Ford 1961 TRUCK 100 SERIES, 1961 TRUCK 800 SERIES Shop Manual

Copyright © 2011, Forel Publishing Company, LLC, Woodbridge, Virginia

All Rights Reserved. No part of this book may be used or reproduced in any manner whatsoever

without written permission of Forel Publishing Company, LLC. For information write to Forel

Publishing Company, LLC, 3999 Peregrine Ridge Ct., Woodbridge, VA 22192

1961-63 Ford Truck Shop Manual

EAN: 978-1-60371-070-1

ISBN: 1-60371-070-1

Forel Publishing Company, LLC

3999 Peregrine Ridge Ct.

Woodbridge, VA 22192

Email address: sales@ForelPublishing.com

Website: http://www.ForelPublishing.com

This publication contains material that is reproduced and distributed under a license from Ford

Motor Company. No further reproduction or distribution of the Ford Motor Company material is

allowed without the express written permission of Ford Motor Company.

NNoottee ffrroomm tthhee PPuubblliisshheerr

This product was created from the original Ford Motor Company’s publication. Every effort has

been made to use the original scanned images, however, due to the condition of the material;

some pages have been modified to remove imperfections.

Although every effort was made to ensure the accuracy of this book, no representations or

warranties of any kind are made concerning the accuracy, completeness or suitability of the

information, either expressed or implied. As a result, the information contained within this book

should be used as general information only. The author and Forel Publishing Company, LLC

shall have neither liability nor responsibility to any person or entity with respect to any loss or

damage caused, or alleged to be caused, directly or indirectly by the information contained in

this book. Further, the publisher and author are not engaged in rendering legal or other

professional services. If legal, mechanical, electrical, or other expert assistance is required, the

services of a competent professional should be sought.

Disclaimer

GROUP

INDEX

•

•

•

•

•

•

I

I:

•

TRUCK

ENGINES

FORDOMATIC

HUISI-O-MAlIC

AND

IGNITION

FUEL

COOLING

::=::::=~==

TRANSMUIC

IDENTifiCATION

EXHAUST

SYSTEM

SYSTEM

SYSTEM

AND

TRANSMISSIONS

DRIVE

SYSTEMS

AND

HEAVY-DUTY

TRANSMISSION

-=-

-=.II

:

•

I

100-800

•

•

•

I

I

•

•

•

•

•

•

•

•

•

SERIES

STEERING

BRAKES

GENERATING

~

~~~

LIGHTS, INSTRUMENTS,

~---

~~IN

MAINTENANCE

BO

:

D

DOORS,

~T~

ER

~

IO

AND

SY

;

ST

;

EM

;

S

;,;

ACCESSORIES

:

Y

=

C

:

O

:

N

=

ST

=

R

WINDOWS

~R~T~

RI

~M~

AND

GUIDES

STARTING

~

;,;

::::

AND

;

Ucr

::

IO

:

N

::::::

,

AN

~D~S~E~

AT

~S:;::::=

LUBRICATION

~

~

III"'IC='l

II."E"j

~

II"'I"=l

K.I.:.I

•

SERVICE

FORD

FORD

F,

"ST

PRlNTING

- C

,~/;O

FORD MOT

DEPARTMENT

DIVISION

MOTOR

OR

COMPAN

COMPANY

.

DEARBORN.

Y

MICHIGAN

INDEX

SPECIFICATIONS

0'

EACH

GROUP

AT

IND

FOREWORD

This manual provides information for the proper servicing

of

1961 100-800 Series Ford Trucks. Service procedures for the

Ranchero are cove red

in

the 1961 Ford Falcon Shop Manual .

The descriptions and speci

fications contained in this manual

we

re in effect at the time the manual was approved for printin

g.

The Ford Division

of

Ford Motor Company reserves the right

to discontinu e models at any tim

e,

or change specifications

or design, without noti

ce

and without incurring obligatioll.

SERV

ICE

DEPARTMENT

FORD

DIVISION

FORD

MOTOR

COMPANY

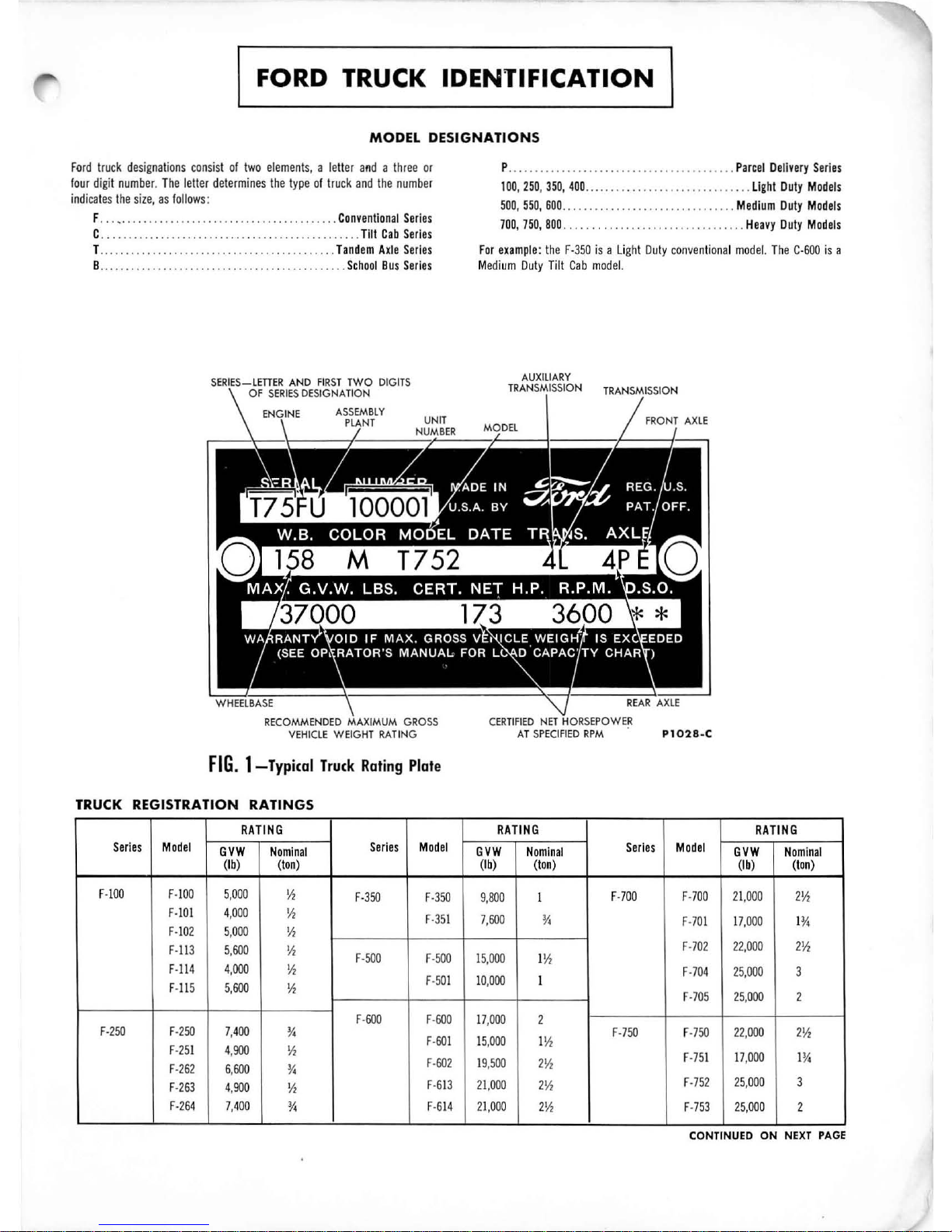

FORD TRUCK IDENTIFICATION

MODEL DESIGNATIONS

Ford truck

designations

consist

of two

elements,

a l

eUer

and

a three

or

four

digi

t

number

. T

he letter

determines

the type

of

truck

and

the number

in

dicates the

size.

as

foHows

:

F.

C.

T

..........

..

.

B .. .

..

Conventional

Ser

ies

.

...

Tilt

Cab S

eri

es

.....

Tand

em Axle S

eries

. ..

School Bus

Serie

s

DIGITS

RECOMMENDED

GR

OSS

VEHiClE WEIGHT RATI

NG

FIG.

l-Typi{al

Tru{k

Roling

Plale

TRUCK REGISTRATION RATINGS

RATING

Series

Model

GVW

Nominal

Series

Mod

el

(Ib) (

Ion

)

F·100

F·loo

5,

000

V,

F·350

F·350

F

·10

1

4,000

V,

F·

351

F·102

5.000

V,

F·m

5,600

v,

F

·SOO

HOO

F·1l4

4,000

V,

F·

ll5

5,600

V,

HOI

f·

6OO

F·

600

F

·2SO

F

·2SO

7,

400

II

F

·25

1

4,

900

V,

F

·60

1

F

·262

6,600

II

F·

602

F

·263

4.900

V,

F·613

F ·

264

7,400

II

F·614

p

.......

.. .

Parcel Delivery

Series

10

0,25

0, 350,

400

....

..

.....................

lighl

Duly

Mode

ls

500,

550,

600 ....

............

....

...

.......

Medium

Duly

Models

700, 750,

800

.

. H

eavy Dul

y Mode

ls

For

example:

the

F-350

is a light

Duty

conventional model. The

C-600

is

a

Medium Duty

Tilt

Cab mode

l.

AUX

ILI

ARY

T

RANSMISSION TRANSMISSION

CER

TIFI

ED

NET

HOllSEf'OVVER

AT

SPECIFIED

RPM

P1028·C

RATING

RATING

GVW

Nominal

Series

Mod

el

GVW

Nominal

(lb

)

(Ion)

(Ib)

(Ion

)

9,

800

I

F·700

F·

700

21

,000

2Yz

7,600

II

F·701

17,000

III

F·

702

22,000

2Yz

15,000

l

Yz

10,000

I

F·

704

25,000

3

F

·705

25,000

2

17,

000

2

15,000

I

V,

F·750

F·

7SO

22,000

2

Yz

1

9,500

2Yz

F·751

1

7,000

1%

21.000

2Yz

F

·752

25,000

3

21,000

2Y2

F·

753

25,000

2

CONTINUEO

ON

NEXT

PAGE

FORD

TRUCK

IDENTIFICATION

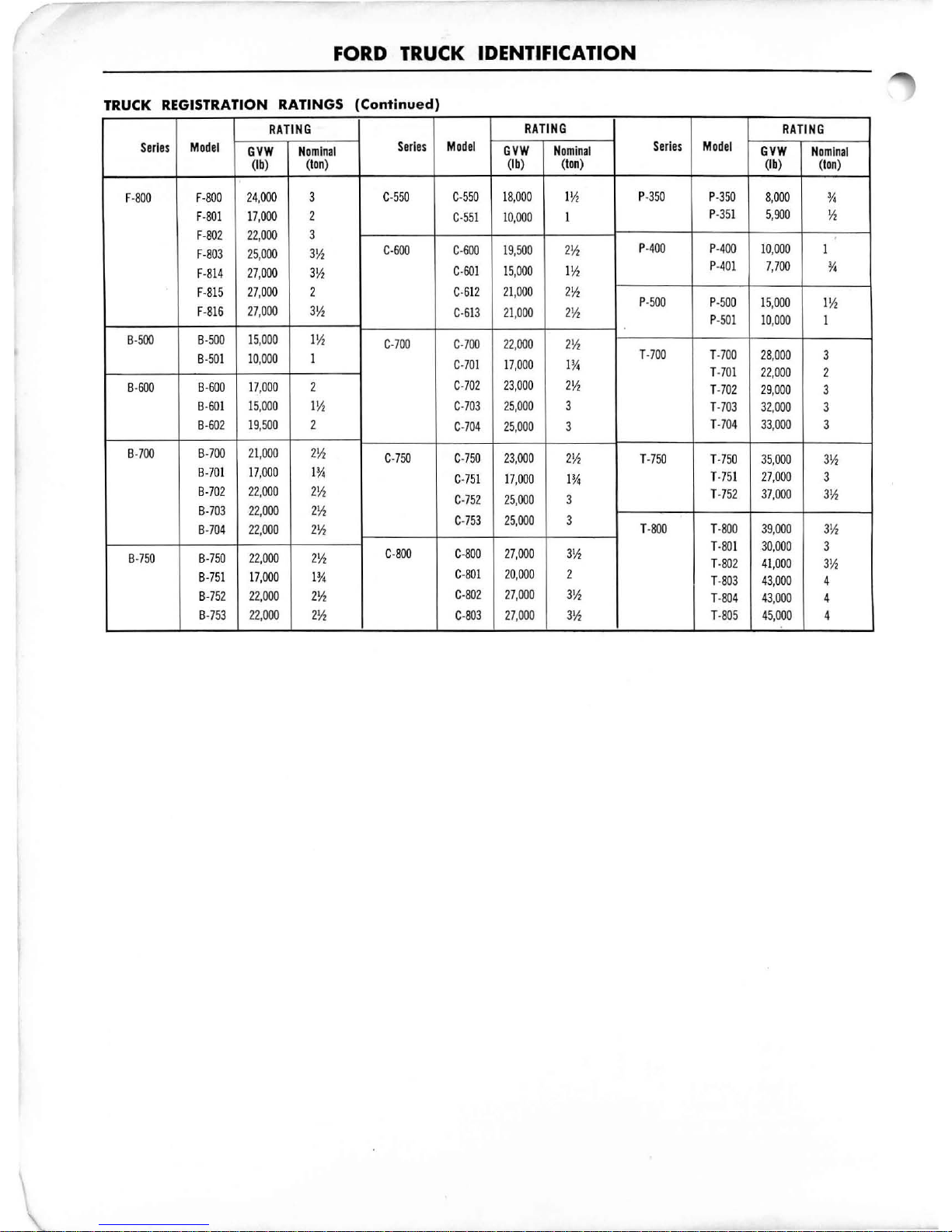

TRUCK REGISTRATION RATINGS

(Continued)

RATING

RATING

RATING

Series

Mod.1

GVW

N

omi

nal

Series

Mod.1

GVW

Nominal

Series

Mod.1

GVW

Nominal

(Ib)

(Ion)

(Ib)

(Io

n)

(Ib) (

Ion

)

F

·800

F·800

24,000

3 C·

550

C·550 18,000

I

Yz

P·

350

P·350

8,

000

V.

F·801

17,000

2

C·5

51 10,00

0 1

P·

351

5,

900

V.

F·

802

22,000

3

F·803

25,000

3Y2

C·600

C·

600

19,500

2

V.

P·

400

P·

400

10,000

I

F·814

27,000

312

C·60

1

15,000

l

Yz

P·

401

7,700

Yo

F·8

15

27,000

2

C·

611

21,

000

2Yz

27,000

3

V.

P·

500

P

·500

15,000

l

Yl

F·816

C·

613

21,000

2V.

P·

501

10,000

1

B·

500

B·500

15,

000

lY.

C·700

C·

700

12,

000

2V.

B·50

1

10,000

1

T·700

T

·70

0

28,000

3

C·

701

17,000

1

~

T-701

22,000

2

B·600

B

·600

17,

000

1

C·702

23,000

2Y1

T

·701

19,000

3

B·601

15

,00

0

1

1'2

C·703

25

,00

0

3

T·7

03

31,000

3

B·602

19,50

0 1

C·

704

25,000

3

T·7

04

33,000

3

B·

700

B·700

21,

000

2Yz

C·750

C·750

23,000

21'2

T·

750

T·

750

35,000

3Yz

B·701

17,000

1%

C·751 17,000

1%

T·

751

27,000

3

B·7

02

22,000

2112

C·

752

25,000

3

T

·752

37,000

3

Yz

B·7

03

22,000

2

V.

22,00

0

2V.

C·

753

25,000

3

T·

800

T·

800

39,000

3

Yz

B·704

C·

800

C·

800

17,000

3Y2

T·801

30,000

3

B·

750

B·7

50

22,000

2Yz

T·

802

41,000

3Yz

B

·751

17,000

1%

C·S01 10,

000

1

T·

803

43,000

4

B·75

2

22,000

2

12

C·

S01 17,00

0

3Yz

T·

804

43,000

4

B·

753

22,000

2

Yz

C·S03

2

7,00

0

3Yz

T·8

05

45,000

4

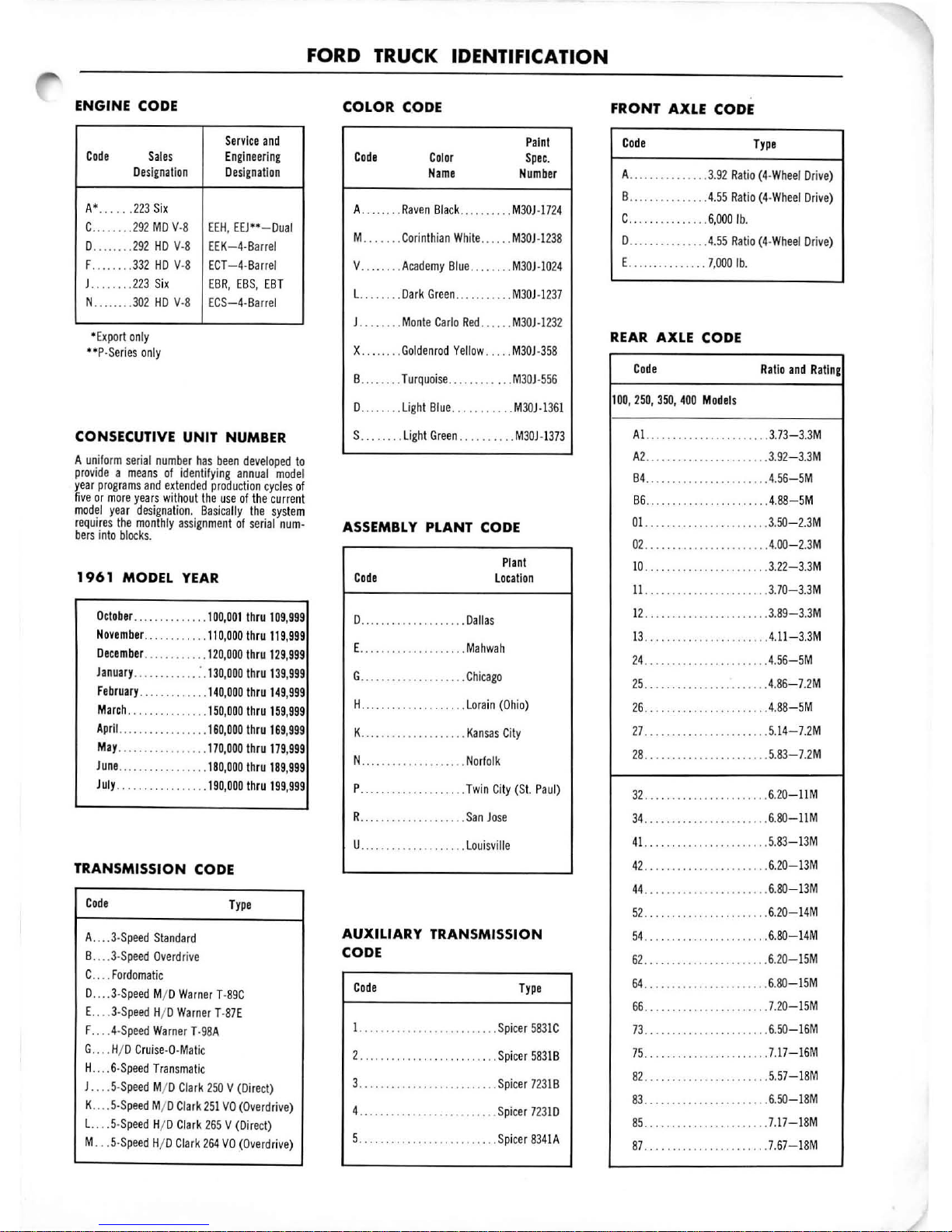

ENGINE CODE

Code

Sale

s

Designation

A

*,

.

.223

Six

C

....

.. .

292

MD

V-S

D .

.....

.

292

HD V

-S

F .. .. _ .

332

HD

V-S

J.

...

.. . .

223

Six

N

._

.. __ .

302

HD V-S

"

Export only

" P

·Series

only

Service

and

Engineering

D

esignation

EEH, EU**-Dual

EEK-4-Barrel

Eel

-4-Barrel

EBR,

EBS, EBT

ECS-4-

Barre

l

CONSECUTIVE

UNIT

NUMBER

A

uniform

serial number

has

been

developed

to

pro

vide a means

of identifying annu

al

mod

el

year

programs

and

extended

product

ion

cycles

of

five

or

more

years

with

out

the

use

of the current

mo

del

year designati

on.

Basically the

syste

m

requ

ires the mo

nth

ly

assignmen

t of

ser

ial

num

·

bers

into b

locks.

1961

MODEL

YEAR

October ...

_ ..

__

.....

100,001

thru

109,999

November

. _ .. _ .

110,000

thru

119

,999

Oecember

....

...... _120,000

thru

129,999

January

_.

__ ...

.. _ : .

130,000 thru

139,999

February

__

. _

........

140,000

thru

149,999

Mmh

.....

_ .. ... _ .. _

150,000

thru

159,999

Apr

il

__

.....

... _ ....

160,000

thru

169,999

May

..

.

....

170,0

00

thru

179,999

June

.......

.. .

......

180

,000

thru

189,999

Ju

ly

...

. ... .

190,000

thru

199,999

TRANSMISSION CODE

Cod

e

T

ype

A ...

3-Spe

ed

Standard

B

....

3-Speed

Overdri

ve

C ... F

ordo

matic

D

...

.

3-S

peed

M/ D

Warner T-S9C

E ... 3-

Speed

H/D

War

ner T-87

E

f .

..

.4-Spe

ed

Warn

er T·9

8A

G ... HID

Cruise

-O-

Mat

ic

H ... 6·

Speed Transmatic

J ... 5-Speed Mj D Cl

ark

250 V (Direc

t)

K

_ ..

5-Spee

d M/D

Clark 251

VO

(Overdrive)

l . _ .5-

Speed

H/D Cl

ark

265 V (Direct)

M

...

5-S

peed

H/D

Clark

264

VO

(Overdrive)

FORD TRUCK IDENTIFICATION

COLOR CODE

Code

A ..

M.

Color

Name

.. R

aven

Black

..

..

Corinthian

White

..

P

aint

Spec

.

Number

. _ .. M30J-

1724

. .

M30J-1238

V.

· .

...

..

Academy Blue

_ .

M30J -10

24

l · .

.....

Dark

Green

...... _ .. _M

30J-1237

J.

...

Monte

Carlo Red

. _ .

M3

0J-

1132

X · ... ...

Golden

rod

Yellow

. ... .

M3

0J-

35S

B

.....

.. Tu

rquoi

se

..

M30J·556

D

.....

.. l

ight

Blue

........... M30J-1361

S. . light

Green

. .

..

_ M30J -1

373

ASSEMBLY PLANT CODE

Cod.

D ..

E. _

.

.....

Dallas

Plant

location

...... Mahwah

G

.....

....

..

Chicag

o

H.. .

.....

Lora

in

(Ohio)

K

_.

.. _ .. _.

__

.

. .

Kansas

City

N ..

. .

Nortol

k

P .....

...

_. _. _

......

Twin City

(SI. Paul)

R

._

.

.... San Jose

u

..

..

............

..

Louisville

AUXILIARY

TRANSMISSION

CODE

Code

Type

I.

. . . . . . . . . .

_.

_ .. _ .

Spicer 5S31C

2.

...... Spic

er

583

1B

3 ..

.

.... Spicer 7231B

4.

· . . . . . . . . . . . . .. Spic

er

723

10

_ . .. ..

.... ....

... _ .. _ .. ..

Spicer

S341A

FRONT AXLE CODE

Code

Typ.

A

._

_ . ..

3_92 Ralio (4-Whee

l D

rive

)

B ..

_

...

4.55

Ratio (4-

Wheel

Driv

e)

C.

_

...

_ ..

6,OOO

lb .

o ......

4_55 Ratio (4-

Wheel Drive)

E.

_

....

.. 7

,0

00

lb .

REAR

AXLE CODE

Code

Rallo

and

Rating

100,

250,

350, 400

Mode

ls

AL

_

A2 ..

B4

..

B6

... ..

...

...•

01

...

_ . . _

__ . __

02

..

__

..

__

. _. _.

10

.

· .

3.73

-13M

__ __ . ____

192

-13M

.. _

....

_ .

4.56-5M

.

..... A_S8-5M

.....

15O-2.3M

.. _

...... 4_00-2.3M

.. _ .. ..

122-3.3M

11

. ..

__

...

__

.. 3.70-13M

1

2. _ ...

___

••.. . 189-3.3M

13. _ ...

......

4.11-3.3M

24

_.

. ..

4.56-5M

25

..

_.

_ .. __

__

.

26

. _

27

..

.

28 .........

_._

32

.

34

..

41.

42

_

44

..

51

..

54

.

62

..

64

.

66

..

73

_ .

75

..

. _ A

.S6-7.2

M

.. . 4_8S-

5M

.5

.l4-7

.2M

...

..... 5_83-7_2

M

...

. _ .6.20-

11M

· _6.SO-

11M

· _

5.S3-13M

..

........ 6.20-13M

..

___

. _

.... 6_SO-13M

.. _ .. .. 6

.20-14M

. .. 6_SO-1

4M

....

6.20-15M

......

6.SO-15M

.

__

.. .

7.20-15M

... 6_SO-16M

..

7.17-16M

S1 ...... _ ......

. .

5.57-18M

.....

6_5O-1SM

.... _ ....

.7.l7-18M

83.

S5

..

87

.

..

_

7.67-1SM

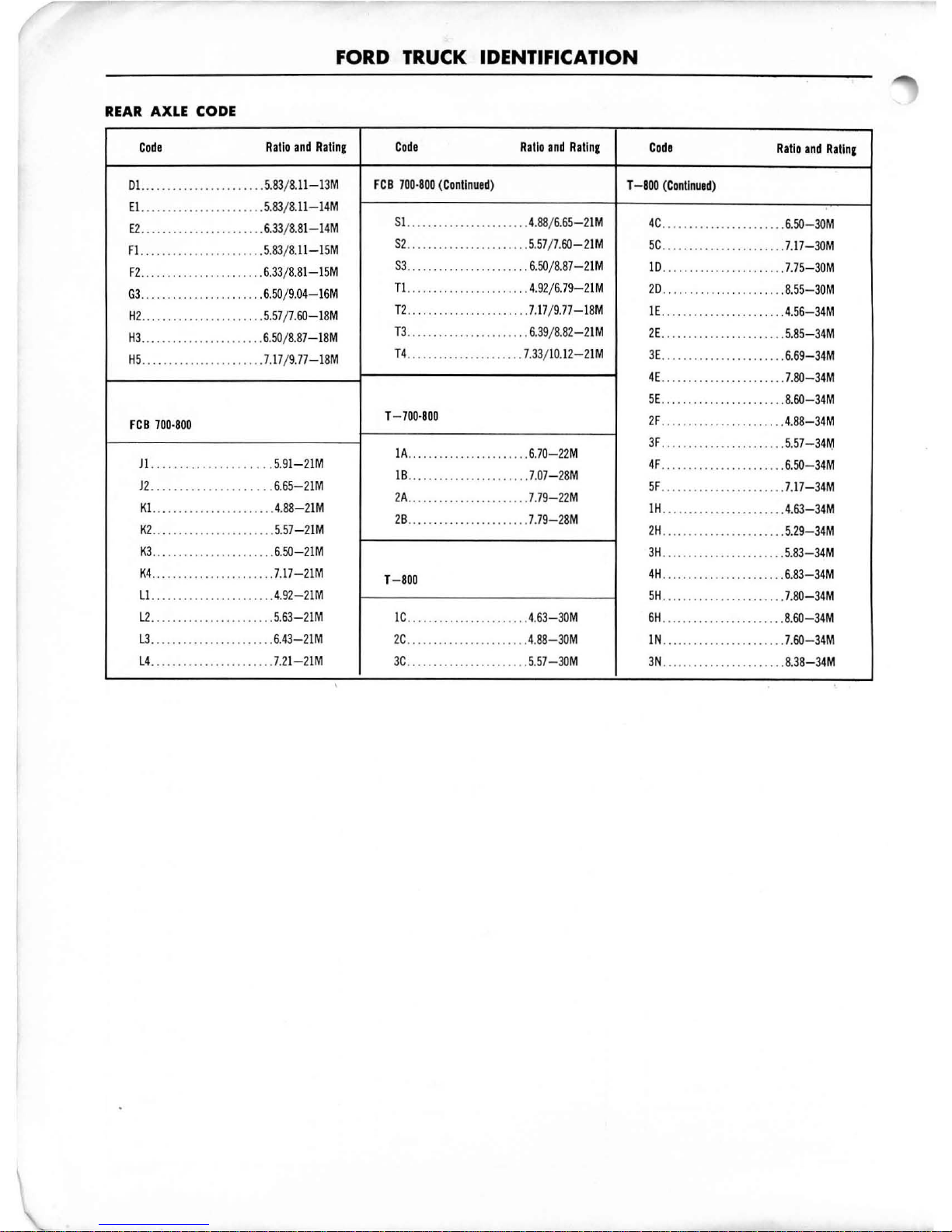

FORD

TRUCK

IDENTIFICATION

REAR

AXLE CODE

Code

D

1.

..

n

..

Rallo

and

Ralln,

· .

5.83

/8.

11-13M

.5.83/8.11-1

4M

E1

............•...

...

· .6

.33/8.8

1-1

4M

Fl

... .... ... .

....

. 5

.83/8.

11-15M

F1.. . .. ..

6.33/8.8

1-1

5M

G3

...

.....

. . .

.......... 6.50

/9.0

4-16M

H1 ..

H3

...

H5

..

FCB

700·800

Jl

)1 .

K1.

.

K1

K3

...

K4

Ll

L1.

L3

.

... ...

5.5

7/ 7

.60-18M

.

6.50/8.87-18M

.....

.7.17/9.77-18M

. .

..

5.91

- 1

1M

·

..

6.65

- 1

1M

.4

.88

- 1

1M

............

5.57-11M

....

6.50

- 1

1M

............

7.17-1

1M

......

.4.91-11M

...

5.63

- 1

1M

L4

....

.......•.•......

.6.43-11M

.7.11-11

M

Code

Rallo

and

Ralln,

FCB

100·800

(

Conllnued)

S1.

..

.

S1

...

.

S3

...

.

n ... .

T1

T3

T4 ..

T

-700·800

lA

... .

lB

...

.

1A

1B

...

T -800

lC

..

1C

.

...... 4.88

/6.65-1

1M

.5.51/1.

6O-11M

.

.•......... 6.50/8.8

1-11M

.

....

.. .

4.91/6.79-11M

.....

7.17

/9.

11-18M

.

........

6.39/8.81

- 1

1M

.7.33/10.11-1

1M

.

....

6.70-11M

..7.

07-18M

...

7.79-11M

......

7.79-18M

3C

......

..

..... 4.63-30M

4.88-30M

....

. 5.

57-30M

Cod.

T -800

(Conllnu.d)

4C

..

5C

..

Rallo

and

Rilln,

.

... 6.50-3lIM

.

...

7.17-3lIM

10

.. ..

......

.7.75-3lI

M

1D

..........

. .. ..

....

.. 8.55-30M

IE

.. .. ..

......

4.56-34M

1E

....

.5.

85-34M

3E.

..

.................. 6.69-34M

4E

.. ..

.... 7.80

-34M

5E

..............

8.60-34M

1F

......

...

..

. . ..

4.88-34M

3F

........

.. .

..........

5.57-34M

4F

.........

.

SF

....

.

IH

1H

3H

..

4H

5H

....

.

6H

....

..

IN

.. .

3N .. ..

. ..

.... 6.50-34M

.. 7.17-

34M

....... 4.63-34M

..... 5.19-34M

.. ... 5.83-3

4M

..

. 6.

83-34M

............

7.80-3

4M

.

8.60-34M

.7.

60-34M

..

8.38

-34M

-----------------------------

GROUP

I

PAR'

PAR'

PAR'

PAR'

ENGINES

EXHAUST

1-

1

GENERAL

1-

2 223

1-3

1-

292MDANDHDV-SENGINES

4 302 AND 332

ENGINE

SIX ENGINE

SERVICE

...

. . . . . . . . . . . . .

HD

V·S

SYSTEMS

. . . . . . . •. •

...........•...

ENGINES

..

..

. . . . . . . .

. . . . . .

AND

PAGE

. . • . . . . 1-2

..

1-27

I-52

..

. • .

..

1-79

PAR'

PAR'

1-

5

1 -6 SPECifiCATiONS

EXHAUST

SYSTEMS

.........

. . . . . ••• . . . . . .. . . • . . . . . . . . 1-98

.

..............

. .

..

1-103

1-2

PAR

'

~

- .

~

1-1

.~

GENERAL ENGINE SERVICE

~

~

Section

Page

1 Engine

Troubl

e Diagnosis

.. 1-2

2

Tune-Up ...

.........

.

....

1-

7

Engine Compression Test. 1-9

Fina

l (Hot) Valve

Lash

..

1-16

Cams

haft

lobe

lift.

. .

..

1-1

7

Manifold Vacuum

Test..

1-17

Prelimin ary (Cold) Valve

Lash

.............

I-I S

Th

is part

covers engine trouble

diagnosis

and

tun

e-up

procedure

s fo r

the 223

Six engine,

the

medium-dut

y

(292) and

th

e h

eavy-duty

(292, 302,

Sec

tion

P

age

3 Cleaning, Inspection, a

nd

R

eco

nditioning

......

......

1-19

Intake Man ifold

........

1-19

Exhaust Manifold

.......

1-19

Valve Rocker

Arm

Shaft

Assembly .

...........

1-19

Push Rods

...........

" 1-19

Cyl

in

der

Heads

.........

1-

19

and 332) V-8 engines.

In

addition,

the

cle anin

g,

inspection,

repair, a

nd

overha

ul

procedu

res

for

these co-

gines arc covered.

D ENGINE TROUBLE

DIAGNOSIS

Engine performance complaints

usua

ll

y fall under

one

of

the basic

h

eadi

ngs li st

ed

in

the

"Engine

Trou

ble Diagnosis

Guide."

When

a

par

ti

cul

ar troub

le can

not

be traced

to a definite cause by a simple

ch

eck,

the poss ible i

te

ms that could be at

fault are listed in the order

of

their

probable occurrence. Check the

items

in

the

order listed.

For

ex-

ample,

under Poor Acceleration th e

ig

nition system

is

listed as a proba-

ENGINE

TROUBLE

DIAGNOSIS GUIDE

ENGINE

WILL

NOT

CRANK

ENGINE CRANKS

NORMALLY,

BUT

WILL

NOT

START

Th

e cause of this trouble is usually

in th e starting system

(Pa

rt

12-2).

If

the starting system

is

not

at

fault, check for a hydrostatic lock

or

a seized engine, as follows:

Remov

e the spa

rk

plug

s,

then

at-

te

mpt

to crank the engine with the

Ch

eck

the fuel suppl

y.

If

there

is

sufficient fuel in the tank, the cause

of

the trouble

prob

ably lies

in

either

the ignition or the fuel system.

To

determine which system is at

fault, perfo rm th e fo

ll

owing test:

Disconnect a spark plug wire.

Ch

eck

the

spa

rk

intensity at

the

end

of

th e wire by installing a terminal

adapter

in

the terminal

of

the wire to

be checke d.

The

n, ho

ld

the adapter

approx

im

ate

ly

o/w

in

ch from the ex-

hau

st manifold and

crank

the engine.

Section

Page

Valves

.................

1-

20

Timing

Chai

n-223

Six

a

nd

292

V-S ..........

1-

21

Timing

Gears

- 302 a

nd

332

HD

V-S

........

. .

..

1-21

Ca

msh

aft.

. . . . . . . . . . . . . . 1-

21

Crankshaft

....

. ......

. . 1-22

Co

nnecting

Rods

........

1-22

Piston

s,

Pi

ns,

and

Rings.. 1-22

Main

and

Con

nectin g

Rod

Bearings

.............

1-

24

Flywheel- M

anua

l-Shift

Tr

ansm issi

ons,

.........

1-24

Cylinder Block

..........

1-25

Oil P

an

and

Oil

Pumps ..

1-25

Crankcase V

entilat

ion

System

Ma

intenance

...

1-26

For

engine remov al, disassembly,

assembly, and installa

ti

on

proce-

dures, refer to the

part

of this

group

which cove rs the

applicable engines.

ble cause

of

the trouble.

All the ignition system items that affect acceleration are

li

sted. Check a

ll

these items

before proceed ing to the next probab

le cause.

starter.

If

the engine

cra

nks, it indi-

cates that wa ter is

leaking into the

cy

lind

ers.

Remo

ve the cylin

der

head

(s)

and

inspect the gasket(s)

andl or head

(s)

for cracks. Examine

the cylind

er

block for crack s.

IF

THERE

IS

NO

SPAR K OR

A WEAK SPARK

AT

THE

SPARK PLUGS

Th

e cause

of

the trouble is in the

ig

nition system.

To

determine if the cause of the

trouble is in the primary

or

the

seco ndary circuit, remove the co il

high tension lead fr

om

the top

of

the distributor and ho

ld

it approx

imatel y 3/ 16 inch from the cylinder

head. With the ignition on, c

rank

the

engine and check for a spar

k.

If

the s

park

at the co

il

high te

n-

CONTINU ED ON

NEXT PAGE

PART

1 -

1-

GENERAL

ENGINE

SERVICE

1-3

ENGINE

TROUBLE

DIAGNOSIS GUIDE

(Continued)

ENGINE CRANKS

NORMALLY,

BUT

WILL

NOT

START

(Continued)

ENGINE STARTS,

BUT

FAILS

TO

KEEP

RUNNING

ENGINE RUNS,

BUT

MISSES

si

an

lead is

goo

d, the

cause

of

th e

trouble

is proba

bly in

the

dis

tribut

or

cap or r

oLO

r.

jf

there

is no spa

rk

or a weak

s

park

at the coil high tensi

on lead,

th e cali

se

of

the

trouble

is

probably

In the primary

circuit, co

il to dis-

trib

utor hig

h tcnsion l

ead, or

th e

coil.

IF

THERE

IS A GOOD

SPARK

AT

THE

SPARK PLUGS

Check the s

park

plugs. If th e s

park

plugs afC

not

at fault.

chec

k the fol-

lowin g item

s:

CHOKE

Check

the c

hok

e linkage

for

bind-

ing or damage.

Make

certa in the

choke plate cl

oses

when the cho

ke

knob

on the ins

tru

ment

panel is

pulled

Ollt and that

the

plate

ope

ns

wh

en

the knob

is

push

ed

in.

FUEL

SUPPLY

AT

CARBURETOR

Work

th e t

hro

ttle by hand seve ral

times.

Each tim

e the

throttle

is actu-

at

ed,

fuel should

spurt

from

the

ac-

cele

rating

pump discha

rge nozz

le(s

).

If

fuel is disc

harged

by the ac-

FUEL

SYSTEM

1dle fu e l

mixture

needle(s) n

ot

pr

operly

adju

sted.

En

gine idle sp

eed

set t

oo

low.

Flo

at selling

incorrect.

Fuel

inlet sys tem not op

era

ting

pr

op

erly.

Dirt

or

watc

r in fue l lines

or

carburetor.

Carburetor

icing.

De

termine

if the miss is steady

or

errat

ic a

nd

at wh

at

speed

the miss

occurs by

operating

the engine at

va rious

speeds

under

load.

MISSES

STEADILY

AT

ALL

SPEEDS

Isol

ate

th e miss by opera

tin g the

en

gi

ne with

one cyl

inder

not

firing.

Thi

s is done by

operating

the

eng

ine

wit h

th

e ignition wire rem

oved from

one spar

k plug at a

time

, until a

ll

cylinder

s h

owe

been

checked. Ground

the

spar

k plug wire

remo

ved.

celcrating

pump,

the

engine

is

prob-

ably floode

d, or

there

is wate r

III

the fu el sys

tem,

or an

eng

ine

me-

ch,m ical item

is

at

fault .

If

fuel is not disc

harged

by the

accelerating

pump, d isc

onnect

th e

carburetor

fuel in l

et

line

at

th

e

carburetor.

Usc a s

uita

ble contai n

er

to calch the fue

l. Crank

the engine

to

see

if

fue

l is

reaching

the

carburetor.

If fue l is

not reac

hin

g the car-

bu

re tor, ch

eck:

The

fue

l p

ump

.

The

fuel filter (

HD

V-S en

gine

s).

The carburetor

fuel inlet line

for

obs

tructi

ons.

T he

fuel pu

mp nexible inlet line

for a collapsed condition

(mecha nical

fuel p

ump).

The

fuel

tank

line f

or

obstruc

-

tions.

The

fu el tank vent.

If fue l is reac

hing

th e

carbu

reto

r,

check:

Th

e fuel inlet

sys

tem

including,

th e fuel inl

et

screen,

the fuel inlet

n

eed

le

and

scat assembly, a

nd the

float assembly.

Fuel

pump

defective

.

Fu

el

pump

safety swit c h

defective

(elec

tric

fuel pump)

.

Ch

cck

for

dirt

in the

carburetor

n

ot allowing fuel

to

enter

or

be di s-

charged from th e idle

sys

tem.

IGNITION

SYSTEM

Leak

age

In

th e high

tens

ion

wiring.

If

th e

engine speed

cha nges when

a

part

icular cylinde r is sh

orte

d Ollt,

th at cylinder

was deliveri

ng

power

before

bei ng sh

orted

out.

If

no

change

in Ihe engine

operation

is

evident

, the miss

was caus

ed

by

th

at cylind

er

no t deliveri ng

power

before

being

shor

ted

out.

1n th

is

case,

check

the :

IGNITION SYSTEM

If

the miss is isol

ate

d in a

par·

tic u

lar

cylinde

r,

perform

a s

park

test on the ignition l

ead

of

the cyl-

ind er.

CONTINUED ON NEXT

PAGE

1-4

GROUP

1-

ENGINES

AND

EXHAUST

SYSTEMS

ENGINE

TROUBLE

DIAGNOSIS GUIDE

(Continued)

ENGINE RUNS,

BUT

MISSES

(Continued)

ROUGH ENGINE

IDLE

If

a good spark docs not occur,

th e trouble is

in

the secondary cir-

cuit

of

the sys tem. Check the sp

ark

plug wire, and

the

distributor

cap.

]f

a good spark occurs, check the

spark

pl

ug.

If the spark plug

is

not

at

fault, a mechanica l

component

of

the

engine

is probably at fault.

ENGINE

Perform

H compression t

es

t to de-

termine which mechanical compq -

nent

of

the engine

is

at

fault (page

1-9).

MISSES

ERRATICALLY

AT

ALL

SPEEDS

EXHAUST

SYSTEM

Exhaust

system restricte d.

IGNITION

SYSTEM

Defective breaker points, con-

denser, secondary wiring, coil,

or

spark plugs.

High

tension leakage across the

coil, rOlor, or distributor cap.

FUEl

SYSTEM

Float setting incorrec

t.

Fuel

inl

et

sys

tem not operating

properly.

Dirt

or water

In

fu

el lines

or

carbureto

r.

Restrictcd [uel filt

er (

HD

V-8 en-

gines).

COOLIN

G SYSTEM

Check

the cooling system for in-

ternal leakage

and/or

for a condi-

FUEL

SYSTEM

Engine idle speed set too low.

Idle fue l mixture ncedle(s)

not

properl

y adjusted.

Fl

oat

selling incorrect.

Air

leaks bctwee n the ca

rburetor

and the manifold and/

or

fittings.

Fuel leakage at the

carb

uretor

fuel bowl(s).

Pow

er valve leaking fue

l.

Idle

fuel system ai r bleeds o r fuel

passages rest

ri

cted.

Fuel bleedin g from the accele rat-

ing

pump

discharge nozzle(s).

Secondary throttle plates not

clos-

ing (4-barre l

carburetor)

.

ti

on

that preve nts

the

engine from

reaching

normal

operating

tempera-

ture.

ENGINE

Perf

orm a

compression

test (page

1-9) to

determine

which mechanical

co

mponent

of

the engine is

at

fault.

MISSES

AT

IDLE

ONLY

FUEl

SYSTEM

Idle fuel mix

tur

e needlc(s) not

properly adj usted.

IGNITION

SYSTEM

Excessive play in the dist

ributor

shaf

t.

Worn

distributor

cam.

EN

GINE

Perform a compression

test (page

t -9) to

determine

which mechanical

co

mp

one

nt

of

the engine

is

at

faull.

MISSES

AT

HIGH

SPEED

ONLY

FUEL

SYSTEM

Power

valve clogged

or

dam

aged.

Low

or

erratic

fuel

pump

pres-

sure.

Fuel

inlet system

not

operating

properly.

Restricted [lIcl filter

(HD

V -8 en-

gines).

COOLING

SYSTEM

Engine overheating.

Improper

secondary thrott le plate

stop

adjustment

(4 - barrel car-

buretors).

Leaking fuel

enrichment

valve.

IGNITION

SYSTEM

I

mprope

rly a

dju

sted

or

defective

br

eaker

points.

Fouled

or

improper

ly adjusted

s

park

plugs.

Incor

rect

ignition timing.

Spark plug misfirin

g.

EXHAUST SYSTEM

Exhaust

gas control valve inop-

erative

or

sticking (223 Six and 292

MD

V-8).

CONTINUED

ON NEX

T PAGE

Loading...

Loading...