Page 1

ColorMaxLP

Digital Color Printer

6/20145

OPERATOR MANUAL

Revision 2

Page 2

Copyright © 2014 Formax. A

No part of this document may be photocopied, reproduced, or translated to another language without the

prior written permission of Formax.

Trademarks

Firefox is a trademark of the Mozilla Foundation.

Intel and Intel Core are trademarks of Intel Corporation in the U.S. and/or other countries.

Java and Oracle are registered trademarks of Oracle and/or its affiliates.

Microsoft, Windows, Windows Vista, and Windows Server are registered trademarks of Microsoft

Corporation in the U.S.A. and/or other countries.

Edition

L801 Printer User Guide Edition 1.3. June 2014.

FCC

This device complies with Part 15 of the FCC rules. Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

ll rights reserved.

2

Page 3

Safety Precautions

Electrical Shock Hazard

Do

not disassemble any part of your printer. There are no user-repairable parts inside

the printer. Disassembly of any part of the printer will void all warranties.

Fire Hazard

Keep the printer well away from all heat sources and flammable substances.

itch your printer off immediately and unplug the power cord from the wall socket if

Sw

you notice any of the following:

• Smoke rising from the printer.

• An acrid smell coming from the printer.

• Sparks being emitted from printer.

Contact your supplier as soon as possible.

WARNING: Hazardous Moving Parts

Keep fingers and other body parts away from the printer.

Installation

• Install the printer on a flat, level surface.

The printer must remain level at all times. Tilting the printer may cause undue

leakage of ink and may damage the printer.

• Avoid wide temperature variations.

Install the printer in a protected location away from direct sunlight, open windows

or any other places subject to temperature extremes.

Power Supply

Input Rating 100–240 VAC, 50/60 Hz, 3.6 A

Operating Temperature 15°C to 35°C

• Always use the Power button on the control panel to turn the printer off. Removing

wer to the printer in any other manner may damage the printer.

po

• Use only the supplied power adapter and cord.

Use of any other power supplies or cords may damage the printer and void your

warranty.

3

Page 4

Printer Usage

• Ensure adequate ventilation to the printer.

Blo

cking ventilation openings around the printer may cause it to overheat and

become damaged.

• Keep liquids and heavy objects away from the printer.

Heavy objects may warp the outer shell, damaging the printer. Liquids may discolor

or damage the skin and, if they penetrate it, may damage the printer beyond repair.

• Use only authorized consumables.

Use of any printhead other than authorized Formax tec

damage the printer and void your warranty. Use of unauthorized inks or ink

cartridges may damage the printer and will void your warranty.

• Clear media jams promptly.

To avoid further problems, promptly attend to all media jams, as well as any other

cause of printer failure.

• If you are moving the printer, allow sufficient time after installation for the

temperature and humidity of the internals of the printer to arrive at equilibrium

with the surroundings.

hnology printheads will

4

Page 5

Contents

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Co

ntents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Setting Up the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Start. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

rts of the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Pa

The Control Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Remove tape and packing materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Unpacking, Setup, and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Connect power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Install ink cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Install printhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Load sample media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Print test label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Install printer driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Troubleshooting Printer Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Change Security Passwords (Administrator) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Using the Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Choosing Label Media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Printing Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Selecting the Media Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Adjusting Alignment for Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Printing Borderless (Full-Bleed) Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Export/Import Custom media size settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Turning Off the Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Software Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Embedded Web Server (EWS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

EWS Printer Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

EWS Security Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

EWS Network Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

EWS Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

EWS Advanced Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Interpreting the Gap/Mark Sensor Readings. . . . . . . . . . . . . . . . . . . . . . . . . . 42

Support Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Printer Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Guidelines for Preventive Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

placing an Ink Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Re

Cleaning the Printhead. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Replacing the Printhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Opening/Closing the Clamshell. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Cleaning Debris from the Cutting Zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Cleaning the Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Cleaning the Media Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

5

Page 6

Replacing the Service Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Re

placing the Aerosol Fan Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Replacing the Waste Ink Absorber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

If Error Messages Appear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

or Print Quality or Incorrect Printout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Po

Other Printing Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Clearing a Media Jam. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Clearing Clogged Ink Nozzles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Color Mixing Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Adjusting Sensor Sensitivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

System Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Config Options on the Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Printer Interface (GPIO) Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Regulatory Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

FCC Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

CE Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Waste Electrical and Electronic Equipment Directive . . . . . . . . . . . . . . . . . 85

6

Page 7

Chapter 1

Setting Up the Printer

Start 8

In

the Box 8

Parts of the Printer 9

The Control Panel 10

Using the Control Panel 11

Selecting the Security Level 12

Unpacking, Setup, and Installation 13

Remove tape and packing materials 13

Connect power 14

Install ink cartridges 15

Install printhead 15

Load sample media 17

Print test label 18

Install printer driver 18

Troubleshooting Printer Setup 20

Change Security Passwords (Administrator) 21

Setting Up the Printer 7

Page 8

Formax

Star

t

Set up the printer on a flat, level surface away from direct sunlight (see Safety

Precautions on page 3). Ensure that there is:

• A power outlet nearby.

• Sufficient space to work with the printer. The media cover and top cover open

upwards, and media loading is from the left side of the printer.

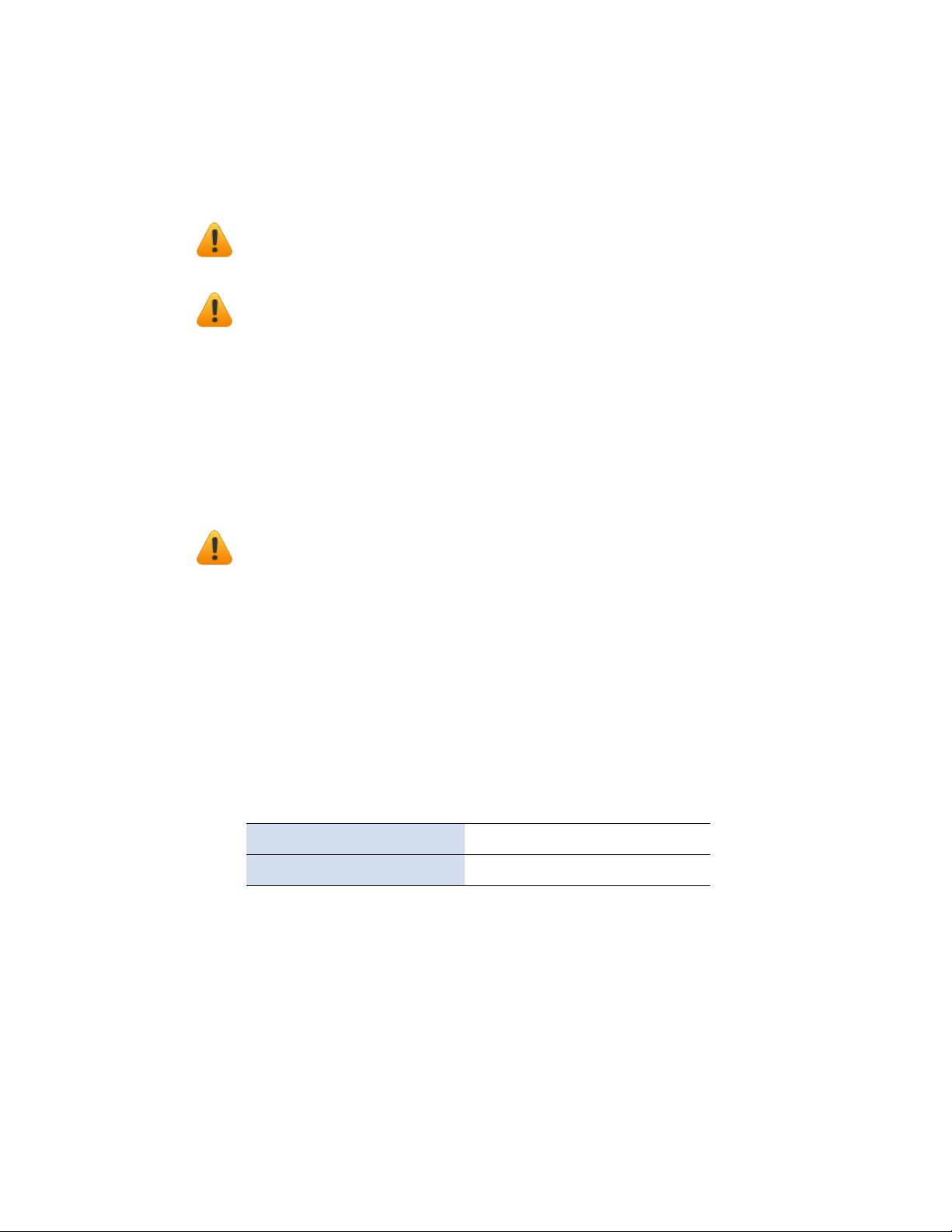

In the Box

ColorMaxLP Label Printer

Ink Cartridges

USB Cable

Sample Label Roll

Printhead

Power Cable

Installation Disc

8 Setting Up the Printer

Page 9

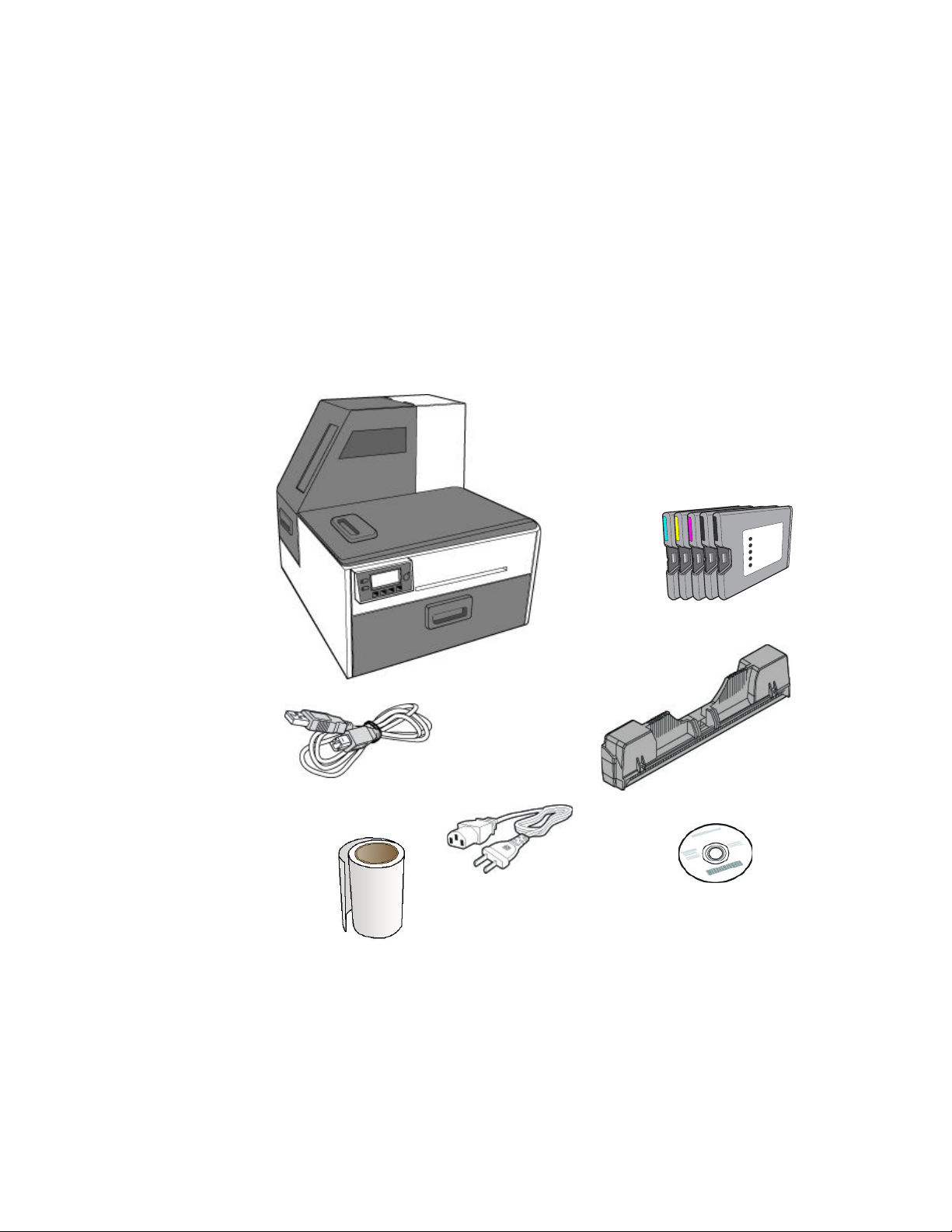

Parts of the Printer

Media Cover

Control Panel

ColorMaxLP Label Printer

Top Cover

Output Slot

Front Cover

GPIO Port

USB Port

Ethernet Port

Power Socket

Power Switch

Setting Up the Printer 9

Page 10

Formax

The Control Panel

Data LED

Status LED

The printer is ready to print when the control panel displays

Status LEDs together with messages indicate the printer status and any potential

problems (Table 1).

The control panel also shows the estimated levels of the ink cartridges. In the example

below, the yellow ink cartridge level is between 25 to 50%.

The icons above the printer buttons indicate their functions, which change depending

on the current operation (see Table 2).

Printer Online

Table 1 Printer LEDs

LED Description

Data LED

Power LED

Power Button

Ink Status

Printer Buttons

Printer Online

. The Data and

Blinking Printer is receiving data from the computer.

On There are print jobs in the printer memory.

Status LED

Blinking • Printhead is being serviced, or

• Attention needed; a message will be displayed. (See If Error

Messages Appear on page 64.)

On • An error has occurred; a message will be displayed. (See If

Error Messages Appear on page 64.)

10 Setting Up the Printer

Page 11

ColorMaxLP Label Printer

Using the Control Panel

The icons above the printer buttons indicate their functions (Table 2).

• When the printer is online, press (

options are described in Config Options on the Control Panel on page 78.

• Press and to scroll through the menus.

Select

• Press (

• Press (

) to select an option or setting.

Return

) to return to the previous menu.

Printer Online

Config

) to access the configuration menus. The

CONFIGURATION

1. Setup

Table 2 Printer Buttons

Function Description

Config Access the Configuration menus.

Up, Down Move through the menu options.

Select Select a menu option or confirm a setting.

Return Return to previous menu.

Unload Media Unload the labels.

Pause, Resume Pause or resume printing.

If printing roll to roll, the printer pauses for 10 seconds,

then prints the next page and pauses again. It will

continue to print and pause.

Cancel Cancel printing.

Setting Up the Printer 11

Page 12

Formax

Selecting the Security Level

By default, the printer powers up in security Level 0 (operator), which does not allow changes to

some printer settings. For the initial Printer Setup, it is recommended that you change the

Security Level to 2 (Administrator) before changing those settings.

NOTE: During initial Setup, Security may already be preset to Level 2. The display will

immediately go to the Language setting if it is.

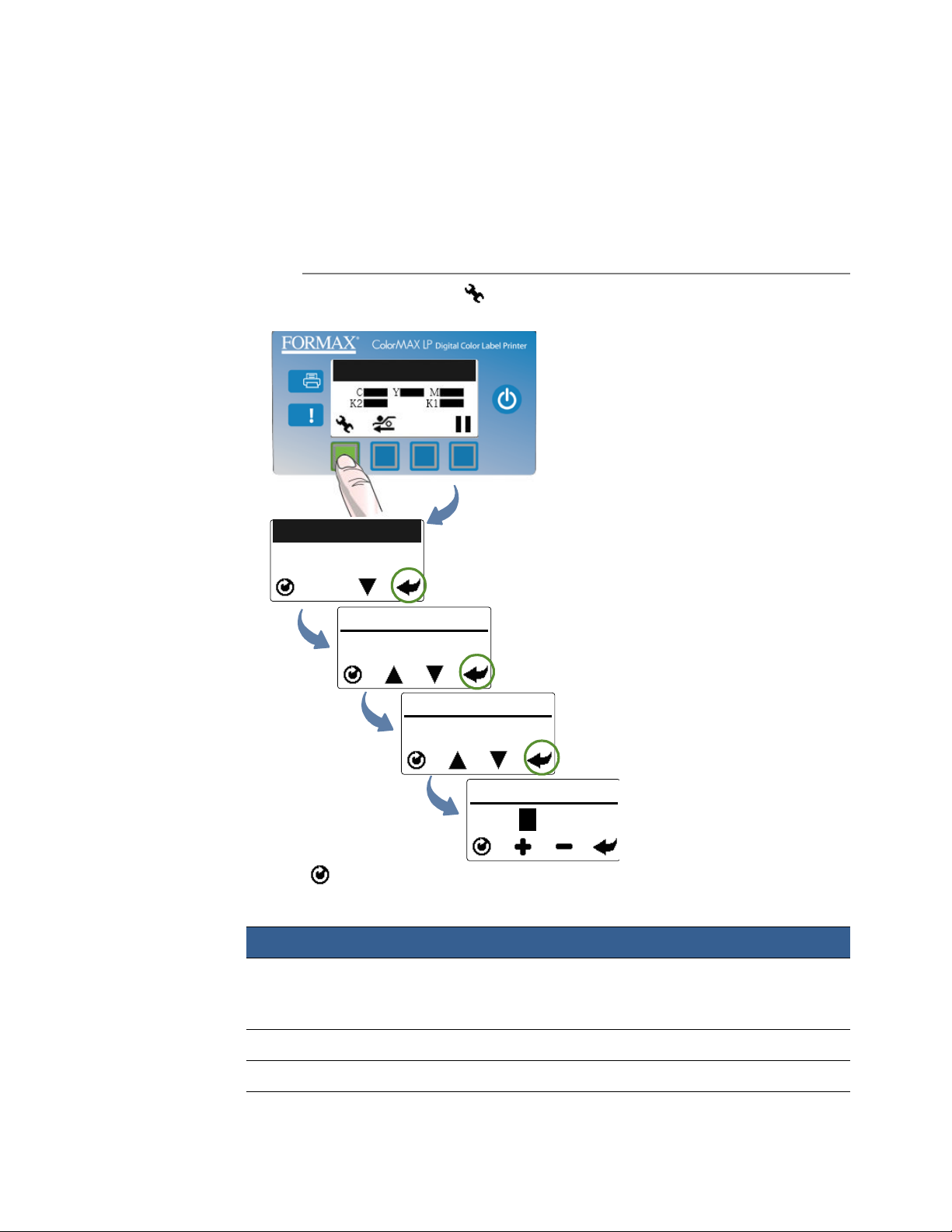

1. On the control panel, select (

2. Enter the 3-digit password (default is 123).

Config

) >

Printer Online

(Config)

CONFIGURATION

1. SETUP

(Select)

SETUP

2. SECURITY

SECURITY

2. Level 2

ENTER PASSWORD

Setup > Security

Enter the first password digit using

the + or - button, then press

Select. Repeat for next two digits.

Authenticated message will

appear with the right password

>

Level 2

.

3. Press to return to the main menu.

Table 3 Security Restrictions

12 Setting Up the Printer

Security Level Restricted Settings

Operator (Level 0) Language, Reset, LCD Contrast, LCD Brightness,

Date/Time, Unit, Service Station, Sensor, Ext Signal

Print, Adjust Offset, DHCP Setting, IP Settings

Supervisor (Level 1) Reset, Day/Time, DHCP Setting, IP Settings

Administrator (Level 2) No restrictions

Items in bold indicate no access to an entire menu; others are specific functions.

Page 13

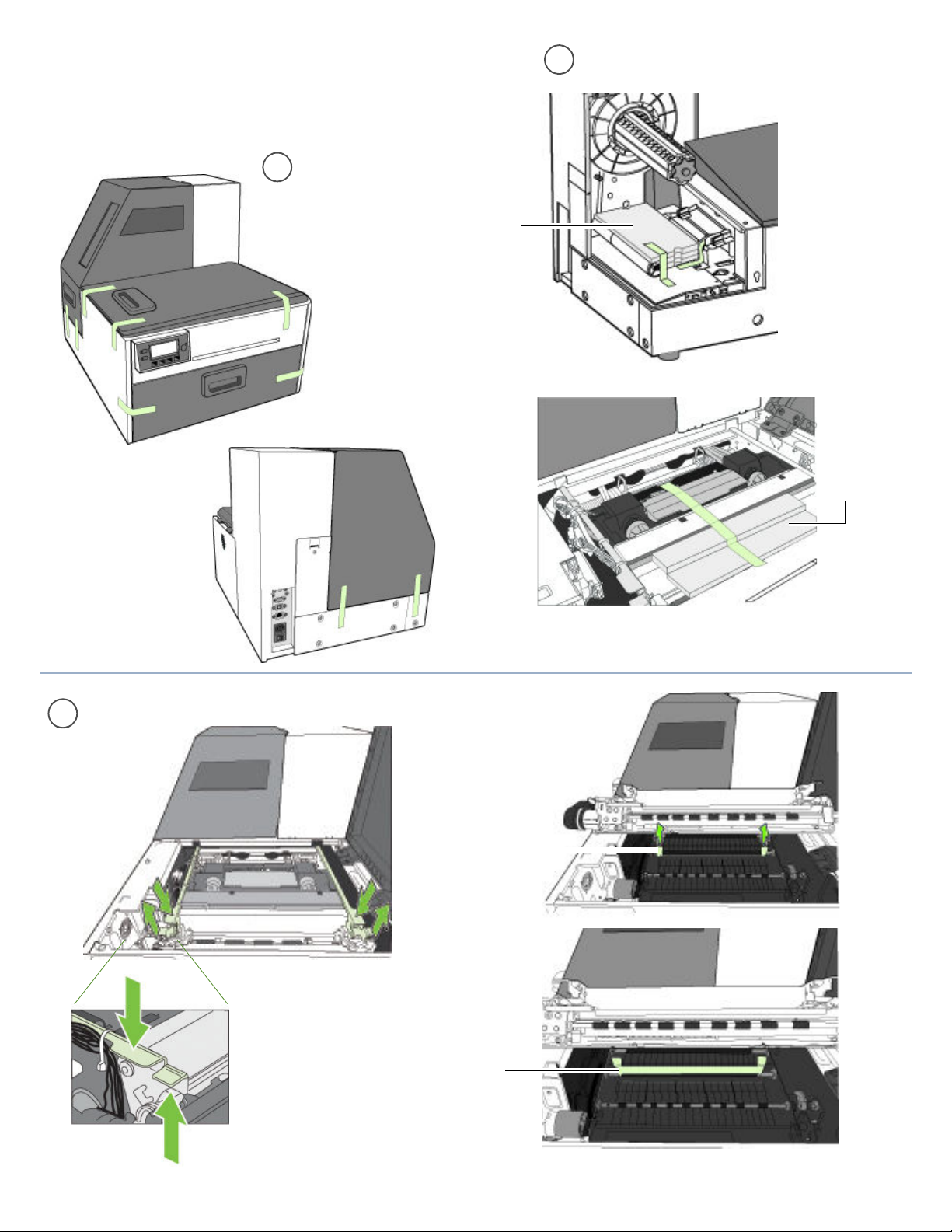

Unpacking, Setup, and Installation

Remove tape and packing materials

1

Remove tapes.

a

Keep all foam

d cardboard

an

packing materials!

Foam

Remove tapes and foam from inside

b

the printer.

Foam

Remove cardboard.

c

Pull tabs

Squeeze latches to

open clamshell

Lift out cardboard

Setting Up the Printer 13

Page 14

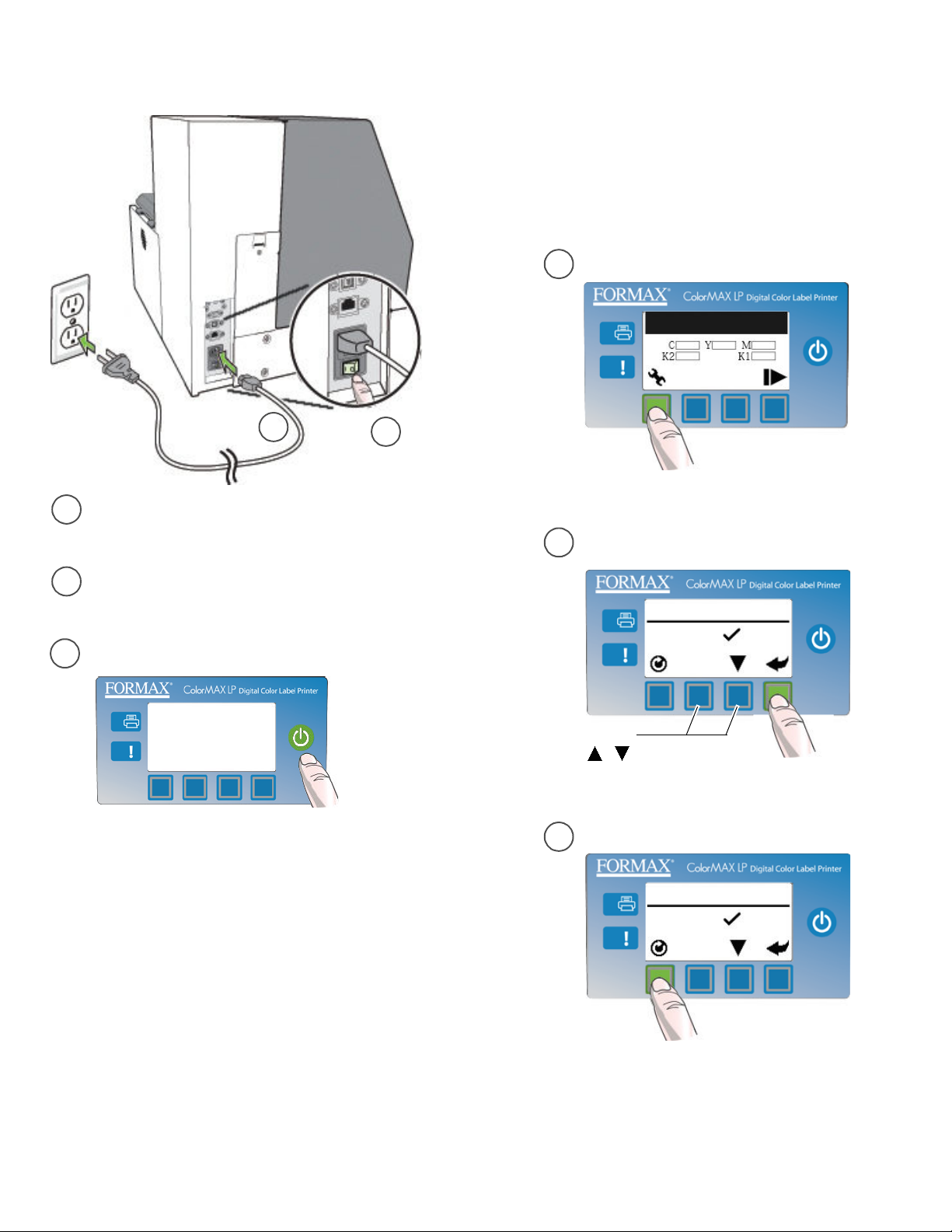

Connect power

2

Choose display language (optional)

After connecting power for the first time, press

Config to set the display language for the control

panel if you want to change from the default

setting of English.

Missing Printhead

Press the Config button

d

a

a

Plug power cable into printer and outlet

b Turn on power switch

the Power button on the control panel

Press

c

b

(Config)

Press

e

language is displayed

For other languages,

press ,

Press the Return button

f

the Select button when the correct

LANGUAGE

1. English

(Select)

14 Setting Up the Printer

LANGUAGE

1. English

(Return)

Page 15

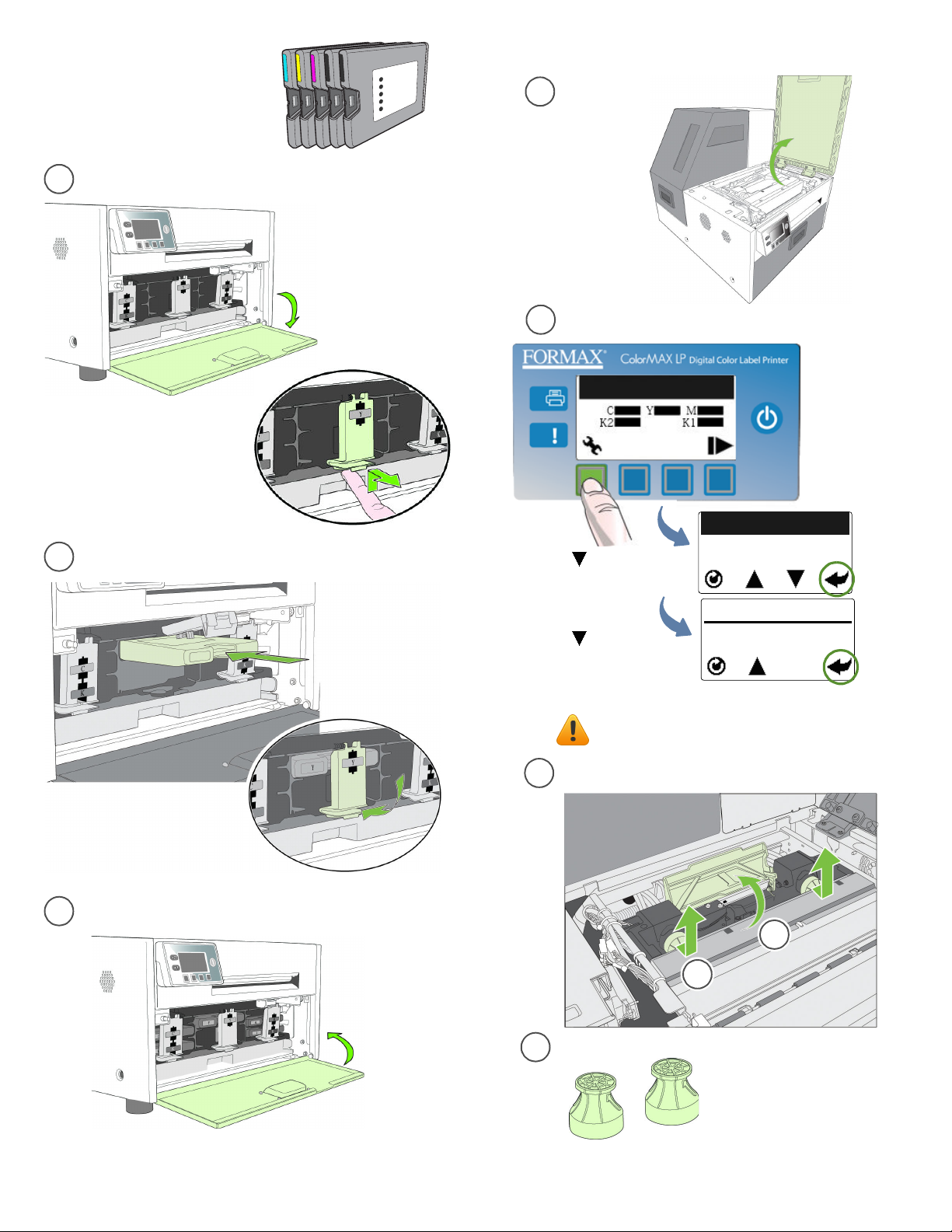

Install ink cartridges Ins

3

Open front of printer and release cartridge latch

a

4

tall printhead

Open Top Cover

a

Press the Config button

b

Missing Printhead

Insert ink cartridge and close cartridge latch

b

Close front of printer

c

Press

until display reads

Printhead, then press

Select

Press until display

reads Replace, then

s Select

pres

Wait for printhead latch to be released.

Do not open latch before it is released!

Open printhead latch fully.

c

CONFIGURATION

3. PRINTHEAD

PRINTHEAD

2. REPLACE

c

(Select)

(Se

lect)

Remove nozzle caps.

d

d

Do not discard the caps!

They should be replaced

if the printhead is removed

from the printer.

Setting Up the Printer 15

Page 16

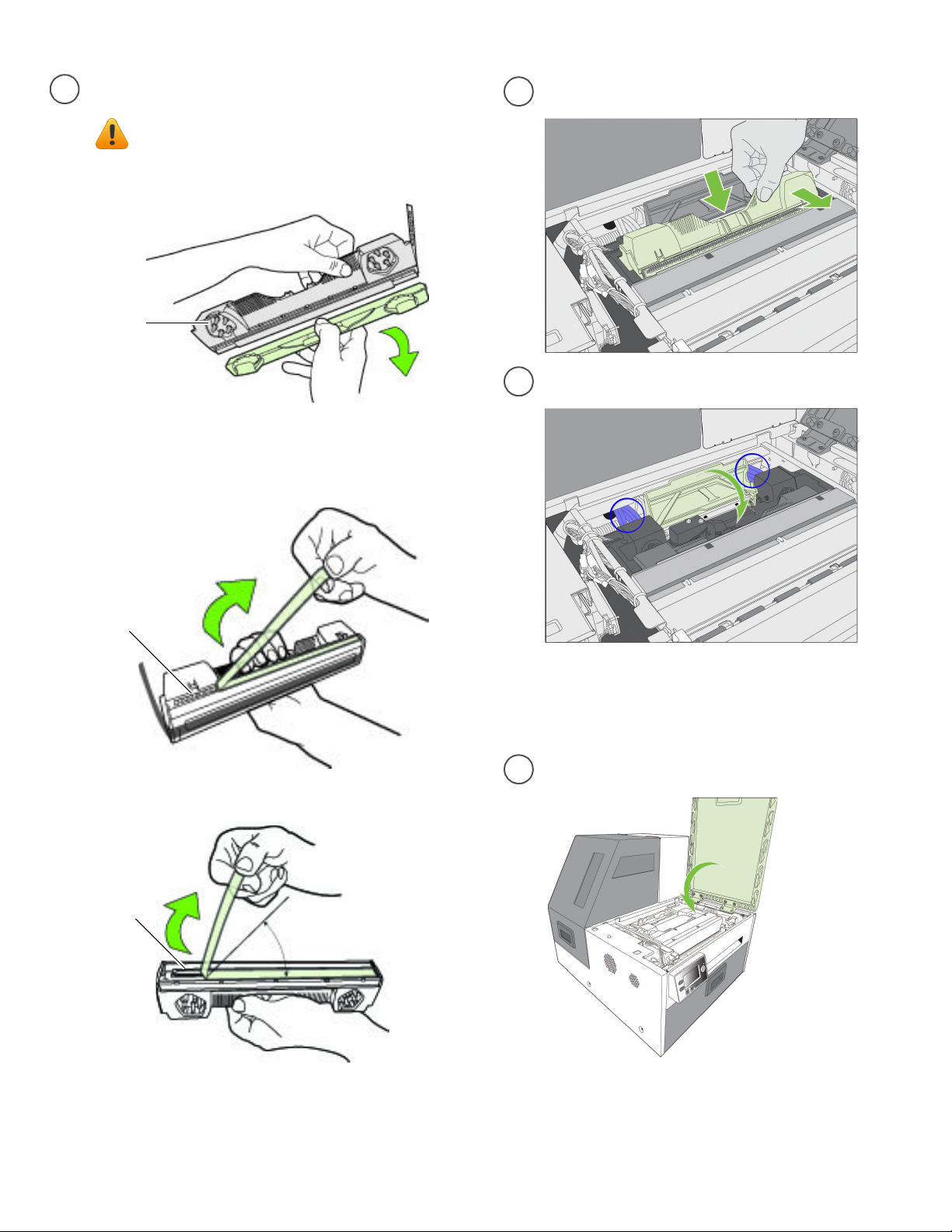

Remove printhead from packaging.

e

Do not touch the ink couplings,

electrical contacts, or nozzles.

Remove cover from ink couplings

ink couplings

Do not discard the cover!

It should be replaced if the printhead is

removed from the printer.

Slowly remove tape from electrical contacts

Insert printhead

f

g

Cl

ose printhead latch

electrical contacts

Slowly remove tape from nozzles

nozzles

No less than 45°

Check that ink is flowing through the tubes

on both sides of the printhead (circled above).

NOTE: If ink is not flowing, remove printhead

and wet nozzles with deionized/distilled water.

h

Close printer cover

16 Setting Up the Printer

Initialization may take several minutes.

e control panel will display Printer Online

Th

when initialization is complete.

Page 17

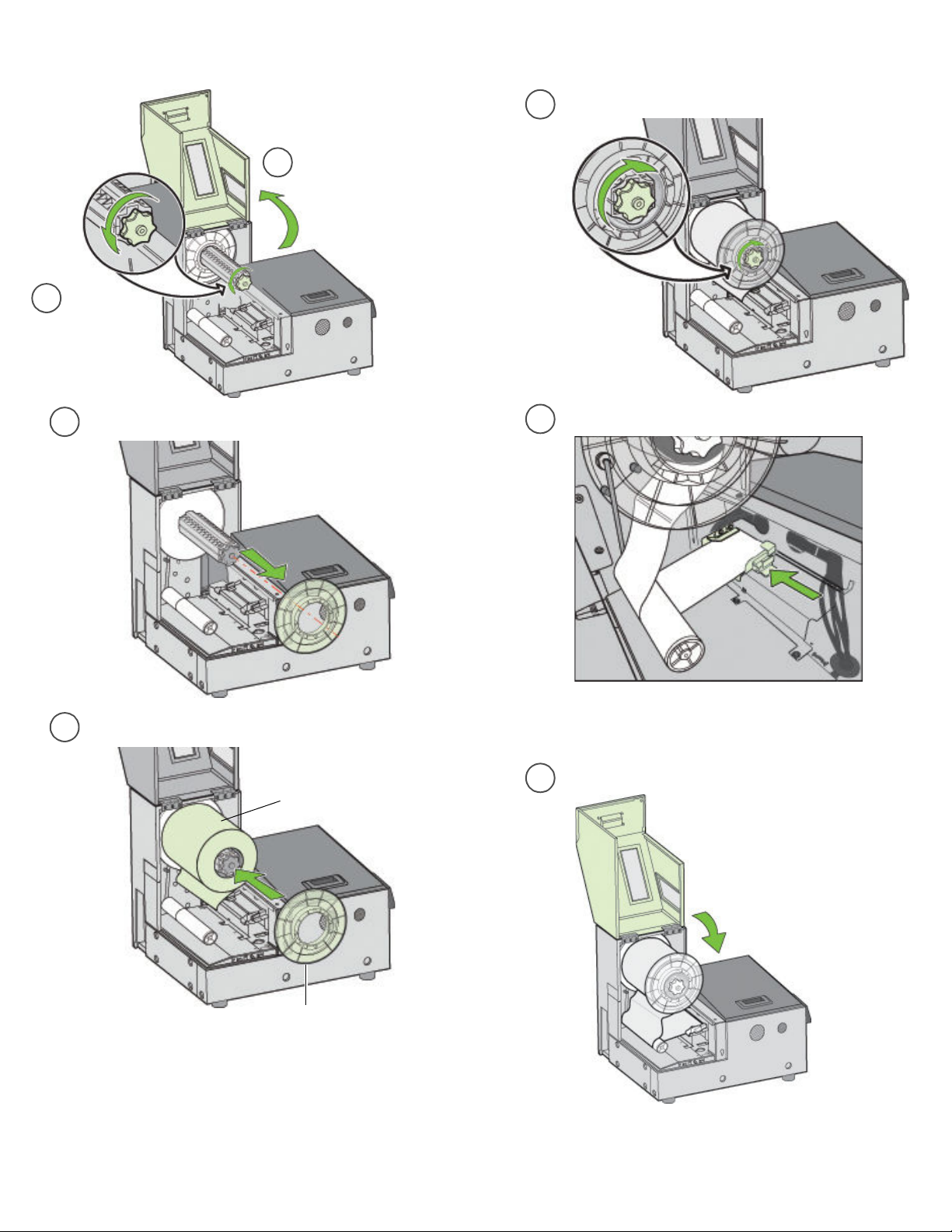

Load sample media

5

Loosen

b

tension knob

Remove Media stop

c

Open Media cover

a

Tighten knob fully

e

Thread media around dancer and into printer

f

Install Media roll

d

Push media roll

against inner guide

Flat side against media roll.

Slide label guide to edge of label.

Wait for printer to load media.

Close Media cover

g

sert media until it stops.

In

Setting Up the Printer 17

Page 18

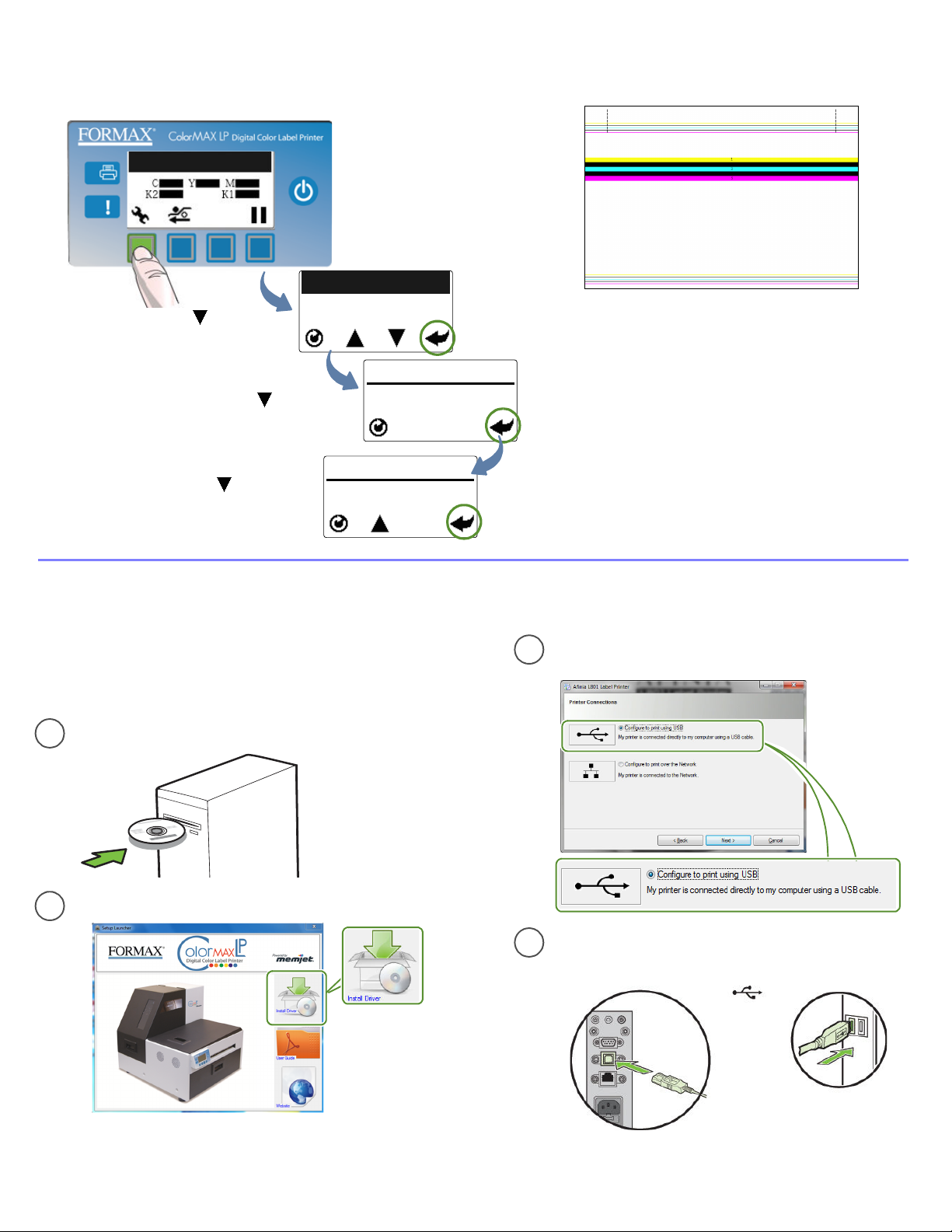

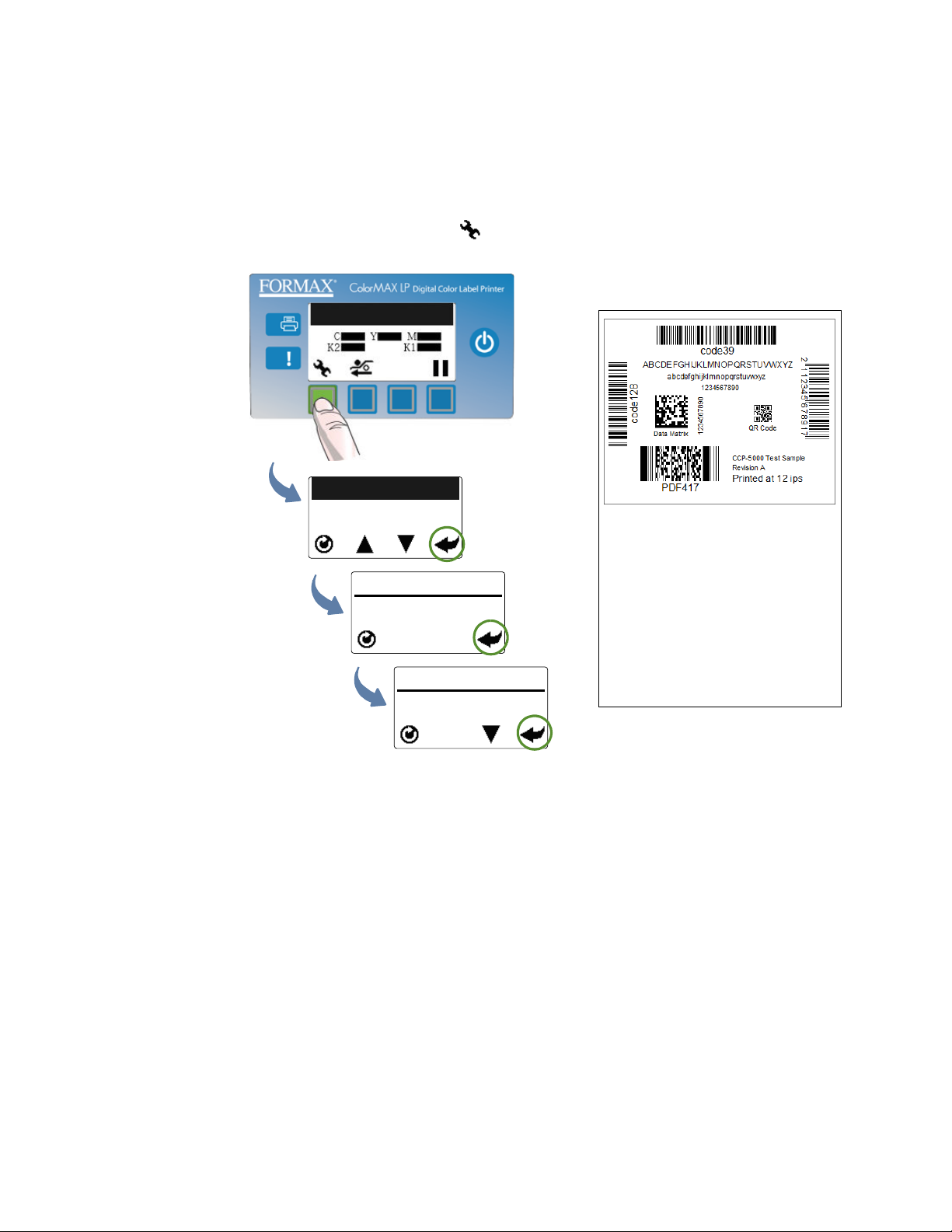

Print test label

6

Req

uires inter-label gap or continuous media.

Printer Online

(Config)

Press until display

reads Maintenance,

then press Select

Press until display

reads Print Test Page,

then press Select

Press until display

reads PQ Plot, then

press Select

CONFIGURATION

2. MAINTENANCE

MAINTENANCE

1. PRINT TEST PAGE

PRINT TEST PAGE

2. PQ PLOT

(Select)

Sample PQ Plot 6x4

Top Section:

• Lines are defined with no missing nozzles

• Li

nes are printed in order: Yellow, Black, Cyan, Black,

Magenta

• Vertical dashed lines are straight

Middle Section:

• All yellow, black, cyan, black, magenta lines are printed

• No color mixing on the color bars

• Numbers 1, 3, 5 are visible

Bottom Section:

• Lines are defined with no missing nozzles

• Lines are printed in order: Yellow, Black, Cyan, Black,

Magenta

Overall:

• No streaking or smearing

Install printer driver

7

Before installing printer driver, ensure that computer

meets minimum system requirements (see System

Requirements on page 76).

To connect printer to computer using USB

Insert Installation disc into computer

a

Select Install Driver from the Installation window

b

Select Configure to print using USB

c

and click Next

Connect USB cable when prompted.

d

Printer Computer

USB

18 Setting Up the Printer

Page 19

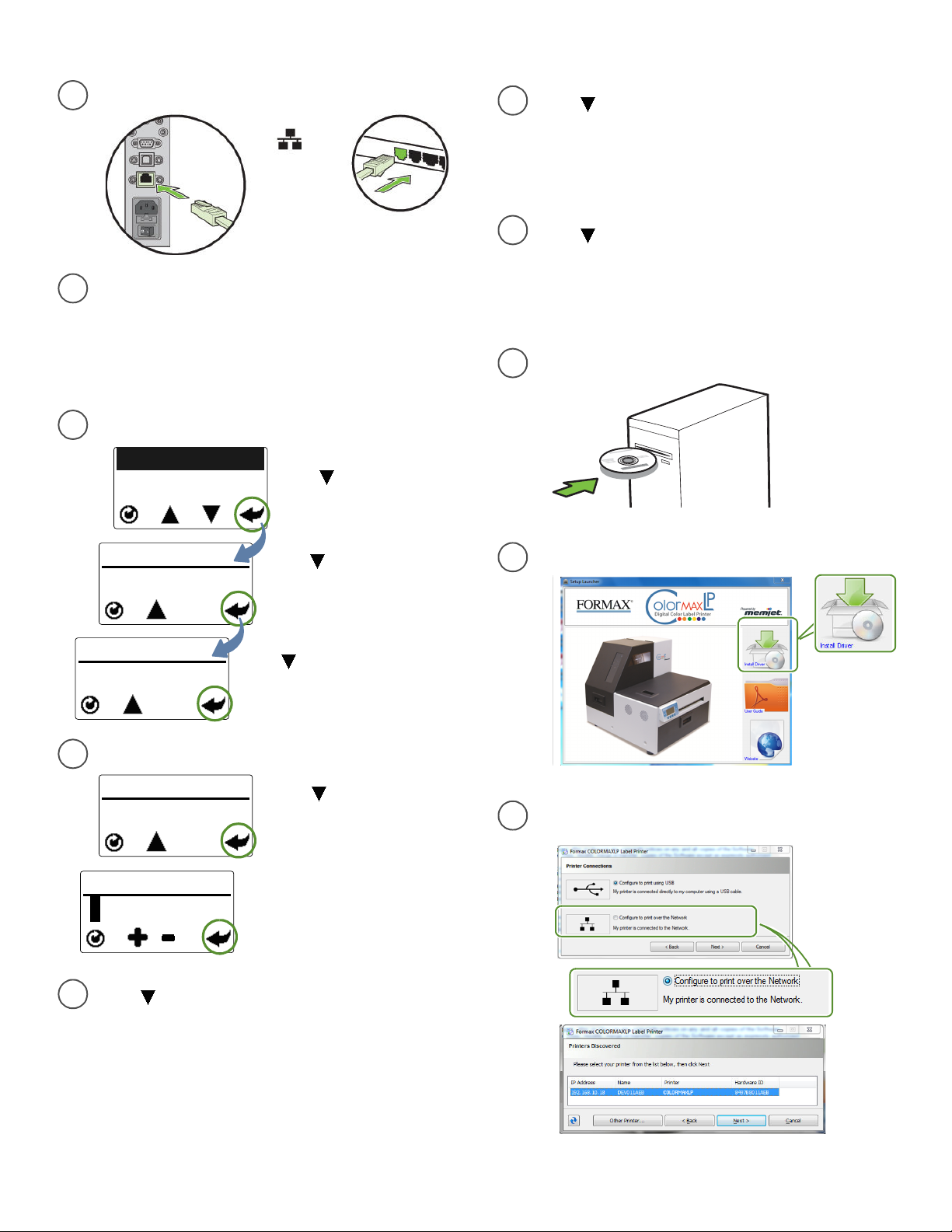

To connect printer to network

Connect printer to network using Ethernet

a

Printer

Network

Press until display reads Default

f

Gateway, then press Select two times.

Enter the Default Gateway using the same

steps as when setting the Static IP address

If you will be using DHCP to set the IP

b

Address, skip to step h.

To assign the printer a Static IP address, the

Security Level must be set to 2. Please see

Selecting the Security Level on page 12.

Set DHCP Settings to Manual

c

CONFIGURATION

8. NETWORK

NETWORK

2. DHCP SETTINGS

NETWORK

2. MANUAL

Press until display reads

Network, then press Select

Press until display reads

DHCP Settings, then press

Select.

Press until display reads Manual,

then press Select. Press Return to go

back to the Network menu

Network

g

Press until display reads Wins Server,

then press Select two times.

Enter the Wins Server using the same steps

en setting the Static IP address

as wh

Insert Installation disc into computer

h

Select Install Driver from the Installation window

i

Set the Static IP Address

d

NETWORK

3. IP SETTINGS

STATIC IP

0 0 0.

e

0 0 0.0 0 0.0 0 0

Press until display reads Subnet Mask,

Press until display reads IP

Settings, then press Select three

times

Enter the first Static IP digit using

the + or - button, then press

Select. Repeat for next eleven

digits. Press Return once when

complete

then press Select two times.

Enter the Subnet Mask using the same

s as when setting the Static IP address

step

Select Configure to print over the Network

j

and click Next

Setting Up the Printer 19

Page 20

Formax

Troubleshooting Printer Setup

If Mech Error 2 o

the following.

Possible Cause Solution

Service station is jammed. Ensure that the cardboard is removed from inside the

Service station was tilted

during shipment.

r Mech Error 3 appears on the control panel during installation, check

printer.

1. Manually open the clamshell to its highest position.

2. On the control panel, select (

Station

>

Eject

. Wait for the printer to eject the service

station.

3. Turn off the printer, beginning with the power

button on the control panel. When the display turns

off, turn off the power switch on the back of the

printer.

4. Verify that the Service Station is free and can be

manually pulled forward to the front bracket. If yes,

proceed to Step 5. If not, contact Technical Support.

5. Align the service station with the guide rails and

slide it back into the printer.

6. Check the alignment: the cap on the service station

must be parallel to the edge of the platen.

Config

) >

Service

Platen

Cap

7. Continue pushing the service station while you

manually rotate the positioning gear backwards to

move the station all the way into the print engine.

8. Close the clamshell.

9. Turn on the printer.

I Forward to eject I

Positioning Gear

I Backward to install I

20 Setting Up the Printer

Page 21

Change Security Passwords (Administrator)

Once the printer has been set up, an administrator should change the security

passwords using the Embedded Web Server (EWS).

ColorMaxLP Label Printer

1. On the Windows Start

2. Click ColorMaxLP Label Printer to

for your printer.

3. Click Login and log in with the default password 123.

4. Click Security Setup to change the password for the EWS as well as the passwords

for the control panel (default password 123).

See EWS Security Setup on page 39 for more information about security on this printer

and Embedded Web Server (EWS) on page 35 on the EWS.

menu, select Formax > ColorMaxL Label Printer > Toolbox.

launch the default web browser and open the EWS

Set Date and Time

Also from the EWS, set the date and time

on the printer by synchronizing with the

host computer. This option can be found in

Advanced Settings.

Setting Up the Printer 21

Page 22

Formax

22 Setting Up the Printer

Page 23

Chapter 2

Using the Printer

Choosing Label Media 24

P

rinting Labels 27

Adjusting Alignment for Printing 30

Printing Borderless (Full-Bleed) Labels 32

Software Tools 35

Embedded Web Server (EWS) 35

EWS Security Setup 39

Support Tools 43

Using the Printer 23

Page 24

Formax

Choo

sing Label Media

Ensure that the label media meets the requirements for the printer (Tab

Table 1 Media specifications

Media Type and Dimensions

Media type Gloss, semi-gloss, and matte.

Label width 2.0” to 8.5” (50.8 mm to 215.9 mm)

Label length Continuous/Roll-to-Roll: Maximum 40” (1.016 m)

Label thickness Maximum 0.01” (0.3 mm, including liner)

Core size Requires 3” (76.2 mm)

Roll diameter Maximum 8” (203.2 mm)

Media Handling

Print mode • Roll to cut

le 1).

Roll to Cut/Print and Present: Maximum 8" (203.2mm)

Minimum 0.005” (0.13 mm)

• Print and present (non-peel)

• Roll to roll

Detection • Gap

• Continuous

• Black mark (3mm wide, 25.4mm long on left)

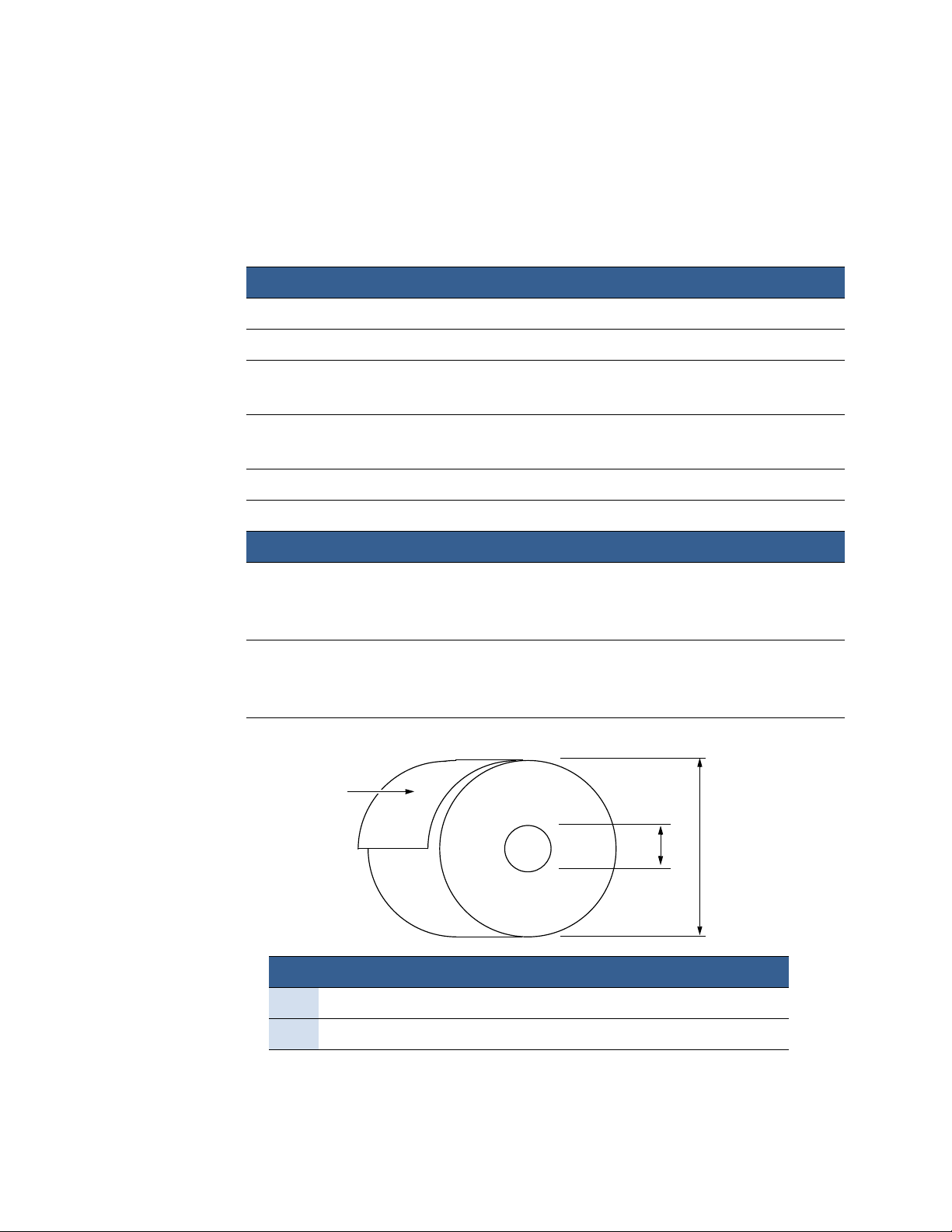

Figure 1 Media Roll

Coating on

the outside

I

Minimum Maximum

I 3.0” (76.0 mm) cardboard core 3.0” (76.0 mm) cardboard core

J N/A Up to 8.0” (203.0 mm)

J

24 Using the Printer

Page 25

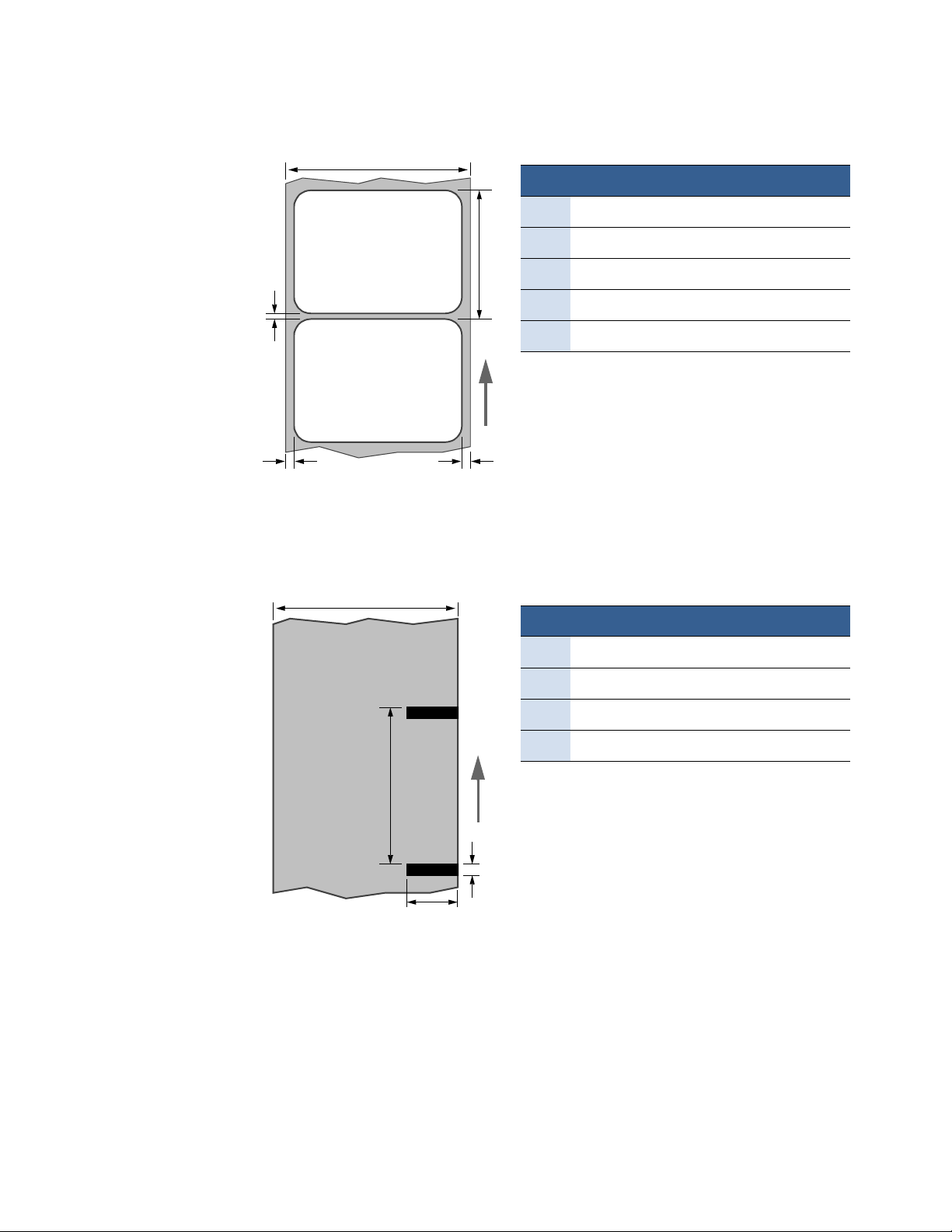

Figure 2 Gap (Transmissive) Media

D

ColorMaxLP Label Printer

Minimum Maximum

A 0.125”(3.0 mm) 0.3” (8.0 mm)

B 0.0 2.0” (50.8 mm)

E

C 0.0 N/A

A

Direction of travel through printer

as seen from above

B C

Figure 3 Black Mark (Reflective) Media

Reverse side of tag stock

D

D 2.0” (50.8 mm) 8.5” (216.0 mm)

E 2.0” (50.8 mm) 40.0” (1.016 m)

Minimum Maximum

D 2.0” (50.8 mm) 8.5” (216.0 mm)

E 2.0” (50.8 mm) 40.0” (1016.0 mm)

H 1.0” (25.4 mm) 8.5” (216.0 mm)

G 0.125” (3.0 mm) 0.3” (8.0 mm)

E

Direction of travel through printer

as seen from below

G

H

Using the Printer 25

Page 26

Formax

Print Test Page

The Barcodes test page is formatted for 4" x 4" labels (inter-label gap,

black-mark, or continuous). Larger labels may be used.

On the control panel, select (

Barcodes

.

Printer Online

(Config)

CONFIGURATION

2. MAINTENANCE

(Select)

MAINTENANCE

1. PRINT TEST PAGE

PRINT TEST PAGE

Config

(Select)

) >

MAINTENANCE

Sample Barcodes Test Page

>

PRINT TEST PAGE

>

1. Barcodes

A successful test print includes:

• Barcodes are readable

• Letters and numbers are readable

• No ink smearing, color mixing, or streaks

• Label is printed in black with no other color visible

(Select)

26 Using the Printer

Page 27

Printing Labels

ColorMaxLP Label Printer

The printer is ready to print when the control panel displays

1. Select the Print command from your application.

2. Select the printer and click the Setup, Properties or similar button.

The print settings displayed are the defaults that were set in the printer driver.

3. Change the print settings if needed.

NOTE: Ensure the media settings (e.g. label size) match the media loaded in the

printer.

4. Print the document.

Any changes to the settings only apply to the current print job. Once you exit the

application, the changes are lost. Make the changes in the printer driver if you wish to

keep the settings as the default for all print jobs.

Printer Online

.

Change Default Settings in Printer Driver

To select the default print settings that will be used for all print jobs:

1. From the Windows Start menu, select Devices and Printers*.

2. Right-click the printer, and select Printing preferences.

The printing preferences contain three tabs as shown in Figure 4.

ke the changes and click OK to save.

3. Ma

It is recommended that any adjustments needed for individual print jobs should

be performed using the drivers.

* For Windows 7. The steps may differ for other Windows versions.

Using the Printer 27

Page 28

Formax

Figure 4 Printing Preferences

Print pages without any gap.

Render entire document to disk before

sending to the printer. Select this option if

labels are skipped when printing large files.

Select Print Pause if labels are skipped when

printing to small labels.

Select Mask Optimization to remove print

artifacts when using multi-layer image files.

Color Selection

Select Color to print the same colors displayed in

application

Select Greyscale to print in black and shades of

grey (composite color)

Select Black Only to use only black ink

Adjust horizontal and vertical print position.

See Adjusting Alignment for Printing on

page 30.

When checked, the settings on

the printer control panel will be

used.

Allows the user to Export the current media settings

and Import previously-saved media settings.

Select whether the current label stock includes a

gap between the labels, has a black mark between

the labels, or is continuous stock.

Used to specify the label size sensing mechanism.

Sheets Per Cut – Cut after printing the specified number of labels.

Print and Present – Print, cut, and present label. Remove the label

to continue printing.

Roll to Roll – Select from these Roll to Roll options if a rewinder is

used (in order shown):

• First label will be blank

• Printing starts with the first label

• Multiple job queue: First label will be blank. Cut will not occur

until the next job specifies a cut or an idle period between jobs

of 10 seconds has passed, whichever comes first

28 Using the Printer

Page 29

Selecting the Media Type

Selecting the media type that matches the media you are printing on will usually give

the best print results.

Select this Media Type: When you are printing on:

Plain Paper Plain (uncoated) paper and labels.

Matte Coated Label Matte coated labels.

Matte Coated Paper Matte coated paper.

Glossy Label Glossy labels. This option optimizes print quality and dry

Premium Gloss Label Glossy labels. This option uses more ink for better color.

ColorMaxLP Label Printer

time.

Using the Printer 29

Page 30

Formax

Adj

usting Alignment for Printing

Always print a few test labels to check the alignment of the image. If the image is not

cen

tered, adjust the Top of Form and/or Left Edge offsets.

A positive value for Top of Form adjusts the image towards the top of the label.

A positive value for Left Edge adjusts the image towards the left of the label.

–

Left

+

–

Right

+

Top

NOTE: Adjustment values entered in the driver and using the control panel are

cumulative. The corresponding values are added together. If you have already

made the correct adjustments in one location, you do not need to enter them

in the other.

30 Using the Printer

Page 31

Adjust Alignment from Printer Driver

ColorMaxLPLabel Printer

The offset settings are found on the Medi

in the Position Adjustment section.

Use the controls to enter in the adjustments

necessary to center the printed image on the

label.

a tab,

Adjust Alignment from Control Panel

This setting requires security Level 1 (supervisor) or higher. Select the security level

before you proceed (see Selecting the Security Level on page 12).

1. On the control panel, select (

ADJUST OFFSET

>

LEFT EDGE

2. Set the offset value.

>

TOP OF FORM

.

or

Config

)

3. Press to return to the main menu.

CONFIGURATION

6. ADJUST OFFSET

ADJUST OFFSET

1. TOP OF FORM

Press , to choose + or – and to set

each digit.

Press to move to next position.

(Config)

(Select)

TOP OF FORM

(Select)

PP

Using the Printer 31

Page 32

Formax

Pri

nting Borderless (Full-Bleed) Labels

The usual approach to borderless printing is to prepare an image slightly larger than

the

label size, then center the larger image over the label so that it prints over the

edges. The following procedure describes where to make the adjustments on the

L801 printer.

Note the following:

• This method requires fine-tuning of the printing position, which will be difficult

if the label gap is very small e.g. 0.1” (3 mm).

• As the maximum label width is 8.5” (215.9 mm), it is also difficult to print

borderless labels of this size. This method works best when the label width plus

bleed allowance does not exceed 8.5” (215.9 mm).

• Print at 6 IPS only.

• You may need to fine-tune the Top of Form/Bottom of Form/Left Edge offset on

the control panel for each label size. For example, the offsets for a 6” x 4” label

may be different from a 2” x 2.5” label. Hence, you need to record the offsets used

for each label size.

Adjustments for Borderless Printing

1. On the General ta

page size slightly smaller than the label (about 0.01” or 0.2 mm in both

direction).

Select Print Speed of 6 IPS and enable Borderless.

2. On the Media tab, adjust the Left Edge to center the image on the label.

3. Print a few labels to check the print position.

Fine-tune using the printer control panel:

(

Config

EXAMPLE:

b of the printer driver (Figure 4), click Custom Sizes to set the

)

ADJUST OFFSET

Left Edge: Horizontal adjustment

+

–

Top of Form/Bottom of Form/Left Edge

+

Top of Form:

Adjust starting line

–

Image/page size

6.08” x 4.08”

Label 6” x 4”

+

Bottom of Form:

Adjust ending line

bleed (Borderless Enabled)

–

32 Using the Printer

Note: The printer automatically determines the bleed/over spray.

Page 33

port/Import Custom media size settings

Ex

Any custom media size settings will be lost if the printer driver is updated. Make a

back

up copy of these settings by saving them to a file. At any time when you update

the printer driver, you may re-import these settings from the backup file.

Export Custom media size settings

ColorMaxLP Label Printer

1. On the Impor

2. Click Export.

3. Enter a filename and click Save.

t/Export tab of the printer driver, select Media Sizes.

Import Custom media size settings

1. On the Import/Export tab of the printer driver, select Media Sizes.

2. Click Import.

3. Select the file that you wish to import your settings and click Open.

Select this option

Using the Printer 33

Page 34

Formax

Turning Off the Printer

Always use the Power button to turn off the printer.

CAUTION: Removing power to the printer in any other manner may

damage the printer.

1. Press the Power button on the control panel, then press (

Printer Online

SWITCH OFF

Select

) to confirm.

1. Confirm

2.Wait for the LCD display

on the control panel to

turn off, then turn off the

Power switch at the back

of the printer.

During a normal

shutdown, the printer will

service the printhead and

save data to the memory

before turning off.

If the Printer Will Not Switch Off

If the printer does not respond when you press the Power button, press and hold the

power button for 5 seconds. The printer should switch off. However, it will not be able

to perform the normal shutdown processes. Do not use this option unless it is

absolutely necessary.

34 Using the Printer

Page 35

Software Tools

• Embedded Web Server (EWS)

• EWS Security Setup

• Support Tools

Embedded Web Server (EWS)

The Embedded Web Server (EWS)* provides remote access to the printer. You can

monit

view additional information and change various settings.

ColorMaxLP Label Printer

or the printer status and check usage metrics. The administrator can also log in to

1. On the Windows Star

the printer is installed on the network, enter the IP address in a web browser* on

any PC on the network and skip step 2.

2. Click ColorMaxLP Label Printer to launch the default web browser* and open the

EWS for your printer.

t menu, select Formax > ColorMaxLP Label Printer > Toolbox. If

The EWS displays printer information and usage metrics on the Printer Status page.

Click Login to log in for full access to all the EWS pages (described in Table 2).

* Recommended: Internet Explorer 8/Firefox 15 or later, at 1280 x 700 or higher resolution.

Requires Java plug-in enabled in browser.

Using the Printer 35

Page 36

Formax

Table 2 EWS pages

EWS Page Description

Printer Status Access to printer information, ink levels, and usage metrics.

Also shows the current printer settings.

Security Setup (See EWS Security Setup on page 39.)

Change Password Set the passwords for accessing the following:

• Embedded Web Server (EWS).

3 to 12 alphanumeric characters. No special characters.

• Level 1 (Supervisor) security on control panel.

• Level 2 (Administrator) security on control panel.

The control panel password must contain 3 digits.

Printer Settings Set the minimum security level allowed to access the

following protected settings:

• Language

• LCD Brightness/Contrast

• Sensor Sensitivity

Network Setup Network settings for the printer.

Diagnostics Perform diagnostics & print a PQ test plot

Print test pages Load 4” x 4” or larger labels (with inter-label gap or

continuous).

• Specify whether the media loaded in the printer is

Continuous, Black mark or with Inter-Label Gap and click

Submit.

This setting applies when printing all test pages and

other printer internal pages.

• Click a test page to print it.

Sensor Threshold

Values

• Trigger the printer to run a length (about 1m or 40”) of

labels while it records the reading of the gap/mark

sensor. At the end of the run, a comma delimited text

(.csv) file is generated. (See Interpreting the Gap/Mark

Sensor Readings on page 42)

• Save and import this file into MS Excel or any

spreadsheet to chart the readings. This is useful for

evaluating if there is sufficient contrast (between the

gap/mark and label) for the printer to detect the

inter-gap/black mark reliably and help with adjusting the

sensor threshold to improve the detection.

• The user needs to open the clamshell and remove the

labels from the printer after each test run. (See Clearing

a Media Jam on page 70)

36 Using the Printer

Page 37

Table 2 EWS pages

EWS Page Description

Advanced Settings

Remote commands • Restart printer

Turn the printer off and on.

• Reset to default settings

Reset settings to the factory defaults.

• Synchronize printer date and time with host PC

Set the printer date and time by synchronizing with the

host PC.

• Zero the tilt sensor

Sets the Tilt Sensor so that the current reading is the zero

mark.

Click Submit to send the selected command to the printer.

ColorMaxLP Label Printer

Mid Job Servicing

Interval

Keep Unused

Printhead Nozzles

Wet Setting

Printer Pause

Settings

Applies to roll-to-roll printing only.

Choose from the four options to determine how frequently

the printer will perform a servicing routine during printing.

Unless the Disable option is selected, printing will pause,

the servicing will occur, then printing resumes

Disable or select the firing frequency of unused printhead

nozzles to keep them hydrated. By default, Automatic mode

is selected, which algorithmically assigns a fixed frequency

suitable for each print mode.

• Pause Mode: The duration between prints

When the printer is in Pause mode, the printer prints a

label at the specified time interval.

• Cap printhead time: The duration between end of Print

and the time when the printhead is moved to the capped

position

When the printer is in Print and Present mode, the

printhead will move to the capped position at a specified

time after the last print.

• Multiple Job Queue: Allowable timeout between jobs

When the printer is set up to print multiple jobs (with no

cut between jobs), this value specifies the max.

allowable time for queuing consecutive jobs before the

printer initial a cut. This prevents damaging the

printhead resulting from prolonged uncapped time.

Continuous Media

Gap Setting

Printer Shutdown

Schedule

Specify the inter label gap when using continuous media.

Click Submit to send the entered value to the printer.

Shutdown the printer daily at a specific time. Click Submit to

send the entered value to the printer.

Using the Printer 37

Page 38

Formax

Table 2 EWS pages

EWS Page Description

Unwinder Settings • Disable Unwinder

Ena

ble this option when using an external unwinder.

• Invert rotation of Unwinder

Enable this option when using Face-in label stock.

Other settings • Retract media when printer is idle for 10 or 30 minutes

(default)

When the media remains in the printer for some time, it

may become deformed and affects the print quality. To

avoid this, select this option.

• Enable virtual printing

Simulate printing to estimate ink usage.

a) Select Enable virtual printing.

b) Print in the usual way. The printer will not actually

print, but will estimate ink usage for the print job.

c) On the Printer Status page, select Ink Status to view

estimates.

The control panel will display

is in this mode.

• Disable cut at the start of a print job

Do not cut the media at the start of a print job. Enable

this option if the printer is used in a clean room to reduce

unwanted paper dust/debris.

• Use fixed USB ID

When enabled, the Host PC uses a fixed internal USB ID

instead of assigning a different USB ID to each printer in

the Plug-N-Play setup process. Enable this option if you

need to hot-swap printers on a PC.

• Enable Enhanced Fast-Time-To-First Label (ETTFL)

Trade off some printhead cleaning routines before the

start of a print job to reduce the time of the first printout

in the Print and Hold mode.

• Enable Extended Printhead Clean Cycle at the End-of-Job

This option adds a Normal printhead clean cycle to the

standard cleaning sequence at the End-of-Job.

• Enable Ink spit every 10 min in standby mode

Enable this option when the printer is used in a dry

environment, characterized by low humidity (~20% RH)

and low temperature. (~15oC or 59oF)

• Enable Maintenance Module Servicing message

When checked, the printer will display an error to notify

the user if there is an issue encountered with the

Maintenance Module which will affect print quality. The

user can service the module at that time.

Simulation

when the printer

38 Using the Printer

Page 39

ColorMaxLP Label Printer

S Printer Status

EW

There are three pages on the Printer Status section, Information, Ink Level, and Local

Sett

ings.

Information

The Information page will provide the Model, Print Engine ID, Firmware Version, Printer

us, and Printed Length. The Serial Number of the printhead is displayed, along with

Stat

the number of labels printed by the current head. In addition, the Total Labels Printed

and Total Cuts Made are listed. You can reset these last two counters independently by

selecting the one to be reset from the drop-down list and clicking the Reset button.

Ink Level

The Ink Level page will show you the amount of ink remaining in each cartridge.

In addition, the Ink Cost can be specified, which will then be used to determine the Ink

Estimate in the Ink Usage section below when the Submit button is clicked. The usage

can be exported to a file in .csv format.

Local Settings

The Local Settings page will give you the current settings for the Print by External

Trigger (On/Off), Unit (inch/mm), the four offsets, the LCD Contrast and Brightness, the

Label Gap Sensor Sensitivity, and the Black Mark Sensor Sensitivity.

Aside from the External Trigger setting (for which you must be logged in to the EWS),

these settings can only be viewed in the EWS. Any changes to these settings must be

performed on the control panel or drivers.

EWS Security Setup

The ColorMaxLP pri

page 12 for the list of security restrictions.

Security Level Description

Level 0

(operator)

Level 1

(supervisor)

Level 2

(administrator)

The administrator can change the passwords through the Embedded Web Server (EWS).

It is recommended that the administrator change the passwords once the printer has

been set up. The default password is 123 for the EWS and the printer control panel.

nter has three levels of security. See

The printer powers up in level 0 by default, which allows users to

access all the functions needed to print, but not to change printer

parameters via the control panel.

The user can access certain printer parameters. A password is

required to access this level.

All parameters are enabled. A password is required to access this

level.

Selecting the Security Level on

Using the Printer 39

Page 40

Formax

Change Passwords

1. Log in to the EWS.

a On the Windows Start menu, select Formax > ColorMaxLP Label Printer > Toolbox.

b Click ColorMaxLP Label Printer to launch the default web browser and open the

EWS for your printer.

c Click Login to log in with your admin password.

2. Select Security Setup, then select Printer Password.

3. Set the password and click Submit.

• The EWS password can have 3 to 12 alphanumeric characters. Special characters

are not allowed.

• The control panel password must contain 3 digits.

Change Security Level for Printer Settings

The administrator can change the security level for the following protected printer

settings, which are enabled at Level 1 by default.

1. Log in to the EWS.

2. Select Security Setup followed by Printer Security.

3. From the dropdown list, select the minimum security level allowed to access each

setting.

For example, if you set Language to Level 0 - Operator, then all security levels will

have access to this setting.

4. Click Submit.

40 Using the Printer

Page 41

ColorMaxLPLabel Printer

EWS Network Setup

The Network Setup page can be used to change the IP information. The same settings

can also be changed from the control panel. Select either Continuous or Gap for the

Media Layout.

EWS Diagnostics

The Diagnostics page can be used to send test prints to the printer. These are the same

t prints available in the control panel.

tes

EWS Advanced Settings

The Advanced Settings page can be used to send Remote Commands to the printer, set

the Mid Job Servicing Interval, and set the printer to Retract media when the printer is

idle for 10 minutes.

The Remote Commands include Restart Printer, Reset to Default Settings, and

Synchronize Printer Date and Time with Host PC. Select the command to send and click

the Submit button.

The Mid Job Servicing Interval is used for Roll-to-Roll printing only to be sure the

nozzles are kept healthy. The three options are as follows:

Minimum: The Mid Job Servicing occurs every 2475” (62865 mm) or 9 minutes,

whichever comes first.

Normal (Default): The servicing occurs every 1650” (41910 mm) or 6 minutes,

whichever comes first.

Maximum: Servicing occurs every 550” (13970 mm) or 2 minutes,

first.

Disable: Turns off any mid Job Servicing. This may negatively impact print quality.

If white streaking appears on the labels during Roll-to-Roll printing, increase the Mid

Job Servicing interval from the current setting.

If color mixing is observed on the labels during Roll-to-Roll printing, decrease the Mid

Job Servicing interval from the current setting.

This setting should only be changed if necessary.

NOTE: Mid Job Servicing will not resolve print issues such as white streaks due to

paper dust or debris accumulation in the print zone.

The Printer retract label idle time option will unload the media by rolling it backwards if

the printer has not been used for 10 or 30 minutes, whichever is selected. This is done

to keep the labels from curling inside the printer, which may cause the label media to

rub against the printhead when printing resumes. This setting is checked by default with

a 10 minute idle time selected.

whichever comes

The media will need to be reloaded after it has been retracted in order to print.

Using the Printer 41

Page 42

Formax

The Enable Virtual Printing se

actually printing in order to determine the amount of ink that will be used during an

actual print. This can be used to help determine the cost of printing a particular label.

tting will allow you to process your label images without

Interpreting the Gap/Mark Sensor Readings

Import the test result .csv file into MS

el (or any spreadsheet) using comma

Exc

as the delimiter from the Diagnostics tab

in the EWS. Column “a2d_refl” and

“a2d_st” reflects the gap (transmissive)

and mark (reflective) sensor readings

respectively.

Next, create a line graph using the

appropriate column of data.

There are 3 possible types of plot:

1. Normal - Sharp spikes at regular

intervals indicating the sensors can

clearly detect the gap or mark on the

media.

42 Using the Printer

2. Noisy - Imperfect spikes at regular

intervals indicate the printer may be

erroneously detecting the

Top-of-Form. For more reliable

detection, reduce the sensitivity of the

appropriate sensor to achieve a plot

that is close to Normal.

3. Bad - Readings are not distinctive.

Increase the sensitivity of the appropriate sensor to achieve as close to a Normal

plot as possible. If the readings do not improve at maximum sensitivity, this indicates

that there is insufficient contrast between the gap (or mark) and the liner. In such a

case, the media is incompatible with the printer.

Page 43

Page 44

Formax

44 Using the Printer

Page 45

Chapter 3

Printer Maintenance

Guidelines for Preventive Maintenance 46

Re

placing an Ink Cartridge 47

Cleaning the Printhead 48

Replacing the Printhead 49

Opening/Closing the Clamshell 52

Cleaning Debris from the Cutting Zone 53

Cleaning the Sensors 54

Cleaning the Media Guide 56

Replacing the Service Station 57

Replacing the Aerosol Fan Filter 60

Replacing the Waste Ink Absorber 61

Printer Maintenance 45

Page 46

Formax

Guideli

Table 3 Maintenance Schedule: For ≥80% Roll to Roll Operation

Part Part Number Every 1M inches

Sensors – Clean – –

Media Guide – Clean – –

Service Station 22929 Inspect Replace –

Aerosol Fan Guard 22943 – Replace –

Waste Ink Absorber 22936 – – Inspect

nes for Preventive Maintenance

Recommended maintenance depends on the print mode that is most frequently used. If

you

mostly print Roll to Roll (≥80%), refer to Table 3. Otherwise, see Table 4. Inspect

means to check the condition and replace if necessary.

Note that these are general guidelines for preventive maintenance. As operating

conditions for your printer may differ, adjust your maintenance schedule accordingly.

Maintenance items not on the tables below should be performed on an as-needed

basis. These maintenance items will be covered before the scheduled maintenance.

(25,400 m)

Every 2.5M inches

(63,500 m)

Every 5M inches

(122,500 m)

1

1. Inspection should occur every 20 cartridges or 6 months, whichever comes first.

Table 4 Maintenance Schedule: For ≥80% Roll to Cut/Print and Cut/Present Operation

Part Part Number Every 1M inches

(25,400 m)

Sensors – Clean – –

Media Guide – Clean – –

Service Station 22929 Replace – –

Aerosol Fan Guard 22934 – Replace –

Waste Ink Absorber 22936 – – Inspect

1. Inspection should occur every 20 cartridges or 6 months, whichever comes first.

NOTE: When using the cutting feature and continuous media or die-cut media with the

outer matrix left in place, the print zone and cutting zone should be inspected

for dust and debris every 3 rolls and cleaned as needed.

Every 2.5M inches

(63,500 m)

Every 5M inches

(122,500 m)

1

46 Printer Maintenance

Page 47

Replacing an Ink Cartridge

1. Open the front cover of the printer.

2. Open the latch and remove the empty ink cartridge.

ColorMaxLP Label Printer

3. Insert the new cartridge and close the latch.

4. Close the front cover.

NOTE: Dispose of the empty ink cartridge according to local regulations.

Printer Maintenance 47

Page 48

Formax

Cleaning the Printhead

The printer provides three automated cleaning cycles for the printhead:

Extended

next level only if print quality does not improve.

1. On the control panel, select (

, and

Extreme

. Always start with the

Config

) >

Normal

cleaning cycle and proceed to the

Printhead

>

Clean

>

Normal

.

Printer Online

(Config)

CONFIGURATION

3. PRINTHEAD

(Select)

PRINTHEAD

1. CLEAN

Normal

,

(Select)

CLEAN

1. Normal

(Select)

2. After the cleaning is completed, try printing again.

3. If issues persist, perform again selecting the Extended cleaning cycle. After cleaning

is complete, try printing again.

4. If issues still persist, perform an Extreme cleaning.

NOTE: Extreme cleaning should not be performed unless absolutely necessary, as it

may shorten the life of the printhead.

5. If issues still persist, the printhead should be replaced.

48 Printer Maintenance

Page 49

Replacing the Printhead

1. Open the printer top cover.

2. On the control panel, select (

Replace

. Wait for the printhead latch to be released, then

open the latch fully.

Config

) >

Printhead

ColorMaxLP Label Printer

>

Do not open latch before

it is released!

3. Hold the printhead by the handle and push it toward the printhead latch. Once the

printhead is released, lift it out of the printer.

Replace the Nozzle Cover

onto the removed printhead.

NOTE: Dispose of the old printhead according to local regulations.

Printer Maintenance 49

Page 50

Formax

4. Remove the new printhead from its packaging.

Do not touch the ink couplings,

electrical contacts, or nozzles.

Do not discard the cover!

It should be replaced if the printhead is

removed from the printer.

Slowly remove tape from electrical contacts

ink couplings

nozzles

electrical contacts

No less than 45°

Slowly remove tape from nozzles

5. Sl

ide the printhead into the slot. Push it toward the front of the printer. It should

snap into place.

50 Printer Maintenance

Page 51

6. Close the printhead latch.

ck that ink is flowing

Che

through the tubes on both

sides of the printhead

(circled above).

7. Close the top cover.

ColorMaxLP Label Printer

Printer Maintenance 51

Page 52

Formax

Openi

ng/Closing the Clamshell

In the following procedures you may need to open

the

clamshell in order to access the areas inside the

printer.

NOTE: If you will have the clamshell open for more

than 5-10 minutes, remove the printhead to

ensure the printhead remains healthy. See

Replacing the Printhead on page 49.

Opening the Clamshell

1. Open the top cover.

2. Squeeze the latches on either side of the clamshell and open the clamshell to its

highest position.

squeeze clamshell latches

52 Printer Maintenance

Clamshell open

Closing the Clamshell

Squeeze and hold the clamshell latches while you gently lower the clamshell back into

ce.

pla

Do not allow the clamshell to drop when closing it.

Page 53

Cleaning Debris from the Cutting Zone

Clear all debris from the cutting zone to avoid contaminating the print zone, especially

fine dust particles.

1. Turn off power to the printer. See Printing Borderless

l-Bleed) Labels on page 32.

(Ful

2. Open the top cover.

3. Vacuum any debris from the cutting zone (shown

below in green).

ColorMaxLP Label Printer

cutter path

4. Open the clamshell and also check below the cutting zone, at the bottom o

printer and in front of the ink cartridges.

5. Close the clamshell and top cover.

6. Open the front cover and remove any cutting debris.

f the

Printer Maintenance 53

Page 54

Formax

Clea

ning the Sensors

Always keep the media path clean as accumulated dust can affect printing.

1. Ope

2. Turn off power to the printer. See Printing Borderless (Full-Bleed) Labels on page 32.

3. Vacuum any dust or debris from the sensors.

4. Clean ink from the TOF sensor if the sensor appears dull

5. Vacuum any paper dust or debris from the print zone.

Figure 5 Location of sensors

n the clamshell to its highest position.

Use the rollers to help you locate the sensors as shown in Figure 5.

a Fold a lint-free cloth to form a tip and lightly moisten with de-ionized water.

Insert it in the opening to clean the TOF sensor.

b Repeat with a clean part of the cloth if necessary.

c Let the sensor dry before continuing.

second roller

6.

Close the Clamshell.

first roller

Transmissive and reflective sensors

behind the second roller

TOF sensor behind the first roller

54 Printer Maintenance

Page 55

ColorMaxLP Label Printer

Clean any debris from the Exit Sensor, which is located near the front right side of

7.

the

top of the clamshell.

Exit sensor on top of clamshell

8. Close the top cover. Turn the printer back on.

Printer Maintenance 55

Page 56

Formax

Cle

aning the Media Guide

Excess ink on the Media Guide can affect print quality.

1. Re

move the printhead. See Replacing the Printhead on page 49.

2. Open the clamshell to its highest position.

3. Slide the white plastic Media Guide to the right. When it will not move further,

gently pull down on the guide.

Media Guide

4. Clean any ink residue from the Media Guide by rinsing with water and drying

thoroughly.

5. Line the Media Guide slots up with the metal tabs on the bottom of the clamshell

and push the guide back on. Slide guide to the left until it stops.

6. Close the Clamshell.

7. Reinstall the printhead and close the top cover.

56 Printer Maintenance

Page 57

eplacing the Service Station

R

NOTE: Before you begin, remove the printhead and cap it with the orange

protective cover, but do not close the latch after removing the

printhead. See Replacing the Printhead on page 49.

Tool

s • Nitrile powder-free gloves

• T20 Torx driver

• Disposable towels

Removal

ColorMaxLP Label Printer

1. Manually Op

2. On the control panel, select (

eject the service station.

3. Move service station towards front of printer.

4. Press the Power button on the control panel to turn off the printer. See Printing

erless (Full-Bleed) Labels on page 32.

Bord

5. Turn off the Power switch at the back of the printer and unplug the power cord.

6. Remove the front panel:

a Use a T20 Torx driver to remove the four screws (labeled 1 to 4) securing the

front panel.

b Release the front panel and disconnect the two cables behind the control panel.

en the clamshell to its highest position.

Config

) >

Service Station

1

>

Eject

. Wait for the printer to

2

3

cables behind

control panel

4

Printer Maintenance 57

Page 58

Formax

7. Pull the service station forward until you can disconnect the flex cable to the wiper

mot

or. Loosen the clip on the connector (

Figure 6) to release the flex cable.

flex cable

Ensure that the flex cable does not come into contact with any metallic

surface. If it is touching metal and the printer is accidentally turned on, it will

short the controller circuit and damage the printer.

Take care when handling the service station. Ink may spill when you tilt the service

station.

clip

Never turn on the Printer with the Service Station disconnected!!!

NOTE: Dispose of the old service station according to local regulations.

Installation

8. Insert the flex cable into the connector on the new service station and push in the

p to secure it.

cli

Figure 6 Flex cable to connector on service station

58 Printer Maintenance

clipflex cable

Page 59

ColorMaxLP Label Printer

Carefully align the service station with the guide rails and slide it into the print

9.

eng

ine.

guide rail

guide rail

10.Manually rotate the positioning gear backwards while uniformly pushing the service

station to move the service station into the print engine.

Figure 7 Positioning gear for service station

11.Reinstall the front panel: Reconnect the two cables to the front panel and replace

the screws.

12. Close the clamshell

nstall the printhead, close the blue latch, and close the covers.

13. I

14. Plug the power cord back in and turn the printer on.

Never turn on the Printer with the Service Station disconnected!!!

Printer Maintenance 59

Page 60

Formax

Rep

lacing the Aerosol Fan Filter

As a general guideline, replace the aerosol fan filter every six months.

Tools • Nitrile powder-free gloves

• Flat-headed screwdriver

1. Tu

rn off power to the printer. SeePrinting Borderless (Full-Bleed) Labels on page 32.

2. Open the clamshell to its highest position.

3. Insert the tip of a flat-blade screwdriver into the slot at the corner of the aerosol fan

assembly, and pry the cover off.

4. Remove the filter (Figure 8) and replace it with a new one.

5. Snap the cover back into place on the aerosol fan assembly.

6. Close the clamshell and top cover. Turn the printer back on.

Figure 8 Fan assembly

slot

filtercoveraerosol fan assembly

60 Printer Maintenance

Page 61

eplacing the Waste Ink Absorber

R

Tools • Nitrile powder-free gloves

1. Open the front cover of the printer.

ColorMaxLP Label Printer

2. Sq

ueeze the latches on both sides of the waste ink absorber and pull it out.

3. Remove the waste ink absorber.

4. Slide the new waste ink absorber into the printer. Push it in until it clicks into place.

5. Close the front cover.

NOTE: Take care when replacing the waste ink absorber to avoid staining hands and

clothing. Dispose of the used waste ink absorber according to local regulations.

Printer Maintenance 61

Page 62

Formax

62 Printer Maintenance

Page 63

Chapter 4

Troubleshooting

If Error Messages Appear 64

P

oor Print Quality or Incorrect Printout 66

Other Printing Problems 69

Clearing a Media Jam 70

Clearing Clogged Ink Nozzles 70

Color Mixing Recovery 72

Adjusting Sensor Sensitivity 73

Troubleshooting 63

Page 64

Formax

If

Error Messages Appear

If error messages are displayed on the printer control panel, check the following table

for

the solution.

Error Message Possible Cause Solution

Clamshell Open The clamshell is open. Close the clamshell.

The clamshell sensor is damaged Contact Technical Support for part replacement.

End of Roll End of roll is detected. Load a new roll of labels.

Front Cover Open The front cover is open. Close the front cover.

Jammed Cutter Debris in the cutting zone. 1. Turn off the printer and unplug the power

cable.

2. Clean any debris from the cutting zone.

See Cleaning Debris from the Cutting Zone on

page 53 for details.

Jammed Media The labels are jammed or cannot

feed into the printer.

Media used exceeds the maximum

thickness of 0.01” (0.3 mm).

The transmissive (gap) or reflective

(black mark) sensor is dirty or

faulty.

Low Ink An ink cartridge is low. Replace the ink cartridge. Check the ink status

Mech Error [01] The printer is not receiving the

correct data.

Mech Error [code]

where [code] <> 01

Printer mechanical fault. Note the error code and contact Technical

Clear the jam and reload the media.

See Clearing a Media Jam on page 70.

Clear the jam and replace the media. See

Choosing Label Media on page 20.

Clean the sensor with a lint free cloth and re-try.

If the error persists, contact Technical Support

for part replacement.

icons on the Control Panel for the color that is

low.

1. Check that the label & image size matches.

Increase or decrease the image size slightly.

2. Cancel the job print (and clear the printer

spooler, if needed) and re-try.

3. If the error persists, contact Technical

Support.

Support.

If Mech Error 2 or Mech Error 3 appears during

installation, see Troubleshoot Printer Setup on

page 12.

Do not attempt to restart the printer more

than 3 times if the same Mech Error appears.

Contact Technical Support.

64 Troubleshooting

Page 65

Error Message Possible Cause Solution

Media Cover Open The media cover is open. Close media cover.

The cover sensor is damaged Contact Technical Support for part replacement.

ColorMaxLP Label Printer

Missing Ink Tank The ink cartridge is not installed or

not a genuine ink cartridge from

the manufacturer (OEM).

The Ink cartridge is not properly

installed.

The ink cartridge is faulty. Replace the ink cartridge.

The electrical contact is obstructed

or dirty.

The ink cartridge latch is damaged

or cannot be closed properly.

Missing Printhead The printhead is not installed or

not a genuine printhead from the

manufacturer (OEM).

The printhead is faulty. 1. Insert another printhead (or a known good

Install a genuine ink cartridge. If the problem

persists, contact Technical Support.

1. Remove and re-insert the ink cartridge.

2. Wait 10-15s for detection. If the ink tank

remains undetected, repeat the process.

3. If the ink tank remains undetected after the

third attempt. Restart the printer and repeat

step (1) & (2).

4. If the problem persists, contact Technical

Support.

Clean contact with a lint free cloth and re-insert.

Contact Technical Support for part replacement.

Install a genuine printhead. If the problem

persists, contact Technical Support.

printhead) and check if the printer is able to

detect the printhead. If the problem persists,

contact Technical Support.

The electrical contact is obstructed

or dirty

1. Clean the contact with a lint-free cloth.

2. Re-insert the printhead. If the problem

persists, contact Technical Support.

No Media No media is detected. Load a new roll of labels.

The media is not properly inserted

Re-load the media.

into the input guide.

Top Cover Open The top cover is opened. Close the top cover.

The top cover sensor is damaged. Contact Technical Support for part replacement.

Out of Ink An ink cartridge is out of ink. Replace the ink cartridge. Check the ink status

icons for the color that is empty.

Wrong Media Problems with the media. See Printer feeds media without printing on

page 69.

Troubleshooting 65

Page 66

Formax

Poo

r Print Quality or Incorrect Printout

Problem Possible Cause Solution

Long stripes of missing

print or ve r ti c a l light

s t re a ks o n s ev er a l

labels

Printed barcode cannot

be scanned

Ink is smudged on the

labels

Ink nozzles are blocked. See Clearing Clogged Ink Nozzles on page 70.

The media is not suitable for

use in this printer.

The barcode is too small. Adjust the size of the barcode.

Ink nozzles are clogged and the

barcode did not print properly.

The media is not suitable for

use in this printer.

Accumulated ink in the print

zone.

Replace the media. See Choosing Label Media

on page 24.

See Clearing Clogged Ink Nozzles on page 70.

Replace the media. See Choosing Label Media

on page 20.

1. Open the clamshell and inspect the print

zone (Figure 9).

2. Lightly moisten a a lint-free cloth with

de-ionized water and gently clean off any ink

from the print zone and printhead.

3. Close the clamshell.

Significant misting on

labels

The media is curled and

touching the printhead.

The media is curled by the

unwinder when the printer is

idle for a period of time.

The service station needs to be

replaced.

Aerosol is not removed because

the fan filter is dirty.

M e d ia u s e d e xc ee d s t h e

max i mum th i ckness of 0 . 01 ”

(0.3 mm).

1. Replace the media. See Choosing Label

Media on page 20.

2. If the problem persists, contact Technical

Support.

1. On the EWS Advanced Settings page, set the

printer to retract the media when it is idle for

more than 10 minutes.

2. If the problem persists, contact Technical

Support.

See Replacing the Service Station on page 56.

Replace the fan filter. See Replacing the Aerosol

Fan Filter on page 60.

Replace the media. See Choosing Label Media

on page 24.

If t he p ro b lem persists , conta c t Tec h n ical

Support.

66 Troubleshooting

Page 67

ColorMaxLP Label Printer

Problem Possible Cause Solution

Mixed or muddy colors The printhead is dirty. 1. Run Extended cleaning cycle from the control

panel ( (

CLEAN

Extended

Config

)

MAINTENANCE

).

If print quality shows some improvement,

repeat Extended cleaning until the print

quality is satisfactory.

2. If print quality does not improve, open the

shell and check for patches of wet ink on

clam

the printhead.

3. Use a lint-free cloth to absorb the ink. Avoid

touching the neighboring nozzles.

4. Check the print quality. Run Extended

cleaning cycle if necessary.

Color ink cartridges are dirty. 1. Remove the yellow (Y) ink cartridge from the

printer.

2. Check the color of the ink through the ink

level prism.

Po si t i on o f p r i nt ed

image drifts vertically

Top o f Fo rm posi tion ne e d s

adjustment.

T h e m e d i a i s n o t lo ad e d

properly.

The media is not suitable for

use in this printer.

T h e p ri n t e r i s u n a b l e t o

correctly detect the inter-label

gap or black mark.

ink level prism

If the ink color is very dark (black) instead of

yellow or iodine, replace all three color ink

cartridges.

Adjust the Top of Form offset from the control

panel or printer driver. See Adjusting Alignment

for Printing on page 30.

Relo a d t he medi a. S ee Loa d ing Med ia on

page 17.

Replace the media. See Choosing Label Media

on page 24.

Adj u st t he sen s itiv i ty of the sen s ors. Se e

Adjusting Sensor Sensitivity on page 73.

Troubleshooting 67

Page 68

Formax

Problem Possible Cause Solution

M i s -r e gi s t ra t i o n or

labels are skipped

L a b el s a re s k i p p e d

when printin g roll to

roll on media with black

mark

Media settings do not match

the media loaded in the printer.

The media does not meet the

specifications.

T h e p r i n t er is u n ab l e to

correctly detect the inter-label

gap or black mark.

T h e p r i n t er is u n ab l e to

correctly detect the inter-label

black mark.

Make sure the settings are correct for the media

(e.g. media size and orientation).

See Choosing Label Media on page 24 for the

media specifications.

1. Clean the sensors. See Cleaning the Sensors

on page 54.

2. If the problem persists, adjust the sensitivity

of th e s e n s o rs . Se e Ad j u st i n g Se n s o r

Sensitivity on page 73.

Ad j ust the media si ze in the printe r d r iver:

reduce the height by 0.1” (3 mm).

68 Troubleshooting

Page 69

ther Printing Problems

O

Problem Possible Cause Solution

ColorMaxLP Label Printer

Printer feeds media without

printing and then displays