Page 1

HCD/HMD/HCF/HMF1650R Ice Machines

Order parts online

www.follettice.com

Operation and Service Manual

208264

Stock Module Identification Plate

Easton Pennsylvania

PART NO

Module No.

SINGLE

PHASE

Product

OZ

HZ

Service No.

PSIG

SERIAL NO

CORPORATION

CHARGE

VOLTS

MADE IN

THE USA

LOW SIDE

MODEL

NSF

U

L

R

C

U

L

MOTOR COMPRESSOR THERMALLY PROTECTED

FULL LOAD AMPS

R

AMPS

AMPS

REFRIGERANT

DESIGN PRESSURE HIGH SIDE

IT FUSE SIZE

MIN. BRANCH CIRCUIT AMPACITY

MAX. BRANCH CIRCU

Following installation, please forward this manual

to the appropriate operations person.

801 Church Lane • Easton, PA 18044, USA

Toll free (877) 612-5086 • +1 (610) 252-7301

www.follettice.com

01034693R00

Page 2

2 Horizon 1650R/N Ice Machines

Page 3

Table of contents

Welcome to Follett Corporation ..................................................................................................................................4

Speci cations ...............................................................................................................................................................5

Operation .......................................................................................................................................................................7

Cleaning, weekly exterior care ..............................................................................................................................7

Cleaning, semi-annual evaporator cleaning ..........................................................................................................7

Service .........................................................................................................................................................................12

Ice machine operation .........................................................................................................................................12

Water system .......................................................................................................................................................13

Electrical system .................................................................................................................................................14

Normal control board operation ....................................................................................................................14

Test points ....................................................................................................................................................15

Error faults ....................................................................................................................................................15

Hard errors ...................................................................................................................................................15

Soft errors .....................................................................................................................................................15

Relay output indication .................................................................................................................................15

Compressor/refrigerant solenoid output .......................................................................................................15

Wiring diagram, evaporator unit ...................................................................................................................16

Wiring diagram, condenser unit ...................................................................................................................17

Gearmotor data ............................................................................................................................................17

Mechanical system ..............................................................................................................................................18

Evaporator disassembly ...............................................................................................................................18

Evaporator reassembly .................................................................................................................................20

Refrigeration system ...........................................................................................................................................23

Condenser unit operation .............................................................................................................................23

Refrigerant pressure data .............................................................................................................................23

Refrigerant charges ......................................................................................................................................23

Refrigeration system diagram.......................................................................................................................24

Refrigerant replacement requirements .........................................................................................................25

Evacuation ....................................................................................................................................................25

Ambients (evaporator unit) ...........................................................................................................................25

Ice capacity test ...........................................................................................................................................25

Bin full detection system .....................................................................................................................................26

Troubleshooting ...................................................................................................................................................27

Replacement parts ..............................................................................................................................................30

Horizon 1650R/N Ice Machines 3

Page 4

Welcome to Follett

Follett equipment enjoys a well-deserved reputation for excellent performance, long-term reliability and outstanding

after-the-sale support. To ensure that this equipment delivers the same degree of service, we ask that you review

the installation manual (provided as a separate document) before beginning to install the unit. Our instructions are

designed to help you achieve a trouble-free installation. Should you have any questions or require technical help at

any time, please call our technical service group at (877) 612-5086 or +1(610)252-7301.

Before you begin

After uncrating and removing all packing material, inspect the equipment for concealed shipping damage. If damage

is found, notify the shipper immediately and contact Follett Corporation so that we can help in the ling of a claim, if

necessary.

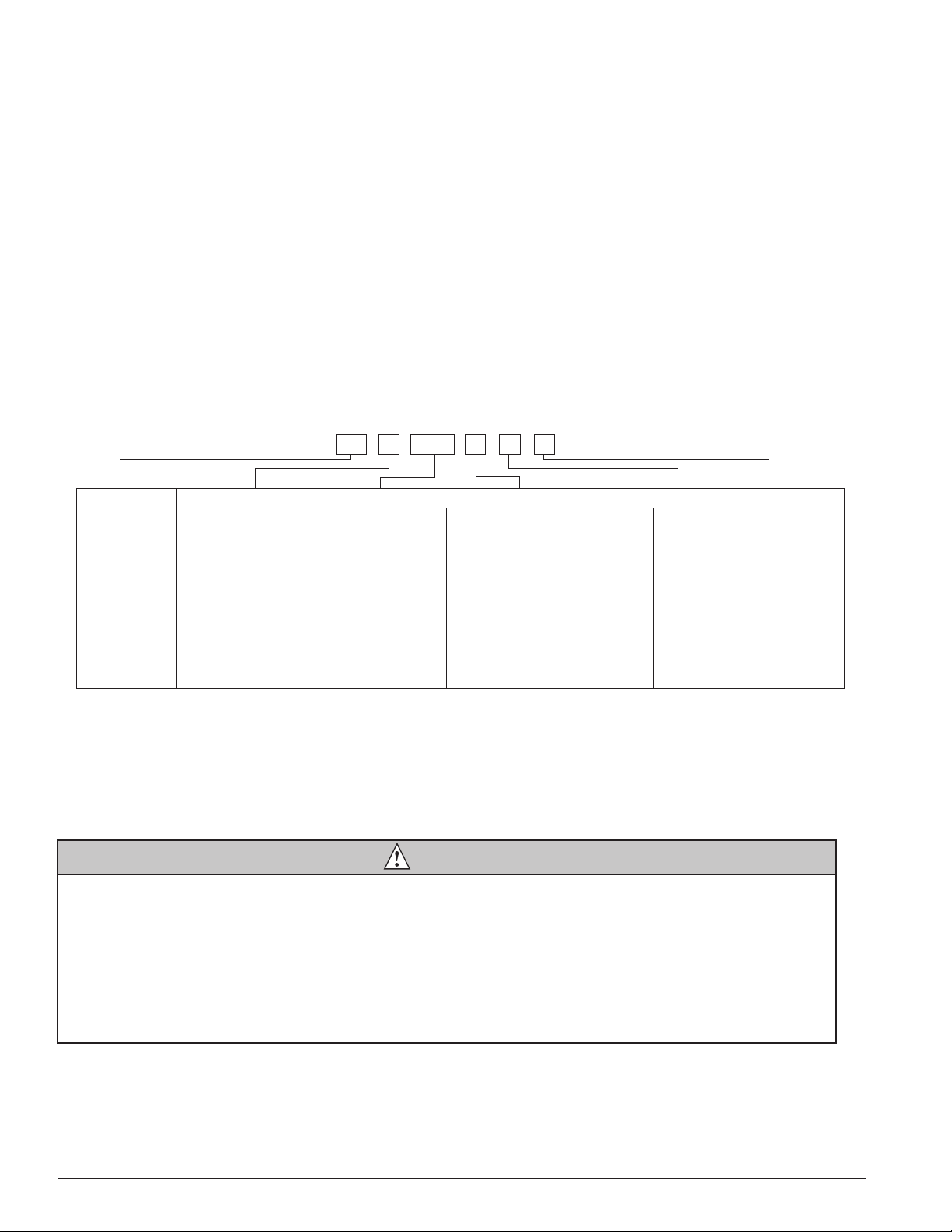

Check your paperwork to determine which model you have. Follett model numbers are designed to provide information

about the type and capacity of Follett equipment. Following is an explanation of the different model numbers in the 1650

series.

Chewblet® Ice Machine Model Number Configurations

R B SD 1650HC

Icemaker Voltage Series Condenser

MC Maestro™

Chewblet

(400 Series)

HC Horizon™

Chewblet

(1000, 1400,

1650 Series)

HM Horizon

Micro

Chewblet

C 208-230/60/1 (icemaking head)

Self-contained only.

D 115/60/1 (icemaking head)

Self-contained and remote.

If remote unit, high side is

208-230/60/1.

E 230/50/1 (icemaking head)

Self-contained only.

F 115/60/1 (icemaking head)

Remote only. High side is

208-230/60/3.

400 up to

454 lb

(206 kg)

1000 up to

1036 lb

(471 kg)

1400 up to

1450 lb

(658 kg)

1650 up to

1580 lb

(717 kg)

A Air-cooled, self-contained

W Water-cooled, self-contained

R Air-cooled, remote condensing unit

N Air-cooled, no condensing unit for

connection to parallel rack system

Application Configuration

V Vision™

H Harmony™

B Ice storage

bin

J Drop-in

M Ice Manager™

diverter valve

system

S RIDE

(RIDE remote

ice delivery

equipment)

T Top-mount

CAUTION

• Moving parts. Do not operate with front cover removed.

• Hot parts. Do not operate with cover removed.

• To reduce risk of shock, disconnect power before servicing.

• Most ice machine cleaners contain citric or phosphoric acid, which can cause skin irritation. Read caution

label on product and follow instructions carefully.

• Ice is slippery. Maintain counters and oors around dispenser in a clean and ice-free condition.

• Ice is food. Follow recommended cleaning instructions to maintain cleanliness of delivered ice.

®

4 Horizon 1650R/N Ice Machines

Page 5

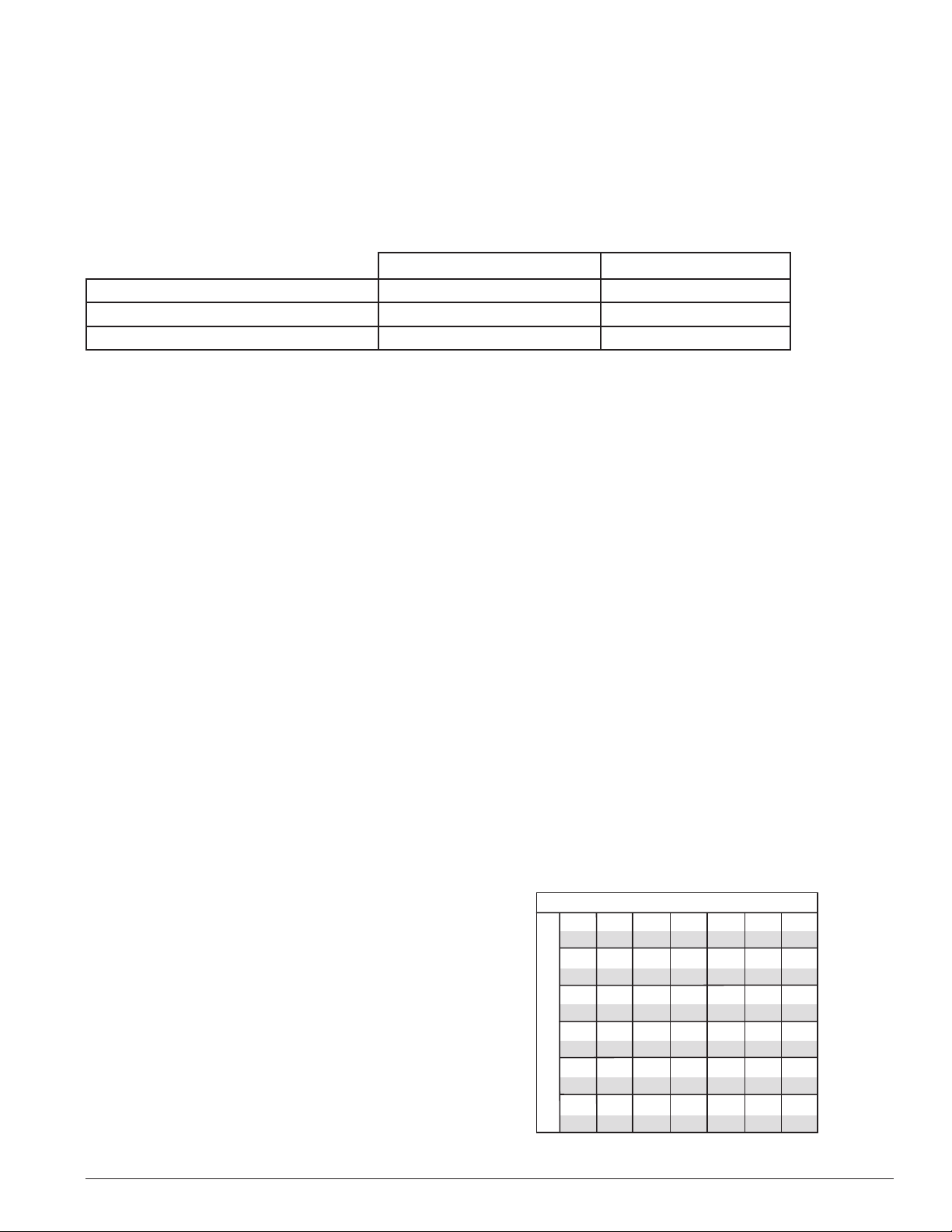

Speci cations

F

C

50

10

60

16

70

21

80

27

90

32

60

16

1669

757

1596

724

1523

691

1440

653

1356

615

70

21

1580

717

1528

693

1474

669

1387

629

1298

589

80

27

1479

671

1451

658

1424

646

1332

604

1240

562

90

32

1422

645

1387

629

1350

612

1267

575

118 3

537

100

38

1366

620

1310

594

1254

569

119 1

540

112 7

511

lbs

kg

lbs

kg

lbs

kg

lbs

kg

lbs

kg

Inlet Water Temperature F/C

Ambient Air Temperature F/C

Ice machine capacity/24 hrs.

Electrical

Separate circuit and equipment ground required.

Evaporator unit

Standard electrical – 115/60/1

Maximum fuse – 15A

Amperage – 6A

Condensing unit

Single-Phase 3-Phase

Electrical 208-230 V, 6 0Hz 208-230 V, 60 Hz

Maximum Circuit HVACR breaker size 50A 35A

Minimum Circuit Ampacity 29.9A 21.2A

Evaporator plumbing

3/8" OD push-in water inlet

3/4" MPT

Notes: 3/4" vented drain line must slope a minimum of 1/4" per ft (6mm per 30.4 cm run).

Drain to be hard piped and insulated.

Water shut-off recommended within 10 ft (3 m).

Follett recommends installation of Follett water lter system (P/N 00130286) in ice machine

inlet water line.

Ambient

Evaporator unit

Air temperature 100 F/38 C max. 50 F/10 C min.

Water temperature 90 F/32 C max. 45 F/7 C min.

Water pressure 70 psi max. (483 kPa) 10 psi min. (69 kPa)

Condenser unit

Air temperature 120 F/49 C max. -20 F/-29 C min.

Refrigeration

3/8" liquid line – insulated

7/8" suction line – insulated

Note: Rack system installations require a capacity of 7,700 BTU/hr at 0 F (-18 C) evaporator temperature.

Evaporator pressure regulator (not supplied) is required.

Weight Ice production

Evaporator unit

190 lb (88 kg)

Condenser unit

Single-phase: 390 lb (177 kg)

3-phase: 340 lb (154 kg)

Horizon 1650R/N Ice Machines 5

Page 6

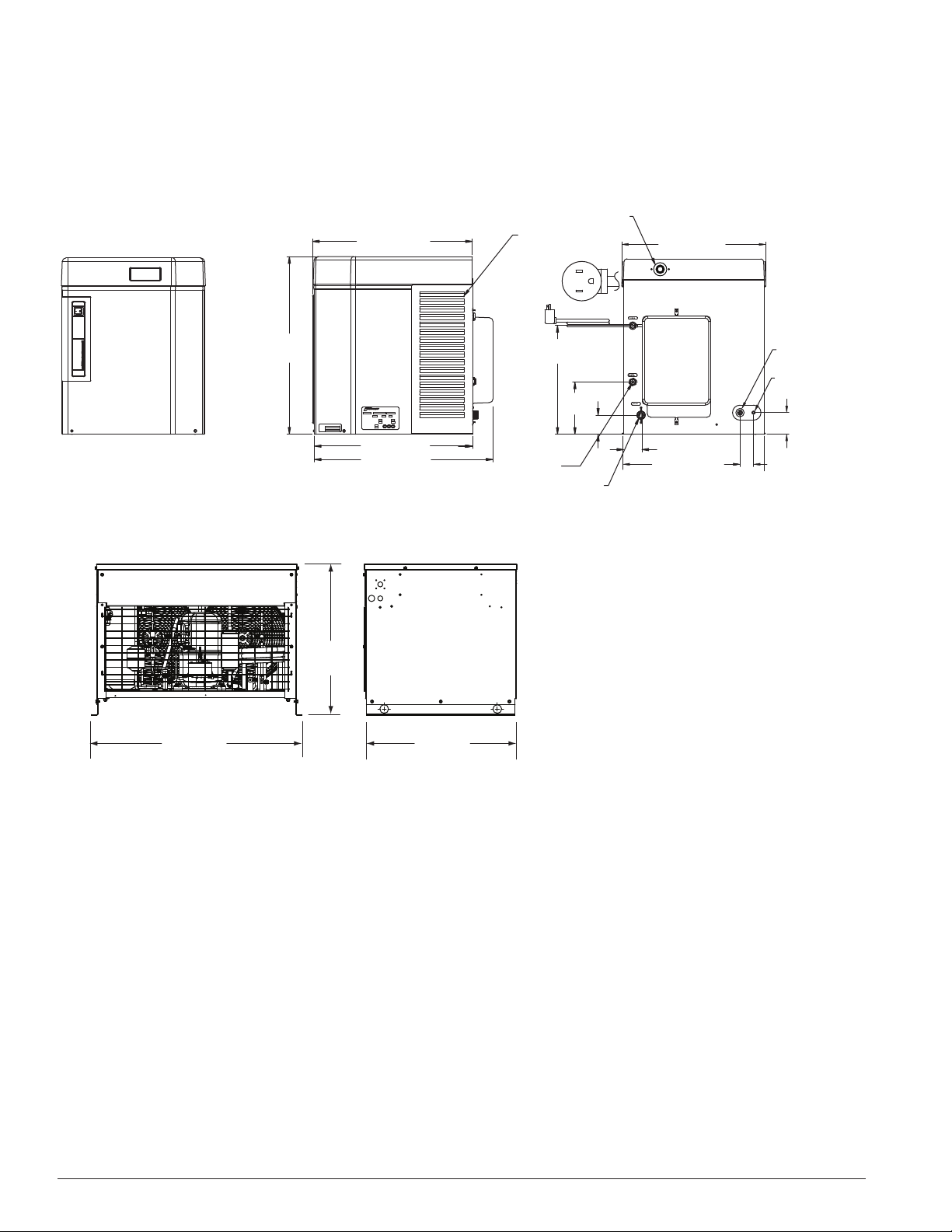

Dimensions and clearances

Entire front of ice machine must be clear of obstructions/connections to allow removal.

1" (26 mm) clearance above ice machine for service.

1" (26 mm) minimum clearance on sides.

Front View Side View Back View

Ice transport tube connection

21.28" (541mm)

Air exhaust

both sides

NEMA 5-15

right angle

L2

G

L1

19.3" (491mm)

Condensing Unit

36.25"

(921 mm)

23.50"

(597mm)

208264

Stock Module Identification Plate

Module No.

Product

Service No.

26.08"

(662 mm)

Easton Pennsylvania

CORPORATION

SERIAL NO

MODEL

PART NO

SINGLE

HZ

VOLTS

FULL LOAD AMPS

PHASE

MOTOR COMPRESSOR THERMALLY PROTECTED

OZ

CHARGE

REFRIGERANT

LOW SIDE

PSIG

DESIGN PRESSURE HIGH SIDE

MIN. BRANCH CIRCUIT AMPACITY

AMPS

MADE IN

ULU

NSF

THE USA

L

RR

MAX. BRANCH CIRCUIT FUSE SIZE

AMPS

C

21.05" (535mm)

23.77" (604mm)

25.5"

(648 mm)

14.47"

(368mm)

6.95"

(177mm)

3/8" OD push-in

water inlet

3/4" MPT drain

2.53"

(65mm)

2.5" (64mm)

15.69" (399mm)

7/8" suction line

3/8" liquid line

2.87

(73mm)

1.81

(46mm)

6 Horizon 1650R/N Ice Machines

Page 7

Operation

LO WATER

C

L

E

A

N

Cleaning and preventive maintenance (all models)

Note: Do not use bleach to sanitize or clean the ice machine.

Preventive maintenance

Periodic cleaning of Follett’s ice machine system is required to ensure peak performance and delivery of clean,

sanitary ice. The recommended cleaning procedures that follow should be performed at least as frequently as

recommended, and more often if environmental conditions dictate.

Cleaning of the ice machine system, in most cases, should be performed by your facility’s maintenance staff or a

Follett authorized service agent. Regardless of who performs the cleaning, it is the operator’s responsibility to see

that this cleaning is performed according to the schedule below. Service problems resulting from lack of preventive

maintenance will not be covered under the Follett warranty.

Weekly exterior care

The exterior may be cleaned with a stainless cleaner such as 3M Stainless Steel Cleaner & Polish or equivalent.

Semi-annual evaporator cleaning (every 6 months)

WARNING

• Wear rubber gloves and safety goggles (and/or face shield) when handling ice machine cleaner or sanitizer.

CAUTION

• Use only Follett approved SafeCLEAN™ Cleaner (P/N 00132001) and NU-CALGON IMS-II SANITIZER.

• Do not mix Cleaner and Sanitizer solutions together.

• DO NOT USE BLEACH.

• It is a violation of Federal law to use these solutions in a manner inconsistent with their labeling.

• Read and understand all labels printed on packaging before use.

Note: Complete procedure for cleaning an sanitizing MUST be followed. Ice must be collected for

10 minutes before putting ice machine back into service.

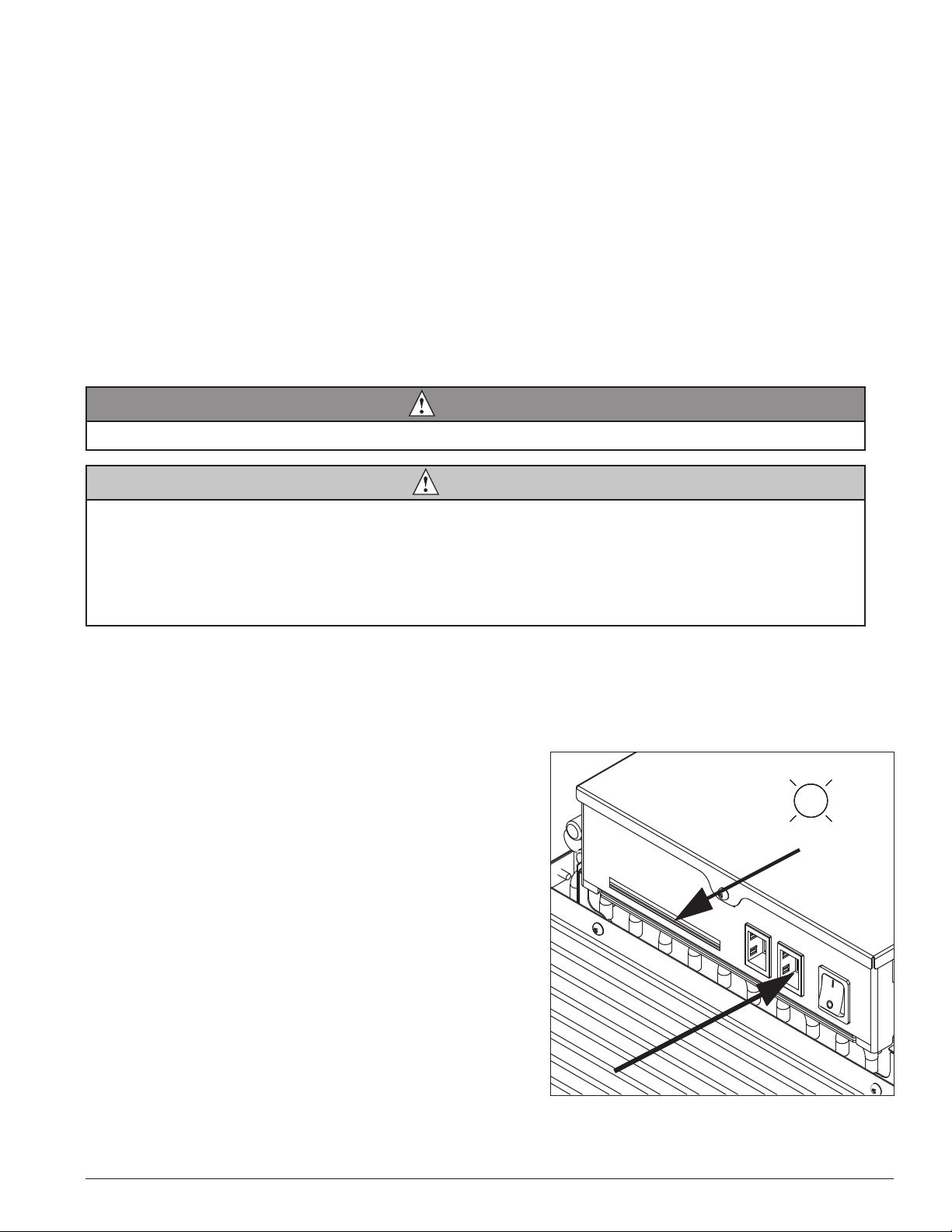

Fig. 1

1. To clean – Remove cover. Press the CLEAN button. The

machine will drain. Wait for the LO WATER light to come

on (Fig. 1).

Note: For Ice Manager diverter valve application, refer

to manual 00175273 for ice machine and diverter valve

cleaning process.

Horizon 1650R/N Ice Machines 7

Page 8

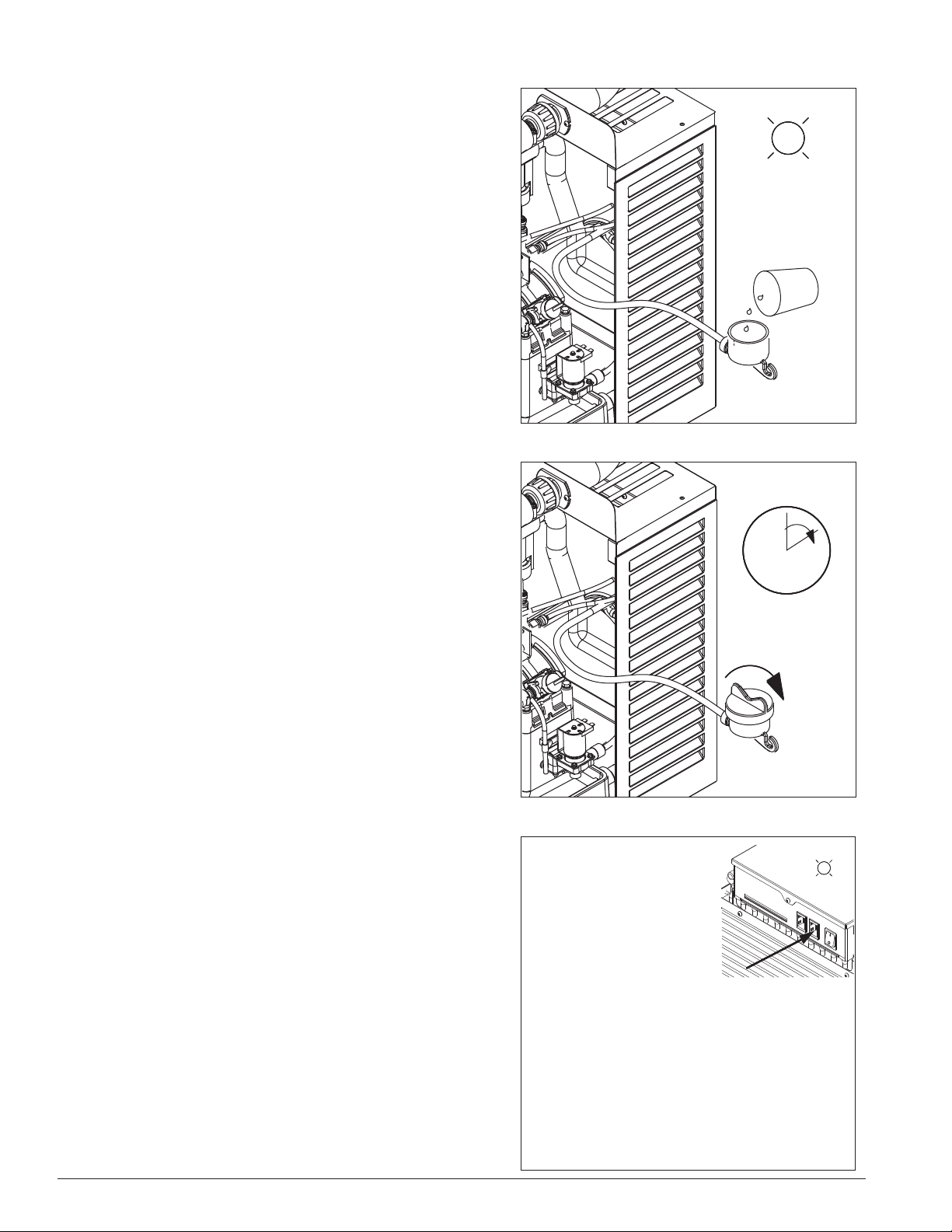

2. Mix 1 gallon (3.8 L) 120 F (49 C) water and

HI WATER

12

LO WATER

N

A

E

L

C

7 oz (198 g) (one 7 oz packet of Follett SafeCLEAN ice

machine cleaner, P/N 00132001). Locate cleaning cup.

Fill until HI WATER light comes on (Fig. 2).

Note: Do not use bleach to sanitize or clean the ice machine.

3. Replace cover on cleaning cup. Wait until machine

restarts. Machine will clean, then ush 3 times in

approximately 12 minutes (Fig. 3).

Fig. 2

Fig. 3

Fig. 4

4. To sanitize – Press CLEAN button. The machine will

drain. Wait for LO WATER light to come on (Fig. 4).

8 Horizon 1650R/N Ice Machines

Page 9

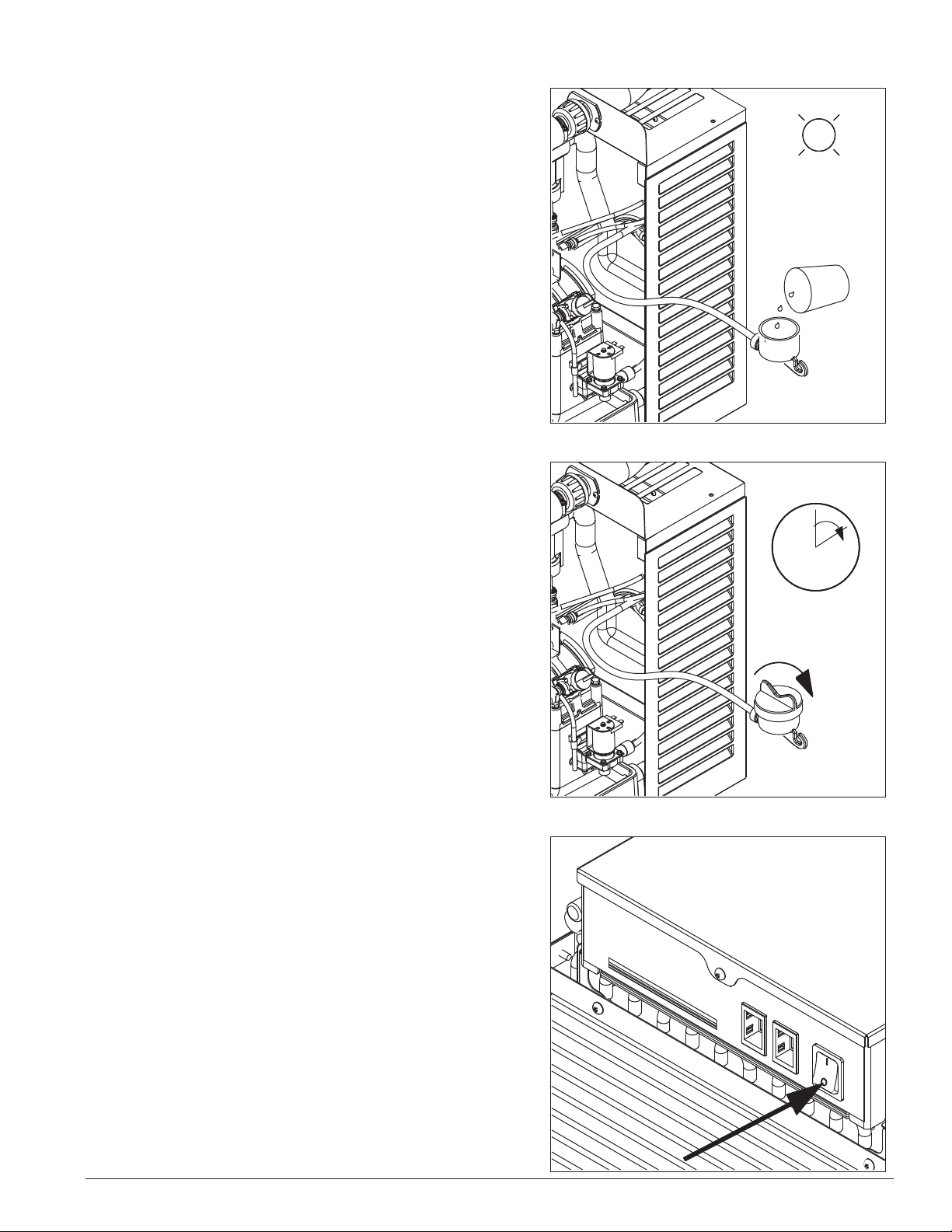

5. Mix 1 gallon 120 F (49 C) water and 1.6 oz (48 ml)

HI WATER

12

NU-CALGON IMS-II SANITIZER. Fill until HI WATER

light comes on (Fig. 5).

Note: Do not use bleach to sanitize or clean the ice machine.

6. Replace cover on cleaning cup. Wait until machine

restarts. Machine will sanitize, then ush 3 times in

approximately 12 minutes (Fig. 6).

Fig. 5

Fig. 6

Fig. 7

7. To clean transport tube – Press power switch OFF

(Fig.7).

Horizon 1650R/N Ice Machines 9

Page 10

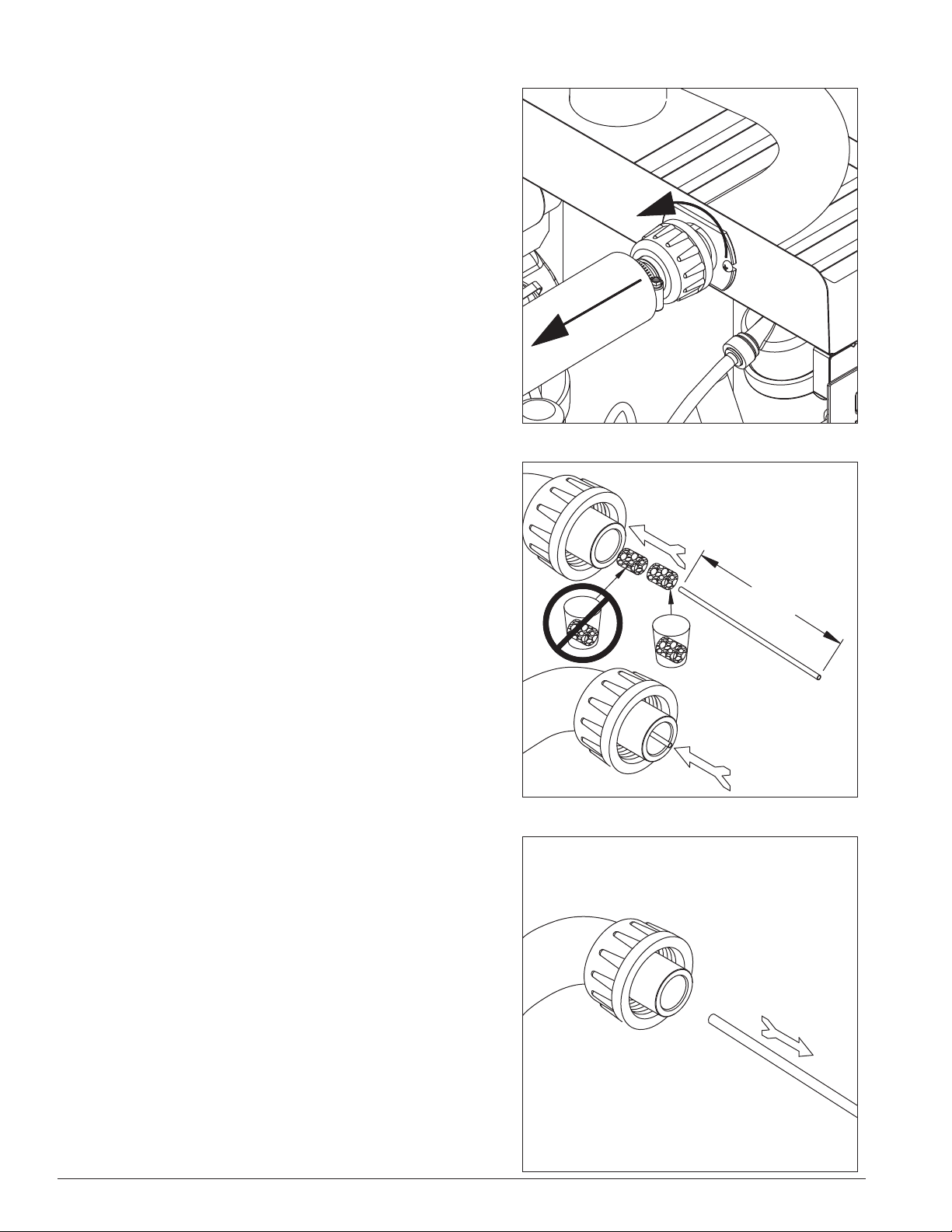

8. Disconnect coupling as shown (Fig. 8).

1

2

3

16"

(407mm)

9. Using disposable food service grade gloves, insert dry

Sani-Sponge™ (kit P/N 00132068). Next, insert SaniSponge soaked in Nu-Calgon IMS-II sanitizer solution.

Push both Sani-Sponges down ice transport tube with

supplied pusher tube (Fig. 9).

Fig. 8

Fig. 9

Fig. 10

10. Remove and discard 16” (407 mm) pusher tube (Fig. 10).

10 Horizon 1650R/N Ice Machines

Page 11

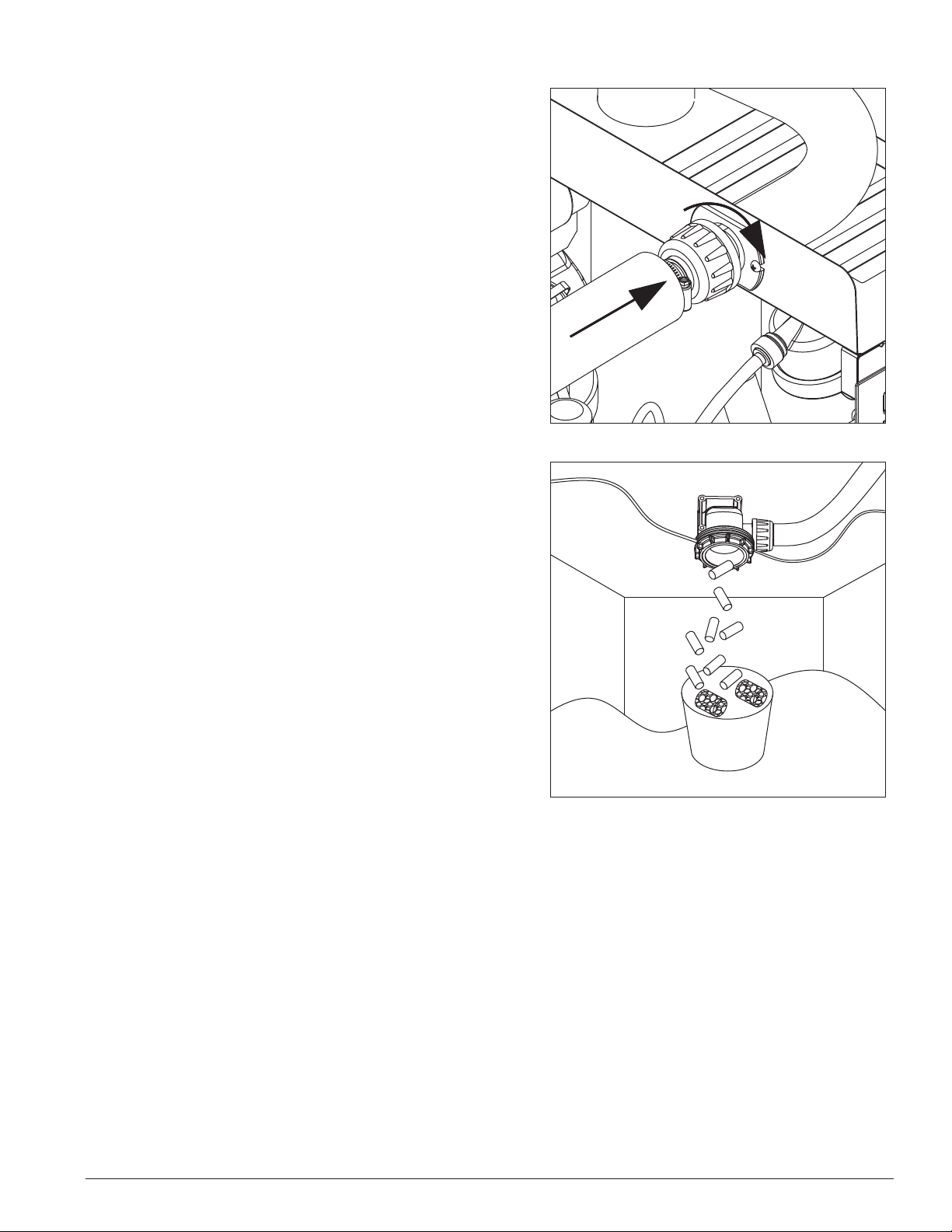

11. Reconnect coupling. Press power switch ON. Ice pushes

Sani-Sponges through tube (Fig. 11).

12. Place a sanitary (2 gallon or larger) container in bin

or dispenser to collect Sani-Sponges and ice for

10minutes. Collect 5.5 lb (3 kg) of ice from unit. Discard

ice and Sani-Sponges (Fig. 12).

Fig. 11

Fig. 12

Horizon 1650R/N Ice Machines 11

Page 12

Service

Ice machine operation (all models)

Follett’s ice machine consists of ve distinct functional systems covered in detail as follows:

• Water system

• Electrical control system

• Mechanical assembly

• Refrigeration system

• Bin full

The Horizon ice machine overview

The Follett Horizon ice machine uses a horizontal, cylindrical evaporator to freeze water on its inner surface. The

refrigeration cycle is continuous; there is no batch cycle. The evaporator is ooded with water and the level is controlled

by sensors in a reservoir. A rotating auger (22 RPM) continuously scrapes ice from the inner wall of the evaporator. The

auger moves harvested ice through the evaporator into an ice extrusion canal. The ice is forced through a restrictive

nozzle that squeezes out the water and creates the Chewblet. The continuous extrusion process pushes the Chewblets

through a transport tube into a dispenser or bin.

A solid state PC board controls and monitors the functionality of the ice machine. In addition to sequencing electrical

components, the board monitors various operational parameters. A full complement of indicator lights allows visual

status of the machine's operation. Additionally, the PC board controls the self- ushing feature of the ice machine. The

evaporator water is periodically drained and replenished to remove minerals and sediment.

A unique “bin full” detection system is incorporated in the Horizon ice machine. A switch located at the ice discharge port

of the machine detects the position of the transport tube. When the bin lls up with ice, the transport tube moves out of

the normal running position, and the switch turns the ice maker off. A domed housing at the end of the transport tube

contains the ice extrusion loads during shut down.

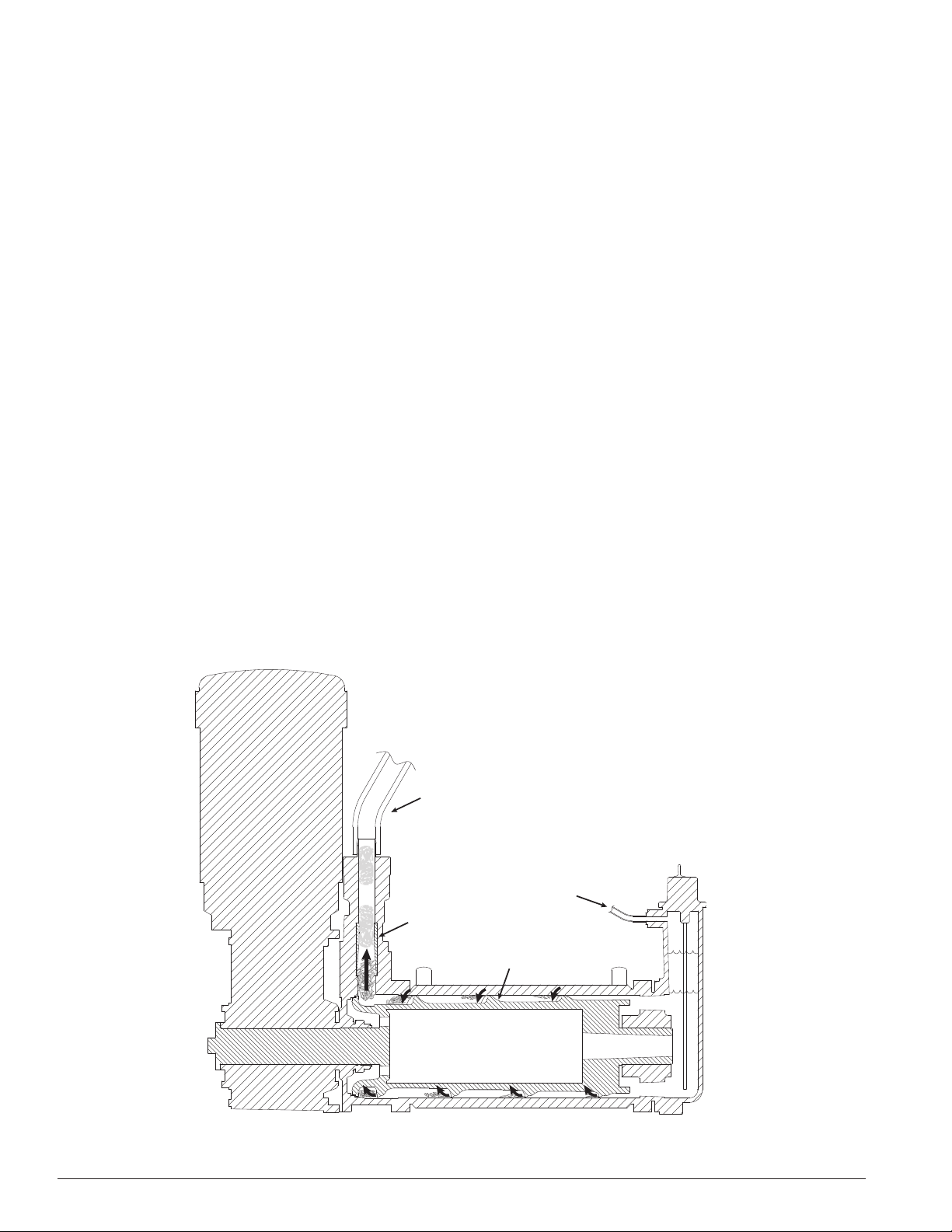

Harvest system diagram

ice

transport

tube

water

inlet

compression

nozzle

auger

12 Horizon 1650R/N Ice Machines

Page 13

Water system

The water level in the evaporator is controlled by a feed solenoid and level detecting sensors. Referencing the

diagram below, water sensing rods extend down into the reservoir at the end of the evaporator assembly. The system

works via electrical conductivity as follows:

One of the longest probes is a common. When water is between any of the other probes and the common, the PC

board will sense the activation. During normal operation, the water level rises and falls between the Normal High and

Normal Low sensors. As water is consumed to make ice, the level will fall until the Normal Low sensor is exposed,

triggering the water feed solenoid on. Water will ll until the Normal High sensor is activated.

Additional sensors are incorporated in the reservoir for alarm and cleaning/ ushing conditions.

Note: The potable water dissolved solids content must be greater than 10 ppm for the water control system to

function properly. If using reverse osmosis water ltration system, ensure T.D.S level is greater than 10ppm.

Water system diagram

Water level diagram

Normal

operating

range

Alarm LO

Normal LO

Common

Normal HI

Horizon 1650R/N Ice Machines 13

Page 14

Electrical system

Normal control board operation

The PC board indicator lights provide all the information necessary to determine the machine’s status. Green

indicator lights generally represent “go” or normal operation; Yellow indicators represent normal off conditions; Red

indicators generally represent alarm conditions, some of which will lock the machine off.

A green light labeled POWER indicates power to the machine. A ashing green light labeled CPU is normal and

indicates that the Central Processing Unit “heart beat” is working. All other normal operation status indicators are

covered as follows:

Ice machine disposition Operating conditions

Legend:

ON OFF

ON or OFF FLASHING

1. Ice machine is making ice.

AUGER ON

REFRIG ON

PURGE

TIME DELAY

CLEANING

SERVICE

HI AMPS

DRAIN CLOG

HI WATER

CPU

LO WATER

2. Ice machine is not making ice.

AUGER ON

REFRIG ON

PURGE

TIME DELAY

CLEANING

SERVICE

HI AMPS

DRAIN CLOG

HI WATER

CPU

LO WATER

3. Ice machine is not making ice.

AUGER ON

REFRIG ON

PURGE

TIME DELAY

CLEANING

SERVICE

HI AMPS

DRAIN CLOG

HI WATER

CPU

LO WATER

LOW BIN

LOW BIN

LOW BIN

POWER

POWER

POWER

1. Normal running.

2. Normal time delay. When the bin lls with ice, the LOW BIN

light goes out and the refrigeration and auger drive systems

immediately shut down. The TIME DELAY light comes on,

initiating the time delay period. When the time delay expires,

the machine will restart provided that the LOW BIN light is on.

3. Normal purge indicator. After a selected period of ice

making time has elapsed (1 or 2 hours), the ice machine will

automatically self- ush. The refrigeration system will shut

down but the gear motor will continue to run. After the ush is

complete the machine will re ll and start without a time delay.

14 Horizon 1650R/N Ice Machines

Page 15

Test points:

The Horizon PC board incorporates on-board test points that can be used to determine various electrical outputs.

The test point holes allow a standard probe to be inserted for quick voltage measurement.

Error faults:

The Horizon PC board monitors various operating parameters including high pressure, auger gearmotor amperage

limits, clogged drain, and high and low water alarm conditions. There are two types of errors namely “hard” or “soft”.

A hard error is one that shuts the machine off and will not allow restart until the reset button is pressed. Even cycling

power will not reset a hard error. A soft error can either be automatically reset should the condition rectify, or if power

is cycled. Should an error occur, consult the troubleshooting guide in this manual or a Follett service technician.

Note: there are two types of LO WATER and HI AMPS errors as listed below.

Soft errors:

HI AMPS: The PC board monitors the amperage of the auger motor. Should the gear motor experience current

draw above the 8.4 amps limit the machine will shut down and the TIME DELAY, HI AMP, and SERVICE LED’s will

be illuminated. After the time delay the machine will restart and the TIME DELAY, HI AMP, and SERVICE LED’s will

clear.

LO WATER: During operation, the water level cycles between the normal low and normal high sensors. Should the

water be shut off to a running machine, a soft error will occur. The error sequence is as follows: During operation,

the water level falls to the normal low sensor, and when it does the water feed solenoid is energized. If water is not

detected at the normal low sensor within 120 seconds, a soft error will occur. The machine will shut down, but the

water feed solenoid will remain energized. Should water return, it will ll to the normal low sensor and the machine

will resume normal operation. The error will clear automatically.

DRAIN CLOG: The drain clog sensor, located in the plastic drain pan behind the drain solenoid, will detect the

presence of water just below the top edge of the pan. If water does not properly ow out of the drain pan it will rise to

the sensor, especially during a self- ushing purge cycle.

Hard error:

HI AMPS:

1. “Two strikes” feature. If the gearmotor has a second HI AMP occurrence during the countdown period (6 hours

after a HI AMP time delay) a hard error will occur and the HI AMP and SERVICE LED’s will be illuminated.

2. No current. To prevent the refrigeration system from running without gearmotor rotation the PC board will indicate

HIGH AMP and SERVICE if the drive relay is energized and there is no current draw.

LO WATER:

1. There is a sensor in the water reservoir that reaches down to the very bottom. The machine will not start if water is

not present at this sensor.

2. A hard error will occur should water not be present within 60 seconds of power up or if the sensors are

disconnected or damaged.

Relay output indication:

Each relay on the board has an indicator light associated with its output. For example, when the relay for the water

feed solenoid is energized, the adjacent indicator light glows green.

Comp/Sol output:

The output for the compressor is labeled COMP/SOL.

Horizon 1650R/N Ice Machines 15

Page 16

Wiring diagram, evaporator unitEvaporator unit wiring diagram

FCV-2FCV-1

20Watt20Watt

120Vac

120Vac

#32

#30

#31

#33

TP7

TP8

DRAIN

INPUT

WATER

J13

J14

J15

J16

J17

J18

H2O

H2O

IN

DRN

J21

J12

J11

TP4

D10

M1

N

L1

GND

J52

1/2hp Max

MOTOR

P52

3

2

GND

120Vac 60Hz

6Amp DRAW RUNNING

~

BLK

5

2

S1

J9

J8

J10

D15

O I

1

4

#21

N

#20 WHT

MAIN OFF/ON

J6

J7

TP11

AMP

240Vac / 20FLA

J5

J4

SENSING

L1

K3

J50

CB1

C NO

CONTROL PC BOARD

1

1

1

FCV-3

20Watt

#22

TP3

SOL

COMP

K1

J24

120Vac

#23

#24

NOC

D5

1

1

J3

J31

J32

RESET

SWITCH

REFRIG

JUMPER

2

J33

J34

3

J1

DRAIN CLOG (R)

#1

#2

#3

#34

TP6

TP5

J2

FAN

DRV

D6

J23J22

D9

1

CONTROL

ICE MANAGER

BLK

RED

1

2

POWER (G)

LOW BIN (G)

AUGER ON (G)

REFRIG ON (G)

TIME DELAY (Y)

CLEANING (Y)

PURGE (Y)

SERVICE (R)

HI AMPS (R)

HI PRESS (R)

LO PRESS (R)

HI WATER (R)

LO WATER (R)

CPU (G)

(OPTIONAL)

GREEN

RED

YELLOW

CLOG

DRAIN

COM

HIGH

NORM

LOW

ALARM

COM

LOW

NORM

J51

4

WATER LEVEL

-V

BLU

3

BIN

FULL

RETURN

OR

BLK

2

1

INPUT 2

(CONTACT CLOSURE)

+V

BRN

OUT (light on)

(3 WIRE)

JUMPER

MOM

S3

CLEAN

ORANGE / BLACK

RED / YELLOW

MAINT

S2

PURGE

BLUE

GREEN

ORANGE

RED

8

LE

BLACK

7

LE

YELLOW

6

LE

4

LE

3

LE

2

LE

Gearmotor data (Brother) Resistance of windings

Gearmotor current 5.0A (nominal) 115 vac gearmotor (Brother) 1.7Ω

Locked rotor amps 15A

16 Horizon 1650R/N Ice Machines

Page 17

Single-phase condensing unit wiring diagram

IMPORTANT:

COMPRESSOR EQUIPPED WITH AN INTERNAL OVERLOAD

PROTECTOR. ALLOW TIME FOR RESET.

USE COPPER CONDUCTORS ONLY.

COMPRESSOR

CONTACTOR

COMPRESSOR

TERMINAL

S

COIL

C

CRANK CASE

R

HP

HEATER

COMPRESSOR

CONTACTOR

BLACK

RED

LP

YELLOW

3-phase condensing unit wiring diagram

DT

P1

L1T2L2

T1

FAN 1

FAN 2

FC

L2

L1

L3 T3T1 F1

L3

T3

WITH BLEEDER

BLACK

RED

YELLOW

F2

START

CAPACITOR

RESISTOR

POTENTIAL RELAY

4

5

6

2

1

RUN

CAPACITOR

COMPRESSOR

CONTACTOR COIL

POWER SUPPLY

230-60-3

COMPRESSOR

TERMINAL

L3

L2

L1 T1

GRD

C

HP LP

T3

T2

CRANK CASE

HEATER

BLACK

D.T.

TO "Y-OUT"

AT PHASE

MONITOR

TERMINAL

BOARD

A

P1

T1L1T2

FAN 1

FAN 2

TO "230 VAC"

B

AT PHASE

MONITOR

A

Y Y-

OUT

FFC

C

C115

ICM402

3 PHASE

MONITOR

L1 L2 L3

TO "L2"

AT TE RMINAL

BOARD

TO "L1"

B

AT TERMINAL

BOARD

230

VAC

VAC

TO "C"

C

AT PHASE

MONITOR

L1

L2 L3 T3T1 F1 F2

TO "P1"

AT TERMINAL

BOARD

L2

L3

T3

S R

RED

YELLOW

Horizon 1650R/N Ice Machines 17

Page 18

Mechanical system

Evaporator disassembly

1. Press PURGE button to purge evaporator, and then turn

power OFF.

2. Unscrew and remove stream divider as shown.

3. Unplug and remove gearmotor as shown.

4. Remove all traces of petrol-gel from the auger shaft.

Fig. 13

Fig. 14

Fig. 15

5. Unscrew and disconnect transport tube from louvered

docking assembly.

6. Unplug sensor at the electrical box.

7. Remove vent tube from shuttle housing as shown.

18 Horizon 1650R/N Ice Machines

Page 19

8. Unscrew and disconnect transport tube from louvered

docking assembly.

9. Unplug sensor at the electrical box.

10. Remove vent tube from shuttle housing as shown.

11. Remove and discard mating ring and seal.

12. Carefully remove auger.

Fig. 16

Fig. 17

Fig. 18

Evaporator reassembly

1. Remove and inspect O ring seal. Discard if damaged in

any way.

2. Clean O ring groove. Lubricate O ring with petrol-gel and

reinstall.

Horizon 1650R/N Ice Machines 19

Page 20

3. Press new mating ring into main housing as shown.

Lube

with soap

touch

Do not

Cardboard

disc

4. Lube the shaft with liquid soap in the area shown and

slip on seal and spring.

Note: Do not touch the sealing surfaces. Use cardboard disk to

install.

5. Reinstall main housing as shown.

Fig. 19

Fig. 20

Fig. 21

6. Orient auger shaft with keyway in the upward position.

7. Force main housing into position against evaporator and

Note: Shuttle housing

removed for clarity

place 1/4" (7 mm) diameter Phillips screwdriver into hole

in the auger shaft.

8. Replace V-band clamp as shown.

9. Replace nut on V-band clamp and tighten.

10. Remove screwdriver.

20 Horizon 1650R/N Ice Machines

Page 21

11. Reconnect transport tube to louvered docking assembly.

Apply

petrol-gel

12. Plug sensor in at the electrical box.

13. Reconnect vent tube to the shuttle housing as shown.

14. Apply a coat of petrol-gel to the auger shaft.

15. Install gearmotor, making sure that insulation is properly

seated between gearmotor and main housing as shown.

16. Firmly tighten four gearmotor bolts in place.

Fig. 22

Fig. 23

Fig. 24

14. Insert a bolt into the auger shaft and nger tighten.

15. Using a wrench, rotate the shaft clockwise to align the

keyways in the gear housing and the shaft so as to

accept the key.

16. Insert the key into the keyway.

Horizon 1650R/N Ice Machines 21

Page 22

17. Remove bolt and reinstall the washer and bolt. Place

Apply

petrol-gel

retainer over bolt and secure with nut and washer.

18. Lubricate body of stream divider with petrol-gel and

reinstall.

19. Plug gearmotor power cord into electrical box

Fig. 25

Fig. 26

22 Horizon 1650R/N Ice Machines

Page 23

Refrigeration system

Condenser unit operation

The condensing unit is weatherproof and equipped to operate in ambient temperatures from -2 0 F to 120 F

(-29 C to 48.9 C). The condensing unit is controlled by a low pressure control, which works in concert with a

refrigerant solenoid valve on the evaporator module. On start-up, the refrigerant solenoid valve opens and suction

pressure rises above the “on” set point of the control. The compressor and fan turn on and the refrigeration system

operates. Upon shut down, the refrigerant solenoid closes. The compressor will pump down the ice machine

evaporator and suction line until the low “off” set point is reached, at which point the compressor and fan will turn off.

Low ambient operation: Reliable operation at low outdoor ambient temperature is achieved with a pumpdown cycle,

a crankcase heater and a head pressure control valve. When the outdoor ambient falls, the condensing pressure

falls. This causes the discharge pressure to fall as well. When the discharge pressure falls below the dome pressure,

the valve modulates open to the discharge port which allows discharge gas to bypass the condenser. Mixing the

discharge gas with the liquid creates a high pressure at the condenser outlet, reducing the ow and causing liquid

to back up in the condenser. Flooding the condenser reduces the area available for condensing. This reduction in

effective condenser surface area results in a rise in condensing pressure. During summer conditions, the discharge

pressure is high, thus closing the discharge port of the valve. Hence, there is full liquid ow from the condenser to

the receiver.

A check valve is installed in the liquid line between the receiver and the condenser to prevent liquid migration from

the receiver to the condenser during the off cycle. The low pressure control will start the condensing unit anytime the

low side pressure rises above the set point and pump the refrigerant out until the pressure falls to the set point. The

crankcase heater, which is energized whenever the condensing unit has power, keeps the compressor oil warmer

than the coldest location in the system. This minimizes off cycle refrigerant migration. If power to the condensing unit

is interrupted after the system is charged, the compressor should not be started unless the crankcase heater has

been energized for at least 24 hours immediately prior to compressor startup. However the compressor can safely be

started during the refrigeration system charging process (without the warm-up period) once sufficient refrigerant is in

the system to maintain a positive pressure on the suction side of the compressor.

Under normal ambient operating conditions the left side condenser fan motor, when viewing the outdoor condensing

unit from the compressor side, is not energized; therefore,the fan will pinwheel. During hot summer days, at elevated

temperatures, the left side condenser fan will be energized to maintain the BTU efficiency of the condensing unit.

For additional information, please reference Horizon ice machine installation instructions for remote condensing units.

Refrigerant pressure data

Air-cooled condensers (air) 70 F/21 C 90 F/32 C

Pressure (psig)

discharge/suction @ evap. 229/29 242/30

Refrigerant charges

R404A ice machine charge speci cations

Model Line Run Charge

1650 0 – 50 ft (0 – 15.2 m) 11 lb (4.9 kg)

50 - 75 ft (15.2 - 22.9 m) 12 lb (5.4 kg)

75 - 100 ft (22.9 - 30.5 m) 13 lb (5.9 kg)

100 ft+ (30,5+m) Not Recommended

Horizon 1650R/N Ice Machines 23

Page 24

Refrigeration system diagram

TYPICAL

CONDENSING UNIT

low side service valve

with service port

condenser

head control valve, 180 PSI

EVAPORATOR UNIT

sight glass

high side service valve

with service port

compressor

check valve

high side

service port

filter-drier

heat exchanger

high side

refrigeration

line run

filter-drier

receiver

14 pounds

filter-drier

sight glass

high side

service valve

with service port

low side

service valve

with service port

High pressure vapor

thermostatic

expansion

valve

High pressure liquid

solenoid valve

low side

service port

Low pressure liquid

high side

service valve

with service port

low side

service valve

with service port

Low pressure vapor

low side

refrigeration

line run

24 Horizon 1650R/N Ice Machines

Page 25

Refrigerant replacement requirements

1. Non-contaminated refrigerant removed from any Follett refrigeration system can be recycled and returned to

the same system after completing repairs. Recycled refrigerant must be stored in a clean, approved storage

container. If additional refrigerant is required, virgin or reclaimed refrigerant that meets ARI standard 700-88

must be used.

2. In the event of system contamination (for example, a compressor burn out, refrigerant leak, presence of

non-condensibles or moisture), the system must be repaired, evacuated and recharged using virgin or reclaimed

refrigerant that meets ARI standard 700-88.

3. Follett Corporation does not approve of recovered refrigerants. Improper refrigeration servicing procedures will

void the factory warranty.

Evacuation

Evacuate the system to a level of 500 microns. When the 500 micron level is reached, close valves and both manifold

and shut down the vacuum pump. Allow the system to sit for approximately 20 minutes. During this period the system

pressure should not rise. If the system pressure rises and stabilizes there is moisture in the system and further

evacuation is needed. If the pressure continues to rise check the system for leaks.

Ambients (evaporator unit) Minimum Maximum

Air temperature

Water temperature2 45 F/7 C 90 F/32.2 C

1

Ambient air temperature is measured at the air-cooled condenser coil inlet.

2

Ambient water temperature is measured in the ice machine oat reservoir.

1

50 F/10 C 100 F/37.8 C

Ice capacity test

Ice machine production capacity can only be determined by weighing ice produced in a speci c time period.

1. Replace all panels on ice machine.

2. Run ice machine for at least 15 minutes.

3. Weigh and record weight of container used to catch ice.

4. Catch ice for 15 or 20 minutes.

5. Weigh harvested ice and record total weight.

6. Subtract weight of container from total weight.

7. Convert fractions of pounds to decimal equivalents (ex. 6 lb 8 oz = 6.5 lb).

8. Calculate production using following formula:

1440 min. x wt. of ice produced

= Production capacity/24 hr. period

Total test time in minutes

9. Calculated amount per 24 hours should be checked against rated capacity for same ambient and water

temperatures in Ice Production Tables.

Horizon 1650R/N Ice Machines 25

Page 26

“Bin full” detection system

The Follett Horizon ice machine incorporates a unique “bin full” detection system, that consists of the shuttle and

actuator. The shuttle incorporates a ag and sensor. Referencing the gure below, the normal running position of

the ag is down, out of the sensor. When the bin lls to the top and ice can no longer move through the tube, the

machine will force the shuttle ag up into the sensor, shutting the machine off. The shuttle actuator, located above

the ice bin allows the ice to curl up within it when the bin is full to contain any forces. In this way, there are no loads

generated that would tend to lift off the lid of the bin.

Shuttle ag and sensor

Shuttle actuator

Running

Off

Running

26 Horizon 1650R/N Ice Machines

Off

Page 27

Troubleshooting

FLASHINGON or OFF

Legend:

OFFON

Please see “Service” section for a description of each function.

Ice machine disposition Possible causes Corrective action

1. Ice machine is in running

condition but not making ice.

LOW BIN

AUGER ON

REFRIG ON

PURGE

TIME DELAY

CLEANING

SERVICE

HI AMPS

HI PRESS

DRAIN CLOG

HI WATER

CPU

LO WATER

2. Machine in TIME DELAY without

full bin.

LOW BIN

AUGER ON

REFRIG ON

PURGE

TIME DELAY

CLEANING

SERVICE

HI AMPS

HI PRESS

DRAIN CLOG

HI WATER

CPU

LO WATER

3. Ice machine is not making ice.

HI AMPS.

.

4. Ice machine is not making ice.

Drain clog.

LOW BIN

AUGER ON

REFRIG ON

PURGE

TIME DELAY

CLEANING

SERVICE

HI AMPS

HI PRESS

DRAIN CLOG

HI WATER

CPU

LO WATER

.

1. Defective compressor.

2. Defective start relay.

3. Defective start capacitor.

4. Defective run capacitor.

5. Defective main contactor.

POWER

6. No output from PC board.

7. Machine in Purge cycle.

1. Ice jamming due to improperly

installed transport tube causing

a false shuttle.

2. Shuttle stuck in up position.

3. Damaged or improperly installed

POWER

thermostat (open).

4. Transport tube backed-out of

coupling.

1. Poor water quality causing ice to

jam auger.

2. Damaged shuttle mechanism or

thermostat (closed).

3. Kinked transport tube

(thermostat systems).

4. Intermittent drive output from

PC board. Evaporator will freeze

causing a hi amps error.

5. Gearmotor is unplugged.

1. Drain hose kinked or plugged

causing water to back up.

2. Improper oor drain routing/pitch

causing water to back up.

3. High TDS levels and leaking

POWER

drain solenoid may cause an

errant drain clog.

1. Replace compressor.

2. Replace start relay.

3. Replace start capacitor.

4. Replace run capacitor.

5. Replace main contactor.

6. Replace PC board.

7. Check for Purge operation.

1. Correct transport tube routing.

2. Repair or replace shuttle

mechanism.

3. Replace or reposition thermostat.

4. Correct coupling installation.

1. Clean ice machine. Increase

ushing frequency.

2. Replace or repair shuttle

mechanism/thermostat.

3. Straighten transport tube.

4. Replace PC board.

5. Plug in gearmotor.

1. Remove kink or blockage from drain

hose.

2. Re-route oor drain.

3. Clean area around drain sensor and/

or replace Drain solenoid valve.

Horizon 1650R/N Ice Machines 27

Page 28

Ice machine disposition Possible causes Corrective action

FLASHINGON or OFF

Legend:

OFFON

5. Ice machine is not making ice.

Locked in PURGE.

AUGER ON

REFRIG ON

PURGE

TIME DELAY

CLEANING

SERVICE

HI AMPS

HI PRESS

DRAIN CLOG

HI WATER

CPU

LO WATER

.

6. The CPU is not ashing.

AUGER ON

REFRIG ON

PURGE

TIME DELAY

CLEANING

SERVICE

HI AMPS

HI PRESS

DRAIN CLOG

HI WATER

CPU

LO WATER

.

7. Ice machine is making ice.

Excessive water in bin or

coming into bin from transport

tube.

AUGER ON

REFRIG ON

PURGE

TIME DELAY

CLEANING

SERVICE

HI AMPS

HI PRESS

DRAIN CLOG

HI WATER

CPU

LO WATER

.

8. Ice machine is not making ice.

Lo water.

AUGER ON

REFRIG ON

PURGE

TIME DELAY

CLEANING

SERVICE

HI AMPS

HI PRESS

DRAIN CLOG

HI WATER

CPU

LO WATER

.

1. A self- ush occurred but could

not drain evaporator due to a

failed drain solenoid valve.

2. A self- ush occurred but could

not drain evaporator due to water

POWER

LOW BIN

reservoir or ice machine not

1. Replace drain solenoid valve.

2. Level ice machine. Check water

reservoir to make sure it is not

tilted towards the compressor.

being level.

1. Processor has been damaged. 1. Replace PC board.

POWER

LOW BIN

1. Failed water sensors. Processor

assumes there is no water when

there is water.

2. Blocked reservoir vent.

1. Clean or replace water probe

assembly. Check wiring connections.

2. Clean or replace vent tubes.

3. Replace water feed solenoid valve.

3. Defective water feed solenoid

valve. Stuck in open position.

POWER

LOW BIN

1. Water supply is turned off.

2. Low water pressure.

3. Defective water feed solenoid

valve. Stuck in closed position.

4. No water feed output from

POWER

LOW BIN

PC board.

1. Turn water supply on. If evaporator

was completely empty the reset

button may have to be pressed to

restart the ice machine.

2. Ice machine will eventually start

when water reaches normal lo level.

3. Replace water feed solenoid valve.

4. Replace PC board.

28 Horizon 1650R/N Ice Machines

Page 29

Horizon 1650R/N Ice Machines 29

Page 30

Replacement parts

Evaporator assembly

Order parts online

www.follettice.com

2

3

20

10

16

24

30

5

23

7

19

18

17

23

27

31

23

21

22

28

1

4

6

15

149

8

12

11

13

25

24

26

24

23

29

33

17

32

40

36

30 Horizon 1650R/N Ice Machines

18

39

37

28

38

18

34

23

35

Page 31

Order parts online

www.follettice.com

Reference # Description Part #

1 Tube, ice transport, molded 00175299

2 Shuttle assembly (includes gasket and nozzle) 00130815

3 Switch, optical 00130849

4 Compression nozzle 00115774

5 Elbow, water 00134502

6 Gasket, shuttle 00115600

7 Stream divider 00142521

8 Auger bolt 00116988

9 Washer 00161513

10 Retainer, auger bolt 00161356

11 Kit, auger bolt (auger bolt, washer, retainer, nut and washer) 00161406

12 Key 00117804

13 Bolts, gearmotor mounting (4) required 00116988

14 Gearmotor, 120 V (includes capacitor) 00130799

15 Gasket, gearmotor 00121632

16 Main housing (includes auger shaft seal and O ring) 00142539

17 Coupling, V-band 00130708

18 O ring 00116962

19 Seal, auger shaft 00112946

20 Cup, sanitizer 00130674

21 Gasket, sanitizer 00124032

22 Cap, sanitizer (includes gasket) 00130880

23 Elbow, water, 1/4" x 3/8" OD 00988030

24 Tubing, water, 1/4" OD 502079

25 Hardware, mounting, evaporator cap 00130989

26 Solenoid, water feed (120 V) 00130823

27 Tee, water 00134494

28 Sensor assembly, water level and drain clog 00171363

29 Cap, evaporator (includes insulation and mounting hardware) 00130740

30 Clip, water shut-off valve 502922

31 Valve, shut-off, water 502921

32 Auger (includes includes seal & O ring) 00945725

33 Evaporator (includes seal, (2) O rings and insulation) 00977447

34 Journal housing and bearing (includes (2) O rings) 00130716

35 Reservoir, water 00130690

36 Base, evaporator 00130732

37 Boot, solenoid 00160309

38 Solenoid, purge (120 V) 00130757

39 Insulation, evaporator 00133876

40 Spacers, solenoid 00160317

Not shown Insulation, evaporator cap 00125468

Not shown Condensate pan 00161612

Not shown Shuttle assembly, Micro Chewblet (includes gasket and nozzle) 00982462

Horizon 1650R/N Ice Machines 31

Page 32

Low side assembly Order parts online

www.follettice.com

2

4

12

3

1

10

7

8

9

13

17

14

16

6

5

11

15

32 Horizon 1650R/N Ice Machines

Page 33

Order parts online

www.follettice.com

Reference # Description Part #

1 Tubing, liquid line (includes insulation) 00142414

2 Tubing, suction line (includes insulation) 00131045

3 Sight glass 00107045

4 Electrical box support 00153635

5 Split system support 00156067

6 Extension 00156075

7 Valve, expansion, thermal (includes TXV insulation and bulb insulation) 00977579

8 Insulation, TXV 502830

9 Valve, shut-off, liquid line 00107060

10 Valve, solenoid 00107052

11 Insulation, bulb, TXV 00106534

12 Hardware, evaporator mounting base (set of four) 00130971

13 Dryer 00134593

14 Valve, shut-off, suction line 00107078

15 Base, split system 00130864

16 Insulation, service valve 00168914

17 Cap, valve, shut-off, suction line 00991026

Horizon 1650R/N Ice Machines 33

Page 34

Electrical box

Order parts online

www.follettice.com

1

2

3

8

4

5

6

7

Reference # Description Part #

1 Cover, electrical box, remote 00130898

2 Board, control circuit, 120 V (includes standoffs) 00132910

3 Stand off’s (set of 6) 00130906

4 Switch, evaporator purge 00114371

5 Switch, evaporator clean 00117036

6 Switch, ice machine power 208867

7 Circuit breaker, 8 amp 00128090

8 Cord, power 00192088

34 Horizon 1650R/N Ice Machines

Page 35

Integration kit – top-mount and RIDE remote ice delivery equipment

Top mount configuration

Order parts online

www.follettice.com

12

10

13

2

2

11

4

5

6

7

12

8

1

RIDE model configuration

1

11

2

4

5

6

7

9

10

2

8

Reference # Description Part #

1 Shuttle actuator 00171322

2 Clamp 500377

3 Actuator elbow (includes gasket and screws) 00171264

4 Screws 209100

5 Gasket 00167122

6 Actuator body 00171272

7 Gasket, coupling 00126532

8 Ring, locking (includes coupling gasket) 00171371

9 Ice transport tube, 10' (3 m) 00171280

9 Ice transport tube, 20' (6 m) 00171298

10 Insulation, transport tube 501176

11 Insulation, elbow 00168922

12 Insulation, actuator 00168930

13 Ice transport tube, top mount, 30" (762 mm) 00171306

Not shown Integration kit, top mount 00171389

Not shown Integration kit, RIDE (requires transport tube) 00171397

Not shown Extension- ll tube, 9" 00135723

Not shown Extension- ll tube, 4" 00153684

Not shown Follett SafeCLEAN ice machine cleaner (case of 24 x 7 oz packets) 00132001

Not shown Sani-Sponge kit 00132068

Horizon 1650R/N Ice Machines 35

Page 36

Skins assembly

Stock Module Identification Plate

Module No.

Product

Service No.

Order parts online

www.follettice.com

1

6

2

5

4

3

14

208264

Stock Module Identification Plate

Easton Pennsylvania

PART NO

Module No.

SINGLE

PHASE

Product

OZ

HZ

Service No.

PSIG

SERIAL NO

CORPORATION

CHARGE

VOLTS

E IN

IDE

S

MAD

USA

E

TH

LOW

MODEL

NSF

U

L

R

C

U

L

MOTOR COMPRESSOR THERMALLY PROTECTED

FULL LOAD AMPS

R

AMPS

AMPS

REFRIGERANT

DESIGN PRESSURE HIGH SIDE

208264

. BRANCH CIRCUIT AMPACITY

N

MI

MAX. BRANCH CIRCUIT FUSE SIZE

16

7

9

8

10

11

15

13

17

12

36 Horizon 1650R/N Ice Machines

Page 37

Order parts online

www.follettice.com

Reference # Description Part #

1 Front cover, split system 00130633

2 Tubing, water, 3/8" OD 502719

3 Tubing, drain 00144923

4 Fitting, drain 00109728

5 Fitting, water inlet 502924

6 Elbow, water inlet 502925

7 Coupling (includes O ring) 00171207

8 O ring 00144675

9 Bulkhead tting 00171215

10 Nut 00902338

11 Hose clamp 500377

18 Plate, strain relief 00192070

13 Louvered docking assembly, split system (includes reference #'s 2, 3, 4, 5,

6, 9, 12, 14, 15, 17, 18)

14 Clamp, drain line 00114520

15 Screws 208568

16 Bulkhead connector kit 00171223

17 Cover, utility access 01017987

00191882

Horizon 1650R/N Ice Machines 37

Page 38

Single-phase condensing unit

Tecumseh Condensing Unit Date Code C0713 and before

Order parts online

www.follettice.com

Side View

16

15

17

10

16

5

11

14

7

18

Top View

10

8

1

14

4

11

2

7

5

6

18

19

20

12

13

17

4

3

6

9

15

12

13

Reference # Description Part #

1 Shroud 00155937

2 Condenser 00977488

3 Head pressure control valve 00977496

4 Condenser fan motor 00173070

5 Condenser fan guard 00123067

6 Receiver 00110627

7 Receiver service valve 00173047

8 Service valve, suction line 00977504

9 Service valve, discharge line 00175935

10 Filter drier, liquid 00175869

11 Compressor (includes start and run capacitors, relay, suction and liquid drier) 00969071

12 Shut-off valve, suction line 00107078

13 Shut-off valve, liquid line 00107060

14 Crankcase heater 00977512

15 Sight glass 00175885

16 Condenser fan blade 00173088

17 Filter drier, suction 00991075

18 Heat exchanger 00977520

19 Contactor 00155952

20 Low pressure switch 00173104

Not shown Check valve 00175893

Not shown Starting relay 00110585

Not shown Gasket, receiver service valve 00175901

Not shown Baffle, shroud 00173096

Not shown Run capacitor 00977462

Not shown Starting capacitor 00977470

Not shown High pressure switch 00173112

Not shown Fan cycling switch 00173120

38 Horizon 1650R/N Ice Machines

Page 39

Single-phase condensing unit

Tecumseh Condensing Unit After Date Code C0713

Order parts online

www.follettice.com

Side View

5

16

14

8

21

13

17

3

Top View

15

19

1

8

4

6

7

18

13

4

22

2

5

11

9

10

12

7

Reference # Description Part #

1 Shroud 01018290

2 Condenser 00185843

3 Head pressure control valve 01021401

4 Condenser fan motor 01018266

5 Condenser fan guard 00123067

6 Receiver 00991034

7 Filter drier, liquid 00998252

8 Compressor (includes start and run capacitors, relay, suction and liquid drier) 01037027

9 Shut-off valve, suction line 00977504

10 Shut-off valve, liquid line 01036805

11 Sight glass 01036771

12 Condenser fan blade 00173088

13 Filter drier, suction 00991075

14 Contactor 00155952

15 Low pressure control 01018316

16 Starting relay, with screws 01038843

17 Suction valve 01036797

18 Discharge valve 01036789

19 Process valve 0103682

20 Run capacitor 00977462

21 Starting capacitor 01036755

22 Heat exchanger 00977520

Not shown Check valve 00175893

Not shown High pressure switch 01018308

Not shown Fan cycling switch 01021393

Not shown Crankcase heater 01036763

Note: Overload is internal to compressor.

20

12

39 Horizon 1650R/N Ice Machines

Page 40

3-phase condensing unit

6

7

3

4

1

4

2

5

8

9

10

11

13

7

8

13

5

14

15

12

16

12

17

18

Order parts online

www.follettice.com

Top View

Side View

Reference # Description Part #

1 Shroud 01018290

2 Condenser 00185843

3 Head pressure control valve 00110619

4 Condenser fan motor 01018266

5 Condenser fan guard 00123067

6 Receiver 00991034

7 Filter drier, liquid 00998252

8 Compressor 00998237

9 Shut-off valve, suction line 00107078

10 Shut-off valve, liquid line 00107060

11 Sight glass 00175885

12 Condenser fan blade 00173088

13 Filter drier, suction 00991075

14 Contactor 00155952

15 Low pressure control 00991109

16 Phase monitor 00991117

17 Suction valve 01036797

18 Discharge valve 01036789

Not shown Check valve 00175893

Not shown High pressure switch 00173112

Not shown Fan cycling switch 00173120

Harmony, Ice Manager, SafeCLEAN, Sani-Sponge and Vision are trademarks of Follett Corporation

Chewblet, RIDE and Follett are registered trademarks of Follett Corporation, registered in the US.

801 Church Lane • Easton, PA 18044, USA

Toll free (877) 612-5086 • +1 (610) 252-7301

www.follettice.com

© Follet Corporation 4/13

01034693R00

Loading...

Loading...