Ford Comet 1966, 1966 Mustang, 1966 Fairlane, 1966 Falcon, 1966 Comet Shop Manual

Copyright © 2006, Forel Publishing Company, LLC, Woodbridge, Virginia

All Rights Reserved. No part of this book may be used or reproduced in any manner

whatsoever without written permission of Forel Publishing Company, LLC. For

information write to Forel Publishing Company, LLC, 3999 Peregrine Ridge Ct.,

Woodbridge, VA 22192

1966 Comet, Falcon, Fairlane and Mustang Shop Manual

ISBN: 0-9673211-3-1

EAN: 978-0-9673211-3-4

Forel Publishing Company, LLC

3999 Peregrine Ridge Ct.

Woodbridge, VA 22192

This publication contains material that is reproduced and distributed under a

license from Ford Motor Company. No further reproduction or distribution of the

Ford Motor Company material is allowed without the express written permission

of Ford Motor Company.

Disclaimer

Although every effort was made to ensure the accuracy of this book, no representations or warranties of

any kind are made concerning the accuracy, completeness or suitability of the information, either expressed

or implied. As a result, the information contained within this book should be used as general information

only. The author and Forel Publishing Company, LLC shall have neither liability n or responsibility to any

person or entity with respect to any loss or damage caused, or alleged to be caused, directly or indirectly by

the information contained in this book. Further, the publisher and author are not engaged in rendering legal

or other professional services. If legal, mechanical, electrical, or other expert assistance is required, the

services of a competent professional should be sought.

GROUP INDEX

Vehicle

Suspension, Steering, Wheels and Tires

Drive

Manual Transmission

Automatic Transmission

Ignition System

Fuel System

Cooling System

Identification

Brakes

Rear Axle

Shaft

and Clutch

Engine

1

2

3

4

5

6

7

8

9

10

11

Exhaust System

Charging System

Starting System

Lighting System, Horns and Instruments

Ventilating, Heating, and Accessories

Body, Doors and Windows

Trim, Seats, and Convertible Tops

Maintenance Schedule

Maintenance Operations

Lubrication Chart

Schematics

12

13

14

15

16

17

18

19

20

21

22

SPECIFICATIONS AND SPECIAL SERVICE TOOLS

AT END OF EACH GROUP

This shop manual provides the Service Technician wlth complete information for the proper servicing of the

1966

Comet,

Falcon,

Fairlane and Mustang cars.

.

The information is grouped according -to the type of work

being performed, such as diagnosis and testing, frequently

performed adjustments and repairs, in-vehicle adjustments,

overhaul, etc. Specifications and recommended special tools

are included.

Refer to the opposite page for important vehicle identifica-

tion data.

The descriptions and specifications in this manual were in

eflect at the time this manual was approved for printing. The

Ford Motor Company reserves the right to discontinue models

at any time, or change specifications or design, without notice

and without incurring obligation.

SERVICE PUBLICATIONS

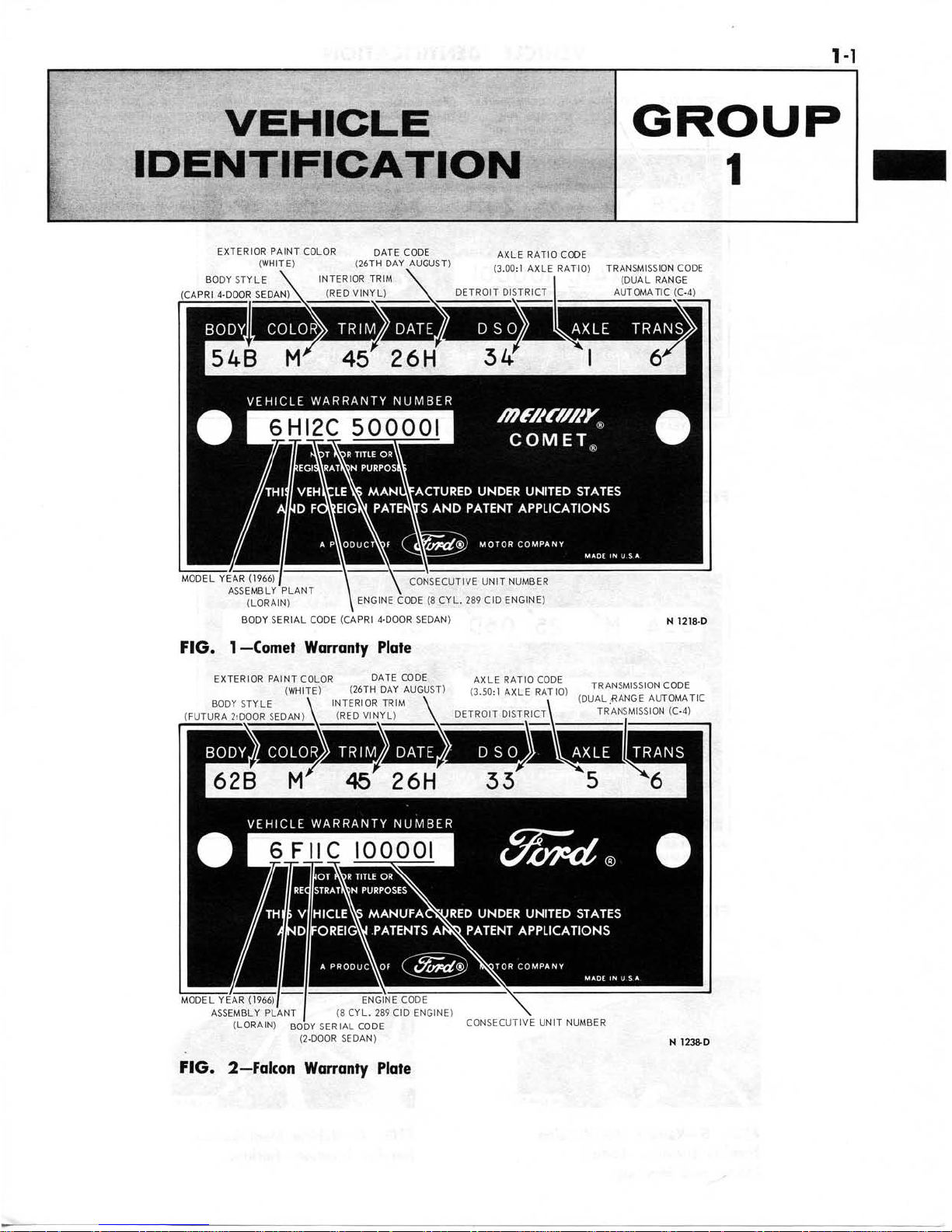

VEHICLE IDENTIFICATION

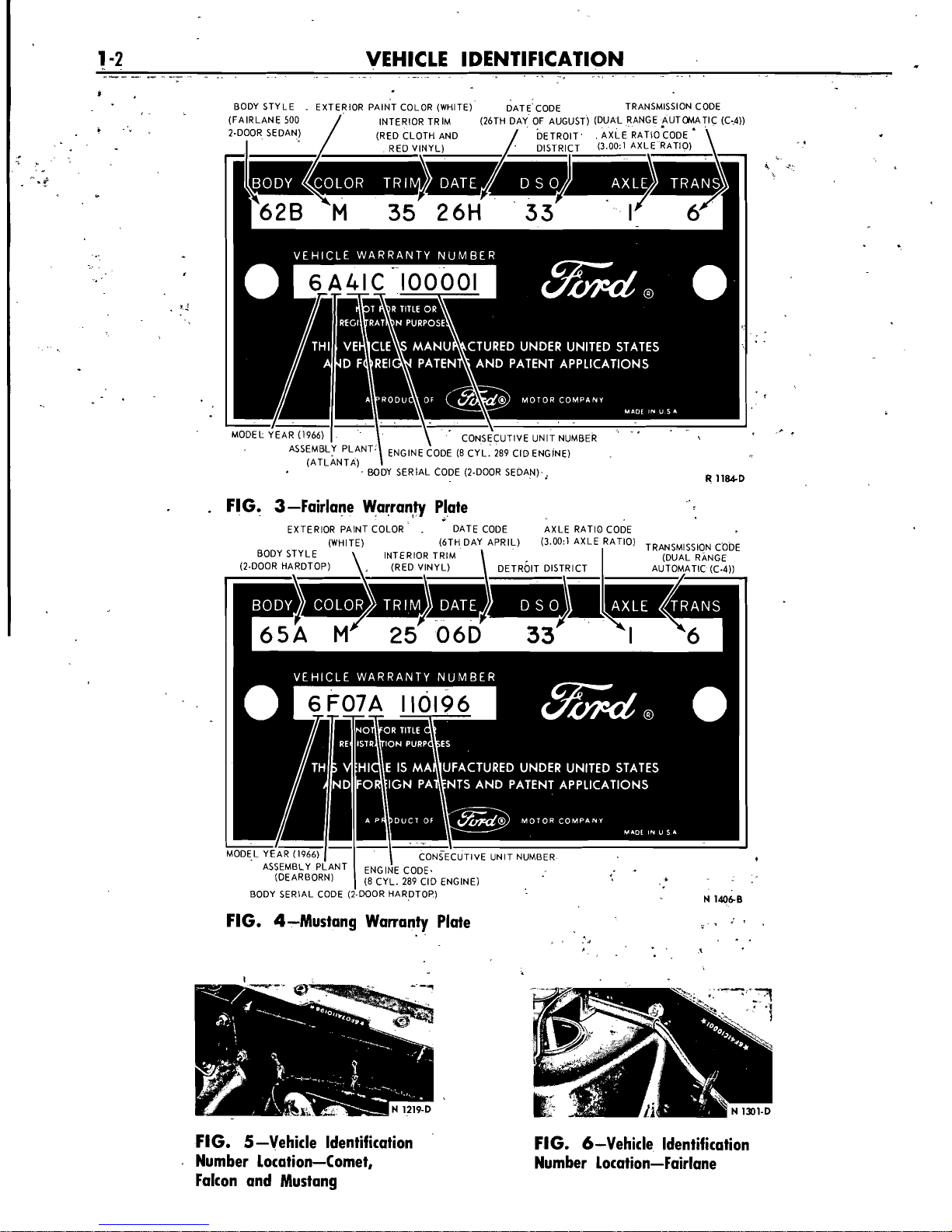

BODY STYLE . EXTERIOR PAINT COLOR (WHITE) DATE CODE TRANSMISSION CODE

(FAIRLANE 500

/

INTFRIOR TRIM (26TH DAY OF AUGUST) (DUAL RANGE AUTOMATIC (C-4))

.

/

2.DOOR SEDAN) (RED CLOTH AND

DETROIT

AXLE

RATIO;ODE

'

I

RED V!NYL)

DISTR~FT

(3.00:l AXLE RATIO)

C

/

MOOEL YEAR (1966)

1

I

.,

-

-

\

*

CONS~CUTIVE UNIT NUMBER

PLANT

ENGINE CODE (8 CYL. 289 CIO ENGINE)

(ATLANTA)

BODY SERIAL CODE (2-DOOR SEDAN)

,

R

1184.D

.

FIG. 3-Fairlane Wprranty Plate

EXTERIOR PAINT COLOR

.

DATE CODE AXLE RATIO CODE

(WHITE)

(6TH DAY APRIL) (3.00:) AXLE RATIO)

CODE

BODY STYLE INTERIOR TRIM

\

(DUAL

RANGE

(2-DOOR HARDTOP)

,

(RED VINYL)

DETROIT

DISTRICT AUTOMATIC (C.4))

\-,-

I-

I

I

M0DE.L

Ashttps://manualmachine.com/~(~~-'cuTlvr

YEAR (1966) UNIT NUMBER

.

z

$

(8 CYL. 289 CIO ENGINE)

FIG. 4-Mustang Warranty Plate

.

I.

.

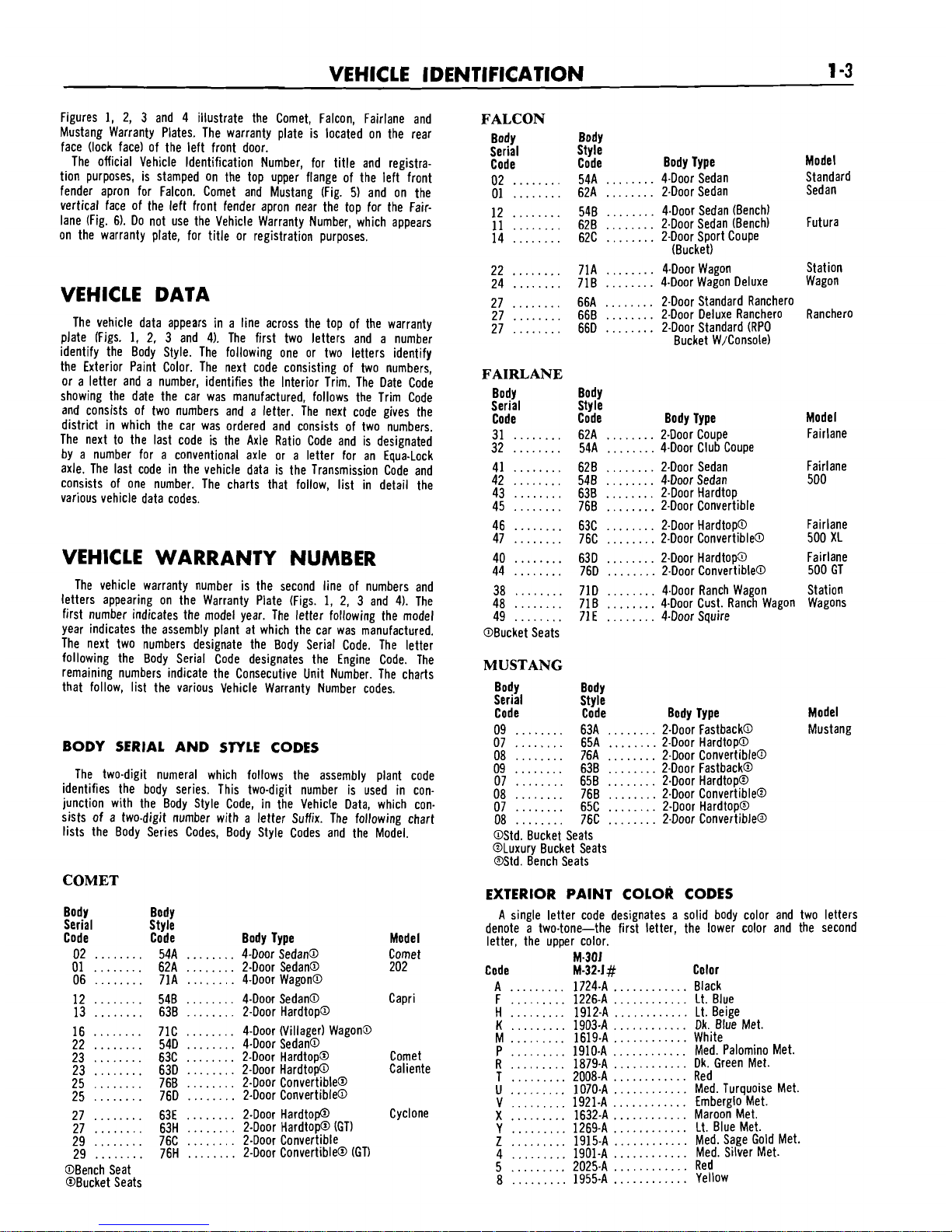

FIG. 5-Vehicle Identification

Number Location--Comet,

Falcon and Mustang

FIG. 6-Vehicle ldentification

Number Location-Fairlane

VEHICLE IDENTIFICATION

1

-3

Figures 1, 2, 3 and 4 illustrate the Comet, Falcon, Fairlane and

Mustang Warranty Plates. The warranty plate is located on the rear

face (lock face) of the left front door.

The official Vehicle Identification Number, for title and registration purposes, is stamped on the top upper flange of the left front

fender apron for Falcon. Comet and Mustang (Fig.

5)

and on the

vertical face of the left front fender apron near the top for the

Fairlane (Fig. 6). Do not use the Vehicle Warranty Number, which appears

on the warranty plate, for title or registration purposes.

VEHICLE DATA

The vehicle data appears in a line across the top of the warranty

plate (Figs. 1, 2, 3 and 4). The first two letters and a number

identify the Body Style. The following one or two letters identify

the Exterior Paint Color. The next code consisting of two numbers,

or a letter and a number, identifies the Interior Trim. The Date Code

showing the date the car was manufactured, follows the Trim Code

and consists of two numbers and a letter. The next code gives the

district in which the car was ordered and consists of two numbers.

The next to the last code is the Axle Ratio Code and is designated

by a number for a conventional axle or a letter for an

Equa-Lock

axle. The last code in the vehicle data is the Transmission Code and

consists of one number. The charts that follow, list in detail the

various vehicle data codes.

VEHICLE WARRANTY NUMBER

The vehicle warranty number is the second line of numbers and

letters appearing on the Warranty Plate (Figs.

1,

2, 3 and 4). The

first number indicates the model year. The letter following the model

year indicates the assembly plant at which the car was manufactured.

The next two numbers designate the Body Serial Code. The letter

following the Body Serial Code designates the Engine Code. The

remaining numbers indicate the Consecutive Unit Number. The charts

that follow, list the various Vehicle Warranty Number codes.

BODY SERIAL AND STYLE CODES

The two-digit numeral which follows the assembly plant code

identifies the body series. This two-digit number is used in conjunction with the Body Style Code, in the Vehicle Data, which consists of a two-digit number with a letter Suffix. The following chart

lists the Body Series Codes, Body Style Codes and the Model.

FALCON

Body Body

Serial Style

Code Code Body Type

........

........

02 54A 4-Door Sedan

........

........

01 62A 2-Door Sedan

........

........

12 548 4-Door Sedan (Bench)

........

........

11 62B 2-Door Sedan (Bench) Futura

14

........

62C

........

2-Door Sport Coupe

(Bucket)

22

........

71A

........

&Door Wagon

Station

........

........

24 71B &Door Wagon Deluxe Wagon

........

........

27 66A 2-Door Standard Ranchero

........

27 66B

........

2-Door Deluxe Ranchero Ranchero

........

........

27 66D 2-Door Standard (RPO

Bucket W/Console)

FAIRLANE

Body Body

Ser~al Style

Code Code Body Type Model

31

........

62A

........

2-Door Coupe Fairlane

........

........

32 54A 4-Door Club Coupe

41

........

62B

........

2-Door Sedan Fairlane

42

........

548

........

4-Door Sedan 500

........

........

43 638 2-Door Hardtop,

........

........

45 76B 2-Door Convert~ble

........

........

46 63C 2-Door Hardtop@ Fairlane

........

........

47 76C

2-Door Convertible@ 500 XL

40

........

63D

........

2-Door Hardtop? Fairlane

........

........

44 76D 2-Door Convert~bleO 500 GT

........

........

38 71D 4-Door Ranch Wagon Station

........

........

48 718 4-Door Cust. Ranch Wagon Wagons

........

........

49 71E 4-D00r Squire

@Bucket Seats

MUSTANG

Body Body

Serial Style

Code Code Body Type Model

09

........

63A

........

2-Door Fastback@ Mustang

........

........

07 65A 2-Door Hardtop@

........

........

08 76A 2-Door Convertible@

09

........

638

........

2-Door Fastback@

07

........

65B

........

2-Door Hardtop@

........

........

08 76B 2-Door Convertible@

........

........

07 65C 2-Door Hardtop@

........

........

08 76C 2-Door Convertible@

OStd.

Bucket Seats

@Luxury Bucket Seats

BStd. Bench Seats

COMET

EXTERIOR PAINT COLOR CODES

Body Body

Serial Style

Code Code Body Type Model

02

........

54A

........

4-Door Sedan@ Comet

01

........

62A

........

2-Door Sedan@ 202

06

........

71A

........

4-Door Wagon@

12

........

548

........

&Door Sedan@ Capri

13

........

63B

........

2-Door Hardtop@

16

........

71C

........

&Door (Villager) Wagon3

22

........

54D

........

4-Door Sedan@

23

........

63C

........

2-Door Hardtop@ Comet

23

........

63D

........

2-Door Hardtop@ Caliente

25

........

76B

........

2-Door Convertible@

25

........

76D

........

2-Door Convertible@

27

........

63E

........

2-Door Hardtop Cyclone

........

27

........

63H 2-Door Hardtop@ (GT)

........

29

........

76C 2-Door Convertible

........

29

........

76H 2-Door Convertible@ (GT)

@Bench

Seat

@Bucket Seats

Model

Standard

Sedan

A single letter code designates a solid body color and two letters

denote a two-tone-the first letter, the lower color and the second

letter, the upper color.

M.301

Code M-32-I# Color

............

.........

A 1724-A Black

F

.........

1226-A

............

Lt. Blue

.........

............

H 1912-A Lt. Beige

............

.........

K

1903-A Dk. Blue Met.

............

.........

M 1619-A White

............

.........

P 1910-A Med. Palomino Met.

............

.........

R 1879-A Dk. Green Met.

............

.........

T 2008-A Red

............

.........

U

1070-A Med. Turquoise Met.

.........

............

V 1921-A Embernlo Met.

~aroon Met.

Lt. Blue Met.

Med. Sage Gold Met.

Med. Silver Met.

Red

Yellow

INTERIOR TRlM CODES

Code Trim Schemes

11

..........

Silver Cloth and Black Vinyl

12

..........

Blue Cloth and Blue Vinyl

15

..........

Red Cloth and Red Vinyl

..........

17 Aqua Cloth and Aqua Vinyl

22

..........

Blue Vinyl

25

..........

Red Vinyl

26

..........

Black Vinyl

27

..........

Aqua Vinyl

..........

32

Blue Cloth and Blue Vinyl

..........

35 Red Cloth and Red Vinyl

36

..........

Black Vinyl

..........

37 Aqua Cloth and Aqua Vinyl

38

..........

Ivy Gold Cloth and Ivy Gold Vinyl

42

..........

Blue Vinyl

44

..........

Emberglo Vinyl

45

..........

Red Vinyl

46

..........

Black Vinyl

47

..........

Aqua Vinyl

48

..........

Ivy Gold Vinyl

52

..........

Blue Cloth and Blue Vinyl

55

..........

Red Cloth and Red Vinyl

..........

57

Aqua Cloth and Aqua Vinyl

62

..........

Blue Vinyl

64

..........

Emberglo Vinyl

65

..........

Red Vinyl

66

..........

Black Vinyl

67

..........

Aqua Vinyl

68

..........

Ivy Gold Vinyl

82

..........

Blue Vinyl

84

..........

Emberglo Vinyl

85

..........

Red Vinyl

86

..........

Black Vinyl

87

..........

Aqua Vinyl

88

..........

Ivy Gold Vinyl

1D

..........

Parchment Cloth and Parchment Vinyl

2D

..........

Parchment Vinyl

..........

3D

Parchment Cloth and Parchment Vinyl

4D

..........

Parchment Vinyl

5D

..........

Parchment Cloth and Parchment Vinyl

OD

..........

Parchment Vinyl

B1

..........

Parchment Vinyl W/Silver

82

..........

Parchment Vinyl W/Blue

84

..........

Parchment Vinyl W/Emberglo

85

..........

Parchment Vinyl W/Red

B6

..........

Parchment Vinyl WIBlack

87

..........

Parchment Vinyl W/Aqua

B8

..........

Parchment Vinyl W/lvy Gold

B9

..........

Parchment Vinyl W/Palomino

C2

..........

Parchment Vinyl W/Blue

C3

..........

Parchment Vinyl W/Burgundy

C4

..........

Parchment Vinyl W/Emberglo

C6

..........

Parchment Vinyl W/Black

C7

..........

Parchment Vinyl W/Aqua

C8

..........

Parchment Vinyl W/Gold

C9

..........

Parchment Vinyl W/Palomino

D2

..........

Parchment Vinyl W/Blue

D3

..........

Parchment Vinyl W/Burgundy

D4

..........

Parchment Vinyl W/Emberglo

D6

..........

Parchment Vinyl W/Black

D7

..........

Parchment Vinyl W/Aqua

D8

..........

Parchment Vinyl W/Gold

D9

..........

Parchment Vinyl W/Palomino

F2

..........

Parchment Vinyl W/Blue

F3

..........

Parchment Vinyl W/Burgundy

F4

..........

Parchment Vinyl W/Emberglo

F6

..........

Parchment Vinyl W/Black

F7

..........

Parchment Vinyl W/Aqua

F8

..........

Parchment Vinyl W/lvy Gold

F9

..........

Parchment Vinyl W/Palomino

H1

..........

White Vinyl W/Silver

H2

..........

White Vinyl W/Blue

H4

..........

White Vinyl W/Emberglo

INTERIOR TRlM CODES (Cont'd.)

Code Trim Schemes

H5

..........

White Vinyl W/Red

H6

..........

White Vinyl W/Black

H7

..........

White Vinyl W/Aqua

H8

..........

White Vinyl W/Palomino

DATE CODES

A number

signify in^

the date precedes the month code letter. A

second-year code letter will be used if the model exceeds 12 months.

Code Code

Month First Year Second Year

January

...........................

A

.........

N

February

..........................

B

.........

P

March

............................

C

.........

Q

.........

.............................

April D R

.........

..............................

May E S

.........

.............................

June

F T

July

..............................

G

.........

U

August

...........................

H

.........

V

September

........................

J

.........

W

October

..........................

K

.........

X

November

.........................

L

.........

Y

.........

.........................

December M

Z

DISTRICT CODES (DSO)

Units built on a Domestic Special Order. Foreign Special Order, or

other special orders will have the complete order number in this

space. Also to appear in this space is the two-digit code number of

the District which ordered the unit. If the unit is a regular production

unit, only the District code number will appear.

COMET

Code District

11

.................

Boston

16

............

Philadel~hia

15

..............

New York

17

............

Wash~ngton

21

................

Atlanta

22

.................

Dallas

23

............

Jacksonville

26

...............

Memohis

31

.................

Buffalo

32

..............

Cincinnati

33

..............

Cleveland

Code District

.................

34 Detroit

41

................

Chicago

42

...............

St. Louis

46

.............

Twin Cities

51

.................

Denver

............

52 Los Angeles

................

53 Oakland

54

.................

Seattle

.........

81 Ford of Canada

......

84 Home Office Reserve

90-99

...............

Export

FALCON, FAIRLANE AND MUSTANG

Code District Code District

...............

.................

11 Boston 45 Davenport

................

12

................

Buffalo 51 Denver

.............

..............

13 New York 52 Des Moines

.............

..............

14 Pittsburgh 53 Kansas City

.................

................

15 Newark 54 Omaha

...............

................

21 Atlanta 55 St. Louis

.................

..............

22 Charlotte 61 Dallas

................

23

............

Philadelphia 62 Houston

...............

24

.............

Jacksonville 63 Memphis

............

25

...............

Richmond 64 New Orleans

..........

26

.............

Washington 65 Oklahoma City

.............

31

..............

Cincinnati 71 Los Angeles

...............

32

...............

Cleveland 72 San Jose

..........

.................

33 Detro~t 73 Salt Lake C~ty

................

.............

34 Indianapolis 74 Seattle

..........

................

35 Lansing 81 Ford of Canada

.............

36

...............

Louisville 83 Government

41

................

Chicago 84

.....

Home Office Reserve

......

42

..................

Fargo 85 American Red Cross

...

...............

43 Rockford 89 Transportation Services

...............

44

.............

Twln C~t~es 90-99 Export

VEHICLE l DENTlFlCATlON

1

-5

REAR AXLE RATIO CODES

A number designates a conventional axle, while a letter designates a

Locking differential.

Code Ratio Code Ratio

1

.................

3.00:l A

................

3.00:l

2

.................

2.83:l L

................

2.83:l

3

.................

3.20:l C

................

3.20:l

4

.................

3.25:l D

................

3.251

5

.................

3.50:l

E

................

3.50:l

6

.................

2.80:l

F

................

2.80:l

8

.................

3.89:l

H

................

3.89:l

TRANSMISSION CODES

Code Type

1

..................

3-Speed Manual

4

..................

Dual Range Automatic (C-6)

5

..................

4-Speed Manual

6

..................

Dual Range Automatic (C-4)

MODEL YEAR CODE

The number 6 designates 1966

ASSEMBLY PLANT CODES

Code Assembly

letter Plant

A

..................

Atlanta

B

..........

Oakville (Canada)

C

.............

Ontario Truck

D

...................

Dallas

E

.................

Mahwah

F

................

Dearborn

G

.................

Chicago

H

...................

Lorain

J

..............

Los Angeles

K

..............

Kansas City

Code Assembly

Letter Plant

...........

L Michigan Truck

N

..................

Norfolk

P

..............

Twin Cities

R

................

San Jose

S

...............

Pilot Plant

T

................

Metuchen

U

................

Louisville

W

..................

Wayne

Y

..................

Wixom

Z

.................

St. Louis

ENGINE CODES

A

..............

8 Cyl. 289 Cu. In. (4V Prem.)

C

..............

8 Cyl. 289 Cu. In. (2V)

K

..............

8 Cyl. 289 Cu. In. (4V Hi-Perf.)

T

..............

6 Cyl. 200 Cu. In. (1V)

..............

Y

8 Cyl. 390 Cu. In.

(2V)

Z

..............

8 Cyl. 390 Cu. In. (4V)

2

..............

6 Cyl. 0200 Cu. In. (1V)

3

..............

8 Cyl. 0289 Cu. In. (2V)

@Low

Compression

CONSECUTIVE UNIT NUMBER

Each model year, each assembly plant begins production with the

number

100001 (Falcon, Fairlane or Mustang) or 500001 (Comet) and

continues

on for each un~t bu~lt.

2-2

GROUP

2

-

BRAKES

Possible Causes

of

Trouble Symptoms

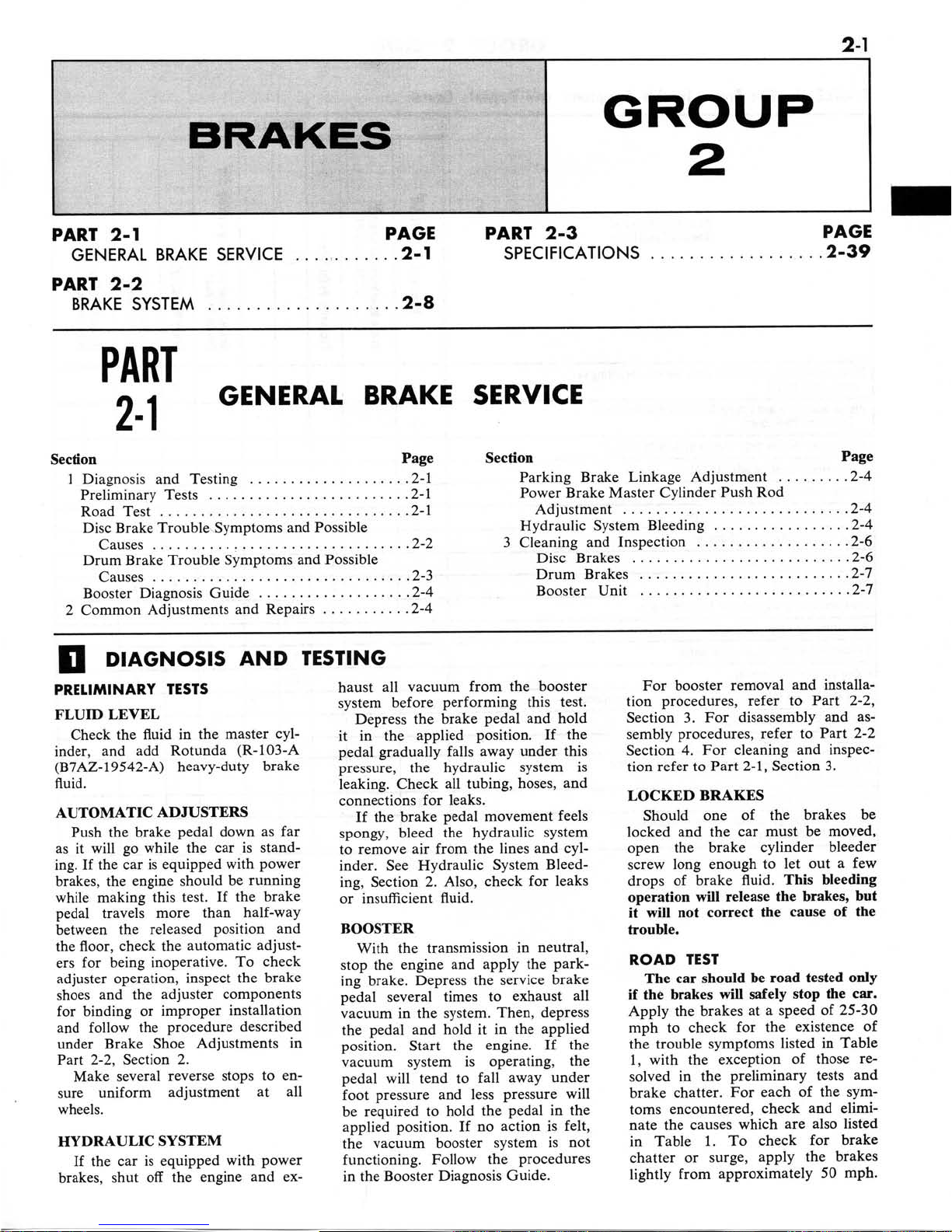

TABLE

1-Disc Brake Trouble Symptoms and Possible Causes

Shoe and Lining Knock-back after violent cornering or

rough road travel

Piston and Shoe and Lining Assembly Not Properly

Seated or Positioned

Air Leak or Insufficient Fluid in System or Caliper

TROUBLE SYMPTOMS

=h=hg

-

e

-

2

.:

z

a

X

X

X

al

an

=

51

e;'

c.-

-

g

a

OY

cum

ZL

X

X

-

u

QJ

.-

-

u

e;

rn

2

.-

w

.-

-

n

.z

-

Ba

c"

.:

"na

r.~,

-&B

:

al

x

C

m

UE=-h

=

u

2

Ma

.-

w

n

n

al

Y

Y

Y

=

ea

w

e

r"

LU

-

,

~n

PART

2-

1

-

GENERAL BRARE SERVICE

2-3

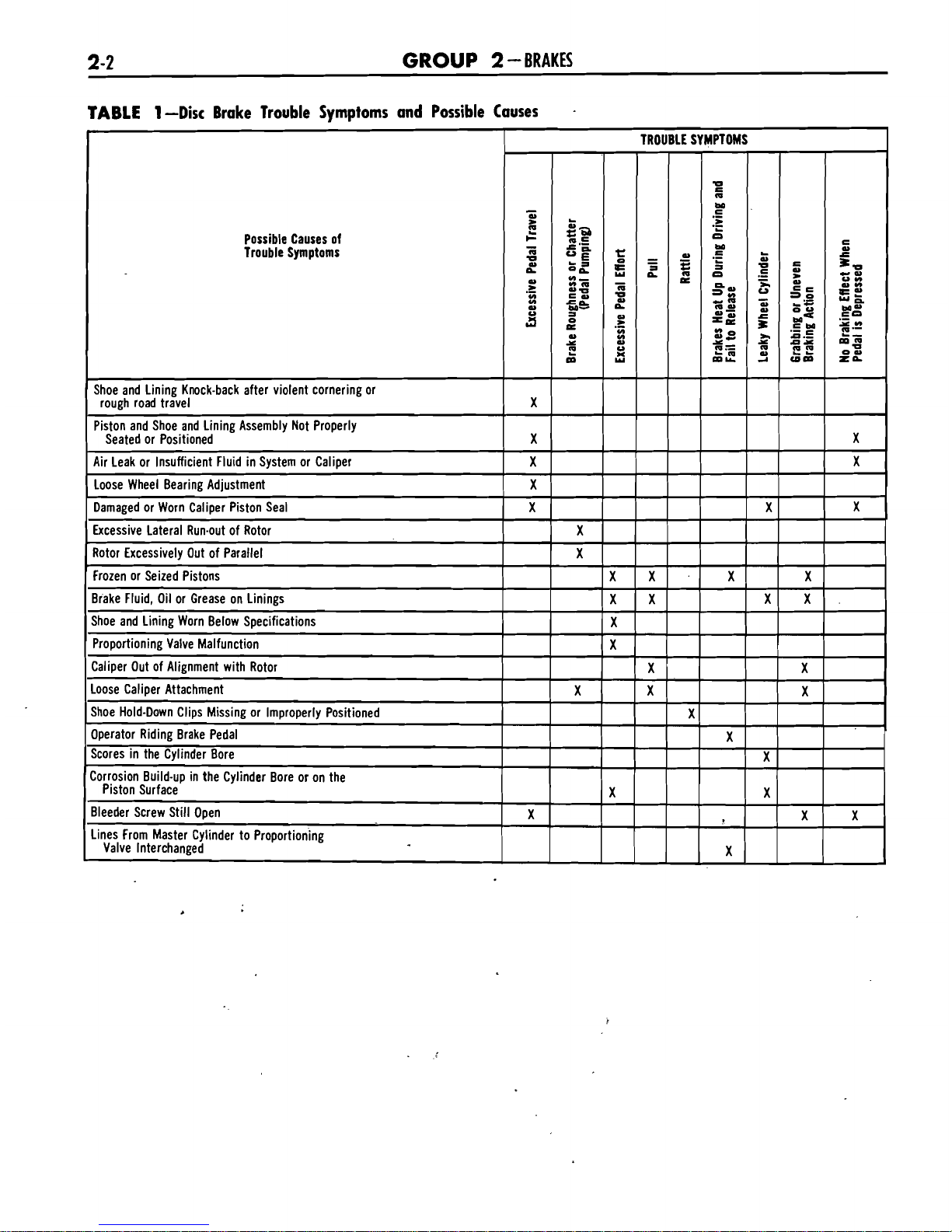

TABLE

2-Drum Brake Trouble Symptoms and Possible Causes

Possible Causes of

Trouble Symptoms

Sticking Booster Control Valve

I

GROUP

2

-BRAKES

BRAKE BOOSTER TROUBLE DIAGNOSIS GUIDE

COMMON ADJUSTMENTS AND REPAIRS

BOOSTER INOPERATIVEHARD PEDAL

BRAKES DRAG OR GRAB

SELF APPLICATION

OF BRAKES WHEN

ENGINE STARTS

PARKING BRAKE

LINKAGE ADJUSTMENT

If the preliminary tests show that leaking or collapsed condition. Re-

the booster is inoperative or if a pair or replace parts as necessary.

hard pedal condition still exists after If the foregoing procedure does

eliminating the causes of Hard not eliminate the trouble, remove

Pedal listed in Table 2, the trouble the booster from the car. Separate

may be caused by vacuum leakage. the booster body from the end plate,

Disconnect the vacuum line (two and check the bellows, booster body,

lines if equipped with an automatic and diaphragm assembly for damage

transmission) at the booster, remove that would cause leaks. When

assemthe vacuum manifold and check bling, be sure that the diaphragm asvalve assembly, and look for a stick- sembly is properly positioned.

Iming or faulty check valve. Check all proper location could cause leakage

vacuum connections for leakage or between the vacuum and atmosobstruction. Check all hoses for a pheric sides of the diaphragm.

If the brakes still drag or grab assembly. Remove and disassemble

after eliminating the causes listed in

the booster. Clean, inspect, and

re-

Table

1,

the condition is probably place parts as necessary.

caused by a sticking valve plunger

Remove and disassemble the seated atmospheric valve. Clean, inbooster. Check the diaphragm for spect, and replace parts as necessary.

being out of locating radii in the Be sure that the diaphragm is

prop-

housing. Check for a sticking or un-

erly located when assembling.

pedal one notch from its normal

released position.

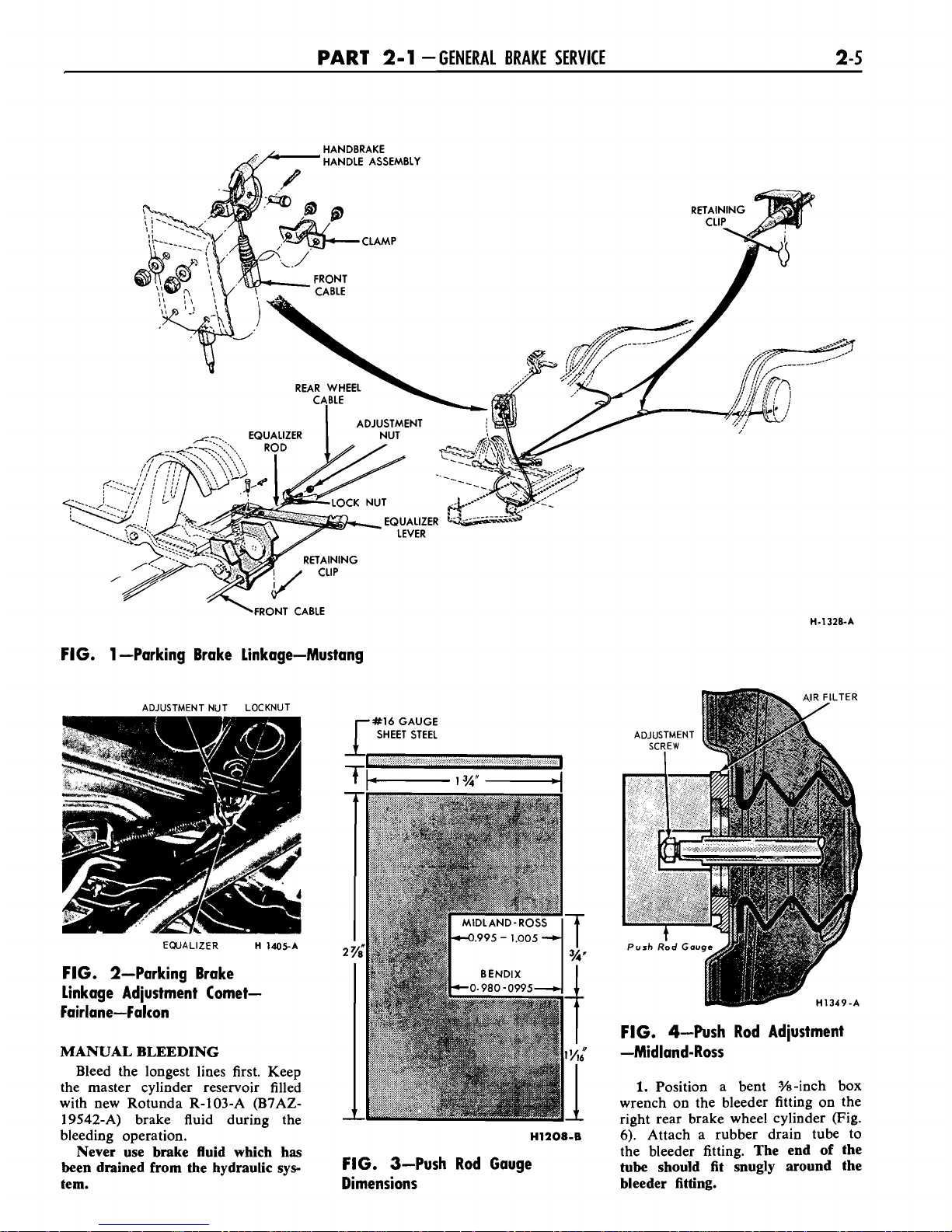

MUSTANG

3.

Raise the car.

4.

Loosen the equalizer lock nut

Check the parking brake cables

and turn the adjusting nut forward

when the brakes are

fully released.

against the equ&zer-until a mod-

If the cables are loose, adjust them

erate drag is felt when turning the

as follows: rear wheels (Fig. 2). Tighten the

1.

Fully release the parking brake

lock nut.

by turning the handle counterclock-

5.

Release the parking brake,

wise and pushing it inward. and' make sure that the brake shoes

.

2.

Pull the parking brake handle

outward to the third notch from its

normal released position.

3.

Raise the car.

4.

Turn the locking adjustment nut

forward against the equalizer (Fig.

1)

until a moderate drag is felt when

turning the rear wheels in the direction of forward rotation.

5.

Release the parking brake, and

make sure that the brake shoes

return to the fully released position

and no drag is felt when turning the

rear wheels.

COMET-FALCONFAIRLANE

Check the parking brake cables

when the brakes are fully released.

If the cables are loose, adjust them

as follows:

1.

Fully release the parking brake

pedal.

2.

Depress the parking brake

'return to the fully released position.

POWER BRAKE MASTER

CYLINDER PUSH ROD

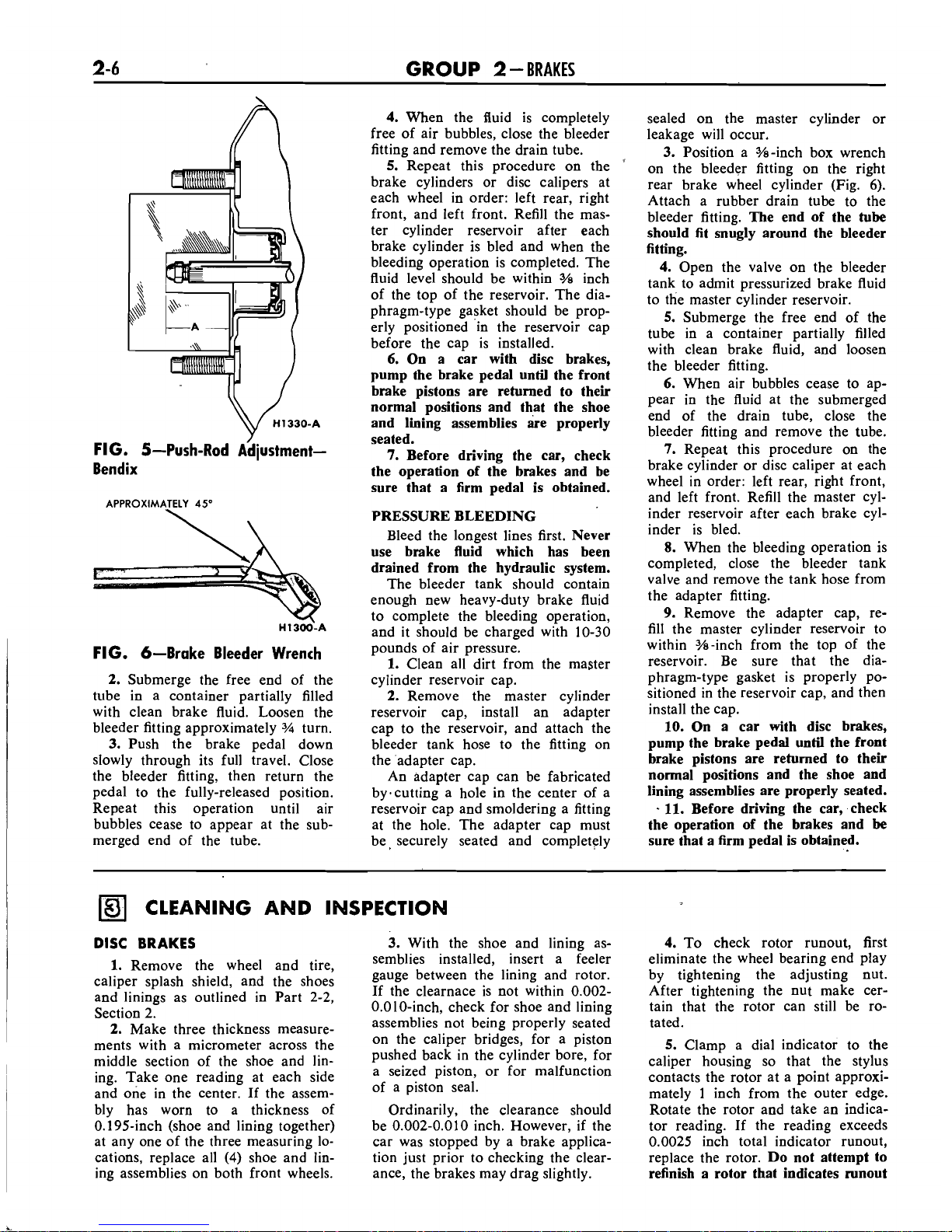

ADJUSTMENT

The push rod is provided with an

adjustment screw to maintain the

correct relationship between the

booster control valve plunger and

the master cylinder piston. Failure

to maintain this relationship will prevent the master cylinder piston from

completely releasing hydraulic pressure and can cause the brakes to

drag, or cause excessive brake pedal

travel.

To check the adjustment of the

screw, fabricate a gauge of the dimension shown in Fig.

3.

Then place

the gauge against the master cylinder mounting surface of the booster

body as shown in Fig.

4

or

5.

The

push rod screw should be adjusted so

that the end of the screw just touches

the inner edge of the slot in the

gauge. Do not set up side forces on

the push rod. Side forces may break

the valve plunger.

This is an approximate adjustment

only.

The push rod should not move

more than

0.015

inch as it contacts

the master cylinder piston. No move-

ment (exact contact) is ideal.

HYDRAULIC SYSTEM

BLEEDING

When any part of the hydraulic

system has been disconnected for repair or replacement, air may get

into the lines and cause spongy pedal

action. Bleed the hydraulic system

after it has been properly con-

nected to be sure that all air is

expelled from the brake cylinders

or disc brake calipers, and lines.

The hydraulic system can be bled

manually or with pressure bleeding

equipment.

With disc brakes, more pumping

of the pedal is required and more

frequent checking of the master cylinder may be necessary while bleeding.

On a car with disc brakes, remove

the front wheels and tires to gain

access to the bleeder fitting on the

disc brake calipers.

PART

2-1

-GENERAL BRAKE SERVICE

2-5

\FRONT

CABLE

FIG. 1 -Parking Brake Linkage-Mustang

ADJUSTMENT NUT LOCKNUT

EQUALIZER

H

1405-A

FIG. 2-Parking Brake

Linkage Adjustment

Comet-

Fairlane-Falcon

MANUAL BLEEDING

Bleed the longest lines first. Keep

the master cylinder reservoir filled

with new Rotunda R-103-A

(B7AZ-

19542-A) brake fluid during the

bleeding operation.

Never use brake fluid which has

been drained from the hydraulic sys-

tem.

r

#16

GAUGE

SHEET STEEL

FIG. 4-Push Rod Adjustment

-Midland-Ross

1.

Position a bent %-inch box

wrench on the bleeder fitting on the

rieht rear brake wheel cylinder (Fig.

14,208-B

6;

Attach a rubber drain tube to

the bleeder fitting.

The end of the

FIG. 3-Push Rod Gauge

tube should fit snugly around the

-

Dimensions

bleeder fitting.

GROUP

2

-

BRAKES

/

FIG. 5-Push-Rod AdjustmentBendix

APPROXIMATELY

45"

\

FIG. 6-Brake Bleeder Wrench

2.

Submerge the free end of the

tube in a container partially filled

with clean brake fluid. Loosen the

bleeder fitting approximately

%I

turn.

3.

Push the brake pedal down

slowly through its full travel. Close

the bleeder fitting, then return the

pedal to the fully-released position.

Repeat this operation until air

bubbles cease to appear at the submerged end of the tube.

4.

When the fluid is completely

free of air bubbles, close the bleeder

fitting and remove the drain tube.

5.

Repeat this procedure on the

'

brake cylinders or disc calipers at

each wheel in order: left rear, right

front, and left front. Refill the master cylinder reservoir after each

brake cylinder is bled and when the

bleeding operation is completed. The

fluid level should be within

3/8

inch

of the top of the reservoir. The diaphragm-type gasket should be properly positioned in the reservoir cap

before the cap is installed.

6.

On a car with disc brakes,

pump the brake pedal until the front

brake pistons are returned to their

normal positions and that the shoe

and lining assemblies are properly

seated.

7.

Before driving the car, check

the operation of the brakes and be

sure that a firm pedal is obtained.

PRESSURE BLEEDING

Bleed the longest lines first.

Never

use brake fluid which has been

drained from the hydraulic system.

The bleeder tank should contain

enough new heavy-duty brake fluid

to complete the bleeding operation,

and it should be charged with 10-30

pounds of air pressure.

1.

Clean all dirt from the master

cylinder reservoir cap.

2.

Remove the master cylinder

reservoir cap, install an adapter

cap to the reservoir, and attach the

bleeder tank hose to the fitting on

the adapter cap.

An adapter cap can be fabricated

byecutting a hole in the center of a

reservoir cap and smoldering a fitting

at the hole. The adapter cap must

be, securely seated and completely

sealed on the master cylinder or

leakage will occur.

3.

Position a %-inch box wrench

on the bleeder fitting on the right

rear brake wheel cylinder (Fig.

6).

Attach a rubber drain tube to the

bleeder fitting.

The end of the

tube

should fit snugly around the bleeder

fitting.

4.

Open the valve on the bleeder

tank to admit pressurized brake fluid

to the master cylinder reservoir.

5.

Submerge the free end of the

tube in a container partially filled

with clean brake fluid, and loosen

the bleeder fitting.

6.

When air bubbles cease to appear in the fluid at the submerged

end of the drain tube, close the

bleeder fitting and remove the tube.

7.

Repeat this procedure on the

brake cylinder or disc caliper at each

wheel in order: left rear, right front,

and left front. Refill the master cylinder reservoir after each brake cylinder is bled.

8.

When the bleeding operation is

completed, close the bleeder tank

valve and remove the tank hose from

the adapter fitting.

9.

~kmove the adapter cap, refill the master cylinder reservoir to

within

%-inch from the top of the

reservoir. Be sure that the diaphragm-type gasket is properly po-

sitioned in the reservoir cap, and then

install the cap.

10.

On a car with disc brakes,

pump the brake pedal until the front

brake pistons are returned to their

normal positions and the shoe and

lining assemblies are properly seated.

+

11.

Before driving the car, check

the operation of the brakes and

be

sure that a firm pedal is obtained.

CLEANING AND INSPECTION

I

I

DISC

BRAKES

I

1.

Remove the wheel and tire,

caliper splash shield, and the shoes

and linings as outlined in Part 2-2,

Section

2.

2.

Make three thickness measurements with a micrometer across the

middle section of the shoe and

lin-

i

ing. Take one reading at each side

and one in the center. If the assembly has worn to a thickness of

0.195-inch (shoe and lining together)

at any one of the three measuring locations, replace all

(4)

shoe and lin-

ing assemblies on both front wheels.

3.

With the shoe and lining assemblies installed, insert a feeler

gauge between the lining and rotor.

If the clearnace is not within

0.002-

0.010-inch, check for shoe and lining

assemblies not being properly seated

on the caliper bridges, for a piston

pushed back in the cylinder bore, for

a seized piston, or for malfunction

of a piston seal.

Ordinarily, the clearance should

be 0.002-0.010 inch. However, if the

car was stopped by a brake application just prior to checking the clearance, the brakes may drag slightly.

4.

To check rotor runout, first

eliminate the wheel bearing end play

by tightening the adjusting nut.

After tightening the nut make cer-

tain that the rotor can still be rotated.

5.

Clamp a dial indicator to the

caliper housing so that the stylus

contacts the rotor at a point approxi-

mately

1

inch from the outer edge.

Rotate the rotor and take an indicator reading. If the reading exceeds

0.0025 inch total indicator

runout,

replace the rotor.

Do not attempt to

refinish a rotor that indicates

runout

PART

2-1

-

GENERAL BRAKE SERVICE

in excess of specification.

When the

runout check is finished be sure to

adjust the bearings

as

outlined in

Group

3,

in order to prevent bearing

failure.

6.

Check the rotor for scoring.

Minor scores can be removed with

a fine emery cloth. If the rotor is

excessively scored, replace it.

7.

Visually check the caliper. If it

is cracked it should be replaced. If

leakage or seized pistons is evident,

disassemble and repair the caliper as

required.

8.

If upon disassembly the caliper

is found to be distorted or damaged,

or if the cylinder bores are scored

or excessively worn, replace the as-

sembly.

The two halves of the caliper as-

sembly should never be separated.

Damage or failure of one requires

replacement of both as a unit.

DRUM BRAKES

1.

Remove the wheel from the

drum, and remove the drum as out-

lined in Part

2-2,

Section

2.

Wash

all the parts except the brake shoes

in a cleaning fluid and dry with com-

pressed air.

2.

Brush all dust from the carrier

plate and interior of the brake drum.

3.

Inspect the brake shoes for excessive lining wear or shoe damage.

If the lining is worn to within

'132

inch of the rivet heads or if the

shoes are damaged, they must be replaced. Replace any lining that has

been oil saturated. Replace the lining in axle sets. Prior to replacement

of the lining, the drum diameter

should be checked to determine if

oversize linings must be installed.

4.

Check the condition of the

brake shoes, retracting springs, and

drum for signs of overheating. If the

shoes have a slight blue coloring, or

if the springs show a change in free

length, indicating overheating, replacement of the retracting and hold

down springs is necessary.

Over-

heated springs lose their force and

could cause the new lining to wear

prematurely if they are not replaced.

5.

If the car has

30,000

or more

miles of operation on the brake linings, or signs of overheating are

present when relining brakes, the

wheel cylinders should be disassembled and inspected for wear and dirt

in the cylinder. The cylinder cups

and other parts contained in the

overhaul kit should be replaced,

thus avoiding future problems.

6.

Inspect all other brake parts

and replace any that are worn or

damaged.

7.

Inspect the brake drums and,

if necessary, refinish. Refer to Part

2-2,

Section 4 for refinishing.

BOOSTER UNITS

Disassembled views of the brake

booster are shown in Figs.

40, 49

and

SO,

Part

2-2.

After disassembly, immerse all

metal parts in a suitable solvent.

Use-only alcohol on rubber parts or

parts containing rubber. After the

parts have been thoroughly cleaned

and rinsed in cleaning solvent, the

metal parts which come in contact

with hydraulic brake fluid or rubber parts should be rewashed in

clean alcohol before assembly. Use

an air hose to blow dirt and cleaning

fluid from the recesses and internal

passages. When overhauling a power

booster, use all parts furnished in the

repair kit.

Discard all old rubber

parts.

Inspect all other parts for damage

or excessive wear. Replace damaged

or excessively worn parts. If the inside of the booster body is rusted

or corroded, polish it with steel wool

or fine emery cloth.

Loading...

Loading...