Page 1

Table of contents

Introduction 2

Instrumentation 3

Controls and features 9

Charging 13

Starting 23

Driving 26

Roadside emergencies 32

Maintenance and care 46

Capacities and specifications 56

Accessories 58

Index 63

All rights reserved. Reproduction by any means, electronic or mechanical

including photocopying, recording or by any information storage and retrieval

system or translation in whole or part is not permitted without written

authorization from Ford Motor Company. Ford may change the contents without

notice and without incurring obligation.

Copyright © 2000 Ford Motor Company

1

Page 2

Introduction

WELCOME TO THE RANGER ELECTRIC VEHICLE

The Ranger Electric Vehicle is very similar to the gas-powered Ranger in

appearance, interior and controls. The Ranger Electric Vehicle was built

to be transparent from the gas-powered Ranger. There are enough

differences that you should read this manual. Operation is the same, but

some functions are different. The regular Ranger owner’s manual covers

common systems. This Owner’s Guide Supplement contains the

information specific to the Ranger Electric Vehicle.

ICONS

The warning icon. Read the following section on Warnings for a full

explanation.

WARNINGS

Provide information which may reduce the risk of personal injury or

prevent possible damage to others, your vehicle and its equipment.

INFORMATION ABOUT THIS GUIDE

The information found in this guide was in effect at the time of printing.

Ford may change the coctents without notice and without incurring

obligation.

2

Page 3

Instrumentation

WARNING LIGHTS AND CHIMES

Service indicator lamp

The service indicator lamp indicates

that a vehicle malfunction has

occurred. The vehicle should be

returned to an authorized Ford

Electric Vehicle (EV) Dealer for service.

Brake warning lamp

The brake warning lamp illuminates

when there is a regenerative braking

system malfunction, low fluid level

in the master cylinder or low fluid

pressure in the hydraulic lines, or

when the parking brake is engaged. If the lamp remains illuminated after

the parking brake is fully released and the master cylinder is full, the

vehicle should be taken to an authorized Ford EV Dealer.

Charging lamp

The charging lamp illuminates when

the key is turned to the ON or

START position while the vehicle is

connected to the power control station (PCS). If the lamp flashes when

the key is in the ON position, there is a vehicle malfunction and the

drive battery cannot be charged. Confirm the vehicle is in park and the

PCS cord is properly attached. If the vehicle is in P (Park) and the PCS

cord is properly connected and the charging lamp continues to flash,

then the vehicle should be taken to an authorized Ford EV Dealer.

!

BRAKE

Low oil pressure lamp

The low oil pressure lamp indicates

that the transaxle oil lubrication

system is operating below the

desired pressure. Oil cannot be

added by the owner. The vehicle

should be returned to an authorized Ford EV Dealer as soon as possible.

Driving in excess of 50 miles to reach an authorized dealer may damage

the transaxle.

3

Page 4

Instrumentation

Electrical hazard warning lamp

The electrical hazard warning lamp

indicates a malfunction in the

high-voltage system. The vehicle will

not charge and must be returned to

an authorized Ford EV Dealer

immediately.

Auxiliary battery lamp

The auxiliary battery lamp indicates

there is an auxiliary battery

charging malfunction. Return the

vehicle to an authorized Ford EV

Dealer immediately.

Low fuel lamp

The low fuel lamp indicates that the

vehicle’s drive battery has reached a

10% state of charge. The vehicle

must be placed on charge. The

indicator will flash when the battery reaches a 0% state of charge.

Power limit lamp

The power limit lamp indicates a

system fault or reduced vehicle

performance to conserve remaining

drive battery power. As the vehicle

nears complete discharge, the power limit lamp will illuminate.

High-voltage accessories (A/C and heat) will be disabled. You will notice

a decrease in vehicle performance and you must return to a PCS (power

control station) immediately. The lamp will begin to flash and the

performance of the vehicle will be severely limited. The vehicle will

continue to operate until the drive battery is completely drained;

however, driving under this condition will damage the battery, resulting

in reduced battery life.

4

Page 5

Instrumentation

Anti-lock brake system (ABS) lamp

The ABS lamp indicates that there

is a malfunction with the ABS. If the

light stays on or continues to flash

after the vehicle is started, return

the vehicle to an authorized Ford

EV Dealer for service.

Econ mode lamp

The econ mode lamp indicates that

the gearshift is in the E (Economy)

position. This mode is recommended

for urban traffic and will improve

range by increasing the effects of regenerative braking and limiting top

speed to 105 km/h (65 mph). The D (Drive) position is recommended for

highway operation at steady speeds.

Power reset lamp

The power reset lamp indicates that

the inertia shutoff switch has been

tripped and all high-voltage power

has been disconnected and power

has been limited to the traction battery. If there is no damage to the

vehicle, reset the switch to reactivate the high-voltage power systems.

ABS

5

Page 6

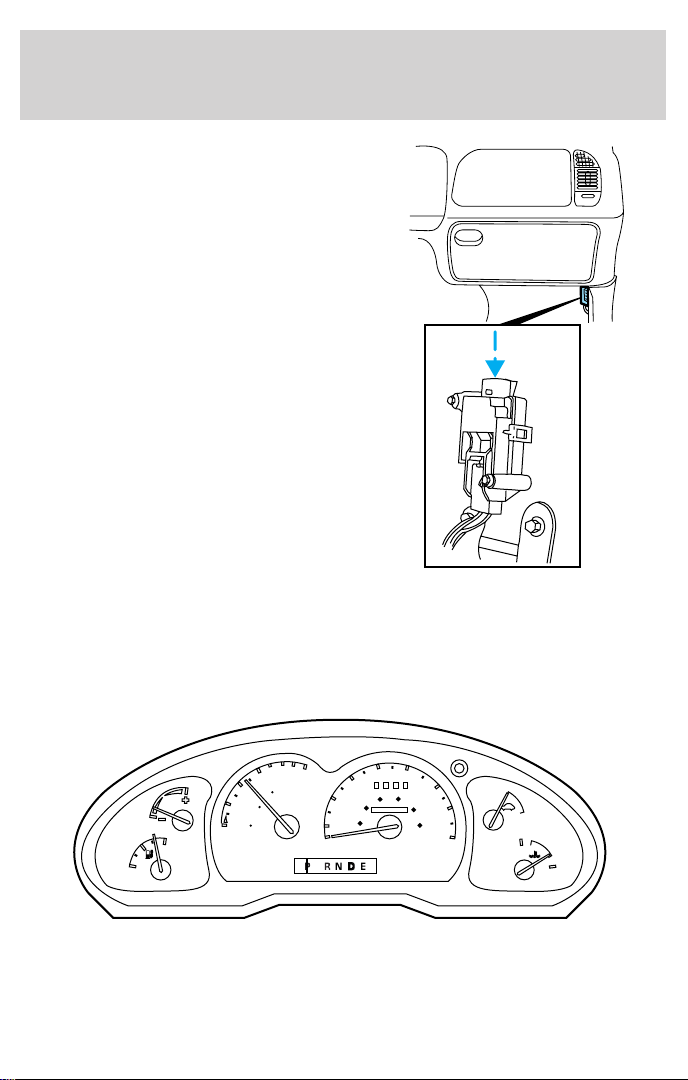

Instrumentation

The inertia shutoff switch is located

by the passenger kick panel. If there

is damage to the vehicle, have the

vehicle towed to an authorized Ford

EV Dealer.

RANGER EV FOR MEXICO AND CANADA

The instrument cluster on the Ranger EV for Mexico and Canada will be

equipped with metric gauges. All gauges operate as described below.

GAUGES

6

40

MPH

30

20

40

50

60 80

000000

60

100

70

120

km/h

ON

80

OFF

H

C

0

6

100

4

MILES

0

DISTANCE

50

TO EMPTY

0

2

km

0

0

20

10

ECON

F

E

Page 7

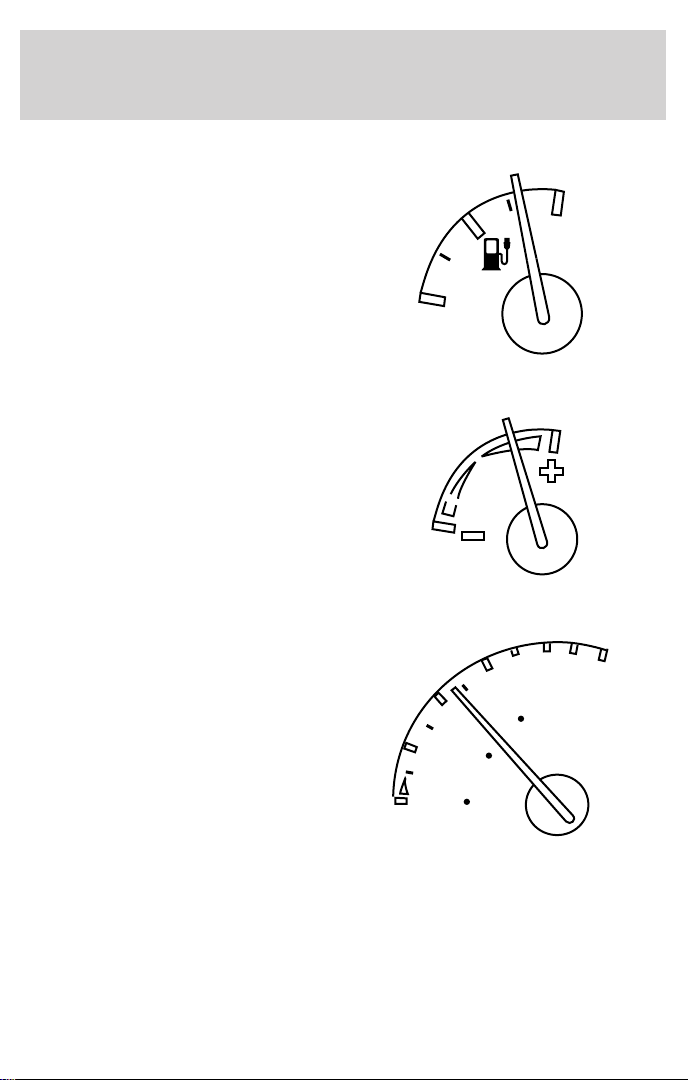

Battery state of charge gauge

The battery state of charge gauge is

the equivalent of a fuel gauge on a

gasoline-powered vehicle. F (Full)

indicates that the battery is

completely charged. E (Empty)

indicates the battery has been

discharged to the point where

additional operation will damage

vehicle systems.

Economy gauge

The economy gauge provides

information about the vehicle’s

energy usage. Economical usage of

the vehicle is indicated by the gauge

reading near the plus (+) side and

will maximize the vehicle’s range.

Distance to empty gauge

The distance to empty gauge

estimates the remaining distance the

vehicle can travel before requiring a

drive battery recharge. The gauge

reading is based on remaining drive

battery energy, driving conditions

and recent vehicle usage.

Instrumentation

E

ECON

0

6

100

4

0

DISTANCE

50

TO EMPTY

km

0

MILES

0

2

0

F

7

Page 8

Instrumentation

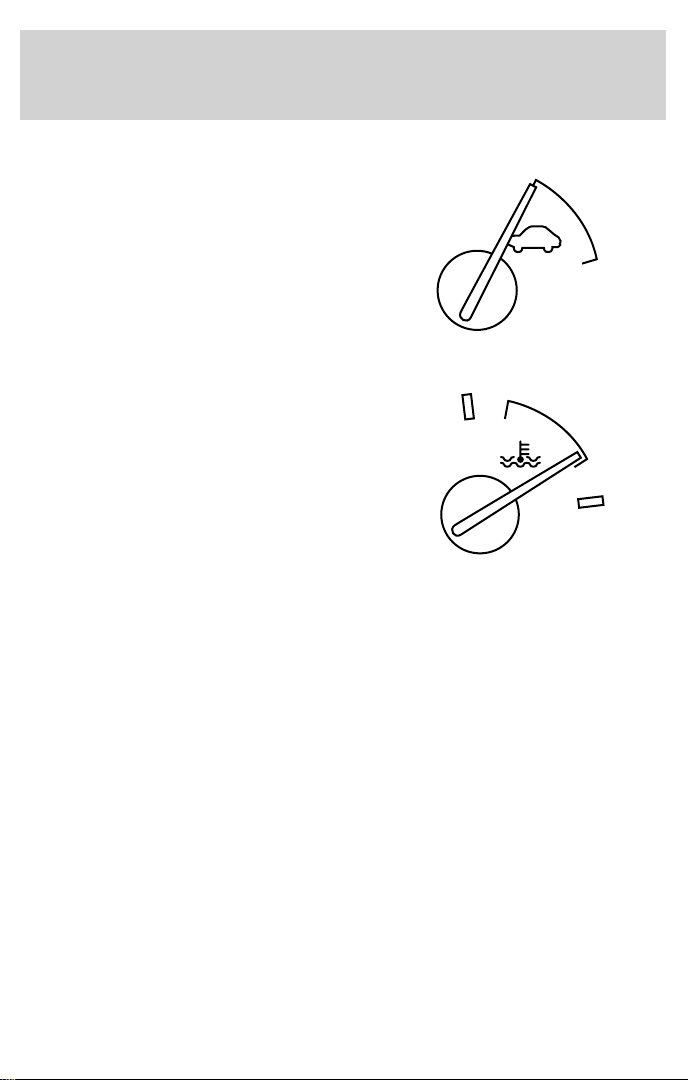

Motor enabled gauge

The motor enabled gauge indicates

that the vehicle is ready to drive.

Turning the ignition switch to the

full START position and releasing

will turn the vehicle on, and the

gauge will move to the ON position.

Temperature gauge

The temperature gauge indicates

the temperature of the vehicle’s

components. Unlike conventional

temperature gauges, it does not

start cold and move to normal. The

gauge sits at normal and moves to

hot or cold when there is a problem.

If the gauge moves to H (Hot),

vehicle performance will be limited

until the coolant temperature or drive battery temperature returns to

normal. The vehicle should be stopped and plugged into a PCS until it

has cooled down. The vehicle may need servicing. If the gauge moves to

C (Cold), the vehicle may have an extended charge time and a reduced

driving range.

ON

OFF

H

C

8

Page 9

Controls and features

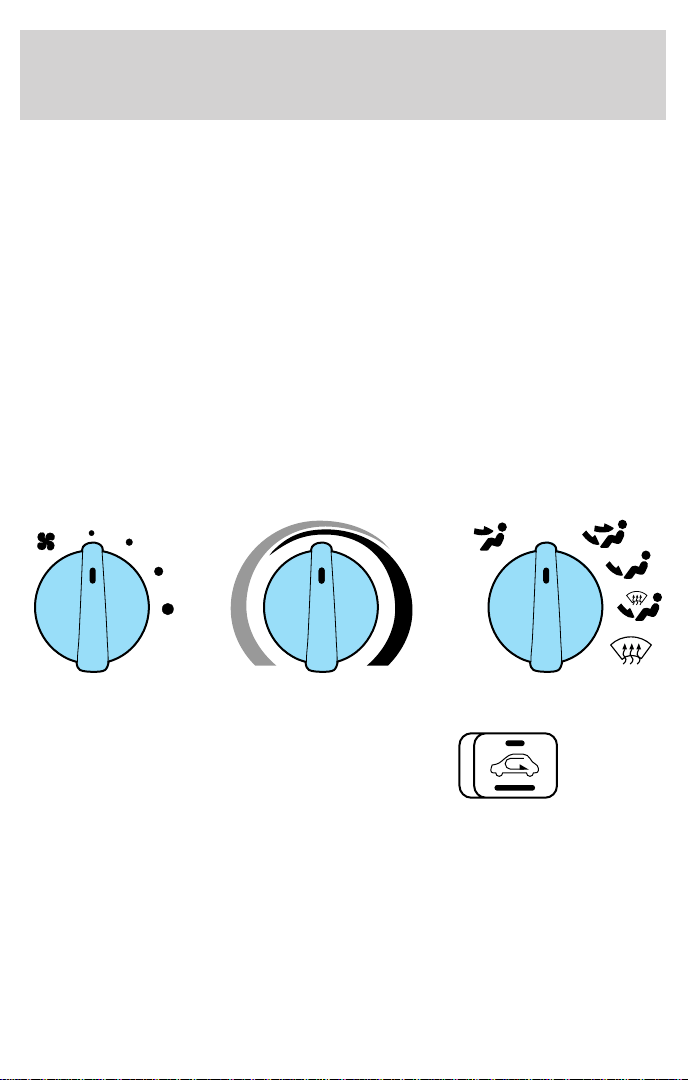

CLIMATE CONTROL SYSTEM

Your vehicle is equipped with an automatic temperature control (ATC)

system designed to maintain a selected temperature with a combination

A/C-Heater system.

Air conditioning (A/C) and heater controls

The control for your air conditioning and heater system is located at the

center of the instrument panel below the radio and will operate in the

KEY-ON position. Your air conditioner and heater will heat and/or cool

your vehicle interior depending on the function position and temperature

you select. The mode selector knob allows you to select heating or

cooling, and determine where the air will be directed. The temperature

control knob setting determines the desired interior temperature of the

vehicle. To turn your air conditioner or heater system on, select any

position except OFF. This will turn the fan on and allows air flow into

the vehicle. To turn your air conditioner or heater system off, select OFF.

This will turn the fan off and stop airflow from coming into the vehicle.

OFF

A/C

MAX

A/C

Recirculation switch

The recirculation switch is located

at the center of the instrument

panel just right of the radio. It

allows switching from outside air to

recirculated air in Panel,

Panel/Floor, and Floor modes. The recirculation switch operates for five

minutes, then shuts off. If more recirculation operation is desired, press

the control again. Note that in MAX A/C and A/C modes, the function is

automatic (stays in recirculation mode) and cannot be switched off. A

table of recirculation switch operation follows.

9

Page 10

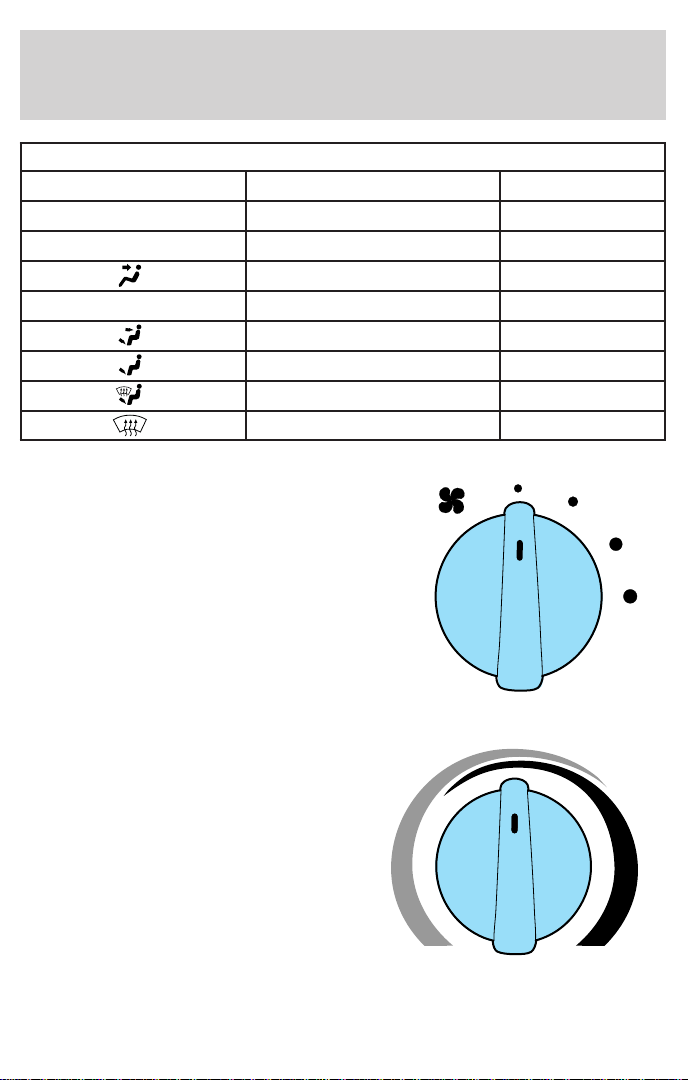

Controls and features

Recirculation Switch Operation

Icon Mode Recirculation

MAX A/C Max A/C Automatic

A/C A/C Automatic

OFF OFF Not Available

Floor/Defrost Not Available

Fan speed knob

The left knob on the control is the

fan control knob, which controls the

volume of air flow. Rotate the knob

to the right to increase fan speed

and increase the amount of air

entering the vehicle. Four fan speed

positions are available and are

indicated by dots beside the control

knob. The largest dot is the

high-speed position.

Panel Selectable

Panel/Floor Selectable

Floor Selectable

Defrost Not Available

Temperature control knob

The temperature control knob is the

rotating knob located at the center

of the control with tapered red and

blue bands surrounding most of the

knob. The wide red part of the band

(full right) is the warm temperature

area. The wide blue part of the band

(full left) is the cool temperature

area. Any position selected between

full right and full left will give a

temperature between maximum

heating 29°C (84°F) and maximum cooling 18°C (64°F) (A/C and MAX

A/C modes only).

10

Page 11

Controls and features

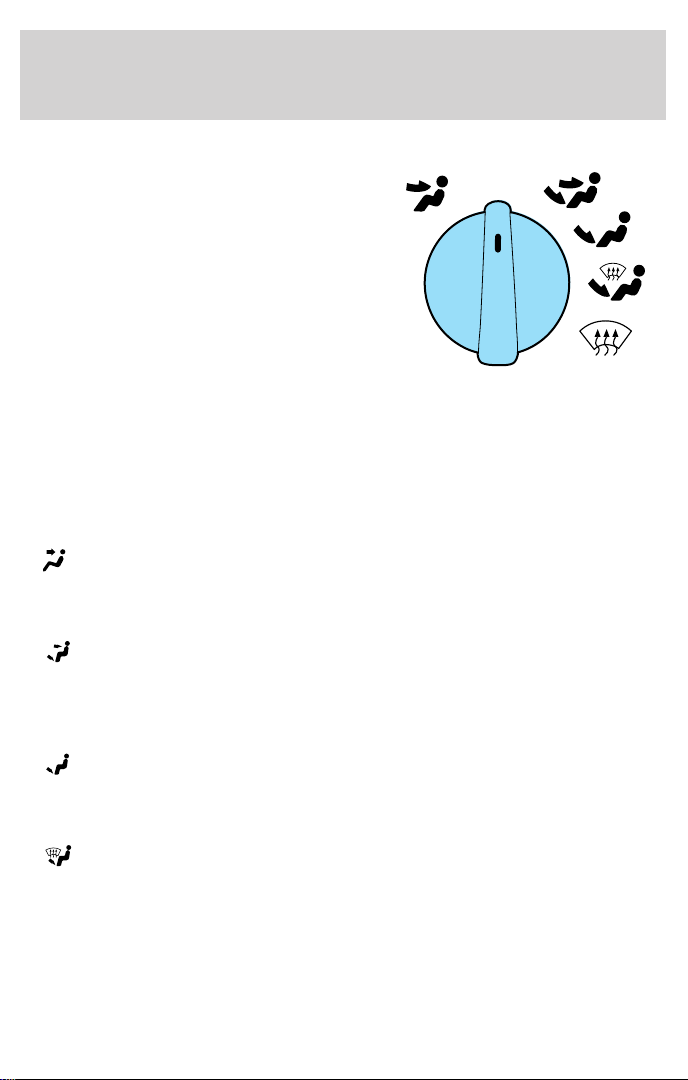

Mode selector knob

The right knob on the control is the

mode selector, which controls the

direction of the airflow inside the

vehicle.

• MAX A/C-Select to distribute recirculated air through the instrument

panel registers. This position produces cool air more rapidly to provide

faster cooling of your vehicle. Using MAX A/C may be noisier and less

economical than A/C.

• A/C-Select to distribute cool recirculated air through the instrument

panel registers. This position should be used for cooling except when

it is extremely hot or fast cooling of the vehicle is needed.

•

•

•

•

(panel)-Select to distribute outside air or recirculated air through

the instrument panel registers. The air may be heated based on

temperature selection. The air cannot be cooled below the outside

temperature regardless of the temperature setting.

(panel and floor)-Select to distribute outside air or recirculated

air through the instrument panel registers and to the floor ducts at

the same time. The air may be heated based on temperature selection.

The air cannot be cooled below the outside temperature regardless of

the temperature setting.

(floor)-Select to distribute outside air or recirculated air through

the floor ducts. The air may be heated based on temperature

selection. The air cannot be cooled below the outside temperature

regardless of the temperature setting.

(floor and defrost)-Select to distribute outside air through the

floor ducts and the windshield defroster ducts at the same time. If the

outside air temperature is 10°C (50°F) or warmer, the air conditioner

will dehumidify the air to prevent fogging. The air may be heated

and/or cooled based on temperature selection.

A/C

MAX

A/C

OFF

11

Page 12

Controls and features

• (defrost)-Select to distribute outside air through the windshield

defroster ducts. Defrost can be used to clear ice or fog from the

windshield. If the outside air temperature is 10°C (50°F) or warmer

the air conditioner will dehumidify the air to prevent fogging. The air

may be heated and/or cooled based on temperature selection.

Operating tips

• In humid weather, select defrost before driving. This prevents your

windshield from fogging. After a few minutes of operation, you may

select another function.

• Remove any snow, ice or leaves from the air intake area of your heater

system that could block the air intake. The intake area is located at

the bottom of the windshield.

• If temperatures below -18°C (0°F), select recirculation before driving.

This will help warm the vehicle interior and minimize degraded

performance at low outside temperatures.

• The use of climate controls will reduce the vehicle’s range. Limit the

use of maximum heating and cooling of the vehicle interior.

12

Page 13

Charging

CHARGING

Charging the Ford Ranger Electric Vehicle is a safe, simple process.

In-garage charging of the Ranger Electric Vehicle has received UL

approval. To maximize range, the vehicle should be connected to a

power control station (PCS) whenever possible to keep the battery fully

charged.

A conductive power control station (PCS) is required to recharge your

Ranger Electric Vehicle. The PCS consists of a “smart” box and a

connector and cable assembly that safely conducts AC power from the

utility supply grid to the vehicle inlet (located at the right front of the

vehicle, next to the right headlamp). An important feature of the PCS is

an integrated control pilot circuit, which performs safety functions such

as verifying the vehicle is present and safely connected, start/stop

control, confirming the smart box is ready to send power, confirming the

vehicle is ready to accept power, and continuously verifying the presence

of an equipment ground. The PCS supplies the power commanded by

the vehicle.

These stations will be in private locations (for example, residential or

fleet garages) or in public sites (for example, shopping malls,

restaurants, parking lots and so on). The PCS uses a 40 amp, 240 volt,

AC electrical supply.

The customer is responsible for ordering the PCS and getting it installed.

Your Ford Dealer will provide information on how to purchase and how

to get your PCS installed.

Consult your PCS owner’s manual for specific instruction on using your

PCS. Additional installations or service requirements that you might need

should be performed by a full service installer. Contact your Ford dealer

for a complete listing. If your installer finds any PCS malfunctions,

contact the PCS manufacturer.

Always follow charging instructions carefully. Failure to do so

may result in vehicle damage, personal injury or death.

13

Page 14

Charging

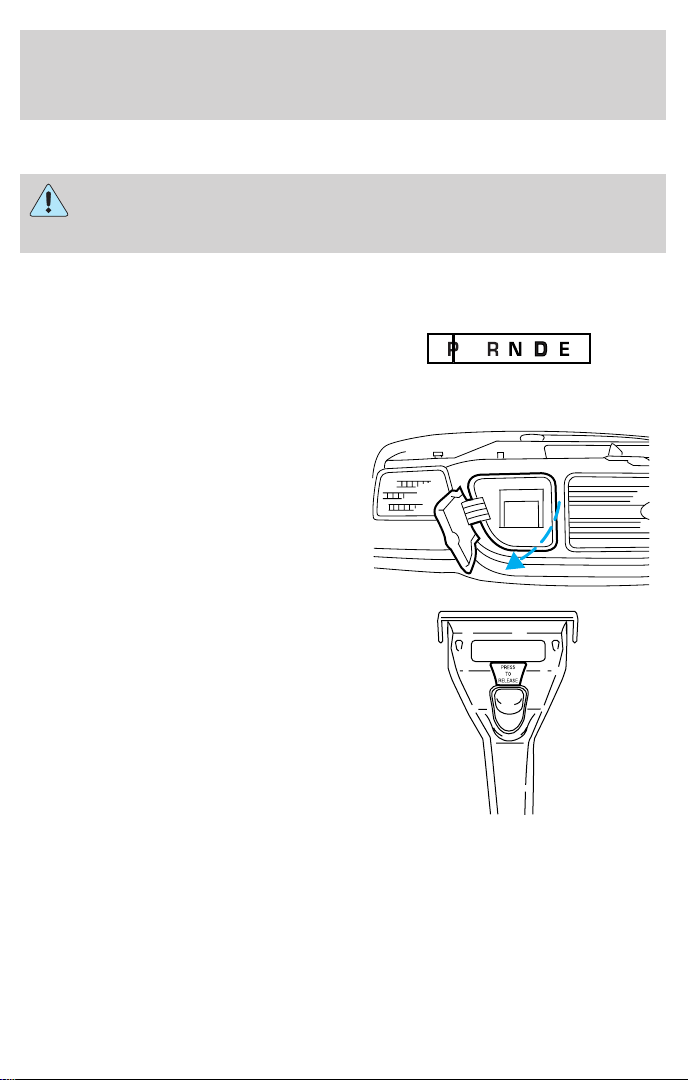

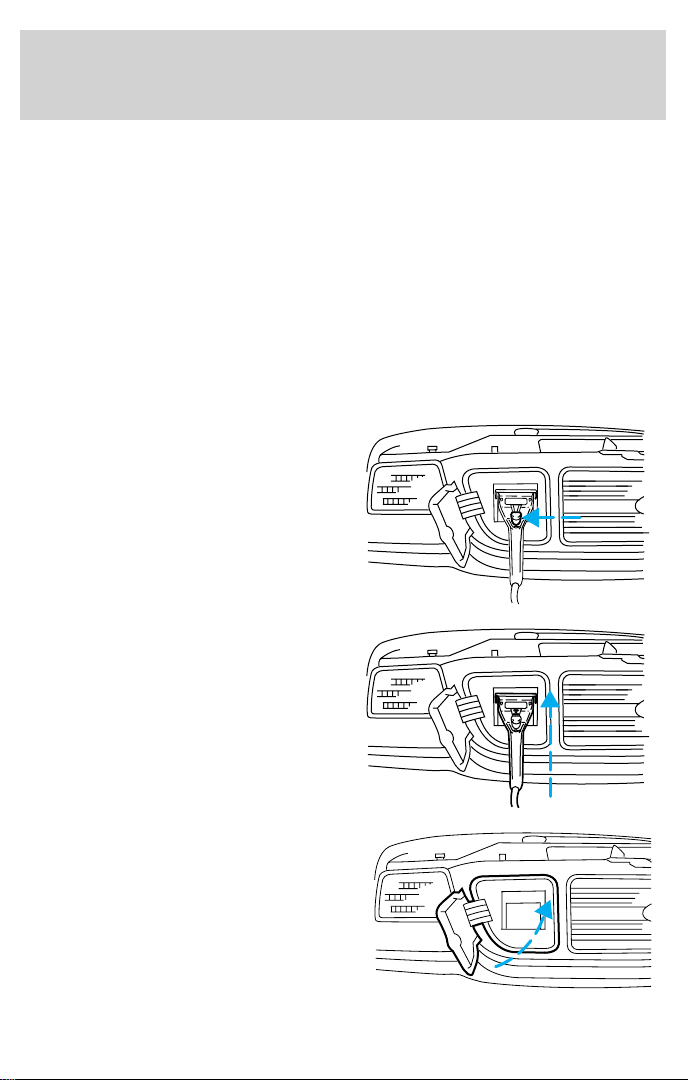

To connect the PCS:

Always set the parking brake fully. Make sure the gearshift lever

is placed in P (Park) position. Turn off the “ignition” whenever

you leave your vehicle.

1. Park the Ranger Electric Vehicle. The vehicle’s charge inlet is at the

right front of the vehicle in the grille, next to the right headlamp.

2. Place the gearshift lever in P

(Park) and set the parking brake.

3. Turn the “ignition” to LOCK and remove the key from the “ignition.”

4. Open the charge inlet access door

in the front grille. The door is

hinged toward the right headlamp

and opens in the same manner as

the fuel filler door.

5. Pick up the PCS connector and

position it so that the release button

is facing upwards.

6. Align the PCS connector to the charge inlet, fully insert the connector

and make sure that the tabs on both sides of the connector engage the

slots in the inlet.

14

Page 15

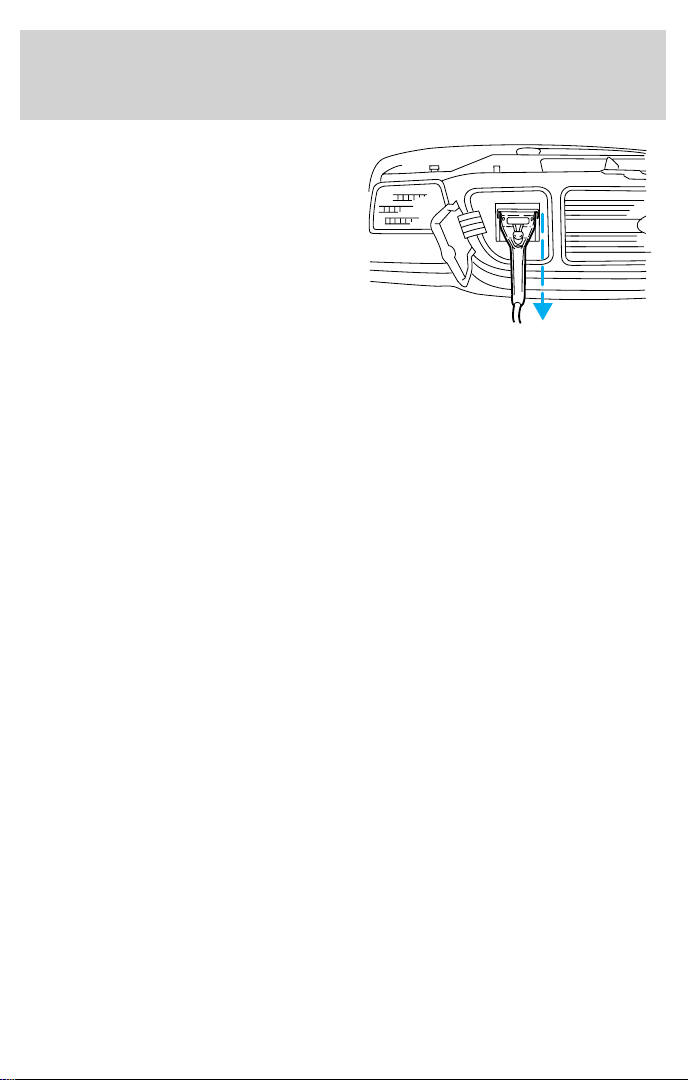

Charging

7. Gently push the connector down,

toward the bumper, until you hear a

click. The click means that the

connector is locked into the inlet.

8. The time required to charge the vehicle depends on the battery

temperature and the state of charge when the vehicle is plugged in. The

normal charge time is 6–8 hours. Reduced supply voltage, from the

recommended 240 volts, may adversely affect the normal charge time.

Estimated charge time

The amount of time required to fully charge the battery pack varies

depending upon the beginning state of charge and battery temperature.

Note that battery temperature is not necessarily the same as outside

temperature. The use of outside temperature to plan charge times,

however, is the most straightforward approach.

Typically it will take 6–8 hours for the vehicle to fully charge from

“empty” to “full.” Use the battery state of charge gauge as a guide to

assess whether enough charge time was allowed. If the gauge does not

indicate “full” when the “ignition” is moved to the ON position, one of

the following may have happened:

• The battery pack may be too warm or too cold. Charge times can

increase to 10 hours or more for warmer or cooler batteries. In sever

temperature conditions (battery temperature less than 5°C [41°F], or

greater than 60°C [140°F] for the lead-acid type and less than

–25°C [–13°F] or greater than 45°C [113°F] for the nickel metal

hydride type) the vehicle will not charge at all.

• The PCS may be malfunctioning.

• The battery pack may be out of electrical balance. The vehicle will

perform a balancing charge, which may take up to four hours for the

lead-acid type or two hours for the nickel metal hydride type over the

normal charging time, and then indicate “full.”

• The gearshift lever was not in P (Park).

15

Page 16

Charging

• The battery pack (lead-acid type only) may be new. Vehicles that have

experienced less than 10 drive/charge cycles need an additional few

hours of charge time.

Refer to charging troubleshooting later in this section.

If none of the above apply, the vehicle should be returned to the PCS to

attempt to complete charging or taken to an authorized Ford EV Dealer.

Lead-acid traction battery

At 25°C (77°F), the drive battery can be charged to 80% capacity in

about three hours; 100% capacity requires approximately six to eight

hours. Completely charging the drive battery is important to ensure

maximum range and battery life. Ford recommended practice is that the

vehicle should always be left on-plug when not in use and be allowed to

fully charge before driving.

Charge time may increase at colder or hotter temperatures. The drive

battery must be above 5°C (41°F) and below 60°C (140°F) before

charging will begin. After being connected to a PCS, the vehicle will

automatically heat or cool the drive battery, as needed. When the battery

reaches the necessary temperature, charging will begin. Following a

complete charge in colder climates, charging will continue at periodic

intervals to maintain the battery at –10°C (14°F).

The Ranger Electric Vehicle should be connected to a PCS

whenever it is not being driven.

If a PCS is not available, the vehicle may be stored off-plug for up to

28 days without suffering permanent damage as long as the initial state

of charge is greater than 50%. The frequency of this type of storage

should be limited to a few occurrences over the life of the vehicle.

Nickel metal hydride traction battery

At 25°C (77°F), the drive battery can be charged to 80% capacity in

about five to six hours; 100% capacity requires approximately six to

eight hours. Completely charging the drive battery is important to ensure

maximum range and battery life. Ford recommended practice is that the

vehicle should always be left on-plug when not in use and be allowed to

fully charge before driving.

Charge time may increase at colder or hotter temperatures. The drive

battery must be above –25°C (–13°F) and below 45°C (113°F) before

charging will begin. After being connected to a PCS, the vehicle will

automatically cool the drive battery as needed. When the battery reaches

16

Page 17

Charging

the necessary temperature, charging will begin. Following a complete

charge in colder climates, charging will continue at periodic intervals to

maintain the battery at –10°C (14°F).

The Ranger Electric Vehicle should be connected to a PCS

whenever it is not being driven.

If a PCS is not available, the vehicle may be stored off-plug for up to

28 days without suffering permanent damage as long as the initial state

of charge is greater than 50%. The frequency of this type of storage

should be limited to a few occurrences over the life of the vehicle.

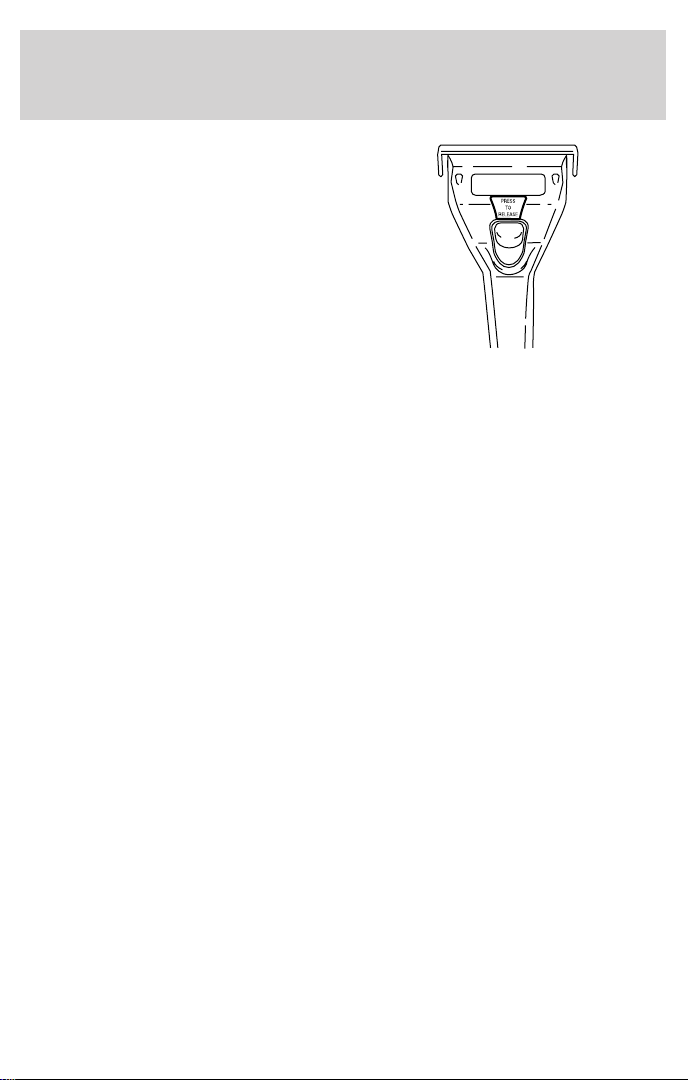

To disconnect the PCS:

1. Push the STOP button on the PCS.

2. Grasp the charge connector and

press the button in the center of the

handle.

3. Pull the charge connector upward

and pull it out of the inlet.

4. Close the charge inlet access door

in the front grille.

17

Page 18

Charging

5. Return the connector and cable

to their proper location.

Charging troubleshooting using SCI systems (SCIT) equipment

If your vehicle fails to charge, follow this procedure to determine if your

Power Control Station (PCS) is operating properly:

1. Make note of any lights that are flashing or steadily illuminated on

your PCS.

2. Determine if the charge connector is properly inserted in the vehicle

inlet and locked in place.

3. Is the charge interrupt light illuminated? If yes, your vehicle may have

undergone a series of faults which forced the PCS to terminate the

charge process.

• Push the stop button.

• Unplug the connector from the vehicle inlet, to clear the fault.

• Inspect the cable and connector for any signs of possible damage (i.e.

cuts, tears or breaks in the cable insulation). If damage is found, stop

any further attempts to charge the vehicle and call the PCS

manufacturer for repair.

• If the cable and connector are undamaged reconnect the PCS to the

vehicle inlet. Is the charge interrupt light still illuminated or flashing?

Consult your authorized Ranger EV dealer to determine possible

vehicle fault.

4. Is the service light illuminated? If yes,

• Disconnect the charge connector vehicle inlet.

• Turn off the power to your PCS at the service or disconnect panel.

Turning off the power may allow the PCS to clear the fault.

18

Page 19

Charging

• Turn the power back on and reconnect the PCS to the vehicle inlet. Is

the service light still illuminated? If so, call the PCS manufacturer for

repair or replacement. The toll free number is located on the PCS.

Charging troubleshooting using Electric Vehicle Infrastructure

(EVI

T

) equipment

If your vehicle fails to charge follow this procedure to determine if your

Power Control Station (PCS) is operating properly:

1. Make note of any lights that are illuminated or any messages being

issued by your PCS.

2. Determine if the charge connector is properly inserted in the vehicle

inlet and locked in place.

3. Is the protection light illuminated? If yes, your vehicle may have

undergone a series of faults which forced the PCS to terminate the

charge process.

• Push the stop button.

• Unplug the PCS charge connector from the vehicle inlet, to clear the

fault.

• Inspect the charge cable and connector for any signs of possible

damage (i.e. cuts, tears or breaks in the cable insulation). If damage is

found, stop any further attempts to charge the vehicle and call the

PCS manufacturer for repair.

• If the charge cable and connector are undamaged, reconnect the

vehicle. Is the charge interrupt light illuminated or flashing? Consult

your authorized Ranger EV dealer to determine possible fault.

4. Is the service light illuminated? If yes,

• Disconnect the PCS charge connector from the vehicle inlet.

• Turn off the power to your PCS at the service or disconnect panel.

Turning off the power may allow the PCS to clear the fault.

• Turn the power back on and reconnect the PCS to the vehicle. Is the

service light still illuminated? If so, call the PCS manufacturer for

repair or replacement.

• Are the ready or charging lights illuminated? If yes, your PCS is

operating correctly. Consult your authorized Ranger EV dealer to

determine vehicle fault.

19

Page 20

Charging

• If turning the PCS power on and off or unplugging and plugging the

charge connector in the vehicle inlet does not cause any of the lights

to illuminate on the PCS, the PCS has either failed or has a damaged

charge cord. Call the PCS manufacturer for repair or replacement. The

toll free number is located on the PCS.

The Ranger Electric Vehicle should be connected to a PCS

whenever it is not being driven.

Battery pack heating/cooling system (lead-acid type)

The battery pack assembly contains 39 eight-volt batteries, wiring, a fan

for ventilation and cooling, a control system and optional heaters for cold

weather climates. These components work automatically when the

vehicle is on-plug charging, and are monitored by the battery pack

control system. Heating and cooling do NOT occur key OFF and off-plug.

The systems are designed to maintain battery pack temperatures when

on-plug as well as during the drive cycle, and may not be able to heat or

cool batteries that have reached excessive temperatures.

Battery temperatures tend to be warmer than outside temperature if driven

and fully charged each day. If left off-plug, the batteries will eventually

equalize to outside underbody temperature, although this process can take

several days to occur. Extended periods off-plug in cold outdoor

temperatures can cause the batteries to take several days to warm up.

The heaters maintain the battery pack at approximately 20° (68°F) and

are effective to at least –20°C (–4°F). The cooling fan utilizes outside air,

and therefore cooling effectiveness depends upon the temperature

difference between the batteries and outside air. The cooling system

works to maintain the batteries at approximately 35°C (95°F).

Equalization

The battery control system will periodically equalize the charge in the

batteries, which smooths out battery-to-battery differences in the ability to

deliver energy. This results in optimum range and battery life. Equalization

is automatically performed approximately every three weeks. The fuel

gauge will indicate if insufficient charge time has been allowed.

The Ranger Electric Vehicle should be connected to a PCS

whenever it is not being driven.

20

Page 21

Charging

Battery pack heating/cooling system (nickel metal hydride type)

The battery pack assembly contains 25 twelve-volt batteries, wiring, two

fans for ventilation and cooling and a control system. Following a

complete charge, battery heating is accomplished by periodically

overcharging the batteries to maintain a minimum acceptable

temperature. These components work automatically when the vehicle is

on-plug charging, and are monitored by the battery pack control system.

Heating and cooling do NOT occur key OFF and off-plug. The systems

are designed to maintain battery pack temperatures when on-plug as well

as during the drive cycle, and may not be able to heat or cool batteries

that have reached excessive temperatures.

Battery temperatures tend to be warmer than outside temperature if

driven and fully charged each day. If left off-plug, the batteries will

eventually equalize to outside underbody temperature, although this

process can take several days to occur. Extended periods off-plug in cold

outdoor temperatures can cause the batteries to cool to below –25°C

(–13°F) and prevent both charging and self-heating.

The Ranger Electric Vehicle should be connected to a PCS

whenever it is not being driven.

Battery self-heating following a complete charge will maintain the battery

at approximately –10°C (14°F). The cooling fan utilizes outside air, and

therefore cooling effectiveness depends upon the temperature difference

between the batteries and outside air. The cooling system works to

maintain the batteries at approximately 25°C (77°F).

Equalization

The battery control system will periodically equalize the charge in the

batteries, which smooths out battery-to-battery differences in the ability

to deliver energy. This results in optimum range and battery life.

Equalization is automatically performed approximately every three

weeks. The fuel gauge will indicate if insufficient charge time has been

allowed.

The Ranger Electric Vehicle should be connected to a PCS

whenever it is not being driven.

21

Page 22

Charging

Partial recharges

A partial recharge is charging the battery pack to less than 100% state of

charge and can be performed occasionally without loss of range or

performance. However, long term multiple partial charges tend to create

imbalances in battery-to-battery state of charge and are strongly

discouraged. Usage patterns should be planned to include a full recharge

each time the vehicle is discharged. On vehicles equipped with the

nickel-metal hydride drive batteries, a full discharge is recommended

periodically to minimize battery memory effect.

22

Page 23

POSITIONS OF THE IGNITION SWITCH

1. ACCESSORY allows the

accessories such as the radio to

operate while the motor is not

powered up.

2. LOCK locks the steering wheel

gearshift lever. Allows key removal.

LOCK

3. OFF disconnects all high-voltage

power from the traction battery.

ACCESSORY

4. ON, warning lights momentarily

illuminated. Key position when driving.

5. START powers up the motor and

turns the Motor Enable Gauge to

the ON position. Powers up all

high-voltage power from the drive

battery.

STARTING THE RANGER ELECTRIC VEHICLE

1. If connected, disconnect the PCS

plug from the charge inlet and close

the charge inlet access door.

Starting

ON

OFF START

ON

OFF

The car will not start until the plug is removed.

23

Page 24

Starting

1. Make sure all vehicle occupants

have buckled their safety belts. For

more information on safety belts

and their proper usage, refer to the

seating and safety restraints chapter

in the Ranger owner guide.

1. Make sure the parking brake is

set.

2. Make sure the gearshift lever is in

P (Park).

3. Turn the key to the START

position and release. The Motor

Enabled gauge will point to the ON

position, indicating the vehicle is on.

4. Check the drive Battery State of

Charge gauge to confirm that the

drive battery is charged sufficiently

for the planned trip.

24

ON

OFF

F

E

Page 25

5. Pull the release lever to release

the parking brake. The Ranger

electric vehicle is now ready to be

driven.

Starting

25

Page 26

Driving

REGENERATIVE BRAKING

Your Ranger Electric Vehicle uses a unique feature known as

regenerative braking. This is used to simulate the engine braking of an

internal combustion engine and assist the standard brake system while

recovering some of the energy of motion back into the battery.

The standard brake system is designed to fully stop the truck if

regenerative braking is not available.

Once the accelerator pedal is released, the vehicle automatically

decelerates slowly. This deceleration is caused by using the spinning

motor as a generator to create electrical current. This recharges the

traction battery and slows the vehicle. In effect, once the accelerator

pedal is released, the motor changes from an energy user to an energy

producer. When the battery is almost fully charged, the amount of

regenerative braking is limited to avoid overcharging.

Regenerative braking does not take the place of the standard friction

brakes; it only assists them. Regenerative braking has also been designed

to interact with the anti-lock brake system (ABS). Regenerative braking

is disabled when the ABS is activated or the battery is fully charged.

ANTI-LOCK BRAKE SYSTEM (ABS)

A noise from the hydraulic pump motor and pulsation in the brake pedal

may be observed during ABS braking events. Pedal pulsation coupled

with noise while braking under panic conditions or on loose gravel or wet

snowy roads is normal and indicates proper functioning of the brake

system. If the vehicle has continuous vibration or shudder while braking,

felt mainly in the steering wheel, the vehicle most likely needs service.

The ABS operates by detecting the onset of wheel lockup during brake

applications and compensating for this tendency.

ABS warning lamp

The ABS warning lamp in the

instrument cluster illuminates if an

ABS fault is detected.

26

ABS

Page 27

Driving

An ABS fault will also illuminate the

BRAKE warning lamp. The base

hydraulic brake system will still be

effective. Have your vehicle serviced

as soon as possible.

Using ABS

• In an emergency or when maximum efficiency from the ABS is

required, apply continuous full force on the brake pedal. The ABS will

be activated immediately (thus allowing you to retain full steering

control of your vehicle) and (providing there is sufficient space) will

enable you to avoid obstacles and bring the vehicle to a controlled

stop.

• We recommend that you familiarize yourself with this braking

technique. Avoid, however, taking any unnecessary risks.

• Regenerative braking is disabled while ABS is active allowing ABS full

control.

STEERING

Your Ranger Electric Vehicle has variable assist power steering. The

power steering uses energy from the battery to help steer your vehicle.

If the amount of effort needed to steer your vehicle changes at a

constant speed, have the power steering system checked. If the power

steering system breaks down (or if the vehicle is turned off), you can

steer the vehicle manually, but it takes more effort.

Avoid holding the steering wheel to the extreme right or left for more

than five seconds if the vehicle is running.

When starting the vehicle at extremely cold temperatures

(-20°C[–4°F]), a 10–second delay will occur prior to power

steering pump start-up. This will result in a delay of power

steering assist during initial start-up.

!

BRAKE

27

Page 28

Driving

TRANSAXLE OPERATION

Your vehicle is equipped with a brake shift interlock that prevents

shifting of the gearshift lever out of park unless the foot brake is applied.

Step on the brake pedal and pull the gearshift lever towards you and

downward to move the gearshift lever.

Hold the brake pedal down while you move the gearshift lever

from P (Park) to another position. If you do not hold the brake

pedal down, your vehicle may move unexpectedly and injure someone.

P (Park)

Always set the parking

brake fully and make sure

the gearshift is latched in P

(Park). Turn off the ignition

whenever you leave your vehicle.

Always come to a complete stop before shifting into P (Park). Make sure

the gearshift lever is in P (Park).

R (Reverse)

With the gearshift lever in R

(Reverse), the vehicle will move

backward. Always come to a

complete stop before shifting into and out of R (Reverse). Regenerative

braking is applied in reverse too, at a level similar to the D (Drive) gear.

When the drive battery is almost fully charged, the amount of

regenerative braking is limited to avoid overcharging.

N (Neutral)

With the gearshift lever in N

(Neutral), the vehicle can be started

and is free to roll. Hold the brake

pedal down while in this gear to prevent movement.

28

Page 29

Driving

D (Drive)

With the gearshift lever in D

(Drive), the vehicle will move

forward. Top speed is limited to

121 km/h (75 mph). The transaxle operates in forward gear. This

selection is recommended for highway operation. Deceleration from

regenerative braking is commanded when the driver lifts off on the

accelerator pedal or when the brake pedal is pressed. However, when the

battery is almost fully charged, the amount of regenerative braking is

limited.

E (Economy)

With the gearshift lever in E

(Economy), the Ranger operates as

in drive, but the effects of

regenerative braking are increased and top speed is limited to 105 km/h

(65 mph). This selection is recommended for urban operation when

extended driving range is desired. The economy mode is used to

maximize the vehicle’s range. A stronger deceleration from regenerative

braking results from releasing the accelerator pedal. In this regard, it

feels similar to low gear on a typical transmission. When the battery is

almost fully charged, the amount of regenerative braking is limited.

Low charge

As the Ranger Electric Vehicle is

driven, the Battery State of Charge

Gauge indicates the battery’s

remaining charge like a fuel gauge

does on a conventional

gasoline-powered vehicle. When the

gauge approaches the Empty (E)

position, the vehicle should be

connected to a PCS before the drive

battery is completely drained.

If the Ranger is driven while the Battery State of Charge Gauge reads E,

there are two warning lights that illuminate in stages to alert the driver

of the vehicle’s condition.

E

F

29

Page 30

Driving

This is the order of what the driver will see:

1. At a 10% battery state of charge,

the low fuel lamp illuminates.

2. At a 0% battery state of charge, the low fuel lamp flashes. Driving the

vehicle below 0% will damage vehicle systems.

3. The power limit lamp illuminates

to indicate that the vehicle’s

performance is being limited to

conserve remaining battery power.

4. The power limit lamp flashes to indicate that the vehicle’s performance

has been further limited.

Driving the vehicle to complete discharge will damage the battery,

resulting in reduced battery life.

Driving on snow and ice

The regenerative braking system interacts with the ABS so if the wheels

begin to slide, ABS will activate and regenerative braking will be

disabled.

Vehicle coasting distance will increase when regenerative braking

is reduced by ABS activation.

Driving on hill or slope terrain

When driving down hills, regenerative braking may be used to maintain

speed while recovering energy similar to the way engine braking is

typically used. E (Economy) gear provides the maximum amount of

“engine braking,” like low gear in an automatic transmission.

Once the accelerator pedal is released, the vehicle automatically and

slowly decelerates. This deceleration is caused by using the spinning

motor as a generator to create electrical current. This recharges the

traction battery and slows the vehicle. In effect, once the accelerator

pedal is released, the motor changes from an energy user to an energy

producer.

When the battery is fully charged, regenerative braking is eliminated to

prevent overcharging of the traction batteries. As the traction batteries

state of charge begins to diminish with driving usage the amount of

regenerative braking is allowed to increase to assist the standard braking

system.

30

Page 31

Driving

Regenerative braking does not take the place of the standard friction

brakes; it only assists them. Regenerative braking has also been designed

to interact with the anti-lock brake system (ABS). Regenerative braking

is disabled when the ABS is activated.

TRAILER TOWING

The Ranger Electric Vehicle should not be used for towing a trailer.

TONNEAU COVER

The cover is intended to improve energy efficiency at freeway speeds.

Keep all the cover supports in place when the cover is installed to keep

water, snow or ice from accumulating in the center and possibly

damaging the cover.

ENERGY TIPS

The Ranger Electric Vehicle has a customer range of approximately

80 kilometers (50 miles) with the standard lead-acid type traction

battery or approximately 160 kilometers (100 miles) with the optional

nickel metal hydride type traction battery. This range is affected by the

use of vehicle accessories, driving habits and weather conditions. To

maximize the vehicle’s range, follow these steps:

• Use the E (Economy) gear.

• Keep the tires properly inflated to 350 kpa (50 psi).

• Keep payloads as light as possible.

• Avoid frequent full throttle usage.

• Maintain a steady speed while driving.

• Cruise at moderate speeds.

• Select routes that minimize the number of starts and stops

encountered.

• Limit the use of max cooling or heating of the vehicle interior.

• Avoid hard acceleration and deceleration.

• Leave the tonneau cover installed on the bed.

In addition to these steps, connect the Ranger to a Power Control

Station (PCS) whenever it is not being driven. This will keep the

battery as charged as possible.

31

Page 32

Roadside emergencies

INERTIA SHUTOFF SWITCH

If the Power Reset Lamp

illuminates, it indicates that the

inertia shutoff switch has been

activated. If there is no damage to

the vehicle, reset the switch to reactivate the high-voltage power systems

and restart the vehicle.

The inertia shutoff switch is located

by the passenger kick panel. If there

is damage to the vehicle, have the

vehicle towed to an authorized Ford

EV repair facility.

32

Page 33

Roadside emergencies

PASSENGER COMPARTMENT FUSE PANEL

The fuse panel is on the left-hand

side of the instrument panel facing

the driver side door. Pull the panel

cover outward to access the fuse.

To remove a fuse, use the fuse

puller provided on the fuse panel

cover.

1234

5678

9101112

14 15 16

13

18 19 20

17

22 23 24

21

26

25

27 28

30

29

31

33

34

36

32

35

33

Page 34

Roadside emergencies

The passenger compartment fuse panel fuses are coded as follows:

Fuse/relay

location

1 10 Instrument cluster

2 7.5 Driver air bag module

3 — Not used

4 10 Left headlamp

5 7.5 Data link connector (DLC)

6 — Not used

7 7.5 Exterior lighting

8 10 Right headlamp

9 10 Traction inverter module (TIM)

10 7.5 Generic electronic module (GEM), shift lock

11 7.5 Traction inverter module (TIM)

12 — Not used

13 10 Brake on/off (BOO) relay, brake on/off

14 10 ABS

15 7.5 Main light switch, instrument cluster

16 30 Windshield wiper motor, windshield wiper

17 10 Cigar lighter

18 — Not used

19 15 Steering wheel sensor, interface adapter

20 10 Radio, generic electronic module (GEM)

21 15 Turn signal flasher relay

22 15 Turn signal flasher relay, multi-function

23 15 Main light switch

24 7.5 Traction inverter module (TIM)

Fuse amp

rating

Description

actuator

(BOO) switch

relays

assembly (IAA) module, contactor box,

battery controller module (BCM), power

steering controller assembly

switch

34

Page 35

Roadside emergencies

Fuse/relay

location

25 7.5 Generic electronic module (GEM)

26 15 Backup lamps

27 10 Battery saver realy, dimmer module, interior

28 7.5 Generic electronic module (GEM)

29 10 Radio

30 — Not used

31 — Not used

32 — Not used

33 15 Highbeam headlamp

34 — Not used

35 — Not used

36 — Not used

LOW VOLTAGE POWER DISTRIBUTION BOX

The power distribution box is

located in the underhood

compartment near the auxiliary

battery. The power distributon box

contains high-current fuses that

protect your vehicle’s main electrical

systems from overloads.

Fuse amp

rating

Description

lamps relay, generic electronic module

(GEM)

Always disconnect the battery before servicing high current

fuses.

35

Page 36

Roadside emergencies

Always replace the cover to the power distribution box before

reconnecting the auxiliary battery or refilling fluid reservoirs.

14

610

1

2

3

4

5

711

812

913

15

16

17

23

18

19

24

20

25

21

26

22

29

30

27

31

28

32

33 37

35

3634

38

The high-current fuses are coded as follows:

Fuse/relay

location

Fuse amp

rating

Description

1 MAXI 50 Fan speed relays, cooling fan, interface

adapter assembly (IAA) module

2 MAXI 60 ABS

3 MAXI 30 ABS

4 MAXI 40 I/P fuse panel fuses 1,5,9,13,17,21,25 and 29

5 MAXI 50 Ignition switch

6 MINI 10 Interface adapter assembly (IAA) module

7 MINI 10 Contactor box

8 MINI 15 Inertia switch, contactor box

9 MINI 10 Driver air bag module

10 MINI 20 Vacuum relay, vacuum pump

11 MINI 10 Battery controller module (BCM)

12 MINI 10 Horn relay, horn switch, horn

13 MINI 30 Power point

14 MINI 15 Cooling/venting blower relay, battery control

module (BCM), cooling/venting blower

36

Page 37

Roadside emergencies

Fuse/relay

location

15 MINI 20 I/P fuse panel fuses 23 and 27

16 — Not used

17 MINI 20 Battery charger

18 — Not used

19 MAXI 40 Heater blower motor relay, heater blower

20 MAXI 20 Coolant pump relay, coolant pump

21 MAXI 20 Oil pump relay, transaxle oil pump

22 MAXI 30 Headlamps, multi-function switch

23 — Not used

24 — Not used

25 MINI 5 ABS active signal

26 J50 Windshield wiper park relay

27 J50 Brake on/off (BOO) relay

28 J50 Windshield wiper hi/low relay

29 — Not used

30 — Not used

31 — Not used

32 150 Coolant pump relay

33 — Not used

34 J50 Vacuum pump relay

35 J50 Horn relay

36 J50 Windshield washer pump relay

37 150 Blower motor relay

38 — Not used

Fuse amp

rating

Description

motor, interface adapter assembly (IAA)

37

Page 38

Roadside emergencies

CHANGING TIRES

If you get a flat tire while driving, do not apply the brakes heavily.

Instead, gradually decrease your speed. Hold the steering wheel firmly

and slowly move to a safe place on the side of the road.

Conventional spare tire information

If you have the optional spare tire, you can use the spare as a regular

tire. The spare is identical to the other tires on your vehicle.

Your Ranger EV is equipped with a low rolling resistance high pressure

designed tire to extend vehicle range. Only the same type of tire

should be used as a replacement.

Location of the spare tire and tools

The spare tire and tools for your vehicle are stowed in the following

locations:

Tool Location

Spare tire In the pickup bed

Jack, jack handle,

wheel nut wrench

Removing the spare tire

1. Position or remove the tonneau cover to gain access to the spare tire.

2. Fold the passenger seat back fully forward.

3. Remove the jack handle and lug wrench from the clips under the jack.

4. Remove the jack from the carrier assembly.

5. Assemble the jack handle to the lug wrench as shown in the

illustrations.

When connecting the jack handle, assemble the following:

• one handle extension and one

typical extension. To assemble,

slide parts together. To

disconnect, depress button and

pull apart.

Behind the passenger seat

38

Page 39

• one wheel nut wrench. Depress

button and slide together.

6. Remove the spare tire security

lock and cable.

7. Remove the retaining bolt and

retainer. If you cannot remove the

bolt by hand, remove it using the

jack handle.

8. Remove the spare tire.

Roadside emergencies

Tire changing procedure

1. Park on a level surface, activate

hazard flashers, and place gearshift

lever in P (Park).

39

Page 40

Roadside emergencies

2. Set the parking brake.

3. Block the diagonally opposite

wheel.

4. Insert tapered end of the lug wrench behind center caps and twist

them off.

5. Loosen each wheel lug nut

one-half turn counterclockwise, but

do not remove them until the wheel

is raised off the ground.

6. Position the jack as shown below and turn the jack handle clockwise

until the tire is a maximum of 25 mm (1 in) off the ground.

Never position a jack or hoist underneath the traction battery

pack. Doing so may result in damage to your vehicle.

40

Page 41

Roadside emergencies

• Front

• Rear

7. Remove the wheel lug nuts with the lug wrench.

8. Replace the flat tire with the

spare tire, making sure the valve

stem is facing outward. Reinstall the

lug nuts until the wheel is snug

against the hub. Do not fully tighten

the lug nuts until the wheel has

been lowered to the ground.

3

1

4

5

9. Lower the wheel by turning the jack handle counterclockwise.

10. Install the wheel lug nuts with the lug wrench.

11. Secure the flat tire.

12. Install the tonneau cover.

13. Stow the jack and lug wrench. Make sure the jack is snug to the wire

clamp by raising the jack until tight.

14. Unblock the wheels.

2

41

Page 42

Roadside emergencies

JUMP-STARTING THE AUXILIARY BATTERY

The Ford Electric Ranger can be jump-started like a gasoline-powered

Ranger. Note that if the traction battery is dead, jumping the auxiliary

battery will not fix the problem. Look at the battery state of charge

gauge to verify the traction battery is not discharged. The auxiliary

battery might be dead from accessories that were left on accidentally,

like the headlights, or dome lamp.

Preparing your vehicle to be jump started

1. Use only a 12–volt supply to start your vehicle. If you connect your

battery to a 24–volt power supply, you can damage your electrical

components.

2. Do not disconnect the battery of the disabled vehicle as this could

damage the vehicle’s electrical system.

3. Park the booster vehicle close to the hood of the disabled vehicle

making sure they do not touch. Set the parking brake on both vehicles

and stay clear of moving parts.

4. Check all battery terminals and remove any excessive corrosion before

you attach the battery cables.

Connecting the jumper cables

1. Position the vehicles so that they

do not touch one another.

2. Switch off the “ignition”. Switch

off any unnecessary electrical

equipment.

3. Connect the positive (+) terminal

of the discharged battery (1) to the

positive (+) terminal of the booster

battery (2).

1

4

42

3

2

Page 43

Roadside emergencies

4. Connect one end of the second

lead to the negative (-) terminal of

the booster battery (3) and the

other end to the module mounting

stud (4), not to the negative (-)

terminal of the discharged battery.

5. Make sure that the jump leads are

clear of moving parts.

Do not connect the end of

the second cable to the

negative ([-]) terminal of the

battery to be jumped. A spark may

cause an explosion of the gases

that surround the battery.

Starting your vehicle

1. Turn the “ignition” ON and start the booster vehicle.

2. Turn the “ignition” ON and start the vehicle with the discharged

battery.

3. Once the vehicle has been started, allow the vehicle to run for

approximately 5 minutes before disconnecting the leads to insure the

auxiliary battery is completely charged back up.

The gases around the battery can explode if exposed to flames,

sparks, or lit cigarettes. An explosion could result in injury or

vehicle damage.

Batteries contain sulfuric acid which burns skin, eyes, and

clothing.

43

Page 44

Roadside emergencies

Removing the jumper cables

1. Remove the jumper cables in

reverse order. Take the cable off the

metallic surface (1) first, followed

by the cable on the negative (-)

booster battery terminal (2).

2. Remove the cable from the

positive (+) terminal of the booster

battery (3) and then the discharged

battery (4).

4

1

2

3

44

Page 45

Roadside emergencies

WRECKER TOWING

There are three approved towing methods:

• Front-wheel lift towing (transaxle in Neutral [N]). Do not tow the

vehicle more than 80 km (50 miles) when front-wheel lift towing.

• Rear-wheel lift towing.

• Flatbed transporting.

If you need to have your vehicle towed, contact a profession towing

service or your roadside assistance center.

Do not tow with slingbelt equipment. Ford Motor Company has not

developed or approved a slingbelt towing procedure.

When calling for a tow truck, tell the operator what kind of vehicle you

have.

45

Page 46

Maintenance and care

SERVICE RECOMMENDATIONS

This vehicle should only be serviced by a Ford trained electric vehicle

technician.

Scheduled maintenance chart

Item Interval

1

yr.2yrs.3yrs.4yrs.5yrs.6yrs.7yrs.8yrs.9yrs.10yrs.

Rotate tires

5000 miles

MAX

Inspect

disc brake

system,

lubricate

caliper

slides

Climate

control

filter (More

frequent

changes

may be

necessary

in dusty

and dirty

conditions)

Replace

vacuum

pump

2A451

Inspect and

lubricate

front wheel

bearings

Inspect

parking

brake

system

xxxxxxxxxx

xxxxxxxxxx

xxxxxxxxxx

xx

xxx

xxx

46

Page 47

Maintenance and care

Item Interval

1

yr.2yrs.3yrs.4yrs.5yrs.6yrs.7yrs.8yrs.9yrs.10yrs.

Inspect

cooling

system

Replace

transaxle

fluid*

Inspect

power

steering

fluid

Inspect

brake fluid

*Replace transaxle fluid every 3 years or 36,000 miles, whichever comes

first.

HOW TO OPEN THE HOOD

1. Inside the vehicle, pull the hood

release handle located under the

bottom right of the steering wheel.

xxxxxxxxxx

xxx

xxxxxxxxxx

xxxxxxxxxx

2. Go to the front of the vehicle and release the auxiliary latch that is

located under the front center of the hood. Lift the hood and support it

with the prop rod.

47

Page 48

Maintenance and care

Identifying components in the underhood compartment:

1

2

3

1. Windshield washer fluid reservoir

2. Coolant reservoir

3. Power steering fluid reservoir

4. Auxiliary battery

5. Brake fluid reservoir

The underhood compartment contains many high-voltage components

and wiring. Do not attempt to service any of these components. Service

must be performed by qualified personnel only.

The high-voltage wiring is

covered in orange convolute for

easy identification. Underhood

high voltage components have

warning labels with one or all of

the following icons.

5

4

48

Page 49

Maintenance and care

WINDSHIELD WASHER FLUID

Check the washer fluid periodically.

If the level is low, add enough fluid

to fill the reservoir. In very cold

weather, do not fill the reservoir all

the way.

Do not put engine coolant

in the container for the

windshield washer fluid.

COOLANT

The EV Ranger is equipped with a

cooling system to cool running

temperatures of electrical

components and the electric drive

motor. Check the level of the

coolant in the reservoir at least once

a month. Be sure to read and

understand Precautions in this

chapter when servicing your vehicle.

If the coolant has not been checked

for a long period of time, the

coolant reservoir may eventually

empty. If this occurs, add coolant to

the coolant reservoir.

Automotive fluids are not

interchangeable; do not use coolant,

antifreeze or windshield washer fluid outside of its specified function and

vehicle location.

49

Page 50

Maintenance and care

Adding coolant

If sprayed on the windshield, coolant could make it difficult to see

through the windshield.

Add a 50/50 mixture of coolant and water to the coolant reservoir. DO

NOT ADD IT DIRECTLY TO THE RADIATOR. Add straight water only in

an emergency, and replace it with a 50/50 mixture of coolant and

distilled water as soon as possible.

Check the coolant level in the coolant recovery reservoir the next few

times you drive the vehicle. If necessary, add enough of a 50/50 mixture

of coolant and water to bring the liquid level to the fill line on the

reservoir.

Use Ford Extended Life Engine Coolant F6AZ-19544–AA or an

equivalent DEX-COOL coolant or a coolant meeting Ford specifications

WSS-M97B44–D. Ford Extended Life Engine Coolant is an orange

colored silicate-free coolant that does not need to be replaced for the life

of your vehicle.

Do not add conventional, green coolant or recycled coolant to

your vehicle if originally equipped with orange coolant.

The use of an improper coolant may void your warranty of your vehicle’s

cooling system.

Always dispose of used automotive fluids in a responsible manner. Follow

your community’s regulations and standards for recycling and disposing

of automotive fluids.

Coolant refill capacity

Have your dealer check the cooling system for leaks if you have to add

more than a litre (quart) of coolant per month.

Severe winter climate

If you drive in extremely cold climates (less than –36°C [-33°F]), it may

be necessary to increase the coolant concentration above 50%. Refer to

the chart on the coolant container to ensure the coolant concentration in

your vehicle is such that the coolant will not freeze at the temperature

level in which you drive during the winter months. Never increase the

coolant concentration above 60%. Leave a 50/50 mixture of coolant and

water in your vehicle year-round in non-extreme climates.

50

Page 51

Maintenance and care

POWER STEERING FLUID LEVEL

Check the power steering fluid at

least twice a year. If adding fluid is

necessary, use only MERCONt ATF.

1. Turn the “ignition” ON.

2. Turn the steering wheel left and

right to the steering stops several

times. Do not keep wheel at steering

stops longer than 5 seconds.

3. Turn the “ignition” OFF.

4. Check the fluid level. It should be

between the MAX and MIN lines on

the reservoir. Do not add fluid above

the MAX level.

5. If the fluid is low, add fluid.

BRAKE FLUID

Checking and adding brake fluid

Brake fluid should be checked and

refilled as needed at least once each

year:

1. Check the reservoir cap before

removal to prevent dirt or water

from entering the reservoir.

2. Visually inspect the fluid level.

3. If necessary, add brake fluid until the level reaches MAX. Do not fill

above this line.

Use only a DOT 3 brake fluid certified to meet Ford specifications. Refer

4.

to Lubricant specifications in the Capacities and specifications chapter.

Brake fluid is toxic.

If you use a brake fluid that is not DOT 3, you will cause

permanent damage to your brakes.

51

Page 52

Maintenance and care

AUXILIARY BATTERY

Your vehicle is equipped with a sealed maintenance-free battery.

For longer, trouble-free operation, keep the top of the battery clean and

dry. Also, make certain the battery cables are always tightly fastened to

the battery terminals.

If you see any corrosion on the battery or terminals, remove the cables

from the terminal(s) and clean with a wire brush. You can neutralize the

acid solution with a solution of baking soda and water. Reinstall the

cables when you are done cleaning them, and apply a small quantity of

grease to the top of each terminal to help prevent corrosion.

TRACTION BATTERY PACK ASSEMBLY

No regular maintenance, other than regular charging is required.

The traction battery pack assembly is located underneath the vehicle

between the wheel base and frame rails. The battery pack assembly

contains wiring, a fan for ventilation and cooling, and a control system.

The standard lead acid battery pack contains 39 eight-volt batteries and

optional heater for cold weather climates. The optional nickel metal

hydride battery pack contains 25 twelve-volt batteries, and an additional

cooling system exhaust fan. The traction battery provides energy to

propel the vehicle and also maintains energy for accessory functions. The

battery pack assembly is a 2,000–pound unit lead-acid type or

1,300–pound unit nickel metal hydride type.

Never position a jack or hoist underneath the traction battery

pack. Doing so may result in damage to your vehicle.

This battery pack should only be serviced by an authorized

electric vehicle technician. Improper handling can result in

personal injury or death.

52

Page 53

Maintenance and care

SERVICING YOUR TIRES

Checking the tire pressure

• Use an accurate tire pressure gauge.

Check the tire pressure when tires are cold, after the vehicle has been

•

parked for at least one hour or has been driven less than 5 km (3 miles).

• Check and adjust tire pressure to recommended specifications found

on the Safety Compliance Certification Label located on the driver

door pillar every 30 days.

Note: Driving the Electric Ranger with tires below recommended

inflation pressure will significantly affect range between charges.

Tire pressure will increase/decrease with every 10°F change in

outside air temperature, decreasing with temperature decreases.

Tire rotation

Because your vehicle’s tires perform different jobs, they often wear

differently. To make sure your tires wear evenly and last longer, rotate

them every 5,000 miles or six months. If you notice that the tires wear

unevenly, have them checked.

• Four-tire rotation.

53

Page 54

Maintenance and care

• Five-tire rotation (if equipped)

Replacing the tires

Replace the tires when the wear

band is visible through the tire

treads.

Your Ranger Electric Vehicle is equipped with a low rolling resistance

high pressure designed tire to extend vehicle range. Only the same

type of tire should be used as a replacement.

When replacing full size tires, never mix radial, bias-belted, or

bias-type tires. Use only the tire sizes that are listed on the tire

pressure decal. Make sure that all tires are the same size, speed rating,

and load-carrying capacity. Use only the tire combinations

recommended on the decal. If you do not follow these precautions,

your vehicle may not drive properly and safely.

54

Page 55

Maintenance and care

Make sure that all replacement tires are of the same size, type,

load-carrying capacity and tread design (e.g., “All Terrain”, etc.),

as originally offered by Ford.

Failure to follow these precautions may adversely affect the

handling of the vehicle and make it easier to lose control and roll

over.

SNOW TIRES AND CHAINS

The use of snow tires and chains is strongly discouraged on the Ranger

Electric Vehicle.

55

Page 56

Capacities and specifications

MOTORCRAFT PART NUMBERS

Component Part Number

Climate control air filter F8YZ-19N619-AA

Auxiliary battery BXT-59

REFILL CAPACITIES

Fluid Ford part name

Brake fluid Ford high

Power steering

fluid

Coolant Ford extended life

Windshield washer

fluid

FLUID SPECIFICATIONS

Fluid

Brake fluid High

Power steering

fluid

Coolant Ford extended

performance DOT

3 motor vehicle

brake fluid

Motorcraft

MERCONt AT F

engine coolant

(New for 1999

model year)

Ultra-clear

windshield

Ford part

name or

equivalent

performance

DOT 3 motor

vehicle brake

fluid

Motorcraft

MERCONt AT F

life engine

coolant (New for

1999 model

year)

Vehicle

type

All Fill to line in

All Fill to line in

All Fill to line in

All Fill to line in

Ford part

number

C6AZ-19542-AB WSA-M6C25-A

XT-2-QDX MERCONt

F6AZ-19544-AA WSS-M97B44-D

Capacity-litres

(quarts)

reservoir

reservoir

reservoir

reservoir

Ford

specification

and DOT 3

WSA-M2C195-A

56

Page 57

Capacities and specifications

Fluid

Windshield

washer fluid

Transaxle fluid Tribolube - L-6

MOTOR DATA

Motor Data

Horsepower 67 kw (90 hp)

Torque 190 Nm (140 lb/ft)

Traction battery modules Standard Lead-acid type,

Ford part

name or

equivalent

Ultra-clear

windshield

concentrate

(Pro Gear 21)

Optional Nickel metal

Ford part

number

C9AZ-19550-AC

or BC

F8AZ-19M544-A

Ford

specification

ESR-M17P5-A

312 volts,

39 (8 volts each)

hydride, 300 volts,

25 (12 volts each)

57

Page 58

Accessories

MOBILE RADIO INSTALLATION GUIDELINES

General information

Ford Motor Company vehicles are designed and tested for safe operation

with properly installed and properly used land mobile/amateur radio

communications equipment with up to 100 Watt transmitter power. This

resource is provided as a supplement to the radio manufacturer’s

installation communication equipment in Ford vehicles. Additional

sources of information are included in this resource. Special design

considerations are incorporated into all Ford vehicle electronic systems

to provide immunity to radio frequency signals. To maintain compatibility

with vehicle electronic systems, mobile radio and telephone equipment

must be properly installed, by trained personnel with experience in this

area.

The following guidelines should be observed:

• The antenna cable should be a fully shielded coaxial cable, and kept as

short as practical. Avoid routing the antenna cable in parallel with

vehicle wiring over long distances.

• Carefully match the antenna and cable to the radio to achieve a low

Standing Wave Ratio (SWR) and to avoid RF currents on the antenna

cable shield. The procedure to accomplish this is described in the

section “Antenna Tuning” below.

Radio transmitters are regulated by the Federal Communications

Commission (FCC) in the United States. Compliance with FCC

regulations is the responsibility of the manufacturer and/or user of the

transmitter equipment and not Ford Motor Company.

58

Page 59

Accessories

Radio wiring and routing

Power connections should be made directly to the battery and fused as

close to the battery as possible.

On the Ranger Electric Vehicle make the connections as follows:

• For the +12V circuit, connect a

weatherproof fuse holder to the

end of the 10 gauge circuit pigtail

that is taped into the harness at

the auxiliary battery positive

terminal. Route and secure the

wire as close as possible to the

vehicle body from the battery to

the transceiver. Pass the wire

from the engine to passengers

compartment through a hole in

the accelerator’s cable hole plug.

Use care when routing this wire to

avoid chafing or pinching. Seal the

hole to prevent moisture intrusion

into the passenger compartment.

59

Page 60

Accessories

• Connect to the auxiliary battery

ground connection using a ring

terminal at the ground M6

weldnut behind the LH (driver’s)

side kick panel.

Maintain as great a distance as

possible between mobile radio

power leads and the vehicle’s wiring.

Avoid running power leads in

parallel with vehicle wiring over long

distances.

Transceiver location

A transceiver location should be selected that provides a solid mounting

point which does not interfere with the vehicle operator controls and

provides adequate ventilation. Do not mount any transceiver,

microphones, speakers, or any other item in the deployment path of the

airbag system.

Before using screws to mount the transceiver equipment, be sure to

check for vehicle wiring under the carpet or behind the instrument panel

which could be pinched, cut or otherwise damaged.

Antenna location and installation

Permanently installed sheet metal mount antennas are preferable over

magnetic, glass, or body lip mounts for anything other than low power or

temporary installations. Most of these alternate antennas can reflect

significant power back at the feed point. This reflected power could then

radiate from the feed line inside the passenger compartment and be

picked up by the vehicle wiring.

60

Page 61

Accessories

Mount the antenna only on the

center of the Ranger Electric

Vehicle roof if it is a sheet metal

mount antenna. Glass mounted

antennas should be mounted as high

as possible in the center of the rear

window.

Antenna Tuning: It is important that the antenna be tuned properly and

reflected power be kept to less than 10% (VSWR less than 2:1). Note:

Your installation should be checked periodically for proper SWR and any

signs of damage or deterioration to maintain proper operation with your

vehicle.

Antenna Cable Routing

Always use a high quality one piece coaxial cable (at least 95% shield

coverage). Connector quality and termination techniques are just as

important. The ARRL handbook provides excellent guidelines for

terminating coaxial cables.

The antenna cable should be treated in the same way as the control and

power cables. Avoid sharp edges and pinches and keep the cable as short

as possible. Also, avoid routing the antenna cable in parallel with vehicle

wiring over long distances. If it is necessary to cross over wiring, cross at

right angles.

Troubleshooting

Most interaction problems can be eliminated by following these

installation guidelines. If vehicle/radio interaction develops following

installation, the source of the problem should be identified prior to

further operation of the vehicle.

Possible causes of vehicle/radio interaction include:

• Antenna location (move antenna to a position on the vehicle roof)

• Antenna feed line routing (locate as far as possible from vehicle

electronics and wiring)

• Inadequate shielding or loose/corroded connectors associated with the

antenna feed line

• Mismatched antenna or high SWR

61

Page 62

Accessories

• Power feeds not connected directly to the vehicle battery

• Power feed routing (locate as far as possible away from vehicle

electronics and wiring)

If any vehicle/radio interaction problems exist after following these

guidelines, contact your radio equipment manufacturer for additional

assistance.

Additional sources of information

The American Radio Relay League, Inc. Technical Information Service

225 Main St, Newington, CT 06111 Phone: (860)594–0200/Fax:

(860)594–0259 email: http://www.arrl.org/tis

Radio Frequency Interference: How to Find It and Fix It ISBN:

0–87259–375–4

Giving Two-Way Radio Its Voice (booklet) Champion Spark Plug

Company Automotive Technical Services Dept. P.O. Box 910, Toledo, OH

43661

62

Page 63

Index

A

Air conditioning ............................9

B

Battery

auxiliary battery .......................52

battery pack heating/cooling

system (lead-acid type) ...........20

battery pack heating/cooling

system (nickel metal hydride

type) ..........................................21

equalization .........................20–21

Brakes ..........................................26

anti-lock .....................................26

anti-lock brake system (ABS)

warning light .............................26

fluid, checking and adding ......51