Page 1

Formax Atlas C200 High-

Speed Automatic Creaser

Instruction Manual

Page 2

Atlas C200

Auto-Feed High-Speed Creaser

9/2016

OPERATOR MANUAL

First Edition

Page 3

INDEX

INTRODUCTION

SAFETYDo’s&Don’ts4

THE ATLAS C200

LabeledPhotograph

THECONTROLS

Theswitchpanel

Featuresontheswitchpanel

QUICKSTARTGUIDE9

OPERATING

Settingthemachine

Programmingthemachine

Readingstoredprogrammes

Paperjamming

PAGE3

6

7

7

20

26

27

29

THESTACKERASSEMBLY

SettingtheStackerunit

PERFORATING

Equipment,spares

Settingthemachine

THEBLADEASSEMBLY

Settingthebladepressure

Settingthebladealignment

REPLACINGCREASINGBLADESETS

Installingnewbladesets

Spares

TROUBLESHOOTING40

DISPATCHKIT48

ACCESSORIES&OPTIONS49

RECOMMENDEDSPARES50

FUSEPOSITIONSANDRATINGS52

PRODUCTRECYCLINGANDDISPOSAL53

30

32

33

35

36

37

39

Page2

CREASING

Page 4

INTRODUCTION

7hH$WODV&Lsafullyautomaticsuctionfeedingcreasing

systemdesignedforusewithbothconventionallithoanddigitalprinters.

ThefeedonthH$WODV&canalsobemanuallyoperatedforuse

withheavystock,verysmallorverylargesheets,embossedorevenirregular

sheets.

Thecreaseisprogrammedfromtheleadingedgeofthesheetusingthe

controlsonthefrontpanel.

Thebladeandanvilaremechanicallycontrolledovertheirentirelength

andcanbeadjustedtoaccommodatevariousweightsofmedia.

IMPORTANT

Theoperatingenvironmentshouldbecontrolledtoatemperaturebetween

16°Cand27°CMaximum

Specification

FeedingSystem................................................Bottomsuctionfeed

Max.SheetSize................................................700mmx500mm(27.5”x19.7”)[900mmx

500mm(35.4”x19.7”)withOptional

extensiontable].

Min.SheetSize(inautomaticmode).................210mmx140mm(8.5”x5.5”)

Max.PaperThickness........................................0.4mm(variesaccordingtohardness,

typeoffold,andsubstrate)

Max.No.CreasesperSheet............................16

Min.DistanceBetweenCreases.......................0.1mm

Max.No.StoredProgrammes..........................Unlimited

Min.CreaseDistancefromLeadingEdge........2.5mm

Min.CreaseDistancefromTailEdge................35mm

InHandFeedModeupto2499.9mmtoLastCreasecanbeProgrammed.

SpeedperHour(A4inhalf)..............................8500

SpeedperHour(A5inhalf)..............................11000

Dimensions.......................................................L:1500mmH:1224mmW:682mm

L:(59”)H:(48.2”)W:(26.8”)

Weight...............................................................156Kgs(+50Kgspacking)

PowerRequirement..........................................1phase230v50Hz

1phase220v60Hz

SoundPowerLevel................................78.5decibels

*Aspartofourcontinuedproductimprovementplan,specificationsandinformation

publishedinthismanualaresubjecttochangewithoutnotice.

Allspecificationsaredependantonapplication,typeofstock,temperature,RHandprint

engineused.

Specificationsquotedweremeasuredonuncoatedandunprintedstock.E&OE.

Page3SYSTEM

Page 5

SafetyDo’s&Don’ts

SafetyDo’s&Don’ts

REGLESDESECURITE:«AFAIRE»ET«ANEPASFAIRE»

Do-readthisoperatormanualfullybeforeoperatingthemachine.

Lirecemoded'emploiavantd'utiliserlamachine.

Do-operatewiththedesignatedACcurrentonly.Useanexclusiveoutlet,as

overloadingmaycausefireoranelectricshock.

Respecterl'alimentationélectriqueindiquée.Branchersurunepriseséparée

carunesurchargepeutentraînerunincendieouunchocélectrique.

Do-installthepowercordoutofthewaytoavoidatrippinghazard.

Installerlecordond'alimentationdemanièreànepaspouvoir

trébucherpardessus.

Do-makesurethatthemainsinletconnectorisalwayseasilyaccessible.

Ménagerunaccèslibreàlaprisedecourant.

Donot-installthemachineinanunstableplacesuchthatittiltsorshakes.

Nepasinstallerlamachinesurunesurfacenonplane,afind'éviter

qu'ellenepencheounevibre.

Donot-unplugtheplugorunplugthepowercordfromtheoutletwithawethand,

thiscancauseanelectricshock.

Nepasinstallerlamachinesurunesurfacenonplane,afind'éviter

qu'ellenepencheounevibre.

Donot-unscrewandremoveanycoversfromthemachine,asitcancausean

electricshockorinjury.

Nedémonteretenleveraucuncarterdelamachine,parcraintededécharge

électriqueoudeblessure.

Donot-placereceptaclescontainingliquidsonanysurface.

Nepasplacerderécipientcontenantunliquidesurlamachine.

Donot-adjustanypartofthemachinewhilstrollersarerunning

N'effectueraucunréglagependantquelesrouleauxfonctionnent.

Donot-operatethemachinewithlooseortrailingclothingorloosehair.

Nepasporterdevêtementsflottantsetrassemblerlescheveuxlongs

lorsdel'utilisationdelamachine.

Donot-underanycircumstancesadjustthepapergatewhenthemachineis

switchedon.

Enaucunecirconstance,réglerleséparateurdepapierlorsquela

machineestbranchée.

Page4

CREASING

Page 6

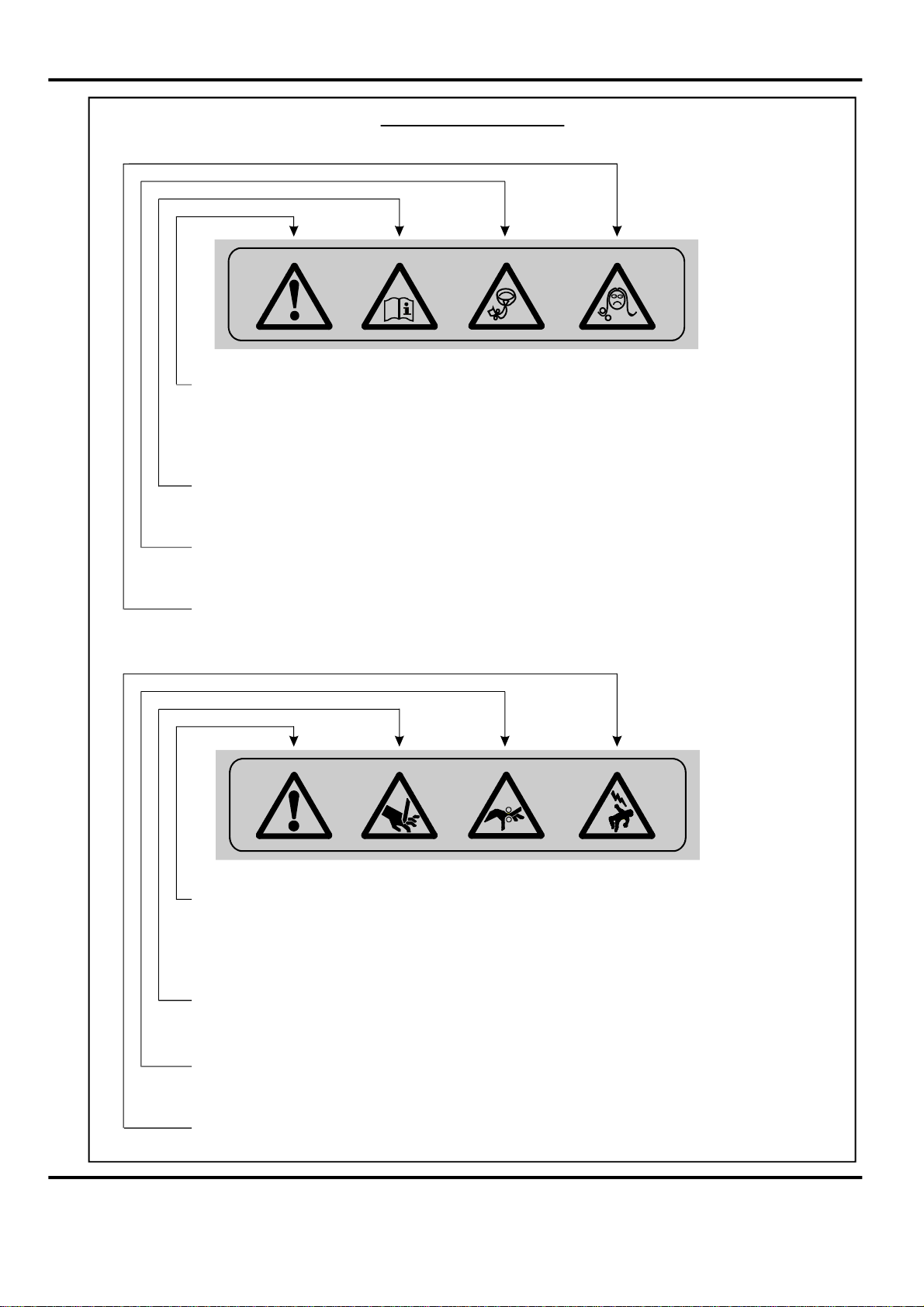

WarningLabels

Do-beawareofanyfingertrapsandrotatingpartswhenoperating

themachine.

Attentionaurisquedesecoincerlesdoigts,etauxpiècesen

mouvementlorsdufonctionnementdelamachine.

Do-readthisoperatormanualfullybeforeoperatingthemachine.

Lirecemoded’emploiavantd’utiliserlamachine.

Donot-operatethemachinewithlooseortrailingclothing.

Nepasporterdevêtementsflottantslorsdel'utilisationdelamachine

Donot-operatethemachinewithloosehair.

Rassemblerlescheveuxlongslorsdel'utilisationdelamachine.

Do-beawareofanyfingertrapsandrotatingpartswhenoperating

themachine.

Attentionaurisquedesecoincerlesdoigts,etauxpiècesen

mouvementlorsdufonctionnementdelamachine.

Do-beawareofsharppointsandblades.

Attentionauxélémentstranchantsetauxcouteaux.

Do-beawareofrotatingrollers.

Attentionauxrouleauxenfonctionnement

Do-beawareoflowcurrentanti-staticshock.

Attentionauxfaibleschocsd'électricitéstatique

Page5SYSTEM

Page 7

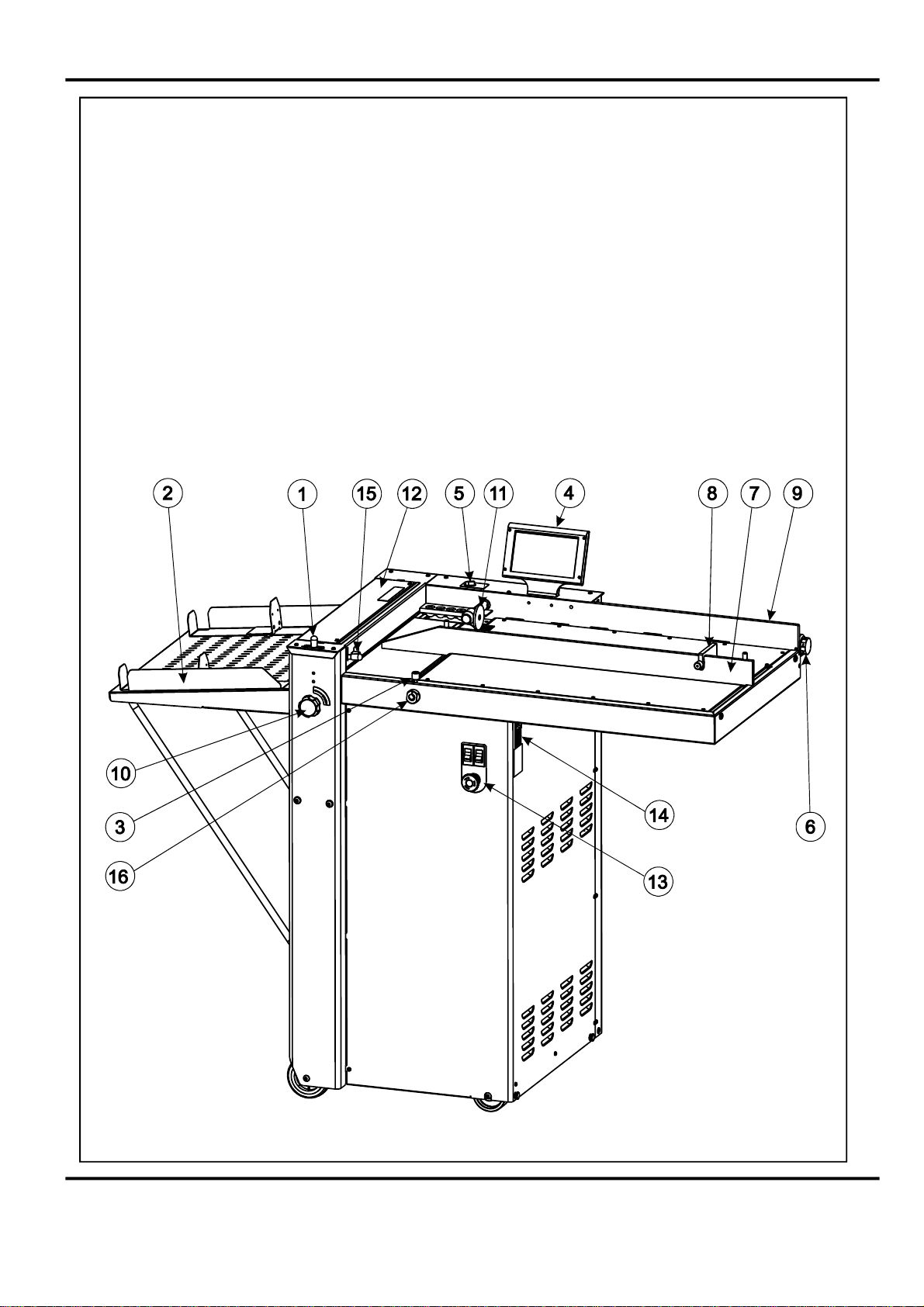

DOCUMENTCREASINGMACHINE

Keytophotographbelow

1Rollertilthandle7Adjustablesidelay13SwitchPanel

2Stackerassembly8BackStop14Fuses

3Suctionslotknob9Fixedsidelay15GapSetKnobandLever

4Touchscreen10Rollertiltknob16VacuumBleedKnob

5Airseparationknob11PaperGate

6Airdistributionknob12ExitGuard

Page6

CREASING

Page 8

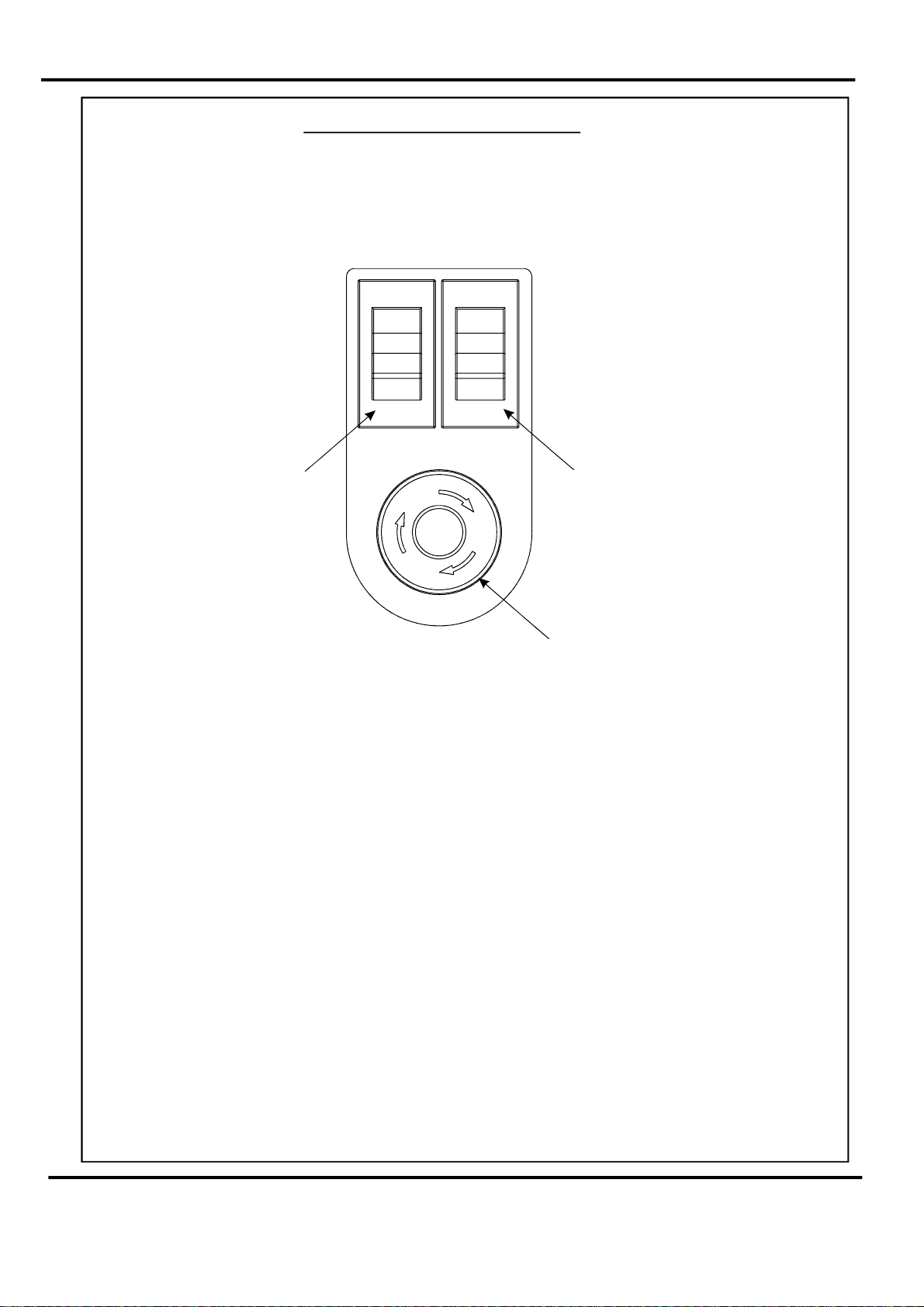

THECONTROLS

THESWITCHPANEL

TheSwitchPanelhouses

industrystandardEmergencyStopswitchwhichwillstopallpowergoingto

hemachinewhenactivated.

t

Co

mpressorSwitch

theCompressorswitch,Systemswitch,andan

SystemSwitch

EmergencyStopSwitch

FeaturesontheSwitchPanel

System

Whenactivat

creasin

Compressorswitch

Allowstheoperatortoswitchoffthecompressorunitinordertoutilisethemachine

tomanuallyfeedsheets.

switch

edthesystemswitchwilloperatethemotorsinordertobeginthe

gsequence.

Page7SYSTEM

Page 9

THECONTROLS

BLANK

PAGE

Page8

CREASING

Page 10

QuickStartGuide

Settingthemachinetooperateinautomaticsheetfeedmode

1.Setthegapbetweenthepapergateandthevacuumrollertoapproximatelytwice

thethicknessofthestocktobecreased.

2.Placethestocktobecreasedontotheloadingtableagainstthefixedsidelay.

3.Releasetheclampsontheadjustablesidelayandslideuptothepaperstack

allowingagapofapproximately0.5mm(1/64inch)betweenthepaperandtheside

lay.

4.Positionthebackstopandslideituptothepaperstack,alsoallowingagap(as

statedintheabovestep).

5.TurntheEmergencyStopbuttonclockwisetoswitchthepoweron.Afterthe

systemstartupprocedurethetouchscreenwillbedisplayedasshownbelow.

IMPORTANT.

Ifyouhavenotbeentrainedtooperatethismachine,westronglyadvisethatyouselect

theredcrossicon.

Werecommendthatyoueitherseektrainingoraskatrainedoperatortorunthemachine

foryou.

Selectthegreentickicononlyifyouhavebeentrainedtooperatethismachine.

Ifyouhavenotbeentrainedtooperatethismachineandyouselectthegreentickicon,

)RUPD[acceptnoresponsibilityforpersonalinjury,damagetothe

machineordamagetomaterialsbeingprocessedbythemachine.

WARNING:-

Waitatleast10seconds,aftermakinganyselectionontheTouchscreen

panel,beforeswitchingthemachineOFF.Failuretodosocouldresultinthe

datastoragebeingcorrupted,andthemachinenotoperating.

Page9SYSTEM

Page 11

QuickStartGuide

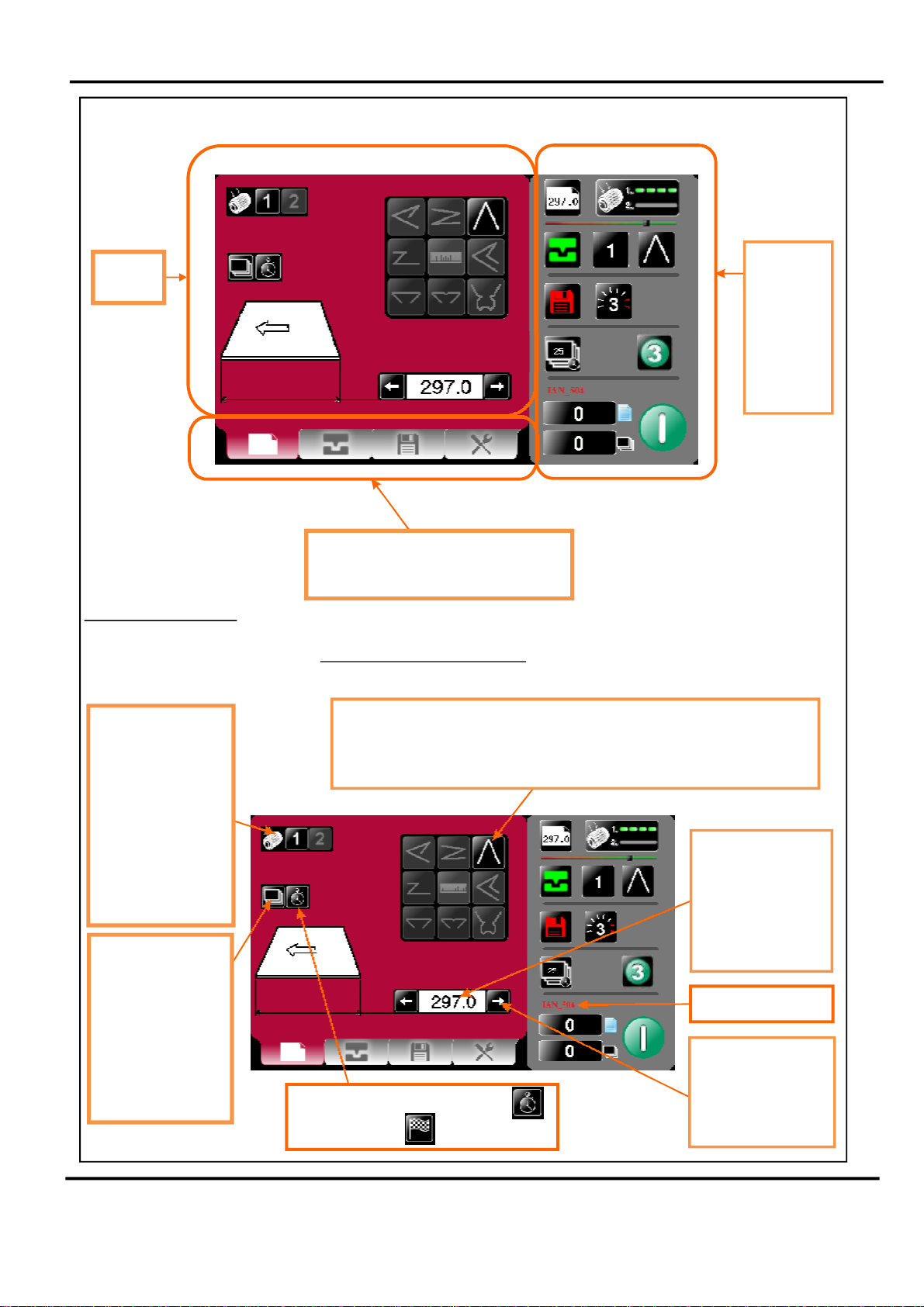

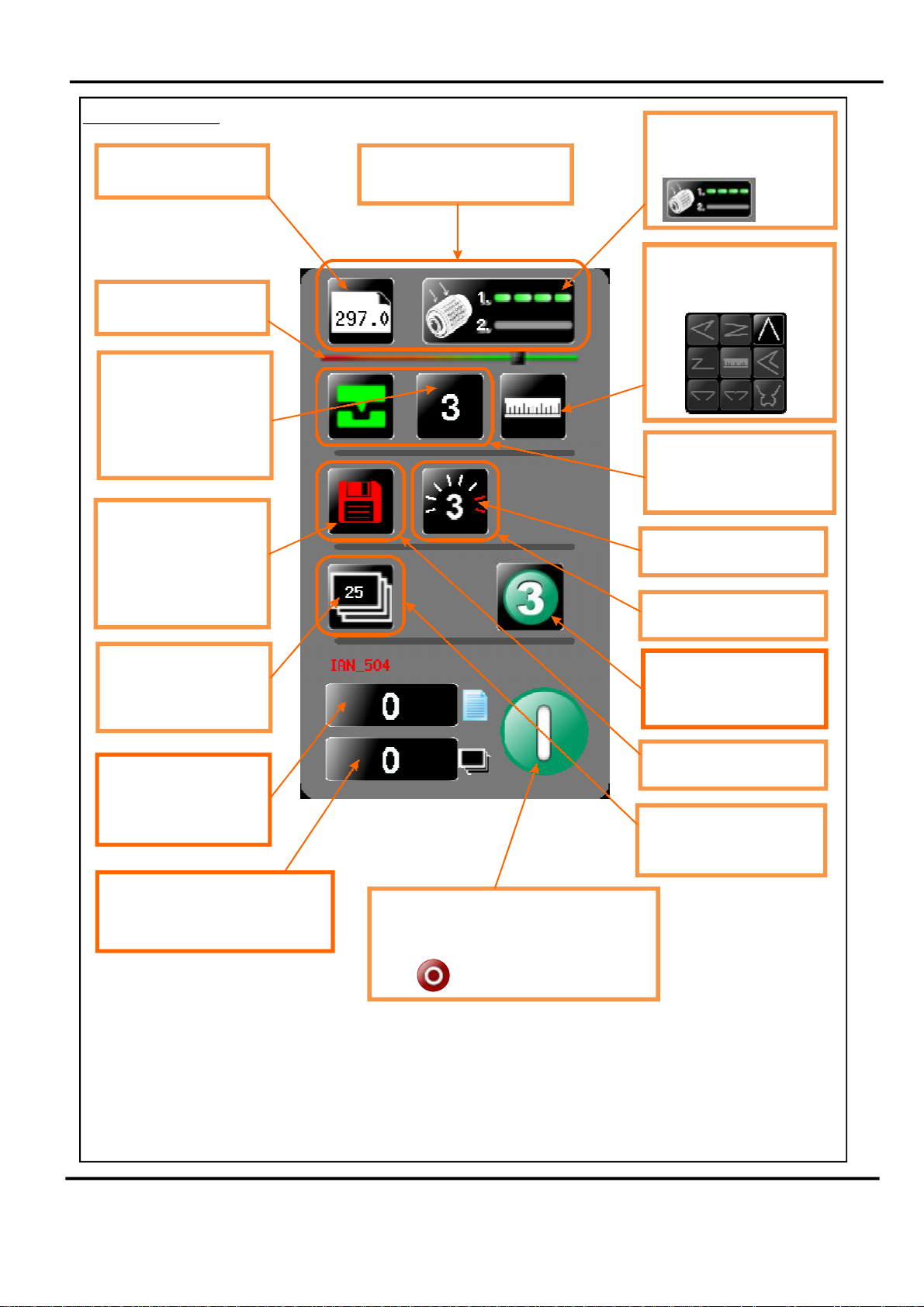

Thetouchscreenislaidoutinto3mainareasasshownbelow:

Setting

page

SettingsPages.

Tabstoenableswitchingbetweensetting

chooseeitherPaper

pages

-

CreaseSetting,StoreorTools

Settings,

PaperSettingsPage.

Statusof

machine

dataentry

area.Also

usedfor

quicklinks

tosetting

pages.

&

VacuumSuck-There

aretwoselections

available-1short

suck&2continuous

forstreamfeeding.

Highlightednumberis

typecurrently

selected.Thestatus

areaalsoshows

currentlyselected

suck.

BatchButton-Image

isidenticaltothat

showninthestatus

area.Onselectionthe

statusareaisreplaced

withacalculatorfor

inputtingnewvalues.

Batchesofany

numericalvalue.

FoldSelection-Forquicksettingofcreasepositionsonstandardsizesheets.

Highlightedfoldistypecurrentlyselected,otherfoldsmaybeselected.

Currentlyselectedfoldisshowninthestatusarea.

Togglebetween,Delaybetweenbatches

andstopafterbatch

PageLength - On

selectionthestatus

areaisreplacedwith

acalculatorfor

inputtingnewvalues.

MinLength=190mm

CurrentJobName

Arrowsmaybe

selectedtoincrease

ordecreasethepage

sizein0.1mm

increments

Page10

CREASING

Page 12

QuickStartGuide

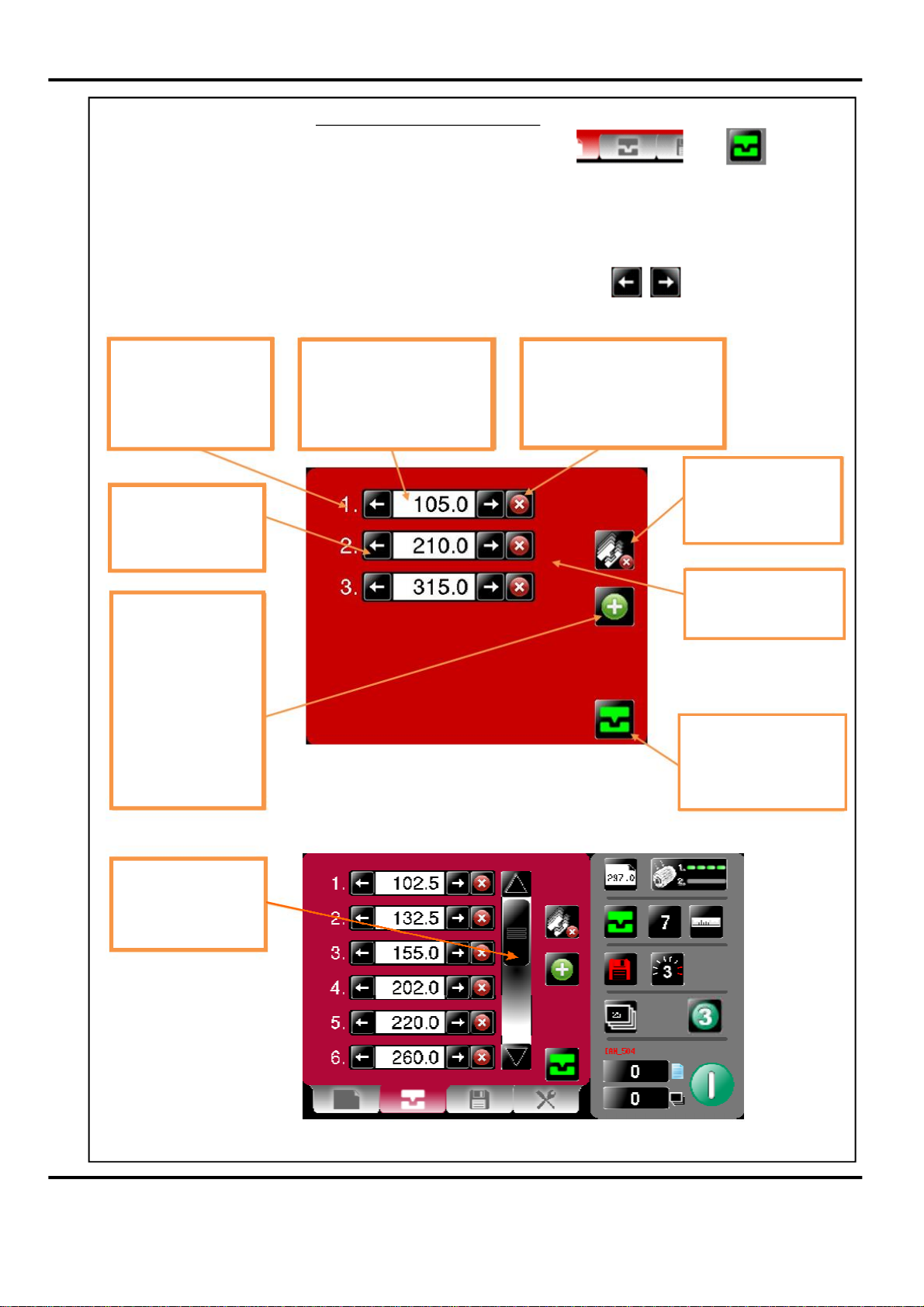

CreasesettingsPages.

Togettothecreasesettingpageclickthelowertaborfrom

thestatusarea.

Ifyouhaveselectedapredefinedstandardcreasetypefromthepapersettings

pagethecreasepositionswillbesetforyou.Thesepositionscanbefinetuned

by±0.1mmincrementsbypressingsidearrowbuttonsforeachcrease.

Numberofcreases–if

morethan6creasesare

addedascrollbarwill

appeartoenable

viewingofallcreases

Arrowsmaybeselected

toincreaseordecrease

thecreaseposition

in0.1mmincrements

Plusboxforinserting

additionalcreases.On

selectionfollowing

creaseswillmovedown

byoneplacea

maximumnumberof6

creasescanbeseenat

anyonetimefurther

creasescanbe

accessedbyuseofthe

scrollbar.

Creaseposition-Onselection

thestatusareaisreplacedwith

acalculatorforinputtingnew

values.

Crossboxfordeletionofcrease.

Ondeletionofcreasefollowing

creaseswillmoveupbyone

place.Youwillbeaskedto

confirmdeletionofthecrease.

Presstoremoveall

creases–youwillbe

askedtoconfirm

deletion.

Scrollbar-usetobring

requiredcreaseinto

view.

Creaseon/offselector

greenison&redisoff.

Thisisalsoindicatedin

thestatusarea.

Additionalcreases

added–scrollbar

appearsformorethan

sixcreases.

Page11SYSTEM

Page 13

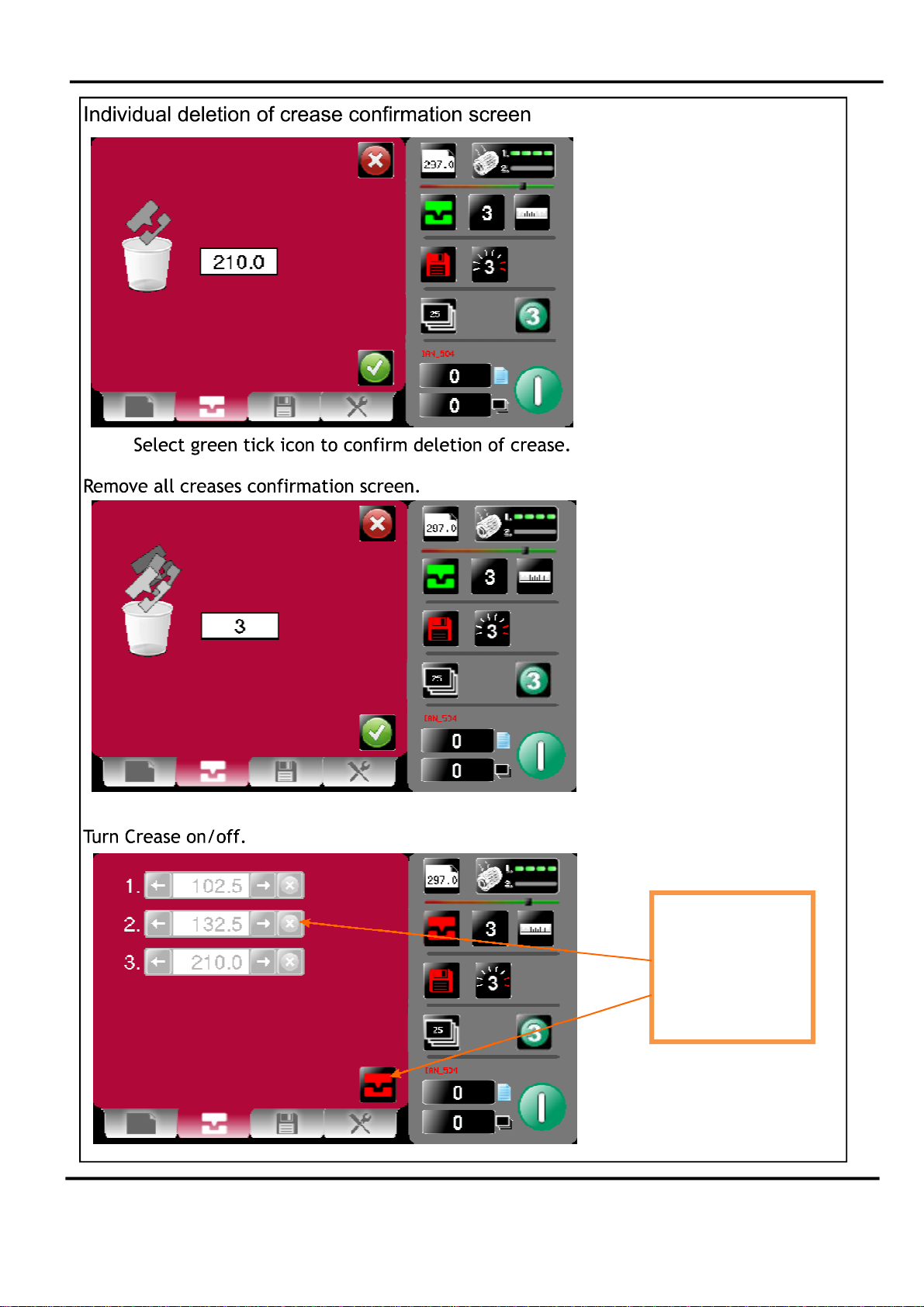

QuickStartGuide

Page12

CreasingturnedoffGreyedoutareasare

unselectable.Status

areawillshow

creasingisoffwith

redicon

CREASING

Page 14

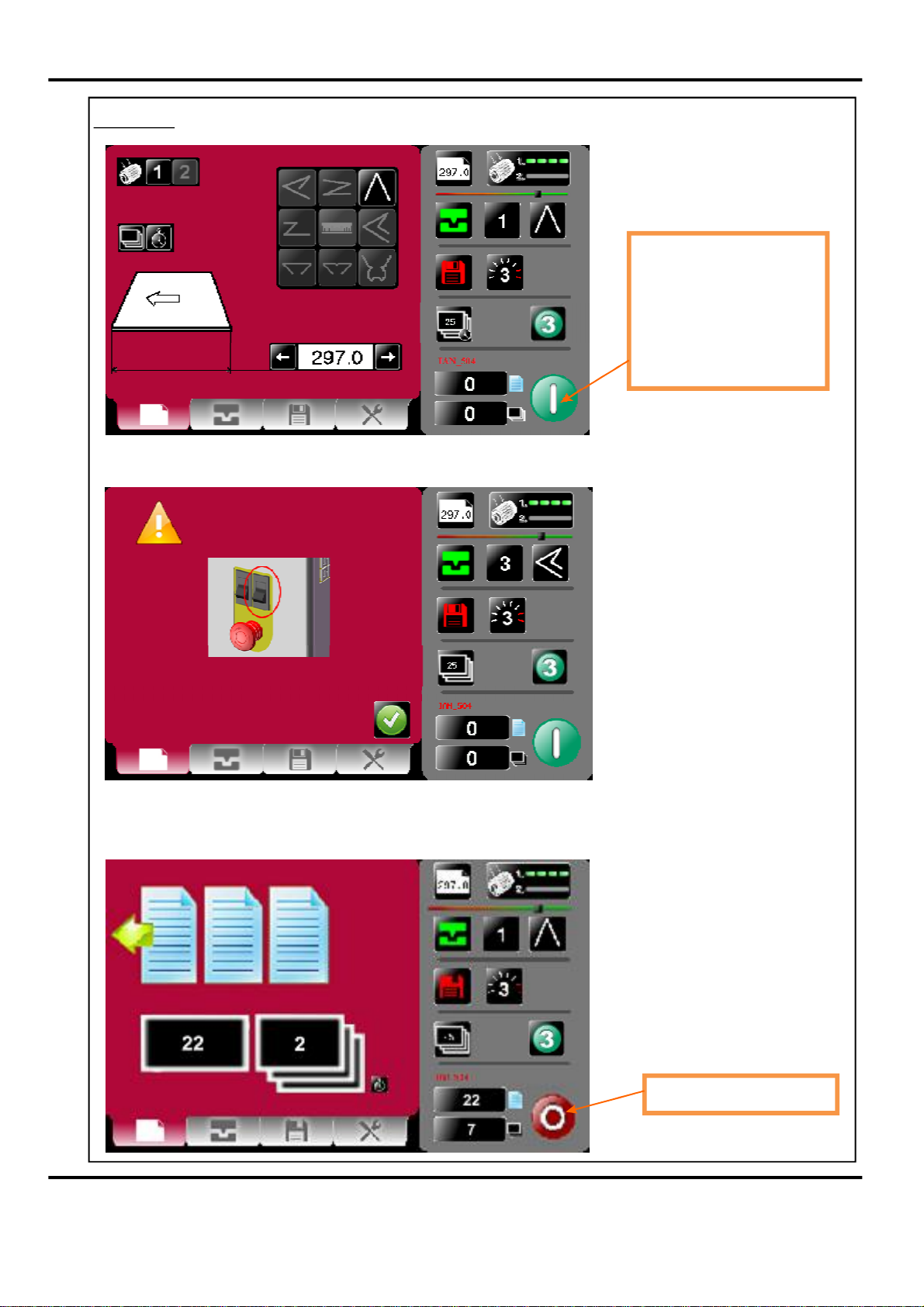

RunJob

SystemSwitchNotOn

QuickStartGuide

Clicktostartmachinewith

settingscurrentlyshown-

youwillreceivea

notificationifsystem

switchisnoton.Press

againtostopJob

PushSystemSwitchdowntostartthemachine.

Themachinerunningscreenwillappear.

Clicktostopmachine

Page13SYSTEM

Page 15

QuickStartGuide

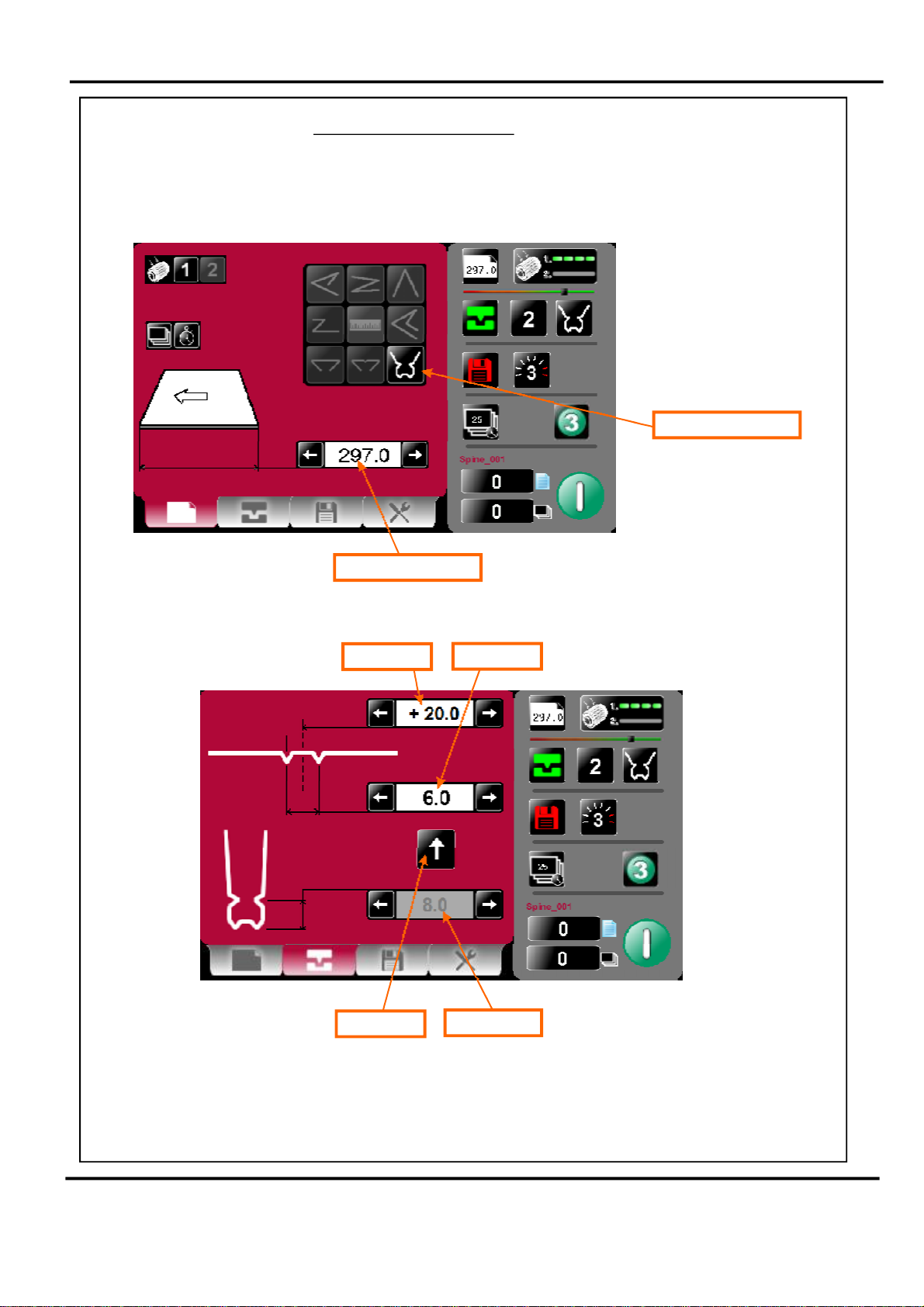

CoverCreaseMode.

1.SelectthePaperSettingsTab.

2.EnterthePaperLengthandthenselecttheCoverCreasebutton.

CoverCreasebutton

PaperLength

3.SelecttheCreaseSettingsTab.

SpineOffset

SpineWidth

ArrowButton

HingeDistance

4.EntertheSpineWidthdimension.Ifnecessary,adjusttheSpineOffsetfromthe

centreofthesheet.

5.SelectthearrowbuttontosetthehingeDimension.

Page14

CREASING

Page 16

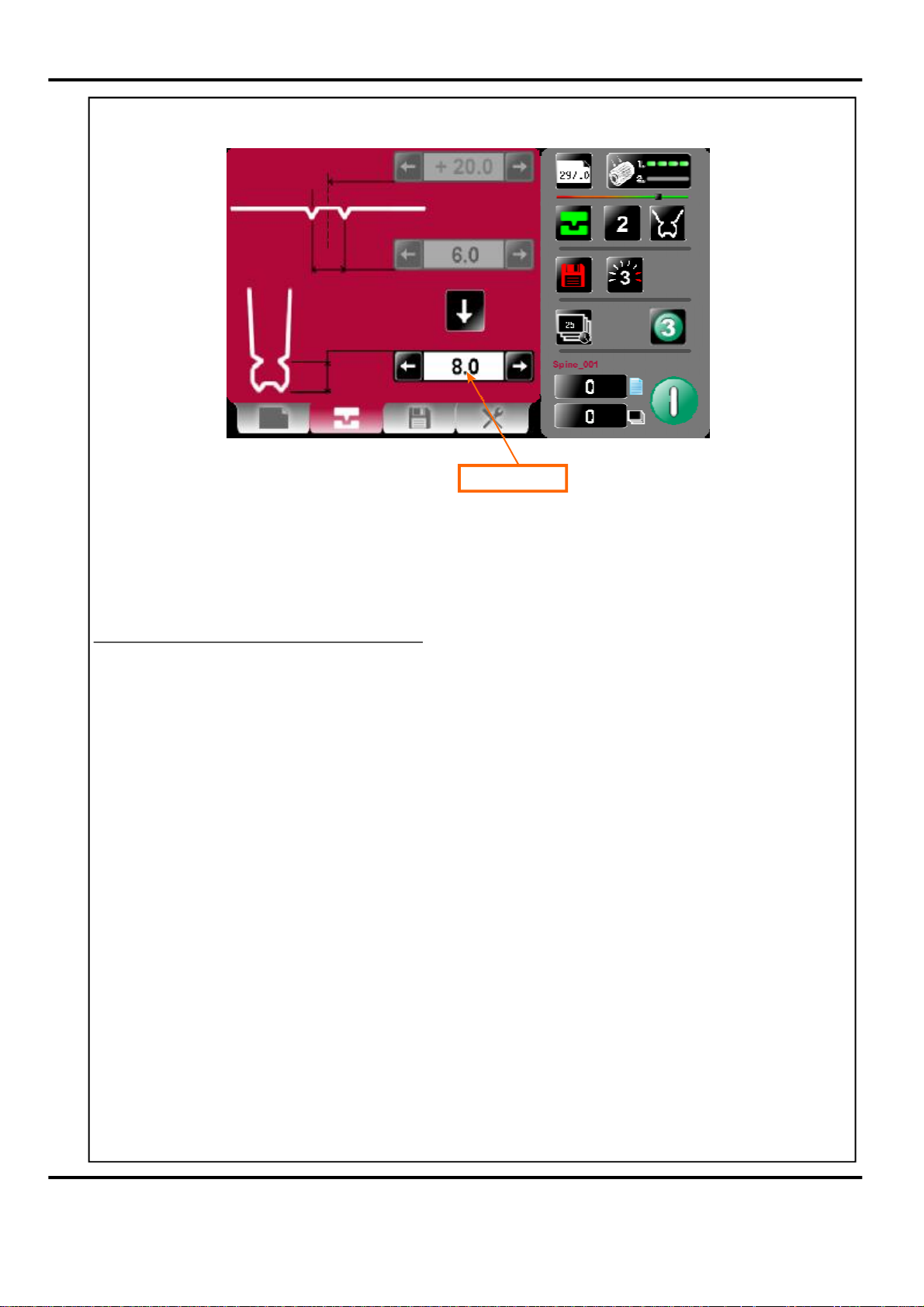

6.EntertheHingeDimension.

QuickStartGuide

HingeDimension

7.SelectthearrowbuttontohighlighttheSpineOffsetandtheSpineWidth

dimensions.

8.RunthesheetsofpaperthroughthemachinetomaketheSpinecreases.

TOMAKETHEHINGECREASES.

9.Removethesheetsofpaperfromthestackertray.,

andputthembackontotheloadingtable.

OFTHESHEETSPOINTINTHESAMEDIRECTIONASBEFORE.

10.SelectthearrowbuttontohighlighttheHingeDimension.

11.RunthesheetsofpaperthroughthemachinetomaketheHingecreases.

MAKESURETHATTHELEADEDGE

TURNTHESHEETSOVER

Page15SYSTEM

Page 17

QuickStartGuide

StatusScreen

Paperlength-inputfrom

thepapersettingscreen

LeadEdgeSensorStrength,

IndicatorBar

Numberofcreases-this

mayalterautomaticallyif

apre-definedfoldis

selected.Adjustments

maybemadeinthe

creasesettingscreen

Greeniconindicates

settingsaresaved-ared

iconwouldshowthat

settingshavebeen

changedbutthejobhas

notbeensaved.

Clickinginthisareawilltakeyou

tothepapersettingpage

CurrentlyselectedVacuum

Sucksetting-forstream

settingchooseselection2

Currentlyselectedfoldtype

-canbeoneofthe

following.

Clickinginthisareawilltake

youtotheCreasesetting

page

Currentmachinespeedsetting

Clickinginthisareawilltake

youtotheToolspage

Batchquantity-thisis

inputfromthebatch

calculatoronthepaper

settingscreen-max.999

Sheetcount-clicktozero

Ascreenwillappearto

confirmthatyouwantto

resetthecount.

Batchcount-clicktozero

Ascreenwillappeartoconfirmthat

youwanttoresetthecount.

Selectthisbuttontoproduce

3testsheetswiththe

settingscurrentlyshown.

Clickinginthisareawilltake

youtotheJobStorepage

Clickinginthisareawilltake

youtothepapersetting

page.

Clicktostartmachinewithsettingscurrently

shown-youwillreceiveanotificationif

systemswitchisnoton.Pressagaintostop

Job

Page16

CREASING

Page 18

QuickStartGuide

TheStatusScreenwillonoccasionsbereplacedwithanInputCalculatorScreen

asshownbelow.

Pre-setPapersizesforquick

insertion–Standardsizesfor

countryoriginwouldbeshown

PapersizeBatchsizeCreaseposition

inputcalculatorinputcalculatorinputcalculator

Pre-setBatchsizesforquick

insertion.

NOTE:

ThegreentickortheredcrossmustbeselectedontheCalculatorScreento

makethelefthandsideofthetouchscreenactiveagain.

Page17SYSTEM

Page 19

ToolsScreen

Inchpaperindirection

ofarrowtoclearjams

QuickStartGuide

MachineSpeedAdjustment:Speedsetting3willgivethefastestthroughputof

stockthroughthemachine.

Usespeedsetting1or2fortroublesomestocks,

ortosynchronisethespeeĚ

ClickonUpArrowto

putAnvilintoTop

DeadCentreposition

(TDC)

CleanLeadEdgeSensor

TouchScreenCalibration

SeePage19

ChangeMachinemeasurement

settings,Imperial/Metric

Inchpaperindirection

ofarrowtoclearjams

Clickingthisiconwill

showMachine

programrevision&

TouchScreen

softwarerevision.

Page18

Touchscreensoftware

version

MainProcessorProgram

version

CREASING

Page 20

QuickStartGuide

TouchScreenCalibration.

1.Switchthemainspoweronandwaitforthemainscreentoappearbefore

commencingtocheckthehorizontalandverticalpositionofthedisplay.

Thepositionofthedisplaywithinthesurroundisachievedbyoperatingthebutton

attherearofthehousing,pressthisanumberoftimestoobtainthecorrect

orientationrequired,movetothenextbuttontomovethepositiontocentralize

horizontal.

2.(i)Selectthetoolsmenutab,andthenSelecttheTouchScreencalibrationicon.

(ii)Usingaplasticpointer,softleadedpencil,birocapetc.andwithgentlepressure.

TouchthecentreofthecrossineachcorneroftheTouchScreen,asprompted,by

thehandgraphics.ThisprocedurewillcalibratetheTouchScreen.

Page19SYSTEM

Page 21

SettingtheMachine

AdjustingthePaperGate

SettheheightofthePaperGatetoapproximatelytwothicknessesofpaper,byturningthe

discj.Anexcessivegapisamostlikelycauseofdoublesheetfeeding.

Thissettingisonlyintendedasaguide,forinstance,sheetswithanupwardcurlwill

requirethissettingtobeincreased.

J

TWOTHICKNESSES

OFPAPER

WARNING.

DONOTADJUSTTHE

PAPERGATEWHILETHE

MACHINEISRUNNINGOR

THESUCTIONDRUMMAY

BECOMEDAMAGED.

SettingtheSuctionSlot

Thesuctionslotislocatedinsidethevacuumrollerandcanbeadjustedbyreleasingand

movingthesuctionknobhorizontallyineitherdirectiontotherequiredposition.

Forlightstockssettheknobtotheleftandforheavierstockssettheknobtotheright.

FIG8.1

Adjustable

SideLay

Suction

SlotKnob

Page20

CREASING

Page 22

SettingtheAdjustableSideLay

Placethepaperstackontotheloadingtableandslideuptothefixedsidelayandpaper

gate.Releasetheclampslocatedateachendofthesidelayandslideuptowardsthe

paperstackasdemonstratedinfig8.1.Allowagapofapproximately0.5mm(1/64inch)

betweenthepaperandthesidelay.

SettingtheBackStop

Positionthebackstopandslideuptowardsthepaperstackallowingagap(asspecified

intheabovestep).

SettingtheAirDistribution

Dependingonthelengthofthesheettobecreased,theairdistributionknobcanbe

rotatedtovariouspositionsinordertosupplyairtodifferentports.Position2is

recommendedformostsheetsizes.However,abetterresultmaybeobtainedbyusing

thesettingsbeloworbyexperimentation.

Position1-

2345-

0-

Port1

ForsheetslongerthanA3(17”)inordertosupplyairtothecentreofthe

stack,ports2,3and4open.

ForA5sheetsor8incheslong,ports1and2open.

ForA4sheetsor11incheslong,ports1and3open.

ForA3sheetsor17incheslong,ports1and4open.

ForsheetslongerthanA3(17”)inordertosupplyairtotheendsofthestack,

ports1and5open.

ForsheetslongerthanA3(17”)inordertosupplyairevenlyalongthestack,

ports1,3and5open.

Port5

AirDistribution

KnobShown

SetToPosn.1

SettingtheAirSeparationPressure

Tocontroltheamountofairsuppliedtotheports,theairseparationknobcanberotated

clockwisetodecreasethepressureoranti-clockwisetoincreasethepressure.

Page21SYSTEM

Page 23

SettingtheRollerTiltMechanism

Therollertiltmechanismhasbeendesignedtocompensateforwhenthecreasing

positiononthesheetisnotsquare.Thiscouldbeduetoaninaccuracyinthemediaorif

therollertiltmechanismhasbeenincorrectlyset.Themechanismwillbesettozero

(square)whenthemachineissupplied.

Tosetthemechanism,unlocktherollertiltknoblocatedbelowtherollertiltinghandleby

turninganti-clockwise.Movetherollertilthandleleftorrightinordertocompensatefor

anyinaccuracy.Whenthepositionisset,ensuretolocktherollertiltknobbefore

operatingthemachine.Repeattheaboveprocedureuntilthecreasingpositionissquare.

Settingthepositionsofdrivewheelsandhubs

Itisimportantthatthedrivewheelsanddrivehubsontherollershaftsarearrangedevenly

acrossthewidthofthemediabeingcreased.Thisisdonetoensurethatthemediais

accuratelydrivenandsupportedthroughtherollers.

Thedrivewheelsandhubsarefixedtotherollersbymeansofagrubscrew.Tolocatethis

grubscrewtherollerscanberotatedbyoperatingthemotormanually.

DONOTROTATETHEDRIVEROLLERSBYHAND.

Tooperatethemotorsmanually,switchthemachine‘on’attheEmergencyStopswitch.

SelecttheToolstabatthebottomofthetouchscreen,thedisplaywillchangeto

thatshownbelow.

Inchpaperindirection

ofarrowtoclearjams

Pressthesystemswitchdownandthenselecttherightorleftarrows,torotatetherollersin

shortpulses.

Lifttheexitguardtoseeifthegrubscrewsinthedrivewheelsandhubscanbeseen.Ifthe

grubscrewscannotbeseen,lowertheexitguardandrotatetherollersbyselectingthe

rightorleftarrows.Loosenthedrivewheelsandhubswitha2mmallenkey.Arrangethe

drivewheelsandhubsasshowninFIG10.1.Inordertoavoidmarkingonsometypesof

mediaensureagapbetweenthedrivewheelsandhubs.

Thisprocedureshouldberepeatedwheninstallingperforatingbladesandanvilsontothe

drivewheelsandhubs.

Leftarrow

Inchpaperindirection

ofarrowtoclearjams

Rightarrow

Page22

CREASING

Page 24

FIG10.1

SetFeed

Thelengthofsuctiononthesheetofpaperbeingfedcanbeadjustedbysettingthefeed

typeasfollows:-

Select1forshortsuck,select2forcontinuoussuck(streamfeeding).

VacuumSuck

Select1forshortsuck

Select2forcontinuoussuck

(Streamfeeding)

NOTES.

1.willgivethequickestthroughputofstockthroughthemachine.

StreamFeed

2.Whenthefirstcreaseislessthan37mmfromtheleadingedgeofthepaperthefeedwill

benoticeablyslowerwhenusingspeeds2and3.

3.Whenthefirstcreaseislessthan50mmfromtheleadingedgeofthepaperthefeedwill

benoticeablyslowerwhenusingspeed3.

Page23SYSTEM

Page 25

Settingtheinfeedrollergapset

Thegapbetweentheinfeedrollersmustbeadjustedtosuitthestockbeingused.Thegap

setcanbeadjustedasfollows:-

1.Placeasamplesheetofthestocktobeusedontothefeedbed.

2.SelecttheToolstabatthebottomofthetouchscreen,thedisplaywill

changetothatshownbelow.

3.Pressthesystemswitchdownandthenselecttheleftarrowonthetouchscreen,to

rotatetherollersinshortpulsesuntilthesheetisgrippedintheinfeedrollers..

4.Testthegripofthesheetintherollersbytryingtoremovethesheetbyhand,the

sheetshouldbelightlygrippedbytherollers.Ifthegriponthesheetistoolightortoo

heavyitcanbeadjustedasfollows:-

(i)Turnthegapsetlockingknobanti-clockwisetounlock.

(ii)Movethegapsetleveruptoincreasethegapordowntodecreasethegap.

(iii)Turnthegapsetlockingknobclockwisetolock.

GapSet

Lever

GapSet

Locking

Knob

Page24

CREASING

Page 26

Page25SYSTEM

Page 27

Programmingthemachine

1.Switchthepower‘on’byturningtheEmergencystopbuttonclockwise

toreleasethesafetylatch.

Settingthepagelength

2.Setthepagelengthofthepaperasdescribedonpage10.

Settingthevacuumsuck

3.Setthevacuumsuckasdescribedonpage10.Settingnumber1forshortsuckand

settingnumber2forcontinuoussuck(streamfeed).

Settingthebatchquantity

4.Selectthebutton.Onselectionthestatusareaisreplacedwithacalculatorfor

inputtingnewvalues.

Settingthecreasepositions

5.(i)Selectthelowertaborfromthestatusareatogettothe

CreaseSettingsPage.

(ii)Setthecreasesasdescribedonpages11and12.

StoringtheJob

6.Thejobthathasbeensetcannowbestoredasfollows.

(i)Selectthelowertaborfromthestatusareatogettothe

StoreSettingsPage.

(ii)Thejobcanbegivenanameandstoredasdescribedbelow.Youcanalsoretrieve

previouslysavedjobs,modifythemordeletejobsthatarenolongerrequired.

Tocreateanewjobnameclickintextarea&

keyboardwillopentoinputjobname.

Loadexistingjobfrom

store

Clickingtosearch

currentlystoredjobs

Clickingtodelete

currentlystoredjobs

Page26

CurrentJobName

YellowTextDenotesSavedJob

RedTextDenotesUnsavedJob

Clickingtosavejob

shown.

CREASING

Page 28

Keyboardf

orenteringjobname.

Saveconfirmationscreen.

DeletelastcharacterDeleteallcharacters

clicksav

jobtostore

eicon

tosave

Toconfirmsaving

ofJobclickhere.

Searchforcurrentjobstoloadormodify.

Youcansearchforjobsbyclickingthesearchicon,thiswillbringupthesearch

keyboardfortextinput.

Typeinjobdescription

o

rfirstfewcharacters

Presssearchicon

tostartsearch

Tochangeyourmind&

ret

urntotheprevious

screenclickhere.

Page27SYSTEM

Page 29

Jobsmatching

charactersintextbox

willbeshowninthis

area-selectingjob

fromthisareawill

showjobsettingsin

therighthandstatus

area.Jobselectedwill

beshownintextbox.

Loadingjobconfirmationscreen.

Togglebetweensearch

results&fulllistof

jobs

Presstoloadjob

shownintextbox.

Theloadedjobcanberunormodifiedandsavedasthesamejobname.

Overwritejobconfirmationscreen.

Tocanceloverwriteof

Jobpresshere.

Toconfirmoverwrite

ofJobpresshere.

Page28

CREASING

Page 30

Deletejobconfirmationscreen.

Tocanceldeletionof

Jobpresshere.

Toconfirmdeletionof

Jobpresshere.

Runningthemachine

Runthejobasdescribedonpage13.Themachinewillcompleteitscreasingoperationifa

sheethasalreadybeenfedthroughthepapergate.

Paperjamming

Intheeventofapaperjamoccurringwhilstthemachineisoperating,selecttheTools

tabatthebottomofthetouchscreen,thedisplaywillchangetothatshown

below.Pressthesystemswitchdownandthenselecttherightorleftarrows,toinchthe

paperforwardsorbackwards.

Inchpaperindirection

ofarrowtoclearjams

Inchpaperindirection

ofarrowtoclearjams

Settingthemachinetooperateinmanualsheetfeedmode

Inordertofeedheavystock,verysmallorverylargesheets,embossedorevenirregular

shapedsheets,itmaybenecessarytofeedthesheetsmanually.Themachinecanbe

programmedandsetupinexactlythesamewayasexplainedwhenoperatingthemachine

automatically.However,thepapergatemustberaisedtoitshighestpositionforthesheets

tobefedfreely.Operatingthemachineinmanualsheetfeedmodewillalsorequirethe

suctionlengthtobecontinuousinordertoaccommodatevarioustypesofstock.Therefore,

thefeedshouldbesetto(VacuumDrumposition2)seepage10.

ThemachinecannowbestartedbyactivatingtheSystemswitchto‘on’.

theCompressorswitch.

StreamFeed

Donotactivate

Selecttheicononthetouchscreenandbegintoslidethesheetsindividuallythrough

thepapergateuntiltheyaredrivenbythedrivebelts.

Tostopfeedingthesheets,selecttheicononthetouchscreenandswitchthe

SystemSwitchoff.

Page29SYSTEM

Page 31

TheStackerAssembly

Thestackerunitonthemachineisusedtocatchthesheetsoncetheyhavebeen

creasedorperforated.

SettingtheStackerassembly

1.Assemblethestackerunittothemachineasshowninfig13.1below.

Important

Ensurethatthestackerunithasbeenassembledtothemachineproperly.However,

ifithasnot,theconnectiononthemagneticswitchwillbebrokenandthemachine

willnotoperate(seeTroubleshootingpagesfordetails).

Therearetwosideguidesonthestackerunit;alefthanded(fixed)guideandaright

handed(movable)guideheldonbyamagneticstrip.Thereisalsoalefthandextension

guide.Theguideswillcontrolthewayinwhichthepaperiscollatedbysettingtheir

positionsonthestackerbed.

2.Placeasinglesheet(fromthestacktobecreased/perforated)ontothestackerbed

againstthefixed‘lefthand’guide.

3.Positionthe‘righthand’sideguideontothestackerbedleavingaminimum

clearanceofapproximately1mmeachsideofthesheet.

LEFTHAND

BACKSTOP

LEFTHAND

SIDEGUIDE

Page30

RIGHTHAND

SIDEGUIDE

RIGHTHAND

BACKSTOP

CREASING

Page 32

TheStackerAssembly

4.Whilstthesheetisbetweenthetwoguidesonthestackerbed,setthedistance

betweenthetopofthesheetandthebackstopflangestoapproximately5mm.

5.Forshortersheets,thebackstopcanbeused(asshowninFIG13.1)toadjustthe

positionofthepaperstack.

TIPS

l

Oneofthebackstopssuppliedwiththemachine(onthe

stackerassembly)canalsobeusedasatoolholderas

demonstratedinthephotograph(left).

l

Thescaleonthebedcanbeusedtomeasurethedesired

creasingorperforatingpositiononthesheet.

Page31SYSTEM

Page 33

Perforating

Note

Perforatingandcreasingcanbecarriedoutsimultaneously.However,ifany

adjustmentismadetotherollertiltmechanisminordertocompensateforthe

perforationlinebeing’outofsquare’,thismayeffecttheaccuracyofthecrease.If

thisoccurscreasingandperforatingmustbecarriedoutasseparateoperations.

Thecomponentsandtoolsrequiredtoinstalltheperforatorarecontainedinthedespatch

kitsuppliedwiththemachine,theyarelistedbelow.

1offSetofstandardperforation‘56tooth’blades.

1offSetofstandardhardenedanvils.

1offPerforatorstripper.

1off3mmbondhuswrench/allenkey

1off2mmbondhuswrench/allenkey

Theperforatorbladesaresplitintotwomatchinghalves

andarefittedtothedrivewheelsasshowninthe

photographusingthefourscrewssupplied.

Ahardenedanvilisfittedtothedrivehubasshowninthe

photographalsousingthefourscrewssupplied.Againthe

anvilsaremadefrommatchinghalves.

Important:Theperforatorbladesareverysharpand

caremustbetakenwhilsthandling.

Donotmixthematchingpairsofbladesoranvils.

Perforating‘Spares’kits

Forperforatingandothertypesofpaper,variousspareskitsareavailablewhichcanbe

assembledtothemachineinthesamefashion.Theyarelistedbelowalongwitharange

ofscoringwheels,

Perforatingblades1-99-41

Anvils1-99-35

56teethPartNumber-Standardstock/

fineperforations.

28teethPartNumber-Mediumstock/

20teethPartNumber-Heavystock/

StandardPartNumber-Forallbladetypes

1-99-12

mediumperforations.

1-99-10

coarseperforations.

Page32

CREASING

Page 34

Allofthebladesandanvilsaresuppliedwithfixings.

Perforating

*Perforatorstripper78-013

*Itisrecommendedthatformultipleperforations,aseparateperforatorstripperisusedfor

everyperforatingbladesetfittedinthecreasingunit.

StandardPartNumber

Settingthemachine

1.Turnthemainssupplytothemachine‘off’.

2.Removethestackerunitandopentheexitguard.

3.Locateandremovetheblades/anvilsfromthedespatchkitsuppliedwiththe

machine.

4.Usingthe2mmallenkey(supplied),loosenthedrivewheelthatistoaccommodate

theblades.

5.Slidethedrivewheelawayfromanyobstructingdrivewheelsorhubsinorderto

mounttheblades.

6.Usingthe2.5mmallenkey(supplied),takeone

ofthematchingpairsandmountontothedrive

FIG16.1

wheel.Donotsecuretheblade.

FIG16.2

7.Mounttheothermatchingpairtothedrivewheel

asshown(fig16.1).Securethebladestothe

wheelensuringnottoovertightengrubscrew.

8.Markonasinglesheetthedesiredperforating

position.Feedthesheetthroughthemachine

manuallyuntilthemarkcanbeseen.Usethis

marktoassistinfixingthepositionofthe

perforatingdrivewheeltotherollerdriveshaft.

9.Usingthe2mmallenkey,loosenthedrivehub

nearesttheperforatingdrive.Slidethedrivehub

awayfromanyobstructingdrivewheelsorhubs

inordertomounttheanvils.

10.Usingthe2.5mmallenkey,takeoneofthe

matchingpairsofanvilsandmounttothedrive

hub.Donotsecuretheanvil.

Page33SYSTEM

Page 35

Perforating

11.Mounttheotheranvilensuringthattheyhavematchedonthedrivehub.Securethe

anviltothehubensuringnottoovertightengrubscrewasshowninfig16.2.

12.Slidethedrivehubtowardstheperforatingdrivewheeluntilthereisaclearance

of0.5mm.

13.Topreventdamagetothebladesortheanvils,donotforcethedrivewheelagainst

thehub.

14.Fixtheperforatorstripperadjacenttothedrivewheelandbladeasshown.

15.Operatethemachineandtesttheperforationsforform.

Itisimportantthatthedrivehubsarearrangedevenlyacrossthewidthofthepaper

inordertoreducetheriskofjamming.

Formultipleperforationsrepeattheaboveprocedure.

Shaftsupportblocksaremountedonthetopandbottomshafts.Iftheyareina

positionthatobstructsperforating,theycanbeslidalongjustenoughtoclearthehubs.

Theyshouldbemountedasneartothecentreofthemachineaspossible,to

maximisesupport.Thedepthofperforationcanbeadjustedbyfirstlooseningthe

socketsetscrews,inthesupportblock,witha2.5mmallenkey.Insertthe2.5mm

allenkeyintothegrubscrew,pushtheallenkeyuptodecreasetheperforatingdepth

ordowntoincreasethedepthofperforation.Re-tightenthesocketsetscrews.

(Note.Thisadjustmentcanalsobecarriedoutonthebottomshaft)

Typicalset-upforperforatingsheets.

2 3

1

4

6

8

5

7

8

FIG17.1

PerforatingdrivewheelwithmountedbladesStandarddrivehub

1-5-

PerforatorstripperUppershaftsupportblock

2-6-

StandarddrivewheelLowershaftsupportblock

3-7-

DrivewheelwithmountedanvilsGrubscrew

4-8Alwaysremovebladesandanvilsoncetheperforatingoperationhasbeen

completedtoavoidmarkingondigitalordelicatemedia.

Page34

CREASING

Page 36

TheBladeAssembly

Adjustingthebladepressure(nopaperrequired)

1.(i)Switchthepower‘on’byturningtheEmergencystopbuttonclockwisetoreleasethe

safetylatch.

(ii)SelecttheToolstabatthebottomofthetouchscreen,thedisplaywill

changetothatshownbelow.

(iii)SelecttheuparrowtomovethebladetotheTopDeadCentreposition.

ClickonUpArrowto

putAnvilintoTop

DeadCentreposition

(TDC)

2.Raisetheexitguard

3.Usinga6mmallenkey,unlocktheshoulderbolts(labelledwithscaletransfer)

positionedateachendofthecreasingblade.

4.Turntheadjustmentcamtoadjustthebladepressure.Increasingthegradientonthe

scalewillincreasethebladepressure.

5.Ensurethattheshoulderboltsarelockedaftersetting.

Thediagrambelowdemonstratestheadjustmentofthebladepressure

Page35SYSTEM

Page 37

TheBladeAssembly

Adjustingthebladealignment

Itisextremelyimportantthatthebladeandanvilassemblywithinthecreasingunitis

correctlyaligned.Misalignmentofthebladeoranvilcanleadtodamagedprofilesand

subsequentlypoorqualitycreasingsoitmust,therefore,becorrectedimmediately.

Ifthebladesetismisaligned,themediabeingdrivenwillbesubjecttoscoringoreven

tearingatanypointalongthecreaseline.

bladeset,adjustmentshouldonlybemadeinsmallincrements.

demonstrateshowthebladealignmentcanbecarriedout.

Adjustmentcanbemadeateitherofthebladeoranvil.Thetwoclearanceholespositionedabovetherollertiltmechanismarethefrontalignment(oneforblade,oneforanvil).

Thetwoholesarerepeatedonthebackofthemachineforthebackalignment.

1.Removethestackerunitfromthemachine

2.Unlockandcentralisetherollertiltmechanisminordertolocatetheheadsofthe

frontalignmentscrews.

3.Usinga3mmallenkey,loosenthecapheadtypelockingscrewslocatedonthe

frontfaceatbothendsoftheblade/anvilasshownbelow.

Pleasenotethattoavoiddamagetothe

Thebelowsketch

4.Usinga4mmallenkey,locatethetwofrontorbackalignmentscrewsintheside

frameinordertoadjusttheblade/anvil.

5.Theupperscrewofthetwo,willadjusttheupperblade/anvilwhereasthe

lowerscrewwilladjustthelowerblade/anvilbothinverysmallincrements.

6.Inordertoobtaintherequiredposition,adjusteitherthebladeortheanvilbya

smallamountandthenoperatethemachinetotesttheformofthecrease.

Repeattheexerciseuntilcentralisationislocated.

7.Usinga3mmallenkey,lockthecapheadtypescrews(asperstep3)onboththe

upperandlowerblade/anvil.

Page36

CREASING

Page 38

1.Beforeremovingthebladeassembly,ensurethatthelowerblade/anvilisNOT

at‘topdeadcentre’,Switchthemachineoff.

2.Removethestackerunitandlifttheexitguard.

ReplacingBladeSet

BladeExtractorTools

3.Usinga6mmallenkey,loosenthesocket

headscrewslocatedinsidetheblade

adjustmentcams.Removethescrewsand

thebladeadjustmentcams.

4.Insertthebladeextractortools(70-055-01&

70-055-02)intotheholesintheadjustment

links,asshown.Pushdownwardsonthe

handlesofthebladeextractortoolsto

releasethebladeassemblyfromthepower

links.

5.Slidethebladeassemblyoutofthecreasing

unitandlayitonaflatsurface.

6.Slidetheadjustmentlinksawayfromthe

dowelslocatedintheendsoftheblades/

anvilsasshowninthephotograph(left)

7.Placethenewbladesetintoposition.

Checkthattheeccentricshoulderboltson

thelinkplateshavebeenpositionedas

showninfig20.1.

8.(Upperblade/anvilonly)

Slidetheadjustmentlinksontothedowels.

FIG20.1

Page37SYSTEM

Page 39

TheBladeAssembly

9.Slidethenewbladesetintotheslotsofthecreasingunitasshowninfig.21.1.

FIG21.1

NOTE.

ThebladesetcanbefittedwiththeANVILatthebottomorwiththeANVILatthetop.

ThebladesetissuppliedfromthefactorywiththeANVILatthebottomasshownin

FIG22A.

ThebladesetcanbechangedtohavetheANVILatthetop(asshowninFIG22B),thiscan

improvetherepeatabilityofthefoldrelativetothecreaseforcertainfoldtypesorwhen

usinglighterstocks.

FIG22BFIG22A

Locatethebladeextractortoolsintotheholesintheadjustmentlinksasshown.Pullthe

handlesofthebladeextractortoolsupwardstoengagethebladeassemblybackintothe

powerlinks.

10.Setthecamgraphicsforbothendsoftheblade/anviltotheirlowestpointonthe

scale(ie.Whenthemarkonthescalereachesthemarkoncamholder)Fastenthesocket

headscrewsontheadjustmentcamsuntiltheyaretight.

Page38

CREASING

Page 40

ro50

11. Pushtheexitguarddownandreplacethestackerassemblybeforeoperatingthe

machine.

12.Switchthemachineonandtestthecreaseforform.

Ifthepressureandthealignmentofthecreaseisnottoasatisfactorylevel,

seepages33-35toadjustthecreasingline.

ReplacingBladeSet

‘Spares’kits

Intheeventofanydamagedorlostcomponentswithinthebladeassembly,spareskits

areavailableonrequest.However,componentswithinthebladesetcannotbeordered

separatelyiesinglebladeoranvil.

ThefollowingBladesetsaresuppliedwiththe$WOas&standard.

StandardBladeset

Consistingofastandardbladeandanvil,bladebrushes,bladelinksandalignmentbolts.

Whenrunninglighterstocksitisrecommendedthatanisused,

thiscanbepurchasedfroP)250$;

NarrowBladeSet

Partnumber76-237-03

.

Page39SYSTEM

Page 41

TroubleShooting

Papercreaseoutofsquare

l

Checkthatthesheetsareallsquareandexactlythesamesizebeforeloadingthe

stackontothetable.

l

l

Checkthattherollertiltmechanismiscorrectlysetandlockedinposition.

Checkthattheadjustablesidelayhasbeencorrectlypositionedie.Nofurtherthan

0.5mmfromthepaperstack.

Paperjamming

l

l

Checkthattheleadingedgeofthepaperisnotbeingdamagedbythepapergate.If

thisisoccurring,checkthatthesuctionslotandthepapergatehavebeencorrectly

set.

Checkthatthefirstcreasepositionisnottooclosetotheleadingedgeofthepaper.

Aminimumdistanceof32mmisrecommended.

Machinewillnotstart

l

l

l

l

Checkthepowersupplytothemachine.

Checkthattheemergencystopbuttonhasbeenreleased.

Checkthattheexitguardisdown.

Checkthatthestackerunitislocatedcorrectlyandhasnotbeendisconnectedfrom

themagneticswitch.

l

Checkthatthelowerblade/anvilisconnectingtothehomeswitch(mountedbelow

thelowerblade/anvil).

Papernotfeeding

l

l

l

l

Checkthatthepaperstackisnottoohighortooheavyforthefeeder.Theheightof

thepaperstackshouldbedefinedbytheweightandthesizeofthestockbeing

creased.

Ensurethattheadjustablesidelayisnotpressedagainstthepaperstack.However,

iftheclearancebetweentheadjustablesidelayandthepaperstackistoogreat,the

airsupplywillescapeinsteadofblowingthroughthepaperthusmakingitdifficultto

feed.

Checkthattheclearancebetweenthepapergateandthesuctionrollerisnotsettoo

low.

Ondigitalmedia,thefeedingperformancemaybeimprovediftheleadingedgeof

thestackistrimmedbeforeloadingontotheMachine.

Page40

CREASING

Page 42

Pro50

l

Checkthattheairdistributionhasbeencorrectlyset.

l

Checkthattheairseparationhasbeensethighenoughtofeedthesheets.

l

Forheavystocks,verysmallorverylargesheets,embossedorevenirregularstock,

itmayberequiredtofeedthesheetsmanually-seepage29forinstructions.

TroubleShooting

Machinenotcounting

Opentheexitandremovethebladeset

(seepages37-39)toaccessthedual

sensorpostlocatedinbetweenthedrive

rollers.Usingasoftbrush,cleanthe

visiblesensorontheendofthepost.

Usethebrushtocleanthesensors

betweenthepostandthebottompaper

guidewhicharenotvisible.

Photograph(left)showsthedualsensor

postcontainingthesensors.

Paperjammedunderpapergate.

Ifpapergetsjammedunderthepapergatethevacuumdrumwillstoprotating,thisisa

safetyfeature.Removethepaperandre-adjustthepapergate.

Page41SYSTEM

Page 43

TroubleShooting

ErrorScreens

Sheetdidnotarrive.

Ifthemachinestopsanderrormessage01isdisplayedonthetouchscreen,this

indicatesthatthepaperdidnotarriveattheendofthesuckprocess;sothemachine

timedout.Pressthegreentickbuttonandthenpressthestartbutton.

PaperCrunch

Ifthemachinestopsanderrormessage02isdisplayedonthetouchscreen,this

indicatesthatapaperjamhasbeendetected.

Pressthesystemswitchdownandthenselecttherightorleftarrows,toinchthe

paperforwardsorbackwards.Seepage29thatdescribeshowtoremovepaperjams.

Pressthegreentickbuttonandthenpressthestartbutton.

Thiserrormessagecouldalsomeanthatthecrunchsensorsarefaultyorneed

cleaning.

DoubleSheetFeed

Ifthemachinestopsanderrormessage03isdisplayedonthetouchscreen,this

indicatesthatadoublesheetfeedhasbeendetected.Checkthatthepapergatehas

beensetcorrectly.Pressthegreentickbuttonandthenpressthestartbutton.

Page42

CREASING

Page 44

TroubleShooting

ErrorScreens(Continued)

BladeNotHome

Ifthemachinestopsanderrormessage04isdisplayedonthetouchscreen,this

indicatesthatthelowerblade/anvilhasnotmadecontactwiththeHOMEswitch.

i.e.bladestillintopposition.Switchthemachineoffandremovethebladesetand

ensurethattheareaisfreefromobstructions.Returnthebladesettothecreasingunit

andswitchthemachineon.Operatethemachineinthenormalsequence,ifthe

displaycontinuestoreaderrormessage04itisadvisedtocontactaServiceEngineer

immediately.

Overlap

Ifthemachinestopsanderrormessage13isdisplayedonthetouchscreen,this

indicatesthatthe‘LeadEdgeSensor’hasseenasheetsubsequenttothefirst

oneasbeinglonger.Againthiscouldactuallybealongersheet,ORitcouldbea

sensorproblem(ifitisarecurringproblem).Checkthatthepapergatehasbeenset

correctly.

dE

Lea

Ifthemachinestopsanderrormessage60isdisplayedonthetouchscreen,this

indicatesthattheleadedgesensorisblocked.

Pressthesystemswitchdownandthenselecttherightorleftarrows,toinchthe

paperforwardsorbackwards.

Pressthegreentickbuttonandthenpressthestartbutton.

Thiserrormessagecouldalsomeanthattheleadedgesensorsarefaultyorneed

cleaning.

dgeSensorBlocked

Page43SYSTEM

Page 45

TroubleShooting

ErrorScreens(Continued)

CleanLeadEdgeSensor-WarningScreens.

1.TheCleanLeadEdgeSensorwarningscreen,shownbelow,willappearwhenthe

RunbuttonispressedandthestrengthoftheLeadEdgeSensorBeamisatabout

50%(i.e.thesliderisataboutthemid-pointpositionalongtheIndicatorScale).

SENSORCLEANINGWARNINGSCREEN

PresstheToolsbuttontocleanthe

Sensors,asdescribedonPages45&46.

PresstheRunbuttontoignoretheWarning,

andcontinuerunningthejob.

2.TheCleanSensor,Error65warningscreen,shownbelow,willappearifthestrength

oftheLeadEdgeSensorBeamisallowedtogetdowntoabout25%.TheLeadEdge

Sensorsshouldideallybecleanedbeforethiswarningscreenappears.

NOTE.

TheLeadEdgeSensorscanbecleanedatanytimebyselectingtheToolsTab

atthebottomoftheTouchscreenandcleaningtheSensorsasdescribedonPages45&

46.

Page44

CREASING

Page 46

TroubleShooting

ErrorScreens(Continued)

LeadEdgeSensorCleaning.

SelecttheToolsmenuontheTouchscreenDisplay,andthenselectthecleansensor

icon

ThescreennowshownisavisualindicationofthestrengthoftheLeadEdgeSensorbeam.

FLASHING(GREEN/BLACK)TO

INDICATETHATTHESOFTWARE

ISINTERROGATINGTHESENSOR

BEAM

SLIDER

INDICATORSCALE

Theverticalindicatorscaleisdividedintofoursections,thepositionofthesliderindicates

thestrengthofthebeam.Thestrengthofthebeamisatitsstrongesttowardsthetophalfof

theindicatorscale(green)andatitsweakesttowardsthebottomhalfoftheindicatorscale

(red).Notethepositionofthesliderontheindicatorscaleandthencleanthesensorsas

describedonPage46.

NOTE:-

handsideoftheTouchscreenDisplayasshownbelow.

Thisverticalindicatorscaleisrepeatedasahorizontalindicatorscaleontheright

HORIZONTALINDICATORSCALE

Page45SYSTEM

Page 47

TroubleShooting

ErrorScreens(Continued)

Tocleantheleadedgesensorsopentheexitguardtoexposethebladeset.Usingthe

SensorCleaningBrush,suppliedinthedispatchkit,insert

thebrushbetweenthebladebrushesandthetopandbottombladestoreachtheupper

andlowerleadedgesensors.(SeeFIG.1andFIG.2below).Movethebrushbackwards

andforwardsseveraltimesacrossthesensorstocleanthem.Notethepositionoftheslider

ontheindicatorscale;theslidershouldhavemovednearertothetopofthescale,

indicatingthatdusthasbeenremovedfromthesensors.Thissensorcleaningoperation

canberepeatedagaintoseeifthesensorbeamstrengthcanbefurtherimproved.The

SensorscanalsobecleanedwithacanofcompressedairpurchasedfromFarnell(Farnell

PartNo.166-3191),oranequivalentproduct.

Page46

CREASING

Page 48

TroubleShooting

Recommendedweeklyoperatormaintenance

l

Cleanallsensors

l

Cleaninfeedrollersandoutputdrivehubsusingthecleaningkitprovided

(Cleaningkitpartnumber90-018)

l

Removeandcleanthebladeassembly

l

Withthebladeassemblyremoved,cleantheslotsandsurroundingareawithin

thecreasingunit.

TechnicianMaintenance

Itisrecommendedthatyourmachineisfullyservicedatleastonceeverysixmonths

byafactorytrainedServiceEngineer.

Page47SYSTEM

Page 49

7-95-29

ITEM PARTNUMBER QTY DESCRIPTION

DISPATCHKIT

70-171

1

2 90-018 1 ROLLERCLEANINGKIT

3

650-040 1 POWERCORDCEUKC193Pin16A2.5Mtrs.

4

403-01-030-006

5

409-01-040-004

620-007 1 HEXAGONBALLDRIVER2mm

6

7

620-020 HEXAGONBALLDRIVER2.5mm

8

620-004 1 ALLENKEY4mm

9

620-026 1 BONDUSLWRENCH4mm

1 OPERATORSMANUAL

12 SCREW-SOCKETCAPHEAD-M3x6LG

1 SCREW-SKT.SETFLATPT.-M4x4LG

1

-

10

11

12

13

14

15

16

620-028 1 BONDUSLWRENCH3mm

620-033 1 BONDUSLWRENCH6mm

624-018 1 DISPATCHBOX

70-055-01 1 BLADEEXTRACTIONTOOL-OPSIDE

70-055-02 1 BLADEEXTRACTIONTOOL-LAYSIDE

08-041-02 1 SLITTINGANVIL-UNDERSIZE.

1-99-12 1 SLITTERPERFBLADE28T

WARNING......

THEBLADESFORANVILANDPERFORATINGSETSARESUPPLIEDAS

MATCHINGPAIRSANDSHOULDNOTBEMIXEDORLEFT

UNPROTECTEDORSERIOUSDAMAGEMAYRESULT.

Page48

CREASING

Page 50

rPro50

ITEM PARTNUMBER DESCRIPTION

1-99-10 PERFORATINGBLADESET20T(Card)1

1-99-12 PERFORATINGBLADESET28T(Singlesheets)2

1-99-41 PERFORATINGBLADESET56T(Fineperforations)3

1-99-35 ANVILSETUSEDWITHABOVEBLADESETS4

76-237-03 BLADESET-NARROW5

70-134 ANTI-STATICKIT6 6

172-04-01 NARROWSHEETKIT7

ACCESSORIES....OPTIONS....

....Maybeobtainedfrom....Mayalsobeobtainedand

yourdealerandfittedtoyourfittedbyyourdealer.Youshould

machineusingtheinstructionsnotattempttofitoptionsas

supplied,orbyreadingyourspecialisttoolsandknowledgeare

operatorsmanual.required.

ACCESSORIESANDOPTIONS

Page49SYSTEM

Page 51

RECOMMENDEDSPARES

PARTNUMBER DESCRIPTION

93-021 FEEDBELT

607-017 TIMINGBELT-120XL037

609-011 ‘O’RINGØ20

94-028 LOCKPINASSEMBLY-SideLay

613-365 EMERGENCYSTOPSWITCH

652-011 SWITCH-LOWCURRENTCOIL-BLACKROCKER

75-500-06 MINIITXMOTHERBOARD-

75-430-01 CONTROLPCBASSEMBLY

174-06-01 SMALLSTEPPERDRIVER-LOWPOWER-PCBASSY

174-19-01 RS232ADAPTORPCBASSY

125-21-02 DUALSTEPPERDRIVERPCBASSEMBLY

75-06-02

76-272 PSUASSEMBLY-ATX12V-300W

655-015 PSUUNIT-SWITCHMODE-24V

655-016

76-230-02 PAPERGUIDEASSEMBLY-BottomSensor

76-155 PAPERJAMSENSORASSEMBLY

76-154 UPPERSENSORASSEMBLY

76-156 BLADEPOSITIONSENSORLEAD

98-013-03 ANTI-STATICBRUSH

609-022 ‘O’RINGØ32

606-035 KNOB-RollerTilt

76-109 POWERLINKBEARING

76-237-02 BLADESET-Standard

76-042 DRIVEBELT-FEEDBED

607-042 TIMINGBELT160XL

607-048 TIMINGBELTTWINGRIP-200DXL050

TOUCHSCREENASSY-7”(NEWCONTROLLER)

PSUUNIT-SWITCHMODE-48V

608-019 SHOULDERBOLT

76-082 PERFORATOR-DRIVEHUBASSEMBLY

76-083 PERFORATOR-DRIVEWHEEL

76-177-02

76-175-02

76-019-02

78-013

613-351

613-191

INPUTROLLER-Upper

INPUTROLLER-Lower

OUTPUTSHAFT-Wide

PERFORATORSTRIPPERASSEMBLY

MICROSWITCH-GuardCircuit

MICROSWITCH-HomeCircuit

Page50

CREASING

Page 52

RECOMMENDEDSPARES

PARTNUMBER DESCRIPTION

75-040 STACKERSWITCHASSEMBLY

602-056 BEARING-DRAWNCUPNEEDLEROLLER-Ø15XØ21X12

602-085 BEARING-DRAWNCUPNEEDLEROLLERØ10XØ14X10

76-145-02 GAPCONTROLHUB-LAYSIDE

76-148-01 GAPSETLEVERASSY-OPSIDE

76-148-02 GAPSETLEVERASSY-LAYSIDE

76-149-01 LOCKINGLINK-GAPCONTROL

76-150-01 LOCKINGKNOB-GAPCONTROL

76-255 LEAD-FOLDCOMPENSATIONSENSOR

75-427 LEAD-VALVESENSOR

609-024 ‘O’RINGØ6xØ2.5

175-28-01 BUTTERFLYVALVE

76-240 STEPPERDRIVEMOTORASSEMBLY

76-241 STEPPERBLADEMOTORASSEMBLY

681-020

681-011

681-015

652-047

75-530-01 TRANSFORMERASSEMBLY230VTO110V

FUSE500mA-AntI-surge

FUSE315mA-Anti-surge

FUSE4A-Anti-surge

FUSE15A-Anti-surge

NOTE.....

Theitemslistedaboverepresentpartswhicharesubjecttowear,loss,oraccidental

damage,andisincludedforyourguidanceonly.

Replacementofpartsfittedtoyourmachinerequirespecialistknowledgeandshould

thereforebeentrustedtoyourdealer.

Page51SYSTEM

Page 53

FUSEPOSITIONS&RATINGS

(POSITIONETCLASSIFICATIONDESFUSIBLES)

TRANSFORMERASSY.

T500mAH250V(681-020)

PSUs(24V&48V)

(FUSIBLEPSUs(24V&48V)

T4.0AH250V(681-015)

ANTI-STATICUNIT

(IFFITTED)

(FUSIBLEANTI-STATIQUE

(siinstallé)

T315mAH250V(681-011)

MAINSIN

F15AH250V(652-047)

Page52

CREASING

Page 54

PRODUCTRECYCLING&DISPOSAL

EuropeanUnion

DisposalInformationforCommercialUsers

Applicationofthissymbolonyourequipmentisconfirmationthatyou

mustdisposeofthisequipmentincompliancewithagreednational

Procedures.

InaccordancewithEuropeanlegislationendoflifeelectricaland

electronicequipmentsubjecttodisposalmustbemanagedwithin

agreedprocedures.

Priortodisposalpleasecontactyourlocaldealerorrepresentativefor

endoflifetakebackinformation.

DisposalInformationforDomesticUsers

Applicationofthissymbolonyourequipmentisconfirmationthat

youshouldnotdisposeoftheequipmentinthenormalhousehold

wastestream.

InaccordancewithEuropeanlegislation,endoflifeelectricaland

electronicequipmentsubjecttodisposalmustbesegregated

fromhouseholdwaste.

PrivatehouseholdswithinEUMemberStatesmayreturnused

electricalandelectronicequipmenttodesignatedcollection

facilitiesfreeofcharge.Pleasecontactyourlocaldisposal

authorityforinformation.

InsomeMemberStateswhenyoupurchasenewequipmentyour

localretailermayberequiredtotakebackyouroldequipment

freeofcharge.Pleaseaskyourretailerforinformation.

OtherCountries

Pleasecontactyourlocalwasteauthoritiesandrequestdisposalinformation.

Page53SYSTEM

Page 55

REVISIONHISTORY

ModNo.Rev. ModDescription Date ModBy

ScreenshotgraphicschangedtoshowtheLeadEdgeSensorIndicator

Bar,onallrelativepages.Newpagesinsertedtodescribehowtousethe

4 ECO2809 02/01/13 BAL

CoverCreaseModeforPerfectBoundCovers.(Pages14&15).New

pagesinsertedtoshowtheCleanLeadEdgeSensorWarningScreens

andhowtocleantheLeadEdgeSensors.(Pages44to46)

Page54

CREASING

Loading...

Loading...