Page 1

Horizon™ Ice Machine Installation Instructions

for Ice Storage Bin Top-mount Applications

HCD/HMD700RBT

HCD/HMD700NBT

(See model number con gurator on page 2 for details.)

Order parts online

www.follettice.com

remote condensing

801 Church Lane • Easton, PA 18040, USA

Toll free (877) 612-5086 • +1 (610) 252-7301

www.follettice.com

01012681R01

Page 2

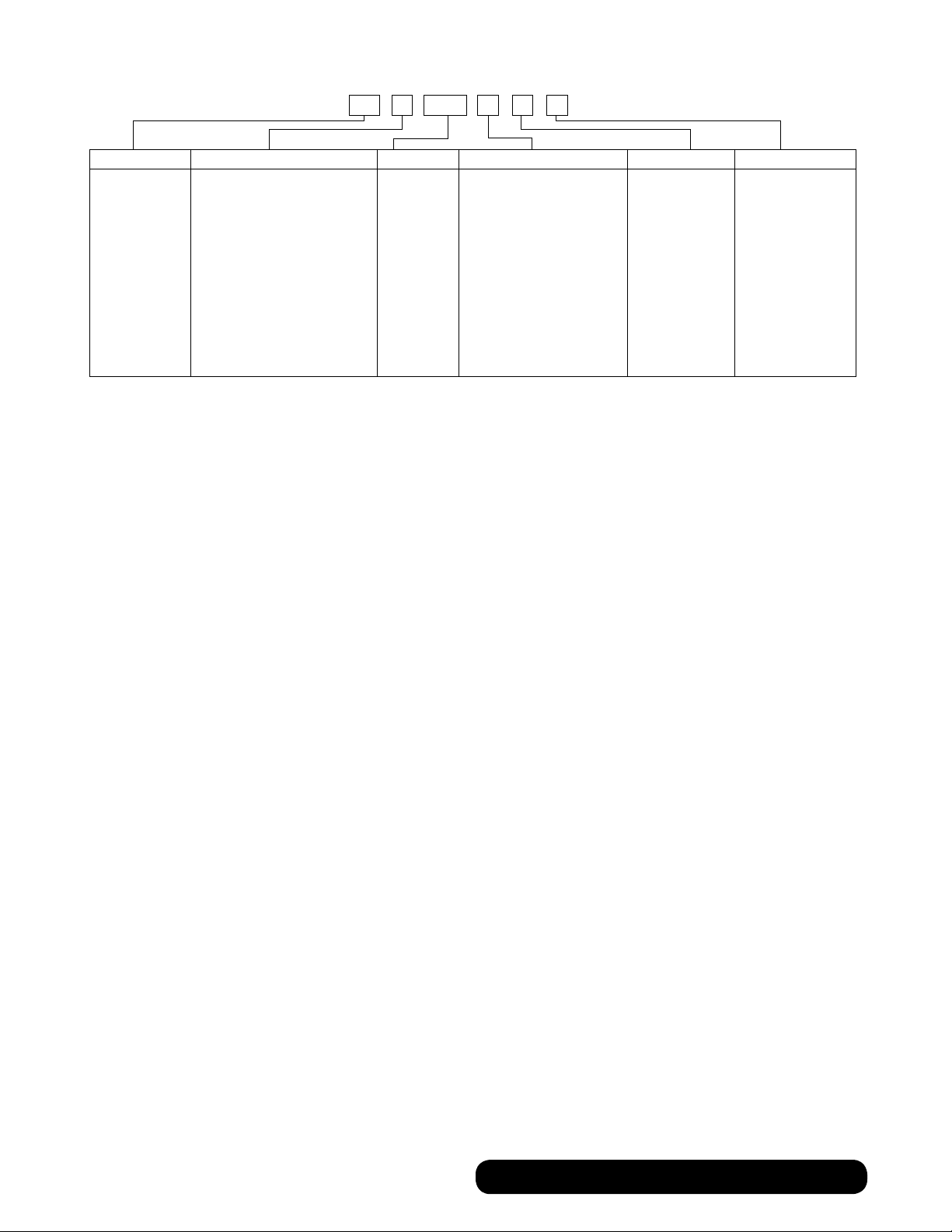

Chewblet® Ice Machine Model Number Configurations

A V SC 700HC

MC Maestro™

Chewblet

(400 Series)

HC Horizon

Chewblet

(1000, 1400,

1650 Series)

HM Horizon

Micro

Chewblet

C 208-230/60/1 (icemaking head)

Self-contained only.

D 115/60/1 (icemaking head)

Self-contained and remote.

If remote unit, high side is

208-230/60/1.

E 230/50/1 (icemaking head)

Self-contained only.

F 115/60/1 (icemaking head)

Remote only. High side is

208-230/60/3.

400 up to

454 lbs

(206kg)

700 up to

750 lbs

(340kg)

1000 up to

1036 lbs

(471kg)

1400 up to

1450 lbs

(658kg)

1650 up to

1580 lbs

(717kg)

A Air-cooled, self-contained

W Water-cooled,

R Air-cooled, remote

N Air-cooled, no condensing

connection to parallel rack

CondenserSeriesVoltageMachine

self-contained

condensing unit

unit for

system

V Vision™

H Harmony™

B Ice storage

bin

J Drop-in

M Ice Manager™

diverter valve

system

ConfigurationApplication

®

S RIDE

(RIDE remote ice

delivery equipment)

T Top-mount

2

remote condensing BIN • TOP-MOUNT

Page 3

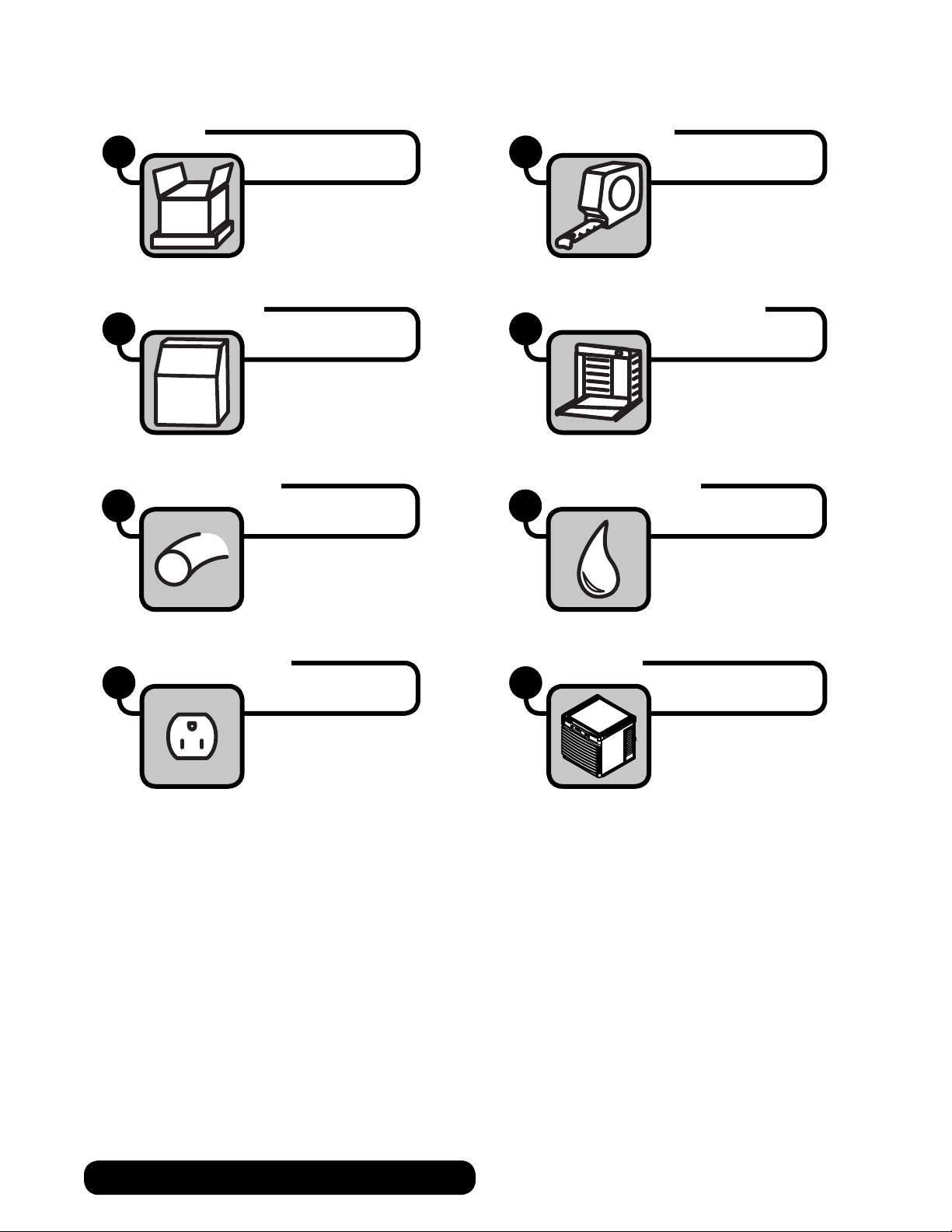

Read and complete the following 8 installation steps

Unpack

1

Bin preparation

3

Ice transport tube

5

Site preparation

2

Louvered docking assembly

4

External connection

6

Internal connection

7

Front cover

8

BIN • TOP-MOUNT remote condensing

3

Page 4

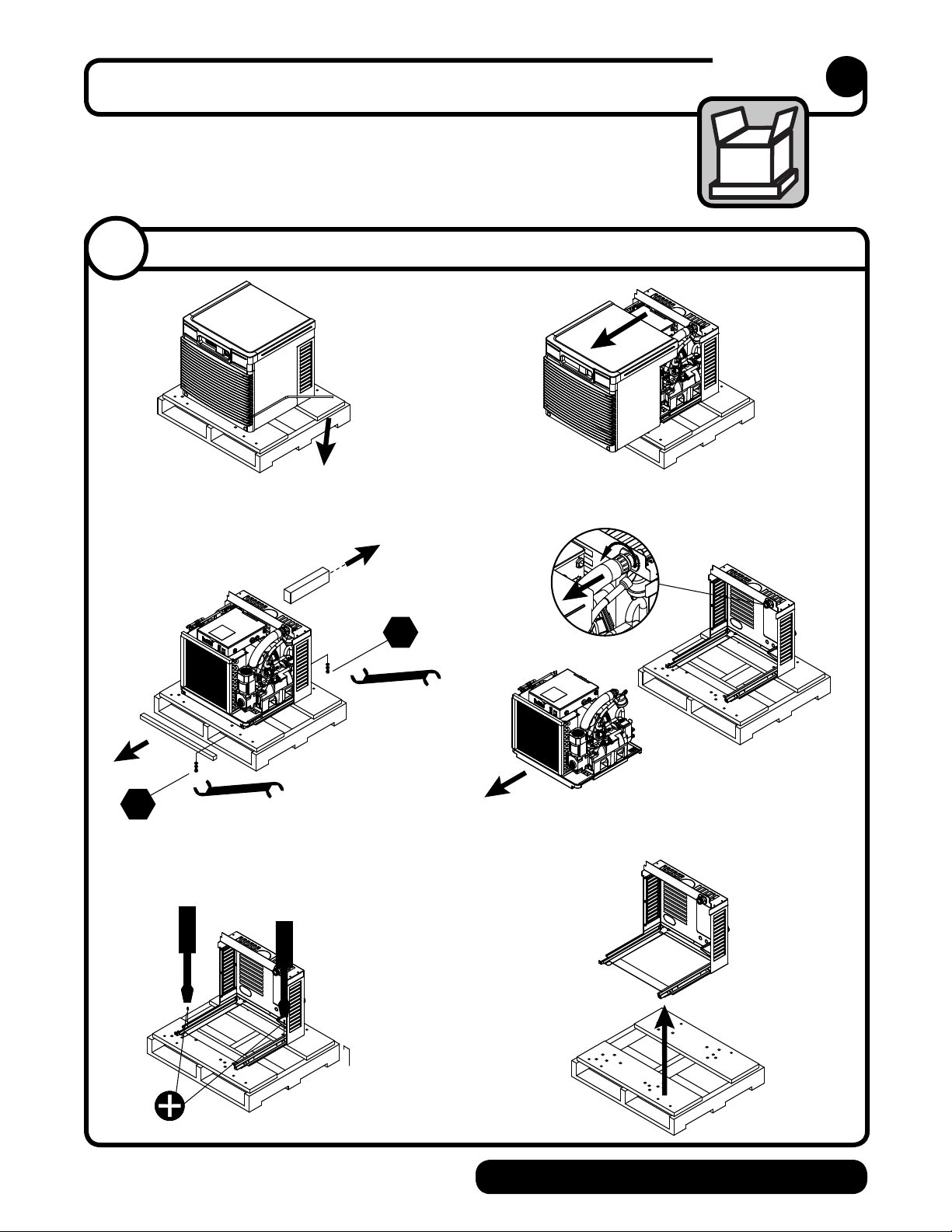

Carefully unpack and inspect the contents of your Follett ice machine.

7/16"

7/16"

Unpack

1

1. 1

Unpack ice machine

4

remote condensing BIN • TOP-MOUNT

Page 5

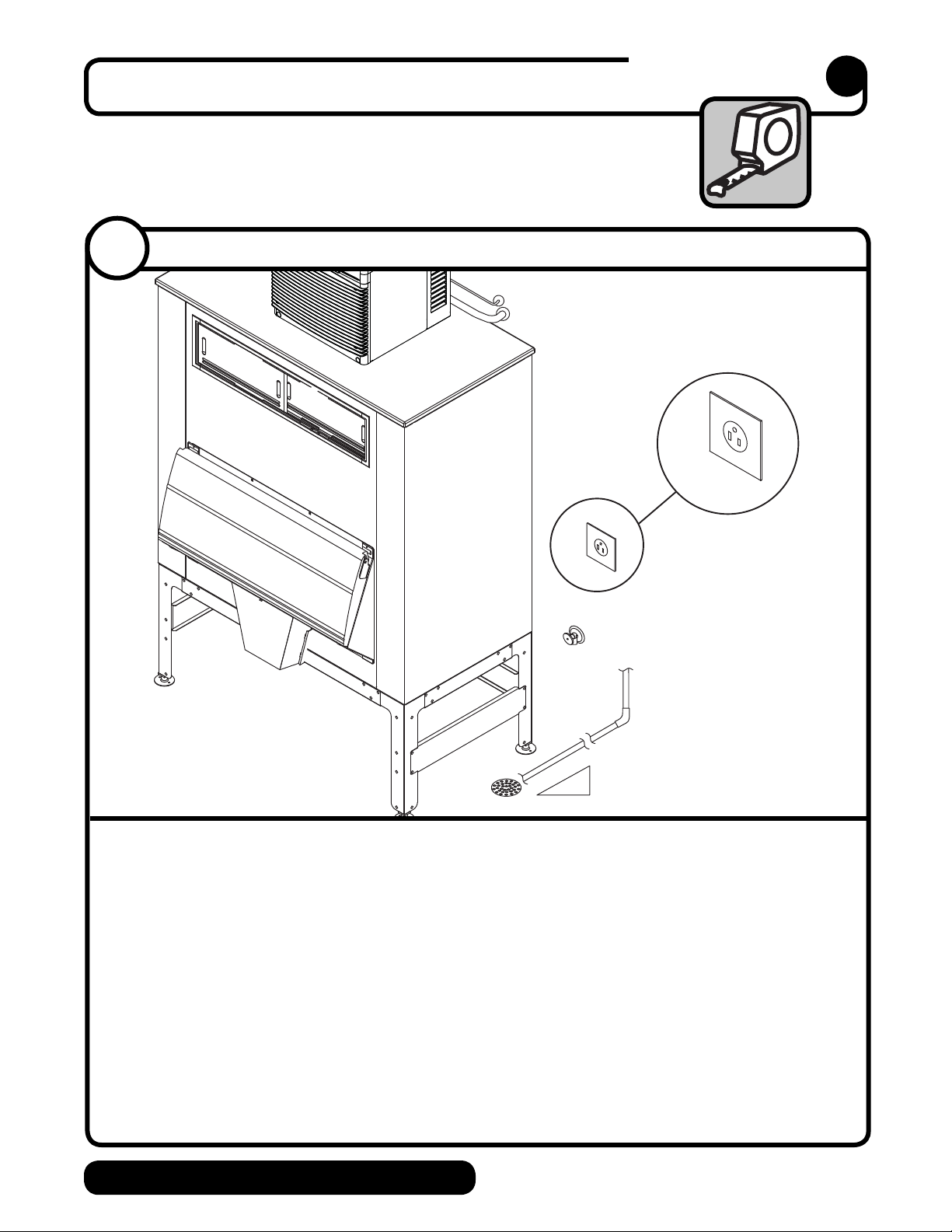

Site preparation

Prepare the installation site.

Provide drainage, water supply and electrical power to within 6 feet (2m) of ice

machine in accordance with local and national codes. Outdoor installation is

not recommended and will void warranty.

2

2.1

2.1

Installation site requirements

3/8" ∅ (9,5mm)

➎

➍

NEMA

5-15

➊

➋

1'

➌

Electrical

• 120/60/1-6 amps

Potable water supply

• 10-70 psi (69-483kpa)

• 45-90 F (7-32 C)

• Water supply must be treated by a scale-inhibiting lter (item# 00130286)

Drain

• The drain line from the ice machine must be vented and have at least 1/4” per foot pitch

(6,4mm/0,3m)

Refrigeration lines

• 5/8” (15,8mm) diameter suction (insulated)

• 3/8” (9,5mm) liquid

➌

➊

➍

➋

➍

➎

1/4"

BIN • TOP-MOUNT remote condensing

5

Page 6

Prepare the bin.

Bin preparation

3

3.1

• Remove protective tape from

Bin top preparation

gaskets

3.2

Bin top preparation

➋

➊

➊

• Apply gaskets

• Install shuttle actuator

dispenser top and secure with locking nut

➊

through

➋

➌

➌

6

remote condensing BIN • TOP-MOUNT

Page 7

Install the louvered docking assembly.

Louvered docking assembly

4

2.1

4.1

3/8˝ ∅

high pressure

line

low pressure

Louvered docking assembly

2" (50,8mm)

1 13/16" (46mm)

1" (25,4mm)

Stub Typ

2-7/8" (73mm)

5/8˝ ∅

line

➋

➊

sealant

➌

• Mount louvered docking assembly

• “Rough-in” the refrigerant piping

• Seal perimeter of docking station to mounting surface

➊

➋

BIN • TOP-MOUNT remote condensing

➌

7

Page 8

4.2

Refrigerant lines

➊

• Braze supplied expandable refrigerant

lines in place

➊

8

remote condensing BIN • TOP-MOUNT

Page 9

Install the ice transport tube.

Ice transport tube

5

5.1

Ice transport tube

Hot Water

160 F (71 C)

• Cut transport tube to 26” (66 cm) length

• Install supplied ice transport tube insulation

• Heat end of transport tube in cup of 160 F (71 C) hot water to soften and spread with pliers

before making connection to ease assembly

• Connect ice transport tube to coupling on louvered docking station

• Connect ice transport tube to shuttle actuator

➌

➋

➊

BIN • TOP-MOUNT remote condensing

9

Page 10

Connect utilities to louvered docking assembly.

External connections

6

6.1

Water and drain

➋

➊

• Remove access panel if necessary.

• Install drain line

The rigid drain line from the ice machine

must be vented and have at least 1/4” per

foot (6,4mm/0,3m) pitch.

• Install icemaker potable water supply

(Water supply must be treated by a scaleinhibiting lter (item# 00130286)

• Replace access panel

➊

.

➋

10

remote condensing BIN • TOP-MOUNT

Page 11

Connect louvered docking assembly to ice machine.

Internal connections

7

7. 1

Ice transport tube installation

➋

➊

• Slide ice machine into louvered docking

assembly

• Insert ice transport tube all the way into

coupling and tighten nut rmly

➊

➋

7. 2

• Insert potable water line into valve

Water and drain lines

➊

➊

7. 3

• Braze refrigerant lines

Refrigeration lines

7. 4

• Remove twist tie

• Carefully pass plug thru opening and plug

Power cord

into wall outlet

BIN • TOP-MOUNT remote condensing

11

Page 12

7. 5

• Position plate into opening and secure

Power cord

with supplied screw

12

remote condensing BIN • TOP-MOUNT

Page 13

BIN • TOP-MOUNT remote condensing

13

Page 14

Install front cover to ice machine.

Front cover

8

8.1

• Complete installation of condensing unit

Install condensing unit

or connection to rack system.

8.2

Install ice machine front cover

• Slide ice machine cover over machine,

ensuring that tabs on back of cover

slip under louvers on back of louvered

docking assembly

screws through cover

• Place louvered front cover on machine

then tighten two

➊,

➋

NOTICE

§ Ice machine MUST be sanitized prior to operation!

§ Consult Operation and Service Manual provided with ice machine for sanitizing instructions.

§ To prevent circuit breaker overload, wait 15 minutes before restarting this unit. This allows the compressor to

equalize and the evaporator to thaw.

14

remote condensing BIN • TOP-MOUNT

Page 15

BIN • TOP-MOUNT remote condensing

15

Page 16

Horizon, Maestro, Harmony, Ice Manager, SafeCLEAN, Sani-Sponge and Vision are trademarks of Follett Corporation.

Follett, RIDE and Chewblet are registered trademarks of Follett Corporation, registered in the US.

801 Church Lane • Easton, PA 18040, USA

Toll free (877) 612-5086 • +1 (610) 252-7301

www.follettice.com

01012681R01

© Follett Corporation 8/13

Loading...

Loading...