Page 1

Page 2

Copyright © 2009, Forel Publishing Company, LLC, Woodbridge, Virginia

All Rights Reserved. No part of this book may be used or reproduced in any manner whatsoever

without written permission of Forel Publishing Company, LLC. For information write to Forel

Publishing Company, LLC, 3999 Peregrine Ridge Ct., Woodbridge, VA 22192

1961 Ford Thunderbird Shop Manual

EAN: 978-1-60371-011-4

ISBN: 1-60371-011-6

Forel Publishing Company, LLC

3999 Peregrine Ridge Ct.

Woodbridge, VA 22192

Email address: webmaster@ForelPublishing.com

Website: http://www.ForelPublishing.com

This publication contains material that is reproduced and distributed under a license from Ford

Motor Company. No further reproduction or distribution of the Ford Motor Company material is

allowed without the express written permission of Ford Motor Company.

NNoottee ffrroomm tthhee EEddiittoorr

This product was created from the original Ford Motor Company’s publication. Every effort has

been made to use the original scanned images, however, due to the condition of the material;

some pages have been modified to remove imperfections.

Although every effort was made to ensure the accuracy of this book, no representations or

warranties of any kind are made concerning the accuracy, completeness or suitability of the

information, either expressed or implied. As a result, the information contained within this book

should be used as general information only. The author and Forel Publishing Company, LLC

shall have neither liability nor responsibility to any person or entity with respect to any loss or

damage caused, or alleged to be caused, directly or indirectly by the information contained in

this book. Further, the publisher and author are not engaged in rendering legal or other

professional services. If legal, mechanical, electrical, or other expert assistance is required, the

services of a competent professional should be sought.

Disclaimer

Page 3

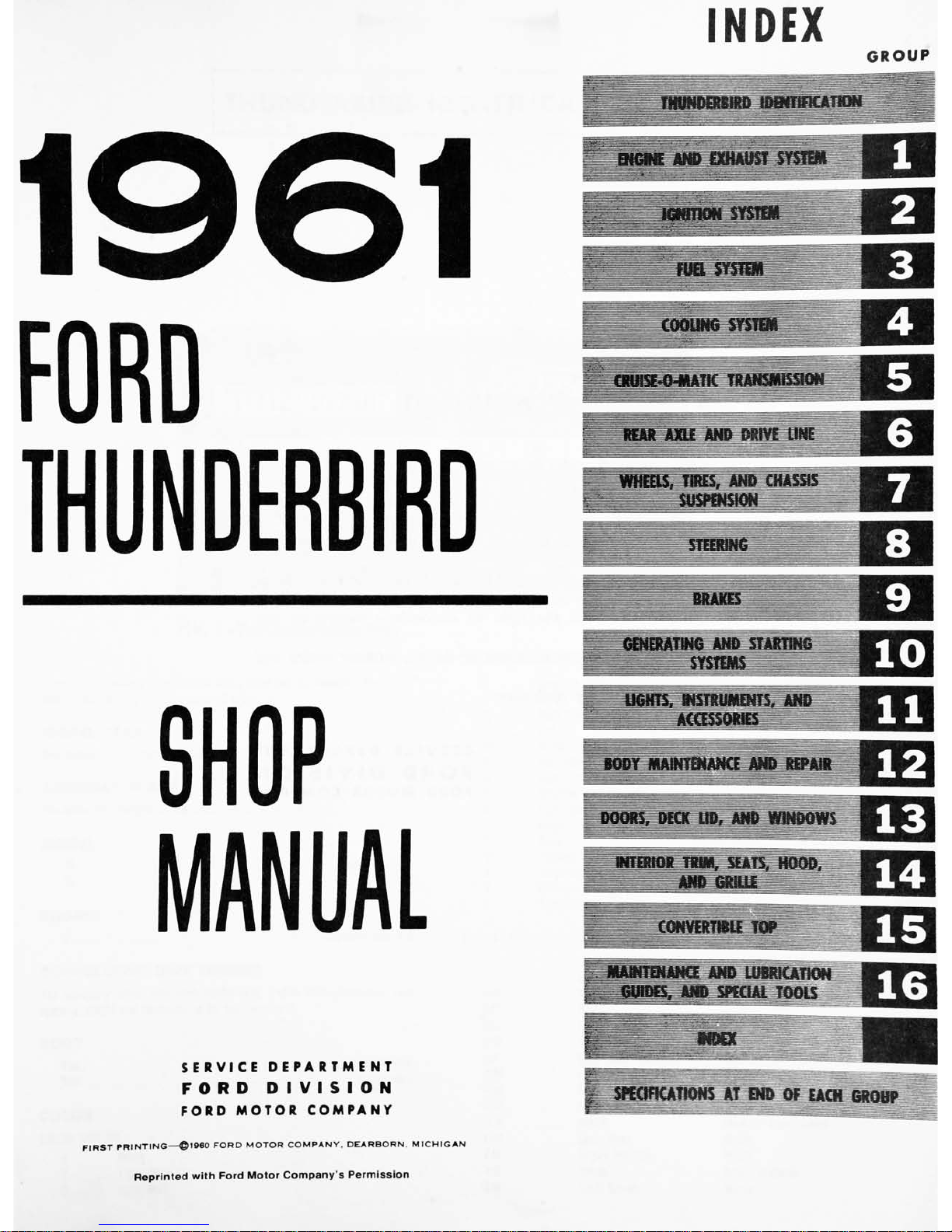

INDEX

GROUP

SERVICE

DEPARTMENT

FORD

DIVISION

FORD

MOTOR

COMPANY

FIRST

PRINTING

1900

FORD

MOTOR

COMPANY,

DEARBORN.

MICHIGAN

Reprinted

with

Ford

Motor Company's

Permission

Page 4

FOREWORD

This

manual

provides

information

for

the

proper

servicing

of

the

1961

Thunderbird.

The

descriptions

and

specifications

contained

in

this

manual

were

in

effect

at

the

time

the

manual

was

approved

for

printing.

The

Ford

Division

of

Ford

Motor

Company

reserves

the

right

to

discontinue

models

at

any

time,

or

change

specifications

or

design,

without notice

and

without

incurring

obligation.

SERVICE

DEPARTMENT

FORD

DIVISION

FORD

MOTOR

COMPANY

Page 5

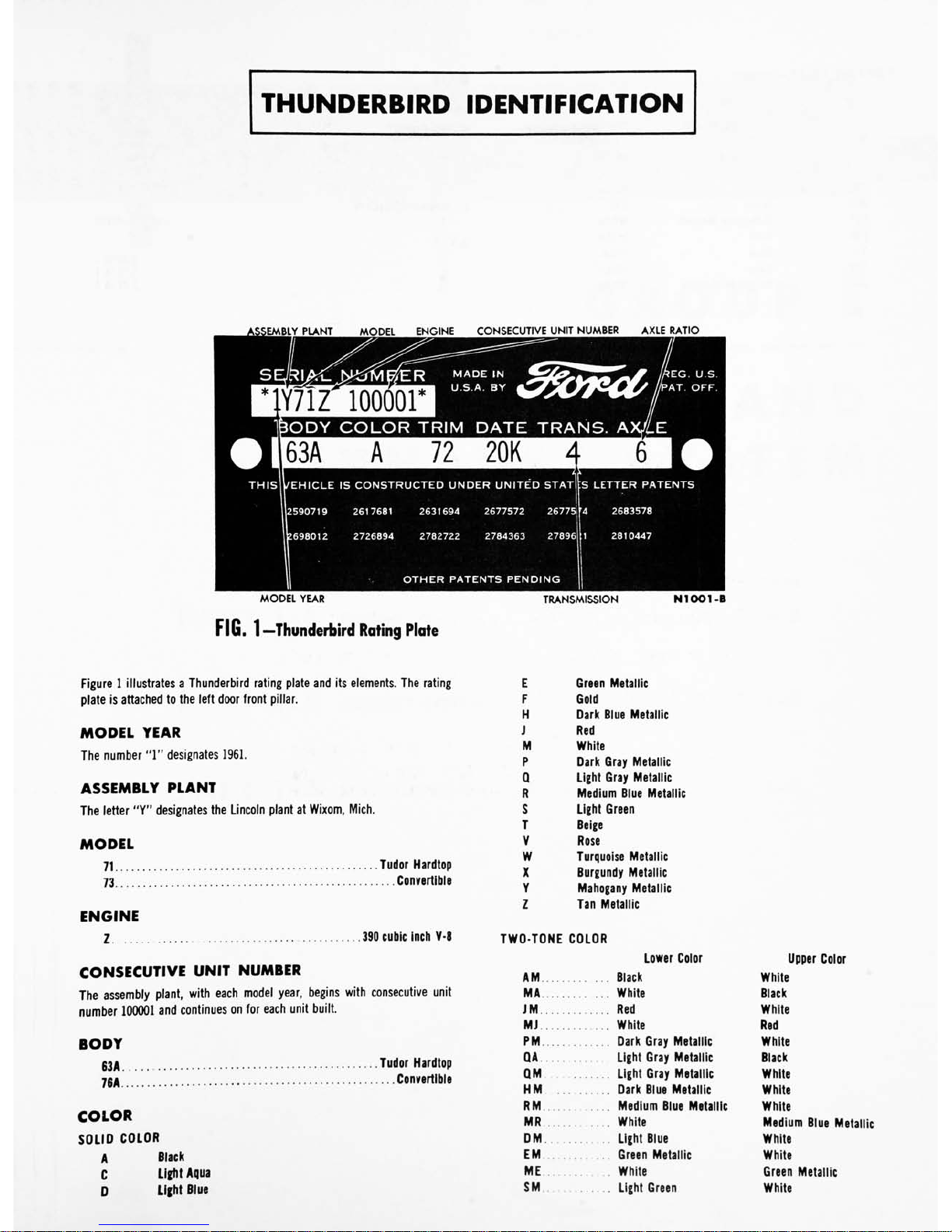

THUNDERBIRD

IDENTIFICATION

>EMBLY

PLANT

MODEL

ENGINE

CONSECUTIVE

UNIT

NUMBER

AXLE

RATIO

1Y71Z

100001

TP

MADE

IN

U.S.A.

BY

&&F<1'

*EG.

U.S.

'AT.

OFF.

BODY

COLOR

TRIM

DATE

TRANS.

A.

THIS

U/EHICLE

IS

CONSTRUCTED

UNDER

UNITED

STAT

CS

LETTER

PATENTS

2590719

2617681

2631694

2677572

26775ir4

2683578

'.698012

2726894

2782722

2784363

27896

1

2810447

OTHER

PATENTS

PENDING

MODEL

YEAR

FIG.

1

Thunderbird

Rating

Plate

TRANSMISSION

NIOOl-B

Figure

1

illustrates

a

Thunderbird

rating

plate

and

its

elements.

The

rating

plate

is

attached

to

the

left

door

front

pillar.

MODEL

YEAR

The

number

"1"

designates

1961.

ASSEMBLY

PLANT

The

letter

"Y"

designates

the

Lincoln

plant

at

Wixom,

Mich.

MODEL

71

Tudor

Hardtop

73

Convertible

ENGINE

1

390

cubic

inch

V-8

CONSECUTIVE

UNIT

NUMBER

The

assembly

plant,

with

each

model

year,

begins

with

consecutive

unit

number

100001

and

continues

on

for

each

unit

built.

BODY

53A

Tudor

Hardtop

70A

Convertible

COLOR

SOLID

COLOR

A

Black

C

Light

Aqua

D

Light

Blue

E

Green

Metallic

F

Gold

H

Dark

Blue

Metallic

J

Red

M

White

P

Q

R

Dark

Gray

Metallic

Light

Gray

Metallic

Medium

Blue

Metallic

S

T

V

Light

Green

Beige

Rose

W

Turquoise

Metallic

X

Y

z

Burgundy

Metallic

Mahogany

Metallic

Tan

Metallic

TWO-TONE

COLOR

Lower

Color

AM

Black

MA

White

JM

Red

MJ

White

PM

Dark

Gray

Metallic

QA

Light

Gray

Metallic

QM

Light

Gray

Metallic

HM

Dark

Blue

Metallic

RM

Medium

Blue

Metallic

MR

White

DM

Light

Blue

EM

Green

Metallic

ME

White

SM

Light

Green

Upper

Color

White

Black

White

Red

White

Black

White

White

White

Medium

Blue

Metallic

White

White

Green

Metallic

White

Page 6

TWO-TONE

COLOR-Continued

Lower

Color

Upper

Color

WM

Turquoise

Metallic

White

MW

White

Turquoise

Metallic

CM

Light

Aqua

White

TZ

Beige

Tan

ZM

Tan

White

MZ

White

Tan

YM

Mahogany

Metallic

White

FM

Gold

White

VA

Rose

Black

VM

Rose

White

XM

Burgundy

Metallic

White

DATE

The

date

code

shows

the

day

and

month

when

the

Thunderbird

was

com

pleted.

The

months

are

designated

as

follows:

A

January

G

July

B

February

H

August

C

March

J

September

D

April

K

October

E

May

L

November

F

June

M

December

TRANSMISSION

4

AXLE

6

3..

H.

Cruise-O-Matic

3.00

to

1

3.10

to

1

2.91

to

1

Page 7

GROUP

I

ENGINE

AND

EXHAUST

SYSTEM

PAGE

PART

1-1

ENGINE

1.

P

A

RT

1-2

EXHAUST

SYSTEM

1-45

PART

1-3

SPECIFICATIONS

1-47

Page 8

12

Section

Page

1

Description

1-2

2

Engine

Trouble

Diagnosis.

.

1-6

3

Tune-Up

1-12

Engine

Compression

Test

.

1-13

Camshaft

Lobe

Lift

1-16

Valve

Clearance

1-16

Manifold

Vacuum

Test.

.

1-17

4

Engine

Removal

and

Installation

1-17

5

In-Chassis

Repair

Operations

1-19

Engine

Supports

1-19

Section

Page

Valve

Rocker

Aim

Shaft

Assembly

1-19

Intake

Manifold

1-21

Exhaust

Manifold

1-22

Regulator

Valve

Positive

Crankcase

Ventilation

System

1-23

Cylinder

Heads

and

Valves

1-23

Valve

Stem

Seal

Replacement

1-26

Cylinder

Front

Cover

and

Timing

Chain

1-27

Section

Page

Camshaft

1-29

Camshaft

Rear

Bearing

Bore

Plug

Replacement.

.

1-30

Hydraulic

Valve

Lifter

Replacement

1-30

Crankshaft

Lower

Rear

Oil

Seal

Replacement

1-31

Main

and

Connecting

Rod

Bearing

Replacement

1-32

Piston

and

Connecting

Rod

Assembly

1-32

Flywheel

1-36

Oil

Pan

and

Oil

Pump

..

.

1-36

Oil

Filter

Replacement.

.

.

1-36

6

Work

Stand

Repair

Operations

1-38

Crankshaft

1-38

Camshaft

Bearing

Replacement

1-40

Engine

Disassembly

1-40

Cylinder

Block

Cleaning

and

Inspection

1-42

Engine

Assembly

1-42

7

Crankcase

Ventilation

System

Maintenance

1-44

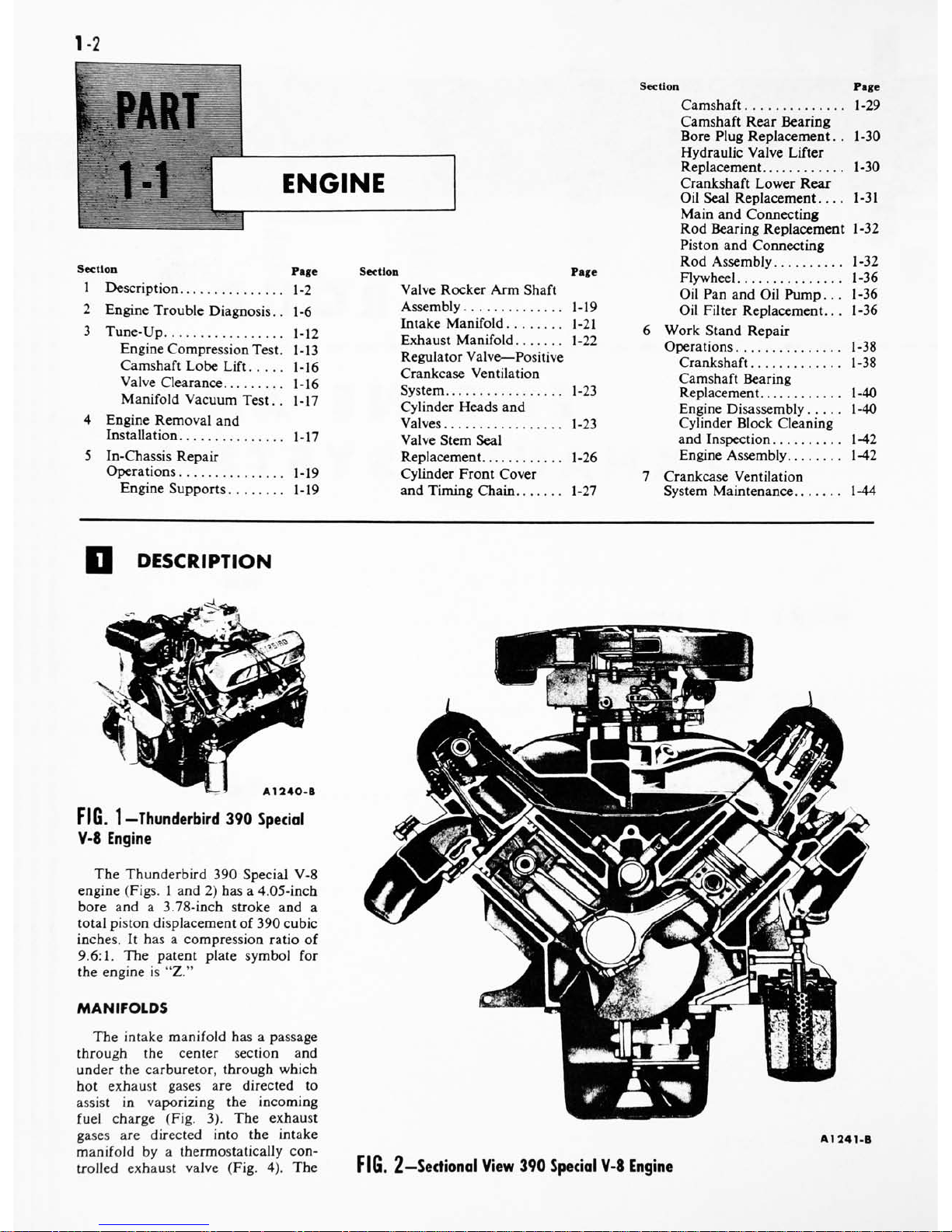

DESCRIPTION

A1240-B

FIG.

1

Thunderbird

390

Special

V-8

Engine

The

Thunderbird

390

Special

V-8

engine

(Figs.

1

and

2)

has

a

4.05-inch

bore

and

a

3.78-inch

stroke

and

a

total

piston

displacement

of

390

cubic

inches.

It

has

a

compression

ratio

of

9.6:1.

The

patent

plate

symbol

for

the

engine

is

"Z."

MANIFOLDS

The

intake

manifold

has

a

passage

through

the

center

section

and

under

the

carburetor,

through

which

hot

exhaust

gases

are

directed

to

assist

in

vaporizing

the

incoming

fuel

charge

(Fig.

3).

The

exhaust

gases

are

directed

into

the

intake

manifold

by

a

thermostatically

con

trolled

exhaust

valve

(Fig.

4).

The

A1241-B

FIG.

2

-Sectional

View

390

Special

V-8

Engine

Page 9

PART

1-1

-ENGINE

1-3

AIR

INLET

A1242-A

FIG.

3

Intake

Manifold

Exhaust

Gas

Passages

valve

is

located

at

the

outlet

of

the

right

exhaust

manifold.

When

the

valve

is

in

the

closed

or

heat

on

posi

tion,

part

of

the

exhaust

gases

are

di

rected

from

the

right

exhaust

mani

fold,

through

the

heat

riser

passage,

to

the

left

exhaust

manifold.

When

the

valve

is

open

or

in

the

heat

off

position,

more

of

the

exhaust

gases

from

the

right

manifold

are

permitted

OPEN

(HEAT

OFF)

CLOSED

(HEAT

ON)

A1073-A

FIG.

4

Exhaust

Gas

Control

Valve

4

1243-A

FIG.

5-lntake

Manifold

Fuel

Passages

AIR HEAT

CHAMBER

A

1206-

A

FIG.

6

Automatic

Choke

Heat

Chamber

to

flow

directly

out

of

the

exhaust

system

in

the

normal

manner.

The

intake

manifold

has

two

sets

of

fuel

passages,

each

with

its

own

separate

inlet

connection

to

the

car

buretor

(Fig.

5).

The

right

barrels

of

the

carburetor

feed Nos.

1,

4,

6,

and

7

cylinders

and

the

left

barrels

feed

Nos.

2,

3,

5,

and

8

cylinders.

The

distributor

is

mounted

at

the

left front

of

the

intake

manifold.

Warm

air

for

the

automatic

choke

is

drawn

from

the

heat

chamber

of

the

right

exhaust

manifold

(Fig.

6).

CYLINDER

HEADS

The

cylinder

head

assemblies

con

tain

the

valves

and

the

valve

rocker

arm

shaft

assembly.

The

combus

tion

chambers are

machined

in

the

head.

Valve

guides

are

an

integral

VALVE

OPEN

LIFTER

BODY

A1244-A

FIG.

7

-Valve

Port

Arrangement

part

of

the

head.

The

valves

are

ar

ranged

from

front

to

rear

on

both

banks

E-I-E-I-I-E-I-E

(Fig.

7).

CYLINDER

BLOCK

The

cylinders

are

numbered

from

front

to

rear,

on

the

right

bank

1,

2,

3

and

4

and

on

the

left

bank

5,

6,

7

and

8.

The

firing

order

is

1-5-4-2-6-3-

7-8.

The

oil

pump,

mounted

inside

the

oil

pan

at

the

front,

is

driven

by

the

distributor

through

an

intermediate

drive

shaft.

The

crankshaft

is

supported

by

five

main

bearings.

Crankshaft

end

thrust

is

controlled

by

the

flanges

of

the

No.

3

main

bearing.

The

pistons

have

two

compression

rings

and

one

oil

control

ring.

The

top

compression

ring

is

chrome-

plated

and

the

lower

compression

ring

is

phosphate-coated.

The

oil

con

trol

ring

assembly

consists

of

a

ser

rated

spring

and

two

chrome-plated

steel

rails.

VALVE

TRAIN

The

intake

and

exhaust

valve

as

semblies

are

the

rotating-type

which

VALVE

CLOSED

DISC

VALVE

BASE

CIRCLE

A1245-A

FIG.

8

Typical

Hydraulic

Valve

Lifter

Operation

Page 10

14

GROUP

1-

ENGINE

AND

EXHAUST

SYSTEM

rotate

each

time

the

valve

opens

and

closes.

The

push

rods

are

solid

steel

with

oil

cushioned

sockets.

The

camshaft

is

supported

by

five

bearings

pressed

into

the

block.

It

is

driven

by

a

sprocket

and

timing

chain

in

mesh

with

a

sprocket

on

the

crank

shaft.

Camshaft

end

play

is

controlled

by

a

thrust

button

and

spring

located

between

the

camshaft

sprocket

bolt

and

the

cylinder

front

cover.

An

ec

centric,

bolted

to

the

front

end

of

the

camshaft,

operates

the

fuel

pump.

Hydraulic

valve

lifters

are

used

which

provide

zero

valve

lash.

The

operation

and

parts

identification

of

the

hydraulic

valve

lifters

are

shown

in

Fig.

8.

When

the

valve

is

closed,

the

lifter

assembly

is

on

the

base

circle

of

the

camshaft

lobe

and

the

valve

push

rod

is

in

its

lowest

position.

With

the

lifter

assembly

in

this

position,

the

plunger

spring

expands

forcing

the

plunger

upward.

This

action

is

trans

mitted

to

the

valve

rocker

arm

via

the

valve

push

rod

until

there

is

solid

contact

between

the

valve

and

the

valve

end

of

the

valve

rocker

arm

(zero

valve

lash).

In

this

position,

the

oil

hole

in

the

lifter

and

plunger

is

indexed

with

the

lifter

oil

gallery

and

oil

is

forced

under

pressure

into

the

plunger.

This

creates

a

pressure

dif

ferential

above

and

below

the

valve

disc.

The

high

pressure

above

the

valve

disc

forces

the

valve

disc

open

and

the

oil

fills

the

area

below

the

plunger,

equalizing

the

pressure

on

each

side

of

the

valve

disc.

Whenever

clearance

between

the

valve

and

the

valve

rocker

arm

tends

to

be

present,

the

plunger

spring

expands

pushing

the

plunger

until

there

is

solid

contact

between

all

parts

of

the

valve

train

mech

anism.

As

the

camshaft

rotates

(valve

opening),

the

valve

lifter

is

raised

and

the

sudden

increase

in

oil

pres

sure

below

the

plunger

forces

the

valve

disc

closed

and

the

lifter

be

comes

a

hydraulic

ram.

During

this

period,

a

slight

leakage

of

oil

from

below

the

plunger

occurs.

As

the

high

point

on

the

camshaft

lobe

ro

tates

past

the

lifter,

the

push

rod

forces

the

valve

lifter

down

and

re

seats

the

valve.

The

pressure

on

the

oil

below

the

plunger

is

relieved

and

the

valve

disc

opens

so

that

the

chamber

can

again

be

filled.

This

cycle

is

repeated

for

each

revolution

of

the

camshaft.

Kd

if

-L

If

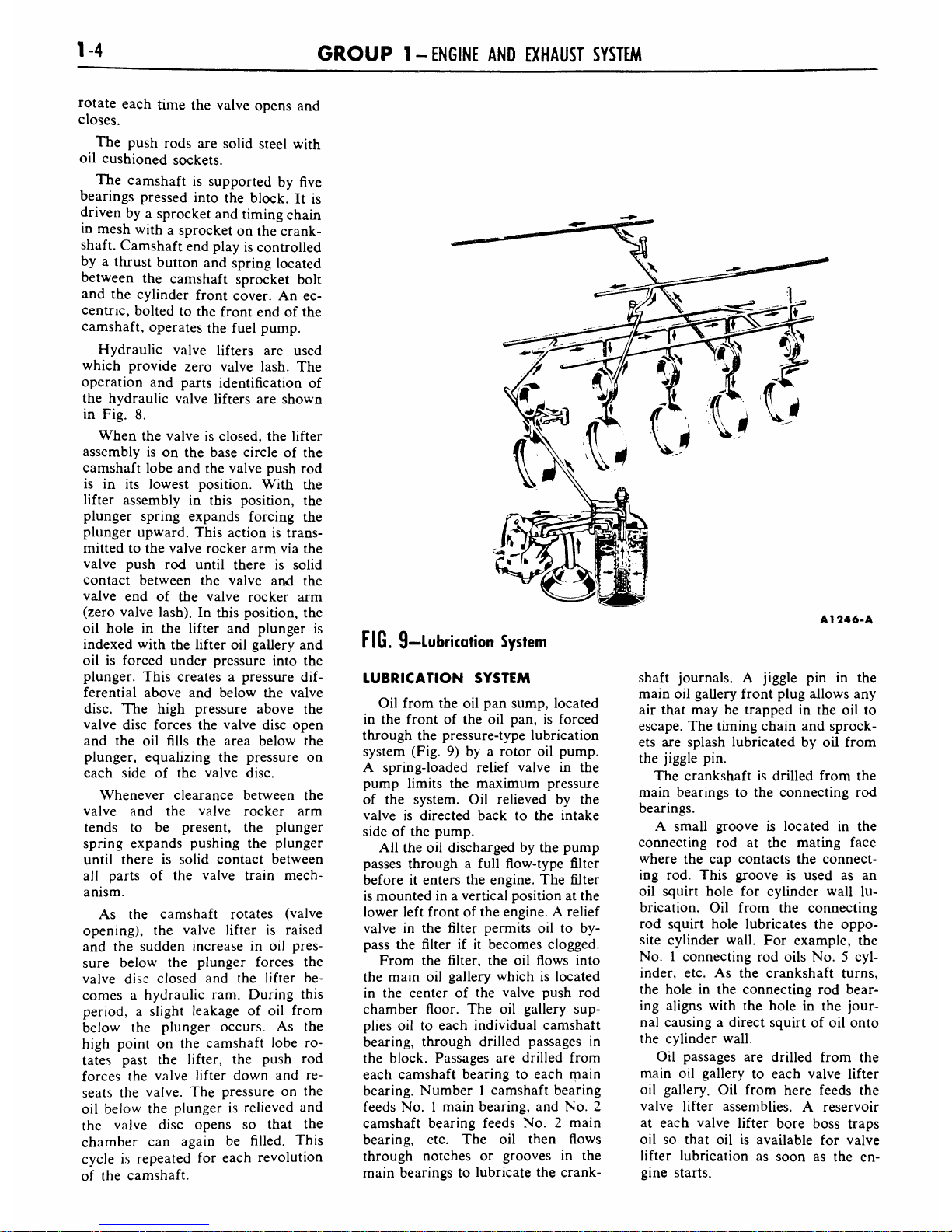

FIG.

9

Lubrication

System

LUBRICATION

SYSTEM

Oil

from

the

oil

pan

sump,

located

in

the

front

of

the

oil

pan,

is

forced

through

the

pressure-type

lubrication

system

(Fig.

9)

by

a rotor

oil

pump.

A

spring-loaded

relief

valve

in

the

pump

limits

the

maximum

pressure

of

the

system.

Oil

relieved

by

the

valve

is

directed

back

to

the

intake

side

of

the

pump.

All

the

oil

discharged

by

the

pump

passes

through

a

full

flow-type

filter

before

it

enters

the

engine.

The

filter

is

mounted

in

a

vertical position

at

the

lower

left

front

of

the

engine.

A

relief

valve

in

the

filter

permits

oil

to

by

pass

the

filter

if

it

becomes

clogged.

From

the

filter,

the

oil

flows

into

the

main

oil

gallery

which

is

located

in

the

center

of

the

valve

push

rod

chamber

floor.

The

oil

gallery

sup

plies

oil

to

each

individual

camshaft

bearing,

through

drilled

passages

in

the

block.

Passages

are

drilled

from

each

camshaft

bearing

to

each

main

bearing.

Number

1

camshaft

bearing

feeds

No.

1

main

bearing,

and

No.

2

camshaft

bearing

feeds

No.

2

main

bearing,

etc.

The

oil

then

flows

through

notches

or

grooves

in

the

main

bearings

to

lubricate

the

crank-

A1246-A

shaft

journals.

A

jiggle

pin

in

the

main

oil

gallery

front

plug

allows

any

air

that

may

be

trapped

in

the

oil

to

escape.

The

timing

chain

and sprock

ets

are

splash

lubricated

by

oil

from

the

jiggle

pin.

The

crankshaft

is

drilled from

the

main

bearings

to

the

connecting

rod

bearings.

A

small groove

is

located

in

the

connecting

rod

at

the

mating

face

where

the

cap

contacts

the

connect

ing

rod.

This

groove

is

used

as

an

oil

squirt

hole

for

cylinder

wall

lu

brication.

Oil

from

the

connecting

rod

squirt

hole

lubricates

the

oppo

site

cylinder

wall.

For

example,

the

No.

1

connecting

rod

oils

No.

5

cyl

inder,

etc.

As

the

crankshaft

turns,

the

hole

in

the

connecting

rod

bear

ing

aligns

with

the

hole

in

the

jour

nal

causing

a

direct

squirt

of

oil

onto

the

cylinder

wall.

Oil

passages

are

drilled

from

the

main

oil

gallery

to

each

valve

lifter

oil

gallery.

Oil

from

here

feeds

the

valve

lifter

assemblies.

A

reservoir

at

each

valve

lifter

bore

boss

traps

oil

so

that

oil

is

available

for

valve

lifter

lubrication

as

soon

as

the

en

gine

starts.

Page 11

PART

1-1

-ENGINE

1-5

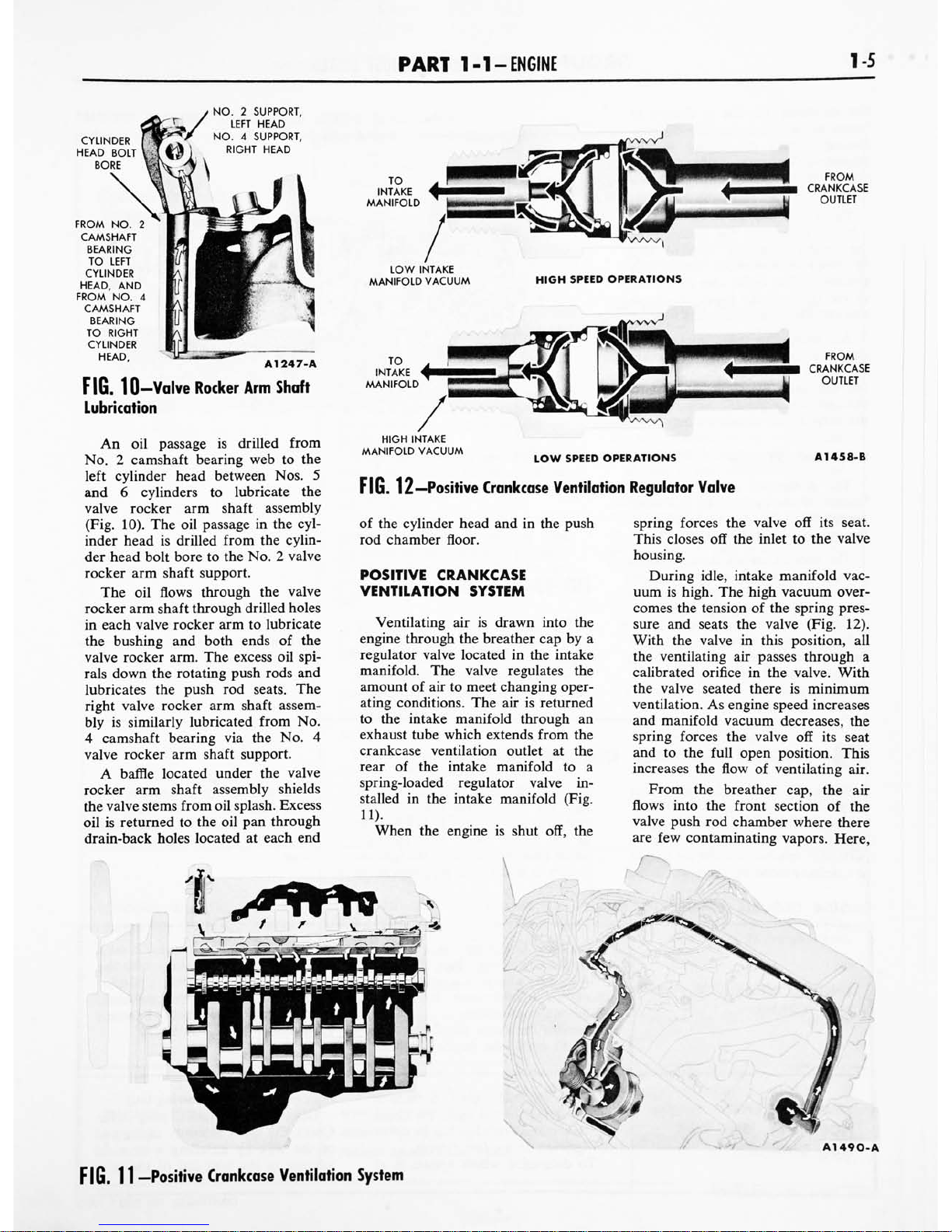

NO.

2

SUPPORT,

LEFT

HEAD

NO.

4

SUPPORT,

RIGHT

HEAD

FROM

NO.

2

CAMSHAFT

BEARING

TO

LEFT

CYLINDER

HEAD,

AND

FROM

NO.

4

CAMSHAFT

BEARING

TO

RIGHT

CYLINDER

HEAD,

A

1247-A

FIG.

10-Valve

Rocker

Arm

Shaft

Lubrication

An

oil

passage

is

drilled

from

No.

2

camshaft

bearing

web

to

the

left

cylinder

head

between

Nos.

5

and

6

cylinders

to

lubricate

the

valve

rocker

arm

shaft

assembly

(Fig.

10).

The

oil

passage

in

the

cyl

inder

head

is

drilled

from

the

cylin

der

head

bolt

bore

to

the

No.

2

valve

rocker

arm

shaft

support.

The

oil

flows

through

the

valve

rocker

arm

shaft

through

drilled

holes

in

each

valve

rocker

arm

to

lubricate

the

bushing

and

both

ends

of

the

valve

rocker

arm.

The

excess

oil

spi

rals

down

the

rotating

push

rods

and

lubricates

the

push

rod

seats.

The

right

valve

rocker

arm

shaft

assem

bly

is

similarly

lubricated

from

No.

4

camshaft

bearing

via

the

No.

4

valve

rocker

arm

shaft

support.

A

baffle

located

under

the

valve

rocker

arm

shaft

assembly

shields

the

valve

stems

from

oil

splash.

Excess

oil

is

returned

to

the

oil

pan

through

drain-back

holes

located

at

each

end

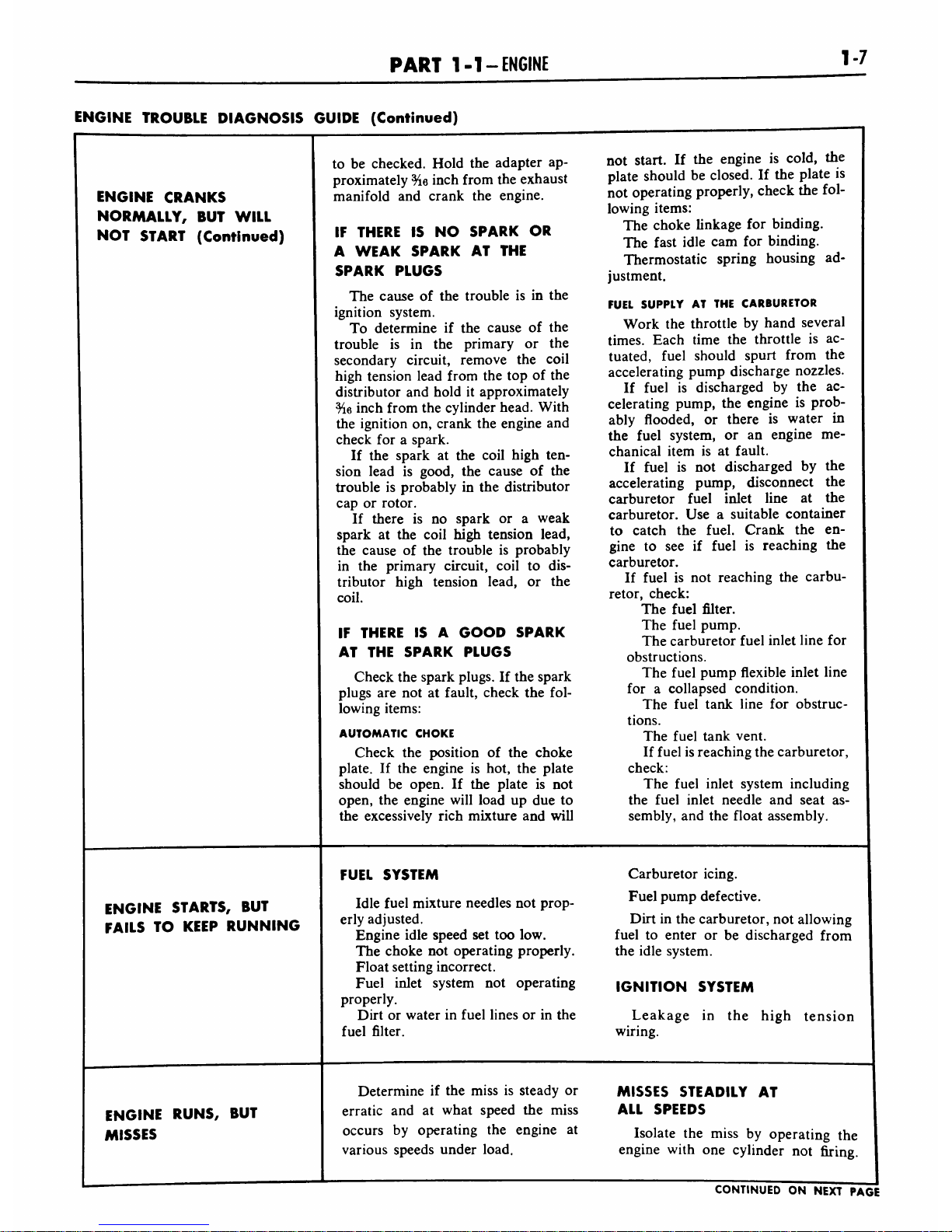

LOW

INTAKE

MANIFOLD

VACUUM

HIGH

SPEED

OPERATIONS

HIGH

INTAKE

MANIFOLD

VACUUM

LOW

SPEED

OPERATIONS

A1458-B

FIG.

12

Positive

Crankcase

Ventilation

Regulator

Valve

of

the

cylinder

head

and

in

the

push

rod

chamber

floor.

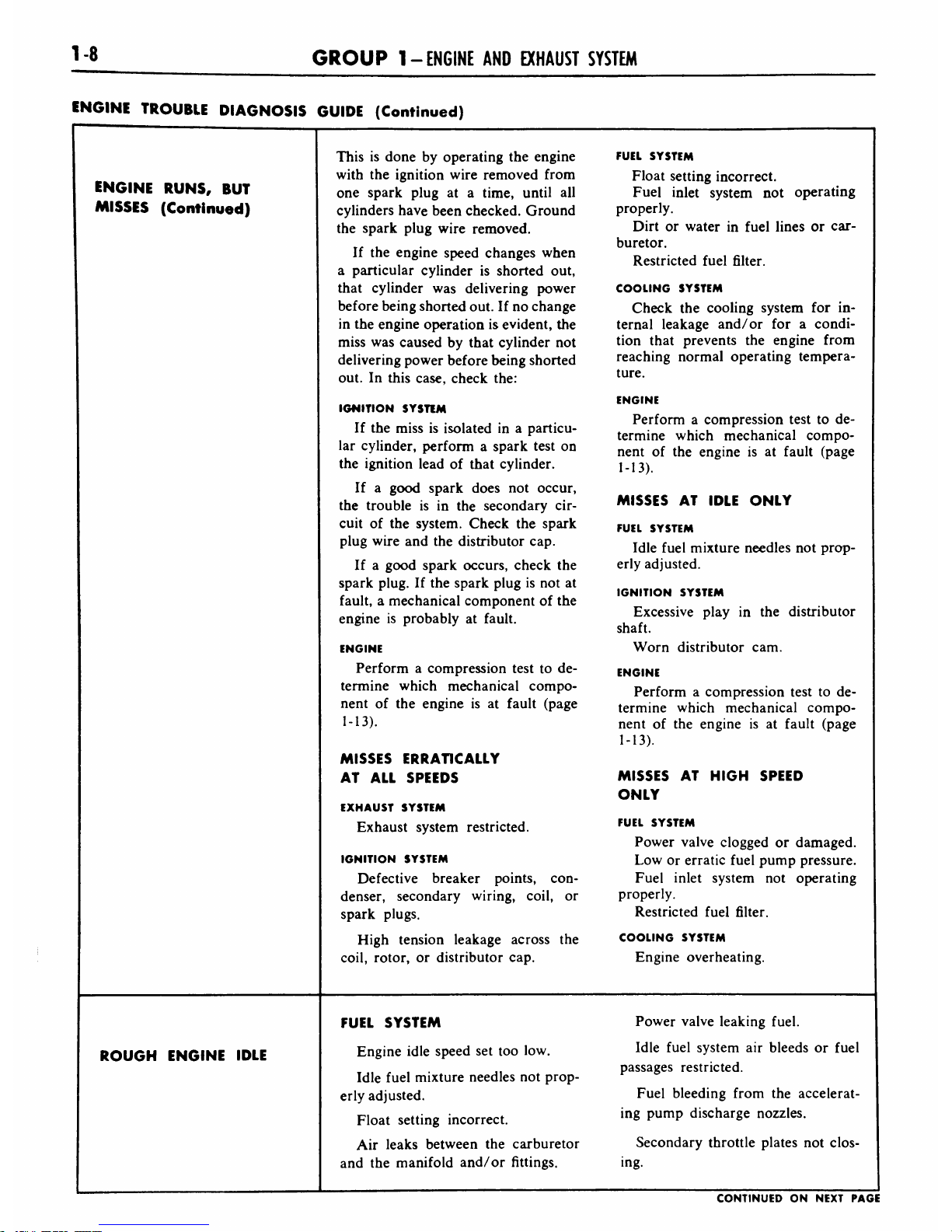

POSITIVE

CRANKCASE

VENTILATION

SYSTEM

Ventilating

air

is

drawn

into

the

engine

through

the

breather

cap

by

a

regulator

valve

located

in

the

intake

manifold.

The

valve

regulates

the

amount

of

air

to

meet

changing

oper

ating

conditions.

The

airisreturned

to

the

intake

manifold

through

an

exhaust

tube

which

extends

from

the

crankcase ventilation

outlet

at

the

rear

of

the

intake

manifold

to

a

spring-loaded

regulator

valve

in

stalled

in

the

intake

manifold

(Fig.

11).

When

the

engine

is

shut

off,

the

tt^^ft*

spring

forces

the

valve

off

its

seat.

This

closes

off

the

inlet

to

the

valve

housing.

During

idle,

intake

manifold

vac

uum

is

high.

The

high

vacuum

over

comes

the

tension

of

the

spring

pres

sure

and

seats

the

valve

(Fig.

12).

With

the

valve

in

this

position,

all

the

ventilating

air

passes

through

a

calibrated

orifice

in

the

valve.

With

the

valve

seated

there

is

minimum

ventilation.

As

engine

speed

increases

and

manifold

vacuum

decreases,

the

spring

forces

the

valve

off

its

seat

and

to

the

full

open

position.

This

increases

the

flow

of

ventilating

air.

From

the

breather

cap,

the

air

flows

into

the

front

section

of

the

valve

push

rod

chamber

where

there

are

few

contaminating

vapors.

Here,

&&%*

A1490-A

FIG.

11

Positive

Crankcase

Ventilation

System

Page 12

16

GROUP

1-

ENGINE

AND

EXHAUST

SYSTEM

the

incoming

air

has

a

chance

to

warm

up

before

contacting

contam

inating

vapors

originating

in

the

crankcase.

Warm

ventilating

air

mini

mizes

the

formation

of

crankcase

sludge.

The

ventilating

air

is

directed

by

a

baffle,

located

on

the

underside

of

the

intake

manifold,

upward

into

the

front

of

both

valve

rocker

arm

chambers.

The

baffle

also

directs

air

to

the

front

of

the

lower

crankcase

and

into

the

timing

chain

chamber.

Air

from

the

valve

rocker

arm

chamber

and

from

the

crankcase

flows

into

the

rear

of

the

valve

push

rod

chamber.

All

air

is

then

drawn

through

the

regulator

valve

and

is

discharged

into

the

intake

manifold.

COOUNO

SYSTEM

The

coolant

is

drawn

from

the

bottom

of

the

radiator

by

the

water

pump

which

delivers

the

coolant

to

the

cylinder

block

(Fig.

13).

The

coolant

travels

through

cored

passages

to

cool

the

entire

length

of

each

cylinder

wall.

Upon

reaching

the

rear

of

the

cylinder

block,

the

coolant

is

directed

upward

into

the

cylinder

heads

where

it

cools

the

combustion

chambers,

valves,

and

valve

seats

on

its

return

to

the

front

of

the

engine.

TO

RADIATOR

SUPPLY

TANK

FIG.

13

Cooling

System

The

coolant

from

each

cylinder

head

flows

through

the

water

pas

sages

in

the

intake

manifold

and

past

the

water

thermostat,

if

it

is

open,

into

the

radiator

supply

tank.

A1249-B

If

the

thermostat

is

closed,

a

small

portion

of

the

coolant

is

returned

to

the

water

pump

for

recirculation.

The

entire

system

is

pressurized

to

13-15

psi.

ENGINE

TROUBLE

DIAGNOSIS

Engine

performance

complaints

usually

fall

under

one

of

the

basic

headings

listed

in

the

"Engine

Trouble

Diagnosis

Guide."

When

a

particular

trouble

can

not

be

traced

to

a

definite

cause

by

a

simple

check,

the

possible

items

that

could

be

at

fault

are

listed

in

the

order

of

their

probable occurrence.

Check

the

items

in

the

order

listed.

For

example,

under

Poor

Acceleration,

the

ignition

system

is

listed

as

a

probable

cause

of

the

trouble.

All

the

ignition

system

items

that

affect

acceleration

are

listed.

Check

all

these

items

before

proceeding

to

the

next

probable

cause.

ENGINE

TROUBLE

DIAGNOSIS

GUIDE

ENGINE

WILL

NOT

CRANK

The

cause

of

this

trouble

is

usually

starter.

If

the

engine

cranks,

it

indi-

in

the

starting

system

(Part

10-2).

cates

that

water

is

leaking

into

the

If

the

starting

system

is

not

at

fault,

cylinders.

Remove

the

cylinder

check

for

a

hydrostatic

lock

or

a

head(s)

and

inspect

the

gaskets(s)

seized

engine

as

follows:

and/

or

head(s)

for

cracks.

Examine

Remove

the

spark

plugs,

then

at-

the

cylinder

block

for

cracks.

tempt

to

crank

the

engine

with

the

ENGINE

CRANKS

NORMALLY,

BUT

WILL

NOT

START

-

Check

the

fuel

supply.

If

there

is

fault

perform

the

following

test:

sufficient

fuel

in

the

tank,

the

cause

Disconnect

a

spark

plug

wire.

of

the

trouble

probably

lies

in

either

Check

the

spark

intensity

at

the

end

the

ignition

or

the

fuel

system.

of

the

wire

by

installing

a

terminal

To

determine

which

system

is

at

adapter

in

the

terminal

of

the

wire

CONTINUED

ON

NEXT

PAGE

Page 13

PART

1-1

-ENGINE

1-7

ENGINE

TROUBLE

DIAGNOSIS

GUIDE

(Continued)

ENGINE

CRANKS

NORMALLY,

BUT

WILL

NOT

START

(Continued)

to

be

checked.

Hold

the

adapter

ap

proximately

%e

inch

from

the

exhaust

manifold

and

crank

the

engine.

IF

THERE

IS

NO

SPARK

OR

A

WEAK

SPARK

AT

THE

SPARK

PLUGS

The

cause

of

the

trouble

is

in

the

ignition

system.

To

determine

if

the

cause

of

the

trouble

is

in

the

primary

or

the

secondary

circuit,

remove

the

coil

high

tension

lead

from

the

top

of

the

distributor

and

hold

it

approximately

Vie

inch

from

the

cylinder

head.

With

the

ignition

on,

crank

the

engine

and

check

for

a

spark.

If

the

spark

at

the

coil

high

ten

sion

lead

is

good,

the

cause

of

the

trouble

is

probably

in

the

distributor

cap

or

rotor.

If

there

is

no

spark

or

a

weak

spark

at

the

coil

high

tension

lead,

the

cause

of

the

trouble

is

probably

in

the

primary

circuit,

coil

to

dis

tributor

high

tension

lead,

or

the

coil.

IF

THERE

IS

A

GOOD

SPARK

AT

THE

SPARK

PLUGS

Check

the

spark

plugs.

If

the

spark

plugs

are

not

at

fault,

check

the

fol

lowing

items:

AUTOMATIC

CHOKE

Check

the

position

of

the

choke

plate.

If

the

engine

is

hot,

the

plate

should

be

open.

If

the

plate

is

not

open,

the

engine

will

load

up

due

to

the

excessively

rich mixture

and

will

not

start.

If

the

engine

is

cold,

the

plate

should

be

closed.

If

the

plate

is

not

operating

properly,

check

the

fol

lowing

items:

The

choke

linkage

for

binding.

The

fast

idle

cam

for

binding.

Thermostatic

spring

housing

ad

justment.

FUEL

SUPPLY

AT

THE

CARBURETOR

Work

the

throttle

by

hand

several

times.

Each

time

the

throttle

is

ac

tuated,

fuel

should

spurt

from

the

accelerating

pump

discharge

nozzles.

If

fuel

is

discharged

by

the

ac

celerating

pump,

the

engine

is

prob

ably

flooded,

or

there

is

water

in

the

fuel

system,

or

an

engine

me

chanical

item

is

at

fault.

If

fuel

is

not

discharged

by

the

accelerating

pump,

disconnect

the

carburetor

fuel

inlet

line

at

the

carburetor.

Use

a

suitable

container

to

catch

the

fuel.

Crank

the

en

gine

to

see

if

fuel

is

reaching

the

carburetor.

If

fuel

is

not

reaching

the

carbu

retor,

check:

The

fuel

filter.

The

fuel

pump.

The

carburetor

fuel

inlet

line

for

obstructions.

The

fuel

pump

flexible

inlet

line

for

a

collapsed

condition.

The

fuel

tank

line

for

obstruc

tions.

The

fuel

tank

vent.

If

fuel

is

reaching

the

carburetor,

check:

The

fuel

inlet

system

including

the

fuel

inlet

needle

and

seat

as

sembly,

and

the

float

assembly.

ENGINE

STARTS,

BUT

FAILS

TO

KEEP

RUNNING

FUEL

SYSTEM

Idle

fuel

mixture

needles

not

prop

erly

adjusted.

Engine

idle

speed

set

too

low.

The

choke

not

operating

properly.

Float

setting

incorrect.

Fuel

inlet

system

not

operating

properly.

Dirt

or

water

in

fuel

lines

or

in

the

fuel

filter.

Carburetor

icing.

Fuel

pump

defective.

Dirt

in

the

carburetor,

not

allowing

fuel

to

enter

or

be

discharged

from

the

idle

system.

IGNITION

SYSTEM

Leakage

in

the

high

tension

wiring.

ENGINE

RUNS,

BUT

MISSES

Determine

if

the

miss

is

steady

or

erratic

and

at

what

speed

the

miss

occurs

by

operating

the

engine

at

various

speeds

under

load.

MISSES

STEADILY

AT

ALL

SPEEDS

Isolate

the

miss

by

operating

the

engine

with

one

cylinder

not

firing.

CONTINUED

ON

NEXT

PAGE

Page 14

1-8

GROUP

1-

ENGINE

AND

EXHAUST

SYSTEM

ENGINE

TROUBLE

DIAGNOSIS

GUIDE

(Continued)

This

is

done

by

operating

the

engine

FUEL

SYSTEM

with

the

ignition

wire

removed

from

Float

setting

incorrect.

ENGINE

RUNS,

BUT

one

spark

plug

at

a

time,

until

all

Fuel

inlet

system

not

operating

MISSES

(Continued)

cylinders

have

been

checked.

Ground

properly.

the

spark

plug

wire

removed.

Dirt

or

water

in

fuel

lines

or

car

buretor.

Restricted

fuel

filter.

If

the

engine

speed

changes

when

a

particular

cylinder

is

shorted

out,

that

cylinder

was

delivering

power

COOLING

SYSTEM

before

being

shorted

out.

If

no

change

Check

the

cooling

system

for

in

in

the

engine

operation

is

evident,

the

ternal

leakage

and/

or

for

a

condi

miss

was

caused

by

that

cylinder

not

tion

that

prevents

the

engine

from

delivering

power

before

being

shorted

reaching

normal

operating

tempera

out.

In

this

case,

check

the:

ture.

ENGINE

IGNITION

SYSTEM

If

the

miss

is

isolated

in

a

particu

Perform

a

compression

test

to

de

termine

which

mechanical

compo

lar

cylinder,

perform

a

spark

test

on

nent

of

the

engine

is

at

fault

(page

the

ignition lead

of

that

cylinder.

1-13).

If

a

good

spark

does

not

occur,

the

trouble

is

in

the

secondary

cir

MISSES

AT

IDLE

ONLY

cuit

of

the

system.

Check

the

spark

FUEL

SYSTEM

plug

wire

and

the

distributor

cap.

Idle fuel

mixture

needles

not

prop

If

a

good

spark

occurs,

check

the

erly

adjusted.

spark

plug.

If

the

spark

plug

is

not

at

IGNITION

SYSTEM

fault,

a

mechanical

component

of

the

engine

is

probably

at

fault.

Excessive

play

in

the

distributor

shaft.

ENGINE

Worn

distributor

cam.

Perform

a

compression

test

to

de

ENGINE

termine

which

mechanical

compo

Perform

a

compression

test

to

de

nent

of

the

engine

is

at

fault

(page

termine

which

mechanical

compo

1-13).

nent

of

the

engine

isatfault

(page

1-13).

MISSES

ERRATICALLY

AT

ALL

SPEEDS

MISSES

AT

HIGH

SPEED

ONLY

EXHAUST

SYSTEM

Exhaust

system

restricted.

FUEL

SYSTEM

Power

valve

clogged

or

damaged.

IGNITION

SYSTEM

Low

or

erratic

fuel

pump

pressure.

Defective breaker

points,

con

Fuel

inlet

system

not

operating

denser,

secondary

wiring,

coil,

or

properly.

spark

plugs.

Restricted

fuel

filter.

High

tension

leakage

across

the

COOLING

SYSTEM

coil,

rotor,

or

distributor

cap.

Engine

overheating.

FUEL

SYSTEM

Power

valve

leaking

fuel.

ROUGH

ENGINE

IDLE

Engine

idle

speed

set

too

low.

Idle

fuel

system

air

bleeds

or

fuel

Idle

fuel

mixture

needles

not

prop

passages

restricted.

erly

adjusted.

Fuel

bleeding

from

the

accelerat

Float

setting

incorrect.

ing

pump

discharge

nozzles.

Air

leaks

between

the

carburetor

Secondary

throttle

plates

not

clos

and

the

manifold

and/or

fittings.

ing.

CONTINUED

ON

NEXT

PAGE

Page 15

PART

1-1

-ENGINE

1-9

ENGINE

TROUBLE

DIAGNOSIS

GUIDE

(Continued)

ROUGH

ENGINE

IDLE

(Continued)

Improper

secondary

throttle

plate

EXHAUST

SYSTEM

stop

adjustment.

Exhaust

gas

control

valve

inopera

tive

or

sticking.

IGNITION

SYSTEM

ENGINE

Improperly

adjusted

or

defective

Loose

engine

mounting

bolts

or

breaker

points.

worn

insulator.

Fouled

or

improperly

adjusted

Cylinder

head

bolts

not

properly

spark

plugs.

tightened.

r

r

Crankcase

ventilation

regulator

Incorrect

ignition

timing.

vajve

defective

or

a

restricted

exhaust

Spark

plug

misfiring.

tube.

POOR

ACCELERATION

IGNITION

SYSTEM

Leaky

power

valve,

gaskets,

or

ac

celerating

pump

diaphragm.

Incorrect

ignition

timing.

_.

i*:-

_

,

,

6

.

.

f

..

..

Dirt

or

corrosion

in

accelerating

Fouled

or

improperly

adjusted

spark

plugs.

^

Improperly

adjusted

or

defective

Distributor

vacuum

passages

in

breaker

points.

the

carburetor

blocked.

Distributor

not

advancing

prop-

Restricted

fuel

filter.

erly.

...

everru

EXHAUST

SYSTEM

FUEL

SYSTEM

Exhaust

gas

control

valve

stuck

Inoperative

accelerating

pump

in-

closed

let

ball

check.

Inoperative

accelerating

pump

dis

charge

ball

check.

BRAKES

PUmP

diaphragm

dC"

Improper

adjustment.

Float

setting

incorrect.

Throttle

linkage

not

properly

ad-

TRANSMISSION

^Accelerating

pump

stroke

not

Improper

band

adjustment.

properly

adjusted.

Converter

One-Way

Clutch.

ENGINE

DOES

NOT

DEVELOP

FULL

POWER,

OR

HAS

POOR

HIGH

SPEED

PERFORMANCE

FUEL

SYSTEM

Excessive

play

in

the

distributor

shaft.

Restricted

air

cleaner.

Distributor

cam

worn.

Restricted

fuel

filter.

Fou,ed

Qr

^^i

adjusted

Clogged

or

undersize

main

jets

k

.

and/

or

low

float

setting.

T

'.

,.

,

.

.

Clogged

or

undersize

secondary

.

ImProPerly

adJust^

or

defective

.

t

breaker

points.

Power

valve

clogged

or

damaged.

Secondary

throttle

plates

not

COOLING

SYSTEM

opening.

Fuel

pump

pressure

incorrect.

Thermostat

inoperative

or

incor-

Distributor

vacuum

passage

in

rect

heat

ran8e-

the

carburetor

blocked.

Check

the

cooling

system

for

in

ternal

leakage

and/or

for

a

condition

IGNITION

SYSTEM

that

Prevents

tne

en8'ne

from

reach

ing

normal

operating

temperature.

Ignition

timing

not

properly

ad

justed.

EXHAUST

SYSTEM

Defective

coil,

condenser,

or

rotor.

Exhaust

gas

control

valve

inopera-

Distributor

not

advancing

prop-

tive

or

sticking.

erly.

Restriction

in

system.

CONTINUED

ON

NEXT

PAGE

Page 16

1-10

GROUP

1-

ENGINE

AND

EXHAUST

SYSTEM

ENGINE

TROUBLE

DIAGNOSIS

GUIDE

(Continued)

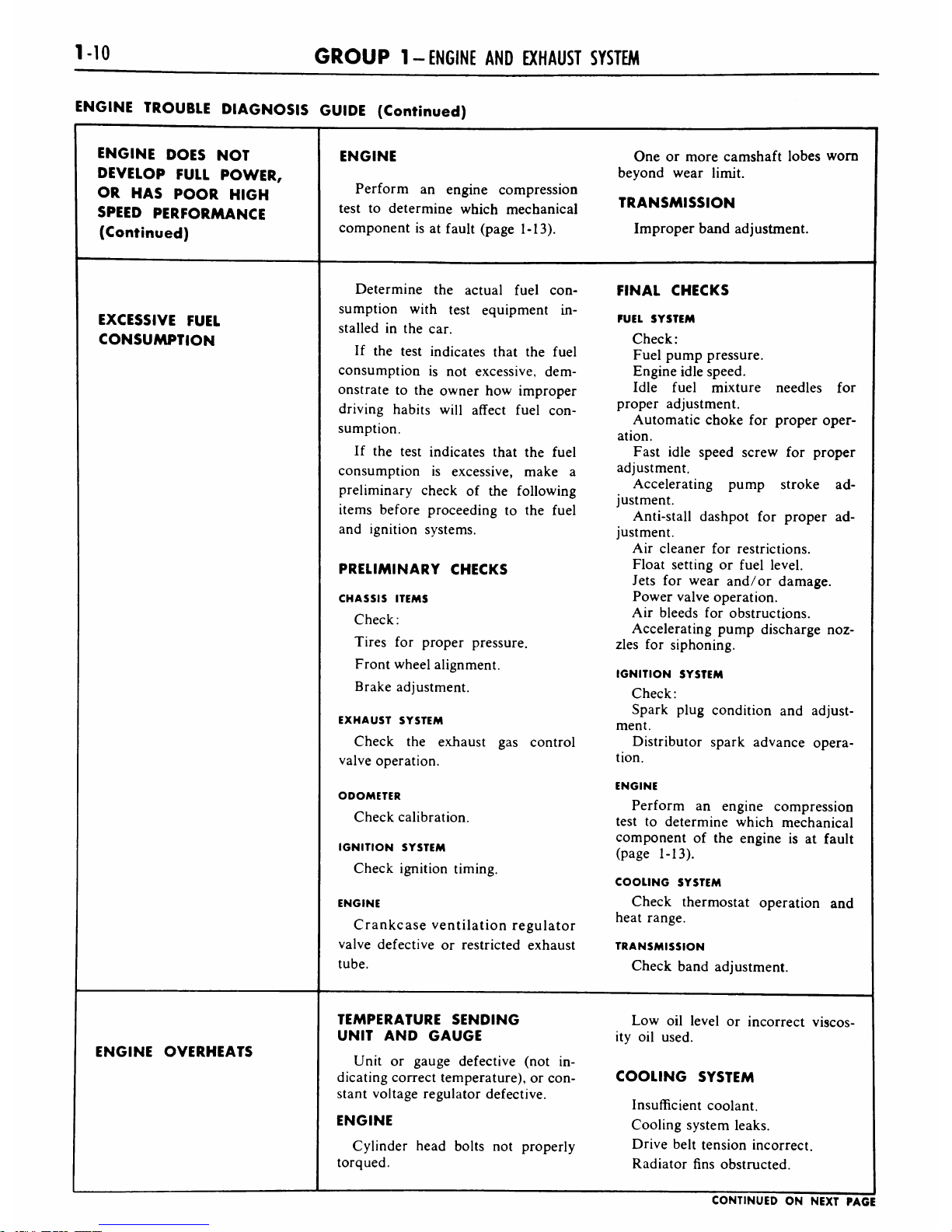

ENGINE

DOES

NOT

ENGINE

One

or

more

camshaft

lobes

worn

DEVELOP

FULL

POWER,

beyond

wear

limit.

OR

HAS

POOR

HIGH

Perform

an

engine

compression

TRANSMISSION

SPEED

PERFORMANCE

test

to

determine

which

mechanical

(Continued)

component

is

at

fault

(page

1-13).

Improper

band

adjustment.

Determine

the

actual

fuel

con

FINAL

CHECKS

sumption

with

test

equipment

in

EXCESSIVE

FUEL

stalled

in

the

car.

FUEL

SYSTEM

CONSUMPTION

Check:

If

the

test

indicates

that

the

fuel

Fuel

pump

pressure.

consumption

is

not

excessive,

dem

Engine

idle

speed.

onstrate

to

the

owner

how

improper

Idle

fuel

mixture

needles

for

driving

habits

will

affect

fuel

con

proper

adjustment.

sumption.

Automatic

choke

for

proper

oper

ation.

If

the

test

indicates

that

the

fuel

Fast

idle

speed

screw

for

proper

consumption

is

excessive,

make

a

adjustment.

preliminary

check

of

the

following

Accelerating

pump

stroke

ad

justment.

items

before

proceeding

to

the

fuel

Anti-stall

dashpot

for

proper

ad

and

ignition

systems.

justment.

Air

cleaner

for

restrictions.

PRELIMINARY

CHECKS

Float

setting

or

fuel

level.

Jets for

wear

and/or

damage.

CHASSIS

ITEMS

Power

valve

operation.

Check:

Air

bleeds

for

obstructions.

Accelerating

pump

discharge

noz

Tires

for

proper

pressure.

zles

for

siphoning.

Front

wheel

alignment.

IGNITION

SYSTEM

Brake

adjustment.

Check:

Spark

plug

condition

and

adjust

EXHAUST

SYSTEM

ment.

Check

the

exhaust

gas

control

Distributor

spark

advance

opera

valve

operation.

tion.

ENGINE

ODOMETER

Perform

an

engine

compression

Check

calibration.

test

to

determine

which

mechanical

IGNITION

SYSTEM

Check

ignition

timing.

component

of

the

engine

is

at

fault

(page

1-13).

COOLING

SYSTEM

ENGINE

Check

thermostat

operation

and

Crankcase

ventilation

regulator

heat

range.

valve

defective

or

restricted

exhaust

TRANSMISSION

tube.

Check

band

adjustment.

TEMPERATURE

SENDING

Low

oil

level

or

incorrect

viscos

UNIT

AND

GAUGE

ity

oil

used.

ENGINE

OVERHEATS

Unit

or

gauge

defective

(not

in

dicating

correct

temperature),

or

con

COOLING

SYSTEM

stant

voltage

regulator

defective.

Insufficient

coolant.

ENGINE

Cooling

system

leaks.

Cylinder

head

bolts

not

properly

Drive

belt

tension

incorrect.

torqued.

Radiator

fins

obstructed.

CONTINUED

ON

NEXT

PAGE

Page 17

PART

1-1

-ENGINE

1-11

ENGINE

TROUBLE

DIAGNOSIS

GUIDE

(Continued)

ENGINE

OVERHEATS

(Continued)

Thermostat

defective.

Thermostat

improperly

installed.

Cooling

system

passages

blocked.

Water

pump

inoperative.

IGNITION

SYSTEM

Incorrect

ignition

timing.

LOSS

OF

COOLANT

COOLING

SYSTEM

Leaking

radiator.

Loose

or

damaged

hose

connec

tions.

Water

pump

leaking.

Radiator

cap

defective.

Overheating.

ENGINE

Cylinder

head

gasket

defective.

Intake

manifold

to

cylinder

head

gasket

defective.

Cylinder

head

or

intake

manifold

bolts

not

properly

torqued.

Cylinder

block

core

plugs

leak

ing.

Temperature

sending

unit

leak

ing.

Cracked

cylinder

head

or

block,

or

warped

cylinder

head

or

block

gasket

surface.

ENGINE

FAILS

TO

REACH

NORMAL

OPERATING

TEMPERATURE

TEMPERATURE

SENDING

UNIT

AND

GAUGE

Unit

or

gauge

defective (not

in

dicating

correct

temperature)

or

con

stant

voltage

regulator

defective.

COOLING

SYSTEM

Thermostats

inoperative

or

of

in

correct

heat

range.

NOISY

HYDRAULIC

VALVE

LIFTER

A

noisy

valve

lifter

can

be

located

by

operating

the

engine

at

idle

speed

and

placing

a

finger

on

the

face

of

the

valve

spring

retainer.

If

the

lifter

is

not

functioning

prop

erly,

a

shock

will

be

felt

when

the

valve

seats.

Another

method

of

identifying

a

noisy

lifter

is

by

the

use

ofapiece

of

hose.

With

the

engine

operating

at

idle

speed,

place

one

end

of

the

hose

near

the

end

of

the

valve stem

and

the

other

end

to the

ear

and

listen

for

a

metallic

noise.

Repeat

this

procedure

on

each

intake

and

exhaust

valve

until

the

noisy

lift-

er(s)

has

been

located.

The

most

common

causes

of

hy

draulic

valve

lifter

troubles

are

dirt,

gum,

varnish,

carbon

deposits,

and

air

bubbles.

Dirt

in

the

lifter

assembly

can

prevent

the

disc

valve

from

seating,

or

it

may

become

lodged

between

the

plunger

and

body

surfaces.

In

either

case,

the

lifter

becomes

inop

erative

due

to

failure

to

"pump-up,"

or

because

the

internal

parts

are

no

longer

free

to

function

properly.

When

dirt

is

found

to

be

respon

sible

for

lifter

malfunction,

remove

the

lifter

assembly

and

thoroughly

clean

it.

Recommended

engine

oil

and

filter

change

intervals

should

be

followed

to

minimize

lifter

prob

lems

caused

by

dirt.

Deposits

of

gum

and

varnish

cause

similar

conditions

to

exist

which

may

result

in

lifter

malfunc

tion.

If

these

conditions

are

found

to

be

present,

the

lifter

should

be

disassembled

and

cleaned

in

solvent

to

remove

all

traces

of

deposits.

Air

bubbles

in

the

lubricating

oil,

caused

by

an

excessively

high

or

low

oil

level,

may

likewise

cause

lifter

malfunction.

A

damaged

oil

pick

up

tube

may

allow

air

to

be

drawn

into

the

lubricating

system.

To

check

for

the

presence

of

air,

remove

a

valve

rocker

arm

cover

and

note

the

condition

of

the

oil

as

it

flows

from

the

valve

rocker

arm

shaft

as

sembly.

Perform

corrective

action

as

required

to

remove

air

from

the

lubri

cating

oil.

Page 18

M2

GROUP

1-

ENGINE

AND

EXHAUST

SYSTEM

TUNE-UP

The

Tune-Up

Schedule

(Table

1)

is

for

either

an

A.

B,

or

C

tune-up.

Perform

all

operations

in

the

se

quence

listed.

The

recommended

mileage

interval

for

an

A

tune-up

is

4000

miles,

for

a

B

tune-up

it

is

8000

miles,

and

for

a

C

tune-up

it

is

12,000

miles.

For

a

detailed

descrip

tion

of

an

operation

procedure,

refer

to

the

operation

number

under

"Tune-Up

Procedure."

TUNE-UP

PROCEDURE

The

tune-up

is

divided

into

3

ma

jor

parts.

TABLE

1-Tune-Up

Schedule

The

first

part

is

performed

with

the

engine

not

operating.

The

first

step

consists

of

visual

and

mechani

cal

checks

and

adjustments.

The

sec

ond

step

consists

of

an

instrument

check.

Always

follow

the

instructions

of

the

manufacturer

of

the

test

equip

ment

used.

The

second

part

of

the

tune-up

covers

items

that

can

be

done

while

the

engine

is

warming

up

for

carbu

retor and

valve

adjustments.

The

third

part

of

the

tune-up

should

be

performed

with

the

engine

operating

at

normal

operating

tem

perature.

For

the

engine

to

reach

normal

operating

temperature,

it

should

be

operated

for

30

minutes

at

fast

idle

(1200

rpm).

For

more

detailed

information

on

corrective

action

to

be

taken

when

a

particular

defect

is

encountered,

re

fer

to

the

appropriate

part

of

the

manual.

At

the

end

of

the

"Tune-Up

Pro

cedure,"

additional

engine

checks

and

adjustments

are

described

for

use

as

necessary.

Operation

No.

Operation

ABC

ENGINE

NOT

OPERATING

MECHANICAL

CHECKS,

TESTS,

AND

ADJUSTMENTS

1

Clean,

adjust,

and

test

spark

plugs.

X

2

Take

a

compression

reading

of

each

cylinder.

X

3

Replace

spark

plugs.

X

4

Check

and

tighten

intake

manifold

bolts.

X

5

Check

and

adjust

the

deflection

of

the

drive

belts.

X

6

Replace

fuel

filter.

X

7

Check

and

adjust

carburetor

fuel

level.

X

8

Clean

the

distributor

cap

and

rotor.

X

X

9

Lubricate

the

distributor

cam,

lubricating

wick,

and

the

distributor

bushing.

X

10

Clean

battery

cables

and

terminals.

X

11

Clean

positive

crankcase

ventilation

system.

X

INSTRUMENT

CHECKS

12

'

Check

battery

state

of

charge.

x

Operation

No.

Operation

A

B

C

13

Check

and

adjust

breaker

point

dwell.

X

14

Check

and

adjust

spark

advance.

X

15

Perform

a

spark

intensity

test

of

each

spark

plug

wire.

X

16

Check

fuel

pump

pressure

and

capacity

X

WHILE

ENGINE

IS

WARMING-UP

17

Clean

carburetor

air

cleaner.

X

18

Inspect

the

radiator,

hoses,

and

engine

for

coolant

leaks.

X

19

Check

and

adjust

ignition

timing.

X

ENGINE

OPERATING

AT

NORMAL

TEMPERATURE

20

Adjust

accelerator

pump

link

to

seasonal

position.

X

21

Check

and

adjust

engine

idle

speed.

X

22

Check

and adjust

idle

fuel

mixture.

X

23

Check

and

adjust

anti-stall

dashpot

clearance.

X

Page 19

PART

1-1

-ENGINE

1-13

B1390-A

FIG.

14

Cleaning

Plug

Electrode

ENGINE

NOT

OPERATING

Perform

the

following

tests

with

the

engine

off

and

at

room

tempera

ture.

MECHANICAL

CHECKS,

TESTS,

AND

ADJUSTMENTS

1.

Clean,

Adjust,

And

Test

Spark

Plugs.

Remove

the

wire

from

each

spark

plug

by

grasping

the

moulded

cap

only.

Clean

the

area

around

each

spark

plug

with

compressed

air,

then

re

move

the

spark

plugs.

Clean

the

spark

plugs

onasand

blast

cleaner

following

the

equip

ment

manufacturer's

instructions.

Remove

carbon

and

other

deposits

from

the

threads

with

a

stiff

wire

brush.

Clean

the

electrode

surfaces

with

a

small

file

(Fig.

14).

Dress

the

electrode

to

secure

flat

parallel

sur

faces

on

both

the

center

and

side

electrode.

After

cleaning,

inspect

the

plug

for

a

cracked

or

broken

insulator,

badly

B1391-A

FIG.

15

Gapping

Spark

Plug

pitted

electrodes,

or

other

signs

of

failure.

Replace

as

required.

Set

the

gap

of

all

serviceable

or

new

plugs

to

0.032-0.036

inch

by

bending

the

ground

electrode

(Fig.

15).

After

the

gap

has

been

adjusted,

check

the

plugs

on

a

testing

machine.

Compare

the

sparking

efficiency

of

the

cleaned

and

gapped

plug

with

a

new

plug.

Replace

the

plug

if

it

fails

to

meet

requirements.

Apply

a

coat

ing

of

oil

to

the

shoulder

of

the

plug

where

the

insulator

projects

through

the

shell,

and

to

the

top

of

the

plug,

where

the

center

electrode

and

termi

nal

project

from

the

insulator.

Place

the

spark

plug

under

pressure.

Leak

age

is

indicated

by

air

bubbling

through

the

oil.

If

the

test

indicates

compression

leakage,

replace

the

plug.

If

the

plug

is

satisfactory,

wipe

it

clean.

Install

the

spark

plugs

and

torque

them

to

15-20

ft-lbs.

2.

Take

A

Compression

Reading

Of

Each

Cylinder.

Remove

the

spark

plugs.

Remove

the

coil

high

tension

lead

at

the

distributor

cap.

Set

the

primary

throttle

plates

and

choke

plate

in

the

wide

open

position.

Install

a

compression

gauge

in

No.

1

cylinder.

Using

a

remote

starter

switch,

crank

the

engine

several

times

and

record

the

highest

reading

recorded.

Note

the

number

of

compression

strokes

required

to

obtain

the

highest

reading.

Repeat

the

test

on

each

cylinder,

cranking

the

engine

the

same

num

ber

of

times

for

each

cylinder

as

was

required

to

obtain

the

highest

reading

on

the

No.

1

cylinder.

A

variation

of

20

pounds

from

specified

pressure

of

180

psiissatis

factory.

However,

the

compression

of

all

cylinders

should

be

uniform

within

10

pounds.

A

reading

of

more

than

the

allow

able

tolerance

above

normal

indi

cates

excessive

deposits

in

the

cyl

inder.

A

reading

of

more

than

the

allow

able

tolerance

below

normal

indi

cates

leakage

at

the

cylinder

head

gasket,

piston

rings,

or

valves.

A

low

even

compression

in

two

adjacent

cylinders

indicates

a

cylin

der

head

gasket

leak.

This

should

be

checked

before

condemning

the

rings

or

valves.

To determine

whether

the

rings

or

the

valves

are

at

fault,

squirt

the

equi

valent

of

a

tablespoon

of

heavy

oil

into

the

combustion

chamber.

Crank

the

engine

to

distribute

the

oil

and

repeat

the

compression

test.

The

oil

will

temporarily

seal

leakage

past

the

rings.

If

approximately

the

same

reading

is

obtained,

the

rings

are

satisfactory,

but

the

valves

are

leak

ing.

If

the

compression

has

increased

10

pounds

or

more

over

the

original

reading,

there

is

leakage

past

the