Ford 1963 Galaxie, 1963 Fairlane, 1963 Thunderbird, 1963 Falcon, 1963 Econoline Service Manual

...

www.carburetor-manual.com

Would you like some Free Manuals?

http://carburetor-manual.com/free-shop-manual-club-t-13.html

Also visit http://freeshopmanual.com for more Free Manuals

Also Visit my website for 7 FREE Download Manuals starting

with this one.

"The ABC's of Carburetion"

Click Here Now

file:///C|/Documents%20and%20Settings/Tim/Desktop/carburetor-manual-welcome/index.htm[4/25/2009 11:42:20 AM]

1963

FORD

SERVICE

SPECIFICATIONS

TRUCK

, ECONOLlNE, FALCON

BUS

AND FALCON

CLUB

WAGON

GALAXIE, FAIRLANE,

FALCON AND THUNDERBIRD

SERVICE

DEPARTMENT

FORD

D .

IVISIO

N

Qio..;>

MOTOR

COMPANY

FIRST PRINTING -

SEPTEMBER

1962

@

1962

FORD

MOTOR

COMPANY'

DEARBORN

, MICHIGAN

FOREWORD

This

booklet

conta

ins service specifications for

the 1963 Ford Galaxie,

Fairlane,

Thunderbird,

Falcon,

Econoline, Falcon

Station

Bus, Falcon

Club

Wagon

and

Truck.

The

booklet

is

divided

into

two

main

parts

as

indicated

on

the

title

page.

Part

1 covers

the

Ford

Truck,

Econoline,

Falcon

Station

Bus

and

Falcon

Club

Wagon.

Part

2

cove

"s

the

Ford

Galaxie,

Fairlane,

Thunderbird

and Palcon.

The

specifications contained in this

booklet

were in effect

at

the

time

the

booklet

was

approved

for

printing.

The

Ford

Division

of

Ford

Motor

Company

reserves

the

right

to

discontinue

models

at

any

time,

or

change

specifications 0" design,

without

notice

and

without

incurring

obligat

ion,

Ca

rl

T. Doma"

National Se rvice Manager

FORD DIVISION

I"ord

Motor Company

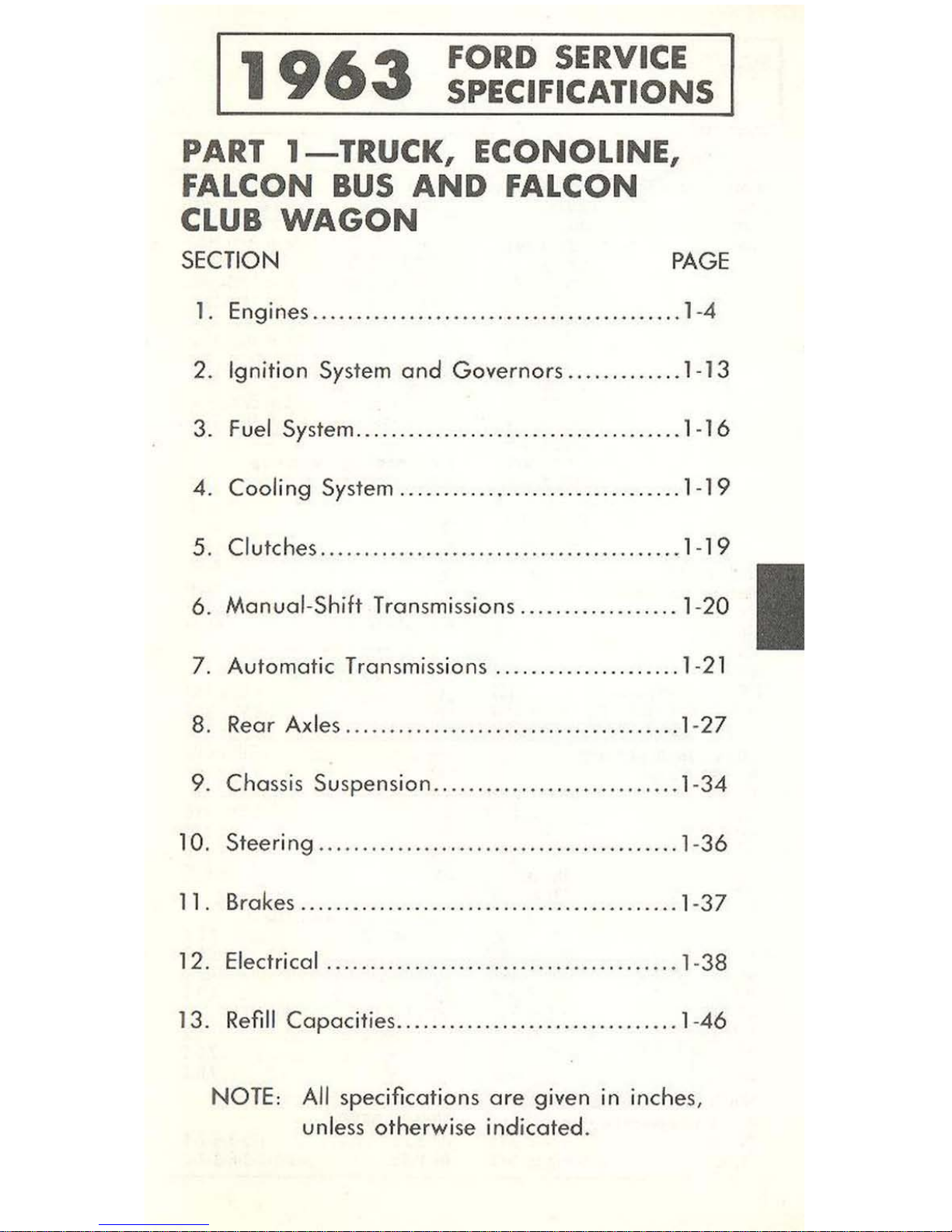

1963

FORD SERVICE

SPECIFICATIONS

PART

l-TRUCK,

ECONOLlNE,

FALCON

BUS

AND

FALCON

CLUB

WAGON

SECTION

PA

GE

1.

Engines ..

................

.......

.........

.....

...

1-4

2.

Ignition Syste m

and

Governors

.............

1-13

3.

Fuel System .

............

...

...

...

.......

........ 1-16

4. Cool ing System

...........

...............

..

....

1-19

5.

Clutches .

...................

..

...................

1·19

6. Manual-Shift Transmissions

....

............

.. 1·20

7. Aut

omat

ic Trans m

iss

ions

.......

.. .

........

... 1-2 1

8. Rear

Ax

les

..................

....

................

1

·27

9. Chassis Suspension

............................

1·34

10. Steer

ing

...........................

....

......... . 1

-36

11

. Brakes .. ....... .. .. ... ..

.......

..............

.... 1·37

12. Electrical ......

.........

...

...

..................

. 1-38

13.

Re

fill

Capac

ities

.............

......

...........

.. 1-46

NOTE:

All

specifica

tions a re given

in

inches.

unless oth

erw

ise indicated.

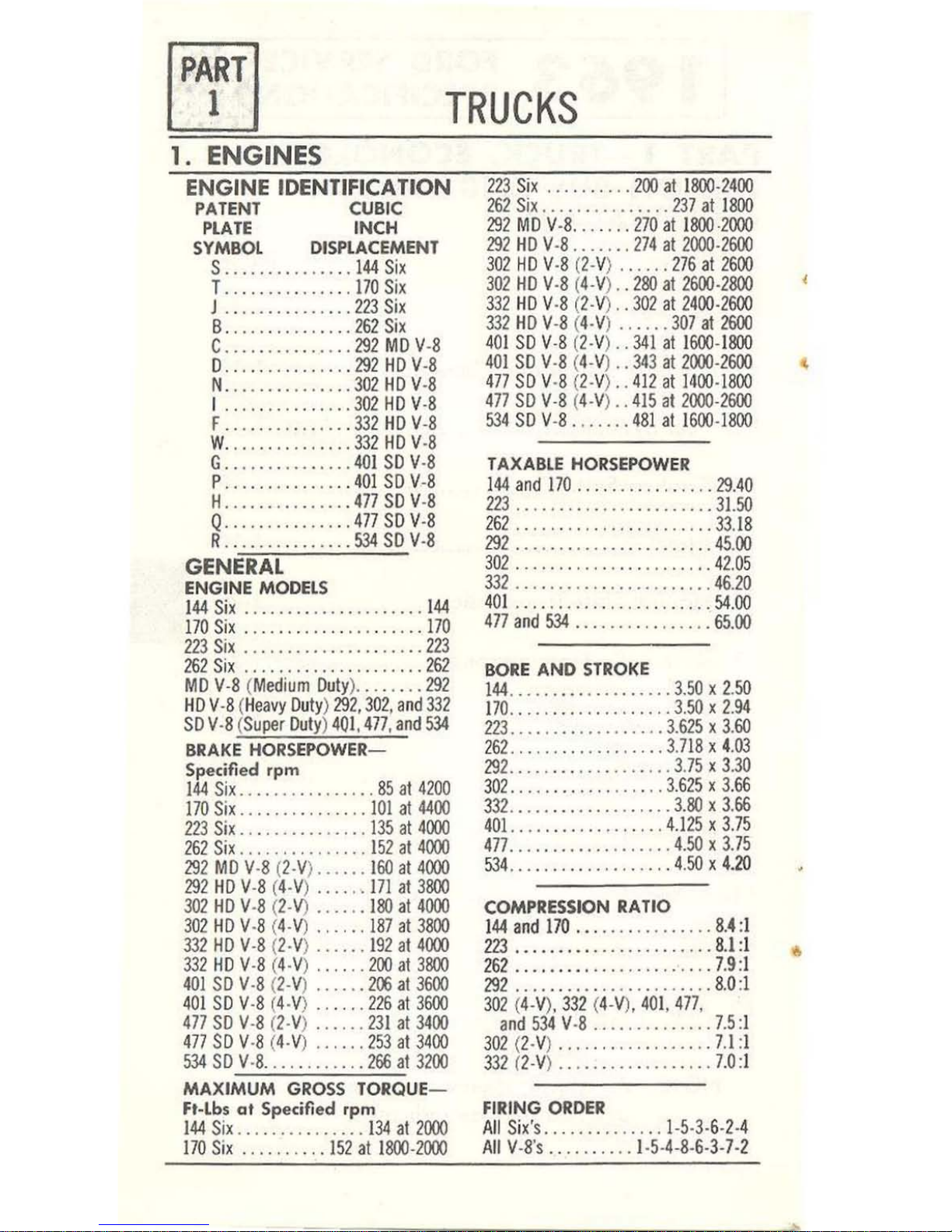

TRUCKS

1.

ENGINES

ENGINE IDENTIFICA

liON

PATENT CUBIC

PL

ATE

INCH

SYMBOL DISPLACEME

NT

S .. .. .. ..

...

.. . .

144

Six

T .....

.......... 170

Six

J ..

...•••.•.....

223

Six

B ..

...

..........

262

Six

C

....

..•..•...

..

292

MD

V-8

D .. ....

.........

292HDV-8

N .

..........

....

302

HDV-8

1 ..•.•

••.

.••

•. •• 30

2HDV-8

F .. ..

........

...

332

HDV-8

W

........

...

....

332

HD V-8

G .

...

...

........ 401 SD V·8

P .

..............

401 SDV-8

H

....

.. ....

...

..

477

SD V

-8

Q

.....

.. ..

....

..

477

SD V-8

R .......

....... .

534

SD

V·8

GENERAL

ENGINE MODELS

1

44

Six

.. ..

.. ..

...........

.. 144

170 Six ....

........

..

.......

170

223

Six

...............

. .....

223

262

Six

.. .. .. ...............

262

MD

V·8 (

Medium Duly) ........

292

HD V -8 (Heavy Duly) 292. 30

2, a

nd

332

SD V-8 (

Super

Dul

y) 401. 4

77. and

534

BRAKE

HORSEPOWER-

Specifi

ed rpm

144

Six

................

85

al

4200

170

Six

.. ..

...........

101

al

4400

223

Six

...............

135

al 4000

262

Six

...............

152 al

4000

29

2 MD V

-8

(2-

V)

......

160

al

4000

292

HD V-8 (

4-V

) .

...

..

171

al

3800

302

HD

V-8 (2

-V)

......

1

80

al

4000

302

HD V-8 (4·

V) ... . . .

187

al

3800

332

HD

V-8 (2·V) ...

... 192

al

4000

332 HD

V-8 (4-V) ..

....

200

al

3800

401

SO

V·8 (2-V) ......

2~

al

3600

401

SD

V-8 (4-V) .... ..

226

al

3600

477

SD

V-8

(2·

V)

...... 231

al 3400

477

SD

V·8 (4-

V) ....

..

253

al 3400

534

SD

V -8 ... ..

.......

266

al 3200

MAXIMUM

GROSS TORQUE-

Ft-lbs at Spe

cifi

ed

rpm

144

Six

...............

1

34

al

2000

1

70

Six ....

...

.. .

152

al

1800-2000

123 Six ..

.....

.. .

200

al 1800-2400

262

Six

...............

237

al 1800

292

MD

V-8 . .. ....

170

al 1800·2000

292

HD V·8

.....

..

274

al

2000-2600

302

HD

V-8

(2-V) ..

.... 276

al

2600

302 HD

V-8 (4-V) ..

280

al

2600-2800

331

HD

V-8 (2-

V)

. .

302

al

2400·2600

332

HD V-8 (

4-V

) _ ..

...

307

al

2600

40

1 SD V-8 (2-V)

..

341

al 1600-1800

401 SO V·8 (4.V)

.. 343

al

2000-2600

477

SD V·8 (2-V) ..

412

al 1400-1800

477

SD

V-8

(4

-V)

..

415

al

2000-2600

534 SO

V-8

....... 481

al 1

600-1800

TAXABLE HORSEPOWER

1

44 and 1

70

............

....

29.40

223

.......................

31.50

262

...

. .. ....

...........

..

33.18

292

.......

..

....

.. _ ....... 45.

00

302

...

....

.......

..

....

...

42.

05

332

.......................

46.20

401 .. . . ..

...............

..

54.00

477

and

534

.. .

....

.....

....

65.00

BORE

AND

STROKE

144

.....

...

........... 3.5

0 x

2.50

1

70

.. . ..

...

.. .

........ 3.50 x 2.94

223 ..................

3.615

x 3.

60

162

..............

.. .. 3.718

x 4

.03

292

...................

3

.75 x 3.30

302 .........

.. .

......

3.625

x 3.

66

332 .....

..............

3.80 x 3.66

40

1.

........ ..

. _ ..

... 4.125 x 3.75

477

...

....

...

.........

4.50 x 3.

75

534

.......

..

.....

..... 4.

50

x

4_20

COMPRESSION RATIO

144 and 170

................

8.4:

1

2

23 ................

" .

.. .. 8.1:

1

262 .....

....

.........

.. . .. 7.

9:1

292 ..........

.............

8.

0:1

301

(4-V).

332

(4-V).

40

1,

477

.

a

nd

534

V·8

.............

. 7.5

:1

302

(2-V) .

...

.. .

...

.. ...... 7.1:1

332

(2-V)

..................

7.0

:1

FIRING

ORDER

All Six·s

............

.. 1-5-3-6-2

-4

All

V-8·s ..

........

1-5-

4-8-6-3

-7-2

,

ENGINES

1-5

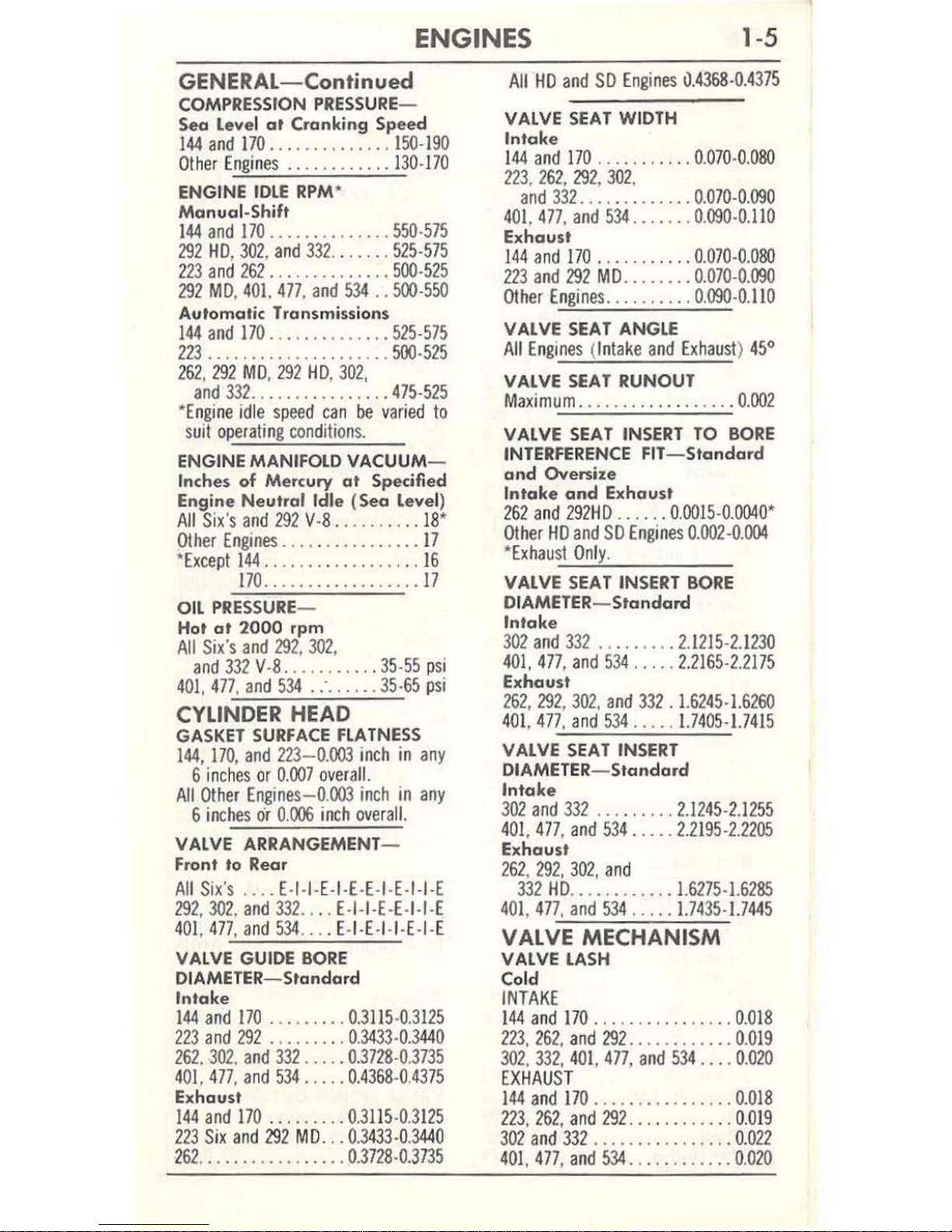

GENERAL-Continued

COMPRESSION

PRESSURE

-

Sea

Level at

Cranking Speed

144

and

170

...

...........

150·190

Other Eng

ines ............

130·170

ENGINE

IDLE

RPM

'

Manual-Shift

144

and

170 ..............

550·575

292 HD,

302, and

332

.......

525·575

223

and

262 ...........

.

..

500·525

292

MD, 401.

477

,

and

534

..

500·550

Automatic Transmission s

144

and

170

..............

525·575

223

.....................

500·525

262,

292

MD, 292

HD,

302,

and

332

................

475·525

""

Engine

idle

speed

can

be

varied

to

suit

operating

conditions.

ENGINE

MANIFOlD

VACUUM

-

Inches of Mercury

at

Specified

Engine Neutral

Idle (Sea

level

)

A

ll

Six's

and

292 V·8 ......

.... 18'

Olher

Engines

................

17

'

Excepl

144

..................

16

170

..................

17

OIL

PRESSURE

-

Hot

at

2000

rpm

All

Six's

and

292,

302

,

and

332 V·8

...........

35·55

psi

401,

477

,

and

534

. c

......

35·65

psi

CYLINDER

HEAD

GASKET

SURFACE

FlATNESS

144, 170,

and

223-0.003

inch

in

any

6

inches

or

0.007

ove

ral

l.

All

Other Engines

-O.OO3

inch

in

any

6 inches

or

0.006

inch

overall.

VALVE ARRANGEMENT-

Front to Rear

All

Six's

....

E·I·I·E·I·E·E·I·E·

I·I

·E

292,302, and

332 .... E·I·

I·E

·E·I·I·E

401.

477

,

and

534 ....

E·I

·E·

I·I·E·

I·E

VALVE GUIDE

BORE

DIAMETER- Standard

Intake

144

and 170

.........

0.3115·0.3125

223

and

292 .......

..

0.3433·0.3440

262,

302, and

332 .....

0.3728·0.3735

401,

477,

and

534

.... .

0.4368·0.4375

Exhaust

144

and

170

.. . , .

.... 0.3115·0.3125

223

Six

and

292

MD

. ..

0.3433·0.3440

262

.................

0.3728·0.3735

All

HD

and

SO

Engines

0.4368·0.4375

VALVE

SEAT

WIDTH

Intake

144

and

170

.......

.... 0,070·0.0BO

223, 262,

292, 302.

and

332

....

....

.....

0.070·0.090

401,477, and

534

.....

.. 0.

090·0.110

Exhaust

144

and

170

. .......

...

0.070·0.0BO

223

and

292

MD

........

0.070·0.090

Other

Engines

.......... 0.090·0.110

VALVE

SEAT

ANGLE

All

Engines (In

lake

and

Exhausl

) 45·

VALVE

SEAT

RUNOUT

Maxi

mum ........

......

.... 0.002

VALVE

SEAT

INSERT

TO

BORE

INTERFERENCE

FIT-S

tanda

,d

and Oversize

Intake

and

Exhaust

262

and

292

HD .

.....

0.0015

·0.004

0'

Other

HD

and

SO

Engines

0.002·0.004

'

Exhaus"'I..:O"nl"-y.

____

_

VALVE

SEAT

INSERT

BORE

DIAMETER-

Standam

Intake

302

and

332

.. .

......

2.1215·2.1230

401,

477,

and

534

.....

2.2165·2.2175

Exhaust

262,

292,

302,

and

332 . 1.6245·1.6260

401,477,

and

534

.....

1.7405·1.7415

VALVE

SEAT

INSERT

DIAMETER- Standard

Intake

302

and

332

...... , ..

2.1245·2.1255

401,477, and

534

.....

2.2195·2.2205

Exhaust

262, 292,

302,

and

332

HD

..........

, .

1.6275·1.6285

401,

477

, a

nd

534

.....

1.74

35·

1.7445

VALVE MECHANISM

VALVE

LASH

Cold

INTAKE

144

and

170

.......

, .. .

...

..

O.oI8

223,

262,

and

292

............

O.oI9

302,

332,

401,

477, and

534

.... 0.020

EXHAUST

144

and

170

................

0.018

223,

262,

and

292

............

0.019

302 and

332

.........

.......

0.022

401,477,

and

534

............ 0.020

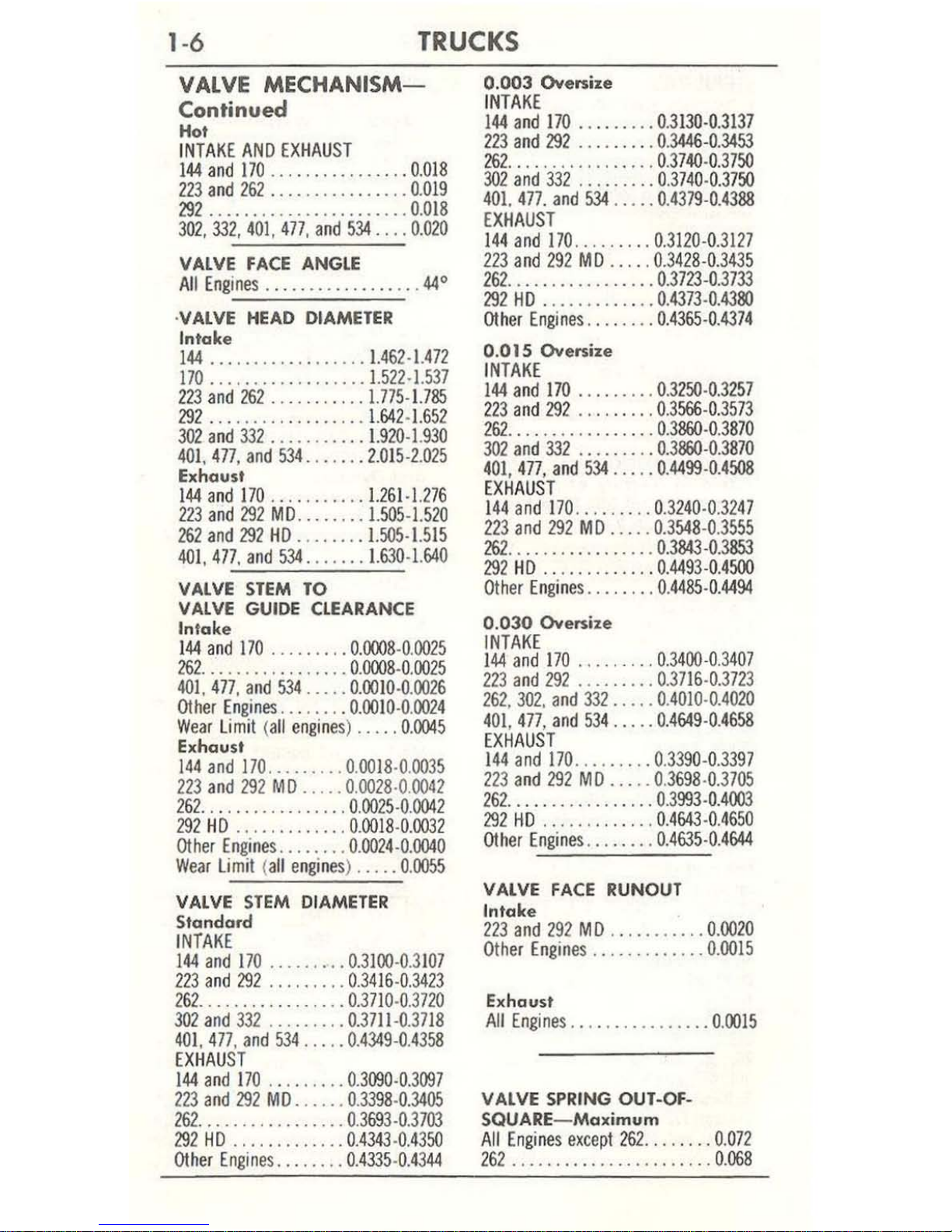

1-6

TRUCKS

VALVE

MECHANISM-

Continued

HoI

I

NTAKE

AND

EXHAUST

144

and

170

................ 0.018

223 and

262 ............

. _ . _ 0.

019

292

____ . ______

....... _ .... 0.018

302.332.401.477. and

534

.. _.0_

020

VALVE

FACE

ANGLE

All

Engines

. _.

_.

__

. _

....

__

. _ . 44'

·VALVE HEAD DIAMETER

Intake

144

...

_. _. _. _ ....... _ 1.462-1.472

170

_. _ ..

___

... _

.... _.1.522-1.5

37

223

and

262

_.

_. _ ..... .

1.775-1.785

292

...

......

.. _. _

....

1.642-1.652

302

and 332

_____

. _ ....

1.920-1.930

401.477. and

534

_ ..

...

. 2.015-2.

025

Exhaust

144

and

170

___ ..

____

..

1.261-1.276

223

and

292

MD

.....

___

1.505-1.520

262

and

292

HD _.

_. _ ... 1.505-1.515

401

.

477

.

and

534 .... _ ..

1.630-1.640

VALVE

STEM

TO

VALVE GUIDE CLEARANCE

Intake

144

and

170

___

. _ ....

0_0008

-0.

0025

262

__

.. _ ....

_ . _ . _

.. _ 0_0008

-0.

0025

401.

477

. and

534

. _

...

0.0010-0.0026

Other Engines

. __ .

__

. _

0.0010

-0.

0024

Wear

Limi

t (

all

engines) ..... 0.0045

Exhaust

144

and

170. _. _ ..... 0.0018

-0.0035

223 and

292

MD

_ ..

_.0.0028-0.0042

262

___ .

__ __ . __

..

_ . _ .0.

0025

-0.

0042

292

HD _

....

...

_ .

___

0_0018

-0_

0032

Other Engines

________ 0_0024-0_0040

Wear

l i

mit (all engines

) __

___ 0_0055

VALVE

STEM DIAMETER

Standard

INTAK

E

144

and

170

____

.....

0.3100-0.3

107

223

and

292 .........

0.34

16-0_

3423

262

..

____ . _.

__

. _ .

__ .0.3

710-0.3

720

302

and

332

__ ......

_ 0.3711-0.3

718

401.477. and

534

... _.0.4349

-0.

4358

EXHAUST

144

and

170 .........

0.3tBO-0.3tB7

2

23

and 292

MD

_ .

___

. 0

.3398-

0.3405

161_ ...............

_

0.3693-0.3703

291

HD _ ........

__

..

0.4343

-0.

4350

Other

Engine

s.

_ .

.....

0.4335

-0.

4344

0.003

Oversize

INTAKE

144 and 170

... _ . _ .. _

0.3130-0.3137

123

and

291

_ .. ___ . _ .0.

3446-0.3453

262

. _ ..

..

_ . _ . _ .

..

__ .0.3740-0.3750

302

and

332

...

.. _

...

0.3740-0.3750

401. 477.

and

534

. _ • _ .

0.4379-0_4388

EXHAUST

144

and

170

. _ ... _ ...

0.3120-0.3127

223

and

292

MD

... __

0.3428-0.3435

262.

____

__ . ____

... _

.0.3723-0.3733

292

HD

. _

.....

__ . _

..

0.4373-0_4380

Other

Engines

. _____

..

0.4365-0_4374

0.

015

Oversize

IN

TAK

E

144

and

170 ... ___ . _.

0.3250-0.3257

223 and

291 ___ ..

____ 0.3566-0.3573

262

____ . _

__

...

. _ . _ ..

0.3860-0.3870

302

and

332

. _ . _ .. _ . _

0.3860-0.3870

401,

477,

and

534

. _ .. _

0_4499-0.4508

EXHAUST

1

44

and

170

.... _. _ ..

0.3240-0.3147

113

and

292

MD.

_ .

.. 0.3

548-0.3555

262

__

. _ . _

__

.....

....

0.3843-0.3853

291

HD

. __ .... ______

0_4493-0_4500

Other Eng

ines ___

. _ . _ . 0_

4485-0.4494

0.030 Oversize

INTAKE

144

and 170

____

. _

...

0.3400-0.3407

2

23

and

292

.......

__

0.3716-0.3723

262. 302.

and 332

_ . _ . _ 0_

4010

-0.

4020

401, 477, and

534

. _ .

__

0.4649-0_4658

EXHAUST

1

44

and

170

........ _ 0.3390-0.3397

223

and

292

MD

. _

.. _ 0.3698-0.3

705

262

_ . _ .. _ .

__

. _ . ___ .. 0.

3993-0.4003

292

HD

. _.

__ ..... ...

0.4643-0.4650

Other Engines

. _ .

__

. _ .

0.4635-0.4644

VALVE

FACE

RUNOUT

Intake

223

and

292

MD

. _ ..

__ .... _

0.0010

Othe

r En

gines ______

. _

..... 0_0015

Ex

haust

All

Engines

__

. _ . _ .

___

.....

_ 0.

0015

VALVE SPRING OUT -OF-

SQUARE-Maximum

All

Engines

except

262 ........ 0.072

262

_ . _

...

..

___

. __

...

..... _ 0.

068

ENGINES

1-7

VALVE

MECHANISM-

Continued

VALVE

SPRING

FREE

LENGTH-

Approximate

144

aad

170

...... ' ........

..

2.00

262

........................

1.96

401,477,

and

534

......

....

...

2.07

Other

Engines

......

...

......

2.00

VALVE

SPRING

PRESSURE-

Pounds at Specified Length

Valve

Closed

144

and

170

....

47.75·56.25

at

1.585

Wear

Lim

it

43

at

1.585

262

....

.............

71·79

at

1.65

Wear

Limit

64

at

1.65

401, 477,

and

534 .....

84·89

at

1.70

Wear

Limit

76

at

1.70

Other

Engines

......

..

71

·79

at

1.78

Wear

Dmit

64

at

1.78

Valve Open

144

and

170

.......

112·122

at

1.222

Wear

Limit

101

at

1.222

262

..............

161·177

at

1.260

Wear

Limit

145

at

1.260

401,477,

and

534

....

178·192

at

1.28

Wear

Limit

161

at

1.28

Other

Engines

......

161·177

at

1.39

Wear

Limit

145

at

1.39

VALVE

SPRING

ASSEMBLED

HEIGHT

-Pad

to Retainer

144

and

170

....... 1·9/16

- 1·39/

64

262

.. ..

...........

1·5/

8-1·11/16

401,477,

and

534

.. 1·11

/16-1.23/

32

Other

Engines

......

1·3

/4-

1·25/32

VALVE

PUSH

ROD

RUNOUT-

Maximum

All

Engines

.................

0.

025

ROCKER

ARM

SHAFT

0.0.

144, 170,

223, 262,

292. 302

,

and

332 .......

..

....

0.780·0.781

Other

Engines

........

..

0.781·0.782

VALVE

TAPPET

DIAMETER-

Standard

223.

.... . .

.......... 0.4983·0.4989

292

and

262

......... 0.4989·0.4995

144,170,302,332,401.

477

and

534

...

......

.. 0.

8740·0.8745

VALVE

TAPPET

TO

TAPPET

BORE

CLEARANCE

223.

. .

...

...........

0.

0011·0

.0027

Wear

Limit 0.0055

262

and

292

......

. .. 0.

0005·0.0021

Wear

Li

mit

0.0055

Other

Engines ....

....

0.0005·0.0020

Wear

Limit

0

.005

ROCKER

ARM

TO

ROCKER

SHAFT

CLEARANCE

144

and

170

.......... 0.002·0.0045

Wear

Limit

0.006

223,

262,

and

292

...

. ..

0.002

·0.004

Wear

Limit

0.007

302

and

332

....... ' ...

0.002

·0.

004

Wear

Limit

0.008

401.

477

,

and

534

.....

.. 0.

001·0.003

Wear

Limit

0.007

ROCKER

SHAFT

BORE

DIAMETER

All

Engines

............

0.783·0.784

CAMSHAFT,

TIMING

CHAIN,

AND

TIMING

GEARS

CAMSHAFT

END

PLAY

All

Engines

............

0.

001

·0.

007

Wear

Limi

t 0.

012

CAMSHAFT

JOURNAL

TO

BEARING

CLEARANCE

All

Engines

.......

....

. 0.

001

·0.

003

Wear

Limit

0.006

CAMSHAFT

JOURNAL

RUNOUT

All

Engines

.................

0.005

CAMSHAFT

JOURNAL

OUT

·Of·ROUND

144, 170,262,302,332,

401,477

and

534

.................

0.0005

223

and

292

................

0.001

CAMSHAFT

LOBE

liFT

Intake

144

and

170

...............

0.

2405

223

and

262

................

0.

273

292 ...

............

........

0.264

302

and

332

................

0.244

401,477

.

and

534

............

0.278

1-8

TRUC

KS

CAMSHAFT,

TIMING

CHAIN,

AND

TIMING

GEARS

-

Continued

Exhau.st

144 and 170

...............

0.2395

223

and

262

................

0.

273

292

.......................

0.

262

302 and

332

................

0.

265

40

1.

477

.

and 534 ............

0.

278

LOBE

LIFT

lOSS- Maximum

Intake

and Exhaust

..........

0.005

CAMSHAFT GEAR

TO

CRANKSHAFT GEAR BACKLASH

26

2.

302.

332. 401.

477

.

a

nd

534

.............

0.

002

·0.

004

ASSEMBLED

SPROCKET

OR

GEAR F

ACE

RUNOUT

1

44.

170.

223. 262. and

292

.... 0.006

O

ther Engin

es ....

...........

0.

001

TIMING CHAtN DEFLECTION

1

44.

170.223.

and

292

..........

0.5

CAMSHAFT JOURNAL

DIAMETER- Standard

1

44 and

170

.........

1.8095·1.8105

223.

262. and

292

....

1.9255·1.9265

302

and

332

.........

2.1238·2.1248'

401.

477

.

and

534

......

2.370·2.3

71'

Front Journal

302

and

332

.........

2.4738

·2.

4748

40

1.

477.

and

534

....... 2.474·2.475

-Nos. 2.

3.

4.

and 5 journals

only

.

CAMSHAFT

BEARINGS

INSIDE DIAMETER-

ASSEMBLED

144

and 1

70

..........

1.8115· 1.81

25

223.262

. and

292

.....

1.9275·1.9285

302

and

332

..........

2.

126

·2.

127'

40

1.

477.

and

534

......

2.372·2.373'

-Nos. 2.

3.

4.

and 5 bearings onl

y-

No

. 1

bearing 2.476

·2.

477

LOCATION

IN

RElATiON

TO

FRONT

FACE

OF

BLOCK

CAM

BEARING

BORE

- No. 1 Bearing

Only

1

44 and 170

...........

0.

115·0.125

223.262.292.302.

and

3320.

005

·0.

020

4

01.

477

. a

nd

534

.......

0.3

10·

0.330

FLYWHEEL

ASSEMBLED

FLYWHEEl CLUTCH

F

ACE

RUNOUT

All Engm

es

.................

0.010

ASSEMBLED

FLYWHEEl

O.

D. RUNOUT

144.

223. 262.

and

292

........

0.007

Ot

her

Engm

es ...............

0.006

CRANKSHAFT

MAIN

BEARING JOURNAL

DIAMETER- Standard

144 and 170

...

......

2.2482·2.

2490

223

and

292

......... 2.4980·2.4988

2

62

..............

... 2.4976

·2.

4984

302 and

332

......

..

2.6230·2.

6238

401.

477

.

and

534

..... 3.1246·3.1254

CON NECTING ROD JOURNAL

DIAMETER ,

1

44

and

170

.........

2.1232·2.1240

223

and

262

.........

2.2980

·2.

2988

292

..........

.......

2.1

880·2.1888

302

and

332

......... 2.2482 ·2.2490

401.

477

.

and

534

.....

2.7092·2.7100

MAIN

BEARING JOURNAL

RUNOUT

144and 170

..

0.0025·Wear Lim

it 0.0035

223

and

262

..

O.OO3·Wear

Lim

it

0.004

292

.. .

......

0.002·Wear

Limit

0.003

Olher

Engine

s 0.

002·Wear Limit

0.003

CONNECTING

ROD

AND

MAIN

BEARING JOURNALS

OUT-OF-ROUND

All

Engines

................

0.0004

CONNECTING

ROD

AND

MAIN

BEARING JOURNALS

TAPER

All

Engines

................

0.

0003

THRUST

BEARING JOURNAL

LENGTH

144

and

170

............

1.275· 1.277

223

and

262

...........

1.359·1.361

292.302.

and

332

.......

1.1

24·

1.126

401.

477. and

534

.......

1.279·1.281

MAIN

BEARING

JOURNAL

THRUST

FACE

RUNOUT

A

ll

Engi

nes

.................

0.

001

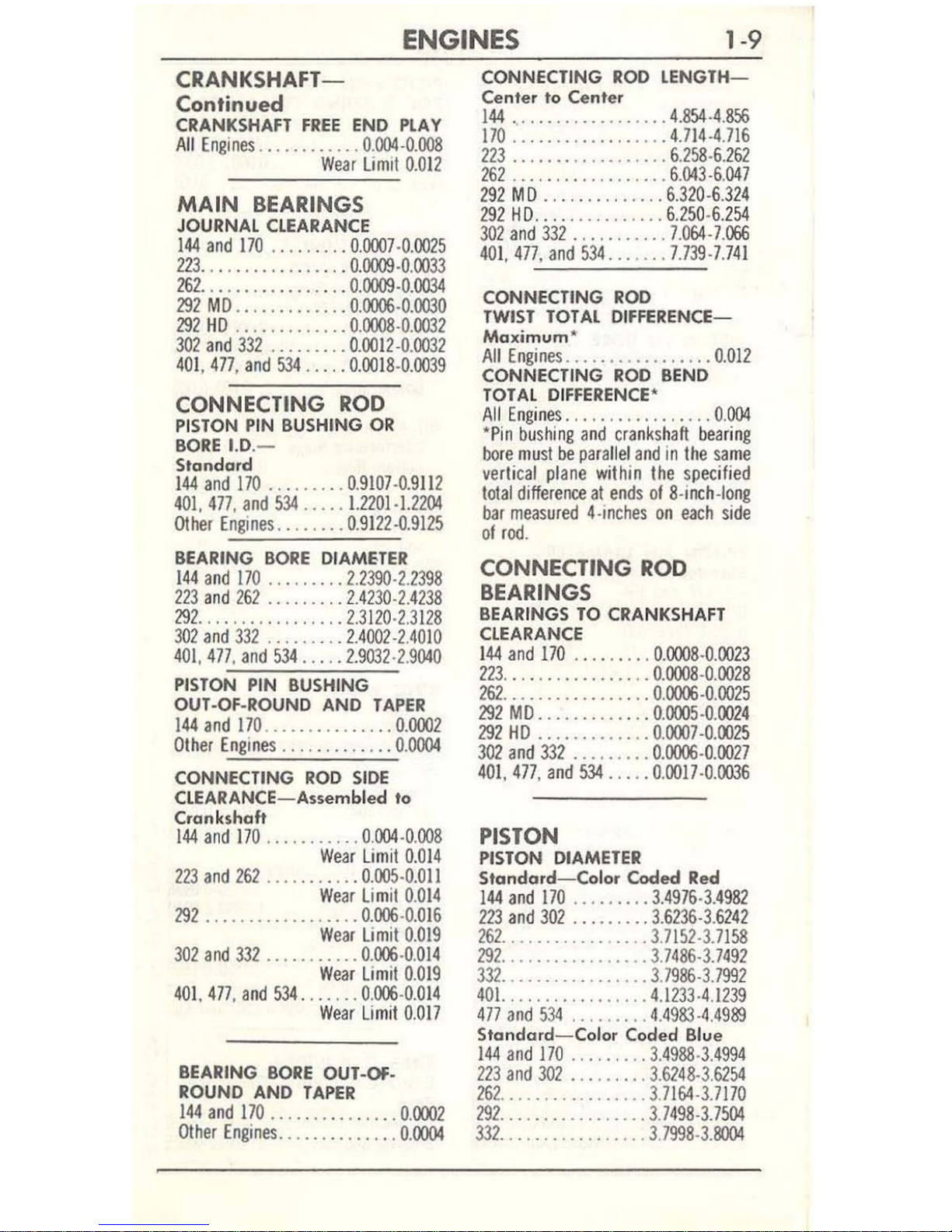

ENGINES

1-9

CRANKSHAFT-

Continued

CRANKSHAFT

FREE

END

PLAY

All

Engines ............

0.

004

-0.

008

Wear

Limil 0.011

MAIN

BEARINGS

JOURNAL CLEARANCE

144

and

170

.. ... .. .. 0.

0007·0.0015

113 .........

. . .... .. 0.

0009

·0.0033

161

.......

...

....

... 0.

0009·0.0034

191

MO ............

. 0.

0006·0.0030

191

HO

............

. 0.

0008

·0.

003

1

301 and 331

........

. 0.

0011

·0.0031

401, 477, and

534 .....

0.00

18·0.

0039

CONNECTING

ROD

PISTON PIN BUSHING

OR

BORE

1.0

.-

Standard

1

44

and

170

......... 0.9107·0.9111

401,477, and

534

.....

1.1101·1.1104

Oth

er

Engin

es

........ 0.9111

·0.

9115

BEARING BO

RE

DIAMHER

144

and 170

.......

..

1.1390·1.1

398

113

and

162

....

...

.. 1.4130·1.4138

191

..............

... 1.3110·

1.3

118

3

01

and 331 ..

....

. ..

1.4001·1.4010

401.

477. and

534 ... .. 1.9

031·2.9

040

PISTON PIN BUSHING

OUT-Of

-ROUND AND

TAPER

144

and

170

.............

.. 0.

0001

Olher

Engines ............

. 0.

0004

CONNECTING

ROO

SIDE

CLEARANCE-Assembled

to

Crankshaft

144

and

170

........... 0.004

·0.008

Wear Lim

il

0.014

113 and 161

..........

. 0.005·0.011

Wear Limil 0.014

191

..................

0.

006

·0.016

Wear

Lim

il 0.

019

3

01

and

331

........... 0.006

·0.

014

Wear

Limil 0.019

401.

477. and

534

. ..

.... 0.006

·0.014

Wear Limil

0.017

BEARING

BORE

OU

T-Of-

ROUND AND

TAPER

144

and

170

...............

0.

000

1

Other

Engines

.............. 0.0004

CONNECTING

ROO

LENGTH-

Center

to C

enter

144

'.'

................

4.854

·4.

856

170

..................

4.714·4.7

16

1

13

..................

6.158·6.161

161

.................. 6.043·6.

047

191

MO .............. 6.310·6.314

291

H O

....

...........

6.150·6.154

301

and

332

........... 7.064

·7.

066

401.

477

,

and

534

.......

7.739·7.741

CONNECTING

ROO

TWIST TOTAL DIFFERENCE-

Max

imum

*

All

Engines .................

0.012

CONNECTING

ROO

BEND

TOTAL

DIFFERENCE

'

All

Engines

. . .

..............

0.004

"

Pin

bushing

and

crankshaft

bearing

bore

must

be pa

rallel

and

in

the

same

vertical

plane

within

the

specified

lolal

difference

al

ends of 8·inch.10ng

bar

measured 4·inches

on

each

side

of

rod

.

CONNECTING

ROD

BEARINGS

BEARINGS

TO

CRANKSHAFT

CLEARANCE

144

and

170

.... . . ...

0.0008

·0.

0013

11

3 . . . ....

.......... 0.0008

·0.

0028

161

.................

0.

0006

·0.0025

192

MO

.............

0.

0005

·0.

0024

191

HO

.............

0.

0007·0.0025

301

and

331 ......... 0.0006·0.0027

401.

477. and

534

..... 0.0017

·0.

0036

PISTON

PISTON DIAMETER

Standard- Color Coded

Red

144

and

170

.........

3.4976

·3.

4981

113

and

301

......... 3.6136

·3.

6141

162

............

.....

3.7152·3.7

158

192

.................

3.7486·3

.7491

331

.................

3.7986·3

.7991

40

1.

................

4.1

133·4.1139

477

and 534

......... 4.4983

·4.

4989

Standard- Color Coded Blue

144

and

170

......... 3.49

88·

3.4994

113 and 301

......... 3.6248·3.

6154

161

.................

3.

7164

·3.7

170

191

.................

3.7

498·3.7504

331

..............

...

3.7

998

·3.

8004

1-10

TRUCK

S

PI

STO

N-

Conti

nued

401.

................

4.1245·4.1251

477

and

534

.........

4.4995

·4.5001

0.003 Oversize

144

and

1

70

.........

3.5000·3.5006

223

and

302

......... 3.6260

·3.

6266

262

.................

3.7176·3.7

182

292

....

""

.........

3.7510·3.7516

332.

__

..............

3.

8010

·3.

8016

401.

................

4.1257·4.1263

477

and

534

.........

4.5007·4.5013

PISTON

TO

BORE CLEARANCE

- Bottom of Skirt

144

and

170

.........

0.0018·0.0036

Wear

lim it

0.008

262

.....

__

.....

.. ..

0.00

14·

0.0032

401.

477.

and

534 ____ . 0.0011·0.00

29

Wear

Umit

0

.008

All

Olher Engines

.....

0.0008·0.0026

Wear

limil 0

.008

PISTON PIN

DIAMETE

R

Standard

401.

477.

a

nd

534

.....

1.2198·1.2201

Olher

Engines ........

0.9120·0.9123

0.

001

Oversi

ze

401.

477.

and

534

.....

1.2208

·1.22

11

Other Engines rExcepl

144

and

170

1

__

...

__

' .

__

..

__

0.9130·0.9133

0.

002

Ov

ersize

401. 477.

and

534

.....

1.221

8·1.222

1

Other

Engrnes ,Excepl

144

a

nd

170

1

.................

0.

9140·0.9

143

PISTON PIN

LENGTH

144

. 1

70.223.262.

and

292

.............

3.010·3.030

302

__

................

3.008·3.028

332

..

________

.,

______

3.156·3.176

401

..................

3.335·3.350

477

and

534

...........

3.840·3.8

55

PISTON

PIN

TO

PISTO

N

CLEARANCE

401.477

. and

534

.....

0.0003·0.0005

Wear

limit

0.001

othe

r Engi

nes ........

0.0001·0.0003

Wear

limit 0.

0008

PISTON

PIN

TO

CONNECTING

ROD

BUSHING

CLEARANCE

401.477

, and

534

.....

0.0001·0.0006

other Engines (Except

1

44

and

170

)

.....

...

.........

0.0001·0.0005

Wear

lim it (

all

engines) ......

0.

001

PIST

ON

RIN

GS

SIDE CLE

ARANCE

Compression

Ring

144, 170, 223.

162

,

and

291

...........

0.

0019

·0.

0036

Wear limil

0.006

301

a

nd

332

Top

Ring .

0.0024·0.0041

Bottom

Ri

ng

.........

0.003

·0.

005

W

ear

lim

it

0

.006

401.477.

a

nd

534

Top and

I

ntermedia

te

Rin

gs

..

0.0029·0.0046

Bottom Ring

.......

0

.0025·0.004

5

Wear

lim

it

0.

006

Oil

Ring

144. 170. 223. 162.

and

292

..................

Sn

ug

302

and

332 .........

0.0018

·0.

0052

Wear lim

it

0.

007

401.477

,

and

534

..... 0.00

14·0.

0031

Wear

limit

0.007

RING

WID

TH

C

ompression

Ring

Top Ring

144,

170,261

,

and

292

.0.

0774

·0.

0781

Bottom

Ring

144

and

170

.....

....

0.0770·0.0780

123

and

162

......... 0.0929·0.0936

292

..............

...

0.0774

·0.

078

1

othe

r E

ngines

Top

and Intermediate

Rings

.............

0.0929·0.0936

Bottom

Ring

.......

0.0930·0.0940

Oil

Rin

g*

302. 331.

401.

477

.

and

534 .....

......

0.1859·0.1866

'Width

specified

is

for

one

rin

g.

Two

r

ings used

per

groove

on

302

and

332

.

RI

NG

GA

P WIDTH

Co

mpr

ession

Ring

- Standa

rd

80

..

1

44

and

1

70 ............

0.010·0.020

223.262

, and

292

........ 0.010

·0.

025

ENGINES

1-11

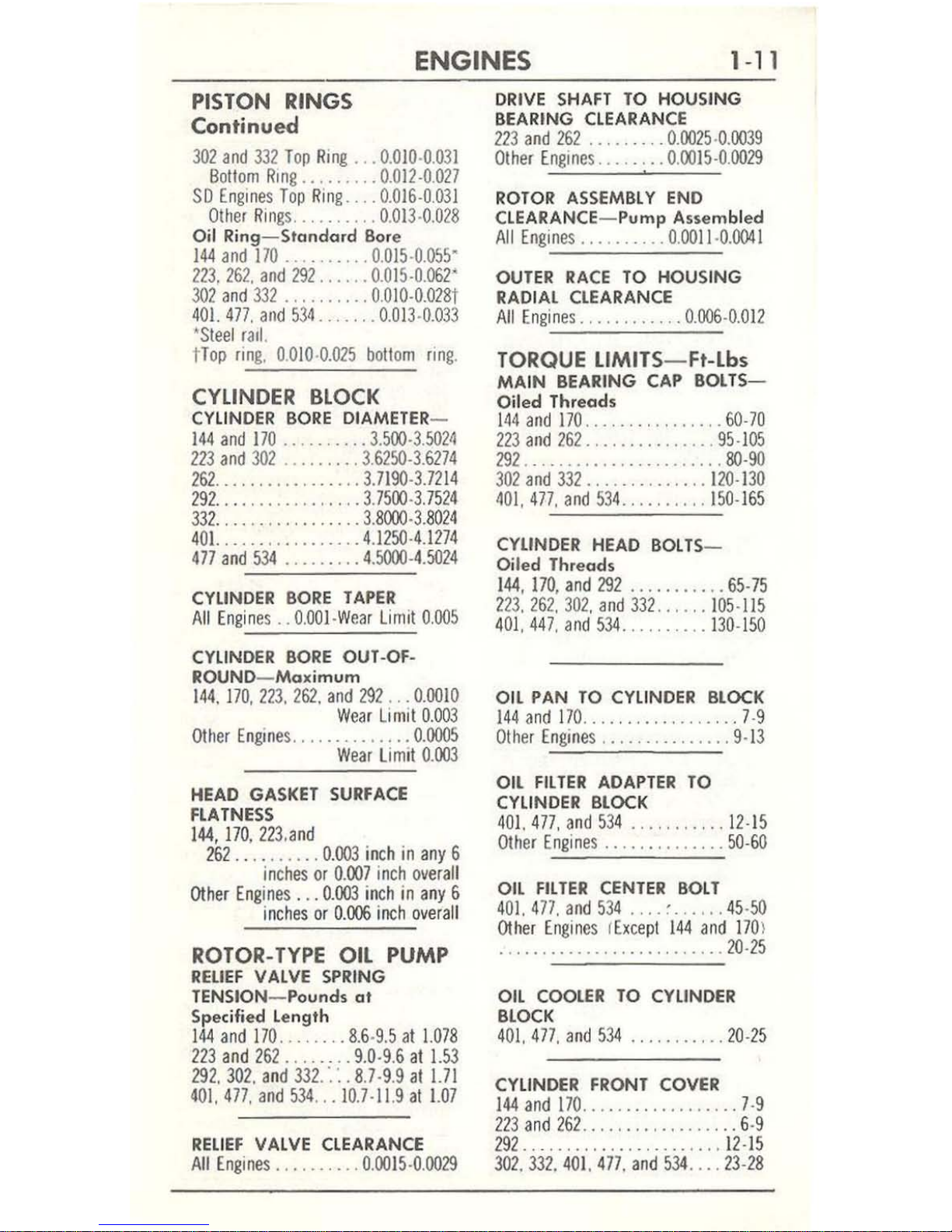

PISTON RINGS

Continued

302

and

332

Top

Ring

...

0.010·0.03

1

Bollom

Ring

......... 0.012

·0.

027

SO

Engines

Top

Ring ....

0.016·0.031

OIher

Rin

gs

.......... 0.013·0.

028

Oil

Ring

- Standa

rd

Bor

e

144

and

170

.......... 0.015·0.055"

223.262.

and

292

......

0.015·0.062-

302

and

332

..........

0010-0.0281

401.

477. and

534

....... 0.013-0.033

'S

leel

r,,1.

tTop

ring

. 0.

010·0.025

bollom

flng

.

CYLINDER

BLOCK

CYLINDER

BORE

DlAMETER-

144

and 170

..........

3.500·3.5024

223

and

302

......

... 3.6250

·3.

6274

262

.................

3.7190·3.7214

292

....

.............

3.7500·3.7524

332

...

.. .

...........

3.8000-3.8024

401.

................

4.

1250-4.1274

477

and

534

......... 4.5000-4.502

4

CYliNDER

BORE

TAPER

A

ll Engines

.. O.OOI-Wear

limil

0.005

CYLINDER

BORE

OUT ·OF-

ROUND- Maximum

144. 170,223. 262.

and

292

.. .

0.0010

Wear

limil

0.003

Other

Engines

..............

0.0005

Wear

lim

ll

0.003

HEAD GASKET

SURFACE

flATNESS

144,170,223,and

262

... .

......

0.003 inch

in

any

6

inches

or

0.007 inch

overa

ll

Other

Engines ...

0.003 inch

in

any

6

in

ches

or

0.006

inch over

all

ROTOR-

TYPE

OIL PUMP

RELIEF

VALVE

SPRING

TENSION

- Pounds at

Specified length

144 and

170 .....

...

8.6-9.5

al

1.078

223 and

262

........

9.0·9.6

at

1.53

292.302.

and

332

.·.·

..

8.7·9.9

al

1.71

401.

477.

and

534

...

10.7 -11.9

al

1.07

RELIEF

VALVE CLEARANCE

All

Engines

.......... 0.0015

-0.

0029

DRIVE

SHAFT

TO

HOUSING

BEARING CLEARANCE

223

and

262

.....

.... 0.0025

·0.

0039

OIher

Engines

........ 0.tX)]5-0.0029

,

ROTOR

ASSEMBLY

END

CLEARANCE- Pump Asse

mbled

All

Engines

.......... 0.0011·0.0041

OUTER

RACE

TO

HOUSING

RADIAL CLEARANCE

All

Engines

............

0.006-0.0

12

TORQUE

L1MITS

- FI-Lb.

MAIN

BEARING CAP

BOL TS-

Oiled Threads

144

and 170

................

60-70

223

and

262

...............

95·105

292 .....

.......

....

......

SO-90

302

and

332

.............. 120-

130

401,

477.

and

534

..........

150-165

CYLINDER HEAD

BOLTS

-

Oi

led Threads

144, 170, and

292

...

........

65-

75

223. 262,

302,

and

332

......

105·115

401.

447. and

534

........

..

130-150

OIL PAN

TO

CYLINDER BLOCK

144

and

170

..................

7·9

Olher

Engines

...............

9-13

OIL

FILTER

ADAPTER

TO

CYLINDER BLOCK

401.

477, and

534

......

..

...

12-15

OIher

Engines

..............

50-60

OIL

FILTER

CENTER

BOLT

401.

477.

and

534

.... , ...... 45·

50

Other

Engine

s I

Excepl

144

and 170

)

.

......

.....

......

...

.....

20·25

OIL

COOLER

TO CYLINDER

BLOCK

401.

477.

and

534

...........

20·25

CYliNDER FRONT COVER

144

and

170

...... ..

..........

7-9

223

and

262

.........

. ..

....

.. 6·9

292

.. ..

.............

.

..... 12·

15

302.332.40

1.

477.

and

534

.... 23-28

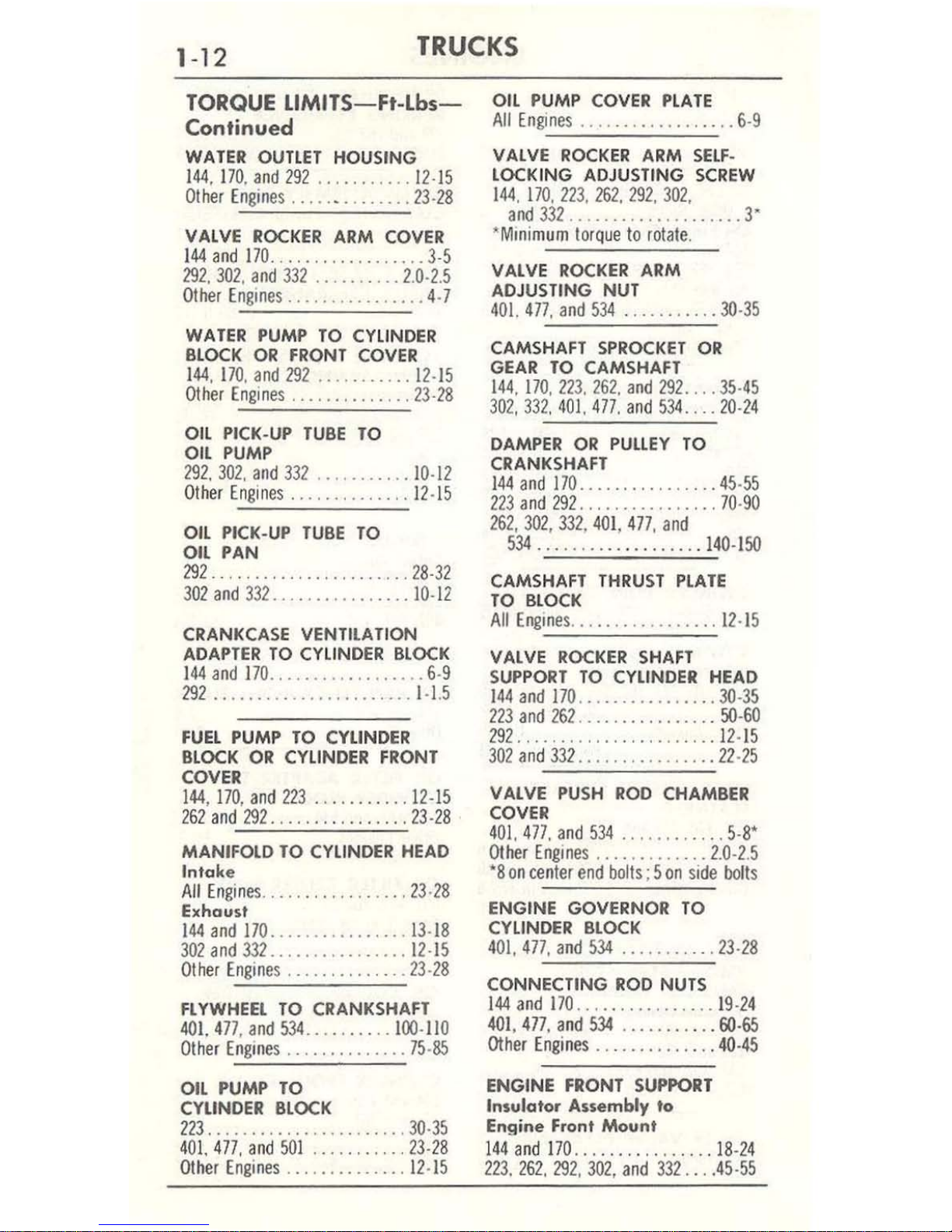

1-12

TRUCKS

TORQUE

LlMITS-Ft-Lbs-

Continued

WATER OUTlET HOUSING

144

, 170,

and

292

...........

12·15

Other

Engines .............. 23·

28

VALVE

ROCKER

ARM

COVER

144 and

170

..........

...

.....

3-5

292, 302, and

332

..........

2.0·2.5

Other

Engines

................

4-7

WATER

PUMP

TO

CYLINDER

BLOCK

OR

FRONT

COVER

144

, 170,

and

292

...........

12·15

Other Engines

.......

....

... 23-28

OIL

PICK-UP

TUBE

TO

OIL

PUMP

192,

302, and 332

...........

10·12

Other Engines

..............

12

-15

OIL PICK-UP

TUBE

TO

OIL PAN

292 .....

............

...... 28-

32

302

and

332

................

10·12

CRANKCASE VENTILATION

ADAPTER

TO

CYLINDER

BLOCK

144 and

170

..................

6·9

292

.......................

1-

1.5

FUEL

PUMP

TO

CYLINDER

BLOCK

OR

CYLINDER FRONT

COVER

144,170, and

223 ...........

12-15

262

and

291

.........

.......

23-28

MANIFOLD TO

CYLINDER

HEAD

Intake

A

ll

En

gines

.................

23·28

Exhaust

144

and

170

................

13·18

302

and

332..

..............

12-15

Other Engines

..............

23-28

FLYWHEEL

TO

CRANKSHAFT

401.

477

,

and

534

.....

.. .

..

100-110

Other

Engines

..............

75-85

OIL PUMP

TO

CYLINDER

BLOCK

223 .......................

30-35

401.

477, and

501

........... 23-

28

Other

Engines

..............

12-15

OIL PUMP

COVER

PLATE

All

Engines

................

, .6·9

VALVE

ROCKER

ARM

SELF

-

LOCKING ADJUSTING

SCREW

144, 170, 223,

262, 292

, 302,

and 332

....................

3"

~MlOi

mum

torque

to

rotate

.

VALVE

ROCKER

ARM

ADJUSTING NUT

401.

477, and

534 ...........

30-35

CAMSHAFT

SPROCKET

OR

GEAR

TO

CAMSHAFT

144,170,223,262,

and

292

.... 35-

45

302,332,

401.

477, and

534

.... 20-

24

DAMPER

OR

PULLEY

TO

CRANKSHAFT

144

and

170

......

...

....

... 45-

55

223

and

292 ..............

.. 70-

90

262,

302,

331, 401

,

477

,

and

534 .......

............

140·150

CAMSHAFT

THRUST

PLATE

TO

BLOCK

All

Engines

.................

12

·15

VALVE

ROCKER

SHAFT

SUPPORT

TO

CYLINDER HEAD

144

and

170

................

30-35

223

and

262

...............

. 50-

60

292 ......

..........

... ..

.. 12-

15

302

and

332

... , ............

22-25

VALVE

PUSH

ROD

CHAMBER

COVER

401.

477.

and

534

........

..

..

5·8'

Other

Engines

.............

2.0·2.5

'8

on

center

end

bolts

; 5

on

side

bolls

ENGINE GOVERNOR

TO

CYLINDER

BLOCK

401, 477, and

534

........

.. . 23-

28

CONNECTING

ROD

NUTS

144

and

170

................

19·

24

401, 477. and

534

......

.....

GO-

65

Other

Engines ......

.....

... 40-45

ENGINE FRONT

SUPPORT

Insulator Assembly to

Engine

Front

Mount

144

and 170

.........

....

...

18-24

223. 262, 292,

302, and

332

...

.45-55

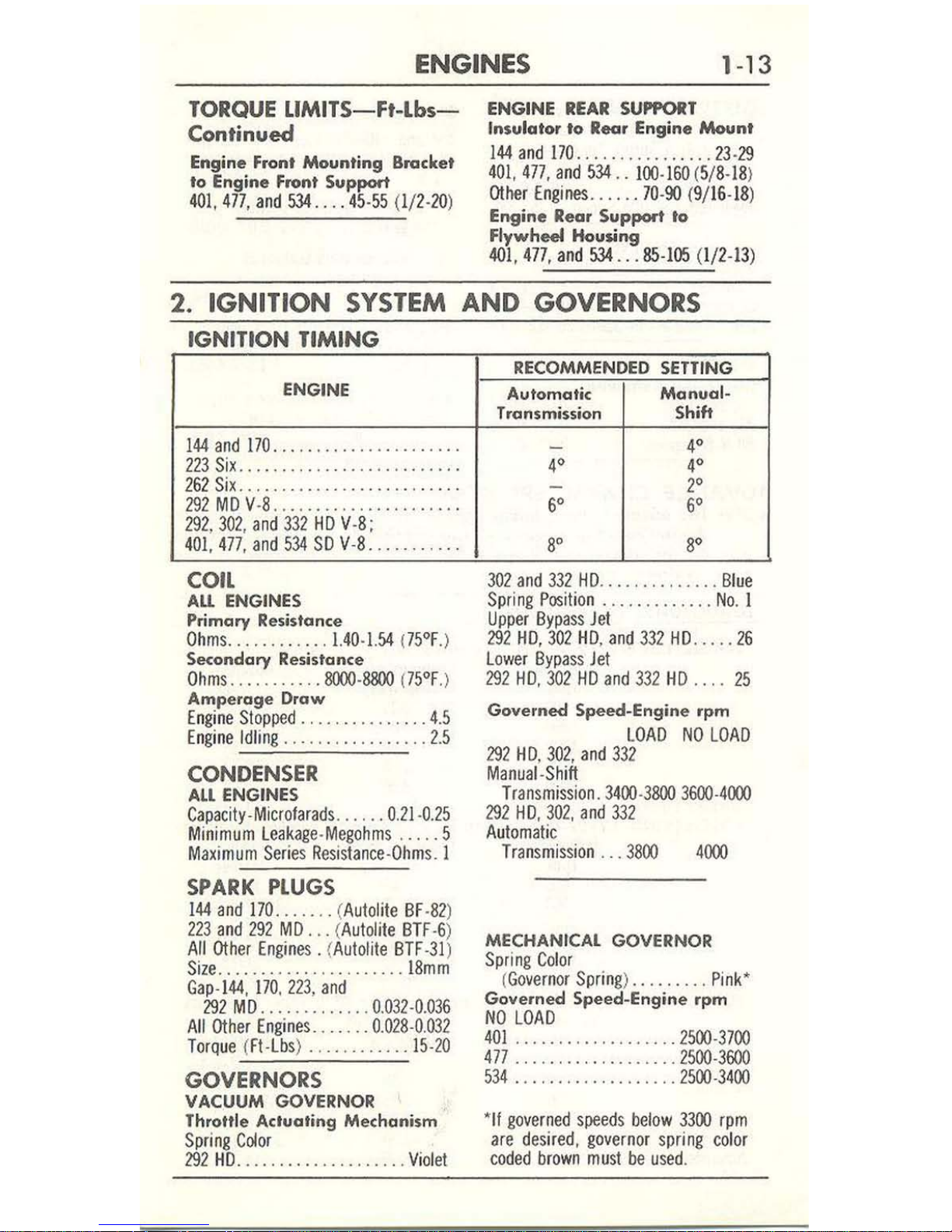

ENGINES

1-

13

TORQUE

LlMITS-Ft-lbs-

Continued

Engine Front

Mounting

Bracket

'0

Engine Front Support

401,

477,

and

534

....

45·55

(1/2·20)

ENGINE

REAR

SUPPORT

Insulator to Rear Engine

Moun.

144

and

170

................

23·29

401,477, and

534

.. 1

00·160

(5/

S·1S

)

Othfr

Engines

......

70·90 (9/

16·

1S)

Engine Rear Support to

Flywheel

Houfing

401,477,

and

534

...

85·1OS (1/2-13

)

2.

IGNITION

SYSTEM

AND GOVERNORS

IGNITION

TIMING

ENGINE

144

and

170

..... ,

., ......... , ....

223

Six ....

.....................

.

262

Six

......

.. .

................

.

292

MD

V·S

........

....

...

....

...

292,302, and

332

HD

V·S

;

401,477, and

534

SO

V·S ...

...

... ..

COil

AU

ENGINES

Primary

Resistance

Ohms

............ 1.40·1.54 U5°F

.)

Secondary

Resist

ance

Ohms

.. .

...

...

..

8000·8800 175°F

.)

Amperage

Draw

Engine

Sioppild

..........

..... 4

.5

Engine Idl

ing

..... .

...

...

.....

2.5

CONDENSER

All

ENGINES

Capacily·Microfarads

....

..

0.21·0.25

Minimum

leakage-Megohms

....

. 5

Maximum

Series

Resistance-Ohms

. 1

SPARK

PLUGS

144

and

170

....... (Autolite BF·S2)

223

and

292

MD

... (

Autolite

BTF

·6)

All

Other

Engines. (Autolite

BTF·31

)

Size ...

...

.. .. .

...

. ..

..... 18mm

Gap·I44, 170

, 223,

and

292

MD

.............

0.032 ·0.036

All

Other

Engines ......

. 0.

02S·0.03

2

Torq

ue (Ft·

Lbs

) .. ... .

....

.. 15·2

0

GOVERNORS

VACUUM

GOVERNOR

Throttle Actuating Mechanism

Spring

C~or

292

HD

...

...........

...

...

Violet

RECOMMENDE

D

SETTING

Automatic

Manual-

Transmission Shift

-

4°

4° 4°

-

2°

6°

6°

S'

so

302

and

332

HD

..............

Bl

ue

Spring

Position

.............

No

. 1

Upper

Bypass

Jet

292 HD,

302

HD,

and

332

HD .....

26

lower

Bypass Jet

292 HD, 3

02

HD

and

332

HD ....

25

Governed

Speed-Engine

rpm

LOAD

NO

LOAD

29

2 H

D,

302,

and

332

Manual·Shift

Transmission. 3400·3800

3600·4000

292

HD,

302,

and

332

Au

tomatic

Transmission

... 3800

4()(x)

MECHANICAL

GOVERNOR

Spring Col

or

(

Governor

Spring

) .

........

Pink

'

Governed Speed-Engine rpm

NO

LOAD

401

................... 2500·3700

477 ....

.........

......

2500·3600

534 ...

........

........

2500·3400

'If

governed

spileds below

3300

rpm

are

desired, governor

spring col

or

coded

brown

must

be

used

.

1-14

TR

UCKS

DISTRIBUTOR-General

All

SIX

CYLINDER

ENGINES

Br

eaker

Arm

Spri

ng

Tension-

GEAR

lOCATION

144 and

170-Dis

tan

ce Irom

bottom

of

gea

r to bottom of mounting

Ounc

es

........

..

......

..

17 ·20

rib

................

. 2.

510

-2.

515

Contact

Spacing .... ..

. .

0.024

·0.

026

223

and

262

- Distance

between base

Dwe

ll Angle

at Idl

e S

pee

d .. . 35° ·38°

a

nd

gear

..........

. .

0.005

-0.

008

All

V-8

ENGINES

Breaker

Arm Spr

ing T

ension

-

292-0

istance

froni bottom

of

mounti

ng flange

to

botto

m

Dunces ....

.... .

......... 17-2O

of

gear.

............

. 4.

991

-4.

996

Contact

Spaci

ng

...

.. ... 0.

014

-0.

016

Dwell

Angle at Idle Speed 26° -28·

1!2

° 3

02

and 332-Distance from

bott

om

of

mounting flange

to

bottom

SHAFT

END

PlAY

-

of

gear ..............

4.

927-4.953

Distributor Removed

144 and 170 .

.......... 0.022-0.033

401,477

, and 534- Distance

from

botto

m of mo

unt

ing lIan

ge

to

223

and

262 ........... 0.005

-0.

008

All

V-8 Engines

.....

... 0.022-0.030

bott

om of

gea

r .. .. .

.. 3.0

77 -3.

071

ADV

AN

CE

CHARACTERISTI

CS

NO

TE: The adv

ance

characteristics

giv

en

app

ly to the distributor

with

the indicated

numb

er

only. Th

e distributor number is st

amped

on

th

g distributor hous

;ng

or

on

a plate aHached to the

distributor housing.

LOADOMA

TIC

DISTR

tBU

TORS

144 S

ix

(C3UF-12127-E) Set

test sta

nd to:

1000 rpm, 0°, 0 i

nch

es

of

Mercu

ry.

Distr

ibu

tor

Vacuum-Inches

Advance-

r

pm

of

Mercury

Degree

s

500

0.30 1-2

800

O.

SO

4-3/4-5-3/4

1

200

L

SO

8~

1600

3.

00

10-11

2000

3.

90

11

-21-1/4

Ad

vance limi

t ...

...

...................

10.00

......

_ ..

13

-1/2

t

70 Six

(C3UF-12127 -D) Set

tes

t s

tand to:

1000 rpm, 0

°.

0 i

nches

of

Mercury.

Dis

tributor

Vacuum-Inches

A

dvance

-

rp

m

of Merc

ury

Degrees

600

0.

45

1/

4-1

-1/4

800

0

.75

3-

1/2-4-1/2

1

200

1.7

5 7 -8

1600

2.

90

9-3/4-

10-3

/4

2000

3.7

0

11-

12-1/4

Advan

ce limit

.........................

10.00

.........

..

.. ..

15

223

Six

(C3TF-12

127 -

D)

Set

test stan

d to: 150 rpm,

0°, 0 inches

of Mercu

ry.

Di

stribut

or Vacuum-Inch

es

Adva

nce·

r

pm

of

Mercury

Degrees

500

~

1

~~

600

0

.45

3-1/2-4

-1/1

1200

1.75

7-1/

2-8-1

/2

1

600

3

.10

9-10-

1/4

2000

4.

20

10-11-1

/4

Advance Limit

...

....

1000 .......

...

...

8.00 _ ..

... _ . _

....

14-3/4

..

,

•

IGNITION

SYSTEM

AND GOVERNORS 1 -15

2625;

. (C2TF-12127-A) Settest

stand

to: 1000 rpm, 0', 0

inches

of

Mercury.

Distributor

Vacuum-Inches

Advance

-

rpm

of

Mercury

Degrees

400

0.42

0-

1·1/4

~

1m

~6

1000

1.62

)

·3/4-8·3

/4

1200

2.32

8·

1/2

- 9·1/2

2000

5.65

8·1

12-

9·1

/2

1600

).30

10

·3/4-

12·1

/4

Advance

limit. . .. ..

............

...

.

..10.00

...............

13

DUAL ADVANCE

DISTRIBUTORS

292

MD

V-8

(C3TF-12127-A)

VACUUM

ADVANCE. Set

test

stand to:

1000

rpm, 0'

, 0

inches

of

Mercury

.

Distributor

Vacuum-Inches

Advance·

rpm

of

Mercury

Degrees

1000

6 0- 1

1000

9 1

-4

1000

12

3·1/2-

6·1

/2

Advance

limit

.................................

....

.......

. '

..

20

CENTRfFUGAL

ADVAN

CE.

Set

test

stand

to:

250

rpm

, 0'. 0 inches

of

Mercury.

Distributor

Vacuum-Inches

Advance-

rpm

of

Mercury

Degrees

500

0

1-2

)00

0

5-6

1

000

0

8-9·1/4

1

500

0

11

-12

·1/4

2000

0

13

·3/

4-15

·1/4

Advance

limit

..............

...

..........

Not

Appficab

le

302

and

332

HD

V~8

(

C2TF-12102-0)

with

Governor

VACUUM

ADVANCE.

Set

test

stand

to: 1000

rpm

, 0'. 0

inches

of

Mercu

ry.

Distributor

Vacuum-Inches

Advance

-

rpm

of

Mercury

Degrees

1000

7·1

/2

I·

4·1/4

1000

II

5- )·3/4

1000

14

5·1/2- 8

·112

Advance

limit

...........................

20

.......

..

.........

8·1

/2

CENTRIFUGAL

ADVANCE. Set test s

tand to:

250

rpm

, 0

', 0 Inches

of

Mercury

.

Distributor

Vacuum-Inch

es

Advance

-

rpm

of

Mercury

Degrees

325

0 0

4

25

0 3/4-1

·3/

4

600

0

6-

)

~

0

~9

2

000

0

10

·3/4-12·1/4

Standard

Transm ission

Gov

ernor

at

Distributor

rpm

Opens

at

1~

Closes

at

1900

Automatic

Transmission

Gov

ernor

Opens

at 1900

Closes

at

2000

1-16

TRUCKS

DUAL

ADVANCE DIS

TRIBUTOR

S - Continued

401, 477,

and

534

SO

v-a

\COTF-12127-C-Stand

ard

and

C3TF.12127 -H- Transistorized)

VACUUM

ADVANCE.

Set

test stand to:

1000

rpm,

O~

0 inches

of

Mercury.

Distributor

Vacuum-Inche:;

Advance

-

rpm

of

Mercury

Degree

s

IIXX>

5·1

/2

0-

2·1/2

IIXX>

9

5-

7·3/4

I

IXX>

10 5·1/2-8·1

/2

Advance

Limit

..........

...

...

...

..... ,0

.....

...

...

. ,

....

. :8.1/2

CENTRIFUGAL

ADVANCE, Set

test

stand to:

250

rpm

, 0·, 0

inches

of

Mercury

.

Distributor

Vacuum-Inches

Advance·

rpm

of

Mercury

Degrees

350

0 0

500

0 1·1/4- 2·1/4

llOO

0

10

·1/4-11·3/4

1400

0

12

·1/

4-14

·1/4

Advance

Limit

...

, .. ,

2500

.... ,

....

. , 0

.......

.. "

......

.14.1

/4

CENTRIFUGAL ADVANCE

DISTRIBUTOR

WITH GOVERNOR

292

HD

v-a (COTF-12102-C)

Set test

sta

nd to:

150

rpm,

0·. 0 inches

of

Mercury

,

Distributor rpm

Advance-Degrees

400

0

500

1/1- 1·1

/2

900

5·1/2- 6·1/1

IB

8·~9·1

/2

1000

10

·3/4-12·1/4

Advance

Limit

.... , .............. , .... , ............

, .

......

, . ..

..

18

Engine

Gove

rnor

at

Distributor

rpm

.

Opens ...........

, . ,

...

. 1

800

Cl

oses

.....

, ,

..........

. 1

900

3_

FUEL

SYSTEM

FUEL

PUMPS

MECHANICAL FUel PUMP

Fuel Pump Pressure-

ps i

at

500

rpm

144,170,113,16

1.

and

292

MD 3.3·5.5

191

HD

........... , ....... 3.5·6.5

302

and 332

HD

.. ,

.........

3.5·7.0

Mi

nimum Fuel

Pump

Vol

ume

-

Flow

at

500

rpm

All

Engines .. I Pint

within

30

seconds

Minimum

Intake

Static

Vacuum

at

500

rpm

All

Engines ...........

..

....

, ,6.0

ELECTR

IC FUel

PUMP

fue

l Pump

Minim

um

Volume

-

at

11

.8-12.3

volts

at

2 psi

ENGINE

I

QUART

FLOW

401

SO

V·8

.,.,

.. Within

36 s

econd

s

477

SO

V·8, ,

....

Wit

hin

33 s

econds

534 SO

V·8 ...

...

Within

30

seconds

CARBURETORS

SINGLE-BARRel

Identification

Part No.,

Prefix

and

Suff

ix,

appear

on

upper

edge

of main body above

mounting

stud

hole (accel

erato

r

pu

mpside).

C3UF·

9510

·A·

144

and

Manual·Shift

Transmission.

C3UF·951O·B·170

and

Manual·Shift

Transmissio

n.

C3TF ·951O

·C·

Parc

el

Delive

ry with

123

and

Manual·Shift

Tra

nsmission.

C3

TF ·9510

·D-

Parcel Delivery

with

223 and

Automatic Transmissio

n.

C3TF ·9510·A-213

and

Manual·Shift

Tr

ansmissio

n.

C3TF·9510

-B-

213

and

Automatic

Tr

ansmissio

n.

C3TF·

951O·E-262

and

Manual·Shift

Tr

ansmissio

n.

•

•

FUEL

SYSTEM

1·17

Main

Mete

ring Jet Ident. No.

0·5,000

feet

C3UF·951O

·A,

.......

..

.......

52F

C3UF·951O·B

.................

57F

C3TF

·951O·E

..........

....... 69F

C3TF

·951O·

A,

B,

C.

and

-D ..

....

65F

S,OOO ·10,000

feet

C3UF

·9510·A

...

.....

.........

50F

C3UF·951O

·B

.................

55

F

C3TF·951O·E.

................

67F

C3TF

·951O-A,B,C,

and·D

......

63F

10

,000·15.000

feet

C3UF·9510

·A

.................

48F

C3UF·9510

·B

.................

53F

C3TF

·951O·E

...........

'.'

.....

65

C3TF.951O·A,B,C, and·D

.......

61

Float

Setting-Dry

From

bottom

of

float

to

air

horn

,

with

airhorn

inverted

~

1/

64

inch:

All

Carburetors

.......

...... 1 inch

.

Venturi Size

C3TF·951O-AcB,C

,D,

anM

.

1·13/64

C3UF·95IO·A

..............

1·1/64

C3UF·951O

·B

..............

1·7/64

Spark Control Valve I

dent. No.

C3UF·951O·Aand,B

...........

Red

All

others

..................

Plain

Anti-Stall Dashpot Clearance

C3TF·9510·D-1·

1/2·2 tur

ns

out,

with

diaphra

gm

bottomed.

Initial Idle Mixture Adjustment

144, 170

...........

3·4

turns

open

223,

262

...........

4·5

turns

open

Power Valve

Opens

at-

inch

es

of mercury

All

C3TF·9510·E

...........

5.5·7

.5

C3UF·951O·A.

and

·B, a

nd

C3TF

·951O·C

and-D

..........

6·8

DUAL

Identificati

on

Part

No.

appears

on

choke

plate

flange.

C3TF·9510·H·292

LD

and

manual

·

sh

ift

transmission

.

C3TF·951O·J·292

LD

and

automatic

transmissio

n.

C3TE·951O

·K·

292

MD

with

manua

l·

sh

ift

or

automatic

transmission

.

C3TE·951O·E·3

02

HD

C3TE·951O·B·332

HD

C3TE

·951O·G-401

SD

C3TE·951O·D·477

SD

Main

Meter

ing Jet Ident, No.

0·5,000

leet

C3TE·951O·K

,

C3TF·9510·H, and

·J

..........

48

Cm

·951O·B

..................

62

C3TE·951O·D

, and·

E.

...........

58

cm

·951O·G.

' . .

...............

57

5,000·10,000

feet

C3TE

·951O·K,

C3TF

..

951O

·H,

and

·J

..........

46

C3TE·951O

·B ..................

60

C3TE·9510·D,

and

·E

.......

...

..

56

C3TE·951O·G

..................

55

10,000·15,000

feet

C3TE·951O·K,

C3TF·9510·H,

and-J

..........

44

C3TE·951O

·B

..................

58

C3TE·951O·D, and·E

............

54

C3TE·951O

·G ..................

53

Power

Valve

Ident. No.,

or

color

ALL

ALTITUDES

C3TE·9510

·E

..................

45

C3TE·951O

·K,

C3TF·951O·H

, and-J

.......

Green

C3TE·951O·G

..................

35

C3TE·951O

·B

and·D

.....

....

...

55

POWER

VALVE

OPENS

AT

C3TE·951O·B

·

........

6.5·9.5

inches

of

mercury

C3TE.951O·K

,

C3TF ·%IO·H,

and

-J

·

.........

.

7·10 inches

of

mercury

C3TE·951O

·E

·

..........

.

2-5

inches

of

mercury

C3TE·951O·G

·

..........

. 4-7

inches of

mercury

C3TE·9510·D

·

........

5.5·8.5 inches

of

mercu

ry

Dry F

lo

at

Setting

-

Initial Setting Only

Top

of

float

parallel

wit h top

of

fuel

bowl, bowl

inverted (except

292

).

292

Engines-21/32"

from

top

surface

of

main

body

to

top

surface

of

float,

with

float

in

uppermost

position.

Fast

(Cold) Idle Adjustment

0.010·0.015

inch

clearance

between

fast

idle

screw

and

fast

idle

cam.

Fuel

level

Setting

Lower

edge

of sight

plug

opening

"'-

1/

16

inch (except

292

).

292

Engines

-29/32"

below

top

sur·

face of main

body.

1-18

TRUCK

S

CARBURETORS-

Continued

Venturi Size

C3TE-951O-K,

C3TF-951O-

H, a

nd

-J

__

.................

1-1/32 inches

C3TE

-9510-B,

-0,

-E,

and

-G

___

..

_______

1-3/16

inch

es

Anti-Stall Dashpot Clearance

. . . _ .

____ . __

..

__

..

__ 0.060

-0.

090

Governor By-Pass Jet No.

C3TE-951O-

B a

nd -E.

_ .

... Upp

er

29

_________

..

__

...

____

... Lower 59

Initial Idle Mixture Adjustment

_ .

__________

. _

l-l

-l/

2 turns open

4-BARREl

Identification

Part N

o_

appe

ars

on c

hoke pla

te

nang

e_

C3TE-

9510-F-2

92

HD and

Manua

l-

Shi

ft transmis

sion or

Auto

matic

transmis

sion.

C3

TE-951O-K-302

HD

V

-8

C3TE-9510-L

-332

HD

V

-8

C3TE-9510-

H-4

01 SO V

-8

C3TE

-9510-C-477

SO

V

-8

C3TE-9510-D

-53

4 SO V-8

Main

Metering Jet

Identification No.

PRIMAR

Y .

0-

5,000

feet

C3TE-

951O

-F

__ __

_______

..

__ . __

52

C3TE-951O-K

and

-L ____

____ . __

52

C3

TE-

951O

-H and

-0

___________

49

C3TE-951O

-C

____

... ____

_______

50

5,

000-10,000

feet

C3TE-

951O

-F, -

K,

and

-L. _

__ . ___ 50

C3TE-951O

-C

__________

.. . _____

49

C3TE-951O

-H,

and

-0 ____ .

______

48

10,000-15

,000

feet

C3TE-9510

-C, -F, -K,

and

-L

___

__

48

C3TE-

951O

-H,

and

-0

________ . __

47

SECONDARY

0-

5000

feet

C3TE-951O

-F

__________________

58

C3TE-951O-D _

____

. _.

__________ 62

C3TE-

951O

-H, -C, a

nd

-

L.

______

_

65

5,

000-10,000

feet

C3TE-951O-F

_____ . __________

56

C3TE-951O-D_

. _ . _ ..

__

...

_ ..

___

60

C3TE-951O-H, -C_ and -

L.. ______

63

10

,000-15,000 feet

Cm-951O

-F

______

...

_______

54

C3TE-951O-D ________

.......

.. _

58

C3TE-

951O

-H,

-C, and

-L

__

...

___

61

Power

Valve