Page 1

1

Chapter 1

Routine maintenance and servicing

Air cleaner element renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Air cleaner temperature control check . . . . . . . . . . . . . . . . . . . . . . . .29

Auxiliary drivebelt check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Battery electrolyte level check . . . . . . . . . . . . . . .see

“Weekly checks”

Battery terminal check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Brake hydraulic fluid renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Brake hydraulic system seal and hose renewal . . . . . . . . . . . . . . . . .32

Brake pipe and hose check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Choke adjustment check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Contact breaker point renewal and distributor lubrication

- OHV engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Crankcase ventilation system check . . . . . . . . . . . . . . . . . . . . . . . . .28

Emission control filter element renewal - CVH engines . . . . . . . . . . .30

Engine coolant renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Engine idle speed check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Engine oil and filter renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Engine valve clearance check - OHV engines . . . . . . . . . . . . . . . . . .18

Exhaust system check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Fluid leak check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Fluid level checks . . . . . . . . . . . . . . . . . . . . . . . . .see “Weekly checks”

Front and rear brake pad/shoe check . . . . . . . . . . . . . . . . . . . . . . . . .4

Front wheel alignment check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Gearbox oil level check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Handbrake check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Hinge and lock check and lubrication . . . . . . . . . . . . . . . . . . . . . . . .14

HT lead, distributor cap and ignition circuit check . . . . . . . . . . . . . . .13

Ignition timing and contact breaker gap (dwell angle) check

- OHV engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Intensive maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Mixture adjustment check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Road test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Roadwheel security check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Seat belt check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Spark plug check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Spark plug renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Steering and suspension security check . . . . . . . . . . . . . . . . . . . . . .24

Throttle damper operation check . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Timing belt renewal - CVH engines . . . . . . . . . . . . . . . . . . . . . . . . . .34

Tyre checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .see “Weekly checks”

Underbody inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Wiper blade check . . . . . . . . . . . . . . . . . . . . . . . .see “Weekly checks”

1•1

Contents

Easy, suitable for

novice with little

experience

Fairly easy, suitable

for beginner with

some experience

Fairly difficult,

suitable for competent

DIY mechanic

Difficult, suitable for

experienced DIY

mechanic

Very difficult,

suitable for expert DIY

or professional

Degrees of difficulty

5

4

3

2

1

Servicing Specifications

Lubricants and fluids See end of “Weekly checks”

Capacities

Engine oil

With filter:

1.0 and 1.1 OHV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.25 litres (5.7 Imp pints)

1.3,1.4 and 1.6 CVH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.50 litres (6.2 Imp pints)

Without filter:

1.0 and 1.1 OHV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.75 litres (4.8 Imp pints)

1.3, 1.4 and 1.6 CVH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.25 litres (5.7 Imp pints)

Cooling system (including heater)

1.0 and 1.1 OHV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.5 litres (9.7 Imp pints)

1.3 and 1.4 CVH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.3 litres (11.1 Imp pints)

1.6 CVH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.0 litres (14.1 Imp pints)

Fuel tank

All models - pre 1985, except XR2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 litres (7.5 gallons)

XR2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38 litres (8.4 gallons)

All models - 1985 on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40 litres (8.8 gallons)

Gearbox

4-speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.8 litres (4.9 Imp pints)

5-speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.1 litres (5.5 Imp pints)

Page 2

1•2 Servicing Specifications

Engine

Oil filter type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion C104

Valve clearances (only OHV applicable):

Inlet:

At operating temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.22 mm (0.009 in)

Cold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.20 to 0.25 mm (0.008 to 0.010 in)

Exhaust:

At operating temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.59 mm (0.023 in)

Cold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.56 to 0.61 mm (0.022 to 0.024 in)

Cooling system

Drivebelt tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.0 mm (0.16 in) total deflection at the midpoint of the belt’s longest run

Fuel system

Air filter element type:

1.0 and 1.1 (OHV) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion W153

1.3 (CVH) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion W127

1.4 (CVH) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion W179

1.6 (CVH) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion W201

Ignition system

Spark plugs:

Make and type:

Mechanical system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion RS9YCC or RS9YC

Electronic system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion RC7YCC or RC7YC

Electrode gap:

RS9YCC and RC7YCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.80 mm (0.032 in)

RS9YC and RC7YC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.75 mm (0.030 in)

Note: The spark plug gap quoted is that recommended by Champion for their specified plugs listed above. If spark plugs of any other type are to

be fitted, refer to their manufacturer’s recommendations.

Contact breaker points gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.40 to 0.50 mm (0.016 to 0.020 in)

Dwell (mechanical ignition):

Angle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48° to 52°

Variation (from idle to 2000 rpm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4° maximum

Overlap (lobe-to-lobe variation) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3° maximum

Timing (initial):

1.0 litre OHV (pre 1986) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12° BTDC

1.1 litre OHV (pre 1986) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6° BTDC

Ignition HT lead set:

Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 k ohms maximum per lead

Type:

Mechanical system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion CLS 8 boxed set

Electronic system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion CLS 9 boxed set

Brakes

Front brake pad friction material minimum thickness . . . . . . . . . . . . . . 1.5 mm (0.059 in)

Rear brake shoe friction material minimum thickness . . . . . . . . . . . . . . 1.0 mm (0.04 in)

Tyres

Tyre sizes:

Note: Manufacturers often modify tyre sizes and pressure recommendations. The following is intended as a guide only. Refer to your vehicle

handbook or a Ford dealer for the latest recommendations.

XR2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185/60 HR 13

Other models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135 SR 13, 155/70 SR 13 or 165/65 SR 13

Tyre pressures: See end of “Weekly checks”

Torque wrench settings Nm lbf ft

Engine oil drain plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 18

Radiator coolant drain plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5 1.1

Gearbox oil filler/level plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 20

Roadwheel bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 74

Spark plugs:

OHV engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 to 20 10 to 15

CVH engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 20

Brake caliper piston housing bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 17

Page 3

The maintenance intervals in this manual

are provided with the assumption that you will

be carrying out the work yourself. These are

the minimum maintenance intervals

recommended by the manufacturer for

vehicles driven daily. If you wish to keep your

vehicle in peak condition at all times, you may

wish to perform some of these procedures

more often. We encourage frequent

maintenance, because it enhances the

efficiency, performance and resale value of

your vehicle.

If the vehicle is driven in dusty areas, used

to tow a trailer, or driven frequently at slow

speeds (idling in traffic) or on short journeys,

more frequent maintenance intervals are

recommended.

When the vehicle is new, it should be

serviced by a factory-authorised dealer

service department, in order to preserve the

factory warranty.

Maintenance schedule 1•3

1

Every 250 miles (400 km) or weekly

mm Refer to “Weekly checks”

Every 6000 miles (10 000 km) or

6 months - whichever comes sooner

mm Renew engine oil and filter (Section 3)

mm Check brake pads or shoes for wear (front and

rear) (Section 4)

mm Check operation of brake fluid level warning

indicator (Section 4)

mm Inspect engine bay and underside of vehicle for

fluid leaks or other signs of damage (Section 5)

mm Check function and condition of seat belts

(Section 6)

mm Check condition and security of exhaust system

(Section 7)

mm Check tightness of wheel nuts (Section 8)

mm Check choke adjustment (Section 9)

mm Check idle speed (Section 10)

mm Check mixture adjustment (Section 11)

mm Check spark plugs (Section 12)

mm Check HT leads, distributor cap and ignition circuit

(Section 13)

mm Check operation of latches, check straps and

locks; lubricate if necessary (Section 14)

mm Check ignition timing and contact breaker gap

(dwell angle) (OHV engines) (Section 15)

mm Check operation of throttle damper (where

applicable) (Section 16)

Every 12 000 miles (20 000 km) or

12 months - whichever comes sooner

(continued)

mm Renew spark plugs (Section 21)

mm Check gearbox oil level (Section 22)

mm Renew distributor contact breaker points and

lubricate distributor - OHV engines (Section 23)

mm Check security and condition of steering and

suspension components, gaiters and boots

(Section 24)

mm Inspect underbody and panels for corrosion or

other damage (Section 25)

mm Inspect brake pipes and hoses (Section 26)

mm Road test (Section 27)

mm Check crankcase ventilation system (Section 28)

Every 24 000 miles (40 000 km) or 2

years - whichever comes sooner

mm Check air cleaner temperature control (Section 29)

mm Renew emission control filter element - CVH

engines (Section 30)

mm Renew air cleaner element (Section 31)

Every 36 000 miles (60 000 km) or 3

years - whichever comes sooner

mm Renew brake hydraulic system seals and hoses if

necessary (Section 32)

mm Renew brake hydraulic fluid (Section 33)

mm Renew timing belt - CVH engines (Section 34)

mm Check front wheel alignment (Section 35)

Every 12 000 miles (20 000 km) or

12 months - whichever comes sooner

mm Check tightness of battery terminals, clean and

neutralise corrosion (Section 17)

mm Check engine valve clearances - OHV engines

(Section 18)

mm Check handbrake mechanism (Section 19)

mm Check condition and tension of auxiliary drivebelt

(Section 20)

Every 2 years, regardless of mileage

mm Renew coolant (Section 36)

Page 4

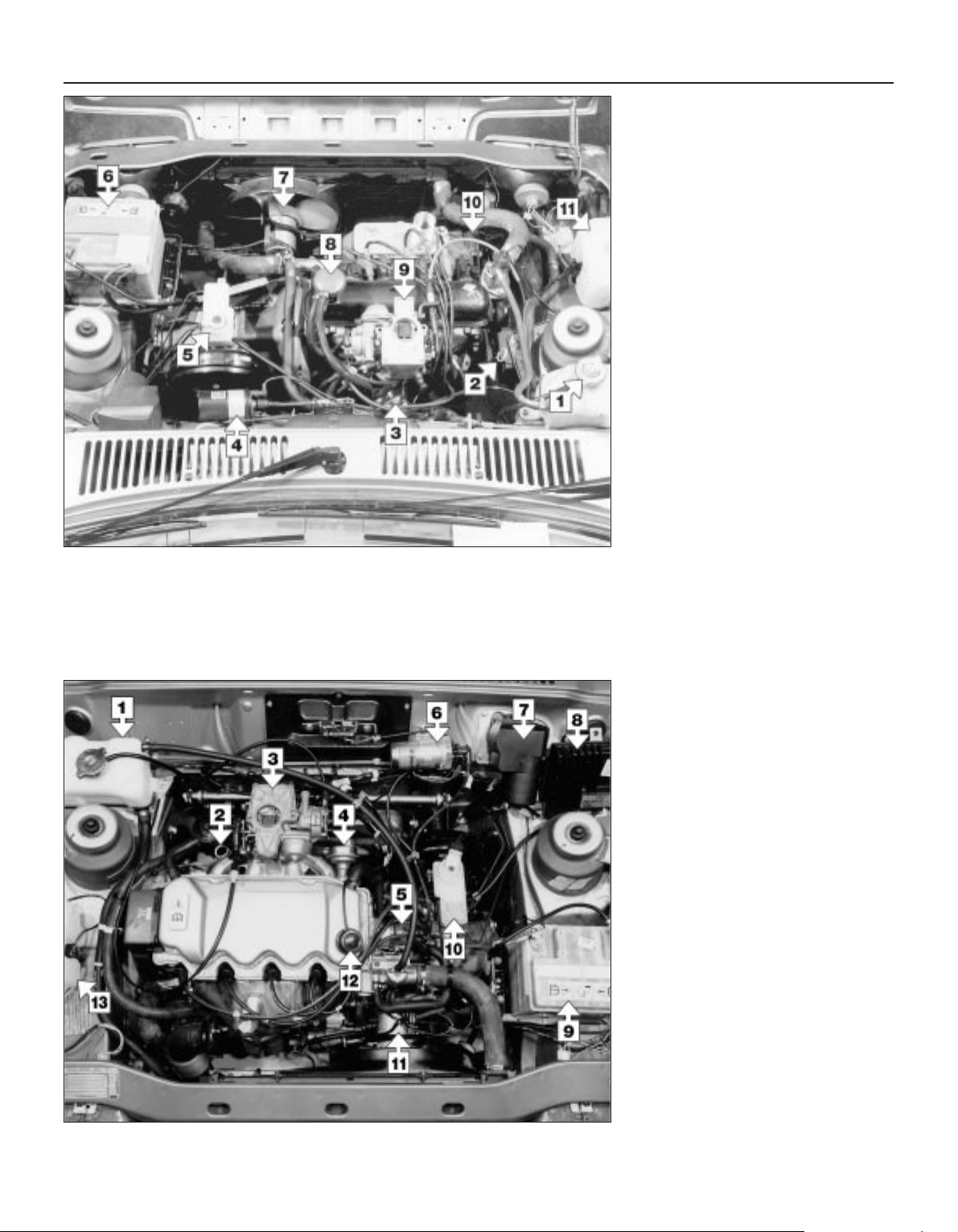

1•4 Maintenance - component location

Engine compartment - OHV

1 Coolant expansion tank

2 Engine oil dipstick

3 Oil filter

4 Ignition coil

5 Brake fluid reservoir

6 Battery

7 Cooling fan

8 Oil filler cap

9 Carburettor (air cleaner removed)

10 Alternator

11 Washer reservoir

Engine compartment - CVH

1 Coolant expansion tank

2 Engine oil dipstick

3 Carburettor (air cleaner removed)

4 Fuel pump

5 Distributor

6 Ignition coil

7 Windscreen wiper motor

8 Ignition amplifier module

9 Battery

10 Brake fluid reservoir

11 Cooling fan

12 Oil filler cap

13 Washer reservoir

Page 5

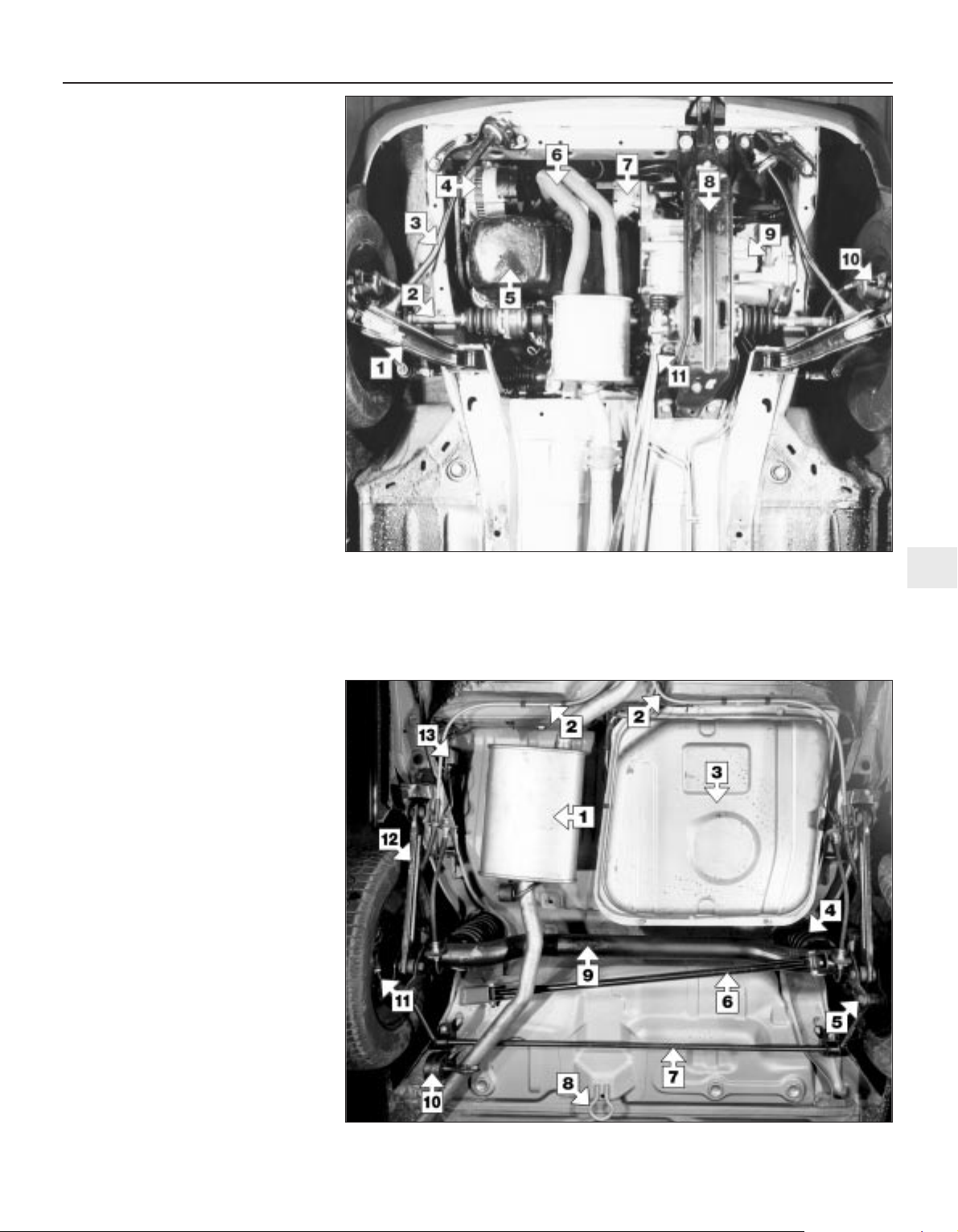

Maintenance - component location 1•5

1

Underside view of car at rear

1 Rear silencer

2 Brake secondary cable

3 Fuel tank

4 Suspension coil spring

5 Shock absorber lower mounting

6 Panhard rod

7 Anti-roll bar (certain models only)

8 Towing eye

9 Axle beam

10 Exhaust system mounting

11 Handbrake adjustment check plunger

12 Suspension trailing arm

13 Brake pressure control valve

Underside view of car at front - CVH

1 Suspension arm

2 Driveshaft

3 Tie-bar

4 Alternator

5 Sump

6 Exhaust

7 Starter motor

8 Engine/gearbox bearer

9 Gearbox

10 Disc brake caliper

11 Gearchange rod and stabilizer rod

Page 6

1 Introduction

This Chapter is designed to help the home

mechanic maintain his/her vehicle for safety,

economy, long life and peak performance.

The Chapter contains a master

maintenance schedule, followed by Sections

dealing specifically with each task in the

schedule. Visual checks, adjustments,

component renewal and other helpful items

are included. Refer to the accompanying

illustrations of the engine compartment and

the underside of the vehicle for the locations

of the various components.

Servicing your vehicle in accordance with

the mileage/time maintenance schedule and

the following Sections will provide a planned

maintenance programme, which should result

in a long and reliable service life. This is a

comprehensive plan, so maintaining some

items but not others at the specified service

intervals, will not produce the same results.

As you service your vehicle, you will

discover that many of the procedures can and should - be grouped together, because of

the particular procedure being performed, or

because of the close proximity of two

otherwise-unrelated components to one

another. For example, if the vehicle is raised

for any reason, the exhaust can be inspected

at the same time as the suspension and

steering components.

The first step in this maintenance

programme is to prepare yourself before the

actual work begins. Read through all the

Sections relevant to the work to be carried

out, then make a list and gather together all

the parts and tools required. If a problem is

encountered, seek advice from a parts

specialist, or a dealer service department.

2 Intensive maintenance

If, from the time the vehicle is new, the

routine maintenance schedule is followed

closely, and frequent checks are made of fluid

levels and high-wear items, as suggested

throughout this manual, the engine will be

kept in relatively good running condition, and

the need for additional work will be minimised.

It is possible that there will be times when

the engine is running poorly due to the lack of

regular maintenance. This is even more likely

if a used vehicle, which has not received

regular and frequent maintenance checks, is

purchased. In such cases, additional work

may need to be carried out, outside of the

regular maintenance intervals.

If engine wear is suspected, a compression

test will provide valuable information

regarding the overall performance of the main

internal components. Such a test can be used

as a basis to decide on the extent of the work

to be carried out. If, for example, a

compression test indicates serious internal

engine wear, conventional maintenance as

described in this Chapter will not greatly

improve the performance of the engine, and

may prove a waste of time and money, unless

extensive overhaul work is carried out first.

The following series of operations are those

most often required to improve the

performance of a generally poor-running

engine:

Primary operations

a) Clean, inspect and test the battery

b) Check all the engine-related fluids

c) Check the condition and tension of the

auxiliary drivebelt

d) Renew the spark plugs

e) Inspect the distributor cap and HT leads -

as applicable

f) Check the condition of the air cleaner

filter element, and renew if necessary

g) Renew the fuel filter (if fitted)

h) Check the condition of all hoses, and

check for fluid leaks

i) Check the idle speed and mixture settings

- as applicable

If the above operations do not prove fully

effective, carry out the following secondary

operations:

Secondary operations

a) Check the charging system

b) Check the ignition system

c) Check the fuel system

d) Renew the distributor cap and rotor arm -

as applicable

e) Renew the ignition HT leads - as applicable

3 Engine oil and filter renewal

1

1 Frequent oil and filter changes are the most

important preventative maintenance

procedures which can be undertaken by the

DIY owner. As engine oil ages, it becomes

diluted and contaminated, which leads to

premature engine wear.

2 Before starting this procedure, gather

together all the necessary tools and materials.

Also make sure that you have plenty of clean

rags and newspapers handy, to mop up any

spills. Ideally, the engine oil should be warm,

as it will drain better, and more built-up

sludge will be removed with it. Take care,

however, not to touch the exhaust or any

other hot parts of the engine when working

under the vehicle. To avoid any possibility of

scalding, and to protect yourself from

possible skin irritants and other harmful

contaminants in used engine oils, it is

advisable to wear gloves when carrying out

this work. Access to the underside of the

vehicle will be greatly improved if it can be

raised on a lift, driven onto ramps, or jacked

up and supported on axle stands (see

“Jacking and vehicle support”). Whichever

method is chosen, make sure that the vehicle

remains level, or if it is at an angle, so that the

drain plug is at the lowest point.

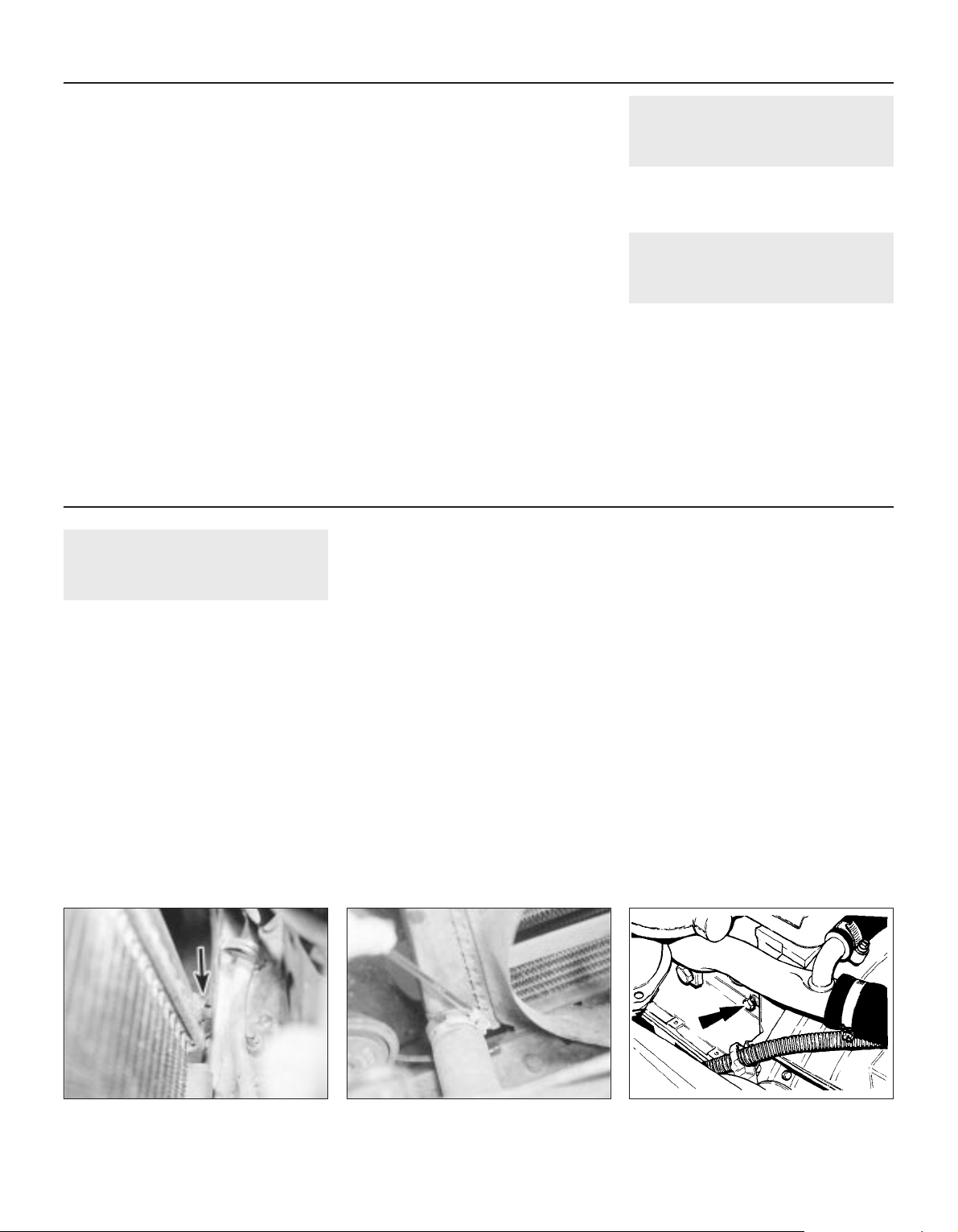

3 Slacken the drain plug about half a turn (see

illustration). Position the draining container

under the drain plug, then remove the plug

completely. If possible, try to keep the plug

pressed into the sump while unscrewing it by

hand the last couple of turns. Recover the

sealing washer from the drain plug.

4 Allow some time for the old oil to drain,

noting that it may be necessary to reposition

the container as the oil flow slows to a trickle.

5 After all the oil has drained, wipe off the

drain plug with a clean rag. Check the sealing

washer for condition, and renew it if

necessary. Clean the area around the drain

plug opening, and refit the plug. Tighten the

plug to the specified torque.

6 Move the container into position under the

oil filter.

7 Using an oil filter removal tool if necessary,

slacken the filter initially, then unscrew it by

hand the rest of the way (see illustration).

Empty the oil from the old filter into the

container, and discard the filter.

8 Use a clean rag to remove all oil, dirt and

sludge from the filter sealing area on the

engine. Check the old filter to make sure that

the rubber sealing ring hasn’t stuck to the

engine. If it has, carefully remove it.

1•6 Maintenance procedures

3.3 Removing the sump drain plug

6000 Mile (10 000 Km) / 6 Month Service

Remove the engine oil drain

plug quickly so that the

stream of oil runs into the

container, not up your sleeve!

Page 7

9 Apply a light coating of clean engine oil to

the sealing ring on the new filter, then screw it

into position on the engine. Tighten the filter

firmly by hand only - do not use any tools.

Wipe clean the filter and sump drain plug.

10 Remove the old oil and all tools from

under the car, then lower the car to the

ground (if applicable).

11 Remove the oil filler cap and withdraw the

dipstick. Fill the engine, using the correct

grade and type of oil (see “Lubricants and

fluids” and “Capacities” in the Specifications).

An oil can spout or funnel may help to reduce

spillage. Pour in half the specified quantity of

oil first, then wait a few minutes for the oil to

fall to the sump. Continue adding oil a small

quantity at a time until the level is up to the

lower mark on the dipstick. Finally, bring the

level up to the upper mark on the dipstick.

Insert the dipstick, and refit the filler cap.

12 Start the engine and run it for a few

minutes; check for leaks around the oil filter

seal and the sump drain plug. Note that there

may be a delay of a few seconds before the oil

pressure warning light goes out when the

engine is first started, as the oil circulates

through the engine oil galleries and the new oil

filter, before the pressure builds up.

13 Switch off the engine, and wait a few

minutes for the oil to settle in the sump once

more. With the new oil circulated and the filter

completely full, recheck the level on the

dipstick, and add more oil as necessary.

14 Dispose of the used engine oil safely.

4 Front and rear brake

pad/shoe check

1

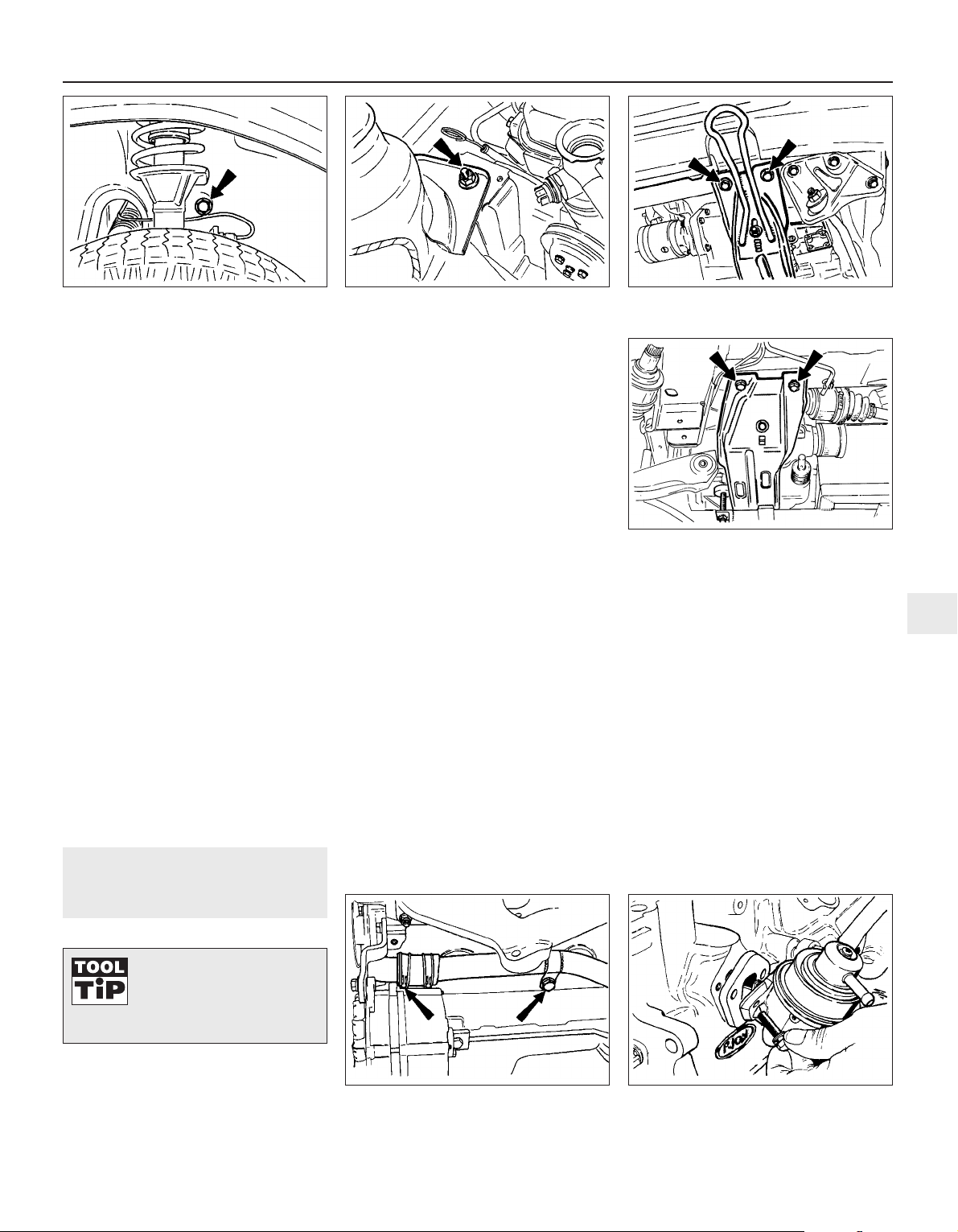

1 Firmly apply the handbrake, then jack up

the front and rear of the car and support it

securely on axle stands (see “Jacking and

vehicle support”).

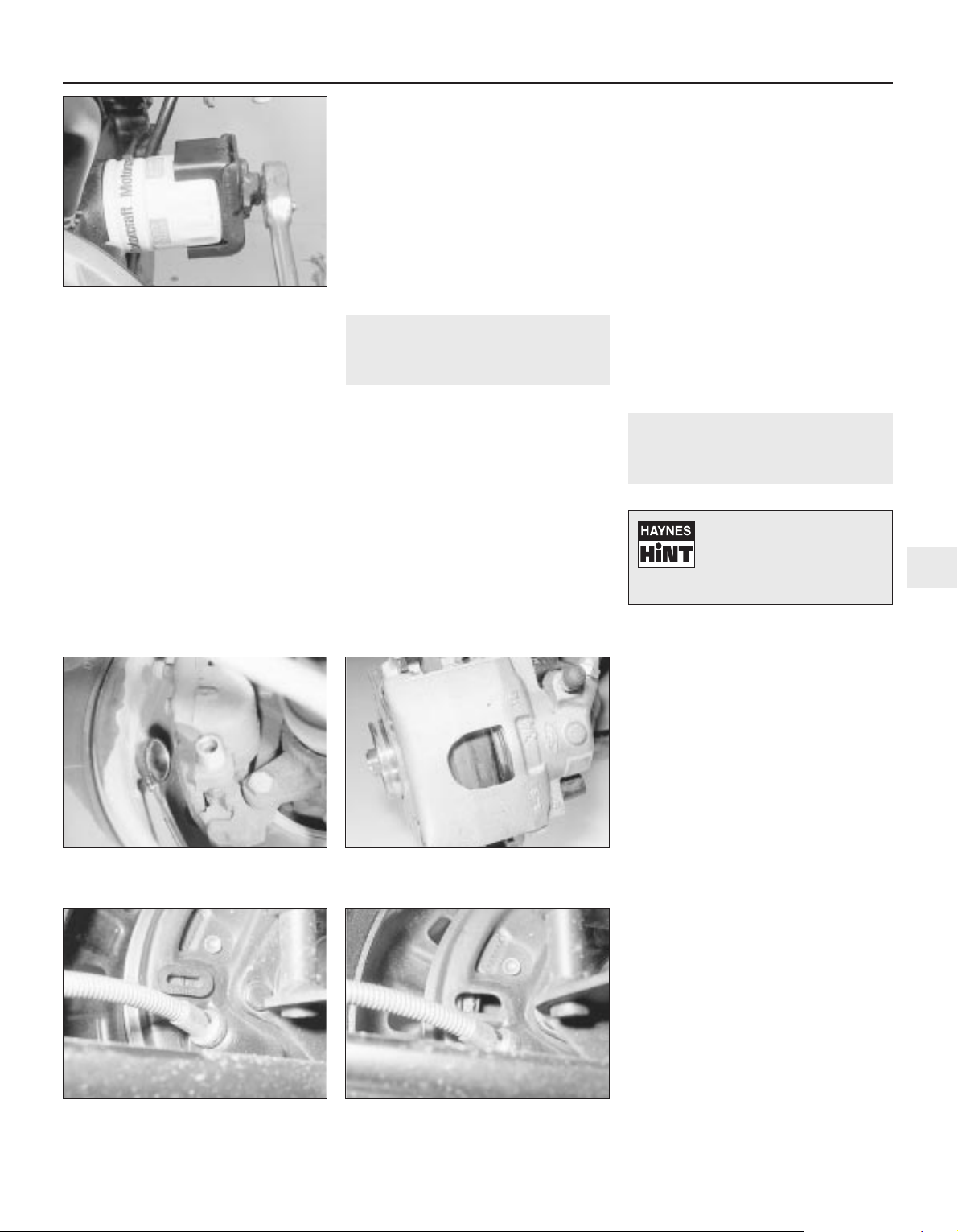

2 For a quick check, the front brake disc pads

can be inspected without removing the front

wheels by inserting a mirror between each

caliper and roadwheel (see illustrations). If

any one pad is worn down to the minimum

specified thickness, all four pads (on both

front wheels) must be renewed.

3 For a comprehensive check, the brake disc

pads should be removed and cleaned. The

operation of the caliper can then also be

checked, and the condition of the brake discs

can be fully examined on both sides. Refer to

Chapter 9 for further information.

4 The rear brake shoe friction material can be

inspected for wear without removing the

roadwheels. Working beneath the vehicle,

prise the plug from the brake backplate and

using an inspection lamp or torch, check that

the friction material thickness is not less than

the minimum given in the Specifications (see

illustrations). If any one of the shoes has

worn below the specified limit, the shoes must

be renewed as an axle set (4 shoes).

5 At the same interval, check the function of

the brake fluid level warning light. Chock the

wheels, release the handbrake and switch on

the ignition. Unscrew and raise the brake fluid

reservoir cap whilst an assistant observes the

warning light: it should come on as the level

sensor is withdrawn from the fluid. Refit the

cap.

6 On completion, refit the wheels and lower

the car to the ground.

5 Fluid leak check

1

1 Visually inspect the engine joint faces,

gaskets and seals for any signs of water or oil

leaks. Pay particular attention to the areas

around the rocker cover, cylinder head, oil

filter and sump joint faces. Bear in mind that

over a period of time some very slight

seepage from these areas is to be expected

but what you are really looking for is any

indication of a serious leak. Should a leak be

found, renew the offending gasket or oil seal

by referring to the appropriate Chapter(s) in

this manual.

2 Similarly, check the transmission for oil

leaks, and investigate and rectify and

problems found.

3 Check the security and condition of all the

engine related pipes and hoses. Ensure that

all cable-ties or securing clips are in place and

in good condition. Clips which are broken or

missing can lead to chafing of the hoses,

pipes or wiring which could cause more

serious problems in the future.

4 Carefully check the condition of all coolant,

fuel and brake hoses. Renew any hose which

is cracked, swollen or deteriorated. Cracks

will show up better if the hose is squeezed.

Pay close attention to the hose clips that

secure the hoses to the system components.

Hose clips can pinch and puncture hoses,

resulting in leaks. If wire type hose clips are

used, it may be a good idea to replace them

with screw-type clips.

5 With the vehicle raised, inspect the fuel

tank and filler neck for punctures, cracks and

Every 6000 miles or 6 months 1•7

4.2b Inspect the disc brake pads through

the caliper housing aperture

4.4b . . . to check the rear brake linings for

wear

4.4a Remove the inspection plug from the

rear brake backplate . . .

4.2a Using a mirror to check disc brake

pads for wear

3.7 Removing the engine oil filter with a

clamp wrench

1

Leaks in the cooling system

will usually show up as

white or rust-coloured

deposits around the area

adjoining the leak.

Page 8

other damage. The connection between the

filler neck and tank is especially critical.

Sometimes a rubber filler neck or connecting

hose will leak due to loose retaining clamps or

deteriorated rubber.

6 Similarly, inspect all brake hoses and metal

pipes. If any damage or deterioration is

discovered, do not drive the vehicle until the

necessary repair work has been carried out.

Renew any damaged sections of hose or pipe.

7 Carefully check all rubber hoses and metal

fuel lines leading away from the petrol tank.

Check for loose connections, deteriorated

hoses, crimped lines and other damage. Pay

particular attention to the vent pipes and

hoses which often loop up around the filler

neck and can become blocked or crimped.

Follow the lines to the front of the vehicle

carefully inspecting them all the way. Renew

damaged sections as necessary.

8 From within the engine compartment,

check the security of all fuel hose attachments

and pipe unions, and inspect the fuel hoses

and vacuum hoses for kinks, chafing and

deterioration.

9 Check the condition of all exposed wiring

harnesses.

6 Seat belt check

1

1 Periodically check the belts for fraying or

other damage. If evident, renew the belt.

2 If the belts become dirty, wipe them with a

damp cloth using a little detergent only.

3 Check the tightness of the anchor bolts and

if they are ever disconnected, make quite sure

that the original sequence of fitting of

washers, bushes and anchor plates is

retained.

7 Exhaust system check

1

With the vehicle raised on a hoist or

supported on axle stands (see “Jacking and

vehicle support”), check the exhaust system

for signs of leaks, corrosion or damage and

check the rubber mountings for condition and

security (see illustration). Where damage or

corrosion are evident, renew the system

complete or in sections, as applicable, using

the information given in Chapter 4.

8 Roadwheel security check

1

With the wheels on the ground, slacken

each wheel bolt by a quarter turn, then

retighten it immediately to the specified

torque.

9 Choke adjustment check

2

On models equipped with carburettors of

Ford manufacture, refer to Chapter 4, Section

9 and check that the choke is adjusted within

the stated parameters.

10 Engine idle speed check

3

Note: Refer to the precautions given in

Section 1 of Chapter 4 before proceeding.

Note: Before carrying out any carburettor

adjustments, ensure that the ignition timing

and spark plug gaps are set as specified. To

carry out this adjustment, an accurate

tachometer will be required.

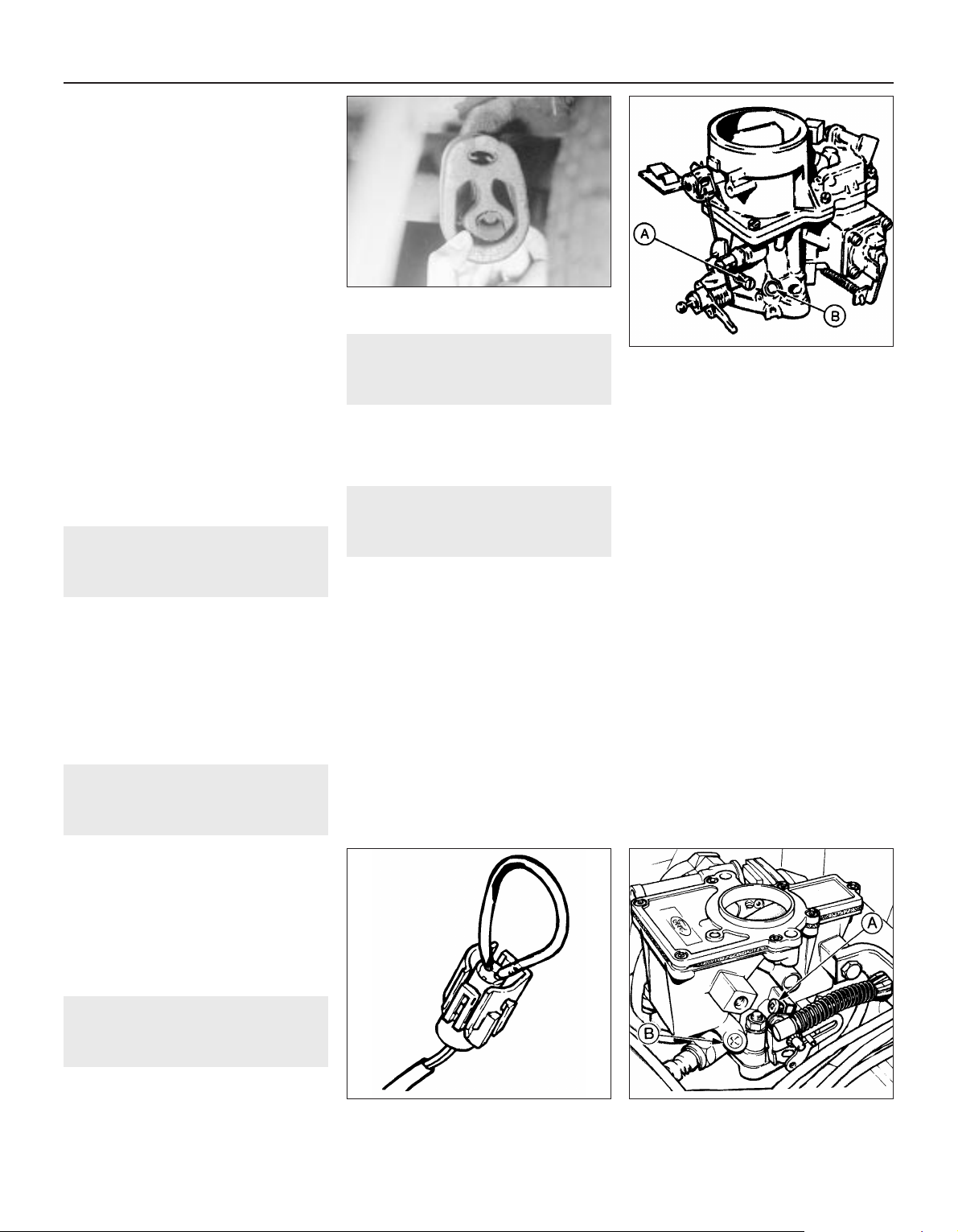

Ford 1V carburettor

1 Ensure that the air cleaner is correctly fitted,

and that all vacuum hoses and pipes are

securely connected and free from restrictions,

then run the engine until it is at normal

operating temperature.

2 With the engine at normal operating

temperature, adjust the idle speed screw (see

illustration) to obtain the specified idle speed,

using a tachometer to ensure accuracy.

Ford VV carburettor

3 This procedure must be carried out with the

radiator cooling fan in operation. To keep the

fan running during the adjustment procedure,

disconnect the wiring multi-plug from the

thermal switch (located in the thermostat

housing) and bridge the two contacts in the

plug with a short length of wire (see

illustration). Disconnect the wire and refit the

multi-plug on completion of the adjustments.

Make sure that the engine and ignition are

switched off when connecting and

disconnecting the bridging wire.

4 Ensure that the air cleaner is correctly fitted,

and that all vacuum hoses and pipes are

securely connected and free from restrictions,

then run the engine until it is at normal

operating temperature.

5 With the engine at normal operating

temperature, connect a tachometer in

accordance with the manufacturer’s

instructions.

6 Start the engine, run it at 3000 rpm for 30

seconds and then let it idle. Turn the idle

speed adjusting screw in or out as necessary

to bring the speed to that given in the Specifications (see illustration).

1•8 Every 6000 miles or 6 months

7.1 Inspect the exhaust system rubber

mounting

10.3 Temporary bridging wire in cooling

fan thermal switch multi-plug

10.6 Ford VV carburettor idle speed screw

(A) and mixture screw (B)

10.2 Ford 1V carburettor idle speed screw

(A) and mixture screw (B)

Page 9

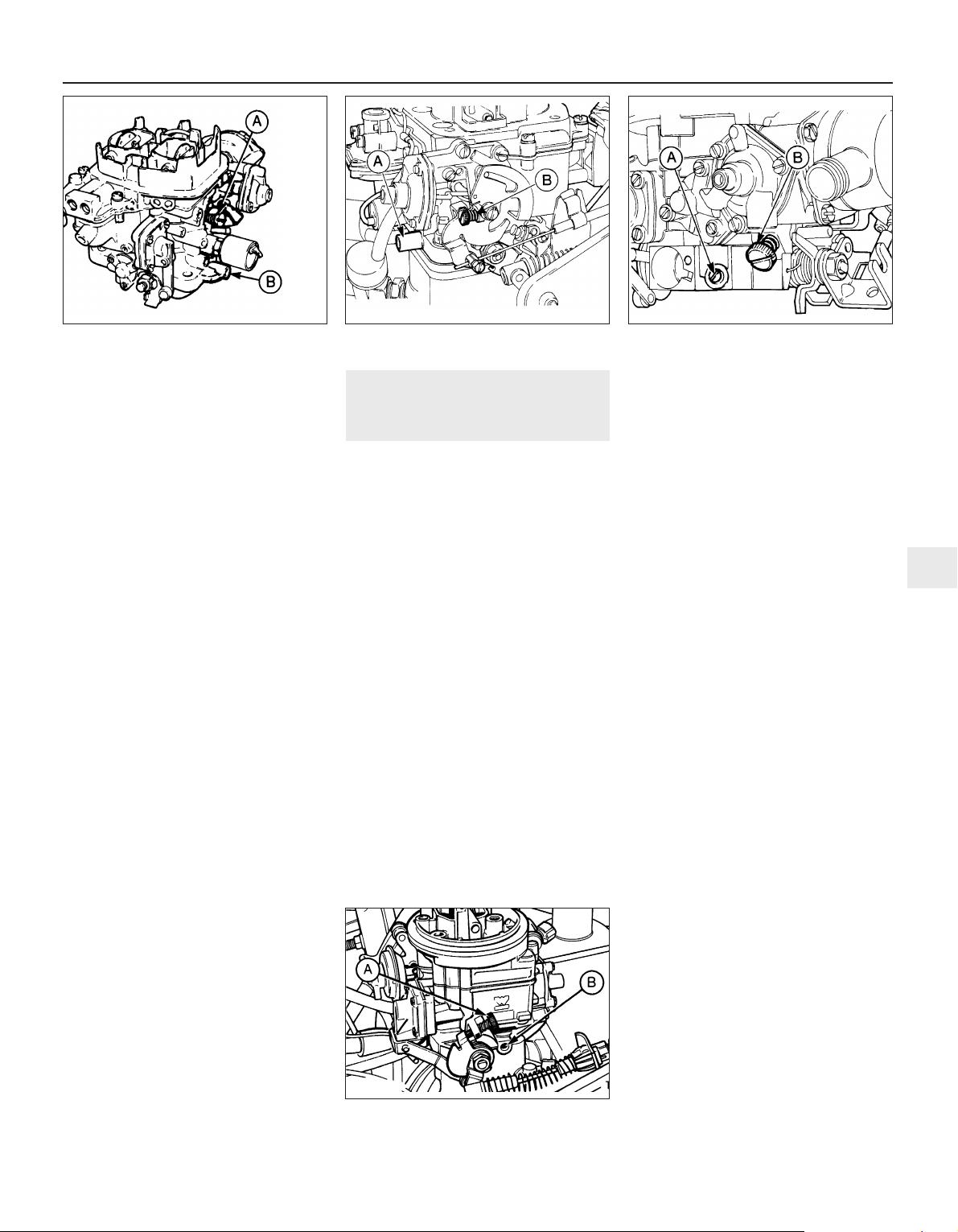

Weber 2V carburettor

7 Refer to the information relating to the Ford

1V carburettor for details, and to the

accompanying illustration (see illustration)

for the adjusting screws. Ensure that the

engine fan is operating by pulling the two

wires from the sensor, and connecting the

wires with a jumper lead.

Weber 2V DFTM

8 Before carrying out this adjustment, ensure

that the air cleaner is correctly fitted and that

all vacuum hoses and pipes are securely

connected and free from restrictions. Run the

engine until it is at normal operating

temperature.

9 The cooling fan must be kept running

during the adjustment procedure. To do this,

disconnect the wiring multi-plug from the

thermal switch (located in the thermostat

housing) and bridge the two contacts in the

plug with a short length of wire.

10 Start the engine and turn the idle speed

adjustment screw (see illustration) to obtain

the specified idle speed, using a tachometer

to ensure accuracy.

Weber 2V TLD carburettor

11 Refer to the information relating to the

Weber 2V DFTM carburettor for details, and to

the accompanying illustration (see illustration)

for the adjusting screws.

Weber (1V) TLM carburettor

12 Before carrying out this adjustment,

ensure that the air cleaner is correctly fitted

and that all vacuum hoses and pipes are

securely connected and free from restrictions.

Run the engine until it is at normal operating

temperature.

13 Connect a reliable tachometer to the

engine in accordance with the manufacturer’s

instructions.

14 Increase the engine speed to 3000 rpm

and hold it at this speed for 30 seconds, then

allow the engine to idle. Adjust the idle speed

to within the specified range by turning the

idle speed screw (see illustration).

11 Mixture adjustment check

3

Note: Refer to the precautions given in

Section 1 of Chapter 4 before proceeding.

Note: Before carrying out any carburettor

adjustments, ensure that the ignition timing

and spark plug gaps are set as specified. To

carry out the adjustments an accurate

tachometer and an exhaust gas analyser (CO

meter) will be required. Adjustment of the idle

mixture setting should not be attempted in

territories where this may cause a violation of

exhaust emission regulations. Where these

regulations are less stringent the following

procedures may be used.

Ford 1V carburettor

1 Ensure that the air cleaner is correctly fitted

and that all vacuum hoses and pipes are

securely connected and free from restrictions,

then run the engine until it is at normal

operating temperature.

2 Using a small screwdriver, prise out the

tamperproof plug (if fitted) over the idle

mixture screw.

3 Connect the CO meter and tachometer

according to the manufacturer’s instructions.

4 Adjust the idle speed to the specified setting.

5 Run the engine at 3000 rpm for 30 seconds

to clear the inlet manifold of excess fuel.

Repeat this operation every 30 seconds

during the adjustment procedure.

6 Turn the idle mixture screw in the desired

direction to achieve the fastest possible

engine speed consistent with smooth, even

running or the correct specified CO reading

on the meter scale.

7 If necessary, readjust the idle speed setting

on completion. Fit a new tamperproof plug to

the mixture screw.

Ford VV carburettor

8 This procedure must be carried out with the

radiator cooling fan in operation. To keep the

fan running during the adjustment procedure,

disconnect the wiring multi-plug from the

thermal switch (located in the thermostat

housing) and bridge the two contacts in the

plug with a short length of wire. Disconnect

the wire and refit the multi-plug on completion

of the adjustments. Make sure that the engine

and ignition are switched off when connecting

and disconnecting the bridging wire.

9 To adjust the mixture accurately, connect a

CO (exhaust gas) analyser and a tachometer

in accordance with the manufacturer’s

instructions.

10 Ensure that the air cleaner is correctly

fitted and that all vacuum hoses and pipes are

securely connected and free from restrictions,

then run the engine until it is at normal

operating temperature.

11 Using a thin, sharp screwdriver, prise out

the tamperproof plug which covers the

mixture screw.

12 Start the engine and run it at 3000 rpm for

30 seconds, then allow it to return to idle. Turn

the mixture screw in (weak) or out (rich) until

the CO level is within the specified range as

indicated on the analysing equipment. The

adjustment must be carried out within 30

seconds; otherwise, again increase the engine

speed for 30 seconds before continuing with

the adjustment.

13 Once the mixture is correct, adjust the idle

speed then recheck the mixture.

14 Switch off the engine and remove the

tachometer and the exhaust gas analyser. Fit

a new tamperproof plug to the mixture screw.

15 In the absence of a suitable exhaust gas

analyser, an approximate setting of the

mixture screw may be made by turning the

screw inwards (engine idling) until the idle

speed just begins to drop. Unscrew the screw

Every 6000 miles or 6 months 1•9

10.11 Weber 2V TLD carburettor mixture

screw (A) and idle speed screw (B)

10.14 Weber (1V) TLM carburettor idle

speed screw (A) and mixture screw (B)

10.10 Weber 2V DFTM carburettor mixture

screw (A) and idle speed screw (B)

10.7 Weber 2V carburettor idle speed

screw (A) and mixture screw (B)

1

Page 10

the smallest amount necessary to achieve

smooth idle. The CO level of the exhaust gas

should be checked by your dealer at the

earliest opportunity and further adjustment

carried out as may be necessary.

Weber 2V carburettor

16 Refer to the information relating to the

Ford 1V carburettor for details. Ensure that

the engine fan is operating by pulling the two

wires from the sensor, and connecting the

wires with a jumper lead.

Weber 2V DFTM carburettor

17 The cooling fan must be kept running

during the adjustment procedure. To do this,

disconnect the wiring multi-plug from the

thermal switch (located in the thermostat

housing) and bridge the two contacts in the

plug with a short length of wire.

18 Ensure that the air cleaner is correctly

fitted and that all vacuum hoses and pipes are

securely connected and free from restrictions,

then run the engine until it is at normal

operating temperature.

19 Using a small screwdriver, prise out the

tamperproof plug (if fitted) over the idle

mixture screw.

20 Connect the CO meter and tachometer

according to the manufacturer’s instructions.

21 Adjust the idle speed to the correct setting.

22 Run the engine at 3000 rpm for 30

seconds to clear the inlet manifold of excess

fuel. Repeat this operation every 30 seconds

during the adjustment procedure.

23 Turn the idle mixture screw in the desired

direction to achieve the fastest possible

engine speed consistent with smooth, even

running; or the correct specified CO reading

on the meter scale.

24 If necessary, readjust the idle speed

setting. Refit the cooling fan multi-plug and fit

a new tamperproof plug.

Weber 2V TLD carburettor

25 Refer to the information relating to the

Weber 2V DFTM carburettor for details.

Weber (1V) TLM carburettor

26 Ensure that the air cleaner is correctly

fitted and that all vacuum hoses and pipes are

securely connected and free from restrictions,

then run the engine until it is at normal

operating temperature.

27 With the engine at normal operating

temperature, connect a tachometer and

exhaust gas analyser in accordance with the

manufacturer’s instructions.

28 Prise out the tamperproof plug from the

mixture screw hole in the throttle valve block.

29 Wait for the radiator cooling fan to

operate, then raise the engine speed to 3000

rpm, hold it at this speed for 30 seconds,

return to idle and check the exhaust CO level

on the exhaust gas analyser. If it is not as

specified, turn the mixture screw (clockwise to

weaken) and repeat the checking procedure.

30 On completion, fit a new tamperproof

plug.

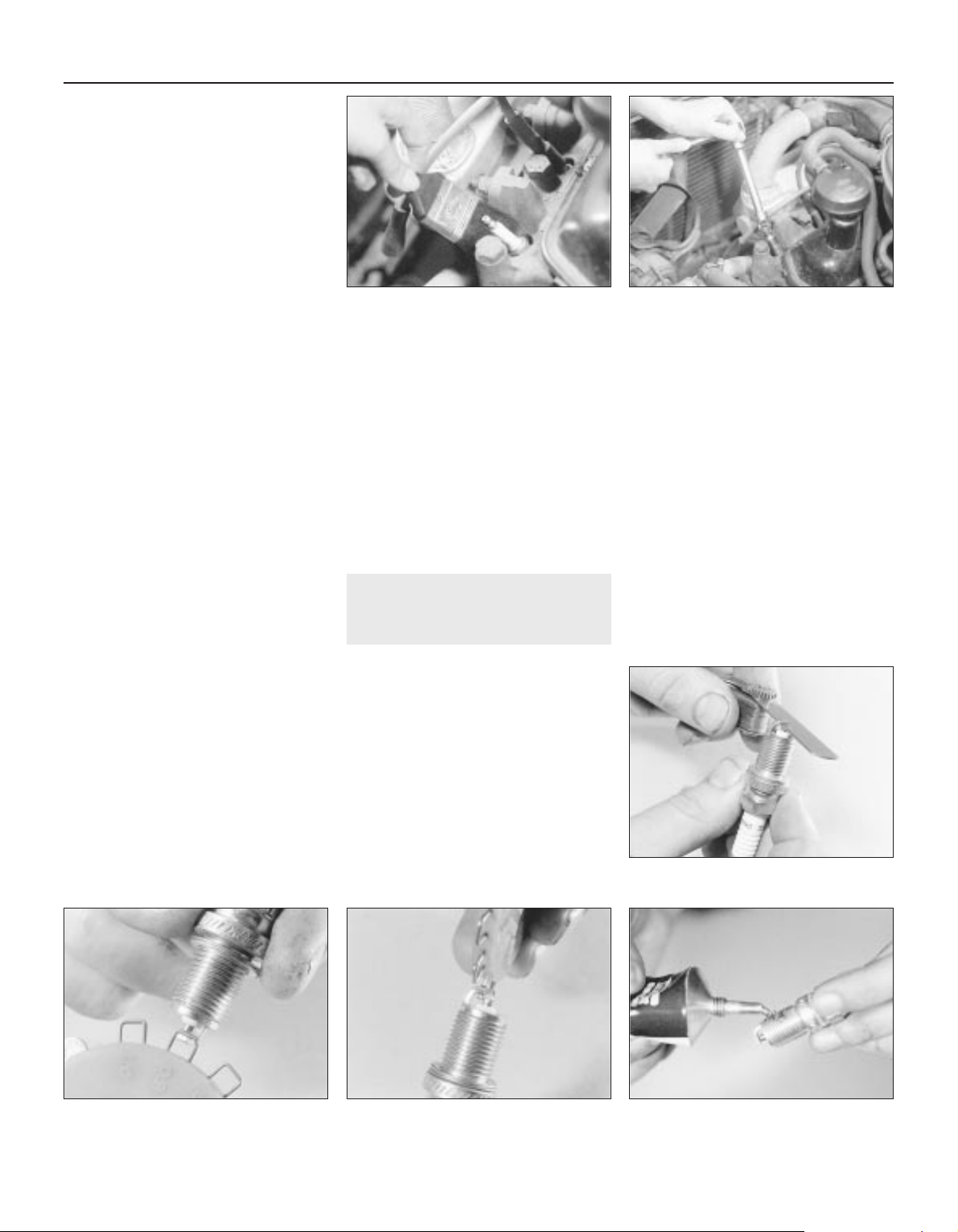

12 Spark plug check

1

1 Pull the HT lead from each plug by grasping

the end connector. Clean around each spark

plug (see illustration). Remove each plug

(see illustration) and check its electrode gap,

which should be within the limits stated in

Specifications.

2 To adjust the gap, bend the outer electrode

with a proper spark plug gapping tool.

Recheck the gap using feeler blades or wire

gauges (see illustrations).

3 Note that the correct functioning of each

plug is vital for the correct running and

efficiency of the engine. It is essential that the

plugs fitted are appropriate for the engine and

the suitable type is specified at the beginning

of this Chapter. Spark plug cleaning is rarely

necessary and should not be attempted unless

specialised equipment is available as damage

can easily be caused to the firing ends.

4 The appearance of a removed spark plug

can give some indication of the condition or

state of tune of the engine, but as modern

engines run on a weaker fuel/air mixture in

order to conform to current emission control

regulations, a rather whiter appearance of the

spark plug electrode area must be expected

than was the case on older cars. As the

mixture control is preset during production, a

black appearance of the plug electrode will

normally be due to oil passing worn piston

rings or valve stem oil seals, unless the

carburettor has been tampered with.

5 When installing the plugs use a long reach

socket, apply a little grease to the threads of the

plugs (see illustration)and tighten them only to

the specified torque wrench setting. Overtightening may damage the plug or its seat.

1•10 Every 6000 miles or 6 months

12.1a Clean around each spark plug . . .

12.2a Measuring a spark plug electrode

gap with a feeler blade

12.5 Lightly grease the spark plug threads

before fitting

12.2c Adjusting a spark plug electrode

gap with a special tool

12.2b Measuring a spark plug electrode

gap with a wire gauge

12.1b . . . before using a socket to remove

the spark plugs

Page 11

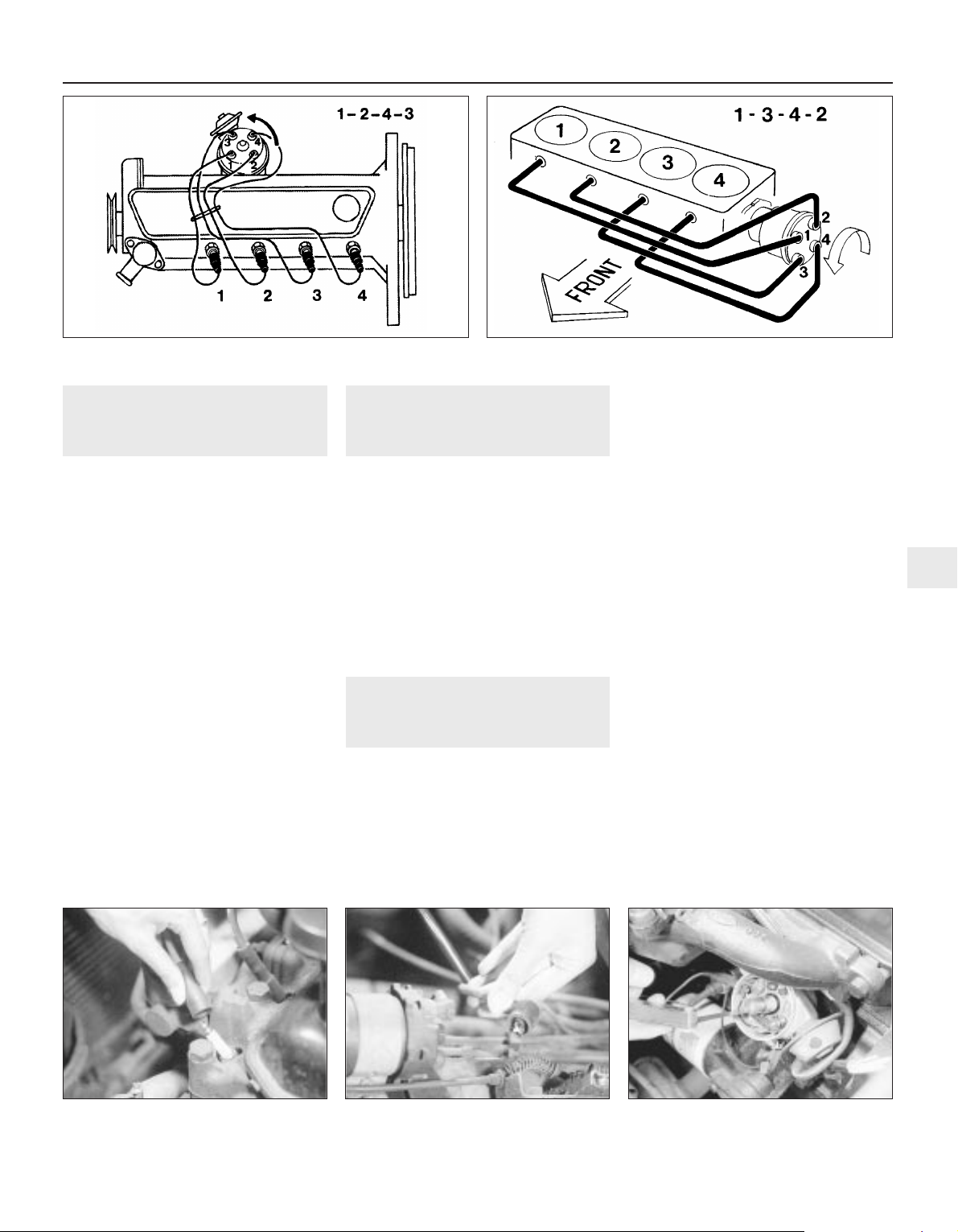

13 HT lead, distributor cap and

ignition circuit check

1

1 Clean each HT lead by wiping along its

length with a fuel-moistened cloth and inspect

it for damage.

2 Note the fitted position of each lead before

disconnection (see illustrations). When

removing a lead from a spark plug or the HT

coil, pull the lead off by its rubber connector

(see illustration).

3 The socket contacts on the distributor cap

should be cleaned if they appear corroded

(see illustration). A smear of petroleum jelly

(not grease) applied to the ferrule on the end

of the HT lead will help to prevent corrosion.

4 Remove the distributor cap and rotor arm.

5 Examine the rotor arm and inside of the

distributor cap . If the contacts are corroded

or are excessively burnt, or if the carbon

centre contact in the cap is worn away, renew

the cap or rotor, as necessary. Check

carefully for hairline cracks and signs of

arcing. Make sure that the HT leads are

reinstalled in their correct firing order.

6 Check that all HT and LT electrical leads are

correctly routed and clear of all moving or hot

engine components. Ensure that all lead

connections are secure and where applicable,

protected.

14 Hinge and lock check and

lubrication

1

1 Work around the vehicle, and lubricate the

bonnet, door and tailgate hinges with a light

machine oil.

2 Lightly lubricate the bonnet release

mechanism and exposed sections of inner

cable with a smear of grease.

3 Check the security and operation of all

hinges, latches and locks, adjusting them

where required.

4 Check the condition and operation of the

tailgate struts, renewing them if either is

leaking or is no longer able to support the

tailgate securely when raised.

15 Ignition timing and contact

breaker gap (dwell angle)

check - OHV engines

3

Contact breaker gap (dwell

angle)

1 Access to the distributor is improved by

removing the air cleaner unit.

2 Prise down the distributor cap retaining

clips or remove the securing screws, as

appropriate. Remove the distributor cap and

rotor.

3 Apply a spanner to the crankshaft pulley

bolt and turn the crankshaft until the

distributor points are fully open, with the heel

of the cam follower on the highest point of

one of the lobes of the cam.

4 Using feeler blades, check the points gap

(see illustration). If the blade is not a sliding

fit, release the screw at the fixed contact so

that the contact will move and adjust the gap

to that specified. Retighten the screw, refit the

rotor and cap. Take care not to contaminate

the points with oil from the feeler blades.

5 This method of adjustment should be

regarded as second best as on modern

engines, setting the points gap is usually

carried out by measuring the dwell angle.

6 The dwell angle is the number of degrees

through which the distributor cam turns

during the period between the instants of

closure and opening of the contact breaker

points. Checking the dwell angle not only

gives a more accurate setting of the contact

breaker gap, but this method also evens out

any variations in the gap which could be

caused by pitting of the points, wear in the

distributor shaft or its bushes, or difference in

height of any of the cam peaks.

7 The dwell angle should be checked with a

dwell meter connected in accordance with the

maker’s instructions. Refer to the Specifications for the correct dwell angle. If the dwell

angle is too large, increase the points gap. If it

is too small, reduce the gap.

Every 6000 miles or 6 months 1•11

13.2c Pull the HT lead connector - not the

lead

15.4 Checking the contact breaker points

gap using a feeler blade

13.3 Inspect each HT lead end ferrule for

corrosion

13.2b HT lead connections - CVH engines13.2a HT lead connections - OHV engines

1

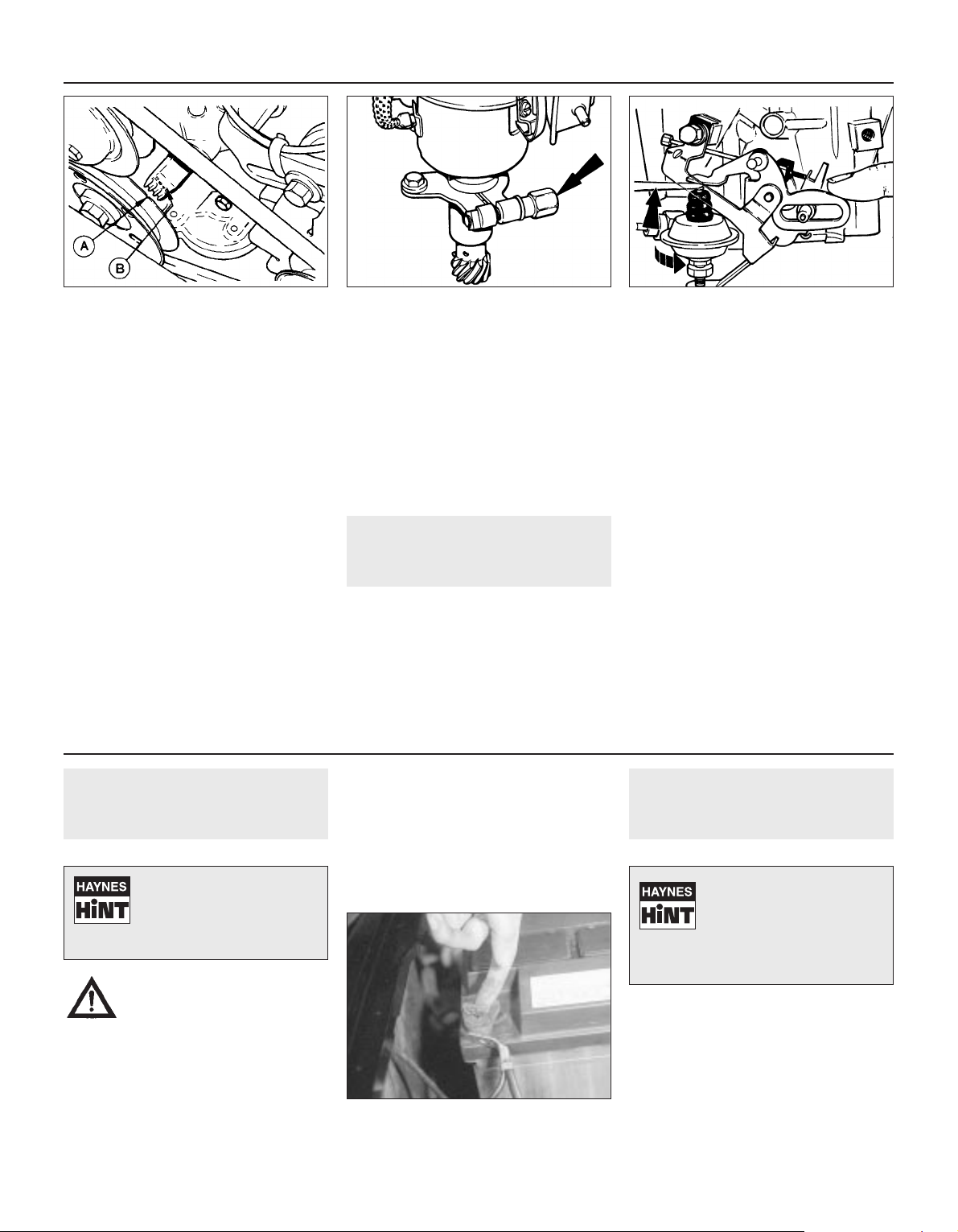

Page 12

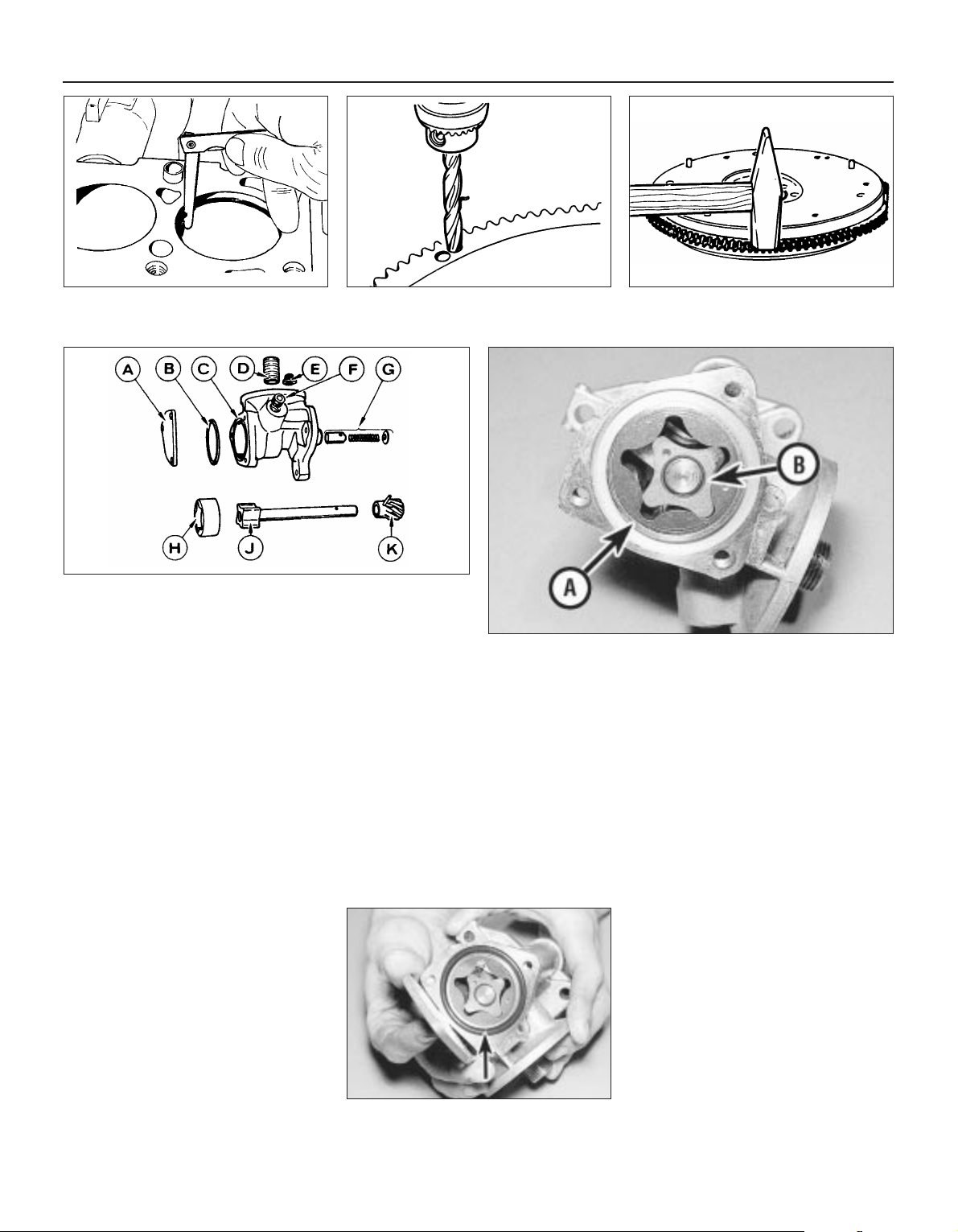

8 The dwell angle should always be adjusted

before checking and adjusting the ignition

timing, as follows:

Ignition timing

9 Before checking the timing, check and

adjust the dwell angle with the engine at

normal operating temperature.

10 Increase the contrast of the notch in the

crankshaft pulley and the appropriate mark on

the timing index (refer to Specifications) by

applying quick-drying white paint (see

illustration).

11 Connect a timing light (stroboscope) in

accordance with the manufacturer’s

instructions.

12 Start the engine and allow it to idle.

13 Disconnect the vacuum pipe from the

distributor and plug the pipe with a piece of rod.

14 If the timing light is now directed at the

engine timing marks, the pulley notch will

appear to be stationary and opposite the

specified mark on the scale. If the marks are

not in alignment, release the distributor clamp

pinch-bolt (see illustration) and turn the

distributor in whichever direction is necessary

to align the marks.

15 Retighten the pinch-bolt, switch off the

engine, remove the timing light and reconnect

the vacuum pipe.

16 It may now be necessary to check and

adjust the engine idle speed if the distributor

setting has to be varied to any extent.

16 Throttle damper operation

check

2

1 To check the operation of the throttle

damper fitted to models equipped with a Ford

VV carburettor, proceed as follows:

2 Warm up the engine to normal operating

temperature, then switch off. Connect a

tachometer in accordance with the

manufacturer’s instructions. To keep the fan

running during the adjustment procedure,

disconnect the wiring multi-plug from the

thermal switch (located in the thermostat

housing) and bridge the two contacts in the

plug with a short length of wire.

3 Start the engine and increase its speed to

3200 ± 150 rpm by means of the idle speed

adjustment screw. When the speed has

stabilised, switch off the engine.

4 Rotate the secondary throttle lever

clockwise to remove any play between the

primary and secondary throttle levers, but

ensure that the primary lever does not move.

5 Using a feeler blade, unscrew the damper

until a clearance of 0.1 to 0.3 mm exists

between the damper plunger and the

secondary throttle lever (see illustration).

Hold the damper in this position and tighten

the locknut.

6 Start the engine and return the idle speed to

the specified rpm. Disconnect the tachometer

and bridging wire, refit the multi-plug, then

refit the air cleaner.

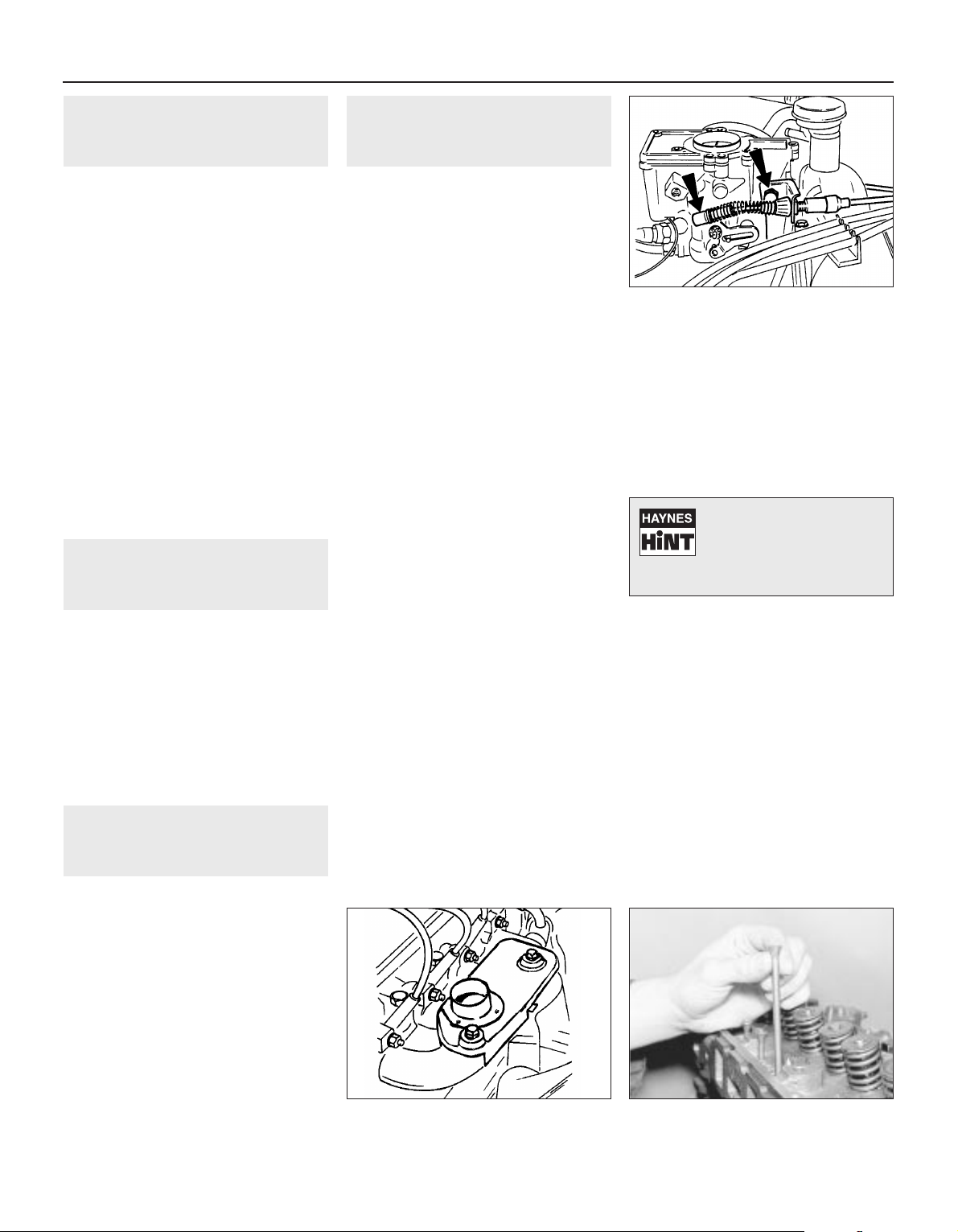

17 Battery terminal check

1

1 To clean the battery terminals disconnect

them, negative earth first, after having first

removed the cover (where fitted). Use a wire

brush or abrasive paper to clean the

terminals. Bad corrosion should be treated

with a solution of bicarbonate of soda, applied

with an old toothbrush. Do not let this solution

get inside the battery.

2 Coat the battery terminals with petroleum

jelly or a proprietary anti-corrosive compound

before reconnecting them (see illustration).

Reconnect and tighten the positive (live) lead

first, followed by the negative (earth) lead. Do

not overtighten.

18 Engine valve clearance

check - OHV engines

2

1 This operation should be carried out with

the engine cold and the air cleaner, spark

plugs and rocker cover removed.

2 Using a ring spanner or socket on the

crankshaft pulley bolt, turn the crankshaft in a

clockwise direction until No 1 piston is at top

dead centre (TDC) on its compression stroke.

This can be verified by checking that the

pulley and timing cover marks are in

1•12 Every 6000 miles or 6 months

15.10 Ignition timing marks - mechanical

ignition system

A Crankshaft pulley notch

B Timing cover scale

16.5 Setting throttle damper clearance

using a feeler blade (arrowed) -

Ford VV carburettor

17.2 Protect each battery terminal before

reconnection

15.14 Distributor clamp plate pinch-bolt

(arrowed)

12 000 Mile (20 000 Km) / 12 Month Service

To keep corrosion to a

minimum, coat the battery

terminals with petroleum

jelly or a proprietary anti-

corrosive compound.

When checking valve

clearances, it will be easier

to turn the engine by hand if

the spark plugs are removed

but take care not to allow dirt to enter

the spark plug holes.

Warning: Before carrying out

any work on the vehicle battery,

read through the precautions

given in “Safety first!” at the

beginning of this manual.

Page 13

alignment and that the valves of No 4 cylinder

are rocking. When the valves are rocking, this

means that the slightest rotation of the

crankshaft pulley in either direction will cause

one rocker arm to move up and the other to

move down.

3 Numbering from the thermostat housing

end of the cylinder head, the valves are

identified as follows:

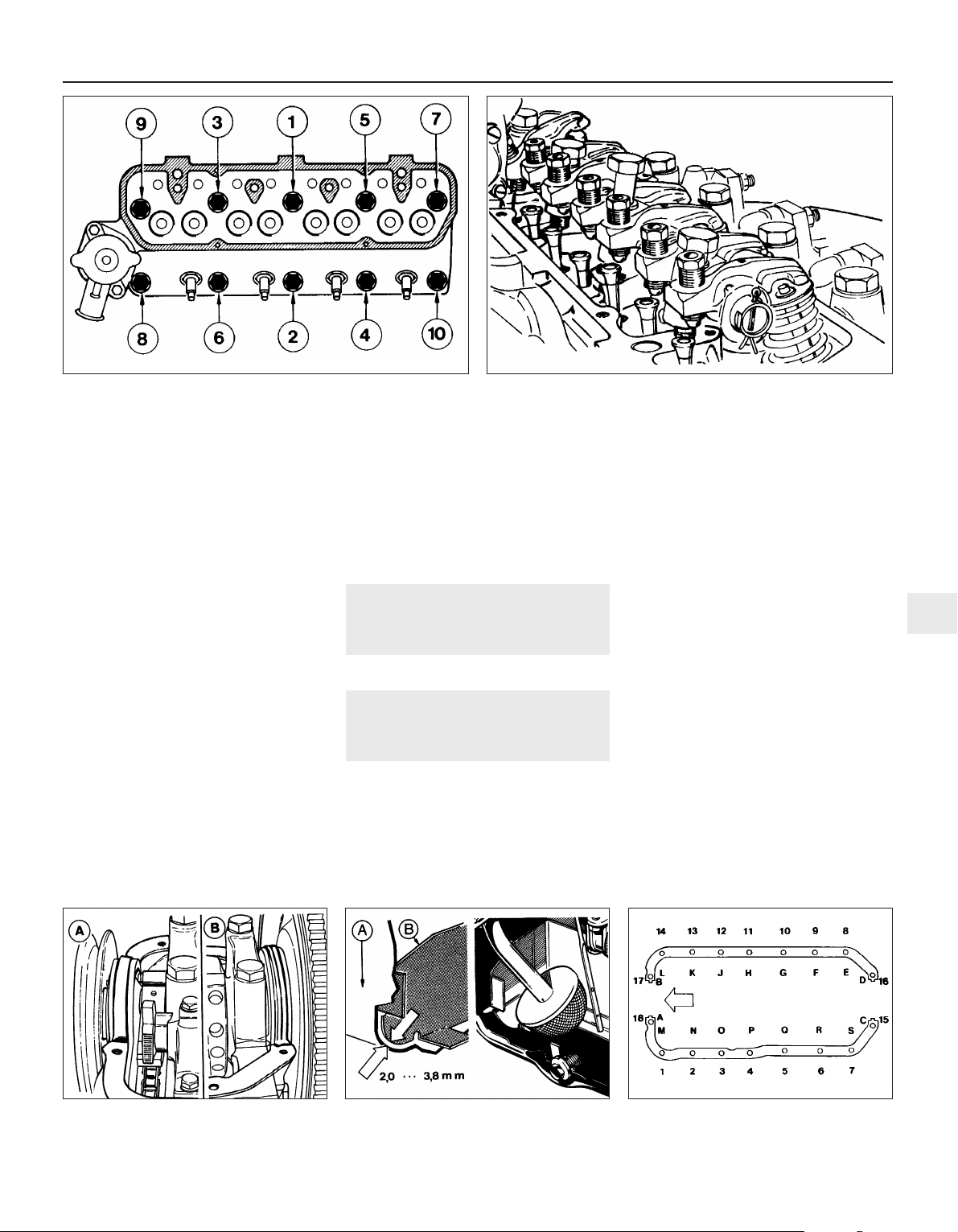

Valve No Cylinder no

1 - Exhaust 1

2 - Inlet 1

3 - Exhaust 2

4 - Inlet 2

5 - Exhaust 3

6 - Inlet 3

7 - Exhaust 4

8 - Inlet 4

4 Adjust the valve clearances by following the

sequence given in the following table. Turn

the crankshaft pulley 180° (half a turn) after

adjusting each pair:

Valves rocking Valves to adjust

7 and 8 1 (Exhaust), 2 (Inlet)

5 and 6 3 (Exhaust), 4 (Inlet)

1 and 2 7 (Exhaust), 8 (Inlet)

3 and 4 5 (Exhaust), 6 (Inlet)

5 The clearances for the inlet and exhaust

valves are different (see Specifications). Use a

feeler blade of the appropriate thickness to

check each clearance between the end of the

valve stem and the rocker arm. The blade

should be a stiff sliding fit. If it is not, turn the

adjuster bolt with a ring spanner. These bolts

are of stiff thread type and require no locking

nut. Turn the bolt clockwise to reduce the

clearance and anti-clockwise to increase it

(see illustration).

6 Refit the rocker cover, spark plugs and air

cleaner on completion of adjustment.

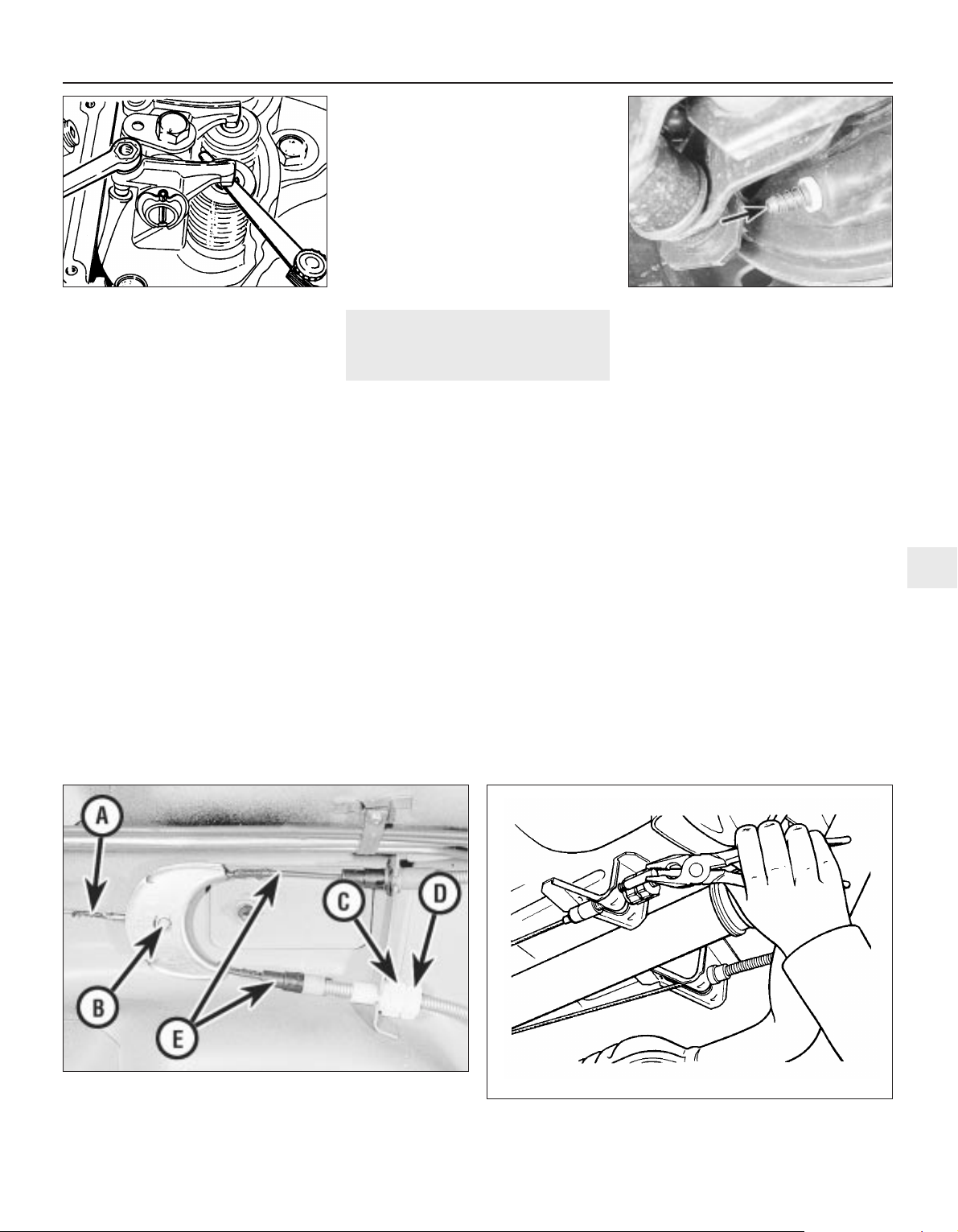

19 Handbrake check

2

Pre-September 1985 models

1 Adjustment of the handbrake is normally

automatic by means of the self-adjusting

mechanism working on the rear brake shoes.

2 However, due to cable stretch, checking of

the handbrake adjustment is recommended.

Adjustment must be carried out if the

movement of the lever becomes excessive

(more than six notches). Proceed as follows:

3 Chock the front wheels then fully release

the handbrake.

4 Raise and support the vehicle at the rear

with safety stands.

5 On adjustment check that the plunger

protrudes from each rear brake backplate

(see illustration), their respective length of

movement indicating the handbrake

adjustment condition. Before checking their

movement (stroke) length, firmly apply the

footbrake to ensure that the automatic

adjuster mechanism is fully actuated.

6 Now check the plunger stroke movement. If

the total movement of both sides added

together is between 0.5 and 3.0 mm then

adjustment is satisfactory. This should give

three to six clicks (notches) of handbrake

application movement. If there is no

measurable plunger movement or if the total

measurement exceeds that specified adjust

as follows.

7 Loosen the handbrake cable locknut, then

rotate the adjuster sleeve (see illustration) so

that the plungers can just rotate and the total

movement of both plungers is as specified

above.

8 Hand tighten the locknut against the sleeve

so that two engagement clicks are felt, then

further tighten another two clicks using a

suitable wrench.

Models from September 1985

9 Proceed as above, noting that since

September 1985 a locking pin has been fitted

to the cable adjuster abutment bracket to lock

the adjuster sleeve and locknut together.

10 Should it be necessary to adjust the

cable, the locking pin must be removed by

pulling it out using pliers (see illustration).

After adjustment a new nylon locking pin must

be used and can be fitted by carefully tapping

it into place.

Every 12 000 miles or 12 months 1•13

19.10 Removing the handbrake cable adjuster locking pin

19.7 Handbrake cable assembly

A Primary cable

B Equaliser

C Adjuster sleeve

D Locknut

E Secondary cable

19.5 Handbrake adjustment indicator

plunger

18.5 Adjusting a valve clearance - OHV

1

Page 14

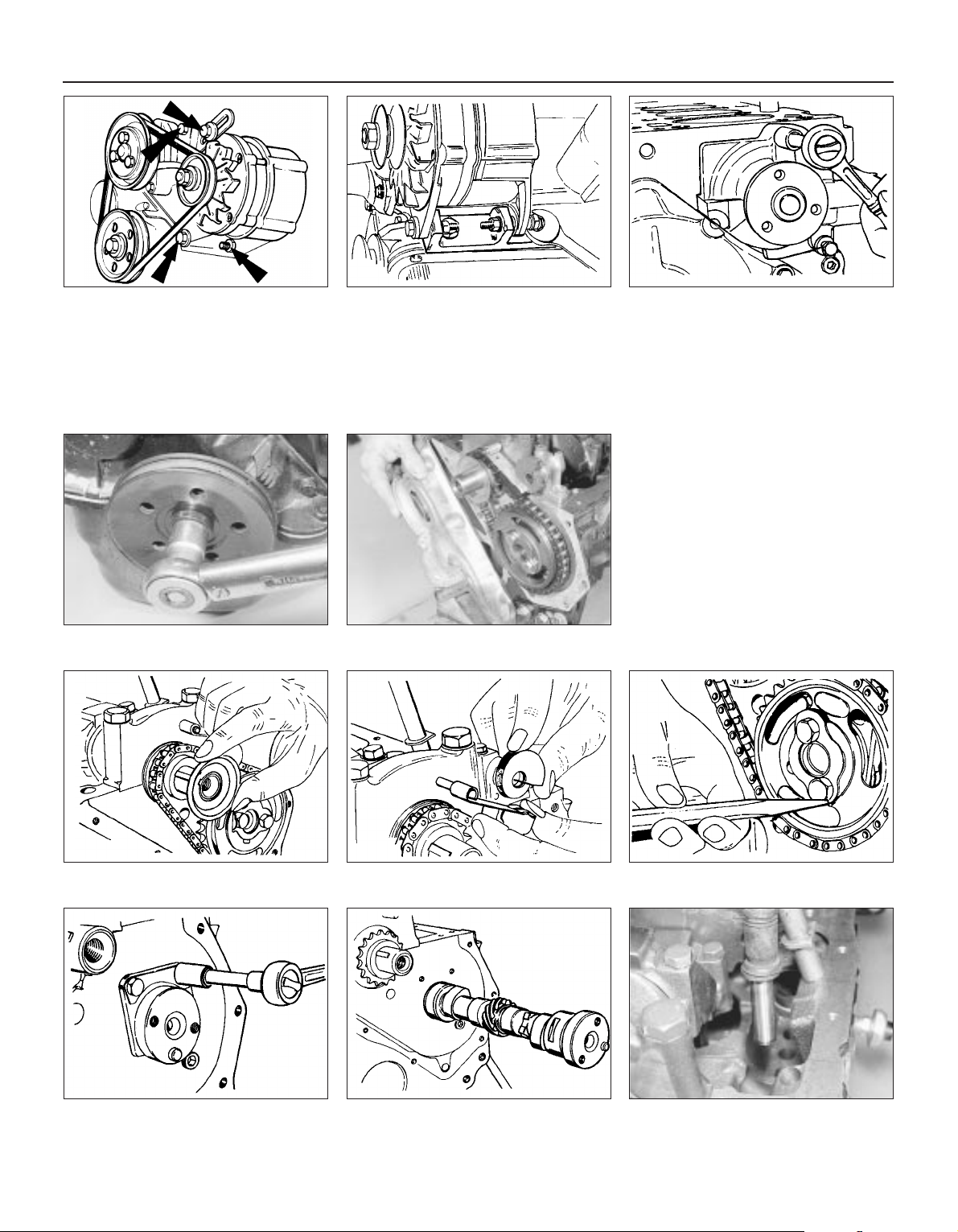

20 Auxiliary drivebelt check

2

Inspection

1 Check the full length of the drivebelt for

cracks and deterioration. It will be necessary

to turn the engine in order to check that

portion of the drivebelt is in contact with the

pulleys.

2 Check that the total deflection of the

auxiliary drivebelt is 4.0 mm at the mid point

of its longest run (see illustration).

3 Note that if the belt is too slack, it will slip

and soon become glazed or burnt and the

coolant pump (OHV) and alternator will not

perform correctly, with consequent

overheating of the engine and low battery

charge. If the belt is too tight, the bearings in

the alternator and/or coolant pump will soon

be damaged.

4 If necessary, renew or tension the belt as

follows:

Renewal

5 To remove a belt, slacken the alternator

mounting bolts and the bolts on the adjuster

link (see illustration), push the alternator in

towards the engine and slip the belt from the

pulleys.

6 Fit the belt by slipping it over the pulley rims

while the alternator is still loose on its

mountings. Never be tempted to remove or fit

a belt by prising it over a pulley without

releasing the alternator. Either the pulley will

be damaged or the alternator or coolant pump

will be distorted.

Tensioning

7 To change the belt tension, pull the

alternator away from the engine until the belt

is fairly taut and nip up the adjuster strap bolt.

A little trial and error may be required to

obtain the correct tension.

8 Do not lever against the body of the

alternator to tension the belt or damage may

occur.

9 Recheck the tension of the drivebelt after

the engine has been run for ten minutes.

21 Spark plug renewal

1

1 The correct functioning of the spark plugs is

vital for the correct running and efficiency of

the engine. It is essential that the plugs fitted

are of the type appropriate for the engine.

2 Make sure that the ignition is switched off

before inspecting the HT leads to see if they

carry their cylinder numbers - if not, number

each lead using sticky tape or paint.

3 Where necessary, for improved access,

remove the air cleaner assembly.

4 Disconnect the leads from the plugs by

pulling on the connectors, not the leads.

5 Clean the area around each spark plug

using a small brush, then using a plug

spanner (preferably with a rubber insert),

unscrew and remove the plugs. Cover each

exposed spark plug hole with a clean rag to

prevent the ingress of any foreign matter.

6 Before fitting new spark plugs, check that

the threaded connector sleeves are tight.

7 Check the electrode gap of each plug with

a feeler blade of the specified thickness and if

necessary, bend the outer electrode with a

proper spark plug gapping tool to set the gap

to the specified clearance.

8 Coat the threads of each plug with suitable

anti-seize compound, taking care not to

contaminate the electrodes.

9 Screw in the spark plugs by hand, then

tighten them to the specified torque. Do not

exceed the torque figure.

10 Push the HT leads firmly onto the spark

plugs and where necessary, refit the air

cleaner assembly.

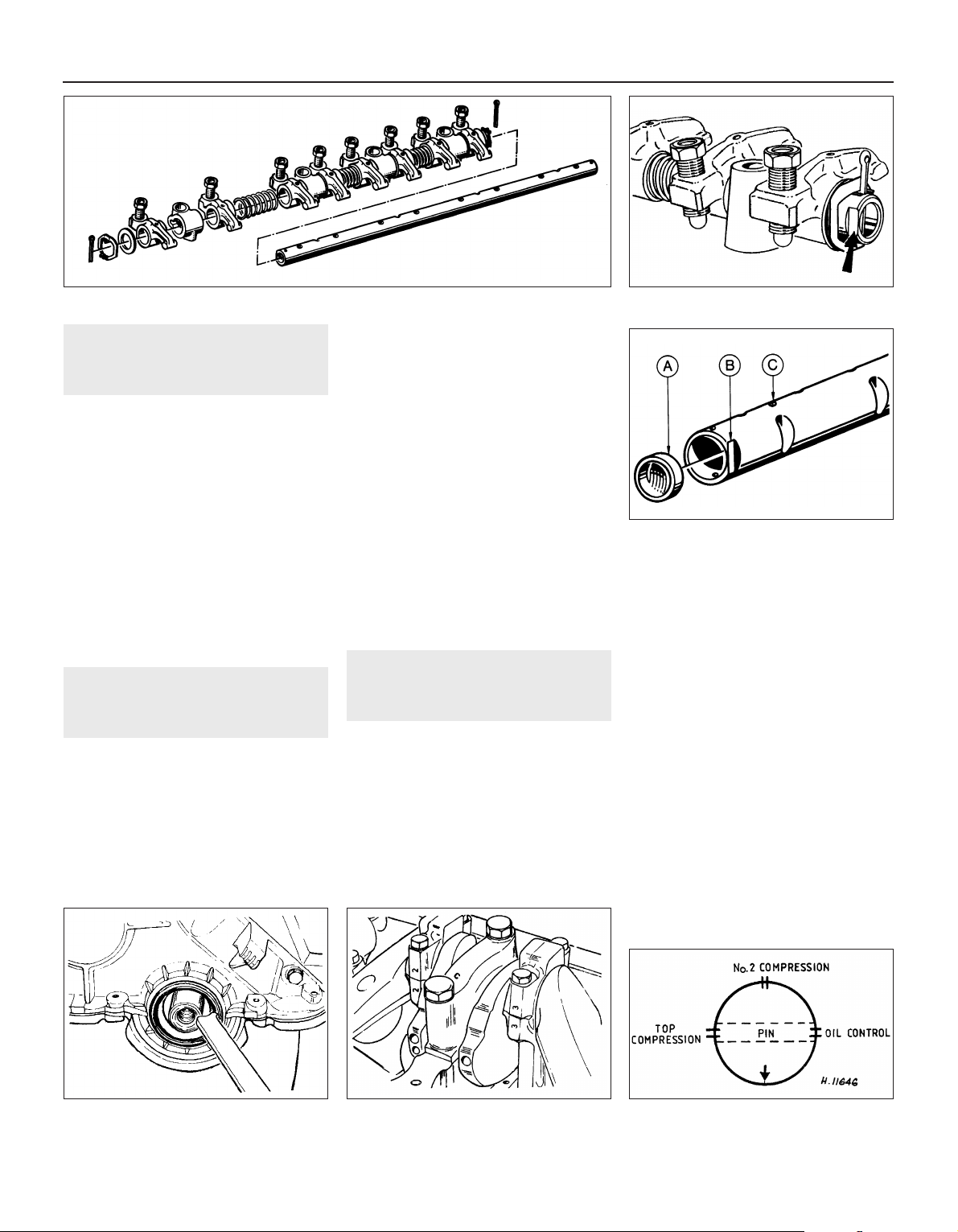

22 Gearbox oil level check

1

Caution: Gearbox oil can foam when hot

and give a false level reading. Allow the

gearbox to cool before checking the oil

level.

Note: Regular oil changing is not specified by

the manufacturers but the gearbox oil can be

drained if necessary (prior to removal of the

unit or after traversing a flooded road for

example) by removing the selector shaft

locking mechanism (see illustration).

1 The following procedure should be adopted

when checking the oil level on all gearbox

types.

2 Ensure that the car is standing on level

ground and the gearbox is cool.

3 Unscrew the filler plug from the front face of

the gearbox. The plug is of socket-headed

type and a suitable key will be required for

removal (see illustration).

4 With the plug removed, check the oil level.

To do this accurately, make up an oil level

check dipstick from a short length of welding

rod or similar material. Make a 90° bend in the

rod, then mark the downward leg in 5 mm

increments. The dipstick is then inserted

through the filler plug orifice so that the

unmarked leg rests flat on the plug orifice

1•14 Every 12 000 miles or 12 months

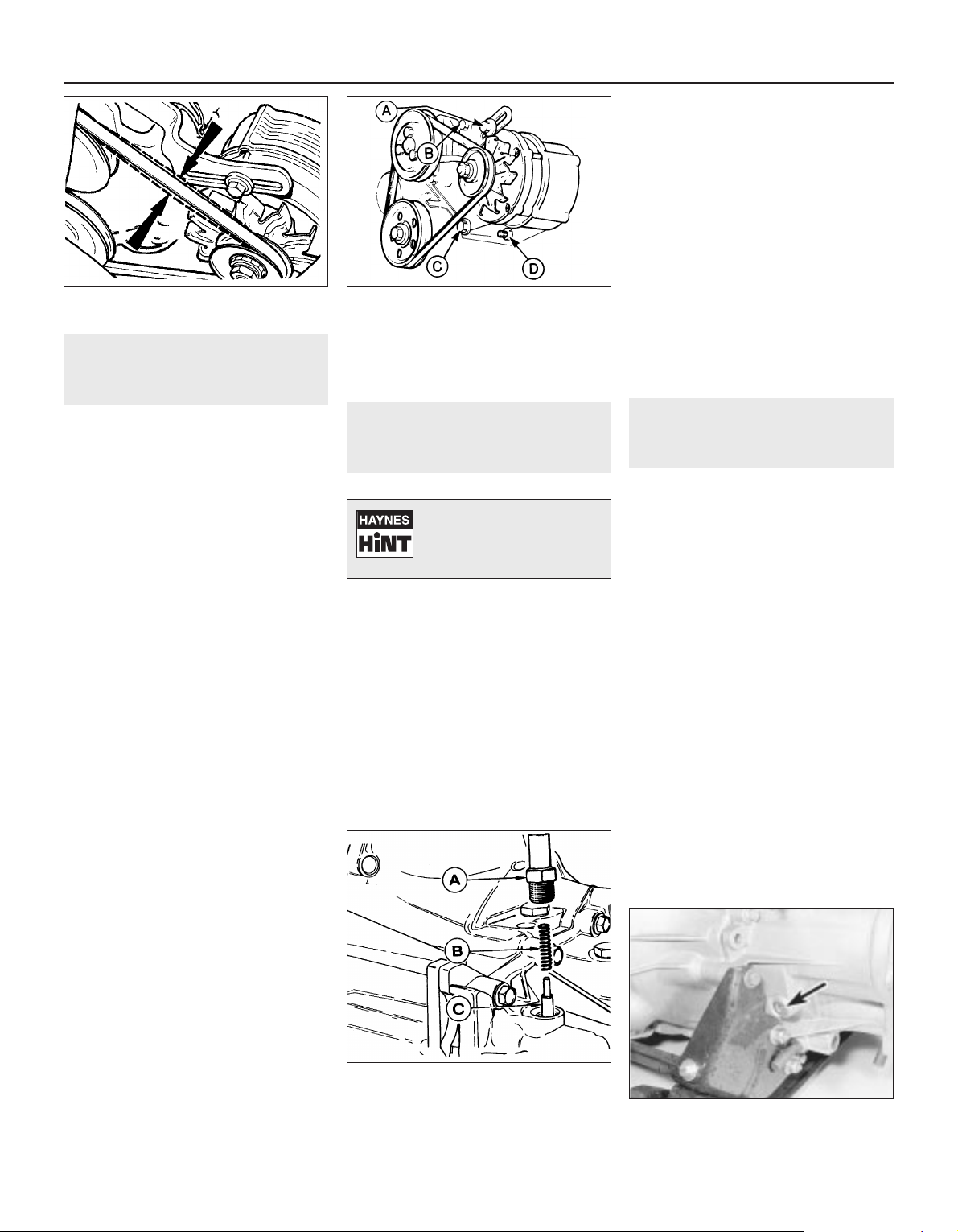

20.2 Auxiliary drivebelt tension checking

point - OHV

22.3 Gearbox oil filler plug location

(arrowed)

22.0 Remove the selector shaft locking

mechanism to drain the gearbox oil

A Selector shaft

cap nut

B Spring

C Interlock pin

20.5 Alternator adjuster and mounting

bolts - OHV

A Adjuster link clamp bolt

B Adjuster link-to-block bolt

C Lower front mounting bolt

D Lower rear mounting bolt

Number each HT lead using

sticky tape or paint before

removal so as to avoid

confusion when refitting.

Page 15

threads, with the marked leg dipped in the oil.

Withdraw the dipstick and read off the level of

oil.

5 On gearboxes manufactured up to August

1985 the oil level must be maintained between

5 and 10 mm below the lower edge of the filler

plug hole.

6 On gearboxes manufactured from

September 1985 onwards the oil level must

be maintained between 0 and 5 mm below the

lower edge of the filler plug hole.

7 To determine the date of gearbox

manufacture, locate the aluminium build code

tag which will be attached to one of the

gearbox housing retaining bolts. The gearbox

part number is stamped on the tag and if the

last letter of the part number suffix is a “D”,

then the gearbox is of the early type. If the last

letter of the suffix is an “E”, then the gearbox

is of the later type.

8 Top-up the gearbox with the specified type

of oil if necessary until the level is correct for

the gearbox type (see “Lubricants and fluids”).

Take care not to overfill the unit as this can

lead to excessive heat build-up, increased

leakage and impaired gear changing.

9 On completion, refit the filler plug.

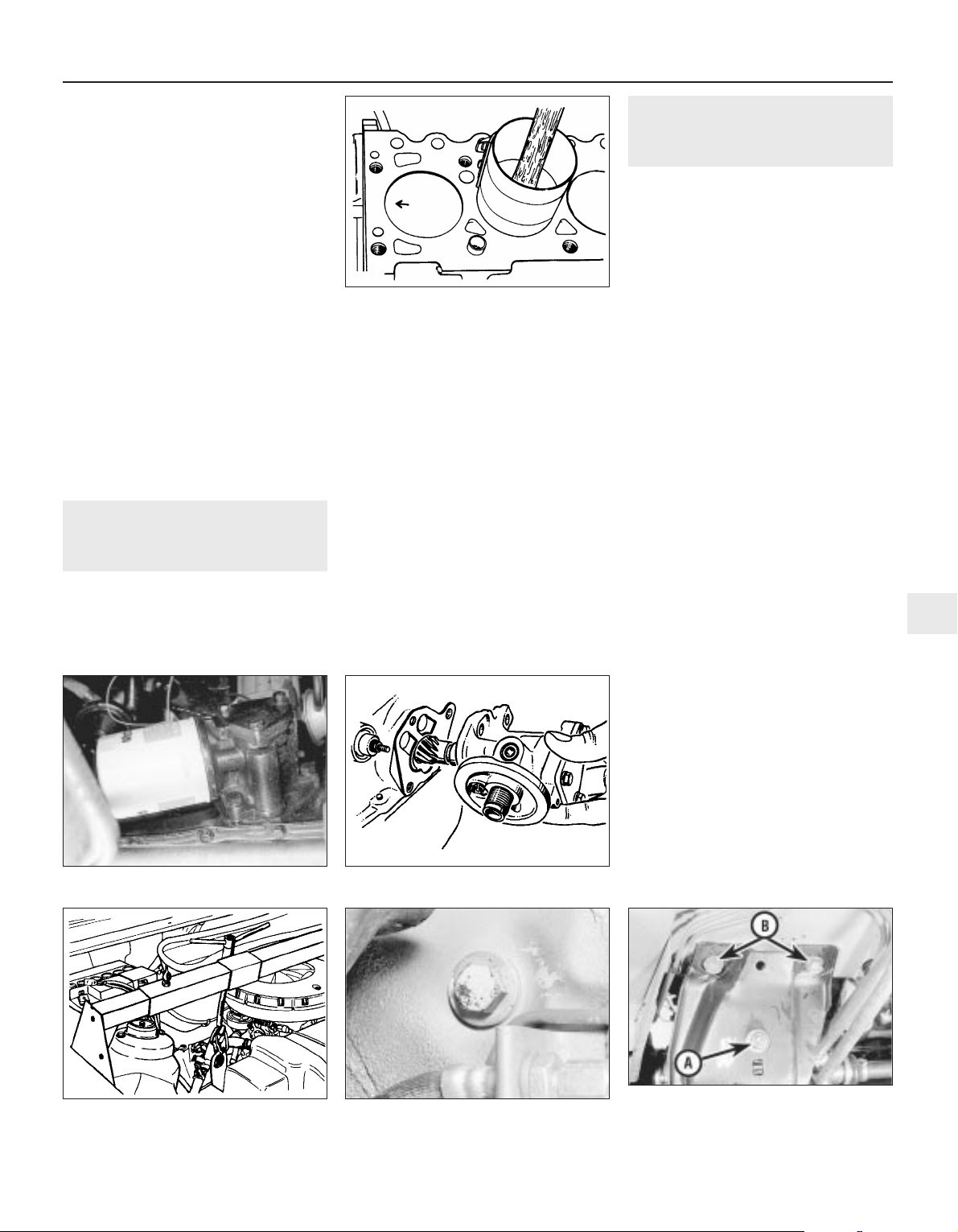

23 Contact breaker point

renewal and distributor

lubrication - OHV engines

3

1 If necessary, remove the air cleaner

assembly to allow ready access to the

distributor. Identify and disconnect the leads

from the spark plugs, prise down the

distributor cap clips or remove the screws,

and place the cap and leads to one side.

2 Remove the rotor arm.

3 Pull off the contact breaker LT lead from the

points (see illustration).

4 Unscrew and remove the screw from the

fixed contact arm. Take great care not to drop

the screw into the interior of the distributor: if

necessary, cover the openings in the

baseplate with rag before starting to remove

the screw.

5 With the screw removed, lift out the contact

breaker assembly.

6 Fit and adjust the new contact breaker set,

leaving the securing screw loose until the gap

has been set.

7 Apply a little high melting-point grease to

the distributor cam. (Grease may be supplied

with the new contact breaker set.)

8 Refit the rotor arm and the distributor cap

and reconnect the spark plug leads in their

previously noted location.

9 Check and adjust the dwell angle and the

ignition timing.

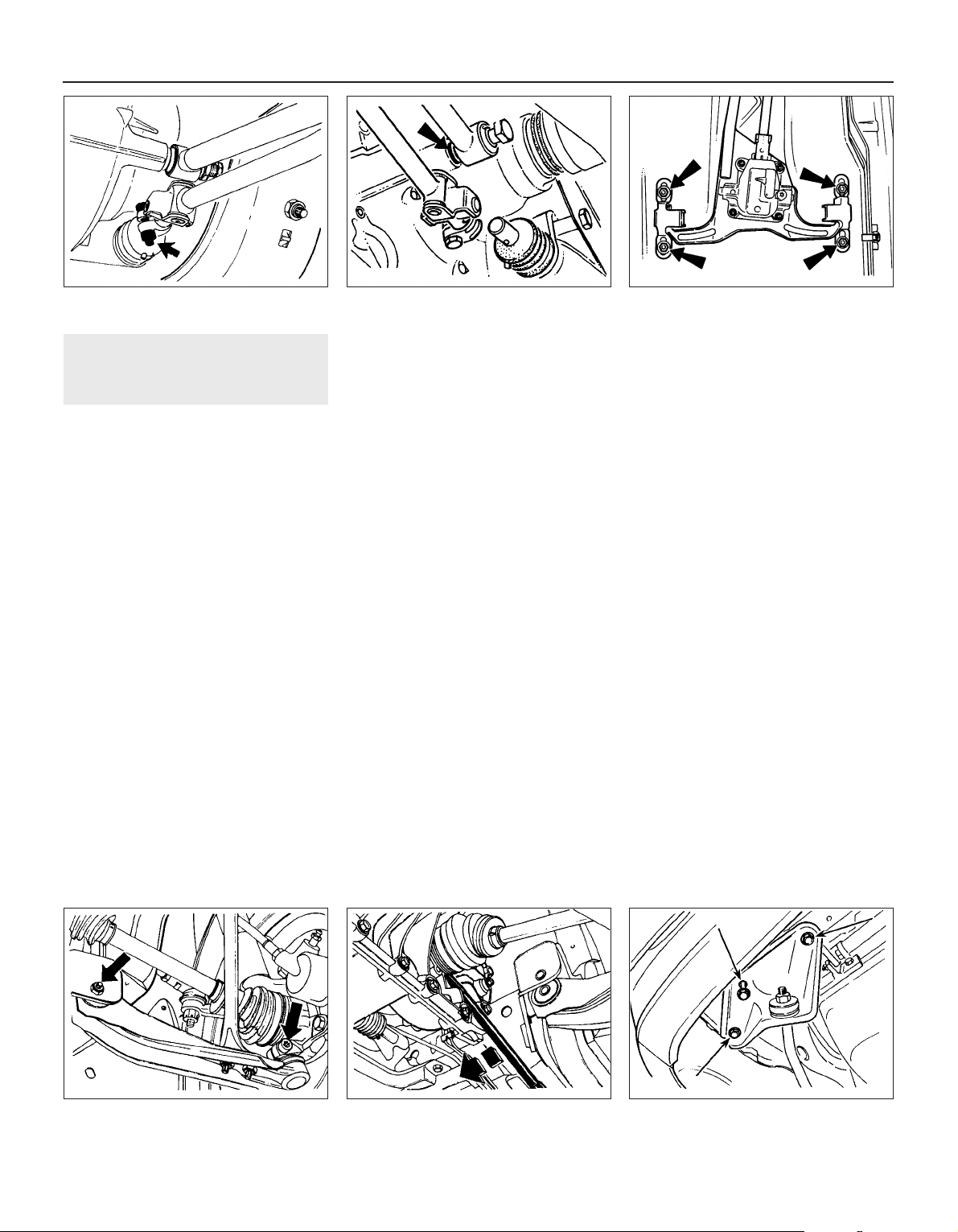

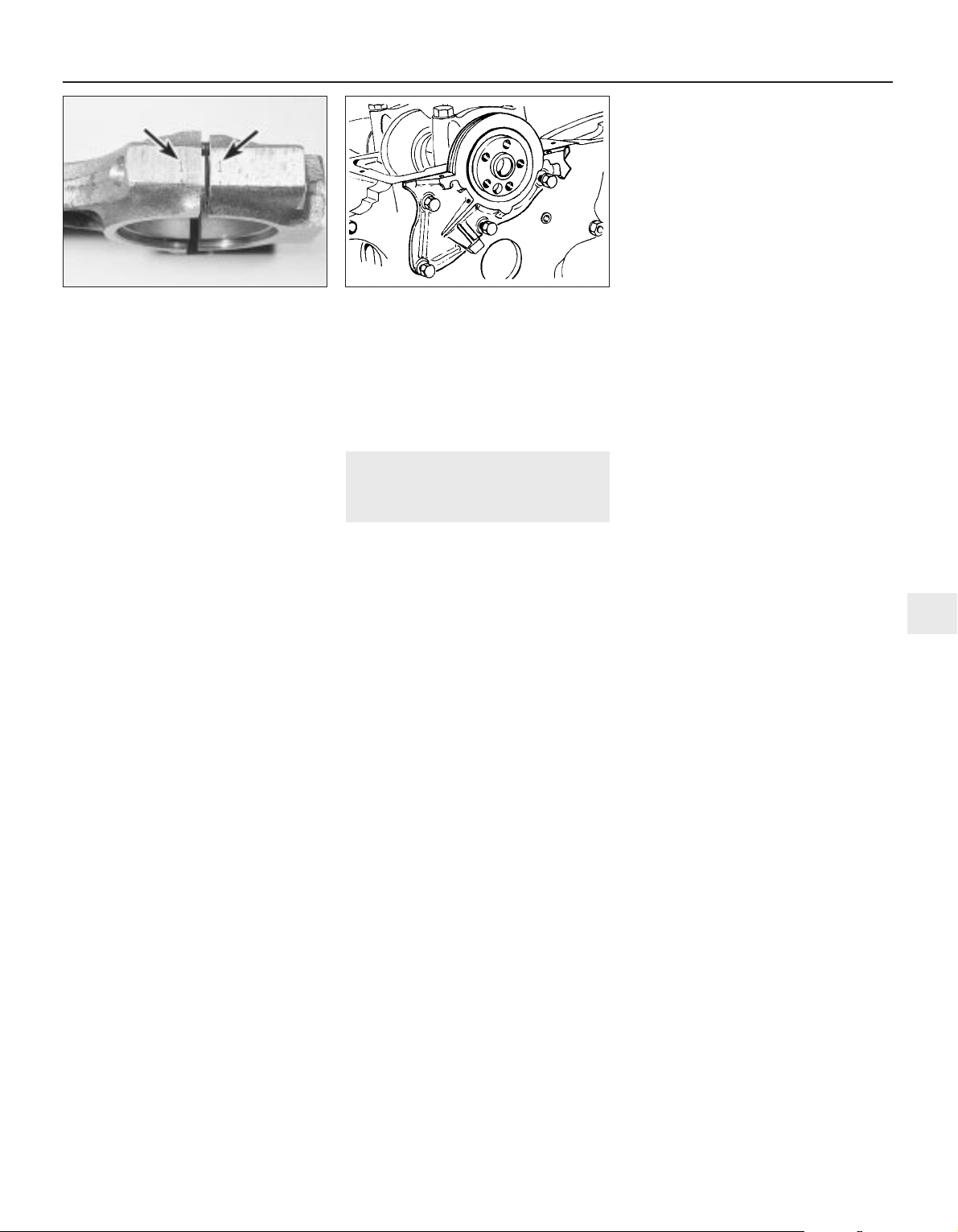

24 Steering and suspension

security check

1

1 Check the shock absorbers by bouncing

the vehicle up and down at each corner in

turn. When released, it should come to rest

within one complete oscillation. Continued

movement, or squeaking and groaning noises

from the shock absorber suggests that

renewal is required.

2 With the weight of the vehicle on its

roadwheels, inspect all of the suspension

flexible bushes for wear and check the torque

wrench settings of all bolts and nuts.

3 Raise and support the vehicle. Examine all

steering and suspension components for

wear, damage and fluid leakage. Pay

particular attention to dust covers and gaiters

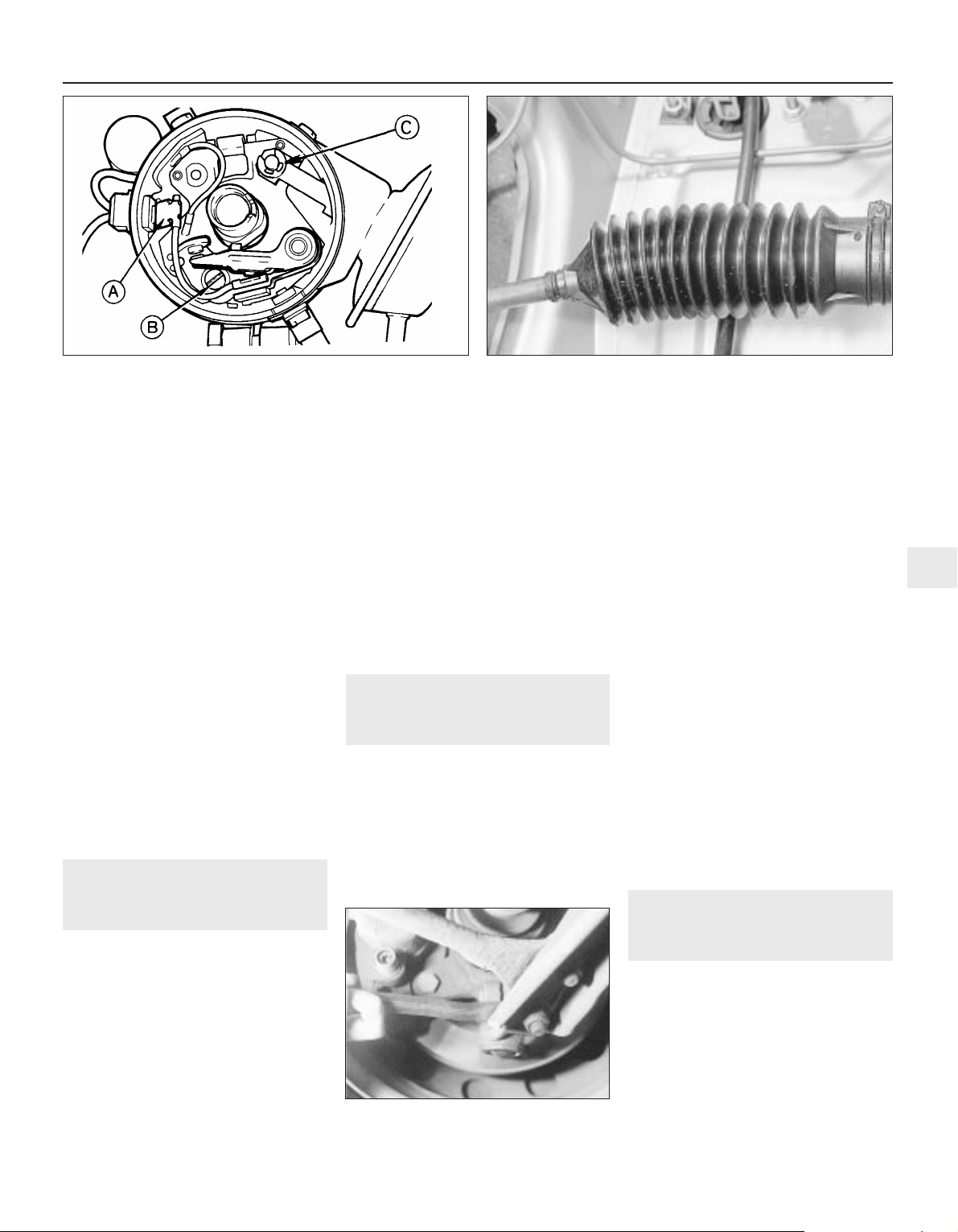

(see illustration), which if renewed promptly

when damaged can save further damage to

the component protected.

4 At the same intervals, check the front

suspension lower arm balljoints for wear by

levering up the arms (see illustration).

Balljoint free movement must not exceed 0.5

mm. The track rod end balljoints can be

checked in a similar manner, or by observing

them whilst an assistant rocks the steering

wheel back and forth. If the lower arm balljoint

is worn, the complete lower arm must be

renewed.

5 Wheel bearings can be checked for wear by

spinning the relevant roadwheel. Any

roughness or excessive noise indicates worn

bearings, which must be renewed, as no

adjustment is possible. It is unlikely that any

wear will be evident unless the vehicle has

covered a very high mileage. It should be

noted that it is normal for the bearings to

exhibit slight endfloat, which is perceptible as

wheel rock at the wheel rim.

25 Underbody inspection

1

1 Except on vehicles with a wax-based

underbody protective coating, have the whole

of the underframe of the vehicle steamcleaned, engine compartment included, so

that a thorough inspection can be carried out

to see what minor repairs and renovations are

necessary.

2 Steam-cleaning is available at many

garages and is necessary for the removal of

the accumulation of oily grime which

sometimes is allowed to become thick in

Every 12 000 miles or 12 months 1•15

24.4 Apply leverage to check for excessive

balljoint wear

24.3 Inspect the steering rack bellows23.3 Contact breaker points removal

A LT lead connector

B Securing screw

C Vacuum advance strut

circlip

1

Page 16

certain areas. If steam-cleaning facilities are

not available, there are some excellent grease

solvents available, which can be brushapplied; the dirt can then be simply hosed off.

3 After cleaning, position the vehicle over a pit,

or raise it at front and rear on ramps or axle

stands (see “Jacking and vehicle support”).

4 Using a strong light, work around the

underside of the vehicle, inspecting it for

corrosion or damage. If either is found, refer

to Chapter 11 for details of repair.

26 Brake pipe and hose check

1

1 Periodically inspect the rigid brake pipes for

rust and other damage, and the flexible hoses

for cracks, splits or “ballooning” (see

illustration). Have an assistant depress the

brake pedal (ignition on) and inspect the hose

and pipe unions for leaks. Renew any

defective item without delay.

27 Road test

1

Instruments and electrical

equipment

1 Check the operation of all instruments and

electrical equipment.

2 Make sure that all instruments read

correctly, switch on all electrical equipment in

turn to check that it functions properly.

Steering and suspension

3 Check for any abnormalities in the steering,

suspension, handling or road “feel”.

4 Drive the vehicle, and check that there are

no unusual vibrations or noises.

5 Check that the steering feels positive, with

no excessive “sloppiness”, or roughness, and

check for any suspension noises when

cornering, or when driving over bumps.

Drivetrain

6 Check the performance of the engine,

clutch, transmission and driveshafts.

7 Listen for any unusual noises from the

engine, clutch and transmission.

8 Make sure that the engine runs smoothly

when idling, and that there is no hesitation

when accelerating.

9 Where applicable, check that the clutch

action is smooth and progressive, that the

drive is taken up smoothly, and that the pedal

travel is not excessive. Also listen for any

noises when the clutch pedal is depressed.

10 Check that all gears can be engaged

smoothly, without noise, and that the gear

lever action is not abnormally vague or

“notchy”.

Check the operation and

performance of the braking

system

11 Make sure that the vehicle does not pull to

one side when braking, and that the wheels

do not lock prematurely when braking hard.

12 Check that there is no vibration through

the steering when braking.

13 Check that the handbrake operates

correctly, without excessive movement of the

lever, and that it holds the vehicle stationary

on a slope.

14 Test the operation of the brake servo unit

as follows. With the engine off, depress the

footbrake four or five times to exhaust the

vacuum. Start the engine, holding the brake

pedal depressed. As the engine starts, there

should be a noticeable “give” in the brake

pedal as vacuum builds up. Allow the engine

to run for at least two minutes, and then

switch it off. If the brake pedal is depressed

now, it should be possible to detect a hiss

from the servo as the pedal is depressed.

After about four or five applications, no further

hissing should be heard, and the pedal should

feel considerably firmer.

28 Crankcase ventilation

system check

1

1 Inspect the crankcase ventilation system

for blockage or damage. A blocked hose can

cause a build-up of crankcase pressure,

which in turn can cause oil leaks.

2 Inspect each hose for distortion, perishing

and correct routing.

3 Clean the oil filler cap with solvent and

check that the vent hose connections are not

blocked (see illustration).

4 Clean the emission control orifice located in

the oil filler assembly with solvent (see

illustration).

1•16 Every 12 000 miles or 12 months

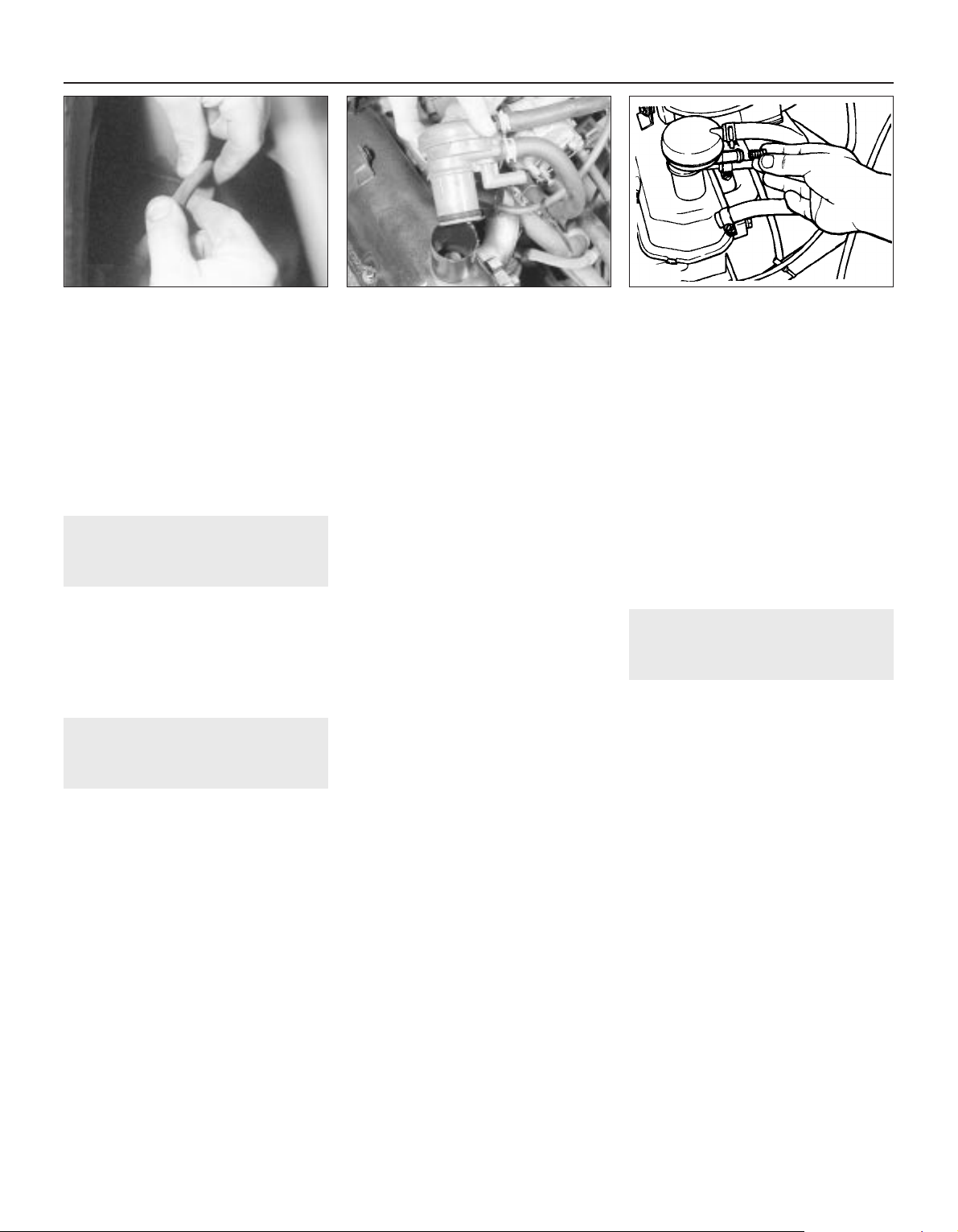

26.1 Bend flexible brake hoses to check

for splitting and decay

28.4 Clean emission control orifice in

solvent - OHV shown

28.3 Oil filler cap and breather hoses

Page 17

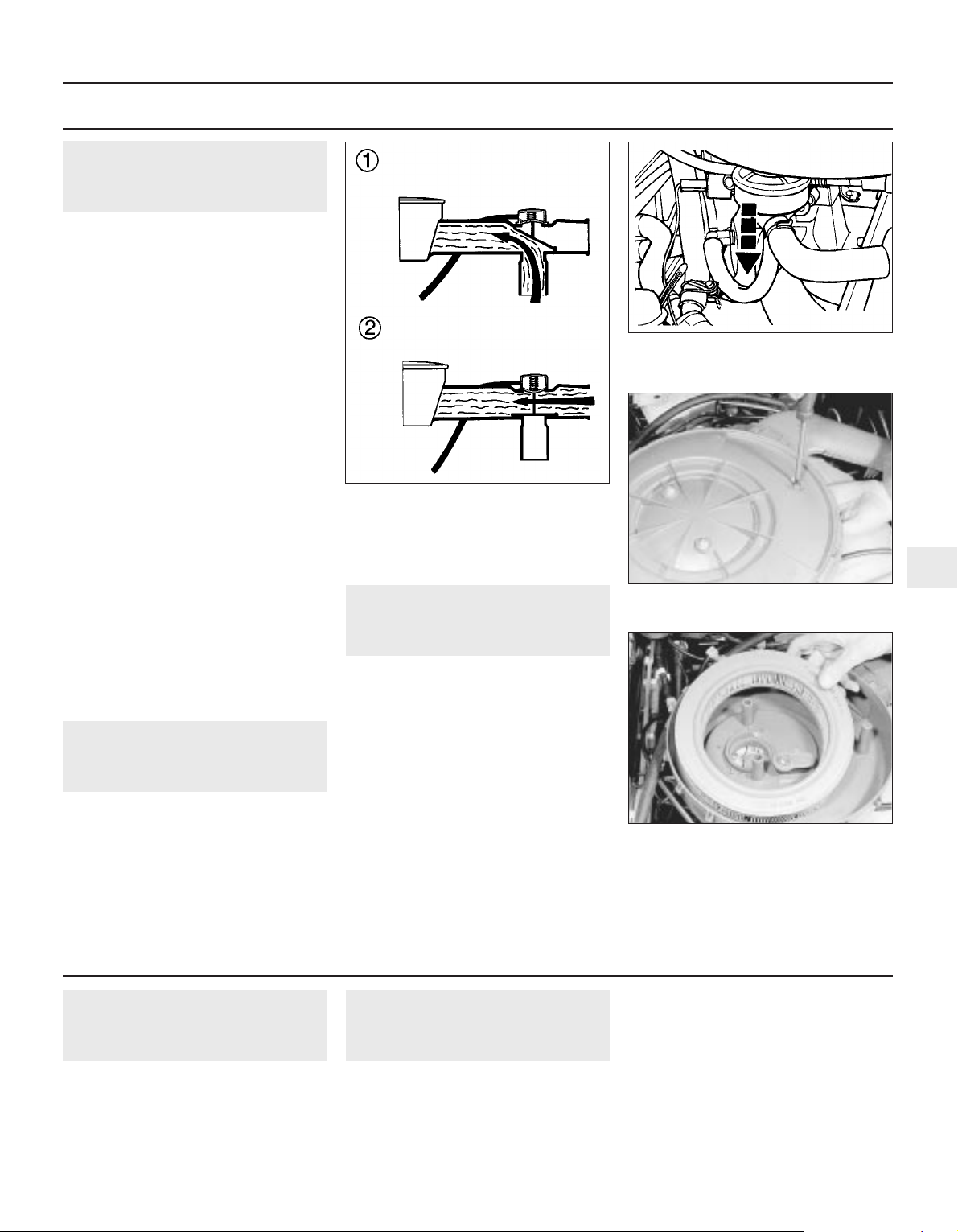

29 Air cleaner temperature

control check

2

Note: A vacuum pump will be required for this

check if the heat sensor or diaphragm unit is

at fault.

1 The air cleaner temperature control unit can

be checked for operation whilst the engine is

cold. Look into the air inlet spout and check

that the air control flap valve is in the shut

position (see illustration).

2 Now start the engine and allow it to idle.

The flap valve should open fully to allow the

warm air to be drawn into the cleaner unit

from the exhaust manifold ducting. As the

engine warms up to its normal operating

temperature the flap valve should

progressively close to allow cooler air to enter

the cleaner unit.

3 If the valve is stuck in the shut position,

check the vacuum lines for condition and

security. If these are in order, then the heat

sensor or diaphragm unit is at fault. Proceed

as follows:

4 Detach the diaphragm-to-heat sensor

vacuum pipe (at the sensor end) and connect

up a vacuum pump to the diaphragm. Pump

and apply a vacuum up to 100 mm of mercury

and retain this whilst checking the air flap.

5 If the flap opens, the heat sensor is

defective and must be renewed, but if it

remains shut then the diaphragm or control

flap is faulty.

6 Disconnect the vacuum pump and

reconnect the vacuum pipe to the sensor unit.

30 Emission control filter

element renewal - CVH

engines

1

1 Gain access to the emission control filter by

detaching the hose from the air cleaner unit

(see illustration).

2 Withdraw the used filter and fit a new item.

Ensure that the hose is securely reconnected.

31 Air cleaner element renewal

1

1 Renew the air cleaner element by first

removing the air cleaner unit lid. To do this,

undo and remove the retaining screws and

prise free the lid from the retaining clips

around its periphery (see illustration).

2 Remove and discard the paper element and

wipe out the air cleaner casing (see

illustration).

3 Place the new element in position and refit

the lid.

32 Brake hydraulic system seal

and hose renewal

3

If in doubt as to the condition of any of the

brake system seals and hoses, then renew

defective items whilst referring to the relevant

Sections of Chapter 9.

33 Brake hydraulic fluid renewal

2

1 An assistant and bleeding equipment will

be needed. A considerable quantity of

hydraulic fluid will be required - probably

about 2 litres.

2 Slacken the front wheel nuts. Raise and

support the front of the vehicle and remove

the front wheels.

3 Remove the hydraulic fluid reservoir cap.

4 Open both front bleed screws one full turn.

Attach one bleed tube to each screw, placing

the free end of each tube in a jar.

5 Pump the brake pedal to expel fluid from

the bleed screws. Pause after each upstroke

to allow the master cylinder to refill.

Every 24 000 miles or 2 years 1•17

31.1 Remove the air cleaner lid securing

screws . . .

30.1 Detach hose downwards for access

to crankcase emission filter in air cleaner

body

29.1 Air cleaner inlet sensor and

diaphragm flap valve operating modes

1 Sensor cold 2 Sensor hot

1

24 000 Mile (40 000 Km) / every 2 years

36 000 Mile (60 000 Km) / every 3 years

31.2 . . . to expose the air cleaner element

Page 18

6 When air emerges from both bleed screws,

stop pumping. Detach the left-hand caliper

without disconnecting it and remove the

inboard brake pad.

7 Depress the caliper piston, using a

purpose-made tool or a blunt item such as a

tyre lever, to force more fluid out of the

caliper. Hold the piston depressed and have

the assistant pump the pedal until air emerges

from the bleed screw again.

8 Tighten the bleed screw on the left-hand

caliper. Loosely refit the caliper and pad so

that the piston is not accidentally ejected.