Page 1

Cut-True 15M

Manual Paper Cutter

9/2014

OPERATOR MANUAL

SECOND EDITION

Page 2

Page 3

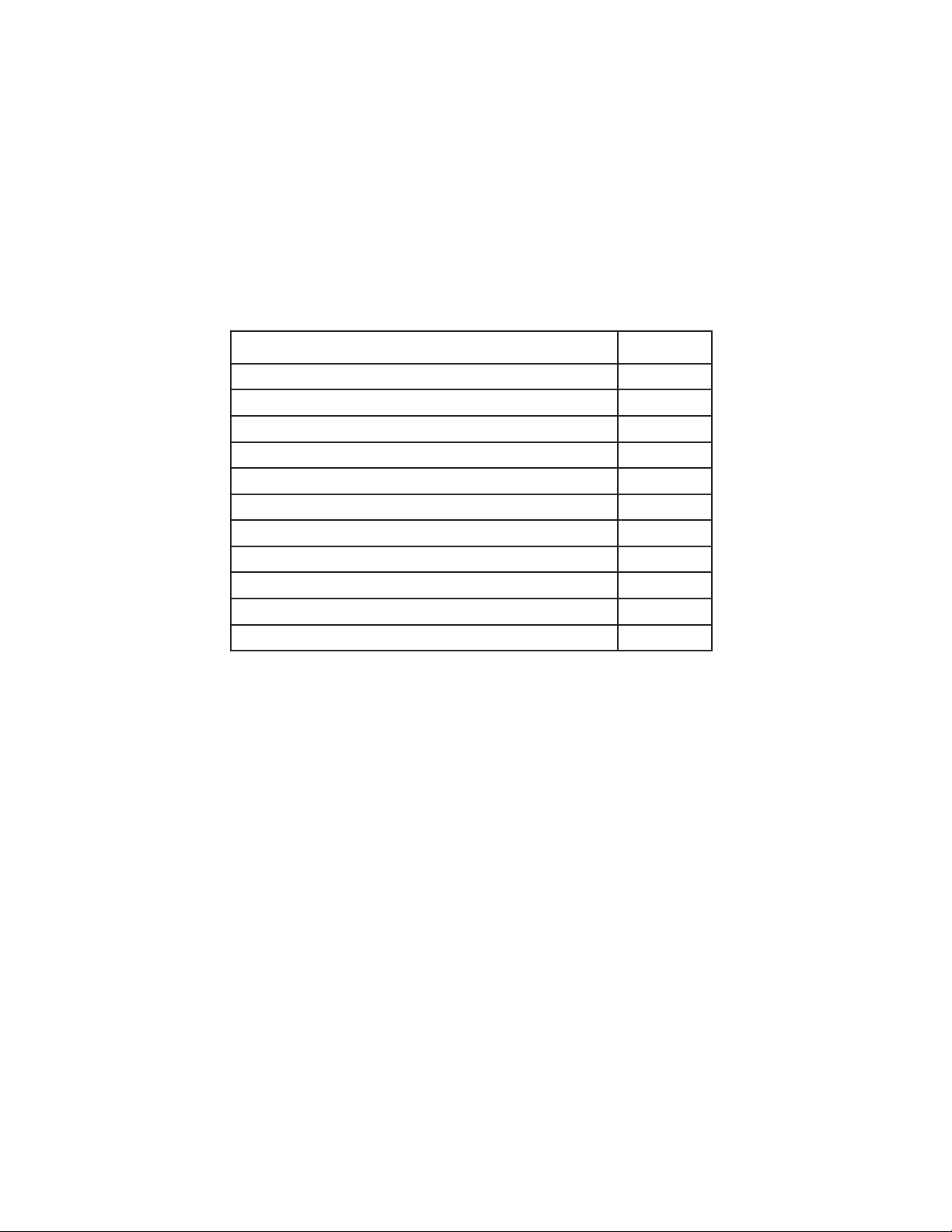

TABLE OF CONTENTS

TOPIC PAGE

Specications 1

Safety Guidelines 1

Assembly 2

Overview 3

Description of Equipment Parts 3 - 4

Operation 4

Maintenance 5

Replacing the Cutting Stick 5

Cutting Blade Maintenance 5

Replacing the Cutting Blade 5 - 7

Page 4

Cut-True 15M Guillotine Cutter

SPECIFICATIONS

Cutting Action: Manual lever handle

Maximum Cutting Width: 16.9” (430mm)

Maximum Paper Stack Height: 2.15” (55mm)

LED Laser Cut Line: Yes

Clamp Style: Spindle-guided clamping wheel

Back Gauge Adjustment: Manual crank

Back Gauge Reading: Scale, in both inches and metric

Blade Change Safety Tool: Included

Dimensions: 42.5” H x 26.8” W x 29.1” D (1080 H x 680 W x 740 D mm)

Weight: 133 lbs. (60kg)

Safety Certications: CE approved

SAFETY GUIDELINES

* Operators should read this manual prior to using the cutter

* The Cut-True 15M should only be used by one person at a time.

* The knife lever should be lowered using both hands.

* After making each cut, the knife lever should be moved back to the full upright and locked position.

* Do not disassemble the front Plexiglas safety cover.

* Do not grasp underneath the knife edge.

* When changing the blade, carefully follow the instructions in this manual, and be sure to use the supplied

Blade Change Safety Tool.

1

Page 5

ASSEMBLY

The handgrip of the blade lever arm, the spindle guided clamp wheel and the back gauge crank with screw are packed

separately in the box with the machine. Install these parts rst.

The chassis and stand of the machine should be connected as follows:

1. Set the legs so the 4 threaded pins point upward.

2. Assemble the crossbars of the stand so the color labels on each match the corresponding legs.

3. Place the chassis correctly onto the assembled stand.

NOTE: When attaching the cutter to the chassis, the screw on the top of each leg must accurately aim at the

triangle holes on the corners of the underside of the cutter. These must be afxed properly to keep the machine

table from collapsing.

4. Fit the supplied washer over each of the threaded pins on the legs and tighten the hexagonal nut using a 13mm

wrench.

Battery installation/replacement:

Fit two D batteries into the battery holder on the underside of the chassis.

When the LED cutting light eventually becomes dim, replace the batteries with fresh ones.

2

Page 6

OVERVIEW

DESCRIPTION OF EQUIPMENT PARTS

1. Safety Gadget Protects operators from blade lever arm’s moving parts

2. Blade Lever Arm Lever-action provides robust cutting with minimal effort. After each cut, the

lever must be returned to its full upright and locked position.

3. Blade Locking Device Connected to the front safety guard (7), it prevents operation when the

safety guard is in the up/open position.

4. Cutting Blade Heat-treated high-carbon steel blade.

5. Blade Carrier Holds the blade during operation. Blade is attached with 5 screws.

6. Cutting Stick Plastic stick which protects the edge of the blade during cutting. Can be

repositioned and used up to 8 times before being replaced.

7. Front Safety Guard Prevents operators from placing hands or other objects in the cutting area.

Must be in the lowered/closed position in order to operate the cutter.

guard can only be reopened when the knife lever is in the upright, locked

position.

8. Spindle-Guided Clamp System Holds the paper stack securely while cutting. Turn the hand wheel clockwise

to lower the clamp. Turn it counter-clockwise to release.

9. Blade Housing Cover Attached to the machine with four screws. Only disassemble in case of

blade change or maintenance. Before removing the cover, the safety gadget, hand wheel and lever arm handgrip must be removed.

The

3

Page 7

10. Blade Adjustment Access The blade height can be adjusted up to 2mm by using the adjustment screw.

To lower the blade (+), turn to the left. To raise the blade (-), turn to the right.

NOTE: If the blade is adjusted too low, it will cut deeply into the cutting stick,

damaging not only the stick but the cutting blade. The optimal blade height

is when the last sheet in a stack is cut accurately.

11. Back Gauge Crank The crank is indirectly connected with the Back Gauge: to engage the crank,

simply push it towards the machine, then turn. To release, pull the crank

toward the operator.

To move the back gauge toward the operator, turn clockwise.

To move the back gauge away from the operator, turn counterclockwise.

The scale behind the crank is used for ne adjustments. “O” indicates a

whole cm, “1-9” indicated corresponding mm.

12. Back Gauge This is moved by rotating the Back Gauge Crank. Used to move the paper

stack in the appropriate cutting position.

13. Side Gauge with Scale In mm/cm and inches.

14. Stand Steel stand, assembly required.

15. Light Switch Controls the LED Laser Line.

16. Paper Alignment Bar Steel side bar helps to align the paper prior to cutting.

17. Rear Safety Cover Clear acrylic cover is provided for operator safety and helps to prevent dust

buildup.

18. Wooden Push Block (not shown) Used to help align paper stacks for precise cutting.

19. Blade Change Safety Tool

(not shown)

20. Tool Kit (not shown) Includes T-wrench and interchangeable bits for use in adjustments and

This device is used to safely remove the blade when it needs to be resharpened or replaced.

blade replacement.

OPERATION

1. Turn on the LED Laser Light.

2. Raise the blade lever arm to the upright, locked position.

3. Raise the front safety cover. Slide the paper stack into the cutter along the left edge, using the alignment bar for

guidance. Push it as far back as possible toward the back gauge, without placing hands under the cutting blade.

4. Push in the back gauge crank to engage the handle, then turn it clockwise to bring the back gauge toward the

front until the paper is properly matched with the measurement guide on the side of the machine. Use the ne adjustment ring if needed. The LED Laser Light will indicate the position of the blade to help with paper positioning.

5. Release the back gauge crank handle by pulling it toward you. This disengages the crank and prevents unintentional movement.

6. Use the wooden push block to align the front and right edges of the paper stack.

7. Turn the spindle hand wheel clockwise to clamp the paper securely in place.

8. Lower the front safety cover.

9. Use both hands to grasp the blade lever arm and bring it down to cut through the paper stack. When the cut is

complete, raise the lever arm to its top position until it locks into place.

10. Turn the spindle hand wheel counter-clockwise to release the paper stack.

11. Lift the front safety cover and remove the paper stack.

4

Page 8

MAINTENANCE

All moving parts with screws should be checked periodically to be sure the screws are tight. They may become loose in

the process of transportation. Users should also check and tighten the screws after more than 200 cutting cycles.

All moving parts should be lubricated and oiled periodically to maintain performance and equipment life. Before lubricating, these parts should be cleaned to remove paper dust and old deposits of oil and grease.

REPLACING THE CUTTING STICK

The cutting stick is the surface the blade contacts during the cutting process. It can be turned or rotated and used twice on

each side, 8 times altogether.

If the last piece of paper in the stack is not cut through cleanly, and the blade adjustment has been adjusted properly

cutting stick should be turned, rotated or replaced.

The cutting stick sits in a channel in the base of the cutter, just below the blade carrier. To remove it, simply grasp it in the

center using the nger cutout and lift upward and out. Turn the stick 180 degrees to use the same cutting side, or rotate to

a new side if the rst has already been used twice.

NOTE: When the cutting stick is rotated or replaced, the blade height must be readjusted. A blade which cuts too deeply

damages not only the cutting stick but the blade itself. The optimal blade height is when the last sheet in a stack is cut

accurately. The blade height can be adjusted up to 2mm by using the adjustment screw (10, in the Parts Description). To

lower the blade (+), turn to the left. To raise the blade (-), turn to the right.

, the

CUTTING BLADE MAINTENANCE

The cutting blade is made of heat-treated high-carbon steel and is designed for repeated use. However, over time the

blade will become dull, and not perform to the highest standards. Cutting heavy paper or cardboard will dull the blade

more quickly than thinner paper stock. A dull blade will not cut accurately. If the blade jams in the paper stack or leaves a

groove in the paper, it should be changed immediately.

If the blade is not making clean, accurate cuts, check the following:

* Have you rotated or replaced the cutting stick?

* Have you correctly adjusted the height of the blade?

If so, the blade will need to be replaced. The blade can either be re-sharpened by a professional, or it can be replaced

with a new blade. To avoid injury, follow the Blade Changing Procedure and use the Blade Change Safety Tool, included

with the cutter.

REPLACING THE CUTTING BLADE

1. Remove the safety gadget. Lift the bottom, grasp the

side and gently pop off.

5

Page 9

2. Lower the blade lever arm to horizontal position.

3. Remove the four screws on the front safety cover,

then remove the cover itself.

4. Remove the right blade screw (A).

5. Raise the blade lever arm to its top position.

6. Remove the screw on the clamp handwheel and

remove the wheel.

7. Remove the handgrip from the blade lever arm by

twisting the handgrip toward the left and unscrewing it.

7. Remove four screws on the blade housing cover.

9. Move the blade lever arm to a 75+ angle and slide the

blade housing cover off.

A

10. Raise the blade lever arm to upright position.

11. Remove the far left blade screw.

12. Remove the screws to the left and right of center.

NOTE: Do Not remove the center screw.

13. Attach the Blade Change Safety Tool to the blade,

screwing in the handles to the holes to the left and

right of center. Tighten securely.

14. Remove the center screw. The blade and safety tool

should remain in place.

After steps 1-9, the cutter should look like this.

Center screw

6

Page 10

15. Slowly turn the handles of the safety tool slightly

to the left, just enough to release the blade from

the machine. NOTE: The blade and safety tool are

heavy.

16. Remove the blade and safety tool together.

17. Carefully remove the old blade from the blade

change safety tool. Set it on a at surface and

unscrew the handles. Cap the old blade with a

protective pad to prevent injury.

18. Place the new blade with the beveled cutting edge

facing up, and the screw holes at the top, as shown

here. Remove the protective pad from the new

blade.

To attach the blade change tool, place it over the

blade and screw the handles into the lower set of

screw holes. Then reverse the procedure to install

the new blade.

19. After installing the new blade, it will need to be ad-

justed for proper positioning and cutting depth.

20. Carefully move the blade to the cutting stick by low-

ering the blade lever arm. NOTE: Keep hands and

objects out of the path of the blade.

21. Turn the blade adjustment screw (X) to the right

(-) until you have a visible ray of light between the

blade and the cutting stick.

22. Adjust the blade to touch the cutting stick evenly by

using the three screws at the top (Y).

23. Raise the blade lever arm to the top position and

lock it. Then make a trial cut with a single sheet of

paper. If the paper is not cut through completely, the

blade must be adjusted using the screws (X) and/

or (Y).

NOTE: The three (Y) screws are for horizontal

adjustment and the (X) screw is for minor up-down

adjustment.

24. Reassemble the blade housing cover, the front

safety cover, and reattach the spindle handwheel,

the lever arm handgrip and the safety gadget.

X

7

Loading...

Loading...