Page 1

7102 Series / 7102XT Series

High-Capacity Modular Inserter Systems

11/2014

OPERATOR MANUAL

Page 2

Table of Contents

Introduction ...................................................................................................11

Introduction.......................................................................................................1

Safety notes ...................................................................................................32

Safety notes.....................................................................................................3

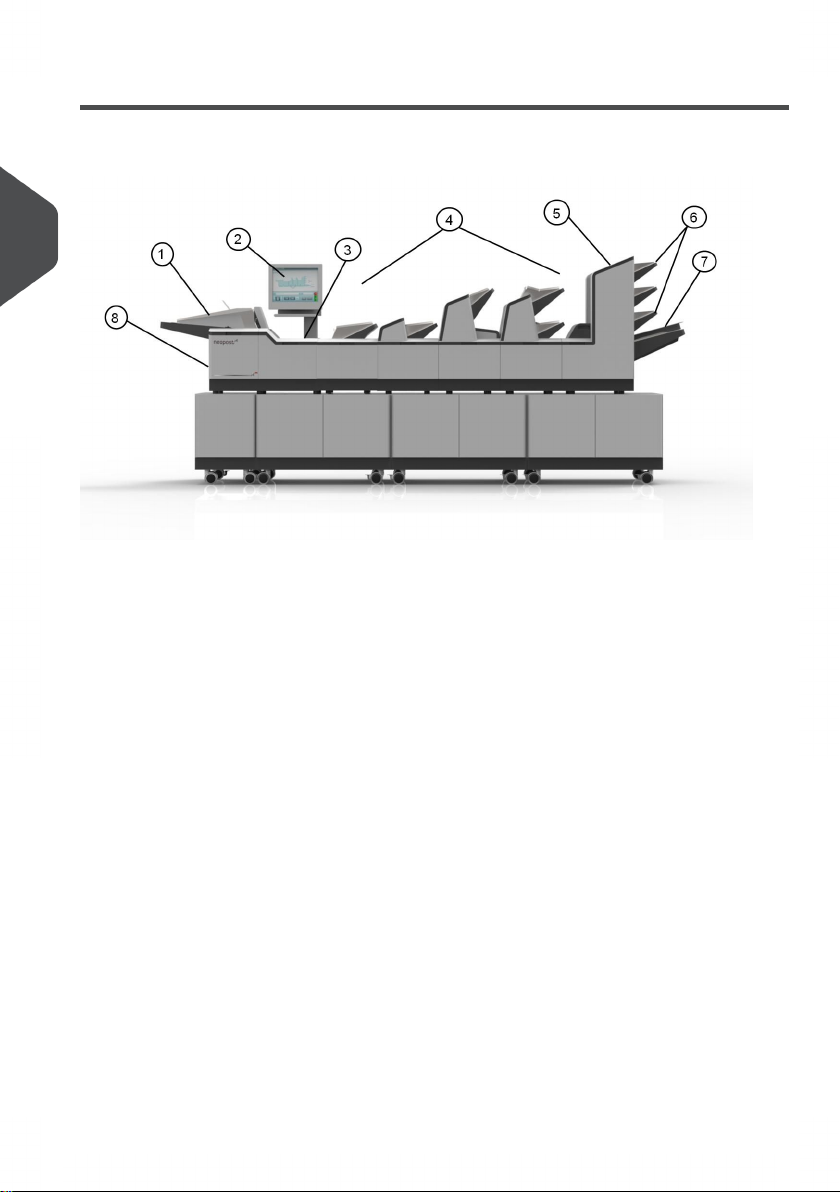

Description of machine ................................................................................73

Description of operation...................................................................................7

Identification of parts........................................................................................8

Control Panel ...............................................................................................104

The Job Screen..............................................................................................10

The Run Screen.............................................................................................11

The Menu Screen...........................................................................................20

Running an existing job .............................................................................215

Running an existing job..................................................................................21

Switching the user ......................................................................................236

How to switch the user...................................................................................23

User Access Rights........................................................................................24

Creating a job ..............................................................................................267

Creating a job.................................................................................................26

Creating the Job Settings...............................................................................26

Creating an envelope.....................................................................................45

Creating a document......................................................................................47

Creating an enclosure....................................................................................50

Loading the paper hoppers ........................................................................518

Loading the envelope hopper.........................................................................51

Loading the feeder hopper.............................................................................54

Loading the tower folder hoppers...................................................................56

Page 3

Daily Mail (Tower Folder)................................................................................66

Adjusting the catch tray..................................................................................69

Operator Maintenance ................................................................................709

Cleaning the sensors......................................................................................70

Clearing paper jams.......................................................................................78

Technical Specification ..............................................................................8110

Inserter head..................................................................................................81

Tower Folder...................................................................................................84

Insert Feeder..................................................................................................86

Feeder Folder.................................................................................................87

Mechanical & Electrical..................................................................................88

Glossary of terms .......................................................................................9111

Glossary of terms...........................................................................................91

Page 4

Introduction1

Introduction

With this inserter you have an advanced, medium-volume folding and inserting machine.

Its modular construction allows multiple feed units to be fitted, with a maximum of 17 feed

units for 7102XT and 9 feed units for 7102. Its sophisticated software control optimises

the order and flow of documents for collating at the insert head before insertion into the

envelope. All fold and adjustments take place automatically according to the requirements

programmed in by the operator.

In order to ensure the long usage of this machine and its components, and above all the

safe use of the machine, you must read and adhere to the operating instructions and safety

notes. Always be aware of all warnings and notes that are mounted or noted on the machine

itself.

All persons entrusted with the handling of this machine must also be familiar with the

operating manual.

Save this handbook carefully, so that the information it contains may be available at all

times.

Pictograms

General Warnings

1

English

Warning of danger from electricity or electrical shock

Information / Note indicating important information regarding the handling of the machine.

1

Page 5

Notes on the use of this handbook

This document contains all general information and explanatory text necessary in order to

1

be able to carry out the operation of the machine.

When some action is expected from the operator, this will always be explicitly stated, and

where relevant, accompanied by an illustration or graphic.

Always read through each step, so that you will obtain all of the necessary information. Do

English

not anticipate what you believe will follow in the handbook: It will prevent you from making

mistakes!

Chronology and Reference

This handbook is structured chronologically, and therefore ordered sequentially for the

operationally ready machine. It assumes that the machine has been installed in the correct

environment by an Authorised Service Engineer and that the operator or his or her supervisor

has had a degree of operator training.

When you are unfamiliar with the machine, it is best to read through the handbook from

beginning to end. You will be guided step by step, and in this way you can easily and quickly

have the machine in operation.

If you are already familiar with the machine, it will make things easy if you use this handbook

as a reference work.

2

Page 6

Safety notes2

Safety notes

For your own safety and the operating safety of the machine, read the following notes

carefully before starting your machine. Always be aware of all warnings and notes that are

mounted or noted on the machine itself. Save this handbook carefully, so that the information

it contains may be available at all times.

The machine is of advanced construction and reliable in operation. Nevertheless, the device

does present hazards when operated by untrained personnel. The same applies to use

that is inappropriate and not in keeping with its intended purpose.

In not adhering to this handbook, there is the danger of

• An electrical shock.

• Injuries from the intake at the rotating rollers.

• Damage to the machine.

To stop the machine in an emergency, open any cover.

General safety notes

Please, read these notes with care.

Save these instructions for later use.

All notes and warnings found on the machine are to be followed.

2

English

Installing the machine

The machine must be installed only by an Authorised Service

Engineer.

3

Page 7

A safe, level position is necessary, when installing the machine, with sufficient space all

round to operate it. The machine is to be protected from moisture. If moving the machine,

ensure that the castor brakes are off, and push on the stand, not the machine.

Ensure there is at least 1 metre of free space between the operator side of the machine

and a wall or barrier. To provide access to the mains switch, the opposite side of the machine

must be at least 150mm from a wall or barrier. Do not place surrounding furniture or other

objects where your path may be obstructed.

2

Electrical danger

The machine may only be connected to a voltage of 230V/50Hz or 115V/60 Hz,depending

upon model.

English

The mains plug may only be connected with a socket having an installed protective contact!

The protective effect will be compromised by the use of an extension line without a protective

grounding conductor. All interruptions of the protective grounding conductor, within or

outside of the machine, are prohibited. The device is double pole fused! When fuse failure

occurs, electrical machine parts can still carry voltage. When making the connection to the

mains power, be aware of the connection values on the nameplate. Inspect the voltage

setting on the device’s power input module. Run the supply lines in such a way, that no-one

may trip over them. Do not place any objects upon the supply line. When the machine is

not in use over a long period of time, it should be disconnected from the power supply. In

this way, damage would be prevented in the event of excess voltage. Protect the device

from moisture. When moisture enters the machine, there is the danger of electrical shock.

Never open the machine except the top cover. For reasons of electrical safety, the machine

may only be opened by authorized Service Agents.

Operating safety

Never reach into the machine when it is running! This could only occur if a safety interlock

were to fail.

The danger of injuries exists, through pulling in and crushing on the rotating rollers. In

addition, keep long hair and parts of loose clothing far from the machine in operation. If a

safety interlock fails, your Service Agent must be contacted immediately!

In order to prevent damage to the machine, only factory authorized accessory parts should

be used.

Cleaning the machine

Prior to cleaning the exterior of the machine, it should be disconnected from the power

supply. When cleaning the machine, do not use liquid or spray cleaners, but only a cloth

dampened with water.

Cleaning sensors

When cleaning sensors use only non-flammable airdusters.

Other types may use flammable propellants, which could result in fire or explosion.

Allow machine to be checked by the Service Technician

In the following cases, the mains plug must be unplugged and the device left for the

authorized Service Technician:

• When the mains cable or plug is worn or damaged.

• When water or other liquid has entered the device.

• When the device does not function properly, in spite of following the instructions

provided.

• When the device has fallen down or the housing is damaged.

• When there are noticeable differences in the normal operation of the machine.

4

Page 8

Spare Parts

When repair work is carried out, only original spare parts or spare parts corresponding to

the original parts may be used.

Repairs

Do not disassemble the machine any further than is described in this handbook. Other than

the top cover, the opening of the machine by unauthorized personnel is not permitted.

Repairs may only be carried out by an authorized Service Technician.

Modification is not permitted:

For safety reasons, your own reworking and modifications are not permitted.

Please contact your Service Techncian, for all questions relating to

service and repair. In this way, you ensure the operational safety

of your machine.

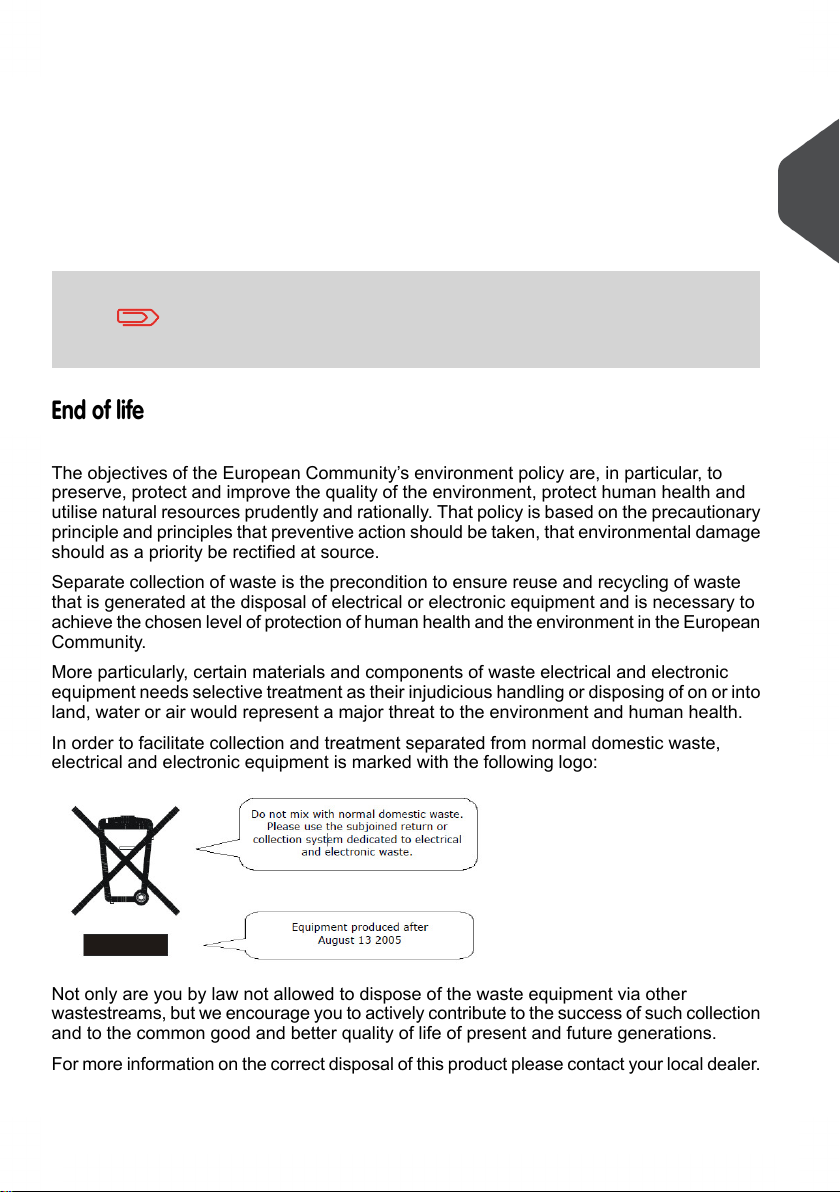

End of life

The objectives of the European Community’s environment policy are, in particular, to

preserve, protect and improve the quality of the environment, protect human health and

utilise natural resources prudently and rationally. That policy is based on the precautionary

principle and principles that preventive action should be taken, that environmental damage

should as a priority be rectified at source.

Separate collection of waste is the precondition to ensure reuse and recycling of waste

that is generated at the disposal of electrical or electronic equipment and is necessary to

achieve the chosen level of protection of human health and the environment in the European

Community.

More particularly, certain materials and components of waste electrical and electronic

equipment needs selective treatment as their injudicious handling or disposing of on or into

land, water or air would represent a major threat to the environment and human health.

In order to facilitate collection and treatment separated from normal domestic waste,

electrical and electronic equipment is marked with the following logo:

2

English

Not only are you by law not allowed to dispose of the waste equipment via other

wastestreams, but we encourage you to actively contribute to the success of such collection

and to the common good and better quality of life of present and future generations.

For more information on the correct disposal of this product please contact your local dealer.

5

Page 9

FCC Compliance

This equipment has been tested and found to comply with the limits

for a Class B digital device, pursuant to Part 15 of the FCC Rules.

2

This equipment generates, uses and can radiate radio frequency energy and, if not installed

English

and used in accordance with the instructions, may cause harmful interference to radio

communications. However there is no guarantee that interference will not occur in a particular

installation.

If this equipment does cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user is encouraged to try to

correct the interference by one or more of the following measures:

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

• Consult the Technical Support department for help.

These limits are designed to provide reasonable protection against

harmful interference in a residential installation.

Changes or modifications not expressly approved by the party

responsible for compliance could void the user’s authority to operate

the equipment.

6

Page 10

Description of machine3

Description of operation

The function of the machine is to fold forms to ‘C’, ‘Z’, ‘V’ or double forward fold, either

singly, in fixed multiples or in varying groups. Enclosures such as inserts, BR envelopes

etc. may be added. Folded forms and enclosures are collated in the collation area in the

inserter head before insertion into the envelope. Forms may be inserted without sealing

the envelope for subsequent checking or hand insertion.

There is a batch processing facility, allowing a preset number of cycles to be completed

before the machine automatically stops.

The machine is OMR/Barcode/2D compatible for use with a reading feeder or tower folder,

allowing a group of forms to be collated on the track prior to folding. A number of barcode

symbologies may be read.

The machine consists of a number of modules, depending upon the build ordered - these

modules are briefly described below:

• Inserter head - Collates all documents in a pocket before insertion, feeds the

envelope, inserts the pack and seals the flap.

• Feeder - Feeds shortform inserts (cards, BR envelopes, booklets etc.) onto the track

for subsequent insertion. Available with single or twin feed hoppers. An

OMR/Barcode/2D version is also available.

• Feeder Folder - Track mounted folder for folding document inserts. Fitted with a

2-plate folder mechanism for C, Z or V folds. Single hopper only.

• Tower Folder - Mounts at the end of the machine. Folds documents either separately

or in groups, using an accumulator if required. Fitted with either a 1 x 1000, 3 x 500

or 1 x 1000 plus 1 x 500 sheet trays. Uses a 3-plate folding mechanism. An

OMR/Barcode version is also available (top or bottom read).

The machine is equipped with PC controlled operating software from where jobs can be

programmed and run. The number of jobs that can be programmed is limited only by the

capacity of the PC. Input is via touchscreen monitor.

A daily mail function can be used as an optional feature on a flex folder or versatile feeder.

This allows groups of documents, stapled or loose, to be hand-fed; they will then be folded

and inserted into an envelope (flex folder only). If other hoppers are loaded, further forms

can be collated.

No manual setting of the fold plates or envelope closer is required, these being adjusted

automatically according to the settings in the selected program.

The envelope output conveyor replace a standard receiving tray, and can be installed

in two possible orientations, straight-on or at a 90-degree angle to the system.

3

English

7

Page 11

Identification of parts

The main parts of the machine are shown below.

3

English

8

Page 12

1. Envelope feeder

Holds up to RU800 envelopes (;7). Fitted with aVHQVLQJ conveyor

that operates ondemand to move the envelope stack forward.

2. Touch-sensitive monitor

Runs the IMOS operating software and responds to button pushes.

3. Collation and insertion area

Folded forms, either singly or in groups, are collated here into one pack, along with

enclosures. The pack in then inserted into the envelope.

4. Feeders/Folders

These are track mounted units, with an end-station variant also available. Up to 17

feed trays for a ;7 for a may be fitted.

The feeder (single or twin) feeds enclosures such as inserts, flyers, BREs etc. The

hopper holds up to 1000 inserts. A reading variant for OMR/ BCR/2D is

also available, as is a feeder folder for long documents.

5. Tower Folder

This is a folder unit and is only available as an end module. It can be fitted to the

insertion head on its own, or in conjunction with feeders. It is fitted with various options

of feedWUD\V and an accumulator (see following page).

6. Feed Trays

Fitted to the Tower Folder. 3 options available: 3 x 500-Tray, 1 x 500 with 1 x

1000-Trays & 1 x00-Tray; all variants can be mark reading as an option.

7. Accumulator

$WWDFKHG to the Flex Tower and allows groups of forms to be collated together before

folding as a group.,W is also fitted with a diverter tray

8. Closer/Eject Area

This is where the envelope flap is closed and sealed before ejected the filled envelope

into a receiving tray or onto a conveyor.

3

English

Items 1, 2, 3 & 8 are all part of the Insertion Head Unit.

9

Page 13

Control Panel4

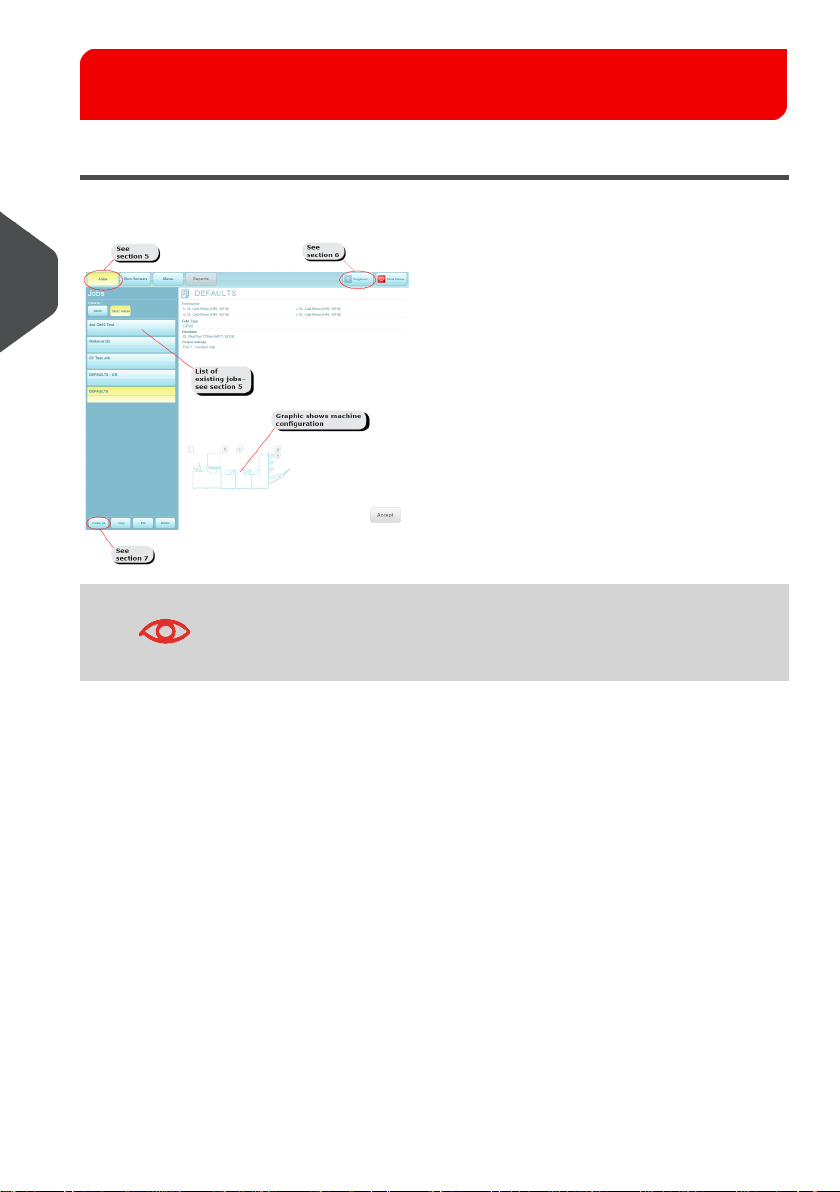

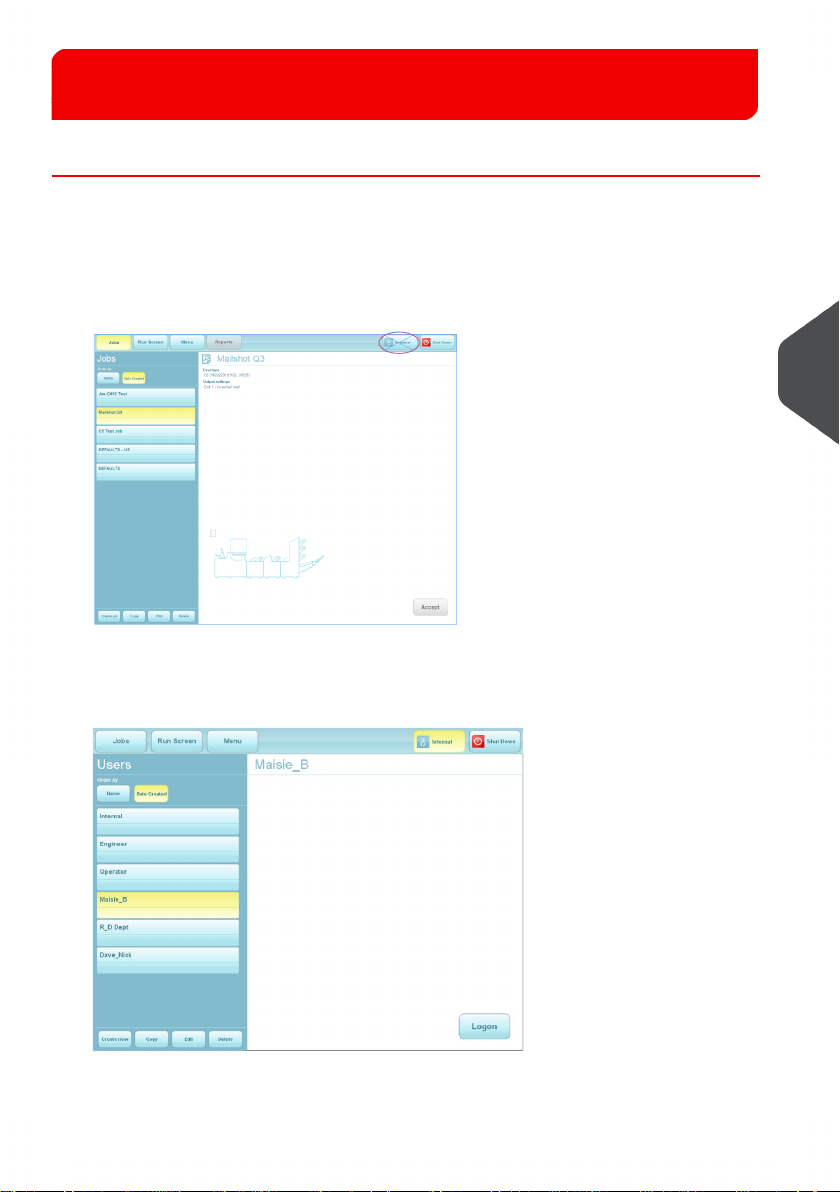

The Job Screen

This is the screen displayed when the machine starts up.

4

English

See Running an Existing Job on page 21 for running an existing

job directly from this screen.

10

Page 14

The Run Screen

The Run Screen displayed

This is the screen you will see after an existing job has been selected in the Job Menu.

* This button closes down the IMOS operating software - it does not switch the machine

off.

To change the current user or job, click on the buttons and you will be presented with a list

of all those that have been created, and allow you to select any one. Note that to change

to a different user will require the appropriate password to be entered. To view and adjust

the settings for the envelope and document inserters, click on the relevant part of the

machine graphic (see the following pages for details).

Important: you must be logged in as Supervisor to change the current user or job.

4

English

11

Page 15

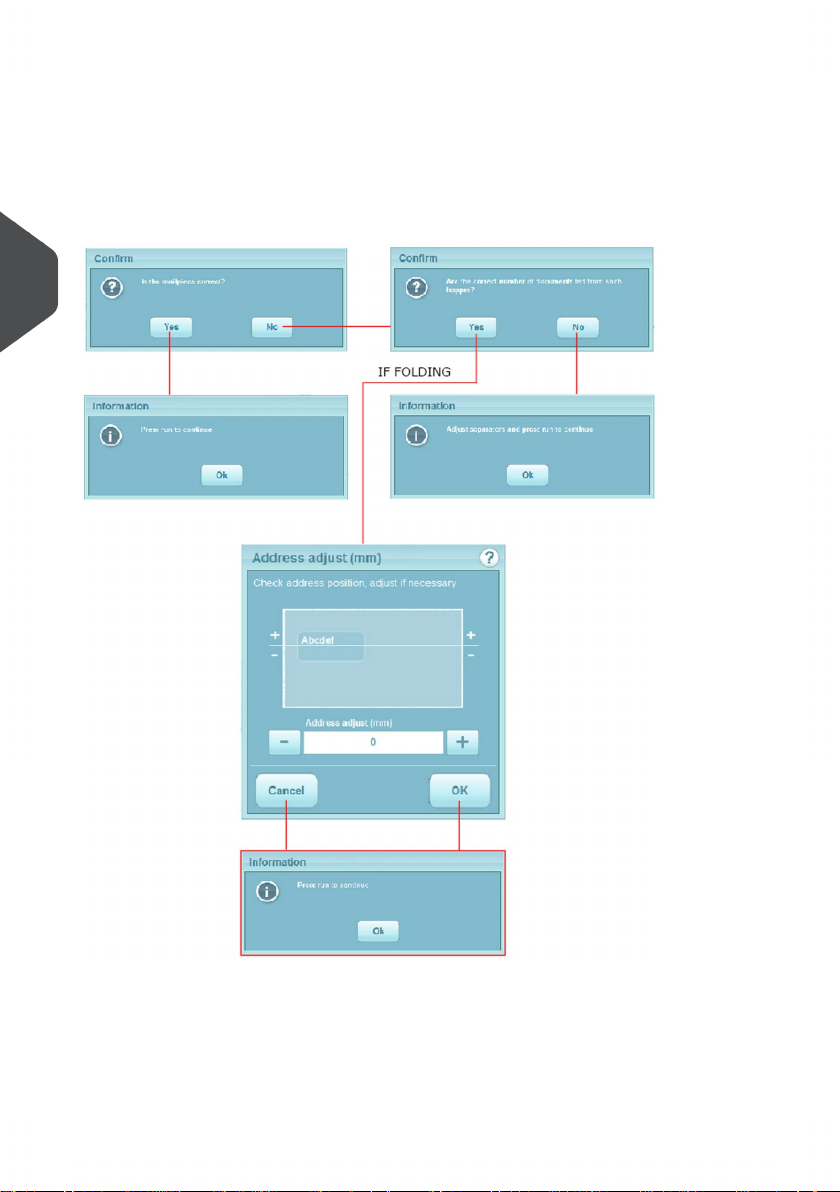

Address adjustment

After pressing the Run button, the first piece will be processed and the machine will stop

to allow you to adjust the vertical alignment of the address, if required.

Remove the filled envelope and adjust as necessary, as shown below:

4

English

12

Page 16

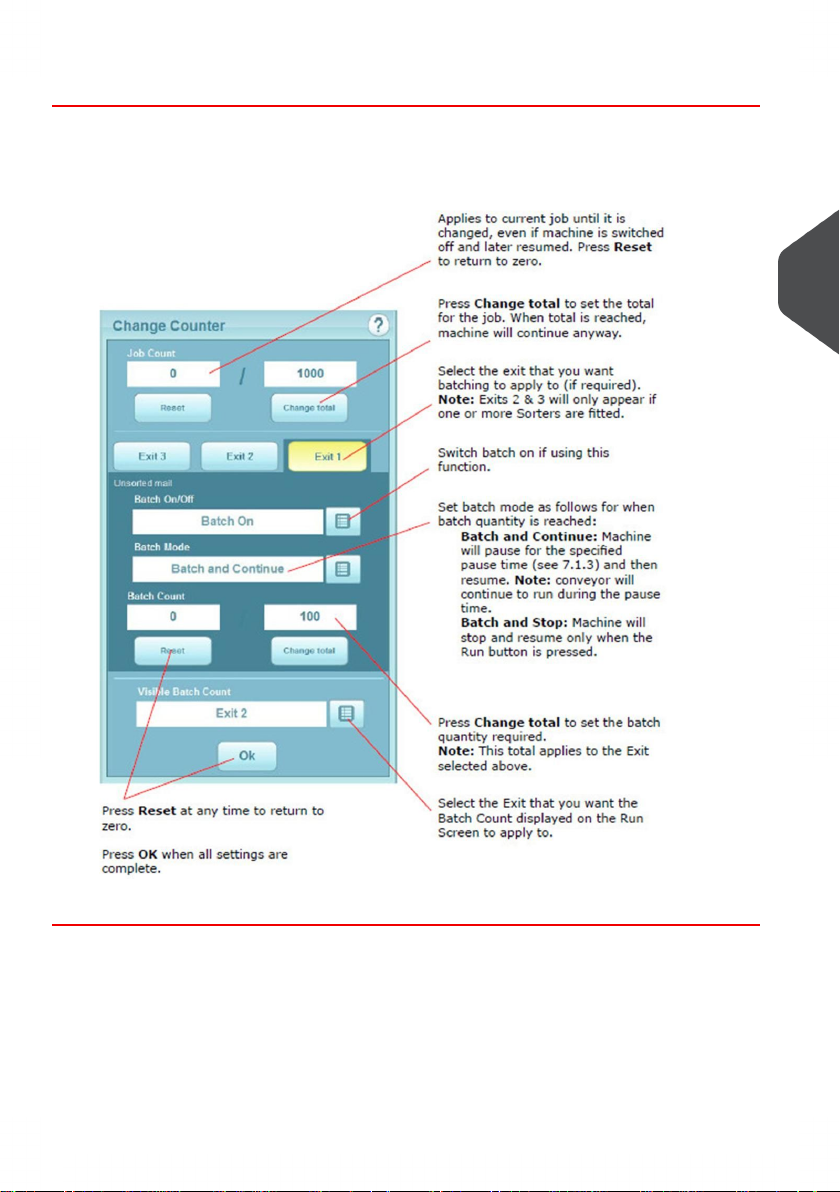

Counters Settings

Press the Edit button next to the counters to display the Change Counter box as

1.

follows:

4

English

13

Page 17

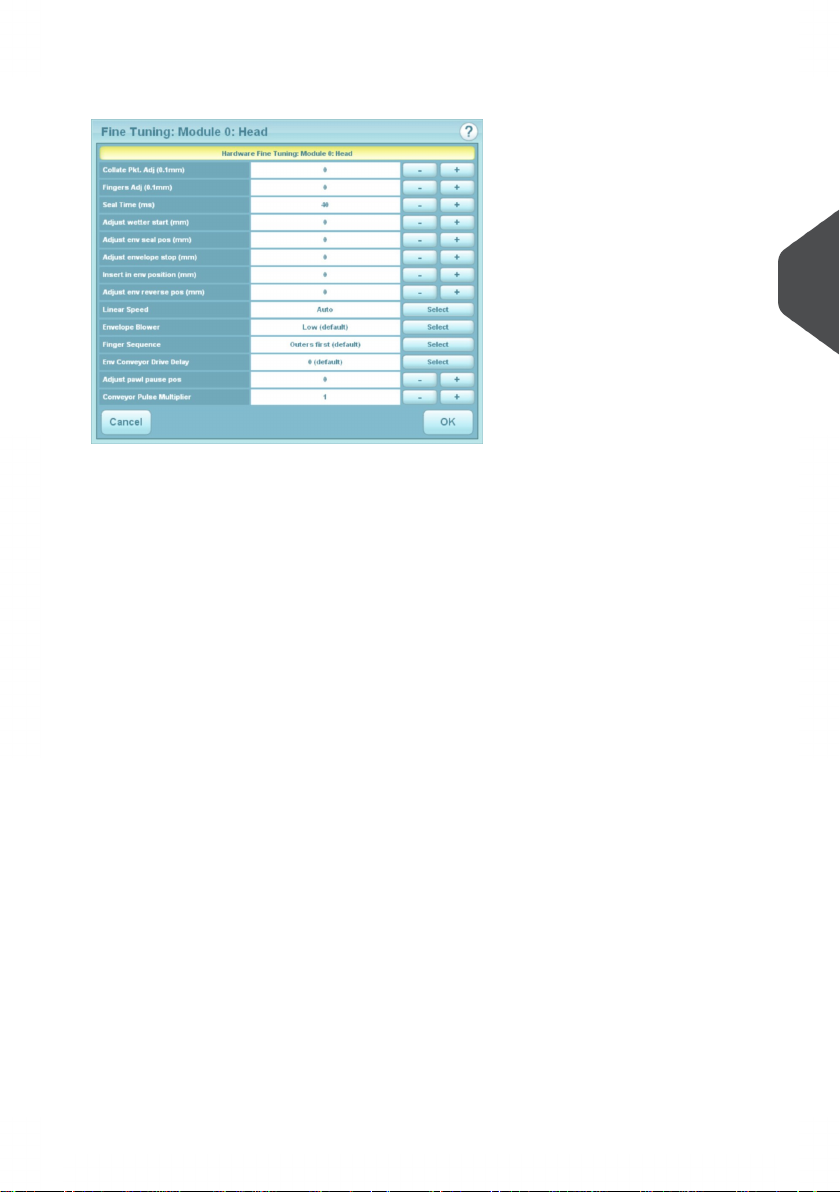

Adjusting the Envelope Inserter settings

Unit Fine Tuning

All fine adjustments apply only to the current job and will not affect

any other jobs. Note also that settings available will depend upon

user access rights (see User Access Right on page 24).

4

1. Select the inserter icon on the machine graphic in the Run screen to display the fine

tuning screen.

English

14

Page 18

2. Select Hardware Fine Tuning to display further information.

You can change:

- The width of the collate pocket guides.

- The overall width of the insert fingers.

- The time allowed for the flap to seal before the envelope is ejected.

- Adjustment of the point at which the wetter beam drops to wet the flap. +ve

increases wetting in 1mm steps (moves start point towards insertion area).

- Adjustment of the amount of envelope travel into the sealing rollers. +ve = further

forward, away from exit direction.

- Adjustment of the envelope stop position for insertion. +ve = further forwards,

towards exit direction.

- Adjustment of the amount of insertion of the insert pack into the envelope. +ve

= further forwards past the flap crease.

- Adjustment of the amount of envelope forward travel after flap wetting, before

reversing to enter the sealing rollers. +ve = further forward into the output rollers,

towards the exit direction. for high-window envelopes, this should be set to

20 - 50mm +ve.

- Adjustment of inserter head speed. Set a lower speed if insert packs are not

being fully inserted, eg. for long packs.

- Control of blower fan which assists envelope opening. Increase to open envelope

more, eg. for thick packs, decrease for single sheets or thin packs.

- Changing finger sequence if envelopes are not opening properly. Try other

settings if this is the case.

- Adjustment of number of envelopes that will feed before the detection flags

switches the conveyor back on after it has stopped. Increase number if envelopes

are ‘bunching’.

- Adjustment of degree of pause of the insertion pawls after inserting pack.

Increase if pawls start moving too soon and contacting inserted pack before it

has moved towards closer.

- Control of the overlap of sealed packs on the output conveyor. Higher number

will increase conveyor speed and reduce overlap.

- Collate Slowdown: Select ‘Not on Last Form’ for thick packs if the final document

in the pack does not feed fully into the collate pocket.

4

English

15

Page 19

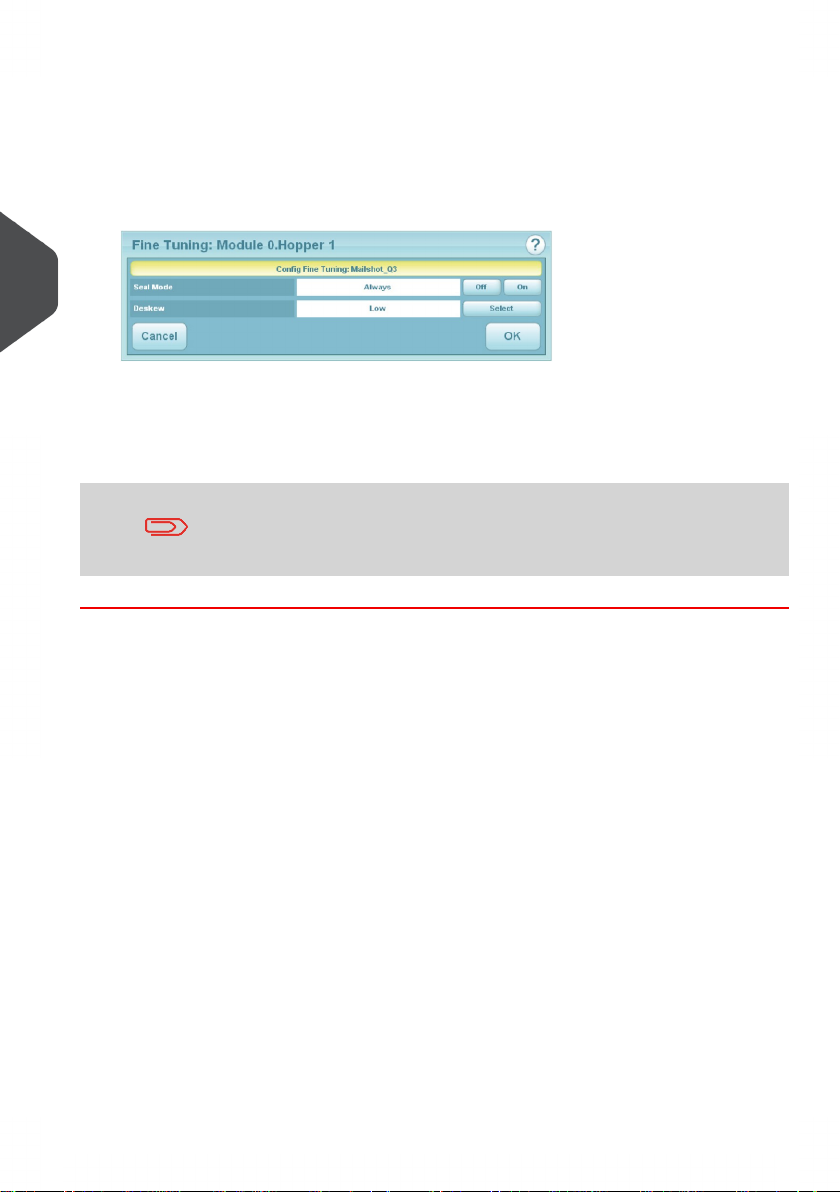

3. When all adjustments are complete, select the 'Unit' button for hopper settings, as

described below.

Hopper Fine Tuning

1. From here you can adjust hopper settings. Select the envelope icon on the machine

graphic in the Run screen then Document Fine Tuning to display further information.

4

English

You can change:

- Whether or not the envelope is sealed. Select ‘Off’ if, for example, later hand

insertion of an insert or any other item will be required.

- The setting of the amount of envelope deskew required. use higher settings

only when necessary – machine operates faster on lower settings.

All fine adjustments apply only to the current job and will not affect

any other jobs

16

Page 20

Adjusting the Document Unit settings

Unit Fine Tuning

The fine tuning options available will depend upon whether a

Feeder or Tower Folder is fitted. Note also that settings available

will depend upon user access rights (see User Access Rights on

page 24).

1. Select the document or insert icon on the machine graphic in the Run screen to display

the fine tuning screen.

4

English

17

Page 21

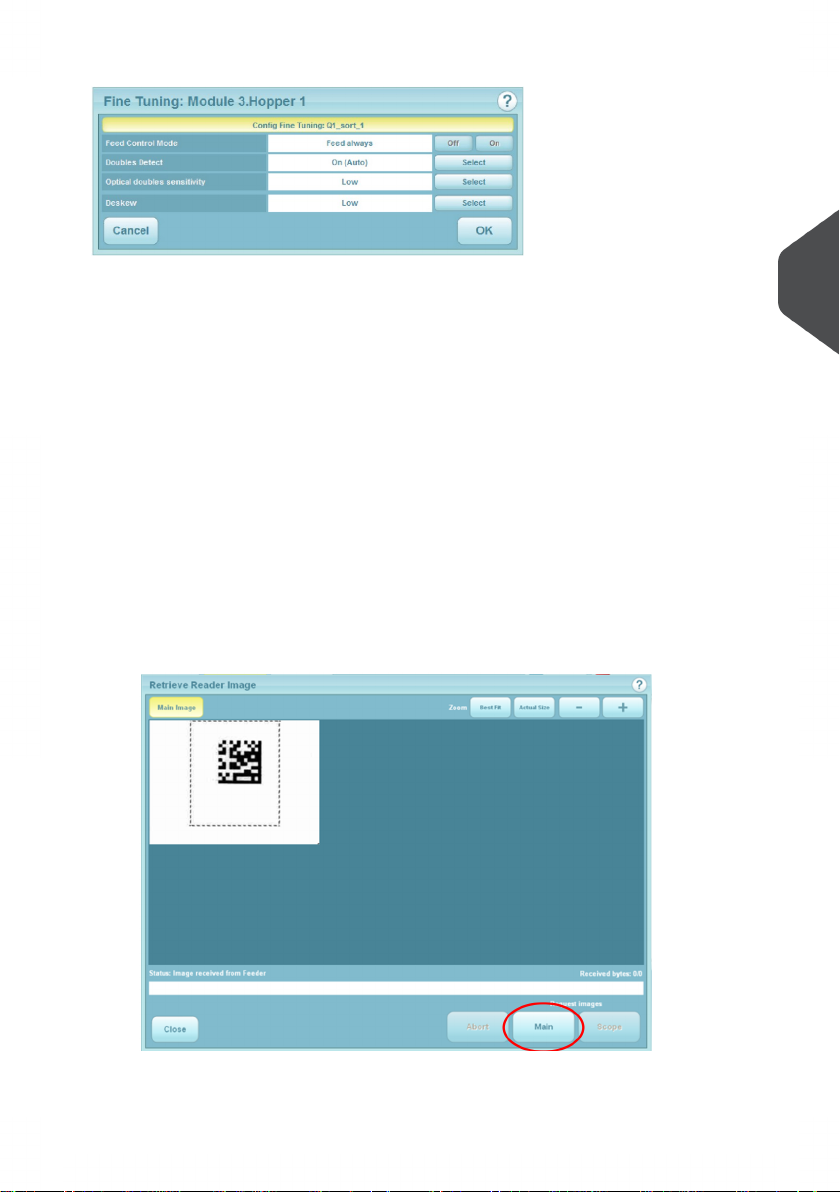

Hopper Fine Tuning

1. From here you can adjust hopper settings (depends per module due to DFC).

4

English

18

Page 22

You can select:

- Feed Always or not. If you select Off, the unit is disused until it is turned back

on again.

- Whether doubles detection is turned on or off. Turn off if booklets or very thick

inserts are being fed. If turned on, select whether Optical or Mechanical detection,

or Auto (software decides).

- Optical doubles sensitivity (valid only if Optical Doubles On is selected). Low

set-ting is more tolerant to high contrast printing.

- Amount of deskew; use higher settings only when necessary – machine operates

faster on lower settings.

- Only for Reading units. Reset Seq. Count - if Sequence OMR marks are being

used and the job is disrupted for any reason, select this button to reset the

sequence.

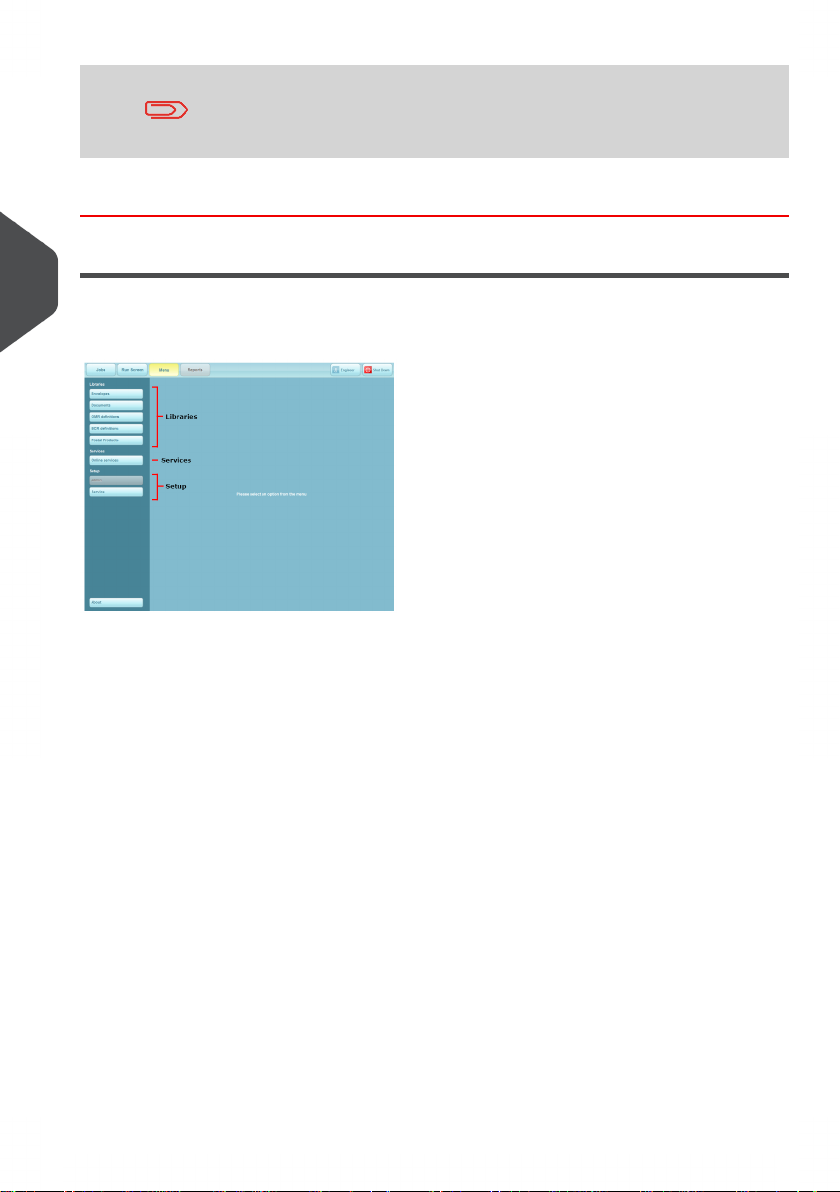

- Only for Reading units. Retrieve CIS Image - if selected, images of the label

as seen by the CIS reader will be displayed. The images will be of the final 2

documents in the group and can be useful for error checking by confirming that

the whole label was read, for example, or comparing the 2 images.

-

4

English

19

Page 23

All fine adjustments apply only to the current job and will not affect

any other jobs

The Menu Screen

4

The Menu screen allows various functions to be selected. These functions are described

in detail further in this document.

English

20

Page 24

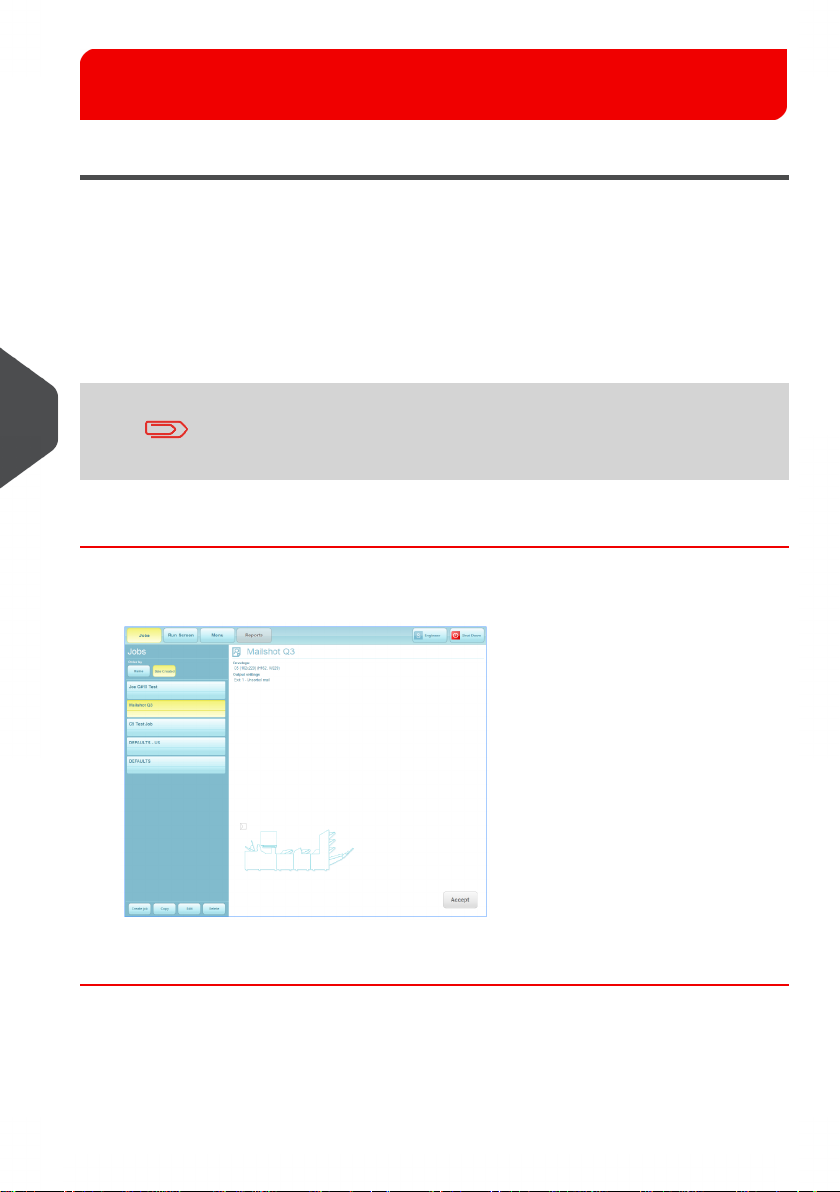

Running an existing job5

Running an existing job

This section describes running an existing pre-programmed job. To create a new job, see

Creating a job on page 26.

If the IMOS operating software is not already running, it must be started using the icon on

the monitor screen. To access the PC to switch it on, open the cupboard door below the

inserter head.

Before running a job, the paper hoppers must be loaded with stationery - see Loading the

paper hoppers on page 51 for details.

5

Paper is normally loaded in the Tower face-up and feet-first if

non-reading, but may be either way up if reading, depending upon

whether top or bottom reading. See also appendix A.

When using the cascade function, the Run button must be pressed

while the machine is still running, after you have reloaded the empty

hopper. This ensures the paper is fed to its pre-load position.

If this is not carried out the machine will stop, even though the

hopper is full: if this happens, press the Run button to continue.

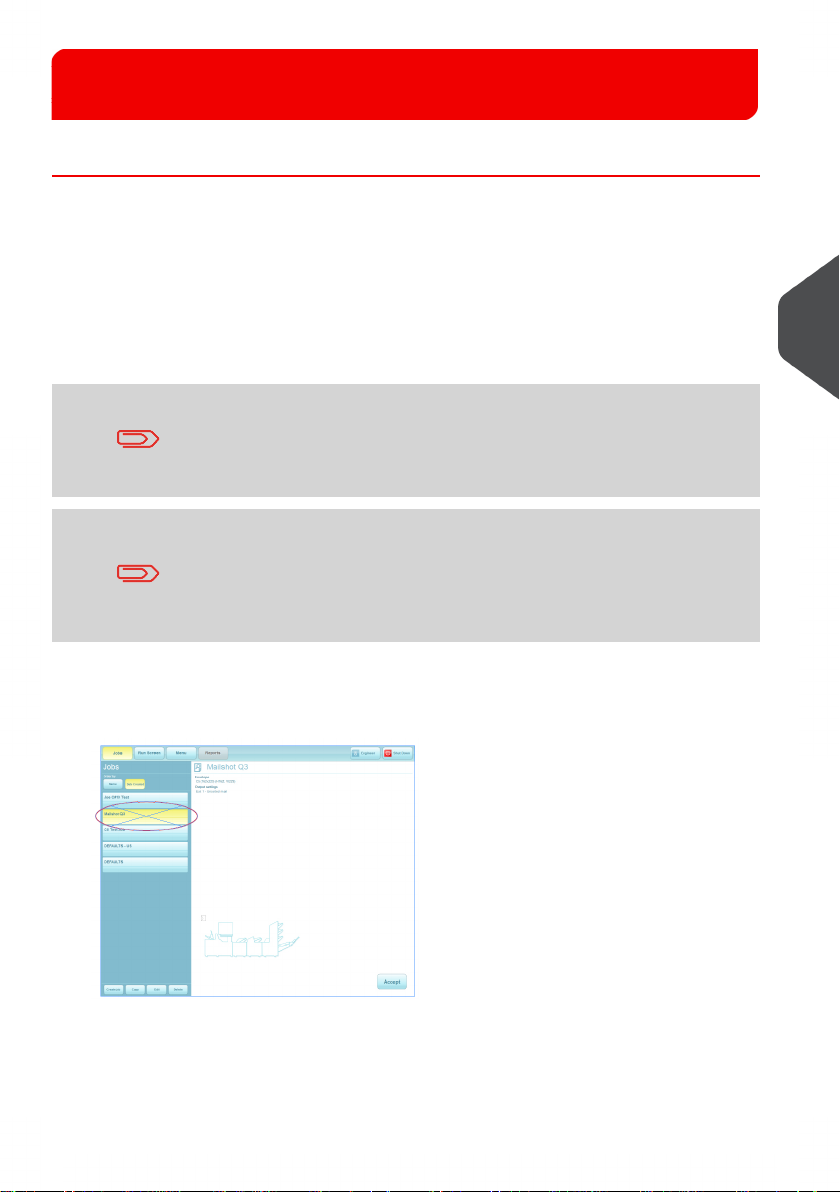

1. If the Job screen is not already displayed, press the Jobs button at the top and select

the required job from the list (use the scroll arrows if needed).

English

2. Summary of selected job is shown.

21

Page 25

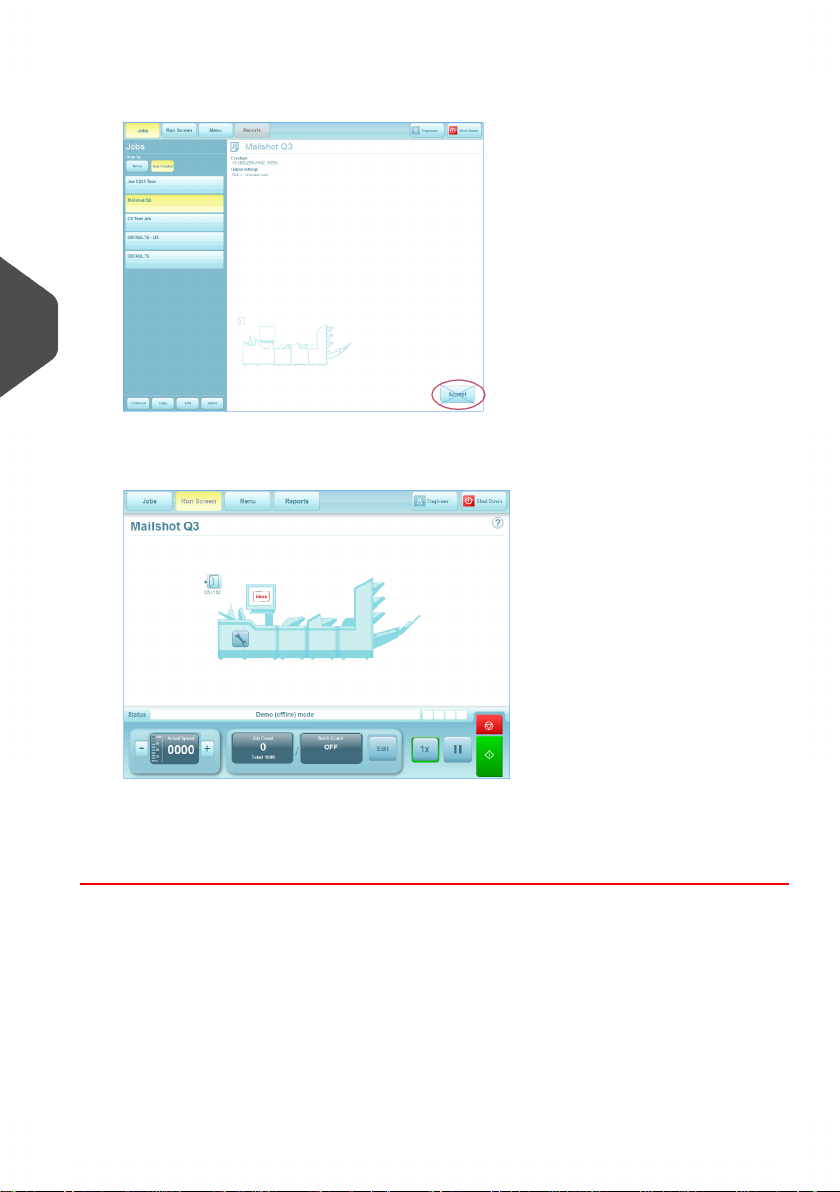

3. If you are happy with your selection, press Accept, otherwise, select another job.

5

English

4. Load the paper and envelopes in the hoppers indicated.

5. Press the Run button to begin operating.

See also The Run Screen on page 11 for a full description of the controls.

22

Page 26

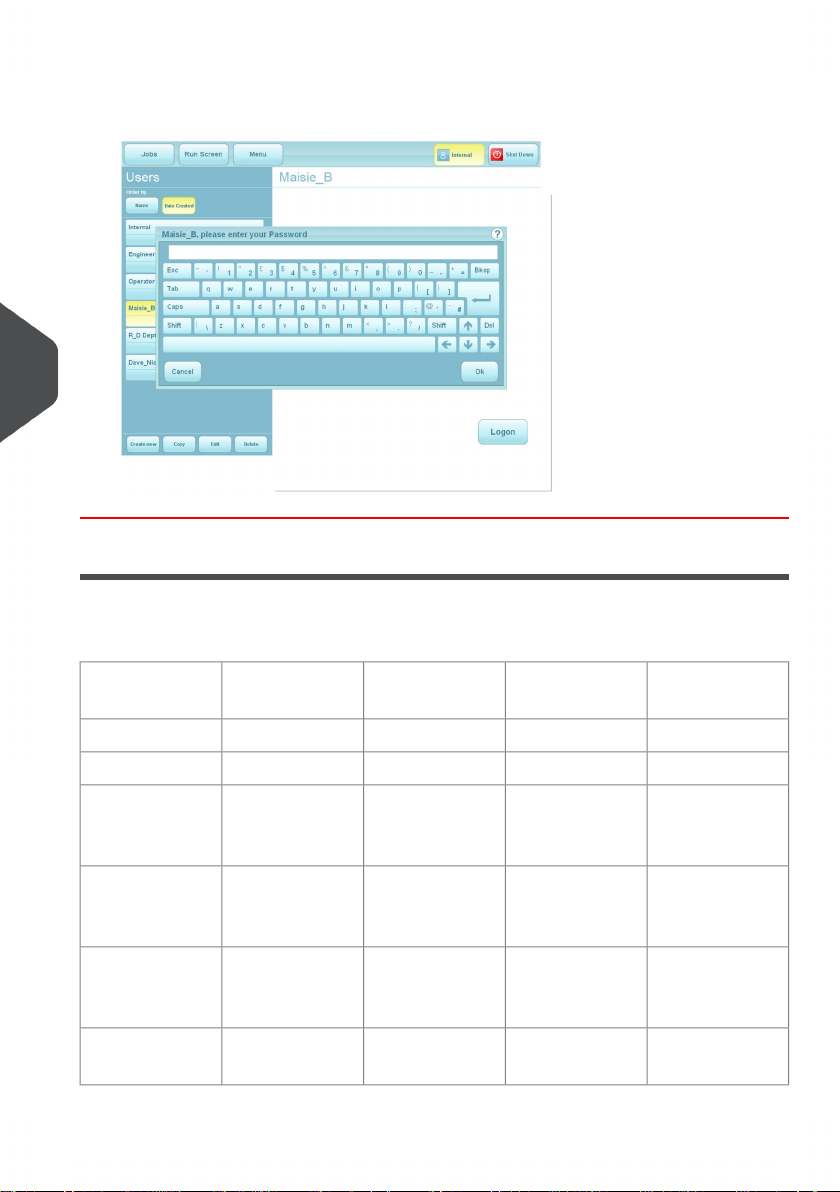

Switching the user6

How to switch the user

Each user has their own password and access rights, allocated by the Supervisor. To switch

user, the password must be known.

Press the Switch User button in the Job screen1.

2. Select the user from the list. Use the scroll arrows if necessary.

3. Press the Logon button.

6

English

23

Page 27

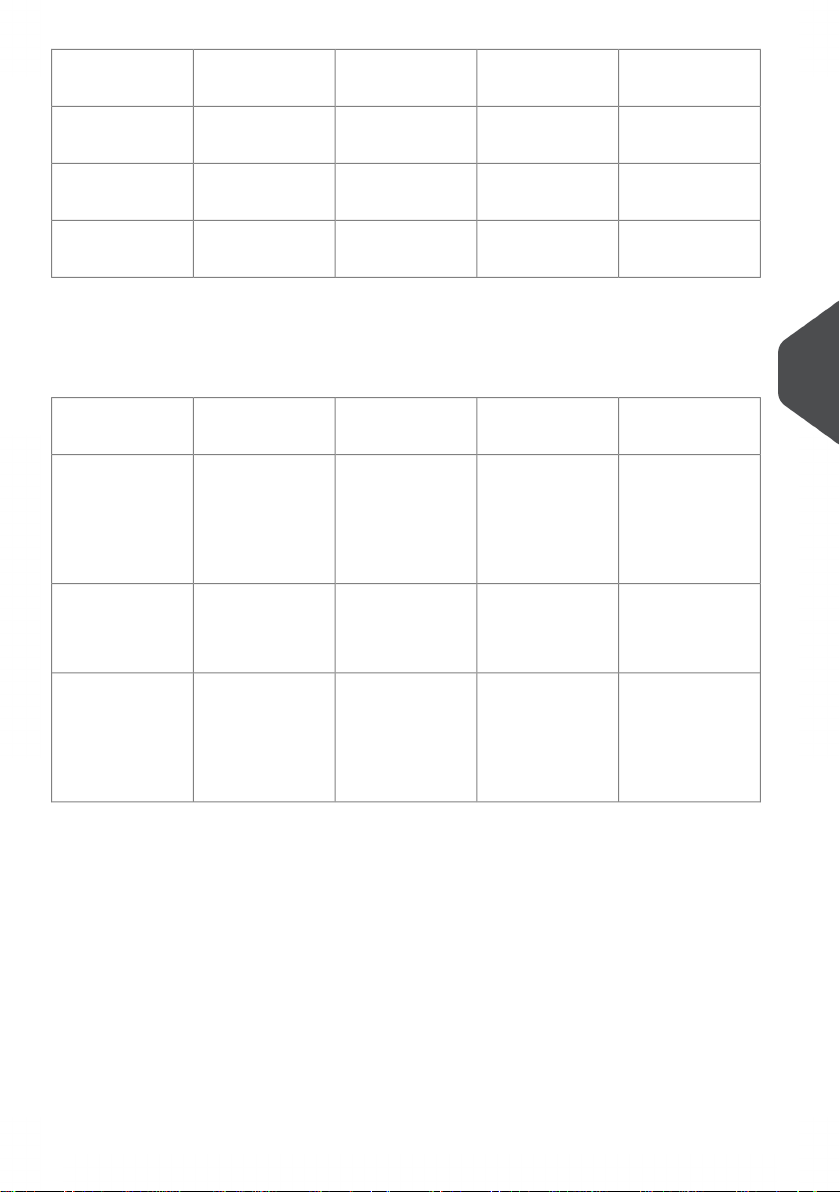

4. Enter the password using either the keyboard or the on-screen keypad. The user has

now changed.

6

English

User Access Rights

There are 4 levels of access rights that can be allocated to each user. These are described

below:

with

Wizard

raries

from Wizard

Libraries from

Outside Wizard

tuning

24

OperatorRights

Operator

SupervisorEngineerExpert

YYYYChange Jobs

YYYYRun Machine

YYYNProgramme Jobs

YYYNAdd items to Lib-

YYNNAdd Items to

YYNNMechanical Fine

Page 28

YYYNDocument Fine

tuning

YYNNEnter Service

Menu

YYNNEnter Admin

Menu

YYNNPC Shutdown

on Exit?

Additionally, the ‘System Security Level’ can be set by a Supervisor. This is the level where

a user does not have to enter a password to perform certain operations. Any access rights

needed above this level will require the user to logon with a password.

Level

of ‘Operator’

Expert OperatorLeast secureLow (default)

More secureMedium

Standard Operator

Operator can

run/edit/

create jobs but

cannot access

the main menu.

Operator can

only run jobs.

On StartupDescriptionEffective role

Job screen

displayed

Job screen displayed

6

English

NoneMost secureHigh

Operator’ has no

access

to the system. All

users

have to logon.

User screen

displayed

25

Page 29

Creating a job7

Creating a job

Creating a job consists of a number of steps:

• Defining the Mailset (Envelope, document & enclosures)

• Defining the Fold Settings

• Setting required Output Options

• Saving the Job to a Jobname

When defining the Document in the Mailset, OMR or Barcode definitions can be enabled

if required.

7

For an OMR of Barcode definition to be used it must first have been

created - see Creating a document

English

Creating the Job Settings

Press the Create Job button in the Job screen.

1.

You will now need to define the mailset (envelope, documents and enclosures). This

is described on the following page.

26

Page 30

Defining the mailset

Selecting the envelope

1. Press the Select button to choose an envelope from the available library.

2. Select the required envelope from the library and press the OK button.

7

English

If there are no envelopes in the library, or if you wish to create a

new one, see Creating an envelope on page 45.

27

Page 31

3. You now have a choice: carry on to select a document, or further define the envelope

usage, ie. sealing mode and deskew.

The following assumes you want to further define the envelope usage. When you have

finished you will return to the screen shown here.

Press the Settings button.

7

English

4. Select the required Sealing mode (usually this will be ‘Always’).Press the Edit

advanced button if you wish to change the deskew setting.

28

Page 32

5. From here, you can turn adjust the degree of deskew, or turn it off if you require. This

might be done to speed the machine up if, for example, an envelope is unlikely to

skew, eg. a C5 or other longer envelope. The default deskew setting is ‘Low’.

Selecting the document

1. Press the Select button to choose a document from the available library.

7

English

29

Page 33

2. Select the required document from the library and press the OK button.

7

English

3. You now have a choice: carry on to select enclosures, or further define the document

usage, eg. form count, cascading, hand-feed etc.

The following assumes you want to further define the document usage. When you

have finished you will return to the screen shown here.

Press the Settings button.

If there are no documents in the library, or if you wish to create a

new one, see Creating a document on page 47

30

Page 34

4. Adjust the forms count if using multiples, whether or not cascading is to be used,

whether or not daily mail (hand-feed) is to be used or whether or not External feed

(FFPD) is to be used. Press the OK button when done. For further settings, press the

Edit Advanced button.

7

English

31

Page 35

5. If you wish to choose an orientation other than the auto-selected default, press Auto

to enable the selector button.

7

English

If required adjust the degree of deskew, or turn it off if you require, for example if a

document type is found to feed reliably without skewing.

Thickness doubles can currently be checked optically only on a flex folder, or turned

off, if for example, documents are substantially different from the calibration document,

such as abnormally dark with heavy printing.

Selecting ‘Auto’ allows the software to choose between optical and mechanical

checking if the document is moved to a versatile feeder fitted with a mechanical system.

Feed control mode is ‘Feed Always’ as default, but can be turned off to disable the

hopper. It can also e set to ‘Selective Feed’ for reading-enabled units. This works in

conjunction with ‘Item ID’ .

Item ID allows you to define an ID number for the document which accords with the

relevant Select mark in the OMR or Barcode label. This will then feed the document

when that mark is read.

Sequence handling mode determines how sequence marks (if used) are handled

when a document set is broken up (for example, to change a job in the middle of a

document set). The mode must be set to ‘Full’ for the first pass, and then changed to

‘Mailset’ for the second pass after the job has been changed. The machine will not

then expect an unbroken sequence.

32

Page 36

Selecting the enclosure

1. If you are using enclosures (inserts, BREs, booklets etc.), press the Select button.

7

2. Select the required enclosure from the library and press the OK button.

If there are no enclosures in the library, or if you wish to create a

new one, see section Creating an enclosure on page 50.

English

33

Page 37

3. You now have a choice: carry on to select further enclosures if required, remove the

enclosure you have selected, or further define the enclosure usage, eg. form count,

cascading, handfold etc.

The following assumes you want to further define the enclosure usage. When you

have finished you will return to the screen shown here.

Press the Settings button. Settings and Advanced Settings are same for

enclosures as for documents- see steps 4,5 of section Selecting the document

7

English

Paper is normally loaded in the Tower face-up and feet-first if nonreading, face down and head-first if reading. This may vary: see

also orientation chart in Loading the flex folder hoppers

34

Page 38

4. If further enclosures are required, press the Select button and repeat steps 1 to 4.

Repeat as required up to the limit of available stations.

You now have a choice: to proceed and move on to Fold Settings, or to assign the

documents/enclosures to specific hoppers.

The following assumes you want to assign the documents/enclosures to specific

hoppers. This will override the hopper that the software automatically assigns.

If you do not want to assign the documents/enclosures to specific hoppers,

press the Next button shown in the previous screen.

Otherwise, press the Document Placement button shown in the previous screen.

This will display a placement box:

7

English

35

Page 39

5. Select the document that you want to move, then select the hopper that you want to

assign it to.

If you want to undo a manual placement, press ‘Auto place documents’ to revert.

Otherwise press ‘Save’.

7

English

The mailset is now defined, and the screen will show that this is chosen.

36

Page 40

Defining the fold

You will now define the fold settings.

The machine will automatically select the optimum fold type. If you wish to change

1.

this, deselect ‘Auto’ and set the required fold.

The machine may not perform properly if you change the fold

type incorrectly.

7

English

If you wish to make adjustments to the fold lengths, or just check them, press the

Adjust fold button.

37

Page 41

2. Make adjustments as required and press the OK button.

For Max. & Min. fold lengths for each fold plate, see ‘Technical

Specifications on page 81'.

7

English

3. If you wish to make adjustments to the collation mode or Max no. of sheets folded

together, press the Edit advanced button.

38

Page 42

4. Choose whether to collate leading edges of documents as they feed through the folder,

then folded together without entering the accumulator, or to feed separately into the

accumulator before folding. Sheets are fed singly by default, so each sheet is folded

and inserted separately. Set max number for folding together. Groups bigger than this

will be split into a) max number, followed by b) remainder.

The maximum that can be fed into the accumulator defaults to 9 (Max. collate), but

can be up to 25.

This will depend upon the paper type.

7

English

Multi-envelope mode allows two separate jobs to be run in succession using the same

document set. If set to ‘Split Oversize’, this splits, folds and inserts as for ‘Max Fold’

described above. If set to ‘Divert Oversize’, all groups numbering greater than the

number set in ‘Divert/Split Threshold’ will be diverted to the divert tray, and if set to

‘Divert Undersize’, the same will apply for groups below the threshold.

The machine is then stopped, the job is changed and the forms in the divert tray are

put back into the document set, and the new job is run.

‘Divert Action’ allows the option of the machine stopping automatically upon divert, or

to continue, allowing the operator to intervene.

When you have finished, fold settings are now complete and the screen will show that

this is ticked.See also Table 1 on the following page.

Table 1

Handling of folded forms

Shown below are handling of oversized/undersized groups under different

circumstances.

39

Page 43

7

English

Multi envelope

mode

Split oversized

Divert oversized

Divert undersized

Maximum Fold

When folding,

the group or

sub-group is folded on reaching

this limit

Not used (As for

Split Oversize if

oversize not yet

detected).

Not used (As for

Split Oversize if

undersize not

yet detected).

Maximum in

accumulator

When not folding or diverting,

the group or

subgroup is

ejected towards

divert or head

unit on reaching

this limit

Not used (As for

Split Oversize).

Not used (As for

Split Oversize).

Divert/Split

threshold

Not used

The complete

group is assembled in the

accumulator

and then diverted if prime document count is

equal or greater

than this limit

The complete

group is assembled in the

accumulator

and then diverted if prime document count is

less than this

limit

Comment

Mechanical limits of folder and

accumulator for

given stationery

Typically used

for diverting

large groups for

re-processing

into a larger envelope

Typically used

for diverting

small groups for

re-processing

into a smaller

envelope

40

Page 44

Defining the output settings

Select Settings for Unsorted Mail in the Output Settings screen.1.

7

English

41

Page 45

2. Set Batching to Batch On if required and set required quantity in Batch Quantity.Set

Batch Mode as follows:

Batch and Continue:

Machine will pause for the specified pause time, and then resume.

Conveyor will continue to run during the pause time.

Batch and Stop:

Machine will stop and resume only when the Run button is pressed.

Select Envelope Count under Batch Control, currently the only available option.

Set the Batch Complete Pause Time as described in Batch and Continue above.

When settings are complete, press the Save button.

7

3. If a conveyor is fitted, select Conveyor Settings to adjust the Jog functions as follows:

Single Jog Adjust: Adjusts default jog step (gap) between mailpieces. Note that steps

English

are unitless.

Batch Complete Jog Step: Adjusts gap before machine performs action described

in ‘Batch Mode’.

Mark Reading Jog Step: Adjusts gap created after Jog mark is read.

Autoend Jog Step: Adjusts gap created before machine autoends.

When settings are complete, press the Save button.

42

Page 46

Output Settings for unsorted mail are now complete. If you are using Mail Sorting,

refer to the INF Output Sorter Operator Manual.

The output settings are now defined, and the screen will show that this is ticked.

You will now save the job.

7

English

43

Page 47

Saving the job

Press the keyboard icon to display the virtual keyboard.1.

7

English

2. Enter a name for the job using either the virtual or physical keyboard.

Repeat steps 1 & 2 to enter a brief description for the job. This is the description that

will appear in the job list when the machine is started.

3. Enter a name for the job using either the virtual or physical keyboard.

You have now successfully created a new job and it will appear in the job list.

44

Page 48

Creating an envelope

In order for an envelope to appear in the envelope library, it must first be created.

Begin creating a job (see Creating the Job Settings on page 26)1.

2. At the point where you need to select an envelope, press the Create New button.

3. Enter a name for the envelope: press the virtual keyboard icon and enter the name

using either the physical or virtual keyboard.

Select an envelope type. The default width and height for that type will then be shown.

If you want to adjust the size, the type will change to ‘Custom’.

If you want to adjust the envelope weight and flap depth, press the Edit Advanced

button.

7

English

45

Page 49

4. Adjust the weight as required. Note that the weight is the actual weight of the envelope,

not the paper weight.

Adjust the wetting rate if required. The number shown is the quantity of envelopes

sealed before the pump tops up the wetter tank. Default is 25.

Press the Save button when done.

The envelope will now be available in the envelope library under the name you have

given it.

7

English

The envelope is now fully defined and is available for use.

46

Page 50

Creating a document

In order for a document to appear in the document library, it must first be created.

Begin creating a job (see Creating the Job Settings on page 26)1.

2. At the point where you need to select a document, press the Create New button.

3. Enter a name for the document: press the virtual keyboard icon and enter the name

using either the physical or virtual keyboard.

Select a document type and size and orientation. The default width and height for that

type will then be shown. If you want to adjust the size, the type will change to ‘Custom’.

Change the thickness for thick documents, eg. booklets. If you want to make further

adjustments, or select a reading definition, press the Edit Advanced

7

English

47

Page 51

4. Select the address position. This defaults to ‘Top’; specify middle, bottom or none if

required.

Specify whether the document is to be folded (eg. a booklet would not be) and its

thickness and weight. Note this is the actual weight of the document, not the paper

weight.

The thickness is more applicable to booklets - if no figure is specified, 80gsm paper

will be assumed.

If the document uses an OMR or barcode label, select a reading definition.

This is obtained under licence as an option and must already

exist on the machine.

7

English

If the document does not use an OMR or barcode label, press the Save button,

otherwise, proceed as follows.

48

Page 52

5. Press the Region of Interest button to specify the position of the label.

6. Specify the position of the label and select whether edge detection is required – this

detects the edge of the paper and should normally be On.

Turn Off if coloured or densely printed paper is giving false readings: the machine

will then use default dimensions for label position. Press the Save button when done.

The document is now fully defined and is available for use.

7

English

49

Page 53

Creating an enclosure

In order for an enclosure to appear in the enclosure library, it must first be created.

Begin creating a job (see Creating the Job Settings on page 26)1.

2. At the point where you need to select an enclosure, press the Create New button.

7

English

3. The procedure for defining an enclosure is the same as that for a document, described

in Creating a document on page 47. It is the document type that you select that

determines whether it appears in the document or enclosure library.

See Creating a document on page 47 for the remainder of the settings.

The enclosure is now fully defined and is available for use.

50

Page 54

Loading the paper hoppers8

Loading the envelope hopper

Using the black knob, adjust the side guide to give 1-1.5mm clearance each side of

1.

the envelope.

8

English

51

Page 55

2. Adjust the angle of the backrest (see below) and load the envelopes into the hopper,

flaps forward, so that the lower edges follow the contour of the surface and down into

the pick-up roller. Move the backrest forward (see below) so the the envelopes are

fully forward, but not tightly packed.

8

English

3. Move the backrest forward by squeezing the handle upwards to release the rollers

from the track.

Adjust the width of the panels to suit the envelope.

Adjust the angle by loosening the knob each side.

C4: Fully raised

DL/DL+: Fully lowered

52

If the envelopes feed erratically, try a backrest angle in-between.

Page 56

Adjusting the envelope separator

The separator prevents more than one envelope being fed at a time.

1. To adjust the separator, open the side cover on the insertion head; the adjustor knob

is visible below the envelope conveyor. Turning clockwise decreases the gap,

anti-clockwise increases it.

2. To set the separator gap, empty the hopper, then slide an envelope into the gap and

turn the knob until the separator will just grip the envelope as you withdraw it.

3. Close the side cover when you have finished.

8

English

53

Page 57

Loading the feeder hopper

Move the guides to give 1 - 1.5mm clearance each side of the insert.1.

8

English

2. Draw back the weighted rollers and load the insert pack so that the leading edge is

feeding into the nip of the feed rollers. Move the weighted roller forward to support

the pack.

Tower feeder is shown; single feeder is similar, with one hopper

only.

Adjusting the separator

The separator prevents more than one enclosure being fed at a time.

1. The feeder separator has 4 settings, marked A to C on the slide. Before running the

job, the gap must be set to suit the thickness of material being processed - this prevents

54

Page 58

more than one item being fed at a time. Note that there is an intermediate setting

between each marked position, allowing finer adjustment.

Slide positions:

A = 0 to 0.75mm

B = 0.75 to 1.5mm

C = 1.5 to 2.5mm

D = 2.5 to 4.0mm

(A - C only on Tower Feeder)

Most jobs will use position A. If you use the wrong setting, an error

will appear on the control panel.

8

English

For problem enclosures, the feed rollers can be changed to optional

alternatives.

55

Page 59

Loading the tower folder hoppers

The tower folder may be fitted with 500-sheet or 1000-sheet hoppers, or only a single

00-sheet hopper. The example shown has 1 x 500-sheet and 1 x 1000-sheet hoppers.

1. On 500-sheet hoppers, ORRVHQ the black knob next to the side guides (arrowed) and

move the guides to give 1-1.5mm clearance each side.

On 1000-sheet hoppers, press down on the tray to lower it. /RRVHQ the black knob

above the hopper (arrowed) and use the tabs to move the guides to give 1-1.5mm

clearance each side. The tray will raise automatically when the machine is started.

8

2. Tighten the knobs.

56

Paper orientation in the hoppers will depend upon the job

requirement - see the paper orientation chart.

Page 60

Accumulator

7KH accumulatorVide guides must be adjusted

to suit the paper - use the preset size markings to set the paper width.

8

1. Raise the top of the accumulator so that it locks in place and place a piece of paper

between the side guides.

2. Loosen the black knob next to the side guides (arrowed) and move the guides to give

1-1.5mm clearance each side.

3. Pull out the handle at the end (arrowed) to lower the accumulator top.

English

57

Page 61

Adjusting the separator

The separator prevents more than one document being fed at a time.

1. Open the side cover on the operator side and turn the knob in the required direction

to open or close the gap. The markings next to the knob indicate which direction to

turn it.

8

English

58

Page 62

2. To set the separator gap, empty the hopper, then slide a form into the gap and turn

the knob until the separator will just grip the form as you withdraw it.

Table 2

Paper Orientations

Paper orientations for various applications are shown below.

European Sizes:

Tower Fold

Configurations

UK & European Sizes

Job

Code

CF1

CF2

Job

Description

A4

Form

(297mm

x

210mm)

Document

printed

with

top address

A4

Form

(297mm

x

210mm)

Document

middle

address

Fold

Type

"C"

Fold

"C"

Fold

Face

Down

Head

First

Face

Down

Feet

First

Face

Up

Feed

First

Fold Pannel LengthsForm Input Orientation

Fold

Plate

1

68mm

(121mm

long

envelope

90mm

(110mm

envelope)

183mm

(121mm

long

envelope)

194mm

(110mmprinted

envelope)

FoldPlate

2

115mm

(121mm

long

envelope )

104mm

(110mm

longlongwith

envelope)

FoldPlate

3

115mm

(121mm

long

envelope)

104mm

(110mm

longlong

envelope)

8

English

59

Page 63

8

English

CF3

ZF1

ZF2

A4

Form

(297mm

x

210mm)

Document

printed

with

bottom

address

Address

upside

down

in window

A4

Form

(297mm

x

210mm)

Document

printed

with

top address

A4

Form

(297mm

x

210mm)

Document

printed

with

top address

"C"

Fold

"Z"

Fold

"Z"

Fold

60mm

(121mm

long

envelope)

90mm

(110mm

long

envelope)

229mm

(121mm

long

envelope)

103mm

(110mm

long

envelope)

68mm

(121mm

long

envelope

90mm

(110mm

long

envelope)

115mm

(121mm

long

envelope)

104mm

(110mm

long

envelope)

115mm

(121mm

long

envelope)

104mm

(110mm

long

envelope)

115mm

(121mm

long

envelope)

104mm

(110mm

long

envelope)

60

ZF3

"Z"

Fold

Page 64

VF1

VF2

A4

Form

(297mm

x

210mm)

Document

printed

with

bottom

address

A4

Form

(297mm

x

210mm)

Document

printed

with

top address

A4

Form

(297mm

x

210mm)

Document

printed

with

bottom

address

Address

upside

down

in window

"V"

Fold

"V"

Fold

114mm

(121mm

long

envelope)

103mm

(110mm

long

envelope)

149mm

149mm

115mm

(121mm

long

envelope)

104mm

(110mm

long

envelope)

8

English

61

Page 65

8

English

DFF1

DFF2

Europcon

16"

torm

(106mm

x

210mm)

Document

printed

with

top address

Europcon

16"

torm(106mm

x

210mm)

Document

printed

with

bottom

address

Address

upside

down

in window

Double

Forward

Fold

Double

Forward

Fold

177mm

(121mm

long

envelope)

199mm

(110mm

long

envelope)

177mm

(121mm

long

envelope)

199mm

(110mm

long

envelope)

115mm

(121mm

long

envelope)

104mm

(110mm

long

envelope)

115mm

(121mm

long

envelope)

104mm

(110mm

long

envelope)

62

American Sizes:

Page 66

D16403 Tower Fold

Configurations

American Sizes

Job

Code

ACF1

ACF2

Job

Description

US Letter

format

(11" x

8½")

Document

printed

with

top address

US Letter

format

(11" x

8½")

Document

printed

with

middle

address

Fold

Type

Fold

"C"

Fold

Face

Down

Head

First

Face

Down

Feet

First

Face

Up

Feed

First

Fold Pannel LengthsOrientation In Hopper

Fold

Plate

1

02mm

(#10"C"

Envelope)

181mm

(#10

Envelope)

FoldPlate

2

99mm

(#10

Envelope)

FoldPlate

3

99mm

(#10

Envelope)

8

English

63

Page 67

8

English

ACF3

AZF1

AZF2

AZF3

US Letter

format

(11" x

806")

Document

printed

with

bottom

address

US Letter

format

(11" x

8½")

Document

printed

with

top address

US Letter

format

(11" x

806")

Document

printed

with

top address

US Letter

format

(11" x

8½")

Document

printed

with

bottom

address

"C"

Fold

"Z"

Fold

"Z"

Fold

"Z"

Fold

82mm

(#10

Envelope)

197mm

(#10

Envelope)

98mm

(#10

Envelope)

140mmAVF1

82mm

(#10

Envelope)

33mm

(#10

Envelope)

99mm

(#10

Envelope)

99mm

(#10

Envelope)

99mm

(#10

Envelope)

64

Page 68

AVF2

AD-

FF1

US Letter

format

(11" x

8½")

Document

printed

with

top address

US Letter

format

(11" x

8½")

Document

printed

with

bottom

address

Address

upside

down

in window

US

Legal

format

(14" x

8½")

Document

printed

with

top address

"V"

Fold

"V"

Fold

Double

Forward

Fold

110mm

197mm

(# Envelope)

8

English

99mm

(#10

Envelope)

65

Page 69

US

Legal

format

(14" x

8½")

Document

ADFF2

printed

with

bottom

address

Address

upside

down

in window

Double

Forward

Fold

197mm

(# Envelope)

8

English

Daily Mail (Tower Folder)

Daily mail allows a group of forms to be hand-fed, folded and inserted on a Flex Folder or

Versatile Feeder. This section descibes the Flex Folder – see Flex Folder for Versatile

Feeder.

A group of forms up to a total of 6mm thick may be fed, but be aware of the folding capacity

of 8 forms of 80gsm (20lbs bond). The forms may be stapled or not, as required (see below

for stapling restrictions).

99mm

(#10

Envelope)

Stapling Restrictions

66

Page 70

Using Daily Mail

To use daily mail, define a new mailset (as described in Defining the mailset on page 27)

or edit the document settings in an existing job.

Select Settings for the document and set ‘Hopper feed mode’ to Daily Mail.

8

English

67

Page 71

When daily mail has been enabled as described, press the Run button and feed the post

into the accumulator tray. The machine will wait for 30 seconds after pressing the button if you exceed this before inserting the documents, press the button again.

To turn the function off, switch ‘Hopper feed mode’ back to Default in Document Settings.

You may find it easier to feed the paper by unhooking the divert

tray and removing it.

8

English

68

Page 72

Adjusting the catch tray

If a Catch Tray is being used for ejected envelopes, it should be adjusted to suit the

ejected envelopes.

8

English

69

Page 73

Operator Maintenance9

Cleaning the sensors

The optical sensors consist of two halves: emitter and receiver. These can become

obstructed due to paper dust and should periodicaly be cleaned using a nonflammable

airduster. Both halves must be cleaned.

This section shows where the sensors are located. For most sensors, an indicator arrow

is pierced showing you where the jet of the airduster should be directed. For some sensors,

the retaining bush is visible next to the lens: ensure you spray into the lens, not the bush.

Cleaning the sensors

Sensors are retained with a bush next to the lens: where this is

visible, ensure that you spray into the lens (arrowed), not the bush.

9

Insertion head

English

Direct the airduster into the openings arrowed and spray liberally.

1. Open the perspex top cover and raise the collate clamshell (closest to the envelope

hopper) so that it locks in place.

Picture shown is viewed looking inside the collation area towards the envelope hopper

70

Page 74

2. Picture is viewed looking inside the collation area away from the envelope hopper.

Clean all sensors arrowed.

3. Lower the collate clamshell and open the upper conveyor (furthest from the envelope

hopper) so that it locks in place.

Picture is viewed looking inside the collation area away from the envelope hopper.

Insert the airduster nozzle deep into the hole and spray liberally. Note the the upper

sensor half is not easy to see and is mounted on a bar.

Lower the conveyor.

9

English

71

Page 75

4. Lower the side cover and raise the overguide inside the closer cavity, latching it in

place.

Clean the sensors arrowed.

9

5. Picture is viewed looking down on the envelope hopper, at the front.

English

Clean the one-piece reflective sensor.

72

Page 76

6. Lower the front output cover below the envelope feeder.

Clean the sensors indicated. Note that the upper sensor is in two halves. The lower

sensor is a one-piece reflective type.

Feeder

There is a sensor on the feed hopper of a feeder, and a pair located in the lower

conveyor section.

1. Remove all paper from the feed hopper and direct the airduster into the cutout indicated.

9

English

73

Page 77

2. Open the side cover and push the lowermost lever forward to lower the conveyor.Clean

the sensor located next to the gearwheel in the centre of the track as shown, with the

upper half directly above it.

9

A single feeder is shown, twin-feeder is similar. Conveyor sensor

English

applies also to feederfolder.

Feeder-Folder

There is a sensor in the front transport assembly on a feeder-folder, and another two

on the top. There is also one in the lower conveyor (see Feeder).

1. Raise the cover at the front of the feederfolder. Using the blue tab, release the latch

of the transport assembly and lift it upwards. Direct the airduster into the cutouts

indicated.

74

Page 78

Ensure the lever is fully latched when closing.

2. Raise the top cover. Direct the airduster into the cutout (the lower sensor in the picture),

and into the gap to clean both halves of the upper sensor.

9

English

75

Page 79

Flex Folder

1. Open the folder top cover and clean the sensors indicated.Direct the jet into the gap

under the sensors, or into the hole indicated.

9

English

76

Page 80

2. Open the top cover open, direct the jet into the holes indicated.

Note: The sensors are in two halves, with the opposite halves located in the cover.

9

English

77

Page 81

Clearing paper jams

If paper jams occur, the area affected will normally be shown in the error message on the

screen. Use one of the clearance methods described below to clear the jammed paper.

Inserter Head

1. Open the side cover on the operator side of the machine, and lower the front sealer

cover.

9

English

Check for jammed paper in the open cavities.

If the paper is not fully visible, turn the blue knobs to wind it into view.

Open the front closer cover using the blue tab and check for jammed paper.

78

Page 82

Feeder (Single and Twin) & Feeder Folder

1. Open the side cover on the feeder.

Use the blue tabs to push forward the levers indicated to open the cavities and access

the jammed paper.

If the paper is not fully visible, turn the blue knobs to wind it into view.

single feeder is shown; twin-feeder and feeder-folder are similar.

9

Tower Folder

1. Open the side cover on the flex folder.

Base Unit

Using the blue tab, open the folder assembly to access the jammed paper.

If the paper is not fully visible, turn the blue knobs to wind it into view.

Page 83

9

English

When closing the folder assembly, ensure it is fully latched on both sides.

Tower Unit

Using the release handle, open the top cover to access the jammed paper.

If the paper is not fully visible, turn the blue knobs to wind it into view.

80

Page 84

Technical Specification10

Inserter head

Parameters

Pack thickness

Maximum pack thickness is defined as the internal dimension of

a rigid opening that a filled envelope will fall through under its

own weight.

up to 6mm (¼”)All envelope sizes:

Pack clearance

10

Cycling speed

Monthly volume

The minimum clearances required between the inserts and envelopes

are dependent on insert pack thickness.

Clearance is the total clearance and is defined as the difference between

the largest overall dimensions of the pack and the internal dimensions

of the envelope (see below). The required clearances are summarised

as follows:

Pack <3mm: Depth 6mm (¼”) Width 16mm (5/8”)

Pack >3mm <6mm: Depth 12mm (½”) Width 19mm (¾”)

English

Series: Up to 4500 envelopes per hour (based on 1 xOHWWHU folded

sheet into a envelope).

;7 Series: Up to 5500 envelopes per hour (based on 1 xOHWWHU folded

sheet into a envelope).

Speeds for other conditions available on request.

Series: Up to 150,000 filled envelopes per month.

;7 Series: Up to 180,000 filled envelopes per month.

81

Page 85

Envelope

weight

General envelope requirements

-er capacity)

Envelope details

10

English

Minimum: 70gsm (18lbs bond)

Maximum: 100gsm (28lbs bond)

• Envelope to be good quality machine-fill type. Dimensions and

quality to be consistent across manufactured batches.

• Side seams must be securely glued to the top of the seam.

• Flap crease must be pre-scored to enable the envelope flap to

open flat.

• No glue seepage must be evident on interior or exterior of envelope.

• Windows to be securely affixed to within 1.5mm

(1/16”) of top and side edges. Top edge to be flat and

free from puckering.

Up to 00 filled envelopes (assumes 1 document inserted)2XWSXWFRQYH\

82

Page 86

10

English

83

Page 87

Envelope sealing fluid

10

Tower Folder

English

Parameters

Paper Size

Paper weight

Built-in wetter tank, automatically pump-fed by 10-litre wetter container

located in stand. Optional low-level float switch available.

Minimum width: 140mm (5½”)

Maximum width: 228mm (9”)

Minimum length: 140mm (5½”)

Maximum length: 406mm (16”)

Note: The maximum suggested width difference between inserts is

32mm (1¼”): this may be increased subject to test. If this difference

is exceeded, the insertion fingers will not cover the edges of the narrow

insert and may cause insertion problems. Sandwiching a narrow insert between two wider ones may resolve this.

Minimum 60gsm (16lbs bond)

Maximum 120gsm (32lbs bond) for folded documents

Maximum 4mm thick for unfolded inserts (subject to test)

84

Page 88

Folding capa-

1000

city

Fold lengths

Hopper capacity

C, Z or V-fold: 8 sheets 80gsm (20lbs bond)*

Double-forward fold: 4 sheets 80gsm (20lbs bond)*

* Up to 2 x 8 split sets into one envelope dependent upon

pack thickness.

Fold Plate 1: 229mm Max, 48mm Min.

Fold Plate 2: 229mm Max, 50mm Min.

Fold Plate 3: 202mm Max, 50mm Min.

Tower Folder can be ordered in 3 configurations as follows:

3 x 500 sheets of 80gsm (20lbs bond)

1 x 1000 sheets of 80gsm (20lbs bond)

1 x 500 + 1 x 1000 sheets of 80gsm (20lbs bond)

10

English

Daily mail

Up to 8 sheets of 80gsm (20lbs bond) for C, Z or V fold, up to 4 sheets

of 80gsm (20lbs bond) for double forward fold. May be stapled or not.

Max. thickness of staple 3mm. Allowable staple positions are shown

below.

85

Page 89

Insert Feeder

Insert Sizes(Single hopper)

Paper weight

Hopper capacity

10

Insert Sizes(Tower hopper)

English

Paper weight

Hopper capacity

Parameter

Minimum width: 140mm (5½”)*

Maximum width: 241mm (9½”)

Minimum length: 76mm (3”) for module 1

89mm (3½”) for following

modules

Maximum length: 152mm (6”)

*For individual items. Min. pack width:

210mm (8¼”)

Minimum 60gsm (16lbs bond) min.

Maximum 4mm (5/32”) thickness

Up to 300 BREs or 150 2mm booklets

Note: Quantities shown above are maxima.

Depending

upon other conditions, actual quantities may

be lower

than those shown.

Minimum width: 140mm (5½”)*

Maximum width: 241mm (9½”)

Minimum length: 76mm (3”) for module 1

89mm (3½”) for following

modules

Maximum length: 152mm (6”)

*For individual items. Min. pack width:

210mm (8¼”)

Minimum 60gsm (16lbs bond) min.

Maximum 2mm (5/64”) thickness (top tray)

Maximum 4mm (5/32”) thickness (lower tray)

Up to 200 BREs or 100 2mm booklets

Note: Quantities shown above are maxima.

Depending

upon other conditions, actual quantities may

be lower

than those shown.

86

Page 90

Requirements

Feeder Folder

Parameters

Depth:

Width:

Thickness:

Enclosures must be flexible enough to suit

path constraints.

Some enclosures may require special tyres.

140mm (51/2”) min. (89mm (3½”) for unfolded inserts)

406mm (16”) max. (139mm (5½”) for unfolded inserts)

140mm (51/2”) min. (Widths below 168mm

(6.6”) require narrow finger kit A3348A).

229mm (9”) max.

60gsm (16lbs bond) min.

70gsm (18lbs bond) min. for OMR/Barcode

paper

120gsm (32lbs bond) max.

10

Depth of output doc:

Daily Post:

89mm (31/2”) min.

152mm (6”) max.

Up to 500 sheets of 80gsm (20lbs bond)Hopper capacity:

Up to 3 sheets (C or Z fold) or 5 sheets (V

fold) of 80gsm (20lbs bond). May be stapled

or not, but staples on ‘Z’ fold only. Max.

thickness of staple 2mm. Allowable staple

positions shown below. Note: all daily post

forms must be the same length.

Note: Daily Post is not available as an option

if a CIS reader is fitted.

English

87

Page 91

Mechanical & Electrical

Noise level:

<73dbA (following ISO 11202).

Electrical:

115VAC230VAC

60Hz50HzFrequency

2AHead: 1AInput Current

1ASingle Feeder: 0.5A

1ATwin Feeder: 0.5A

1ACIS Feeder: 0.5A

2ATower Folder: 1A

10

Power Requirement and Voltage Tolerance:

230V / 50 Hz (voltage tolerance +10%/10%)

115V / 50/60 Hz (voltage tolerance +6%/10%)

Operating Temperature:

English

10 - 40 deg C (50 - 104 deg F)

Operating humidity:

30 - 80% RH

Display Properties:

Dimensions:

Inserter Head

15”Screen Size:

1024 x 768 pixelsScreen Resolution:

Full Colour Touch ScreenScreen Technology:

720mm (28.3”)Length:

475mm (18.7”)Width:

88

Page 92

Tower Folder

Feeder Folder

Reading Feeder

600mm (23.6”)Height:

56Kg (123lbs)Weight:

490mm (19.3”)Length:

475mm (18.7”)Width:

915mm (36.0”)Height:

75Kg (165lbs)Weight:

408mm (16.0”)Length:

475mm (18.7”)Width:

710mm (27.9”)Height:

43Kg (95lbs)Weight:

10

408mm (16.0”)Length:

475mm (18.7”)Width:

550mm (21.6”)Height:

25Kg (55lbs)Weight:

English

Single Feeder

Twin Feeder

408mm (16.0”)Length:

475mm (18.7”)Width:

520mm (20.4”)Height:

25Kg (55lbs)Weight:

408mm (16.0”)Length:

89

Page 93

Processing Speed

Ambient light:

Although the machine may operate in sunlight, it is not designed for use in direct sunlight,

or where sunlight is exposed to the machine through windows or skylights. The light-sensitive

sensors can be affected in these conditions. It is therefore recommended to:

1. Locate the machine out of direct sunlight

2. Protect the machine from direct sunlight using blinds or similar blocking devices.

10

If the machine can only be located where it may be exposed to direct sunlight, then please

contact Technical Support department, who may be able to advise on the use of blocking

material on the inside of the Perspex cover where necessary.

English

475mm (18.7”)Width:

700mm (27.6”)Height:

25Kg (55lbs)Weight:

4500 filled envelopes per hour.6HULHV:

5500 filled envelopes per hour. ;76HULHV:

1. All stationery should be allowed to acclimatise near the

machine for at least 24 hours before use to prevent rapid

absorption of moisture in the material, or condensation forming

on the machine. Failure to acclimatise the material may cause

pre-gumming of envelopes or otherwise impair machine

performance.

2. The machine will function with humidity levels lower than 30%

RH, but high levels of static may be generated, impairing

machine performance.

3. The machine will function with humidity levels higher than 80%

RH, but moisture absorption into the material may impair

machine performance.

4. Condensation must not be present under any circumstances.

5. The machine will function at temperature levels above 28 deg

C (82 deg F) and below 18 deg C (64 deg F). However,

temperature levels outside these limits may impair the machine

performance.

6. Material processed directly from laser printers may have high

levels of static causing material to stick together. If double

feeding occurs, then Hi-Grip separators may be required contact IPSS department.

90

Page 94

Glossary of terms11

Glossary of terms

Address carrier

Address position

DescriptionTerm

The address carrier is the document that

carries the address of the person for who the

mail set is meant. The address carrier can

consist of one or more sheets, from which

at least the first sheet must contain the address. The address must remain visible while

enclosures are added and the document set

is folded. The fold type and selected envelope must ensure that the address is visible

behind the window in the envelope. For personalized mailings there is always an address carrier present as long as envelope

printing is not supported. Normally there is

one address carrier.

11

Automatic

English

Position of the address on the address carrier, measured from the upper left corner. The

address position consists of a horizontal x

coordinate, a vertical y coordinate, a horizontal width w and a vertical height h.

The feature of an inserting system to automatically determine its job settings by

measuring the sizes of documents and envelope. From all feeders that are loaded one

sheet will be taken. Based on the maximum

document length (which is also the length of

the document set) and the length of the envelope the fold type is determined.

91

Page 95

Automatic job

Barcode Reading (BCR)

Business Reply Envelope (BRE)

Daily Mail

Deskew

11

English

Document

A job that is created with the Automatic job

functionality.

Barcode Reading is intended for reading and

interpreting printed barcodes. The codes give

information to the inserting system about

how to build-up and handle a set.

Envelope included in outgoing mail sets for

addressee response purposes.

See Feeder linking.Cascading

See Letter fold.C-fold

Capability of an inserting system to manually

insert mail sets one by one into the system,

which are then inserted into an envelope.