Ford Comet 1964, 1964 Falcon Shop Manual

Copyright © 2007, Forel Publishing Company, LLC, Woodbridge, Virginia

All Rights Reserved. No part of this book may be used or reproduced in any manner

whatsoever without written permission of Forel Publishing Company, LLC. For

information write to Forel Publishing Company, LLC, 3999 Peregrine Ridge Ct.,

Woodbridge, VA 22192

1964 Ford Car Shop Manual

(with Technical Service Bulletin 1090-1, dated March 16, 1964)

Form 7760-64

ISBN: 1-60371-001-9

EAN: 978-1-60371-001-5

Forel Publishing Company, LLC

3999 Peregrine Ridge Ct.

Woodbridge, VA 22192

Email address: webmaster@ForelPublishing.com

Website: http://www.ForelPublishing.com

This publication contains material that is reproduced and distributed under a

license from Ford Motor Company. No further reproduction or distribution of the

Ford Motor Company material is allowed without the express written permission

of Ford Motor Company.

Disclaimer

Although every effort was made to ensure the accuracy of this book, no representations or warranties of

any kind are made concerning the accuracy, completeness or suitability of the information, either expressed

or implied. As a result, the information contained within this book should be used as general information

only. The author and Forel Publishing Company, LLC shall have neither liability n or responsibility to any

person or entity with respect to any loss or damage caused, or alleged to be caused, directly or indirectly by

the information contained in this book. Further, the publisher and author are not engaged in rendering legal

or other professional services. If legal, mechanical, electrical, or other expert assistance is required, the

services of a competent professional should be sought.

FOREWORD

This shop manual provides the Service Technician with com-

plete information for the proper servicing of the

1964

Comet

and Falcon cars.

The information is grouped according to the type of work

being performed, such as diagnosis and testing, frequently

performed adjustments and repairs, in-vehicle adjustments,

overhaul, etc. Specifications and recommended special tools

are included.

Refer to the opposite page for important vehicle identification data..

The descriptions and

specificarions in this manual were in

eflect at the time this manual was approved for printing. The

Ford Motor Company reserves the right to discontinue models

at any time, or change specifications or design, without notice

and without incurring obligation.

,

SERVICE DEPARTMENT

FORD MOTOR COMPANY

September

1997

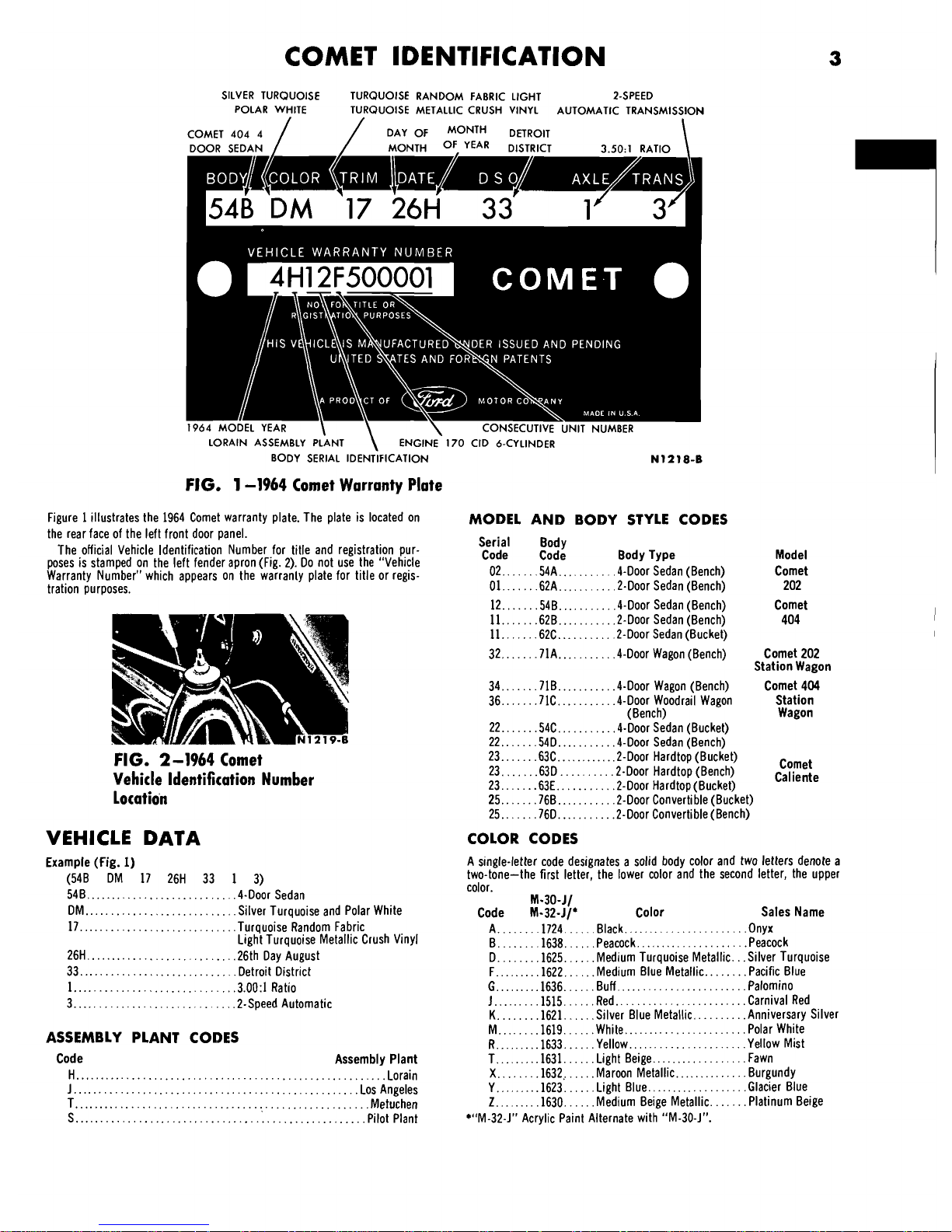

COMET IDENTIFICATION

SILVER TURQUOISE TURQUOISE RANDOM FABRIC LIGHT ?-SPEED

POLAR WHITE TURQUOISE METALLIC CRUSH VINYL AUTOMATIC TRANSMISSION

COMET 404 4

/

/

DAY OF DETROIT

\

DOOR SEDAN

DM

17

26H

33

LORAIN ASSEMBLY PLANT

\

ENGINE'

170 CID 6-CYLINDER

BODY SERIAL IDENTIFICATION

N1218-B

FIG. 1-1964 Comet Warranty Plate

Figure 1 illustrates the 1964 Comet warranty plate. The plate is located on

the rear face of the left front door panel.

'The official Vehicle ldentification Number for title and registration pur-

poses is stamped on the left fender apron (Fig. 2). Do not use the

"Veh~cle

Warranty Number" which appears on the warranly plate for tltle or reglstration purposes.

FIG. 2-1964 Comet

Vehicle ldentification Number

Locatio'n

VEHICLE

DATA

Example (Fig.

1)

(548 DM 17 26H 33 1 3)

548..

.........................

.4-Door Sedan

DM..

.........................

.Silver Turquoise and Polar White

17..

..........................

.Turquoise Random Fabric

Light Turquoise Metallic Crush Vinyl

26H..

.........................

.26th Day August

33

............................

.Detroit District

1

.............................

.3.00:1 Ratio

3.

............................

.2-Speed Automatic

ASSEMBLY PLANT CODES

Code Assembly Plant

H..

.......................................................

Lorain

J

....................................................

Los Angeles

T..

.....................................................

Metuchen

S.

...................................................

.Pilot Plant

MODEL AND BODY STYLE CODES

Serial Body

Code Code Body Type Model

02..

....

.54A..

........

.&Door Sedan (Bench) Comet

01..

....

.62A..

........

.2-Door Sedan (Bench)

202

12..

....

.54B.

.........

.4-Door Sedan (Bench) Comet

11..

....

.62B..

........

.2-Door Sedan (Bench) 404

11..

....

.62C..

........

.2-Door Sedan (Bucket)

32..

....

.71A..

........

.4-Door Wagon (Bench) Comet 202

Station Wagon

....

........

34.. ,718.. .4-Door Wagon (Bench) Comet 404

36..

....

.71C..

........

.4-D00r Woodrail Wagon Station

(Bench) Wagon

22..

....

.54C..

........

.4-Door Sedan (Bucket)

22..

....

.54D..

........

.&Door Sedan (Bench)

23..

....

.63C..

.........

.2-Door Hardtop (Bucket)

Comet

23..

....

.63D..

.......

.2-Door Hardtop (Bench)

Caliente

23..

....

.63E..

........

.2-Door Hardtop (Bucket)

25..

....

,768..

........

.2-Door Convertible (Bucket)

25..

....

,760..

........

.2-Door Convertible(Bench)

COLOR CODES

A single-letter code designates a solid body color and two letters denote a

two-tone-the first letter, the lower color and the second letter, the upper

color.

M-30-J/

Code M-32-JI* Color Sales Name

.....

...

....................

A,. ,1724.. .Black.. .Onyx

.....

....

..................

8.. ,1638.

.Peacock.. .Peacock

D..

.....

,1625..

...

.Medium Turquoise Metallic.

.

.Silver Turquoise

F..

......

,1622..

...

.Medium Blue Metallic..

.....

.Pacific Blue

.....................

......

....

6..

,1636. .Buff.. .Palomino

......

...

.....................

1..

,1515.. .Red.. .Carnival Red

.....

...

.......

K..

,1621.. .Silver Blue Metallic.. .Anniversary Silver

.....

...

....................

M.. ,1619.. .White.. .Polar White

......

...

...................

R..

,1633.. .Yellow.. .Yellow Mist

...............

......

...

T.. .1631..

.Light Beige.. .Fawn

X..

.....

,1632,.

...

.Maroon Metallic..

...........

.Burgundy

................

......

....

Y.. ,1623. .Light Blue.. .Glacier Blue

......

... .....

2..

,1630.. .Medium Beige Metallic. .Platinum Beige

*"M-32-J" Acrylic Paint Alternate with "M-30-J".

TRIM CODES

A two-digit number indicates the type of trim and trim color.

If, due to unavailability or other difficulties in production, a particular trim

set is not intended for service (minor deviation from intended trim), the

warranty plate code will be followed with a numerical designation-For

example: 52-1, 52-2.

If the trim set is serviced directly, the warranty plate code will bear an

alphabetical suffix-For example: 52-A,

52-8.

Code Trim Schemes

Random Fabric and Crush Vinyl

12..

..........

.Blue..

...................

.Light Blue Metallic

....................

14..

..........

.Beige..

.Light Beige Metallic

16..

..........

.Black..

...........

:.

....

..Black

17..

..........

.Turquoise..

.........

:.

...

.Light Turquoise Metallic

Bright Check Fabric and Crush Vinyl

21..

..........

.Silver Blue.

..............

.Light Silver Blue Metallic

22..

..........

.Blue.

.................

:. .

.Light Blue Metallic

24..

..........

.Beige..

...................

.Light Beige Metallic

26..

..........

.Black..

...................

.Black

27..

..........

.Turquoise..

..............

.Light Turquoise Metallic

Crush Vinyl

(0)

Crinkle

32..

...................................

.Light Blue Metallic

35..

...................................

.Red

36..

...................................

.Black

37.

...................................

..Light Turquoise Metallic

39..

...................................

.Medium Palomino

(0)

Block Stripe Fabric and Crush Vinyl

:

42..

..........

.Blue..

..................

..Light Blue Metallic

44..

..........

.Beige..

.....

:

............

.Light Beige Metallic

46..

..........

.Black..

..................

.Black

DSO AND DISTRICT CODES

Units built on a Domestic Special Order, Foreign Special Order, or other

special orders will have the complete order number in this space. Also to

appear in this space is the two-digit code'number of the District which

ordered the unit. If the unit isa regular production unit, only the District

code number will appear.

Code District Code

,

District

:

...................

11..

......:....

:

....

.Boston 34.. .Detroit

...................

12..

...........

.Philadelphia 41.. .Chicago

13..

..............

.New York 44..

..................

.St. Louis

................

14..

..

.:

.........

.Washington 45.. .Twin Cities

...................

21..

................

.Atlanta 51.. .Denver

................

.................

22.. .Dallas 52.. Los Angeles

..................

.

24..

............

.Jacksonville 53.. .Oakland

...................

25:.

...............

Mem~his 54.. .Seattle

.

.

31.

.................

.Buffalo 81..

............

.Ford of Canada

32..

.............

;.Cincinnati . 84..

.......

.Home Office Reserve

33..

..............

.Cleveland 90-99..

.................

.Export

REAR AXLE RATIO CODES

A number designates a-conventional axle, while a letter designates an EquaLock differential.

Code Ratio

1..

......................................................

.3.00:1

3..

......................................................

.3.20:1

4..

......................................................

.3.25:1

5..

......................................................

.3.50:1

6

........................

.:..

............................

.2.80:1

TRANSMISSION CODES

Crush Vinyl

(0)

Crinkle

Code

..................

.Light Blue Metallic

1

..................

.Red

3

..................

Black

4

..................

.Light Turquoise Metallic

5

-

69..

...................................

.Medium Palomino

(0)

.

Crush Vinyl

(0)

Crinkle

72.

..............................

..Medium and Light Blue Metallic

75..

..............................

.Red

76..

.......................

.I..

...

.Black

..

..............

...........

79..

;

.:

.Medium Palomino

(0)

Crinkle Vinyl

89.

...............................

.Medium Palomino

..

DATE CODES

A number signifying thedate precedes the month code letter. A second-year

code letter will be used

~f

the model exceeds 12 months.

Code Code

First Year Second Year

Month

............

.............................

January.. .A,. N

............

February..

............................

.B.. P

March..

...............................

.C..

............

Q

...........

.........................

April..

.......

:

D.. .R

............

May..

..................................

E.. S

..........

June

.................................

..F.. ..T

...........

July

...................................

.G..

.U

...........

August..

...............................

H..

.V

.............

September..

............................

J.. W

............

October.

...........

..

.................

K..

X

November..

............................

L..

............

Y

December..

.............................

M..

............

Z

Type

.3-Speed Manual

...........

...........

.2-Speed Automatic

...........

.Dual Range 3-Speed Automatic

............

.4-Speed Manual

VEHICLE WARRANTY NUMBER

'

Example (Fig.

lj:

4H

12F 500001

4..

..............................

.I964 Model Year

H..

..............................

.Lorain Pilot Plant Assembly

12..

.............................

.4-Door Sedan

.

F..

..............................

.8;Cylinder, 260 Cubic Inch Disp.

500001..

..........................

First Unit Built

(Consecutive Unit

NO.)

MODEL YEAR CODE

The numeral "4" designates 1964.

ENGINE IDENTIFICATION CODES

Code Engine

U...

...................................

.6-Cylinder 170 Cubic Inch

T..

....................................

.6-Cylinder 200 Cubic Inch

F..

....................................

.8-Cylinder 260 Cubic Inch

K..

....................................

.8-Cylinder 289 Cubic Inch

*4

......

:..

..............................

.6-Cylinder 170 Cubic Inch

*6..

.....................................

.8-Cylinder 260 Cubic Inch

.

*Low Compression!

CONSECUTIVE UNIT. NUMBER

Each model yea!, each assembly ,plant begins production with the number

500001 and

continues

on for each car butlt.

FALCON IDENTIFICATION

DYNASTY

GREEN TURQUOISE CORD FABRIC LIGHT AUTOMATIC

WlMBLEDON WHITE

TURQUOISE

METALLIC CRUSH VINYL

TRANSMISSION

FUTURA DAY OF MONTH

DETROIT 3.50:1

-

- -

1964 MODEL

YEAR

\

\

CONSECUTIVE

UNIT

NUMBER

LORAIN ASSEMBLY PLANT

\

ENGINE 170 CID 6-CYLINDER

BODY SERIAL IDENTIFICATION

N1238-6

FIG.

3-1964

Falcon Warranty Plate

Figure 1 illustrates the 1964 Falcon Warranty Plate. The plate is located on

the rear face of the left front door panel.

MODEL AND BODY STYLE CODES

The official Vehicle Identification Number for title and registration purposes

Serial Body Body

is stamped on the left cowl-to-front-spring pocket strut (Fig. 4). Do not use

Code Code

Type Model

the "Vehicle Warranty Number" which appears on the Warranty plate for

02..

...

.54A..

....

.&Door Sedan

title or registration purposes.

02..

...

.54D..

....

.4-Door Sedan (RPO) Standard

01..

...

.62A..

....

.2-Door Sedan

Sedan

Vehicle ldentification Number

Location

VEHICLE

DATA

Example

(Fig. 3):

(628 DM 27 26H 33 5 3)

628..

.........................

Futura 2-Door Sedan

DM..

........................

.Dynasty Green and Wimbledon White

27..

.........................

.Turquoise Cord Fabric

Light Turquoise Met. Crush Vinyl

26H..

........................

.26th Day August

33..

.........................

.Detroit District

5..

..........................

.3.50:1 Ratio

3..

..........................

.2-Speed Automatic

ASSEMBLY PLANT CODES

Code Assembly Plant

A..

...................................................

.Atlanta

H.

....................................................

Lorain

K

.................................................

.Kansas City

R..

.................................................

.San Jose

S..

................................................

.Pilot Plant

T..

..................................................

Metuchen

01..

...

.62D..

....

.2-Door Sedan (RPO)

16..

...

.54B..

....

.+Door Sedan ((Bench)

19..

...

.62B..

....

.2-Door Sedan (Bench)

17..

...

.63B..

....

.2-Door Hardtop (Bench)

11..

...

.63C..

....

.2-Door Hardtop (RPO Bucket) Futura

13..

...

.63D..

....

.2-Door Hardtop Sprint (RPO Bucket)

15..

...

.76A..

....

.Convertible (Bench)

12..

...

.76B..

....

.Convertible (RPO Bucket)

14..

...

.76D..

....

.Convertible Sprint (RPO Bucket)

21..

...

.59A..

...

.2-Door Wagon

22..

...

.71A..

....

.4-Door Wagon

Station

24..

...

,718..

....

.4-Door Wagon Deluxe Wagons

26..

...

.71C..

....

.4-Door Squire

27..

...

.66A..

....

.2-Door Standard Ranchero

Ranchero

27..

...

,668..

....

.2-Door Deluxe Ranchero

29..

...

.78A..

....

.Standard Sedan Delivery

Sedan

29..

...

.78B..

....

.Deluxe Sedan Delivery

Delivery

COLOR CODES

A single letter code designates a solid body color and two letters denote a

two-tone-the first letter, the lower color and the second letter, the upper

color.

M-30-J/

Code

M-32-J#

Color Sales Name

A,.

.....

,1724..

...

.Black..

....................

.Raven Black

..

D..

.....

,1625.

....

.Medium Turquoise Metallic.. Dynasty Green

.....

F..

......

,1622..

...

.Medium Blue Metallic..

.Guardsman Blue

......

...

......................

G.. ,1636.. .Buff.. .Prairie Tan

1..

......

,1515..

...

.Red..

.......................

.Rangoon Red

........

K..

.....

,1621..

...

.Silver Mink Metallic.

.Silvermore Gray

M..

.....

,1619.

....

.White..

.....................

Wimbledon White

X..

.....

.1632.

.....

.Maroon Metallic..

...........

.Vintage Burgundy

Y..

......

,1623..

...

.Light Blue..

................

.Skylight Blue

.....

2..

......

,1630..

...

.Medium Beige Metallic..

.Chantilly Beige

#"M-32-J" Acrylic Paint Alternate with "M-30-J".

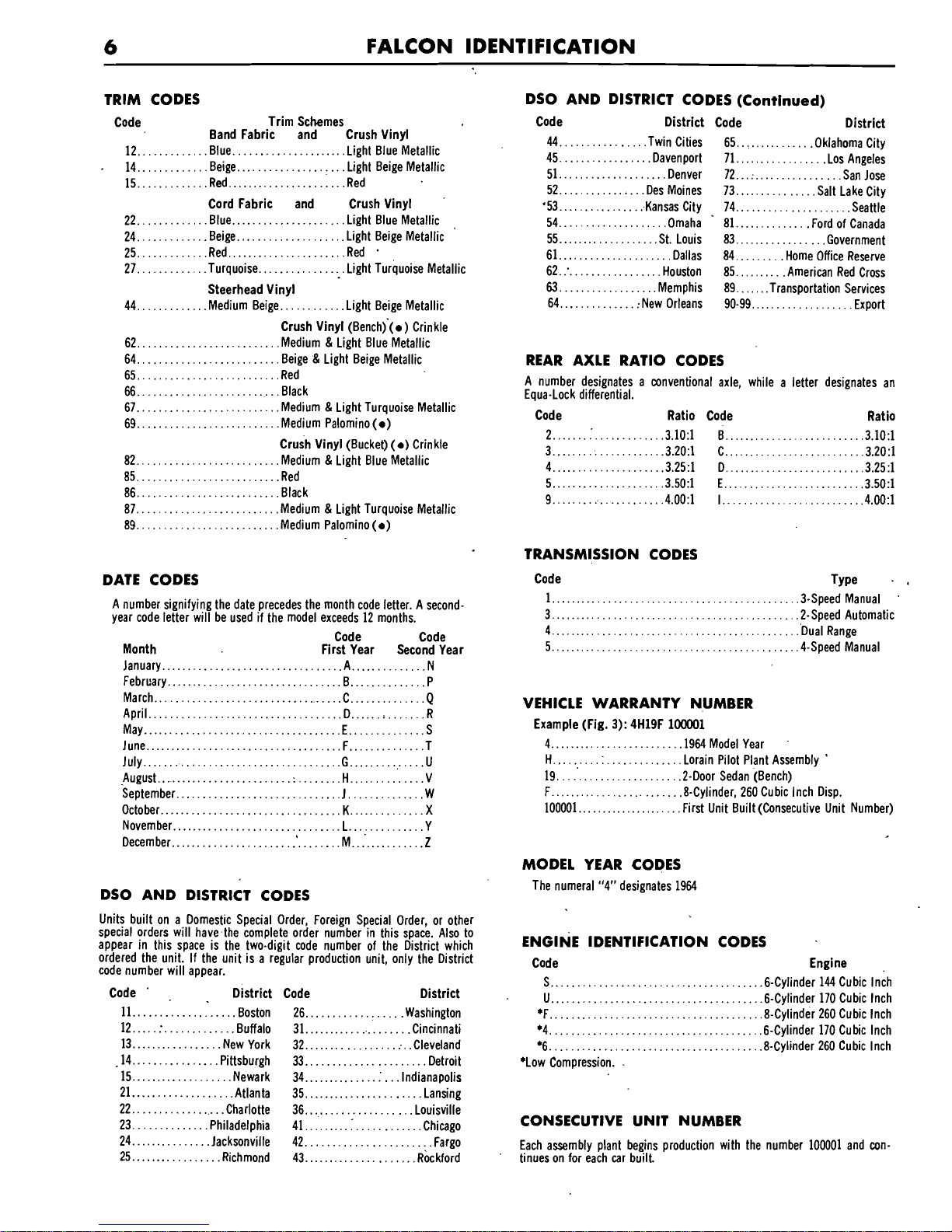

6

FALCON IDENTIFICATION

TRIM CODES

Code Trim Schemes

Band Fabric and Crush Vinyl

12..

.........

..Blue..

..................

.Light Blue Metallic

.

14..

..........

.Beige..

.................

.Light Beige Metallic

15..

..........

.Red..

...................

.Red

Cord Fabric and Crush Vinyl

.

22..

..........

.Blue..

..................

.Light Blue Metallic

.

24..

..........

.Beige..

................

..Light Beige Metallic

.

..........

...................

25.. .Red.. .Red

27..

..........

.Turquoise..

.............

.Light ~urquoise Metallic

Steerhead Vinyl

44..

..........

.Medium Beige..

.........

.Light Beige Metallic

Crush Vinyl

(Bench)'(a) Crinkle

62..

.......................

.Medium & Light Blue Metallic

64..

........................

Beige & Light Beige Metallic

65..

.......................

.Red

66..

.......................

.Black

67..

.......................

.Medium & Light Turquoise Metallic

69..

.......................

.Medium Palomino (a)

Crush Vinyl (Bucket) (a) Crinkle

82..

.......................

.Medium & Light Blue Metallic

85..

.......................

.Red

86..

........................

Black

87..

.......................

.Medium & Light Turquoise Metallic

89..

.......................

.Medium Palomino (a)

DATE CODES

A

number signifying the date precedes the month code letter. A second

year code letter will be used if the model exceeds 12 months.

Code Code

Month First Year Second Year

January..

..............................

.A,.

............

N

February..

.............................

.B..

...........

.P

March..

...............................

.C..

...........

.Q

April..

...............

..

..............

D..

....

;,

......

R

May..

..................................

E..

............

S

June

...................................

.F...

..........

.T

July..

.................................

.G

.............

.U

.......................

........

...........

August..

:

H..

.V

September..

.........................

.J,

.............

W

October..

.............

..

...

..

.........

K..

............

X

November.

..............................

L..

............

Y

December..

..............................

M..

...........

.Z

DSO AND DISTRICT CODES

Units built on a Domestic Special Order, Foreign Special Order, or other

special orders will have-the complete order number in this space. Also to

appear in this space is the two-digit code number of the District which

ordered the unit. If the unit is a regular production unit, only the District

code number will appear.

Code

'

,

District Code District

11..

...............

..Boston

12.

....

:.

...........

.Buffalo

13.

...............

.New York

.............

-14.. .Pittsburgh

15..

................

.Newark

21..

................

.Atlanta

22..

...............

.Charlotte

23..

...........

.Philadelphia

24..

............

.Jacksonville

25..

..............

.Richmond

26..

...............

.Washington

31..

..................

.Cincinnati

32..

...............

:.

.Cleveland

33..

....................

Detroit

34..

.................

Indianapolis

35..

...................

.Lansing

36..

..................

Louisville

41..

.......

:.

..........

.Chicago

42.

......................

Fargo

43..

...................

~ockford

DSO AND DISTRICT CODES (Continued)

Code District Code District

44..

.............

.Twin Cities

65..

:.

..........

.Oklahoma City

45..

..............

.Davenport

71..

...............

Los Angeles

51..

.................

.Denver

72..

.

;.

..............

.San Jose

52..

..............

Des Moines

73..

............

.Salt Lake City

'53..

...............

Kansas City

74..

..................

.Seattle

54..

.................

.Omaha

81..

...........

.Ford of Canada

55..

................

.St. Louis

83..

..............

.Government

61..

..................

.Dallas

84..

......

.Home Office Reserve

62.:.

...............

.Houston

85..

.......

.American Red Cross

63.

................

.Memphis

89..

....

.Transportation Services

64

..............

:New Orleans

90-99.

.................

.Export

REAR AXLE RATIO CODES

A number designates a conventional axle, while a letter designates an

Equa-Lock differential.

Code Ratio Code Ratio

2..

.....

:.

...........

.3.10:1

0..

.......................

.3.10:1

3..

..................

.3.20:1

C..

.......................

.3.20:1

4

....................

.3.25:1

D.

........................

.3.25:1

5..

..................

.3.50:1

E..

.......................

.3.50:1

9..

..................

.4.00:1

1..

.......................

.4.00:1

TRANSMISSION CODES

Code Type

-

.

1..

...........................................

.3-Speed Manual

.

...........................................

3.. .2-Speed Automatic

4..

...........................................

.Dual Range

5..

...........................................

.4-Speed Manual

VEHICLE WARRANTY NUMBER

Example (Fig.

3):

4H19F 100001

4..

......................

.I964 Model Year

H.

.........

:.

.............

Lorain Pilot Plant Assembly

.

19.

.....................

.2-Door Sedan (Bench)

F..

......................

.8-Cylinder, 260 Cubic Inch Disp.

100001

.....................

First Unit Built (Consecutive Unit Number)

MODEL YEAR CODES

The numeral "4" designates 1964

ENGINE

IDENTIFICATION

CODES

Code Engine

.

S..

....................................

.6-Cylinder 144 Cubic Inch

U..

....................................

.6-Cylinder 170 Cubic Inch

*F..

....................................

.8-Cylinder 260 Cubic Inch

*4..

....................................

.6-Cylinder 170 Cubic Inch

....................................

*6.. .8-Cylinder 260 Cubic Inch

*Low Compression.

.

CONSECUTIVE UNIT NUMBER

Each assembly plant begins production with the number 100001 and continues on for each car built.

2

-1

PART 2-1 PAGE PART 2-3 PAGE

GENERAL BRAKE SERVICE

..........

.2-1

SPECIFICATIONS

..............

.2-20

PART 2-2

BRAKE SYSTEM

.................

.2-6

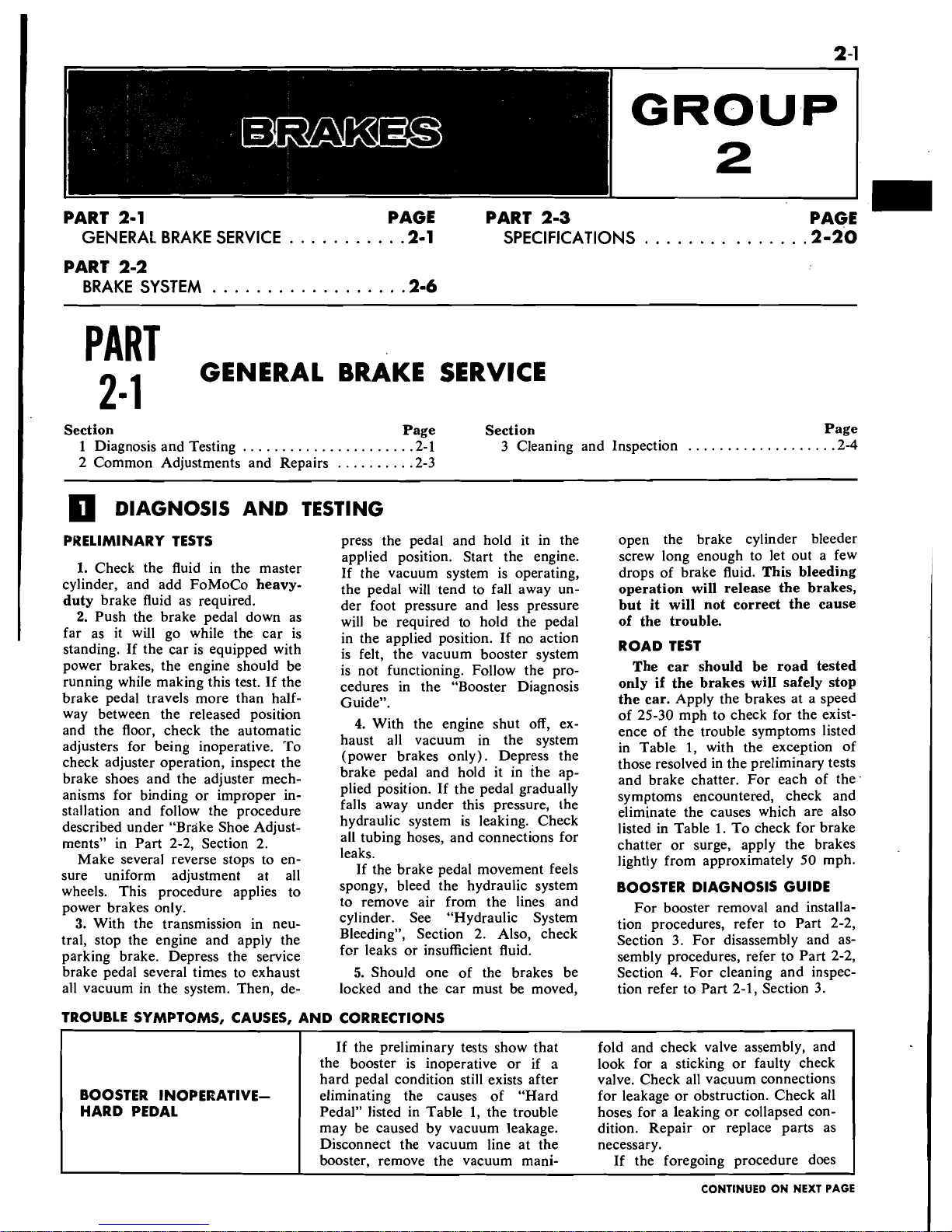

PART

2-1

GENERAL BRAKE SERVICE

Section Page Section Page

..................

1 Diagnosis and Testing

.....................

.2-1

3 Cleaning and Inspection

.2-4

2 Common Adjustments and Repairs

.........

.2-3

DIAGNOSIS AND TESTING

PRELIMINARY TESTS

1.

Check the fluid in the master

cylinder, and add

FoMoCo

heavy-

duty

brake fluid as required.

2.

Push the brake pedal down as

far as it will go while the car is

standing. If the car is equipped with

power brakes, the engine should be

running while making this test. If the

brake pedal travels more than halfway between the released position

and the floor, check the automatic

adjusters for being inoperative. To

check adjuster operation, inspect the

brake shoes and the adjuster mechanisms for binding or improper installation and follow the procedure

described under "Brake Shoe Adjustments" in Part 2-2, Section 2.

Make several reverse stops to ensure uniform adjustment at all

wheels. This procedure applies to

power brakes only.

3.

With the transmission in neutral, stop the engine and apply the

parking brake. Depress the service

brake pedal several times to exhaust

all vacuum in the system. Then, de-

press the pedal and hold it in the

applied

position. Start the engine.

If the vacuum system is operating,

the pedal will tend to fall away under foot pressure and less pressure

will be required to hold the pedal

in the applied position. If no action

is felt, the vacuum booster system

is not functioning. Follow the procedures in the "Booster Diagnosis

Guide".

4.

With the engine shut off, ex-

haust all vacuum in the system

(power brakes only). Depress the

brake pedal and hold it in the applied position. If the pedal gradually

falls away under this pressure, the

hydraulic system is leaking. Check

all tubing hoses, and connections for

leaks.

If the brake pedal movement feels

spongy, bleed the hydraulic system

to remove air from the lines and

cylinder. See "Hydraulic System

Bleeding", Section 2. Also, check

for leaks or insufficient fluid.

5.

Should one of the brakes be

locked and the car must be moved,

TROUBLE SYMPTOMS, CAUSES, AND CORRECTIONS

open the brake cylinder bleeder

screw long enough to let out a few

drops of brake fluid.

This bleeding

operation will release the brakes,

but it will not correct the cause

of the trouble.

ROAD TEST

The car should be road tested

only if the brakes

wilI safely stop

the car.

Apply the brakes at a speed

of 25-30 mph to check for the existence of the trouble symptoms listed

in Table 1, with the exception of

those resolved in the preliminary tests

and brake chatter. For each of the

symptoms encountered, check and

eliminate the causes which are also

listed

in

Table 1. To check for brake

chatter or surge, apply the brakes

lightly from approximately 50 mph.

BOOSTER DIAGNOSIS GUIDE

For booster removal and installation procedures, refer to Part 2-2,

Section 3. For disassembly and assembly procedures, refer to Part 2-2,

Section

4.

For cleaning and inspec-

tion refer to Part 2-1, Section 3.

BOOSTER INOPERATIVEHARD PEDAL

If the preliminary tests show that

the booster is inoperative or if a

hard pedal condition still exists after

eliminating the causes of "Hard

Pedal" listed in Table 1, the trouble

may be caused by vacuum leakage.

Disconnect the vacuum line at the

booster, remove the vacuum mani-

fold and check valve assembly, and

look for a sticking or faulty check

valve. Check all vacuum connections

for leakage or obstruction. Check all

hoses for a leaking or collapsed condition. Repair or replace parts as

necessary.

If the foregoing procedure does

CONTINUED ON NEXT PAGE

2-2

GROUP

SOBRAKES

TROUBLE SYMPTOMS, CAUSES, AND CORRECTIONS (Continued)

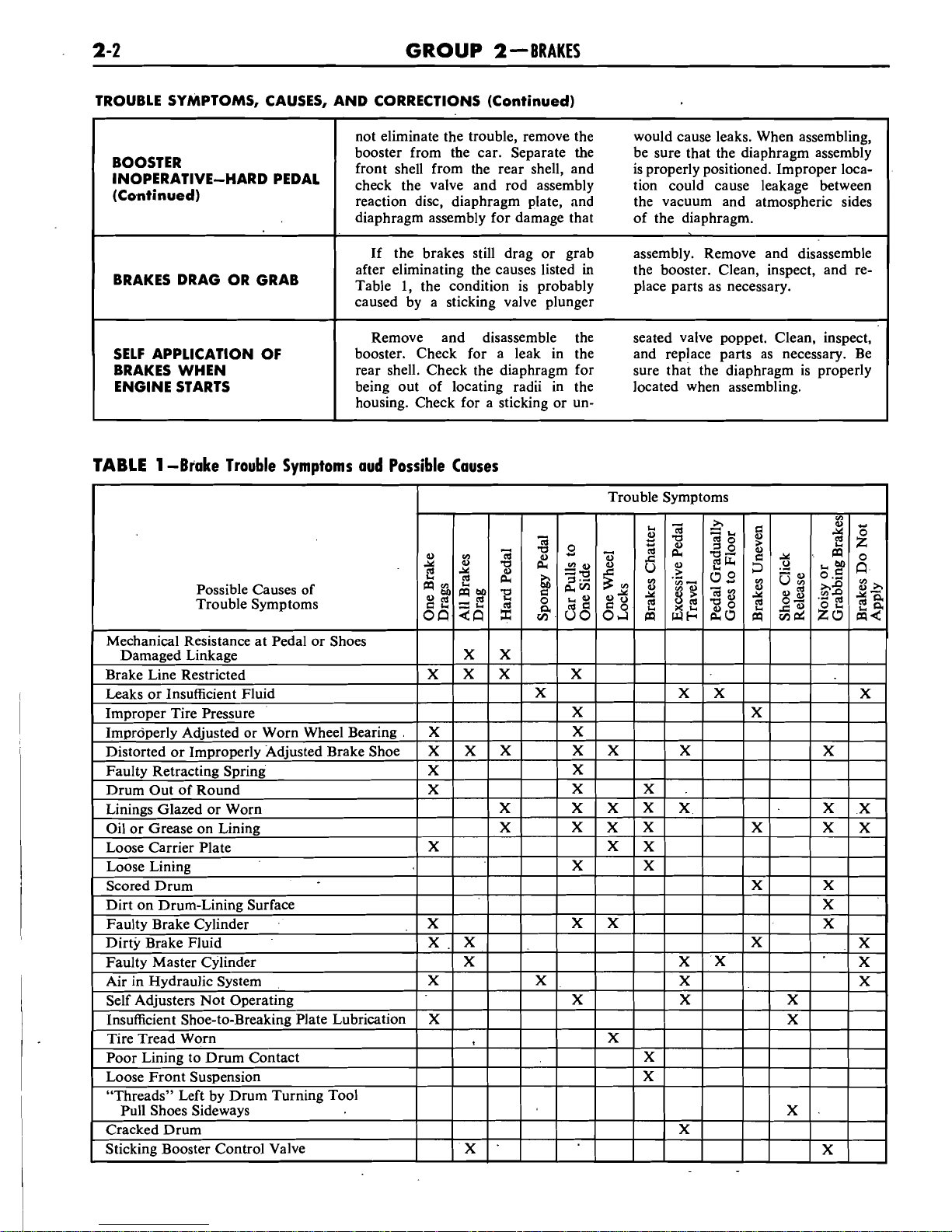

TABLE

1

-Brake Trouble Symptoms aud Possible Causes

BOOSTER

PEDAL

(Continued)

BRAKES DRAG OR GRAB

SELF

APPLICATION OF

BRAKES WHEN

ENGINE STARTS

Trouble Symptoms

-

a

Possible Causes of

Trouble Symptoms

not eliminate the trouble, remove the

would cause leaks. When assembling,

booster from the car. Separate the

be sure that the diaphragm assembly

front shell from the rear shell, and

is properly positioned. Improper locacheck the valve and rod assembly tion could cause leakage between

reaction disc, diaphragm plate,

and the vacuum and atmospheric sides

diaphragm assembly for damage that

of the diaphragm.

If the brakes still drag or grab assembly. Remove and disassemble

after eliminating the causes listed

in

the booster. Clean, inspect, and reTable

1,

the condition is probably place parts as necessary.

caused by a sticking valve plunger

Remove and disassemble the seated valve poppet. Clean, inspect,

booster. Check for a leak in the and replace parts as necessary. Be

rear shell. Check the diaphragm for sure that the diaphragm is properly

being out of locating radii in the located when assembling.

housing. Check for a sticking or

un-

PART

2

-1 - GENERALJBRAKE SERVICE

2

-3

COMMON ADJUSTMENTS AND REPADRS

'FRONT

CABLE

FIG.

1

-Parking Brake Linkage

PARKING BRAKE

and no drag is felt when turning

LINKAGE ADJUSTMENT

the rear wheels.

Check the parking brake cables

MASTER CYLINDER PUSH

when the brakes are fully released.

ROD ADJUSTMENT-

If the cables are loose, adjust them

POWER BRAKES

as follows.

1.

Fully release the parking brake

by turning the handle counterclockwise and pushing it inward.

2.

Pull the parking brake handle

outward one notch from its normal

released position.

3.

Raise the car.

"'4.EF"ifi'

tbi: 16ck''nut 'in ?frolit df

tti&)kqu+lii~~ ('~ig..

1

y:

kGeia1 .turns

f$<+jja<dd:..

'."';?,.

'

'%.?~uni'.the adjustment nut forward against the equalizer until a

moderate drag is felt when turning

the rear wheels.

6.

When the cables are properly

adjusted, tighten the lock nut in the

direction of forward rotation against

the equalizer.

7.

Release the parking brake, and

make sure that the brake shoes re-

turn to the fully released position

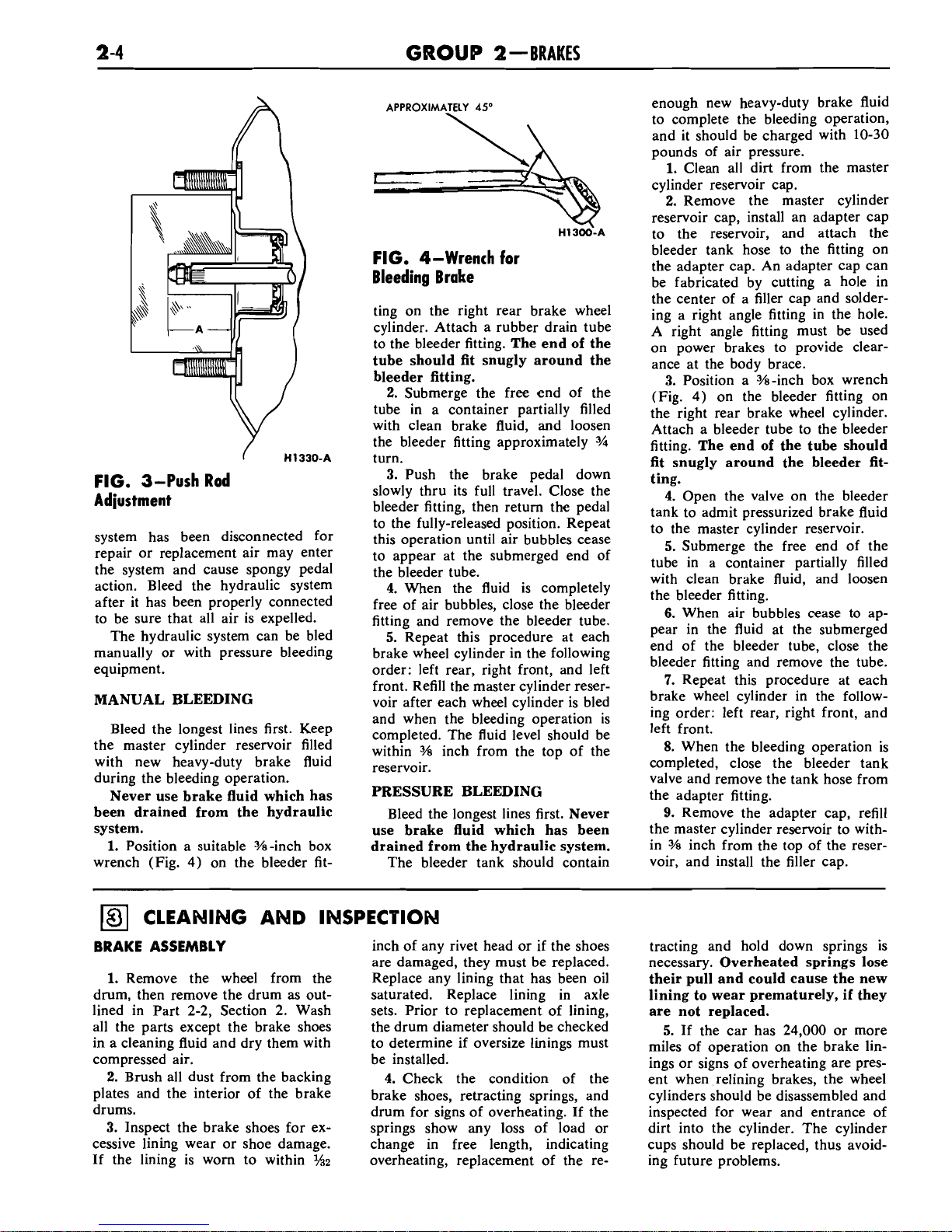

The push rod is provided with an

adjustment screw to maintain the

correct relationship between the

booster control valve plunger and the

master cylinder piston. Failure to

maintain this relationship will prevent

the master cylinder piston from

completely releasing ,hydraulic pressure and can cause the brakes to

drag, or cause excessive brake pedal

travel.

To check the adjustment of the

screw, fabricate a gauge of the di-

mensions shown in Fig.

2.

Then

place the gauge against the. master

cylinder mounting surface of the

booster body as shown in Fig.

3.

The

push rod screw should be adjusted

so that the end of the screw just

touches the inner edge of the slot

in the gauge. Do not set up side

forces on the push rod. Side forces

may break the valve plunger.

This

is

an approximate adjust-

ment only.

The master cylinder pis-

ton should not move more than

0.015

inch as it contacts the push rod. No

movement (exact contact) is ideal.

,

HYDRAULIC SYSTEM BLEEDING.

When any part of the hydraulic

FIG.

2-Push

Rod

Gauge Dimensions

GROUP

2-BRAKES

FIG. 3-Push Rod

Adiustment

system has been disconnected for

repair or replacement air may enter

the system and cause spongy pedal

action. Bleed the hydraulic system

after it has been properly connected

to be sure that all air is expelled.

The hydraulic system can be bled

manually or with pressure bleeding

equipment.

MANUAL BLEEDING

Bleed the longest lines first. Keep

the master cylinder reservoir filled

with new heavy-duty brake fluid

during the bleeding operation.

Never use brake fluid which has

been drained from the hydraulic

system.

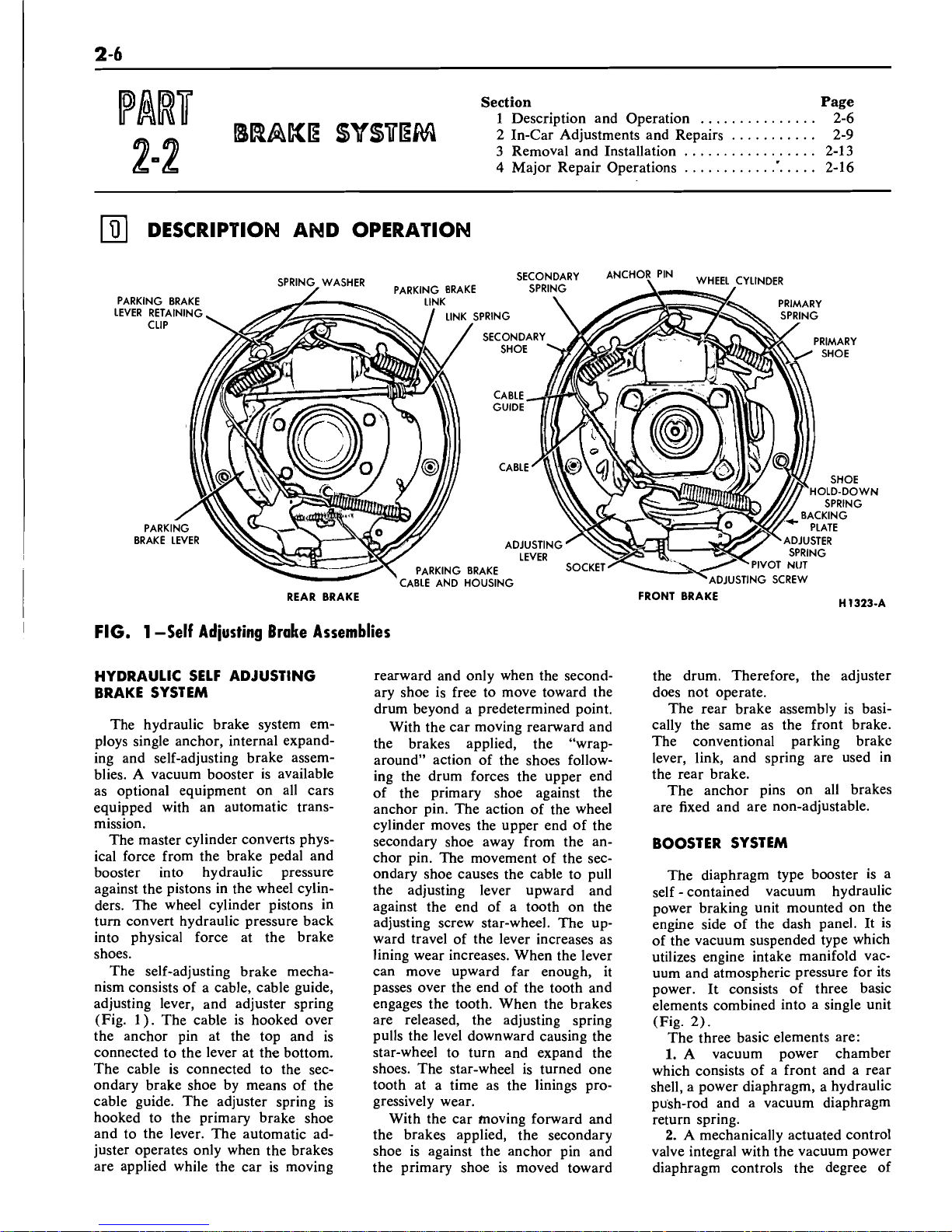

1.

Position a suitable %-inch box

wrench (Fig.

4)

on the bleeder fit-

APPROXIMATELY

45'

\

FIG. 4-Wrench for

Bleeding Brake

ting on the right rear brake wheel

cylinder. Attach a rubber drain tube

to the bleeder fitting.

The end of the

tube should fit snugly around the

bleeder fitting.

2.

Submerge the free end of the

tube in a container partially filled

with clean brake fluid, and loosen

the bleeder fitting approximately

J/4

turn.

3.

Push the brake pedal down

slowly thru its full travel. Close the

bleeder fitting, then return the pedal

to the fully-released position. Repeat

this operation until air bubbles cease

to appear at the submerged end of

the bleeder tube.

4.

When the fluid is completely

free of air bubbles, close the bleeder

fitting and remove the bleeder tube.

5.

Repeat this procedure at each

brake wheel cylinder in the following

order: left rear, right front, and left

front. Refill the master cylinder reser-

voir after each wheel cylinder is bled

and when the bleeding operation is

completed. The fluid level should be

within

%

inch from the top of the

reservoir.

PRESSURE BLEEDING

Bleed the longest lines first.

Never

use brake fluid which has been

drained from the hydraulic system.

The bleeder tank should contain

CLEANING AND INSPECTION

BRAKE ASSEMBLY

1.

Remove the wheel from the

drum, then remove the drum as outlined in Part

2-2,

Section

2.

Wash

all the parts except the brake shoes

in a cleaning fluid and dry them with

compressed air.

2.

Brush all dust from the backing

plates and the interior of the brake

drums.

3.

Inspect the brake shoes for excessive lining wear or shoe damage.

If the lining is worn to within

%z

inch of any rivet head or if the shoes

are damaged, they must be replaced.

Replace any lining that has been oil

saturated. Replace lining in axle

sets. Prior to replacement of lining,

the drum diameter should be checked

to determine if oversize linings must

be installed.

4.

Check the condition of the

brake shoes, retracting springs, and

drum for signs of overheating. If the

springs show any loss of load or

change in free length, indicating

overheating, replacement of the re-

enough new heavy-duty brake fluid

to complete the bleeding operation,

and it should be charged with

10-30

pounds of air pressure.

1.

Clean all dirt from the master

cylinder reservoir cap.

2.

Remove the master cylinder

reservoir cap, install

an

adapter cap

to the reservoir, and attach the

bleeder tank hose to the fitting on

the adapter cap. An adapter cap can

be fabricated by cutting a hole in

the center of a filler cap and soldering a right angle fitting in the hole.

A right angle fitting must be used

on power brakes to provide clearance at the body brace.

3.

Position a %-inch box wrench

(Fig.

4)

on the bleeder fitting on

the right rear brake wheel cylinder.

Attach a bleeder tube to the bleeder

fitting.

The end of the tube should

fit snugly around the bleeder fitting.

4.

Open the valve on the bleeder

tank to admit pressurized brake fluid

to the master cylinder reservoir.

5.

Submerge the free end of the

tube in a container partially filled

with clean brake fluid, and loosen

the bleeder fitting.

6.

When air bubbles cease to appear in the fluid at the submerged

end of the bleeder tube, close the

bleeder fitting and remove the tube.

7.

Repeat this procedure at each

brake wheel cylinder in the follow-

ing order: left rear, right front, and

left front.

8.

When the bleeding operation is

completed, close the bleeder tank

valve and remove the tank hose from

the adapter fitting.

9.

Remove the adapter cap, refill

the master cylinder reservoir to within

%

inch from the top of the reser-

voir, and install the filler cap.

tracting and hold down springs is

necessary.

Overheated springs lose

their pull and could cause the new

lining to wear prematurely, if they

are not replaced.

5.

If the car has

24,000

or more

miles of operation on the brake linings or signs of overheating are present when relining brakes, the wheel

cylinders should be disassembled and

inspected for wear and entrance of

dirt into the cylinder. The cylinder

cups should be replaced, thus avoid-

ing future problems.

PART

2-1

-GENERAL BRAKE SERVICE

2

-5

6.

Inspect all other brake parts

and replace any that are worn or

damaged.

7.

Inspect the brake drums and, if

necessary, refinish them. Refer to

Part

2-2,

Section 4 for refinishing.

BOOSTER UNIT

A disassembled view of the brake

booster is shown in Fig.

5.

MOUNTING

VALVE

AND ROD

After disassembly, immerse all

metal parts

in

a suitable solvent. Use

only alcohol on rubber parts or parts

containing rubber. After the parts

have been thoroughly cleaned and

rinsed

in

cleaning solvent, the metal

parts which come in contact with

hydraulic brake fluid or rubber parts

should be rewashed in clean alcohol

before assembly. Use

an

air hose to

blow dirt and cleaning fluid from the

recesses and internal passages. When

overhauling a power booster, use all

parts furnished in the repair kit.

Discard all old rubber parts.

Inspect all other parts for damage

or excessive wear. Replace damaged

or excessively worn parts. If the in-

side of the booster shells are rusted

or corroded, polish them with steel

wool or fine emery cloth.

SEAL

I

VACUUM

SEAL REAR SHELL

CHECK VALVE

SEAL

PRIMARY

\

CUP

$TON

FIG.

5-Brake Booster and Master Cylinder Disassembled

PART

Section

Page

...............

BRAKE SYSTEM

1

Description and Operation 2-6

2

In-Car Adjustments and Repairs

...........

2-9

.................

2-2

3 Removal and Installation 2-13

4

Major Repair Operations

............'.....

2-16

DESCRIPTION AND OPERATION

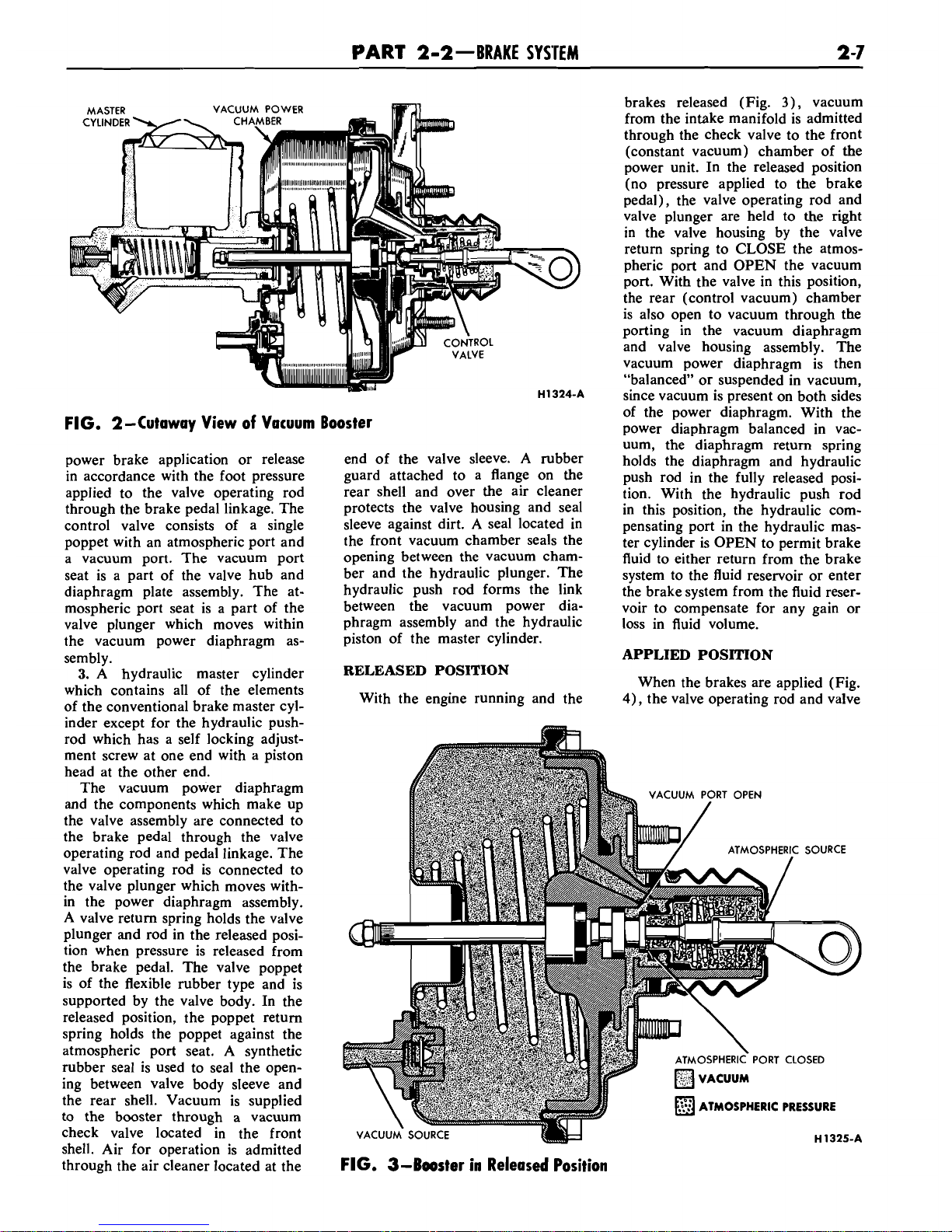

REAR BRAKE FRONT BRAKE

FIG.

1

-Self Adjusting Brake Assemblies

HYDRAULIC SELF ADJUSTING

rearward and only when the second- the drum. Therefore, the adjuster

BRAKE SYSTEM

ary shoe is free to move toward the

does not operate.

The hydraulic brake system employs single anchor, internal expanding and self-adjusting brake assemblies. A vacuum booster is available

as optional equipment on all cars

equipped with an automatic transmission.

The master cylinder converts physical force from the brake pedal and

booster into hydraulic pressure

against the pistons in the wheel cylinders. The wheel cylinder pistons in

turn convert hydraulic pressure back

into physical force at the brake

shoes.

The self-adjusting brake mechanism consists of a cable, cable guide,

adjusting lever, and adjuster spring

(Fig.

1). The cable is hooked over

the anchor pin at the top and is

connected to the lever at the bottom.

The cable is connected to the secondary brake shoe by means of the

cable guide. The adjuster spring is

hooked to the primary brake shoe

and to the lever. The automatic adjuster operates only when the brakes

are applied while the car is moving

drum beyond a predetermined point.

With the car moving rearward and

the brakes applied, the "wraparound" action of the shoes following the drum forces the upper end

of the primary shoe against the

anchor pin. The action of the wheel

cylinder moves the upper end of the

secondary shoe away from the an-

chor pin. The movement of the secondary shoe causes the cable to pull

the adjusting lever upward and

against the end of a tooth on the

adjusting screw star-wheel. The up-

ward travel of the lever increases as

lining wear increases. When the lever

can move upward far enough, it

passes over the end of the tooth and

engages the tooth. When the brakes

are released, the adjusting spring

pulls the level downward causing the

star-wheel to turn and expand the

shoes. The star-wheel is turned one

tooth at a time as the linings progressively wear.

With the car moving forward and

the brakes applied, the secondary

shoe is against the anchor pin and

the primary shoe is moved toward

The rear brake assembly is basi-

cally the same as the front brake.

The conventional parking brake

lever, link, and spring are used in

the rear brake.

The anchor pins on all brakes

are fixed and are non-adjustable.

BOOSTER SYSTEM

The diaphragm type booster is a

self-contained vacuum hydraulic

power braking unit mounted on the

engine side of the dash panel. It is

of the vacuum suspended type which

utilizes engine intake manifold vacuum and atmospheric pressure for its

power. It consists of three basic

elements combined into a single unit

(Fig.

2).

The three basic elements are:

1.

A vacuum power chamber

which consists of a front and a rear

shell, a power diaphragm, a hydraulic

pu'sh-rod and a vacuum diaphragm

return spring.

2.

A

mechanically actuated control

valve integral with the vacuum power

diaphragm controls the degree of

PART

2-2-BRAKE

SYSTEM

2

-7

FIG. 2-Cutaway View of Vacuum

power brake application or release

in accordance with the foot pressure

applied to the valve operating rod

through the brake pedal linkage. The

control valve consists of a single

poppet with an atmospheric port and

a vacuum port. The vacuum port

seat is a

part of the valve hub and

diaphragm plate assembly. The atmospheric port seat is a part of the

valve plunger which moves within

the vacuum power diaphragm assembly.

3.

A hydraulic master cylinder

which contains all of the elements

of the conventional brake master cyl-

inder except for the hydraulic

pushrod which has a self locking adjustment screw at one end with a piston

head at the other end.

The vacuum power diaphragm

and the components which make up

the valve assembly are connected to

the brake pedal through the valve

operating rod and pedal linkage. The

valve operating rod is connected to

the valve plunger which moves within the power diaphragm assembly.

A valve return spring holds the valve

plunger and rod in the released posi-

tion when pressure is released from

the brake pedal. The valve poppet

is of the flexible

rubber type and is

supported by the valve body. In the

released position, the poppet return

spring holds the poppet against the

atmospheric port seat. A synthetic

rubber seal is used to seal the opening between valve body sleeve and

the rear shell. Vacuum is supplied

to the booster through a vacuum

check valve located in the front

shell. Air for operation is admitted

through the air cleaner located at the

Booster

end of the valve sleeve. A rubber

guard attached to a flange on the

rear shell and over the air cleaner

protects the valve housing and seal

sleeve against dirt.

A

seal located in

the front vacuum chamber seals the

opening between the vacuum chamber and the hydraulic plunger. The

hydraulic push rod forms the link

between the vacuum power diaphragm assembly and the hydraulic

piston of the master cylinder.

RELEASED POSITION

With the engine running and the

brakes released (Fig.

3),

vacuum

from the intake manifold is admitted

through the check valve to the front

(constant vacuum) chamber of the

power unit. In the released position

(no pressure applied to the brake

pedal), the valve operating rod and

valve plunger are held to the right

in the valve housing by the valve

return spring to CLOSE the atmos-

pheric port and OPEN the vacuum

port. With the valve in this position,

the rear (control vacuum) chamber

is also open to vacuum through the

porting in the vacuum diaphragm

and valve housing assembly. The

vacuum power diaphragm is then

"balanced" or suspended in vacuum,

since vacuum is present on both sides

of the power diaphragm. With the

power diaphragm balanced in vacuum, the diaphragm return spring

holds the diaphragm and hydraulic

push rod in the fully released position. With the hydraulic push rod

in this position, the hydraulic compensating port in the hydraulic master cylinder is OPEN to permit brake

fluid to either return from the brake

system to the fluid reservoir or enter

the brake system from the fluid reservoir to compensate for any gain or

loss in fluid volume.

APPLIED POSITION

When the brakes are applied (Fig.

4),

the valve operating rod and valve

VACUUM PORT OPEN

/

ATMOSPHERIC SOURCE

I

ATMOSPHERIC

PRESSURE

FIG. 3-Booster in Released Position

GROUP

2-BRAKES

the counter force reacts through the

valve plunger, valve operating rod,

and pedal linkage against the driver's foot. This reaction force is in

direct proportion to the hydraulic

pressure developed within the brake

system.

HOLDING POSITION

'

During brake application, the "reaction" force which opposes the

force applied by the driver, tends to

close the atmospheric port. When

both atmospheric and vacuum ports

are CLOSED, the booster is said to

be

in

the holding position. With both

valves closed, any degree of brake

application attained will be held until either the atmospheric port is

reopened

by an increase , in pedal

C PORT OPEN

pressure to further increase the brake

application or by a decrease in pedal

pressure to

reopen

the vacuum port

PRESSURE

to decrease the brake application.

Whenever the pressure applied to

"1326-A

the brake pedal is held constant for a

moment, the valve returns to its

holding position. However, upon

plunger move to the left in the power

and the valve plunger in proportion

the

position

diaphragm assembly to compress the to their respective contact areas. The the

the

brake

pedal

valve return spring and bring the pressure acting against the valve overmles the reaction force- In this

poppet valve into contact with the plunger and valve operating rod position the valve plunger and at-

vacuum valve seat

in

the valve hous- tends to move the valve plunger

mospheric

seat are

held

ing to "CLOSE the vacuum port. slightly

to

the right in relation to

from the valve Poppet to admit maxi-

Any additional movement of the the diaphragm and valve housing

mum

atmosphere Pressure to the rear

valve operating

iod in the applied di- assembly to close off the atmospheric

(right) chamber. With the

rection moves thevalve plunger away

port. The driver is thus assured a

(left) chamber open to manifold

from the poppet valve to "OPEN"

"feel" of the brake, since part of

vacuum, full power application, is

the atmospheric port and admit

atmosphere through the air cleaner

and passages in the diaphragm

plate to the right side of the power

chamber. With vacuum present on

the left side of the diaphragm and

VACUUM PORT

-

valve housing and atmospheric pressure present on the right side of the

ATMOSPHERIC

SOURCE

diaphragm, a force is developed to

move the vacuum power diaphragm

,

assembly, hydraulic push rod and

hydraulic piston to the left to close

the compensating port and force hydraulic fluid under pressure through

-

the residual check valve and brake

tubes into the brake wheel cylinders.

As hydraulic pressure is developed in

the hydraulic cylinder, a counter

force (to the right) acting through

the hydraulic push rod, sets up a reaction force against the vacuum

power diaphragm and valve plunger

through the rubber reaction disc (located at the end of the hydraulic

push rod). The rubber reaction disc

acts similar to a column of fluid to

distribute the pressure between the

H

1327-~

vacuum power diaphragm assembly

FIG.

5-Booster in Holding Position

Loading...

Loading...