Page 1

7200 Series

Mid-Volume Modular Inserting System

12/2011

OPERATOR MANUAL

FIRST EDITION

Page 2

Table Of Contents

1 Introduction ........................................................................................ 3

1.1 Pictograms ........................................................................... 3

1.2 Notes on the use of this handbook ............................................. 4

2 Safety notes ........................................................................................ 4

2.1 General safety notes ................................................................ 5

2.2 End of life ............................................................................... 6

3 Description of machine ........................................................................8

3.1 Description of operation ............................................................ 8

3.2 Identication of parts ............................................................... 9

4 Control Panel ..................................................................................... 11

4.1 The Job Screen .......................................................................11

4.2 The Run Screen ......................................................................12

4.3 The Menu Screen ....................................................................16

4.2.1 The Run Screen displayed .............................................12

4.2.2 To adjust the Envelope Inserter settings ..........................13

4.2.3 To adjust the Document Unit settings ..............................15

5 Running an existing job ..................................................................... 17

6 Switching the user ............................................................................. 19

6.1 How to switch the user ............................................................19

6.2 User access rights ...................................................................19

7 Creating a job .................................................................................... 21

7.1 Creating the Job Settings .........................................................21

7.1.1 Dening the mailset .....................................................22

7.1.2 Dening the fold ..........................................................31

7.1.3 Dening the output settings ..........................................33

7.1.4 Saving the job .............................................................35

7.2 Creating an envelope ..............................................................36

7.3 Creating a document ...............................................................38

7.4 Creating an enclosure .............................................................40

8 Loading the paper hoppers ................................................................ 41

8.1 Loading the envelope hopper ....................................................41

8.2 Loading the versatile feeder hopper ..........................................42

8.3 Loading the ex folder hoppers .................................................45

8.4 Paper Control Lever ................................................................48

8.5 Daily Mail (Handfeed) ..............................................................49

8.5.1 Stapling Restrictions .....................................................49

8.5.2 Using Daily Mail ...........................................................49

8.5.3 Setting the Separator Gap (see also section 8.2 ‘Adjusting the

Separator’). .........................................................................50

1

Page 3

2

9 Operator Maintenance ....................................................................... 51

9.1 Cleaning the sensors ...............................................................51

9.2 Clearing paper jams ................................................................57

9.3 Changing the feed tyres ..........................................................59

9.4 Adjust the CIS reader ..............................................................60

10 Technical Specication .................................................................... 61

10.1 Inserter head .......................................................................61

10.2 Flex tower ............................................................................66

10.3 Versatile feeder ....................................................................68

10.4 Mechanical & Electrical ..........................................................69

11 Glossary of terms ............................................................................ 70

Page 4

3

1 Introduction

With this inserter you have an advanced, medium-volume folding and inserting machine.

Its modular construction allows up to 8 feed units to be tted, with a maximum of 11 feed

trays. Its sophisticated software control optimises the order and ow of documents for

collating at the insert head before insertion into the envelope. All fold and adjustments take

place automatically according to the requirements programmed in by the operator.

In order to ensure the long usage of this machine and its components, and above all the

safe use of the machine, you must read and adhere to the operating instructions and safety

notes. Always be aware of all warnings and notes that are mounted or noted on the machine

itself.

All persons entrusted with the handling of this machine must also be familiar with the

operating manual.

Save this handbook carefully, so that the information it contains may be available at all

times.

1.1 Pictograms

General Warnings

Warning of danger from electricity or electrical shock

Information / Note indicating important information regarding the handling of

the machine.

Page 5

4

1.2 Notes on the use of this handbook

This document contains all general information and explanatory text necessary in order to

be able to carry out the operation of the machine.

When some action is expected from the operator, this will always be explicitly stated, and

where relevant, accompanied by an illustration or graphic.

Always read through each step, so that you will obtain all of the necessary information. Do

not anticipate what you believe will follow in the handbook: It will prevent you from making

mistakes!

Chronology and Reference

This handbook is structured chronologically, and therefore ordered sequentially for the

operationally ready machine. It assumes that the machine has been installed in the

correct environment by an Authorised Service Engineer and that the operator or his or her

supervisor has had a degree of operator training.

When you are unfamiliar with the machine, it is best to read through the handbook from

beginning to end. You will be guided step by step, and in this way you can easily and quickly

have the machine in operation.

If you are already familiar with the machine, it will make thing easy if you use this

handbook as a reference work.

2 Safety notes

For your own safety and the operating safety of the machine, read the following notes

carefully before starting your machine. Always be aware of all warnings and notes that

are mounted or noted on the machine itself. Save this handbook carefully, so that the

information it contains may be available at all times.

The machine is of advanced construction and reliable in operation. Nevertheless, the device

does present hazards when operated by untrained personnel. The same applies to use that

is inappropriate and not in keeping with its intended purpose.

In not adhering to this handbook, there is the danger of

• an electrical shock,

• injuries from the intake at the rotating rollers,

• damage to the machine.

IMPORTANT: To stop the machine in an emergency,

open any cover.

Page 6

5

2.1 General safety notes

Caution!

Please, read these notes with care.

Save these instructions for later use.

All notes and warnings found on the machine are to be followed.

Important! The machine must be installed only by an Authorised

Installing

the

machine

Ensure there is at least 1 metre of free space between the operator side of

The machine may only be connected to a voltage of 230V/50Hz or 115V/60

Electrical

danger

The mains plug may only be connected with a socket having an installed

Service Engineer. A safe, level position is necessary, when installing the

machine, with sufcient space all round to operate it. The machine is to be

protected from moisture. If moving the machine, ensure that the castor

brakes are off, and push on the stand, not the machine.

the machine and a wall or barrier. To provide access to the mains switch, the

opposite side of the machine must be at least 150mm from a wall or barrier.

Do not place surrounding furniture or other objects where your path may be

obstructed.

Hz,depending upon model.

protective contact! The protective effect will be compromised by the use of

an extension line without a protective grounding conductor. All interruptions

of the protective grounding conductor, within or outside of the machine,

are prohibited. The device is double pole fused! When fuse failure occurs,

electrical machine parts can still carry voltage. When making the connection

to the mains power, be aware of the connection values on the nameplate.

Inspect the voltage setting on the device’s power input module. Run the

supply lines in such a way, that no-one may trip over them. Do not place any

objects upon the supply line. When the machine is not in use over a long

period of time, it should be disconnected from the power supply. In this way,

damage would be prevented in the event of excess voltage. Protect the device

from moisture. When moisture enters the machine, there is the danger of

electrical shock. Never open the machine except the top cover. For reasons

of electrical safety, the machine may only be opened by authorized Service

Agents.

Never reach into the machine when it is running! This could only occur if a

Operating

safety

The danger of injuries exists, through pulling in and crushing on the rotating

In order to prevent damage to the machine, only factory authorized accessory

Prior to cleaning the exterior of the machine, it should be disconnected from

Cleaning

the

machine

When cleaning sensors use only non-ammable airdusters, eg. part number

Cleaning

sensors

safety interlock were to fail.

rollers. In addition, keep long hair and parts of loose clothing far from the

machine in operation. If a safety interlock fails, your Service Agent must

be contacted immediately!

parts should be used.

the power supply. When cleaning the machine, do not use liquid or spray

cleaners, but only a cloth dampened with water.

9103707C. Other types may use ammable propellants, which could result in

re or explosion.

Page 7

6

In the following cases, the mains plug must be unplugged and the device

Allow

machine to

• When the mains cable or plug is worn or damaged.

be checked

• When water or other liquid has entered the device.

by the

• When the device does not function properly, in spite of

Service

Agent

• When the device has fallen down or the housing is

• When there are noticeable differences in the normal

When repair work is carried out, only original spare parts or spare parts

Spare Parts

Do not disassemble the machine any further than is described in this

Repairs

Modication is not permitted:

For safety reasons, your own reworking and modications are not

Please contact your Service Agent, for all questions relating to service and

left for the authorized Service Agents:

following the instructions provided.

damaged.

operation of the machine.

corresponding to the original parts may be used.

handbook. Other than the top cover, the opening of the machine by

unauthorized personnel is not permitted. Repairs may only be carried out

by an authorized Service Agent.

permitted.

repair. In this way, you ensure the operational safety of your machine.

2.2 End of life

The objectives of the European Community’s environment policy are, in particular, to

preserve, protect and improve the quality of the environment, protect human health and

utilise natural resources prudently and rationally. That policy is based on the precautionary

principle and principles that preventive action should be taken, that environmental damage

should as a priority be rectied at source.

Separate collection of waste is the precondition to ensure reuse and recycling of waste that

is generated at the disposal of electrical or electronic equipment and is necessary to achieve

the chosen level of protection of human health and the environment in the European

Community.

More particularly, certain materials and components of waste electrical and electronic

equipment needs selective treatment as their injudicious handling or disposing of on or into

land, water or air would represent a major threat to the environment and human health.

Page 8

7

In order to facilitate collection and treatment separated from normal domestic waste,

electrical and electronic equipment is marked with the following logo:

Do not mix with normal domestic waste.

Please use the subjoined return or

collection system dedicated to electrical

and electronic waste.

Equipment produced after

August 13 2005

Not only are you by law not allowed to dispose of the waste equipment via other wastestreams, but we encourage you to actively contribute to the success of such collection and

to the common good and better quality of life of present and future generations.

For more information on the correct disposal of this product please contact your local dealer.

Page 9

8

3 Description of machine

3.1 Description of operation

The function of the machine is to fold forms

to ‘C’, ‘Z’, ‘V’ or double forward fold, ei-

ther singly, in xed multiples or in varying

groups. Enclosures such as inserts, BR envelopes etc. may be added. Folded forms and

enclosures are collated in the collation area

in the inserter head before insertion into the

envelope. Forms may be inserted without

sealing the envelope for subsequent checking or hand insertion.

There is a batch processing facility, allowing

a preset number of cycles to be completed

before the machine automatically stops.

The machine is OMR/Barcode compatible

for use with a mark-reading feeder or tower

folder, allowing a group of forms to be collated on the track prior to folding. A number

of barcode symbologies may be read.

The machine consists of a number of modules, depending upon the build ordered -

these modules are briey described below:

• - Collates all documents

Inserter head

in a pocket before insertion, feeds the

envelope, inserts the pack and seals the

ap.

Versatile-Feeder - Feeds shortform inserts

(cards, BR envelopes, booklets etc.) onto

the track for subsequent insertion. Available as a single feeder with one feed

hopper or a double feeder with two feed

hoppers. An OMR/Barcode version (with

one feed hopper) is also available.

Feeder Folder• - Mounts on the track,

either in conjunction with a tower (see

below) or as the last station. Fitted with

one feed hopper, and folds forms up to

14” long using a 2-plate folding mechanism. An OMR/Barcode version is also

available.

Tower• - Mounts at the end of the

machine. Folds documents either separately or in groups, using an accumulator if required. Fitted with either one or

two feed pods, each consisting of either

2 x 500 sheet trays or 1 x 1000 sheet

tray. Uses a 3-plate folding mechanism.

An OMR/Barcode version is also available.

The machine is equipped with PC controlled

operating software from where jobs can be

programmed and run. The number of jobs

that can be programmed is limited only by

the capacity of the PC. Input is via touchscreen monitor or keyboard/mouse.

A daily post function can be used as an

otional feature on a tower. This allows

groups of documents, stapled or loose, to

be hand-fed; they will then be folded and

inserted into an envelope. If other hoppers

are loaded, further forms can be collated.

No manual setting of the fold plates or

envelope closer is required, these being

adjusted automatically according to the

settings in the selected program.

An optional output conveyor can be speci-

ed, to replace the standard receiving tray.

This is available in two lengths.

Page 10

9

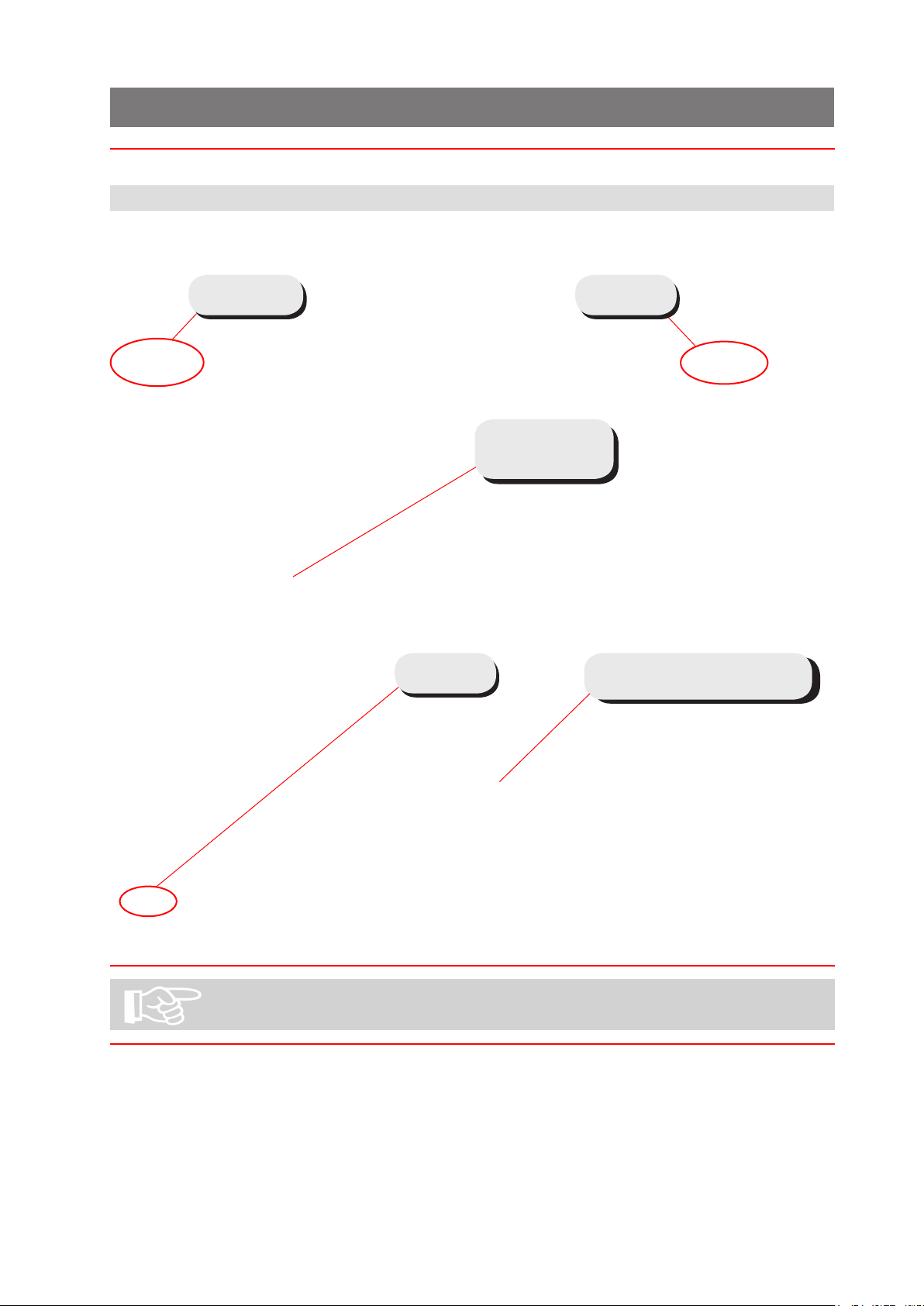

3.2 Identication of parts

The main parts of the machine are shown below.

1

2

3

4

5

6

8

1 Envelope feeder

Holds up to 800 envelopes (DL). Fiited with a sensing conveyor that operates

on demand to move the envelope stack forward.

2 Touch-screen monitor

Runs the IMOS operating software and responds to button pushes. A key-

board and mouse are also included.

7

3 Collation and insertion area

Folded forms, either singly or in groups, are collated here into one pack,

along with enclosures. The pack in then inserted into the envelope.

Note: Items 1, 2, 3 & 8 are all part of the Insertion Head Unit.

4 Versatile Feeder

These are track mounted units, with an end-station variant also available. Up

to 8 may tted (7 if a ex tower unit is tted - see below).

The Versatile Feeder feeds enclosures such as inserts, yers, BREs etc. The

hopper holds up to 1000 80gsm inserts. A mark reading variant for OMR/

Barcode/2D is also available.

5 Flex Tower

This is a folder unit and is only available as an end module. It can be tted

to the insertion head on its own, or in conjunction with Versatile Feeders. It

is tted with various options of feed trays and an accumulator (see following

page).

Page 11

10

6 Feed Pods

Fitted to the Flex Tower. Either a 1-Tray or a 2-Tray Flex Tower is available.

Each one is tted with either 2 x 500-sheet trays, or 1 x 1000-sheet tray;

both variants can be mark reading as an option.

7 Accumulator

Fitted to the Flex Tower and allows groups of forms to be collated together

before folding as a group. It is an optional item, it is also tted with a divert-

er tray.

8 Closer/Eject Area

This is where the envelope ap is closed and sealed before ejected the lled

envelope into a receiving tray or onto a conveyor.

Page 12

11

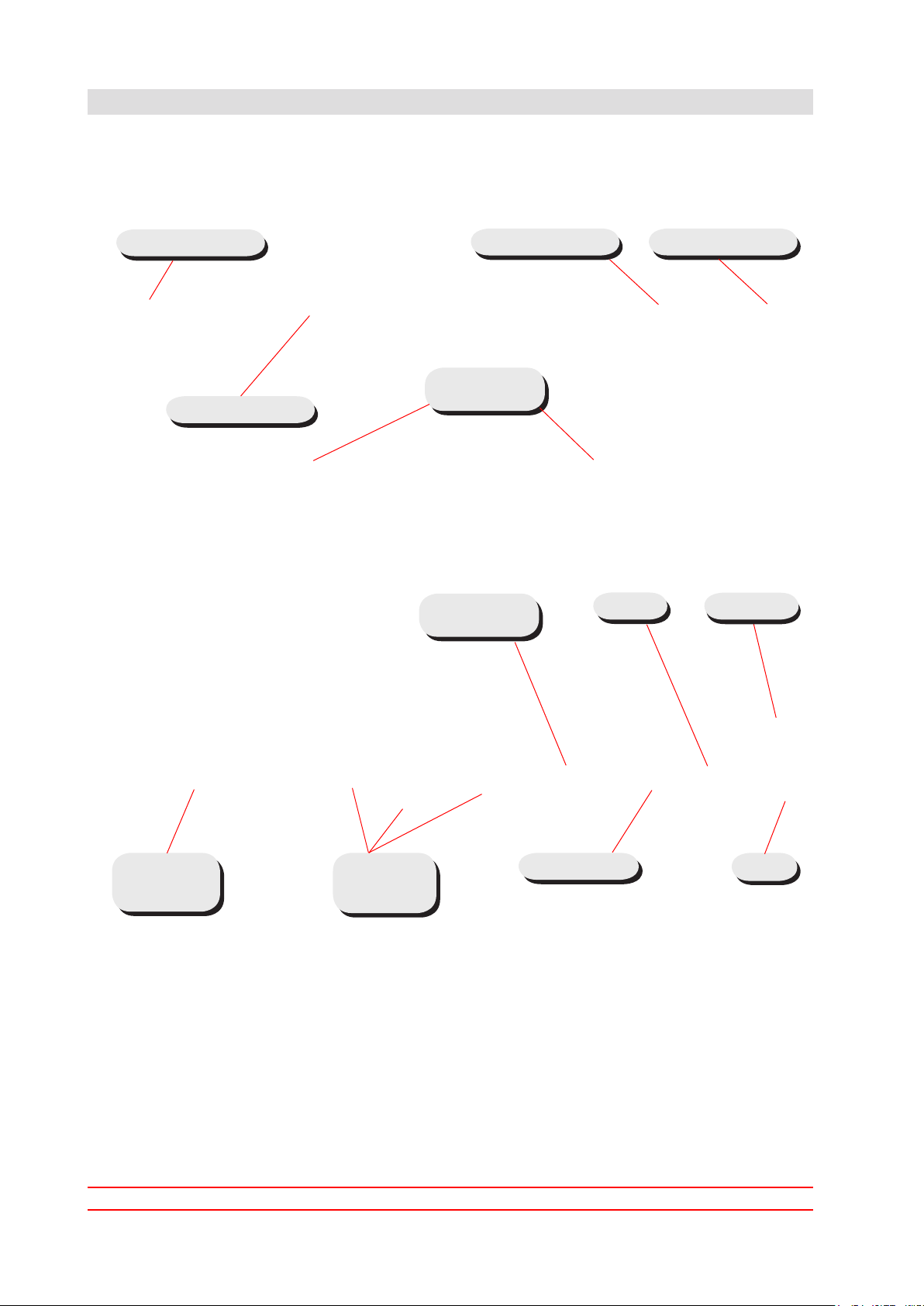

4 Control Panel

4.1 The Job Screen

This is the screen displayed when the machine starts up.

See

section 5

See

section 7

See

section 6

List of

existing jobs–

see section 5

Graphic shows machine

conguration

See section 5 for running an existing job directly from this screen.

Page 13

12

4.2 The Run Screen

4.2.1 The Run Screen displayed

This is the screen you will see after an existing job has been selected in the Job

Menu.

See section 4.1

See section 3

See section 6

Paper load

indicators

Zero the

counts etc.

Pause

Close IMOS*

Autoend

Speed

controls &

indicator

Count

& time

indicators

Single cycle

Run

* This button closes down the IMOS operating software - it does not switch the

machine off.

To change the current user or job, click on the buttons and you will be presented

with a list of all those that have been created, and allow you to select any one.

Note that to change to a different user will require the appropriate password to be

entered. To view and adjust the settings for the envelope and document inserters,

click on the relevant part of the machine graphic (see the following pages for details).

Page 14

13

4.2.2 To adjust the Envelope Inserter settings

Unit Fine Tuning

All ne adjustments apply only to the current job and will not

affect any other jobs.

Select the inserter icon on

the machine graphic in the

Run screen to display the

ne tuning screen. Select

Hardware Fine Tuning to

display further information.

You can change:

a: The width of the collate

pocket guides.

b: The overall width of the

insert ngers.

c: The time allowed for

the ap to seal before the

envelope is ejected.

d: Adjustment of the point

at which the wetter beam

drops to wet the ap. +ve

increases wetting in 1mm

steps (moves start point

towards insertion area).

e: Adjustment of the point at which the wetter beam lifts. +ve increases duration,

ie. a greater length of ap is wetted befor the beam is lifted.

f. Adjustment of the amount of envelope travel into the sealing rollers. +ve = fur-

ther forward, away from exit direction.

g. Adjustment of the envelope stop position for insertion. +ve = further forwards,

towards exit direction.

h. Adjustment of the amount of insertion of the insert pack into the env

= further forwards past the ap crease.

i. Adjustment of the amount of envelope foward tra

reversing to enter the sealing rollers. +ve = further forward into the output rollers,

towards the exit direction. Note: for high-window envelopes, this should be

set to 20 - 50mm +ve.

vel after ap wetting, before

elope. +ve

When all adjustments are complete, select the ‘Unit’ button for hopper settings, as described overleaf.

Page 15

14

Hopper Fine Tuning

From here you can adjust

hopper settings. Select the

envelope icon on the machine graphic in the Run

screen then Document

Fine Tuning to display

further information. You

can change:

a: Whether or not the envelope is sealed. Select ‘Off’ if, for example, later hand

insertion of an insert or any other item will be required.

b: The setting of the amount of envelope deskew required. Note a higher level will

slow the machine more.

Important: All ne adjustments apply only to the current job and will not

affect any other jobs.

Important: All ne adjustments apply only to the current job

and will not affect any other jobs

Page 16

15

4.2.3 To adjust the Document Unit settings

Unit Fine Tuning

The ne tuning options available will depend upon whether a

Versatile Feeder or Flex Folder is tted.

Select the document or insert icon on the machine graphic in the Run

screen to display the ne tuning screen.

Hopper Fine Tuning

From here you can adjust

hopper settings. You can

select:

a: Feed Always or not. If you

select Off, the unit is disused

until it is turned back on

again.

b: Whether doubles detection

is turned on or off. Turn off if

booklets or very thick inserts

are being fed. Note: refers only to optical detection - mechanical detection may also be tted.

c: Only for Reading units. Retrieve CIS Image - if selected, images of the label as seen

by the CIS reader will be displayed. The images will be of the nal 2 documents in the group

and can be useful for error checking by conrming that the whole label was read, for exam-

ple, or comparing the 2 images.

Important: All ne adjustments apply only to the current job

and will not affect any other jobs

Page 17

16

4.3 The Menu Screen

The Menu screen allows various functions to be selected. These functions are described in detail further in this document.

Page 18

17

5 Running an existing job

This section describes running an existing pre-programmed job. To create a new

job, see section 7.

If the IMOS operating software is not already running, it must be started using the

icon on the monitor screen. To access the PC to switch it on, open the cupboard

below the inserter head.

Before running a job, the paper hoppers must be loaded with stationery - see section 8 for details.

1 If the Job screen

is not already displayed,

press the Jobs button

at the top and select the

required job from the list

(use the scroll arrows if

needed).

2 Summary of se-

lected job is shown.

3 If you are happy

with your selection, press

Accept, otherwise, select

another job.

Page 19

18

4 Load the paper and

envelopes in the hoppers

indicated.

5 Press the Run but-

ton to begin operating.

See also section 4.2 for

a full description of the

controls.

Paper is normally loaded in the Tower face-up and feet-rst if non-

reading, face down and head-rst if reading. This may vary: see

also appendix A.

Page 20

19

6 Switching the user

6.1 How to switch the user

Each user has their own password and access rights, allocated by the Supervisor. To

switch user, the password must be known.

1 Press the Switch

User button in the Job

screen

2 Select the user

from the list. Use the

scroll arrows if necessary.

3 Press the Logon

button.

Page 21

20

4 Press the Login button.

6.2 User Access Rights

4 Enter the password

using either the keyboard

or the on-screen keypad.

The user has now

changed.

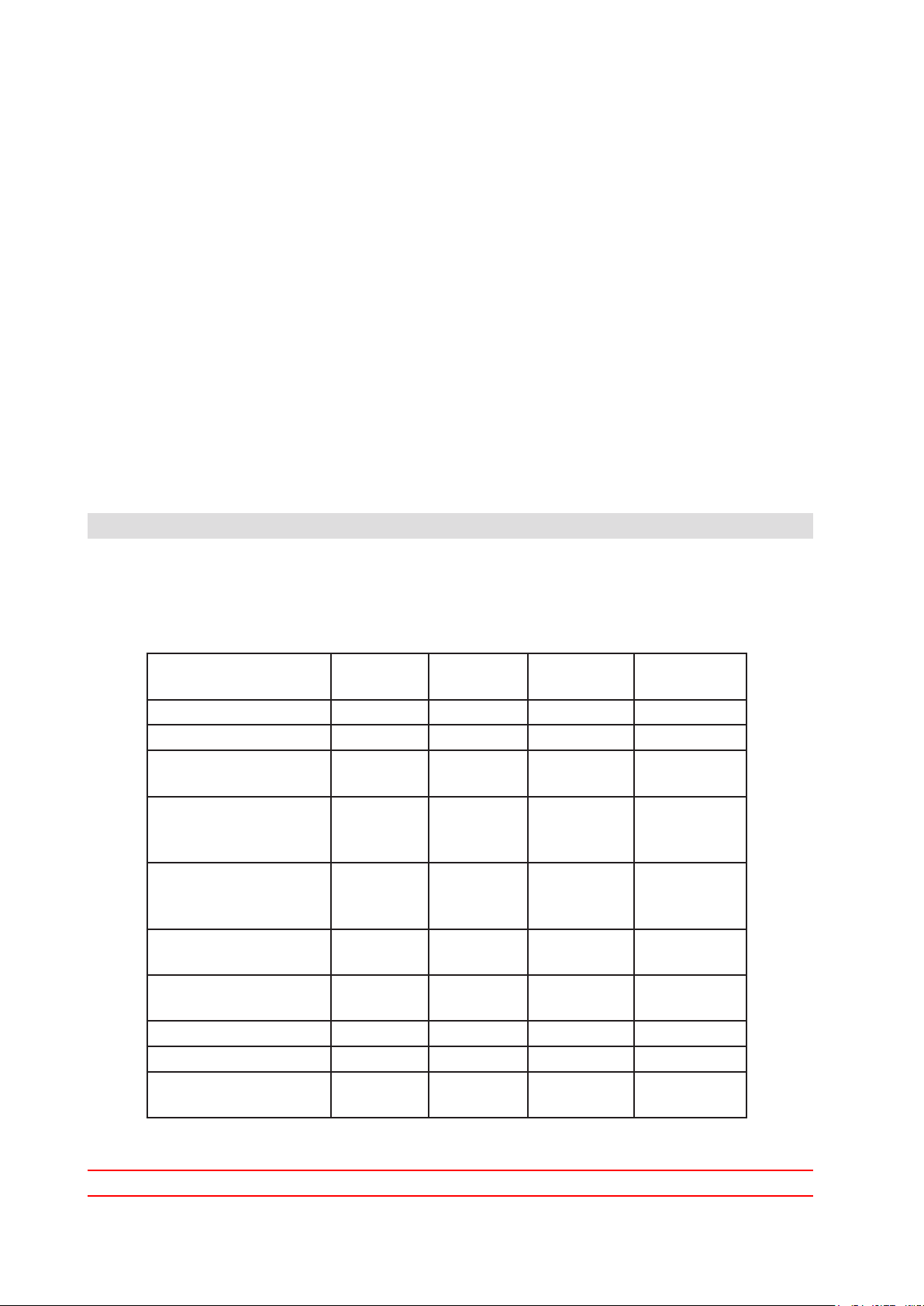

There are 4 levels of access rights that can be allocated to each user. These are

described below:

Rights Operator Expert

Operator

Change Jobs Y Y Y Y

Run Machine Y Y Y Y

Programme Jobs

with Wizard

Add items to

Libraries from

Wizard

Add Items to

Libraries from

Outside Wizard

Mechanical Fine

tuning

Document Fine

tuning

Enter Service Menu N N Y X

Enter Admin Menu N N X Y

Avoid PC shutdown

on IMOS Exit

N Y Y Y

N Y Y Y

N N Y Y

N N Y Y

N Y Y Y

N Y Y

Engineer Supervisor

Page 22

21

7 Creating a job

Creating a job consists of a number of steps:

Dening the Mailset (Envelope, document & enclosures)•

Dening the Fold Settings•

Setting required Output Options•

Saving the Job to a Jobname•

When dening the Document in the Mailset, OMR or Barcode denitions can be enabled if required.

Note that for an OMR of Barcode denition to be used it must rst have

been created - see section 7.3.

7.1 Creating the Job Settings

1 Press the Cre-

ate Job button in the Job

screen.

2 Press the Auto-

matic button.

You will now need to dene the mailset (envelope, documents and enclosures). This

is described on the following page.

Page 23

22

7.1.1 Dening the mailset

Selecting the envelope

3 Press the Select

button to choose an envelope from the available

library.

4 Select the required

envelope from the library

and press the OK button.

If there are no envelopes in the library, or if you wish to create a new

one, see section 7.3.

Page 24

23

5 You now have a

choice: carry on to select

a document, or further

dene the envelope usage, ie. sealing mode and

deskew.

The following assumes

you want to further dene

the envelope usage. When

you have nished you

will return to the screen

shown here.

Press the Settings button.

6 Select the required

Sealing mode (usually this

will be ‘Always on’).

Press the Edit advanced

button if you wish to

change the deskew setting.

Page 25

24

7 From here, you

can turn adjust the degree

of deskew, or turn it off if

you require. This might be

done to speed the ma-

chine up if, for example,

an envelope is unlikely to

skew, eg. a C5 or other

longer envelope.

The default deskew setting is ‘Low’.

Page 26

25

Selecting the document

8 Press the Select

button to choose a document from the available

library.

9 Select the required

document from the library

and press the OK button.

If there are no documents in the library, or if you wish to create a

new one, see section 7.4.

Page 27

26

10 You now have a

choice: carry on to select

enclosures, or further de-

ne the document usage,

eg. form count, cascading,

hand-feed etc.

The following assumes you

want to further dene the

document usage. When

you have nished you

will return to the screen

shown here.

Press the Settings button.

11 Adjust the forms

count if using mutliples,

whether or not cascading

is to be used, and whether

or not daily mail (handfeed) is to be used. Press

the OK button when done.

For further settings, press

the Edit Advanced button.

Page 28

27

12 If you wish to

choose an orientation other than the auto-selected

default, press Auto to enable the selector button.

If required adjust the

degree of deskew, or turn

it off if you require, for example if a document type

is found to feed reliably

without skewing.

Thickness doubles can

currently be checked opti-

cally only on a ex folder,

or turned off, if for exam-

ple, documents are substantially different from

the calibration document,

such as abnormally dark

with heavy printing.

Selecting ‘Auto’ allows the software to choose between optical and mechanical

checking if the document is moved to a versatile feeder tted with a mechanical

system.

Feed control mode is ‘Feed Always’ as default, but can be turned off to disable the

hopper. It can also e set to ‘Selective Feed’ for reading-enabled units. This works in

conjunction with ‘Item ID’ - see below.

Item ID allows you to dene an ID number for the document which accords with

the relevant Select mark in the OMR or Barcode label. This will then feed the document when that mark is read.

Sequence handling mode determines how sequence marks (if used) are handled

when a document set is broken up (for example, to change a job in the middle of a

document set). The mode must be det to ‘Full’ for the rst pass, and then changed

to ‘Mailset’ for the second pass after the job has been changed. The machine will

not then expect an unbroken sequence.

Page 29

28

Selecting the enclosure

13 If you are using

enclosures (inserts, BREs,

booklets etc.), press the

Select button.

14 Select the required

enclosure from the library

and press the OK button.

If there are no enclosures in the library, or if you wish to create a new

one, see section 7.5.

Page 30

29

15 You now have a

choice: carry on to select

further enclosures if required, remove the enclosure you have selected,

or further dene the enclosure usage, eg. form

count, cascading, handfold etc.

The following assumes you

want to further dene the

enclosure usage. When

you have nished you

will return to the screen

shown here.

Press the Settings button. Settings and Advanced Settings are same for en-

closures as for documents - see steps 12 & 13.

Paper is normally loaded in the Tower face-up and feet-rst if non-

reading, face down and head-rst if reading. This may vary: see

also orientation chart in section 8.3.

Page 31

30

16 If further enclo-

sures are required, press

the Add button and repeat

steps 13 to 18.

Repeat as required up to

the limit of available stations.

You now have a choice: to

proceed and move on to

Fold Settings, or to assign

the documents/enclosures

to specic hoppers.

The following assumes

you want to assign the

documents/enclosures to

specic hoppers. This will

override the hopper that

the software automatically

assigns.

If you do not want to assign the documents/enclosures to specic hoppers, press the Next button shown in the previous screen.

Otherwise, press the Document Placement button shown in the previous screen.

This will display a selector box:

17 Deselect ‘Auto’ to

enable the selector box.

Select the hopper that you

wish to assign the relevant

document to and press

the Ok button.

The hopper is now assigned to that document.

Page 32

31

The mailset is now dened, and the screen will show that this is ticked.

You will now dene the fold settings.

7.1.2 Dening the fold

18 The machine will

automatically select the

optimum fold type. If you

wish to change this, deselect ‘Auto’ and set the

required fold. Caution:

the machine may not

perform properly if you

change the fold type

wrongly.

If you wish to make adjustments to the fold

lengths, or just check

them, press the Adjust

fold button.

19 Make adjustments

as required and press the

OK button.

Page 33

32

20 If you wish to

make adjustments to the

collation mode or Max no.

of sheets folded together,

press the Edit advanced

settings button.

21 Choose whether to

collate leading edges of

documents as they feed

through the folder, then

folded together without

entering the accumulator, or to feed separately

into the accumulator before folding. Sheets are

fed singly by default, so

each sheet is folded and

inserted separately. Set

max number for folding

together. Groups bigger

than this will be split into

a) max number, followed

by b) remainder.

The maximum that can be fed into the accumulator defaults to 9, but can be up to

25. Note: This will depend upon the paper type.

Multi-envelope mode allows two separate jobs to be run in succession using the

same document set. If set to ‘Split Oversize’, this splits, folds and inserts as for

‘Max Fold’ described above. If set to ‘Divert Oversize’, all groups numbering greater

than the number set in ‘Divert/Split Threshold’ will be diverted to the divert tray,

and if set to ‘Divert Undersize’, the same will apply for groups below the threshold.

The machine is then stopped, the job is changed and the forms in the divert tray

are put back into the document set, and the new job is run.

‘Divert Action’ allows the option of the machine stopping automatically upon divert,

or to continue, allowing the operator to intervene.

When you have nished, fold settings are now complete and the screen will show

that this is ticked. You will now dene the output settings.

Page 34

33

7.1.3 Dening the output settings

22 Select whether

batch mode is to be used,

and the quantity. The

machine will then process

this number of cycles,

then stop. This will be

repeated until the machine

is stopped.

To dene the batch jog

steps, franker and MPPC

modes, press the Edit ad-

vanced settings button.

23 Select batch jog

steps and pause time. This

means that as each batch

is fed onto the conveyor,

it will move the specied

amount (the steps are

unitless), and pause for

the specied time.

The franking machine

mode and job are described on the following

page.

Page 35

34

Mode Options

• The franking conveyor will be run continuously while the in-

• Level 2/3 function – envelopes will not be franked.

• Level 2/3 function – envelopes will be franked

Not Used:• The franking conveyor will be driven like a standard con-

veyor, pulsed on each envelope.

Dumb:

serter is running.

Pass-through:

Franking Machine:

according to the program settings in the franking machine.

Job Options

Current Job:• Run the currently selected job ‘as-is’.

For most purposes, Mode will be set to ‘Franking Machine’ and Job

will be set to ’Current Job’.

Page 36

35

The output settings are now dened, and the screen will show that this is ticked.

You will now save the job.

7.1.4 Saving the job

24 Press the keyboard

icon to display the virtual

keyboard.

25 Enter a name for

the job using either the

virtual or physical keyboard.

Repeat steps 26 & 27 to

enter a brief description

for the job. This is the description that will appear

in the job list when the

machine is started.

26 Enter a name for

the job using either the

virtual or physical keyboard.

You have now successfully created a new job

and it will appear in the job list.

Page 37

36

7.2 Creating an envelope

In order for an envelope to appear in the envelope library, it must rst be created.

1 Begin creating a

job (see section 7.1)

2 At the point where

you need to select an envelope, press the Create

button.

3 Enter a name for

the envelope: press the

virtual keyboard icon and

enter the name using either the physical or virtual

keyboard.

Select an envelope type.

The default width and

height for that type will

then be shown. If you

want to adjust the size,

the type will change to

‘Custom’.

If you want to adjust the

envelope weight and ap

depth, press the Edit Advanced button.

Page 38

37

4 Adjust the weight

as required. Note that the

weight is the actual weight

of the envelope, not the

paper weight.

Press the Save button

when done.

The envelope will now be

available in the envelope

library under the name

you have given it.

The envelope is now fully dened and is available for use.

Page 39

38

7.3 Creating a document

In order for a document to appear in the document library, it must rst be created.

1 Begin creating a

job (see section 7.1).

2 At the point where

you need to select a document, press the Create

button.

3 Enter a name for

the document: press the

virtual keyboard icon and

enter the name using either the physical or virtual

keyboard.

Select a document type

and size. The default

width and height for that

type will then be shown.

If you want to adjust the

size, the type will change

to ‘Custom’.

If you want to make further adjustments, or se-

lect a reading denition,

press the Edit Advanced

button.

Page 40

39

4 Select the address

position. This defaults to

‘Top’; specify middle, bottom or none if required.

Specify whether the document is to be folded (eg. a

booklet iwould not be) and

its thickness and weight.

Note this is the actual

weight of the document,

not the paper weight.

The thickness is more applicable to booklets - if no

gure is specied, 80gsm

paper will be assumed.

If the document uses an OMR or barcode label, select a reading denition. Note:

this is obtained under licence as an option and must already exist on the

machine.

If the document does not use an OMR or barcode label, press the Save button, otherwise, proceed as follows.

5 Press the Region of Interest button to specify the position of the label.

6 Specify the posi-

tion of the label and press

the Save button when

done.

The document is now fully dened and is available for use.

Page 41

40

7.4 Creating an enclosure

In order for an enclosure to appear in the enclosure library, it must rst be created.

1 Begin creating a

job (see section 7.1).

2 At the point where

you need to select an enclosure, press the Create

button.

3 The procedure for

dening an enclosure is

the same as that for a

document, described in

section 7.3. It is the document type that you select

that determines whether it

appears in the document

or enclosure library.

See section 7.3 for the

remainder of the settings.

The enclosure is now fully dened and is available for use.

Page 42

41

8 Loading the paper hoppers

8.1 Loading the envelope hopper

Using the black knob,

adjust the side guide to

give 1-1.5mm clearance

each side of the

envelope.

Adjust the angle of the

backrest (see below) and

load the envelopes into

the hopper, aps forward

so that the lower edges

follow the contour of the

surface and down into

the pick-up roller. Move

the backrest forward

(see below) so the the

envelopes are fully

forward, but not tightly

packed.

Move the backrest forward by squeezing

the roller bar upwards to release the

rollers from the track.

Adjust the angle by slackening the knob

each side.

C4: Fully raised

DL/DL+: Fully lowered

Note:

If the envelopes feed erratically, try a

backrest angle in-between.

Page 43

42

8.2 Loading the versatile feeder hopper

1. Slacken the black knob

next to the side guides

(arrowed) and move the

guides to give 1-1.5mm

clearance each side of

the enclosure. Tighten

the knob.

2. Slacken the black

knob under the backrest

(arrowed) and move it

forwards to support the

enclosures as shown.

Ensure the enclosures are

directed down into the

feed rollers. Tighten the

knob.

Adjusting the separator

The separator prevents more than one enclosure being fed at a time.

To adjust the separator, turn the knob on

the back of the feed hopper.

Clockwise decreases the gap,

anti-clockwise increases it.

To set the separator gap, empty the

hopper, then slide an enclosure into the

gap and turn the knob until the separator

will just grip the enclosure as you

withdraw it.

To help you establish an initial setting,

there is a setting gauge on the separator

unit, visible after opening the feeder side

cover. See following page.

Page 44

43

1. Look into the aperture

shown and you will see

the setting gauge on the

side of the separator unit.

There is an 80gsm mark

as a starting point for

single sheets, and mm

settings underneath the 0

line for booklets etc. See

also section 8.5 ‘Daily

Post’.

2. Now adjust the gap as

previously described to

set it precisely.

For problem enclosures, the feed rollers can be changed to optional

alternatives; see section 9.3

See following page for load capacities of different stationery types.

Note: these are a guideline only - actual quantities may vary. The

label on the side quide will also provide an indication.

Page 45

44

1000 Sheets of 80gsm (20lbs

bond) or 400 BRE (DL)

130 x 2.5mm A5 Booklets

40 x 6mm A4 Booklets

500 x 0.5mm A5 Booklets

Page 46

45

8.3 Loading the ex folder hoppers

The ex folder may be tted with 500-sheet or 1000-sheet hoppers, or only a single

500-sheet hopper. The example shown has 2 x 500-sheet and 1 x 1000-sheet

hoppers.

1. On 500-sheet hoppers, slacken the black knob next to the side guides (arrowed)

and move the guides to give 1-1.5mm clearance each side.

On 1000-sheet hoppers,

slacken the black knob

above the hopper

(arrowed) and use

the tabs to move the

guides to give 1-1.5mm

clearance each side.

2. Tighten the knobs.

Paper orientation in the hoppers will depend upon the job

requirement - see the paper orientation charts on page 50.

Accumulator

If the ex folder is titted with an optional accumulator, the side guides must be

adjusted to suit the paper.

Raise the top of the accumulator so that

it locks in place and place a piece of

paper between the side guides.

Slacken the black knob next to the side

guides (arrowed) and move the guides

to give 1-1.5mm clearance each side.

Actuate the latch (arrowed) to lower the

accumulator top.

Page 47

46

Fold Plate 2

If fold-plate 2 is being used in the folding operation, it must be adjusted as shown

below (see chart on the following page for guide on fold plate usage).

1. Open the side cover on

the ex folder. Slacken

the fold plate knob

indicated and adjust it

according to the length

setting on the scale.

2. Tighten the knob.

3. Raise the two transport

assemblies so that they

latch in place, and lift the

roller assembly below

them.

4. Slide the indicated

latch away from you. This

will open fold plate 2 for

use (most applications do

not use fold plate 2).

5. Lower the roller and

transport assemblies,

ensuring they are latched

in place.

Page 48

47

Paper Orientations

Paper orientations for various applications are shown below.

European Sizes:

American Sizes:

Page 49

48

8.4 Paper Control Lever

The paper control lever is located in the collate area, and raises or lowers overguide

strips in the paper path. For normal running, the overguide strips should be lowered

to assist paper movement. However, in some cases (such as a single lightweight

sheet, or a thick pack with a lightweight prime document on top), it may assist

paper movement to raise the overguide strips.

1. Raise the perspex top cover to

obtain access to the collate area.

2. Move the lever rearwards (ie.

away from the envelope feeder)

for normal running.

3. Move the lever forwards (ie.

towards the envelope feeder) for

single sheets, lightweight prime

documents etc.

4. Lower the perspex top cover.

Page 50

49

8.5 Daily Mail (Handfeed)

Daily post allows a group of forms to be hand-fed, folded and inserted on a

Versatile Feeder. A group of forms up to a total of 6mm thick may be fed, but be

aware of the folding capacity of 8 forms of 80gsm (20lbs bond). The forms may be

stapled or not, as required (see below for stapling restrictions).

8.5.1 Stapling Restrictions

No staples in

area shown

8.5.2 Using Daily Mail

To use daily mail, dene a new mailset (as described in section 7.1.1) or edit the

document settings in an existing job.

Select Settings for the document and set ‘Daily Mail’ to Yes.

Save the document settings, then press Next until you reach the Save button to

save the job.

cont.

Page 51

50

8.5.3 Setting the Separator Gap (see also section 8.2 ‘Adjusting the Separator’).

Now set the separator gap to suit the daily mail. As a general guide, the gap should

be set to approx. 1mm greater than the pack or booklet thickness. If the document

is an 80gsm sheet, set the gap to 1mm.

If the thickness is unknown, proceed as follows:

Open the separator gap wide •

enough to allow the document

to pass through. Insert a

corner of the document

between the separator

wheels as shown - this avoids

snagging the grooves in the

tyres (particularly useful for

thin documents).

Close the separator gap until •

there is some friction on the

document, then rotate the

separator knob in reverse

direction 1 turn (this will give

clearance of 1mm).

When daily mail has been enabled as described, and the gap has been set, press

the Run button and feed the post into the hopper tray. The machine will wait

for 30 seconds after pressing the button - if you exceed this before inserting the

documents, press the button again.

To turn the function off, switch ‘Daily Mail’ back to No in Document Settings.

Page 52

51

9 Operator Maintenance

9.1 Cleaning the sensors

The optical sensors consist of two halves: emitter and receiver. These can become

obstructed due to paper dust and should periodicaly be cleaned using a non-

ammable airduster. Both halves must be cleaned.

This section shows where the sensors are located. For most sensors, an indicator

arrow is pierced showing you where the jet of the airduster should be directed. For

some sensors, the retaining bush is visible next to the lens: ensure you spray into

the lens, not the bush.

Insertion head

Sensors are retained with a bush next to the lens: where this is

visible, ensure that you spray into the lens (arrowed), not the bush.

Direct the airduster into the openings arrowed and spray liberally.

Open the perspex top

cover and raise the collate

clamshell (closest to the

envelope hopper) so that

it locks in place.

Picture shown is viewed

looking inside the collation

area towards the envelope

hopper.

Page 53

52

Picture is viewed looking

inside the collation area

away from the envelope

hopper.

Clean all sensors arrowed.

Lower the collate clamshell

and open the upper

conveyor (furthest from

the envelope hopper) so

that it locks in place.

Picture is viewed looking

inside the collation area

away from the envelope

hopper.

Insert the airduster nozzle

deep into the hole and

spray liberally. Note the

the upper sensor half is

not easy to see and is

mounted on a bar.

Lower the conveyor.

Lower the side cover and

raise the overguide inside

the closer cavity, latching

it in place.

Clean the sensors

arrowed.

Page 54

53

Picture is viewed looking

down on the envelope

hopper, at the front.

Clean the one-piece

reective sensor.

Page 55

54

Versatile Feeder

Open the feeder top

covers at the front, if the

feeder is the rst station.

If a subsequent station,

open the side cover and

approach from the side.

Picture is viewed looking

towards the front.

Clean the sensor arrowed.

The upper half is located

on a bracket above the

lower half.

Open the feeder top

covers at the front. Picture

is viewed from the side.

Clean the one-piece

reective sensor.

Page 56

55

Open the side cover and

push the lowermost lever

forward to lower the

conveyor.

Clean the sensor located

in the centre of the track

as shown, with the upper

half directly above it.

Page 57

56

Flex Folder

Open the folder top cover

and clean the sensors

indicated.

For the two sensors shown

side-by-side, direct the

nozzle of the airduster into

the gap at the front of the

them and spray liberally.

TRANSPORT

VERTICAL

TRANSPORT

ASSEMBLY

Open the side cover and

raise the two transport

assemblies so that they

latch.

Swing forward the vertical

transport assembly and

clean the sensor halves

indicated. Note: these

are not easy to see, and

a separate light such as a

torch may help.

When returning the

transport assemblies,

ensure that they latch

back into place properly.

Page 58

57

9.2 Clearing paper jams

If paper jams occur, the area affected will normally be shown in the error message

on the screen. Use one of the clearance methods described below to clear the

jammed paper.

Inserter head

Open the side cover on the operator side of the machine.

Versatile Feeder

Open the side cover on the versatile feeder.

Push forward the levers

indicated to open the

cavities and access the

jammed paper.

If the paper is not fully

visible, turn the blue

knobs to wind it into view.

Flex Folder

Open the side cover on the ex folder.

Base Unit

Using the release handles,

raise the 2 upper plattens

indicated and latch them

in place. Raise the roller

assembly below them to

access the jammed paper.

Note: the roller assembly

does not latch in place.

If the paper is not fully

visible, turn the blue

knobs to wind it into view.

Page 59

58

Tower Unit

Using the release handle,

swing open the vertical

platten indicated and latch

it in place. Raise the roller

assembly below them to

access the jammed paper.

Note: the roller assembly

does not latch in place.

If the paper is not fully

visible, turn the blue

knobs to wind it into view.

Page 60

59

9.3 Changing the feed tires

Certain documents (eg. glossy materials) may not not feed properly with the

standard feed rollers. Sets of optional feed tires are available to assist feeding.

These can be tted as follows.

Remove the 3 knobs

indicated and open the

side guides to their widest

extent.

Lift the feed bed out of the

chassis to access the feed

shafts beneath.

Slide the spring-loaded

collars inboard and lift the

feed shafts out of their

bearing hubs. The feed

tires can be pried off the

rollers and replaced with

alternative items.

When replacing the shafts,

ensure that the drive pins

are properly located in the

hubs.

Page 61

60

9.4 Adjusting the CIS reader

If a CIS reader is tted to a Flex Folder, it must be adjusted to align with the label,

as described below

On a 500-sheet hopper

pod, remove both feed

trays to access the CIS

reader as shown.

Slacken the knob and slide

the reader as required,

using the tabs. Tighten the

knob.

Note: the CIS reader

should be moved fully

left or right, depending

upon which side of the

paper the label is on.

On a 1000-sheet hopper

pod, remove all paper

from the machine and

operate a single cycle to

raise the tray.

From below the tray,

slacken the knob securing

the cover as shown, and

lift the cover out to access

the CIS reader.

Adjust the reader as

described above and

replace the cover.

Page 62

61

10 Technical Specication

Width Clearance

Envelope

Insert

Depth Clearance

10.1 Inserter head

Pack thickness Maximumpackthicknessisdenedastheinternal

dimensionofarigidopeningthatalledenvelopewillfall

throughunderitsownweight.

#10&DLEnvelopes: upto6mm(¼”)

C5/C4Envelopesandabove: upto6mm(¼”)

Pack clearance Theminimumclearancesrequiredbetweentheinsertsand

envelopesaredependentoninsertpackthickness.

Clearanceisthetotalclearanceandisdenedasthe

differencebetweenthelargestoveralldimensionsofthe

packandtheinternaldimensionsoftheenvelope(see

below).Therequiredclearancesaresummarisedas

follows:

Pack<3mm:Depth6mm(¼”)Width16mm(5/8”)

Pack>3mm<6mm:Depth12mm(½”)Width19mm(¾”)

Cycling speed Upto4800envelopesperhour(basedon1xA4folded

sheetintoaC5/C65orDLor#10(114mmx229mm)

envelope).

Upto3900envelopesperhour(basedon1xA4folded

sheetwith1xenclosureintoaC5/C6orDLor#10

(114mmx229mm)envelope).

Speedsforotherconditionsavailableonrequest.

Page 63

62

Monthly volume Up to 200,000 lled envelopes per month.

C5 or below - up to 800 of 90gsm (20lbs bond)

Envelope

C4 (at type) - up to 100gsm (28lbs bond)

Hopper

capacity

Envelope weight Minimum: C5 or below - 70gsm (18lbs bond)

Minimum: Above C5 - 90gsm (24lbs bond)

Maximum: 110gsm (28lbs bond)

General

envelope

requirements

• Envelope to be good quality machine-ll type.

Dimensions and quality to be consistent across

manufactured batches.

•

Side seams must be securely glued to the top of the

seam.

Flap crease must be pre-scored to enable the

•

envelope ap to open at.

no glue seepage must be evident on interior or •

exterior of envelope.

cont.

Page 64

63

Envelope details

Horizontal portion of throat

Max. = Envelope Width - 75mm(3")

Flap Shoulder Angle

Min.70mm (2

3

4

")

Minimum open

throat area

50°Min. 90°Max.

Min.

(

13

32

")

10mm

Throat angle

5°Min. 20°Max.

(

13

32

")

Min. 10mm

Max. = Envelope Width - 75mm(3")

Envelope Width Max. 330mm(13") Min. 225.5mm(8 7/8")

Min.70mm (2

3

4

")

Horizontal portion of throat

Flap Shoulder Angle

Body Depth

Max. 254mm(10")

Min. 98.5mm(3 7/8")

Minimum open

throat area

Min.

50°Min. 90°Max.

(

13

32

")

10mm

Throat angle

5°Min. 20°Max.

Min. 10mm

(

13

32

")

Flap Length

Max. 65mm (2½")

Min. 32mm (1

1

4

")

Side Seam style envelope

Commercial style envelope

Body Depth

Max. 254mm(10")

Min. 98.5mm(3 7/8 ")

Flap Length

Max. 65mm (2½")

Min. 32mm (1

1

4

")

Min. 10mm (

13

32

")

Max. 25mm (1")

Throat Depth

Envelope Width Max. 330mm(13") Min. 225.5mm(8 7/8")

Throat Depth

Max. 25mm (1")

Min. 10mm (

13

32

")

Page 65

64

Glue area

The bottom flap of the envelope

should be in-line or below the top of

the seam shoulders

Good example

Top edge of window to be flat

and free from puckering

Bad example - Out of

Specification

Windows to be securely affixed to

within 1.5mm (

1

16

") of top and side

edges.

Position of internal side seams to

give a minimum of 5mm (

3

16

")

clearance or overlap to the edge of

any insert

20mm minimum

14mm minimum to edge

of address carrier

Flap crease to be scored sufficiently to prevent distortion of envelope

between window and flap crease when closing and sealing.

Window width to be less than

40% of envelope width.

Page 66

65

Maximum distortion allowable on a

twisted envelope to be 10mm

(

3

8

") when envelope measured

sitting flat on a table

Built-in wetter tank, automatically pump-fed by 10-litre

Envelope

sealing uid

wetter container located in stand. Optional low-level oat

switch available.

Page 67

66

10.2 Flex tower

Paper Size Minimim width: 148mm (5¾”)

Maximum width: 305mm (12”)

Minimum length: 93mm (3 ⅝”)

Maximum length: 406mm (16”)

Paper weight Minimum 70gsm (18lbs bond)

Maximum 120gsm (32lbs bond)

Folding capacity C, Z or V-fold: 8 sheets 80gsm (18lbs bond)*

Double-forward fold: 4 sheets 80gsm (18lbs bond)*

* Multiple folded sets dependent upon pack thickness.

Hopper capacity Tower can be ordered with 1 or 2 pods, each tted with 1

or 2 hoppers as follows:

2 x 500 sheets of 80gsm (18lbs bond)

1 x 1000 sheets of 80gsm (18lbs bond)

Examples shown above are for illustration only. Other

congurations are available.

cont.

Page 68

67

Daily mail Up to 8 sheets of 80gsm (20lbs bond) for C, Z or V fold,

up to 4 sheets of 80gsm (20lbs bond) for double forward

fold, up tp 25 sheets of 80gsm (20lbs bond) unfolded.

May be stapled or not. Max. thickness of staple 3mm.

Allowable staple positions are shown below.

No staples in

area shown

Page 69

68

10.3 Versatile feeder

Enclosure Size Minimim width: 148mm (5¾”)

Maximum width: 305mm (12”)

Minimum length: 93mm (3 ⅝”)

Maximum length: 216mm (8½”)

Enclosure weight Minimum 80gsm (20lbs bond)

Maximum 6mm (¼”) thickness

Hopper capacity 1000 sheets of A4 80gsm (18lbs bond)

500 sheets of A4 Z-folded 80gsm (18lbs bond)

250 x 2.4mm booklets

400 x C5 envelopes

270 x DL envelopes

Note: quantities shown above are maxima. Depending

upon other conditions, actual quantities may be lower

than those shown.

Requirements

Some enclosures may require special tyres.

Daily mail Up to 25 sheets of 80gsm (20lbs bond) unfolded. May be

Enclosures must be exible enough to suit path

constraints.

stapled or not. Max. thickness of staple 3mm. Allowable

staple positions are shown below.

No staples in

area shown

Page 70

69

10.4 Mechanical & Electrical

Noise level:

xxdbA (3 x Versatile feeders, 1 x Flex tower, measured at 1.6m

height, 1m from nearest cover).

Heat Output (BTU/Hour):

Rated current x rated volts x 3.412 (eg. 2464 BTU/Hour for typical

conguration of 3 x versa feeders + ex tower folder).

Heat Output (Watts):

Rated current x rated volts (eg. 722W for typical conguration of 3 x

Versatile feeders + Flex tower folder).

Electrical:

230VAC 115VAC

Frequency 50Hz 60Hz

Input Current Head: 0.85A Head: 1.6A

Versa Feeder: 0.58A Versa Feeder: 1A

CIS Feeder: 0.58A CIS Feeder: 1A

Flex Tower: 0.55A Flex Tower: 1.4A

Fuse Rating T6.3A T10A

(Insert Head)

Weights:

Unpackaged Packaged

Inserter Head 97Kg 122Kg

Versatile Feeder 60Kg TBA

Flex Tower* 120Kg TBA

Conveyor 20Kg TBA

Stand Units 35Kg ea. TBA

* 2-pod version (each with 2 x 500 sheet-trays), and including accu-

mulator with diverter tray.

Sizes:

Inserter Head 1150L 550W 600H

Versatile Feeder 700L 550W 800H

Flex Folder* 1000L 550W 900H

* Fitted with 4 x 500-sheet trays and accumulator

Page 71

70

11 Glossary of terms

Term Description

Address carrier The address carrier is the document that carries the address of

the person for who the mail set is meant. The address carrier

can consist of one or more sheets, from which at least the rst

sheet must contain the address. The address must remain visible

while enclosures are added and the document set is folded. The

fold type and selected envelope must ensure that the address

is visible behind the window in the envelope. For personalized

mailings there is always an address carrier present as long as

envelope printing is not supported. Normally there is one address

carrier.

Address

position

Automatic The feature of an inserting system to automatically determine its

job settings by measuring the sizes of documents and envelope.

From all feeders that are loaded one sheet will be taken. Based

on the maximum document length (which is also the length of

the document set) and the length of the envelope the fold type is

determined.

Automatic job A job that is created with the Automatic job functionality.

Barcode

Reading (BCR)

Business Reply

Envelope (BRE)

Cascading See Feeder linking.

C-fold See Letter fold.

Daily Post Capability of an inserting system to manually insert mail sets one

Deskew A system of straightening a skewed document or enclosure

Document A document is one of the components of a mail set. A document

Barcode Reading is intended for reading and interpreting printed

barcodes. The codes give information to the inserting system

about how to build-up and handle a set.

Envelope included in outgoing mail sets for addressee response

purposes.

by one into the system, which are then inserted into an envelope.

Optionally, depending on settings, additional enclosures can be

added and the mail set can be folded. This function is intended

for small amounts of mail that each can have a different build-up.

by driving it into a set of drive rollers that have been briey

stopped. This removes the skew, and after a set period of time,

the rollers restart. Deskew slows the machine down and can be

disabled or adjusted for amount of deskew for forms that are not

prone to skewing.

can consist of one or more sheets. Documents can be divided

into address carriers and enclosures. For personalized mailings

there is always one address carrier and an optional number of

enclosures.

Position of the address on the address carrier,

measured from the upper left corner. The address

position consists of a horizontal x coordinate, a

vertical y coordinate, a horizontal width w and a

vertical height h.

Page 72

71

Term Description

Document set The document set is the physical collection of address carrier and

enclosure(s) that is under production in the inserting system.

The document set is completed during production and is to be

inserted into the envelope. The number of enclosures can range

from 0 to the limit imposed by the number of available feeders,

whilst observing the overall pack thickness. Once the document

set has been inserted into an envelope it is called mail set.

Double

Document

Detection

Double parallel

fold

Double Document Detection is the sensor that measures the

thickness of a sheet to check if the inserting system does not

accidentally take more sheets than intended. DD sensors exist

on feeders (double sheet detection). Currently DD detection

on Neopost inserting systems perform relative measurements,

which means that they need a cycle to ‘learn' the thickness of

a sheet. Also the length of the document is measured so partly

overlapping sheets will be detected.

The double parallel fold is a type of fold where the document is

rst folded halfway and the resulting folded set is again folded

halfway. This fold is illustrated in the picture below. The position

of both folds is adjustable.

Envelope The envelope is the packaging of a mail set. Window envelopes

are envelopes that have a transparent section through which the

address on the address carrier can be read. Besides the normal

top closing window envelopes there are also bottom closing

envelopes.

Face down Situation in which the front of a sheet is facing downwards when

placed in a document feeder.

Face down

leading

Face down

trailing

Face up Situation in which the front of a sheet is facing upwards when

Face up leading Situation in which the front of a sheet is facing upwards and the

Face up trailing Situation in which the front of a sheet is facing upwards and

Feeder A feeder is a module for the input of documents to the inserting

Situation in which the front of a sheet is facing downwards

and the top of the sheet is closest to the separation unit in a

document feeder, ie. the front end of the tray.

Situation in which the front of a sheet is facing downwards and

the bottom of the sheet is closest to the separation unit in a

document feeder, ie. the front end of the tray.

placed in a document feeder.

top of the sheet is closest to the separation unit in a document

feeder, ie. the front end of the tray.

the bottom of the sheet is closest to the separation unit in a

document feeder, ie. the front end of the tray.

system. The feeder separates documents sheet by sheet from the

stack of documents in the feeder tray.

Page 73

72

Term Description

Feeder linking

(Cascading)

Feeder tray Part of the feeder that contains the stack of documents or

Flexcode OMR An OMR code for which the meaning of the OMR marks can be

FlexFeed® The exFeed® is the feeding part of the system.

High Capacity

Feeder

High Capacity

Vertical Stacker

Insert To insert is the action of inserting a document set into an

Inserter An inserter is the module where the document set is inserted into

Inserting

system

Insert‘n

Frank™

(mailing

system)

Job A job is an actually produced collection of mail sets based on

Job counter The counter that registers the number of mail sets that is

Letter fold

(also known as

C-fold)

Linking See Cascade.

+LFDSIHHGHU Feeder with high capacity feeder tray.

Multiples The feature of an inserting system in which more than one sheet

OMR Optical Mark Recognition (see further table entry).

OMR code

denition

Operator The person operating an inserting system.

The ability to load two feeders with the same document type

where the inserting system automatically switches to a second

feeder when the rst feeder is empty and vice versa. In the mean

time the rst feeder can be relled, so the inserting system can

keep running without having to stop for relling the feeders.

envelopes.

programmed in a dedicated way for a specic customer. This is

normally used to support the OMR codes from other suppliers.

Feeder that has a capacity up to 1000 sheets (on a Tower unit).

Optional stacker that is mounted on the exit of the system, to

stack lled envelopes.

•

envelope.

For native English speaking customers an insert is also a short •

document, not to be folded, usually an enclosure.

the envelope, the envelope is closed and if necessary sealed.

The system of all the modules that cooperate to perform the

inserting function (accumulate document set, fold and insert) and

have a single point of control.

Interface for the Neopost franking system.

a certain job denition at a certain point in time for a specic

purpose. It consists of:

•

The job denition used for the production

Information about the batch size•

produced as part of a specic job.

Fold type in which a document set is folded twice in which the

folded aps are on top of each other. This fold is illustrated

below. The position of both folds is adjustable.

is taken from a feeder.

Standard 1-track OMR code denition. Species the amount

of reading marks used and the functionality linked to each of

them (how each should be interpreted). A denition is a licenced

option.

Page 74

73

Term Description

Optical Mark

Recognition

(OMR)

Output

Conveyor

Pod The feed hopper unit tted to a Tower. A Tower is available with

Reading error Condition in which the system could not reliably read or interpret

Reading marks Marks added to documents containing nishing instructions that

Receiving tray Fitted at the output for lled envelopes to be ejected into. Basic

Remote

diagnostics

Service

engineer

Single fold A single fold implies the document set is folded once. The fold

Optical Mark Recognition is intended for reading and interpreting

printed codes. These codes are one or more black marks which

are read from a document. These marks give information to the

inserting system about how to build-up and handle a set.

Fitted at the output for lled envelopes to be ejected onto. Higher

capacity alternative to a receiving tray. 2 lengths are available.

either 1 or 2 pods, each one consisting of either 2 x 500-sheet

trays or 1 x 1000-sheet tray.

the OMR reading marks or barcode from a sheet.

can be identied by an reading head and interpreted according to

the used OMR code denition.

alternative to an Output Conveyor.

The feature that makes it is possible to analyze a problem on an

inserting system from a remote location.

Technical engineer whose task it is to resolve problems with

systems in the eld. Besides dealing with problems, service

engineers are also responsible for preventive maintenance.

position is adjustable. This fold is illustrated below:

Stop counter Counter which sets the amount of envelopes to be lled. After

lling this amount of envelopes the system will stop.

Supervisor Person who is responsible for the technical state of the system.

Normally a supervisor has access to programming functions,

which are restricted for standard users.

Test run A test run is intended to validate the settings of the inserting

system:

•

Inspect and adjust the stop position of the envelope.

Check the fold settings for one set.•

Check whether the address is correctly positioned behind the •

envelope window.

Tray (or

hopper)

Vertical

transport

Contains a stack of paper for a printer or inserter. This paper is

supplied to the system for further processing.

The vertical transport section between hoppers and folder/

collator below .

Page 75

74

Term Description

Z-fold (also

known as

zigzag fold)

A Z-fold means that a document is folded twice in such a

way that each folded ap is on a different size of the folded

document, resulting in a Z-shape. This fold is illustrated below.

The position of both folds is adjustable.

Page 76

Page intentionally

left blank

76

Loading...

Loading...