Page 1

2007 PCED On Board Diagnostics Introduction

Procedure revision date: 03/29/2006

Acronyms and Definitions

This acronyms and definitions listing contains technical terms applicable to Ford Motor Company

Note:

products. It is not intended to be an all-inclusive dictionary of components and their functions. If a detailed

description of a particular system or component is desired, refer to the applicable section within this PC/ED

Manual or refer to the Workshop Manual for the specific vehicle being repaired.

2V: Two valves per engine cylinder

3V: Three valves per engine cylinder

4V: Four valves per engine cylinder

A/C: Air Conditioning

A/CC: Air Conditioning Clutch

A/CCR: Air Conditioning Clutch Control Relay

ACCS: Air Conditioning Cycling Switch

ACDS: Air Conditioning Diagnostic Switch (refrigerant containment switch)

ACET: Air Conditioning Evaporator Temperature

ACP: Air Conditioning Head Pressure or A/C cycling switch input state

ACPSW: Air Conditioning Pressure Switch

ACPT: Air Conditioning Pressure Transducer (Switch)

A/D: Analog-to-Digital. Analog-to-Digital signal conversion.

AFCM: Alternative Fuel Control Module

AIR: Secondary Air Injection

AIR EVAL: Air System Evaluated. Displays a YES or NO status indicating whether the AIR System

has been evaluated for On Board Diagnostic (OBD) purposes.

AIRM: Secondary Air Pump Monitor

APP: Accelerator Pedal Position

ARB: Air Resource Board

ASCII: American Standard Code Information Interchange

ATDC: After Top Dead Center. The location of the piston after it has reached the top of its stroke.

Measured in degrees of crankshaft rotation.

BARO: Barometric Pressure

BJB: Battery Junction Box

BPA: Brake Pedal Applied

BPP: Brake Pedal Position

BPS: Brake Pedal Switch/Speed Control Deactivation

BTDC: Before Top Dead Center. The location of the piston before it has reached the top of its stroke.

Measured in degrees of crankshaft rotation.

CAC: Charge Air Cooler. A device which lowers the temperature of pressurized intake air.

Page 2

CAFE: Corporate Average Fuel Economy. A set of federal requirements and regulations which

govern fuel economy standards.

CAN: Controller Area Network

CCM: Comprehensive Component Monitor

CD A through J: Coil Driver 1 through 10

CGND: Case Ground. Provides a ground source for the PCM case.

CHT: Cylinder Head Temperature

CHTIL: Cylinder Head Temperature Indicator Lamp

CKP: Crankshaft Position

CL: Closed Loop. An operating condition or mode which enables operation based on sensor

feedback.

CMP, CMP1, CMP2: Camshaft Position. CMP1 and CMP2 on V engines where applicable.

CMS: Catalyst Monitor Sensor. The downstream HO2S.

CMVSS: Canadian Motor Vehicle Safety Standards

CO: Carbon Monoxide. A colorless, odorless, and toxic gas that is a component of auto exhaust

emissions.

CO 2 : Carbon Dioxide. A colorless, odorless gas that is a normal by-product of the combustion of

fuel.

CONT: Continuous Memory. The portion of keep alive memory (KAM) used to store DTCs generated

during the continuous memory self-test.

COP: Coil On Plug. Ignition coil on plug assembly.

CPP: Clutch Pedal Position

CT: Closed Throttle. A mode in which the PCM varies the pulse width of the fuel injectors to obtain

the air/fuel mixture appropriate for closed throttle operation.

CTO: Clean Tach Output. Signal used to drive the instrument panel tachometer.

CV: Canister Vent Solenoid. A solenoid which seals the evaporative emission (EVAP) system from

the atmosphere during the EVAP monitor test.

DC: 1. Direct Current. Electric current flowing in one direction. 2. Duty Cycle. The voltage

measurement of ON time versus the full cycle period, expressed in percent.

DCL: Data Communication Link. A communication path between various in-vehicle electronic

modules.

DI: Distributor Ignition. A system in which the ignition coil secondary circuit is sequenced by a

distributor.

DIS: Distributorless Ignition System. A system in which the ignition coil secondary circuit is

sequenced without a distributor.

DLC: Data Link Connector. SAE standard J1962 connector providing access to vehicle diagnostic

information.

DMM: Digital Multimeter

DOHC: Dual Overhead Cam. An engine configuration that uses 2 camshafts positioned above the

valves.

DOL: Data Output Line. A circuit that sends certain information from the PCM to the instrument

cluster.

DPFE: Differential Pressure Feedback EGR. A system that uses a pressure transducer to control the

Page 3

operation of the exhaust gas recirculation (EGR) vacuum regulator solenoid.

DTM: Diagnostic Test Mode. A level of capability in an OBD system.

DTC: Diagnostic Trouble Code. An alpha/numeric identifier for a concern identified by the OBD

system.

E-85: Fuel containing 85% ethanol alcohol

ECT: Engine Coolant Temperature

ECU: Electronic Control Unit. A module that handles the control strategy and monitors system inputs

or outputs.

EEC: Electronic Engine Control

EEGR: Electric Exhaust Gas Recirculation System

EEPROM: Electrically Erasable Programmable Read-Only Memory. An electronic component in the

PCM that allows the electronic storage of information.

EGR: Exhaust Gas Recirculation. A process in which a small amount of exhaust gas is routed into the

combustion chamber.

EGRMC (1-4): Electric Exhaust Gas Recirculation Motor Control

EGRT: Exhaust Gas Recirculation Valve Temperature. A temperature sensor that is threaded into the

bottom of the intake plenum.

EI: Integrated Electronic Ignition. An electronic ignition system that has the ignition control module

(ICM) integrated into the PCM.

EI-HDR: Electronic Ignition-High Data Rate. Formerly known as Electronic Distributorless Ignition

System.

EMI: Electromagnetic Interference. Usually caused by ignition voltage spikes, solenoids, relay

operation, or noisy generator contacts.

EOL: End of Line. A system designed specifically for use at assembly plants to make sure all new

vehicles conform to design specifications.

EONV: Engine Off Natural Vacuum

EOT: Engine Oil Temperature

EPA: Environmental Protection Agency

E-Quizzer: Enhanced Quizzer

ESM: EGR System Module

ESOF: Electronic Shift-on-the-Fly

ETB: Electronic Throttle Body

ETC: Electronic Throttle Control

ETCREF: Voltage Reference (5V) for ETC (APP VREF, TP VREF).

EVAP: Evaporative Emissions. A system to prevent fuel vapor from escaping into the atmosphere.

EVAPCP: Evaporative Canister Purge Solenoid. A solenoid which controls the venting of fuel vapor

from the evaporative emissions canister into the intake manifold for combustion.

EVO: Electronic Variable Orifice

FCIL: Fuel Cap Indicator Lamp. Indicates that the fuel filler cap is not correctly installed.

FEAD: Front End Accessory Drive

FEPS: Flash EEPROM Programming Signal. An 18-volt DC signal input from the scan tool used by

the PCM to initiate programming.

FFV: Flexible Fuel Vehicle

Page 4

FLI: Fuel Level Input. Provides information on the amount of liquid fuel in the fuel tank. Used by the

EVAP monitor to calculate the fuel tank vapor volume. Displayed as a percentage.

FMEM: Failure Mode Effects Management. Operating strategy that maintains limited vehicle function

in the event of a PCM or EEC component failure.

FP: 1. Fuel Pump. Indicates whether the pump has been commanded ON or OFF by the PCM. 2.

Fuel Pump (Modulated). Fuel pump duty cycle percentage.

FPDM: Fuel Pump Driver Module. A module that controls the electric fuel pump.

FRP: Fuel Rail Pressure

FRPT: Fuel Rail Pressure Temperature

FSS: Fan Speed Sensor

FTP: Fuel Tank Pressure

FUEL PR: Fuel Pressure. Measurement of the force of the fuel delivered by the fuel pump.

FUELPW: Fuel Pulse Width. Displays the commanded pulse width at the time of the last data update.

FUELPW1: Fuel Injector Pulse Width #1. Corresponds to injectors normally affected by HO2S11.

FUELPW2: Fuel Injector Pulse Width #2. Corresponds to injectors normally affected by HO2S21.

FUELSYS: Fuel System Status (OPEN/CLOSED Loop). Formerly known as LOOP.

FWD: Front Wheel Drive

GND: Ground

GPM: 1. Grams per Mile. 2. Gallons per Minute.

GVW: Gross Vehicle Weight

GVWR: Gross Vehicle Weight Rating

HC: 1. Hydrocarbon. A by-product of combustion and a component of auto exhaust emissions. 2.

High Compression.

HLOS: Hardware Limited Operating Strategy. A mode of operation where the PCM uses fixed values

in response to internal PCM concerns in place of output commands.

HO: High Output

HO2S: Heated Oxygen Sensor. Provides information on rich or lean exhaust conditions to the PCM.

HTR11, HTR12, HTR13, HTR21, HTR22: HO2S Heater. Heater element for the HO2S sensor.

Hz: Hertz. Cycles per second.

IAC: Idle Air Control. Electrical control of throttle bypass air.

IAT: Intake Air Temperature

IAT2: Intake Air Temperature 2. Used on supercharged vehicles.

IC: Integrated Circuit. A small semi-conductor device capable of many separate circuit functions.

IFS: Inertia Fuel Switch

IMRC: Intake Manifold Runner Control. Controls or modifies airflow in the intake air system.

IMRCM: Intake Manifold Runner Control Monitor. Monitors the IMRC circuits for concerns.

IMTV, IMTV1, IMTV2: Intake Manifold Tuning Valve. Controls airflow through runners in a split intake

manifold.

INJ1, INJ2, INJ3, INJ4, INJ5, INJ6, INJ7, INJ8, INJ9, INJ10: Injector number or its signal output from

the PCM.

IPC: Independent Plausibility Checker

ISO: International Standards Organization

Page 5

KAM: Keep Alive Memory. A portion of the memory within the PCM that must have power even when

the vehicle is not operating.

KAPWR: Keep Alive Power. A dedicated and unswitched power circuit that maintains KAM.

KOEO Self-Test: Key On Engine Off self-test. A test of the EEC system conducted by the PCM with

power applied and the engine at rest.

KOER Self-Test: Key On Engine Running self-test. A test of the EEC system conducted by the PCM

with the engine running and the vehicle at rest.

Km/h: Kilometers per Hour

kPa: Kilopascal. Unit of pressure. 3.386 kPa equals 1 (in-Hg).

L: Liters. The unit of volume in the metric measuring system. One liter equals 1.06 quarts.

LEV: Low Emissions Vehicle

LONGFT: Long-Term Fuel Trim. Fuel flow adjustment determined by the PCM.

M-85: Fuel containing 85% methanol alcohol

MAF: Mass Air Flow

MAP: Manifold Absolute Pressure. The internal pressure of the intake manifold.

MFI: Multiport Fuel Injection. A fuel-delivery system in which each cylinder is individually fueled.

MIL: Malfunction Indicator Lamp. An indicator lamp alerting the driver of an emission related concern.

MISF: Misfire. Any event in the cylinder that causes a sudden change in acceleration of the

crankshaft.

MON: Motor Octane Number

MSOF: Manual Shift-on-the-Fly

MY: Model Year

NA: Naturally Aspirated. An engine that is not supercharged or turbocharged.

NC: Normally Closed

NGS: New Generation Self-Test Automatic Readout (STAR) tester

NO: Normally Open

NO X : Oxides of Nitrogen. Gasses formed at high combustion temperatures.

OASIS: On-line Automotive Service Information System

OBD, OBD-II: On Board Diagnostics, On Board Diagnostics Second Generation. A system that

monitors the PCM input and output control signals.

OCT ADJ: Octane Adjust. Compensating strategy that adjusts for changes in fuel octane.

OEM: Original Equipment Manufacturer

OHC: Overhead Cam. An engine configuration that uses a single camshaft positioned above the

valves.

OL: Open Loop. An operating condition based on instructions not modified by PCM feedback.

ORVR: On-Board Refueling Vapor Recovery

OSC: Output State Control

OSS: Output Shaft Speed

OTM: Output Test Mode

PATS: Passive Anti-Theft System

PCM: Powertrain Control Module. Formerly known as the electronic engine control (EEC) processor.

PCV: Positive Crankcase Ventilation. A system which allows the controlled flow of crankcase vapors

Page 6

into the combustion chamber.

PID: Parameter Identifier. Identifies an address in the PCM memory which contains operating

information.

PIP: Profile Ignition Pickup. Provides crankshaft position information for ignition synchronization.

PPM: Parts per Million. A measure used in emission analysis.

PROM: Programmable Read-Only Memory. Similar to ROM, except without program instructions.

PSP: Power Steering Pressure. Indicates the pressure in the power steering system.

PSPT: Power Steering Pressure Transducer

PTO: Power Take-Off

PW: Pulse Width. The length of time an actuator, such as a fuel injector, remains energized.

PWM: Pulse Width Modulation. Controls the intensity of an output by varying the signal duty cycle.

PWR GND: Power Ground. The main ground circuit in the EEC system.

RAM: Random Access Memory. Memory into which information can be written as well as read.

RF: Radio Frequency

RFI: Radio Frequency Interference

RFS: Returnless Fuel System

ROM: Read-Only Memory. Computer memory that can be accessed and used, but not altered.

RPM: Revolutions Per Minute

RTN: Return. A dedicated sensor ground circuit.

RWD: Rear Wheel Drive

SAE: Society of Automotive Engineers

SCB: Supercharger Bypass

SCBC: Supercharger Bypass Control. A system that allows manifold vacuum to be bled away from

the supercharger wastegate actuator to allow for maximum boost.

SFI: Sequential Multiport Fuel Injection. A multiport fuel delivery system in which each injector is

individually energized and timed relative to its cylinder intake event.

SHRTFT: Short-Term Fuel Trim. Fuel flow adjustment in response to the HO2S sensor(s) input during

closed-loop operation.

SIG RTN: Signal Return. A dedicated sensor ground circuit that is common to 2 or more sensors.

SOHC: Single Overhead Cam

TA: Traction Assist

TAC: Throttle Actuator Control

TACM, TACMP, TACMN, TACP (+/-): Throttle Actuator Control Motor +/- used in the ETC system.

TB: Throttle Body. A device that controls airflow through the engine via a butterfly valve and has an

air bypass channel around the throttle plate.

TC: 1. Traction Control. Combines anti-lock braking and axle torque reduction to control wheel

slippage. 2. Turbocharger.

TDC: Top Dead Center

TP: Throttle Position sensor. A potentiometer that provides throttle angle and rate information for the

PCM.

TP1: Throttle Position 1

TP2: Throttle Position 2

Page 7

TSB: Technical Service Bulletin. Notifies technician of any known vehicle concerns, procedures, or

general repair information.

VCT, VCT1, VCT2: Variable Camshaft Timing. VCT1 and VCT2 on V engines where applicable.

VECI: Vehicle Emission Control Information

VIN: Vehicle Identification Number. A unique identification number given to every vehicle produced.

Includes information about the year, model, engine, and plant origin of the vehicle.

VMV: Vapor Management Valve. Also known as EVAPCP. Refer to EVAPCP.

VBPWR: Vehicle Buffered Power. A PCM-supplied power source that supplies regulated voltage.

VPWR: Vehicle Power. A switched circuit that provides power to the EEC system. Compare to battery

voltage (B+).

VREF: Reference Voltage. A dedicated circuit that provides an approximately 5.0 volt signal used as

a reference by certain sensors.

WOT: Wide Open Throttle. A condition of maximum airflow through the throttle body.

Transmissions:

The automatic transmission naming convention is as follows:

Note:

The first character, a number, is the number of forward gears.

!

The second character, either the letter F or R, represents front (transaxle) or rear

!

(transmission) wheel drive.

The next set of characters, a grouping of numbers, represents the design torque capacity of

!

the transmission/transaxle.

! The last character, if used, is one of the following:

E for electronic shift

!

N for non-synchronous shift

!

S for synchronous shift

!

W for wide ratio

!

As an example, for the 4F27E transaxle, the number of forward gears is 4, the character F indicates

front transaxle, 27 represents 270 ft-lbs of torque capacity and the character E represents an

electronic shift.

A/T: Automatic Transmission

CCS: Coast Clutch Solenoid

EPC, EPC1, EPC2: Electronic Pressure Control

ESS: Electronic Shift Scheduling

ISS: Intermediate/Input Shaft Speed Sensor

M/T: Manual Transmission/Transaxle

OCS: Overdrive Cancel Switch

OSS: Output Shaft Speed. Indicates the rotational speed of the transmission output shaft.

PNP: Park/Neutral Position switch.

REVERSE or REV: Transmission Reverse Switch Input

SSA/SSB/SSC/SSD/SSE: Shift solenoids. Devices in an automatic transmission that control the

shifting by varying fluid flow when commanded by the PCM.

Page 8

SS1/SS2/SS3: Shift solenoids. Devices in an automatic transmission that control the shifting by

varying fluid flow when commanded by the PCM.

TCC/TCCH: Torque Converter Clutch. When energized, causes a mechanical engagement and

disengagement of the torque converter clutch.

TCIL: Transmission Control Indicator Lamp. Indicates that the TCS has been activated.

TCS: Transmission Control Switch. Modifies the operation of electronically controlled transmissions.

TFT: Transmission Fluid Temperature. Indicates the temperature of transmission fluid.

TR, TR1, TR2, TR3, TR4: Transmission Range. The range in which the transmission is operating.

TSS: Turbine Shaft Speed. Indicates the rotational speed of the transmission turbine shaft.

VSS: Vehicle Speed Sensor. A magnetic pickup device that generates an AC signal that is

proportional to the vehicle speed.

VSOUT: Vehicle Speed Output. A pulse width modulated vehicle speed signal.

Page 9

2007 PCED On Board Diagnostics Introduction

Procedure revision date: 03/29/2006

Introduction

The descriptions and specifications contained in this manual were in effect at the time this manual

Note:

was approved for publication. Ford Motor Company reserves the right to discontinue models at any time, or

change specifications or design without notice and without incurring obligation.

Important Safety Notice

Appropriate repair methods and procedures are essential for the safe, reliable operation of all motor

vehicles, as well as the personal safety of the individual doing the work. This manual provides general

directions for repairing vehicles with tested, effective techniques. Following them helps to establish reliability.

There are numerous variations in procedures, techniques, tools, and parts for repairing vehicles, as well as

in the skill of the individual doing the work. This manual cannot possibly anticipate all such variations and

provide advice or cautions as to each. Accordingly, anyone who departs from the instructions provided in

this manual must first establish that they compromise neither their personal safety nor the vehicle integrity

by their choice of methods, tools, or parts.

Notes, Cautions, and Warnings

As you read through the procedures, NOTES, CAUTIONS, and WARNINGS are found throughout the

publication. Each one is there for a specific purpose. NOTES give added information that help to complete a

particular procedure. CAUTIONS are given to prevent making errors that could damage the vehicle.

WARNINGS are to remind the technician to be especially careful in those areas where carelessness may

cause personal injury. The following list contains some general WARNINGS that should be followed when

working on a vehicle.

Always wear safety glasses for eye protection.

!

Use safety stands whenever a procedure requires working under the vehicle.

!

Make sure that the key is always in the OFF position, unless otherwise required by the procedure.

!

Set the parking brake when working on the vehicle. If the vehicle is equipped with an automatic

!

transmission, place the gear selector in PARK unless otherwise instructed for a specific operation. If

the vehicle is equipped with a manual transmission, the gear selector should be in REVERSE (engine

OFF) or NEUTRAL (engine ON) unless instructed otherwise for a specific operation. Place wood

blocks (4 inch x 4 inch or larger) against the front and rear surfaces of the tires to help prevent the

vehicle from moving.

Operate the engine in a well-ventilated area to avoid the danger of carbon monoxide poisoning.

!

Keep yourself and your clothing away from moving parts when the engine is running, especially the

!

drive belts.

Page 10

To prevent serious burns, avoid contact with hot metal parts such as the radiator, exhaust manifold

!

(s), tail pipe(s), three-way catalytic converter(s), and muffler(s).

Do not smoke while working on a vehicle.

!

To avoid injury, always remove rings, watches, loose hanging jewelry, and loose clothing before

!

beginning work on a vehicle.

When it is necessary to work under the hood, keep hands and other objects clear of the radiator fan

!

blades.

Preface

This manual provides a step-by-step approach for diagnosing driveability, emission, and powertrain control

system symptoms. Before beginning diagnosis, it may be helpful to reference any Technical Service

Bulletins (TSBs) or On-line Automotive Service Information System (OASIS) information when this is

available. TSB/OASIS information is available on either the Professional Technician Society (PTS) or

Motorcraft® website.

For the diesel engines, refer to the appropriate Diesel Powertrain Control/Emissions Diagnosis

Note:

Manual. For the Escape Hybrid or Mariner Hybrid, refer to the Escape Hybrid, Mariner Hybrid Powertrain

Control/Emissions Diagnosis Manual.

This manual is used in conjunction with the Workshop and Wiring Diagrams Manuals. The Workshop

Manuals are used to provide additional diagnostic or component removal and installation information. Refer

to the Wiring Diagrams Manuals for vehicle specific wiring information and component, connector, and splice

locations.

The following is a description of the information contained in each section of this manual.

Section 1: Description and Operation

This section contains description and operation information on powertrain control systems and components

and provides the technician with a general knowledge of the powertrain control system. Use this section

when general information about the powertrain control system is desired.

Section 2: Diagnostic Methods

This section contains information on specific diagnostic tasks that are used during diagnosis. Descriptions of

specific diagnostic methods are included, as well as detailed instructions on how to access or carry out the

task.

Section 3: Symptom Charts

All diagnosis begins in Section 3 with QT Step 1: Powertrain Control Module (PCM) Quick Test. If the PCM

Page 11

Quick Test is completed and no diagnostic trouble codes (DTCs) are retrieved, the technician is directed to

Step 2: No Diagnostic Trouble Codes (DTCs) Present Symptom Chart Index. The No Diagnostic Trouble

Codes (DTCs) Present Symptom Chart Index contains the list of symptoms addressed in this manual, and

directs the technician to the appropriate Step 3: No Diagnostic Trouble Codes (DTCs) Present Symptom

Chart. If no PCM DTCs are present and the vehicle symptom is not listed in Step 2: No Diagnostic Trouble

Codes (DTCs) Present Symptom Chart Index, the technician should go to the appropriate Workshop Manual

section to continue diagnosis.

Section 4: Powertrain Diagnostic Trouble Code (DTC) Charts and

Descriptions

This section contains the Diagnostic Trouble Code (DTC) Charts and Descriptions. These charts and

descriptions are referenced if a DTC is retrieved in Section 3 . Also included in this section are the list of

possible causes and diagnostic aids.

Section 5: Pinpoint Tests

All pinpoint tests are included in this section. Never enter a pinpoint test unless directed there. When

directed to a pinpoint test, always read the information included at the beginning of the pinpoint test.

Section 6: Reference Values

This section contains the Typical Diagnostic Reference Values charts. The technician is directed to these

charts from Pinpoint Test Z in Section 5 .

How to Use the Diagnostic Procedures

Use the information about the vehicle driveability or emission concerns to attempt to verify/recreate

!

the symptom. Look for any vehicle modifications or aftermarket items that may contribute to the

symptom. A check of any applicable TSBs or OASIS messages may be useful if this information is

available.

Go to Section 3 , QT Step 1: Powertrain Control Module (PCM) Quick Test. Carry out the PCM quick

!

test steps. Follow any notes as directed.

If the PCM quick test is completed, no DTCs were retrieved, and no special notes applied, go to Step

!

2: No Diagnostic Trouble Codes (DTCs) Present Symptom Chart Index.

Select the symptom that best describes the vehicle symptom (for multiple symptoms select the one

!

that is most evident). Go to Step 3: No Diagnostic Trouble Codes (DTCs) Present Symptom Chart

that is indicated. If no PCM DTCs are present and the vehicle symptom is not listed in the No

Diagnostic Trouble Codes (DTCs) Present Symptom Chart Index, go to the appropriate Workshop

Manual section to continue diagnosis.

The No Diagnostic Trouble Codes (DTCs) Present Symptom Charts contain areas to be tested for

!

diagnosis of the vehicle symptom. The chart is arranged to place the higher probability or easiest to

test items toward the top of the chart. However, the technician is not required to follow this order due

Page 12

to reasons such as variations in vehicle type, vehicle repair history, or technician experience.

Deleted Vehicles:

The System/Component column indicates the areas that are tested. This column may also

"

contain a quick system/component test.

The Reference column indicates where to go for the System/Component testing. All references

"

are to the beginning of a pinpoint test in Section 5 of this manual unless noted otherwise. If

referred to a pinpoint test in this manual or a Workshop Manual section, go to the procedures.

Follow the directions given in those procedures, including directions to other tests or sections.

If a damaged part is found, repair as directed. If no concern is found, and diagnosis in that

area is complete, return to the No Diagnostic Trouble Codes (DTCs) Present Symptom Chart

and continue to the next item.

If a quick system/component test is in the System/Component column, the Reference column

"

indicates where to go if the test failed.

During diagnosis, if directed to test a system/component that is not contained on that vehicle, go to

!

the next step.

If the No Diagnostic Trouble Codes (DTCs) Present Symptom Chart for the vehicle symptom is

!

completed and no concern is found, return to Step 2: No Diagnostic Trouble Codes (DTCs) Present

Symptom Chart Index to address the next most prominent symptom. If all diagnosis is complete and

no concern is found, it may be helpful to GO to Pinpoint Test Z in Section 5 to continue diagnosis.

The installation of any new component that affects the PCM adaptive learning strategies (idle speed,

!

refueling event, or fuel trim) requires the reset of keep alive memory (KAM). Refer to Section 2,

Resetting The Keep Alive Memory (KAM) .

After any repair, reconnect any components and remove any test equipment. Verify that the vehicle is

!

operating correctly and the original complaint is no longer present. If a DTC was present, clear the

DTCs and repeat the self-test to verify the repair.

If a symptom is determined to be intermittent, a careful visual and physical underhood inspection of

!

connectors, wiring harnesses, vacuum lines, and components is required. The Customer Information

Worksheet may contain more detailed symptom information. Before an in-depth diagnosis begins,

start the engine and wiggle wires, tap on components while listening for an indication of a concern

(such as an RPM change or a relay clicking).

Information about engine conditions is stored when a DTC that illuminates the malfunction indicator lamp

(MIL) is set. This information is called freeze frame data and may be helpful in diagnosing intermittent

concerns. Refer to Section 2, Freeze Frame Data for more information.

What's New in this Manual

The following is a list of changes to this manual for 2007:

New Vehicles:

Explorer Sport Trac

!

Page 13

Ford GT

!

Lincoln LS

!

Other Changes:

Computer-controlled shutdown feature for equipped vehicles

!

Crown Victoria, Grand Marquis, Town Car and Ranger equipped with new 170-pin PCM

!

Mustang with new 5.4L supercharged engine

!

Page 14

2007 PCED On Board Diagnostics SECTION 1: Description and Operation

Procedure revision date: 03/29/2006

Catalyst and Exhaust Systems

Overview

The catalytic converter and exhaust systems work together to control the release of harmful engine exhaust

emissions into the atmosphere. The engine exhaust gas consists mainly of nitrogen (N), carbon dioxide (CO

) and water vapor (H 2 O). However, it also contains carbon monoxide (CO), oxides of nitrogen (NO x ),

2

hydrogen (H), and various unburned hydrocarbons (HCs). The major air pollutants of CO, NO x , and HCs,

and their emission into the atmosphere must be controlled.

The exhaust system generally consists of an exhaust manifold, front exhaust pipe, front heated oxygen

sensor (HO2S), rear exhaust pipe, catalyst HO2S, a muffler, and an exhaust tailpipe. The catalytic converter

is typically installed between the front and rear exhaust pipes. On some vehicle applications, more than one

catalyst is used between the front and rear exhaust pipes. Catalytic converter efficiency is monitored by the

on board diagnostic (OBD) system strategy in the PCM. For information on the OBD catalyst monitor, refer

to the description for the Catalyst Efficiency Monitor in this section.

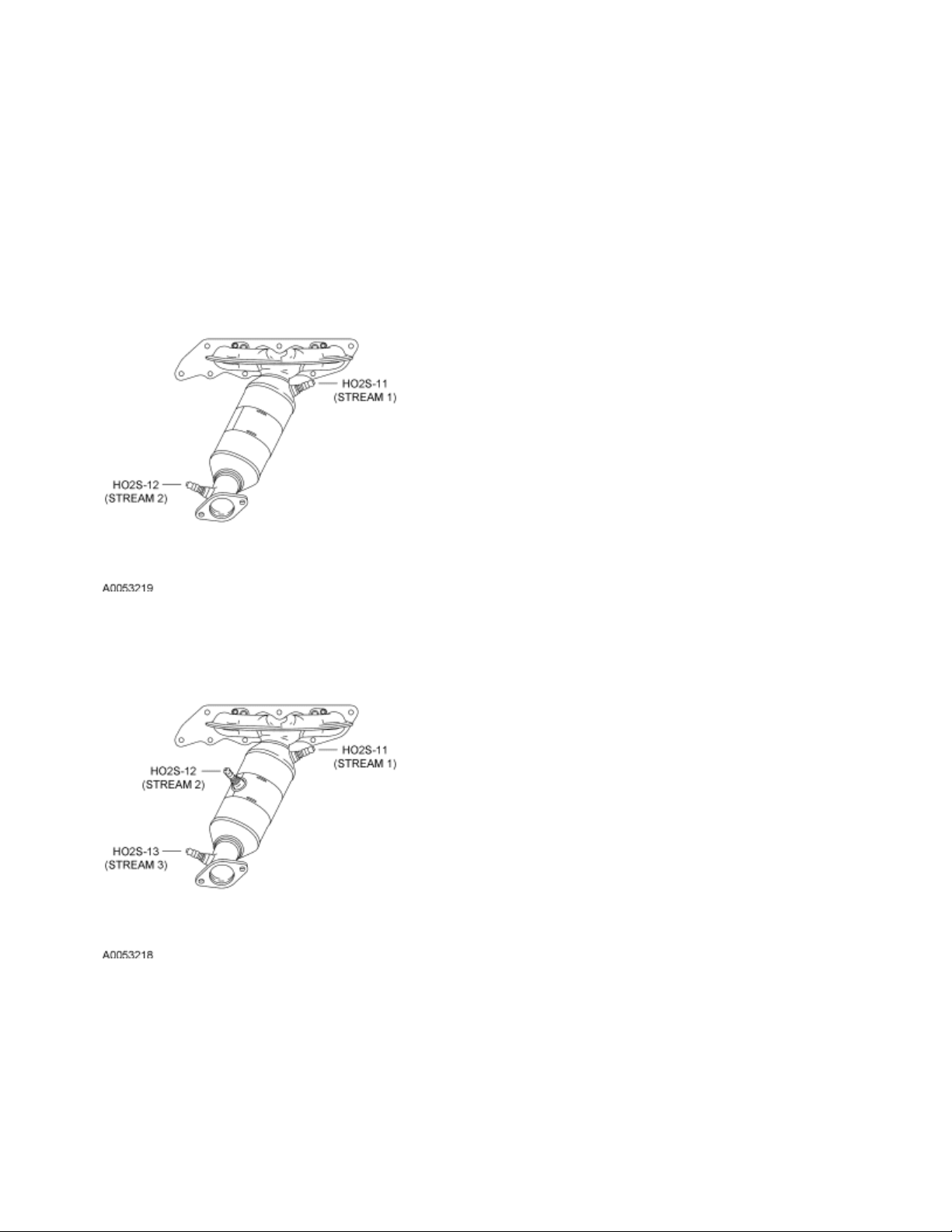

The number of HO2Ss used in the exhaust stream and the location of these sensors depend on the vehicle

emission certification level (LEV, LEV-II, ULEV, PZEV). On most vehicles only 2 HO2Ss are used in an

exhaust stream. The front sensors (HO2S11/HO2S21) before the catalyst are used for primary fuel control

while the ones after the catalyst (HO2S12/HO2S22) are used to monitor catalyst efficiency. However, some

partial zero emission vehicles (PZEV) use 3 HO2Ss for each engine bank. The stream 1 sensors

(HO2S11/HO2S21) located before the catalyst are used for primary fuel control, the stream 2 sensors

(HO2S12/HO2S22) are used to monitor the light-off catalyst, and the stream 3 sensors (HO2S13/HO2S23)

located after the catalyst are used for long term fuel trim control to optimize catalyst efficiency (fore aft

oxygen sensor control). Current PZEV vehicles use only a 4-cylinder engine, so only the bank 1 HO2Ss are

used.

Page 15

V-Engines

In-Line Engines

Catalytic Converter

A catalyst is a material that remains unchanged when it initiates and increases the speed of a chemical

reaction. A catalyst also enables a chemical reaction to occur at a lower temperature. The concentration of

exhaust gas products released to the atmosphere must be controlled. The catalytic converter assists in this

task. It contains a catalyst in the form of a specially treated ceramic honeycomb structure saturated with

catalytically active precious metals. As the exhaust gases come in contact with the catalyst, they are

changed into mostly harmless products. The catalyst initiates and speeds up heat producing chemical

reactions of the exhaust gas components so they are used up as much as possible.

Light Off Catalyst

As the catalyst heats up, converter efficiency rises rapidly. The point at which conversion efficiency exceeds

50% is called catalyst light off. For most catalysts this point occurs at 246°C to 302°C (475°F to 575°F ) . A

fast light catalyst is a 3-way catalyst (TWC) that is located as close to the exhaust manifold as possible.

Because the light off catalyst is located close to the exhaust manifold it lights off faster and reduces

emissions more quickly than the catalyst located under the body. Once the catalyst lights off, the catalyst

quickly reaches the maximum conversion efficiency for that catalyst.

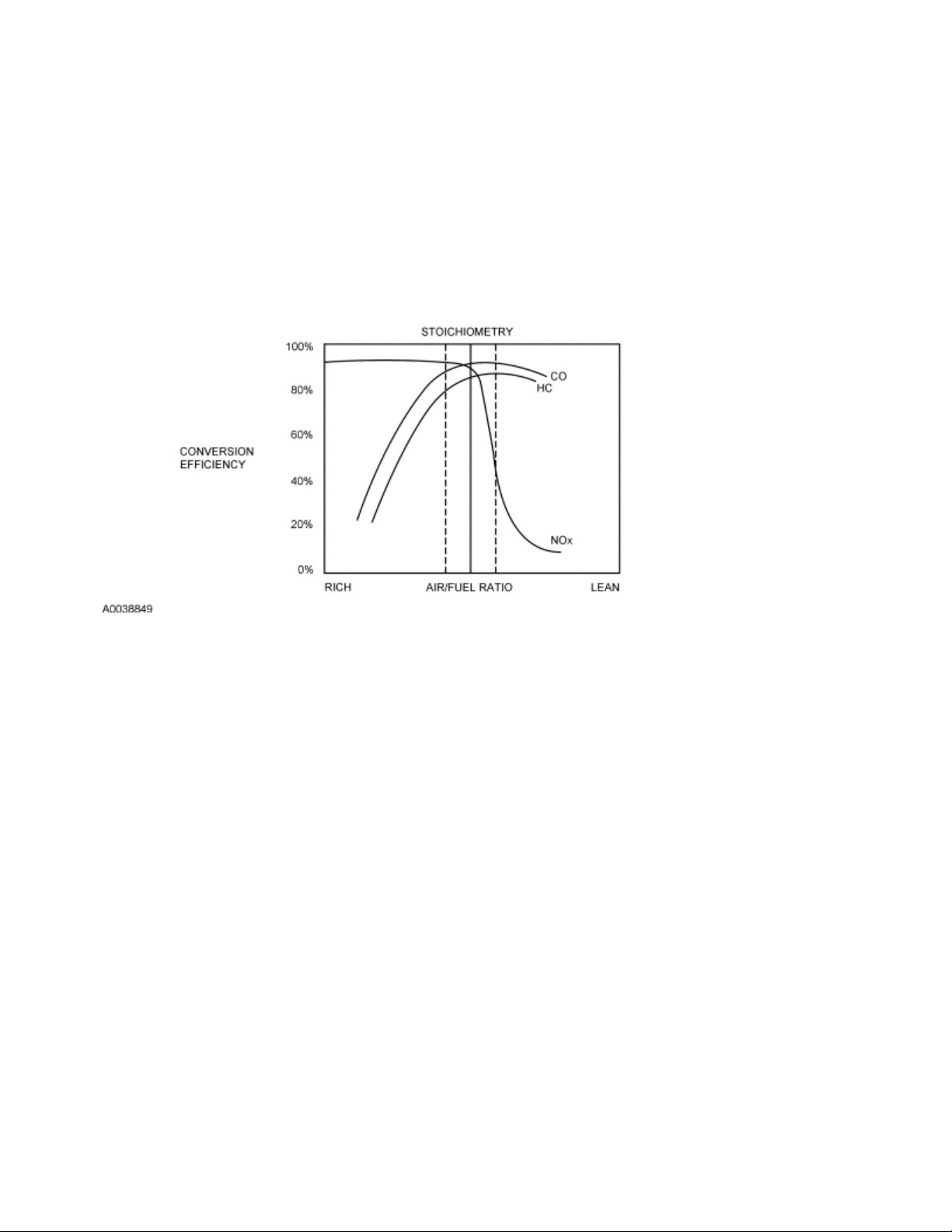

Three-Way Catalyst (TWC) Conversion Efficiency

A TWC requires a stoichiometric fuel ratio, 14.7 pounds of air to 1 pound of fuel (14.7:1), for high conversion

efficiency. In order to achieve these high efficiencies, the air/fuel ratio must be tightly controlled with a

narrow window of stoichiometry. Deviations outside of this window greatly decrease the conversion

efficiency. For example a rich mixture decreases the HC and CO conversion efficiency while a lean mixture

decreases the NO x conversion efficiency.

Page 16

TWC Conversion Efficiency Chart

Exhaust System

The purpose of the exhaust system is to convey engine emissions from the exhaust manifold to the

atmosphere. Engine exhaust emissions are directed from the engine exhaust manifold to the catalytic

converter through the front exhaust pipe. A HO2S is mounted on the front exhaust pipe before the catalyst.

The catalytic converter reduces the concentration of CO, unburned HCs, and NO x in the exhaust emissions

to an acceptable level. The reduced exhaust emissions are directed from the catalytic converter past

another HO2S mounted in the rear exhaust pipe and then on into the muffler. Finally, the exhaust emissions

are directed to the atmosphere through an exhaust tailpipe.

On some PZEV, there is a total of 3 HO2S in the exhaust stream. One near the exhaust manifold (stream 1),

one in the middle of the light-off catalyst (stream 2), and the third (stream 3) is mounted after the light-off

catalyst.

Page 17

Typical Bank 1 Catalyst 2 HO2S Configuration

Typical Bank 1 Catalyst 3 HO2S Configuration

Underbody Catalyst

The underbody catalyst is located after the light off catalyst. The underbody catalyst may be in line with the

light off catalyst, or the underbody catalyst may be common to 2 light off catalysts, forming a Y pipe

configuration. For an exact configuration of the catalyst and exhaust system for a specific vehicle, refer to

the Workshop Manual Section 309-00, Exhaust System.

Page 18

Three-Way Catalytic (TWC) Converter

The TWC converter contains either platinum (Pt) and rhodium (Rh) or palladium (Pd) and rhodium (Rh). The

TWC converter catalyzes the oxidation reactions of unburned HCs and CO and the reduction reaction of NO

. The 3-way conversion can be best accomplished by always operating the engine air fuel/ratio at or close

x

to stoichiometry.

Exhaust Manifold Runners

The exhaust manifold runners collect exhaust gases from engine cylinders. The number of exhaust

manifolds and exhaust manifold runners depends on the engine configuration and number of cylinders.

Exhaust Pipes

Exhaust pipes are usually treated during manufacturing with an anti-corrosive coating agent to increase the

life of the product. The pipes serve as guides for the flow of exhaust gases from the engine exhaust manifold

through the catalytic converter and the muffler.

Heated Oxygen Sensor (HO2S)

The HO2Ss provide the powertrain control module (PCM) with voltage and frequency information related to

the oxygen content of the exhaust gas. For additional information on the HO2S, refer to Engine Control

Components in this section.

Muffler

Mufflers are usually treated during manufacturing with an anti-corrosive coating agent to increase the life of

the product. The muffler reduces the level of noise produced by the engine, and also reduces the noise

produced by exhaust gases as they travel from the catalytic converter to the atmosphere.

Page 19

Page 20

2007 PCED On Board Diagnostics SECTION 1: Description and Operation

Procedure revision date: 03/29/2006

Catalyst Efficiency Monitor

The catalyst efficiency monitor uses an oxygen sensor before and after the catalyst to infer the hydrocarbon

(HC) efficiency based on the oxygen storage capacity of the catalyst. Under normal closed-loop fuel

conditions, high efficiency catalysts have significant oxygen storage. This makes the switching frequency of

the rear heated oxygen sensor (HO2S) very slow and reduces the amplitude of those switches as compared

to the switching frequency and amplitude of the front HO2S. As the catalyst efficiency deteriorates due to

thermal and chemical deterioration, its ability to store oxygen declines. The post-catalyst or downstream

HO2S signal begins to switch more rapidly with increasing amplitude, approaching the switching frequency

and amplitude of the pre-catalyst or upstream HO2S. The predominant failure mode for high mileage

catalysts is chemical deterioration (phosphorus deposits on the front brick of the catalyst), not thermal

deterioration.

In order to assess catalyst oxygen storage, the catalyst monitor counts front HO2S switches during partthrottle, closed-loop fuel conditions after the engine is warmed-up and the inferred catalyst temperature is

within limits. Front switches are accumulated in up to 3 different air mass regions or cells. While catalyst

monitoring entry conditions are being met, the front and rear HO2S signal lengths are continually being

calculated. When the required number of front switches has accumulated in each cell, the total signal length

of the rear HO2S is divided by the total signal length of the front HO2S to compute a catalyst index ratio. An

index ratio near 0.0 indicates high oxygen storage capacity, hence high HC efficiency. An index ratio near

1.0 indicates low oxygen storage capacity, hence low HC efficiency. If the actual index ratio exceeds the

threshold index ratio, the catalyst is considered failed.

Inputs from engine coolant temperature (ECT) or cylinder head temperature (CHT), intake air temperature

(IAT), mass air flow (MAF), crankshaft position (CKP), throttle position (TP), and vehicle speed sensors are

required to enable the Catalyst Efficiency Monitor.

Typical Monitor Entry Conditions:

Minimum 330 seconds since start-up at 21°C (70°F)

!

Engine coolant temperature is between 76.6°C - 110°C (170°F - 230°F)

!

Intake air temperature is between -7°C - 82°C (20°F - 180°F)

!

Time since entering closed-loop is 30 seconds

!

Inferred rear HO2S sensor temperature of 482°C (900°F )

!

EGR is between 1% and 12%

!

Part throttle, maximum rate of change is 0.2 volts/0.050 sec

!

Vehicle speed is between 8 and 112 km/h (5 and 70 mph)

!

Fuel level is greater than 15%

!

First Air Flow Cell

!

!

!

Engine RPM 1,000 to 1,300 RPM

Engine load 15 to 35%

Page 21

Inferred catalyst temperature 454°C - 649°C (850°F - 1,200°F)

!

Number of front HO2S switches is 50

!

Second Air Flow Cell

!

Engine RPM 1,200 to 1,500 RPM

!

Engine load 20 to 35%

!

Inferred catalyst temperature 482°C - 677°C (900°F - 1,250°F )

!

Number of front HO2S switches: 70

!

Third Air Flow Cell

!

Engine RPM 1,300 to 1,600 RPM

!

Engine load 20 to 40%

!

Inferred catalyst temperature 510°C - 704°C (950°F - 1,300°F)

!

Number of front HO2S switches is 30

!

The DTCs associated with this test are DTC P0420 (Bank 1 or Y-pipe system) and P0430 (Bank 2).

Because an exponentially weighted moving average algorithm is used to determine a concern, up to 6

driving cycles may be required to illuminate the MIL during normal customer driving. If the KAM is reset or

the battery is disconnected, a concern illuminates the MIL in 2 drive cycles.

General Catalyst Monitor Operation

Monitor execution is once per drive cycle. The typical monitor duration is 700 seconds. In order for the

catalyst monitor to run, the HO2S monitor must be complete and the secondary AIR and EVAP system

functional with no stored DTCs. If the catalyst monitor does not complete during a particular driving cycle,

the already accumulated switch/signal data is retained in the KAM and is used during the next driving cycle

to allow the catalyst monitor a better opportunity to complete.

Rear HO2S can be located in various configurations to monitor different kinds of exhaust systems. In-line

engines and many V-engines are monitored by their individual bank. A rear HO2S is used along with the

front, fuel control HO2S for each bank. Two sensors are used on an in-line engine and 4 sensors are used

on a V-engine. Some V-engines have exhaust banks that combine into a single underbody catalyst. These

systems are referred to as Y-pipe systems. They use only 1 rear HO2S along with the 2 front, fuel-control

HO2S. The Y-pipe system uses 3 sensors in all. For Y-piped systems, the 2 front HO2S signals are

combined by the PCM software to infer what the HO2S signal would have been in front of the monitored

catalyst. The inferred front HO2S signal and the actual single, rear HO2S signal is then used to calculate the

index ratio.

Exhaust systems that use an underbody catalyst without a downstream/rear HO2S are not monitored by the

catalyst efficiency monitor.

Most vehicles that are part of the low emission vehicle (LEV) catalyst monitor phase-in, monitor less than

100% of the catalyst volume. Often this is the first catalyst brick of the catalyst system. Partial volume

monitoring is done on LEV and ultra low emission vehicle (ULEV) vehicles in order to meet the 1.75

emission standard. The rationale for this strategy is that the catalyst nearest the engine deteriorate first,

allowing the catalyst monitor to be more sensitive and illuminate the MIL correctly at lower emission

Page 22

standards.

Many applications that use partial-volume monitoring place the rear HO2S after the first light-off catalyst can

or after the second catalyst can in a 3-can per bank system. (A few applications placed the HO2S in the

middle of the catalyst can, between the first and second bricks).

Some partial zero emission vehicles (PZEV) use 3 sets of HO2S per engine bank. The front sensors or

stream 1 (HO2S11/HO2S21) are the primary fuel control sensors. The next sensors downstream or stream

2 in the exhaust are used to monitor the light-off catalyst (HO2S12/HO2S22). The last sensors downstream

or stream 3 in the exhaust (HO2S13/HO2S23) are used for very long term fuel trim in order to optimize

catalyst efficiency (fore aft oxygen sensor control). For additional heated oxygen sensor information, refer to

the Heated Oxygen Sensor (HO2S) Monitor in this section.

Index ratios for ethanol (flex fuel) vehicles vary based on the changing concentration of alcohol in the fuel.

The threshold to determine a concern typically increases as the percent of alcohol increases. For example, a

threshold of 0.5 may be used at E10 (10% ethanol) and 0.9 may be used at E85 (85% ethanol). The

thresholds are adjusted based on the percentage of alcohol in the fuel. Standard fuel may contain up to 10%

ethanol.

Catalyst Efficiency Monitor

Page 23

Page 24

2007 PCED On Board Diagnostics SECTION 1: Description and Operation

Procedure revision date: 03/29/2006

Cold Start Emission Reduction Monitor

Overview

The cold start emission reduction monitor is an on-board strategy designed for vehicles that meet the low

emissions vehicle-II (LEV-II) emissions standards. The monitor works by validating the operation of the

components of the system required to achieve the cold start emission reduction strategy. There are 2 types

of monitors:

cold start emission reduction component monitor

!

cold start emission reduction system monitor

!

Cold Start Emission Reduction Component Monitor

Two different tests are carried out during the cold start emission reduction component monitor. The low idle

airflow test which checks the performance of the idle air control strategy and the spark timing monitor test

which checks the spark timing strategy.

Low Idle Air Flow Test

When the cold start emission reduction monitor is enabled, the powertrain control module (PCM) commands

the idle air control system to increase the RPM, which elevates engine air flow. While this cold start emission

reduction elevated air flow is requested, the low idle air flow test compares the measured idle air flow from

the mass air flow (MAF) sensor to the commanded idle air control strategy. For the purpose of detecting low

air flow failures, the low air flow test uses the measured air flow and the commanded air flow to create a low

air flow index.

Low idle air flow test operation:

DTC: P050A cold start idle air control system performance

!

Monitor execution: Once per driving cycle, from start up with the cold start emissions reduction active

!

Monitor sequence: none

!

Monitoring duration: 7 seconds

!

Low idle air flow test entry conditions:

Engine coolant temperature is between 4.4°C (40°F) and 82.2°C (180°F)

!

Barometric pressure is between 76.2 kPa (22.5 in-Hg) and 105 kPa (31 in-Hg)

!

Engine off soak time is at least 50 minutes

!

Throttle is at closed position

!

Page 25

Spark Timing Monitor Test

The PCM is equipped with a spark conduction capture circuit which measures the timing and duration of the

spark delivered by processing the flyback voltage signal from the primary side of the ignition coil. When the

cold start emission reduction monitor is enabled, the spark control strategy in the PCM commands the spark

timing strategy to retard the spark timing. While retarded spark timing is requested, the spark timing monitor

compares the measured spark timing from the spark conduction capture circuit to the commanded spark

timing from the spark control strategy. For the purpose of detecting spark timing failures, the spark timing

monitor increments a fault filter if the measured spark timing is advanced by more than 5 degrees from the

commanded spark timing. A failure is indicated if the fault filter exceeds a value of 200, equivalent to a

failure duration of approximately 4 seconds.

Spark timing monitor test operation:

DTC: P050B cold start ignition timing performance

!

Monitor execution: once per driving cycle, from start up with the cold start emission reduction monitor

!

active

Monitor sequence: none

!

Monitoring duration: 7 seconds

!

Spark timing monitor test entry conditions:

Engine speed is between 400 RPM and 2,000 RPM

!

Engine position and cylinder identification are synchronized

!

There is no concerns with the ignition coils primary circuits

!

Cold Start Emission Reduction System Monitor

The powertrain control module (PCM) uses the cold start emission reduction system monitor to calculate the

actual catalyst warm up temperature during a cold start. The actual catalyst warm up temperature

calculation uses measured engine speed, measured air mass and commanded spark timing inputs to the

PCM. The PCM then compares the actual temperature to the expected catalyst temperature model. The

expected catalyst temperature model calculation uses desired engine speed, desired air mass and desired

spark timing inputs to the PCM. The difference between the actual and expected temperatures is reflected in

a ratio. This ratio is a measure of how much loss of catalyst heating occurred over the period of time and

when compared with a calibrated threshold it helps the PCM to determine if the cold start emission reduction

system is working properly. This ratio correlates to tailpipe emissions, and a malfunction indicator lamp (MIL)

illuminates when the calibrated threshold is exceeded. The monitor is disabled if a concern is present in any

of the sensors or systems used for expected catalyst temperature model calculation.

Cold start emission reduction system monitor test operation:

DTC: P050E cold start engine exhaust temperature out of range

!

Monitor execution: once per driving cycle, from start up with the cold start emission reduction monitor

!

Page 26

active

Monitor sequence: the monitor collects data during first 15 seconds of the cold start

!

Monitoring duration: the monitor completes 300 seconds after initial engine start

!

Cold start emission reduction system monitor entry conditions:

Engine coolant temperature at the start of the monitor is between 1.67°C (35°F) and 37.78°C (100°F)

!

Barometric pressure is above 74.5 kPa (22 in-Hg)

!

Catalyst temperature at the start of the monitor is between 1.67°C (35°F) and 51.67°C (125°F)

!

Fuel level is above 15%

!

Power take-off operation is disabled

!

Page 27

2007 PCED On Board Diagnostics SECTION 1: Description and Operation

Procedure revision date: 03/29/2006

Comprehensive Component Monitor (CCM)

The CCM monitors for concerns in any powertrain electronic component or circuit that provides input or

output signals to the PCM that can affect emissions and is not monitored by another on board diagnostics

(OBD) monitor. Inputs and outputs are, at a minimum, monitored for circuit continuity or correct range of

values. Where feasible, inputs are also checked for rationality, and outputs are also checked for correct

functionality.

The CCM covers many components and circuits and tests them in various ways depending on the hardware,

function, and type of signal. For example, analog inputs such as throttle position or engine coolant

temperature are typically checked for opens, shorts, and out-of-range values. This type of monitoring is

carried out continuously. Some digital inputs like brake switch or crankshaft position rely on rationality

checks - checking to see if the input value makes sense at the current engine operating conditions. These

types of tests may require monitoring several components and can only be carried out under the appropriate

test conditions.

Outputs such as coil drivers are checked for opens and shorts by monitoring a feedback circuit or smart

driver associated with the output. Other outputs, such as relays, require additional feedback circuits to

monitor the secondary side of the relay. Some outputs are also monitored for correct function by observing

the reaction of the control system to a given change in the output command. An idle air control solenoid can

be functionally tested by monitoring the idle RPM relative to the target idle RPM. Some tests can only be

carried out under the appropriate test conditions. For example, the transmission shift solenoids can only be

tested when the PCM commands a shift.

The following is an example of some of the input and output components monitored by the CCM. The

component monitor may belong to the engine, ignition, transmission, air conditioning, or any other PCM

supported subsystem.

1. Inputs:

Air conditioning pressure (ACP) sensor, camshaft position (CMP) sensor, crankshaft position (CKP)

sensor, engine coolant temperature (ECT) sensor, engine oil temperature (EOT) sensor, fuel rail

pressure (FRP) sensor, fuel rail pressure temperature (FRPT) sensor, fuel tank pressure (FTP)

sensor, intake air temperature (IAT) sensor, mass air flow (MAF) sensor, throttle position (TP) sensor.

2. Outputs:

EVAP canister purge valve, EVAP canister vent (CV) solenoid, fuel injector, fuel pump (FP), idle air

control (IAC), intake manifold runner control (IMRC), shift solenoid, torque converter clutch (TCC)

solenoid, variable camshaft timing (VCT) actuator, wide open throttle A/C cutout (WAC).

3. CCM is enabled after the engine starts and is running. A DTC is stored in KAM and the MIL is

Page 28

illuminated after 2 driving cycles when a concern is detected. Many of the CCM tests are also carried

out during an on-demand self-test.

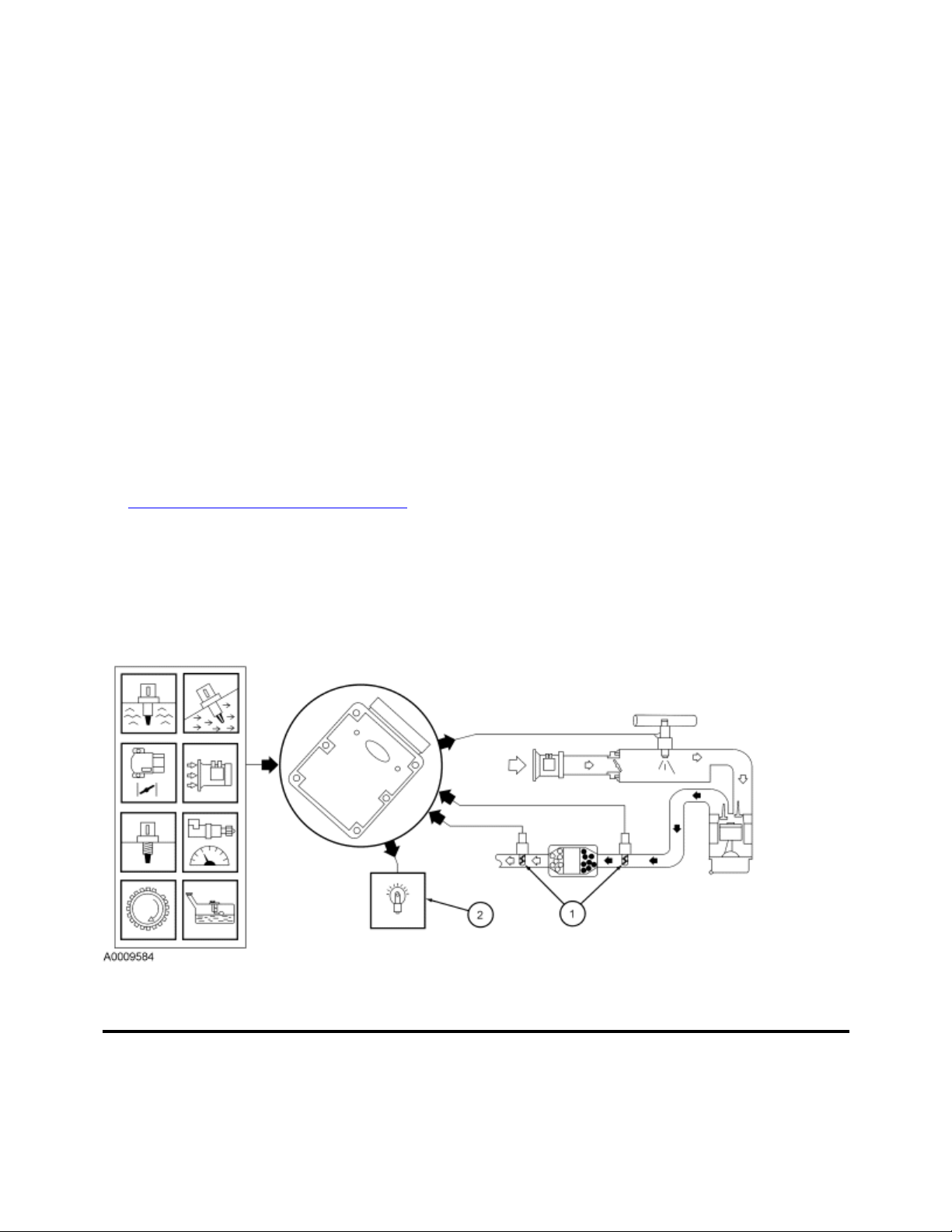

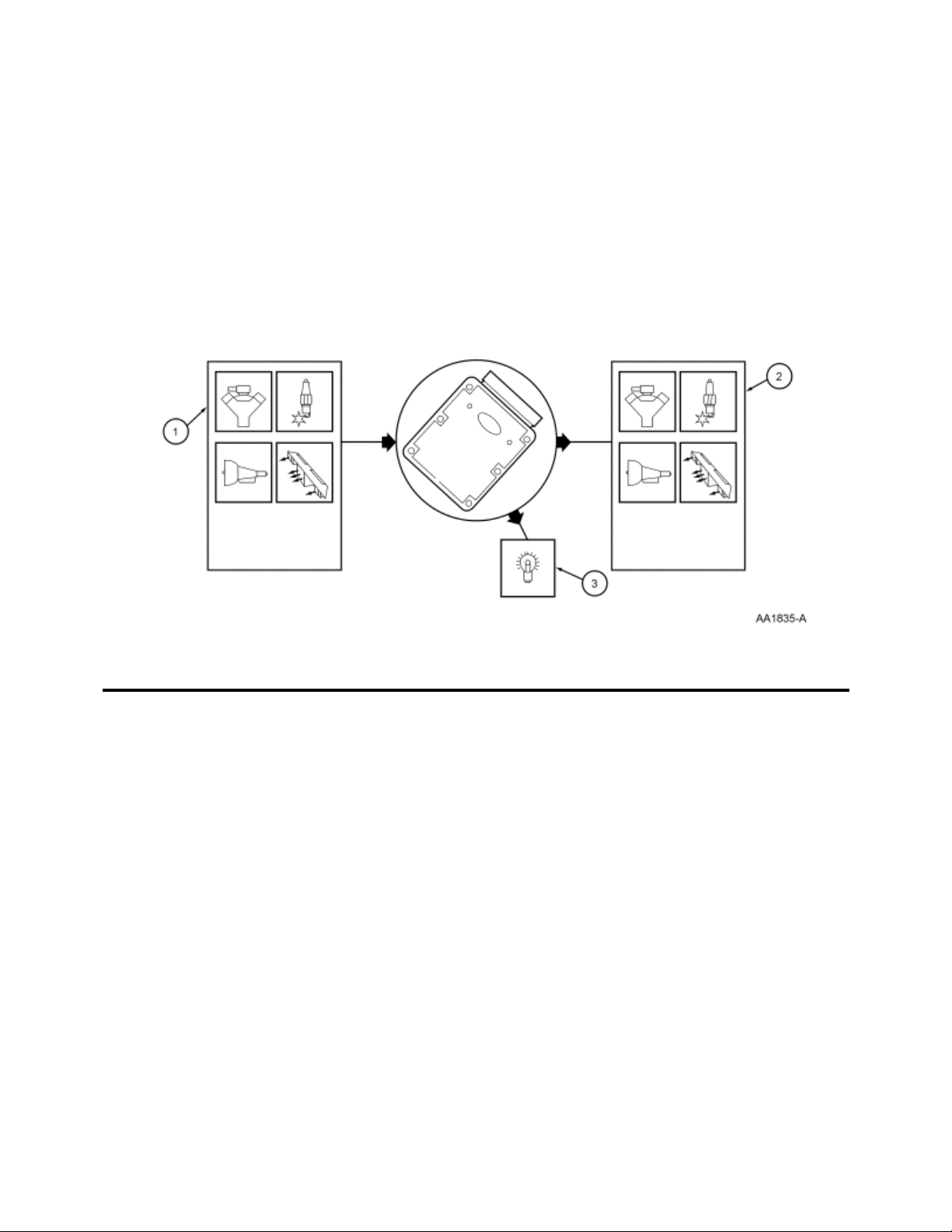

Comprehensive Component Monitor (CCM)

Page 29

2007 PCED On Board Diagnostics SECTION 1: Description and Operation

Procedure revision date: 03/29/2006

Electric Exhaust Gas Recirculation (EEGR) System Monitor

The EEGR system monitor is an on-board strategy designed to test the integrity and flow characteristics of

the EGR system. The monitor is activated during EGR system operation and after certain base engine

conditions are satisfied. Input from the engine coolant temperature (ECT) or cylinder head temperature

(CHT), intake air temperature (IAT), throttle position (TP), crankshaft position (CKP), mass air flow (MAF),

and manifold absolute pressure (MAP) sensors is required to activate the EGR system monitor. Once

activated, the EGR system monitor carries out each of the tests described below during the engine modes

and conditions indicated. Some of the EGR system monitor tests are also carried out during a key on engine

off (KOEO) or key on engine running (KOER) self-test.

The EEGR monitor consists of an electrical and functional test that checks the stepper motor and the EEGR

system for correct flow. The powertrain control module (PCM) controls the EEGR valve by commanding

from 0 to 52 discreet increments or steps to get the valve from fully closed to fully open. The stepper motor

electrical test is a continuous check of the 4 electric stepper motor coils and circuits to the PCM. A concern

is indicated if an open circuit, short to power, or short to ground has occurred in one or more of the stepper

motor coils or circuits for a calibrated period of time. If a concern has been detected, the EEGR system is

disabled, setting diagnostic trouble code (DTC) P0403. Additional monitoring is suspended for the remainder

of the drive cycle, or until the next engine startup.

After the vehicle has warmed up and normal EEGR flow rates are being commanded by the PCM, the

EEGR flow check is carried out. The flow test is carried out once per drive cycle when a minimum amount of

exhaust gas is requested and the remaining entry conditions required to initiate the test are satisfied. If a

concern is detected, the EEGR system, as well as the EEGR monitor, is disabled until the next engine

startup.

The EEGR flow test is done by observing the behavior of 2 different values: MAP - the analog MAP sensor

reading, and inferred MAP - calculated from the MAF sensor, throttle position and RPM. An EGR flow

concern is indicated by either a no flow condition or a low flow condition prior to exceeding 1.5 times the

applicable emission standard. The criteria used to determine which flow concern threshold applies is based

upon whether or not the applicable emission standards are exceeded on the federal test procedure test

cycle without EGR delivery.

When the flow test entry conditions have been satisfied, EEGR is commanded to flow at a calibrated test

rate (about 10%). At this time, the value of MAP is recorded (EGR-ON MAP). The value of inferred MAP

EGR-ON inferred MAP is also recorded. Next the EEGR is commanded off (0%). Again, the value of MAP is

recorded (EGR-OFF MAP). The value of EGR-OFF inferred MAP is also recorded. Typically, 7 such

ON/OFF samples are taken. After all the samples have been taken, the average EGR-ON MAP, EGR-ON

inferred MAP, EGR-OFF MAP and EGR-OFF inferred MAP values are stored.

The difference between the EGR-ON and EGR-OFF value is calculated as follows:

Page 30

MAP-delta equals EGR-ON MAP — EGR-OFF MAP

!

Inferred MAP-delta equals EGR-ON inferred MAP — EGR-OFF inferred MAP

!

If the sum of MAP-delta and inferred MAP-delta exceeds a maximum threshold or falls to less than a

minimum threshold, DTC P0400 (high or low flow concern) is registered.

As an additional check, if the EGR-ON MAP exceeds a maximum threshold (BARO, a calibrated value),

DTC P0400 (low flow) is set. This check is carried out to detect reduced EGR flow on systems where the

MAP sensor is located in the intake manifold plenum.

Note: BARO is inferred at engine startup using the KOEO MAP sensor reading. It is updated during high,

part-throttle or high RPM engine operation.

If the inferred ambient temperature is less than -7°C ( 2 0 °F ) , g r e a t e r t h a n 5 4 °C ( 1 3 0 °F ) , o r t h e a l t i t u de is

greater than 8,000 feet (BARO less than 22.5 in-Hg), the EEGR flow test cannot be reliably done. In these

conditions, the EEGR flow test is suspended and a timer starts to accumulate the time in these conditions.

When the vehicle leaves these extreme conditions, the timer starts to decrement, and if conditions permit,

attempts to complete the EGR flow monitor. If the timer reaches 800 seconds, the EEGR flow test is

disabled for the remainder of the current driving cycle and the EGR monitor is set to a ready condition.

A DTC P1408, like the P0400, indicates a EGR flow concern (outside the minimum or maximum limits) but is

only set during the KOER self-test. The P0400 and P0403 are MIL codes. P1408 is a non-MIL code.

Page 31

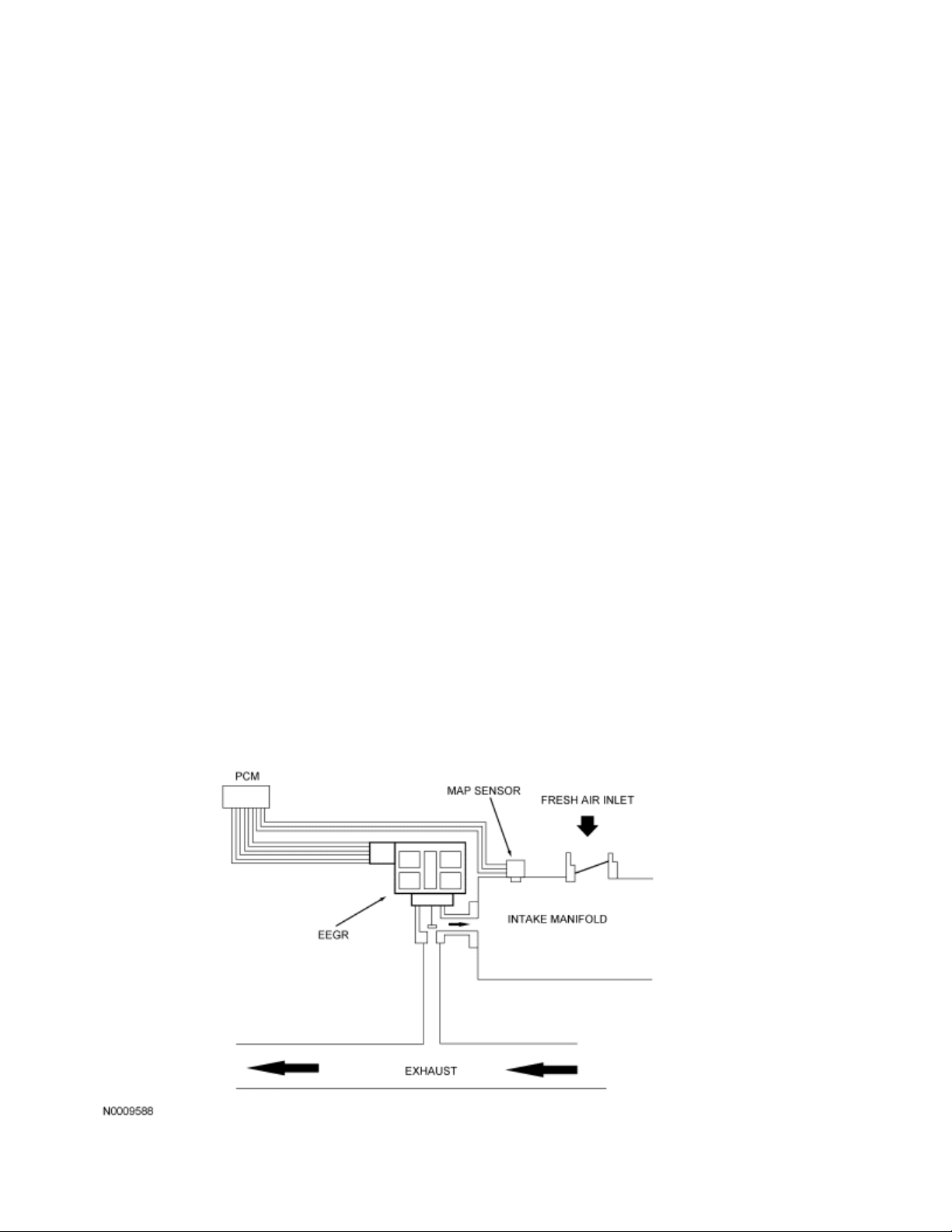

EEGR System Monitor

Page 32

2007 PCED On Board Diagnostics SECTION 1: Description and Operation

Procedure revision date: 03/29/2006

Electronic Engine Control (EEC) System

Overview

The EEC system provides optimum control of the engine and transmission through the enhanced capability

of the powertrain control module (PCM). The EEC system also has an on board diagnostics (OBD)

monitoring system with features and functions to meet federal regulations on exhaust emissions.

Some vehicle applications use a stand-alone transmission control module (TCM). Even though it is still part

of the EEC system, the TCM communicates with the PCM, the anti-lock brake system (ABS) module, the

instrument cluster, and the four-wheel drive (4WD) control modules using the high speed controller area

network (CAN) communications network. The TCM incorporates a stand alone OBD-II system. The TCM

independently processes and stores diagnostic trouble codes (DTCs), freeze frame, support PIDs as well as

J1979 Mode 09 CALID and calibration verification number. The TCM does not directly illuminate the

malfunction indicator lamp (MIL), but requests the PCM to do so. The TCM is located inside the transmission

assembly. It is not repairable, with the exception of reprogramming.

Below is a list of transmissions that use a TCM:

AWF21 (FWD) 6-speed automatic transmission

!

FNR5 (FWD) transmission

!

F21 (FWD) transmission

!

ZF CFT30 (FWD) continuously variable transmission (CVT)

!

ZF 6HP26 (RWD) transmission

!

ZF 6R (RWD)

!

6R60 (RWD)

!

For additional information on these transmissions and TCM diagnostics, refer to the Workshop Manual

Section 307-01, Automatic Transmission/Transaxle.

The EEC system has 2 major divisions: hardware and software. The hardware includes the PCM, sensors,

switches, actuators, solenoids, and interconnecting terminals. The software in the PCM provides the

strategy control for outputs (engine hardware) based on the values of the inputs to the PCM. The EEC

hardware and software are discussed in this section.

This section contains detailed descriptions of the operation of the EEC system input sensors and switches,

output actuators, solenoids, relays and connector pins (including other power-ground signals). For additional

information on the input sensors and output actuators, refer to Engine Control Components in this section.

The PCM receives information from a variety of sensor and switch inputs. Based on the strategy and

calibration stored within the memory chip, the PCM generates the appropriate output. The system is

Page 33

designed to minimize emissions and optimize fuel economy and driveability. The software strategy controls

the basic operation of the engine and transmission, provides the OBD strategy, controls the MIL,

communicates to the scan tool via the data link connector (DLC), allows for flash electrically erasable

programmable read only memory (EEPROM), provides idle air and fuel trim, and controls failure mode

effects management (FMEM).

Modifications to OBD Vehicles

Modifications or additions to the vehicle may cause incorrect operation of the OBD system. Install anti-theft

systems, remote starters, cellular telephones and aftermarket radios carefully.

by tapping into or running wires close to the powertrain control system wires or components.

Do not install these devices

Page 34

2007 PCED On Board Diagnostics SECTION 1: Description and Operation

Procedure revision date: 03/29/2006

Engine Control Components

Transmission inputs, which are not described in this section are discussed in the applicable Workshop

Note:

Manual transmission section.

Accelerator Pedal Position (APP) Sensor

The APP sensor is an input to the powertrain control module (PCM) and is used to determine the torque

demand. There are 3 pedal position signals in the sensor. Signal 1, APPS1, has a negative slope

(increasing angle, decreasing voltage) and signals 2 and 3, APPS2 and APPS3, both have a positive slope

(increasing angle, increasing voltage). During normal operation APPS1 is used as the indication of pedal

position by the strategy. The 3 pedal position signals make sure the PCM receives a correct input even if 1

signal has a concern. There are 2 reference voltage circuits and 2 signal return circuits for the sensor. For

additional information, refer to Torque Based Electronic Throttle Control (ETC) in this section.

Air Conditioning (A/C) Clutch Relay (A/CCR)

The PCM PIDs WAC and wide open throttle air conditioning cutoff fault (WACF) are used to monitor

Note:

the A/CCR output.

The A/CCR is wired normally open. There is no direct electrical connection between the A/C switch or

electronic automatic temperature control (EATC) module and the A/C clutch. The PCM receives a signal

indicating that A/C is requested. For some applications, this message is sent through the communications

network. When A/C is requested, the PCM checks other A/C related inputs that are available, such as A/C

pressure switch and A/C cycling switch. If these inputs indicate A/C operation is OK, and the engine

conditions are OK (coolant temperature, engine RPM, throttle position), the PCM grounds the A/CCR output,

closing the relay contacts and sending voltage to the A/CCR.

Air Conditioning (A/C) Cycling Switch

The A/C cycling switch may be wired to either the ACCS or ACPSW PCM input. When the A/C cycling

switch opens, the PCM turns off the A/C clutch. For information on the specific function of the A/C cycling

switch, refer to the Workshop Manual Section 412-00, Climate Control System. Also, refer to the applicable

Wiring Diagrams Manual for vehicle specific wiring.

If the ACCS signal is not received by the PCM, the PCM circuit will not allow the A/C to operate. For

additional information, refer to wide open throttle air conditioning cutoff (WAC) in this section.

Page 35

Some applications do not have a dedicated (separate) input to the PCM indicating that A/C is requested.

Volts

Resistance (K ohms)

100

212

194

176

158

140

122

104

This information is received by the PCM through the communication link.

Air Conditioning Evaporator Temperature (ACET) Sensor

The ACET sensor measures the evaporator air discharge temperature. The ACET sensor is a thermistor

device in which resistance changes with temperature. The electrical resistance of a thermistor decreases as

the temperature increases, and the resistance increases as the temperature decreases. The PCM sources a

low current 5 volts on the ACET circuit. With SIG RTN also connected to the ACET sensor, the varying

resistance changes the voltage drop across the sensor terminals. As A/C evaporator air temperature

changes, the varying resistance of the ACET sensor changes the voltage the PCM detects.

The ACET sensor is used to more accurately control A/C clutch cycling, improve defrost/demist

performance, and reduce A/C clutch cycling.

These values can vary 15 % due to sensor and VREF variations. Voltage values were calculated for

Note:

VREF equals 5.0 volts.

A/C EVAPORATOR TEMPERATURE

(ACET) SENSOR VOLTAGE AND

RESISTANCE

°C °F

90

80

70

60

50

40

30 86 2.74 24.25

20 68 3.26 37.34

10 50 3.73 58.99

0 32 4.14 95.85

-10 14 4.45 160.31

-20 -4 4.66 276.96

0.47 2.08

0.61 2.80

0.80 3.84

1.05 5.34

1.37 7.55

1.77 10.93

2.23 16.11

Page 36

Air Conditioning (A/C) High Pressure Switch

The A/C high pressure switch is used for additional A/C system pressure control. The A/C high pressure

switch is either dual function for multiple speed, relay controlled electric fan applications, or single function

for all others.

For refrigerant containment control, the normally closed high pressure contacts open at a predetermined A/C

pressure. This results in the A/C turning off, preventing the A/C pressure from rising to a level that would

open the A/C high pressure relief valve.

For fan control, the normally open medium pressure contacts close at a predetermined A/C pressure. This

grounds the ACPSW circuit input to the PCM. The PCM then turns on the high speed fan to help reduce the

pressure.

For additional information, refer to the Workshop Manual Section 412-00, Climate Control System or the

Wiring Diagrams Manual.

Air Conditioning Pressure (ACP) Sensor

The ACP sensor is located in the high pressure (discharge) side of the A/C system. The ACP sensor

provides a voltage signal to the PCM that is proportional to the A/C pressure. The PCM uses this information

for A/C clutch control, fan control and idle speed control.

Page 37

Page 38

Typical A/C Pressure Sensor

Brake Pedal Position (BPP) Switch

The BPP switch is sometimes referred to as the stoplamp switch. The BPP switch provides a signal to the

PCM indicating that the brakes are applied. The BPP switch is normally open and is mounted on the brake

pedal support. Depending on the vehicle application the BPP switch can be hardwired as follows:

to the PCM supplying battery positive voltage (B+) when the vehicle brake pedal is applied.

!

to the anti-lock brake system (ABS) module, or lighting control module (LCM), the BPP signal is then

!

broadcast over the network to be received by the PCM.

to the ABS traction control/stability assist module. The ABS module interprets the BPP switch input

!

along with other ABS inputs and generates an output called the driver brake application (DBA) signal.

The DBA signal is then sent to the PCM and to other BPP signal users.

Typical BPP Switch

Brake Pedal Switch (BPS)/Brake Deactivator Switch

The BPS, also called the brake deactivator switch, is for vehicle speed control deactivation. A normally

closed switch supplies battery positive voltage (B+) to the PCM when the brake pedal is not applied. When

the brake pedal is applied, the normally closed switch opens and power is removed from the PCM.

On some applications the normally closed BPS, along with the normally open BPP switch, are used for a

brake rationality test within the PCM. The PCM misfire monitor profile learn function may be disabled if a

brake switch concern occurs. If one or both brake pedal inputs to the PCM is not changing states when they

were expected to, a diagnostic trouble code (DTC) is set by the PCM strategy.

Camshaft Position (CMP) Sensor

The CMP sensor detects the position of the camshaft. The CMP sensor identifies when piston number 1 is

on its compression stroke. A signal is then sent to the PCM and used for synchronizing the sequential firing

of the fuel injectors. Coil-on-plug (COP) ignition applications use the CMP signal to select the correct ignition

Page 39

coil to fire.

Vehicles with 2 CMP sensors are equipped with variable camshaft timing (VCT). They use the second

sensor to identify the position of the camshaft on bank 2 as an input to the PCM.

There are 2 types of CMP sensors: the 3-pin connector Hall-effect type sensor and the 2-pin connector

variable reluctance type sensor.

Typical Synchronizer Hall-Effect CMP Sensor

Typical Variable Reluctance CMP Sensor

Canister Vent (CV) Solenoid

During the evaporative emissions (EVAP) leak check monitor, the CV solenoid seals the EVAP canister from

the atmospheric pressure. This allows the EVAP canister purge valve to obtain the target vacuum in the fuel

tank during the EVAP leak check monitor.

Page 40

Typical Canister Vent (CV) Solenoid

Check Fuel Cap Indicator

The check fuel cap indicator is a communications network message sent by the PCM. The PCM sends the

message to illuminate the lamp when the strategy determines that there is a failure in the vapor

management system due to the fuel filler cap not being sealed correctly. This would be detected by the

inability to pull vacuum in the fuel tank, after a fueling event.

Clutch Pedal Position (CPP) Switch

The CPP switch is an input to the PCM indicating the clutch pedal position. The PCM provides a low current

voltage on the CPP circuit. When the CPP switch is closed, this voltage is pulled low through the SIG RTN

circuit. The CPP input to the PCM is used to detect a reduction in engine load. The PCM uses the load

information for mass air flow and fuel calculations.

Typical Clutch Pedal Position (CPP) Switch

Page 41

Coil On Plug (COP)

The COP ignition operates similar to a standard coil pack ignition except each plug has one coil per plug.

The COP has 3 different modes of operation: engine crank, engine running, and CMP failure mode effects

management (FMEM). For additional information, refer to Ignition Systems in this section.

Coil On Plug (COP)

Coil Pack

The PCM provides a grounding switch for the coil primary circuit. When the switch is closed, voltage is

applied to the coil primary circuit. This creates a magnetic field around the primary coil. The PCM opens the

switch, causing the magnetic field to collapse, inducing the high voltage in the secondary coil windings and

firing the spark plug. The spark plugs are paired so that as one spark plug fires on the compression stroke,

the other spark plug fires on the exhaust stroke. The next time the coil is fired the order is reversed. The

next pair of spark plugs fire according to the engine firing order.

Coil packs come in 4-tower, 6-tower horizontal and series 5 6-tower models. Two adjacent coil towers share

a common coil and are called a matched pair. For 6-tower coil pack (6 cylinder) applications, the matched

pairs are 1 and 5, 2 and 6, and 3 and 4. For 4-tower coil pack (4 cylinder) applications, the matched pairs

are 1 and 4, and 2 and 3.

When the coil is fired by the PCM, spark is delivered through the matched pair towers to their respective

spark plugs. The spark plugs are fired simultaneously and are paired so that as one fires on the

compression stroke, the other spark plug fires on the exhaust stroke. The next time the coil is fired, the

situation is reversed. The next pair of spark plugs fire according to the engine firing order.

Page 42

Four-Tower Coil Pack

Typical Six-Tower Coil Pack

Cooling Fan Clutch

The cooling fan clutch is an electrically actuated viscous clutch that consists of 3 main elements:

! a working chamber

Page 43

a reservoir chamber

!

a cooling fan clutch actuator valve and a fan speed sensor (FSS)

!

The cooling fan clutch actuator valve controls the fluid flow from the reservoir into the working chamber.

Once viscous fluid is in the working chamber, shearing of the fluid results in fan rotation. The cooling fan

clutch actuator valve is activated with a pulse width modulated (PWM) output signal from the PCM. By

opening and closing the fluid port valve, the PCM can control the cooling fan clutch speed. The cooling fan

clutch speed is measured by a Hall-effect sensor and is monitored by the PCM during closed loop operation.

The PCM optimizes fan speed based on engine coolant temperature (ECT), engine oil temperature (EOT),

transmission fluid temperature (TFT), intake air temperature (IAT), or air conditioning requirements. When

an increased demand for fan speed is requested for vehicle cooling, the PCM monitors the fan speed

through the Hall-effect sensor. If a fan speed increase is required, the PCM outputs the PWM signal to the

fluid port, providing the required fan speed increase.

Cooling Fan Clutch with Fan Speed Sensor (FSS)

Crankshaft Position (CKP) Sensor

The CKP sensor is a magnetic transducer mounted on the engine block adjacent to a pulse wheel located

on the crankshaft. By monitoring the crankshaft mounted pulse wheel, the CKP is the primary sensor for

ignition information to the PCM. The pulse wheel has a total of 35 teeth spaced 10 degrees apart with one

empty space for a missing tooth. The 6.8L 10-cylinder pulse wheel has 39 teeth spaced 9 degrees apart and

one 9 degree empty space for a missing tooth. By monitoring the pulse wheel, the CKP sensor signal

indicates crankshaft position and speed information to the PCM. By monitoring the missing tooth, the CKP

sensor is also able to identify piston travel in order to synchronize the ignition system and provide a way of

tracking the angular position of the crankshaft relative to a fixed reference for the CKP sensor configuration.

Page 44

The PCM also uses the CKP signal to determine if a misfire has occurred by measuring rapid decelerations

between teeth.

Typical Crankshaft Position (CKP) Sensor

Cylinder Head Temperature (CHT) Sensor

The CHT sensor is a thermistor device in which resistance changes with the temperature. The electrical

resistance of a thermistor decreases as temperature increases, and the resistance increases as the

temperature decreases. The varying resistance affects the voltage drop across the sensor terminals and

provides electrical signals to the PCM corresponding to temperature.

The CHT sensor is installed in the cylinder head and measures the metal temperature. The CHT sensor can

provide complete engine temperature information and can be used to infer coolant temperature. If the CHT

sensor conveys an overheating condition to the PCM, the PCM initiates a fail-safe cooling strategy based on

information from the CHT sensor. A cooling system concern such as low coolant or coolant loss could cause

an overheating condition. As a result, damage to major engine components could occur. Using both the CHT

sensor and fail-safe cooling strategy, the PCM prevents damage by allowing air cooling of the engine and