Page 1

FCSD

Technical Training

INTERACTIVE STUDY GUIDE

2005

EXPEDITION/NAVIGATOR

NEW MODEL TECHNICIAN

TRAINING

FCS-14000-DL

2005 EXPEDITION/NAVIGATOR NEW MODEL TECHNICIAN TRAINING

COURSE CODE: 30N29F002-SEP-04

Page 2

Page 3

IMPORTANT SAFETY NOTICE

Appropriate service methods and proper repair procedures are essential for the safe, reliable operation of all motor vehicles, as

well as the personal safety of the individual doing the work. This manual provides general directions for accomplishing service

and repair work with tested, effective techniques. Following them will help assure reliability.

There are numerous variations in procedures, techniques, tools and parts for servicing vehicles, as well as in the skill of the

individual doing the work. This manual cannot possibly anticipate all such variations and provide advice or cautions as to each.

Accordingly, anyone who departs from instructions provided in this manual must first establish that he compromises neither his

personal safety nor the vehicle integrity by his choice of methods, tools or parts.

As you read through the procedures, you will come across NOTES, CAUTIONS, and WARNINGS. Each one is there for a

specific purpose. NOTES give you added information that will help you to complete a particular procedure. CAUTIONS are given

to prevent you from making an error that could damage the vehicle. WARNINGS remind you to be especially careful in those

areas where carelessness can cause personal injury. The following list contains some general WARNINGS that you should

follow when you work on a vehicle.

•

Always wear safety glasses for eye protection.

•

Use safety stands whenever a procedure requires you to

be under the vehicle.

•

Be sure that the ignition switch is always in the OFF

position, unless otherwise required by the procedure.

•

Set the parking brake when working on the vehicle. If you

have an automatic transmission, set it in PARK unless

instructed otherwise for a specific service operation. If you

have a manual transmission it should be in RE-VERSE

(engine OFF) or NEUTRAL (engine ON) unless instructed

otherwise for a specific service operation.

•

Operate the engine only in a well-ventilated area to avoid

the danger of carbon monoxide.

•

Keep yourself and your clothing away from moving parts should be taken to ensure that the electric cooling fan is

when the engine is running, especially the fan and belts. completely disconnected when working under the hood.

•

To prevent serious burns, avoid contact with hot metal

parts such as the radiator, exhaust manifold, tail pipe,

catalytic converter and muffler.

•

Do not smoke while working on the vehicle.

•

To avoid injury, always remove rings, watches, loose

hanging jewelry, and loose clothing before beginning to

work on a vehicle. Tie long hair securely behind your

head.

•

Keep hands and other objects clear of the radiator fan

blades. Electric cooling fans can start to operate at any

time by an increase in underhood temperatures, even

though the ignition is in the OFF position. Therefore, care

The recommendations and suggestions contained in this manual are made to assist the dealer in improving his dealership parts and/or

service department operations. These recommendations and suggestions do not supersede or override the provisions of the Warranty

and Policy Manual, and in any cases where there may be a conflict, the provisions of the Warranty and Policy Manual shall govern.

The descriptions, testing procedures, and specifications in this handbook were in effect at the time the handbook was approved

for printing. Ford Motor Company reserves the right to discontinue models at any time, or change specifications, design, or

testing procedures without notice and without incurring obligation. Any reference to brand names in this manual is intended

merely as an example of the types of tools, lubricants, materials, etc. recommended for use. Equivalents, if available, may be

used. The right is reserved to make changes at any time without notice.

WARNING: MANY BRAKE LININGS CONTAIN ASBESTOS FIBERS. WHEN WORKING ON BRAKE COMPONENTS, AVOID

BREATHING THE DUST. BREATHING THE ASBESTOS DUST CAN CAUSE ASBESTOSIS AND CANCER.

Breathing asbestos dust is harmful to your health.

Dust and dirt present on car wheel brake and clutch assemblies may contain asbestos fibers that are hazardous to your health when

made airborne by cleaning with compressed air or by dry brushing.

Wheel brake assemblies and clutch facings should be cleaned using a vacuum cleaner recommended for use with asbestos fibers.

Dust and dirt should be disposed of in a manner that prevents dust exposure, such as sealed bags. The bag must be labeled per OSHA

instructions and the trash hauler notified as to the contents of the bag.

If a vacuum bag suitable for asbestos is not available, cleaning should be done wet. If dust generation is still possible, technicians

should wear government approved toxic dust purifying respirators.

OSHA requires areas where asbestos dust generation is possible to be isolated and posted with warning signs. Only technicians

concerned with performing brake or clutch service should be present in the area.

Copyright 2004 Ford Motor CompanyProduced and Coordinated by

Technical Support Operations

Ford Customer Service Division

September, 2004

Page 4

CUSTOMER EXPECTATIONS

Customer Expectations: Service

1.

Make it convenient to have my vehicle

serviced at your dealership. explanation of the service performed.

2.

The Service Advisor should

demonstrate a genuine concern for of time after my service visit to ensure

my service needs. that I’m completely satisfied.

3.

Fix it right the first time.

4.

Complete servicing my vehicle in a

timely and professional manner.

Expectation 3

‘‘Fix It Right The First Time, on Time.’’

Both service advisors and technicians are important players when it comes to Expectation

#3.

5.

Provide me with a clear and thorough

6.

Call me within a reasonable amount

7.

Be responsive to questions or

concerns I bring to your attention.

Why

Customers tell us ‘‘Fixing It Right The First Time, on Time’’ is one of the reasons they

would decide to return to a dealer to buy a vehicle and get their vehicles serviced.

Technician Training

It is our goal to help the technician acquire all of the skills and knowledge necessary to

‘‘Fix It Right The First Time, on Time.’’ We refer to this as ‘‘competency.’’

Technician’s Role

Acquire the skills and knowledge for competency in your specialty via:

STST New Model

– Self Study – Self Study

– FordStar Broadcasts – FordStar Broadcasts

– Ford Multimedia Training (FMT) – Instructor Led

– Instructor Led

The Benefits

The successful implementation of expectations means:

– Satisfied customers

– Repeat vehicle sales

– Repeat service sales

– Recognition that Ford and Lincoln/Mercury technicians are ‘‘the Best in the

Business’’

Page 5

TABLE OF CONTENTS

INTRODUCTION ............................................................................................................... Intro-1

Technical Training ........................................................................................................Intro-1

Ground Rules for Successful Completion....................................................................Intro-1

Logging On................................................................................................................... Intro-2

Keypad Operation ......................................................................................................... Intro-3

In-Dealership Training Map.......................................................................................... Intro-4

Purpose .........................................................................................................................Intro-5

Agenda ..........................................................................................................................Intro-5

LESSON 1: OVERVIEW......................................................................................................... 1-1

Objectives .......................................................................................................................... 1-1

Mechanical and Chassis Features.................................................................................... 1-2

Exterior Features............................................................................................................... 1-6

Interior Features ................................................................................................................ 1-8

Lifting and Jacking ........................................................................................................... 1-10

Maintenance Check Points .............................................................................................. 1-11

LESSON 2: CHASSIS............................................................................................................ 2-1

Objectives .......................................................................................................................... 2-1

Wheels and Tires............................................................................................................... 2-2

Driveshaft ......................................................................................................................... 2-11

Front Drive Axle/Differential............................................................................................. 2-12

LESSON 3: POWERTRAIN ................................................................................................... 3-1

Objectives .......................................................................................................................... 3-1

Engine - 5.4L..................................................................................................................... 3-2

Electronic Engine Controls.............................................................................................. 3-36

Fuel Tank and Lines ........................................................................................................ 3-38

Engine Special Service Tools.......................................................................................... 3-39

Automatic Transmission .................................................................................................. 3-40

Transmission Cooling ...................................................................................................... 3-62

6HP26 Transmission Special Service Tools................................................................... 3-63

LESSON 4: ELECTRICAL..................................................................................................... 4-1

Objectives .......................................................................................................................... 4-1

Climate Controlled Seats ................................................................................................... 4-2

Warning Devices................................................................................................................ 4-3

Instrument Cluster Lighting................................................................................................ 4-4

Charging System............................................................................................................... 4-5

Vehicle Security Module.................................................................................................... 4-6

Module Communication Network....................................................................................... 4-7

APPENDIX................................................................................................................Appendix-1

Appendix: Essential Special Service Tools .......................................................... Appendix-1

Order Form........................................................................................................... Appendix-3

Glossary Of Terms ............................................................................................... Appendix-5

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 i

Page 6

TABLE OF CONTENTS

NOTES

2005 Expedition/Navigator New Model Technician Training02-SEP-04ii

Page 7

INTRODUCTION

FCSD

Technical Training

The distance learning course you are about to take is intended to give you new knowledge and information about

diagnosing and servicing Ford and Lincoln/Mercury vehicles. We hope you will apply this knowledge and

information to ‘‘Fix It Right The First Time’’ as part of the effort to satisfy our customer, the owners of Ford and

Lincoln/Mercury products.

Ground Rules for Successful Completion

This course is what we call ‘‘score based.’’ Successful completion of this course requires a passing score of 80%

or greater on the Post-Test questions. Achievement of 80% or greater will result in a ‘‘PASS’’ in your STARS

training history. A score of less than 80% results in a ‘‘FAIL’’ in your STARS training history. If you logon and

participate in the class, but choose NOT to answer any of the questions, you will receive an ‘‘AUDIT’’ in your

training history. You may return to complete the test in a future class session, if desired. Completion of the test

will replace the ‘‘AUDIT’’ in your STARS training history.

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 Intro-1

Page 8

INTRODUCTION

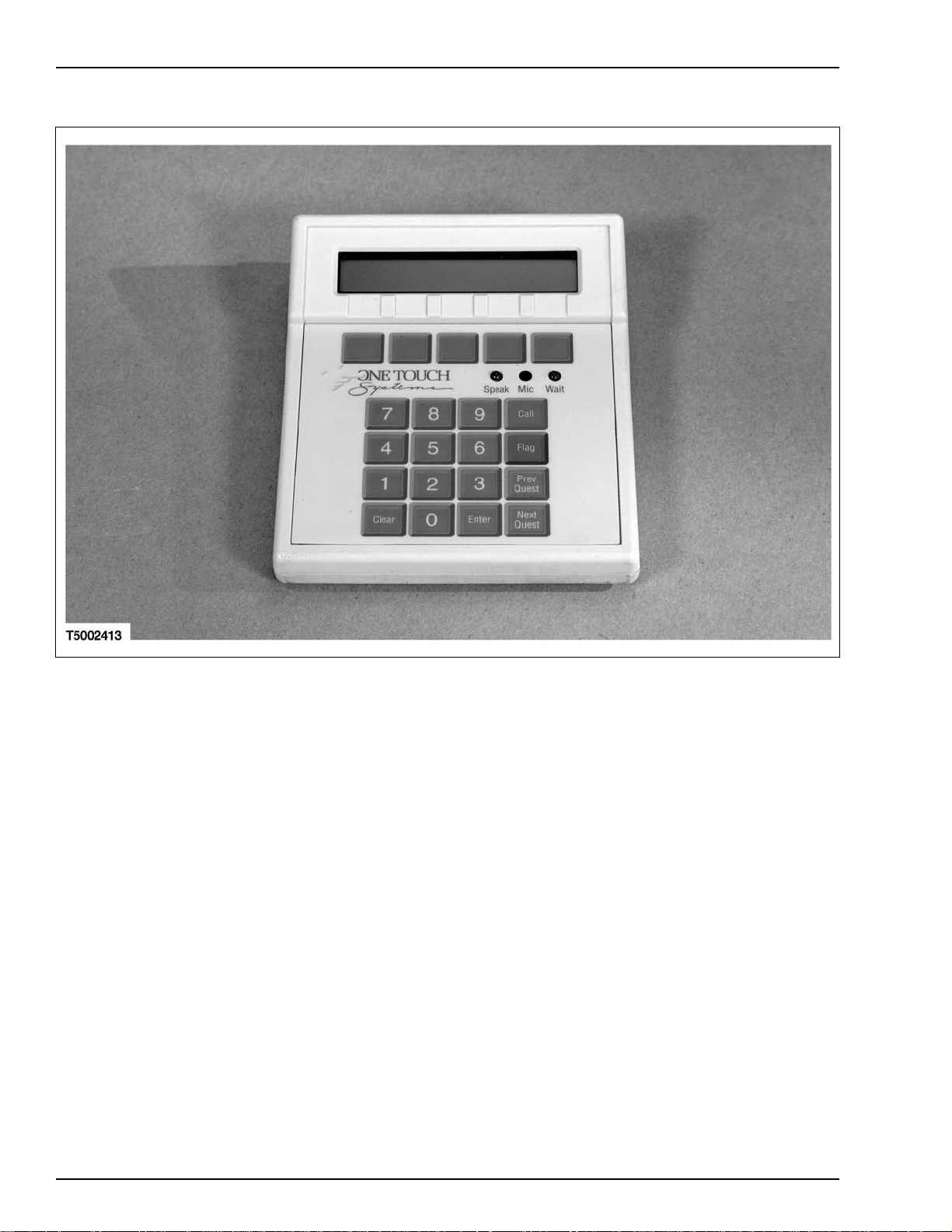

LOGGING ON

Your response keypad transmits data and voice between you and the host site via telephone lines and satellite. It is

your ‘‘lifeline,’’ connecting you to the instructor as well as to other participants. Using the keypad, you can

become fully involved in the seminar, asking questions and contributing relevant comments.

To log on at the beginning of the broadcast session:

1. Enter your Social Security number (in response to the keypad prompt). If you press an incorrect key, press

CLEAR and re-enter the numbers.

2. Press ENTER.

3. The system validates your ID number by displaying your name on your keypad. If your name does not appear

on the keypad, re-enter your ID number.

4. If you cannot successfully log on, contact the FORDSTAR Help Desk:

USA Dealers call 1–800–790–HELP (4357).

Canadian Dealers call 1–800–467–8925.

2005 Expedition/Navigator New Model Technician Training02-SEP-04Intro-2

Page 9

INTRODUCTION

KEYPAD OPERATION

CALL Key

•

Press the CALL key if you have a question or comment. This places you in the call queue. The system indicates

your name and location to the instructor.

•

It takes approximately 60 seconds for the instructor to respond. If you change your mind about asking the

question, simply press the CALL key again. As long as the instructor has not accepted your call, this takes you

out of the call queue.

WAIT and SPEAK Lights

•

The red WAIT light illuminates when your call is received and placed in the call queue.

•

When the instructor calls on you, the green SPEAK light illuminates and your microphone is activated.

•

The microphone is the gray dot between the SPEAK and WAIT lights. Speak in a normal tone of voice from a

normal sitting position. The instructor will hear you — as will all the other students, wherever they are located.

FLAG Key

•

Use the FLAG key when requested by the instructor. The FLAG key is usually used to alert the instructor that

you have completed tests or exercises.

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 Intro-3

Page 10

INTRODUCTION

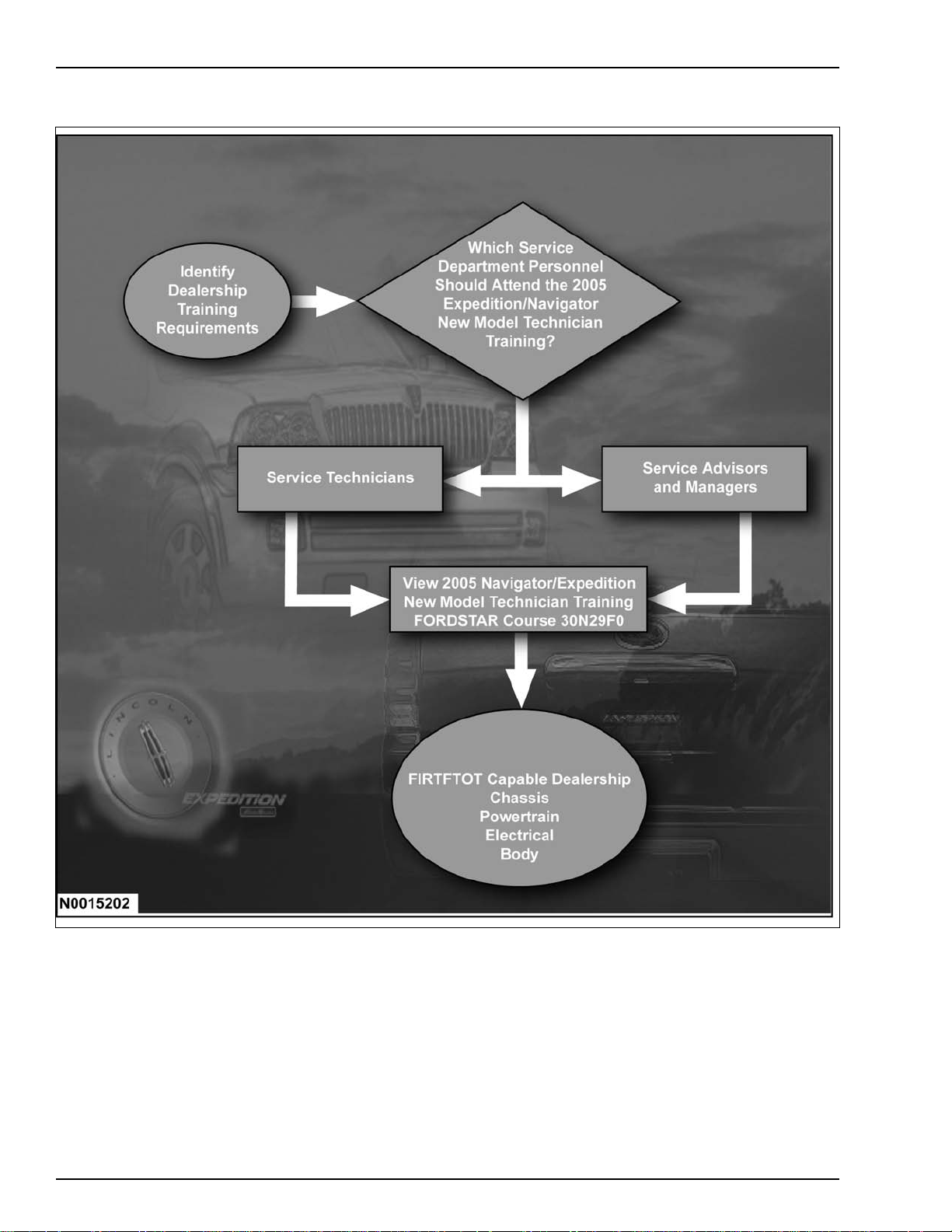

IN-DEALERSHIP TRAINING MAP

2005 Expedition/Navigator New Model Technician Training02-SEP-04Intro-4

Page 11

INTRODUCTION

PURPOSE

The purpose of this FORDSTAR course is to provide Ford and Lincoln/Mercury service technicians with the

knowledge needed to understand new systems, new or updated components and unique diagnostic and service

procedures for the 2005 Expedition/Navigator.

AGENDA

The information in this course is presented in the following lessons:

•

Lesson 1: Overview

•

Lesson 2: Chassis

•

Lesson 3: Powertrain

•

Lesson 4: Electrical

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 Intro-5

Page 12

INTRODUCTION

NOTES

2005 Expedition/Navigator New Model Technician Training02-SEP-04Intro-6

Page 13

OBJECTIVES

•

Identify the new powertrain applications for Expedition and Navigator.

•

Identify exterior features.

•

Identify interior features.

•

Identify lifting and jacking points.

•

Identify maintenance check points.

LESSON 1: OVERVIEW

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 1-1

Page 14

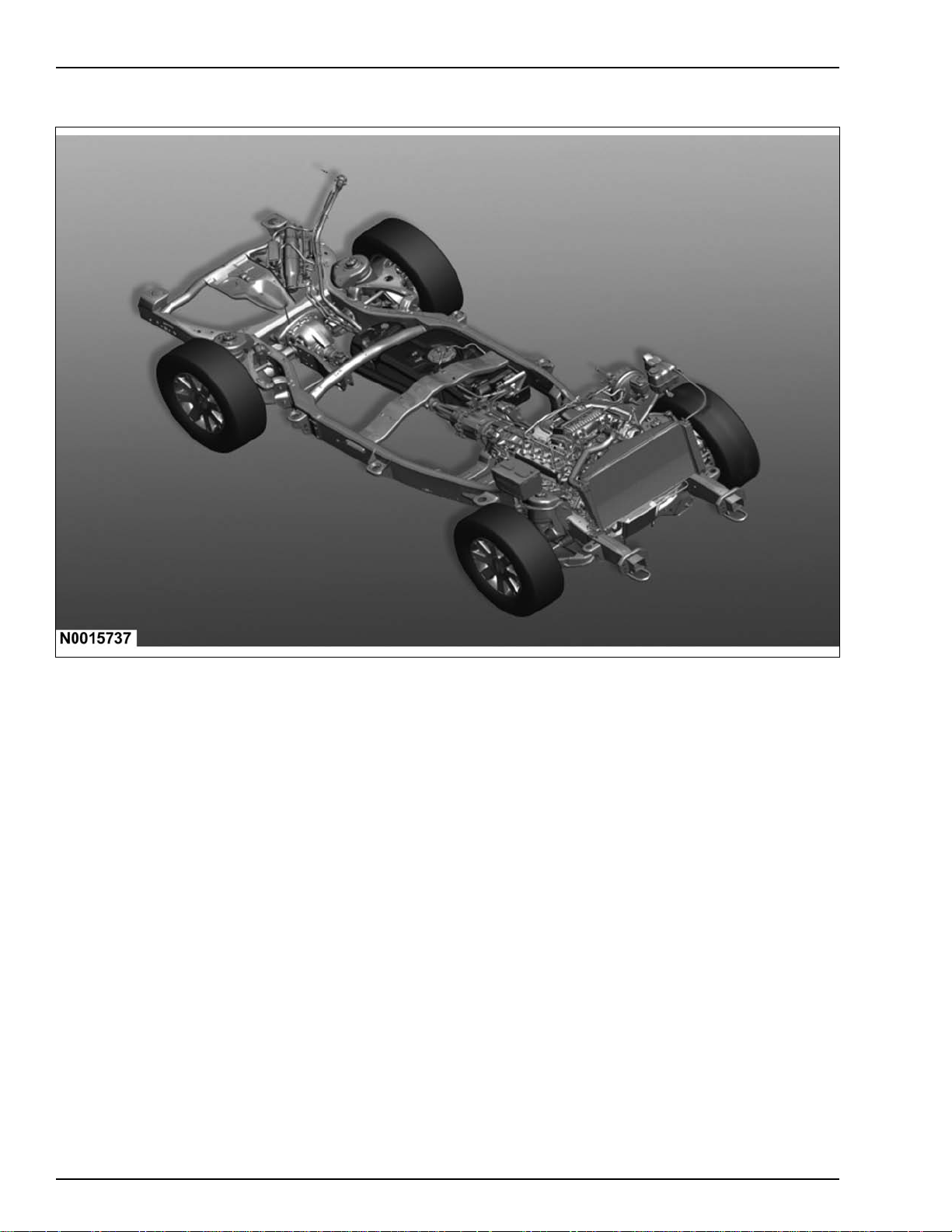

LESSON 1: OVERVIEW

Mechanical and Chassis Features

Mechanical and Chassis Features

•

5.4L 3-Valve Triton Engine w/Variable Cam Timing.

•

6HP26 Automatic Transmission (Navigator only).

•

4R75E Automatic Transmission (Expedition only).

2005 Expedition/Navigator New Model Technician Training02-SEP-041-2

Page 15

Engine - 5.4L

LESSON 1: OVERVIEW

5.4L 3-Valve Triton Phaser

The 2005 Expedition and Navigator are available with one engine:

•

New for 2005, the 5.4L 3-valve Triton V8.

– 300 horsepower @ 5,000 rpm

– 365 lb-ft of torque @ 3,750 rpm

– Variable cam timing

– Three valves per cylinder

–Electronic Throttle Control (ETC)

Rather than focusing on a single item to gain improvements in power, Ford used an approach that included

advancements on multiple fronts. These improvements contribute to overall power with reduced NVH, at low

engine speeds. Some of these changes are outlined below:

•

The three-valve design achieves same benefits as a four-valve design.

– Three-valve design balances the forces generated by the valve and spring movement.

– Reduces engine noise.

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 1-3

Page 16

LESSON 1: OVERVIEW

•

Variable Cam Timing (VCT) varies cam timing to match performance demands.

•

Charge Motion Control Valves (CMCV) manage the flow of air into the cylinders.

•

Vibration-resistant ribbing and reinforcement in the lower engine block help manage and tune sound and

vibration.

– The engine block ribbing strengthens the block wall similar to cross reinforcements in a building wall.

2005 Expedition/Navigator New Model Technician Training02-SEP-041-4

Page 17

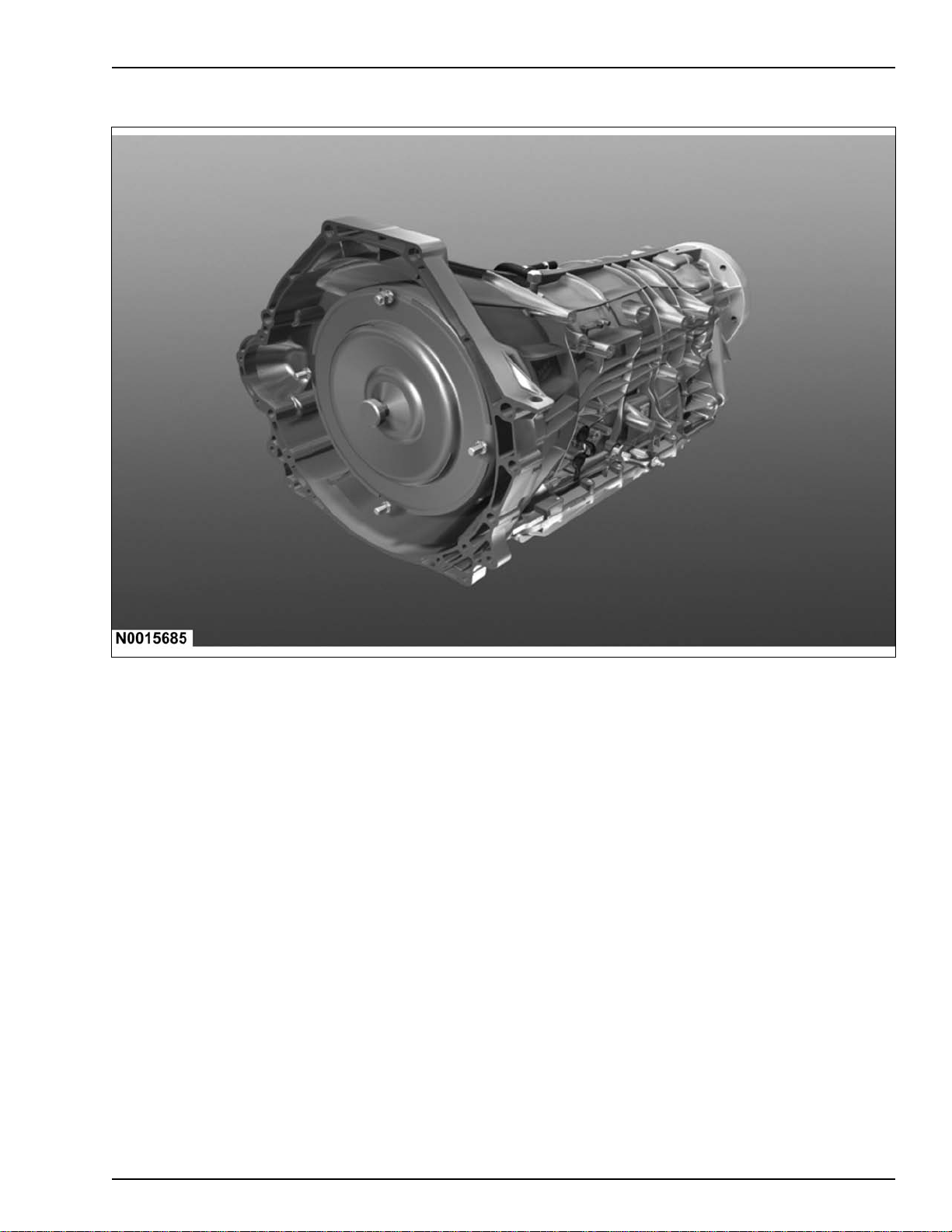

Automatic Transmission

LESSON 1: OVERVIEW

6HP26 Transmission

The 2005 Expedition will use the 4R75E automatic transmission like the 2004 and 2005 F-150, while the

Navigator uses the all-new 6HP26 automatic.

The 6HP26 6-speed transmission uses total electronic control for all functions. The Transmission Control Module

(TCM) and the main control valve body units are combined and installed as a single unit inside the automatic

transmission. Hydraulic functions are directed by electronic solenoids to control:

•

engagement feel

•

shift feel

•

shift scheduling

•

modulated Torque Converter Clutch (TCC) applications

•

engine braking

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 1-5

Page 18

LESSON 1: OVERVIEW

Exterior Features

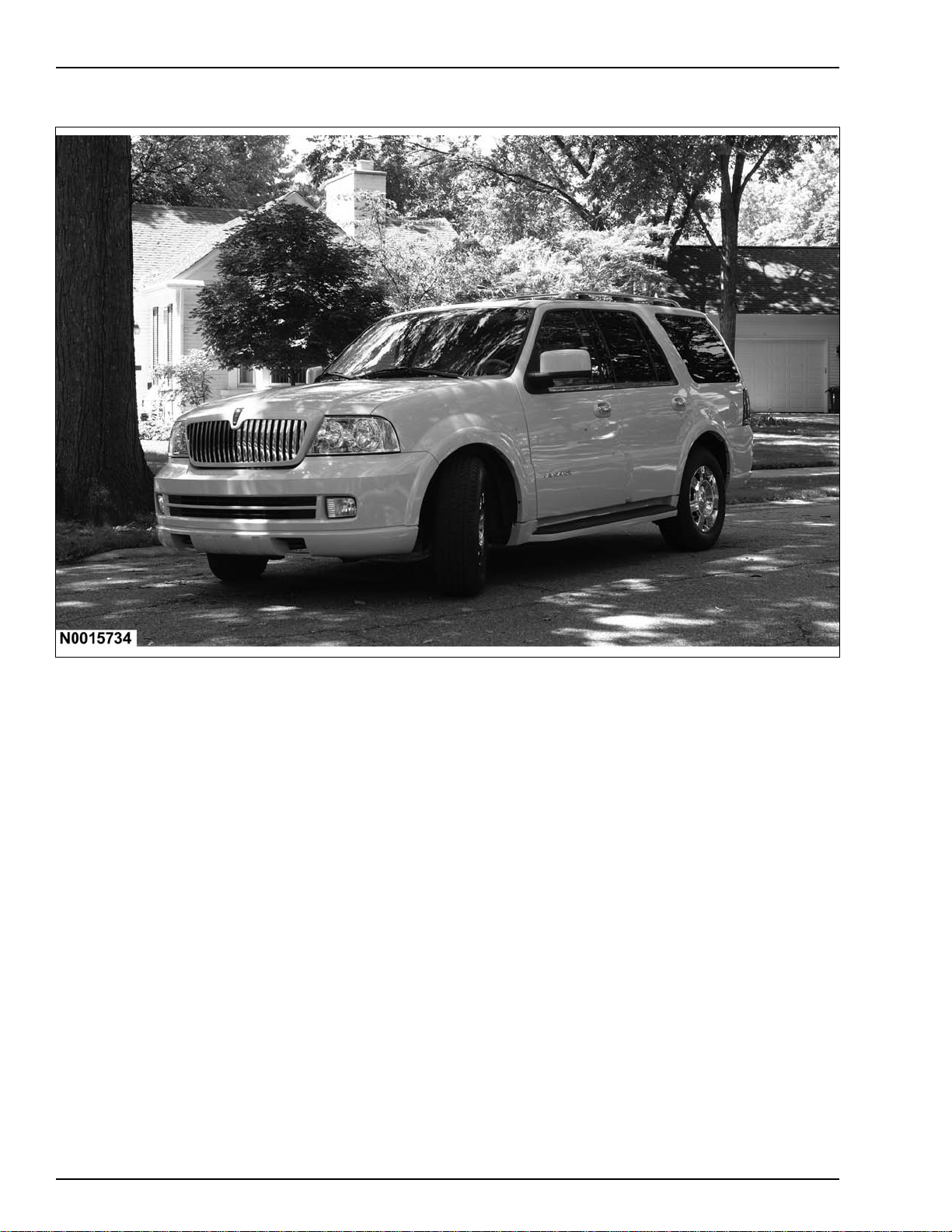

2005 Navigator Exterior

•

New body side cladding

– Bold new body side cladding is added to the 2005 Lincoln Navigator. The cladding is painted body color and

enhances as well as protects the exterior appearance.

•

New front fascia

– An agressive front fascia is standard on the Lincoln Navigator and comes with integral fog lamps and front

spoiler. High Intensity Discharge (HID) headlamps are optional on all models.

2005 Expedition/Navigator New Model Technician Training02-SEP-041-6

Page 19

LESSON 1: OVERVIEW

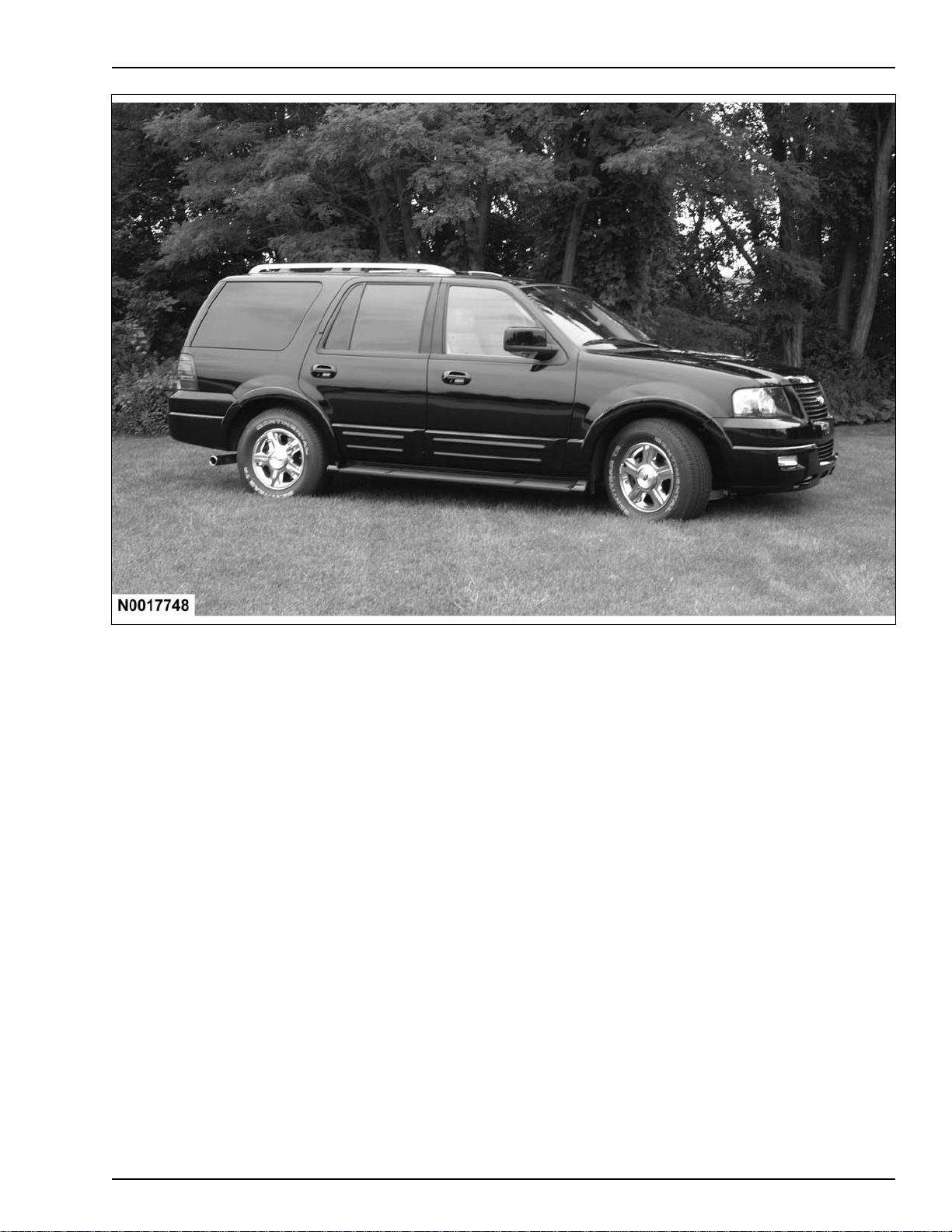

2005 Expedition Exterior

•

New badging for Limited and FX4 (mid 4th quarter availability).

– Expedition for 2005 comes with new badging when equipped with the Limited and FX4 packages.

•

New power fold side view mirrors.

– Expedition Limited for 2005 comes with new power fold side view mirrors. The mirrors are controlled by a

switch that is integral with the power mirror switch.

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 1-7

Page 20

LESSON 1: OVERVIEW

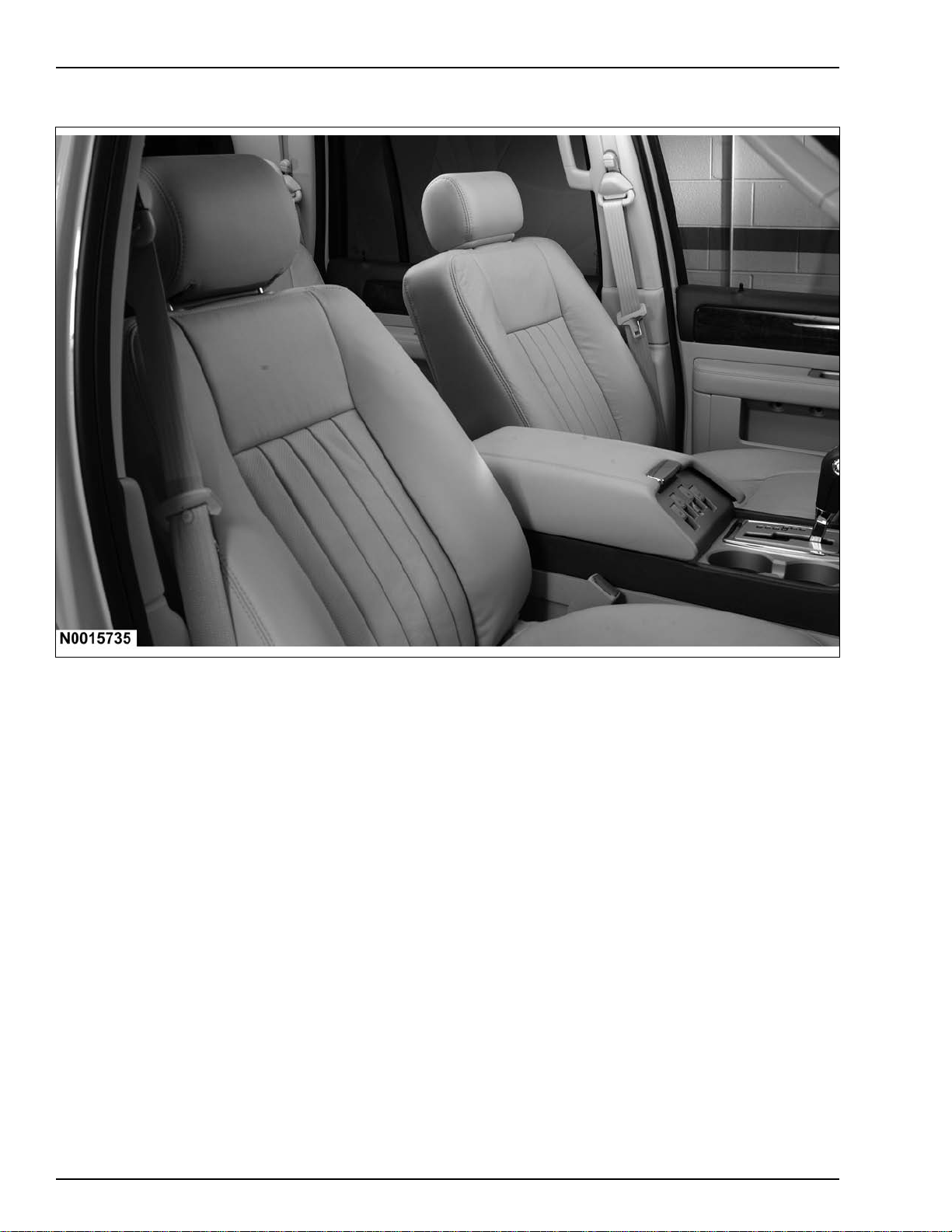

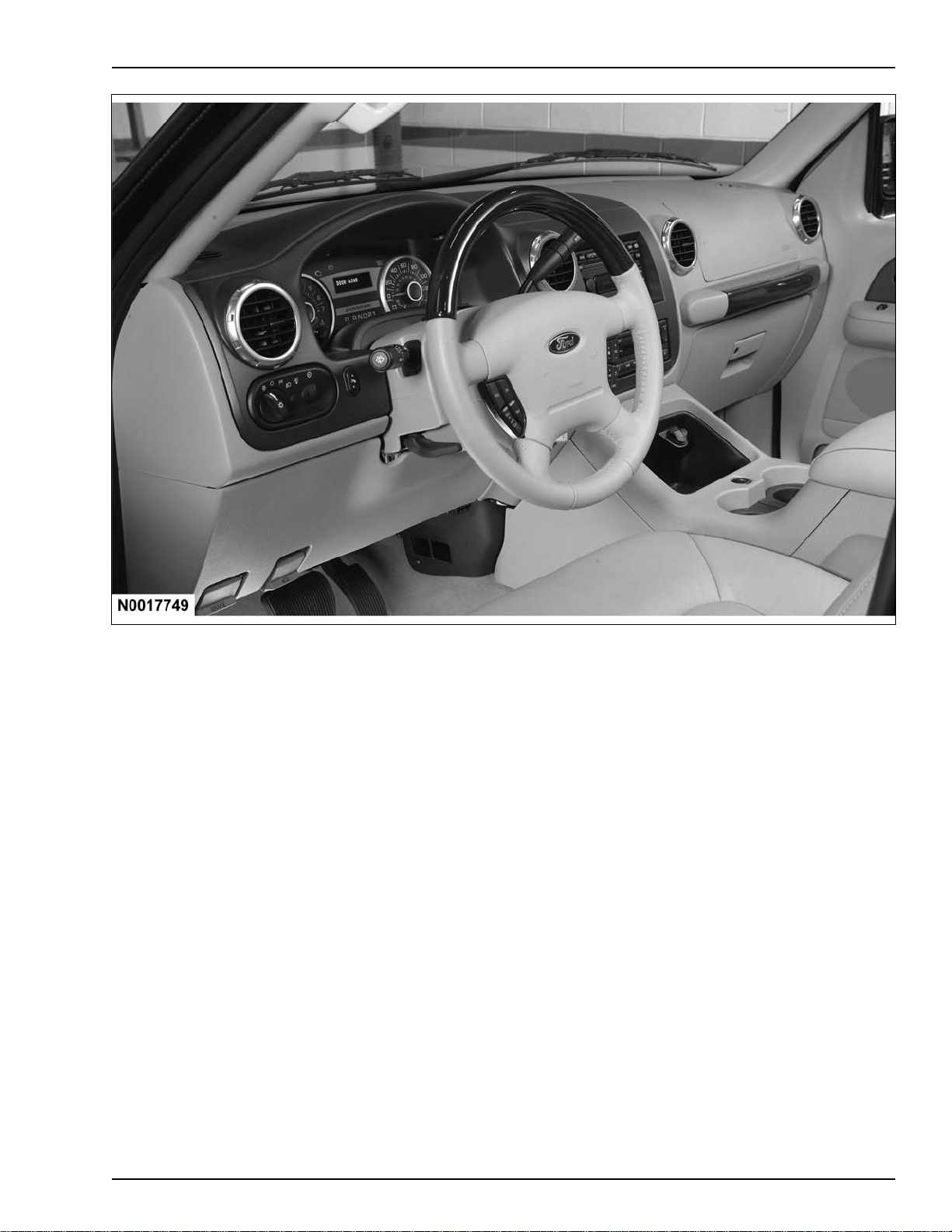

Interior Features

2005 Navigator Interior

•

New 6HP26 automatic transmission gear selector.

– Lincoln Navigators are equipped with a new 6HP26 transmission. The gear selector allows for manual or

automatic selection of first through fourth gear (O/D disabled) and first through sixth (O/D enabled). O/D is

enabled by moving the gear selector handle to the left while in the D6/D4 gate and is disabled by moving it

to the right.

– To accomodate the new gear selector for the 6HP26 transmission, the center console has been updated.

•

New front seats.

– The 2005 Lincoln Navigator features restyled front seats to improve seating comfort and support.

2005 Expedition/Navigator New Model Technician Training02-SEP-041-8

Page 21

LESSON 1: OVERVIEW

2005 Expedition Interior

The 2005 Expedition receives minor trim and finish updates as:

•

Power fold side view miror switch (Limited only).

– The power fold mirrors are operated from a switch that is integral with the power mirror switch.

– In contrast to the power folding mirror switch already available in the Navigator, to retract or extend the

folding mirrors, rotate the mirror adjustment knob to the center position. Pressing the switch down one time

will fold the mirrors inward. Pressing the button again will return the mirrors to their normal position.

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 1-9

Page 22

LESSON 1: OVERVIEW

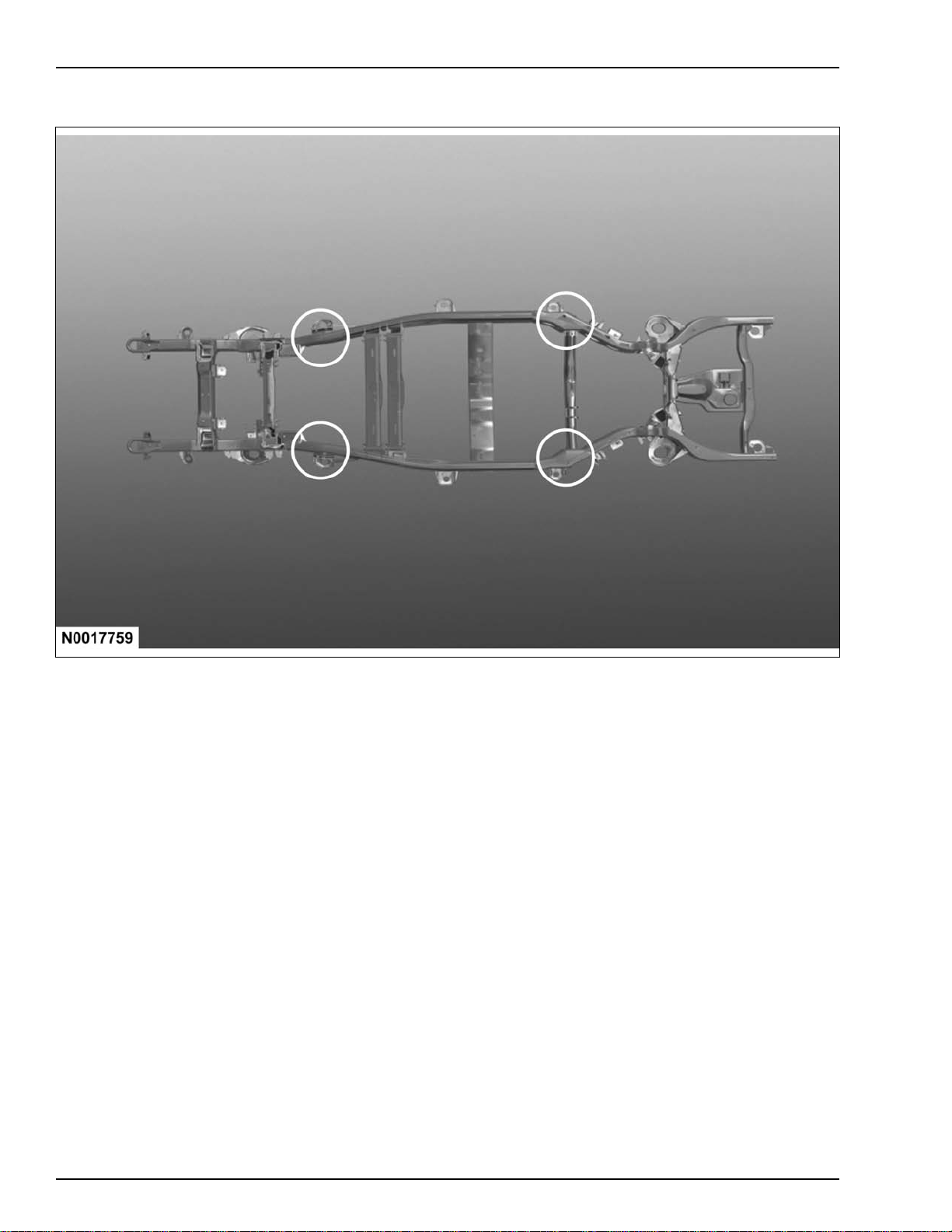

Lifting and Jacking

Lifting and Jacking Points

The front and rear lifting and jacking locations are as indicated.

2005 Expedition/Navigator New Model Technician Training02-SEP-041-10

Page 23

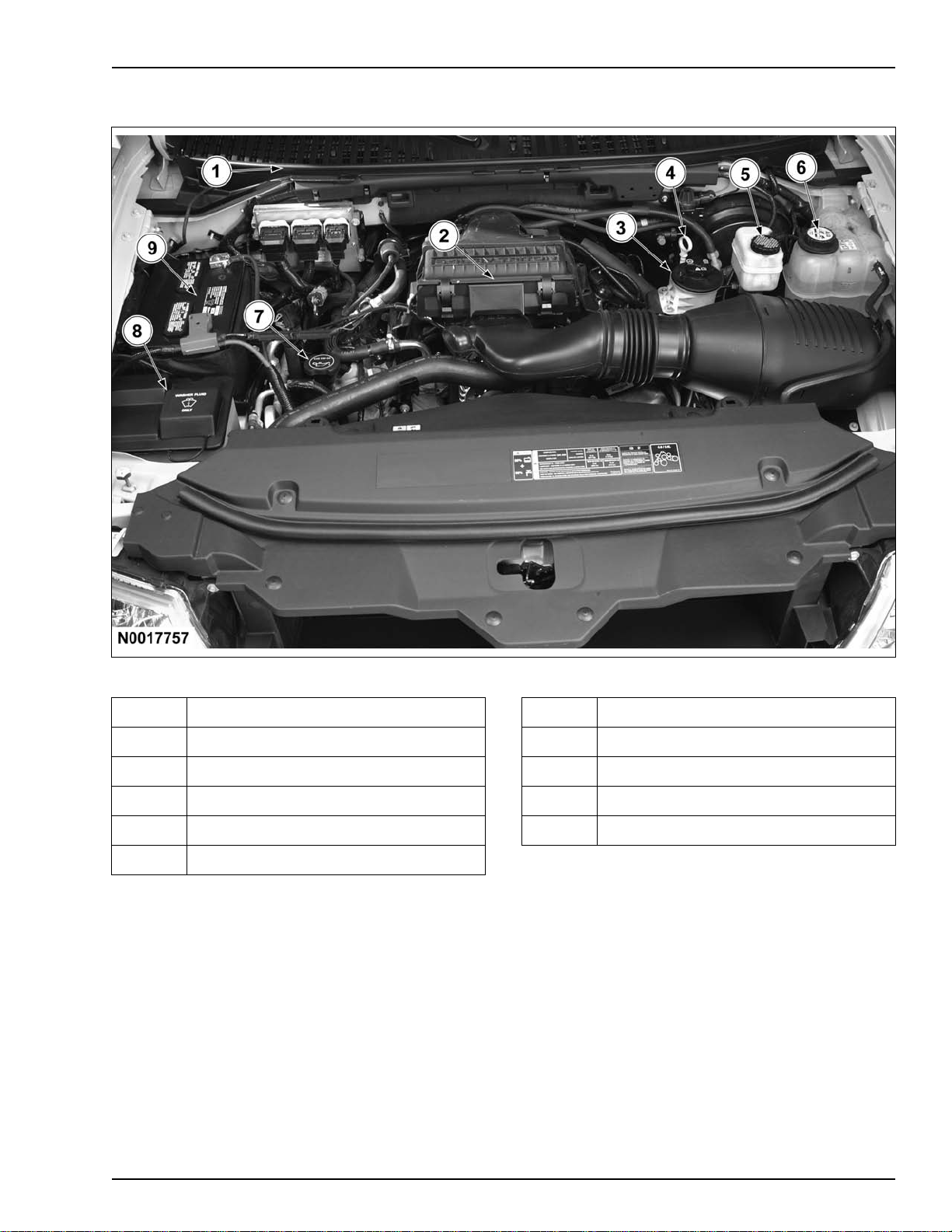

Maintenance Check Points

LESSON 1: OVERVIEW

Maintenance Check Points (Navigator Shown)

Item Description Item Description

1 Cabin Air Filter 6 Engine Coolant

2 Engine Air Filter 7 Engine Oil Fill

3 Power Steering Fluid 8 Windshield Washer Solvent

4 Engine Oil Dipstick 9 Battery

5 Brake Fluid

All maintenance point locations are carry-over from 2004 with the exception of the transmission fluid (on Lincoln

Navigator) and air filter element (on both). Expedition has a conventional transmission dipstick located near the

right rear corner of the engine. Refer to the Workshop Manual for the proper maintenance schedule and fluid

specifications.

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 1-11

Page 24

LESSON 1: OVERVIEW

NOTES

2005 Expedition/Navigator New Model Technician Training02-SEP-041-12

Page 25

OBJECTIVES

•

Identify changes to the TPMS.

•

Identify new suspension system features.

•

Identify new drive axle/differential driveline features.

LESSON 2: CHASSIS

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 2-1

Page 26

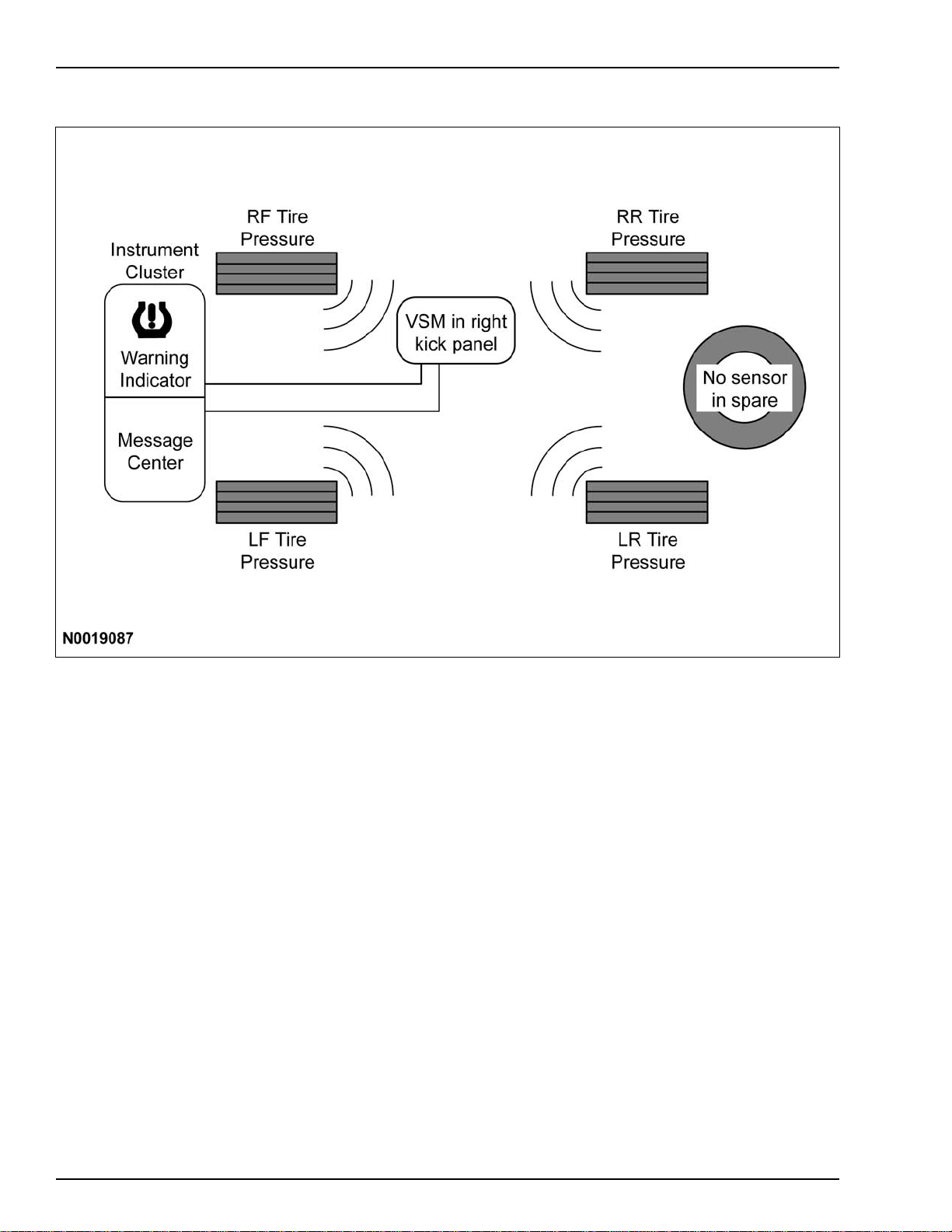

LESSON 2: CHASSIS

Wheels and Tires

Tire Pressure Monitor

•

TPMS functionality is integrated into Vehicle Security Module (VSM) located in the right kick panel.

•

Communicates with sensor at 315 MHz.

•

Blue colored sensor (315 MHz), unique for 2005 Expedition and Navigator.

•

Sensor Training process is same as previous TPM system (with exception of spare tire).

•

2004 sensor (Black, 433 MHz) will NOT work on 2005 Expedition or Navigator.

•

Sensor removal and installation process is same as 2004 system.

•

Cluster messages for TPMS are different than 2004.

•

A separate warning indicator is used on Expedition models that are not equipped with the optional message

center.

2005 Expedition/Navigator New Model Technician Training02-SEP-042-2

Page 27

LESSON 2: CHASSIS

TPMS General Information

Temperature fluctuation changes tire inflation pressure 7KPa per 12 degrees Celsius (1 psi per 10 degrees F)

Article #: SSM 17496 Date: 01/16/2004: TPMS SYSTEM-DO NOT USE AFTERMARKET WHEELS. SOME

2003-2004 EXPEDITION/NAVIGATOR/AVIATOR/EXPLORER/MOUNTAINEER VEHICLES MAY

EXHIBIT A TIRE PRESSURE MONITORING SYSTEM (TPMS) WARNING, OR OTHER RELATED

CONDITIONS, IF AFTERMARKET WHEELS ARE INSTALLED. FORD MOTOR COMPANY DOES NOT

RECOMMEND USING AFTERMARKET WHEELS ON ANY VEHICLES, ESPECIALLY TPMS EQUIPPED

VEHICLES. ORIGINAL EQUIPMENT (OE) WHEELS ARE SPECIFICALLY DESIGNED TO

ACCOMMODATE TPMS SENSORS. AFTERMARKET WHEELS MAY NOT BE COMPATIBLE WITH

THESE SENSORS, AND USE OF NON-OE WHEELS MAY RESULT IN ILLUMINATION OF THE TPMS

WARNING INDICATOR, LOSS OF TIRE PRESSURE, TPMS SENSOR DAMAGE OR LOSS OF TPMS

FUNCTIONALITY. FORD DOES NOT SUPPORT DISABLING THE TPMS SYSTEM. IT IS THE

INSTALLER’S RESPONSIBILITY TO ENSURE AFTERMARKET WHEELS PROVIDE EQUIVALENT FIT

AND FUNCTION AS THE OE WHEELS BEING REPLACED INCLUDING TPMS FUNCTIONALITY.

NOTE: This SSM also applies to 2005 model year Expedition and Navigators vehicles.

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 2-3

Page 28

LESSON 2: CHASSIS

Functionality - 2005 Model Year

Sensor Wheel Package

Item Description Item Description

1 Blue, 315 Mhz Tire Pressure Sensor

•

4-sensor system (road tires only, does not include spare).

•

RF-based.

– Sensors transmit pressure and unique ID to VSM (integrated system).

– Receiver (TPM integral to VSM) receives information, processes information, and communicates status to

the cluster via MS-CAN link.

•

TPMS warnings displayed on message center (if equipped).

•

All units use NHTSA defined telltale.

2005 Expedition/Navigator New Model Technician Training02-SEP-042-4

Page 29

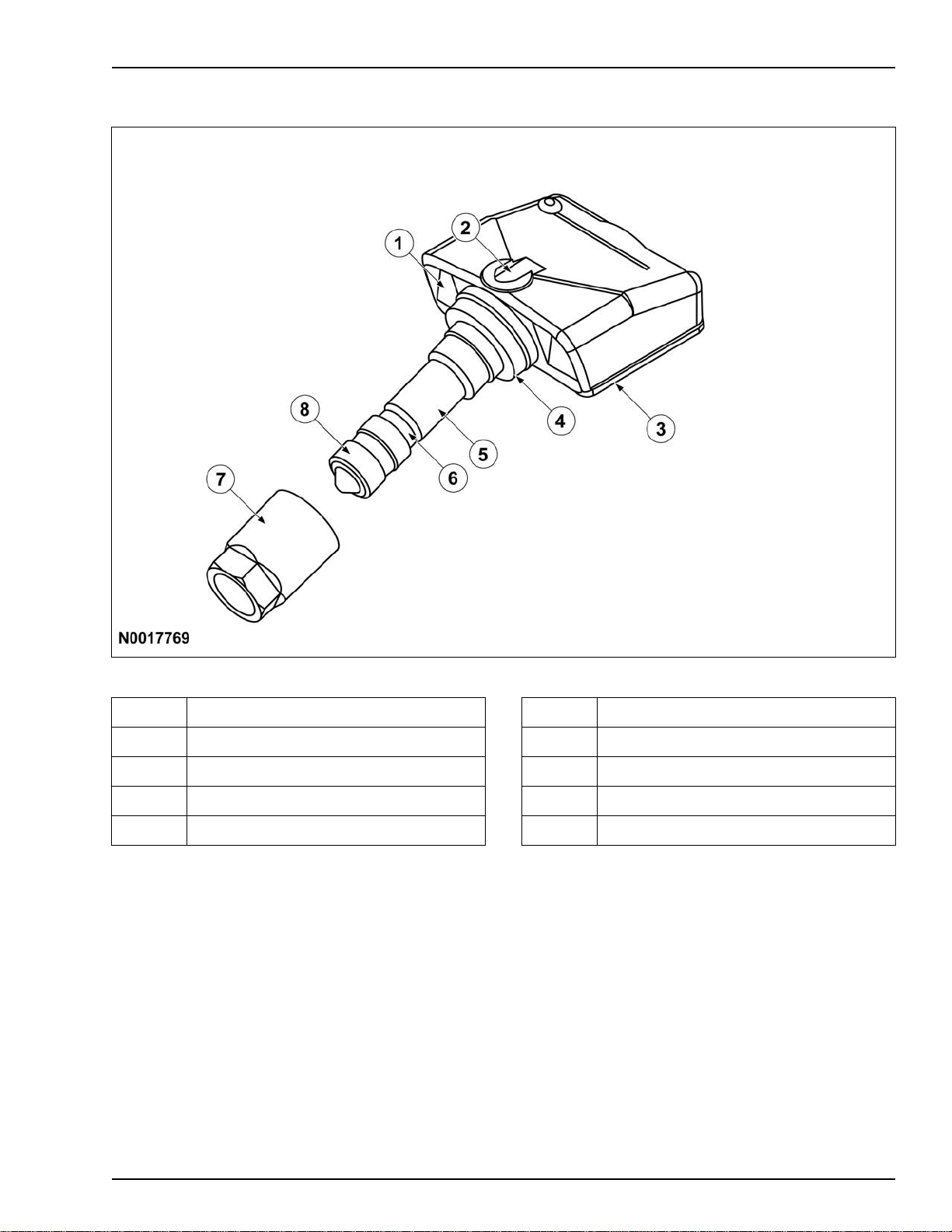

Sensor Description

LESSON 2: CHASSIS

TPMS Sensor

Item Description Item Description

1 Transmitter Case 5 Aluminum Valve

2 Air Hole: Top 6 Inside: Core

3 Potted Surface: Bottom 7 Nut

4 Grommet 8 Cap

•

315 MHz (Blue), Manchester Encoded, AM.

•

Pressure Sampling / Transmission.

– Stationary – 15 minute sample /1 hour transmission.

– Rolling – 30 second sample/1 minute transmission.

•

Motion switch sampling rate – 10 second.

•

Full Scale Pressure Range: 0 – 64 psi.

•

24 Bit Electronic ID Code.

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 2-5

Page 30

LESSON 2: CHASSIS

Module Description

•

TPM System integrated into Vehicle Security Module (VSM).

•

Module designed to:

– Receive tire pressure and sensor information (315MHz transmissions from sensors).

– Process input information, determine correct status, and associate sensors with module (learn).

– Communicate status to message center via MS-CAN.

– Output to horn relay (self test and manual learn mode).

2005 Expedition/Navigator New Model Technician Training02-SEP-042-6

Page 31

LESSON 2: CHASSIS

Cluster Messages

The following are messages that can be displayed on the message center (if equipped on Expedition models,

standard on Navigator).

•

Customer (Normal Message)

– LOW TIRE PRESSURE

•

Customer (System Check)

– TIRE PRESSURE SYSTEM ACTIVE

•

Service

– TIRE TRAINING COMPLETED

– TRAIN RF TIRE

– TRAIN LF TIRE

– TRAIN RR TIRE

– TRAIN LR TIRE

– TIRES NOT TRAINED - REPEAT

•

System Faults

– TIRE PRESSURE MONITOR FAULT

– TIRE PRESSURE SENSOR FAULT

The following are operating conditions for the TPM warning indicator:

•

Low tire pressure: Warning indicator is ON SOLID.

•

Sensor/Monitor fault: The warning indicator flashes for approximately 20 seconds after the event occurs and

after every key cycle until condition is corrected.

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 2-7

Page 32

LESSON 2: CHASSIS

DTCs

DTC Description

B1342 ECU Defective

B2477 Module Configuration Failure

B2868 Left Front Sensor Fault

B2869 Right Front Sensor Fault

B2870 Right Rear Sensor Fault

B2871 Left Rear Sensor Fault

B2872 Tire Sensor Fault

B1217 Horn Relay Circuit Failure

C2780 ECU in Manufacturing Mode

2005 Expedition/Navigator New Model Technician Training02-SEP-042-8

Page 33

TPMS PIDs

LESSON 2: CHASSIS

NGS Name WDS Name Description

LF_ID LF_ID_VSM LEFT FRONT TIRE SENSOR

ID

RF_ID RF_ID_VSM RIGHT FRONT TIRE SENSOR

ID

RR_ID RR_ID_VSM RIGHT REAR TIRE SENSOR

ID

LR_ID LR_ID_VSM LEFT REAR TIRE SENSOR ID

LF_PRES LF_PSI_VSM BP COMPENSATED

PRESSURE CALCULATED BY

MODULE (BARO COMP

VALUE)

RF_PRES RF_PSI_VSM BP COMPENSATED

PRESSURE CALCULATED BY

MODULE (BARO COMP

VALUE)

RR_PRES RRO_PSI_VSM BP COMPENSATED

PRESSURE CALCULATED BY

MODULE (BARO COMP

VALUE)

LR_PRES LRO_PSI_VSM BP COMPENSATED

PRESSURE CALCULATED BY

MODULE (BARO COMP

VALUE)

TPM_TT N/A TIRE PRESSURE TELL TALE

STATUS. (VSM commanding

telltale status to cluster)

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 2-9

Page 34

LESSON 2: CHASSIS

Possible Failure Modes and Root Causes

•

TPMS indicator light stays ON continuously. Message center (if equipped) Displays: ‘‘Low Tire Pressure’’.

– Causes:

1. Air pressure is low or not set to required placard pressure.

2. Spare tire currently in use.

– Solution:

1. Check tire pressure with digital gauge. If issue still persists, then retrieve DTC and follow pin point test

F2 described in service manual.

2. Repair original tire and install road wheel/tire.

•

TPMS indicator light Flashes for approx. 20 sec. At key ON position. Message center (if equipped) Displays:

‘‘Tire Pressure Sensor Fault’’.

– Causes:

1. TPMS sensors failed, missing sensor, after market wheels or sensor incorrectly trained.

2. Vehicle may have sat stationary for 10 or more days. This will not always happen, but in some cases, if

vehicle is parked and is stationary for 10 or more days, you may see this event.

– Solution:

1. Train TPMS sensors. If issue still persists then retrieve DTC and follow pin point test C described in

Workshop Manual.

2. Drive vehicle for 5 minutes and cycle the ignition key to the RUN position. Verify the fault is gone and

clear the DTC.

•

TPMS indicator light Flashes for approx. 20 sec. At key ON position. Message center (if equipped) Displays:

‘‘Tire Pressure Monitor Fault’’.

– Causes:

1. Module failure.

2. All four TPMS sensors have failed, are missing or are incorrectly trained.

3. No MS-CAN communication.

– Solution:

1. Refer to pin point test C described in the Workshop Manual.

2. Train the TPMS sensors. If training cannot be completed, you may have the wrong sensors (MY 04

Black 433 MHz sensors), or you’re missing all sensors.

3. Refer to Workshop Manual for communication issues.

NOTE: Always refer to the Workshop Manual for complete diagnostic information.

2005 Expedition/Navigator New Model Technician Training02-SEP-042-10

Page 35

Driveshaft

LESSON 2: CHASSIS

Driveshaft

•

Navigator 4x2 models use a unique 2-piece driveshaft.

•

Staked U-Joint Service.

– The original u-joints are staked in place. There is no retaining clip.

– The factory u-joints require the use of a special cutting tool to remove the stakes prior to the removal of the

u-joint cups. After appropriately mounting the driveshaft in a vise, the cutting tool (which is part of the

u-joint replacement kit) is rotated by using a ratchet handle to remove the stakes. Once the stakes are

removed, remove and replace the u-joints in the conventional manner. Refer the appropriate section of the

Workshop Manual for further details.

•

New torsional dampener.

– A torsional dampener effectively isolates vibrations produced within the driveline from the rest of the

vehicle.

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 2-11

Page 36

LESSON 2: CHASSIS

Front Drive Axle/Differential

Front Drive Axle/Differential

•

New companion flange

– The design of the front axle companion flange is unique to the 2005 Expedition and Navigator. When

servicing, be sure to obtain the proper parts for your specific application.

2005 Expedition/Navigator New Model Technician Training02-SEP-042-12

Page 37

OBJECTIVES

•

Identify new 5.4L 3-valve engine features.

•

Explain the operation of the VCT system.

•

Explain the revised procedure for camshaft or phaser assembly replacement.

•

Identify 6HP26 automatic transmission features.

•

Explain the basic functions of the 6HP26 transmission controls.

•

Explain the basic shift control strategies of the 6HP26 transmission.

LESSON 3: POWERTRAIN

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 3-1

Page 38

LESSON 3: POWERTRAIN

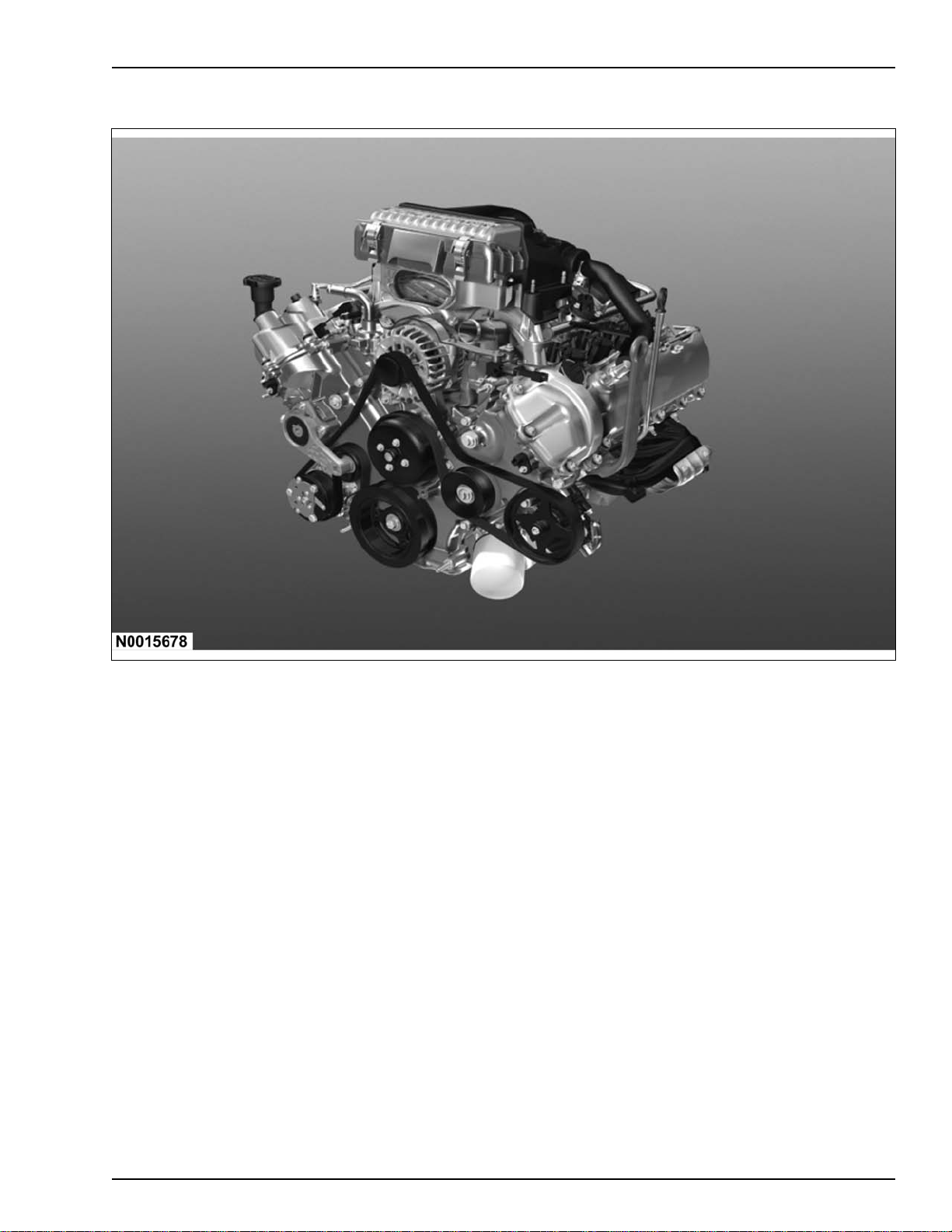

Engine - 5.4L

5.4L 3-Valve Triton Phaser

The 2005 Expedition and Navigator are available with one engine:

•

New for 2005, the 5.4L 3-valve Triton V8.

– 300 horsepower @ 5,000 rpm

– 365 lb-ft of torque @ 3,750 rpm

– Variable cam timing

– Three valves per cylinder

Rather than focusing on a single item to gain improvements in power, Ford used an approach that included

advancements on multiple fronts. These improvements contribute to overall power with reduced NVH, at low

engine speeds. Some of these changes are outlined below:

•

The three-valve design achieves same benefits as a four-valve design.

– Three-valve design balances the forces generated by the valve and spring movement.

– Reduces engine noise.

•

Variable Cam Timing (VCT) varies cam timing to match performance demands.

2005 Expedition/Navigator New Model Technician Training02-SEP-043-2

Page 39

LESSON 3: POWERTRAIN

•

Charge Motion Control Valves (CMCV) manage the flow of air into the cylinders.

•

Vibration-resistant ribbing and reinforcement in the lower engine block help manage and tune sound and

vibration.

– The engine block ribbing strengthens the block wall similar to cross reinforcements in a building wall.

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 3-3

Page 40

LESSON 3: POWERTRAIN

5.4L Three-Valve Head

The three-valve head has two smaller intake valves and one larger exhaust valve.

•

The three-valve head includes all of the advantages of the four-valve head with fewer parts and less noise.

CAUTION: Remove the spark plugs before removing the heads. The spark plugs are long and can be

damaged if left in the head. The gap is non-adjustable.

The spark plugs used in the 3-valve head require a special 9/16 inch socket. Rotunda Tools, among others, sells

the socket for under $10.00. Order item number SKT4419 from the Rotunda Technician Tool Program (RTTP).

2005 Expedition/Navigator New Model Technician Training02-SEP-043-4

Page 41

Air Filter

LESSON 3: POWERTRAIN

Intake Air Filter Module (IAFM)

The intake air distribution and filtering design has been replaced with:

•

New split line welded Intake Air Filter Module (IAFM).

The IAFM is a one piece, plastic component that houses the air filter element and Mass Air Flow (MAF) sensor.

CAUTION: When removing the air inlet tube from the IAFM, be sure to disengage the retaining tab

at the top of the tube. This can be accomplished by first removing the air filter element and then

pushing down on the retaining tab (accessed through the air filter door). The tube can then be

removed without damage.

•

The air filter replacement procedure has changed.

– Air filter tray slides out of the intake assembly.

– Remove the air filter from the tray for replacement.

– A Motorcraft brand air filter is strongly recommended because of better sealing characteristics.

NOTE: During installation, ensure the filter tray is fully seated. Engine noise may leak into the underhood

compartment and introduce unnecessary NVH.

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 3-5

Page 42

LESSON 3: POWERTRAIN

Mass Air Flow (MAF) Sensor

The compact Mass Air Flow (MAF) sensor is located on the IAFM.

•

This sensor combines the Intake Air Temperature (IAT) and the MAF sensor.

2005 Expedition/Navigator New Model Technician Training02-SEP-043-6

Page 43

Electronic Throttle Control (ETC)

LESSON 3: POWERTRAIN

ETC Throttle Body

•

The 5.4L 3V engine used in both the Expedition and Navigator utilizes Electronic Throttle Control (ETC). This

system functions and is serviced similarly to the systems used on the Thunderbird and LS. Warning indications

are via an instrument cluster mounted message center or warning light. This is covered in greater detail in

Lesson 4. Refer to the Work Shop Manual for additional information on ETC service and diagnostics.

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 3-7

Page 44

LESSON 3: POWERTRAIN

Charge Motion Control Valves (CMCV)

The Charge Motion Control Valves (CMCV) are electronically controlled metal flaps at the end of each intake

runner, eight in total (four per bank on one rod, operated together).

•

CMCVs work to speed up the intake air charge and induce a ‘‘tumble’’ effect into the combustion chamber at

low engine speeds and loads.

– Causes a thorough mix of the air/fuel charge.

– Results in a quick, efficient burn which helps reduce emissions.

– Close at low engine speeds and light loads.

– Helps manage noise, vibration and harshness.

2005 Expedition/Navigator New Model Technician Training02-SEP-043-8

Page 45

LESSON 3: POWERTRAIN

CMCV Motor

The CMCVs use one electronically controlled motor to operate the CMCVs for both sides of the intake manifold.

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 3-9

Page 46

LESSON 3: POWERTRAIN

CMCV Block Diagram

The CMCVs are controlled electronically by the PCM.

•

The inputs used by the PCM for the CMCV operation are:

– Engine Speed

– Throttle Position

– Air Temperature

– Cylinder Head Temperature

•

The CMCV system does not use a feedback loop.

•

The CMCVs open at a predetermined engine speed.

– At higher RPM, they do not affect the intake air charge.

– Proper stoichiometric air/fuel ratio (14.7:1) is easiest to achieve when the intake air is moving quickly.

– CMCVs close to help the intake air charge move more quickly at low RPM

– When the opening is narrower, the air charge moves more quickly as it enters the combustion chamber

(Bernoulli’s Principle).

– Bernoulli’s Principle states that when a given volume of air passes through a smaller passage, it will cause

the air to speed up.

2005 Expedition/Navigator New Model Technician Training02-SEP-043-10

Page 47

VCT System

LESSON 3: POWERTRAIN

5.4L Variable Cam Timing Solenoid Electrical Connector

Conventional camshafts are permanently synchronized with the engine crankshaft to operate the intake and

exhaust valves at a specific point in each combustion cycle. Variable Cam Timing (VCT), however, allows the

valves to operate at variable points in the combustion cycle.

•

The VCT system on the 5.4L provides several important benefits:

– Eliminates the need for an EGR system.

– Improved low speed performance (torque) and high-speed operation (horsepower).

– Enhanced idle quality.

– Lower exhaust emissions.

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 3-11

Page 48

LESSON 3: POWERTRAIN

VCT Operation

VCT

The theory of operation for the 5.4L VCT is similar to the 3.9L VCT used on the Lincoln LS and 2004 Ford

F-150 w/5.4L.

•

The major differences are:

– The 5.4L VCT system controls both intake and exhaust valve timing because the 3-valve setup uses one

camshaft for both intake and exhaust valves.

– On the 3.9L, the VCT only controls the intake camshafts.

– Parts look different and are serviced differently (5.4L vs. 3.9L).

– Part names are different than those used on the 3.9L.

•

The VCT can vary cam timing within a range of 60 degrees of crankshaft rotation.

– Defaults to full advance.

– Requires engine oil at preset temperature before VCT will function.

2005 Expedition/Navigator New Model Technician Training02-SEP-043-12

Page 49

LESSON 3: POWERTRAIN

The basics of VCT operation are:

•

A hydraulic timing mechanism (VCT phaser) rotates the camshafts in relation to their drive sprockets.

– Provides performance that is precisely tailored to the engine speed and load.

– VCT is electronically controlled (PCM duty cycled) and hydraulically operated.

•

The VCT solenoid moves a spool valve to control the flow of oil through the VCT system.

– Oil flows from the head into the VCT valve body.

– Oil flows through the advance or retard passages as directed by the spool valve.

•

Major sensor inputs:

– CMP

– Oil temperature sensor

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 3-13

Page 50

LESSON 3: POWERTRAIN

5.4L 3-Valve Camshaft Position Sensor

The VCT system requires a cam position sensor for each camshaft.

•

The PCM can then monitor the actual camshaft position relative to the requested position.

2005 Expedition/Navigator New Model Technician Training02-SEP-043-14

Page 51

LESSON 3: POWERTRAIN

Oil Temperature Sensor

The VCT system uses a replaceable oil temperature sensor, located on the oil pan.

•

Engine oil temperature has a direct effect on VCT operation.

– Cold engine oil has high viscosity and slower flow characteristics.

– The VCT system is disabled at oil temperatures below -7°C (18°F).

– The PCM uses time-since-start, engine oil temperature and engine rpm to calculate VCT solenoid operation.

– Time-since-start ranges from 60 seconds when cold to 10 seconds when hot.

•

Recommended engine oil change intervals must be followed to ensure the integrity of VCT system.

– Oil Capacity - 6.6L (7.0 quarts).

– Oil Specification - Motorcraft SAE 5W20 Premium Synthetic Blend Motor Oil.

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 3-15

Page 52

LESSON 3: POWERTRAIN

Phaser Components

VCT Phaser

The VCT components include:

•

Camshaft phaser sprockets.

•

Right and left camshaft phaser sprocket assembly bolt and washer.

•

VCT valve bodies (housing).

•

VCT solenoids.

•

Right and left camshafts.

NOTE: The phaser, phaser sprocket, vanes and the return spring are serviced as an assembly.

2005 Expedition/Navigator New Model Technician Training02-SEP-043-16

Page 53

LESSON 3: POWERTRAIN

Phaser Oil Vanes

The oil vanes create oil cavities for valve-directed oil to rotate the camshaft in relation to the crankshaft.

•

Oil pushes on one side of the vanes to rotate the cam in one direction to advance timing.

•

Oil pushes on the other side of the vane to rotate the cam in the other direction to retard timing.

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 3-17

Page 54

LESSON 3: POWERTRAIN

VCT Phaser Disassembled

The VCT phaser varies camshaft timing in response to oil pressure exerted on either side of the vanes.

CAUTION: Only use hand tools to remove the camshaft phaser sprocket assembly or damage may

occur to the camshaft or camshaft phaser unit.

CAUTION: Always install a new bolt and washer whenever the VCT phasers are loosened. The base

part number is 6279. The same part number is used for both sides.

NOTE: These bolts are one-time torque only and are available separately or as part of the phaser replacement kit.

CAUTION: Handle the cam and phaser carefully. Damage will occur if dropped or mishandled.

2005 Expedition/Navigator New Model Technician Training02-SEP-043-18

Page 55

LESSON 3: POWERTRAIN

VCT Solenoid Removal

The VCT solenoid is serviced separately from the VCT valve body. No special tools are needed to remove the

solenoid. The retaining bolt is captured in the mounting tab.

1. Disconnect the solenoid electrical connection.

2. Remove the valve cover grommet.

3. Remove the hold-down bolt.

4. Remove the solenoid.

CAUTION: Do not drop the solenoid screw into the front cover. If the screw drops into the front

cover, the front cover must be removed to retrieve the screw. Do not use power tools to remove the

screw.

CAUTION: Use care to prevent contamination from falling in the valve body spool bore. Thoroughly

clean around cam cover and solenoid seal before removing the seal and solenoid.

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 3-19

Page 56

LESSON 3: POWERTRAIN

VCT Valve Body Oil Passages

Item Description Item Description

1 Solenoid filter 5 Oil passage back into head

2 Oil passage to advance side of VCT 6 Oil metering orifice

3 Oil passage to retard side of VCT 7 Oil passage from head

4 Oil passage to chain tensioner

The valve body and solenoid work together to route oil to the vanes in the camshaft phaser to operate the VCT

system.

NOTE: The solenoid filter is not removable or serviceable and is located in the valve body. The filter is designed

to be self-cleaning and should not require any service. Oil change interval recommendations are still important.

2005 Expedition/Navigator New Model Technician Training02-SEP-043-20

Page 57

LESSON 3: POWERTRAIN

Locking Pin

The locking pin locks the camshaft in a fully advanced position when the engine is off.

•

The pin locks the phaser to the camshaft during startup.

•

After startup, oil pressure at the VCT assembly will unlock this pin, allowing VCT operation to resume.

– Makes it easier to start engine.

– Reduces noise on startup.

•

VCT does not control valve timing until the oil temperature reaches 32°F (0°C).

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 3-21

Page 58

LESSON 3: POWERTRAIN

Phaser/Camshaft Removal Procedure

Remove Valve Cover

The phaser replacement procedure has been revised for the 5.4L 3V engine. This revision allows for the servicing

of either the left or right phaser or camshaft without having to remove the engine front cover.

Remove the left and/or right valve cover(s).

2005 Expedition/Navigator New Model Technician Training02-SEP-043-22

Page 59

LESSON 3: POWERTRAIN

Set Crankshaft Damper Notch to 1 o’clock Position

Set the crankshaft keyway to 12 o’clock. The machined notch on the back face of the damper pulley should

appear at about the 1 o’clock position.

NOTE: The number one piston should have just passed TDC when the crank was turned the normal rotational

direction of engine operation.

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 3-23

Page 60

LESSON 3: POWERTRAIN

Cam Lobe Positioning

Item Description Item Description

1 Intake Lobe 2 Exhaust Lobe Pointing Inward

The camshaft must be positioned with the #1 or #8 exhaust lobe facing inward to the 3 o’clock position.

•

If the lobes are not positioned this way, the crankshaft will require one full additional rotation to 12 o’clock.

2005 Expedition/Navigator New Model Technician Training02-SEP-043-24

Page 61

LESSON 3: POWERTRAIN

Mark Crankshaft Damper

The damper spoke pointing upwards just to the left of the machined notch is the one with the keyway cut in it.

Chalk mark that spoke for easy viewing.

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 3-25

Page 62

LESSON 3: POWERTRAIN

Loosen One Turn

Loosen the camshaft phaser bolt one turn. Do not remove the bolt.

CAUTION: DO NOT use an impact wrench when loosening the phaser bolt. Impact tools can

damage internal phaser components.

2005 Expedition/Navigator New Model Technician Training02-SEP-043-26

Page 63

LESSON 3: POWERTRAIN

Remove Only the Indicated Followers

When removing the followers, remove the exhaust followers from the exhaust manifold side of the camshaft and

the intake followers from the intake side.

•

On the right side:

– #1 cylinder - exhaust only

– #4 cylinder - both intake

•

On the left side:

– #8 cylinder - exhaust only

– #5 cylinder - both intake

•

Use ESST 303-1039 Valve Spring Compressor

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 3-27

Page 64

LESSON 3: POWERTRAIN

Set Crankshaft Damper Spoke to 6 o’clock Position

Rotate the marked damper spoke clockwise to the 6 o’clock position.

CAUTION: It is imperative that the engine is only rotated to the 6 o’clock position in a clockwise

rotation.

NOTE: The only time the engine is turned counter-clockwise back to the 12 o’clock keyway position is during

the re-assembly procedure.

2005 Expedition/Navigator New Model Technician Training02-SEP-043-28

Page 65

LESSON 3: POWERTRAIN

Inset Timing Chain Wedge Tool

Assemble the ESST 303-636 Timing Chain Wedge to the ESST 303-637 Handle. Insert the timing chain wedge

tool between the chain spans. Four to six clicks will hold it.

Mark the chain to the phaser for reinstallation.

The ‘‘R’’ on the right phaser (and the ‘‘L’’ on the left) that was used on the 2004 F-150 is no longer used.

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 3-29

Page 66

LESSON 3: POWERTRAIN

Loosen #1 Camshaft Bearing Cap Bolts

Mark the cam caps for proper reinstallation.

NOTE: The camshaft bearing caps must be installed in their original locations. Record camshaft bearing cap

locations.

Loosen the camshaft bearing caps. Start with the #1 cap because it contains a thrust surface groove. If the cam

were to be moved in some fashion with this cap intact, the cap could be damaged or broken.

Remove the remaining cap bolts according to Workshop Manual procedures.

2005 Expedition/Navigator New Model Technician Training02-SEP-043-30

Page 67

LESSON 3: POWERTRAIN

Remove the Phaser Bolt

The remaining followers will be loose on the lifters. Be sure to keep them in place so that the camshaft can be

reinstalled.

Remove the CMP sensor.

Fully withdraw the camshaft sprocket phaser bolt by hand.

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 3-31

Page 68

LESSON 3: POWERTRAIN

Remove the Phaser

Using extreme care, withdraw the phaser from the nose of the camshaft. It may be necessary to slightly tip up the

cam from the rear to allow chain disengagement.

CAUTION: Do not let the camshaft set in the cylinder head unattended. The cam may fall out.

2005 Expedition/Navigator New Model Technician Training02-SEP-043-32

Page 69

Cam and Phaser Reassembly

LESSON 3: POWERTRAIN

Seating Cam Followers

Care should be taken to ensure that the remaining followers are properly seated prior to camshaft installation.

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 3-33

Page 70

LESSON 3: POWERTRAIN

Phaser Pin and Cam Notch

Item Description Item Description

1 Phaser Pin 2 Cam Notch

It is extremely important to align the phaser pin with the camshaft end notch.

NOTE: If these are not aligned during installation, the phaser and camshaft will be damaged.

2005 Expedition/Navigator New Model Technician Training02-SEP-043-34

Page 71

LESSON 3: POWERTRAIN

Installing the Bearing Caps

Install the camshaft bearing caps in the reverse order of removal.

NOTE: The camshaft bearing caps must be installed in their original locations.

The front thrust cap should be installed last to prevent the cap from breaking.

Next, install the phaser bolt by hand. Remove the timing chain wedge. Rotate the crankshaft pulley

counter-clockwise back to the 12 o’clock position.

NOTE: Tighten the phaser bolt to 40 Nm (30 lb-ft), plus 90 degrees.

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 3-35

Page 72

LESSON 3: POWERTRAIN

Electronic Engine Controls

Electronic Engine Controls

•

New integrated 4x4 strategy.

– 4x4 operational strategy is now incorporated into the PCM. This eliminates the need for a separate module to

control the transfer case.

•

The PCM utilizes a 190 pin connector.

•

New PCM controlled, electronically heated PCV port.

– This electrically heated systems uses a heating element enclosed in the PCV tube (mounted on the left side of

the intake manifold) to prevent the valve or tube from freezing.

– On this application the PCV heater uses an inline thermostatic switch. When ambient air temperature nears

0°C (32°F) this switch completes the Positive Crankcase Ventilation Valve Heater Control (PCVHC) circuit

and turns the heater ON. The PCV heater is off when the engine is not running to prevent unnecessary

battery drain.

•

Dual knock sensors.

– Dual knock sensors (mounted in the engine valley) provide feedback to the electronic engine control system

for controlling spark knock. These sensors are accessed by removing the intake manifold assembly.

2005 Expedition/Navigator New Model Technician Training02-SEP-043-36

Page 73

LESSON 3: POWERTRAIN

•

New premium fuel calibration (Navigator).

– The aggressive spark and fuel programming requires 91 octane (or higher) fuel for maximum performance.

Expedition requires 87 octane fuel for optimal performance.

NOTE: Refer to the Workshop Manual for diagnostic and service procedures for these items.

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 3-37

Page 74

LESSON 3: POWERTRAIN

Fuel Tank and Lines

Fuel Tank and Lines

•

New fuel filter

– The fuel filter is located on the front side of the fuel tank. It can be accessed by removing the road debris

shield. Quick connect fittings are used for connection to the fuel lines.

•

The fuel tank sending unit tool (SST310-123) is required to service the fuel pump and/or sending unit. This tool

was released as part of the 2004 F-150 tool kit.

2005 Expedition/Navigator New Model Technician Training02-SEP-043-38

Page 75

Engine Special Service Tools

LESSON 3: POWERTRAIN

Engine Special Service Tools

Item Description Item Description

1 ESST 307-516/1 Installer, Teflon Seal 7 ESST 310-123 Remover/Installer Tank

(4R75E Tool) Sender Unit

2 ESST 307-516/2 Installer, Teflon Seal 8 ESST 205-086-1 Adaptor for 205-086

(4R75E Tool)

3 ESST 307-516/3 Installer, Teflon Seal 9 ESST 418-F395 Diagnostic Service

(4R75E Tool) Tool, Restraint System

4 ESST 307-516/4 Installer, Teflon Seal 10 ESST 303-1046 Locking Tool, Cam

(4R75E Tool) Phaser

5 ESST 310-122 Fuel Pressure Gauge 11 ESST 303-1040 Alignment Pins,

Connector Cylinder Head

6 ESST 303-1039 Compressor, Valve

Spring

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 3-39

Page 76

LESSON 3: POWERTRAIN

Automatic Transmission

Description

6HP26 Transmission

The 6HP26 transmission uses planetary gears with multiple clutches and electronic controls. The Transmission

Control Module (TCM) and the main control valve body units are combined and installed as a single unit inside

the automatic transmission. This transmission has the following features:

•

six forward speeds.

•

a torque converter with an integral converter clutch.

•

electronic shift and pressure controls.

•

a single planetary gear set.

•

a double planetary gear set.

•

two fixed multi-disc clutches.

•

three multi-plate clutches.

All hydraulic functions are directed by electronic solenoids to control:

•

engagement feel.

2005 Expedition/Navigator New Model Technician Training02-SEP-043-40

Page 77

•

shift feel.

•

shift scheduling.

•

modulated Torque Converter Clutch (TCC) applications.

•

engine braking.

This transmission has a mechatronic unit (valve body) which contains:

•

Turbine Shaft Speed (TSS) sensor.

•

Output Shaft Speed (OSS) sensor.

•

An internal P, R, N, D6, D4, 3, 2, 1 selector shaft position sensor.

•

Transmission Fluid Temperature (TFT) sensor.

LESSON 3: POWERTRAIN

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 3-41

Page 78

LESSON 3: POWERTRAIN

Operation

6HP26 Cutaway

Engine power reaches the transmission by a torque converter with an integral converter clutch. The six forward

gears and one reverse gear are obtained from both single and double planetary sets.

This automatic transmission is a six-speed electronically controlled transmission comprised of a TCM, main

control valve body unit, torque converter, one solenoid valve and six pressure regulators. Gear selection is

achieved by the control of automatic transmission fluid flow to operate various internal clutches. The TCM

operates the electrical components and provides for the control of gear selection shift pressure which increases

refinement and torque converter slip.

In the event of a system fault, the TCM also provides for Failure Mode Effect Management (FMEM) to maintain

maximum functional operation of the transmission with a minimum reduction in driver, passenger or vehicle

safety. In the event of a total loss of control or electrical power, the basic transmission functions PARK,

REVERSE, NEUTRAL and DRIVE are retained. Also 3rd or 5th gear is retained by the hydraulic system. The

gear retained depends on the gear selected at the time of the failure.

The 2005 Lincoln Navigator is not equipped with a dedicated O/D enable/disable switch. To disable the O/D

function, the operator must move the gear selector from the D6 (sixth gear) to the D4 (fourth gear) position. Since

this transmission uses a two speed O/D (fifth and sixth gears), upshifts are limited to fourth gear. A gear selector

position sensor (located in the gear selector assembly) provides an input to the TCM for control of this function.

2005 Expedition/Navigator New Model Technician Training02-SEP-043-42

Page 79

Identification Tag

LESSON 3: POWERTRAIN

Identification Tag

The identification tag is located on the left side of the case just rearward of the manual control lever.

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 3-43

Page 80

LESSON 3: POWERTRAIN

Range Selection

Shifter Pattern

The transmission has eight range positions: P, R, N, D6, D4, 3, 2 and 1.

In the Park position:

•

There is no power flow through the transmission

•

The parking pawl locks the output shaft to the case

•

The engine can be started

•

The ignition key can be removed

In the Reverse position:

•

The vehicle can be operated in a rearward direction, at a reduced gear ratio

•

The backup lamps are illuminated

In the Neutral position:

•

There is no power flow through the transmission

•

The output shaft is not held and is free to turn

•

The engine can be started

2005 Expedition/Navigator New Model Technician Training02-SEP-043-44

Page 81

LESSON 3: POWERTRAIN

The D6 position is the normal position for most driving conditions. It provides:

•

Automatic shifts 1-6 and 6-1

•

Apply and release of the torque converter clutch

•

Maximum fuel economy during normal operation

•

Engine braking in sixth gear

The D4 position provides:

•

Automatic shifts 1-4 and 4-1

•

Apply and release of the torque converter clutch

•

Engine braking in fourth gear

The Manual 3 position provides:

•

Manual 3rd gear only

•

Engine braking in third gear

The Manual 2 position provides:

•

Manual 2nd gear only

•

Engine braking in second gear

The Manual 1 position provides:

•

First gear operation only

•

Engine braking for descending steep grades

External Controls

•

New floor shift mechanism.

– Lincoln Navigators are equipped with a new 6HP26 transmission. This six speed transmission required a

new style transmission gear selector. This gear selector allows for manual selection of first through fourth

gear, as well as automatic control of first through fourth (O/D disabled) and first through sixth (O/D

enabled). O/D is enabled by moving the gear selector handle to the left while in the D6/D4 gate, and is

disabled by moving it to the right.

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 3-45

Page 82

LESSON 3: POWERTRAIN

Shift Patterns

•

Under certain conditions the transmission automatically downshifts to a lower gear range (without moving the

range selector lever). There are three categories of automatic downshifts:

– coastdown

– torque demand

– forced or kickdown shifts

•

Coastdown

The coastdown downshift occurs when the vehicle is coasting to a stop.

•

Torque Demand

The torque demand downshift occurs (automatically) during part throttle acceleration when the demand for torque

is greater than the engine can provide at that gear ratio. If applied, the transmission will disengage the Torque

Converter Clutch (TCC) to provide added acceleration.

•

Kickdown

For maximum acceleration, the driver can force a downshift by pressing the accelerator pedal to the floor. A

forced downshift into a lower gear is possible below calibrated speeds. Specifications for downshift speeds are

subject to variations due to tire size, engine and transmission calibration requirements.

2005 Expedition/Navigator New Model Technician Training02-SEP-043-46

Page 83

Shift Elements

LESSON 3: POWERTRAIN

Shift Elements

Item Description Item Description

1 Double Planetary Gearset 6 Overdrive Clutch

2 Forward Clutch 7 Low/Reverse Clutch

3 Transmission Case (Fixed) 8 Single Planetary Gearset

4 Direct Clutch 9 Stator Shaft

5 Intermediate Clutch 10 Turbine Shaft

The shift elements are:

– Three rotating multi-plate clutches: forward, direct and overdrive.

– Two fixed multi-disc clutches: intermediate and overdrive.

All gear shifts from 1st to 6th or from 6th to 1st are power-on overlapping shifts. That is, during the shift, one of

the clutches must continue to transmit the drive at lower main pressure until the other clutch is able to accept the

input torque.

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 3-47

Page 84

LESSON 3: POWERTRAIN

The shift elements are engaged hydraulically. The transmission fluid pressure builds up between the cylinder and

the piston, pressing the clutches together.

The purpose of these shift elements is to carry out in-load shifts with no interruption to traction.

Multi-plate clutches forward, direct and overdrive supply power from the engine to the planetary gear train.

Multi-disc brakes intermediate and low/reverse press against the transmission housing in order to achieve a torque

reaction effect.

2005 Expedition/Navigator New Model Technician Training02-SEP-043-48

Page 85

Multi Plate Clutch

LESSON 3: POWERTRAIN

Multi Plate Clutch

Item Description Item Description

1 Clutch Pack Cluster 6 Turbine Shaft

2 Piston 7 Lubricating Oil Passage

3 Cylinder 8 Cup Spring

4 Ring Gear (Planetary Gearset 1) 9 Baffle Plate

5 Main Pressure Supply to Clutch 10 Inner Plate Carrier

Multi plate clutches are used exclusively throughout the 6HP26 transmission. No bands are used.

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 3-49

Page 86

LESSON 3: POWERTRAIN

Fluid Pan, Gasket and Filter

Fluid Pan, Gasket and Filter

The transmission fluid pan, gasket and filter is a one-piece assembly. All transmission fluid is drawn from the

transmission fluid pan by the fluid pump and passes through the filter.

To drain and fill the 6HP26 transmission, perform the following steps:

Drain

With the vehicle in NEUTRAL, position it on a hoist.

1. Remove the fluid pan drain plug and allow the fluid to drain.

2. Remove the pan assembly and replace the entire unit.

Fill

1. Install the fluid pan drain plug and tighten to 8 Nm (71 lb-in).

2. Remove the fluid fill plug located on the RH rear side of the case near the transmission electrical connector.

3. Fill the transmission with approximentally 4.7 liters (5 quarts) of new Mercon SP automatic transmission

fluid through the fluid fill hole. Stop when the fluid runs out of the bottom of the hole.

4. Install the fluid fill plug located on the RH rear side of the case near the transmission electrical connector.

2005 Expedition/Navigator New Model Technician Training02-SEP-043-50

Page 87

LESSON 3: POWERTRAIN

5. Start the engine. Move the transmission range selector lever through all the gear ranges, checking for

engagements.

6. With the engine idling (600-750 rpm) in PARK and the transmission temperature at 30°C-50°C

(86°F-122°F), check and adjust the transmission fluid level.

7. If more fluid is needed, remove the fluid fill plug on the side of the case and fill until the fluid runs out of the

bottom of the hole.

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 3-51

Page 88

LESSON 3: POWERTRAIN

Transmission Control Module (TCM) and Main Control Valve Body

Transmission Control Module (TCM) and Main Control Valve Body

The Main Control assembly (7A100) referred to as the mechatronic unit is made up of the following components,

the TCM processor, seven control solenoids, and a typical main control assembly. The main control component

houses valves and springs within the two halves (upper and lower). The mechatronic unit is attached to the case

of the transmission and is accessible through the pan/filter assembly.

CAUTION: When removing the TCM/main control valve body assembly, it is important to first

remove the connection adaptor. This is accomplished by releasing the white locking mechanism and

pulling out on the adaptor. Failure to remove the adaptor before removing the TCM/main control

valve body assembly will result in damage to the adaptor or TCM/main control valve body assembly.

2005 Expedition/Navigator New Model Technician Training02-SEP-043-52

Page 89

LESSON 3: POWERTRAIN

Transmission Electronic System

The TCM receives input signals from certain transmission-related sensors and switches. The TCM uses these

signals to control the following operations:

•

Shift timing

•

Line pressure (shift feel)

•

Torque converter clutch

To accomplish this, the TCM uses six pressure control solenoids and one shift solenoid to control transmission

operation. Five pressure regulators and one solenoid valve are used to control direct transmission fluid flow to

select internal clutches and control the fluid pressure at the clutch. A separate pressure regulator is used

exclusively for torque converter clutch control.

The following provides a brief description of each of the sensors and actuators used to control transmission

operation.

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 3-53

Page 90

LESSON 3: POWERTRAIN

Transmission Control Module (TCM)

Transmission Control Module (TCM)

The TCM is mounted on top of the main control valve body. The control module has been designed to operate

correctly in the environment in which the TCM is located.

The TCM is activated and deactivated by the ignition supply and is connected to the transmission link harness by

a 16-pin connector.

The TCM monitors all TCM inputs and outputs to confirm correct system operation. If a fault occurs, the TCM is

able to carry out default action. It informs the driver of the problem through the instrument cluster message

center.

The TCM is programmable. The WDS can be used to flash selected program strategies within the TCM.

2005 Expedition/Navigator New Model Technician Training02-SEP-043-54

Page 91

Solenoids

LESSON 3: POWERTRAIN

Solenoids

Item Description Item Description

1 SSA (EDS1) 5 SSD (EDS4)

2 SSB (EDS2) 6 SSE (MV1)

3 SSC (EDS3) 7 TCC (EDS6)

4 PCA (EDS5)

The hydraulic module contains one solenoid valve. The solenoid valve is activated by the TCM and is either open

or closed. It is used to switch the position valve.

There are six electronic pressure control valves, which convert an electronic current into a proportional hydraulic

pressure. They are energized by the TCM and actuate the valves belonging to the relevant switching elements.

The TCM monitors each pressure regulator and solenoid for open and short circuits. The TCM also checks that

the current being delivered to each solenoid or pressure regulator is within valid limits. If current exceeds

predetermined limits, the TCM sets a DTC, illuminates the MIL and enters the limp-home mode.

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 3-55

Page 92

LESSON 3: POWERTRAIN

Controller Area Network (CAN) Interface

Controller Area Network (CAN) Interface

For the TCM to carry out shift point and shift quality management, a number of external signals are required. For

shift point management, the TCM requires Output Shaft Speed (OSS) sensor, Accelerator Pedal Position (APP)

sensor, Brake Pedal Position (BPP) switch and Transmission Range (TR) sensor. The High Speed Controller

Area Network (HS-CAN) bus is used to share information between control modules.

2005 Expedition/Navigator New Model Technician Training02-SEP-043-56

Page 93

Sensors Integrated With TCM

LESSON 3: POWERTRAIN

Sensors Integrated With TCM

Item Description Item Description

1 Output Shaft Speed (OSS) Sensor 3 Turbine Shaft Speed (TSS) Sensor

2 Transmission Fluid Temperature (TFT)

Sensor

•

Several sensors are located on the TCM and main control valve body unit.

•

The Turbine Shaft Speed (TSS) sensor is a Hall effect type sensor.

•

The Output Shaft Speed (OSS) sensor is a Hall effect type sensor.

•

The Transmission Fluid Temperature (TFT) sensor is a temperature dependent resister (thermister).

– The TCM uses the TFT signal to determine whether a cold start shift schedule is necessary. The cold start

shift schedule allows quicker shifts when the transmission fluid temperature is cold. The TCM also inhibits

torque converter clutch operation at low transmission fluid temperatures.

The TCM can diagnose electrical errors associated with the TSS and OSS sensors while the vehicle is stationary

as well as moving. Plausability monitoring is carried out on the sensor output when the engine is running.

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 3-57

Page 94

LESSON 3: POWERTRAIN

Transmission Range Position Sensor

Transmission Range Position Sensor

The TCM uses the position of this switch, housed on the TCM and main control valve body, to determine the

selected gear range from the range selector lever.

The sensor completes the start circuit in PARK and NEUTRAL, and the back-up lamp circuit in REVERSE. The

sensor also opens/closes a set of switches that are monitored by the TCM to determine the position of the manual

lever (P, R, N, D6, D4, 3, 2, 1).

2005 Expedition/Navigator New Model Technician Training02-SEP-043-58

Page 95

LESSON 3: POWERTRAIN

Transmission Operational Strategies

Adaptive shift strategy is comprised of the following functions:

•

Shift Energy Management - Reduces or increases engine output torque during shifting.

– Reduces excessive energy at the clutch pack.

– Increases transmission service life.

– Improves shift quality.

– Used for trailer towing mode.

•

Pressure Modulation - This function monitors the hydraulic pressure during a shift. This pressure must be

matched accurately to the transmission input torque to provide better shift comfort.

•

Shift Quality Adapts - This function is used to provide a higher quality and consistant shift feel. This is

acheived by monitoring and adapting shift pressures to account for parts wear and differing driving habits.

•

Torque Reduction - This function reduces the engine torque output at the time of upshift.

•

Trailer Towing - This function uses a different shift timing/feel and converter operation schedule. This

schedule reduces the number of gearshifts when towing, climbing hills and while driving at higher altitudes.

2005 Expedition/Navigator New Model Technician Training 02-SEP-04 3-59

Page 96

LESSON 3: POWERTRAIN

TCM Monitoring Functions

The TCM monitors all transmission inputs and outputs to identify possible transmission failures. If a fault is

detected, the TCM takes the appropriate actions to ensure the transmission enters a safe mode of operations. The

PCM then sets a DTC and illuminates the Malfunction Indicator Lamp (MIL).

•

Voltage Supply - This function monitors the vehicle’s battery life.

•

Watchdog Monitoring - This feature has two functions:

– Checks for faults in the driver circuits by activating each driver.

– Checks to see if the safety circuit is functioning correctly.

•

TCM Temperature - If the TCM temperature raises above a predetermined level, the TCM shuts down. Prior

to shutting down, the TCM logs a fault code during the shut down. The transmission enters a mechanical limp

home mode.

•

Pressure Regulator/Solenoid - Each pressure regulator and solenoid is monitored for open and short circuits.

The TCM also checks that the current being delivered to each solenoid valve or pressure regulator is within

limits.

•

Torque Converter Control - The TCM checks and verifies that the torque converter has been engaged