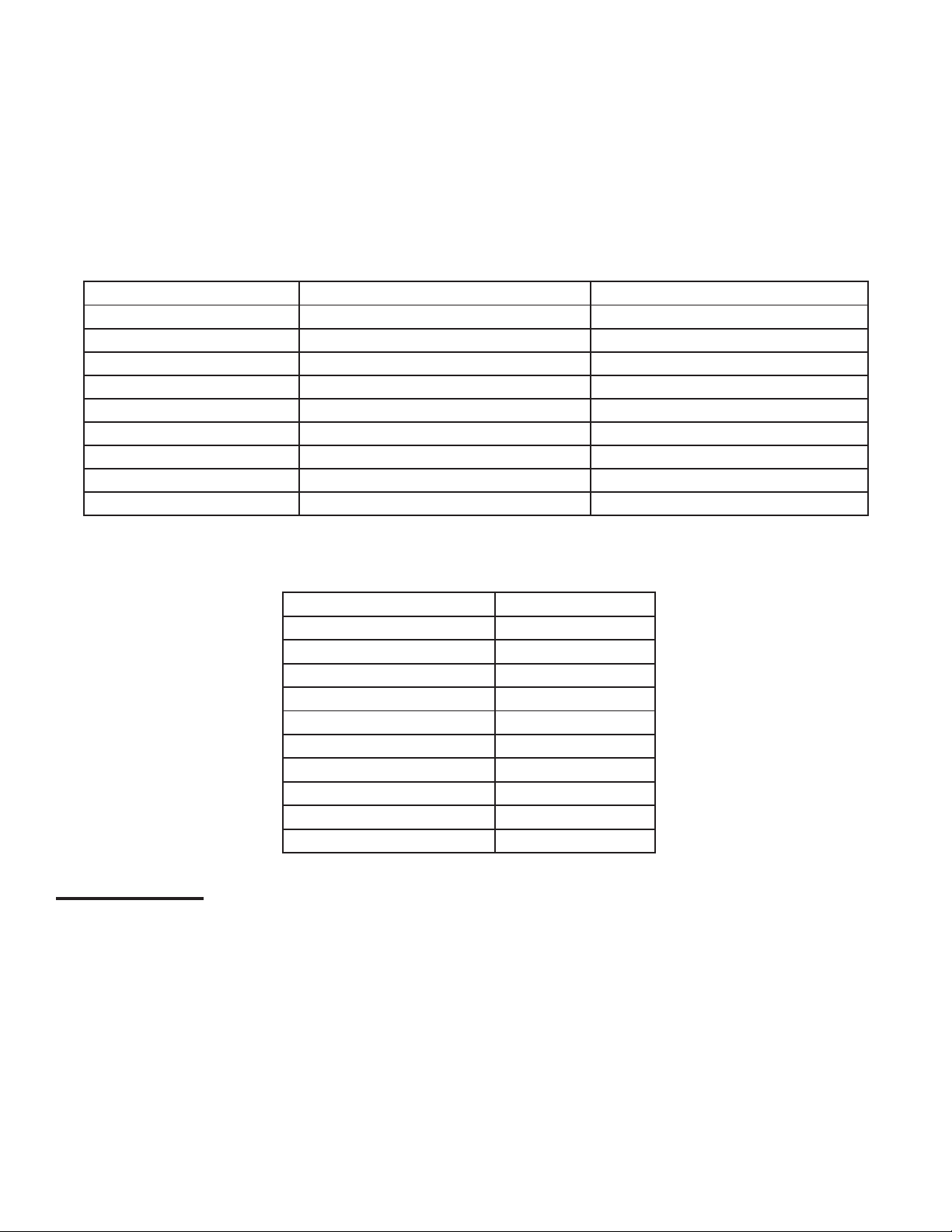

Cutting Data, Speed, Dimensions, Weight

FD 8804CC

Cutting Style: Cross Cut Strip Cut

Shred Size: 1/4” x 2” 1/2”

Sheet Capacity: 75 to 90 105 to 125

Speed: Up to 40 feet per minute Up to 50 feet per minute

Feed Opening: 16” 16”

Dimensions: 31” W x 54” D x 43 1/2” H 29” W x 53” D x 50 1/2” H

Feed Table Dimensions: 26” W x 16” D x 37 1/2” H 28 1/4” W x 16” D x 41 1/2” H

Space Requirements: 34” W x 57” L x 52” H 32” W x 55” L x 59” H

Waste Bin Capacity: 36 gal. 49 gal.

Weight: 661 lbs. 661 lbs.

Motor Specications, Power Requirements

Motor Type Horizontal Geared

Rated Power 8HP

Operating Voltage 220V

Phase 3-Phase

Frequency 50/60Hz

Rated Current 20A

Output RPM 25 RPM

Number of Poles 4 (3 hot & 1 ground)

Total Rated Power Pn 1.5KW

Total Rated Current In 20A

Total EOCR Protection 25A

FD 8804SC

Installation

1. Appropriate power outlet must be available at installation site.

2. The FD 8804 is delivered completely assembled (although it can be

delivered in parts, if necessary.) During transport, be aware of the

shredder’s high center of gravity.

3. The shredder can be moved on its casters. If a fork-lift is used to transport

the machine, be sure to use the designated pick-up points.

4. Install the shredder on a at and even oor without carpeting.

5. Once the shredder is in place, lock the caster brakes, and plug in power

cable to appropriate power source.

5

Power Plug

Power Outlet

Page 9

Start-up and Operation

Main Switch

1. On the right side of the machine, open the orange door leading to the electrical control panel. Push on the

lever (Fig. 1) and the handle will pop out. Pull to open (Fig. 2).

2. Flip the main power switch to the UP position (Fig. 3).

3. Insert key into On-Off switch to right of control panel (Fig. 4). Turn key right, to the On position.

Main Power Switch

Fig. 1 Fig. 2 Fig. 3

Control Panel

Green Touch Pad

Push to start conveyor and cutting

blade operation. Cutting system

operates in feed direction.

LOAD INDICATOR

Lights to show how

close shredder is

to capacity, or if

overloaded.

MODE INDICATORS

Indicators light to show the

shredder’s status: Auto,

Manual, Stop, Reverse

WASTE BIN FULL

Indicator lights when

waste bin is full of

paper shreds.

START

DOOR OPEN

Indicator lights to show

when waste bin door is

open. (Shredder will not

operate if door is open.)

Fig. 4

REVERSE

Blue Touch Pad

Push button to reverse

direction of cutting blades.

STOP

Red Touch Pad

Push button to stop

cutting system. Shredder

remains in standby mode

until Start is pressed.

6

Page 10

Operation

1. Set main switch to ON (Fig. 3). Turn the OFF/ON key switch on the control panel to the ON position.

2. Touch the START pad on the control panel. The conveyor will begin to move in the forward direction.

3. Place the material to be shredded on the feed table, then slide onto the inlet conveyor belt, in appropriate

stacks. (Cross-Cut, up to 90 sheets. Strip-Cut, up to 125 sheets. Sheet capacity may vary due to variables in

paper thickness and power supply.)

NOTE: If material is accidentally placed onto the conveyor belt, DO NOT REACH FOR IT

the Safety Stop bar on the front of the shredder, or press the red STOP pad on the control panel. When the

shredder stops, press and hold the REVERSE pad. The conveyor should operate in reverse, allowing safer

access to the materials. The shredder will stop when the REVERSE pad is released. To resume shredding,

press the START pad.

Turning off the shredder

1. To shut down the shredder, press the STOP pad on the control panel.

2. Turn OFF/ON key switch on the control panel to the OFF position.

3. Open the electrical control panel door, and ip the main power switch DOWN to the off position.

Overloading the motor

If the shred capacity of the machine is exceeded (too large a stack of paper, etc.), the shredder will stop

automatically. To resume shredding:

1. Push and hold the reverse pad until the paper backs completely out of the shredder.

2. Press the red STOP pad or the SAFETY BAR on the front of the machine, then divide the materials into

smaller stacks.

. Instead, press

3. Press the START pad. The conveyor and internal shredding mechanisms will begin to move.

4. Continue shredding, feeding less paper at a time.

Frequent Overloading

If the shredder is repeatedly overloaded, the motor can overheat, which will cause the shredder to switch off

automatically. To resume shredding:

1. Allow the motor to cool down for approximately 20 - 30 minutes before using.

2. Once the motor has cooled sufciently, resume shredding by following standard operating procedure (see

Operation).

NOTE:

To maintain optimum performance and allow constant operation, avoid repeatedly

overloading the shredder. This will prevent time-consuming reversing cycles, and will

provide the highest possible throughput.

7

Page 11

Maintenance and Inspection

Emptying the Waste Bin

Shredded paper and particles accumulate in the shredder waste bin during normal operation. When the red

“Waste Bin Full” lamp lights, empty the waste bin.

1. Switch the shredder off by pressing the STOP pad on the control panel, turn the OFF/ON key switch to

the OFF position and ip the main power switch to the OFF position.

2. Turn the door handle to the right and open the waste bin access door. Pull out and empty the waste bin.

3. Push the waste bin back in, close the door, turn power switches back on and resume shredding.

NOTE: The maintenance procedures

which follow should be performed only

by authorized and trained technicians.

Removing & Reinstalling Side Covers

Each side cover is attached by four Phillips head screws.

1. To remove a cover, insert screwdriver through access holes (Fig. 4),

and remove screws.

NOTE: It is easier to remove the lower two screws rst, then the top

two. When reinstalling the cover, install top screws rst, then lower.

Fig. 4

Conveyor Belt Maintenance

• Checking Belt Tension

When loaded with material, the conveyor belt must not slip, i.e. stand still when material is loaded. If the

belt slips, it must be tightened. Contact the Formax Service Department for assistance.

• Checking Belt for Wear

The upper surface of the conveyor belt can become worn over time. The belt must be replaced when

the woven fabric inlay becomes visible. Contact the Formax Service Department for assistance.

• Cleaning the Conveyor Belt area

The conveyor belt area must be cleaned once a month, or as needed to maintain optimal performance.

1. Switch off the shredder and unplug from wall outlet.

2. Remove the covers on both sides, revealing the cleaning openings in the conveyor belt area.

3. Use compressed air to blow out particles, or a vacuum to remove dirt and dust.

4. Re-install both side covers.

NOTE: Paper clips in the shredded materials may increase the frequency of cleaning necessary, and may

become caught in the sides of the belt.

8

Page 12

• Cleaning the Conveyor Belt Tensioning Station

The tensioning station must be cleaned once a month, or as needed to maintain optimal performance.

1. Switch off the shredder and unplug from wall outlet.

2. Remove the feed table and front panel of tensioning station (Fig. 5).

3. Remove particles and dirt.

4. Re-install the feed table and front panel of tensioning station.

Fig. 5 detail

Fig. 5

Front Underside

Tensioning station

adjuster

• Checking the Cutting Head Chain Tension

Check the chain tension once every week in the rst month, then once a month thereafter.

1. Switch off the shredder and unplug from wall outlet.

2. Remove the right side cover.

3. The sagging of the chain (see Fig. 6) should be 9 - 14 mm, measured from the top inside of

the frame to the cutting head chain.

If it is not within this range, loosen the tension screws until the sagging reaches the

correct level. Retighten the tension nuts.

4. Replace the side cover, plug in the shredder.

NOTE:

Excessive tensioning of the chain can cause premature wear of the chain and bearings.

The smallest allowed chain sagging in the rst month of operation is 5 mm. After that, 9 mm.

Fig. 6

9

Page 13

Lubricating Shredder Mechanisms

• Cutting System:

The cutting system should be oiled once a month or as needed for optimal performance.

1. Open the Cutting Block Access Door on the top of the shredder. Press latch and the handle

will spin around. Pull up on the handle.

2. Spray special cutting block oil through the paper inlet, onto the cutter rolls.

3. Close the Access Door and press the START button on the control panel.

4. Run the cutting system forward and backward several times, without feeding paper. This will

help to remove paper shreds and particles.

• Drive Chains:

The drive chains should be checked during PMs,

and greased as needed.

1. Switch off the shredder and unplug from wall

outlet.

2. Remove both side covers.

3. Grease the cutting system conveyor belt

drive chain (A) and the motor cutting system

drive chain (B).

4. Replace side covers and plug in shredder.

• Synchronizing Wheels:

1. Switch off the shredder and unplug from wall

outlet.

2. Remove left side cover.

3. Grease the synchronizing toothed wheel (C).

4. Replace side cover and plug in shredder.

A

Right Side

B

C

Left Side

Exterior cleaning

• Turn shredder off and unplug from wall outlet.

• Wipe the exterior surfaces with a soft cloth. If the surfaces are very dirty, use a neutral detergent, then wipe

again with a soft cloth.

CAUTION:

• Never put water directly on the surface of the shredder.

• Never clean the case with benzene or thinner, since it will cause discoloration.

10

Page 14

PARTS LISTS

1

2

3

4

5

ITEM CC PART # SC PART # DESCRIPTION QTY

1 8804-SAB-01 8804-SAB-01 SAFETY BAR 1

2 8804-BOL-01 8804-BOL-01 BOLTS FOR LOADING TABLE SUPPORTER 18

3 8804-TOP-05 8804-TOP-05 FRONT CASE 1

4 8804-BOD-01 880413-BOD-01 LOWER FRAME 1

5 8804-WST-01 880413-WST-01 WASTE BIN 1

6 8804-BOD-05 880413-BOD-05 DOOR 1

7 8804-LAT-01 8804-LAT-01 WASTE BIN DOOR LATCH 1

7

6

11

Page 15

10

1

5

2

2

4

3

11

9

ITEM CC PART # SC PART # DESCRIPTION QTY

1 8804-TOP-01 880413-TOP-01 TOP CASE 1

2 8804-TOP-03 880413-TOP-03 UPPER FRAME 2

3 8804-BEL-01 8804-BEL-01 CONVEYOR BELT 1

- 8804-CON-01 880413-CON-01 CONVEYOR 1

4 8804-TOP-02 8804-TOP-02 LOADING TABLE 1

5 8804-DOR-01 8804-DOR-01 CUTTING BLOCK ACCESS DOOR 1

6 8804-TOP-04 8804-TOP-04 REAR CASE UPPER 1

7 8804-BOD-02 880413-BOD-02 REAR CASE LOWER 1

8 8804-BOD-01 880413-BOD-01 LOWER FRAME 1

9 8804-PCB-19 8804-PCB-19 POWER PLUG, 30A 1

10 8804-TOP-07 880413-TOP-07 CONTROL PANEL COVER 1

11 8804-BEL-02 8804-BEL-02 CONVEYOR BELT PLASTIC STRIP 1

6

7

8

12

Page 16

Right Side

7

1

see pg 21

3

9

5

6

8

2

4

Left Side

6

ITEM CC PART # SC PART # DESCRIPTION QTY

1 8804-TOP-06R 8804-TOP-06R LOADING TABLE SUPPORTER, RIGHT 1

2 8804-TOP-06L 8804-TOP-06L LOADING TABLE SUPPORTER, LEFT 1

3 8804-BOD-03 880413-BOD-03 SIDE CASE, RIGHT 1

4 8804-BOD-04 880413-BOD-04 SIDE CASE, LEFT 1

5 8804-PCB-02 880413-PCB-02 ELECTRICITY CONTROL BOX DOOR 1

6 8804-CAT-01 880413-CAT-01 CASTERS 4

7 8804-TOP-07R 8804-TOP-07R LOADING TABLE SIDE PANEL, RIGHT 1

8 8804-TOP-07L 8804-TOP-07L LOADING TABLE SIDE PANEL, LEFT 1

9 8804-HIN-01 8804-HIN-01 WASTE BIN DOOR HINGE 2

13

Page 17

CUTTING HEAD - CC

Right Side

15 1918

16

14

5

17

1

13 14 15

76

3

8

9 1011

12

Left Side

4

2

11

ITEM CC PART # DESCRIPTION QTY

1 8804-CTB-02 SIDE PLATE, RIGHT 1

2 8804-CTB-01 SIDE PLATE, LEFT 1

3 8804-CON-03R CONVEYOR BELT BRACKET, RIGHT 1

4 8804-CON-03L CONVEYOR BELT BRACKET, LEFT 1

5 8804-SPR-02 CONVEYOR DRIVE SPROCKET 1

6 8804-GEA-01 CUTTING HEAD GEAR 1

7 8804-SPR-03 MOTOR SPROCKET 1

8 8804-CCH-02 CONVEYOR CHAIN 1

9 8804-SPR-01 CONVEYOR SPROCKET 1

10 8804-CCH-01 CUTTING HEAD CHAIN 1

11 8804-RUB-01 VIBRATION PROOF RUBBER (025) 4

12 8804-GEA-01 SYNCHRONIZING TOOTHED WHEEL 2

13 8804-CTB-08 SHORT SHAFT 1

14 8804-CTB-07 LONG SHAFT 1

15 8804-MOT-01 MOTOR 1

16 8804-CON-02 CONVEYOR SHAFT HOLDER 2

17 8804-OIL-06 OILER PUMP MOTOR 1

18 8804-CTB-23 MAGNETIC SENSOR BOARD & WIRING HARNESS 1

19 8804-CTB-24 MAGNETIC SENSOR BOARD MOUNTING BRACKET 1

- 8804-CTB-05 MOTOR BASE PLATE 1

- 8804-CTB-00 CUTTING HEAD 1

13

14

Page 18

CUTTING HEAD - SC

Right Side

12

19

1

13

14

6

7

15

3

15

17

18

14

13

9

16

11

10

5

8

Left Side

4

2

11

ITEM SC PART # DESCRIPTION QTY

1 8804-CTB-02 SIDE PLATE, RIGHT 1

2 8804-CTB-01 SIDE PLATE, LEFT 1

3 880413-CON-03R CONVEYOR BELT BRACKET, RIGHT 1

4 880413-CON-03L CONVEYOR BELT BRACKET, LEFT 1

5 8804-SPR-02 CONVEYOR DRIVE SPROCKET 1

6 8804-GEA-01 CUTTING HEAD GEAR 1

7 8804-SPR-03 MOTOR SPROCKET 1

8 8804-CCH-02 CONVEYOR CHAIN 1

9 8804-SPR-01 CONVEYOR SPROCKET 1

10 8804-CCH-01 CUTTING HEAD CHAIN 1

11 8804-RUB-01 VIBRATION PROOF RUBBER (025) 4

12 880413-GEA-01 SYNCHRONIZING TOOTHED WHEEL 2

13 800213-CTB-08 SHORT SHAFT (0.5”) 1

14 800213-CTB-07 LONG SHAFT (0.5”) 1

15 8804-MOT-01 MOTOR, 220V, 60Hz, 8HP 1

16 8804-CON-02 CONVEYOR SHAFT HOLDER 1

17 8804-CTB-23 MAGNETIC SENSOR BOARD & WIRING HARNESS 1

18 8804-CTB-25 MAGNETIC SENSOR BOARD MOUNTING BRACKET 1

19 8804-OIL-06 OILER PUMP MOTOR 1

- 880413-CTB-05 MOTOR BASE PLATE 1

- 880413-CTB-00 CUTTING HEAD 1

15

Page 19

CUTTING HEAD - INTERIOR

CROSS CUT STRIP CUT

3

2

1

ITEM CC PART # SC PART # DESCRIPTION QTY

1 8804-CTB-03 8804-CTB-03 POST 5

2 8804-CTB-07 880413-CTB-07 LONG SHAFT (0.5”) 1

3 8804-CTB-08 880413-CTB-08 SHORT SHAFT (0.5”) 1

- 8804-CTB-09 n/a CUTTER -

- 8804-CTB-10 n/a RING -

- 8804-CTB-11 n/a BEARING (6208 ZZ) -

- n/a 880413-CTB-09 BEARING (6209 ZZ) -

- 8804-CTB-12 n/a CUTTER PRESS WASHER -

- 8804-CTB-13 n/a BEARING WASHER -

- 8804-CTB-14 n/a BEARING NUT -

- 8804-CTB-15 n/a CUTTER NUT -

- 8804-CTB-16 8804-CTB-16 BEARING HOUSING -

- 8804-CTB-17 n/a GUIDE REINFORCEMENT PLATE -

- n/a 880413-CTB-11 GUIDE REINFORCEMENT PLATE A -

- n/a 880413-CTB-12 GUIDE REINFORCEMENT PLATE B -

- 8804-CTB-18 880413-CTB-13 UPPER GUIDE -

- 8804-CTB-19 880413-CTB-14 LOWER GUIDE -

- 8804-CON-02 8804-CON-02 CONVEYOR SHAFT HOLDER 2

16

Page 20

ELECTRICAL

4

5

6

3

10

1

12

9

7

8

13

11

2

ITEM CC/SC PART # DESCRIPTION QTY

1 8804-MOT-01 MOTOR, 220V, 60Hz, 8HP 1

2 8804-ECB-01 ELECTRICITY CONTROL BOX COVER 1

3 8804-PCB-00 ELECTRICITY CONTROL ASSEMBLY 1

4 8804-PCB-14 TERMINAL PLATE 1

5 8804-PCB-18 BREAKER 1

6 8804-PCB-15 MAGNETIC CORE 2

7 8804-PCB-04 EOCR 1

8 8804-PCB-01 ELECTRICITY CONTROL BOX BASE 1

9 8804-PCB-03 ELECTRICITY CONTROL BOX 1

10 8804-DEC-01 CONTROL PANEL DECAL 1

11 8804-TOG-01 ON/OFF TOGGLE SWITCH WITH KEY 1

12 8804-PCB-12 DATA OUTPUT CABLE 1

13 8804-PCB-07 PCB CASE (detail on next page) 1

17

Page 21

2

3

1

4

5

6

7

11

8

10

ITEM CC/SC PART # DESCRIPTION QTY

1 8804-PCB-05 MAIN PCB 1

2 8804-PCB-12 DATA OUTPUT CABLE 1

3 8804-PCB-10 CONTROL PCB CABLE EXTENSION (BODY CABLE) 1

4 8804-PCB-07 PCB CASE 1

5 8804-PCB-20 SENSOR CABLE EXTENSION (BODY CABLE) 1

6 8804-PCB-13 DOOR SENSOR CABLE 1

7 8804-PCB-11 MAIN CABLE 1

8 8804-PCB-19 CONTROL PCB CABLE (SENSOR CABLE) 1

9 8804-PCB-06 CONTROL PCB 1

10 8804-SWI-01 WASTE BIN DOOR SWITCH 1

11 8804-PCB-16 MICRO SWITCH, CUTTING HEAD ACCESS DOOR, 15A 1

12 8804-PCB-08 SENSOR 1

13 8804-PCB-09 SENSOR CABLE 1

14 8804-PCB-21 CONTROL BOARD CASE 1

9

13

12

14

18

Page 22

1

4

2

Front of Shredder

5

3

Underside View, Feed Table and Conveyor

7

Top View with

Access Door open

6

7

(NOT SHOWN)

ITEM CC/SC PART # DESCRIPTION QTY

1 8804-PCB-17 MICRO SWITCH, WASTE BIN FULL SENSOR, 15A 1

2 8804-CTB-20 WASTE GUIDE, REAR 1

3 8804-CTB-06 WASTE GUIDE, RIGHT AND LEFT 2

4 8804-CTB-04 FRONT WASTE PROOF PLATE 1

5 8804-SBM-01 SAFETY BAR MICRO SWITCH 1

6 8804-CTB-21 PAPER DEFLECTOR 1

7 8804-CTB-22 DEFLECTOR MOUNTING BOLTS 4

19

Page 23

EVENFLOW OILING SYSTEM

Oil bottle and bracket mounting location

3

1

4

2

5

SEE DETAIL A

1

8

7

DETAIL A

ITEM PART # DESCRIPTION QTY

1 8804-OIL-01 OILER TUBING - BOTTLE TO PUMP 1

2 8804-OIL-02 OIL BOTTLE BRACKET 1

3 8804-OIL-03 OIL BOTTLE 1

4 8804-OIL-04 BOTTLE BRACKET MOUNTING SCREWS 4

5 8804-OIL-05 OIL DISPENSING ROD ASSEMBLY 1

6 8804-OIL-06 OILER PUMP MOTOR 1

7 8804-OIL-07 OILER PUMP MOTOR MOUNTING SCREWS 2

8 8804-OIL-08 OILER TUBING - PUMP TO DISPENSING ROD 1

6

20

Page 24

Loading...

Loading...