Page 1

6900 Series

Folder/Inserter

OPERATOR MANUAL FIRST EDITION

Page 2

INSERTER IN-3 6900 Series

OPERATOR MANUAL

OPERATOR MANUAL

OPERATOR MANUALOPERATOR MANUAL

1.

1. GENERAL

GENERAL

1.1.

GENERALGENERAL

The

6900

within the mailing process, such as feeding, folding,

collating of documents and inserting and sorting of filled

envelopes a module is available. In this way the 6900 Series adapts

to the customers' needs.

The whole system is operated and programmed via the

central operator panel of the base module, the inserter

(IN-3).

Ser

ies

is a modular mailing system. For each stage

Fig. 1

1/40

1/40

1/401/40

Page 3

Before using this system thoroughly read the operating

instructions. In the European Union an operator manual

printed in the national language(s) is supplied with the

system. If it is not, contact your authorized distributor.

Wa rn i n gs

Wa rn i n gs

Wa rn i n gs Wa rn i n gs

• Before connecting check whether the system is suitable for

the local mains voltage; refer to the type plate. The mains

plug shall be connected only to a socket outlet provided

with a protective earth contact.

• The socket outlet shall be installed near the equipment

and shall be easily accessible.

• The following part is considered the equipment

disconnect device: power supply cord plug.

Safety precautions

Safety precautions

Safety precautions Safety precautions

•This system is only to be operated by fully trained

personnel. The manufacturer accepts no responsibility for

injuries caused by unauthorized operation.

• The opening of covers (except the top and side cover)

must be carried out only by a skilled and authorized

person who is aware of the hazard involved. The system

will not operate with the covers opened.

• Keep long hair, fingers, jewelry, etc. away from turning

parts of the system.

Used symbols

Used symbols

Used symbols Used symbols

In this manual the following symbols are used.

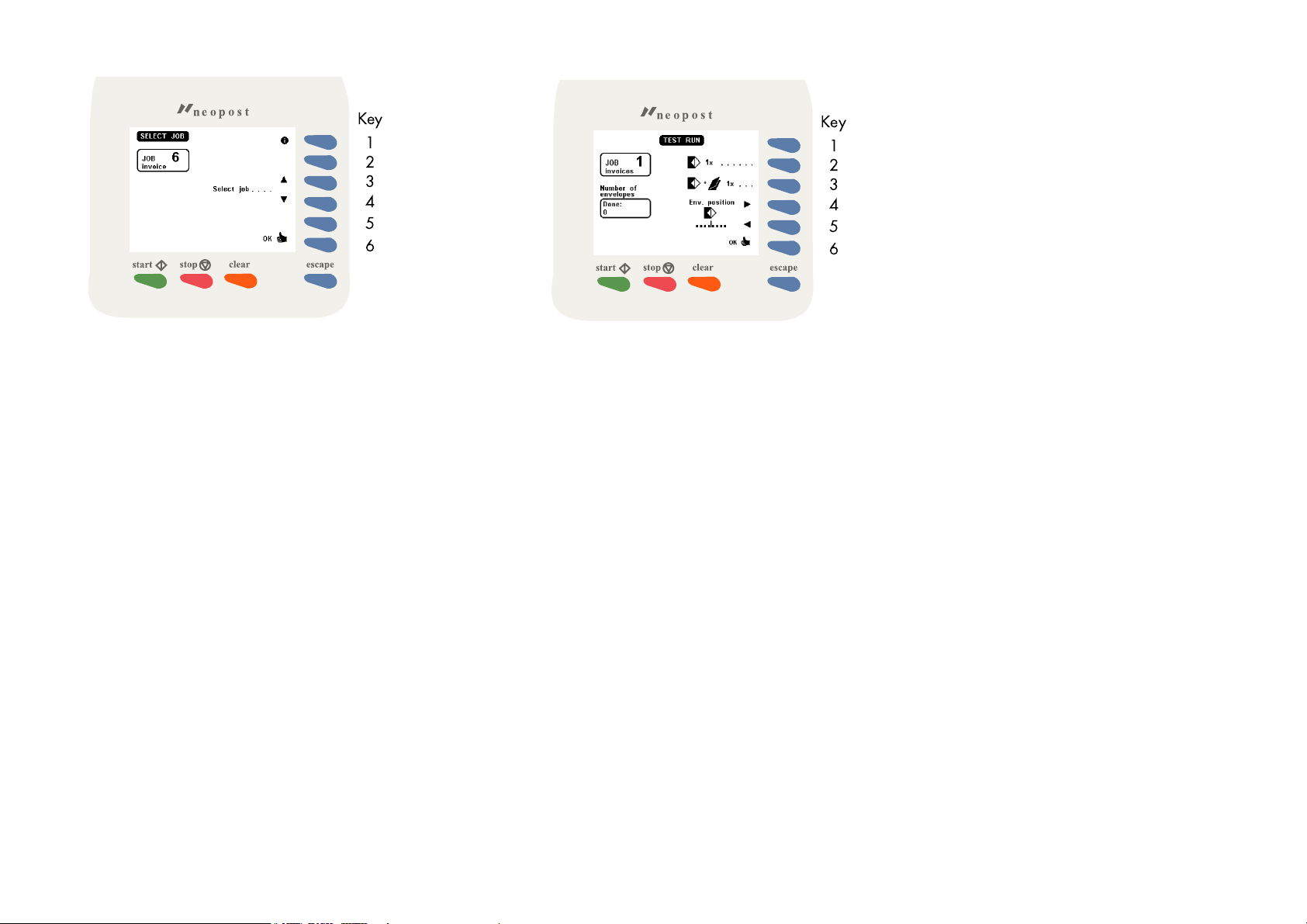

Warning, this symbol indicates a wrong action

which can cause a hazard to health or

damage the system.

Warning, this symbol indicates a hazard to life

because of high voltage.

NOTE

Additional information (Italic)

CONTENTS

CONTENTS

CONTENTSCONTENTS

Section

Section Page

SectionSection

1.

1. GENERAL

GENERAL 1

1.1.

GENERALGENERAL

2.

2. HOW TO USE THE OPERATOR MANUALS

HOW TO USE THE OPERATOR MANUALS 3333

2.2.

HOW TO USE THE OPERATOR MANUALS HOW TO USE THE OPERATOR MANUALS

3.

3. ACCESSORIES

ACCESSORIES 3333

3.3.

ACCESSORIESACCESSORIES

4.

4. UNDERSTANDING THE MACHINE

UNDERSTANDING THE MACHINE 4444

4.4.

UNDERSTANDING THE MACHINE UNDERSTANDING THE MACHINE

4.1 Function 4

4.2 Overview 4

4.3 User interface 4

4.4 Operating controls 5

4.5 Power inlet 5

4.6 Display keys 6

5.

5. OPERATING THE SYSTEM

OPERATING THE SYSTEM 6666

5.5.

OPERATING THE SYSTEM OPERATING THE SYSTEM

5.1 Preparations inserter module 6

5.2 Switching on 7

5.3 Entering the personal pin code 7

5.4 The main menu 7

5.4.1 Job info screen overview 8

5.4.2 Schematic view 10

5.4.3 Selecting a job 11

5.4.4 Test run menu 11

5.4.5 Counters menu 14

5.4.6 Settings menu 14

5.5 Entry to job menu 15

5.6 Operator menu structure 16

5.7 Envelope hopper adjustment 17

5.7.1 Side guides adjustment hopper A 17

5.7.2 Envelope separation hopper A 17

5.7.3 Side guides hopper B 18

5.7.4 Envelope separation hopper B 18

6.

6. PERFORMING A JOB

PERFORMING A JOB 19

6.6.

PERFORMING A JOBPERFORMING A JOB

6.1 Setting up the system 19

6.2 Running a job 22

6.3 Changing settings of a module 23

6.4 Additional functions 23

Page

PagePage

1

1 1

19

19 19

Section

Section Page

SectionSection

7.

7. FAULT FINDING

FAULT FINDING 24

7.7.

FAULT FINDING FAULT FINDING

7.1 General 24

7.1.1 The error screen 24

7.1.2 The information screen 25

7.1.3 The warning screen 25

7.1.4 The call screen 26

7.2 Clearing stoppages 26

7.2.1 Removing documents 26

7.2.2 Stoppage in the document end feed 26

7.2.3 Stoppage at the document feed 26

7.2.4 Removing documents from the hopper 27

7.2.5 Removing envelopes from the insert or sealing table 27

7.2.6 Stoppage on the insert table or sealing table 27

7.2.7 Stoppage in the envelope track 28

8.

8. ERROR CODES

ERROR CODES 29

8.8.

ERROR CODESERROR CODES

8.1 General 29

8.2 Additions to the error lists of other modules 30

9.

9. MAINTENANCE

MAINTENANCE 31

9.9.

MAINTENANCE MAINTENANCE

9.1 General 31

9.2 General cleaning 31

9.3 Cleaning the brushes 31

9.4 Cleaning the sealing roller 31

9.5 Cleaning the moistening cloth 31

10.

10. OPTIONS

OPTIONS 32

10.10.

OPTIONS OPTIONS

10.1 General 32

10.2 More options 32

690 Options 35

10.3

11.

11. SPECIFICATIONS

SPECIFICATIONS 38

11.11.

SPECIFICATIONSSPECIFICATIONS

Page

PagePage

24

2424

29

29 29

31

3131

32

3232

38

38 38

2/40

2/402/40

Page 4

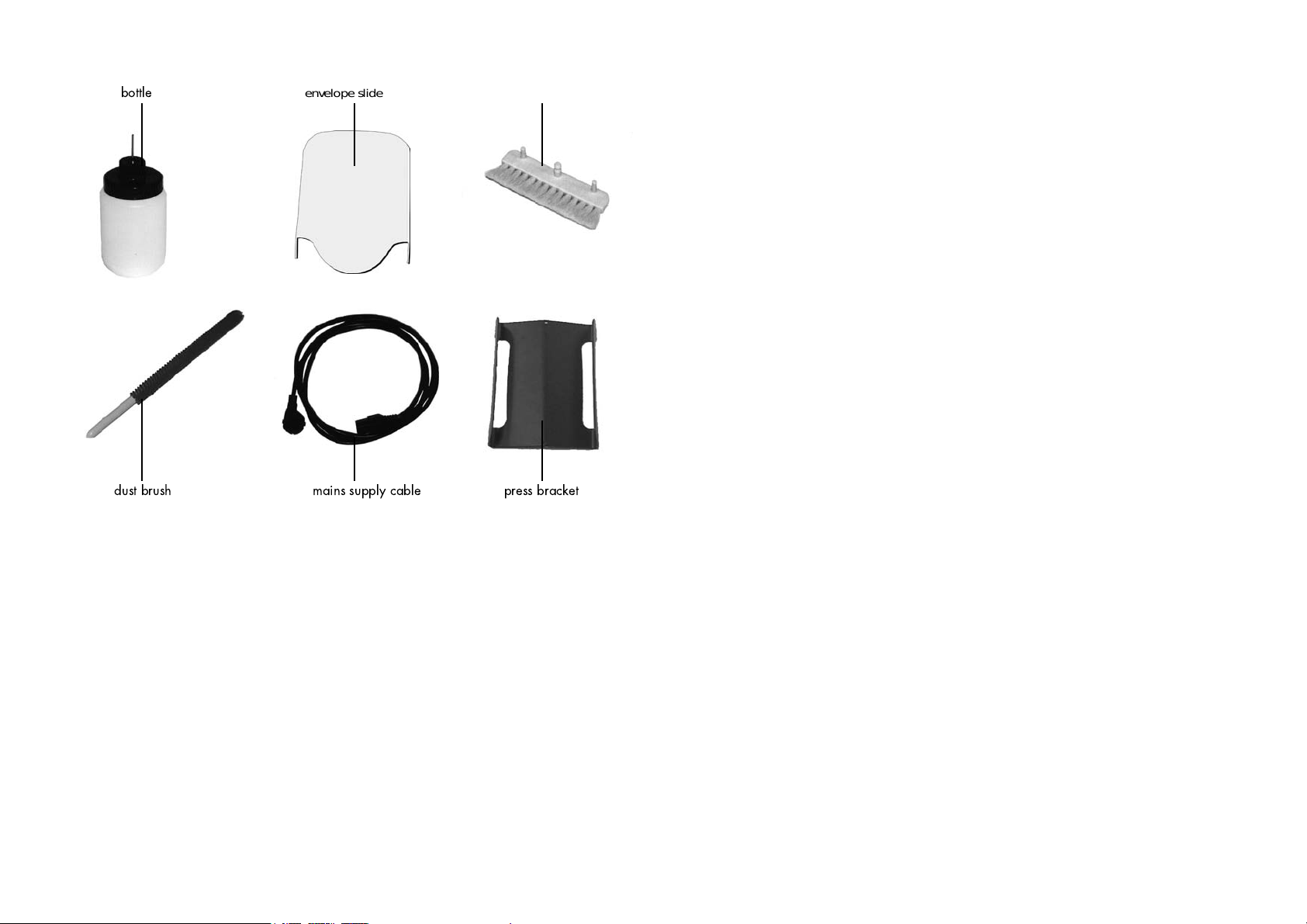

bottle

dust brush mains supply cable press bracket

envelope slide set brushes (3 pcs.)

Fig. 2

2.

2. HOW TO USE THE OPERATOR MANUALS

HOW TO USE THE OPERATOR MANUALS

2.2.

HOW TO USE THE OPERATOR MANUALSHOW TO USE THE OPERATOR MANUALS

This manual, existing of two parts, describes the

inserter (IN-3) module and operating (part 1: operator

manual) and programming of the system (part 2: guide for

job menu).

Use the 6900 Series manual as the main guide. In the text of this

manual we will refer to the other operator manuals if

required.

3.

3. ACCESSORIES

ACCESSORIES

3.3.

ACCESSORIESACCESSORIES

The IN-3 is delivered with the accessories shown in Fig. 2.

3/40

3/40

3/403/40

Page 5

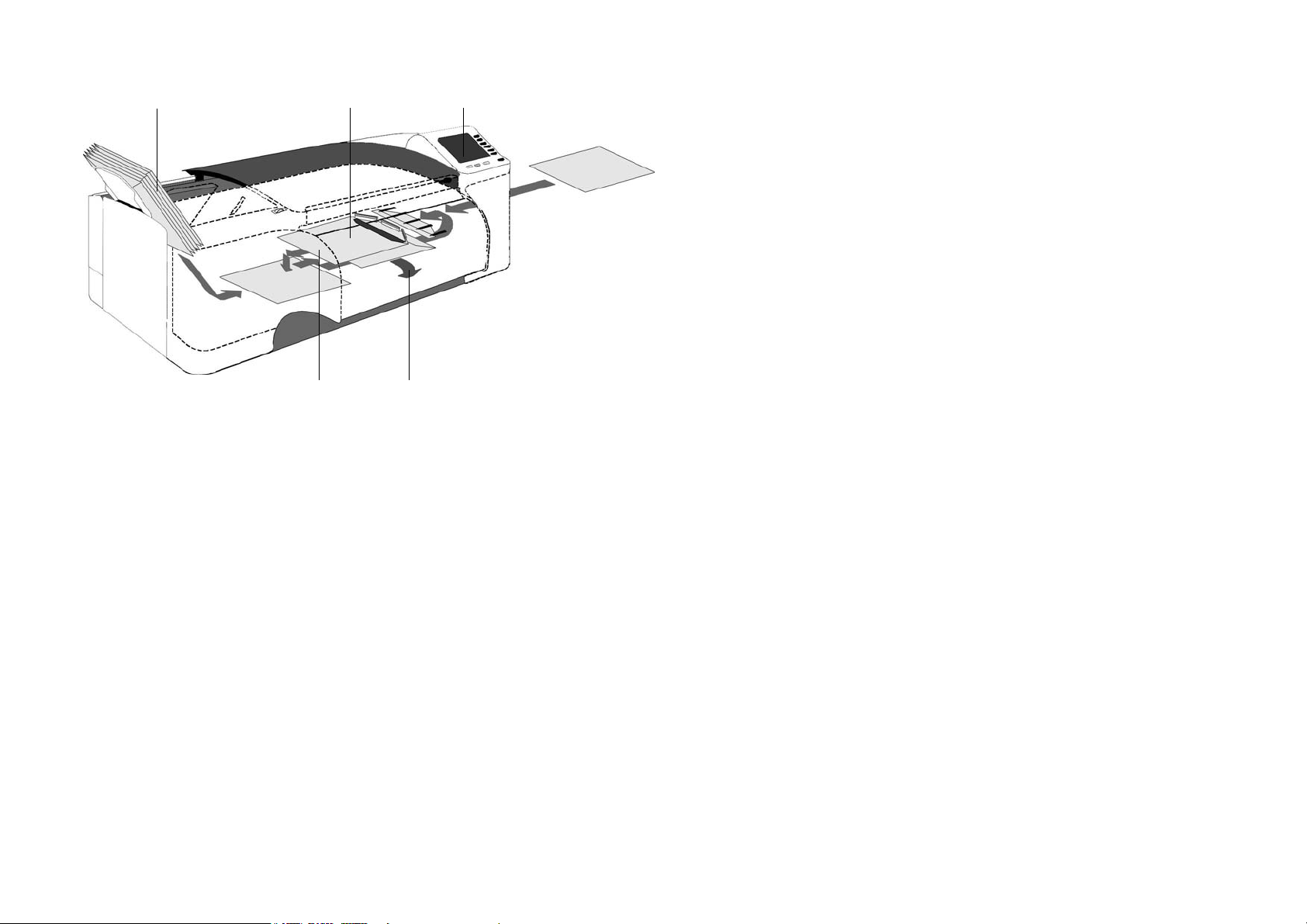

envelope hopper insert position user interface

sealing area exit

4.

4. UNDERSTANDING THE MACHINE

UNDERSTANDING THE MACHINE

4.4.

UNDERSTANDING THE MACHINEUNDERSTANDING THE MACHINE

4.1

4.1 Function

Function

4.14.1

Function Function

4.3

4.3 User interface

User interface

4.34.3

User interface User interface

The user interface of the inserter exists of two menus; the

"main menu" and the "job" menu. These menus are

The inserter inserts documents into envelopes and then seals

the envelopes (or not). Via the central operator panel the

6900 Series system can be operated and programmed.

Settings of a

4.2

4.2 Overview

4.24.2

ll modules are stored centrally at the inserter.

Overview

Overview Overview

See Fig. 3 .

Envelopes are fed from a stack to the insert position. During

this transport the flap is opened. After the envelope has

arrived at the insert position a document is fed to the inserter

and then inserted into the envelope. After insertion, the

envelope flap is moistened (or not) and closed. Then the

envelope is exited.

accessible via a personal pin code.

• The "main" menu is accessible for all operating personnel

and the supervisor. In the main menu jobs can be selected

and performed. After selecting a particular job, all

modules will be set automatically according the job data.

• The "job" menu is only accessible by an authorized user,

the "supervisor", via the supervisor pin code. In the job

menu jobs can be programmed, deleted etc. In a job the

settings of the modules within the system (type of

envelopes, type of documents, type of fold and way to

sort) are recorded. There are more functions in the job

menu. For a description of the job menu see the “Guide

for job menu”.

Fig. 3

The service engineer has access to all menus.

The system can be started, stopped or cleared by pressing

the concerned key located below the display of the inserter,

see section 4.6 page 6.

When a stoppage occurs, the IN-3 operator panel

automatically signals the operator and gives a suggestion

about solving the problem. See chapter 7 and 8.

4/40

4/404/40

Page 6

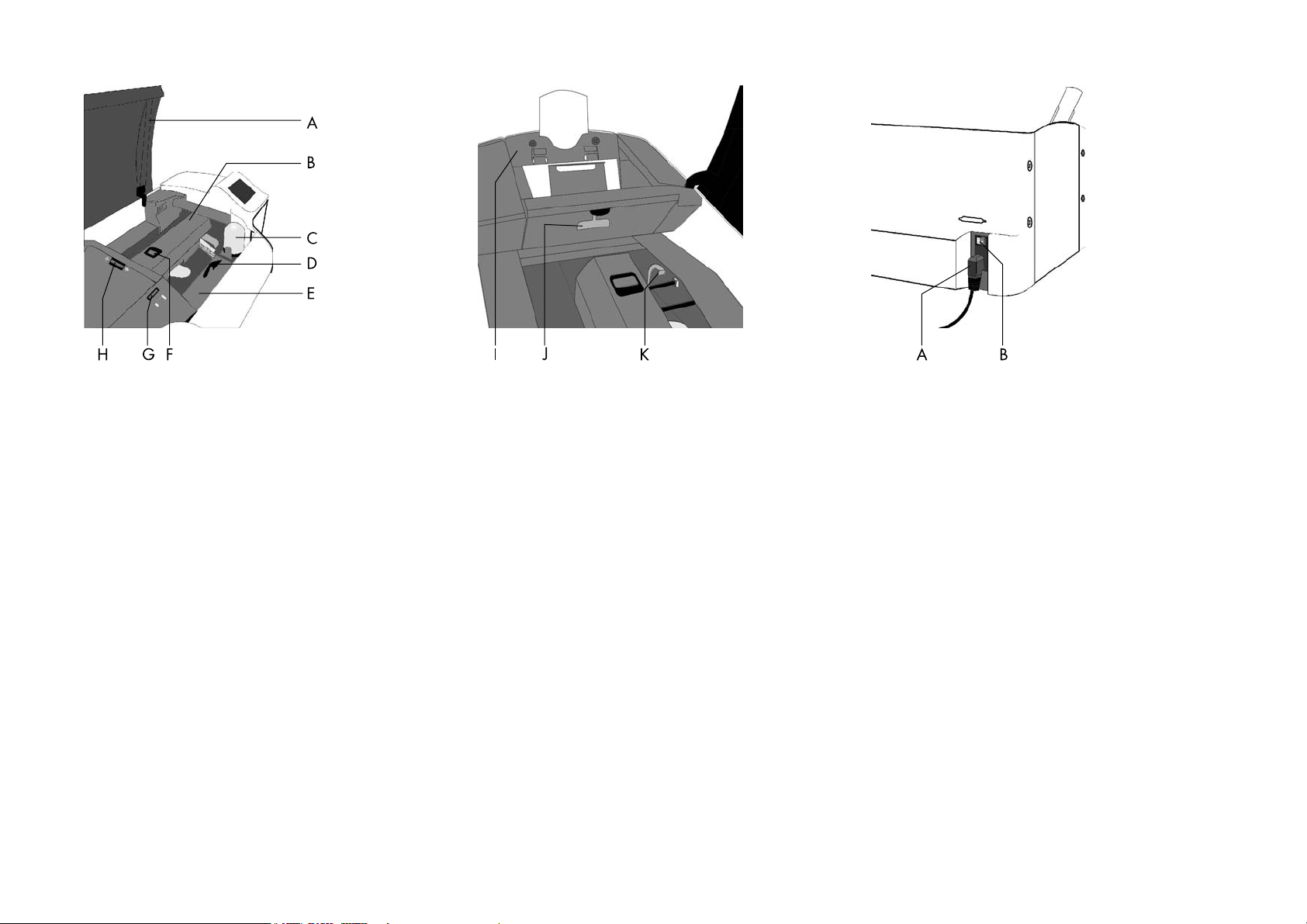

Fig. 4

Fig. 5

Fig. 6

4.4

4.4 Operating controls

Operating controls

4.44.4

Operating controls Operating controls

A: Top cover

B: Loc

C: Bottle

D : Release handle sealing table

E : Sealing table

F : Release handle loc

G: Hopper side guide adjustment wheel

H : Separation adjustment wheel

I : Envelope hopper

J : Release handle hopper

K : Release handle sealing table rollers

4.5

4.5 Power inlet

Power inlet

4.54.5

Power inlet Power inlet

See Fig. 6 . The power inlet B is located at the rear side of

the machine. It contains the power on/off switch and the

main fuse.

See "Warnings", page 2. Connect the main supply cable A

to the power inlet then connect the mains plug to the wall

socket.

5/40

5/40

5/405/40

Page 7

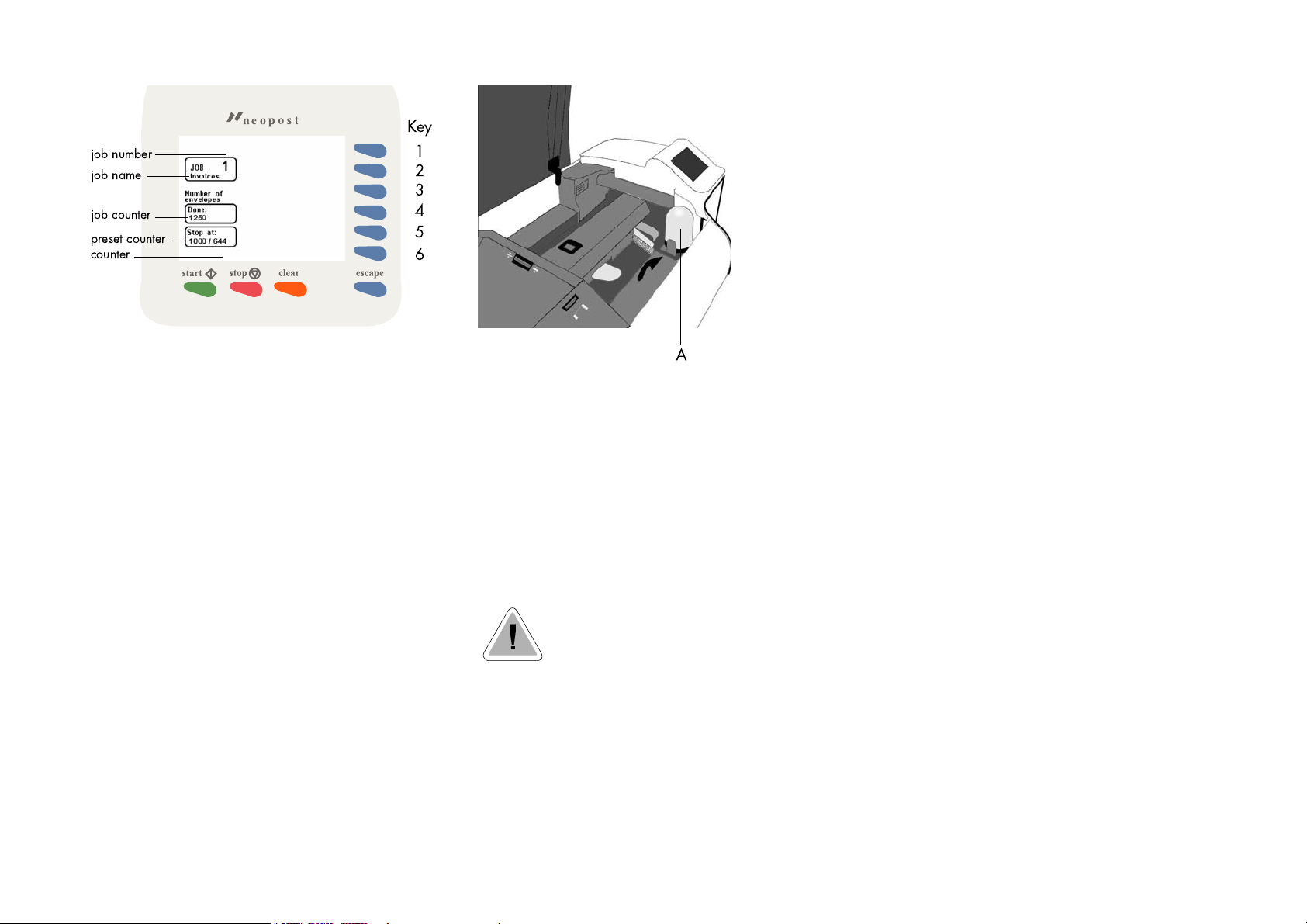

job number

job name

job counter

preset counter

counter

Key

1

2

3

4

5

6

Fig. 7

4.6

4.6 Display keys

Display keys

4.64.6

Display keys Display keys

Key 1 through 6

Key 1 through 6

Key 1 through 6Key 1 through 6

See Fig. 7 . These keys correspond with the function in the

display.

Start key

Start key

Start keyStart key

The system will start to operate.

For more details see 6.2 on page 22.

Stop key

Stop key

Stop keyStop key

The system will stop operating.

Clear key

Clear key

Clear keyClear key

The system will first finish all documents sets that have

already been fed (e.g. to the transport track) by the feed

units, then it stops.

Esc. key

Esc. key

Esc. keyEsc. key

Use this key to exit a (sub) menu without saving any

(altered) settings.

Fig. 8

5.

5. OPERATING THE SYSTEM

OPERATING THE SYSTEM

5.5.

OPERATING THE SYSTEMOPERATING THE SYSTEM

5.1

5.1 Preparations inserter module

Preparations inserter module

5.15.1

Preparations inserter module Preparations inserter module

The bottle A (Fig. 8) must always be filled with water and

the brushes must be moistened. An extra set of brushes is

provided so that one set can be soaked in water whilst the

other set is used. This means there is always a clean set of

brushes ready for usage.

Before moving the system, the bottle and

watertray must be removed.

Refer to the other operator manuals of the used modules for

the required preparations.

If the system is switched off after, for example, a paper

stoppage, the brushes will not rest on the watertray. This

causes the brushes to dry if usage is interrupted for a longer

period.

Always take care that the brushes rest on the watertray.

Therefore the system must be switched on again so that the

brushes will rest on the watertray. The system can then be

switched off.

6/40

6/40

6/406/40

Page 8

Key

1

2

3

4

5

6

Key

1

2

3

4

5

6

Fig. 9

5.2

5.2 Switching on

Switching on

5.25.2

Switching on Switching on

Switch on the inserter using the power switch A, see Fig. 9.

If the AS-1A, PS-3 or franking machine etc. are part of the

system switch these on. Refer to the operator manuals of the

used modules if necessary.

After switching on the pin code screen or the main menu will

appear. In case the pin code screen appears, see section

5.3 for further instructions. In case the main menu screen

appears, see section 5.4 for further instructions.

Fig. 10

5.3

5.3 Entering the personal pin code

Entering the personal pin code

5.35.3

Entering the personal pin code Entering the personal pin code

In Fig. 10 the pin code screen is shown.

Enter your pincode using the keys 1 to 6. If the code is not

correct, a warning “wrong code, try again” will be

displayed. This warning disappears immediately when a

key is pressed.

The pincode screen is not displayed if only the supervisor

code is defined. In this case the main menu as shown in Fig.

11 will be displayed after switching on the system.

5.4

5.4 The main menu

The main menu

5.45.4

The main menu The main menu

The main menu is shown in Fig. 11.

The "main menu" shows 6 different functions:

• go to job info screen (key 1).

• go to the "select job" menu (key 2).

• go to the "test run" menu (key 3).

• go to the "change counters" menu (key 4).

• go to the "settings"menu (key 5).

• go to the "entry to the job menu" (key 6).

Fig. 11

7/40

7/40

7/407/40

Page 9

Key

1

2

3

4

5

6

Key

1

2

3

4

5

6

Key

1

2

3

4

5

6

Fig. 12

5.4.1

5.4.1 Job info screen overview

5.4.15.4.1

Job info screen overview

Job info screen overview Job info screen overview

When key 1 is pressed in the “main menu”, the job info

screen will be displayed (see Fig. 12). The job info screen

shows the following functions:

• select a higher job number (key 1).

• select a lower job number (key 2).

• go to the job data of the upstream (transport) module (key

3).

• go to the job data of the downstream (sorting) module

(key 4) (the job data of the downstream (sorting) module

is shown in Fig. 15).

Press the escape key to go back to the main menu.

Because of the modularity of the system, different

configurations are possible. So take in account that the job

data can differ from which is shown in this job info screen

overview.

Fig. 13

When key 3 is pressed in the “job data” menu the upstream

(transport) module screen is displayed (see Fig. 13). The

screen shows the following functions:

• select a higher job number (key 1).

• select a lower job number (key 2).

• go back to the inserting module (key 4).

• go to next job data screen of the upstream (transport)

module (key 6).

Press the escape key to go back to the main menu.

Fig. 14

When key 6 is pressed in the upstream (transport) module

screen, the screen in Fig. 14 is displayed. The screen shows

the following functions:

• select a higher job number (key 1).

• select a lower job number (key 2).

• go back to the inserting module (key 4).

• go to previous job data screen of the upstream (transport)

module (key 6).

Press the escape key to go back to the main menu.

8/40

Page 10

Key

1

2

3

4

5

6

Fig. 15

When key 4 is pressed in the “job data” menu the

downstream (sorting) module screen is displayed (see Fig.

15). The screen shows the following functions:

• select a higher job number (key 1).

• select a lower job number (key 2).

• go back to the inserter module (key 3).

Press the escape key to go back to the main menu.

9/40

9/409/40

Page 11

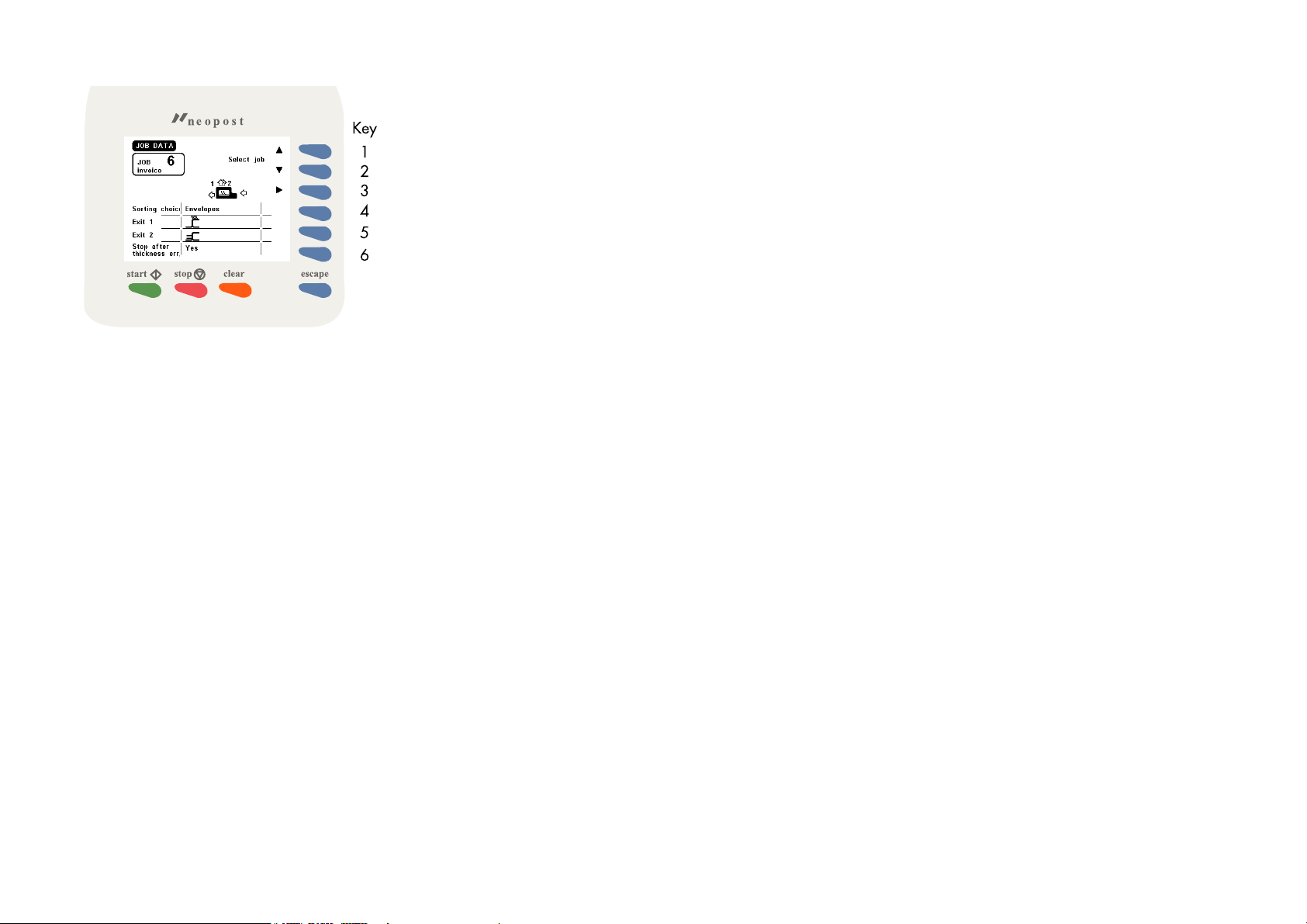

5.4.2

5.4.2 Schematic view

5.4.25.4.2

Schematic view

Schematic view Schematic view

Inserting module Folding module Feeding and accumulation module

Transport module

See pages 17, 18, 19

and the Guide for job menu.

and

Info shown:

Stop at

250

Sorting module

Info shown:

Sorting choice

Exit 1

Exit 2

Stop after

thickness err.

See pages 20 and 32 and

the Guide for job menu.

See page 20 and the

Guide for job menu.

One document is fed.

More documents are fed.

and

Documents with enclosures are fed.

Upstream modules

Job data symbols Job data symbols Job data symbols

means:

The hopper A is selected, envelopes

114

of 114 mm are fed and sealed.

The hopper B is selected.

Both hoppers are selected.

Thickness error detection is activated.

The preset counter is set to

250 document sets.

Job data symbols

means:

Envelopes

The sorting module will sort on

envelopes.

The envelopes fed from hopper A, will

leave the sorter from Exit 1.

The envelopes fed from hopper B, will

leave the sorter from Exit 2.

The system will stop when a thickness

yes

error is detected.

Downstream modules

Info shown:

No fold

means:

No fold

Single fold

Letter fold

Zig-zag fold

Double

parallel fold

Info shown:

means:

The lenght of the fed documents is shown.

297

The number of the fed documents from the

6

feeder station(s) or accumualation station is

set to 6.

Thickness detection is activated.

Optical mark reading is selected (only

available for the accumulation station).

The feeder is selected and used in the job.

The hopper A is linked with the feeder.

The hopper B is linked with the feeder.

Thissymbolisshownunde

accumulation station if the address carrying

document is fed from it.

Refer to operator manuals:

FE 7, FE 8, FE 9, AS 1A, BB 1

and the Guide for job menu.

rthe

feederorthe

10/40

10/4

10/4010/40

Page 12

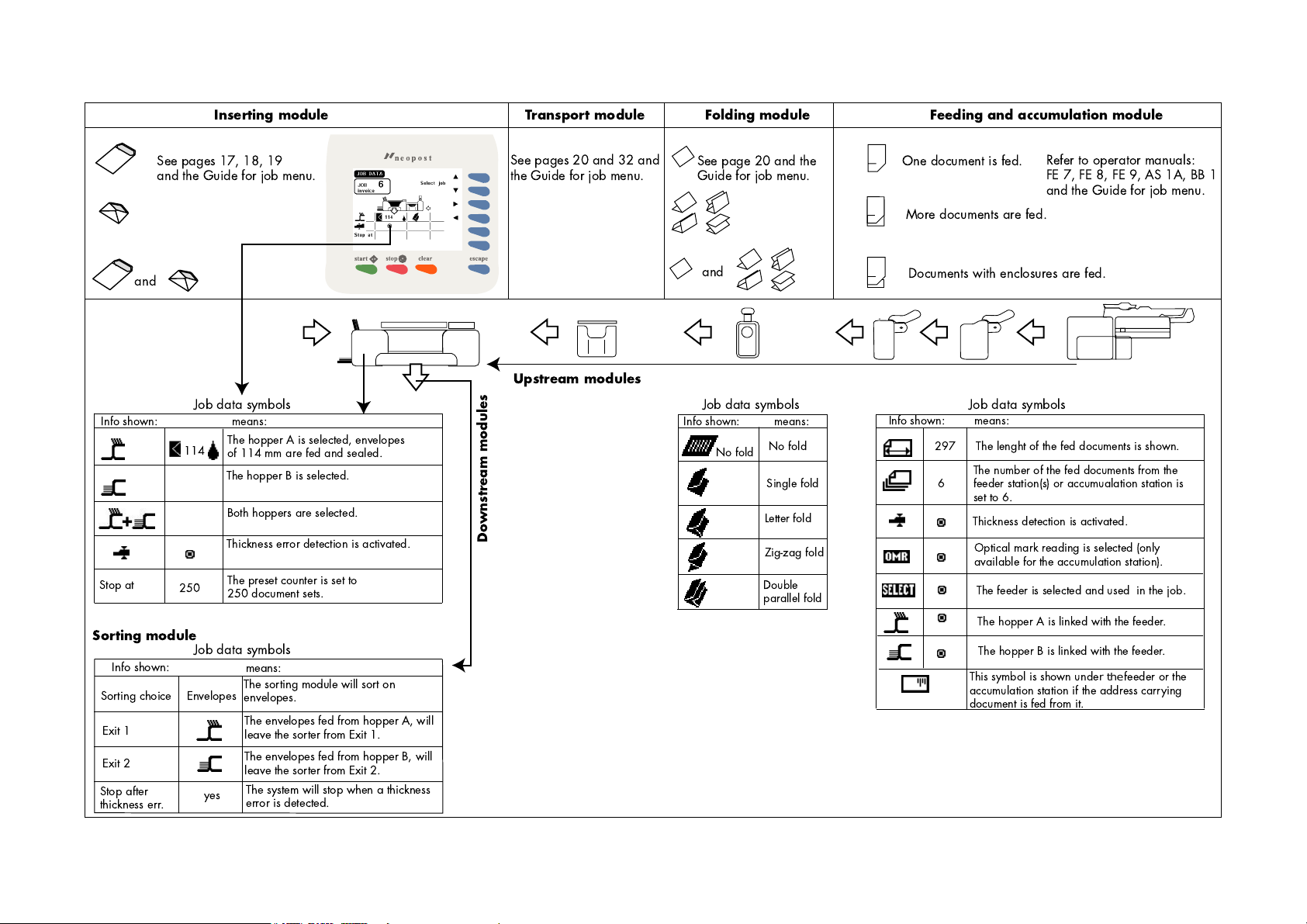

Key

1

2

3

4

5

6

Key

1

2

3

4

5

6

Fig. 16

5.4.3

5.4.3 Selecting a job

5.4.35.4.3

Selecting a job

Selecting a job Selecting a job

After pressing key 2 in the "main menu", the display shows

the "select job" menu (see Fig. 16). The "select job" menu

shows the following functions:

• job data (key 1).

• select a higher job number (key 3).

• select a lower job number (key 4).

• confirm with "OK" (key 6) which will get you back to the

"main menu".

Only programmed jobs can be selected (maximum of 9

jobs).

Fig. 17

5.4.4

5.4.4 Test run menu

5.4.45.4.4

Test run menu

Test run menu Test run menu

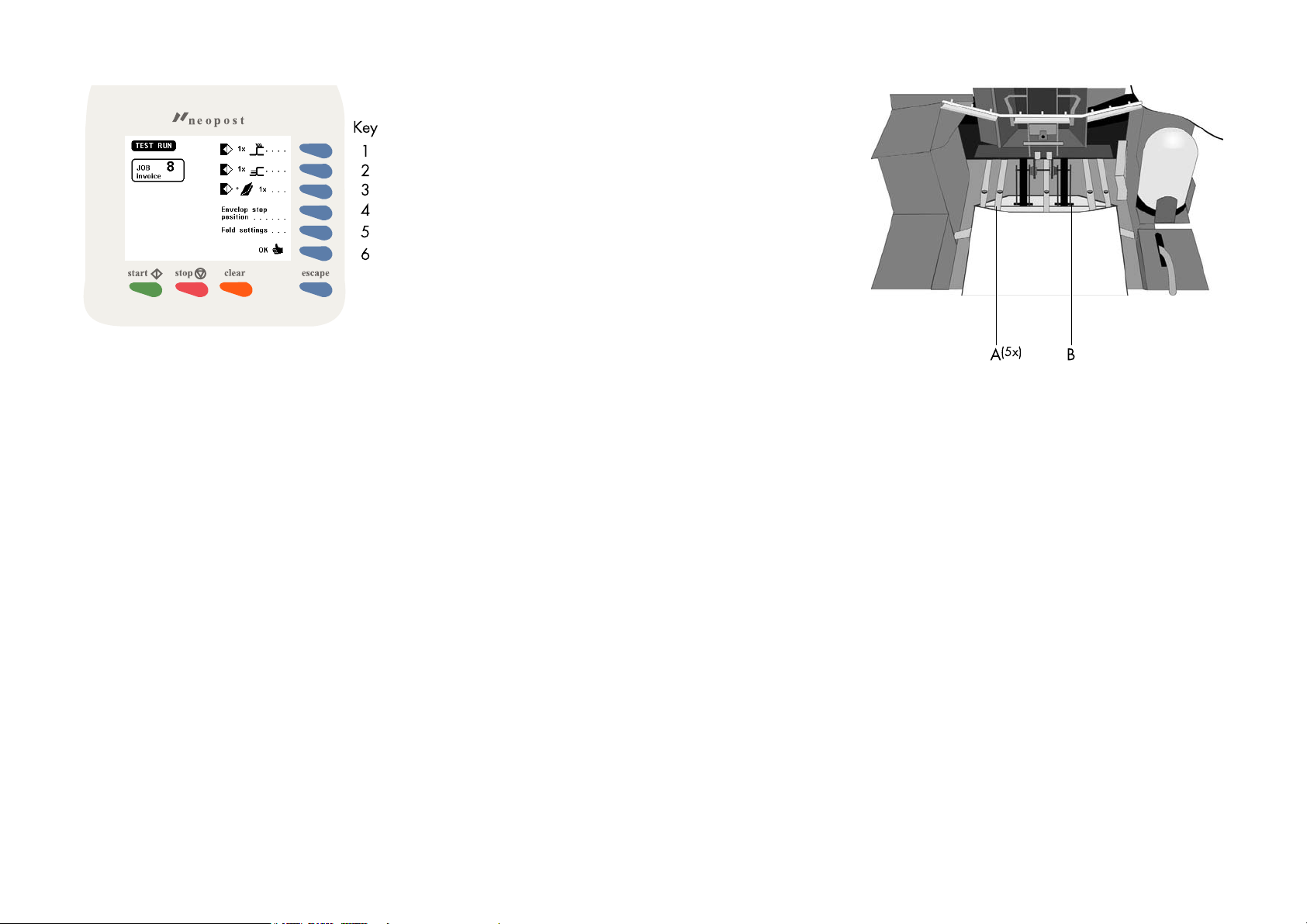

After pressing key 3 in the "main menu" a test run screen will

be displayed. In case an FO-2A is used the screen as

shown in fig. 17 will appear. The purpose of the test run

menu is to check proper envelope feed and to make

adjustments to the envelope stop settings.

The "test run" menu shows the following functions:

• feed one envelope (key 2).

• insert one document (key 3).

• envelope stop position to the right (key 4).

• envelope stop position to the left (key 5).

• confirm settings and return to the main menu (key 6).

In case an FO-3 is used, a screen as shown in fig. 18 will be

displayed. The envelope position keys 4 and 5 of figure 17

have moved to a new submenu (see fig. 18, key 4): after

pressing key 4 this submenu will be entered and the

possibility of adjusting the envelope stop position to the left

or right is available again.

After pressing key 5 a submenu will be entered for fine

tuning the folder settings. For more information see "Fine

tuning the folder settings".

In case the inserter is equipped with a second envelope

hopper (EF-3) the test run menu has been extended and the

following functions for key 1 and 2 have become available

(see fig. 18 for an example):

•

feed one envelope from the standard hopper (key 1).

•

feed one envelope from the second hopper EF-3 (key 2).

11/40

11/40

11/4011/40

Page 13

Feed one envelope

Feed one envelope

Feed one envelope Feed one envelope

Key

1

2

3

4

5

6

Fig. 18

Insert one document

Insert one document

Insert one document Insert one document

(5x)

Envelope stop position adjustment

Envelope stop position adjustment

Envelope stop position adjustment Envelope stop position adjustment

Fig. 19

With this function the proper feed of envelopes can be

tested. First carry out the envelope hopper adjustments, see

section 5.7 on page 17. Then put a stack of envelopes in

the hopper. Use key 1 or key 2 to feed one envelope onto

the insert table. Each time the key is pressed a new

envelope will be fed. No insertion will take place.

The “feed one envelope” function can be used when

adjusting the envelope stop position, see “Envelope stop

position adjustment” on the next page.

12/40

12/40

12/4012/40

With this function the proper functioning of the whole

document and envelope transport will be tested. First carry

out all adjustments, see section 5.7 on page 17. Then load

the system with documents and envelopes.

Use key 3 to make one insert cycle. Each time the key is

pressed another insert cycle will be made. When there is no

envelope waiting on the insert table, the machine feeds one

envelope waiting on the insert table. The document will be

inserted and filled envelope is ejected.

If there are documents on the collating area, these

documents will be inserted and the filled envelope is ejected

(and counted). If there is an empty envelope in the inserter,

this envelope will be ejected.

See notes mentioned in section 6.2 on page 22.

The flap folding line must be positioned under the green

indicator B (Fig. 19). This indicator can be seen after

opening the transparent cover and releasing and lifting the

loc by pulling the release handle of the loc (see page 5).

If necessary, adjust the folding line position by pressing “to

the right” (key 4) or the “to the left” (key 5). Each press

stops the next envelope 1 mm (0,04 inch) to the right (later)

or left (earlier).

Adjustments to the envelope stop position can be made with

the system operating.

Page 14

Envelope fingers adjustment

Envelope fingers adjustment

Envelope fingers adjustment Envelope fingers adjustment

When the envelope stop position is correct the insert fingers

A (Fig. 19) can be adjusted. Adjust the fingers by loosening

the thumb screw on top of each finger (5 in total). Slide the

finger until the tip has entered about 5 mm (0,2 inch) into

the envelope. Re- tighten the screw. The fingers on either

side of the loc can be moved sideways to the desired

position. Place the outer fingers about 10 mm (0,4 inch)

from the edges of the envelope.

Check the finger positions when changing to a different type

of envelope.

Key

1

2

3

4

5

6

Fig. 20

Fine tuning the folder settings

Fine tuning the folder settings

Fine tuning the folder settings Fine tuning the folder settings

In the 6900 Series, if and when the electronic folder FO-3 is used,

the operator has the possibility to adjust the (mechanical) folder

settings during the execution of a specific job. This might be

neccesary for instance when adapting the fold settings to

the current mechanical paper parameters (thickness,

sturdiness et cetera).

After pressing key 5 in figure 18 the menu of figure 20

appears.

The following functions are available:

• test for a folded document 1x (key 1). It makes sense to

do this in the same menu screen.

• Increase/ decrease value of fold setting A (keys 2 and

3). Basically there is no limitation in the values. The

possibilities are same as in the equivalent settings of the

job menu (FO settings).

• as keys 2 and 3, for fold setting B, if relevant (keys 4 and

5). This depends on the fold type. Setting B is relevant for

all fold types except single fold. Note that you cannot

change the fold type in this menu.

• enter and effectuate the settings (key 6). Back to the menu

"test run" menu of figure 18.

• discard the settings (Esc). Back to the "test run" menu of

figure 18.

13/40

13/40

13/4013/40

Page 15

Key

1

2

3

4

5

6

Key

1

2

3

4

5

6

Fig. 21

5.4.5

5.4.5 Counters menu

5.4.55.4.5

Counters menu

Counters menu Counters menu

After pressing key 4 in the "main menu", the display shows

the "change counters" menu (Fig. 21). The "change

counters" menu shows the following functions:

• increase the counters (key 1).

• decrease the counters (key 2).

• reset counters to zero (key 3).

• increase the preset counters (key 4).

• decrease the preset counters (key 5).

• save the counter settings with "OK" (key 6) which will get

you back to the "main menu".

Increase/decrease counters

Increase/decrease counters

Increase/decrease counters Increase/decrease counters

The following counters will be increased or decreased:

•job counter.

•counter.

Reset counters to zero

Reset counters to zero

Reset counters to zero Reset counters to zero

The following counters will be set to zero:

•job counter.

•counter.

Increase and decrease preset counter

Increase and decrease preset counter

Increase and decrease preset counter Increase and decrease preset counter

By pressing key 4 or key 5 the preset counter will be

increased or decreased.

The counter will only be displayed when the preset counter

is set higher than zero.

When pressing key 4 or key 5, the stop counter will initially

be increased or decreased with one unit at a time. When

the key is pressed longer the counter will be raised with ten

units at a time.

Fig. 22

5.4.6

5.4.6 Settings menu

5.4.65.4.6

Settings menu

Settings menu Settings menu

After pressing key 5 in the “main menu”, the screen as

shown in Fig. 22 will be displayed. The “settings” menu

shows the following functions:

• job data (key 1).

• decrease contrast of the display (key 2).

• increase contrast of the display (key 3).

• thickness detection on or off (key 4).

• reset thickness detection (key 5).

• save the counter settings with "OK" (key 6) which will get

you back to the "main menu".

Display contrast

Display contrast

Display contrast Display contrast

By pressing key 2 the display contrast will be decreased. By

pressing key 3 the display contrast will be increased.

14/40

14/4014/40

Page 16

Thickness detection

Thickness detection

Thickness detection Thickness detection

Reset thickness detection

Reset thickness detection

Reset thickness detection Reset thickness detection

5.5

5.5 Entry to job menu

Entry to job menu

5.55.5

Entry to job menu Entry to job menu

Key

1

2

3

4

5

6

Fig. 23

The IN-3 is equipped with a document thickness detector.

The thickness detector controls the thickness of the

document. In this way the machine checks if the envelope

will be filled with the correct amount of documents. The

detector will stop the machine if a document is too thick or

too thin and an error message will be displayed.

The thickness detector is self-setting. After switching on (or

after resetting the thickness detection) the thickness of the

first document passing under the detector is memorized and

compared with the following inserts.

If the thickness of the documents can vary, for example

when a small card is used that can shift in place, it is

recommended to switch off the thickness detection or shift it

to a stable section of the document. The thickness detection

measurement area can only be adjusted by the supervisor.

See section 2.4.3 in the “Guide for job menu”.

By pressing key 5 the thickness detection will be reset.

If the thickness detection is switched off, the text “reset

thickness det.....” will not be displayed in the screen.

When key 6 in the “main menu” is pressed the display

shows the screen in Fig. 23. Only the supervisor can get

access to the job settings after entering the correct code.

Enter your pincode using the keys 1 to 6. If the code is not

correct, a warning “wrong code, try again” will be

displayed. This warning disappears immediately when a

key is pressed.

15/40

15/40

15/4015/40

Page 17

5.6

5.6 Operator menu structure

Operator menu structure

5.65.6

Operator menu structure Operator menu structure

Key

Start key

Start processing

Stop key

Stop processing

Clear key

Empty the system and stop

Escape key

Exit a menu without saving any

altered settings

Select a job number for job

data, see page 8

Select (upstream) transport module data

Select (downstream) sorter module data

1

2

3

4

5

6

Job data, page 8

Select a job

Confirm selected job and go to main menu

Feed one envelope from hopper A, page 12

Feed one envelope from hopper B

Insert one document

Envelope stop position to the right

Envelope stop position to the left

Confirm settings and back to main menu

Increase counters, page 14

Decrease counters

Reset counters to zero

Increase preset counter

Decrease preset counter

Confirm settings and back to main menu

Job data, page 8Enter pincode, page 15

Adjust display contrast, page14

Select thickness detection on or off

Reset thickness detection

Confirm settings and back to main menu

16/40

16/4016/40

Page 18

5.7

5.7 Envelope hopper adjustment

Envelope hopper adjustment

5.75.7

Envelope hopper adjustment Envelope hopper adjustment

Fig. 24

5.7.1

5.7.1 Side guides adjustment hopper A

5.7.15.7.1

Side guides adjustment hopper A

Side guides adjustment hopper A Side guides adjustment hopper A

Fig. 25

5.7.2

5.7.2 Envelope separation hopper A

5.7.25.7.2

Envelope separation hopper A

Envelope separation hopper A Envelope separation hopper A

The IN-3 can be equipped with a second hopper, the EF-3

(see section 10.2 page 32). This hopper is then called

“hopper B”. The IN-3 standard hopper is called “hopper

A”. Although an operator manual is delivered with the EF-3,

on this page you will also find a description of the hopper

adjustments.

Take a stack of about 20 envelopes. Fan the envelopes a bit

(see Fig. 24) and place the envelopes upright in the system

with the flap to the back. Place the press bracket C on the

envelopes.

Adjust the envelope hopper side guides B by turning the

thumbwheel A, to provide just enough space for the

envelopes to move freely. Too much play causes skewing.

When using C4 envelopes check if the blade spring on the

sealing table is up. The spring is visible after lifting the loc.

The purpose of the spring blade is to obtain better support

when using thin A4 sized documents.

Adjust the envelope separation by turning thumbwheel D

(see Fig. 25) until one envelope is just about to be pulled in.

After starting the system it may occur that more than one

envelope at a time is pulled in. If this happens, rotate the

thumbwheel slightly until only one envelope at a time is

pulled in. Adjustments can be made with the system

operating.

17/40

17/40

17/4017/40

Page 19

5.7.3

5.7.3 Side guides hopper B

5.7.35.7.3

Side guides hopper B

Side guides hopper B Side guides hopper B

Fig. 26

5.7.4

5.7.4 Envelope separation hopper B

5.7.45.7.4

Envelope separation hopper B

Envelope separation hopper B Envelope separation hopper B

Take a stack of about 20 envelopes. Fan the envelopes a bit

and place the envelopes in the system with the flap to the

bottom side and trailing.

Adjust the envelope hopper side guides A (Fig. 26) by

turning the thumbwheel C, to provide just enough space for

the envelopes to move freely. Too much play causes

skewing.

18/40

18/4018/40

Adjust the envelope separation by turning knob B (Fig. 26)

counter clockwise until two envelopes, one on top of the

other, can be moved backwards and forwards between the

rollers without resistance. Then turn knob B clockwise until

one envelope will pass between the rollers.

After starting the system it may occur that more than one

envelope at a time is pulled in. If this happens, rotate knob B

clockwise a quarter turn. Repeat if necessary to obtain

correct operation.

Once the envelope separation has been set, a wide variety

of envelopes can be handled.

Page 20

6.

6. PERFORMING A JOB

PERFORMING A JOB

6.6.

PERFORMING A JOBPERFORMING A JOB

6.1

6.1 Setting up the system

Setting up the system

6.16.1

Setting up the system Setting up the system

Switch on the inserter IN-3 and, if part of the system, the AS-1A and PS-3 etc.

Refer to the operator manuals of the used modules.

Inserter IN-3

Inserter IN-3

Inserter IN-3 Inserter IN-3

Action

Action Refer to..

ActionAction

• Check the waterlevel, refill if necessary Refer to section 5.1 Preparations inserter module on page 6

• If required, enter pincode to gain access to the main menu Refer to section 5.3 Entering the personal pin code on page 7

Refer to..

Refer to..Refer to..

• Select the required job

To recognize the correct job number, all jobs should have been given names. If so, the name is visible in the

framework under JOB X.

• Press the Job info key. Use the job info facility as a guide to put the envelopes at the correct enve-

lope hoppers and the documents at the correct feed stations.

• After the correct job has been selected press the OK key to confirm. Now the job information will

be sent to all modules.

• Set the envelope hopper side guides and separation Refer to section 5.7 Envelope hopper adjustment on page 17

• Enter the test menu, press the 1x envelope key to bring an envelope onto the insert table.

• Check the envelope stop position, adjust if necessary.

• Set the envelope fingers

• If necessary, enter the counters menu to change or reset the counters. Refer to section 5.4.5 Counters menu on page 14

• If necessary, enter the settings menu to check the thickness detector settings. Refer to section 5.4.6 Settings menu on page 14

Refer to section 5.4.3 Selecting a job on page 11

Refer to section 5.4.1 Job info screen overview on page 8

Refer to section 5.4.3 Selecting a job on page 11

Refer to section 5.4.4 Test run menu on page 11

19/40

19/40

19/4019/40

Page 21

Transport unit TR-7A, TR-1B

Transport unit TR-7A, TR-1B

Transport unit TR-7A, TR-1B Transport unit TR-7A, TR-1B

Action

Action Refer to..

ActionAction

Refer to the operator manuals of these modules if required.

Refer to..

Refer to..Refer to..

• If necessary adjust the module TR-7A.

Note 1: With the 6900 Series selection of a mode at the TR-7A is not applicable.

Note 2: Information about where to put the address carrying documents and the enclosures can be

found in the job info menu of the inserter.

Note 3: It is possible that there is no TR-7A fold/no fold selector available. In that case the TR-7A is

equipped with so called Twin cycle facility that automizes this setting (see options).

• If necessary adjust the module TR-1B. Refer to the chapter “Adjustments” and follow the instructions.

Fold unit FO-3, FO-2A

Fold unit FO-3, FO-2A

Fold unit FO-3, FO-2A Fold unit FO-3, FO-2A

Action

Action Refer to..

ActionAction

Refer to the operator manuals of these modules if required.

• For the FO-3 no adjustments have to be made. -

• The fold unit has to be set such that the folded documents fit in to the envelope. Refer to the chapter “Adjustments” and follow the instructions.

Feed stations FE-1M, FE-8, FE-7, FE-9, ST-1, PF-45A, PF-65A, SF-4/6

Feed stations FE-1M, FE-8, FE-7, FE-9, ST-1, PF-45A, PF-65A, SF-4/6

Feed stations FE-1M, FE-8, FE-7, FE-9, ST-1, PF-45A, PF-65A, SF-4/6 Feed stations FE-1M, FE-8, FE-7, FE-9, ST-1, PF-45A, PF-65A, SF-4/6

Action

Action Refer to..

ActionAction

Refer to the operator manuals of these modules if required.

• If necessary adjust the modules FE-7, FE-8, ST-1, PF-45A, PF-65A. Refer to the chapter “Adjustments” and follow the instructions.

Refer to the chapter “Adjustments” and follow the instructions.

Refer to..

Refer to..Refer to..

Refer to..

Refer to..Refer to..

• If necessary adjust the module FE-9. Refer to the chapter “Settings” and follow the instructions.

• If necessary adjust the module FE-1M. Set the document hopper guides and the separation.

• Fill the hoppers of the feed units with documents. Refer to the operator manuals of the feed units.

20/40

20/4020/40

Refer to the sections “Side guide adjustment” and “Separation

adjustment”.

Page 22

AS-1A

AS-1A

AS-1A AS-1A

Action

Action Refer to..

ActionAction

Refer to the operator manuals of these module if required.

• If necessary adjust the module AS-1A. Refer to the chapter “Adjustments” and follow the instructions.

3d Party device

3d Party device

3d Party device 3d Party device

Action

Action Refer to..

ActionAction

Refer to the operator manuals of these modules if required.

Refer to..

Refer to..Refer to..

Refer to..

Refer to..Refer to..

21/40

21/40

21/4021/40

Page 23

Key

1

2

3

4

5

6

Fig. 27

6.2

6.2 Running a job

Running a job

6.26.2

Running a job Running a job

Start

Start

StartStart

Test cycle

After all settings have been carried out a few test cycles can

be made by using the "insert one document" function, see

section 5.4.4 page 12 or see fig 27.

Automatic operation

When correct insertion is obtained, start automatic

operation by pressing the "Start" key.

When the “start” key is pressed (after switching on and no

other job is selected), the job information is sent to all

machines in the system. During this time an egg timer will

appear for about 10 seconds. When ready, the system

starts operating.

If documents from a previous job are detected on the

transport track (TR-7A), these are transported to the

collating area of the TR-7A. The system then stops and

indicates that these documents have to be removed.

Remove and press the start key again.

Stop

Stop

Stop Stop

Press the stop key to stop the system.

Job finishing

Job finishing

Job finishingJob finishing

The system can be cleared during the running of a job or

after running out of address carrying documents.

To clear the system, press the clear key. The system will finish

all documents sets that have already been fed (e.g. to the

transport track) by the feed units. Then the system stops.

In case a transport unit is part of the system, see TR-7A

operator manual chapter 6.

With the 6900 Series, use the inserter clear key instead of

using the TR-7A reset key.

With the 6900 Series, remarks about the inserter "pause"key

are not applicable.

Stoppages

Stoppages

StoppagesStoppages

In case of a stoppage, refer to chapter 7 and 8.

22/40

22/4022/40

Page 24

6.3

6.3 Changing settings of a module

Changing settings of a module

6.36.3

Changing settings of a module Changing settings of a module

The settings of feed modules including the AS-1A are stored

in jobs. To provide extra flexibility, it is possible to change

the settings on a module locally (after selecting the job). In

this way it is possible to run different applications using just

one job.

These changes will not be memorized and are lost after

selecting another job or switching off the system.

Below the possible changes in settings are listed:

• all feed modules including AS-1A can be switched on or

off.

• at the FE-7, FE-9 and ST-1 the double document detector

can be switched on or off. Also the value of the multifeed

counter can be changed.

• at FE-8 changes in the "set" menu can be made.

• at the AS-1A all settings mentioned in chapter 4 can be

changed.

6.4

6.4 Additional functions

Additional functions

6.46.4

Additional functions Additional functions

The 6900 Series provides additional operating functions.

They are listed below:

AS-1A

AS-1A

AS-1AAS-1A

• The AS-1A can be locally switched on or off (toggle

function). To switch on or off, press and hold the “Pause”

key for one second. The AS-1A display shows an “u”

when switched off. This “u” is also visible when the AS-1A

is switched off by the IN-3.

• Extra functionality Automix

SF/FS interface box

SF/FS interface box

SF/FS interface boxSF/FS interface box

TM

", see chapter 10.

• The SF/FS interface box (used with crossfold applications

or foot switch) can be locally switched on or off. To switch

the interface box on or off, press and hold the blue reset

key (toggle function) for one second. When switched on,

a yellow (on the interface box) lamp will light.

23/40

23/40

23/4023/40

Page 25

Options

Options

Options Options

7.

7. FAULT FINDING

FAULT FINDING

7.7.

FAULT FINDINGFAULT FINDING

7.1.1

7.1.1 The error screen

7.1.17.1.1

The error screen

The error screen The error screen

Key

1

2

3

4

5

6

Fig. 28

See chapter 10.

24/40

24/4024/40

7.1

7.1 General

General

7.17.1

General General

The IN-3 detects the following error types:

• errors in the paperflow.

• technical errors.

• changes in configuration.

When an error (for example running out of envelopes) is

about to occur a warning screen is displayed.

The error screen (an example is shown in Fig. 28) provides

the following information:

• the error location, indicated by an arrow in the machine

symbol (C).

• the error description (A).

• the suggested solution (B).

Resetting the machine

Resetting the machine

Resetting the machine Resetting the machine

After solving the problem the machine can be reset by

pressing key 6. The error screen will disappear.

Page 26

Key

1

2

3

4

5

6

Key

1

2

3

4

5

6

Fig. 29

7.1.2

7.1.2 The information screen

7.1.27.1.2

The information screen

The information screen The information screen

By pressing key 1 in the error screen, an additional

information screen as shown in Fig. 29 is displayed.

This screen shows more information about the cause of the

error. In this screen also the error code of the error is

displayed. For a complete description of the error codes

chapter 8.

7.1.3

7.1.3 The warning screen

7.1.37.1.3

The warning screen

The warning screen The warning screen

A warning screen is displayed when a refill is necessary. An

example of a message screen is shown in Fig. 30.

Resetting the machine

Resetting the machine

Resetting the machine Resetting the machine

After refilling, the machine can be reset by pressing key 6.

The message screen will disappear.

Fig. 30

Configuration message

Configuration message

Configuration message Configuration message

The following message can occur if a job is selected in the

“job edit” menu:

“System differs from job data. Not corresponding modules

need to be set”.

When selecting a job, the system checks the current device

configuration with the device configuration as stored in the

job.

The operator can either ignore the message and continue

(soft key 6) or cancel the job editing.

This message is not displayed if the replaced or removed

device is switched off for this job, or if the replaced or

removed device has no job settings (i.e. FO-2A or TR-1B

plus foot switch).

If an FO-2A is replaced by an FO-3, the following default

settings for the FO-3 will be used:

• Envelope length > document length A4 + 6 mm margin.

No fold.

• Envelope length > document length ½A4 + 6 mm margin.

Single fold with A = 149 mm.

• Envelope length > document length 1/3 A4 + 6 mm

margin. Letter fold with A = 97 mm and B = 197 mm.

• Envelope length < document length 1/3 A4 + 6 mm

margin. Double parallel fold with A = 200 mm and B =

100 mm.

If the envelope length isn't yet known, the default envelope

length is used.

25/40

25/40

25/4025/40

Page 27

Key

1

2

3

4

5

6

Fig. 31

7.1.4

7.1.4 The call screen

7.1.47.1.4

The call screen

The call screen The call screen

When a technical error occurs the error screen will not

display the machine symbol. Instead a message “Technical

error, call service” will be displayed (see Fig. 31).

This screen indicates that the occured error can not be

solved by operating personnel. Assistance of service

support is needed.

First write down the error code, than switch the inserter off

and on again, to verify system operation. When the error

still occurs contact your service organization.

7.2

7.2 Clearing stoppages

Clearing stoppages

7.27.2

Clearing stoppages Clearing stoppages

When an error in the paperflow occurs, the machine can

give the following suggested solutions:

• remove the document(s).

• remove the envelope.

Fig. 32

7.2.1

7.2.1 Removing documents

7.2.17.2.1

Removing documents

Removing documents Removing documents

When an error occurs in the document feed the error screen

can show the following symbols:

stoppage in the document end feed.

stoppage in the document feed.

Fig. 33

7.2.2

7.2.2 Stoppage in the document end feed

7.2.27.2.2

Stoppage in the document end feed

Stoppage in the document end feed Stoppage in the document end feed

Remove documents in the following way:

• remove documents from the document feed end.

• press the reset key.

7.2.3

7.2.3 Stoppage at the document feed

7.2.37.2.3

Stoppage at the document feed

Stoppage at the document feed Stoppage at the document feed

Remove documents in the following way:

• lift the loc by pulling the release handle A of the loc (see

Fig. 32).

• remove the document.

• close the loc.

• press the reset key.

26/40

26/4026/40

Page 28

Fig. 34

7.2.4

7.2.4 Removing documents from the hopper

7.2.47.2.4

When an error occurs in the hopper the error screen shows

the following symbol:

The envelopes can be removed in the following way:

• remove all envelopes from the hopper.

• open the hopper by pulling release handle A of the

• remove the envelopes from the lower part of the hopper.

• close the hopper with a firm click.

• press the reset key.

Removing documents from the hopper

Removing documents from the hopper Removing documents from the hopper

stoppage in the hopper.

hopper upwards (see Fig. 33 and Fig. 34).

7.2.5

7.2.5 Removing envelopes from the insert or

7.2.57.2.5

When an error occurs in the inner part of the machine, the

error screen can show the following symbols:

Removing envelopes from the insert or

Removing envelopes from the insert or Removing envelopes from the insert or

sealing table

sealing table

sealing table sealing table

stoppage on the insert table.

stoppage on the sealing table.

stoppage in the envelope track.

7.2.6

7.2.6 Stoppage on the insert table or sealing table

7.2.67.2.6

Remove envelopes in the following way:

• lift the loc by pulling the release handle A of the loc (see

• remove the envelope.

• close the loc.

• press the reset key.

Stoppage on the insert table or sealing table

Stoppage on the insert table or sealing table Stoppage on the insert table or sealing table

Fig. 32).

27/40

27/40

27/4027/40

Page 29

7.2.7

7.2.7 Stoppage in the envelope track

7.2.77.2.7

Remove envelopes in the following way:

• lift the loc by pulling the release handle A of the loc (see

• lift the sealing table by pulling the locking handle B of the

• remove the envelope.

• close the sealing table and the loc.

• press the reset key.

28/40

28/4028/40

Stoppage in the envelope track

Stoppage in the envelope track Stoppage in the envelope track

Fig. 32).

sealing table.

Page 30

8.

8. ERROR CODES

ERROR CODES

8.8.

ERROR CODESERROR CODES

8.1

8.1 General

General

8.18.1

General General

The central display of the inserter will display all system-wide errors that occur. When an error occurs, read the information on the screen, press the info key for more information. Follow the

instructions. Generally an error number will be given. This number can be used for reference.

error description

error description suggested solution

error descriptionerror description

suggested solution see also....

suggested solutionsuggested solution

see also.... information

see also....see also....

information Error code

informationinformation

Error code

Error codeError code

Envelope stoppage. Remove envelope,

readjust the envelope separation.

Envelope stoppage. Remove envelope,

readjust the envelope separation.

Envelope stoppage. Remove envelope. Page 26. Envelope doesn’t reach the “track” sensor. 4

Envelope stoppage. Remove envelope. Page 26. Envelope doesn’t reach the “flap” sensor. 5

Envelope stoppage. Remove envelope. Page 26. Envelope not opened or already opened in the

Wrong envelope size or too many envelopes fed

Closed envelope ? Put an open envelope in the hopper. probably closed envelope in hopper. 8

Document stoppage. Remove document. Page 26. Document doesn’t reach the “input” sensor. 9

Document stoppage. Remove document. Page 26. Document doesn’t clear the “input” sensor. 10

Document stoppage. Remove document. Page 26. Insert failure: Document is not clearing the “loc” sen-

Not enough documents inserted Remove envelope and check contents,

To many documents inserted Remove envelope and check contents,

Remove envelope,

place the correct envelopes in the hopper.

reset thickness detection.

reset thickness detection.

Page 7.

Page 17.

Page 6.

Page 17.

Page 17.

Page 26.

Page 15

Page 26.

Page 15

Page 26.

Envelope longer than reference length.

Envelope doesn’t reach the “track” sensor.

envelope hopper.

Wrong envelope size or separation not correctly

adjusted. 7

sor.

Document too thin.

Document too thick.

11

12

13

1

3

6

Envelope stoppage. Remove envelope. Page 26. Document doesn’t clear the “eject” sensor. 14

Envelope stoppage. Remove envelope. Page 26. Document doesn’t reach the “exit” sensor. 15

Envelope stoppage. Remove envelope. Page 26. Document doesn’t clear the “exit” sensor. 16

29/40

29/40

29/4029/40

Page 31

error description

error description suggested solution

error descriptionerror description

suggested solution see also....

suggested solutionsuggested solution

see also.... information

see also....see also....

information Error code

informationinformation

Error code

Error codeError code

Unknown set. Remove set. Page 26. During the system startup a set has been detected.

Remove this set.

Configuration does not match. Switch the inserter off and restore the

configuration.

System can not be set. Select job again. The job settings can not be transmitted correctly.

8.2

8.2 Additions to the error lists of other modules

Additions to the error lists of other modules

8.28.2

Additions to the error lists of other modules Additions to the error lists of other modules

error description

error description suggested solution

error descriptionerror description

Document stoppage. Remove documents. The document (that has been delivered by the Side

Document stoppage. Remove documents. The document to be delivered by the Side Feed unit

Feeding failure. Remove documents. The Side Feed Unit (PF) is empty. Refill the document

System blocked. Remove envelope and check contents,

reset thickness detection.

suggested solution see also....

suggested solutionsuggested solution

see also.... information

see also....see also....

A module of the system has been removed.The configuration is not corresponding with the selected job.

Check if of all covers are closed.

information Error code

informationinformation

Feed unit) does not move during a TR-7A finger

cycle. Clear the paper jam.

does not reach the TR-7A track. Remove paper jam

and adjust arm height of the Side Feed unit.

hopper.

The fold unit (FO-2A, FO-3) is either not present or

not correctly placed (this is indicated by a

microswitch that blocks FO operation). Place or correctly place the fold unit.

62

67

68

Error code

Error codeError code

80

81

120

1

Document stoppage. Remove envelope and check contents,

reset thickness detection.

30/40

30/4030/40

The document does not reach the output of the

folder. This is likely caused by a paper jam in the

FO.

2

Page 32

9.

9. MAINTENANCE

MAINTENANCE

9.9.

MAINTENANCEMAINTENANCE

Fig. 35

9.2

9.2 General cleaning

General cleaning

9.29.2

General cleaning General cleaning

Fig. 36

9.4

9.4 Cleaning the sealing roller

Cleaning the sealing roller

9.49.4

Cleaning the sealing roller Cleaning the sealing roller

Fig. 37

9.1

9.1 General

General

9.19.1

General General

The IN-3 requires just a few maintenance activities for the

operating personnel. These are:

• general cleaning.

• cleaning the brushes.

• cleaning the moistening cloth.

• cleaning the sealing roller.

Disconnect the mains supply before performing

any maintenance.

The user must not attempt to service the

appliance beyond that described in this

operator manual. All other servicing must be

carried out by qualified service personnel only.

Please contact your authorized distributor.

The machine must be kept in proper condition by regularly

removing dust, paper remains, etc. Clean the sealing table

and rubber rollers when dirty. This can be done by using a

slightly wetted cloth.

9.3

9.3 Cleaning the brushes

Cleaning the brushes

9.39.3

Cleaning the brushes Cleaning the brushes

Clean the brushes when dirty or saturated with glue. An

extra set of brushes is provided. The best procedure is to

always soak one set of brushes and use the other set. In that

way there is always a clean set of brushes ready for usage.

To replace the brushes the transparent cover and loc must

be lifted. The loc can be released by pulling the release

handle of the loc (see Fig. 32). The brushes can be removed

one by one by pulling them straight off the brush holder (see

Fig. 35). When replacing the brushes, align the studs on

each brush with the respective holes in the holder.

The sealing roller A (Fig. 36) must be cleaned regularly with

a slightly wetted cloth.

9.5

9.5 Cleaning the moistening cloth

Cleaning the moistening cloth

9.59.5

Cleaning the moistening cloth Cleaning the moistening cloth

Clean the moistening cloth A (Fig. 37) and water tray when

dirty or saturated with glue. To remove the watertray the

transparent cover, loc (by pulling the release handle) and

sealing table (by pulling the locking handle) must be lifted.

Remove the bottle C and then remove the watertray B by

pulling it towards the hopper. Clean the water tray under

running water.

31/40

31/40

31/4031/40

Page 33

Fig. 38

10.

10. OPTIONS

OPTIONS

10.10.

OPTIONSOPTIONS

10.1

10.1 General

General

10.110.1

General General

If applicable, the individual operator manuals will mention

options or special functions (e.g. TR-7A, AS-1A). In general

these options can be installed by the service organisation.

Some options can be activated bij the operator or

supervisor after installation.

10.2

10.2 More options

More options

10.210.2

More options More options

Inserter IN-3

Inserter IN-3

Inserter IN-3 Inserter IN-3

The inserter IN-3 can be equipped with a second envelope

feed hopper, the EF-3 (see Fig. 38). Depending on the way

it is used, it will double the hopper capacity, reduce settings

and/or allow to feed two different envelope sizes (Automix

See page 35.

Transport unit TR-7A

Transport unit TR-7A

Transport unit TR-7A Transport unit TR-7A

See TR-7A operator manual section 4.6. The TR-7A can be

equipped with the so called "Twin cycle" option. With this

option installed the fold/no fold deflector for station 2(3

and 4) is automatically operated. Knob A (Fig. 39) is not

applicable anymore.

On standard transport units the documents fed by station 2,

3 and 4 must have the same type of format in case folding

of (one of) these documents is required. With the "Twin

cycle" option installed it is possible to feed different

document sizes from station 2, 3 and 4. Small documents

that do not require folding and large documents that require

folding can be processed in one run, provided that the

documents that require folding must have the same format

because these are all folded the same way.

TM

).

Fig. 39

These are the possibilities with twin cycle:

• all documents from stations 2, 3 and/or 4 have the same

format and are all folded (no twin cycle).

• all documents from stations 2, 3 and/or 4 bypass the

folder (no twin cycle).

• documents from station 2 bypass the folder, documents

from station 3 (and 4) are folded.

• documents from station 2 are folded, documents from

station 3 (and 4) bypass the folder.

• documents from station 2 and 3 bypass the folder,

documents from station 4 are folded.

• documents from station 2 and 3 are folded, documents

from station 4 bypass the folder.

32/40

32/4032/40

Page 34

When twin cycle is active the automatic deflector inside fold

unit option is not available (See TR-7A operator manual

chapter 8). In that case the equal number of folds rule

applies to all TR-7A stations that process documents that

must be folded.

TM

Twin cycle option is required for Automix

.

Fig. 40

Feed unit FE-7, FE-9, ST-1

Feed unit FE-7, FE-9, ST-1

Feed unit FE-7, FE-9, ST-1 Feed unit FE-7, FE-9, ST-1

Refer to FE-7/FE-9 (see Fig. 40) and operator manual

section 5.3. The display A can be set to P. Service personnel

can program P for any figure between 10 and 25.

Feed unit FE-8

Feed unit FE-8

Feed unit FE-8 Feed unit FE-8

OMR reading code

The OMR reading code of the FE-8 can contain additional

marks to:

• select other feed units on the transport unit to feed.

• control the moistening system of the inserter.

• select the exit of the sorter.

• select the hopper of the inserter (Automix

TM

) see page

35.

• check the sequence of the pages fed (additional security).

• check the OMR reading code (additional security).

33/40

33/40

33/4033/40

Page 35

50 sheets

Matching of two personalised documents

AS-1A

AS-1A

AS-1A AS-1A

Fig. 41

See FE-8 operator manual, section 5.3. The maximum

amount of pages in a set can now be set to 50.

Flexible reading

The FE-8 is capable of reading OMR codes other than the

standard built-in Formax code. Besides that, more than one

reading code can be programmed. If this is the case, the

Settings menu, see FE-8 operator manual section 5.3, will

contain an additional sub menu "6. Flex reading", "Code

x", where x is a number. Using the + and - key a number

corresponding to the appropriate code can be selected.

34/40

34/4034/40

To solve applications where the enclosure must match the

address, the transport unit TR-7A can accommodate two

OMR systems. The most upstream OMR system (FE-8 or

AS-1A) will feed and read the address carrier with OMR

code while the second - downstream- OMR system (FE-8)

will feed and read the enclosure with OMR code.

This matching of two document streams means that both

OMR systems control the integrity of the stack, by means of

a sequence check, independently from each other. This

means that at the start of a job the operator must check that

the first documents fed from both feeders match.

OMR reading code

The OMR reading code of the AS-1A can contain

additional marks to:

• select other feed units on the transport unit to feed.

• control the moistening system of the inserter.

• select the exit of the sorter.

• select the hopper of the inserter (Automix

TM

).

• check the sequence of the pages fed (additional security).

• check the OMR reading code (additional security).

Page 36

Fig. 42

Fig. 43

Automatic selective feeding

With this option active, the other feed units (stations 1 and

2) on the transport unit will feed an enclosure depending on

the number of pages collated by the AS-1A. If the number

of pages in a set, collated by the AS-1A is less than the

number shown by the overflow display, station 1 and

possibly station 2 are allowed to feed a document. The total

number of pages, including enclosures, will not exceed the

number shown by the overflow display.

Flexible reading

The AS-1A is capable of reading OMR codes other than

the standard built in Formax code. Besides that, more than

one reading code can be programmed. If this is the case, a

submenu can be entered to select the appropriate code. To

do so, press both key A and the key B at the same time, see

Fig. 41 and Fig. 42 . The display C (Fig. 43) will indicate a

number. Using the + and - key below display C the number

corresponding to the appropriate code can be selected.

Then again press both key A and the key B at the same time,

to leave the submenu.

Matching of two personalized documents

See section10.2, Feed unit FE-8.

10.3

10.3

10.310.3

6900 Series Options

®

Automix

The Automix

TM

feature enables automatic processing, in

1 run, of a batch of documents which requires inserting into

different sizes of envelopes. For a specific document set an

envelope from either hopper A or hopper B from the IN-3 is

selected. Together with envelope hopper selection, if

required, via the TR-7A "twin cycle" option, documents from

station 2 (3 and 4) are automatically folded/not folded

depending on the type of envelope.

TM

Automix

can be based on:

• OMR mark (hopper selection mark).

• Type of enclosure to be added (selective feed mark).

• Number of pages in a set (AS-1A only, IN-3 dongle level

3 only).

• Combination of selection criteria.

35/40

35/40

35/4035/40

Page 37

The throats of both envelopes should have an equal shape.

Minimum requirements for Automix

TM

- IN-3 equipped with EF-3.

- IN-3 equipped with dongle level 2 or 3.

- TR-7A equipped with "twin cycle" option.

- FE-8 or AS-1A.

OMR mark (hopper selection mark)

OMR mark (hopper selection mark)

OMR mark (hopper selection mark) OMR mark (hopper selection mark)

The reading code of both the AS-1A and the FE-8 can

contain a mark to control from which hopper the inserter

should feed the envelope that belongs to the document.

36/40

36/4036/40

Type of enclosure (selective feed mark)

Type of enclosure (selective feed mark)

Type of enclosure (selective feed mark) Type of enclosure (selective feed mark)

The reading code of both the AS-1A and the FE-8 can

contain marks to control the other feed units on the transport

track. This allows to select for each set the enclosures to be

added. A job can be programmed such that one of the

envelope feed hoppers is linked to one of the feed stations.

If the feed station is selected to feed by the OMR code, then

automatically an envelope will be picked up from the

hopper that has been linked to that feed station.

Number of pages in a set (AS-1A only)

Number of pages in a set (AS-1A only)

Number of pages in a set (AS-1A only) Number of pages in a set (AS-1A only)

Document sets that contain a number of sheets up to the

actual overflow counter setting, will be folded and inserted

in the "small" envelope. If a set exceeds the actual overflow

counter setting, it will not be folded and it will be inserted in

the "big" (C4 size) envelope. Via service an internal set limit

counter can be set to a maximum of documents that are

allowed to be inserted, as desired by the customer. If a set

exeeds this number, the AS-1A will consider the set as an

overflow and will indicate error 60.

Page 38

Optionally this function can be combined with split set. Then

document sets that contain a number of sheets up to twice

the actual overflow counter setting, will be folded and

inserted in the "small" envelope, whereby, depending on

the number of sheets, the set is temporary split in two groups

during the folding process. If a set exceeds twice the actual

overflow counter setting, it will not be folded and it will be

inserted in a "big" (C4 size) envelope. Via service, in the set

up menu an internal set limit counter can be set to a

maximum of documents that are allowed to be inserted, as

desired by the customer. If a set exeeds this number, the

AS-1A will consider the set as an overflow and will indicate

error 60.

To allow processing of thicker sets that are to be inserted in

"big" envelopes, the system can decide to temporary split

up these sets in two parts during the transport to the

collating area of the TR-7A. This depends on the number of

pages within the set and the value of the internal set limit

counter.

If the system encounters a combination of selection criteria,

it will react as follows: the 'big' envelope will be selected if

at least one these criteria indicates the use of a 'big'

envelope. The criteria are evaluated in the following order:

number of pages in a set, OMR hopper selection mark,

selective feed mark.

TM

AS-1A functions extended for

AS-1A functions extended for Automix

AS-1A functions extended for AS-1A functions extended for

"insert arrow key"

Per job, service can set the AS-1A options for either "split

set, Automix

TM

or the combination of these functions. The

operator can then activate or de-activate this functionallity

using the key K, see fig. 11 page 5/12 of the AS-1A

operator manual. The function is active in case yellow led L

is on. In the job data menu the programmed settings will be

displayed below the AS-1A symbol.

Error 60

Error 60 means "Split set too big" and is an overflow

message in case documents are split up in parts. This error

can also appear in case Automix

TM

is active and the set

exceeds the "set limit counter". The part of the set that is

located in the exit track can be removed by pressing key K

(see fig. 11 page 5/12 of the AS-1A operator manual).

Now the AS-1A can behave in two ways:

• if the material is partly ejected but held by the exit rollers,

only these pages should be removed. Pages that are

located on the TR-7A transport track belong to the

previous set and should not be removed.

• if the material is fully ejected onto the TR-7A transport

track, so on top of the pages that are already on the

track, these pages belong to the same set. All material

should be removed.

37/40

37/40

37/4037/40

Page 39

11.

11. SPECIFICATIONS

SPECIFICATIONS

11.11.

SPECIFICATIONSSPECIFICATIONS

This operator manual refers to machines as from serial number 02 BL-5191, IN-3. Refer to the operator manuals of the modules part of the configuration for specifications.

Machine specifications

Machine specifications Paper insert specifications

Machine specificationsMachine specifications

Model

Model

ModelModel

: IN-3 (inserter head of 6900 Series)

Paper insert specifications

Paper insert specificationsPaper insert specifications

Paper qualities

Paper qualitiesPaper qualities

: according to existing feeding equipment (FE-7 and FE-1M)

≤ C5 envelopemin. 45 gsm

> C5 envelopemin. 65 gsm (> 1 sheet)

or min. 80 gsm (1 sheet)

Type

Type

TypeType

Power consumption

Power consumption

Power consumptionPower consumption

Dimensions

Dimensions

DimensionsDimensions

We ig h t

We ig h t

We ig h tWe ig ht

Speed

Speed

SpeedSpeed

: inserting machine for medium office use

: 115 V, 4,6 A, 60 Hz

220 -240 V, 2,3 - 2,5 A, 50 Hz

: IN-3 only 941 x 611 x 400 mm (36.8 x 23.9 x 15.6 inch)

(l x w x h)

Length 690 Series 2223 mm (87.5 inch) (2 stations)

3239 mm (127.5 inch) (4 stations)

: 75 kg

: C5/C6 envelopes up to 4300/hr.

C5 envelopes up to 3200/hr.

C4 envelopes up to 2500/hr.

Envelope quality

Envelope quality

Envelope qualityEnvelope quality

Paper sizes

Paper sizes

Paper sizesPaper sizes

Insert thickness

Insert thickness

Insert thicknessInsert thickness

Folds

Folds

FoldsFolds

Jobs

Jobs

JobsJobs

: 45 to 120 gsm

: minimal (w x h)

130 - 80 mm

(5.1 - 3.1 inch)

: max. 5 mm (0.2 inch) (50 sheets A4, 80 gsm.)

: according to (cross)folding equipment (FO-2A, FO-3,

PF-45A (via SF-4), PF-65A (via SF-6) up to 8 sheets of

80 gsm at once (FO-2A/FO-3)

: 9 jobs programmable via LCD-screen.

maximal (w x h)

243 - 340 mm

(9.55 -13.4 inch)

Noise level

Noise level

Noise levelNoise level

Furniture

Furniture

FurnitureFurniture

38/40

38/4038/40

:

≤ 70 dBA

: special furniture (console-look) is delivered with the 6900 Series.

Hopper capacity

Hopper capacity

Hopper capacityHopper capacity

Options

OptionsOptions

Life expectancy

Life expectancy

Life expectancyLife expectancy

: 450 C5/C6 envelopes (800 w/EF-3)

250 C4 envelopes (475 w/EF-3)

documents: according to existing feeding equipment

: extended OMR-reading, cross folding

: 5 years at 120.000 inserts per month (7.2 million cycles)

Page 40

Envelope and insert specifications

Envelope and insert specifications

Envelope and insert specificationsEnvelope and insert specifications

Maximum insert specifications are based on single sheets. When multiples are handled, more room inside the envelope is needed

depending on application.

Manufacturer: Neopost Industrie BV

Address: De Tijen 3, 9201 BX Drachten

The Netherlands

AAAAB

mm140903232102080130

minimum size

inches 5.5 3.55 1.25 1.25 0.4 0.8 3.15 5.11

mm 255 345 90 90 50 70 B-5 A-12 5

maximum size

inches 10 13.6 3.5 3.5 1.95 2.75 B-0.2 A-0.47 0.2

Remarks

• If J exceeds 2 mm (0.08”) then the maximum size of G and H should be B-15 (0.6”) respectively A-25 (1”).

• The specification of the paper handling equipment is often wider than that of the envelopes and documents handled. The

condition of material handled will limit the specified environmental conditions.

• We recommend that materials to be handled are stored at a temperature of 20°C (68°F) with a relative humidity factor of 50%.

If difference in temperature occurs between store room and mailing area, the material has to stored near the machine at least 24

hours before use.

BC

BB

CD

CC

DE

DD

EF

EE

FG

FF

GH

GG

HJ

HH

J

JJ

45 g/m2

Note: this equipment has been tested and found to comply

with the limits for class A digital device, pursuant to Part 15 of

the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with this

instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the

user will be required to correct the interference at his own

expense.

39/40

39/40

39/4039/40

89.41.02 index A - 06/02 Specifications and design are subject to chanche without prior notice.

Page 41