Page 1

Formax Atlas C300

High-Speed Automatic

Creaser and Folder

Instruction Manual

Page 2

Atlas C300

Auto-Feed High-Speed Creaser/Folder

3/2017

OPERATOR MANUAL

First Edition

Page 3

INDEX

INTRODUCTION&SPECIFICATION

TheAtlas C300 Creaser and Perforator

SAFETYDo’s&Don’ts5

THEAtlas C-300

LabeledPhotograph

THESWITCHPANEL

Detaileddiagramanddescription

Featuresontheswitchpanel

OPERATINGTHEAtlas C300

AdjustingthePapergate

SettingtheSuctionSlot

SettingtheVacuumBleed

SettingtheAdjustableSideLay

SettingtheBack-Stop

SettingtheAirDistribution

SettingtheAirSeparationPressure

SettingthePositionsoftheDriveWheelsandHubs

PAGE4

7

8

9

10

10

11

11

11

11

11

12

TOUCHSCREENOPERATION

TouchscreenLayout

PaperSettingsPage

RollerGapSet&TiltMechanismPage

CreaseSettingsPages

Creasesin‘SetByFold’mode

Creasesin‘SetByPosition’mode

FoldSettingsPages

Foldsin‘SetByFold’mode

Foldsin‘SetByPosition-’mode

Exampleof‘SetByPosition’mode

DeliverySettingsPage

StatusScreen

RunningtheJob

Settingthemachinetooperateinmanualsheetfeedmode

StorePages

ToolsMenu

TouchscreenCalibration

DeflectTrimAdjustment

THEBLADEASSEMBLY

Adjustingthebladepressure

14

15

17

20

21

23

24

26

27

29

30

31

32

35

36

37

38

Page2

FOLDING

Page 4

INDEX

REPLACINGCREASINGBLADESETS

Installingnewbladesets

SpareBlades

PERFORATING

Equipment,Spares

Settingthemachine

RecommendedPositionoftheDriveWheelsandHubs

REMOVINGPAPERJAMS46

TROUBLESHOOTING

Papercreaseoutofsquare

CreasePositionInaccuracy 47

Paperfoldoutofsquare

PaperJamming

Machinewillnotstart

Papernotfeeding

Crackingoftheprintedmaterialalongthecrease

UsingtheCorrectBladeSet

PAGE39

42

43

44

45

47

47

47

48

48

48

49

ERRORSCREENS

0150

SheetdidNotArrive

0250

PaperCrunch

0350

DoubleSheetFeed

0450

BladeNotHome

0551

BladeBusy

0651

BladeHomeFailure1

0751

BladeHomeFailure2

0852

FlyingHomeFailure

0952

Clip1NOTClear

1052

Clip1NOTBlocked

1152

Clip2NOTClear

1253

Clip2NOTBlocked

1353

Overlap

DISPATCHKIT60

ACCESSORIESANDOPTIONS61

RECOMMENDEDSPARES62-63

MACHINECALIBRATIONHISTORYSHEET64

FUSEPOSITIONS&RATINGS65

PRODUCTRECYCLINGANDDISPOSAL66

Page3SYSTEM

Page 5

INTRODUCTION

INTRODUCTIONANDSPECIFICATION

Itistonotethattopreventcracking,whenusingdryinkortonerbasedprint

IMPORTANT

engines,thematerialbefullyacclimatisedforatleast48hoursbeforeputtingan

imageontothepaper.

IMPORTANT

16°Cand27°CMaximum.

FeedingSystem................................................Bottomsuctionfeed

Max.SheetSize................................................700mmx385mm(27.5”x15”)[900mmx

Min.SheetSize.................................................210mmx140mm(8.3”x5.5”)(dependant

Max.PaperThickness...................................0.40mm(variesaccordingtohardness,

Min.PaperThickness.......................................0.11mm

Max.No.CreasesperSheet..............................9

Max.No.FoldsperSheet..................................2

Max.No.StoredProgrammes...........................Unlimited

Min.RepeatCreaseDistance.............................40mm(1.6”)

Min.RepeatFoldDistance................................70

Min.CreaseDistancefromLeadingEdge..........50mm(1.96”)

Min.FoldDistancefromLeadingEdge.............50mm(1.96”)(dependingonpaperweight)

Min.CreaseDistancefromTailEdge.................50mm(1.96”)

Min.FoldDistancefromTailEdge....................50mm(1.96”)(dependingonpaperweight)

Min.FoldLength...............................................70mm(2.75”)

SpeedperHour(A4inhalf)...............................6000sheets

Note:

Dimensions.......................................................L:2020mmH:1265mmW:680mm

Weight...............................................................190Kgs(+50Kgspacking)

PowerRequirement..........................................1phase230v50Hz

SoundPowerLevel.....................80.0decibels

*Aspartofourcontinuedproductimprovementplan,specificationsandinformation

publishedinthismanualaresubjecttochangewithoutnotice.

Allspecificationsaredependantonapplication,typeofstock,temperature,relative

humidity,RHandprintengineused.

Specificationsquotedweremeasuredonuncoatedandunprintedstock.E&OE.

theoperatingenvironmentshouldbecontrolledtoatemperaturebetween

Theproductionspeedvariesaccordingtothematerialsizeand

thefoldtype.

must

Specification

385mm(35.4”x15”)withOptional

extensiontable].

onstiffnessofpaperandtypeoffold).

typeoffold,andsubstrate).

(variesaccordingtohardness,

typeoffold,andsubstrate).

mm(2.75”)(dependingonpaperweight)

L:(79.5”)H:(49.8”)W:(26.8”)

1phase220v60Hz

Page4

Page 6

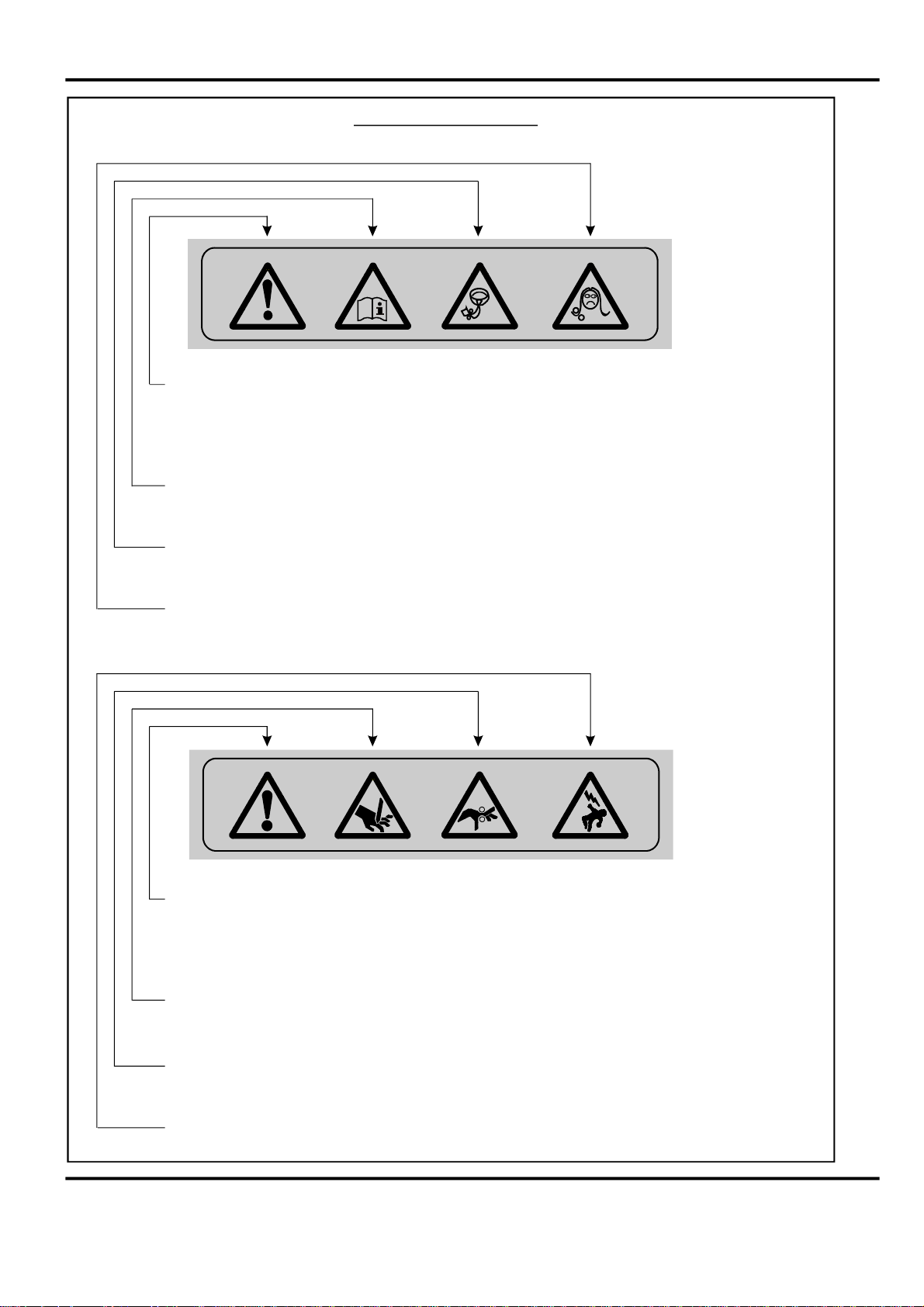

SafetyDo’s&Don’ts

SafetyDo’s&Don’ts

REGLESDESECURITE:«AFAIRE»ET«ANEPASFAIRE»

Do-readthisoperatormanualfullybeforeoperatingthemachine.

Lirecemoded'emploiavantd'utiliserlamachine.

Do-operatewiththedesignatedACcurrentonly.Useanexclusiveoutlet,as

overloadingmaycausefireoranelectricshock.

Respecterl'alimentationélectriqueindiquée.Branchersurunepriseséparée

carunesurchargepeutentraînerunincendieouunchocélectrique.

Do-installthepowercordoutofthewaytoavoidatrippinghazard.

Installerlecordond'alimentationdemanièreànepaspouvoir

trébucherpardessus.

Do-makesurethatthemainsinletconnectorisalwayseasilyaccessible.

Ménagerunaccèslibreàlaprisedecourant.

Donot-installthemachineinanunstableplacesuchthatittiltsorshakes.

Nepasinstallerlamachinesurunesurfacenonplane,afind'éviter

qu'ellenepencheounevibre.

Donot-unplugtheplugorunplugthepowercordfromtheoutletwithawethand,

thiscancauseanelectricshock.

Nepasinstallerlamachinesurunesurfacenonplane,afind'éviter

qu'ellenepencheounevibre.

Donot-unscrewandremoveanycoversfromthemachine,asitcancausean

electricshockorinjury.

Nedémonteretenleveraucuncarterdelamachine,parcraintededécharge

électriqueoudeblessure.

Donot-placereceptaclescontainingliquidsonanysurface.

Nepasplacerderécipientcontenantunliquidesurlamachine.

Donot-adjustanypartofthemachinewhilstrollersarerunning

N'effectueraucunréglagependantquelesrouleauxfonctionnent.

Donot-operatethemachinewithlooseortrailingclothingorloosehair.

Nepasporterdevêtementsflottantsetrassemblerlescheveuxlongs

lorsdel'utilisationdelamachine.

Donot-underanycircumstancesadjustthepapergatewhenthemachineis

switchedon.

Enaucunecirconstance,réglerleséparateurdepapierlorsquela

machineestbranchée.

Page5SYSTEM

Page 7

WarningLabels

Do-beawareofanyfingertrapsandrotatingpartswhenoperating

themachine.

Attentionaurisquedesecoincerlesdoigts,etauxpiècesen

mouvementlorsdufonctionnementdelamachine.

Do-readthisoperatormanualfullybeforeoperatingthemachine.

Lirecemoded’emploiavantd’utiliserlamachine.

Donot-operatethemachinewithlooseortrailingclothing.

Nepasporterdevêtementsflottantslorsdel'utilisationdelamachine

Donot-operatethemachinewithloosehair.

Rassemblerlescheveuxlongslorsdel'utilisationdelamachine.

Do-beawareofanyfingertrapsandrotatingpartswhenoperating

themachine.

Attentionaurisquedesecoincerlesdoigts,etauxpiècesen

mouvementlorsdufonctionnementdelamachine.

Do-beawareofsharppointsandblades.

Attentionauxélémentstranchantsetauxcouteaux.

Page6

Do-beawareofrotatingrollers.

Attentionauxrouleauxenfonctionnement

Do-beawareoflowcurrentanti-staticshock.

Attentionauxfaibleschocsd'électricitéstatique

FOLDING

Page 8

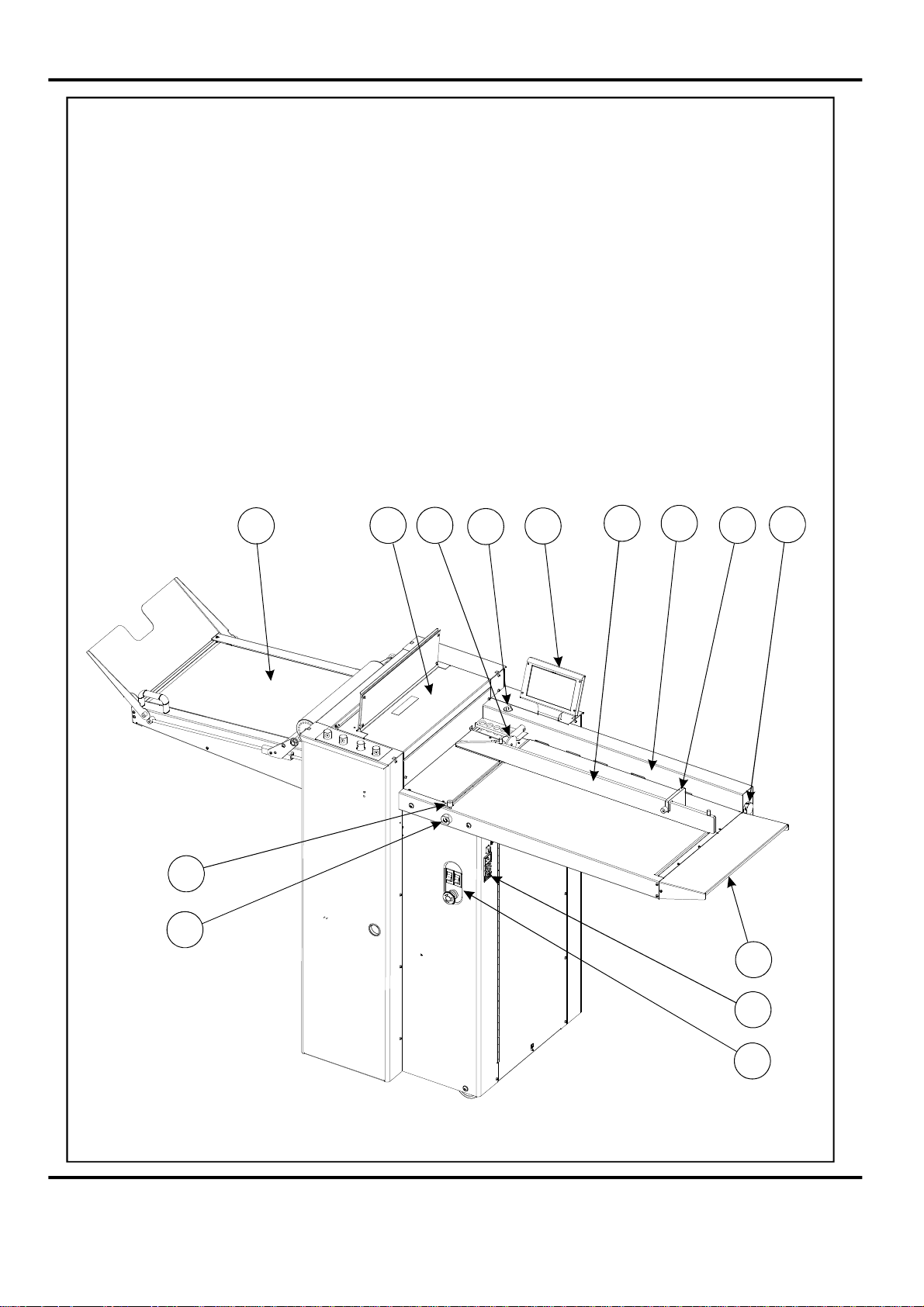

Atlas C300 Creaser Folder

Keytophotographbelow

1Deliveryassembly6AirSeparationKnob11PaperGate

2Vacuumbleedknob7Adjustablesidelay12Topcover

3Suctionslotknob8Backstop13Touchscreen

4Switchpanel9Fixedsidelay14OptionalExtensionTable

5Airdistributionknob10Fuses

1

3

2

12611

13

7

9

8

5

14

10

4

Page7SYSTEM

Page 9

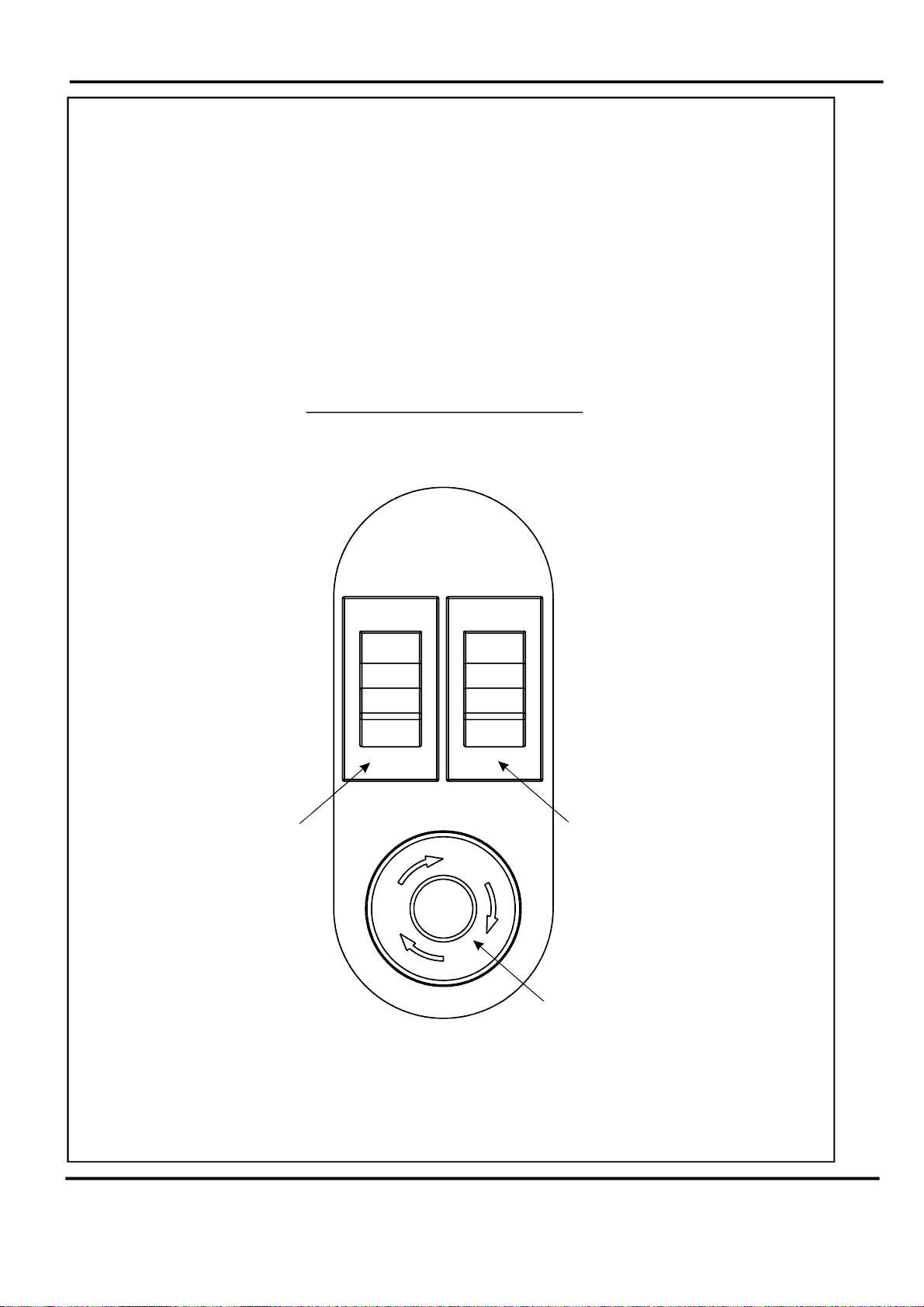

TheSwitchPanel

TheSwitchPanelhousestheCompressorswitch,Systemswitch,andan

industrystandardEmergencyStopswitchwhichwillstopallpowergoingto

themachinewhenactivated.

THESWITCHPANEL

CompressorSwitch

Page8

SystemSwitch

EmergencyStopSwitch

FOLDING

Page 10

TheSwitchPanel

Systemswitch

Whenactivatedthesystemswitchwilloperatethemotorsinordertobeginthe

creasingsequence.

Compressorswitch

Allowstheoperatortoswitchoffthecompressorunitinordertoutilisethemachine

tomanuallyfeedsheets.

FeaturesontheSwitchPanel

Page9SYSTEM

Page 11

Operatingthe Atlas C300

AdjustingthePaperGate

SettheheightofthePaperGatetoapproximatelytwothicknessesofpaper,byturningthe

discj.Anexcessivegapisamostlikelycauseofdoublesheetfeeding.

Thissettingisonlyintendedasaguide,forinstance,sheetswithanupwardcurlwill

requirethissettingtobeincreased.

J

TWOTHICKNESSES

OFPAPER

WARNING.

DONOTADJUSTTHE

PAPERGATEWHILETHE

MACHINEISRUNNINGOR

THESUCTIONDRUMMAY

BECOMEDAMAGED.

SettingtheSuctionSlot

Thesuctionslotislocatedinsidethevacuumrollerandcanbeadjustedbyreleasingand

movingthesuctionknobhorizontallyineitherdirectiontotherequiredposition.

Forlightstockssettheknobtotheleftandforheavierstockssettheknobtotheright.

RollerGap3

Knob

RollerGap2

Knob

AirSeperation

Knob

RollerGap1

Knob

BladeTilt

Knob

Adjustable

SideLay

Suction

SlotKnob

Page10

Vacuum

BleedKnob

FOLDING

Page 12

OperatingtheAtlas C300

SettingtheVacuumBleed

Situatedonthefrontofthefeedtable,theVacuumBleedKnobisusedtoallowmore

controlofthesuctiononthevacuumdrum.

Whenlightweightpaperisbeingfedthroughthemachineturntheknobclockwiseto

reducethepossibilityofmarking,ordamagetotheleadingedgeofthepaper.

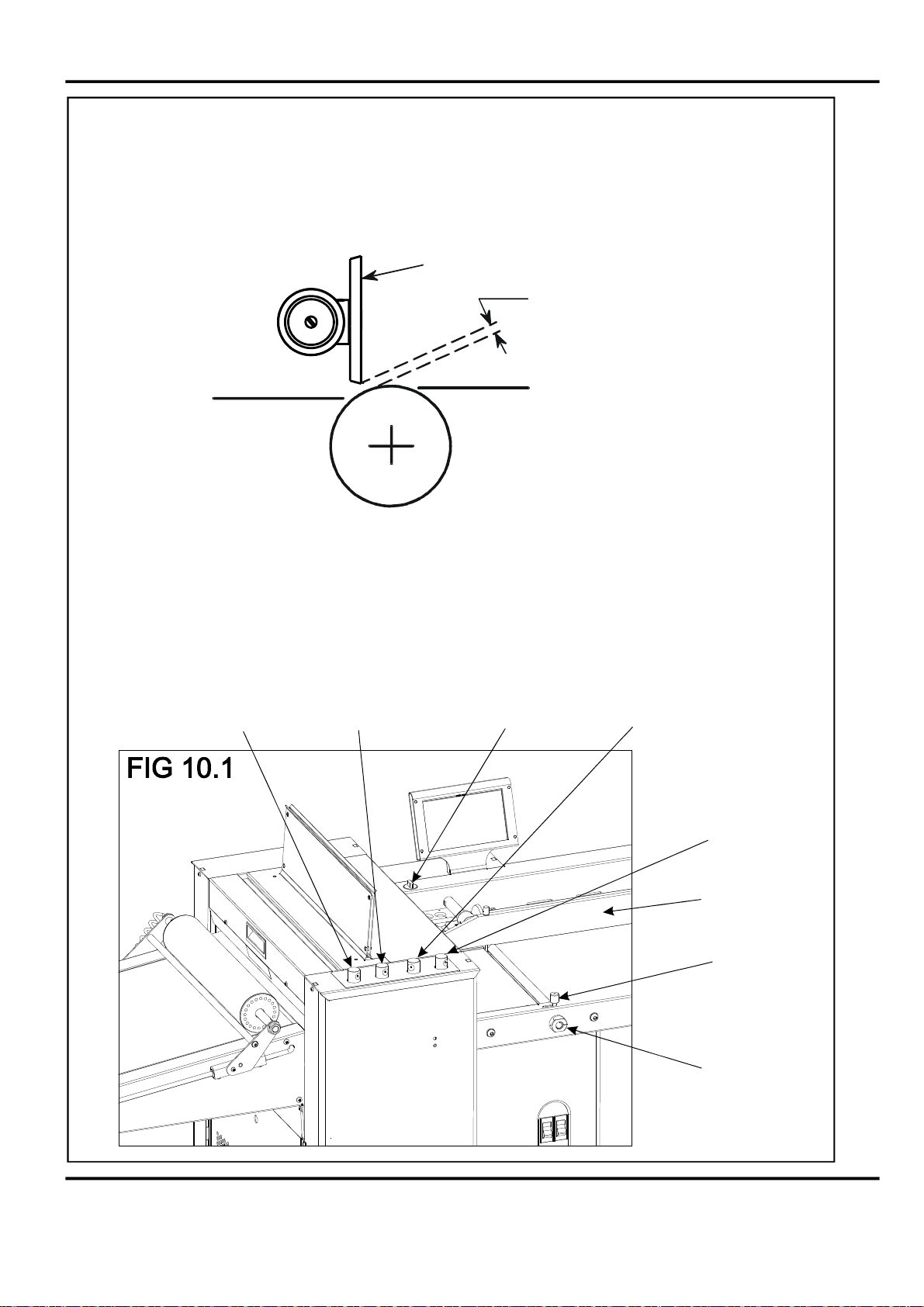

SettingtheAdjustableSideLay

Placethepaperstackontotheloadingtableandslideuptothefixedsidelayandpaper

Gate.Releasetheclampslocatedateachendofthesidelayandslideuptowardsthe

paperstackasdemonstratedinfig10.1.Allowagapofapproximately0.5mm(1/64inch)

betweenthepaperandthesidelay.

SettingtheBackStop

Positionthebackstopandslideuptowardsthepaperstackallowingagap(asspecified

intheabovestep).

SettingtheAirDistribution

Dependingonthelengthofthesheettobecreased,theairdistributionknobcanbe

rotatedtovariouspositionsinordertosupplyairtodifferentports.Position2is

recommendedformostsheetsizes.However,abetterresultmaybeobtainedbyusing

thesettingsbeloworbyexperimentation.

Position1-

2345-

0-

ForsheetslongerthanA3(17”)inordertosupplyairtothecentreofthe

stack,ports2,3and4open.

ForA5sheetsor8incheslong,ports1and2open.

ForA4sheetsor11incheslong,ports1and3open.

ForA3sheetsor17incheslong,ports1and4open.

ForsheetslongerthanA3(17”)inordertosupplyairtotheendsofthestack,

ports1and5open.

ForsheetslongerthanA3(17”)inordertosupplyairevenlyalongthestack,

ports1,3and5open.

Port1 Port5

AirDistribution

KnobShown

SetToPosn.1

SettingtheAirSeparationPressure

Tocontroltheamountofairsuppliedtotheports,theairseparationknobcanberotated

clockwisetodecreasethepressureoranti-clockwisetoincreasethepressure.

Page11SYSTEM

Page 13

OperatingtheAtlas C300

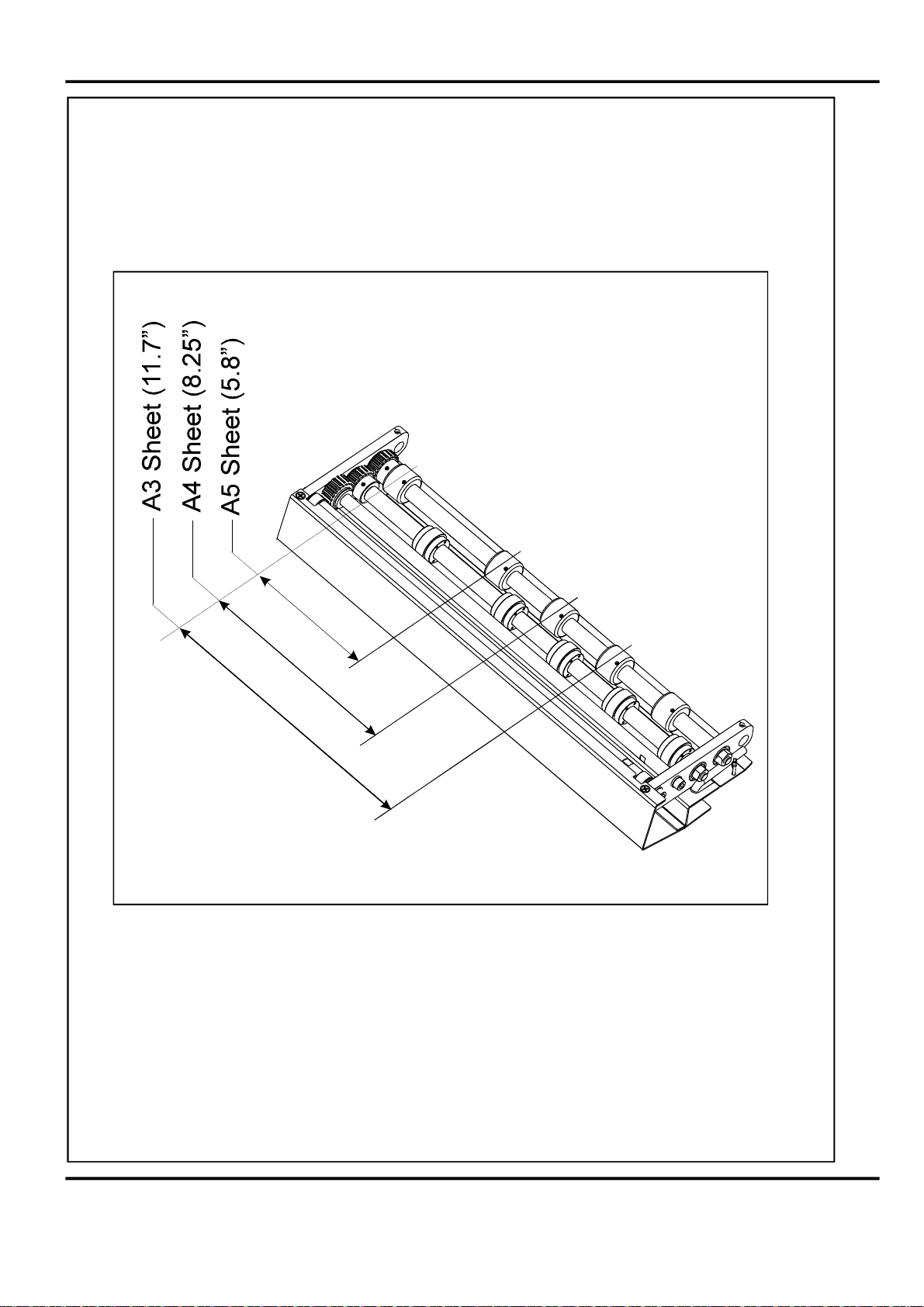

Settingthepositionsofdrivewheelsandhubs

Itisimportantthatthedrivewheelsanddrivehubs,ontherollershafts,arearrangedacross

thewidthofthemediabeingcreased;thisisdonetoensurethatthemediaisaccurately

drivenandsupportedthroughtherollers.Asuggestedlayout,,isshown

below(seeFIG15.1).Thesuggestedlayout,isdifferent,andisshownon

page45(seeFIG38.1).

Thedrivewheelsandhubsarefixedtotherollersbygrubscrews.

whenperfing,

whenFolding

FIG15.1

Page12

WHEEL&HUBARRANGEMENT,(WHENFOLDING)

FOLDING

Page 14

Page 15

OperatingtheAtlas C300

TOUCHSCREENOPERATION

1.TurntheEmergencyStopbuttonclockwisetoswitchthepoweron.Afterthe

systemstartupprocedurethetouchscreenwillbedisplayedasshownbelow.

IMPORTANT.

Ifyouhavenotbeentrainedtooperatethismachine,westronglyadvisethatyouselect

theredcrossicon.

Werecommendthatyoueitherseektrainingoraskatrainedoperatortorunthemachine

foryou.

Selectthegreentickicononlyifyouhavebeentrainedtooperatethismachine.

Ifyouhavenotbeentrainedtooperatethismachineandyouselectthegreentickicon,

MorganaSystemsLtdacceptnoresponsibilityforpersonalinjury,damagetothe

machineordamagetomaterialsbeingprocessedbythemachine.

WARNING:-

Waitatleast10seconds,aftermakinganyselectionontheTouchscreen

panel,beforeswitchingthemachineOFF.Failuretodosocouldresultinthe

datastoragebeingcorrupted,andthemachinenotoperating.

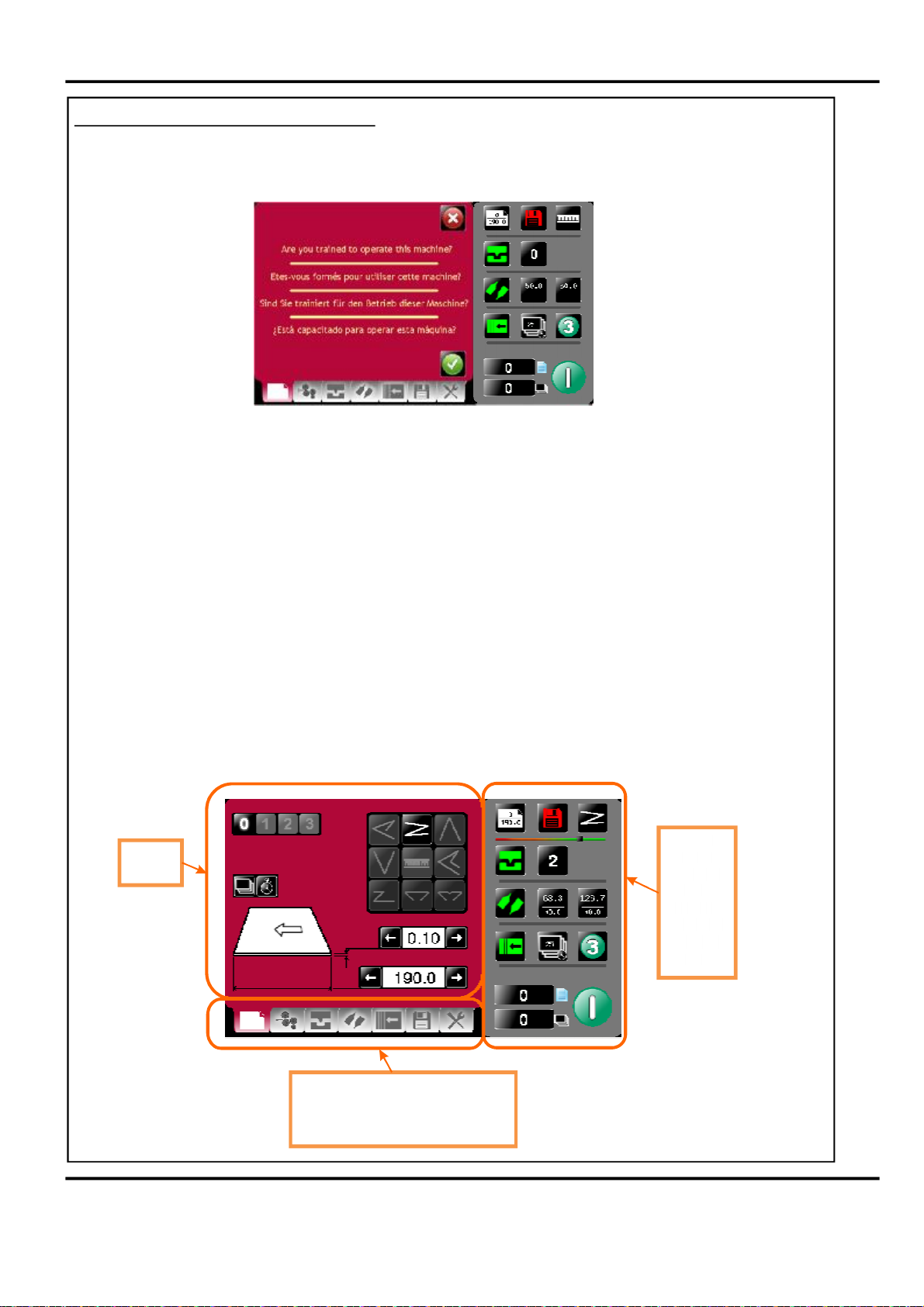

Thetouchscreenislaidoutinto3mainareasasshownbelow:

Setting

page

Tabstoenableswitchingbetweensetting

chooseeitherPaper

pages

settings,CreaseSetting,Foldsettings,

Deliverysettings,StoreandTools.

Settings,Gap

Statusof

machine

dataentry

area.Also

usedfor

quicklinks

tosetting

pages.

&

Page14

FOLDING

Page 16

OperatingtheAtlas C300

SettingPages.

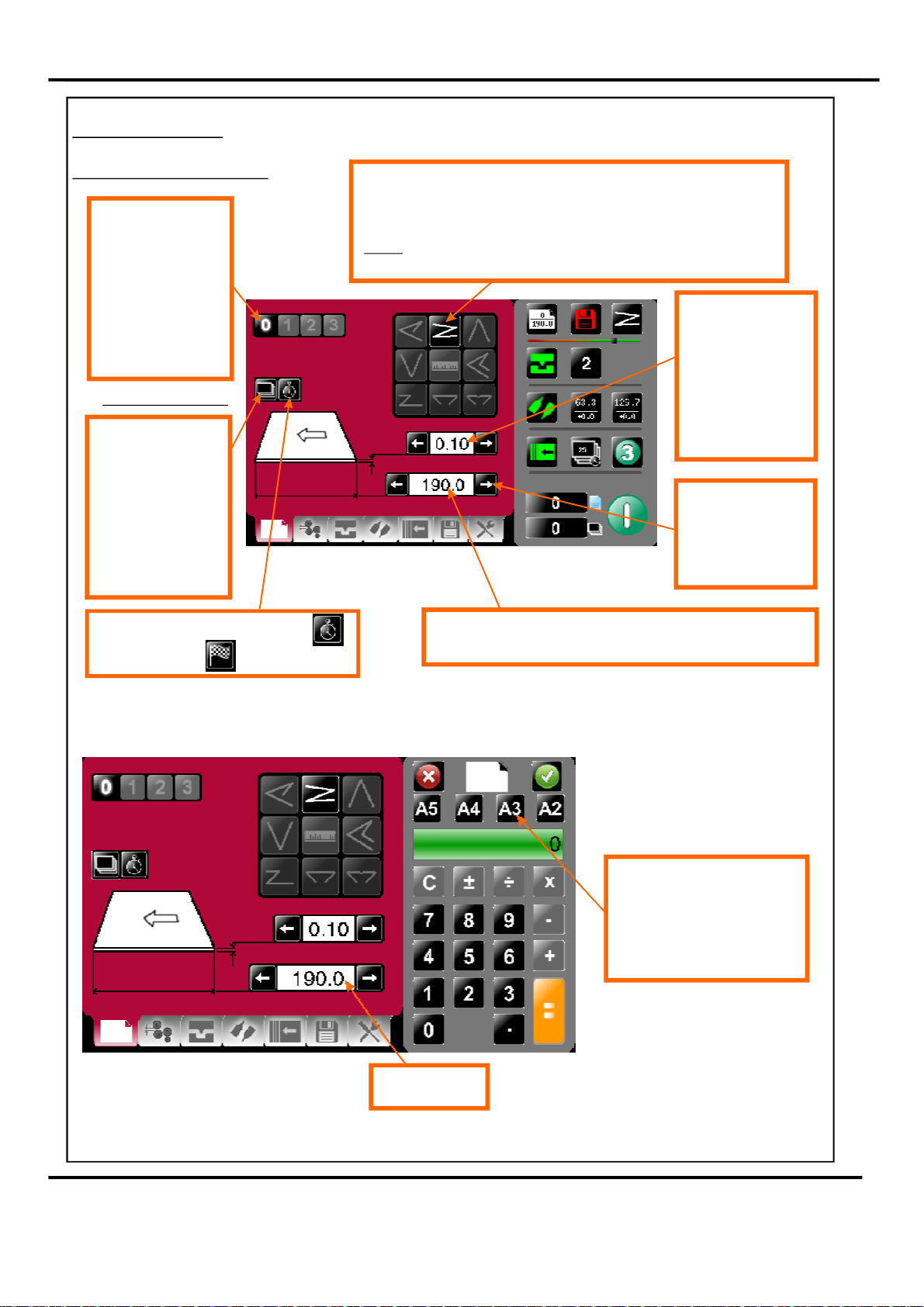

PapersettingsPage

PaperType-Asa

guidechooseas

follows:

0-approx0.1thk

1-approx0.2thk

2-approx0.3thk

3-approx0.3+thk

SeePage25

BatchButton-Image

isidenticaltothat

showninthestatus

area.Onselectionthe

statusareaisreplaced

withacalculatorfor

inputtingnewvalues.

Batchsizesof1to

998maybeset.

FoldSelection-Forquicksettingoffoldpositionsonstandardsizesheets.

Highlightedfoldistypecurrentlyselected,otherfoldsmaybeselected.

Currentlyselectedfoldisshowninthestatusarea.

NOTE:SelecttheRulerIcontosetFoldpositionsmanually(’SetbyPosition’mode).

PageThickness-On

selectionofstatus

areaisreplacedwith

acalculatorfor

inputtingnewvalues

Range=0.1to0.4mm

Incrementsof0.01mm

Arrowsmaybe

selectedtoincrease

ordecreasethepage

sizein0.1mm

increments

Togglebetween,Delaybetweenbatches

andstopafterbatch

PapersizeSelection.

PaperLength-Onselectionthestatusareaisreplacedwitha

calculatorforinputtingnewvalues.Lengthrange=190mm-900mm

Pre-setPapersizesfor

quickinsertion-Standard

sizesforcountryorigin

wouldbeshown.

Paperinput

Page15SYSTEM

Page 17

OperatingtheAtlas C300

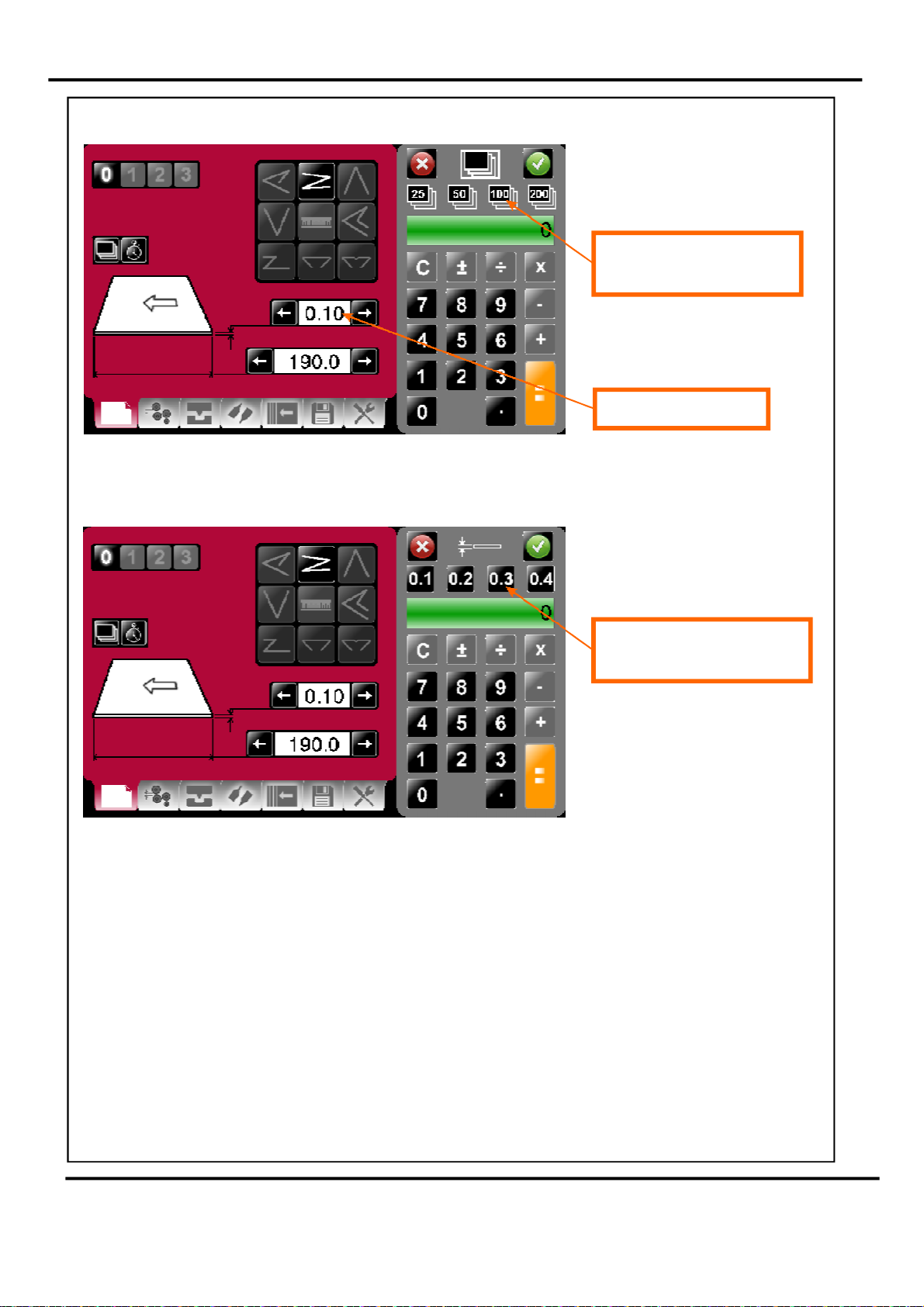

BatchsizeSelection.

Pre-setBatchsizesforquick

insertion.

PaperThicknessinput

PaperThicknessSelection.

Pre-setPaperThicknesssizes

forquickinsertion.

Page16

FOLDING

Page 18

OperatingtheAtlas 300

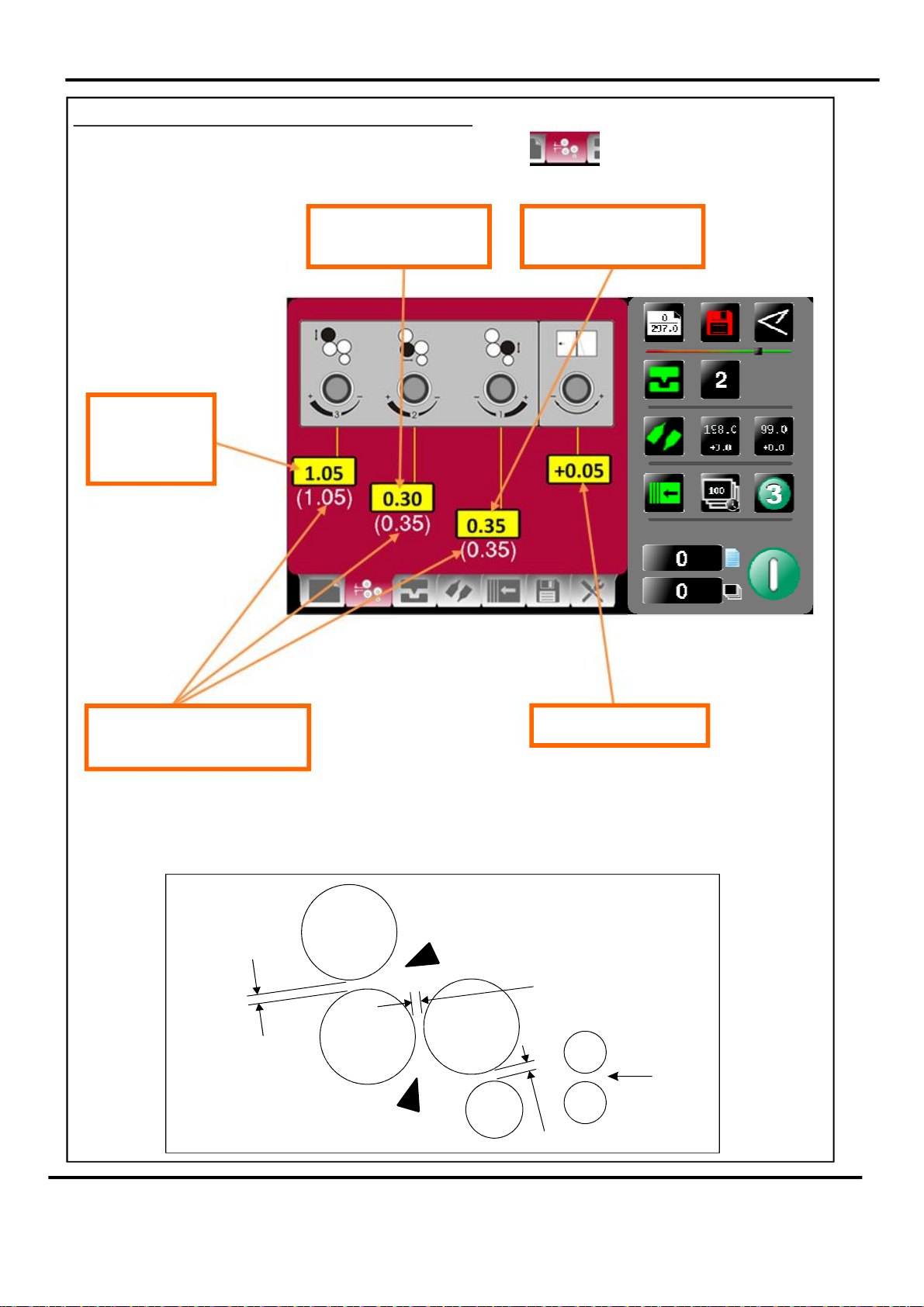

RollerGapSet&TiltMechanismPage.

Togettotherollergapsettingpageclickthelowertab

Rollergapsmaybeintherangeof0.05mmto1.5mm,withincrementsof0.05mm

Currentgap

settingfor3rd

FoldRoller

Currentgapsetting

for2ndFoldRoller

Currentgapsetting

for1stFoldRoller

Recommendedgapvalues-

basedonpaperthickness.

CurrentsetTiltAngle

SettingtheRollerGaps(Gap1,Gap2&Gap3)

Therollergapscanbeadjustedtosuitthethicknessofthematerialbeingcreasedor

folded;andthetypeoffoldbeingproduced.Therollergapsmayalsorequireadjustment

ifcrackingoftheprintisnoticeable.(seeFig13.1below).

FIG13.1

RollerGap3

K1

K2

RollerGap2

INFEED

RollerGap1

Page17SYSTEM

Page 19

OperatingtheAtlas 300

Thegapsettings(Gap1,Gap2&Gap3)canthenbeadjustedbyrotatingtheRoller

GapSetKnobs(seeFIG10.1onpage10).

IMPORTANT.

Whensettingrollergaps,youfirstadjustthegaptoavaluegreaterthanthatrequired

andthendecreasethevaluetotherequiredsetting.(Donotsetthegap,fromavaluelower

thanthatrequired).

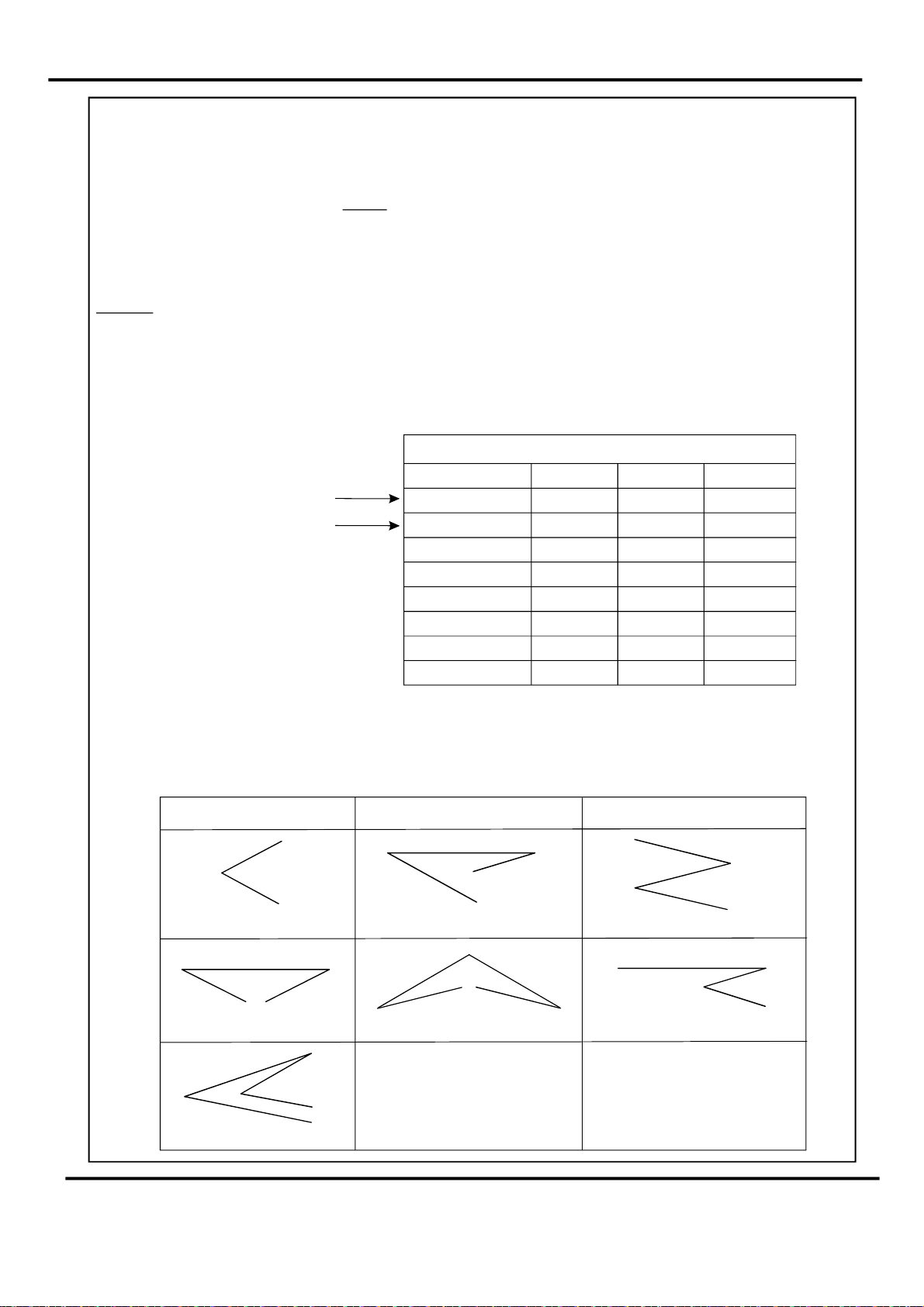

PROCEDURE.(FORSETBYPOSITION).

NOTE.

UsetheonscreenguideforSetbyFold.

(i)MeasurethethicknessofthesheetusingaDigitalVernierCalliper.

(ii)SetrollerGAP1tothevernierreading.

(iii)SetrollerGAP2androllerGAP3,(forthetypeoffoldbeingproduced),usingthe

GAPSETGUIDEtableshownbelow.

HalfFoldonKnife1

HalfFoldonKnife2

must

GAPSETGUIDE

FOLDTYPE GAP1GAP2GAP3

HalfK1

HalfK2

Letter

Concertina

Gate

ClosedGate

Engineering

Double X2X4X

2X

2X

3X

3X

3X

3X

3X

2X

X

X

X

X

X

X

X

X

X

X

X

X

X

Example1:-Whenproducingafold,ifGAP1is0.2(X)thensetGAP2to0.4

HalfK1

(2xX)andsetGAP3to0.4(2xX).

Example2:-Whenproducingafold,ifGAP1is0.3(X)thensetGAP2to0.3(X)

Gate

andsetGAP3to0.9(3xX).

FOLDTYPES

HALF

GATE

DOUBLE

LETTER

CLOSEDGATE

CONCERTINA

ENGINEERING

Page18

FOLDING

Page 20

OperatingtheAtlas C300

SettingtheBladeTiltMechanism

Thebladetiltmechanismhasbeendesignedtocompensateforwhenthecreasing

positiononthesheetisnotsquare.Thiscouldbeduetoaninaccuracyinthemediaoran

unexplainedfeedissue.Themechanismwillbesettozero(square)whenthemachineis

supplied.TheBladeTiltMechanismcanbeadjustedifnecessarybyrotatingtheBladeTilt

Knob(seeFIG10.1onpage10).

Page19SYSTEM

Page 21

peratingtheAtlas C300

O

CreaseSettingsPages.

Togettothecreasesettingpageclickthelowertaborfromthe

statusarea.

IfyouhaveselectedapredefinedstandardFoldTypefromthepapersettingspage

thecreasepositionswillbesetforyou.Thesepositionscanbefinetunedby

incrementsbypressingthearrowbuttonsforeachcrease.

Creasesin‘SetByFold’mode.

Creasetrim-Onselection

thestatusareais

replacedwithacalculator

forinputtingnewvalues.

±0.1mm

Creaseon/offselector

greenison&redisoff.

Thisisalsoindicatedin

thestatusarea.

Trimmingcreasesin‘SetByFold’mode.

Turncreasingoff.

Greyedoutareaindicates

thetrimisnotselectable

Creasesmaybetrimmed

by0.1mmincrements

withintherangeof

5.0mmto+5.0mm.

Statusshowscreasingoff

icon

Thisbuttontoggles

creasingon&off.

Page20

FOLDING

Page 22

OperatingtheAtlas C300

Creasesin‘SetByPosition’mode.

Arrowsmaybeselected

toincreaseordecrease

Thepagesizein0.1mm

increments

Numberofcreases-if

morethan6creasesare

addedascrollbarwill

appearfortoenable

viewingofallcreases.

Alsoshowninstatusarea.

Crossboxfordeletionof

crease.Ondeletionof

creasefollowingcreases

willmoveupbyone

place.Youwillbeasked

toconfirmdeletionofthe

crease.

Creaseposition-Onselectionthe

statusareaisreplacedwitha

calculatorforinputtingnewvalues,a

maximumof9creasescanbeadded.

Presstoremoveall

creases-youwillbe

askedtoconfirm

deletion.

Plusboxforinserting

additionalcreases.On

selectionfollowing

creaseswillmovedown

byoneplaceamaximum

numberof6creasescan

beseenatanyonetime

furthercreasescanbe

accessedbyuseofthe

scrollbar.

Trimmingcreasesin‘SetByPosition’mode.

Additionalcreases

added-scrollbar

appearsformorethan

sixcreases.

Creasesmaybetrimmed

by0.1mmincrements

withintherangeof

5.0mmto+5.0mm.

Page21SYSTEM

Page 23

OperatingtheAtlas C300

Turncreaseon/off.

Greyedoutareaindicates

thetrimisnotselectable

Individualdeletionofcreaseconfirmationscreen.

Statusshowscreasingoff

icon

Thisbuttontoggles

creasingon&off.

Crease150mmfromlead

edgewillbedeleted.

Removeallcreasesconfirmationscreen.

Page22

Allcreases-inthiscase7

offwillbedeleted.

FOLDING

Page 24

OperatingtheAtlas C300

FoldSettingsPages.

TogettotheFoldsettingpageclickthelowertaborfromthe

statusarea.

IfyouhaveselectedapredefinedstandardFoldTypefromthepapersettingspage

thecreasepositionswillbesetforyou.Thesepositionscanbefinetunedby

incrementsbypressingthearrowbuttonsforeachcrease.

Foldsin‘SetByFold’mode.

K1Foldtrim-Onselection

thestatusareaisreplaced

withacalculatorfor

inputtingnewvalues.

Trimrangeis-5.0to+5.0

withincrementsof0.1mm

±0.1mm

WithFoldingturnedoffthe

deflectpositionedcanbe

trimmed.

Trimrangeis-5.0to+5.0

withincrementsof0.1mm

Foldingcanbetrimmed

forfineadjustments.

Trimrangeis-5.0to+5.0

withincrementsof

0.1mm

Foldingon/offselector

greenison&redisoff.

Thisisalsoindicatedin

thestatusarea.

Page23SYSTEM

Page 25

OperatingtheAtlas C300

Foldsin‘SetByPosition’mode.

Folddistancefromlead

edgeforknives(K1&K2)

incrementsof0.1mm

K1deflectbutton

K1indeflectposition.

Thiscanbemicroadjusted.

Trimrangeis-5.0+5.0

withincrementsof0.1mm

K1&K2indeflectposition.

Thiscanbemicroadjusted.

K1microadjustselected

Clickingthisiconswitches

deflectoff&K1returnsto

itsoriginalposition.

Trimrangeis-5.0+5.0

withincrementsof0.1mm

Page24

FOLDING

Page 26

OperatingtheAtlas C300

NOTES:Ifacreasepositionisadjusted,thefoldwillmovewithit.

Ifafoldpositionisadjusted,thenonlythefoldwillmove.

Adjustafoldonlyifthefoldappearstobegivinganoutofsquareor

inconsistentresult.

Thefoldisprobablytooclosetothecentreofthecreaseandwillbetryingto

foldfromonesideofthecreasetotheoppositesideofthecrease,or

wanderingbetweenonesideofthecreasetotheother.(seebelowfor

explanation).

PaperType-0,1,2and3,isafoldcompensationforvariationsin

paperthickness,hardnessandsubstrate.

l Papertype ‘0’

beusedbutbewaresomethinstockswillallowthefoldtowanderfromonesideof

thecreasetotheother.(Usetrimstoovercomethis).

-Thecreaseandfoldaresetatexactlythesameposition.Thismay

Papertype‘1’‘2’‘3’

l

shouldbetriedoutwiththestockinuse.

Generallyahighernumberwillbebestforathickerstock,butsomesettingswill

swapthefoldfromonesidetotheothersideofthecrease,thisenablestheuserto

choosethesidethatthecreasewillbeseen.Forexample,onafrontcover.

andwillmovethefoldrelativetothecreaseand

SETBYPOSITION

IMPORTANTNOTES.

1.Ifthefoldistoonear,oronthecenterlineofthecrease;thefoldmaytrytofold

diagonallyacrossthecreaseprofileandpullthefoldoutofsquaretothepaper.

Thebestfoldsquarenessisachievedwhenthefoldisonthecenterlineofthe

crease,itshouldbetoonesideofthecreasecenterlineasshownbelow.

Unlessthebladeisonthebottomorknife2.

Thusforacreasesettingof100forexample,thefoldshouldbesettoafigure

slightlysmallerorgreaterthan100.

not

.

idealfoldline

centerlineofcrease

2.Whenusingalldimensionsarefromtheleadingedgeofthepaper

asshownintheexampleonpage26.

SetByPosition,

idealfoldline

Page25SYSTEM

Page 27

OperatingtheAtlas C300

ExampleofSetbyPosition.

FeedDirection

LeadingEdge

PaperLength=350mm(13.8”)

SETTINGS

Crease1=97.0mm(3.8”)

Crease2=179.0mm(7”)

Crease3=260.0mm(10.2”)

Fold1=179.0mm(7”)

Fold2=260mm(10.2”)

Crease2

Fold1

9mm

(0.35”)

=179.0

(7”)

Crease1 Crease2 Crease3

Fold1 Fold2

Alldimensionsarefromtheleadingedgeofthepaper

LeadingEdge

Crease3

Fold2

LeadingEdge

=260.0

(10.2”)

Page26

FirstFold

FinishedDocument

SecondFold

9mm(0.35”)

LeadingEdge

9mm(0.35”)

FOLDING

Page 28

OperatingtheAtlas C300

DeliverySettingsPage.

TogettotheDeliverysettingpageclickthelower

Rollerpositionmaybe

microadjustedbyclicking

here.

Shinglemaybemicro

adjustedbyclickinghere.

Rolleradjustment

calculator.

TheDeliverycanbe

toggledOnorOffby

clickinghere.

Shingleadjustment

calculator.

Deliveryon/offstatus

redisoffgreenison.

Page27SYSTEM

Page 29

OperatingtheAtlas C300

SettingtheDeliveryConveyorSystem.

WARNINGS:-

1.TheMachinewillstartifthedeliveryunitisnotinitsupposition.

2.Ifthedeliveryisturnedofftherollerwillfeedtothefarendofthebeltconveyorandpark

thereuntilturnedonagain.

3.Ifthedeliveryisturnedonwhenusingthe‘SetbyFold’modeofoperation;theRoller

PositionandShingleLengthareautomaticallyset,relativetothepaperlengthandtypeof

foldselected.

4.Whenusingthe‘SetbyPosition’modeofoperation;theRollerPositionandShingle

Lengthmustbeadjustedmanuallytosuitthejob.(SeeFIG17.1below).

5.Whentheoptimumsettingsfortherollerpositionandshinglelengthareachievedthey

canbestoredwiththejob.

NOTE.

WhensettingthemachinetodoaDoubleFoldorEngineeringFold,withapaperlengthof

279mm(11”)orless,thestackerrollerwilltraveltothefarendoftheconveyorandstop.

Thisisduetotheshortnessofthefoldedpaperexitingfromthemachine.

not

FIG17.1

Page28

FOLDING

Page 30

OperatingtheAtlas C300

StatusScreen.

Greeniconindicatessettingsare

saved-arediconwouldshowthat

settingshavechangedbut

thejobhasnotbeensaved.

Paperlength&Paper

Type-inputfromthe

papersettingscreen.

LeadEdgeSensorStrength,

IndicatorBar

Numberofcreases-this

mayalterautomaticallyif

apre-definedfoldis

selected.Adjustments

maybemadeinthe

creasesettingscreen.

Indicatorforstatusof

knives.

Clickinginthisareawilltake

youtothestorepage

Clickinginthisareawilltake

youtothepapersetting

page.

Currentlyselectedfoldtype

-canbeoneofthe

following.

Clickinginthisareawilltake

youtothecreasesetting

page.

K1&K2On.

K1Off&K2On

K1On&K2Off

K1&K2Off

Clickinginthisareawilltake

youtothedeliverysetting

page.

Sheetcount-clicktozero

Ascreenwillappearto

confirmthatyouwantto

resetthecount.

Batchcount-clicktozero

Ascreenwillappeartoconfirmthat

youwanttoresetthecount.

FoldPositions&Trim

settings

Clickinginthisareawilltake

youtotheFoldsetting

page.

Selectthisbuttontoproduce

3testsheetswiththe

settingscurrentlyshown.

Batchquantity-thisis

inputfromthebatch

calculatoronthepaper

settingscreen-max.999

Clicktostartmachinewithsettingscurrently

shown-youwillreceiveanotificationif

systemswitchisnoton.Pressagaintostop

Job

Page29SYSTEM

Page 31

OperatingtheAtlas C300

RunJob.

SystemSwitchNotOn.

Clicktorunmachine.

Themachinerunningscreenwillappear.

ClicktoconfirmSystem

switchison&thenclick

runbuttonagain

Runcount

BatchCount

JobCount

Clicktostopmachine.

Page30

FOLDING

Page 32

OperatingtheAtlas C300

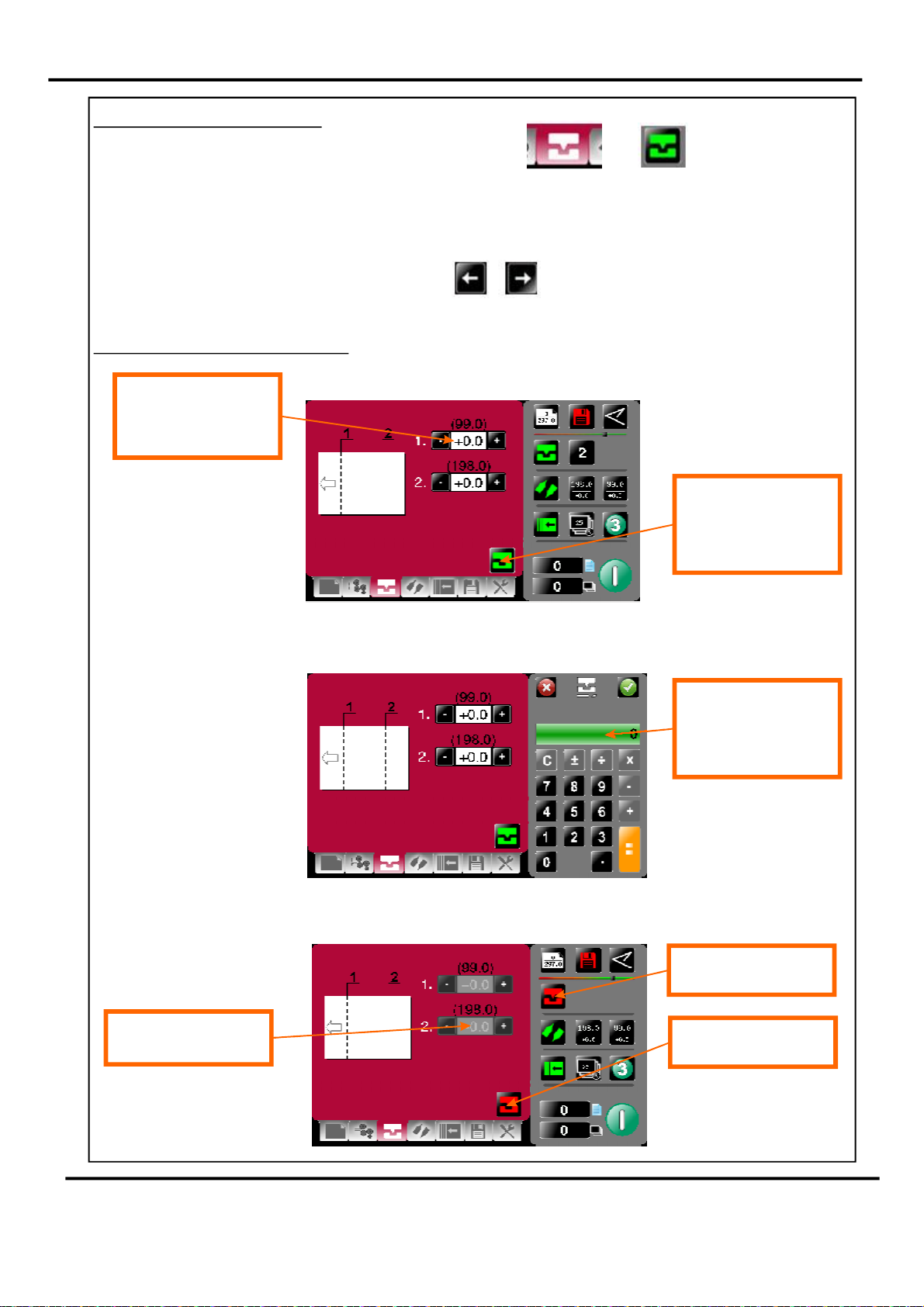

Settingthemachinetooperateinmanualsheetfeedmode

Inordertofeedheavystock,verysmallorverylargesheets,embossedorevenirregular

shapedsheets,itmaybenecessarytofeedthesheetsmanually.

Themachinecanbeprogrammedandsetupinexactlythesamewayasexplainedwhen

operatingthemachineautomatically.However,thepapergatemustberaisedtoitshighest

positionforthesheetstobefedfreely.

ThemachinecannowbestartedbyactivatingtheSystemswitchto‘on’.

theCompressorswitch.

Selecttheicononthetouchscreenandbegintoslidethesheetsindividuallythrough

thepapergateuntiltheyaredrivenbythedrivebelts.

Tostopfeedingthesheets,selecttheicononthetouchscreenandswitchthe

SystemSwitchoff.

NOTE.

Ifthedelaybetweenfeedingsheetsisexcessive,thesystemwilltimeout.

Donotactivate

Page31SYSTEM

Page 33

OperatingtheAtlas C300

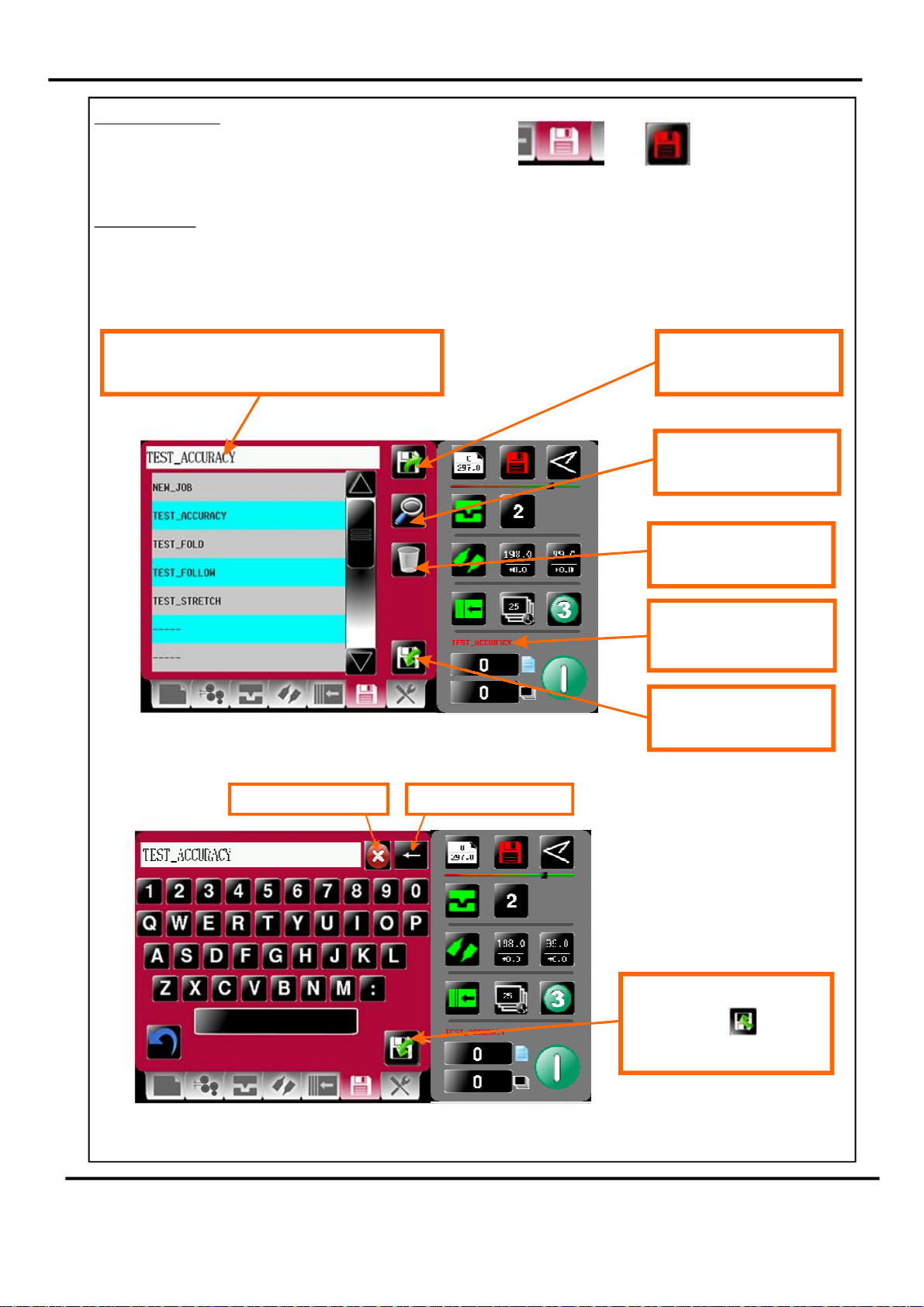

StorePages.

TogettotheStoresettingpageclickthelowertaborfromthe

statusarea.

NewJobs.

Havingsetupyourjobyoucangivethejobanameandsaveittoastore.Youcan

alsoretrievepreviouslysavedjobs,modifythemordeletejobsyounolongerrequire.

Tocreateanewjobnameclickintextarea&

keyboardwillopentoinputjobname.

Keyboardforenteringjobname.

Loadexistingjobfrom

store

Clickingtosearch

currentlystoredjobs

Clickingtodelete

currentlystoredjobs

CurrentJobName

YellowTextDenotesSavedJob

RedTextDenotesUnsavedJob

Clickingtosavejob

shown.

DeletelastcharacterDeleteallcharacters

Page32

ReturntoStoreMenu&

clicksaveicontosave

jobtostore

FOLDING

Page 34

OperatingtheAtlas C300

Saveconfirmationscreen.

Toconfirmsaving

ofjobclickhere.

Searchforcurrentjobstoloadormodify.

Youcansearchforjobsbyclickingthesearchicon,thiswillbringupthe

searchkeyboardfortextinput.

Tochangeyourmind&

returntotheprevious

screenclickhere.

Jobsmatching

charactersintextbox

willbeshowninthis

area-selectingjob

fromthisareawill

showjobsettingsin

therighthandstatus

area.Jobselectedwill

beshownintextbox.

Typeinjobdescription

orfirstfewcharacters

Presssearchicon

tostartsearch

Togglebetweensearch

results&fulllistof

jobs

Presstoloadjob

shownintextbox.

Page33SYSTEM

Page 35

Operatingthe Atlas C300

Loadingjobconfirmationscreen.

Loadedjobmaybemodifiedandthenre-savedasthesamejobname.

Tocancelloadingof

Jobpresshere

Toconfirmloadingof

Jobpresshere

Overwritejobconfirmationscreen.

Deletejobconfirmationscreen.

Tocanceloverwriteof

Jobpresshere.

Toconfirmoverwrite

ofJobpresshere

Tocanceldeletionof

Jobpresshere

Page34

Toconfirmdeletionof

Jobpresshere

FOLDING

Page 36

OperatingtheAtlas C300

ToolsMenu.

TogettotheToolspageclickthelowertab

Inchpaperindirection

ofarrowtoclearjams

ClickonUpArrowto

putAnvilintoTop

DeadCentreposition

(TDC)

CleanLeadEdgeSensor

TouchScreenCalibration

SeePage36

ChangeMachinemeasurement

settings,Imperial/Metric

Touchscreensoftware

revision

ToggleK2ONandOFF

UsedtoSetDeflectTrims

SeePage37

Inchpaperindirection

ofarrowtoclearjams

Clickingthisiconwill

showMachine

programmerevision&

TouchScreensoftware

revision.

Machinemainboard

softwarerevision

Page35SYSTEM

Page 37

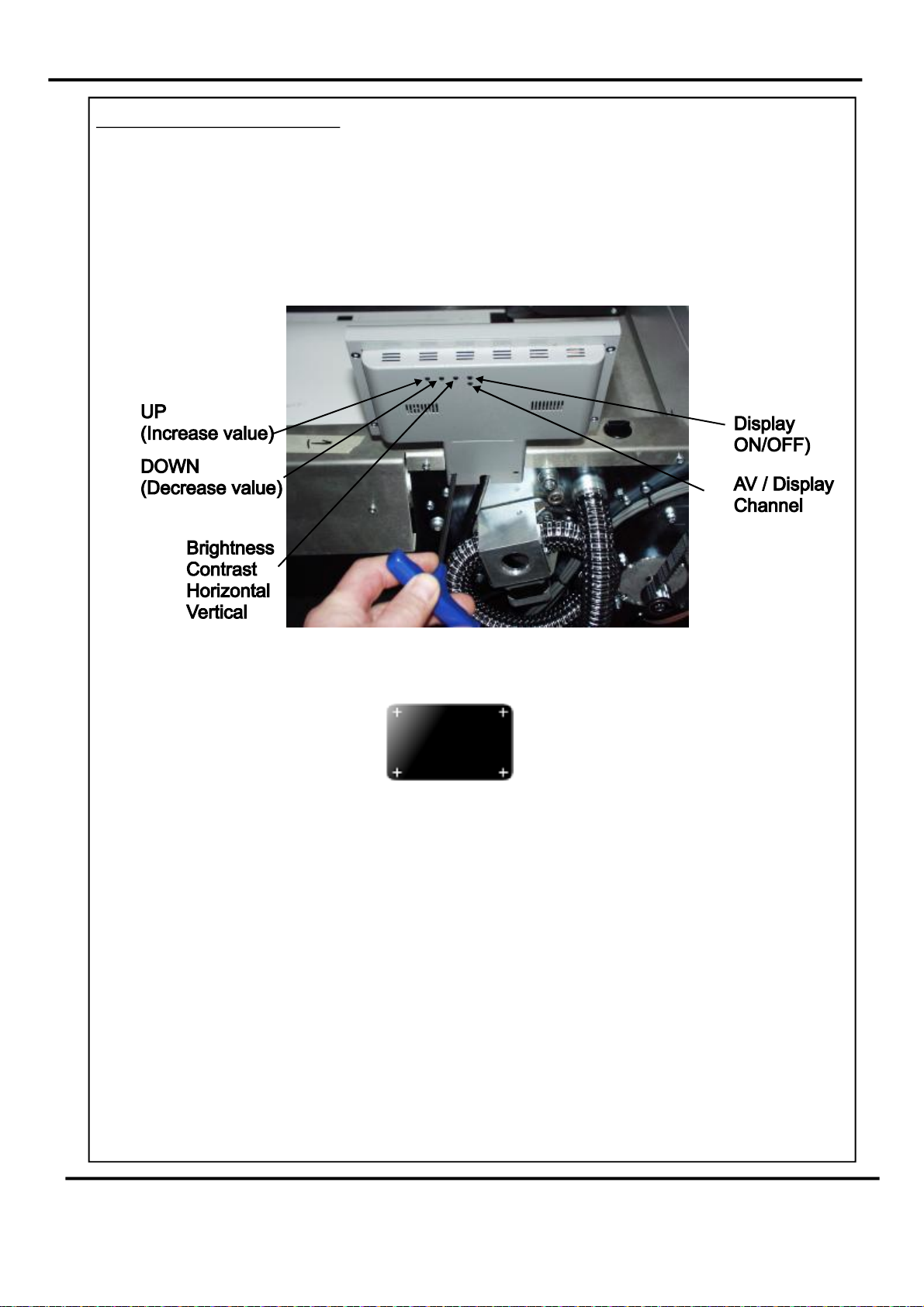

OperatingtheAtlas C300

TouchSc

1.Switc

reenCalibration.

commencingtocheckthehorizontalandverticalpositionofthedisplay.

Thepositionofthedisplaywithinthesurroundisachievedbyoperatingthebutton

attherearofthehousing,pressthisanumberoftimestoobtainthecorrect

orientationrequired,movetothenextbuttontomovethepositiontocentralize

horizontal.

hthemainspoweronandwaitforthemainscreentoappearbefore

2.(i)Selectthetoolsmenutab,andthenSelecttheTouchScreencalibrationicon.

(ii)Usingaplasticpointer,softleadedpencil,birocapetc.andwithgentlepressure.

TouchthecentreofthecrossineachcorneroftheTouchScreen,asprompted,by

thehandgraphics.ThisprocedurewillcalibratetheTouchScreen.

Page36

FOLDING

Page 38

OperatingtheAtlas C300

DeflectTrimAdjustments

Thedefl

withoutdamagingtheleadedge.

ConductthistestwithK2turnedoffusingthe'Tools'menu.

IfmarkingoccursonK1thenfollowthesegeneralrules.

•

EnsureK2isturnedonusingthe'Tools'menu.

IfmarkingoccurswhenK2isturnedonthenfollowthesegeneralrules.

ecttrimsmayneedtobecalibratedtoallowthesheettopassthroughthemachine

1.K1DoubleDeflectTrim

Inthetoolsmenu

RollermarksarecausedbytheFoldknifebeingtoolate,andsominussomeK1

Deflecttrim.

Generalscuffingofthesheetundersidearecausedbythefoldknifebeingtooearly,

•

addsomeK1deflecttrim.

2.K2DoubleDeflectTrim

•

RollermarksarecausedbytheFoldknifebeingtoolate,andsominussomeK2

deflecttrim.

Generalscuffingofthesheetuppersidearecausedbythefoldknifebeingtooearly,

•

AddsomeK2deflecttrim.

Page37SYSTEM

Page 39

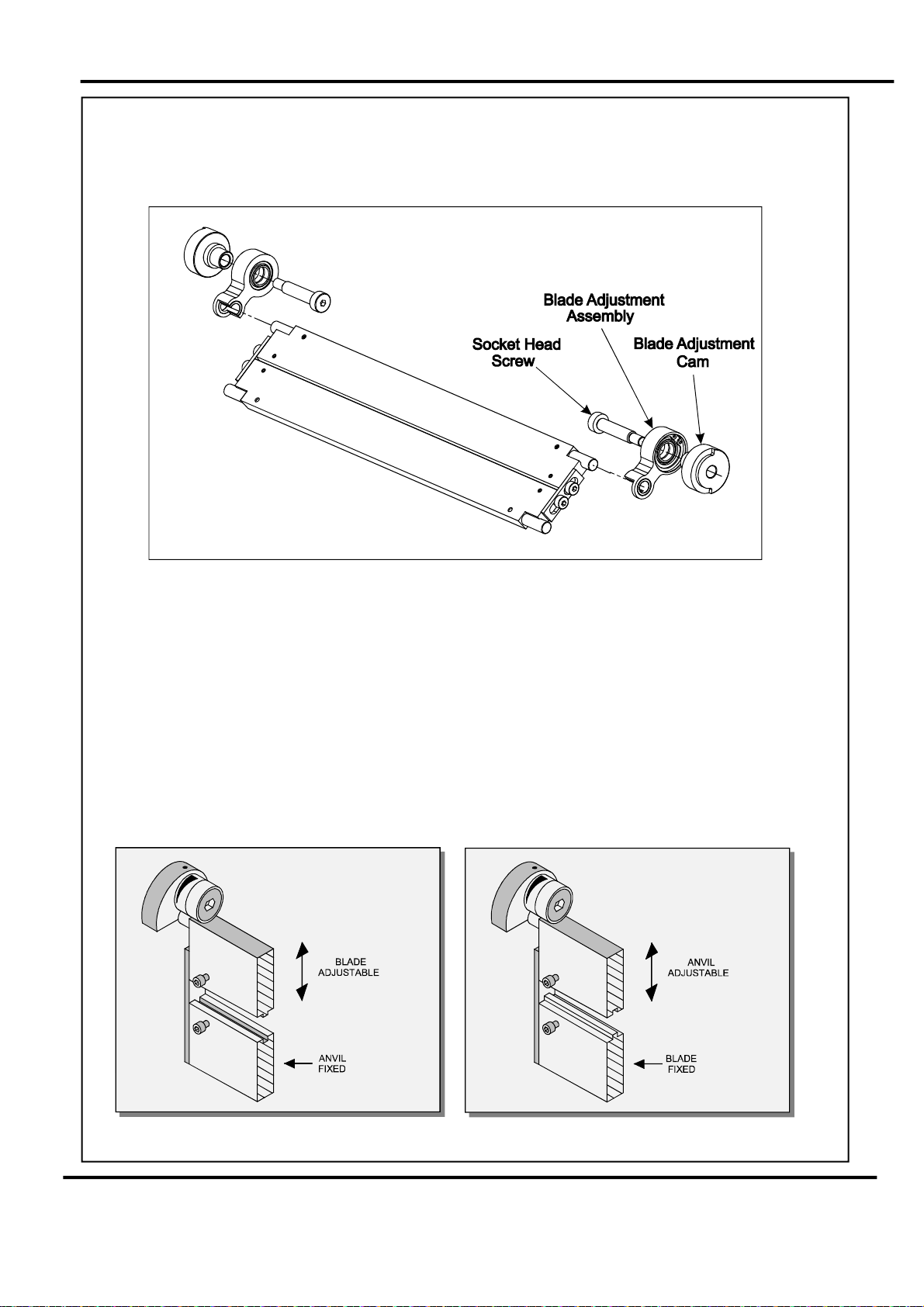

TheBladeAssembly

Adjustingthebladepressure(nopaperrequired)

1.(i)Switchthepower‘on’byturningtheEmergencystopbuttonclockwisetoreleasethe

safetylatch.

(ii)SelecttheToolstabatthebottomofthetouchscreen,thedisplaywill

changetothatshownbelow.

(iii)Activatethesystemswitchto‘ON’

(iv)SelecttheuparrowtomovethebladetotheTopDeadCentreposition.

ClickonUpArrowto

putAnvilintoTop

DeadCentreposition

(TDC)

2.Raisetheexitguard

3.Usinga5mmallenkey,unlockthesocketheadscrewspositionedateachendofthe

creasingblade.

4.Rotatethebladeadjustmentcamsuntiltheyarejusttight,andthenbackoffslightly

beforetighteningthesocketheadscrews.

Thediagrambelowdemonstratestheadjustmentofthebladepressure

5

Page38

FOLDING

Page 40

ReplacingBladeSets

1.Beforeremovingthebladeassembly,ensurethatthelowerblade/anvilisat‘TopDead

Centre’,seepage38.

2.Liftthetopcover.

3.Usinga5mmallenkey,removethetwosocketheadscrews,oneeachendoftheBlade

Set,asshowninFIG32.1below.

FIG32.1

4.RemovetheSheetGuideAssembly,bypullingupwardsonthetwoflanges,oneeach

end,asshowninFIG32.2andFIG32.3below.

Flange

SheetGuideAssembly

FIG32.2 FIG32.3

5.TheBladeSetcannowberemovedfromthemachineusingtheBladeExtractorTools

showninFIG32.4below.

FIG32.4

BladeExtractorTools

Page39SYSTEM

Page 41

ReplacingBladeSets

6.InserttheBladeExtractorTools,oneateachendoftheBladeSet,asshownin

FIG33.1below.

FIG33.1

NoteThePositionofThe

BladeExtractorTool

UnderTheLipofThe

BladeAdjusterAssembly

7.LevertheBladeAssemblyinthedirectionshowninFIG33.2tounclipandreleasethe

BladeSet.

FIG33.2

Page40

FOLDING

Page 42

ReplacingBladeSets

8.Slidethebladeassemblyoutofthecreasingunitandlayitonaflatsurface.

9.Slidethebladeadjustmentcamsandthebladeadjustmentassembliesawayfromthe

dowelslocatedintheendsoftheblades/anvilsasshowninFIG34.1below.

FIG34.1

10.Slidethebladeadjustmentassembliesandthebladeadjustmentcamsontothe

dowelsofthenewbladeset.

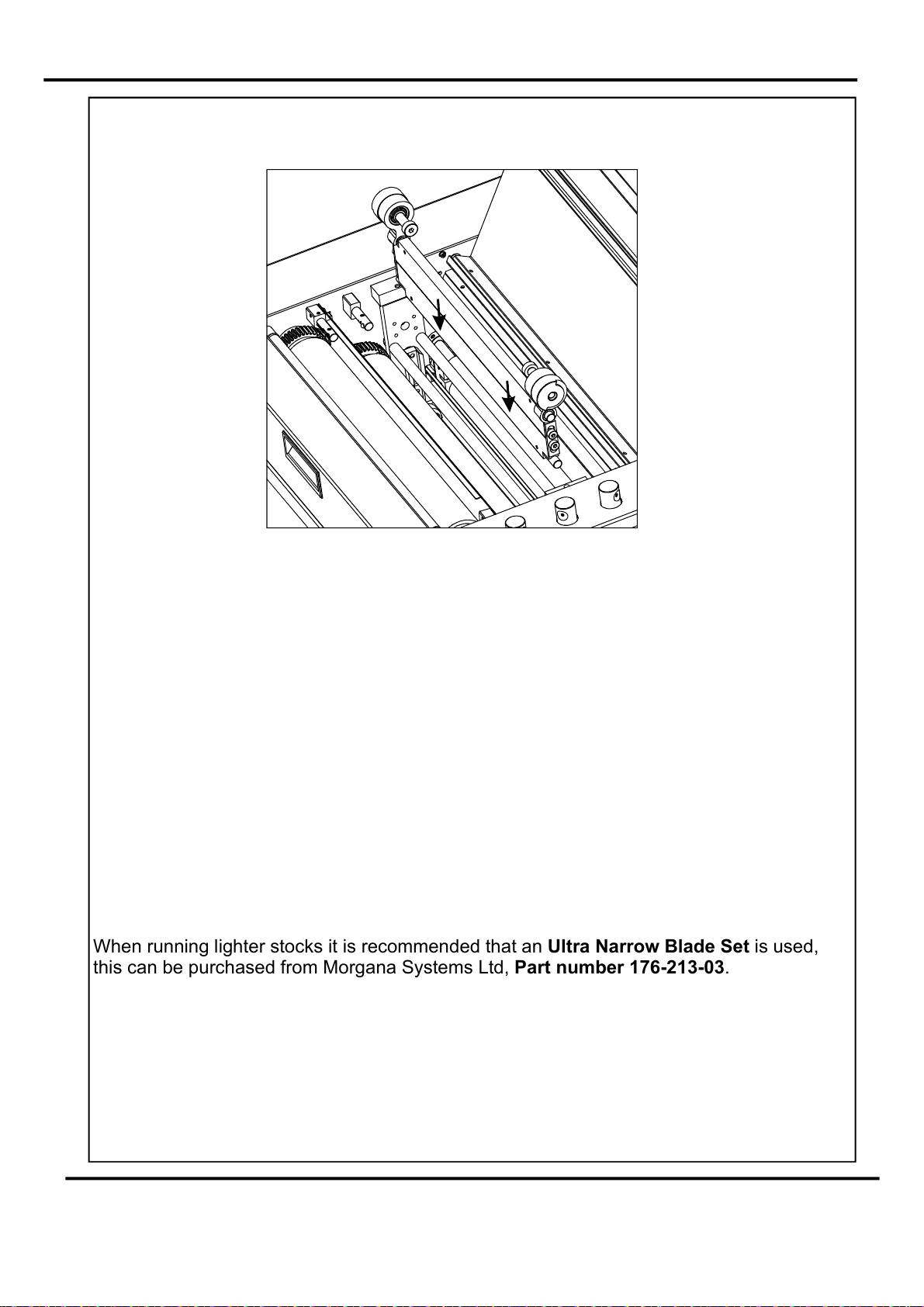

11.SlidethenewbladesetintotheslotsofthecreasingunitasshowninFIG.34.3.

NOTE.

ThebladesetcanbefittedwiththeANVILatthebottomorwiththeANVILatthetop.

ThebladesetissuppliedfromthefactorywiththeANVILatthebottomasshownin

FIG34.2A.

ThebladesetcanbechangedtohavetheANVILatthetop(asshowninFIG34.2B),this

canimprovetherepeatabilityofthefoldrelativetothecreaseforcertainfoldtypesor

whenusinglighterstocks.

FIG34.2BFIG34.2A

SYSTEM

Page41

Page 43

ReplacingBladeSets

12.Rotatethebladeadjustmentcamsuntiltheyarejusttight,andthenbackoffslightly.

Resetbladeto‘TopDeadCentre’andmakefinaladjustments.

FIG34.3

13.RefittheSheetGuideAssembly

14.Closethetopcover

15.Switchthemachineonandtestthecreaseforform.

ThefollowingBladesetsaresuppliedasstandard.

StandardBladesetPartnumber176-213-02

Consistingofastandardbladeandanvil,pre-setforyourmachine.

NarrowBladesetPartnumber176-213-01

Consistingofastandardbladeandanarrowanvil,pre-setforyourmachine.

NOTE.

Bladesetsareindividuallysetforeachmachineatthepointofmanufacture.

ReplacementBladesetswillthereforeneedtobesetupbyafactorytrainedservice

engineer.

DonotattempttouseaBladesetfromanotheDigifoldPro.

Whenrunninglighterstocksitisrecommendedthatanisused,

thiscanbepurchasedfromMorganaSystemsLtd,

UltraNarrowBladeSet

Partnumber176-213-03

.

Page42

FOLDING

Page 44

Perforating

Oncethemachineisset-up,theMachinecanbeusedtoperforateorcrease.

Notes

1.Perforatingandcreasingcanbecarriedoutsimultaneously.However,ifany

adjustmentismadetotherollertiltmechanisminordertocompensateforthe

perforationlinebeing’outofsquare’,thismayeffecttheaccuracyofthecrease.If

thisoccurscreasingandperforatingmustbecarriedoutasseparateoperations.

2.Byadjustingtheoutfeeddrivetyresrelativetothedrivehubsitispossibletostear

thesheet,(i.e.Byplacingthetyreontopofthehubonesideofthepaperwillstear

fasteronthatside).

Thecomponentsandtoolsrequiredtoinstalltheperforatorarecontainedinthedespatch

kitsuppliedwiththemachine,theyarelistedbelow.

1offSetofstandardperforation‘28tooth’blades.

1offSetofstandardhardenedanvils.

1off3mmbondhuswrench/allenkey

1off2mmbondhuswrench/allenkey

Theperforatorbladesaresplitintotwomatchinghalvesand

arefittedtothedrivewheelsasshowninthephotograph

usingthefourscrewssupplied.

Ahardenedanvilisfittedtothedrivehubasshowninthe

photographalsousingthefourscrewssupplied.Againthe

anvilsaremadefrommatchinghalves.

Important:Theperforatorbladesareverysharpand

caremustbetakenwhilsthandling.

Donotmixthematchingpairsofbladesoranvils.

Perforating‘Spares’kits

Forperforatingandothertypesofpaper,variousspareskitsareavailablewhichcanbe

assembledtothemachineinthesamefashion.Theyarelistedbelowalongwitharange

ofscoringwheels,

Perforatingblades1-99-41

56teethPartNumber-Standardstock/

fineperforations.

28teethPartNumber-Mediumstock/

20teethPartNumber-Heavystock/

Anvils1-99-35

StandardPartNumber-Forallbladetypes

1-99-12

1-99-10

Mediumperforations.

coarseperforations.

Page43SYSTEM

Page 45

Perforating

Allofthebladesandanvilsaresuppliedwithfixings.

*Perforatorstripper177-05-01

*Itisrecommendedthatformultipleperforations,aseparateperforatorstripperisusedfor

everyperforatingbladesetfittedinthecreasingunit.

StandardPartNumber

Settingthemachine

1.Turnthemainssupplytothemachine‘off’.

2.Opentheperforatorassemblytogetaccesstothedrivewheelsandhubs.

3.Locateandremovetheblades/anvilsfromthedespatchkitsuppliedwiththe

machine.

4.Usingthe2mmallenkey(supplied),loosenthedrivewheelthatistoaccommodate

theblades.

5.Slidethedrivewheelawayfromanyobstructingdrivewheelsorhubsinorderto

mounttheblades.

FIG37.1

6.Usingthe2.5mmallenkey(supplied),takeone

halfofthematchingpairofbladesandmounton

tothedrivewheel.Donotsecuretheblade.

FIG37.2

7.Mounttheotherhalfofthebladetothedrive

wheelasshown(FIG37.1).Securethebladesto

thewheelensuringnottoovertightengrubscrew.

8.Markonasinglesheetthedesiredperforating

position.Feedthesheetthroughthemachine

manuallyuntilthemarkcanbeseen.Usethis

marktoassistinfixingthepositionofthe

perforatingdrivewheeltotherollerdriveshaft.

9.Usingthe2mmallenkey,loosenthedrivehub

nearesttheperforatingdrive.Slidethedrivehub

awayfromanyobstructingdrivewheelsorhubs

inordertomounttheanvils.

10.Usingthe2.5mmallenkey,takeonehalfofthe

matchingpairofanvilsandmounttothedrive

hub.Donotsecuretheanvil.

11.Mounttheotherhalfoftheanviltothedrivehub

asshown(FIG37.2).Securetheanvilstothedrive

hubensuringnottoovertightenthegrubscrews.

Page44

FOLDING

Page 46

Perforating

12.Slidethedrivehubtowardstheperforatingdrivewheeluntilthereisaclearance

of0.5mm(0.020”).

13.Topreventdamagetothebladesortheanvils,donotforcethedrivewheelagainst

thehub.

14.Fixtheperforatorstripperadjacenttothedrivewheelandbladeasshown.

15.Operatethemachineandtesttheperforationsforform.

Itisimportantthatthedrivehubsarearrangedevenlyacrossthewidthofthepaper

inordertoreducetheriskofjamming.

Formultipleperforationsrepeattheaboveprocedure.

1

4

3

5

2

FIG38.1

Fig38.1

14

-Perforatingdrivewheelwithmountedblades-Drivehubwithmountedanvils

25

-Perforatorstripper-Standarddrivehub

3

-Standarddrivewheel

Demonstratesatypicalset-upforperforatingsheets.

Alwaysremovebladesandanvilsoncetheperforatingoperationhasbeen

completedtoavoidmarkingondigitalordelicatemedia.

Page45SYSTEM

Page 47

RemovingPaperJams

RemovingPaperJams

Intheeventofapaperjamoccurring,whilstrunningthemachine,followthesteps

describedbelowtoallowaccesstoremovethejammedpaper.

1.Unlockandlowerthedeliveryunit,openthetopcoverandtheperforatorunit;see

FIG39.1below.

2.Ifthepaperisjammedinthefoldrollers;trytorotatethetopfoldroller,usingboth

hands.Positionthethumbsunderthetiebarandspreadthefingersoutabovethetie

bar.

FIG39.1

TieBar

TopFoldRoller

TopCover

Page46

DeliveryUnit

PerforatorUnit

FOLDING

Page 48

TroubleShooting

Papercreaseoutofsquare

Checkthatthesheetsareallsquareandexactlythesamesizebeforeloadingthe

stackontothetable.

Checkthattheadjustablesidelayhasbeencorrectlypositionedie.Nofurtherthan

0.5mm(0.020”)fromthepaperstack.

Checkthatthebladetiltmechanismiscorrectlyset.

CreasePositionInaccuracy

Checkthatthecreaseprofilehasnotbeensettoodeep.

CheckthatthecorrectBladeSetisfitted.(StandardBladeSetformaterial

thicknessof0.25mm(0.010”)andabove,NarrowBladeSetformaterialthicknessof

0.25mm(0.010”)andbelow).

Paperfoldoutofsquare

Note:-thebestfoldsquarenessmaybeachievedwhenthefoldisnotonthecenter

ofthecrease,buttoonesideortheother.

Trythisfirst.

Checkthatthefoldistoonesideofthecreasecenterline.

Checkthattherollergapsarenottootightandsquashingthecrease.

Checkthattherollergapsarenottoolargeandallowingthepapertoslide

(especiallysoonglossypaper).

Paperjamming

Checkthattheleadingedgeofthepaperisnotbeingdamagedbythepapergate.

Ifthisisoccurring,checkthatthesuctionslotandthepapergatehavebeen

correctlyset.

Checkthatthefirstcrease/foldpositionisnottooclosetotheleadingedgeof

thepaper.Aminimumdistanceof50mm(1.96”)isrecommended.

IfjammingisoccurringinthePerforator-adjusttheHubs(seePages12&45).

Page47SYSTEM

Page 49

TroubleShooting

Machinewillnotstart

Checkthepowersupplytothemachine.

Checkthattheemergencystopbuttonhasbeenreleased.

Checkthatthetopcoverisdown.

Checkthattheperforatorassemblyisinitsclosedposition.

Checkthatthedeliveryunitisintheupposition,andlocatedcorrectly,(themachine

willnotstartifthedeliveryunitisnotinitsupposition).

Papernotfeeding

Checkthatthepaperstackisnottoohighortooheavyforthefeeder.Theheightof

thepaperstackshouldbedefinedbytheweightandthesizeofthestockbeing

creased.

Ensurethattheadjustablesidelayisnotpressedagainstthepaperstack.However,if

theclearancebetweentheadjustablesidelayandthepaperstackistoogreat,the

airsupplywillescapeinsteadofblowingthroughthepaperthusmakingitdifficultto

feed.

Checkthattheclearancebetweenthepapergateandthesuctionrollerisnotsettoo

low.

Ondigitalmedia,thefeedingperformancemaybeimprovediftheleadingedgeofthe

stackistrimmedbeforeloadingontotheDigifold.

Checkthattheairdistributionhasbeencorrectlyset.

Checkthattheairseparationhasbeensethighenoughtofeedthesheets.

Forheavystocks,verysmallorverylargesheets,embossedorevenirregularstock,

itmaybenecessarytofeedthesheetsmanually-seepage31.

CrackingofthePrintedMaterialalongtheCrease.

Crackingofthematerialalongthecreasemaybecausedbythefollowing:-

Pressuretooheavyonthetopblade-reducepressure.

Crackingononeedgecausedbymisalignmentoftheanvilandblade.

Whenusingdryinkortonerbasedprintengines,thematerialbefully

acclimatisedforatleast48hoursbeforeputtinganimageontothepaper.

must

Page48

FOLDING

Page 50

TroubleShooting

UsingtheCorrectBladeSet.

TwoBladesetsaresuppliedwiththemachine.

TheStandardBladesetissuitableformaterialthicknessesof0.25mm(0.010”)and

greater.

TheNarrowBladesetissuitableformaterialthicknessesof0.25mm(0.010”)and

smaller.

IftheStandardBladeSetisusedtocreaseandfoldmaterialslessthan0.25mm

(0.010”)inaccurateresultscanbeproduced.

IftheNarrowBladeSetisusedtocreaseandfoldmaterialsgreaterthan0.25mm

(0.010”)crackingcanoccur.Moreimportantlythiscouldcausethemainmotorto

temporarilystall.Thisprobablywon’tbethatnoticeableuntilyoulookattheresults,

wherebythecreasepositionwillvary.

Page49SYSTEM

Page 51

TroubleShooting

Sheetdidnotarrive.

Ifthemachinestopsanderrormessage01isdisplayedonthetouchscreen,this

indicatesthatthepaperdidnotarriveattheendofthesuckprocess;sothemachine

timedout.Pressthegreentickbuttonandthenpressthestartbutton.

PaperCrunch

Ifthemachinestopsanderrormessage02isdisplayedonthetouchscreen,this

indicatesthatapaperjamhasbeendetected.

Pressthesystemswitchdownandthenselecttherightorleftarrows,toinchthe

paperforwardsorbackwards.Seepage39thatdescribeshowtoremovepaperjams.

Pressthegreentickbuttonandthenpressthestartbutton.

ErrorScreens

DoubleSheetFeed

Ifthemachinestopsanderrormessage03isdisplayedonthetouchscreen,this

indicatesthatadoublesheetfeedhasbeendetected.Checkthatthepapergatehas

beensetcorrectly.Pressthegreentickbuttonandthenpressthestartbutton.

BladeNotHome

Ifthemachinestopsanderrormessage04isdisplayedonthetouchscreen,this

indicatesthatthelowerblade/anvilhasnotmadecontactwiththeHOMEswitch.

i.e.bladestillintopposition.Switchthemachineoffandremovethebladesetand

ensurethattheareaisfreefromobstructions.Returnthebladesettothecreasingunit

andswitchthemachineon.Operatethemachineinthenormalsequence,ifthe

displaycontinuestoreaderrormessage04itisadvisedtocontactaServiceEngineer

immediately.

Page50

FOLDING

Page 52

TroubleShooting

ErrorScreens(Continued)

BladeBusy

Ifthemachinestopsanderrormessage05isdisplayedonthetouchscreen,this

indicatesthatthebladeisbusy.Trytooperatethemachineagain,Ifthisfailsitis

advisedtocontactaServiceEngineer.

BladeHomeFailure1

Ifthemachinestopsanderrormessage06isdisplayedonthetouchscreen,this

indicatesthattheremaybesomecreasingerrors,andthatthecreasingpressure

shouldbechecked,(alsocheckforadoublethatmayhavegotthrough,causingthis

error).

BladeHomeFailure2

Ifthemachinestopsanderrormessage07isdisplayedonthetouchscreen,this

indicatesthatthecreasebladedidnotgetbacktoitshomepositioncorrectlyor

atthecorrecttime.Causes,canbeexcessivebladepressure(suspectadouble),or

Somekindofjamwhichcausedmorethanonesheetthicknesstobecreased.

Page51SYSTEM

Page 53

TroubleShooting

FlyingHomeFailure

Ifthemachinestopsanderrormessage08isdisplayedonthetouchscreen,this

indicatesthatthehomesignalwasmissedduringcreasing.Checkthattheblade

pressureisnottoohigh.

ErrorScreens(Continued)

Clip1NOTclear

Ifthemachinestopsanderrormessage09isdisplayedonthetouchscreen,this

indicatesthatthesensorisorwasblockedwhenitshouldhavebeenclear.

i.e.Ajaminthepaperpathorthewronglengthofpaperhaspassedthroughthe

sensor.

Tocorrect-checkifpaperispresentandcheckthatthepaperpathisclearbefore

restarting.Seepage46thatdescribeshowtoremovepaperjams.

Clip1NOTBlocked

Ifthemachinestopsanderrormessage10isdisplayedonthetouchscreen,this

indicatesthatthesensordidnotseethepaperatthecorrecttime.

i.e.Ajaminthepaperpath.

Tocorrect-Checkifpaperhasjammedinthemachinepriortothesensor.

Seepage46thatdescribeshowtoremovepaperjams.

(BackSensor)

(BackSensor)

Clip2NOTclear

Ifthemachinestopsanderrormessage11isdisplayedonthetouchscreen,this

indicatesthatthesensorisorwasblockedwhenitshouldhavebeenclear.

i.e.Ajaminthepaperpathorthewronglengthofpaperhaspassedthroughthe

sensor.

Tocorrect-checkifpaperispresentandcheckthatthepaperpathisclearbefore

restarting.Seepage46thatdescribeshowtoremovepaperjams.

Page52

(TopSensor)

FOLDING

Page 54

TroubleShooting

Clip2NOTBlocked (TopSensor)

Ifthemachinestopsanderrormessage12isdisplayedonthetouchscreen,this

indicatesthatthesensordidnotseethepaperatthecorrecttime.

i.e.Ajaminthepaperpath.

Tocorrect-Checkifpaperhasjammedinthemachinepriortothesensor.

Seepage46thatdescribeshowtoremovepaperjams.

ErrorScreens(Continued)

SENSORPOSITIONS

Clip1

(BackSensor)

Clip2

(TopSensor)

Overlap

Ifthemachinestopsanderrormessage13isdisplayedonthetouchscreen,this

indicatesthatthe‘LeadEdgeSensor’hasseenasheetsubsequenttothefirst

oneasbeinglonger.Againthiscouldactuallybealongersheet,ORitcouldbea

sensorproblem(ifitisarecurringproblem).Checkthatthepapergatehasbeenset

correctly.

Page53SYSTEM

Page 55

TroubleShooting

ErrorScreens(Continued)

LeadE

Ifthemachinestopsanderrormessage60isdisplayedonthetouchscreen,this

indicatesthattheleadedgesensorisblocked.

Pressthesystemswitchdownandthenselecttherightorleftarrows,toinchthe

paperforwardsorbackwards.

Pressthegreentickbuttonandthenpressthestartbutton.

Thiserrormessagecouldalsomeanthattheleadedgesensorsarefaultyorneed

cleaning.

dgeSensorFault

.

Page54

FOLDING

Page 56

ErrorScreens(Continued)

CleanLeadEdgeSensor-WarningScreens.

1.TheCleanLeadEdgeSensorwarningscreen,shownbelow,willappearwhenthe

RunbuttonispressedandthestrengthoftheLeadEdgeSensorBeamisatabout

50%(i.e.thesliderisataboutthemid-pointpositionalongtheIndicatorScale).

SENSORCLEANINGWARNINGSCREEN

PresstheToolsbuttontocleanthe

Sensors,asdescribedonPages56&57.

PresstheRunbuttontoignoretheWarning,

andcontinuerunningthejob.

2.TheCleanSensor,Error65warningscreen,shownbelow,willappearifthestrength

oftheLeadEdgeSensorBeamisallowedtogetdowntoabout25%.TheLeadEdge

Sensorsshouldideallybecleanedbeforethiswarningscreenappears.

NOTE.

TheLeadEdgeSensorscanbecleanedatanytimebyselectingtheToolsTab

atthebottomoftheTouchscreenandcleaningtheSensorsasdescribedonPages56&

57.

Page55SYSTEM

Page 57

TroubleShooting

ErrorScreens(Continued)

LeadEdgeSensorCleaning.

SelecttheToolsmenuontheTouchscreenDisplay,andthenselectthecleansensor

icon

ThescreennowshownisavisualindicationofthestrengthoftheLeadEdgeSensorbeam.

FLASHING(GREEN/BLACK)TO

INDICATETHATTHESOFTWARE

ISINTERROGATINGTHESENSOR

BEAM

SLIDER

INDICATORSCALE

Theverticalindicatorscaleisdividedintofoursections,thepositionofthesliderindicates

thestrengthofthebeam.Thestrengthofthebeamisatitsstrongesttowardsthetophalfof

theindicatorscale(green)andatitsweakesttowardsthebottomhalfoftheindicatorscale

(red).Notethepositionofthesliderontheindicatorscaleandthencleanthesensorsas

describedonPage57.

NOTE:-

handsideoftheTouchscreenDisplayasshownbelow.

Thisverticalindicatorscaleisrepeatedasahorizontalindicatorscaleontheright

HORIZONTALINDICATORSCALE

Page56

FOLDING

Page 58

ErrorScreens(Continued)

Tocleantheleadedgesensorsopenthetopcoverunittoexposethebladeset.Usingth

SensorCleaningBrush(partnumber601-185),suppliedinthedispatchkit,slid

thebrushundertheballholderandpushitthroughtoreachtheupperandlowerleadedg

sensors.(SeeFIG.3andFIG.4below).Movethebrushbackwardsandforwardsseveral

timesacrossthesensorstocleanthem.Notethepositionofthesliderontheindicator

scale;theslidershouldhavemovednearertothetopofthescale,indicatingthatdustha

beenremovedfromthesensors.Thissensorcleaningoperationcanberepeatedagaint

seeifthesensorbeamstrengthcanbefurtherimproved.TheSensorscanalsobe

cleanedwithacanofcompressedair.

e

e

e

s

o

,

Page57SYSTEM

Page 59

TroubleShooting

Recommendedweeklyoperatormaintenance

Cleanallsensors.

Theleadedgesensorhousingislocatedonthelayedgesideofthemachinebetweentheinput

rollershafts.Withaslimbrushthesensorscanbecleanedwhenrequired.Passthebrushunder

theballholderandpushthroughuntilitpassestheinfeedrollers.Alternativelyitcanbeblown

withcompressedair.

TheJamSensorissituatedjustaftertheedgesensorandisinlineacrossthepaperpathwith

thereceiverintheoperatorsidesideplate.Thisisnotusualysensitivetodustbutifrequiredcan

beblownwithcompressedair.

Clip1sensorissituatedonthelowerguidesbeneaththedeliveryconveyorandcanbe

cleanedwhenrequiredusingaslimbrush.

Clip2sensorissituatedontheupperguidesinsidethetopcoverandcanbecleaned

whenrequiredusingaslimbrush.

Cleaninfeedrollersandoutputdrivehubsusingthecleaningkitsupplied

(cleaningkitpartnumber90-018).

Removeandcleanthebladeassembly.

TechnicianMaintenance

ItisrecommendedthatyourMachineisfullyservicedatleastonceeverysixmonthsbyafactory

trainedServiceEngineer.

Page58

FOLDING

Page 60

BLANK

PAGE

Page59SYSTEM

Page 61

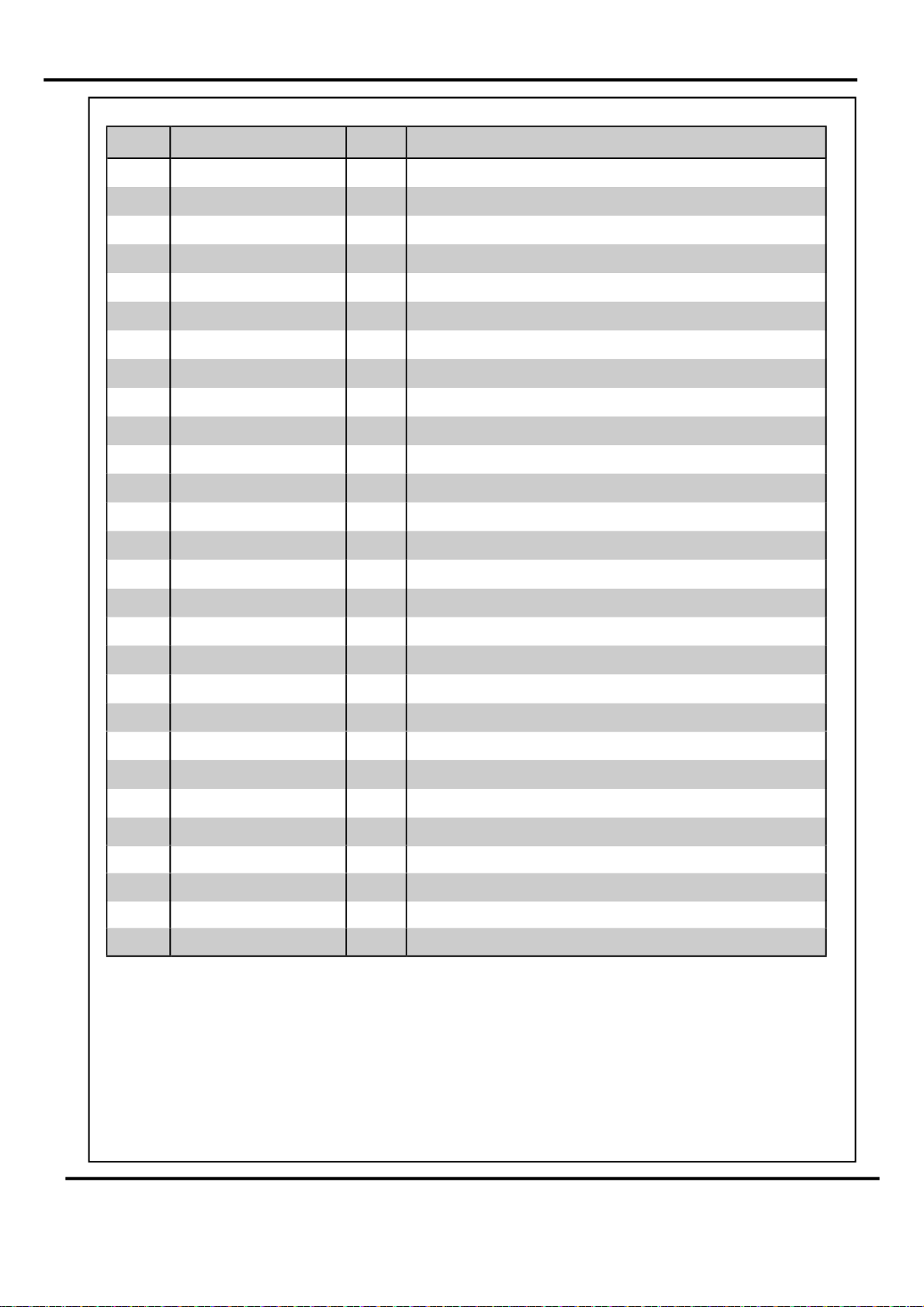

DISPATCHKIT

ITEM PARTNUMBER QTY DESCRIPTION

174-036

1

2 90-018 1 ROLLERCLEANINGKIT

650-040 1 POWERCORDC19UK16A2.5m

3

170-009-01 2 BLADEREMOVALTOOL

4

601-167 1 DIGITALTHICKNESSGAUGE

5

403-01-030-006

6

7

409-01-040-004

8

620-007 1 HEXAGONBALLDRIVER2mm

620-020 HEXAGONBALLDRIVER2.5mm

9

1 OPERATORSMANUAL

12 SCREW-SOCKETCAPHEAD-M3x6LG

1 SCREW-SKT.SETFLATPT.-M4x4LG

1

-

10

620-026 1 BONDUSLWRENCH4mm

11

620-027 1 BONDUS WRENCH5mmL

12

624-025 1 STATIONERYTUBE330MMX50MM

13

170-002-01 QUICKSTARTCHART

14 624-018 1 DISPATCHBOX

15

1-99-35 1 SLITTINGANVILSET

1-99-12 1 SLITTERPERFBLADE28T16

613-229 1 WRITE-ONSERIALNO.LABEL17

65-104 1 SPECIFICATIONLABELMSL/CE18

1

Page60

FOLDING

Page 62

ACCESSORIESANDOPTIONS

ITEM PARTNUMBER DESCRIPTION

1

2

3

4

5

6

7

8

9

10

172-022-01

AC-75

AC-76

AC-77

AC-79

AC-70

172-04-01

173-169-01

AC-60

178-01-02

LOADINGTABLEEXTENSION

PERFORATINGBLADESET20T(Card)

PERFORATINGBLADESET28T(SingleSheets)

PERFORATINGBLADESET56T(FinePerfs)

ANVILSETUSEDWITHABOVEBLADESETS

DOUBLESHEETDETECTORKIT

NARROWSHEETKIT

ETHERNETKIT

DYNAMICBLADESET-ULTRANARROW

STACKERASSEMBLY-

ACCESSORIES....OPTIONS....

....Maybeobtainedfrom....Mayalsobeobtainedand

yourdealerandfittedtoyourfittedbyyourdealer.Youshould

machineusingtheinstructionsnotattempttofitoptionsas

supplied,orbyreadingyourspecialisttoolsandknowledgeare

operatorsmanual.required.

Page61SYSTEM

Page 63

RECOMMENDEDSPARES

PARTNO. DESCRIPTION

125-21-02DualStepperDriverBoard

125-25-01SmallStepperDriver-HighPower

174-06-01SmallStepperDriver-LowPower

174-01-02ControllerPCBAssembly+Chip

174-19-01RS232AdaptorPCBAssy.

75-500-01MiniITXMotherboard-

126-059-02Link-PaperGuide

128-026-03DeliveryBelt

145-093-02KnifeDriverPin-M8

76-261Lead-DeliveryInputConnector

173-57-01Lead-BladePositionSensor

173-45-01Lead-TiltPot

173-46-01Lead-GapSet3Pot

173-47-01Lead-GapSet2Pot

173-48-01Lead-GapSet1Pot

173-06-01PowerSupply-48V

173-06-02PowerSupply-24V

76-272PSUAssembly-ATX12V-300W

173-49-01StepperMotor-crease

76-240StepperMotor-Drive

76-257StepperMotor-FoldKnives

175-31-01InputrollerAssembly-Lower

175-31-04InputRollerAssembly-Upper

175-042-01FeedBelt

175-10-01EdgeSensorAssembly

75-06-02TouchScreenAssembly-7”(NewController)

175-11-01SensorBarAssembly

175-11-02SensorBarAssembly-Clip

175-11-03SensorBarAssembly

175-12-011stBladeAssembly

175-12-022ndBladeAssembly

175-125-01ConnectingLinkAssembly-Drive

175-125-02ConnectingLinkAssembly-KnifeHubs

175-29-01FoldRoller-1st

175-29-02FoldRoller-2nd

175-29-03FoldRoller-3rd

175-29-04FoldRoller-Fixed

Page62

FOLDING

Page 64

RECOMMENDEDSPARES

PARTNO.

DESCRIPTION

172-05-01PaperGateAssembly

175-21-01VacuumRollerAssembly

176-02-01BladeAdjusterAssembly

176-081-01WormWheel-GapSet

176-213-01DynamicBladeSet-Narrow

176-213-02DynamicBladeSet-Standard

177-01-01PerforatorAssembly

602-160PlainBush-creaseGuideBlock

604-100GasSpring-Perf.Unit

604-103GasSpring-Delivery

607-005Belt-VacuumRoller

607-045MultiBeamCoupler

607-171TimingBelt-Drive

607-175Belt-Drive

607-183TimingBelt-190XL062

681-020Fuse-500mA-20x5mm-Anti-surge

681-011Fuse-315mA-20x5mmAnti-surge-Ceramic

681-019Fuse-6.3A-20x5mm-Anti-surgeCeramic

652-047Fuse-15A-32x6.3mm-Anti-surge

613-351MicroSwitch-Guard

613-365EmergencyStopSwitch-DoublePole

626-007Anti-StaticSensorBar

652-011Switch-LowCurrentCoil-Black

75-512Anti-StaticTransformer-UL

175-28-01ButterflyValve-Stepper

76-262StepperMotor-RollerDrive

76-258StepperMotor-BeltDrive

76-259StepperMotor-RollerPosition

76-266Lead-FoldKnivesSensor

124-01-27Lead-DeliveryRollerPot

175-072-01Lead-JamDetector-Emitter

175-072-02Lead-JamDetector-Receiver

75-530-01TransformerAssy.-230Vto110V

NOTE.....

Theitemslistedaboverepresentpartswhicharesubjecttowear,loss,oraccidental

damage,andisincludedforyourguidanceonly.

Replacementofpartsfittedtoyourmachinerequirespecialistknowledgeandshould

thereforebeentrustedtoyourdealer.

Page63SYSTEM

Page 65

MACHINECALIBRATIONHISTORY

Date:-

TotalCount:-

VacSuckTrim

VacParkTrim

Stretch

LeadEdgeTrim

FollowStretch

Del.RollerTrim

Knife1Trim

Knife2Trim

K1DeflectTrim

K2DeflectTrim

K1Travel

K2Travel

Date:-

TotalCount:-

VacSuckTrim

VacParkTrim

Stretch

LeadEdgeTrim

FollowStretch

Del.RollerTrim

Knife1Trim

Knife2Trim

K1DeflectTrim

K2DeflectTrim

K1Travel

K2Travel

SerialNumber:-

TotalCount:-

VacSuckTrim

VacParkTrim

Stretch

LeadEdgeTrim

FollowStretch

Del.RollerTrim

Knife1Trim

Knife2Trim

K1DeflectTrim

K2DeflectTrim

K1Travel

K2Travel

Page64

Date:-

FOLDING

Page 66

FUSEPOSITIONS&RATINGS

(POSITIONETCLASSIFICATIONDESFUSIBLES)

TRANSFORMERASSY.

T500mAH250V(681-020)

PSUs(24V&48V)

(FUSIBLEPSUs(24V&48V)

T6.3AH250V(681-019)

ANTI-STATICUNIT

SPAREFUSE

POSITION

(POSITIONPORTE

FUSIBLE)

MAINSIN

F15AH250V(652-047)

Page65SYSTEM

Page 67

PRODUCTRECYCLING&DISPOSAL

DisposalInformationforCommercialUsers

Applicationofthissymbolonyourequipmentisconfirmationthatyou

mustdisposeofthisequipmentincompliancewithagreednational

Procedures.

InaccordancewithEuropeanlegislationendoflifeelectricaland

electronicequipmentsubjecttodisposalmustbemanagedwithin

agreedprocedures.

Priortodisposalpleasecontactyourlocaldealerorrepresentativefor

endoflifetakebackinformation.

DisposalInformationforDomesticUsers

Applicationofthissymbolonyourequipmentisconfirmationthat

youshouldnotdisposeoftheequipmentinthenormalhousehold

wastestream.

InaccordancewithEuropeanlegislation,endoflifeelectricaland

electronicequipmentsubjecttodisposalmustbesegregated

fromhouseholdwaste.

PrivatehouseholdswithinEUMemberStatesmayreturnused

electricalandelectronicequipmenttodesignatedcollection

facilitiesfreeofcharge.Pleasecontactyourlocaldisposal

authorityforinformation.

InsomeMemberStateswhenyoupurchasenewequipmentyour

localretailermayberequiredtotakebackyouroldequipment

freeofcharge.Pleaseaskyourretailerforinformation.

OtherCountries

Pleasecontactyourlocalwasteauthoritiesandrequestdisposalinformation.

Page66

FOLDING

Page 68

REVISIONHISTORY

ModNo.Rev. ModDescription Date ModBy

ScreenshotgraphicschangedtoshowtheLeadEdgeSensorIndicator

Bar,onallrelativepages.

4 ECO2809 02/01/13 BAL

NewpagesinsertedtoshowtheCleanLeadEdgeSensorWarning

ScreensandhowtocleantheLeadEdgeSensors.(Pages55to57)

Page67SYSTEM

Loading...

Loading...