Page 1

6606 Series Inserters

8/2014

Operator Manual

Page 2

Table of Contents

How this Help Works ....................................................................................11

Help Menu........................................................................................................1

User Guide.......................................................................................................1

Meet your Document System .......................................................................32

Introduction.......................................................................................................3

System Overview.............................................................................................4

Operating Controls...........................................................................................6

Control Panel....................................................................................................7

Power Up..........................................................................................................7

How to Operate the Touch Screen...................................................................9

Open a Web Browser.....................................................................................11

What is a Job?................................................................................................11

Job List...........................................................................................................12

Job Overview..................................................................................................13

High Capacity Document Feeder (HCDF)......................................................15

Production Feeder (FD 6606-00).................................................................15

Thin Booklet Feeder (FD 6606-15).. .............................................................16

Catch Tray......................................................................................................17

Shut Down the System...................................................................................18

Working with Jobs ......................................................................................193

Introduction.....................................................................................................19

Use an Existing Job........................................................................................19

Create a New Job...........................................................................................20

About Automatic Jobs....................................................................................21

Create an Automatic Job................................................................................21

Create a Manual Job......................................................................................23

Create an Test Mail Set..................................................................................35

Page 3

Mail Sets.........................................................................................................41

Change to Another Feeder Tray.....................................................................47

Link Feeder Trays...........................................................................................47

Edit a Job.......................................................................................................48

Save a Job.....................................................................................................49

Delete or Move an Enclosure.........................................................................50

Copy a Job.....................................................................................................51

Lock a Job......................................................................................................51

Rename a Job................................................................................................53

Delete a Job...................................................................................................54

Loading the System ....................................................................................554

Document Orientation....................................................................................55

Document Feed Trays....................................................................................56

Load Envelopes..............................................................................................66

Adjust the Side Guides and Envelope Separation.........................................67

Fill the Sealing Liquid Reservoir.....................................................................68

Options ........................................................................................................695

Support for Curved Reply Envelopes (option for Thin Booklet Feeder).........69

Power Stacker Support..................................................................................69

High Capacity Envelope Hopper (FD 6606-30/EF-4).....................................70

High Capacity Conveyor Belt (FD 6606-25)..................................................72

Settings menu .............................................................................................746

Open the Settings Menu.................................................................................74

Open the Settings Menu (Supervisor)............................................................76

Supervisor Settings Menu..............................................................................78

Connect the System to the Internet ..........................................................957

Options for Connection...................................................................................95

Set up a Wired Connection............................................................................95

Set up a Wireless Connection........................................................................97

Test the Connection........................................................................................99

Page 4

Reading ......................................................................................................1008

Introduction...................................................................................................100

OCR Code Description.................................................................................101

BCR Code Description.................................................................................104

OMR Code Description................................................................................108

Flex Reading Code Description....................................................................112

Create Jobs with Reading............................................................................113

Reading Settings..........................................................................................119

Exit Selection with Reading..........................................................................122

Operator Maintenance ..............................................................................1239

Maintenance Schedule.................................................................................123

Clean and Replace Brushes.........................................................................124

Replace or Clean Moistening Cloth..............................................................125

Calibrate Photocells.....................................................................................126

Fault Finding .............................................................................................12710

Messages.....................................................................................................127

Clear Stoppages...........................................................................................130

Operator Troubleshooting.............................................................................136

Troubleshooting Table..................................................................................137

Specifications ............................................................................................14211

Technical Specifications...............................................................................142

Hopper and Feeder Capacity.......................................................................143

Configuration Dimensions............................................................................143

Document and Insert Specifications.............................................................143

Envelope and Document Set Specifications................................................144

Production Feeder Specifications...............................................................145

Thin Booklet Feeder Specifications.............................................................146

High Capacity Envelope Hopper Specifications...........................................147

High Capacity Conveyor Belt Specifications................................................148

Terminology ...............................................................................................14912

Page 5

How this Help Works1

Help Menu

The help button [?] gives access to help topics via a pull-down menu.

The contents of the help menu can be different for your situation. The help menu can contain

the following topics:

• Search; use the search engine to find a specific topic.

• User Guide; user instructions describing how to use the system.

• FAQ's (option); when the system is connected to the internet, frequently asked

questions are answered here (option).

• What can I do here; a list with relevant help topics related to the current screen.

• Remote assistance (option); online remote assistance for helpdesk guidance. Call

the phone number that is displayed and follow the instructions of the support assistant.

User Guide

1

English

You can use this guide as follows:

• Use the contents overview to browse the contents.

• Use the keyword search, to enter a keyword for the search. The information button

at the keyword search supplies detailed information on how to optimize the search.

• If necessary, use the advanced search to narrow down your keyword search to better

matching results.

1

Page 6

To navigate through the User Guide:

• Tap to select

• Swipe up/down to scroll

• Double tap to zoom

1

English

• Pinch in/out to zoom in/out

See also How to operate the touchscreen on page 9.

When you use the User Guide, you can minimize it, to operate the system. Use the minimize

button to minimize the User Guide.

The help button shows a purple color when the User Guide is minimized. When you click

the help button, the User Guide is restored.

2

Page 7

Meet your Document System2

Introduction

The system is a folding and inserting system for processing mail easily. The system:

• feeds documents

• folds the documents

• inserts the documents into envelopes

• seals the envelopes

• stacks the envelopes

Automatic monitoring ensures the correct number of documents per envelope. The system

can be operated by means of a user friendly interface. The settings of the system (type of

documents, type of envelopes and the type of fold) are recorded in so called jobs. These

jobs can be created by the operator.

The system is equipped with a variety of special features, such as:

• mail set thickness detection

• job wizard for creating jobs

• Double Feed Control

• feeder tray linking

• feeder tray swapping

• daily mail

• Flexible Feeders on page 4

• Divert Deck on page 4

• Folding Power on page 4

Operator and supervisor

2

English

You can use the system as operator and as supervisor. The supervisor has access to more

settings than the operator. You can switch from operator to supervisor in every screen.

When you switch to supervisor, you see immediately the result: extra tabs appear for the

advanced settings. Also the side menu contains extra functions.

3

Page 8

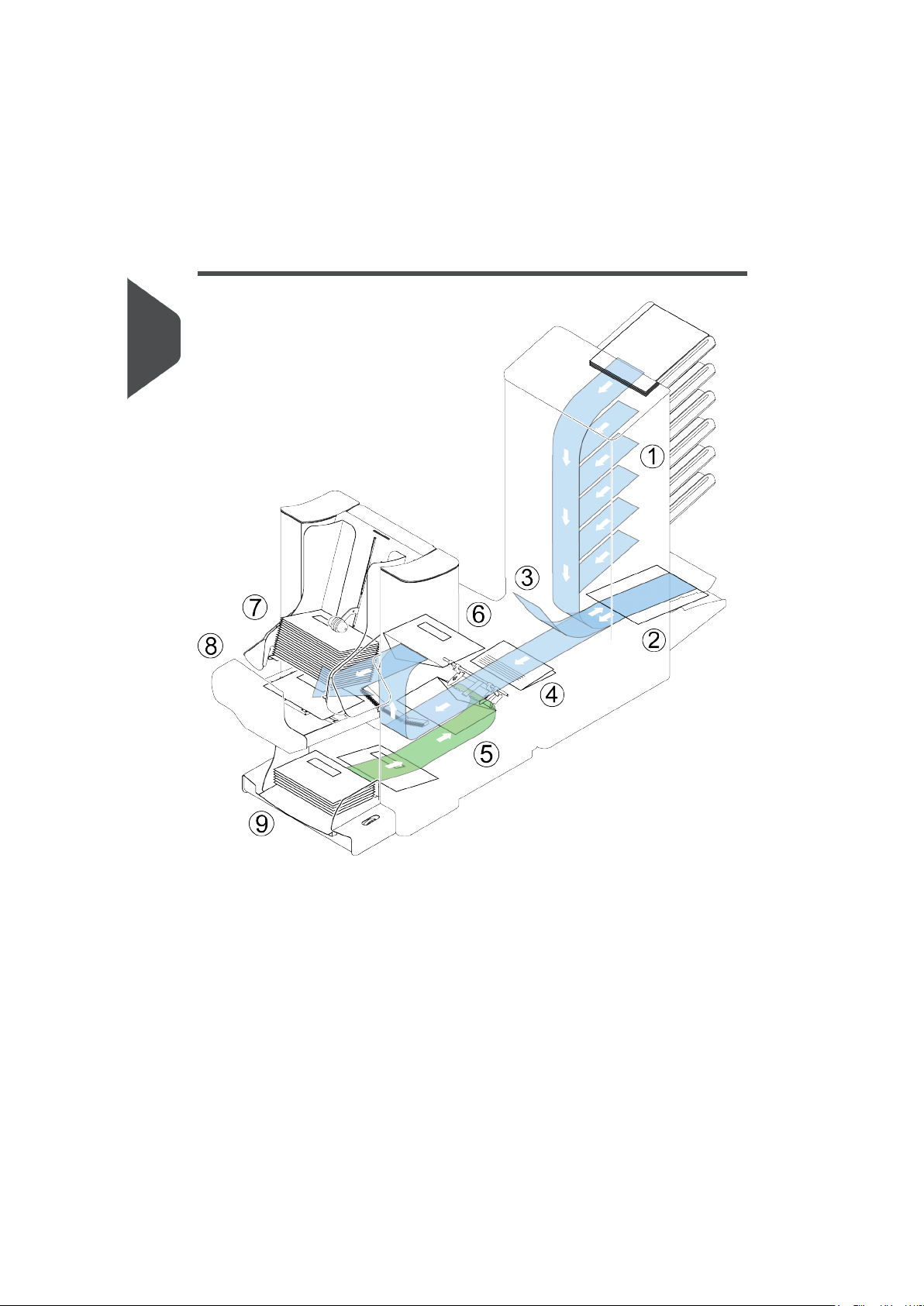

System Overview

2

English

The figure shows an overview of the system.

Document Feeders (1)

The Document Feeders are the

automatic and the special feeder. The automatic feeder does not require any adjustments for

the separation. From a feeder you can feed one or more documents (multi feed). The feeders

have a double feed control (DFC). DFC detects if more documents are fed instead of one.

You can link feeders. This means that two feeders can be linked as pairs. When the first

feeder is empty, the system switches to the other feeder. Meanwhile the empty feeder can

be refilled without stopping the system.

feeding part of the system. There are two types of feeders: the

4

Page 9

| Page 5 | feb-24-2014 01:32 | Meet your Document System

The upper automatic feeder is equipped with a 'daily mail' function. You can use this feeder

to process sets of documents that you cannot process automatically (stapled documents

and sets with varying thickness).

Collating Area (2)

All documents of a document set are collated and aligned in the collating area.

Divert Deck(3)

The Divert Deck automatically throws out incorrect sets of documents. In this way the

system does not need to stop. Correct sets will be transported to the folding unit.

Folding Unit (4)

The fold unit folds the documents. The following fold types are possible (see Terminology

on page 149):

• No fold

• V-fold

• C-fold

• Z-fold

• Double V-fold

Inserter (5)

After the documents are folded, the documents are transported to the inserter. The inserter

inserts the documents into a waiting envelope. The inserter seals the envelope or not,

depending on the settings. Automatic monitoring ensures the correct number of inserts per

envelope.

Present on Deck (6)

The documents inserted (or not) can leave the inserter from the upper unit (present on

deck). This can occur when:

• Clearing the machine;

• Making a test set;

• Depending on the reading code.

Stacker (7)

The documents inserted (or not) are transported to the stacker depending on the

programmed job. The stacker automatically stacks inserted documents.

Side exit (8)

The documents inserted are transported to the side exit depending on the programmed

job. The side exit can be used for sorting and stacking of documents into the catch tray as

well as transporting to the optional conveyor belt or franking/mailing machine.

Envelope Hopper (9)

Envelopes that are placed on a stack by the user, are fed one by one into the system by

the envelope hopper.

2

English

5

Page 10

| Page 6 | feb-24-2014 01:32 | Meet your Document System

Operating Controls

2

English

A - catch tray (optional)

B - side exit / stacker unit

C - side guides stacker

D - power inlet, power switch

E - USB (service only)

F - unlocking lever for upper unit

G - USB (2x), RS232 and ethernet

H - control panel

I - vertical transport

J - hand grip vertical transport cover

K - document feed tray

L - collator arm

M - Divert Deck

N - Folding unit

O - locking handle Folding unit

P - handle for manual transport of the envel-

ope

Q - handle for manual transport of the mail

set

R - unlocking handle for rollers envelope

track

S - sealing liquid reservoir

T - side cover (opened)

U - thumb wheel for side guide adjustment

V - side guides envelope feed tray

W - flap for envelope separation adjustment

X - envelope support

6

Page 11

| Page 7 | feb-24-2014 01:32 | Meet your Document System

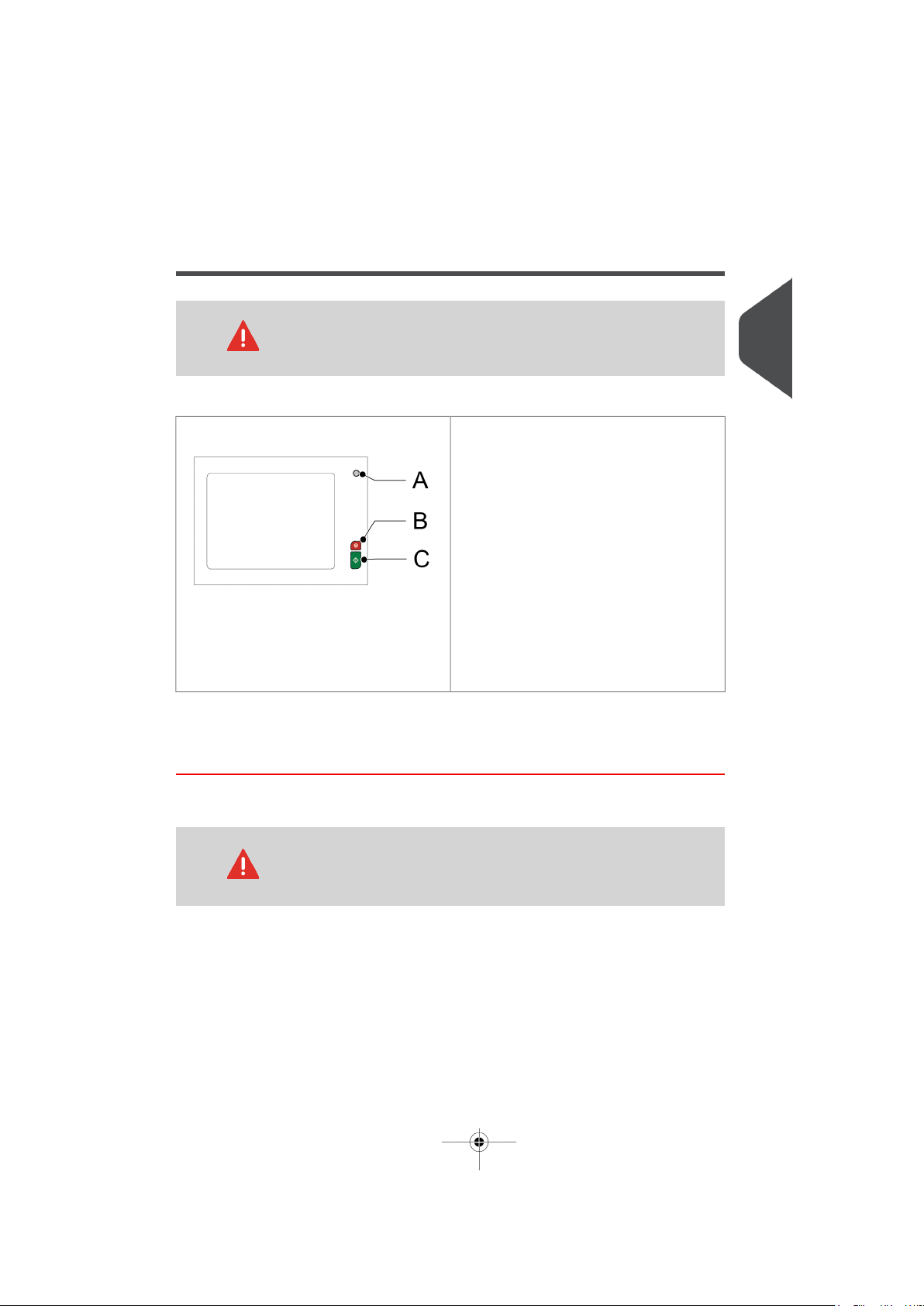

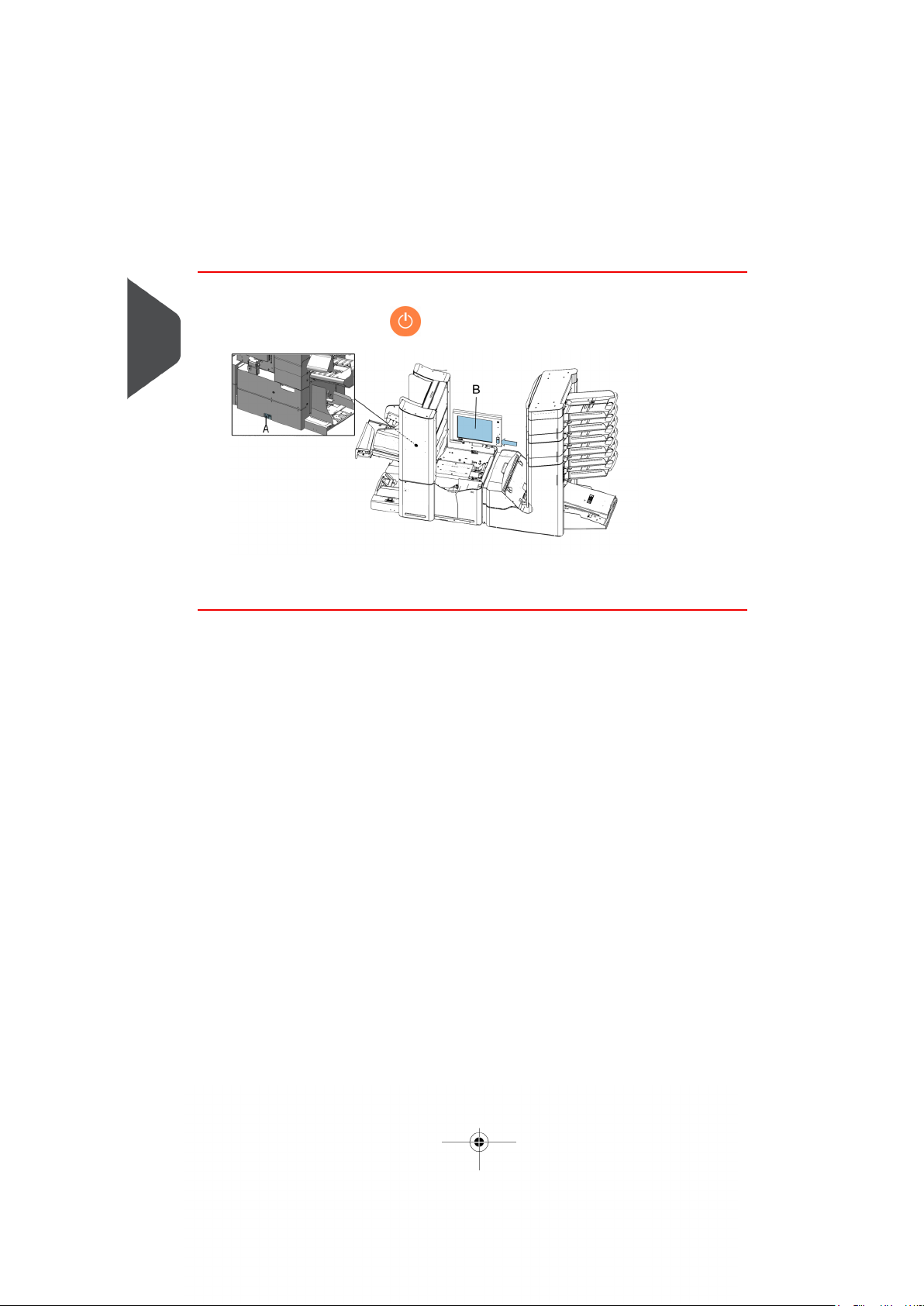

Control Panel

The touch screen is covered with a thin pressure-sensitive layer.

To avoid permanent damage of the touch screen, do not use sharp

objects to press on the touch screen.

2

The control panel consists of the touch screen and the following buttons:

A: On/Off button. Switches the system on or

off. If the system is not used for one hour,

the system switches to the power save

mode. Press the On/Off button to switch back

to the user mode.

B: Stop button. The system completes the

current mail set and stops, leaving the system empty and ready for a new set. The Stop

button and [Stop] on the touch screen have

the same functionallity.

C: Start button. The system starts to process

mail sets. The Start button and [Start] on

the touch screen have the same functionallity.

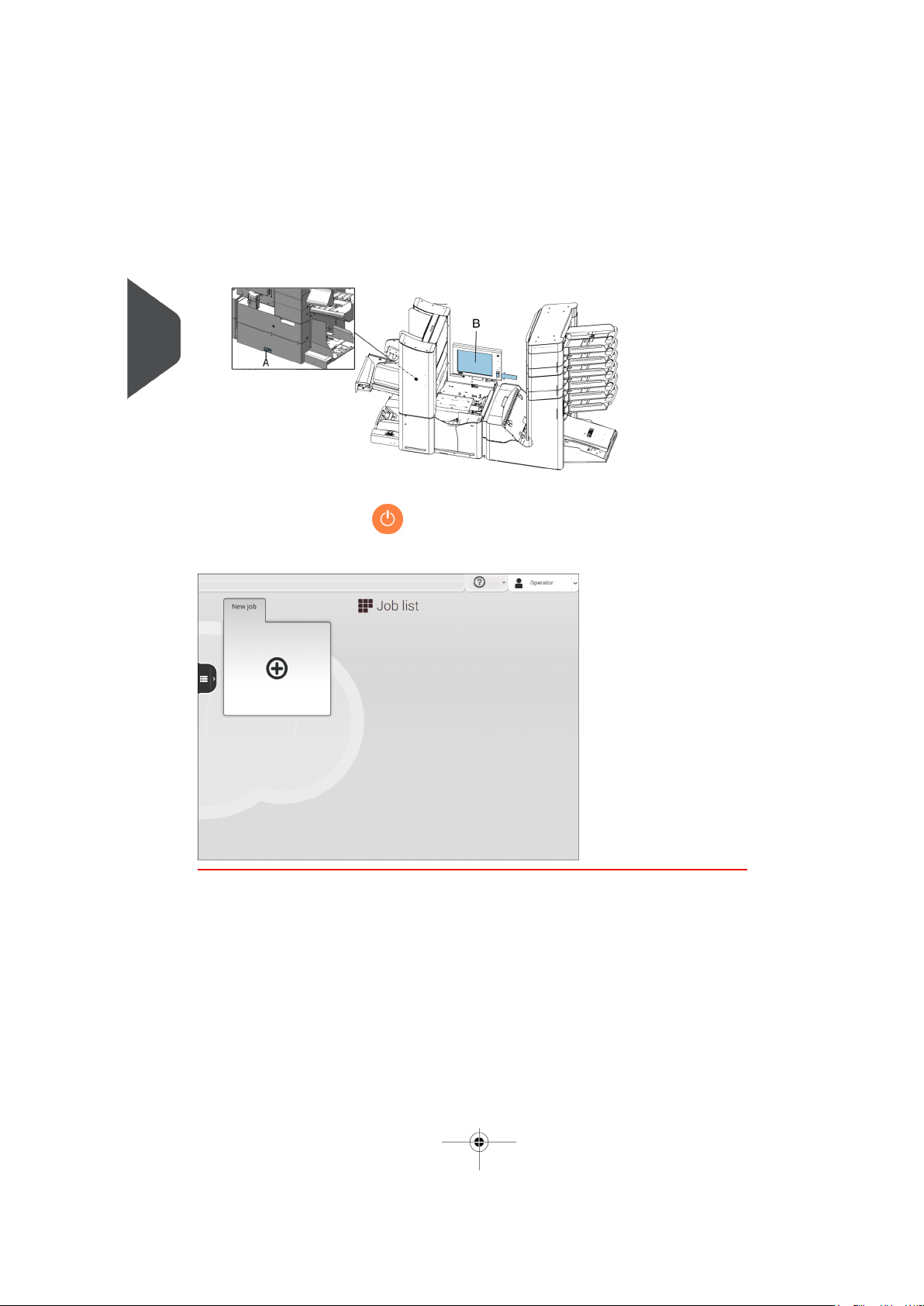

Power Up

To start up the system:

You can severely damage the machine if it is connected to the

incorrect mains voltage. Before plugging in the machine, check if

the local voltage is the same as the voltage mentioned on the type

plate.

English

1. Connect the system to the mains power supply.

7

Page 12

| Page 8 | feb-24-2014 01:32 | Meet your Document System

2. Use the power switch A to switch the system on. The power switch is located on the

back of the system.

2

English

3.

Press the on/off button next to the display B.

The touch screen shows the Job list screen.

8

Page 13

| Page 9 | feb-24-2014 01:32 | Meet your Document System

How to Operate the Touch Screen

You can operate the touch screen like a tablet:

• Tap: touch and release the screen with your finger

2

English

• Swipe: touch the screen, hold it and move your finger(s) left or right

• Tap and hold: touch the screen with your finger and hold it for two seconds

9

Page 14

| Page 10 | feb-24-2014 01:32 | Meet your Document System

2

English

Some screens have a side menu. Which functions the side menu contains, depends on

the screen you are working in, and on authorization on page 3.

To open the side menu, tap the icon on the left.

10

Page 15

| Page 11 | feb-24-2014 01:32 | Meet your Document System

Open a Web Browser

You can open a web browser in the user interface of the system. Open the web browser

as follows:

Tap on the logo in the upper left corner of the screen.1.

2. Tap the cross in the upper left corner of the screen to close the web browser.

If you work with a special keyboard for your language, you can switch the keyboard back

to the English version on page 82 to type e.g. a web address.

What is a Job?

If you have to process a lot of mail sets of the same type (for example bills), you can save

the settings to a 'job'. The next time you just select the job and immediately start without

defining any settings.

The following settings are saved in a job:

• Envelope type/size;

• Sealing on/off;

• Which document feeders should be used, how many documents should be fed from

each feeder and document height for each feeder;

• Feeder linking on/off;

• If BREs or insert cards should be included;

• Address position;

• Fold settings;

• Double feed control settings;

• Reading settings (option);

• Exit select settings;

• Batch Counter, defining the number of mail sets that the job must process. The job

will automatically stop processing when this number is reached.

2

English

11

Page 16

| Page 12 | feb-24-2014 01:32 | Meet your Document System

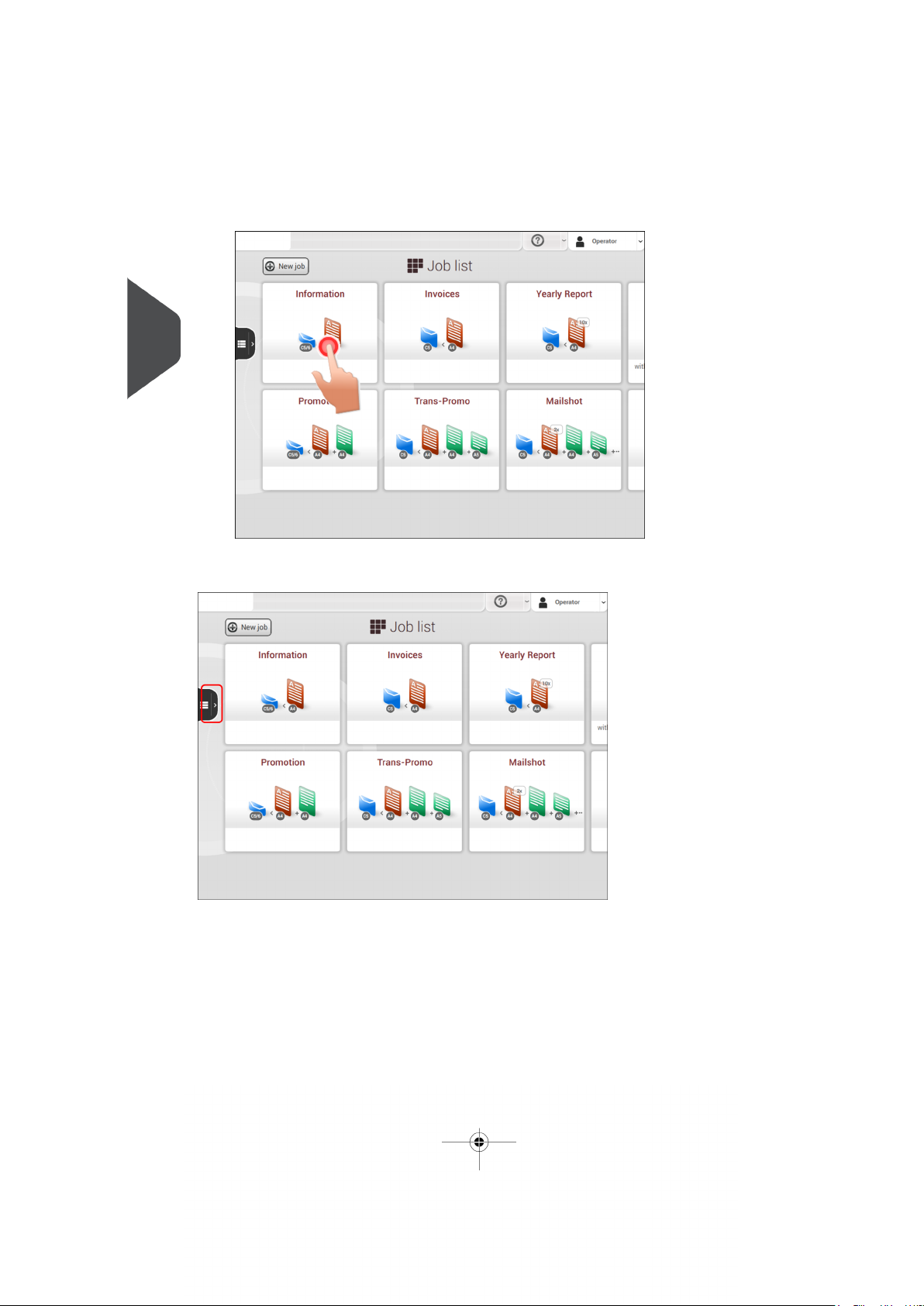

Job List

2

English

When you start up the system, the ‘Job list’ menu appears.

1. Open a web browser on page 11

2. Help menu on page 1

3. Login, see Introduction on page 3

4. Side menu

The side menu contains the settings menu (see Settings menu operator on page 74). When

you are logged in as supervisor, the settings menu is extended with advanced settings

(see Settings menu supervisor on page 76).

If you want more information on a job, select the job. With the [Job list] button you get

back to the home menu.

See also: Working with Jobs on page 19.

12

Page 17

| Page 13 | feb-24-2014 01:32 | Meet your Document System

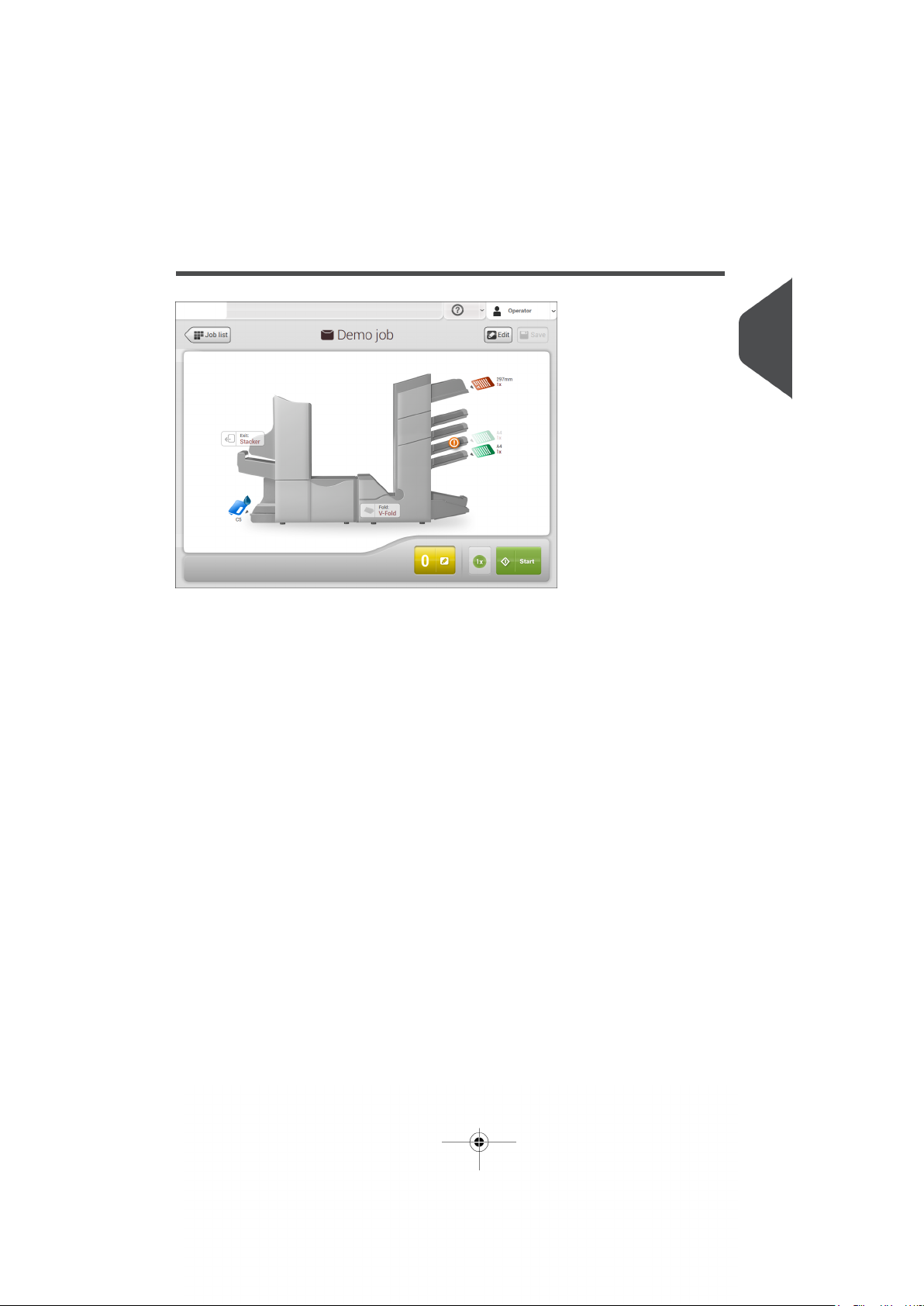

Job Overview

If you want more information on a job, select the job in the Job List menu.

The touch screen shows the following information of the selected job:

• Job name

• Job settings (for example the document and envelope type)

• How to load envelopes and documents for this job

• The number of envelopes that have been processed with this job

In this screen you can change the following settings:

• Counter settings (see Change the counter settings on page 31)

• Job settings (see Editing a job on page 48)

• Move documents between feeders (see Change to an other feeder tray on page 47)

• Link feeders (see Link feeder trays on page 47)

• Start the job or run a test run (see Performing a test run)

2

English

13

Page 18

| Page 14 | feb-24-2014 01:32 | Meet your Document System

The following is a list of symbols or icons and their descriptions.

2

English

Main document.

Shows the correct document

orientation; A is the address.

ally insert mail-sets one by

one into the system.

NotificationNext to this symbol, a message appears, e.g.

Sealing liquid low, empty

feeder.

Envelope, sealing onEnvelopes will be sealed. The

symbol shows the correct

envelope orientation.

Feeder linkingLinking means

that when one feeder is

empty, the system automatically starts feeding documents

from the other feeder. This

symbol at the feeders shows

if the feeders are linked.

DFC/mail set thickness detectionDouble feed control

and/or mail set thickness detection has been set to 'off'.

By default the dfc/mail set

thickness detection will be set

to 'on' and the icon will not be

shown.

Exit settingThis icon shows

what kind of exit setting has

been set.

1x buttonAfter tapping this

button the system will create

an example mail set.

Document with reading

Shows the correct document

orientation; A is the address.

EnclosureDaily mailFeature to manu-

Envelope sealing offEnvel-

opes will not be sealed. The

symbol shows the correct

envelope orientation.

When sealing is off, the flap

of the envelope is closed but

not moistened.

Change feeder traysPossibility to change from one feeder tray to another.

Fold type

This icon shows what kind of

fold type has been set.

Counter settingShows on

what number the counter has

been set.

Start button

Tapping this button runs the

job.

14

Page 19

| Page 15 | feb-24-2014 01:32 | Meet your Document System

Job list buttonAfter tapping

this button the job list screen

will be shown.

Edit buttonGives access for

editing a job.

Stop buttonButton to stop

the system The current mail

set will be completed and the

system stops, being empty

and ready for a new set.

Save buttonSave the job or

changes that have been

made to a job.

High Capacity Document Feeder (HCDF)

The High Capacity Document Feeder (HCDF) is an option that can be delivered from factory,

or added to a 2 or 4 station version by a service engineer. The High Capacity Document

Feeder has a capacity for up to 725 sheets. The normal document feeder tray has a capacity

of 325 sheets.

For more information on the operation of the HCDF, refer to the topic on loading documents

for the HCDF on page 63.

2

English

Production Feeder

The Production Feeder is a feeder that can be loaded with a high number of

documents. This feeder is intended to be used for Business Reply Envelopes (BRE),

but also 'standard' documents up to 356 mm (14") length can be processed with it.

For more information on the operation of the Production Feeder, refer to the topic on

loading documents for the Production Feeder on page 59.

15

Page 20

| Page 16 | feb-24-2014 01:32 | Meet your Document System

2

English

Thin Booklet Feeder (FD 6606-15)

The Thin Booklet Feeder is used to feed booklets, regardless of the thickness of the

cover, to the document flow from the feeder to the inserter. Because of the location of the

Thin Booklet Feeder (downstream the feeder module) documents feeded by the Thin

Booklet Feeder will not be folded.

When the Thin Booklet Feeder is added to the configuration, this is shown in the

screens at the operator panel.

For more information on the operation of the Thin Booklet Feeder, refer to the topic on

loading documents for the Thin Booklet Feeder.

16

Page 21

| Page 17 | feb-24-2014 01:32 | Meet your Document System

Catch Tray

2

English

For stacking envelopes leaving from the side exit a catch tray can be mounted. You can

select the catch tray in the Output settings tab of the job definition (see Exit settings on

page 29).

Instead of a catch tray at the right hand (RH) side of the system it is also possible to install

a catch tray on the left hand (LH) side. To achieve this it is necessary to reverse the side

exit of the Stacker from RH to LH.

Contact your supplier for more information about this option.

17

Page 22

| Page 18 | feb-24-2014 01:32 | Meet your Document System

Shut Down the System

1.

Press the [On/Off] button next to display B to shut down the system.

2

English

When the system is busy, it completes and inserts the current set, stops and will be shut

down.

18

Page 23

| Page 19 | feb-24-2014 01:32 | Working with Jobs

Working with Jobs3

Introduction

With the system you can process mail sets in the following ways:

• Using an existing job. Existing jobs are shown in the Job list and saved via the

'automatic' or 'manual' job creation process. How to use an existing job is described

in Using an existing job on page 19.

• Automatic job: The system automatically picks one sheet from each filled feeder

and processes them into mail sets.

The automatic feature is described in About Automatic jobs on page 21.

• Manual job: various settings, not available in an Automatic job, can be set in a

'manual job. This includes the use of daily mail. Working with manual jobs is described

in Create a manual job on page 23.

Use an Existing Job

If you want to use an existing job:

3

English

Open the job list.1.

2. Tap the icon of the job you want to use.

3. Load the feeders as shown on the display.

4. Tap [1x] to create an example mail set, see Example mail set on page 35.

5. Select an exit for the example mail set.

19

Page 24

| Page 20 | feb-24-2014 01:32 | Working with Jobs

6. Check the example mail set.

7. If example mail set is OK: tap [Start].If the example mail set is not OK: adjust the

address position or envelope stop position or check and re-adjust the job settings.

If desired tap the counter button to set the counters. See Counter

settings on page 31.

3

8. Tap [Start] to start the job.

9. Press the [Stop] button to finish the job.

English

10. Tap [Job list] to return to the job list.

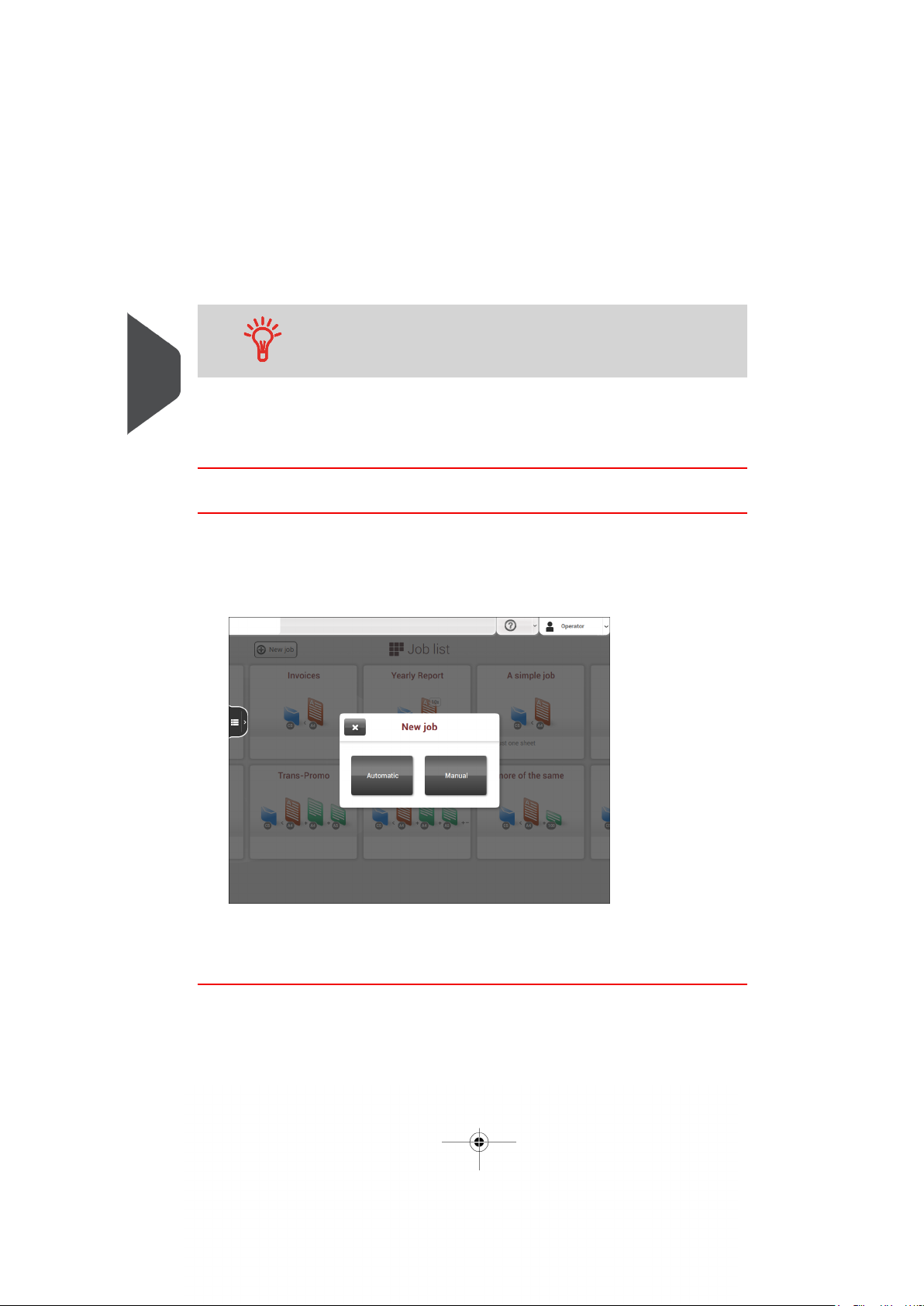

Create a New Job

To create a new job:

From the Job list menu, tap [New job].1.

2. Choose [Automatic] or [Manual] to create a new job.

3. If you choose 'Automatic' follow the description as can be found in Create an Automatic

job on page 21.

4. If you choose 'manual' follow the description as can be found in Create a manual job.

20

Page 25

| Page 21 | feb-24-2014 01:32 | Working with Jobs

About Automatic Jobs

You can save every automatically created job and edit it like any job.

An Automatic job processes mail sets according to the following rules:

• The machine picks one sheet from each filled feeder;

• The picked documents will be folded (if necessary) and inserted into an envelope;

• Only the feeders that feed successfully will be selected;

• Only the Double Feed Control (DFC) of the upper feeder will be selected (this is done

automatically).

The following features are not supported with Automatic job processing.

• Linked feeders (the option where, if one feeder is empty, the system automatically

continues using another feeder)

• Multiple sheet feeding (picking more than one sheet from a certain feeder)

• Daily mail

• Reading functionality

• No envelopes (use envelopes yes/no)

• Exit select

If you want to use any of these features, you have to use Manual jobs to process the mail

set.

3

English

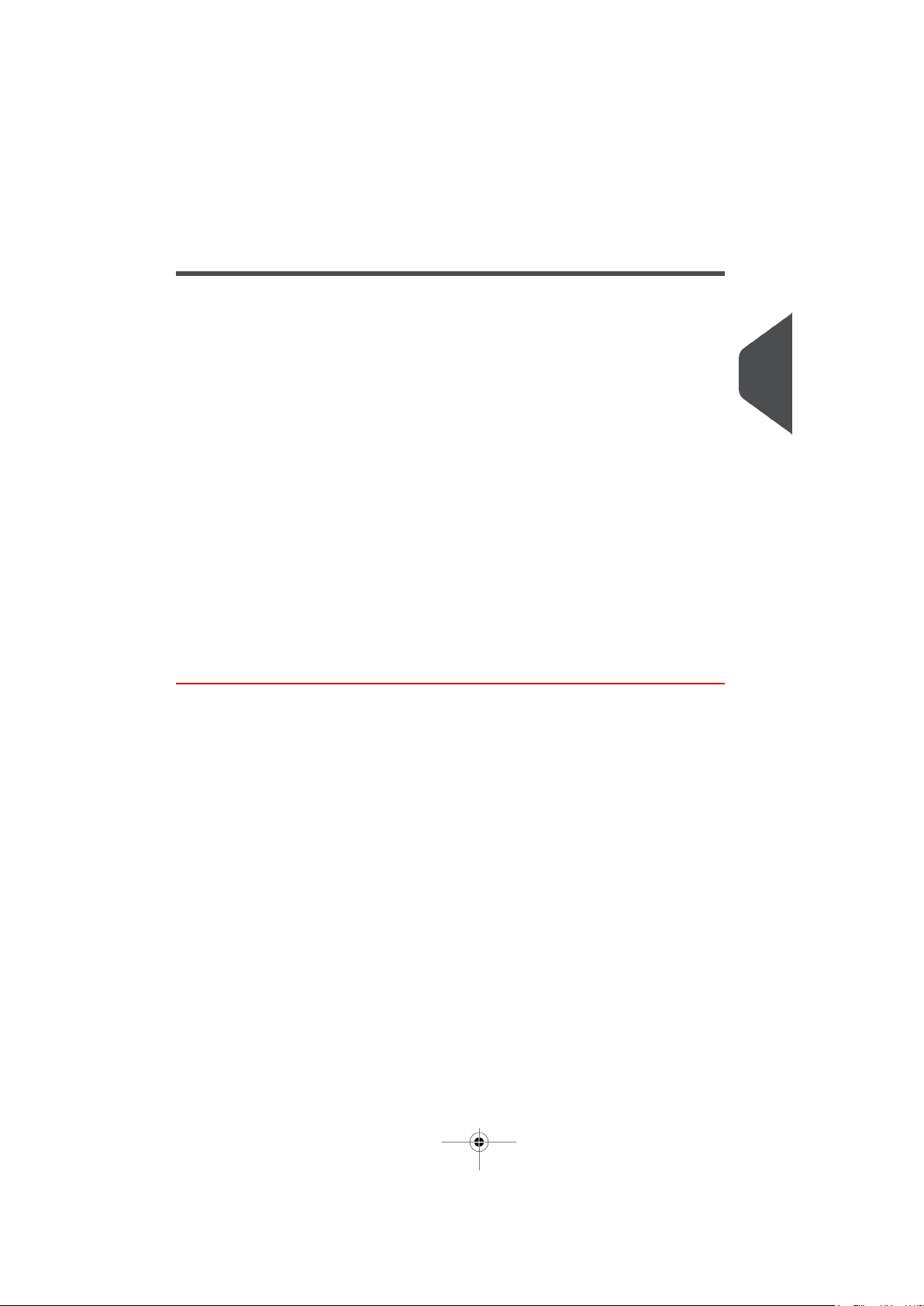

Create an Automatic Job

Proceed as follows if you want to create an automatic job:

From the Job list menu, tap [New job].1.

21

Page 26

| Page 22 | feb-24-2014 01:32 | Working with Jobs

2. Tap [Automatic] to start an Automatic job.

3

English

3. Fill the envelope hopper, load your documents and tap [1x] to create an example mail

set.

4. Make sure that the address position and the envelope stop position is correct. If

not, adjust the address position on page 36 and envelope stop position on page 39.

5. If necessary, tap the counter symbol to set the counters. See counter settings on page

31.

6. Tap [Start] to start the job.

7. Tap [Stop] to finish the job.

Tap [Save] if you want to save the settings of the Automatic job to a new job.

22

Page 27

| Page 23 | feb-24-2014 01:32 | Working with Jobs

Create a Manual Job

Introduction

Creating jobs manually is easy: the user interface guides you through the job definition with

clear steps.

These steps are:

• Define the mail set: envelope type, main document and optional enclosures.

• Define how to fold the document set.

• Define the exit of the system that should be used for this job.

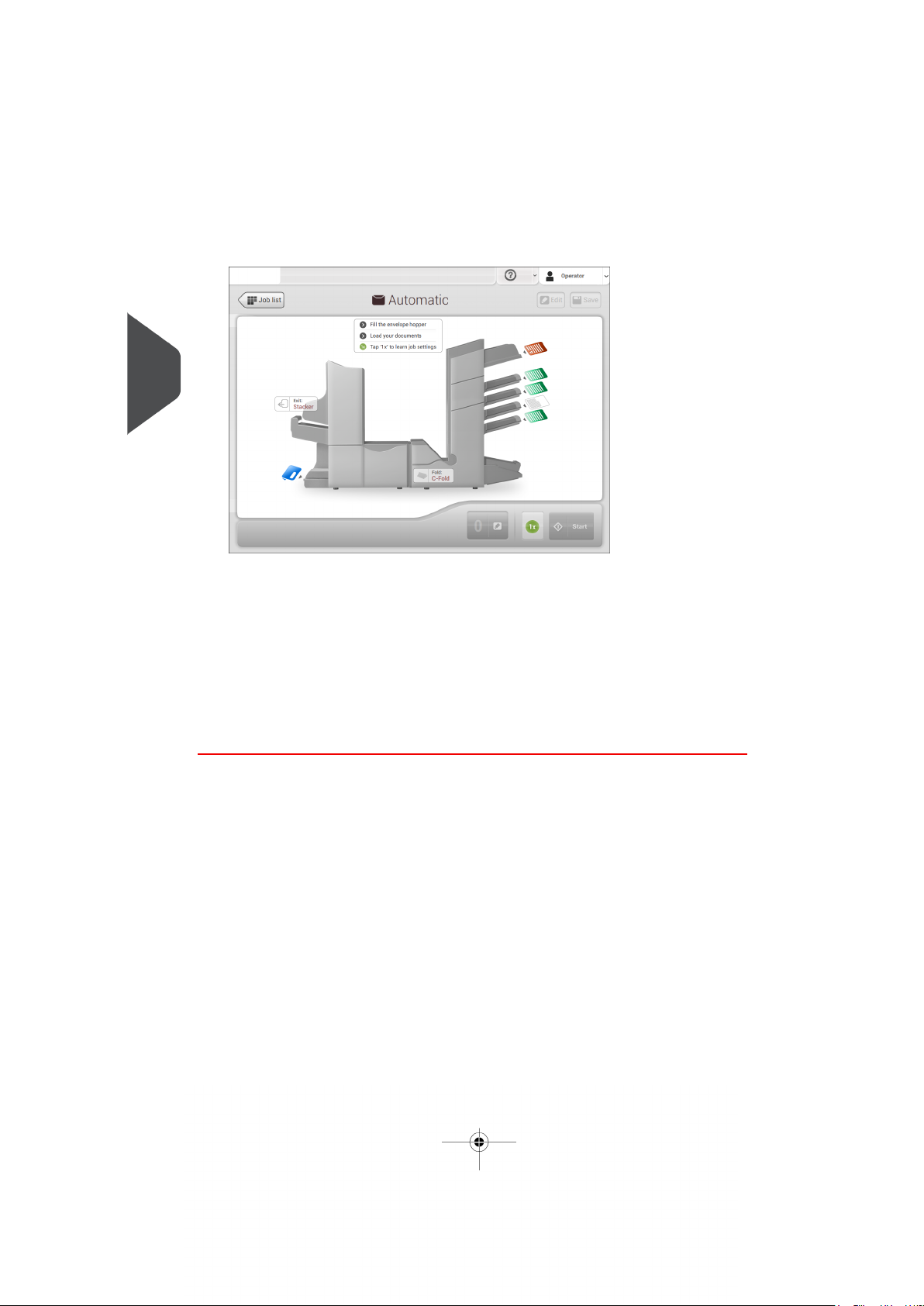

Create a Job Manually

To create a job manually:

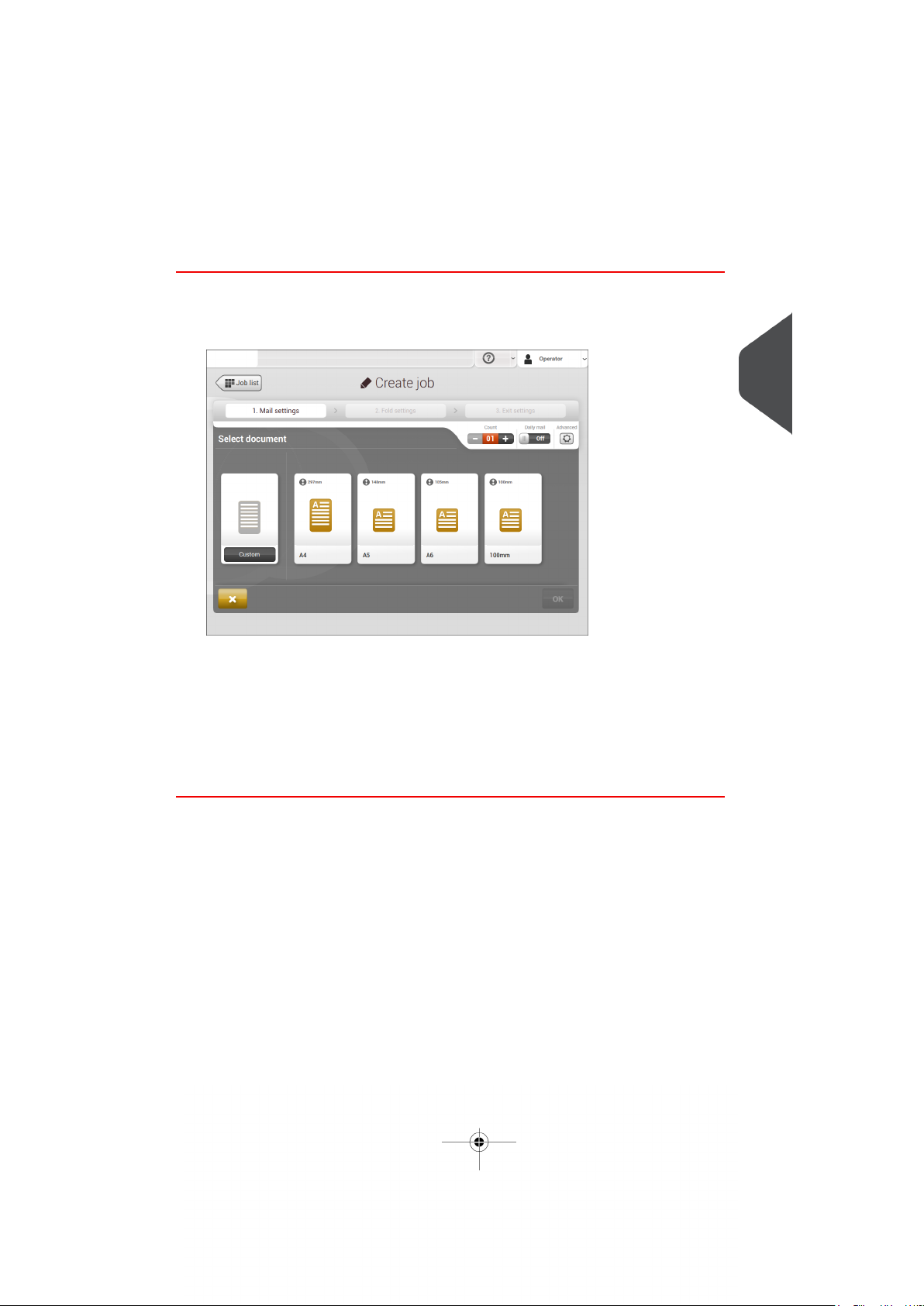

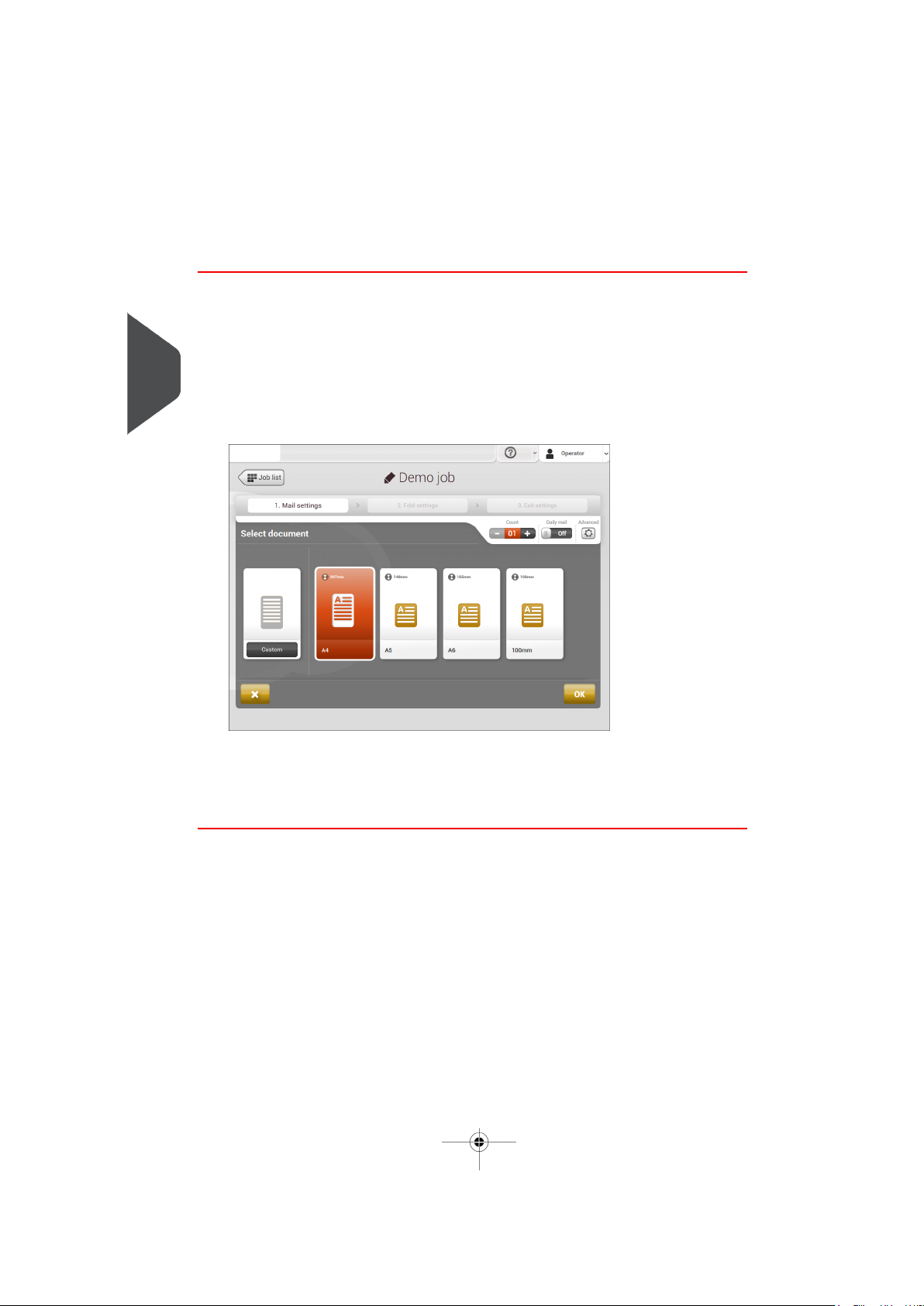

1. From the Job list menu, tap [New job].

2. Choose [Manual] to define the job settings.

3

English

Continue with the envelope settings (see Envelope on page 24).

23

Page 28

| Page 24 | feb-24-2014 01:32 | Working with Jobs

Mail Settings

Envelope

3

1. Tap [Envelope].

English

2. Select a predefined envelope or create a custom envelope on page 45.Optionally tap

[Use envelope] to set the use of envelopes to 'off' if you want to Create a job without

the use of envelopes.

3. Tap [Sealing] to switch it on or off.

By default the envelopes will be sealed.

4. Confirm the envelope settings with [OK].

Continue with the main document settings (see Main Document on page 25).

24

Page 29

| Page 25 | feb-24-2014 01:32 | Working with Jobs

Main Document

1. Tap [Main document].

3

English

2. Select a predefined document or create a custom document on page 46.

3. Change the [Count] to add more than one document from a feeder (multiple sheet

feeding).

4. Optionally tap Daily Mail on page 43 to set Daily Mail to 'on' or tap [Advanced] to set

the DFC Settings on page 26.

5. Confirm the document settings with [OK].

Continue with the enlosure settings (see Enclosure on page 27).

25

Page 30

| Page 26 | feb-24-2014 01:32 | Working with Jobs

Switch DFC on or off for feeders

For every feeder you can switch the double feed control (DFC) on or off.

To change the DFC settings:

Tap the job that you want the change the DFC settings for.1.

2. Tap [Edit].

3

3. Tap the document that you want to change the DFC for.

4. Tap [Advanced].

English

5. Tap Double Feed Control to switch it on or off.

6. Tap Continue on double to switch it on or off. If Continue on double is on, the machine

will not stop if two sheets are fed instead of one. The document-set that contains the

double sheets will be diverted.

26

Page 31

| Page 27 | feb-24-2014 01:32 | Working with Jobs

Enclosure

1. Tap [Add enclosure].

3

English

2. Select a predefined document or create a custom document on page 46 as

your enclosure.

If you want to remove an enclosure from the job, or change the order of the enclosures,

see Delete or move an enclosure on page 50.

27

Page 32

| Page 28 | feb-24-2014 01:32 | Working with Jobs

3. Change the [Count] for more than one document from a feeder.

4. Confirm the enclosure settings with [OK].

Continue with the fold settings (see Fold settings on page 28).

Fold Settings

3

Default the machine suggests the most logical fold type. This fold type is highlighted in

purple. However, you can select other fold types and change their settings.

English

Tap a fold type.1.

2. If necessary, tap [Settings] to change the fold settings.

3. Tap [>].

If you want to revert to the machine recommended fold type, switch [Use recommended

fold] to On.

Continue with the exit settings (see Exit settings on page 29).

28

Page 33

| Page 29 | feb-24-2014 01:32 | Working with Jobs

Exit Settings

Select the Exit Settings:

1.

3

English

The system has two exits: the stacker and the side exit. In the Exit settings of the job,

you define which exit is used. When Reading is on, more options for exit selection are

available on page 122. Standard (without reading), you choose between:

- Fixed exit: tap [Settings] to select which exit must be used for this job. If you

select stacker, you can choose to let the system continue on the side exit if the

stacker is full.

- Batching: tap [Settings] to define after what number of mail sets, the system

must switch to the other exit.

- Thickness: tap [Settings] to define the exit for document-sets that are too thin

or too thick. At the inserter, the thickness is measured and compared to a

reference thickness. Depending on the selection in this menu the envelopes

exit to the stacker or the side exit. The first document-set determines the

reference thickness.

2. Optionally tap the [Advanced] button to set the mail set thickness detection on page

30 settings.

3. Tap [>].

Continue with Finish the job definition and start the job on page 34, or set the counter

settings on page 31.

29

Page 34

| Page 30 | feb-24-2014 01:32 | Working with Jobs

Switch the mail set thickness detection on and off

You can switch the mail set thickness detection to 'yes' (= on) or 'no' (= off). By default the

mail set thickness detection is set to 'yes'.

To change these settings:

3

If the job uses reading, you cannot switch on the Mail Set Thickness

Detection (DFC) for the document set. With reading, the document

set size can be different for every set.

English

1. Select the job that you want the change the mail set thickness detection setting for.

2. Tap [Edit].

3. Navigate to 3.Exit settings.

4. Tap [Advanced].

30

Page 35

| Page 31 | feb-24-2014 01:32 | Working with Jobs

5. Tap the 'Double Feed Control' button to switch it on or off.

6. Tap the 'Continue on double' button to switch it on or off. If Continue on double is on,

the machine will not stop if two sheets are fed instead of one. The mail set that contains

the double sheets will be presented on deck.

7. Enter the 'Measurement area offset'. After the DFC detects the document set, it delays

the thickness measurement. It starts measuring as soon as the offset has passed.

3

English

Change the Counter Settings

The counter settings are job related.

31

Page 36

| Page 32 | feb-24-2014 01:32 | Working with Jobs

In the Counter submenu you can set the (daily) Job counter, the Stop counter and the Job

total counter. The following will be shown in the Counter submenu:

• Job counter (as shown), the daily job counter: number of mail sets that have been

processed using this job, after tapping [Start].

• Stop counter/Stop at value: set a number (of processed mail sets) after which the

system stops processing. You can set from 5 through 9999. The system will continue

processing mail sets until the job counter reaches the stop counter value. The system

3

English

stops and can be restarted.

When the processing of mail sets has been interrupted the system shows how many

mail sets have been completed. This is shown at 'completed so far'.

• Job total counter: total number of mail sets that have been processed using this job.

To reset/set the counters proceed as follows:

In the Job overview screen tap the counters button.1.

32

Page 37

| Page 33 | feb-24-2014 01:32 | Working with Jobs

2. Tap the reset button for the daily job counter to set it to zero.

3. Tap the [on/off] button to set the Stop counter to ‘on’ or ‘off’. If you set the Stop counter

to ‘on’ you can enter the ‘Stop at value’. Enter a value from 5 through 9999.

4. Tap the reset button for the Job total counter to set it to zero.

3

English

If you set the Job total counter to zero the number history of this

job will be lost.

5. Tap [OK] to go back to the job overview screen and tap [Start].

33

Page 38

| Page 34 | feb-24-2014 01:32 | Working with Jobs

Finish the Job Definition and Start the Job

When you have finished the exit settings, the touch screen shows an overview of the job

settings.

3

English

In this screen you can change the following settings:

• Move documents between feeders (see Change to an other feeder tray on page 47)

• Link feeders (see Link feeder trays on page 47)

• Change the counter settings (see Change the counter settings on page 31)

When you are ready with these settings, proceed as follows:

Load the documents on page 55 as indicated on the Job info screen.1.

2. Tap [1x] to create a test mail set (see Test mail set on page 35).

3. If desired, you can save the job (see Save a job on page 49).

4. Tap [Start] to start the job.

34

Page 39

| Page 35 | feb-24-2014 01:32 | Working with Jobs

Create an Test Mail Set

Before starting an existing job or a new, manual created job, it is possible to create a test

mail set.

This test run is intended to validate the settings of the Inserting System:

• Check if the address is correctly positioned behind the envelope window.

See Adjusting the Address position on page 36.

• Inspect and adjust the stop position of the envelope. See Adjusting the Envelope

Insert fingers on page 37.

• Check the fold settings for one set. See Fold settings on page 28.

When you tap the [1x] button, you can choose between three test mail sets:

3

English

• Selected exit: creates one mail set that leaves the system at the defined exit. Use

this option to test the complete process.

• Present on deck: creates one mail set without sealing. The mail set leaves the system

from the upper unit. Use this option to verify and adjust the address position.

• Envelope stop position: separates one envelope and transports the envelope to the

envelope stop position. Use this option to verify and adjust the envelope stop position.

After a test mail set, the system asks if the mailset is ok or not ok. When you select not

ok, you are guided through a wizard that helps you to find the cause.

35

Page 40

| Page 36 | feb-24-2014 01:32 | Working with Jobs

See also:

• Adjusting the address position on page 36

• Verifying the Insert Position on page 39

• Adjusting the envelope insert fingers on page 37

Adjust the Address Position

If the address on your mail is not correctly positioned behind the envelope window, change

3

the address position as follows:

English

1. Choose a job and tap [1x].

2. Tap Mail set not OK if asked if the mail set is correct.

3. Tap Address position not correct.

4. Change the address position: slide the position indicator to the correct position.

Adjusting the address position is only possible after creating an

example mail set (by using the [1x] button).

5. Tap the green button to create another example mail set or tap [OK] to confirm the

settings.

36

Page 41

| Page 37 | feb-24-2014 01:32 | Working with Jobs

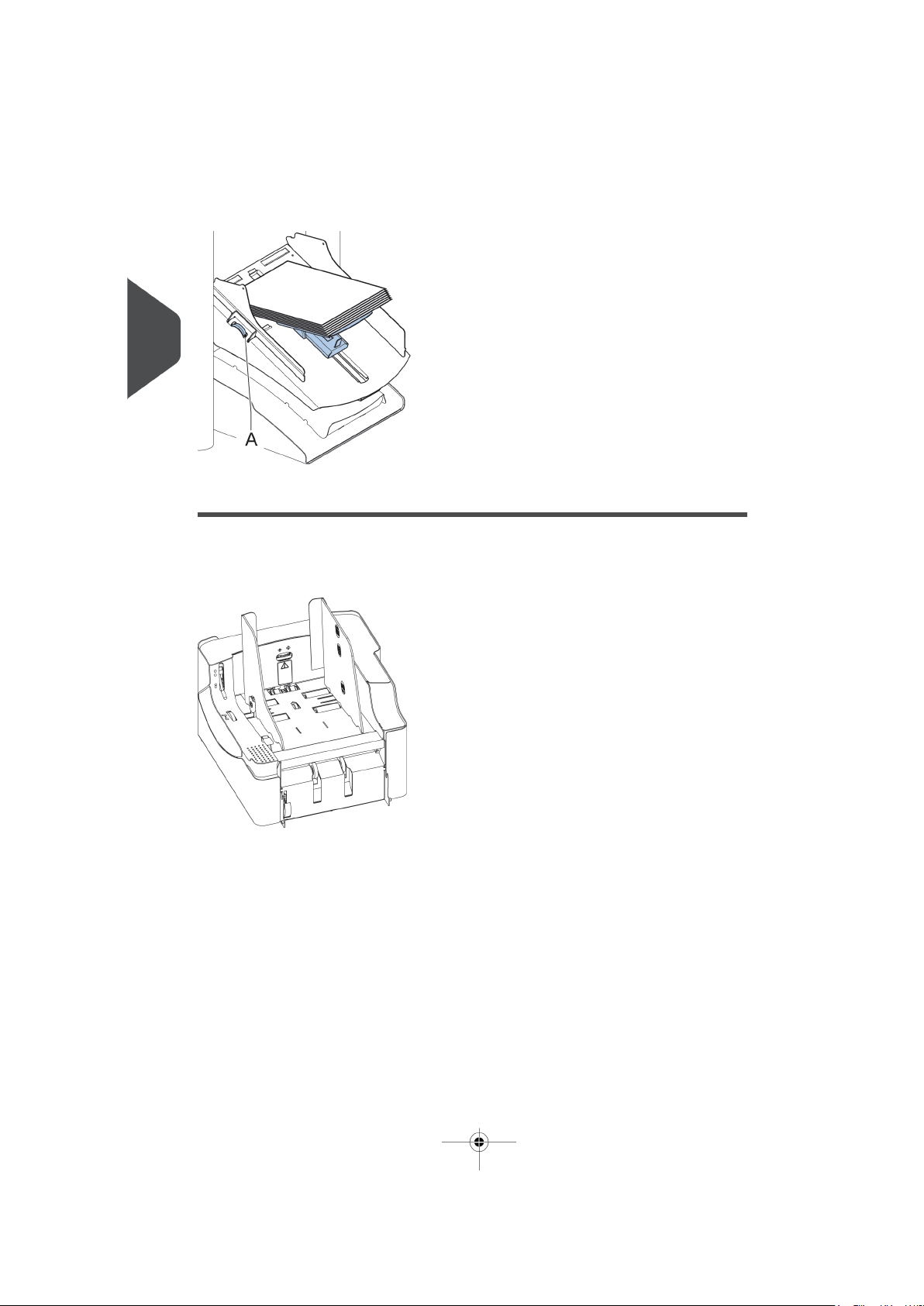

Adjust the Envelope Insert Fingers

To verify that the position of the fingers is correct:

Choose a job and tab [1x] (envelope only).1.

3

English

2. Tap the 'Envelope stop position' button.

3. Lift the unlocking lever A of the upper unit and pull up the upper unit.

37

Page 42

| Page 38 | feb-24-2014 01:32 | Working with Jobs

4. Tap the arrow to move to the next screen.

3

English

5. Follow the instructions on screen.

38

Page 43

| Page 39 | feb-24-2014 01:32 | Working with Jobs

If the insert fingers are not correct, adjust the fingers as follows:

1. Loosen the knurled knob C on top of each finger.

2. Adjust each finger so that the tip enters about 5 mm (0.2 inch) into the envelope.

3. Re-tighten the knurled knob.The fingers can be moved sideways to the desired position.

4. Place the outer fingers D about 5 to 10 mm (0.2 to 0.4 inch) from the edges of the

envelope.

3

English

Check the position of the insert fingers when changing to a different

type of envelope.

5. Tap the envelope button on the touch screen to fetch another envelope.

6. Make sure that the finger position is correct. If not, repeat the steps for adjusting the

fingers.

Verify the Insert Position

To verify the insert position:

This adjustment must only be checked in case of problems or when

changing the envelope type.

1. Choose a job and tap [1x] (envelope only).

39

Page 44

| Page 40 | feb-24-2014 01:32 | Working with Jobs

2. Lift the unlocking lever A of the upper unit and pull up the upper unit.

3

3. Follow the instructions on screen.

English

4. Tap the envelope button to fetch another envelope.

5. Make sure that the insert position is correct. If not, repeat the steps for adjusting the

insert position.

40

Page 45

| Page 41 | feb-24-2014 01:32 | Working with Jobs

Mail Sets

Adjust the Separation of Special Feeders

Adjust the separation of special feeders as follows:

Push knob A forward until it clicks.1.

3

English

2. Turn knob A counter clockwise to open the separation gap.

3. Place a document on the feeder tray and slide it into the system until it can go no

further.

4. Turn knob A clockwise to get resistance.

5. Move the document to and fro. The separation is adjusted correctly when a slight

resistance is felt on the document. Turn knob A counter clockwise again if the

resistance was set too high.

6. Pull the knob A back again when ready.

41

Page 46

| Page 42 | feb-24-2014 01:32 | Working with Jobs

Process a Mail Set with BRE or Inserts

A mail set with BRE or insert consists of a main document (address carrier), a BRE or an

insert and perhaps other enclosures. This set is inserted into an envelope.

From the Job list menu, tap [New job].1.

2. Add the BRE as a (custom) enclosure.

3

3. Follow the job creation process (see Create a manual job on page 23).

English

42

Page 47

| Page 43 | feb-24-2014 01:32 | Working with Jobs

Process Mail Sets with Daily Mail

To process mail sets with Daily Mail:

Create a Manual job on page 23 and select [DailyMail] for your Main document.1.

3

English

2. Complete the job settings.

3. Tap [start] to start the job.

A daily mail switch notification and instruction appears on the screen.

4. Turn down the left side guide A of the upper tray. Now you can see the Daily Mail

handle B.

5. Move the handle B to the right to enable the Daily Mail function.

6. Turn side guide A upwards.

43

Page 48

| Page 44 | feb-24-2014 01:32 | Working with Jobs

7. Place the document or document set in the feeder tray (see Loading documents on

page 58). The document or document set will be folded and inserted into the envelope

as described in the selected job.

8. Place the next document or document set in the feeder tray. The system will keep

running to process the inserted document or document set.

9. When finished with Daily Mail, tap [stop] to stop the job.

10. Set the Daily Mail handle B to the ‘AUTO’ position to disable the Daily Mail and enable

3

the automatic document separation.

English

Process Mail Sets with Very Long or Very Short Documents

When you define a job for very long or very short documents, the system asks you to adjust

the document stoppers as indicated on the display.

To adjust the collator stop position:

Lift and hold the collator arm D.1.

2. To remove a stopper: push it towards the system to release tab Z from the slotted

hole. Tip the stopper over and lift to release tabs X and Y.

3. To place a stopper: insert the tabs X and Y into the slotted holes. Click tab Z into the

slotted hole.

4. Repeat these steps for the remaining stoppers.

5. Close the collator.

44

Page 49

| Page 45 | feb-24-2014 01:32 | Working with Jobs

Create a Job with Custom Envelopes

Makes sure that your custom envelopes fit within the specifications

(see Envelope Specifications on page 144).

1. Create a Manual job on page 23 and select envelope.

2. Tap [Custom].

3. Enter the envelope height.

4. Tap the [Flap] tab if you use open flap envelopes.

5. Select if you want to feed envelopes with flaps up (On) or with flap down (Off).

3

English

6. Tap [OK] to save and close the envelope settings.

7. Complete the Fold Settings and Exit Settings to complete the job and tap [Save] to

save the job.

Follow the instructions as described in 'Create test mail set' on page 35.

45

Page 50

| Page 46 | feb-24-2014 01:32 | Working with Jobs

Create a Job with Custom Documents

Makes sure that your custom documents fit within the specifications

(see Document Specifications on page 143).

3

1. Create a Manual job on page 23 and select a custom document as your main

document or enclosure.

2. Tap [Custom] to create a custom document.

English

3. Enter the height of the document.

4. Tap the [Address] tab to set the address position for a main document.

5. Confirm the document settings with [OK].

6. Complete the Fold Settings and Exit Settings to complete the job and tap [Save] to

save the job.

Follow the instructions as described in 'Create a test mail set' on page 35.

46

Page 51

| Page 47 | feb-24-2014 01:32 | Working with Jobs

Change to Another Feeder Tray

You cannot change the order of the documents in the mail set by

changing feeders. If you want to change the order of the mail set,

see Delete or move an enclosure on page 50.

If you want to move the main document or enclosures to another feeder tray:

Select a job from the Job list.1.

2. Tap the document that you want to move to another feeder tray.

All available feeder trays are marked with a dotted box.

3. Tap the dotted box of the feeder tray where you want to move your document to.

The new feeder tray is selected for feeding of the document.

4. Tap [Save] to save the feeder tray selection to the job.

Link Feeder Trays

Link feeder trays as follows:

Select a job from the Job list.1.

2. Tap the feeder tray that you want to link to another feeder tray.

The link symbol appears.

3

English

47

Page 52

| Page 48 | feb-24-2014 01:32 | Working with Jobs

3. Tap the link symbol.

The figure shows an example of linked feeders.

3

4. Tap [Save] to save the link to the job.

English

When you want to un-link the feeders, tap the feeder trays and tap the un-link symbol.

Edit a Job

To edit an existing job:

From the Job list menu, select a job you want to edit.1.

2. Tap [Edit].

When you tap [edit], you enter the guided job flow that enables you to make the desired

changes.

3. Make the changes you want to make. When you completed the job programming,

tap [Save] to save the changes.

4. Tap [1x] to make sure that the Insert Position and Address Position are correct

(see Verifying the Insert Position on page 39 and Adjusting the Address Position on

page 36).

48

Page 53

| Page 49 | feb-24-2014 01:32 | Working with Jobs

Save a Job

When you have created a new job or edited a job, save the job as follows:

After you have completed the job definition, tap [Save].1.

3

English

2. Enter the job name.

3. If necessary, add a description to the job. The description is visible in the job list.

4. Tap [OK] to save the job.

The job is added to the job list.

49

Page 54

| Page 50 | feb-24-2014 01:32 | Working with Jobs

Delete or Move an Enclosure

If you want to delete an enclosure in your job or change the order of the enclosures, proceed

as follows:

From the Job list menu, select a job you want to edit.1.

2. Tap [Edit].

3

3. Tap and hold the enclosure you want to move or delete.

English

Now drag the enclosure to an other position. Or tap the waste bin to delete the

enclosure from your mail set.

4. Tap the arrow buttons [>] to pass the other job definition steps and close the job editor.

5. Tap [Save] to save the changes.

6. Tap [1x] to make sure that the Insert Position and Address Position are correct

(see Verifying the Insert Position on page 39 and Adjusting the Address Position on

page 36).

50

Page 55

| Page 51 | feb-24-2014 01:32 | Working with Jobs

Copy a Job

To copy existing job settings to a new job:

Tap and hold the job in the Job list menu.1.

3

English

2. Tab [Copy].

3. Enter the name of the new job and tab [OK].

Lock a Job

To lock an existing job:

Log on as supervisor.1.

51

Page 56

| Page 52 | feb-24-2014 01:32 | Working with Jobs

2. Tap and hold the job in the Job list menu.

3

English

3. Tap [Lock].

4. Tap [OK] to confirm.

The job shows a lock in the job list. If the supervisor is logged on, the lock is open. If the

operator is logged on, the lock is closed. The operator cannot edit, delete or rename the

job.

52

Page 57

| Page 53 | feb-24-2014 01:32 | Working with Jobs

Rename a Job

To rename a job:

Tap and hold the job in the Job list menu.1.

3

English

2. Tab [Rename].

3. Enter the name of the new job and tab [OK].

53

Page 58

| Page 54 | feb-24-2014 01:32 | Working with Jobs

Delete a Job

To delete an existing job:

Tap and hold the job in the Job list menu.1.

3

English

2. Tap [Delete].

3. Tap [OK] to confirm.

54

Page 59

| Page 55 | feb-24-2014 01:32 | Loading the System

Loading the System4

Document Orientation

The touch screen shows how to load documents and envelopes into the feeders. The table

shows the meaning of the symbols:

Address carrier face up and leading (top

address)

Address carrier face up and leading (bottom

address)

Address carrier face down and trailing (top

address)

Enclosure face up

Enclosure face down

4

English

55

Page 60

| Page 56 | feb-24-2014 01:32 | Loading the System

Document Feed Trays

Standard Document feed Trays

Install the Document Feed Trays

4

Place the document feeder trays in position:

Hold the document feeder tray slightly inclined as shown in the figure.1.

English

2. Place the front end of the document feeder tray underneath the two black rollers.

3. Move the document feeder tray upwards (lifting the black rollers), until it is possible

to ‘hook’ the feeder tray into place.

4. Move the document feeder tray towards the machine and move the hooks over the

mounting points (on both sides).

5. Let the document feeder tray rest on the machine.

56

Page 61

| Page 57 | feb-24-2014 01:32 | Loading the System

Adjust the Side Guides

To adjust the side guides it is best to remove the document feeder tray from the feeder as

follows:

Push handle A downwards.1.

2. Lift the document feeder tray upwards to unhook it and then pull it out from the feeder.

3. Loosen the knob B half a turn.

4

English

4. Grab the side guides in the middle and push them apart as far as possible.

5. Put a small stack of documents between the side guides.

6. Grab the side guides in the middle and push them towards the documents.The space

between the side guides and the documents should be such that the documents have

just enough play to move freely.

7. Re-tighten knob B.

8. Remove the stack of documents.

9. Replace the document feeder tray (see Installing the Document Feeder Trays on page

56).

57

Page 62

| Page 58 | feb-24-2014 01:32 | Loading the System

Load Documents

Fill the document feeder tray as follows:

Note the Document Orientation when filling the document feeder

trays.

4

1. Open the left-hand side guide A by turning it downwards.

The feed rollers will automatically be lifted.

English

2. Place a stack of documents between the side guides.

3. Turn the left side guide upwards again.

Document Separation

The term ‘Document separation’ refers to the adjustment required for separating the upper

document from the rest of the documents in the stack. This prevents pulling too many

documents from the stack at the same time.

The document separation for the automatic feeders is set automatically; there are no manual

adjustments needed.

Feeders 1 and 2 (the feeders in the two lowest positions) can be special feeders. The

document separation for special feeders must be adjusted manually. While special feeder

trays fit in all positions, adjusting the separation is only possible when they are fitted on

position 1 and 2.

To adjust the separation of special feeders follow the instructions as described in Processing

mail sets with glossy material.

58

Page 63

| Page 59 | feb-24-2014 01:32 | Loading the System

Production Feeder

Adjust the Production Feeder Side Guides

Adjust the side guides:

Take a stack of documents/BREs and place them in the feeder tray.

1.

BREs with flap down and leading (top side pointing to system).

4

English

2. Adjust the side guides by turning the thumb wheel A such that the documents/BREs

just fit and can move without resistance.

Too much play causes skewing.

59

Page 64

| Page 60 | feb-24-2014 01:32 | Loading the System

Adjust the Production Feeder Document Separation

When the Production Feeder is used at an automatic separation feeder, the separation is

set automatically.

The Production Feeder can also be used on a feeder position with a manually adjusted

separation. To adjust, proceed as follows:

Remove the document feeder trays 2 and 3.

1.

4

English

The lowest feeder is feeder 1.

2. Squeeze the two blue handles A and B and shift the feeding plate C as far as possible

to the front.

3. Push knob D forward until it clicks.

4. Place a document/BRE on the feeder tray and slide it in the system till the leading

edge is not visible anymore. Turn knob D counterclockwise if the separation is set to

narrow.

5. Push the document/BRE between the rollers.

6. Turn knob D clockwise to get more resistance and counterclockwise if the separation

is set to narrow.

The separation is adjusted correctly when a slight resistance is felt on the

document/BRE.

7. Pull knob D back when ready.

8. Replace the document feeder trays 2 and 3.

60

Page 65

| Page 61 | feb-24-2014 01:32 | Loading the System

Load Documents (Production Feeder)

To load documents:

When loading the Production Feeder, make sure that the

document/BREs are positioned parallel in relation to the feeding

plate assembly to ensure correct feeding.

The feeding plate assembly will be shifted up automatically (when the system starts

processing) until documents/BREs are underneath the rubber paper pullers.

In case of long documents, use the feeding plate extension B to

support the documents.

1. Squeeze the two blue handles A and B.

4

English

2. Shift the feeding plate assembly C to the rear position.

3. Loosen the stack of documents and place them in the feeder tray.

BREs with flap down and leading (top side pointing to system).

61

Page 66

| Page 62 | feb-24-2014 01:32 | Loading the System

High Capacity Document Feeder

Adjust the Side Guides

To adjust the side guides B:

4

English

Loosen knob D, which is located underneath the feeder tray, half a turn.1.

2. Put a small stack of documents between the side guides.

3. Rotate wheel E.

The space between the side guides and the documents should be such that the

documents have just enough play to move freely.

4. Re-tighten knob D.

62

Page 67

| Page 63 | feb-24-2014 01:32 | Loading the System

Load Documents (HCDF)

To load the document feeder tray:

Pull down lever A.

1.

The feeder rollers C move up to filling level.

2. Place a stack of documents between the side guides (max. 725 sheets, 80 g/m²).

See Document Orientation how to place the documents in the feeder tray.

3. Release lever A.

4

English

63

Page 68

| Page 64 | feb-24-2014 01:32 | Loading the System

Thin Booklet Feeder (FD 6606-15)

Adjust the Side Guides

The side guides can be adjusted as follows:

Place a stack of documents into the feeder tray.1.

4

English

2. Adjust the feeder tray side guides B by turning the thumbwheel C. Provide just enough

space for the documents to move freely. Too much play causes skewing.

64

Page 69

| Page 65 | feb-24-2014 01:32 | Loading the System

Adjust the Document Separation

The document separation can be adjusted as follows:

Check before the adjustment that the release handle D for the

separation unit is in the closed (down) position.

1. Turn the separation adjustment wheel A counter clockwise until a document can be

moved backwards and forwards without resistance.

4

English

2. Turn the separation adjustment wheel clockwise until a slight resistance is felt on the

document when the document is moved backwards and forwards.

3. Turn the separation adjustment wheel clockwise to get more resistance or counter

clockwise to lower the resistance.

4. Check the separation before starting the system. After starting the system it may occur

that more than one document at a time is pulled in. If this happens, turn the separation

adjustment wheel more clockwise to obtain correct operation. For poor feeding turn

the separation adjustment wheel counter clockwise.

65

Page 70

| Page 66 | feb-24-2014 01:32 | Loading the System

Feeder Tray Capacity

To avoid irregular feeding there are three levels for the maximum heights of the feeder tray

capacity. The symbols for these three levels are printed on the right hand side guide of the

feeder tray. The level indication is a guideline.

Maximum feeder tray capacity of booklets with a tough cover (maximum

height: 250 mm).

Maximum feeder tray capacity for booklets with a weak cover (maximum

4

height: 150 mm).

English

Maximum feeder tray capacity for single sheets: minimum sheet quality:

80 gr/m2 (maximum height: 50 mm).

Load Envelopes

Before you load the envelopes, make sure the envelope separation and side guides are

correctly set as described in Adjusting the Side Guides and Envelope Separation on page

67.

Loosen the stack of envelopes and place the stack on top of the bottom envelope.1.

2. Shift the envelope support in or out. The top side of the envelope must touch the

dotted line on the support.

3. Turn the envelope support to distribute the weight of the envelopes evenly on both

sides.

66

Page 71

| Page 67 | feb-24-2014 01:32 | Loading the System

Adjust the Side Guides and Envelope Separation

Adjust the side guides and envelope separation as follows.

Rotate thumb wheel D to move the side guides C apart.1.

2. Put a small stack of envelopes between the side guides.

3. Move the side guides towards the envelopes. The space between the side guides and

the envelopes should be such that the envelopes have just enough play to move freely.

4

English

If the distance between the side guides is too large, the envelopes

will twist sidewards, when transported into the machine.

4. Pull down small lever B to set the separation.

5. Insert one envelope up to the stoppers. The position of the envelope is flap down and

trailing (bottom side of the envelope pointing to the system).

6. Return lever B.

67

Page 72

| Page 68 | feb-24-2014 01:32 | Loading the System

Fill the Sealing Liquid Reservoir

Open the front cover A.1.

4

English

2. Fill the reservoir B to the "Max" lip with sealing liquid.

3. Close the front cover A.

Before starting the job, wait approximately 5 minutes for the brushes to moisten or use

moistened brushes. For instructions on the installation of brushes, see Clean and replace

brushes.

If the liquid reservoir is almost empty the touch screen shows a message to warn you that

you should refill the reservoir.

68

Page 73

| Page 69 | feb-24-2014 01:32 | Options

Options5

Support for Curved Reply Envelopes (option for

Thin Booklet Feeder)

Depending on the quality of the paper, the conditions during storage, etc. envelopes can

be curved. This can cause smaller reply envelopes to skew while being processed by the

Thin Booklet Feeder.

A special support is available to allow curved envelopes to be correctly processed. It can

be used for envelopes with a height up to 110 mm (4.33").

5

English

Power Stacker Support

Depending on the inserted type and amount of documents, the filled envelopes may get

stack fanshaped at the stacker.

To prevent this, an optional power stacker support can be used in order to stack the

envelopes correctly.

69

Page 74

| Page 70 | feb-24-2014 01:32 | Options

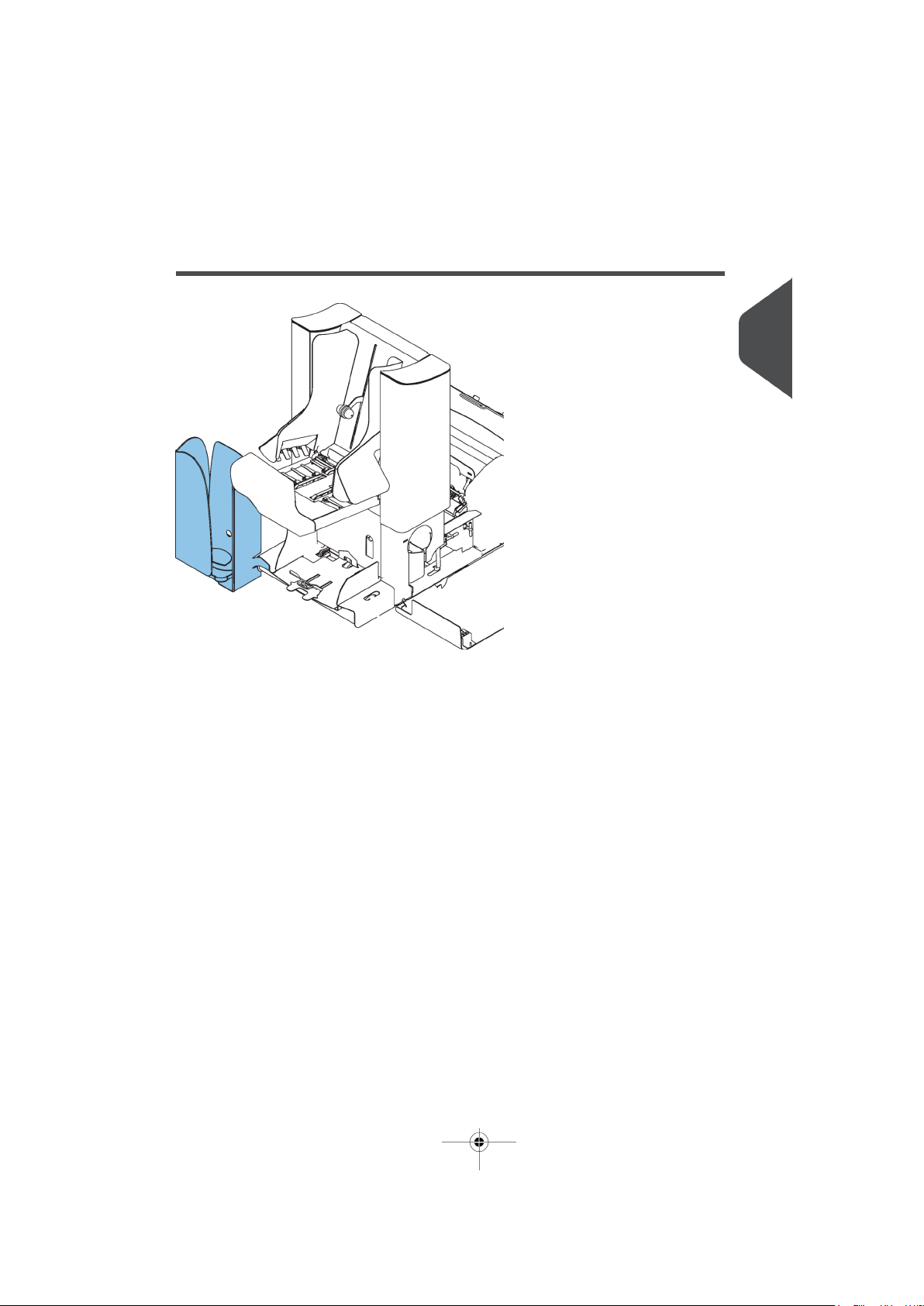

High Capacity Envelope Hopper (FD 6606-30/EF-4)

For feeding large amounts of envelopes a high capacity envelope hopper can be installed.

To start up the high capacity envelope hopper:

Switch on the hopper.

1.

5

English

To ensure correct feeding envelope support A has to be adjusted parallel. Proceed

as follows:

2. Move the high capacity envelope hopper backwards, away from the inserter.

3. Hold an envelope against the hopper plate B as indicated.

4. Place the envelope support A such that the envelope is aligned with recess C.

5. Apply the same alignment at the position of recess D.

6. Adjust the inserter side guides and the separation as described in Loading Envelopes.

7. Put an envelope in the envelope height measurement area.

70

Page 75

| Page 71 | feb-24-2014 01:32 | Options

8. Rotate thumbwheel E to adjust the envelope height setting. The envelope should fit

exactly in the space indicated by the arrows.

9. Rotate thumbwheel F to adjust the side guides so, that the envelopes:- Fit exactly

between the side guides- Can move freely

10. Fill the envelope hopper with envelopes, positioned upside down. The flaps should

face the inserter.

11. Tip over the envelopes.

12. Load the envelope feeder of the inserter with about 50 envelopes.

5

English

13. Press the [Start] button.

The envelopes on the envelope hopper will be transported towards the feeder of the

inserter. Envelopes will be transported and dropped in the inserter feeder until the

envelopes reach a certain level. At that moment a sensor will detect the envelopes

and the high capacity envelope hopper will stop transporting.

When the sensor does not detect envelopes anymore the hopper will start again and

the process will be repeated.

71

Page 76

| Page 72 | feb-24-2014 01:32 | Options

High Capacity Conveyor Belt (FD 6606-25/CS-2)

The high capacity conveyor belt is designed for envelope transport from the inserter or

franking device. The conveyor belt has two operation modes:

• The belt moves continuously.

• The belt moves in intervals. The belt moves about 45 mm (1.7 inch) each time a

sensor detects the passage of an envelope.

The guide plate and side guides prevent the envelopes from falling off the belt.

The conveyor belt switch has three positions:

5

• Mode D: the belt moves in intervals.

• Mode E: the belt is switched off.

• Mode F: the belt moves continuously.

English

72

Page 77

| Page 73 | feb-24-2014 01:32 | Options

With the turning knob (G) it is possible to set the interval distance between envelopes on

the conveyor belt. The distance depends on the type of job and preference of the user.

Guideline:(G)

Minimal interval distance: 15 mm, setting for a job with thin envelopes.

Neutral interval distance: 20 mm

Maximal interval distance: 40 mm, setting for a job with thick envelopes.

5

English

73

Page 78

| Page 74 | feb-24-2014 01:32 | Settings menu

Settings menu6

Open the Settings Menu

In the settings menu for the operator it is possible to edit the display settings and to set the

localisation.

If you want to view or edit any of the Operator Settings:

Go to the Job list and tap the side menu on the left side and select [Settings].1.

6

English

2. Tap [Localisation] if you want to change the document standard or the language.

74

Page 79

| Page 75 | feb-24-2014 01:32 | Settings menu

3. Tap [Display settings] if you want to:- set the 'Key' click to on/off

- set the Volume

- set the Backlight

- set the BrightnessTo set the backlight and brightness, a test pattern is available as

a reference.

6

English

For more information on Open source licenses, see Open source licenses on page 88.

75

Page 80

| Page 76 | feb-24-2014 01:32 | Settings menu

Open the Settings Menu (Supervisor)

Supervisor Settings are all settings that can be found under the Settings Menu when logged

in as supervisor (pin code 2546).

The following flowchart shows which subjects are available via the Supervisor settings

menu.

6

English

If you want to view or edit any of the Supervisor Settings:

76

Login as Supervisor with pin code 2546.1.

Page 81

| Page 77 | feb-24-2014 01:32 | Settings menu

2. Go to the Job list and tap the side menu on the left side and select [Settings].

6

English

77

Page 82

| Page 78 | feb-24-2014 01:32 | Settings menu

Supervisor Settings Menu

Configuration

The Configuration menu contains the configuration information settings for the system.

System Info

The System info part of the Configuration menu shows the following information:

• Flex certificate - this option is used for reading

• Counter since last visit - the counter value since the last service visit

• Last error (description) - The last error and error description generated by the system

6

English

78

Page 83

| Page 79 | feb-24-2014 01:32 | Settings menu

Software Overview

The Software overview part of the Configuration menu shows the versions of the software

that is present in the total system.

6

English

79

Page 84

| Page 80 | feb-24-2014 01:32 | Settings menu

Licensed Options

The Licensed options part of the Configuration menu shows the following information:

• Chip ID

• Serial number

• Installed options

The installed options are enabled with license codes. These license codes, together with

the identification number of the machine enable the relevant options. The enabled and

available software options are displayed in this screen. Contact your dealer for information

about these license codes.

The system supports the following licensed options:

• Remote assistance

• Online help

6

English

• Advanced/Basic reading

• OMR 1 track

• BCR 1D

• BCR 2D

• OCR

• Flex reading

80

Page 85

| Page 81 | feb-24-2014 01:32 | Settings menu

Add a Licensed Option

To add a licensed option:

In the Configuration, Licensed options screen, enter the license code.1.

6

English

2. Tap [Add].The system verifies the license key.

If the license key has been verified successfully, the option is added to the system and can

be used.

Settings

The Settings menu contains the configuration settings for the system.

81

Page 86

| Page 82 | feb-24-2014 01:32 | Settings menu

Localisation

Tap [Localisation] if you want to change the document standard or the language.

6

English

When you need a keyboard to enter e.g. a job name, you get a special keyboard in case

of Russian, Czech and Katakana. But the keyboard has always a button to switch back to

the English keyboard.

82

Page 87

| Page 83 | feb-24-2014 01:32 | Settings menu

Display Settings

See the settings menu for the operator on page 74.

Date-time

Tap [Date/time] to set the:

• Date

• Time

• Date format; you can choose between three format to show the date: dd-mm-yyyy,

mm-dd-yyyy or yyyy-mm-dd

• Time format; you can choose between a '12 hours' notation or a '24 hours' notation

6

English

83

Page 88

| Page 84 | feb-24-2014 01:32 | Settings menu

Production Settings

6

English

Tap [Production settings] to define when envelopes should be cleared from the system.

• Envelopes clearing after job selection: this setting defines if the envelopes should

be cleared when you select a job. 'Ask' means that the system asks if you want to

clear the envelopes.

• Envelopes clearing after job edit: this setting defines if the envelopes should be

cleared when you have edited a job. 'Ask' means that the system asks if you want

to clear the envelopes.

Job Settings

84

Job settings normally will be changed by a service engineer only.

Therefore first consult the service organization before you change

any settings. Changes to the job settings can result in malfunctioning

of jobs.

You can also define the job settings per job. Select a job from the

Job list, tap Edit, navigate to the Exit settings, and tap Advanced

on page 30.

Page 89

| Page 85 | feb-24-2014 01:32 | Settings menu

6

The Job settings part of the Settings menu covers settings that improve the processing of

jobs:

• Flap closer offset: to improve the sealing of specific envelopes you can delay or

advance the moment of sealing. You enter the number of pulses. A minus value

means the sealing is advanced, a plus value means the sealing is delayed. You can

enter a number between -20 and 20.

• System output: mode 1 mode 2

Mode 1 focuses on the versatility of paper parameters (paper thickness; document

length), i.e. correct operation under even extreme paper conditions. Mode 2 is the

default mode, and focuses on high speed. Use Mode 1 with a paper thickness of 65

g/m2 or less, a document length of 12 inch (305 mm) or higher, and for situations

where Mode 2 is not functioning properly. In all other cases use Mode 2.

• BRE with window: if the BRE has a window, set this setting to yes. Only available

with Mode 2.

• Document offset (A in the figure): the extend to which documents are not overlapping

in the vertical transport. In the vertical transport of documents fed by the various

feeders, the documents are partially overlapping each other. This to make sure that

the documents are properly aligned in the collator area. The default value is 50

mm (2.0 inch). The document offset can be varied between 20 mm (0.8 inch) and

250 mm (9.8 inch).

English

85

Page 90

| Page 86 | feb-24-2014 01:32 | Settings menu

6

English

• BRE offset: in the case of offset is “yes”, the last document that was added to the

set is shifted from the rest of the set (offsetting, see below).

• Collator stop optimisation: if set to "off", the system does not show a message,

when a collator stop change can improve the system output.

Explanation of BRE offset: if a BRE is longer than the set fold but shorter than the envelope

height, this BRE can get folded (A in the figure). Under certain conditions (see below) you

can prevent the BRE from being folded. In the case of offset “yes”, the BRE is held back

during a certain distance (B in the figure). This means that the trailing edge of the BRE

leaves the collator last. The document is not folded. During the insertion into the envelope

the documents of the set are aligned.

86

Page 91

| Page 87 | feb-24-2014 01:32 | Settings menu

The conditions are:

• No multi-feed is used for the BREs.

• The document directly under the BRE must have a height of at least 60 mm (2.4 inch)

more than the BRE.

• The height of the BRE is more than the set fold length.

• The folding mode is either V-fold or C-fold (no Z-fold).

• The BRE must be shorter than the envelope height.

The whole BRE offset is based on friction between documents within a set. Therefore it is

necessary to make use of these conditions to reduce the risk of bad transporting, folding

and inserting.

It is possible to use the BRE offset for a BRE and an enclosure

(card) in one set. The extra condition is that this enclosure is equal

to or smaller than the set address fold and should be placed direct

underneath the BRE in the set.

Connectivity

6

English

See Connect the system to the internet on page 95.

87

Page 92

| Page 88 | feb-24-2014 01:32 | Settings menu

Open Source Licenses

6

English

Open source licenses show license information on the open source software that is used

in the system.

Diagnostics

The diagnostics menu contains the basic diagnostics functions available for a supervisor.

System Test