Page 1

6402 Series

Inserters

5/2007

OPERATOR MANUAL

FIRST EDITION

Page 2

Page 3

TABLE OF CONTENTS

1 Health, Safety and Environment ...................................................... 3

1.1 Precautions and Safety Issues ................................................... 3

2 Functional Description..................................................................... 6

2.1 Overview ............ .......................... .......................................... 7

2.1.1 FlexFeed

2.1.2 Collating Area (2) ...................................................... .. .. 8

2.1.3 IntelliDeck

2.1.4 PowerFold

®

(1) ................................................................ 7

®

(3) ............................................................. 8

®

(4) .............................................................. 8

2.1.5 Inserter (6) .................................................................. 8

2.2 Operating Controls .................................................................. 9

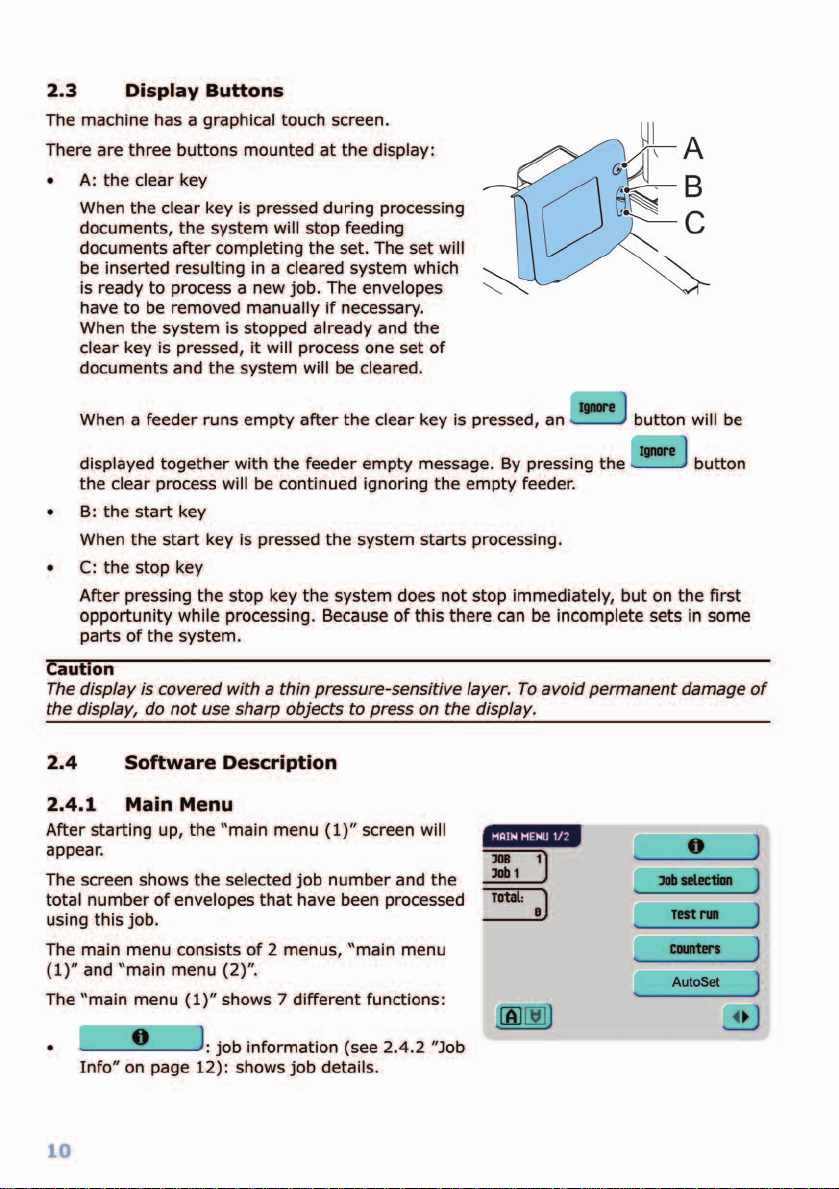

2.3 Display Buttons ...................................................................... 10

2.4 Software Description ....................... .. ... .. ................................. 10

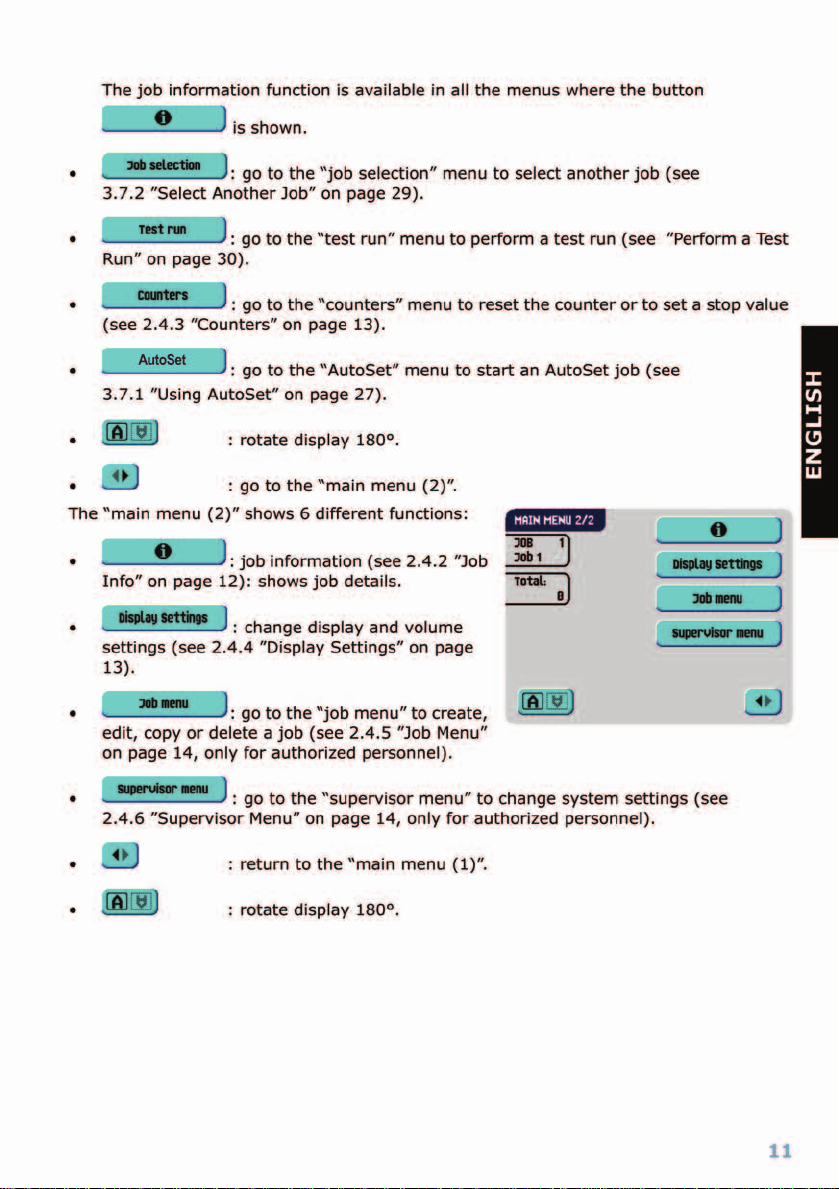

2.4.1 Main Menu ................................................................... 10

2.4.2 Job Info ...................................................................... 12

2.4.3 Counters ..................................................................... 13

2.4.4 Display Settings ........................................................... 13

2.4.5 Job Menu ..................................................................... 14

2.4.6 Supervisor Menu ............................. ...................... .. ..... 14

3 Operating Instructions .................................................................. 20

3.1 Installation ............................................................................ 20

3.2 Preparation ........................................................................... 20

3.2.1 Document Feed Trays ................................................... 20

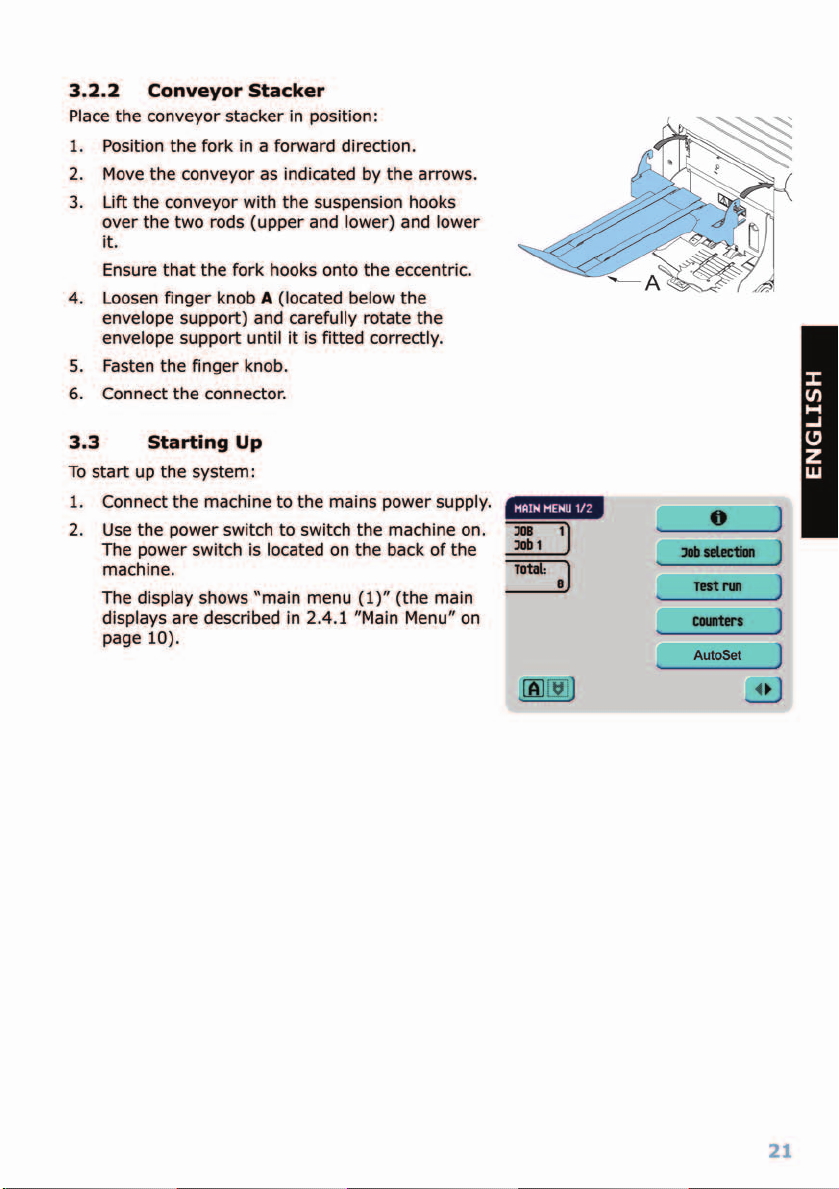

3.2.2 Conveyor Stacker ......................................................... 21

3.3 Starting Up ............................................................................ 21

3.4 Loading Documents ................................................................ 22

3.4.1 Document Orientation ................................................... 22

3.4.2 Side Guides ................................................................. 23

3.4.3 Document Separation .................................................... 23

3.4.4 Filling the Document Feed Tray ...................................... 24

3.4.5 Adjustment of the Document Stoppers ............................ 24

3.5 Loading Envelopes .................................................................. 25

3.5.1 Adjusting Side Guides ................................................... 25

3.5.2 Envelope Separation ..................................................... 25

3.5.3 Feeding Envelopes ........................................................ 26

3.6 Sealing Envelopes .................................................................. 26

3.7 Job Selection or AutoSet

...................................................... 27

3.7.1 Using AutoSet .............................................................. 27

3.7.2 Select Another Job ........................................................ 29

3.8 Run the Daily Mail .................................................................. 30

3.9 Create a Job .......................................................................... 31

3.9.1 Job Settings ................................................................. 32

3.9.2 Envelope Settings ......................................................... 32

3.9.3 Document Settings ....................................................... 33

3.9.4 Fold Settings ................................................................ 34

3.9.5 Optical Mark Recognition Settings (Option) ...................... 36

3.9.6 Double Feed Control Settings ......................................... 37

3.9.7 Job Name .................................................................... 38

ENGLISH

1

Page 4

3.9.8 Mailing/Franking Settings (Option) .................................. 39

3.10 Edit a Job .............................................................................. 40

3.11 Copy a Job ............................................................................ 40

3.12 Delete a Job .......................................................................... 41

4 Options..................................................................... ......... ............ 42

4.1 Activate an Option .................................................................. 42

4.2 Optical Mark Recognition (OMR) ............................................... 42

4.2.1 General ................ ........................... ............................ 42

4.2.2 Alignment .................................................................... 43

4.2.3 Document Orientation ................................................... 44

4.2.4 OMR Codes .................................................................. 44

4.3 Online Services ...................................................................... 48

4.3.1 General ................ ........................... ............................ 48

4.3.2 Start-Up Online Services ............................................... 48

4.3.3 Connection .................................................................. 48

4.3.4 Messages ................................................................... 49

4.3.5 Configuration Menu ....................................................... 50

4.4 Production Feeder................................................................... 51

4.4.1 Function ...................................................................... 51

4.4.2 Preparations ................................................................ 51

4.4.3 Adjust Side Guides ....................................................... 52

4.4.4 Document Separation .................................................... 52

4.4.5 Feeding Documents ...................................................... 52

4.5 insert’n Frank™ (insert’n Mail) ................................................. 53

5 Maintenance .................................................................................. 54

5.1 Operator Maintenance ............................................................. 54

6 Fault Finding.................................................................................. 55

6.1 Error Messages ...................................................................... 55

6.2 Clearing Stoppages ................................................................ 56

6.2.1 Exit, Sealing and Inserting Area ..................................... 56

6.2.2 Envelope Hopper .......................................................... 57

6.2.3 Lower Envelope Track ................................................... 57

6.2.4 PowerFold

6.2.5 FlexFeed

® ............................................................................................................................ 58

® ............................................................................................................................... 58

6.2.6 Collating Area .......................... ....................... .. ........... 58

6.3 Operator Troubleshooting ........................................................ 58

7 Specifications .............................................................................. .. 62

7.1 Technical Specifications ........................................................... 62

7.2 Configuration Dimensions ........................................................ 62

7.3 Other Specifications ................................................................ 62

7.4 Document Specifications ......................................................... 62

7.5 Envelope and Insert Specifications ............................................ 63

8 Terminology .................................................................................. 65

Index.............................................................................................. 72

2

Page 5

1. HEALTH, SAFETY AND ENVIRONMENT

1.1 Precautions and Safety Issues

Thoroughly read this operator manual, before using this machine.

Warnings

• If the feed/fold unit and inserter unit have to be physically separated, the operator

should pay attention to the heavy weight of the unit during separation.

• Before connecting check whether the system is suitable for the local mains voltage.

Refer to the type plate.

Safety Precautions

• Only competent personnel should operate this machine.

If incompetent personnel do operate this machine, the manufacturer does not accept

responsibility for any resulting accidents or injuries.

• Only skilled persons, who are aware of the risks involved, may open the protective

covers.

For safety reasons, the machine will not function when the covers are open.

• Keep long hair, fingers, jewelry, etc. away from rotating and moving parts.

• The power connection must be easily accessible, preferably close to the machine.

• For safety reasons, it is essential that the machine is connected to a socket outlet that

has a protective earth connection.

• Over-current protection in the equipment also relies on the branch circuit protection

(max. 20 A).

• The following part(s) is (are) considered the equipment disconnect device(s):

- Power supply cord plug

- 12-pole connector, located on the right-hand side

ENGLISH

3

Page 6

Conventions

Warning

This symbol:

• Identifies situations where improper use of the machine can result in

personal injury or permanent/catastrophic damage to the machine.

• Indicates that the operator manual should be consulted.

Warning

This symbol indicates a danger caused by high voltage.

Note

A note gives additional relevant information.

.

4

Page 7

5

Page 8

2. FUNCTIONAL DESCRIPTION

The 6402 Series feeds, folds and inserts documents into envelopes and then seals and stacks

the envelopes. Automatic monitoring ensures the correct number of inserts per envelope.

The machine is a sophisticated folding and inserting system which can process large

quantities of mail rapidly and easily. The system can be operated by means of a user

friendly interface.

The settings of the system (types of documents, type of envelopes and the type of fold) is

recorded in so-called jobs. These jobs can be programmed by an authorized user.

The 6402 Series is equipped with a variety of special features as document thickness detection,

programmable jobs,

AutoSet, double feed control, hopper swap, multifeed, and daily mail.

6

Page 9

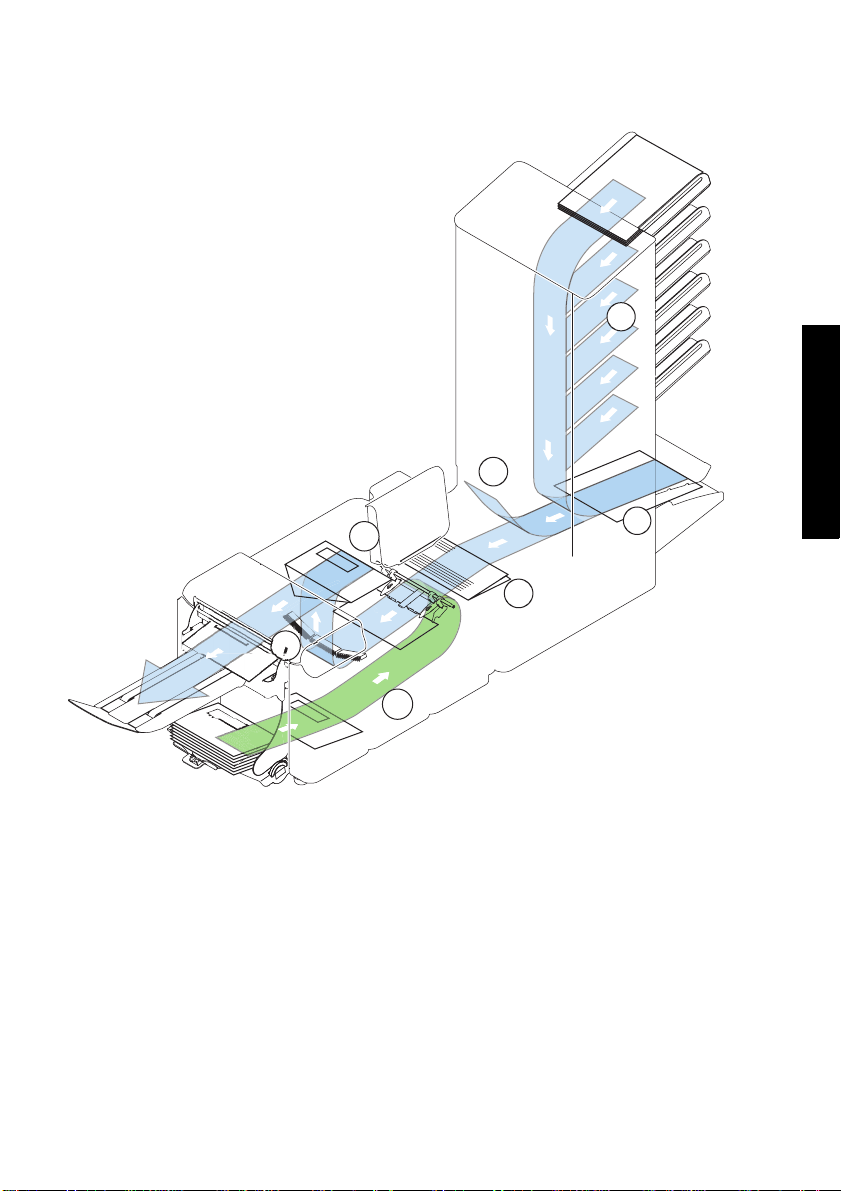

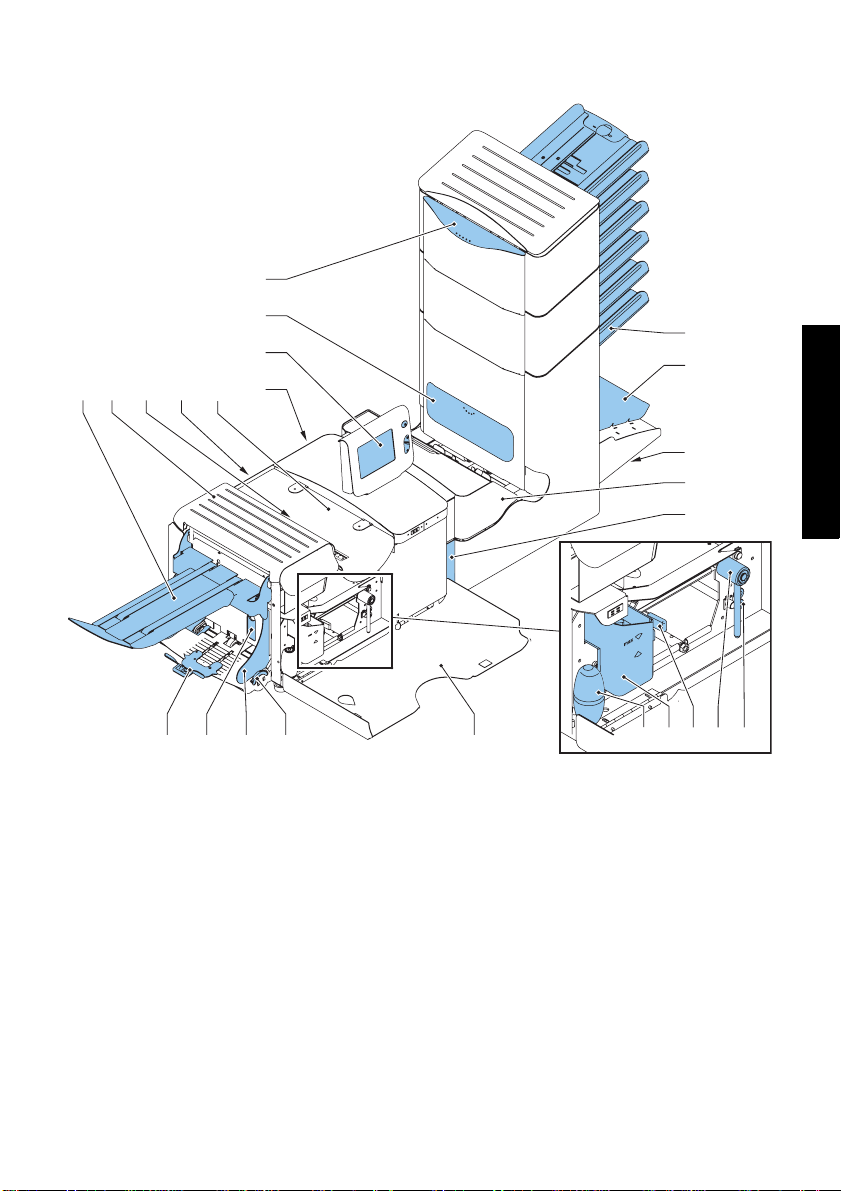

2.1 Overview

The system consists of the following parts:

1. FlexFeed®

2. Collating area

3. Divert Deck

4. Folding area

5. Envelope feeder

6. Inserter

7. Envelope exit (including conveyor

stacker)

1

3

2

6

4

7

5

2.1.1 FlexFeed® (1)

The flexFeed® is the feeding part of the system. There are two types of feeders available:

the automatic and the special feeder. The automatic feeder does not require any

adjustments for the separation. The flexFeed

this way the system can detect faulty sets o f documents. The flexFeed

hopper swap. This means that two feeders can be linked as pairs. When the first feeder is

empty , the system switches to the other feeder . Meanwhile the other empty feeder can be

refilled without stopping. It’s also possible to feed multiple documents from one feeder. In

this way more documents can be fed from one station, for example an original and a copy

of a document.

®

is equipped with double feed control. In

®

is equipped with

ENGLISH

7

Page 10

The upper automatic feeder is equipped with a “daily mail” function for processing

documents or sets of documents which cannot be processed automatically (e.g. stapled).

2.1.2 Collating Area (2)

After feeding, the documents are gathered and aligned in the collating area.

2.1.3 Divert Deck (3)

The Divert Deck automatically throws out incorrect sets of documents. In this way the

system does not need to stop. Correct sets will be transported to the Folding area.

2.1.4 Folding area (4)

The Folding area folds the documents. The following fold types are possible:

•No fold

•Single fold

• Letter fold

• Zig-zag fold

• Double parallel fold

2.1.5 Inserter (6)

After folding the documents are transported to the inserter unit where the documents are

inserted into a waiting envelope. The inserter then seals the envelope (or not) and stacks

them on the conveyor stacker. Automatic monitoring ensures the correct number of

inserts per envelope.

8

Page 11

2.2 Operating Controls

I

H

G

A B D

C

F

E

U TVWX

A conveyor stacker

Bloc cover

C unlocking lever for loc

D power inlet, power switch

Einserter cover

F RS232 connector / USB / modem

G display (operator panel)

H OMR reading head cover

I hand grip vertical transport cover

J document feed tray

Kcollator arm

L operator manual storage space

M folding area

J

K

L

M

N

S

N locking handle

O air plugs for cle aning the sensors

P handle for manual envelope transport

Q unlocking handle for rollers envelope

track

R water reservoir

S bellows for cleaning sensors

T side cover (opened)

U thumb wheel for side guide adjustment

V side guides envelope feed tray

W lever for envelope separation

adjustment

X envelopes support

OPQR

ENGLISH

9

Page 12

Page 13

Page 14

2.4.2 Job Info

To enter the “job info” menu, press .

This menu displays all relevant information about

the selected job.

If the optional OMR is used the "1 track OMR info"

menu is also available using the button.

To return to the “main menu (1/2)”, press .

The “job info” menu contains the following information:

Gives information about the envelope size (ISO format or height in mm).

Shows the type of fold.

3

2

1

Shows the feeders selected to pick documents from (black is selected).

The sign below this icon shows if the document double feed detection for the

relevant feeder is switched on - or off - .

The number under this icon indicates the number of sheets that must be

picked from the relevant feeder.

This sign indicates that the rele vant feeder is set for daily mail.

Below this icon, the format of the document in the relevant feeder is

3

2

indicated (ISO standard or height in mm).

This sign indicates that the relevant feed ers are linked. This means that

when one feeder is empty, the system automatically starts picking

documents from the other feeder.

The sign indicates that for the relevant feeder the Optical Mark Recognition

(OMR) is switched on (optional).

12

Page 15

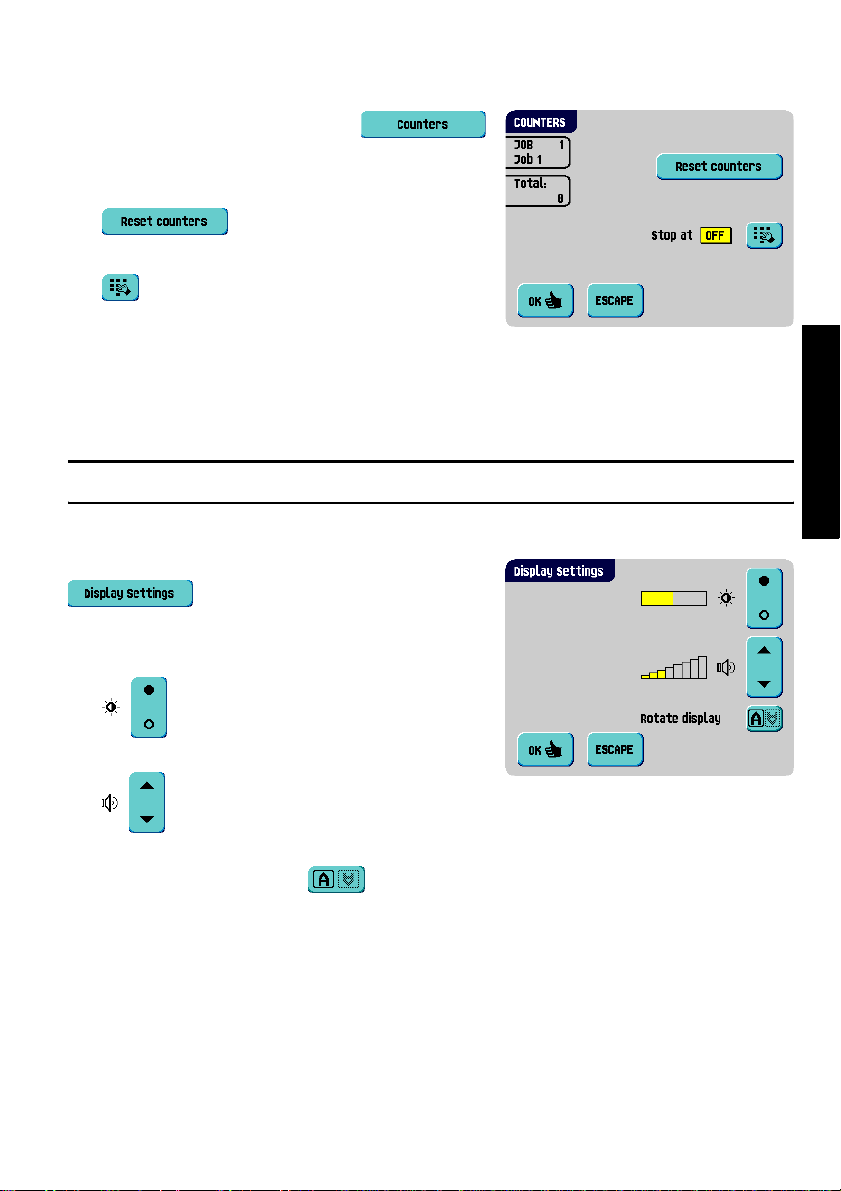

2.4.3 Counters

T o enter the “counters” menu, press

from the “main menu (1)”.

The “counters” menu shows the following functions:

• : press this button to reset the

daily job counter and stop counter to zero.

• : press this button to enter a

stop value.

The stop counter is switched off when it is set to

zero. The display will show “Stop at off”.

The stop counter can be set between 0 (switched off) and 9999. The system will continue

until the job counter reaches the stop counter value. The system stops and can be restarted.

Note

The counter settings are job related.

2.4.4 Display Settings

To enter the “display settings” menu, press

from the “main menu (2)”.

The “display settings” menu shows the following

functions:

• : enables to change the contrast of the

display. The graphic shows the contrast setting.

• : enables to adjust the volume of the

acoustic signals. The graphic shows the volume setting.

• Rotate display: press the button to rotate the display 180 °.

ENGLISH

13

Page 16

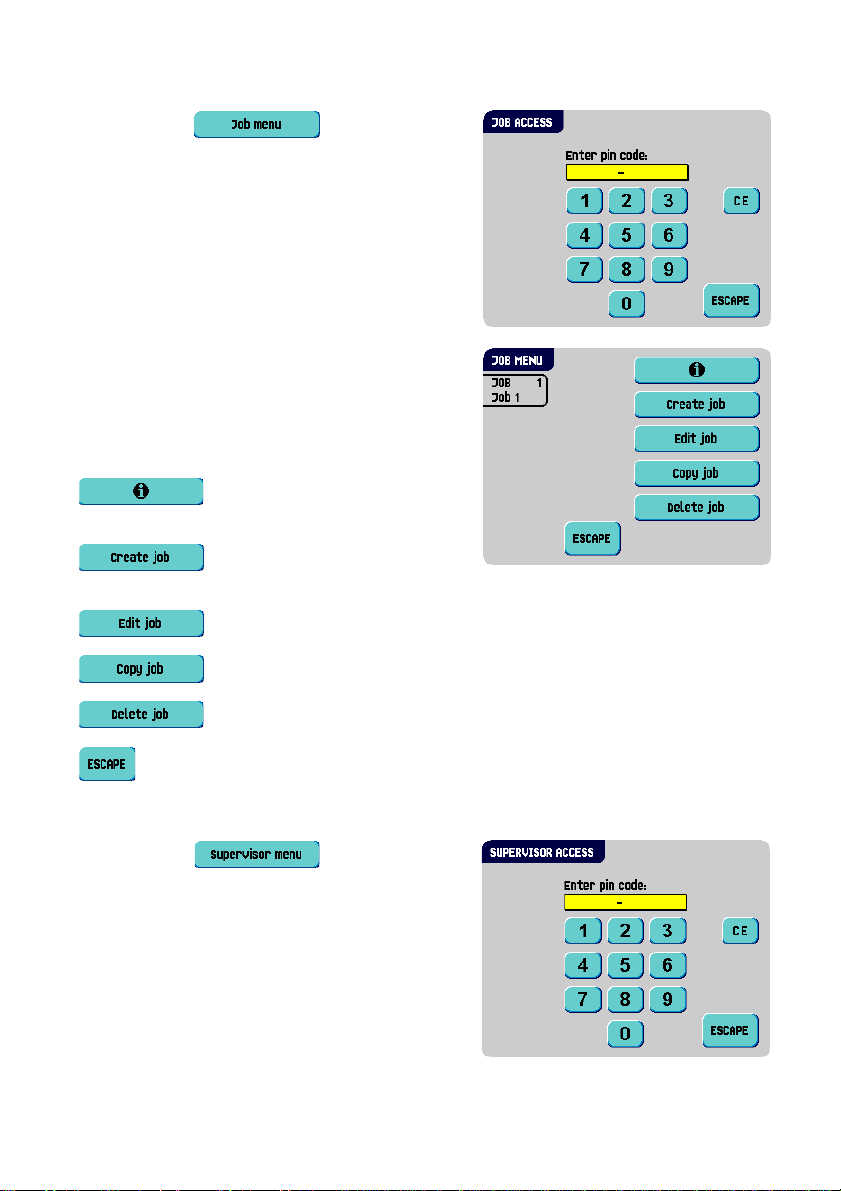

2.4.5 Job Menu

After pressing the button a login

menu opens.

To prevent jobs being edited or deleted without

informing the ‘job owner’, this menu is protected by

a PIN-code. The PIN-code is

When a wrong pin code is entered, the cursor is set

to the first number to try again.

After 3 times entering a wrong pin code the display

shows the “main menu (1)” again.

After entering the correct pin code the “job menu”

appears.

This menu enables the creation, deletion and/or

editing of jobs.

The “job menu” shows the following functions:

• : job information (see 2.4.2 ”Job

Info” on page 12).

• : create a job (see 3.9 ”Create a

Job” on page 31.)

• : edit a job (see 3.10 ”Edit a Job” on page 40).

2546

.

• : copy a job (see 3.11 ”Copy a Job” on page 40).

• : delete a job (see 3.12 ”Delete a Job” on page 41).

• : exit and return to the “main menu (1)”.

2.4.6 Supervisor Menu

After pressing the button a login

menu opens.

Enter the PIN-code 2546 to access the “supervisor

menu”.

14

Page 17

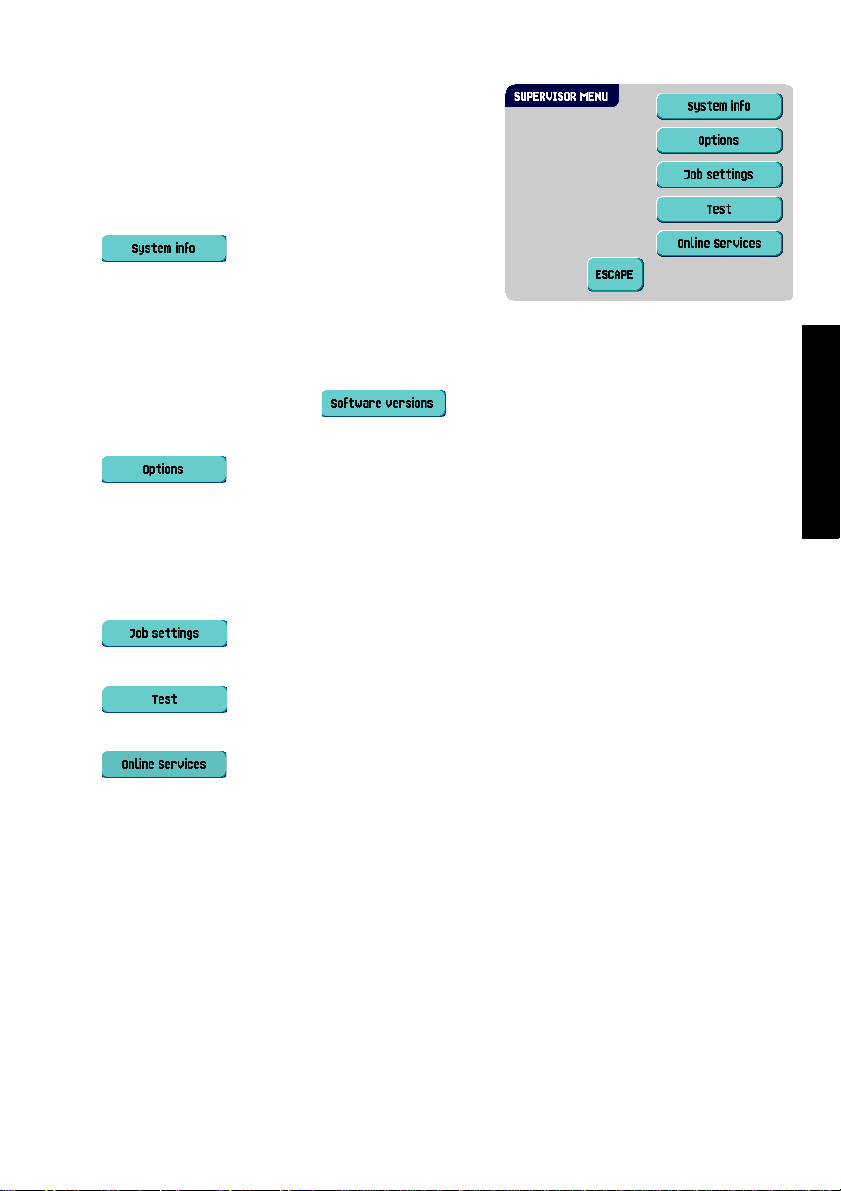

After entering the correct pin code the “supervisor

menu” appears.

This menu enables checking and configuring the

system.

The “supervisor menu” shows the following

functions:

• : shows system information,

like:

- The flex certificate, used for OMR

- The counter since last visit: the counter value since the last service visit

- The last error generated by the system

The screen shows a button : this shows the software versions that are

present in the total system.

• : shows option information and system information:

-The chip ID

-The system ID

- The installed options

For installing new options, see 4.1 ”Activate an Option” on page 42.

• : opens the “job settings” supervisor menu (see ”Job Settings

(Supervisor)” on page 16). From this menu system parameters can be set.

• : opens the “test menu” (see ”Test” on page 18). Use this menu to

test the system.

• : opens the “Online Services” menu ( option, see 4. 3 ”Online Services”

on page 48). This screen enables to connect the system to a server and receive

messages.

ENGLISH

15

Page 18

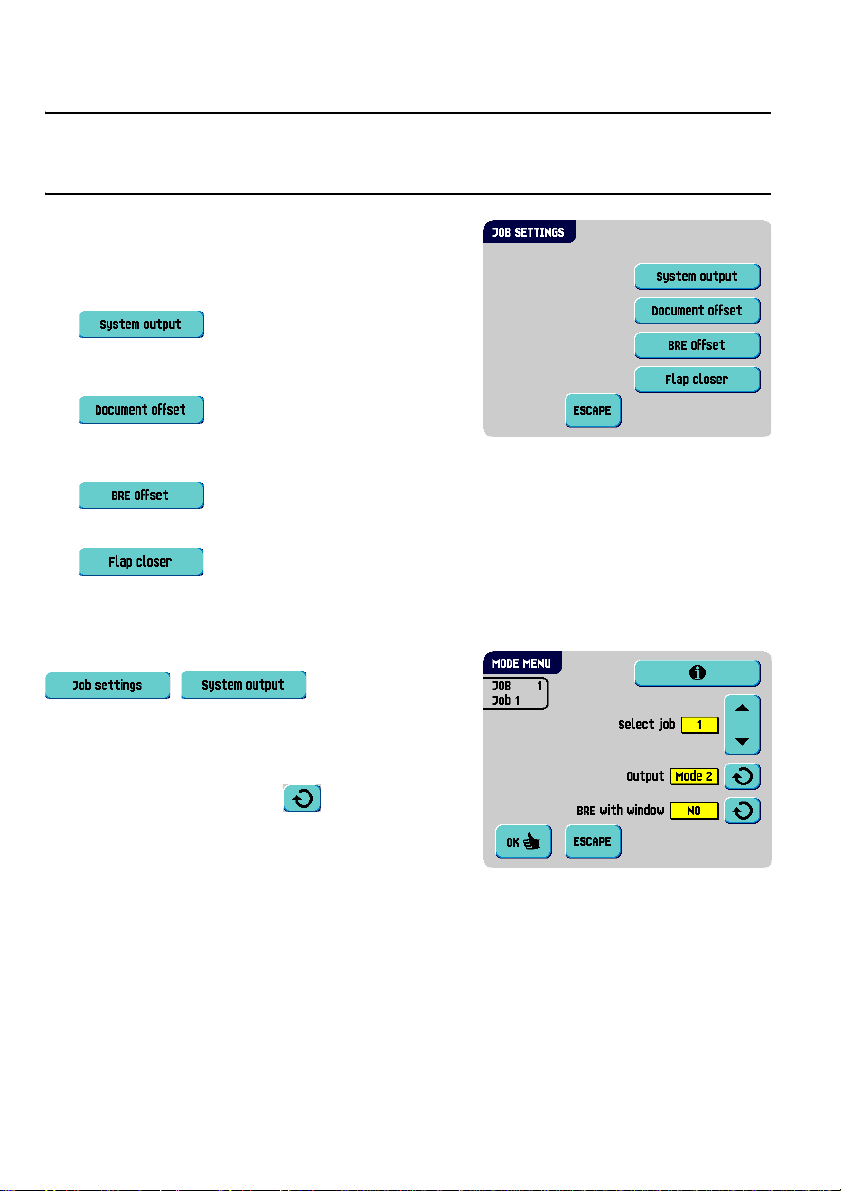

Job Settings (Supervisor)

Caution

Job settings normally will be changed by a service engineer only. Therefore first consult

the supplier’s Helpdesk before changing any settings. Changes to the job settings can

result in malfunctioning of jobs.

The “job settings” menu (supervis or) can be o pened

from the “supervisor menu”. From this menu system

parameters can be set. The “job settings” menu

shows the following functions:

• : opens the “mode menu” to set

the output mode for a job (see ”Mode Menu” on

page 16).

• : opens the “document offset”

menu to set the document offset in a set of

documents for a job (see ”Document Offset” on page 17).

• : opens the “BRE offset” menu to set the BRE offset on or off (see

”BRE Offset” on page 17).

• : opens the “flap closer” menu (see ”Flap Closer” on page 18). Use

this function to improve the envelope sealing process.

Mode Menu

When selecting from the “supervisor menu”

, , the “mode menu”

appears.

In this menu for each of the jobs 1 through 25 and

AutoSet a choice can be made between output

Mode 1 and Mode 2 using the button. Mode 2 is

the default setting.

Mode 1 focuses on the versatility of paper

parameters (paper thickness; document length), i.e.

correct operation under even extreme paper conditions.

Mode 2 focuses on high speed and is achieved as follows:

• During multi feed (more than one page from one feeder) the movement on the

collator is minimal. In mode 1 the divert unit will be used for completing the collating

process (less paper on paper transport).

• During the transportation of a set from the co ll ator into the powerFold

is going into the collator already. This results in temporary overlapping sets with two

different transport directions. In mode 1 the set has left the collator completely before

the next set enters the collator.

®

, the next set

16

Page 19

• Anticipation call for the envelope is used. That means that a (folded) set is leaving the

flexFeed

envelope is on the insert position already before the set leaves the flexFeed

It is advised to use Mode 1 with a paper thickness of 65 g/m

of 12 inch (305 mm) or higher, and for situations where Mode 2 is not functioning

properly. In all other cases Mode 2 is advised.

If you select Mode 2, select if the reply envelope has a window or not.

®

already before the envelope is ready on the insert position. In mode 1 the

2

or less, a document length

®

.

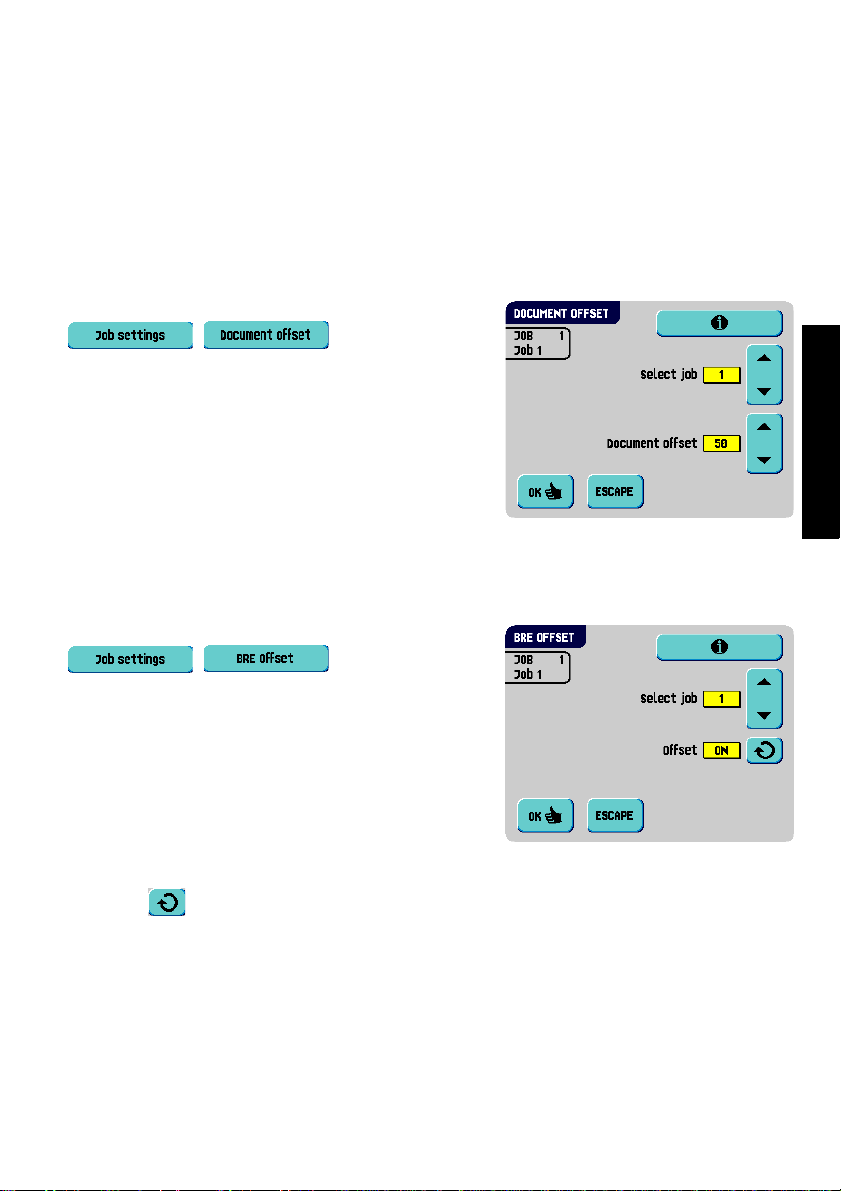

Document Offset

When selecting from the “supervisor menu”

, , the “document

offset” menu appears.

The vertical transport of documents fed by the

various feeders is arranged in such a way that the

documents are partially overlapping each other. This

overlapping scheme ensures that the documents are

properly aligned in the collator area.

In the “document offset” menu you can set the

extend to which the documents are not overlapping

each other, i.e. the document offset value. The default value is 50 mm (2.0 inch). The

document offset can be varied between 20 mm (0.8 inch) and 75 mm (3.0 inch).

BRE Offset

When selecting from the “supervisor menu”

, , the “BRE offset”

menu appears.

If a document is longer than the set address fold but

shorter than the envelope height, this document

sometimes will be unnecessarily folded. Under

certain conditions this document can be prevented

from being folded. This can be implemented with the

menu “BRE offset” (BRE means Business Reply

Envelope).

ENGLISH

For each of the jobs 1 through 25 and AutoSet

using the button.

In the case of offset “on” the last docume nt that was added to the set will be shifted from

the rest of the set (offsetting). This document will be held back during a certain distance.

This means that the trailing edge of this upper document leaves the collator at last. This

document will not be folded. During the insertion into the envelope the documents of the

set will be realigned.

an offset can be switched on or off

17

Page 20

The conditions are:

• The feeder that supplies this upper document (BRE) is set to one document per set

(no multi feeding).

• The document directly beneath this document must be at least 60 mm (2.4 inch)

longer than the BRE.

• The upper document must be longer than the set address fold.

• The folding mode is either single fold or letter fold (no Z-fold).

• The upper document must be shorter than the envelope height.

Note

It is possible to use the BRE offset for a BRE and an enclosure (card) in one set. The extra

condition is that this enclosure is equal to or smaller than the set address fold and should

be placed direct underneath the BRE in the set.

The whole BRE offset is based on friction between documents within a set. Therefore it is

necessary to make use of these conditions to reduce the risk of bad transporting, folding

and inserting.

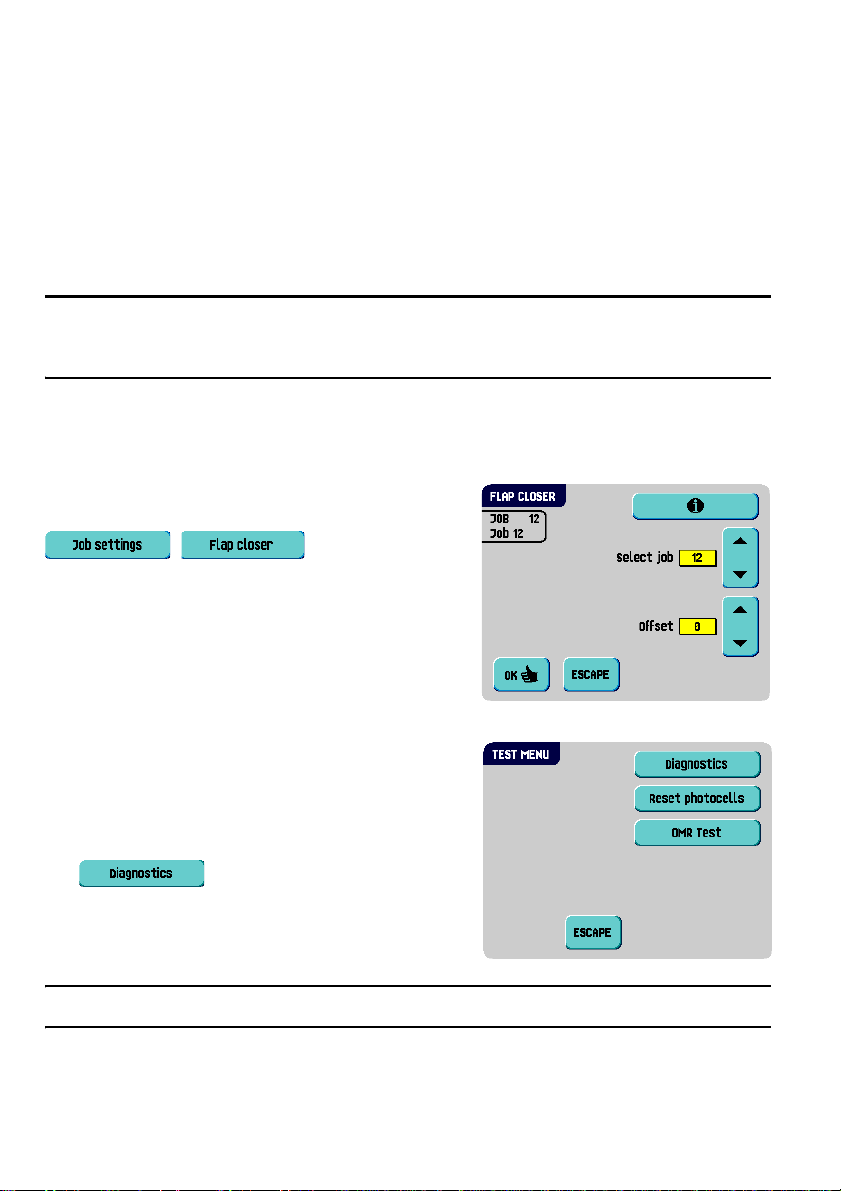

Flap Closer

When selecting from the “supervisor menu”

, , the “flap closer”

menu appears. Use this function to improve the

envelope sealing process for a job. The offset can be

varied between -20 and 20. If for example the offset

is set to +10 the sealing process will be activated 10

pulses later than initially.

For each of the jobs 1 through 25 and AutoSet

an offset can be set.

Test

The “test menu” menu can be opened from the

“supervisor menu”. Use this menu to check the

system, reset all photocells and execute an OMR

test. The menu consists of the following functions:

• : use this function to check if all

motors, clutches and sensors are correctly

connected. This test derives the status of the

actuators and clutches by briefly activating the

actuators and then measuring the current.

Note

Remove all paper and close all covers before testing.

18

Page 21

• : use this function to calibrate all photocells.

Note

Remove all paper and close all covers before calibration.

• : use this function to align and test t he OMR readi ng he ad (see ”OMR

Test” on page 19).

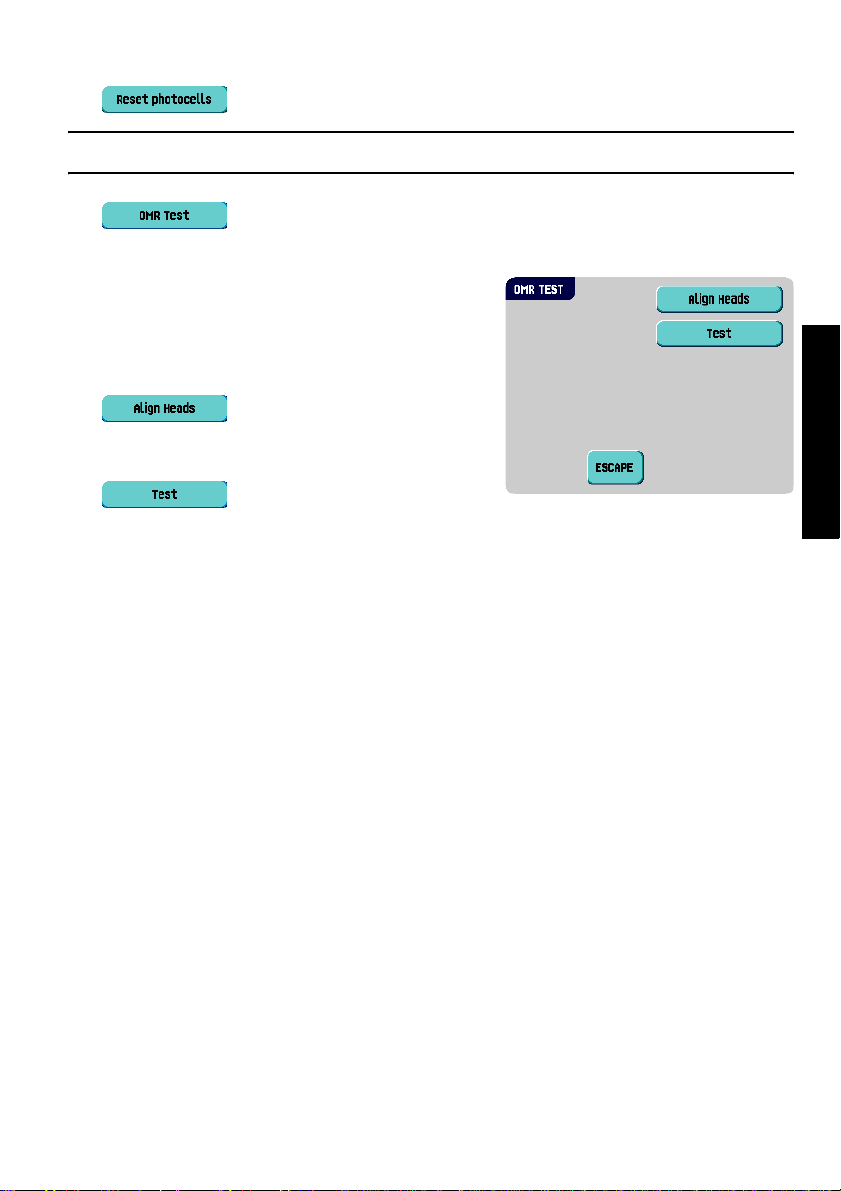

OMR Test

The “OMR test” menu can be opened from the “test

menu”. Use this menu to align and test the OMR

reading head (see ”Reading Head Position” on page

43). The menu consists of the following functions:

• : align the OMR reading head.

Put a document with reading marks in the

feeder and press this button.

• : shows the mark quality and the

number of read marks from the last processed document. Also the gain of the OMR

amplifier is shown.

ENGLISH

19

Page 22

3. OPERATING INSTRUCTIONS

3.1 Installation

Caution

You can severely damage the machine if it is connected to the incorrect power supply.

Before plugging in the machine, check if the local voltage is the same as the voltage

mentioned on the type plate.

3.2 Preparation

3.2.1 Document Feed Trays

Place the document feed trays in position:

1. Hold the document feeder slightly inclined as

shown in the figure.

2. Place the front end of the document feed tray

underneath the two black rollers.

3. Move the document feed tray upwards (lifting

the black rollers), until it is possible to ‘hook’ the

feeder into place.

4. Move the document feed tray towards the

machine and move the hooks over the mounting

points (on both sides).

5. Let the document feed tray rest on the machine.

20

Page 23

Page 24

3.4 Loading Documents

3.4.1 Document Orientation

Fold type

no fold single fold

Type of documents

hopper swap two documents document + enclosureone document

letter fold

zig-zag fold

double

parallel fold

Address carrier in top feeder.

Face up and leading.

Address carrier in bottom feeder.

Face down and trailing.

Address carrier in top linked

pair feeders.

Face up and leading.

Address carrier in bottom linked

pair feeders.

Face down and trailing.

Address carrier in top feeder.

Face up and leading.

Address carrier in bottom feeder.

Face down and trailing.

Address carrier in top feeder.

Face up and leading.

Address carrier in top feeder.

Face down and trailing.

In case the optional extended powerFold® is installed, the following feeding rules apply to

documents with bottom address position:

Type of documents

two documents document + enclosureone document

Address carrier in top feeder.

Face up and trailing.

Address carrier in top feeder.

Face up and trailing.

Fold type

no fold single fold

zig-zag fold

Address carrier in top feeder.

Face up and leading.

hopper swap

Address carrier in top linked

pair feeders.

Face up and trailing.

22

Page 25

3.4.2 Side Guides

To adjust the side guides it is best to remove the

document feed tray from the feeder as follows:

1. Push handle

2. Lift the document feed tray upwards to unhook

it and then pull it out from the feeder.

A

downwards.

A

3. Loosen the knob

4. Grab the side guides in the middle and push

them apart as far as possible.

5. Put a small stack of documents between the side

guides.

6. Grab the side guides in the middle and push

them towards the documents.

The space between the side guides and the

documents should be such that the documents

have just enough play to move freely.

7. Re-tighten knob

8. Remove the stack of documents.

9. Replace the document feed tray (3.2.1 ”Document Feed Trays” on page 20).

B

half a turn.

B

.

ENGLISH

B

3.4.3 Document Separation

The term ‘Document separation’ refers to the adjustment required for separating the

upper document from the rest of the documents in the stack. This prevents picking up to

much documents from the stack at the same time.

The document separation for the automatic feeders is set automatically. There are no

manual adjustments needed.

23

Page 26

The document separation for special feeders must

be adjusted manually as follows:

1. Push the knob

2. Open the left-hand side guide

downwards.

3. Place a document on the feed tray and slide it

about 60 mm (2.4 inch) into the system (turn

the knob

set to narrow).

4. Push the document between the separation

rollers, which are behind the rubber paper

pullers.

5. Turn the knob

resistance or counter clockwise to lower the

resistance.

The separation is adjusted correctly when a slight resistance is felt on the document.

6. Pull the knob

7. Close the left-hand side guide.

B

forward until it clicks.

A

by turning it

B

counter clockwise if the separation is

B

clockwise to get more

B

back again when ready.

A B

3.4.4 Filling the Document Feed Tray

Fill the document feed tray as follows:

1. Open the left-hand side guide A by turning it downwards.

The feed rollers will automatically be lifted.

2. Place a stack of documents between the side guides.

3. Turn the left side guide upwards again.

4. Feed the documents (depending on the type of documents and the type of fold) as

shown in 3.4.1 ”Document Orientation” on page 22.

3.4.5 Adjustment of the Document Stoppers

The document stoppers mark the position at which the documents coming from the feeder

turn towards the folding area. The position of the document stoppers is automatically

determined by the system during the job programming.

24

Page 27

Initially the document stoppers are adjusted for

position B. In this position a wide variety of

documents can be handled (max. 297 mm; 11.7

inch) and adjustment is not needed.

When a job is selected in which a different stopper

position has been programmed, the operator has to

put the document stoppers in the correct position as

indicated by the display.

To adjust the stopper position:

1. Lift and hold the collator arm

2. Squeeze the stopper and pull the front side tab

up.

To replace the stopper:

1. Place the flat back tab into the slotted hole.

2. Push the stopper into position.

A

Stop position

handle documents up to 297 mm (11.7 inch) and stop position

up to 356 mm (14 inch).

can handle documents up to 148 mm (5.8 inch), stop position B can

D

.

3.5 Loading Envelopes

3.5.1 Adjusting Side Guides

Adjust side guides C by rotating thumb wheel D, so

that the envelopes:

• Fit exactly between the side guides

• Can move freely

Note

If the distance between the side guides is too large,

the envelopes will twist sidewards, when transported

into the machine.

C

B

A

B

C

D

C

can handle documents

ENGLISH

3.5.2 Envelope Separation

To set the envelope separation:

A

1. Pull down small lever

2. Insert one envelope up to the stoppers.

A

3. Return lever

Now the envelope separation is set.

.

.

DCA

25

Page 28

3.5.3 Feeding Envelopes

1. Place the bottom envelope between the rollers

(flap down and trailing - bottom side of envelope

pointing to the machine).

2. Loosen the stack of envelopes and place the

stack on top of the bottom envelope.

3. Shift envelope support B in or out, so that the

flap side of the envelope is lifted approximately

20 mm (0.8").

4. Turn envelope support B so the weight of the

envelopes is distributed evenly on both sides.

3.6 Sealing Envelopes

Note

Refer to 5.1 ”Operator Maintenance” on page 54 as well.

Switch the envelope sealing on or off:

1. Lift the handgrip to open the top cover.

2. Shift the blue handle A towards to disable

the envelope sealing or towards to enable

the envelop sealing.

3. Close the top cover.

B

When the sealing of the envelopes is enabled, the

sealing liquid reservoir must be filled:

1. Open the front cover A.

2. Fill the reservoir B to the “Max” level indication

with sealing liquid.

3. Close the front cover A.

Before starting the job, wait approximately 5

minutes for the brushes to moisten.

26

A

B

A

Page 29

Page 30

Insert Position

Note

This adjustment must only be checked in case of problems or when changing the envelope

type.

1. Lift the locking lever of the loc and pull the loc

into the vertical position.

The flap folding line must be positioned under

the green indicator

position as follows:

2. Press on the left or right side of to

adjust the insert position to the left or t he right.

Each button stroke stops the next envelope

0.5 mm (0.02 inc h) to the right (earlier) or to

the left (later).

3. Press to load a new envelope into the insert position.

4. Recheck the insert position, and adjust as required.

If necessary adjust the envelope insert fingers, see ”Adjust the Envelope Insert

Fingers” on page 28.

C

. If not, adjust the insert

Adjust the Envelope Insert Fingers

To adjust the envelope insert fingers:

D

1. Loosen the knurled knob

2. Adjust each finger so that the tip enters about 5 mm (0.2 inch) into the envelope.

3. Re-tighten the knurled knob.

The fingers can be moved sideways to the desired position.

Caution

When adjusting the fingers sideways, be sure that finger A is not positioned over sensor

B

. When an incorrect finger position is adjusted the display shows an error screen.

on top of each finger.

4. Place the outer fingers about 5 to 10 mm (0.2 to 0.4 inch) from the edges of the

envelope.

Check the position of the insert fingers when changing to a different type of envelope.

Address Position

When the envelope position and the position of the fingers is correct:

1. Press to load a folded sheet into the envelope.

The envelope will be sealed (when enabled, refer to 3.6 ”Sealing Envelopes” on page

26) and ejected to the conveyor stacker.

2. Check the position of the address in relation to the address window in the envelope.

28

Page 31

3. If necessary, press the Up or Down button to adjust the address position.

Each key stroke brings the address 1 mm (0.04 inch) with a maximum of 12 mm

(0.48 inch) lower or higher.

If the required address position is beyond the maximum range of 24 mm (0.96 inch),

the AutoSet function can not be used. Use a programmed job instead.

4. Press to make another test run.

5. Recheck the position of the address, and adjust as required.

6. Press to leave this screen to return to the “main menu (1)” or press the

button to immediately start the job.

Starting the Job

To start a job:

1. Press the button to start the job.

During running the display shows the “inserting” menu.

2. Press the button to stop the job. The machine will stop immediately.

3. Press the button to clear the document path to prepare the machine for a new

job.

When an AutoSet

the copy function in the job menu (see 3.11 ”Copy a Job” on page 40) to store the

settings.

job is defined successfully these settings can be stored into a job. Use

ENGLISH

3.7.2 Select Another Job

To select another job:

1. Press to select another

predefined job.

2. Press the arrows to select another job number.

The screen shows the job options of the relevant

job (see 2.4.2 ”Job Info” on page 12).

3. Press to confirm the selected job.

29

Page 32

Perform a Test Run

To perform a test run:

1. Press to display the “test run”

menu.

A message can appear: “Set manual feeding” or

“Set automatic feeding”. In that case:

a Check if the daily mail handle is in the

correct position (see 3.8 ”Run the Daily

Mail” on page 30).

b Correct if necessary.

c Press the button.

d Press again.

The “test run” menu displays.

2. Press to load a new envelope into the insert positio n . This gives the

possibility to check and correct the insert position of the envelope (see ”Insert

Position” on page 28).

3. When the envelope position and the position of the fingers is correct, press

to load a folded sheet in the envelope.

The envelope will be sealed (when enabled, refer to 3.6 ”Sealing Envelopes” on page

26) and ejected to the conveyor stacker.

When finished testing start the job (see ”Starting the Job” on page 29).

3.8 Run the Daily Mail

To process documents or sets of documents, which can not be processed automatically

(e.g. stapled documents), the top feeder is equipped with a daily mail switch.

To switch to the daily mail function:

1. Select a job where the daily mail function has been set to on:

a From the “main menu (1)”, press .

b Search for a job with the daily mail function using the arrows. The daily mail

function can be recognized by the icon in the “job info” screen.

c Press to select the job and return to the “main menu (1)”

30

Page 33

2. Turn left side guide A of the upper tray down.

The Daily Mail handle B will become visible.

3. Move the handle to to enable the Daily

Mail function.

4. Turn left side guide A upwards.

5. Place the document or document set in the

feeder.

If necessary adjust the side guides (see

3.4.2 ”Side Guides” on page 23).

B

6. Press the button to start the job.

The document or document set will be folded and inserted in the envelope as

described in the selected job.

7. Place the following document or document set in the feeder. The machine will keep

running to process the inserted document or document set.

8. When finished with Daily Mail, press the button to stop the job.

9. Turn left side guide A down.

10. Move the Daily Mail handle to the ‘AUTO’ position to disable the Daily Mail and to

enable the automatic document separation.

A

3.9 Create a Job

To create a new job:

1. Press from “main menu (2)” (see 2.4.1 ”Main Menu” on page 10).

2. Enter the pin code.

The “job menu” opens (see 2.4.5 ”Job Menu” on

page 14).

3. Press .

The “create job” menu appears. The new job

must be stored under a job number. The screen

will show the lowest free job number.

Press the arrows to select a higher or lower free

job number (if available).

ENGLISH

4. Press to confirm the selected free job number.

The “job settings” screen opens. The meaning of all buttons and settings will be

explained in 3.9.1 ”Job Settings” on page 32.

31

Page 34

5. Press to save the job with the entered settings under the sp ecified job number

and name.

To name a job, see 3.9.7 ”Job Name” on page 38.

6. Press to perform a test run with the new job settings (see ”Perform a

Test Run” on page 30).

Note

A new selected job number starts with default settings.

3.9.1 Job Settings

From the “job settings” menu the followin g settings

are available:

Envelope settings (see 3.9.2 ”Envelope

Settings” on page 32)

Document settings (see 3.9.3 ”Document

Settings” on page 33)

Fold settings (see 3.9.4 ”Fold Settings” on

page 34)

Optical Mark Recognition (OMR) settings (if

installed) (see 3.9.5 ”Optical Mark

Recognition Settings (Option)” on page 36)

Double feed control settings (see

3.9.6 ”Double Feed Control Settings” on

page 37)

Job name settings (see 3.9.7 ”Job Name” on

page 38)

Mailing/Franking settings (if installed) (see

3.9.8 ”Mailing/Franking Settings (Option)”

on page 39)

3.9.2 Envelope Settings

In this screen the properties of the used envelopes

must be entered.

In the top of the screen, two selection buttons are

displayed, from which one can be selected. The

selected settings button will be highlighted yellow.

• Press to select an envelope size . Use the

button to enter the applicable dimensions.

It is also possible to select ISO standard

envelopes or dimensions in inches (depends on

the installation settings).

32

Page 35

The envelope height can be set between 90 mm (3.5 inch) and 162 mm (6.38 inch).

• Press to set a job without inserting the documents in envelopes (no envelope

mode). This can be useful for jobs, where documents only have to be sorted and/or

folded.

3.9.3 Document Settings

This screen enables the setting of the document

formats and the number of documents that must be

picked from the different feeders.

• Press to set the number of sheets for the

different feeders.

- Press to select a feeder. The selected

feeder will be highlighted.

- Press the arrows to change the number of

sheets that must be picked from the

highlighted feeder.

When the number of documents is 0, the relevant feeder will be deselected.

Note

When a feeder is set to daily mail the number of documents is always 1 and can not be set

in this screen.

Note

The maximum number of sheets per feeder is 25. When folding is used the maximum set

thickness is 8 sheets in letter fold and 10 sheets (80 gr./m2) in single fold. When using

powerFold

sheets is limited further.

®

and bottom address (see 3.9.4 ”Fold Settings” on page 34) the number of

ENGLISH

• Press to enter the document height. The height or the ISO format of the

document will be displayed next to the relevant feeder.

- Press to select a feeder. The selected feeder will be highlighted.

- Press to display a numeric keypad to enter the exact dimension of the

document.

Dimensions can be entered in mm, inches or as standard ISO paper dimensions

(depending on installation settings). The machine will not allow entering

dimensions outer technica l ranges. The document siz e can be set betw een 90 mm

(3.54 inch) and 356 mm (14 inch). The default document size setting of a new

job is 297 mm (11.7 inch).

33

Page 36

• Press to link two feeders. This function enables to fill two adjacent feeders with

the same documents. When the first feeder is empty, the system automatically swaps

to the other feeder.

- Press to select two adjacent feeders. The selected feeders will be

highlighted.

- Press to link two highlighted feeders.

The will be displayed between the selected feeders.

Note

When linking two feeders, the program will automatically apply the number and format of

the documents of the lowest feeder to the other feeder.

• Press to enter the setting of the Daily Mail function.

This function enables to process documents or sets of documents, which can not be

processed automatically (see 3.8 ”Run the Daily Mail” on page 30). The feeder that is

fit for the Daily Mail function will automatically be selected.

- Press to enable the Daily Mail function. The icon appears behind the

daily mail feeder. If you press again the Daily Mail function will be disabled.

3.9.4 Fold Settings

This screen enables the adjustment of the folding

dimensions and the address type.

If the system is equipped with a third fold table and

turning unit (‘extended powerFold

settings” menu consists of two parts:

• In the first part you can set the Address type.

You can switch between Top and Bottom using

®

’) the “fold

the button. If you choose Address type

Bottom you only have three possible fold

settings left.

After pressing the button the second fold setting screen opens.

34

Page 37

• In the second fold setting screen you can select

the fold type.

The following choices are available:

No fold (no settings required)

Single fold

Letter fold

Double parallel fold

Zig-zag fold

Except when no fold is required, the display shows a simple diagram of the docume nt with

the fold positions. To change the fold positions press next to a fold. Enter the

required position of the relevant fold.

The next table shows possible fold positions:

Fold type Minimum position Maximum position

Single fold 75 mm (2.95")

25 mm (0.98") (extended

®

powerFold

)

Letter fold First fold 75 mm (2.95")

25 mm (0.98") (extended

®

powerFold

)

Second fold Position first fold plus

25 mm (0.98")

Zig-zag fold First fold 75 mm (2.95")

25 mm (0.98") (extended

®

powerFold

)

Second fold Position first fold plus

25 mm (0.98")

Double parallel

fold

First fold 75 mm (2.95")

25 mm (0.98") (extended

®

powerFold

)

Second fold Position first fold plus

25 mm (0.98")

Longest document length

minus 25 mm (0.98")

Longest document length

minus 50 mm (1.97")

Longest document length

minus 25 mm (0.98")

Longest document length

minus 100 mm (3.94")

Longest document length

minus 75 mm (2.95")

Longest document length

minus 50 mm (1.97")

Longest document length

minus 25 mm (0.98")

ENGLISH

Note

The display will indicate when entered positions are out of range.

35

Page 38

3.9.5 Optical Mark Recognition Settings (Option)

For a full function description of Optical Mark

Recognition (OMR), see 4.2 ”Optical Mark

Recognition (OMR)” on page 42. Flex-OMR is also

optional. Flex-OMR can read non-Formax codes.

In the “OMR settings” menu it is possible to enable

or disable the OMR function and to adjust the basic

settings for OMR.

The first “OMR settings” menu covers the following

settings:

• Code type: default is the setting “n one”: OMR i s

disabled.

Change the setting using the button. The following codes are possible:

- 1-track OMR for reading Formax codes

- Flex 1-9 for reading non-Formax codes

• Read from feeder: press the button to select a feeder to activate OMR on.

• Reverse reading: reverse reading means that the insert mark is on the first page of

the set. The system will detect the end of a set by detecting the first page of the next

set. Because of the feeding and collating principal reverse reading has the following

limitations:

- The last mark of the code should be pri nted maximally 85 mm ( 3.3 inch) from the

top.

- Enclosures and selective enclosures cannot be handled.

In case the feeder runs empty the last set is still on the collator because the beginning

of the next set could not be detected. In this case the feeder empty message contains

an function. By pressing the button the set on the collator will be

inserted.

Note

Reverse reading is not available in OMR level 0, 1, 2 and 3.

By pressing the button the next “OMR settings”

menu appears. This menu covers the following

settings:

• 1st mark from top: press to set the

position of the first optical mark, measured from

top of the sheet. The value can be varied

between 15 mm (0.6 inch) and 277 mm

(10.9 inch).

36

Page 39

• Max. sheets: select the maximum amount of sheets in the set of documents using the

arrow buttons.

Note

The maximum number of sheets in a set is 25. When the number of sheets exceeds 8 or

10, depending on the fold, the document can not be folded anymore. In this case, the

maximum length of sheets is 156 mm (6.1 inch) for a C5 envelope. Also make sure that

the fold is set to No fold.

Ignoring this will certainly lead to stoppages.

When the maximum number of sheets exceeds the programmed maximum number of

sheets in a set, the machine stops and error VS:110 will be displa yed. After r emoving t he

set and pressing the button, the machine will start and repeat the proces s until an

insert or divert mark is encountered, error VS:135 (final set part) will be displayed.

By pressing the button the next “OMR settings”

menu appears. This menu covers the following

setting:

• Stop on misread: press to set if the

machine should stop or not on misreading an

optical mark.

When “stop on misread” is set to “yes”, the machine

stops after detecting an OMR misreading. The

incorrect set is diverted. After resetting the machine,

the final part of the set is also diverted and the system starts processing again. The

diverted set(s) should be checked by the operator.

When “stop on misread” is set to “no” the machine does not stop after detecting an OMR

misreading. The incorrect set is diverted. The final part of th e set is also diverted and th en

the machine starts processing again. After detecting 5 OMR mi sreadings in a row, the

system stops and an error code is generated.

ENGLISH

3.9.6 Double Feed Control Settings

This screen enables to set the Double Feed Control

(DFC) settings for the different feeders on or off and

to set the thickness measurement.

To set the DFC for the different feeders:

1. Press the button to select a feeder.

2. Press the button to switch the DFC on -

or off - .

37

Page 40

If the DFC is on you can set Continue on double on or off using the button. If

Continue on double is on (“yes”), the machine will not stop if two sheets are feeded

instead of one. The document-set containing the double sheets will be diverted.

When a job is started, the first document taken per feeder is used for a reference

measurement. When a document is exceeding that reference thickness an error will be

displayed.

Note

When Daily mail is selected, the DFC will be switched off automatically.

To set the thickness measurement:

1. Press the button to select the inserter area.

2. Press the button to switch the thickness measurement on - or off - .

If the thickness measurement is on you can set the measurement area:

3. Press the button.

4. Set the measurement area using the arrow buttons.

The standard position of the measurement area is sufficient for a great variety of

documents. Only when using special types of documents, for example small cards, the

position of the measurement area might be adjusted.

When the set thickness is not corresponding the refere nce v alue an error will be display ed.

3.9.7 Job Name

It is possible to store the job with a meaningful job

name, to easily recognize the job. This name will be

displayed in the Main screen during job selection.

1. Enter a job name using the alpha-numeric

keypad.

2. Press to clear a char ac ter le ft of the cu rso r

position (backspace).

3. Press to clear all entered characters and

start again.

38

Page 41

3.9.8 Mailing/Franking Settings (Option1)

If this machine is connected to a mailing/franking

machine, this option allows you to select the

franking mode.

Press the button to select:

•Pass through

The mailing (franking) machine will let the

envelopes pass through without printing/

franking. Press the button to return to

the “job menu”.

•Franking machine

The mailing (franking) machine will print/frank the envelopes according to the local

mailing (franking) machines settings.

If you press the button a screen appears

in which it is possible to link a mailing (franking)

job to the inserter job. Use the arro w buttons to

select a job. If no link is required, select

“Current job” . Press the button to return

to the “job menu”.

• Inserter data

The mailing (franking) machine will print/frank

the envelopes according to the weight and size

data communicated by the inserter.

If you press the button a screen appears via which the weight of single

documents and envelopes and the envelope width can be entered. Use the

and buttons to enter these data. Press the

button to return to the previous screen.

To link a mailing (franking) job to the inserter job, use the arrow buttons to select a

job. If no link is required, select “Current job”. Press the button to return to

the “job menu”.

Refer to the appendix for an extensive description of this option.

ENGLISH

39

Page 42

3.10 Edit a Job

To edit an existing job:

1. Press from “main menu (2)” (see 2.4.1 ”Main Menu” on page 10).

2. Enter the pin code.

The “job menu” opens (see 2.4.5 ”Job Menu” on

page 14).

3. Press .

The “edit job” menu appears.

4. Press the arrows if you want to select an other

job number.

5. Press to confirm the selected job

number.

The “job settings” screen opens. Refer to 3.9.1 ”Job Settings” on page 32 for the

meaning of all buttons and settings.

6. Press to save the job with the entered settings under the sp ecified job number

and name.

To name a job, see 3.9.7 ”Job Name” on page 38.

7. Press to perform a test run with the new job settings (see ”Perform a

Test Run” on page 30).

3.11 Copy a Job

To copy existing job settings or AutoSet jobs to a new job:

1. Press from “main menu (2)” (see 2.4.1 ”Main Menu” on page 10).

2. Enter the pin code.

The “job menu” opens (see 2.4.5 ”Job Menu” on

page 14).

3. Press .

The “copy job” menu appears.

4. Press the arrows if you want to select an other

job number to copy from or to copy to.

40

Page 43

Note

You can only copy job settings to new jobs.

5. Press for details of the job to copy from.

6. Press to copy the job settings.

If all jobs are programmed the display shows “No more free jobs”.

It is possible to copy a AutoSet job into a job. Before a AutoSet job can be copied

AutoSet has to be defined successfully (see 3.7.1 ”Using AutoSet” on page 27).

3.12 Delete a Job

To delete an existing job:

1. Press from “main menu (2)” (see 2.4.1 ”Main Menu” on page 10).

2. Enter the pin code.

The “job menu” opens (see 2.4.5 ”Job Menu” on

page 14).

3. Press .

The “delete job” menu appears.

4. Press the arrows if you want to select an other

job number.

ENGLISH

5. Press for job details.

6. Press . The job will be deleted without a warning.

41

Page 44

4. OPTIONS

4.1 Activate an Option

To activate a new option:

1. From the “supervisor menu” choose .

Software options are enabled using license codes. These license codes, together with

the identification number of the machine enable the relevant options. The enabled

and available software options are displayed in this screen. Contact your dealer for

information about these license codes.

2. Press to activate other software options.

3. Enter the license key code that you received

from the supplier to activate the relevant option

on this machine.

Use the arrow keys to navigate through the

entered characters.

4. Press to confirm the license key and to

return to the “options” menu.

5. Switch the system off and on.

4.2 Optical Mark Recognition (OMR)

4.2.1 General

The folding and inserting system can be equipped with Optical Mark Recognition (OMR) or

Flex-OMR. This allows the system to read special codes that have been printed on the

documents. These codes contain information about the processing of the sheets. With

Flex-OMR, the system can also ‘read’ non-Formax codes.

The sheets with the printed code are placed in a feeder. Depending on the programmed

code, the other feeders can be used as selective feeders to add enclosures.

In case of a zig-zag fold, the address has to be printed on the last page of the set. With

the other fold types, the first sheet of a set always contains the address. A full length code

is printed on every sheet of a set.

The code on the last sheet of the set contains the insert instruction. The other sheets

carry the accumulate instruction. If a parity check is used, this is checked on each sheet.

If the set contains only one sheet, it is the ‘last’ sheet. The code must appear in the same

location on every page regardless of the actual code length.

42

Page 45

4.2.2 Alignment Reading Head Position

The horizontal position of the reading head must be aligned to the same position of the

printed marks on the documents. To align the reading head, proceed as follows:

1. Open the “OMR test” menu from the “Test

menu” (refer to 2.4.6 ”Supervisor Menu” on

page 14).

2. Press to start the alignment

procedure.

3. Put a document with reading marks in the

feeder (either feeder 1 or 2, depending on the

selected job).

4. Press .

The document will be transported to the reading

head position.

5. Open the special OMR reading head cover in the

feeder.

6. Shift the reading head until the red pointer is

positioned exactly above the middle of the

reading marks.

7. Open the vertical transport cover and remove the document.

ENGLISH

8. Press to determine the alignment.

9. Press to finish the alignment procedure.

Note

When the reading head is aligned it is possible that paper guides have to be removed and

placed on the other side of the reading head.

43

Page 46

4.2.3 Document Orientation

Switch on the OMR-function and set the position of the reading marks as described in

“Optical Mark Recognition Settings (Option)” on page 36.

Document orientation:

Fold type

direction

Type of documents

no fold single fold

letter fold

double

parallel fold

address

OMR

start reading

OMR

stop reading

(duplex printed)

direction

first page

Address carrier, face up and leading.

address

1

2

3

3

2

1

zig-zag fold

OMR

stop reading

OMR

start reading

last page

Address carrier, face down and trailing.

4.2.4 OMR Codes Printing Quality

• Marks should be printed in black.

• Marks on the same sheet must have equal intensity.

• Marks must be printed on the same position on every sheet.

• For matrix printers near letter quality (NLQ ) printed characters are preferred to obtain

maximum blackness (double strike).

• Be aware of background ‘noise’. Color changes on the form, background design, a

logo or copy on the opposite side of the sheet that will bleed through can be read by

the reading head causing disturbances of the OMR function.

• The ribbon or toner quality must be checked before printing.

44

Page 47

Minimum Code / Basic Commands

The minimum code is one mark in one line (insert).

However for reliability it is advised to use at least 2

marks.

The first line is the start mark.

A mark printed on the second line means insert. No

mark on the second line means accumulate.

Start mark

Insert/accumulate

Note

In some cases, on request of the customer, the reading of the basic commands can be

reversed by the service organization. This means that no mark is interpreted as an insert

command and that for the accumulate command a mark has to be printed.

Length

Above the first mark and below the last mark a

space of 8.5 mm (0.33") must be kept without

printing. This means that the minimum code area

consists of 6 lines:

• 2 lines to print the (basic) commands

8,5 mm

6,3 mm

• 4 lines free space

Line distance may be 2.54 mm (0.1") to 6.35 mm

(0.4").

8,5 mm

Code Width, Character Spacing and Pitch

The minimum width of the code area is 7 character

spaces. From left to right:

• 2 characters space not printed (4.2 mm; 0.17")

• Track mark (3 characters or 6.3 mm; 0.24")

• 2 character spaces not printed

Pitch 10 or 12 is accepted.

The track mark can be printed using the underline sign (_), which must have a thickness

of at least 0.2 mm (0.08").

Line 1

Line 2

Line 3

Line 4

Line 5

Line 6

4,2 mm4,2 mm

ENGLISH

45

Page 48

Additional Marks

When it is required to control more functions in the

inserter system, the use of more marks is needed.

The following additional functions are possible via

software options:

• Divert mark (divert & continue)

• Stop mark (divert & stop)

• 1 mark: selective feed from station x (max. 6

depending on configuration)

• 1, 2 or 3 marks: respectively sequence c heck 4,

2 and 1

• 1 mark: parity check mark (even)

• 1 mark: safety mark

General remarks:

• The marks must always be used in the above sequence.

• If a function is suppressed the following function will move upwards one line.

• The chosen code must always be used on all material which must be processed by the

Optical Mark Recognition.

• The length of the code and the mark definition is a service setting.

• Other marks/functions are possible via special codes (Flex codes).

Start mark

Insert/accumulate

Divert mark

Stop mark

Selective feed 1

Selective feed 2

Selective feed 3

Selective feed 4

Selective feed 5

Selective feed 6

Sequence check 4

Sequence check 2

Sequence check 1

Parity (even parity)

Safety mark

Divert Mark (Divert & Continue)

The set will be diverted and the system continues.

Stop Mark (Divert & Stop)

The set will be diverted and the system stops indicating error VS:113 (stop mark read).

Selective Feed Mark

The machine will selectively feed an enclosure when commanded so.

Sequence Check

Sheets in a stack can accidentally get out of sequence or can be missing. This can be

detected by the sequence check.

Each sheet has a binary code that is a part of the reading code.

Parity Mark

By adding a parity mark the reading code can be checked. When the OMR-2 code is used

the sum of the marks has to be even.

46

Page 49

Safety Mark

The safety mark is used as an extra security. With

skewed paper the reading head can miss part of the

reading code. In these situations the safety mark is

not read, and the system will give an error.

The safety mark also indicates the end of the

reading code.

This mark must always be present on the document

if it has been activated as an OMR code.

Examples of OMR Code

In the figure the legend for the following example is

shown. In this example feeder station 1 is the

reading feeder. The feeder stations 2 through 6 are

selected for selective feeding.

Example Code

In this example a set of 8 sheets with three selectiv e

feeds (station 2, 3 and 4) and three sequence check

marks is shown.

• The first position is used for the start mark

which must be printed on every sheet.

• The second mark position is used for the insert/

accumulate command. The mark is printed on

the last sheet of the set (inserting is required).

• Position 3, 4 and 5 are reserved for selective

feeding from station 2, 3 and 4. Print a mark on

position 3 when a selective feed from station 2

is required. Print a mark on position 4 when a

selective feed from station 3 is required. Print a

mark on position 5 when a selective feed from

station 4 is required.

• Position 6, 7 and 8 are used for the sequence

check marks.

Normal paper flow Skewed paper flow

Start mark Start mark

Safety mark Safety mark

reading direction reading direction

mark printed

no mark printed

accumalate

insert

or

no selective feed

wanted, mark not

printed

selective feed

wanted, mark

printed

Sheet 1 Sheet 2 Sheet 3 Sheet 4 Sheet 5 Sheet 6 Sheet 7 Sheet 8

selective feeder 6

selective feeder 5

selective feeder 4

selective feeder 3

selective feeder 2

reading feeder 1

ENGLISH

47

Page 50

4.3 Online Services

4.3.1 General

The folding and inserting system can be equipped with Online Services. This option

enables the machine to connect to a central server. During the connection data is

downloaded to and uploaded from the machine. The machine always initiates the

connection, it is not possible to make a connection from outside to the machine. Ask your

supplier if this option is available.

4.3.2 Start-Up Online Services

To start-up Online Services:

1. Select from the “main menu (2)”.

2. Enter the PIN-code 2546 to access the

supervisor menu.

3. Press .

The “Online Services” menu shows the following

functions:

• : opens the “connection” menu to

create a connection to a central server and to view the connection history (see

4.3.3 ”Connection” on page 48).

• : opens the “messages” menu to view received messages (see

4.3.4 ”Messages” on page 49).

• : opens the “configuration” menus to change Online Services settings

(see 4.3.5 ”Configuration Menu” on page 50).

4.3.3 Connection

The machine makes a connection on fixed times. It

is possible that you manually connect the ma chine

to the server. To connect to the server:

1. Press in the “Online Services”

menu.

The display shows the “connection” menu.

2. Press to manually connect the

machine to the OLS server.

You can view the status of the connection on the

screen. The text on the button changes to .

Press to terminate connection with the server.

48

Page 51

The “connection” menu shows the following functions:

• : opens the “history” menu to view the connection history (see

”History” on page 49).

• : this button appears when the machine received new messages and

opens the “messages” menu (see 4.3.4 ”Messages” on page 49).

History

The “history” menu shows previous connections of

the machine to the server.

1. Press or to select a previous

connection.

2. Press to view details on selected

previous connection.

4.3.4 Messages

After pressing in the “On line Services”

menu the display will show messages received from

the server. A message has content like new software

or a new job.

1. Press or to select a message.

ENGLISH

2. Press for more information over a

selected message.

In case new software or a new job can be installed

the button appears.

To install new software or a new job:

1. Press .

The “new software” menu or the “new job” menu appears. Press for

more information on the software or the job.

2. Press to install the new software or the new job or press

to reject the new software or new job.

After pressing a confirmation menu opens:

• In case of new software, press to confirm installation or press to return

to “installation” menu.

49

Page 52

• In case of a new job press or to select a free job number (see 3.9 ”Create

a Job” on page 31).

Press to confirm the selected job number or press to return to message

menu.

After conforming the installation of the new software or new job the “message” menu

appears.

4.3.5 Configuration Menu

After pressing in the “On line Services”

menu the “configuration” menu opens. Use this

menu to modify the OLS settings.

The menu consists of two screens containing the

following functions:

• Dial tone detection on / off

This setting is required if no dial tone is heard

during establishing a connection. The default

value is on. This setting is relevant to some

PABX telephone switch systems.

Press to switch the dial tone detection on or off.

• Telephone number of server: contact your supplier for the telephone number of the

OLS server.

To change the number:

aPress .

b Enter the corre ct number using the numeric keypad.

c Press to confirm the new number.

• Prefix: use this function in case you need to dial a certain number or string to access

an outside line.

aPress .

b Enter the corre ct prefix using the numeric keypad.

c Press to confirm the new number.

• Country: enter the country from where you are dialing.

Select the correct country from a list by pressing or .

• Date and time: enter the current date and time.

aPress .

b Enter the correct date and time using the numeric keypad.

c Press to confirm the new number.

50

Page 53

• Volume of modem: set the modem volume.

a Press or to change the volume of the speaker.

Do not set the volume to zero as the sound of the modem is helpful during

remote assistance.

b Press to confirm modified settings.

4.4 Production Feeder

4.4.1 Function

The Production Feeder can be loaded with a high number of documents. This feeder

is intended to be used for Business Reply Envelopes (BRE), but also ‘standard’

documents up to 356 mm (14") length can be processed with it.

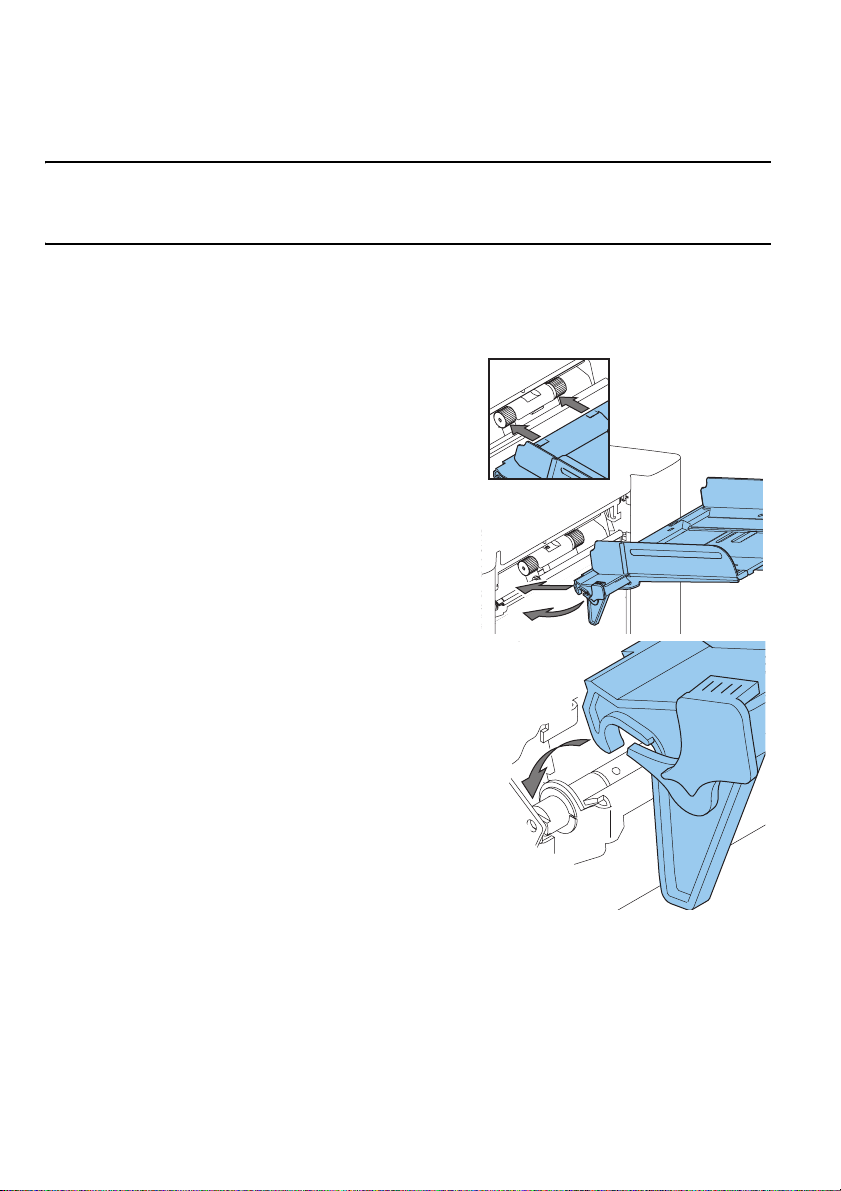

4.4.2 Preparations

The Production Feeder should be installed at

the position of feeder no. 1.

It can be placed into position in the same way as the

other document feeders are fitted.

Proceed as follows:

1. Lift the paper feed rollers with the front edge of

the Production Feeder.

2. Move the Production Feeder forward until it

hooks behind the frame axle.

A

3. Connect the connector A to the socket B.

The Production Feeder is auto-detected by the system when it is switched on. This makes

it easy to switch over from the standard document feed tray to the Production Feeder

and vice versa.

B

ENGLISH

Note

To allow easier hooking on of the Production Feeder it is advised to put the feeding plate

in the rear position (see 4.4.4 ”Document Separation” on page 52).

To make use of a Production Feeder it is not necessary to (re-)program the jobs.

51

Page 54

4.4.3 Adjust Side Guides

Adjust the side guides:

1. T ake a stack of documents/BREs and place them

in the feed tray.

BREs with flap down and leading (top side

pointing to machine).

2. Adjust the side guides by turning the thumb

wheel A so the documents/BREs just fit and can

move without resistance.

Too much play causes skewing.

A

4.4.4 Document Separation

When the Production Feeder is used at an automatic separation feeder, the separation is set

automatically.

The Production Feeder can also be used on a feeder position with a manually adjusted

separation.

To adjust, proceed as follows:

1. Remove feeders 2 and 3.

Note

The lowest feeder is feeder 1.

2. Squeeze the two blue h andles A and B and shift

the feeding plate C as far as possible to the

front.

3. Push knob D forward until it clicks.

4. Place a document/BRE on the feed tray and slide

it in the machine till the leading edge is not

visible anymore. T urn knob

the separation is set to narrow.

5. Push the document/BRE between the rollers.

D

6. Turn knob

and counterclockwise if the separation is set to

narrow.

The separation is adjusted correctly when a

slight resistance is felt on the document/BRE.

7. Pull knob D back when ready.

8. Remount feeders 2 and 3.

clockwise to get more resistance

D

counterclockwise if

A B C

D

4.4.5 Feeding Documents

To feed documents:

1. Squeeze the two blue handles A and B.

52

Page 55

2. Shift the feeding plate C to the rear position.

3. Loosen the stack of documents and place them in the feeder . BREs with flap down and

leading (top side pointing to machine).

The feeding plate assembly will be shifted up automatically (when the system starts

processing) until documents/BREs are underneath the rubber paper pullers.

Note

When filling the Production Feeder, make sure that the document/BREs are positioned

parallel in relation to the feed plate to ensure correct feeding.

Note

When longer documents are used, plate C can be extended by pulling out the adjustable

feed plate extension.

ENGLISH

53

Page 56

5. MAINTENANCE

Disconnect the mains power supply before performing any maintenance.

The user must not attempt to service the appliance beyond that described

in this operator manual. All other servicing must be carried out by qualified

service personnel only.

Please contact your authorized distributor.

5.1 Operator Maintenance

Maintenance

frequency

Daily • Check the system functions.

Weekly • When dirty or saturated, clean the brushes of the envelope

When necessary • When the display warns about dusty sensors, the sensors on the

Maintenance

• Keep the system in proper condition by removing dust, paper

remains, etc.

• When dirty, clean the sealing table and rubber rollers with a

slightly wetted cloth, soaked in warm water.

sealing.

The machine is delivered with an extra set of brushes. To always

have one clean set available, it is recommended to soak one set

in water and use the other set.

Remove the brushes one by one by pulling them down from the

brush holder.

Replace the brushes and make sure that the studs on the brushes

are fitted in the corresponding holes in the brush holder.

• Check moistening cloth and replace if necessary.

When dirty or saturated, clean the moistenin g cloth and the

reservoir.

• Clean feed and insert rollers as instructed by the Service

Engineer.

envelope or document path must be cleaned using the bellows

that is located behind the side cover.

Place the bellows in the upper air plug and firmly squeeze a few

times to blow the dust from the document path sensor.

Repeat this procedure for the lower air plug to clean the envelope