Ford 1949-50-51 F-Series Truck, F-5, F-6, F-3, F-1 Shop Manual

...

1949-50-51

SHOP

WITH 1952 SUPPLEMENT

F-SERIES

TRUCKS

MANUAL

FORD

FORD

MOTOR

D I

YISION

COMPANY

Copyright © 2011, Forel Publishing Company, LLC, Woodbridge, Virginia

All Rights Reserved. No part of this book may be used or reproduced in any manner whatsoever

without written permission of Forel Publishing Company, LLC. For information write to Forel

Publishing Company, LLC, 3999 Peregrine Ridge Ct., Woodbridge, VA 22192

1949-52 Ford Truck Shop Manual

EAN: 978-1-60371-062-6

ISBN: 1-60371-062-0

Forel Publishing Company, LLC

3999 Peregrine Ridge Ct.

Woodbridge, VA 22192

Email address: sales@ForelPublishing.com

Website: http://www.ForelPublishing.com

This publication contains material that is reproduced and distributed under a license from Ford

Motor Company. No further reproduction or distribution of the Ford Motor Company material is

allowed without the express written permission of Ford Motor Company.

NNoottee ffrroomm tthhee PPuubblliisshheerr

This product was created from the original Ford Motor Company’s publication. Every effort has

been made to use the original scanned images, however, due to the condition of the material;

some pages have been modified to remove imperfections.

Disclaimer

Although every effort was made to ensure the accuracy of this book, no representations or

warranties of any kind are made concerning the accuracy, completeness or suitability of the

information, either expressed or implied. As a result, the information contained within this book

should be used as general information only. The author and Forel Publishing Company, LLC

shall have neither liability nor responsibility to any person or entity with respect to any loss or

damage caused, or alleged to be caused, directly or indirectly by the information contained in

this book. Further, the publisher and author are not engaged in rendering legal or other

professional services. If legal, mechanical, electrical, or other expert assistance is required, the

services of a competent professional should be sought.

1949-50-51

RD

SHOP

F-sERIEs

TRUCKS

MANUAL

FORD

Copyri,ht

MOTOR

DEARBORN, MICHIGAN

AU

rilhu

1951

COMPANY

rnerved

FORM

7099-A

FORD

FORD

DIYISION

MOTOR

•

COMPANY

April, 1951

This

manual

plete service

Trucks.

parts,

found here.

procedures plus disassembled views

assemblies used

tician will find

kind

Maintenance

for those

Service

of

everyday

customers. Collision

detail well

work.

principles,

as well for each

Upholstery

for

Step-by-step procedures for

inspection,

this manual.

illustrated disassembled,

ponent

or disassembly.

illustrations will tell

about

trations

parts.

ber

from

have a

In

rently practiced

this

divisions. These five

Part

the

are necessary

fuel system, ignition system,

system.

Part

clutch, covers

transmission, drive line,

running

pension, frames, steering gear,

Part

CESSORIES-covers

and

All

assemblies,

of

trouble

Managers

Electrical men will find simply

their

work.

parts

how

carry

These basic

of

the

any

"Parts

recognition

manual

ONE-POWER

Ford

TWO-CHASSIS-starting

gear

THREE-ELECTRICAr.~

units

combines

information

aspects

or

Repair

in

these

that

working procedures for each

he

will

and

lubrication

interested

and

care

that

illustrated

not

only

of

the

men

will find how-to-do-it procedures

and

repair

In

addition, each assembly

arranged

In

many

the

parts

basic

part

numbers

truck

Ford

engines

(other

will

dealer even

Book."

of

the

in

many

has

been divided

and

to

their

the

(wheels, tires, brakes, springs, sus-

than

under

for

of

the

systems involved will be

men

will find

models.

encounter

in

this

salesmen will find

they

men

will find construction

to

assist

of

operation,

electrical

are

with

in

the

cases, a glance

you

all

go together. These illus-

numbers

permit

specialization

service establishments,

parts

PLANT

the

operation. These include

entire

rear

all

of

ignition which is covered

one cover com-

the

1949-50-51

servicing

data

aspect

can

pass

them

but

units

the

presented

each

order

you

for each

plus

the

you

though

into

are

as follows:

-has

various systems

and

power

axles, etc.)

and

linkages, etc.).

the

electrical systems

PREFACE

Ford

of

step

by

step

of

all

of

The

diagnos-

are covered.

is provided

of

service.

hints

on

to

their

in

collision

written

of

testing

or

systems.

disassembly,

throughout

has

been

of

the

com-

of

assembly

at

these

need

to

know

of

model num-

to

order

you

that

the

train

AND

may

five

to

do

with

(clutch,

and

parts

is cur-

major

with

that

cooling

AC-

the

the

the

not

the

the

Part

in

models.

Part

formation

body

alignment

of

Part

SHOOTING,

been

for

this

quired for

men

chapters.

The

not

but

in each

divided

the

of

unit

izing, a glance

quickly

in which

in maintenance procedures,

specifications,

found in

one

the

involved will

Throughout

hand,

chapter;

numbered

involved.

manual, a glance

will tell

cussed

mechanic

these

have

your

for reference

ONE)

FOUR-BODIE.$-contains

components, including

doors, hoods, fenders,

FIVE-MAINTENANCE,

arranged

the

convenience

part,

has

Table

only

the

also

the

of

into

Table

service

of

the

direct

you

Part

of

the

chapter

even-numbered

and

Thus,

you

at

No

one expects even

trucks

to

occasionally refer

manual

and

accessories for

on

the

maintenance

not

only

of

the

and

AND

in

all

of

quick

been combined

of

Contents

part

chapters

the

five

sections which also are listed

of

Contents.

in

which

vehicle

you

are

the

FIVE.

four

and

direct

this

the

page gives

regardless

exactly

that

point.

to

remember

and

where

at

SPECIFICATIONS-has

the

back

of

quick

the

information

service

break-down

parts.

in

at

to

interested.

information

other

section listings

top

at

you

all times.

FORD

FORD

SERVICE

men

on

that

Each

Regardless

you

which

the

Table

the

portion

Otherwise,

parts. A quick

you

manual

page

of

the

the

what

all details

will

it

will

DIVISION

MOTOR

Ford

complete in-

and

repair

adjustment

body

of

each

the

proper,

shields.

the

book

service men.

and

into

three

the

next

as described above,

have

been established

chapter

are

interested

you

may

of

of

If

you

trouble

you

under

to

the

the

top

gives

the

right-hand, odd-

name

of

top

subject

to

be

of

where

of

the

most

find

that

this

readily available

DEPARTMENT

but

TROUBLE

separately

ordinarily re-

service sales-

separate

page shows

has been

of

the

be

Contents

this

are interested

shooting,

desire will

it

will fall in

glance

the

page

of

each left-

name

the

you

open

two

matter

experienced

of

servicing

you

manual. Keep

COMPANY

Truck

of

all

and

also

In

in

aspect

or

the

special-

will

manual

or

be

at

part

desired.

of

the

section

the

pages

is dis-

will

Preface..

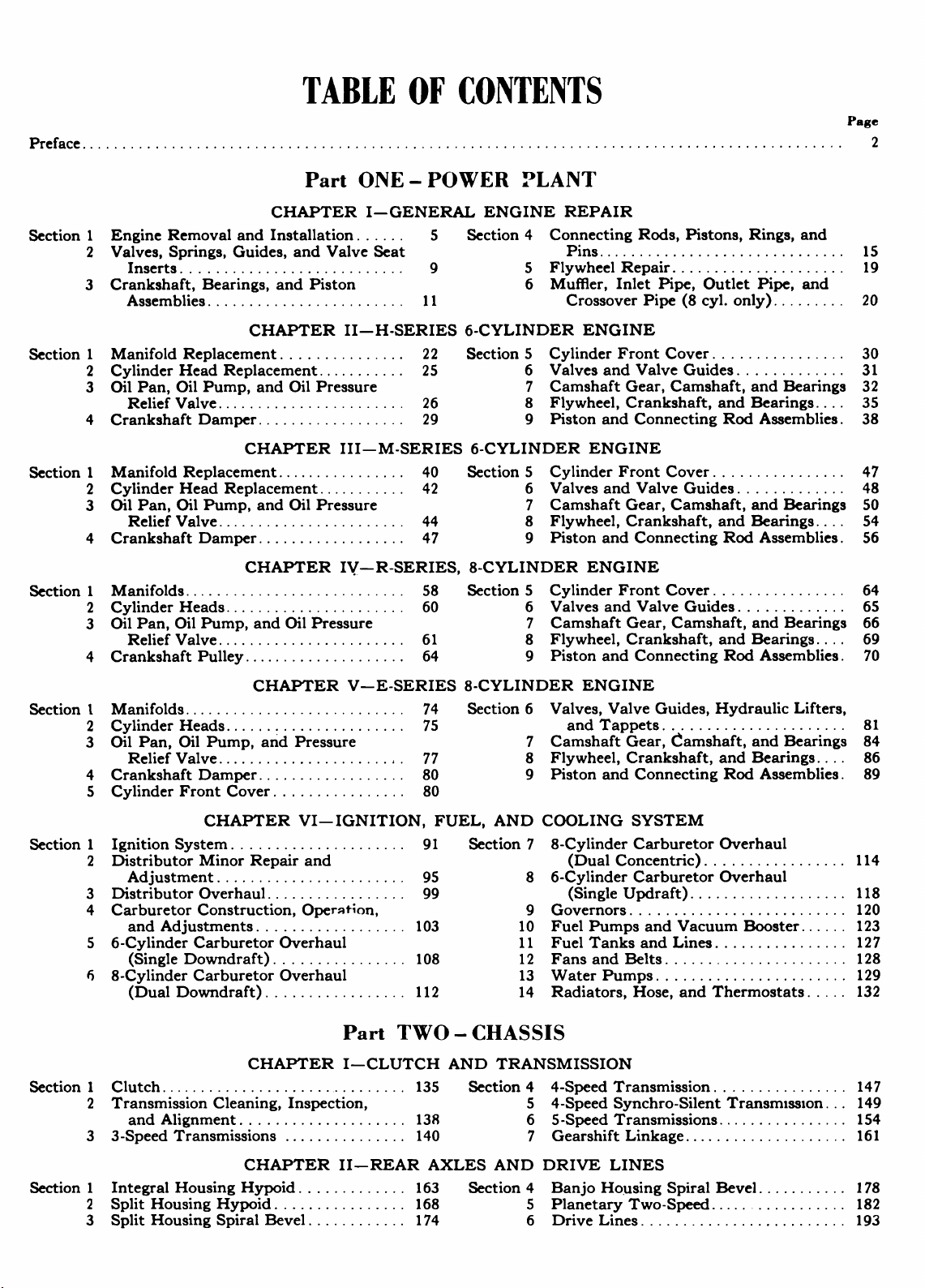

TABLE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

OF

CONTENTS

Page

Section 1

2 Valves, Springs, Guides,

3

Section 1

2

3 Oil

4

Section 1

2

3 Oil

4

Section 1

2

3 Oil

4

Part

CHAPTER

Engine

Crankshaft,

Manifold

Cylinder

Crankshaft

Manifold

Cylinder

Crankshaft

Manifolds...........................

Cylinder

Crankshaft

Removal

Inserts.

Assemblies. . . . . . . . . . . . . . . . . . . . . .

Replacement

Head

Pan,

Relief Valve. . . . . . . . . . . . . . . . . . . . .

Relief

Relief Valve. . . . . . . . . . . . . . . . . . . . .

Oil

Replacement.

Head

Pan,

Oil

Valve. . . . . . . . . . . . . . . . . . . . .

Heads.

Pan,

Oil

and

Installation.

and

Valve

. . . . . . . . . . . . . . . . . . . . . . . . . . 9

Bearings,

Replacement.....

Pump,

Damper.

Replacement.

Pump,

Damper.

Pump,

Pulley.

and

Piston

CHAPTER

..............

and

Oil

Pressure

. . . . . . . . . . . . . . .

CHAPTER

. . . . . . . . . . . . .

and

Oil

. . . . . . . . . . . . . . .

CHAPTER

. . . . . . . . . . . . . . . . . . .

and

Oil

. . . . . . . . . . . . . . . . .

III-M-SERIES

. . . . . . . .

Pressure

IV-R-SERIES,

Pressure

ONE -

I-GENERAL

. . . . . 5

Seat

II-H-SERIES

. . . .

POWER

..

11

,

22

..

25

..

26

..

29

..

40

..

42

..

44

..

47

58

..

60

..

61

..

64

PLANT

ENGINE

Section 4

6-CYLINDER

Section 5

6-CYLINDER

Section 5

8-CYLINDER

Section 5

Connecting

5 Flywheel

6 Muffler,

Cylinder

6 Valves

7

Camshaft

8 Flywheel,

9

Piston

Cylinder

6

Valves

7

Camshaft

8 Flywheel,

9

Piston

Cylinder

Valves

6

7

Camshaft

8 Flywheel,

9

Piston

REPAIR

Rods,

Pistons,

Pins.

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Repair.

Inlet

Crossover

ENGINE

Front

and

Gear,

Crankshaft,

and

ENGINE

Front

and

Gear,

Crankshaft,

and

ENGINE

Front

and

Gear,

Crankshaft,

and

. . . . . . . . . . . . . . . . . .

Pipe,

Outlet

Pipe

(8 cyl.

Cover

...............

Valve

Guides.

Camshaft,

and

Connecting

Cover.

Valve

Camshaft,

Connecting

Cover

Valve

Camshaft,

Connecting

Rod

. . . . . . . . . . . . .

Guides

and

Rod

...............

Guides

and

Rod

Rings,

only).

. . . . . . . . . .

and

Bearings. . ..

............

and

Bearings. . ..

............

and

Pipe,

and

. . . . . .

Bearings

Assemblies. 38

Bearings 50

Assemblies. 56

and

Bearings 66

Bearings. . ..

Assemblies.

..

..

..

, 30

..

..

, 48

, 64

, 65

15

19

20

31

32

35

47

54

69

70

Section 1

2

3 Oil

4

5

Section 1

3

4

Ii 8-Cylinder

Section 1

3 3 -Speed

CHAPTER

Manifolds...........................

Cylinder

Relief

Crankshaft

Cylinder

Ignition

Distributor

2

Adjustment

Distributor

Carburetor

and

6-Cylinder

5

(Single

(Dual

Clutch..............................

2

Transmission

and

Heads..

Pan,

Oil

Valve

Front

System

Construction,

Adjustments

Carburetor

Downdraft)

Carburetor

Downdraft)

Alignment.

Transmissions

. . . . . . . . . . . . . . . . . .

Pump,

.....................

Damper.

Cover

CHAPTER

.....................

Minor

Overhaul.

Repair

.......................

..................

CHAPTER

Cleaning,

. . . . . . . . . . . . . . . . .

V-E-SERIES

arid

Pressure

. . . . . . . . . . . . . . .

...............

VI-IGNITION,

and

................

Oper~t;on,

Overhaul

................

Overhaul

.................

Part

I-CLUTCH

Inspection,

...............

74

..

75

,.

77

..

80 9

, 80

FUEL,

91

95 8

99

103

108

112

TWO

..

- CHASSIS

AND

135

13R

140

8-CYLINDER

Section 6 Valves, Valve Guides,

7

8 Flywheel,

AND

Section 7

9

10

11

12

13

14

TRANSMISSION

Section 4 4-Speed

54-Speed

6 5

7

ENGINE

and

Tappets.

Camshaft

Piston

COOLING

8-Cylinder

6-Cylinder

Governors

Fuel

Fuel

Fans

Water

Radiators,

Gearshift

and

(Dual

(Single

Pumps

Tanks

and

Pumps

-Speed

. . . . . . . . . . . . . . . . . . .

Gear,

Camshaft,

Crankshaft,

Connecting

SYSTEM

Carburetor

Concentric)

Carburetor

Updraft)

..........

and

Belts

Hose,

Transmission

Synchro-Silent

Transmissions.

Linkage.

...................

and

Vacuum

Lines

......................

.......................

and

. . . . . . . . . . . . . . . . .

Hydraulic

and

and

Bearings..

Rod

Assemblies. 89

Overhaul

.................

Overhaul

,

...............

Booster

................

Thermostats

................

Transmission.

. . . . . . . . . . . . .

Lifters,

..

Bearings

..

......

.....

..

..

..

81

84

86

114

118

120

123

127

128

129

132

147

149

154

161

Section 1

2

3

Integral

Split

Housing

Split

Housing

Housing

Hypoid.

Spiral Bevel

CHAPTER

Hypoid. . .........

. . . . . . . . . . . . .

II-REAR

............

AXLES

" 163 Section 4

..

168

174

AND

DRIVE

Banjo

5

Planetary

6

Drive

LINES

Ho~sing

Lines.

Spiral

Two-Speed

. . . . . . . . . . . . . . . . . . . . . .

Bevel.

.................

. . . . . . . .

.. 1 78

182

..

193

Section 1

2

3

4 Shock Absorbers

Frames.............................

Front

Axle

..........................

Springs.............................

.....................

CHAPTER

III-RUNNING

195

196

198

199

Section 5 Steering

GEAR

Gear

.......................

6

Steering Connections. . . . . . . . . . . . . . .

7 Wheels

8

Hubs

and

and

Tires

....................

Bearings

...................

..

Page

201

203

204

209

CHAPTER

Section 1 Types, Description, Model Application.

2

Adjustments........................

3

4

Section 1

3 Lighting

Section 1

Hydraulic

Hydraulic

Generating

2

Starting

Radio

2

Heater.............................

System.

Brake

Part

System

System.

System.

..............................

. . . . . . . . . . . . . . . . .

Boosters. . . . . . . . . . .

THREE

CHAPTER

and

Battery

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

..

..

- ELECTRICAL AND ACCESSORIES

I-ELECTRICAL

.......

..

..

CHAPTER

Part

Section 1

Section 1

Construction

2

Door

Alignment

Door

Locking

2 Window

3

Door

Glass

CHAPTER

Details

....................

CHAPTER

Mechanism.

Regulators.

and

Ventilator

.................

. . . . . . . . . . . . . . .

I-CONSTRUCTION

II-HARDWARE,

. . . . . . . . . .

Assembly

..

..

...

IV-BRAKES

214

217

218

223

249

263

269

282

287

Section 5

Section 4

II-ACCESSORIES

Section 3 Windshield

Brake

6

Brake

7 Air

8

5

Brake

Parking

SYSTEMS

Horns..............................

Instruments

FOUR - BODIES

AND

MAINTENANCE

291

,

295

298 Section 4 Windshield

300 5

301

Section 3 General

GLASS,

AND

Seats

INTERIOR

Assemblies. . . . . . . . . . . . . . . . . .

Drums

and

........................

System.

Brakes

.........................

Wiper

Body

and

Interior

. . . . .

......................

....................

Maintenance.

TRIM

Rear

Trim.

..

...........

. . . . . . . .

Window.

. . . . . . . . . . .

. . . . . .

..

..

..

..

231

236

236

249

276

277

289

296

303

304

CHAPTER

Section 1

Section 1 Engine

Section 1

Section 1 Wheels

Front

2

Radiator

3

Hood

2 Wheel

Brake

3

Power

2 Suspension,

Tire

3

Brakes.............................

2

Brakes.............................

3 Wheel Alignment

4

Rear

5

6

7

8

Axle. . . . . . . . . . . . . . . . . . . . . . . . .

Frame

Engines.............................

Clutch

Cooling.........................

End

Sheet

Grille

......................

and

Component

Part

Tune-up

Alignment.

Adjustment.

Plant.

Wear.

and

and

and

FIVE - MAINTENANCE, TROUBLE SHOOTING,

. . . . . . . . . . . . . . . . . . . . . .

Stp.ering Gear,

. . . . . . . . . . . . . . . . . . . . .

Tires.

Springs

TransmIssIon

III-FRONT

Metal

Replacement.

Parts.

. . . . . . . .

AND

CHAPTER

.....................

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

CHAPTER

and

CHAPTER

. . . . . . . . . . . . . . . . .

and

Steering.

...................

............

END

SHEET

..

308

309

..

312

METAL

Section 4

SPECIFICATIONS

I-MAINTENANCE

..

..

II-TROUBLE

..

..

..

. . . . .

..

..

321

323 5

328

336

346

348

III-SPECIFICATIONS

361

362

365

366

367

369

, 375

376

Section 4

Section 4 Electrical

Section 9

AND

5

6

PROCEDURES

SHOOTING

5

6

10

11

12

13

14

15

RUNNING

Fenders

Cab

Platform

Lubrication

Preventive

Accessories..........................

Power

Fuel

Generating

St~ng

IgnItion

Lights

Wiring

Tools

and

Replacement.

Body

and

Train.

System

Systerr.. . . . . . . . . . . . . . . . . .

............................

and

Diagrams.

and

Equipment.

BOARDS

Running

Replacement

.........................

Maintenance.

Instruments.

. . . . . . . . . . . . . . . . . . . . . .

........................

System

Horns.

Board.

. . . . . . . . . . . . . . . . .

..................

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . .

.........

. . . . . . . . . . .

. . . . . . . . .

. . . . . . . . . . . . .

..

..

..

..

..

..

..

..

..

316

317

, 319

329

334

349

358

360

, 377

, 378

379

379

380

381

383

Part

ONE

8ecUoa

1

Engine

Valves, Springs, Guides,

2

Crankshaft,

3

Connecting

4

Flywheel

5

Muffler,

6

This

Chapter

are

common

various

conveniently list

eliminates

For

added

is included

to

engine

searching

convenience, a

in

the

Removal

Repair

Inlet

brings

all engines.

parts

the

back

and

Installation

Bearings,

Rods, Pistons, Rings,

Pipe,

together

are

tolerances

through

of

and

...........................................

Outlet

Instructions

accompanied

the

complete

the

book.

POWER

General

..............................

and

Valve

Piston

Pipe,

repair

for all engines.

book

list

Seat

Assemblies

ana

Pins

and

Crossover

procedures

for fitting

by

charts

for specifications.

of

specifications

PLANT

Chapter

I

Engine

Inserts

This

.................................

....................

......................

Pipe

that

the

that

sented

subdivided

tition

(luides

of

Repair

(8

cyl.

Engine

first

of

the

body

only)

...

removal

with

according

preliminary

reader

style

and

.........................

.

.

.

.

and

installation

respect

to

engine.

to

the

to

the

engine.

operation

the

procedure

..........

procedures

body

style

This

eliminates

procedures

for

any

Pq.

are

pre-

and

then

are

repe-

and

quickly

combination

5

9

11

15

19

20

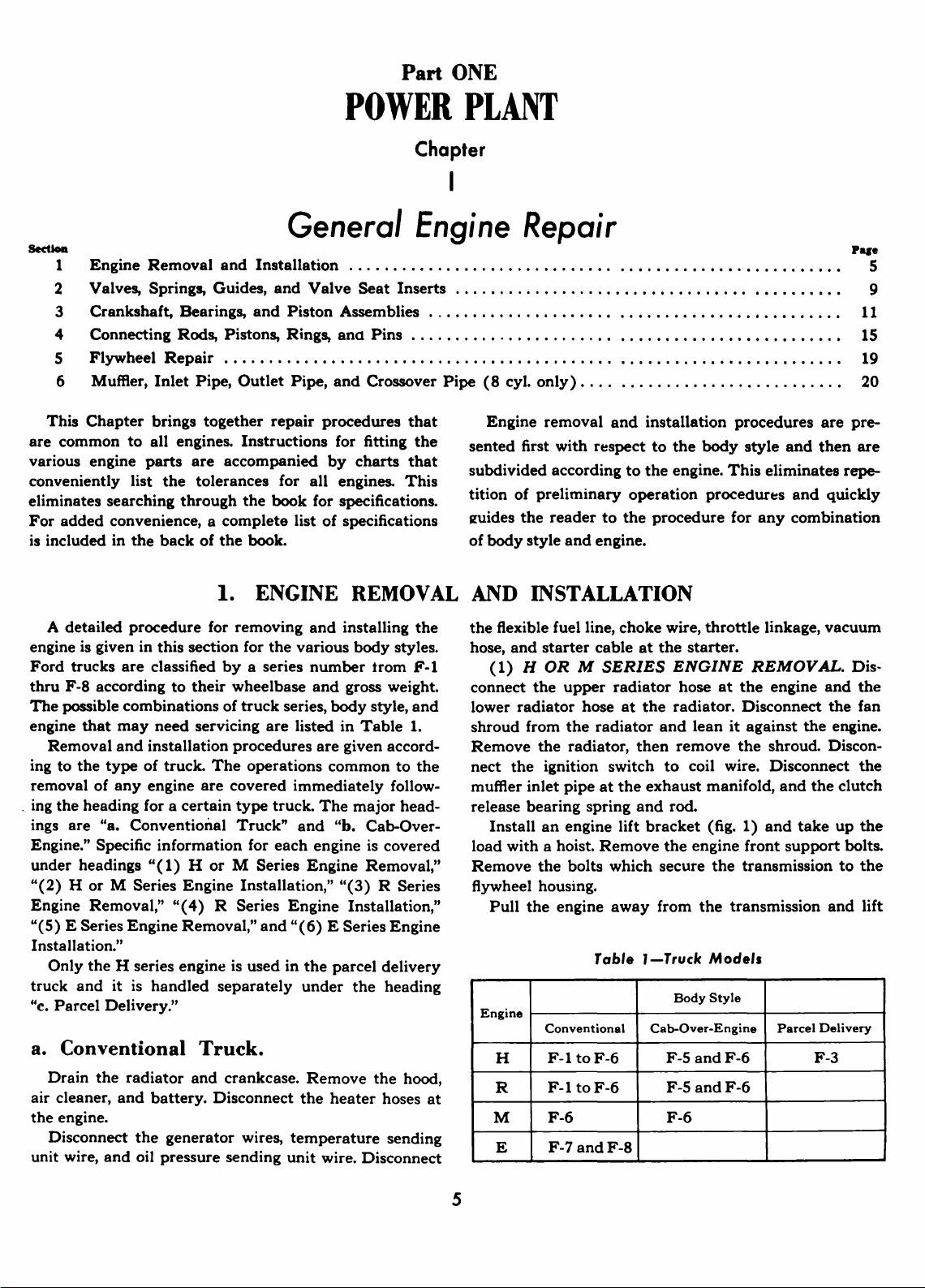

A

detailed

engine is given in

Ford

trucks

thru

F -8

The

possible

engine

Removal

to

the

ing

removal

. ing

the

ings

are

Engine."

under

"(2) H or M Series

Engine

"(5)

truck

"c.

air cleaner,

the

headings

E Series

Installation."

Only

and

Parcel

a.

Conventional

Drain

engine.

Disconnect

unit wire,

procedure

are

according

combinations

that

may

and

type

of

any

heading

"a.

Conventional

Specific

Removal,"

Engine

the

H series

it is

Delivery."

the

radiator

and

the

and

oil

installation

of

engine

for a

"(

battery.

1.

for

this

section

classified

to

their

need

servicing

truck.

The

are

certain

information

1) H or

Engine

"(

4)

R Series

Removal,"

engine

handled

generator

pressure

separately

Truck.

and

Disconnect

ENGINE REMOVAL AND INSTALLATION

removing

for

by

a series

wheelbase

of

truck

procedures

operations

covered

type

Truck"

for

M Series

Installation,"

and

is

used

crankcase.

wires,

sending

and

the

various

number

and

series,

are

listed

are

immediately

truck.

and

each

engine

Engine

Engine

"(6)

in

the

under

Remove

the

temperature

unit

installing

body

trom

gross weight.

body

style,

in

Table

given accord-

common

The

major

"b.

Cab-Over-

is

Removal,"

"(3)

Installation,"

E Series

parcel

the

the

heater

wire.

Disconnect

the

styles.

f'-1

and

1.

to

the

follow-

head-

covered

R Series

Engine

delivery

heading

hood,

hoses

at

sending

the

flexible fuel line,

hose,

and

starter

(1)

H

OR M SERIES

connect

lower

shroud

Remove

nect

muffler

release

load

Remove

flywheel housing.

Engine

radiator

from

the

Install

with

Pull

H

R

M

E

the

upper

the

the

radiator,

ignition

inlet

pipe

bearing

an

engine

a hoist.

the

bolts

the

engine

Conventional

F-l

to

F-l

to

F-6

F-7

andF-8

cable

radiator

hose

radiator

switch

at

spring

Remove

which

away

Tabl.

F-6

F-6

the

lift

choke

wire,

at

the

ENGINE

hose

at

the

radiator.

and

then

remove

to

exhaust

and

rod.

bracket

the

secure

from

J-Truck

Body

Cab-Over-Engine

F-S

F-5

F-6

throttle

starter.

at

the

Disconnect

lean

it

against

the

coil wire.

manifold,

(fig.

1)

engine

and

and

front

the

transmission

the

transmission

Models

Style

F-6

F-6

linkage,

vacuum

REMOVAL.

engine

shroud. DisconDisconnect

and

the

and

the

take

support

Parcel

F-3

and

the

engine.

and

Delivery

Dis-

the

fan

the

clutch

up

the

bolts.

to

the

lift

5

6

the

engine

strike

(2) H OR M SERIES

To

install

ment

transmission into Bny gear. Start

shaft

not

mesh, turn

on

the

shaft slides into

Install

tighten

engine

the engine.

Connect

pipe, and ignition switch

over

Fasten

radiator hoses.

To

starter cable,

temperature and pressure

wires,

and hood.

ing to

(3) R SERIES

upper radiator hoses.

the generator

radiator

Disconnect

pipe,

the

Place

it from dropping

Inst

take

engine front support bolts.

flywheel housing bolts.

transmission

Do

(4)

install

and

mission into

from

the

chassis.

the

grille.

the

engine, lower it into

and

align

it

with

into

the

clutch

the

crankshaft

crankshaft

the

them

front

the

the

engine

the

complete

Bnd

heater hoses.

Fill

the

prevailing temperature.

damper

the

clutch

transmission

to

40-50

support

clutch

and install

fan shroud to

the

vacuum

the

cooling

ENGINE

belt

and generator. Disco

ho

ses

at

the

the

ignition switch

and

the

clutch

road

draft

tube.

a support under

out

all

the

engine

up

the

slack

in

and

lift it from

not

allow

the

engine

R

SERIES

the

engine,

align it

with

any

gear. Start

lower

the

Do

ENGINE

the

flywheel

disc spline.

slowly

retaining

disc spline.

to

flywheel

foot-pounds

bolts.

Remove

spring

engine

hose, throttle linkage,

to

coil wire.

the

sending

Install

system

and

the

installation,

REMOVAL.

Remove

radiator

pedal

retracting spring.

the

of line

the

lift

cables

Pull

to strike

when

hook

Remove

the

ENGINE

it into

flywheel' housing.

the

not

Chapter

allow

the

I-General

engine

INSTALLATION

the

engine

compart-

housing. Shift

the

transmission

If

the

spline

with

a box wrench

bolt

until

housing

torque.

the

lift

bracket

rod,

the

muffler inlet

Lean

the fan shroud

radiator.

radiator.

unit wires, generator

the

battery, air cleaner,

and

Connect

connect

crankcase accord-

grooves

the

bolts

Install

choke

main

main

from

wire,

Remove

the

fan

belt

and

fan,

nnect

the

lower

and

remove

to

coil wire, muffler

transmission

the

assembly

with

a hoist.

the

engine

the

engine

the

INSTALLATION

the

engine

transmission main shaft

the

radiator .

Remove

to

engine

is removed.

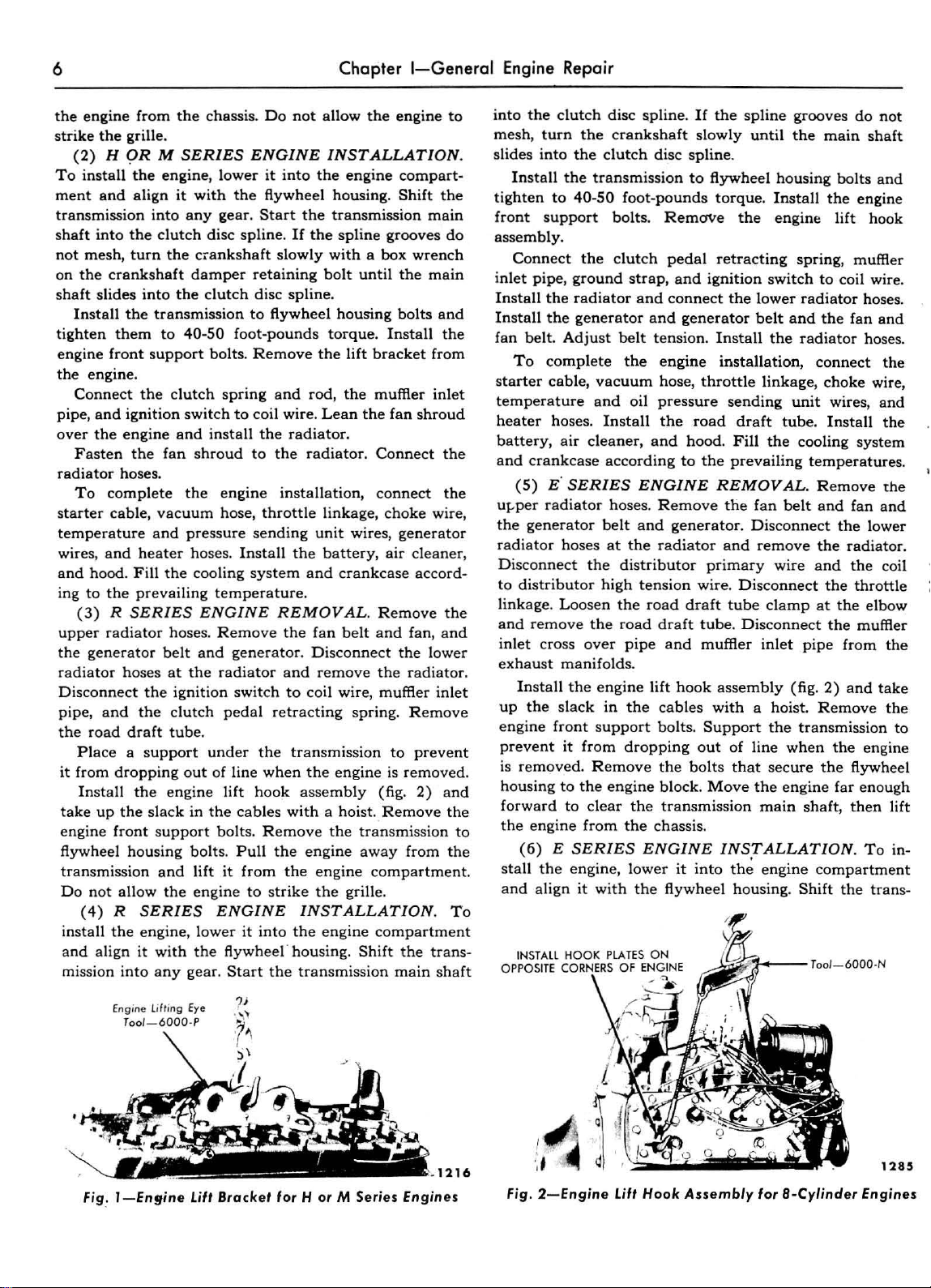

(fig.

Remove

transmission to

away

from

compartment.

grille.

compartment

Shift

the

prevent

2)

.

trans-

to

the

do

and

the

the

the

the

and

inlet

and

the

the

To

Engine Repair

into

the

clutch

mesh, turn

slides into

.

Install

tighten

front

assembly.

inlet

Install

Install

fan belt.

starter cable,

temperature

heater

battery, air cleaner,

and crankcase

uI--per

the

radiator

Disconnect

to

linkage. Loosen

and

inlet cross

exhaust

up

engine

prevent

is

housing

forward

the

stall

and

O

to

support

Connect

pipe, ground strap,

the

the

To

complete

hoses.

(5)

E'

radiator hoses.

generator

hoses

distributor high

remove

manifolds.

Install

the

slack

front support

removed.

to

engine

(6)

E

the

align

INSTAll HOOK

PPOSITE

disc spline.

the

crankshaft

the

clutch

the

transmission

40-50

the

radiator

generator

Adjust

vacuum

and

Install

according

SERIES

belt

the

the

over

the

engine

in

it from dropping

Remove

the engine

to

clear

from

SERIES

engine, lower it

it

with

disc

foot-pounds

bolts.

clutch

and

belt

the

oil

Remove

pedal

and

connect

and

tension.

engine

hose,

pressure

the

and

ENGINE

Remove

and

generator.

at

the

radiator

distributor primary wire

tension

the

road

road draft tube.

pipe

and

lift

hook

the

cables

bolts

the

block.

the

transmission

the

chassis.

ENGINE

the

flywheel housing.

PLATES

ON

OF

ENGINE

If

the

spline

slowly

spline

.

to

flywheel housing

until

grooves do

the

torque. Install

the

engine lift hook

retracting spring, muffler

ignition

generator

Install

installation,

throttle

road

hood..

to

the

REMOVAL.

wire.

draft

muffler

assembly

with

. Support

out

bolts

Move

switch

the

lower radiator hoses.

belt

the

linkage,

sending

draft

Fill

the

prevailing temperatures.

to

and

the

radiator

connect

unit wires, and

tube. Install

cooling

Re

the

fan

belt

and

Disconnect

and

remove

Disconnect

tube

clamp

Disconnect

inlet

the

and

at

pipe

(fig.

a hoist.

the

of line

that

secure

the

main

Remove

transmission to

when

the

engine

shaft, then lift

INSTALLATION.

into

the

engine

compartment

Shift

~

~--To

not

main

shaft

bolts

and

the

engine

coil wire.

fan and

hoses.

the

choke

wire,

the

system

move

the

fan and

the

lower

radiator.

the

coil

the

throttle

the

elbow

the

muffler

from the

2)

and

take

the

the

engine

flywheel

far enough

To

in-

the

trans-

o/_6000·N

fig

E

ngi

ne liffi

Too/_6000

:

'-Engine

ng

Eye

·P

Lift Bracket for H

or

M Series Engines

1216

Fig.

2-fngine

Liff

Hook

Assembly

for

8-Cylinder

1185

fngines

Section

l-Engine

Removal

and

Installation

7

mission

from

until

spline

until

torque

front

turning.

the

gooves

the

Install

support

into

main

main

the

them

any

gear.

Move

shaft

do

not

shaft

flywheel

to

40-50

bolts.

This

the

engine

enters

mesh,

slides

housing

foot-pounds.

Remove

assembly.

Connect

cross

road

and

the

the

rad

sta

ll

the

fan belt.

radiator

To

starter

wire,

heater

Fill

the

prevailing

the

over

pipe

draft

tube. Connect

coil

to

iator

and

generator

Adjust

hoses.

complete

cable,

temperature

hoses.

Install

cooling

temperatures.

muffler

to

the

distributor

connect

and

the

the

vacuum

and

the

system

inlet

exhaust

generator

belt

engine

hose,

pressure

battery,

and crankcase

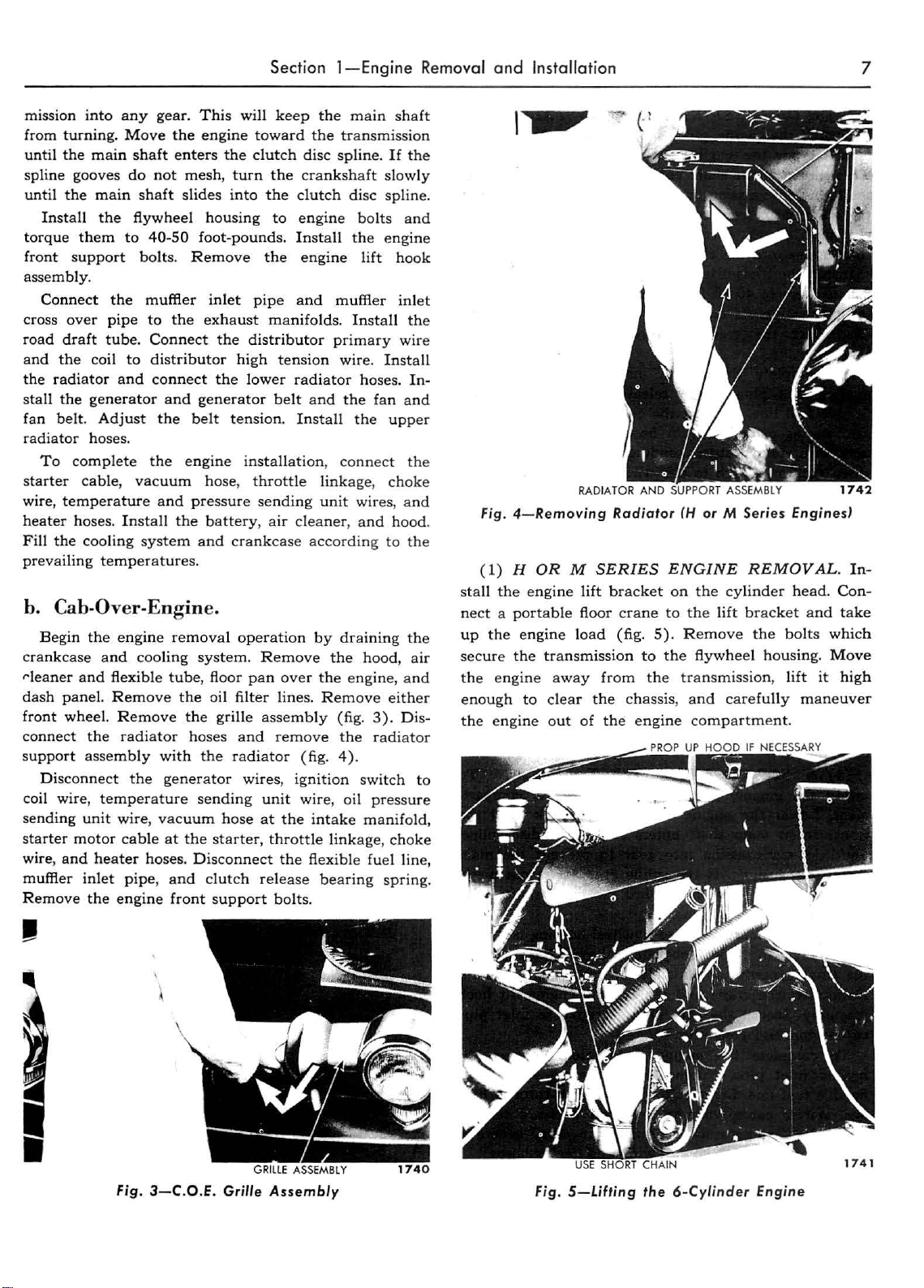

b. Cab.Over.Engine.

Begin

crankcase

,.Ieaner

dash

front

co

nnect

support

coil

sendi

starter

wire,

muffler

Remove

the

engine

and

and

flexible

panel.

Disconnect

wire, temperature

ng

and

wheel.

the

assemb

unit

motor

heater

in

let

the

Remove

Remove

radiator

the

wire,

cable

pipe, and

engine

removal

cooling

tube,

the

ly

with

generator

vacuum

at

hoses. D

front

system.

oi l filter lines.

the

hos

the

sending

the

isconnect

clutch

will

keep

toward

the

clutch

turn

the

into

the

to

the

pipe

manifolds.

the

distributor

high

tension

the

low

er

belt

tension. Install

installation,

throttle

sending

air

operation

Remove

floor

pan

over

grille

assembly

es

and

remove

radiator

wires,

unit

hose

at

the

starter,

support

throttle

the

release

bolts.

the

main

the

transmission

disc

spline.

crankshaft

clutch

engine

Install

engine

and

muffler

primary

wire.

radiator

and

connect

linkag

unit

cleaner,

according

by

draining the

the

the

Remove

(fig.

the

(fig. 4).

ignition

wire

, oil

intake manifold,

link

flexible fuel line,

bea

If

slowly

disc

spline.

bolts

the

engine

lift

Install

Install

hoses.

the

fan

the

upper

e,

choke

wires,

and

hood.

to

hood, a

engine,

either

3). Disradiator

switch

pressure

age,

choke

ring sprin

shaft

the

and

hook

inlet

the

wire

In-

and

the

and

the

ir

and

to

(1) H OR M SERIES

stall

nect a portable

up

secure

the

enough

the engine

g.

\,.,

Fig.

4-Removing

the

the

engine

the

eng

ine

engine

load

transmission

away

to

clear

out

Radiator

lift

bracket

floor c

rane

(fig. 5). Remove

to

from

the

the

chassis,

of

the

engine

(H

or

M

ENGINE

on

the

cylinder

to

the

lift

the

flywhe

transmission,

and

carefully

com

partment.

Series

Engines]

REMOVAL.

head.

bracket

the

el

and

bolts which

housing.

lift

maneuver

Move

it

In-

Con-

take

high

Fig.

\

3-C.O.E

. Grille

Assembly

Fig.

5-Lifting

the

6-Cylinder

Engine

Loading...

Loading...