Page 1

FORMAX

6000 Series

Folder/Inserters

OPERATOR'S MANUAL

FIRST EDITION

Page 2

Page 3

INTRODUCTION

The Formax 6000 Series Folder/Inserters are designed to fold your documents, insert them into

envelopes and seal the envelopes. Small size documents may be inserted alone, without being

folded. They may also be added to larger folded documents. The machine operation is automatic,

quick and user-friendly. Folder/inserters can be used to send invoices, mailshots, payrolls, daily mail,

etc. The information provided in this manual will help you to optimize the functioning and output of

your machine.

Following are the folder/inserter main characteristics:

- One or two automatic feeders for large documents including 8 1/2" x 7", 8 1/2" x 11" and 8 1/2" x 14"

documents.

- Up to two automatic feeders (depending on the model) for small size documents (inserts smaller

than the main envelopes).

- One document manual feeder.

- Inserting documents into envelopes of various sizes including #10, #9 and 6" x 9" with or without a

window.

- Inserting into the same envelope various sheets from the same feeder, such as invoices printed on

several sheets.

- Stores up to 20 job applications for frequent or re-occuring mailings.

- Automatic adjustment of the folding dimensions.

- Adjustment assistance in the form of a simple and interactive control panel.

- Automatic detection of double documents on the automatic feeders.

- Automatic detection of double documents, based on the principle of electronic measurement of

the thickness insensitive to the paper opaqueness.

- Easy to use feeding system and simple jam clearing operations.

- Jam clearing assistance based on the control panel and the software functions.

- Compact with an appearance that fits easily in with the office environment.

STANDARD

In order to comply with standards EN60950 and UL1950, this equipment must be connected to

standard installations of the construction industry. As regards the protection of the internal

wiring, a two-pole protection is required against 5 Amp. current surges. This equipment is in

accordance with standard EN55022, Class A, EN55024, and FCC part 15.

INSTALLATION

The equipment should be installed very close to a grounded mains outlet easy of access and

protected by a 16 Amp. fuse.

CAUTION: NEVER REMOVE THE MACHINE COVERS.

Page 4

Page 5

TABLE OF CONTENTS

SECTION A: GENERAL PRESENTATION 1

1. MACHINE 1

2. CONTROL PANEL 2

3 OPENING THE MACHINE 5

4 INSIDE VIEW 5

SECTION B : PRACTICAL FUNCTIONS 7

1. INSTALLATION AND PUTTING INTO SERVICE 9

1.1 Installation of the feeders 9

1.2 Removal of the feeders 10

1.3 Filling the tank 10

1.4 Putting into service 10

1.4.1User mode (access) 11

1.4.2Language selection 11

1.4.3Maintenance 12

1.4.4Servicing mode (access) 12

1.4.5Supervisor mode 12

2. OPERATION 12

2.1 User mode 13

2.1.1Quick access job 13

2.1.2Selection of a stored job 13

2.1.3Job check 14

2.1.4 Starting the job 15

2.1.5Modification of a job 15

2.1.6Creation of a job 16

2.1.7Counters 16

2.1.8Countdown counter 16

2.2 Supervisor mode 17

2.2.1Length of flap moistening 17

2.2.2Adjustment of the document alignment

(feeders B and C) 17

2.3 Position of the address and adjustment of the folds 17

2.3.1Position of the address 18

2.3.2Adjustment of the folds 18

2.4 Detection of double documents 18

2.4.1General remarks 18

2.4.2Enabling and disabling the double document

Page 6

detection 18

3. DOCUMENT FEEDING 19

3.1 Document feeding in the manual mode (feeder A) 19

3.2 Document feeding in the automatic mode (feeders B

and C) 19

3.3 Envelope feeding (feeder E) 20

3.4 Feeding of inserts and reply envelopes (feeder F) 22

3.5 Feeding of inserts and reply envelopes (feeder D) 24

SECTION C: ASSISTANCE AND

RECOMMENDATIONS 27

1. TROUBLE SHOOTING 29

2. JAM CLEARING 32

2.1 Document Path 33

2.2 Envelope path 34

2.3 Insert path 36

2.4 Inserting area 39

3 CLEANING 41

3.1 Cleaning of the rollers 41

3.1.1Cleaning Procedure 42

3.1.2Drying 47

3.2 Cleaning of the casing 47

SPECIFICATIONS 49

Symbols used

Indicates an essential piece of information that

should not be overlooked.

Signals a delicate issue.

Indicates an interesting idea or a tip.

Illustration through an example.

Page 7

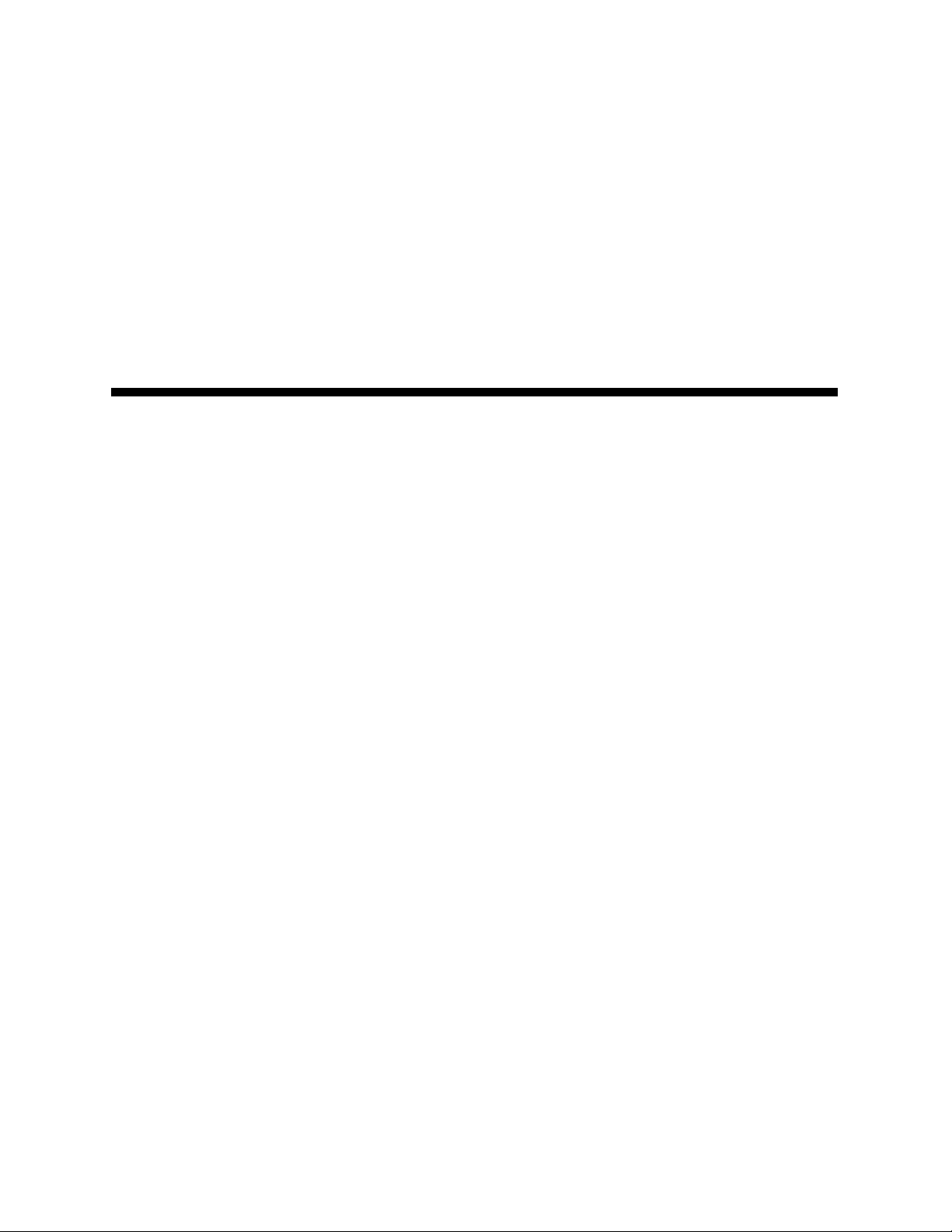

SECTION A: GENERAL PRESENTATION

1. MACHINE

Detail of rear view

1 : Knurled knob (see Section C, 2.3. "Insert Path") 12 : Left door (access to the moistener and the insert path).

2 : Knurled knob (see Section C, 2.3. "Insert Path") 13 : ON/OFF switch.

3 : Control (see Section C, 2.3. "Insert Path") 14 : Mains outlet.

4 : Feeder A (document manual feeder) 15 : Control panel

5 : Document guide. 16 : Machine opening button

6 : Feeder B (automatic document feeder - sheet by sheet). 17 : Guide locking envelopes

7 : Feeder C (optional automatic document feeder - sheet by sheet) 18 : Feeder E (envelopes feeder)

8 : Feeder D (optional feeder for inserts and reply envelopes). 19 : Envelopes guides

9 : Feeder F (feeder for inserts and reply envelopes). 20 : Envelope and insert pressure units

10 :Right door for access to feeder F. 21 : Document pressure unit button

11 : Insert guide locking. 22 : Document guide locking button

1

Page 8

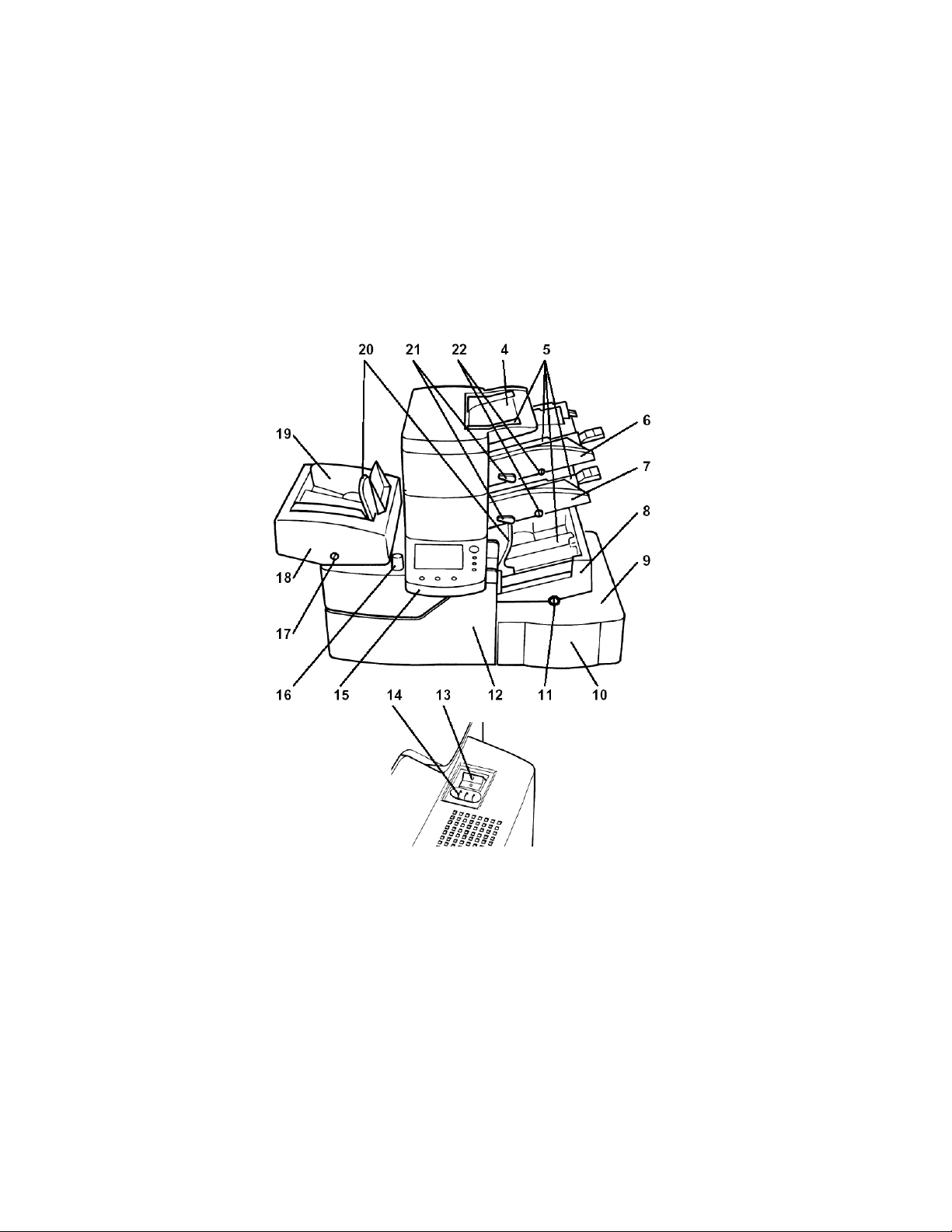

2. CONTROL PANEL

2

Page 9

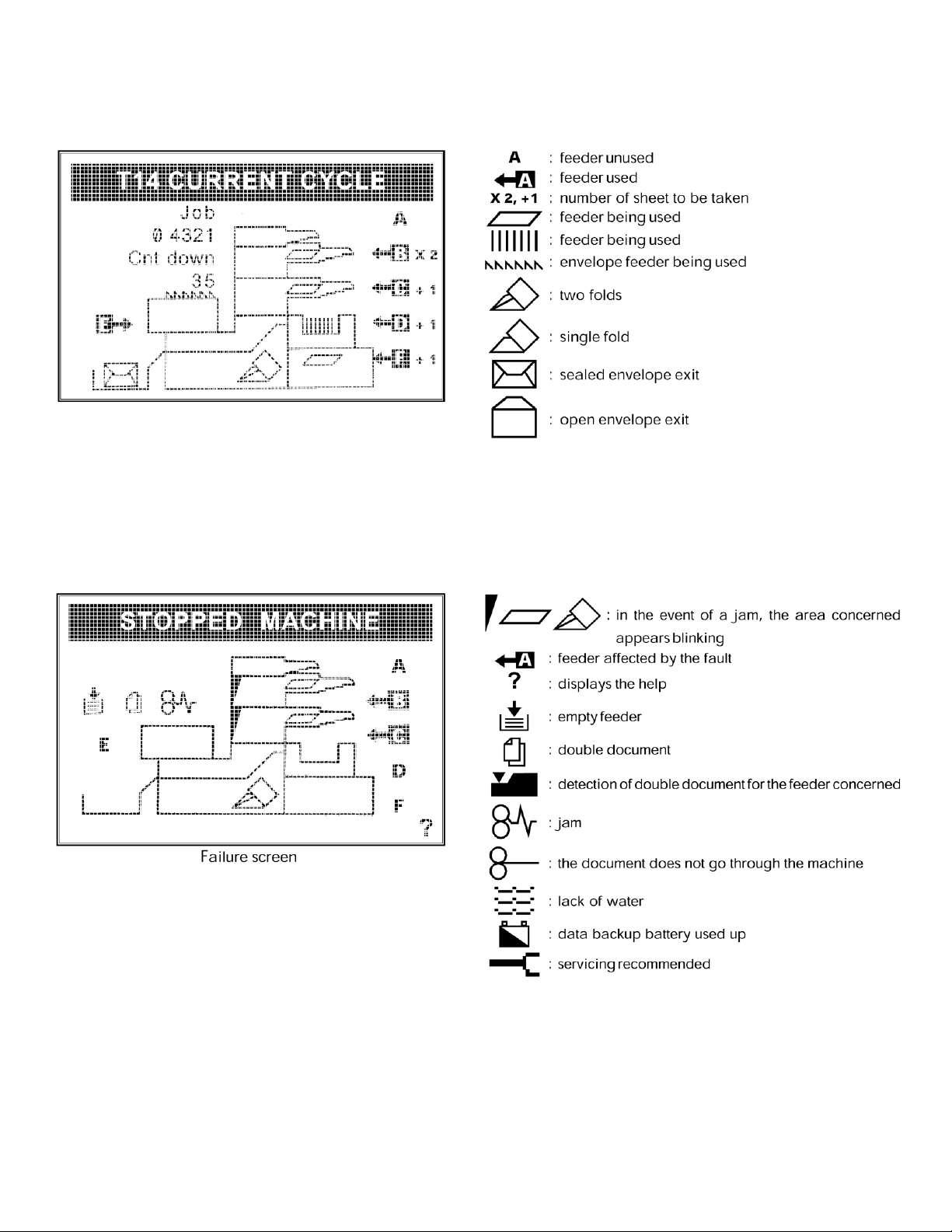

Main Menu Screen

The main menu screen is one of the guide screens. When the machine remains unused for a long

period, the standby screen appears as follows, to return to the initial screen press any key.

Standby Screen

3

Page 10

Job Information Screen

Failure Screen

4

Page 11

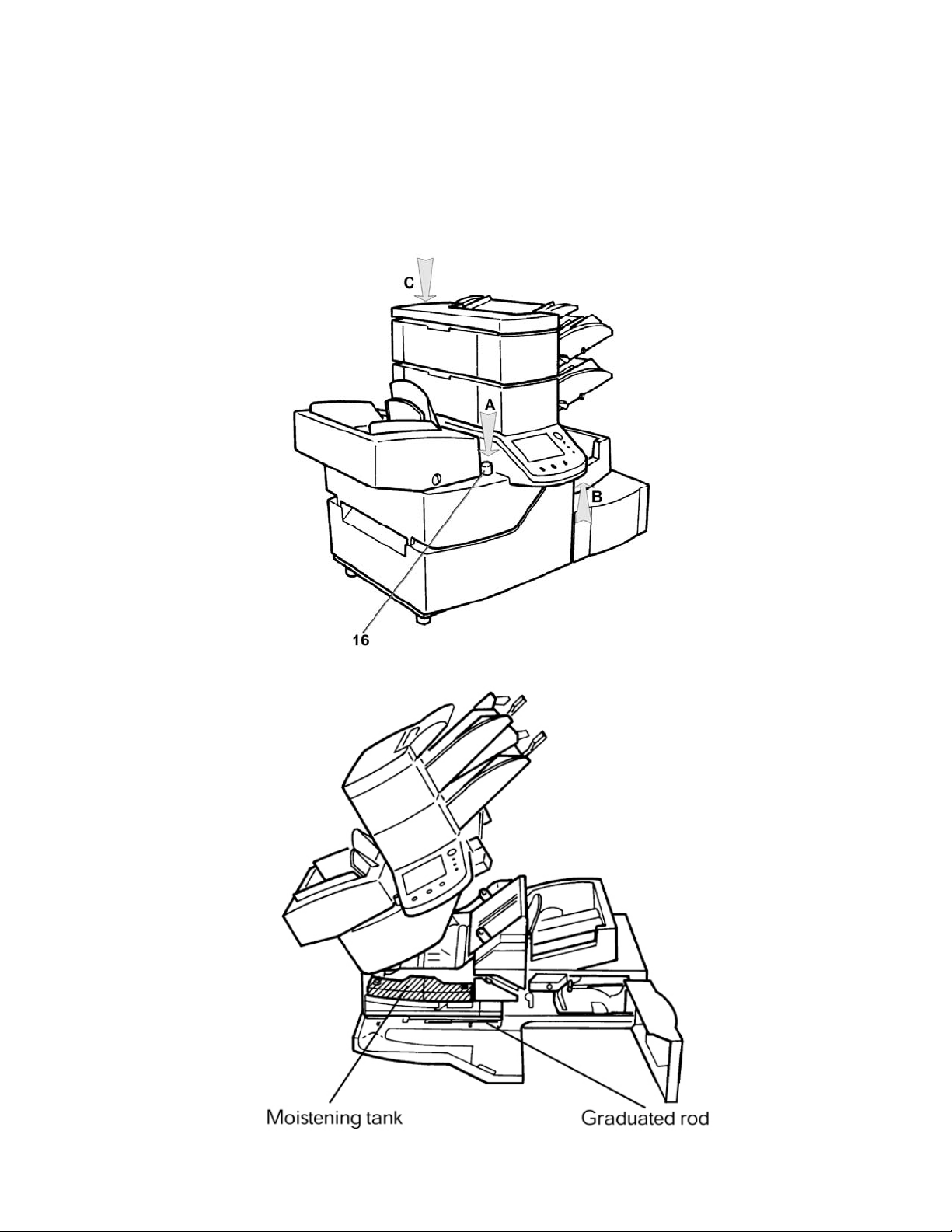

3. OPENING THE MACHINE

- (A) : Press machine opening button (16).

- (B) : Lift the top of the machine (including the feeders fastened toit).

- (C) : To close push down on the top of the machine until it snaps.

4. INSIDE VIEW

5

Page 12

6

Page 13

SECTION B : PRACTICAL FUNCTIONS

1. INSTALLATION AND PUTTING INTO SERVICE 7

1.1 Installation of the feeders 9

1.2 Removal of the feeders 10

1.3 Filling the tank 10

1.4 Putting into service 10

1.4.1 User mode (access) 11

1.4.2 Language selection 11

1.4.3 Maintenance 12

1.4.4 Servicing mode (access) 12

1.4.5 Supervisor mode 26 12

2. OPERATION 12

2.1 User mode 13

2.1.1 Quick access job 13

2.1.2 Selection of a stored job 13

2.1.3 Job check 14

2.1.4 Starting the job 15

2.1.5 Modification of a job 15

2.1.6 Creation of a job 16

2.1.7 Counters 16

2.1.8 Countdown counter 16

2.2 Supervisor mode 17

2.2.1 Length of flap moistening 17

2.2.2 Adjustment of the document alignment

(feeders B and C) 35 17

2.3 Position of the address and adjustment of the folds 17

2.3.1 Position of the address 18

2.3.2 Adjustment of the folds 18

2.4 Detection of double documents 18

2.4.1 General remarks 18

2.4.2 Enabling and disabling the double document

detection 18

3. DOCUMENT FEEDING 19

3.1 Document feeding in the manual mode (feeder A) 19

3.2 Document feeding in the automatic mode

(feeders B and C) 19

3.3 Envelope feeding (feeder E) 20

3.4 Feeding of inserts and reply envelopes (feeder F) 22

3.5 Feeding of inserts and reply envelopes (feeder D) 24

7

Page 14

8

Page 15

1. INSTALLATION AND PUTTING INTO SERVICE

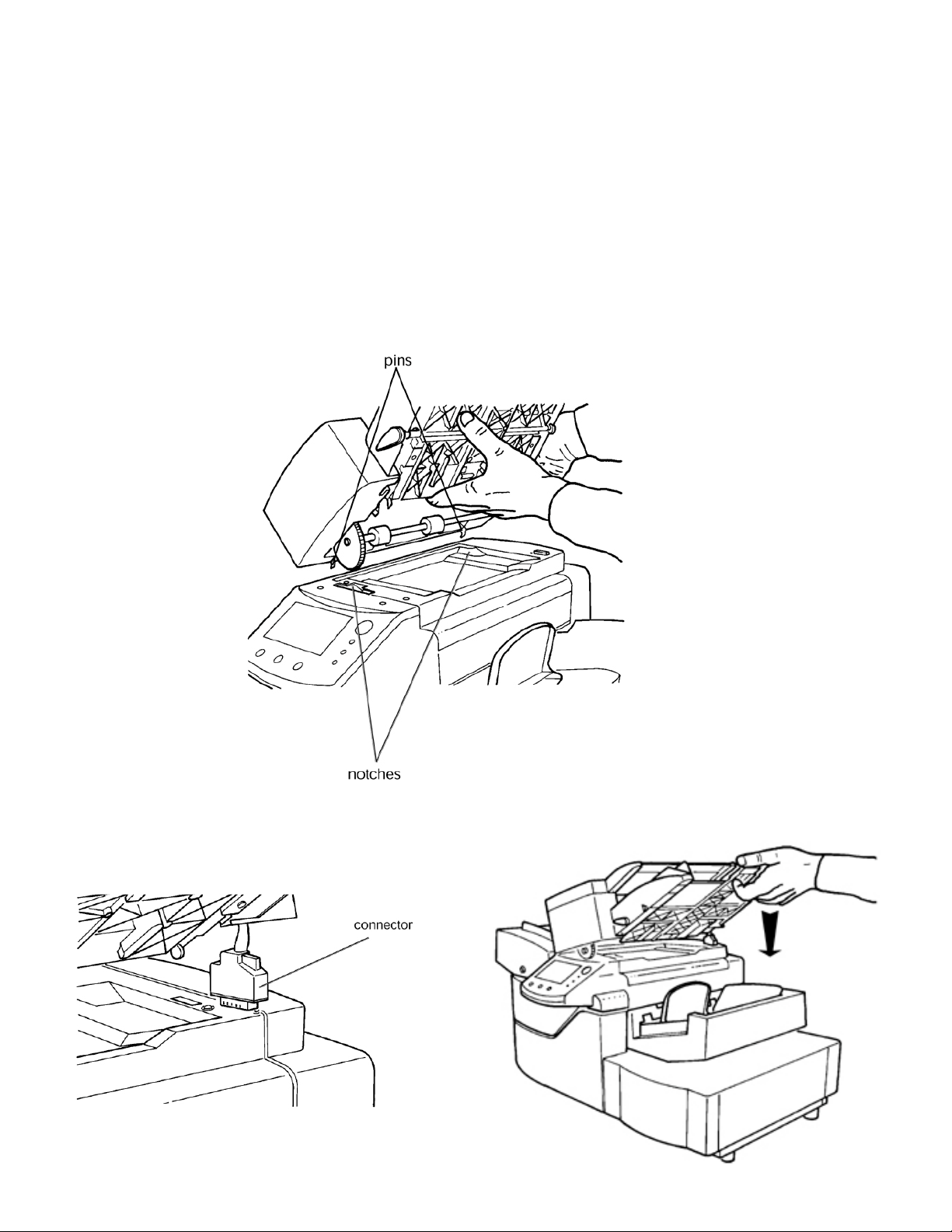

1.1 Installation of the feeders

Noted that the procedure is roughly the same regardless of the feeder selected (the example below

represents feeder C).

- Switch the machine off,

- Insert the two positioning pins into the notches provided for this

purpose on the machine.

- plug in the connector: - flip up the feeder and lower it.

9

Page 16

1.2 Removal of the feeders

- Switch the machine off.

- Lift the feeder.

- Remove the connector (see previous figures).

- Flip up the feeder in order to be to take it out of the notches (see previous figures) and remove it.

1.3 Filling the tank

Open the machine and the left-hand door in order to have access to the tank and fill it with the

container provided.

Note: Do not use distilled water.

1.4 Putting into service

To turn the machine on, press the button at the rear of the machine.

At power up, the below lead-in screen is displayed on the control panel.

ENGLISH

10

Page 17

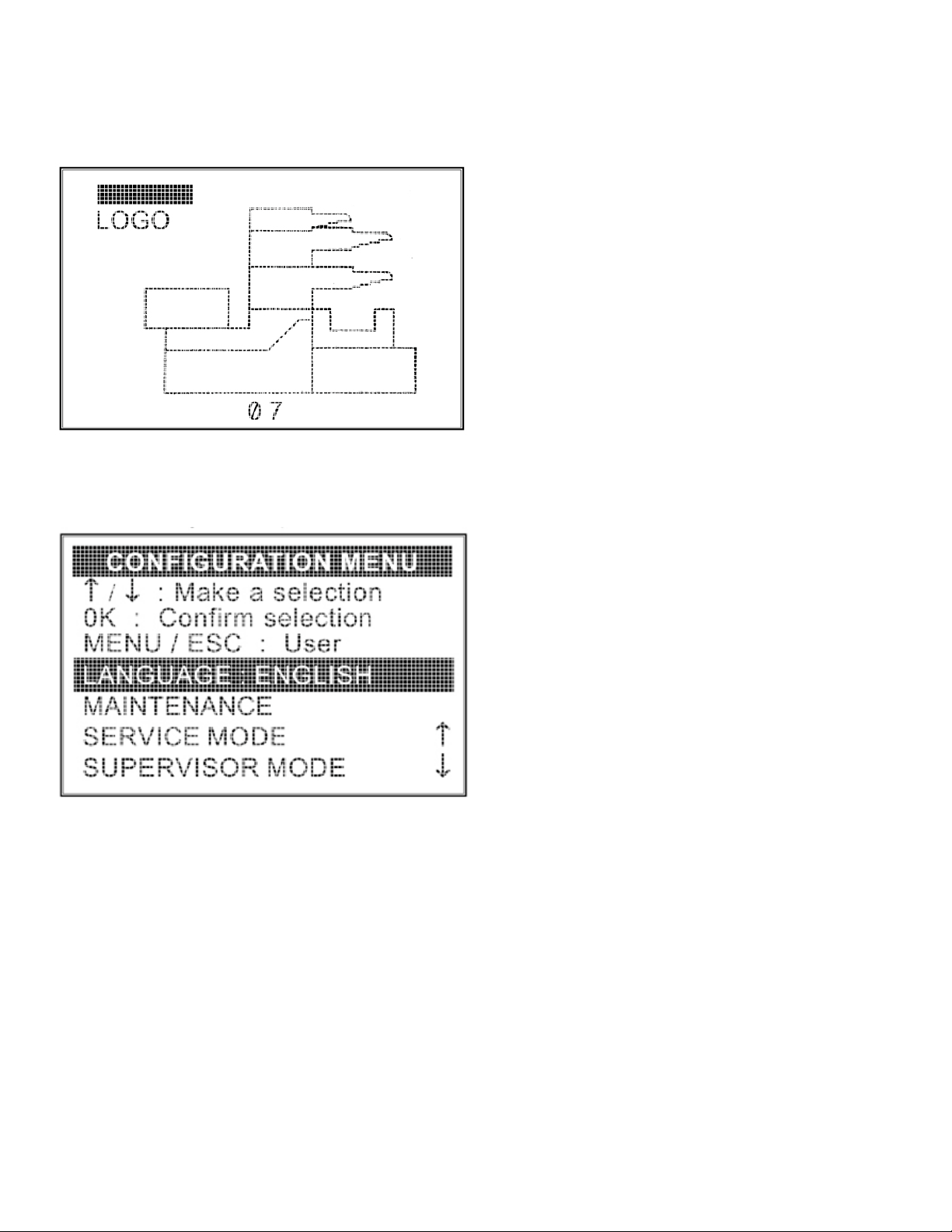

At the top of the screen, a time-filling bar scrolls. Then a countdown starts at the bottom of the

screen.

When the "ESC" key is pressed during the countdown, the machine prompts you to select one of the

following options: language, maintenance, servicing mode or supervisor mode.

CONFIGURATION MENU

1.4.1 User mode (access)

If no key is pressed at the end of the countdown, the screen displays the main menu.

You may use the machine, in accordance with the displayed indications.

1.4.2 Language selection

- To modify the display language, turn the machine off, then turn it on after a few seconds.

- During the countdown press the "ESC" key.

- Select ‘LANGUAGE’ and validate using the "OK" key.

- Select a language in the list available and confirm your choice using the "OK" key.

- Press the "MENU" key to display the general menu.

11

Page 18

1.4.3 Maintenance

See section C, "Cleaning Procedure".

1.4.4 Servicing mode (access)

This mode cannot be accessed by the user, it is designed for the technical services.

1.4.5 Supervisor mode

Commonly used, the supervisor mode gives access to the advanced settings of the machine, as

described below:

- Inserting position,

- Flap moistening length,

- Aligning of documents from feeders B and C,

- Activation of double document detecting function.

This mode is protected by an access code that your servicing agent may provide you.

In order to access the supervisor mode, turn the machine off, then turn it on after a few

seconds. When the countdown appears under the machine diagram, press the "ESC" key .

Select “SUPERVISOR” and confirm the selection by pressing the "OK" key. Enter the

supervisor code and confirm by pressing the "OK" key.

2. OPERATION

To operate this machine you must properly input your application data:

- What documents and what envelopes do you want to use?

- How do you want to combine and fold your documents?

This data is stored in the machine as “jobs” corresponding to each use. Fill the feeder(s) according to

the job to be carried out (see § “Document feeding”).

You may use the machine as follows:

- In the “user mode”, which provides a wide range of basic functionalities or

- In the “supervisor mode” (or expert user) offering a wider range of functionalities.

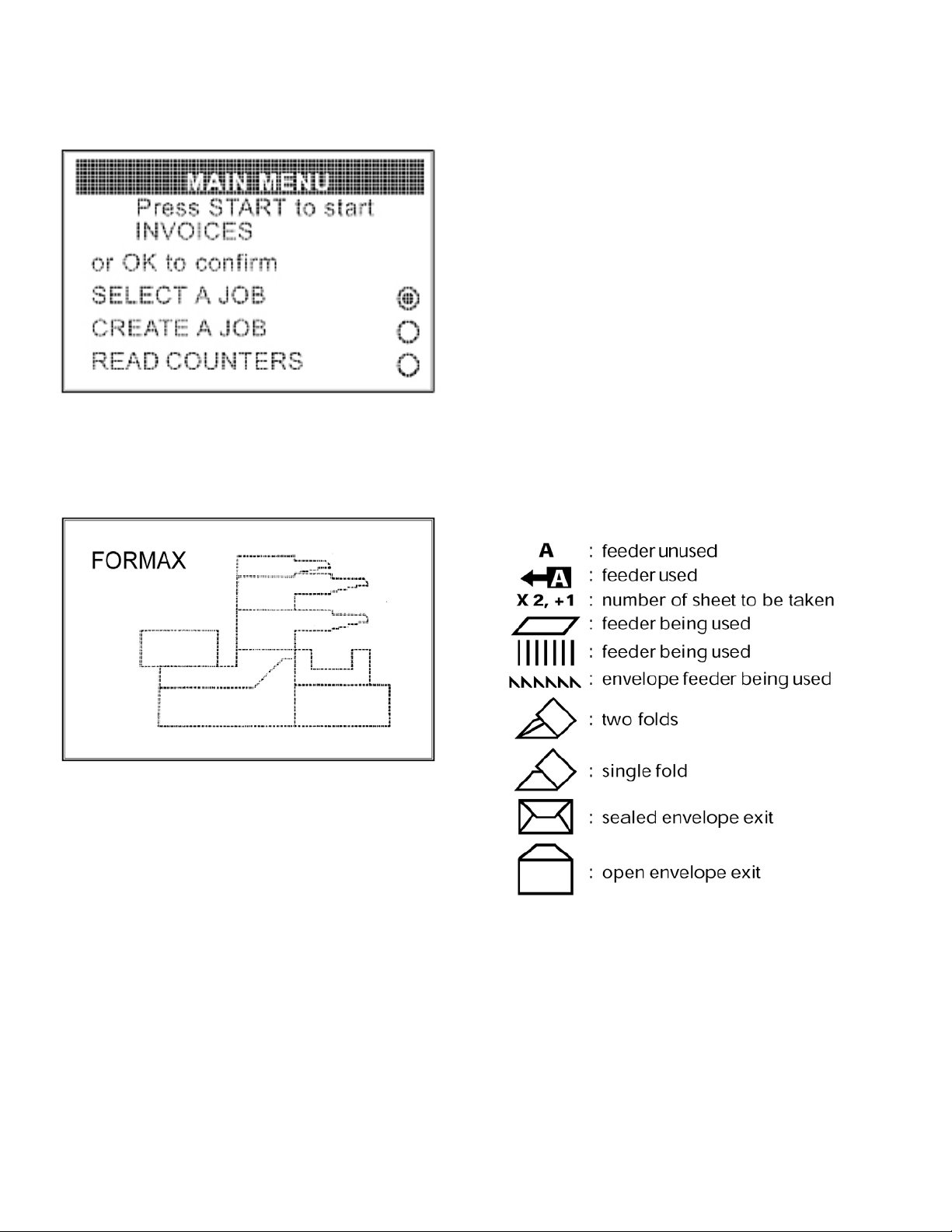

You will be supported and guided at every step of the operation, via both an on-line assistance and

icons displayed on the control screen.

12

Page 19

2.1 User mode

From the MAIN MENU, you may:

- Start the quick access job mentioned at the top of the Main Menu.

- Select another job stored into the machine.

- Create a new job.

- Check the counters.

2.1.1 Quick access job

If the name of the quick access job corresponds to the job you wish to perform, load, as may be

required, the envelopes, documents, inserts and reply envelopes in automatic feeders E, B,

C and F. Then, follow the directions displayed on the control panel. In order to check the content of

the job, choose "SELECT A JOB" and press twice on the "OK" key (to confirm that you want to check

the quick access job). At this stage, select "VERIFY THE JOB" and confirm by pressing the "OK" key.

After checking, go back to the general menu by pushing the "ESC" key.

2.1.2 Selection of a stored job

Choose "SELECT A JOB" and confirm by pressing the "OK" key.

Using selection keys ↓ and ↑, scroll through the numbers and names of the jobs and select the job

required. Confirm your choice by pressing the "OK" key.

13

Page 20

You are now in the starting menu of the selected job:

You may:

- Start the job,

- Check the content of the job,

- Modify the job,

- Adjust the countdown counter.

2.1.3 Job check

Select "VERIFY THE JOB" and confirm by pressing the "OK" key.

14

Page 21

When the "?" key is pressed, a short description of the job is displayed:

After verification press the "ESC" key to get back to the previous menu.

For a more detailed check of the job content, select "MODIFY THE JOB" and confirm by pressing the

"OK" key.

Thus, you will go through the job definition by pressing on the "OK" key after each screen, until the

END OF PROGRAMMMING MENU, which offers the job storage selection. At any time, you may get

back to the previous screen, by pressing on the "ESC" key up to the starting menu of the selected

job.

2.1.4 Starting the job

Load the appropriate feeders with your documents and follow the directions displayed on the control

panel screen.

2.1.5 Modification of a job

Select "MODIFY THE JOB" and confirm by pressing the "OK" key.

In order to modify the job, select the descriptions displayed that match your application. To do so,

use the selection keys and confirm by pressing the "OK" key.

At every step of the modification procedure, you can get back by pressing the "ESC", in order to

make different selections.

At the end of the modification procedure, run a test cycle to verify the application.

15

Page 22

If the modification meets your requirements, you can store the job either under the same number and

the same name as the initial job (if it is not protected; see supervisor mode) or under a different

number and/or name. No job can be performed if it is not stored.

2.1.6 Creation of a job

From the MAIN MENU, select "CREATE A JOB" and confirm by pressing the "OK" key.

Using the selection keys and "OK" key, select the descriptions displayed that match your application.

You will then be able to create a new job. At every step of the creation, you may get back by pressing

the "ESC" key, in order to make different selections.

At the end of the creation procedure run a test cycle to verify the application.

If the job meets your requirements, you can store it under the number and name you wish (apart from

the protected job numbers). No job can be performed if it is not stored.

2.1.7 Counters

The machine is equipped with the below counters:

- A counter of cycles per job. Counters can be reset either individually or all at once.

- A counter totaling the counters of cycles per job.

- A “cycle” counter totaling all the machine cycles.

2.1.8 Countdown counter (Batch Counting)

The machine can operate by counting down the documents, provided that the number of documents

to be processed has been previously set.

To select the quantity, use keys ↓ and ↑ and confirm by pressing "OK".

The “Unlimited Quantity” selection is designed for continuous operation.

When the countdown counter is selected, the countdown value is displayed on the “CURRENT

CYCLE” screen.

16

Page 23

2.2 Supervisor mode

2.2.1 Length of flap moistening

This setting is used to adjust the moistening area on the envelope flap.

It is necessary that the moistening operation be suited to the flap shape or to the envelope thickness.

This setting applies independently to any of the jobs. Therefore, envelopes with special flaps may be

processed in different jobs.

ACTIONS:

- Inadequate moistening area (flap not moistened on the sides): increase the moistening area

(bring the beginning of the moistening closer, using arrow ↓).

- Moistening area too large (documents get damp, water splashes into the machine): reduce

the moistening area (move the beginning of the moistening away, using arrow ↑ ).

Note: If the moistening amount varies slightly with the liquid level, It is advisable to make the

setting with the liquid tank half-full.

2.2.2 Adjustment of the document alignment (feeders B and C)

This adjustment is designed to align the bottom edges of the sheets from feeders B and C.

It applies independently to any of the jobs.

The user is able to adapt the alignment of sheets from feeders B and C to the paper weight.

2.3 Position of the address and adjustment of the folds

The machine folds the documents automatically, based on both the dimensions and the envelope

size.

17

Page 24

2.3.1 Position of the address

If the address is not properly positioned with respect to the envelope window, its position may be

adjusted using the appropriate menu. The menu may be accessed via the program end menu of the

job modification.

2.3.2 Adjustment of the folds

If the user requires specific folds, they may program the fold dimensions via menu "fold

customization" (see "modification of a job").

Note: When inserting several documents from the same feeder into an envelope, be sure to

adjust the folds so that the upper portion of the folded document is slightly (1 mm) longer

than the lower portion.

2.4 Detection of double documents

2.4.1 General remarks

The double document detection prevents any risk of taking two documents from the same feeder and

inserting them unintentionally into one envelope. In order to optimize the system efficiency, we

recommend you:

- Do not to place documents of various thicknesses and qualities into the same feeder.

- Carefully jog the sheets in order to obtain a neat and squared stack,

- Adhere to both the specifications of admissible documents and the storage requirements.

2.4.2 Enabling and disabling the double document detection

Double document detection may be enabled or disabled separately for each document feeder (B and

C) and each insert feeder (D and F), either for all the jobs or for each job individually fulfilled.

Feeders for which double document detection is activated are identified by a symbol.

If no double document detection is enabled, “No” appears under the symbol.

Note: The activation and de-activation of double document detection is only possible in the

supervisor mode.The double document detection should be deactivated in the below

operating cases:

-Documents of variable thicknesses.

-Documents having a weight greater than 120 g/m².

-Reply envelopes.

18

Page 25

3. DOCUMENT FEEDING

3.1 Document feeding in the manual mode (feeder A)

- Draw apart guides (5),

- Place the documents between the guides and adjust the guides to fit the width of the documents,

To start up the cycle:

- Put the document (with the address side facing upward and the top of the page on the right side),

- Push the document into the feeder entry, the machine will start immediately.

3.2 Document feeding in the automatic mode (feeders B and C)

- Avoid mixing in the same feeder documents of different qualities.

- In case of documents particularly difficult to process (uneven, smooth, rough or sticky), use

the half capacity of the feeder.

- Decollate the sheets by bending the stack of paper prior to placing it into the feeder,

- Align the edges of the stack by jogging it on a flat surface.

- To insert several sheets from the same feeder: place the sheets into the bin, in the reverse

order.

19

Page 26

- Release the guides by rotating button (22) to the horizontal position,

- Insert the document stack into the feeder. The documents should be positioned with the address

side facing up and the top of the page to the right,

- Jog the document stack using guides (5) and lock it in position by setting button (22) again to the

vertical position,

- Rotate the pressure unit button (21), then push the document stack into the bottom of the feeder,

- Release the pressure unit button (21), which will get back to its initial position.

3.3 Envelope feeding (feeder E)

- Release the envelope guides (19) by rotating the button (17) to the horizontal position,

- Draw apart the guides (19),

- Decollate the envelopes and jog the sides of the stack,

- Pull the pressure unit (20),

20

Page 27

- Insert the envelopes vertically into the feeder with the flap at the top and facing towards the inside of

the machine.

- Bring the guides (19) close to the envelopes without pressing the envelopes too tightly,

- Lock the guide position by resetting button (17) to the vertical position,

- Push the pressure unit against the envelopes.

Note: Whenever you feed envelopes, make sure that the guides are properly adjusted, i.e. that

the guides are close to the envelope stack without pressing it too tightly

21

Page 28

3.4 Feeding of inserts and reply envelopes (feeder F)

- To open the right door, pull towards the left top towards you.

- Using selector switch (25), select the “envelope” (left-hand) or “insert” (right-hand) position,

Release the guides by pressing on control (24) and draw them apart by pulling the control towards

you.

- Press on the pressure unit control (23) and slide the stack of inserts (or reply envelopes) inside the

feeder.

22

Page 29

- Push the stack of inserts (or reply envelopes) to the left side, against the wall.

- Push the guide control (24) against the inserts (or reply envelopes), without pressing them too

tightly.

- Release the pressure unit (23).

Note: Whenever you carry out a feeding operation, make sure that the guides are properly

adjusted, i.e. that the guides are close to the stack of inserts (or reply envelopes) without

pressing it too tightly.

Special cases:

Reply envelopes with no window:

Flap at the top (or at the bottom) and faces towards the inside of the machine.

Reply envelopes with a window:

Not recommended.

23

Page 30

Pre-folded insert:

Outer fold at the top facing towards the inside of the machine.

Reply envelopes and inserts:

Place the reply envelopes into the feeder D, and place the inserts into the feeder F.

3.5 Feeding of inserts and reply envelopes (feeder D)

- Release guides (5) by rotating button (11) to the horizontal position.

- Draw guides (5) apart.

- Decollate the inserts (or reply envelopes) and jog the sides of the stack.

- Pull the pressure unit (20).

24

Page 31

- Place the inserts (or reply envelopes) in the vertical position, into the feeder.

- Bring guides (5) close to the inserts (or reply envelopes) without pressing them too much.

- Lock the guide position by setting button (11) to the vertical position.

- Push the pressure unit (20) back against the inserts (or reply envelopes).

Note: Whenever you carry out a feeding operation, make sure that the guides are properly

adjusted, i.e. that the guides are close to the stack of inserts (or reply envelopes) without

pressing it too tightly.

25

Page 32

Special cases:

Reply envelopes with no window:

- Flap at the bottom and facing towards the inside (or towards the outside) of the machine.

Reply envelopes with a window:

- Flap at the top and facing towards the inside of the machine.

Pre-folded insert:

- Outer fold at the bottom and facing towards the inside of the machine.

If required, flatten the fold before feeding the insert

26

Page 33

SECTION C: ASSISTANCE AND RECOMMENDATIONS

1. TROUBLE SHOOTING 29

2. JAM CLEARING 32

2.1 Document Path 33

2.2 Envelope path 34

2.3 Insert path 36

2.4 Inserting area 39

3 CLEANING 41

3.1 Cleaning of the rollers 41

3.1.1 Cleaning Procedure 42

3.1.2 Drying 47

3.2 Cleaning of the casing 47

27

Page 34

28

Page 35

1. TROUBLE SHOOTING

Note: In the event of an incident, the machine will trie to eject the document, in order to start

up again immediately. Consult the help option via "?" for further information.

Display / symptom Possible cause Solution

Error in the job selection. Select the appropriate job.

Jam in the inserting area (if the

fault occurs frequently).

Job ill suited to the documents

handled.

Check and/or adjust:

- the fold dimensions

- the alignment of the

documents from feeders B

and C

- the inserting position.

Envelopes or documents

are not up to specifications or

If required, straighten manually

the document (envelope) shape.

out of shape.

Envelopes, inserts, reply

envelopes fed n the wrong

See section B “Document

feeding”.

direction.

Envelope or document- guides

are not properly adjusted.

Rollers of feeders B, C, D, E, F

whether for insertion or folding,

are dirty.

See section B “Document

feeding”.

Clean the rollers of the insertion

and folding feeders. See

section C "Cleaning of the

rollers".

Insert path unlocked. See section C “Insert path”.

Jam in the document, insert or

envelope path (if the fault

occurs frequently).

Jam in the document, insert or

envelope path (if the fault

occurs frequently). (contd.)

Document path unlocked. See section C “Document

path”.

Envelopes, inserts, reply

envelopes fed in the wrong

See section B “Document

feeding”.

direction.

D o c u m e n t s ,

envelopes, inserts not

See section C

“Specifications”.

up to specifications or out of

shape.

Rollers of document, insert,

envelope feeder are dirty.

29

See section C “Cleaning of the

rollers”.

Page 36

Display / symptom Possible cause Solution

Envelope or document guides

are not properly adjusted.

See section B "Document

feeding".

Jam in the document, insert or

envelope path (if the fault

Job ill-suited to the processed

documents.

Select the appropriate job.

occurs frequently). (contd.)

The lower roller is wet. See section C "Cleaning of the

rollers".

Jam in the document exit area Stacker full. Empty the stacker.

Document not properly inserted. See symptom "Jam in the

inserting area".

Documents, inserts, envelopes

do not go through the machine.

Two documents or inserts are

taken at the same time (if the

default occursfrequently).

Dummy double: the machine

stops and the fault is displayed

although there is no double

document taken (if the fault

occurs frequently).

Wrong positioning of the

address in the envelope

window.

The guides are not properly

adjusted.

Documents, inserts or

envelopes not up to

specifications or out of shape.

Rollers of document, insert,

envelope feeder are dirty.

Documents,envelopes, inserts

arenot up to specifications,are

out of shapeor are of different

qualities.

Documents, envelopes, inserts

are not up to specifications, are

out of shape or are of different

qualities.

The folds are not properly

adjusted.

Poor adjustment of the

document alignment (feeders B

See section B "Document

feeding".

See section C "Specifications".

If required, straighten manually

the document (envelope) shape.

See section C "Cleaning of the

rollers".

See section C "Specifications"

and section B "Document

feeding". If required, straighten

manually the document

(envelope) shape. Process

documents individually.

See section C "Specifications"

and section B "Document

feeding". You may also use

the machine in the graceful

degradation mode with the

double document detection

deactivated. See sectionB

"Double document detection".

Adjust the positionof the

address.See section B "Position

of the address".

See section B "Adjustment of

the document alignment".

and C).

30

Page 37

Display / symptom Possible cause Solution

Significant document shift

(feeders B and C).

Poor adjustment of the

documents (feeders B and C).

See section B "Adjustment of

the document alignment".

The letters are left unsealed or

are not properly sealed.

The jam clearing doors of the

feeders are not properly closed.

The documents are not up to

the specifications or are

out of shape.

Close the doors properly. See

section C "Jam clearing".

See section C

"Specifications" and section B

"Document feeding". If required,

straighten manually the

document shape.

The rollers of feeders B and C

are dirty.

See section C

“Cleaning of the rollers”.

The moistening tank is empty. See section B

"Filling the tank".

The documents, inserts or

See section C "Specifications".

envelopes are not up to the

specifications (too many

sheets).

The folds are not up

to requirements.

See section B "Adjustment of

the folds" and "Jobcheck".

The moistening area is too

small.

The document is not properly

inserted.

See section B "Length of flap

moistening".

See symptom "Jam in the

inserting area".

The letter content is damp. Moistening area too wide See section B "Length of the

flap moistening".

The exit roller is wet. Wipe the exit roller (see section

C "Cleaning of the rollers").

Folding significantly

askew.

The operating rate gets slower

or irregular.

Rollers of feeders B, C, D, E, F

or folding rollers are dirty.

The guides are not properly

adjusted.

Documents, inserts or

envelopes not up to

specifications or out of shape.

See section C

"Cleaning of the rollers".

See section B "Document

feeding".

See section C "Specifications".

If required, straighten manually

the document (envelope) shape.

31

Page 38

Display / symptom Possible cause Solution

The operating rate gets slower

or irregular. (contd.)

Rollers of document, insert,

envelope feeder are dirty.

See section C “Cleaning of the

rollers”.

The feeder is empty. See section B "Document

feeding".

The water tank is empty. See section B "Filling the tank".

The backup battery is used up. Replace the battery and call the

after sales service.

All the stored settings are lost.

Double document detection is

faulty.

Double document detection

unavailable on the specified

feeder(s).

Switch the machine off and on.

If the fault persists, you may

operate the machine without the

double document detection. Call

the service to bring this function

again into service.

Job unavailable. The hardware configuration

is no more suited to the job.

The feeder is disconnected. See section B "Installation

of the feeders".

" DOCUMENT TREATMENT

ERROR"

A processing error appears. Remove all the documents

placed or introduced inside the

machine. Close the machine

and press on key "OK" to

continue.

Other faulty conditions. Switch the machine off and on

2. JAM CLEARING

In the event of a jam, you will find a dual assistance, namely:

- The outline of the machine is displayed on the control screen and the area concerned is indicated

for servicing operations.

- When depressing the “?” key, a help message appears to describe the actions to be undertaken.

Note: Follow the instructions displayed on the control screen.

32

Page 39

2.1 Document Path Feeders A, B and C

As the area concerned is identified on the screen by symbol ,

To clear the jam:

- Open the door of the specified feeder.

- Remove the document.

- Close the door.

Document lower path

In case of jam in the document lower path, follow the below procedure:

- Lift the envelope feeder (18),

- Unplug the connector,

- Remove the envelope feeder

33

Page 40

- Open the access door and remove the document,

- Plug in the connector again and put the envelope feeder back in place.

2.2 Envelope path

Upper path of the envelopes

In case of jam in the upper path of the envelopes, follow the below procedure:

- Lift the envelope feeder (18),

- Unplug the connector,

- Remove the envelope feeder

34

Page 41

- remove the jammed envelope and if required, open the access door,

- plug in the connector again and put the feeder back in its place.

Lower path of the envelopes

In case of a jam occurring in the lower path of the envelopes, follow the procedure below:

- Open the machine

- Lower the flap,

- Remove the jammed envelope,

- Make sure that the guides on either side of the flap are properly positioned.

- Close the machine.

35

Page 42

2.3 Insert path

Main path of inserts in feeders D and F

In case of a jam occurring in the main path of inserts in feeders D and F, follow the procedure below:

- Open fully the machine and then open the right-hand and the lefthand doors,

- Rotate the two knurled knobs 1 and 2 until the jammed insert is visible and remove it.

- If it is not possible to move forward the insert by rotating the knurled knobs, unlock the insert path by

turning the control 3 to the left. This will lower the platform,

- Remove the jammed insert,

- Close the machine and the two doors.

Note: Set the machine to its initial position (vertical) in order to avoid any further jam.

Note: If the insert cannot be reached, remove it from the upper path of feeders D or F (see

following paragraphs).

36

Page 43

Upper path of inserts in feeder D

In case of a jam occurring in the upper path of inserts in feeder D, follow the procedure below:

- Lift the feeder (8).

- Unplug the connector.

- Remove the feeder.

- Remove the jammed insert.

- Plug in the connector again and fit the feeder again.

37

Page 44

Upper path of inserts (or reply envelopes) in feeder F

In case of a jam occurring in the upper path of inserts (or reply envelopes) in feeder F, follow the

procedure below:

- Open the right-hand door.

- Lower the pressure unit with the stack of inserts (or reply envelopes) by pressing the appropriate

control.

- Remove the insert (or reply envelope) jammed in the rollers,

- Release the pressure unit and put the stack of inserts (or reply envelopes) back in its place,

- Check the guide adjustment.

38

Page 45

2.4 Inserting area

In case of a jam occurring in the inserting area, follow the procedure below:

- Open the machine,

- Remove the jammed document (or envelope),

- When a document is jammed on the small bar:

- Push the small bar control and remove the small bar by moving it in the direction of the arrow.

- Remove the jammed document.

39

Page 46

- To reinstall the small bar, first insert the bar in its recess and then fit the bar control in the small bar

recess.

Caution: be sure to lock the control in the proper position

- Close the machine.

- Make sure that there is no document in the folding pocket.

- If the fault signal does not go off, make sure that there is no document in the "document path"

(§ 2.1).

Folding pocket

In case of a jam occurring in the folding pocket, follow the procedure below:

- Open the left-hand door,

- Depress the pocket opening control,

- Remove the jammed document,

40

Page 47

- Close the left-hand door.

3 CLEANING

3.1 Cleaning of the rollers

Cleaning the machine on a regular basis will:

- Improve the feeding of the document, insert and envelope feeders.

- Reduce jam risks,

- Protect the roller rubber.

Note: To clean your machine, you will have to stop it for a while, in particular for the drying of

the rollers, which requires at least 10 minutes. During a cleaning operation, we recommend

you to clean the whole machine (feeders used and folding rollers). This will optimize the

functioning of your machine. It is essential to empty the documents from all the feeders

(including the envelopes) prior to any cleaning procedure; otherwise, you will not have access

to the cleaning screen. Be sure to check the F feeder (concealed feeder).

41

Page 48

When does your machine need to be cleaned?

Element Clogging symptoms Action

Feeder A, Band C The documents go through the machine

with difficulty.

Shift between feeder B and feeder C, jams.

Feeder E The envelopes go through the machine

with difficulty, jams.

Feeder D and F The documents go through the machine

with difficulty. Dummy double documents in

feeder D or F.

Folding and inserting

rollers

Letter exit

Jams during insertion, folding significantly

askew. Letter not sealed properly.

Presence of water on the letter. Procedure 4

roller

Preparation of the cleaning kit

Introduce the rod into the holes of the cleaning sheet.

Procedure 1

Procedure 2

Procedure 3

Note: The same sheet can be used once for cleaning all the feeders.

3.1.1 Cleaning Procedure

- Switch off the machine,

- Switch on the machine and wait for twenty seconds,

- When the countdown appears under the machine diagram, Press on "ESC",

- Select "MAINTENANCE" and confirm by "OK",

- Empty all the feeders and confirm by "OK", in order to have access to the cleaning menu (Be sure to

check feeder F).

42

Page 49

Note: It is essential to remove all the documents from the feeders (including the envelopes)

prior to starting up a cleaning operation; otherwise, you will not have access to the cleaning

menu.

PROCEDURE 1 : FEEDER B OR C

This procedure is designed to clean simultaneously all the rollers of the selected feeder.

- Position the cleaning sheet in the feeder as for any standard document, making certain that the rod

is facing outwards.

- Take back the rod against the front of the feeder.

- Select the feeder to be cleaned on the control panel, using the arrows (↓ et ↑);

- Press on start/stop.

- When the machine stops, remove the cleaning sheet by pulling it towards the outside of the

machine. At this stage, you can proceed to the cleaning of another feeder.

43

Page 50

PROCEDURE 2: FEEDER D, E OR F

This procedure is designed to clean simultaneously all the rollers of the selected feeder.

- Position the cleaning sheet into the feeder as for any standard document. Then, move the rod so as

to make it bear towards the front of the feeder.

Note: When cleaning feeder D, be careful to place the left side of the rod on the top of the

feeder. Beginning the cleaning cycle with the rod in the incorrect position may affect the

proper functioning of the machine.

44

Page 51

- Unlock the guides by pressing on control (24) and draw them fully apart by pulling the control.

- Fold the sheet to one third of its length.

- Press the pressure unit button (23) and insert the cleaning sheet into the feeder (with the rod and

the 1/3 fold on the top) making sure that its left edge is against the wall.

- Insert the rod thoroughly at the top.

- Fix the rod on the front side, at the top.

- Release the pressure unit button (23).

- Select the feeder to be cleaned, then press "START/STOP"

- When the machine stops, remove the cleaning sheet by pulling it towards the outside of the

machine, then proceed to clean another feeder.

45

Page 52

PROCEDURE 3: FOLDING ROLLERS

Open the machine and simultaneously rub the three folding rollers and the two inserting rollers with a

cloth impregnated with a multipurpose cleaning product. Dry with a dry cloth.

Note: After cleaning, the rollers should be mat, as any bright traces are the sign of residual

dirt.

46

Page 53

PROCEDURE 4: LETTER EXIT ROLLER

Clean the roller with a cloth impregnated with a multi-purpose cleaning product:

- The roller protective coating

- The letter exit roller

- The letter exit trim

- The covering panel

Dry it with a dry cloth.

3.1.2 Drying

After cleaning the machine, we recommend you to wait for 10 minutes at least, to let the rollers dry

completely. Production can be resumed, after this 10-minute period. It is however advisable to pass

through the machine a few blank documents so as not to stain your original documents with residual

traces of product. To return to the user mode, depress the "MENU" key.

3.2 Cleaning of the casing

Clean the casing of the machine with a damp cloth and a slightly soapy solution.

47

Page 54

48

Page 55

SPECIFICATIONS

Documents - Manuel feeding A

Width of the document : 140 to 216 mm (5.5" to 8.5")

Height of the document : 178 to 356 mm (7" to 14")

Standard size : USA: "letter" 8 1/2"x11"

(216 x 279 mm)

other countries: A4

(210 x 297 mm)

Paper quality and grammage

Coated paper : 90 to 150 g/m² (24 to 40 lb)

Other qualities (printer,

listing, photocopy, offset, recycled) : 60 to 120 g/m² (16 to 32 lb)

Stapled documents allowed

Max. number of sheets : 5 sheets up to 120 g/m²

(32 lb) of coated paper or up

to 80g/m² (20 lb) for other qualities

Documents - Automatic feeder B and C

Width of the sheets : 140 to 225 mm (5.5" to 8.86")

Height of the sheets : 178 to 356 mm (7" to 14")

Standard size : USA: "letter" 8 1/2"x11"

(216 x 279 mm)

other countries: A4

(210 x 297 mm)

Quality and grammage of the sheets:

Coated paper : 90 to135 g/m² (24 to 36 lb)

Other qualities (printer,

listing, photocopy, offset, recycled) : 60 to 120 g/m² (16 to 32 lb)

Feeder capacity : 250 sheets of 80 g/m² (20 lb)

Envelopes - Envelope feeder E

Width of the envelopes : 160 to 175 mm

(6.30" to 6.89") and

220 to 243 mm

(8.66" to 9.57")

Height of the envelopes : 104 to 165 mm

(4.09" to 6.5")

Small envelope recommended size : USA, Canada: #10

(4 1/8" x 9 1/2")

other countries: C6/5 ou DL

49

Page 56

(114 x 229 mm)

Large envelope recommended size : USA, Canada: 6" x 9"

other countries: C5

(162 x 229 mm)

Height of the flap : 30 to 48 mm (1.18" to 1.90")

Shape of the flap : rounded trapezoid

Opening of the throat in center : 9 to 28 mm (.35" to 1.10")

Grammage of the envelopes : 75 to 90 g/m² (20 to 24 lb)

Feeder capacity : 250 envelopes of 80 g/m² (24 lb)

Small size documents - Feeders D and F

Reply envelopes

Width of the envelopes : 140 to 226 mm

(5.5" to 8.90")

Height of the envelopes : 90 to 110 mm

(3.54" to 4.33")

Special US sizes : 3 5/8" x 6.5"

# 9 (3 7/8" x 8 7/8")

Height of the flap : 30 to 48 mm (1.18" to 1.90")

Grammage of the envelopes : 75 to 90 g/m² (20 to 24 lb)

Simple inserts

Width of the sheets : 140 to 226 mm

(5.5" to 8.90")

Height of the sheets : 84 to 153 mm (3.31" to 6")

Quality and grammage of the sheets : Printer, listing, offset, paper board, coated, glazed or mat

Feeder D : 80 to 250 g/m² (24 to 65 lb)

Feeder F : 80 to 170 g/m² (24 to 45 lb;used simultaneously with

feeder D).

Other applications: 80 to 250 g/m² (24 to 65 lb).

Shaped inserts (A4 documents or "letter" folded in 2 or 3, documents of 14" folded in 4)

Width of the folded documents : 140 to 226 mm (5.5" to 8.90")

Height of the folded documents : 84 to 153 mm (3.31" to 6")

Quality and grammage of the sheets : Printer, photocopy,offset:

80 to 120 g/m² (20 to 32 lb)

Coated paper: 90 to 135 g/m²

(24 to 36 lb) using simultaneously feeders D and F.

Other applications:

90 to 170 g/m² (24 to 45 lb).

50

Page 57

Recommended clearance for the document in the envelope

Capacity of insert feeder D:

Reply envelopes* and inserts : 250

Capacity of insert feeder F:

Reply envelopes* and shaped

inserts : 100

Simple inserts : 250

*As regards reply envelopes with a window, we recommend you to use feeder D.

Folding and inserting capacity

Grammage and max. number of

sheets in simultaneous insertion : up to 5 sheets of 80 g/m²

(24 lb) folded in 2 or in 3, or

3 sheets of 80 g/m² (24 lb)

with the addition of an insert and a reply envelope

Grammage and max. number of

sheets in multiple insertion : up to 3 sheets of 80 g/m²

(24 lb) folded in 2 or in 3

(depending on the quality

of the document), or up to 2

sheets of 80 g/m² (24 lb)

folded in 2 or in 3 with the addition of a sheet, an insert

and a reply envelope.

51

Page 58

Number of programmable job : 20

Rate

Max. rate in operation : up to 2200 documents/hour

depending on the operating mode

Capacity of the letter stacker: up to 150 envelopes.

Capacity of the moistening liquid: 0,310 dm3 (18.92 in3)

Dimensions

Width without the letter stacker : 750 mm (29.53")

Width with the letter stacker : 860 mm (33.86")

Depth : 525 mm (20.67")

Height with manual feeding

and feeder B : 472 mm (18.58")

Height with manual feeding

and feeder B and C : 565 mm (22.24")

Weight

Empty weight with all options : 46 kg (101 lb)

Acoustic noise ISO7779

Acoustic pressure at the operator station in automatic insertion 1 sheet : 70 dBA

Environment

Mains voltage

- 50 Hz version : 230 V +10% -10%

- 60 Hz version : 120 V +6% -10%

Average power requirement

in operation : 330 W

Power requirement in standby : 25 W

Ambient temperature in operation : 15° C à 35° C

Max. ambient air humidity

in operation : 20% HR à 70% HR

Safety and quality certifications : UL, CE, FCC

52

Page 59

Loading...

Loading...