Page 1

Cut-True 27S

Semi-Automatic Electric Paper Cutter

9/2014

OPERATOR MANUAL

FIRST EDITION

Page 2

Page 3

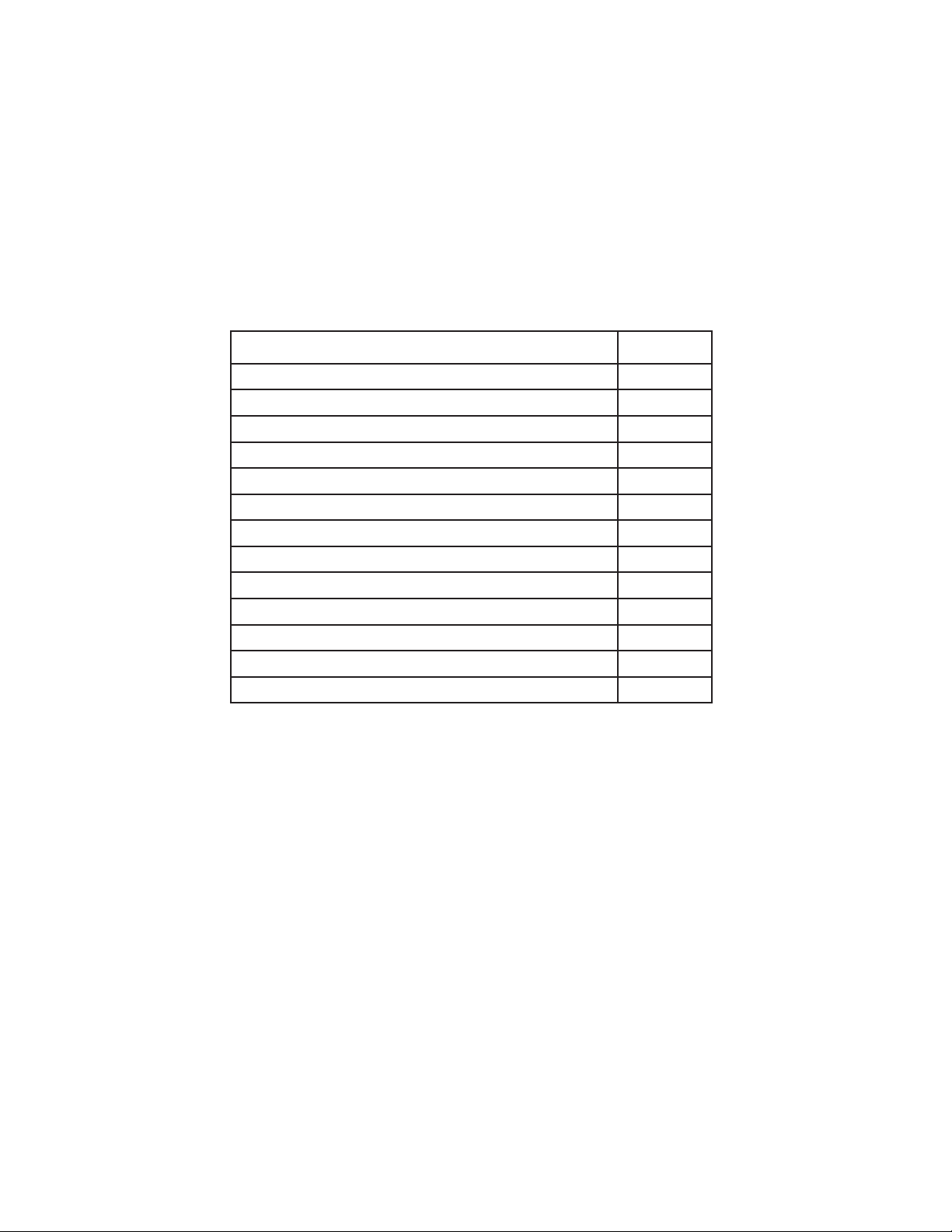

TABLE OF CONTENTS

TOPIC PAGE

Specications 1

Safety Guidelines 1

Installation / Assembly 2

Overview 3

Description of Equipment Parts 3 - 4

Operation 4

Replacing the Cutting Stick 5

Adjusting Blade Height - Cutting Depth 5

General Maintenance 5

Cutting Blade Maintenance 6

Troubleshooting 6

Replacing the Cutting Blade 6 - 8

Maintenance 9 - 11

Page 4

Cut-True 27S Guillotine Cutter

SPECIFICATIONS

Cutting Action: Dual-button electric

Maximum Cutting Width: 18.9” (480mm)

Maximum Paper Stack Height: 3.15” (80mm)

LED / Laser Cut Line: Yes

Clamp Style: Automatic

Back Gauge Adjustment: Manual crank

Back Gauge Reading: Digital readout, in both inches and metric

Blade Change Safety Tool: Included

Dimensions: 51” H x 36” W x 39” D (1300mm H x 920mm W x 1000mm D)

Weight: 595 lbs.

Power Supply: 110V

Safety Certications: CE approved, UL pending

Metal Stand with Shelf: Included, some assembly required

SAFETY GUIDELINES

* Operators should read this manual prior to using the cutter.

* The Cut-True 27S should only be used by one person at a time.

* Keep hands away from the cutting area. The cutter is operated by pressing two “enable switches” simultaneously.

* Do not disassemble Plexiglas safety covers, and never attempt to change the settings of any protective devices.

* Do not grasp underneath the blade edge.

* When changing the blade, carefully follow the instructions in this manual, and be sure to use the supplied Blade

Change Safety Tool. Wear leather gloves to provide additional safety.

* The Cut-True 27S is designed to cut only paper. DO NOT attempt to cut non-paper materials including metal sheets,

wood, plastic or anything other than paper. Machine damage and/or personal injury may occur.

* Be sure to check the safety devices before each operating session.

1

Page 5

INSTALLATION

Please use caution when moving the cutter, and be sure to utilize appropriate lifting devices

when attaching to the stand.

The cutter can be moved by using an overhead motorized lift, pallet jacks, or by hand.

NOTE: Four people are required to move the cutter by hand.

To move the cutter by hand, utilize

the lifting handles located on the front

and back of the machine. To adjust

the handles, loosen the knobs on the

underside and slide the handles to out

to a comfortable position. Retighten

the knobs.

When the cutter is in place and securely attached to the stand, loosen

the knobs, adjust the handles to

their storage position and tighten the

knobs.

Lifting handle

Adjustment knob Adjustment knob

Lifting handles

ASSEMBLY

The side panel, wooden paper pusher, blade safety device, and back gauge crank with screw are packed separately in

the box with the machine. Please set these aside and install after connecting the cutter to the stand.

The cutter should be installed in a location with sufcient space to permit efcient assembly, operation and maintenance.

Do not install in locations with direct sunlight or near a heat source.

The chassis and stand of the machine should be connected as follows:

1. Set the legs so the 4 threaded pins point upward.

2. Assemble the crossbars of the stand so the color labels on each match the corresponding legs. Fasten stand

securely with hexagonal screws.

3. Place the chassis correctly onto the assembled stand.

4. Tighten the four hexagonal nuts.

5. Position stand shelf in place and fasten securely with enclosed screws.

2

Page 6

OVERVIEW

21

1

2

3

4

5

6

2

7

11

8

9

10

12

13

14

15

16

17

18

19

20

22

23

10

24

DESCRIPTION OF EQUIPMENT PARTS

1. Cover Attached to the cutter with four screws. Disassemble only in case of blade

change or maintenance.

2. Enable Switches These switches must be pushed simultaneously to operate the paper clamp

and cutting blade.

3. Power Switch Used to turn on and off power to the cutter.

4. Back Gauge Crank Used to adjust back gauge to appropriate paper size and cut length. It is

indirectly connected with the Back Gauge: to engage the crank, simply

push it towards the machine, then turn. To release, pull the crank toward the

operator.

To move the back gauge toward the operator, turn clockwise.

To move the back gauge away from the operator, turn counterclockwise.

5. Power Light Shows when machine is powered on.

6. Key-Activated Mode Select Switch Turn to right for cutting. Turn to left for blade replacement. Turn to middle to

stop all operations.

7. Digital Measurement Readout Shows the current position of the back gauge, in mm and inches.

8. Rear Safety Cover Clear plexi cover is provided for operator safety and helps to prevent dust

buildup.

9. Front Safety Cover Prevents operators from placing hands or other objects in the cutting area.

Must be in the lowered/closed position in order to operate the cutter. The

guard can only be reopened when the blade is in the upright position.

10. Side Interlock Device A The cutter will not operate if the 6mm T-wrench used for blade adjustments

is still in the adjustment slot.

11. Side Panel Additional workspace.

12. Carrier (support) Carries the blade holder and the entire mechanism of the machine.

13. Safety Interlock Device B The machine can only be operated when the safety guard is closed.

14. Three Socket Headless Screws Adjustable screws for even cutting.

15. Cutting Blade Made of high-quality carbon steel.

3

Page 7

16. Paper Alignment Bars Steel side bar helps to align the paper prior to cutting.

17. Blade Holder Holds blade in place. There are ve screws for blade positioning, (which

should be set up and released step-by-step following the blade replacement

instructions) and adjusting the blade for even operation.

18. Cutting Stick Plastic stick which protects the edge of the blade during cutting. Can be

repositioned and used on all four sides before being replaced.

19. Cutting Stick Access Slot Insert screwdriver here in order to lift and remove cutting stick.

20. Stand Steel stand, assembly required.

21. Side Gauge with Scale In mm/cm and inches.The indicator on the back-gauge shows the mea-

surement. Fine adjustment is done via the back gauge crank (4). Minimum

adjustment is 0.5mm.

22. Back Gauge This is moved by rotating the Back Gauge Crank. Used to move the paper

stack into the appropriate cutting position.

23. LED Laser Cutting Line Shows operator exactly where the blade will cut the paper stack.

24. Blade Adjustment Access The blade height can be adjusted up to 2mm by using the adjustment screw.

To lower the blade (+), turn to the left. To raise the blade (-), turn to the right.

NOTE: If the blade is adjusted too low, it will cut deeply into the cutting stick,

damaging not only the stick but the cutting blade. The optimal blade height

is when the last sheet in a stack is cut accurately.

Wooden Push Block (not shown) Used to help align paper stacks for precise cutting.

Blade Change Safety Tool

(not shown)

Tool Kit (not shown) Includes T-wrench and interchangeable bits for use in adjustments and

This device is used to safely remove the blade when it needs to be

sharpened or replaced.

blade replacement.

OPERATION

1. Plug in the cutter to an appropriate power outlet.

2. Turn on the red power switch.

3. Raise the front safety cover. Slide the paper stack into the cutter along the left edge, using the alignment bar for

guidance. Push it as far back as possible toward the back gauge, without placing hands under the cutting blade.

4. To change the back gauge LED readout between standard and metric, insert

a pin or straightened paper clip into the access hole just above the LED, as

shown in the diagram at right.

5. Push in the back gauge crank to engage the handle, then turn it clockwise

to bring the back gauge toward the front until the paper is properly matched

with the measurement guide on the side of the machine. The LED digital

readout will indicate the position of the cut. The LED Laser Light will indicate

the position of the blade to help with paper positioning.

6. Release the back gauge crank handle by pulling it toward you. This disengages the crank and prevents unintentional movement.

7. Use the wooden push block to align the front and right edges of the paper stack.

8. Lower the front safety cover.

9. Turn the Mode Select Switch key to the right.

10. Press and hold the two clamp engage switches to clamp the paper securely in place. The clamp switches are

indicated by this icon

Insert pin

here

12.25

inch

cm

11. Press and hold the two blade engage switches to cut the paper. The blade switches are indicated by this icon

After cutting, the blade and clamp will each return to the upright position.

12. Lift the front safety cover and remove the paper stack.

4

Page 8

ROTATING / REPLACING THE CUTTING STICK

The cutting stick is the surface the blade contacts during the cutting process. It can be rotated and used on each side,

4 times altogether.

If the last piece of paper in the stack is not cut through cleanly, and the blade depth has been adjusted properly, the cutting stick should be rotated or replaced.

The cutting stick sits in a channel in the base of the cutter, just below the blade carrier. To remove it, rst turn off the

power. Then insert the 5mm screwdriver into the cutting stick access slot (see photo below left) and lift up. Grasp the

cutting stick and remove (see photo below right). Rotate the cutting stick to a new side and re-install.

NOTE: When the cutting stick is rotated or replaced, the blade height must be readjusted. See the next page for blade

height adjustment instructions.

ADJUSTING BLADE HEIGHT / CUTTING DEPTH

When the cutting stick is rotated or replaced, or the blade is replaced, the blade height must be readjusted. A blade which

cuts too deeply damages not only the cutting stick but the blade itself. The optimal blade height is when the last sheet in a

stack is cut accurately. The blade height can be adjusted up to 2mm.

1. The blade adjustment access is on the right side of the cutter, just behind the fuse panel (see picture, below left).

2. Slide the nger knob down and hold in place to open the access door.

3. Insert the T-wrench from the tool kit into the adjustment slot. To lower the blade (+), turn to the left. To raise the

blade (-), turn to the right.

4. NOTE: You must remove the T-wrench before operating to avoid injury or damage to the cutter.

Front of Cutter

GENERAL MAINTENANCE

All moving parts with screws should be checked periodically to be sure the screws are tight. They may become loose in

the process of transportation. Users should also check and tighten the screws after more than 200 cutting cycles.

All moving parts should be lubricated and oiled periodically to maintain performance and equipment life. Before lubricating, these parts should be cleaned to remove paper dust and old deposits of oil and grease.

5

Page 9

CUTTING BLADE MAINTENANCE

The cutting blade is made of heat-treated high-carbon steel and is designed for repeated use. However, over time the

blade will become dull, and not perform to the highest standards. Cutting heavy paper or cardboard will dull the blade

more quickly than thinner paper stock. A dull blade will not cut accurately. Blade lifetime with normal paper is approximately 1,500 cuts (tested in maximum capacity).

NOTE: If the blade jams in the paper stack or leaves a groove in the paper, it should be changed immediately.

If “CUT1500” appears in the LED display, the blade has completed 1,500 cutting passes. Check the blade to see if it is dull

or still sharp enough to cut through one sheet of copy paper.

If the blade is still sharp and does not need to be replaced, reset the counter with the following steps:

1. Turn the select switch key to the right.

2. Press and hold the right enable switch for at least 5 seconds, while simultaneously turning the select switch key

back to the middle position until the message “CAT” appears in the LED display.

3. Release the right enable switch.

If the blade is not making clean, accurate cuts, check the following:

* Have you rotated or replaced the cutting stick?

* Have you correctly adjusted the height of the blade?

If so, the blade will need to be replaced. The blade can either be re-sharpened by a professional, or it can be replaced

with a new blade. To avoid injury, follow the Blade Changing Procedure and use the Blade Change Safety Tool, included

with the cutter.

TROUBLESHOOTING

Blade doesn’t move Check if the main motor magnetic contact is activated.

No power Check power source and all control circuit fuses.

Overload Wait until the breaker automatically resets, which takes around 30-60 seconds.

The indicator light will be off. Reduce size of paper stack or change blade.

Cutter won’t operate after

closing front safety guard

Other issues Please contact your Formax dealer for service.

Press the two “enable switches” again, and check if the safety guard is completely

closed.

Blade Replacement Procedure

1. Remove screws at both ends of the cover.

Lift off and remove the cover.

Select switch in blade change position

2. Turn the power switch ON, and turn the select

switch to the left.

Power switch in ON position

6

Page 10

3. Press two enable switches simultaneously to

move the blade down to the bottom position.

4. Turn the select switch to the middle and turn

off the power. Then lift the plexi safety cover to

remove the rst screw from the right side of the

blade (A).

5. Close the safety cover and turn the select switch

to the left. Then turn on the power. The blade will

move up automatically. Turn the select switch to

the middle and turn off the power.

A

6. Raise the safety cover and remove the rst

screw from the left side (B). Remove the screws

to the left and right of center (C & D), but leave

the center screw in place.

NOTE: Do not remove the center screw.

7. Remove the blade change safety tool from the

tool box and screw the handles into the two holes

to the left and right of center (see photo). Screw

them in tightly, to prevent the blade from falling

out of the holder.

B C D

Center screw

7

Page 11

Blade change safety tool in place

8. Remove the center screw.

9. Grip and loosen both of the blade change tool

handles by turning just a half reverse turn to

remove the blade from the machine. Carefully

move the blade and holder downward in order

to remove it safely from the machine. NOTE: Be

careful to avoid injury from the very sharp blade.

10. Carefully remove the old blade from the blade

change safety tool. Set it on a at surface and

unscrew the handles. Cap the old blade with a

protective pad to prevent injury.

11. Place the new blade with the beveled cutting

edge facing up, and the screw holes at the top,

as shown here. Remove the protective pad

from the new blade.

To attach the blade change tool, place it over

the blade and screw the handles into the lower

set of screw holes. Then reverse the procedure

to install the new blade.

Beveled cutting edge

8

Loading...

Loading...