Page 1

HCC1010A/W, HCC1410A/W, HMC1010A/W, HMC1410A/W

Horizon Elite™ Ice Machines (Self-contained)

Order parts online

www.follettice.com

Operation and Service Manual

After Serial Number L60417

Following installation, please forward this manual

to the appropriate operations person.

801 Church Lane • Easton, PA 18040, USA

HCC1010A/W, HCD1010A/W, HCC1410A/W, HCD1410A/W 1

Toll free (877) 612-5086 • +1 (610) 252-7301

www.follettice.com

01096106R05

Page 2

Contents

Welcome to Follett. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Before you begin ............................................................................... 3

Specications ................................................................................. 4

Operation ..................................................................................... 7

Preventive maintenance ....................................................................... 7

Weekly exterior care .......................................................................... 7

Service .......................................................................................11

The Horizon ice machine overview ..............................................................11

Harvest system diagram .......................................................................11

Water system diagram ....................................................................... 13

Water level diagram ......................................................................... 13

Normal control board operation ................................................................ 14

DIP Switch Settings ......................................................................... 14

Error faults: ............................................................................... 15

Soft errors: ................................................................................ 15

Run errors: ................................................................................ 15

Evaporator ushing sequence: ................................................................. 15

Wiring diagram ............................................................................. 16

Fan motor data ............................................................................. 17

Mechanical System ............................................................................ 18

Reservoir/rear bushing disassembly ............................................................ 25

1010 - Refrigerant pressure data ............................................................... 26

1410 - Refrigerant pressure data ............................................................... 26

Refrigeration system diagram .................................................................. 26

Refrigeration charge ......................................................................... 27

Refrigerant replacement requirements ........................................................... 27

Evacuation ................................................................................ 27

Ice capacity test ............................................................................ 27

Troubleshooting .............................................................................. 28

Replacement parts ............................................................................ 30

2 HCC1010A/W, HCD1010A/W, HCC1410A/W, HCD1410A/W

Page 3

Welcome to Follett

Follett equipment enjoys a well-deserved reputation for excellent performance, long-term reliability and outstanding

after-the-sale support. To ensure that this equipment delivers the same degree of service, we ask that you review

the installation manual (provided as a separate document) before beginning to install the unit. Our instructions are

designed to help you achieve a trouble-free installation. Should you have any questions or require technical help at

any time, please call our technical service group at (877) 612-5086 or +1 (610) 252-7301.

Before you begin

After uncrating and removing all packing material, inspect the equipment for concealed shipping damage. If

damage is found, notify the shipper immediately and contact Follett Corporation so that we can help in the ling of

a claim, if necessary.

Check your paperwork to determine which model you have. Follett model numbers are designed to provide

information about the type and capacity of Follett equipment. Following is an explanation of the different model

numbers in the series.

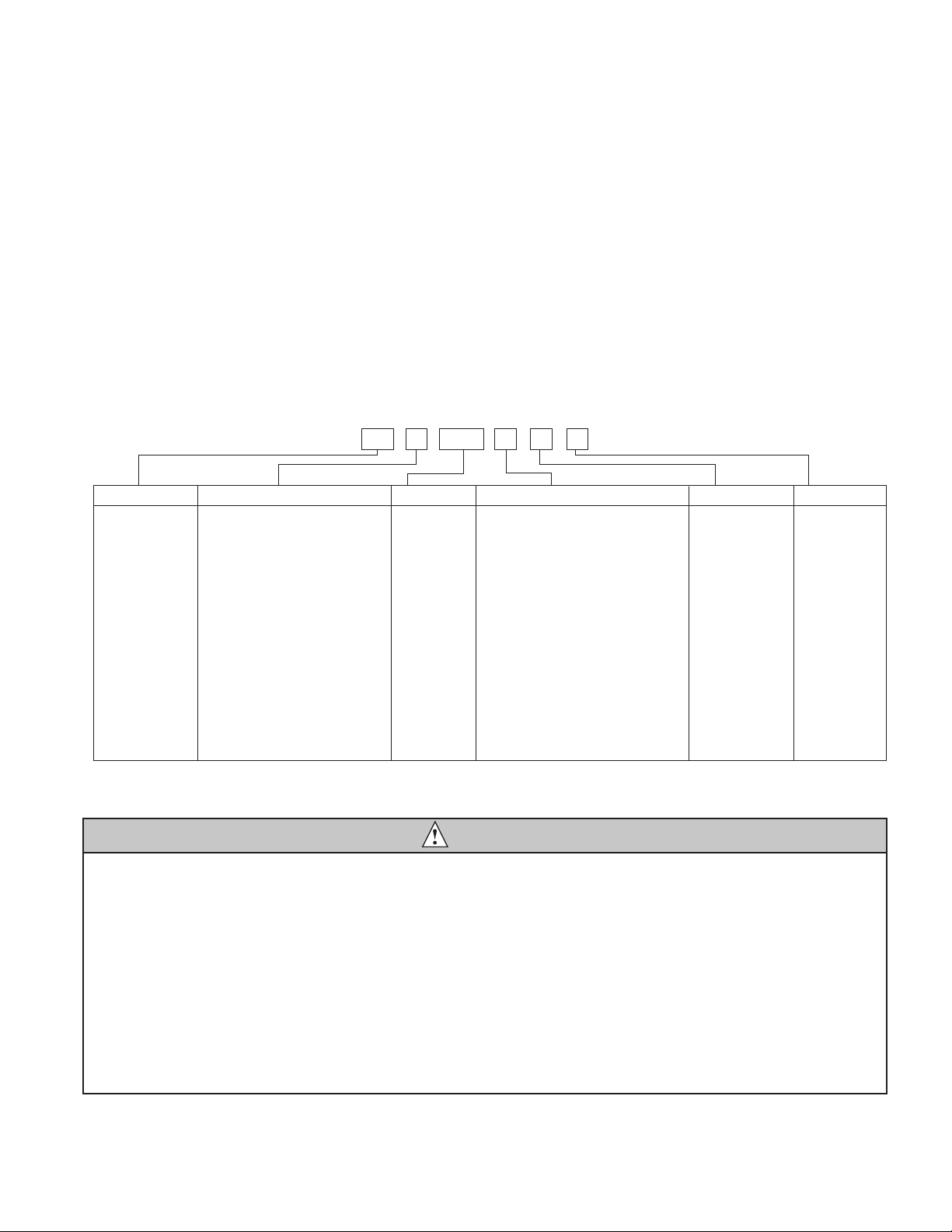

Chewblet® Ice Machine Model Number Configurations

HC 1810D SVA

ConfigurationApplication

S RIDE™

(RIDE remote

ice delivery

equipment)

T Top-mount

MC Maestro™

Chewblet

(425 Series)

HC Horizon

Chewblet

(710, 1010,

1410, 1810,

2110 Series)

HM Horizon

Micro Chewblet

C 208-230/60/1 (icemaking head)

®

Self-contained only.

D 115/60/1 (icemaking head)

Self-contained and remote. If remote

unit, high side is 208-230/60/1.

E 230/50/1 (icemaking head)

Self-contained only.

F 115/60/1 (icemaking head)

Remote only. High side is

208-230/60/3.

425 up to

425 lbs

(193 kg)

710 up to

675 lbs

(306 kg)

1010 up to

1061 lbs

(482 kg)

1410 up to

1466 lbs

(665 kg)

1810 up to

1790 lbs

(812 kg)

2110 up to

2039 lbs

(925 kg)

CondenserSeriesVoltageIcemaker

A Air-cooled, self-contained

W Water-cooled, self-contained

R Air-cooled, remote condensing unit

N Air-cooled, no condensing unit for

connection to parallel rack system

V Vision™

H Harmony™

B Ice storage bin

J Drop-in

M Ice Manager

diverter valve

system

P Cornelius Profile

PR150

CAUTION

• Warranty does not cover exterior or outside installations.

• Moving parts. Do not operate with front cover removed.

• Hot parts. Do not operate with cover removed.

• To reduce risk of shock, disconnect power before servicing.

• Drain line must not be vented.

• Water supply must have particle ltration.

• Most ice machine cleaners contain citric or phosphoric acid, which can cause skin irritation. Read caution label

on product and follow instructions carefully.

• Ice is slippery. Maintain counters and oors around dispenser in a clean and ice-free condition.

• Ice is food. Follow recommended cleaning instructions to maintain cleanliness of delivered ice.

HCC1010A/W, HCD1010A/W, HCC1410A/W, HCD1410A/W 3

Page 4

Specications

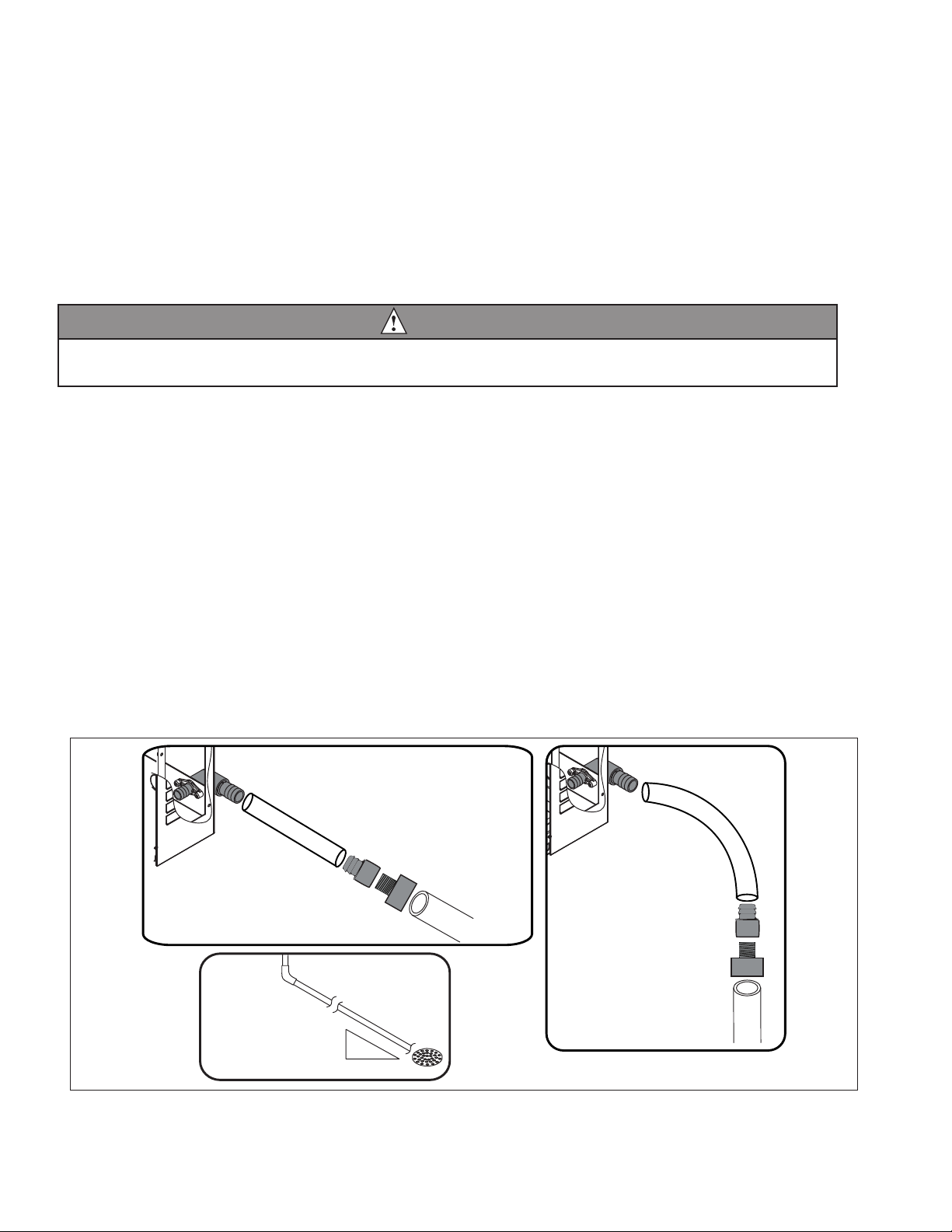

3/4" barb x 3/4" FPT

1" Stand pipe/Drain

2 ft. x 1" OD

silicone tubing

Minimum 8"

radius

3/4" MPT x 1" slip

1" PVC Drain

2 ft. x 1" OD

silicone tubing

3/4" MPT x 1" slip

3/4" barb x 3/4" FPT

1'

1/4" per foot

(6,4 mm per 0,3 m)

Electrical

Each ice machine requires its own separate circuit with electrical disconnect within 10 ft (6m).

Equipment ground required.

Standard electrical:

§ HCC1010: 208-230/60/1 (6 ft (2m) NEMA 6-15 cord and plug provided)

§ HCC1410: 208-230/60/1 (6 ft (2m) NEMA 6-20 cord and plug provided)

§ Amperage: 1010A/W - 11A

1410A/W - 14A

Plumbing

WARNING

This equipment to be installed with adequate backow protection to comply with applicable federal, state,

and local codes.

§ 3/8" OD push-in water inlet (connection inside machine) - 3/8" OD tubing required

§ 3/4" MPT drain

§ 1/4" FPT condenser inlet (water-cooled condenser only)

§ 1/4" FPT condenser drain (water-cooled condenser only)

Notes:

§ Water shut-off recommended within 10 feet (3m).

§ Water supply must have particle ltration. Follett recommends the lter system that has integral scale inhibitors.

(Follett item# 00130286).

§ Follett does not recommend the use of water softeners or bowl scale inhibitors.

Flush drain plumbing

§ 3/4" MPT ush drain connection at the rear of the machine.

§ Drain must slope 1/4" inch per foot (6 mm per 30.4 cm).

§ Drain line should not be shared with any other piece of equipment.

§ Drain line cannot be reduced to a size smaller than 1 inch.

§ Drain should be piped without a vent.

4 HCC1010A/W, HCD1010A/W, HCC1410A/W, HCD1410A/W

Page 5

Ambient

Air temperature 100 F/38 C max. 50 F/10 C min.

Water temperature 90 F/32 C max. 45 F/7 C min.

Water pressure – potable 70 psi max. (483 kPa) 10 psi min. (89 kPa)

Heat rejection

1010 1410

Air-cooled 11,300 BTU/hr 16,000 BTU/hr

Water-cooled 12,800 BTU/hr 16,400 BTU/hr

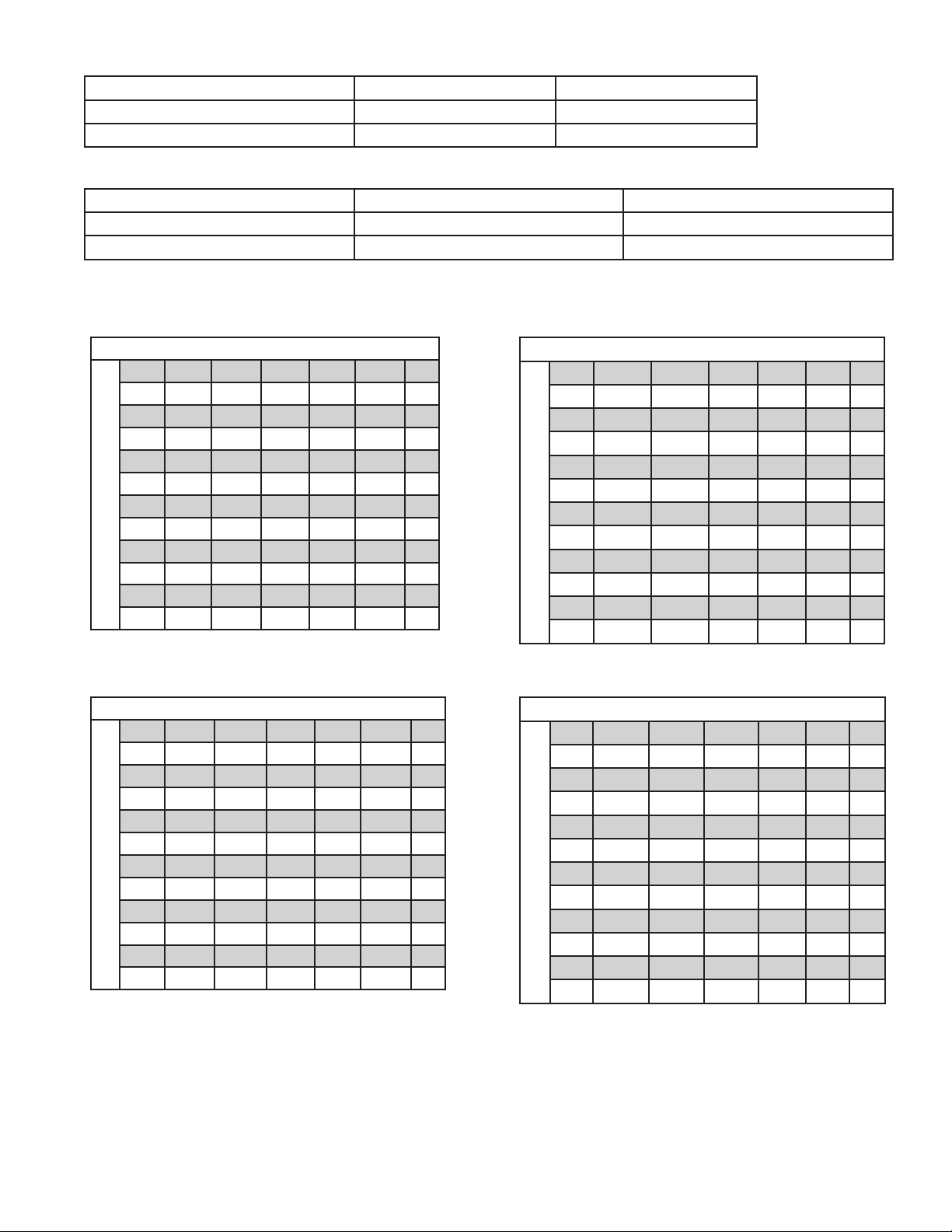

Ice production

1010 Air-cooled ice machine capacity/24 hrs.

Ambient Air Temperature F/C

F 60 70 80 90 100

C 16 21 27 32 38

50 1160 1061 962 825 688 lbs

10 526 481 436 3 74 312 kg

60 1093 1001 909 795 681 lbs

16 496 454 412 361 309 kg

70 1026 941 857 765 674 lbs

21 465 427 389 345 306 kg

80 971 893 815 730 644 lbs

27 440 405 370 331 292 kg

90 917 845 773 694 614 lbs

Evap Potable Water Temperature F/C

32 416 383 351 315 279 kg

1410 Air-cooled ice machine capacity/24 hrs.

Ambient Air Temperature F/C

F 60 70 80 90 10 0

C 16 21 27 32 38

50 1593 1466 1339 1230 1121 lbs

10 723 665 609 558 508 kg

60 1518 1396 1275 116 3 1052 lbs

16 689 633 578 528 477 kg

70 1442 1327 12 11 1097 982 lbs

21 654 602 549 498 445 kg

80 1394 1272 115 0 1050 950 lbs

27 632 577 522 476 431 kg

90 1345 1217 1089 1004 918 lbs

Evap Potable Water Temperature F/C

32 610 552 494 455 416 kg

1010 Water-cooled ice machine capacity/24 hrs.

Condenser Water Temperature F/C

F 50 60 70 80 90

C 10 16 21 27 32

50 1096 1043 1011 947 892 lbs

10 497 473 454 430 405 kg

60 1006 970 938 888 839 lbs

16 456 440 425 403 381 kg

70 917 898 8 74 830 778 lbs

21 416 407 396 376 353 kg

80 874 888 830 787 749 lbs

27 396 403 376 357 340 kg

90 831 807 778 74 5 712 lbs

32 377 366 353 338 323 kg

Evap Potable Water Temperature F/C

1410 Water-cooled ice machine capacity/24 hrs.

Condenser Water Temperature F/C

F 50 60 70 80 90

C 10 16 21 27 32

50 1393 1368 1343 1328 1313 lbs

10 632 621 609 602 596 kg

60 1374 1326 1278 1268 1257 lbs

16 623 6 01 580 575 570 kg

70 1335 1284 1213 1207 1201 lbs

21 606 582 550 547 545 kg

80 1278 1216 1153 11 3 5 1116 lbs

27 580 552 523 515 506 kg

90 1201 1147 1093 1063 1032 lbs

32 545 520 496 482 468 kg

Evap Potable Water Temperature F/C

HCC1010A/W, HCD1010A/W, HCC1410A/W, HCD1410A/W 5

Page 6

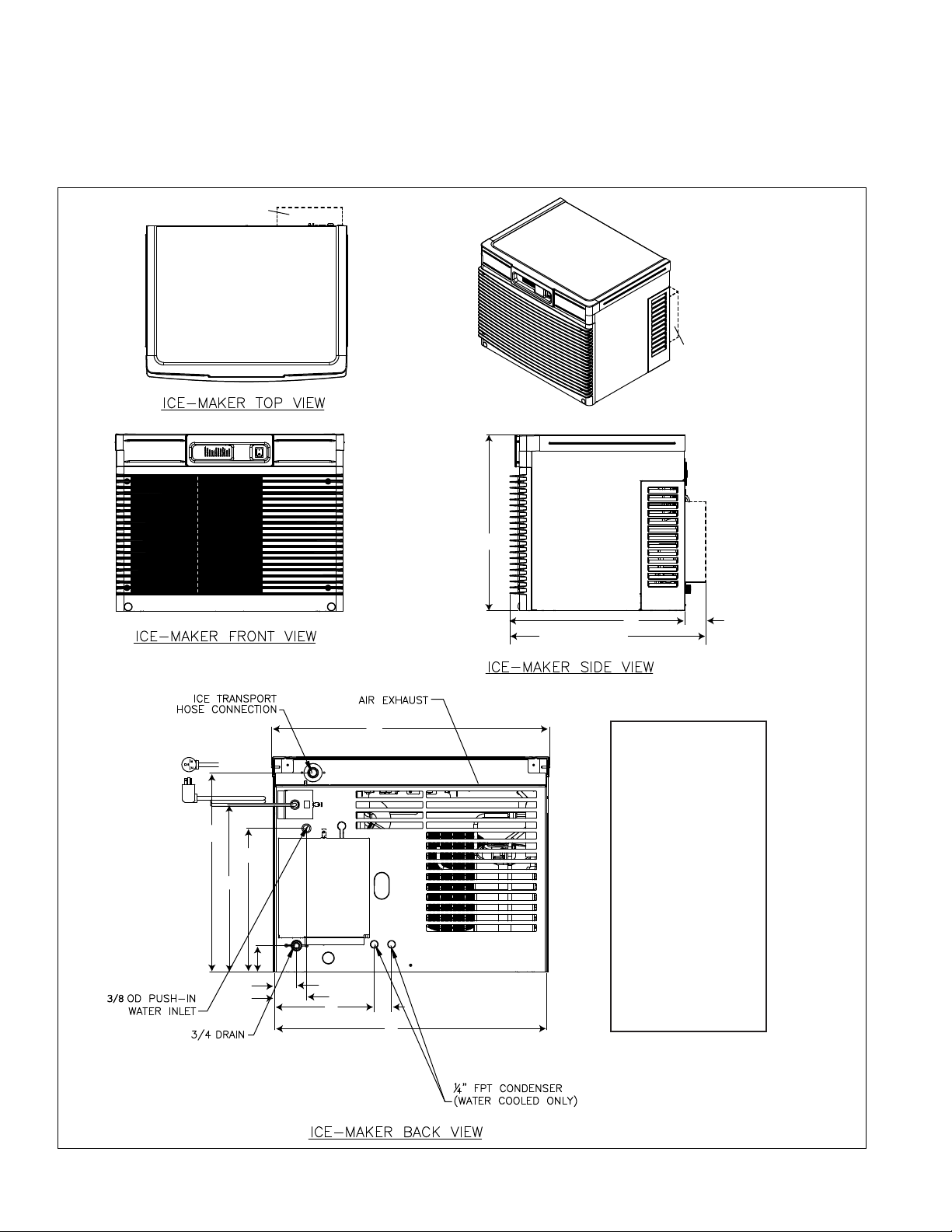

Dimensions and clearances

§ Entire front of ice machine must be clear of obstructions/connections to allow removal.

§ 1" (26mm) clearance above ice machine for service.

§ 1" (26mm) minimum clearance on sides.

§ The intake and exhaust air grilles must provide at least 250 sq in (1615 sq cm) of open area.

§ Air-cooled ice machines – 18" (458 mm) minimum clearance between discharge and air intake-grilles.

1410 ONLY

1410 ONLY

1010: NEMA 6-15

1410: NEMA 6-20

E

F

A

C (1410 ONLY)

N

B

A 22.51" (57.2 cm)

D (1410 ONLY)

B 22.48" (57.1 cm)

C 25.15" (56.3 cm)

D 2.66" (6.8 cm)

E 20.84" (52.9 cm)

F 17.49" (44.4 cm)

G

G 15.00" (38.1 cm)

H 2.73" (6.9 cm)

I 2.30" (5.8 cm)

J 3.34" (8.5 cm)

H

I

J

K

L

M

K 10.44" (26.5 cm)

L 1.81" (4.6 cm)

M 28.50" (72.4 cm)

N 29.15" (74.0 cm)

6 HCC1010A/W, HCD1010A/W, HCC1410A/W, HCD1410A/W

Page 7

Operation

Cleaning/sanitizing and preventive maintenance (all models)

Note: Do not use bleach to sanitize or clean the icemaker.

Preventive maintenance

Periodic cleaning of Follett’s icemaker system is required to ensure peak performance and delivery of clean,

sanitary ice. The recommended cleaning procedures that follow should be performed at least as frequently as

recommended, and more often if environmental conditions dictate.

Cleaning of the condenser can usually be performed by facility personnel. Cleaning of the icemaker system,

in most cases, should be performed by your facility’s maintenance staff or a Follett authorized service agent.

Regardless of who performs the cleaning, it is the operator’s responsibility to see that this cleaning is performed

according to the schedule below. Service problems resulting from lack of preventive maintenance will not be

covered under the Follett warranty.

Weekly exterior care

The exterior may be cleaned with a stainless cleaner such as 3M Stainless Steel Cleaner & Polish or equivalent.

Monthly condenser cleaning (air-cooled icemaker only)

1. Use a vacuum cleaner or stiff brush to carefully clean condenser coils of air-cooled icemakers to ensure

optimal performance.

2. When reinstalling counter panels in front of remote icemakers, be sure that ventilation louvers line up with

condenser air duct.

Semi-annual evaporator cleaning (every 6 months)

WARNING

• Wear rubber gloves and safety goggles (and/or face shield) when handling ice machine cleaner or sanitizer.

CAUTION

• Use only Follett approved SafeCLEAN Plus™ cleaning solution.

• DO NOT USE BLEACH.

• It is a violation of Federal law to use these solutions in a manner inconsistent with their labeling.

• Read and understand all labels printed on packaging before use.

Note: Complete procedure for cleaning an sanitizing MUST be followed. Ice must be collected for 10minutes

before putting ice machine back into service.

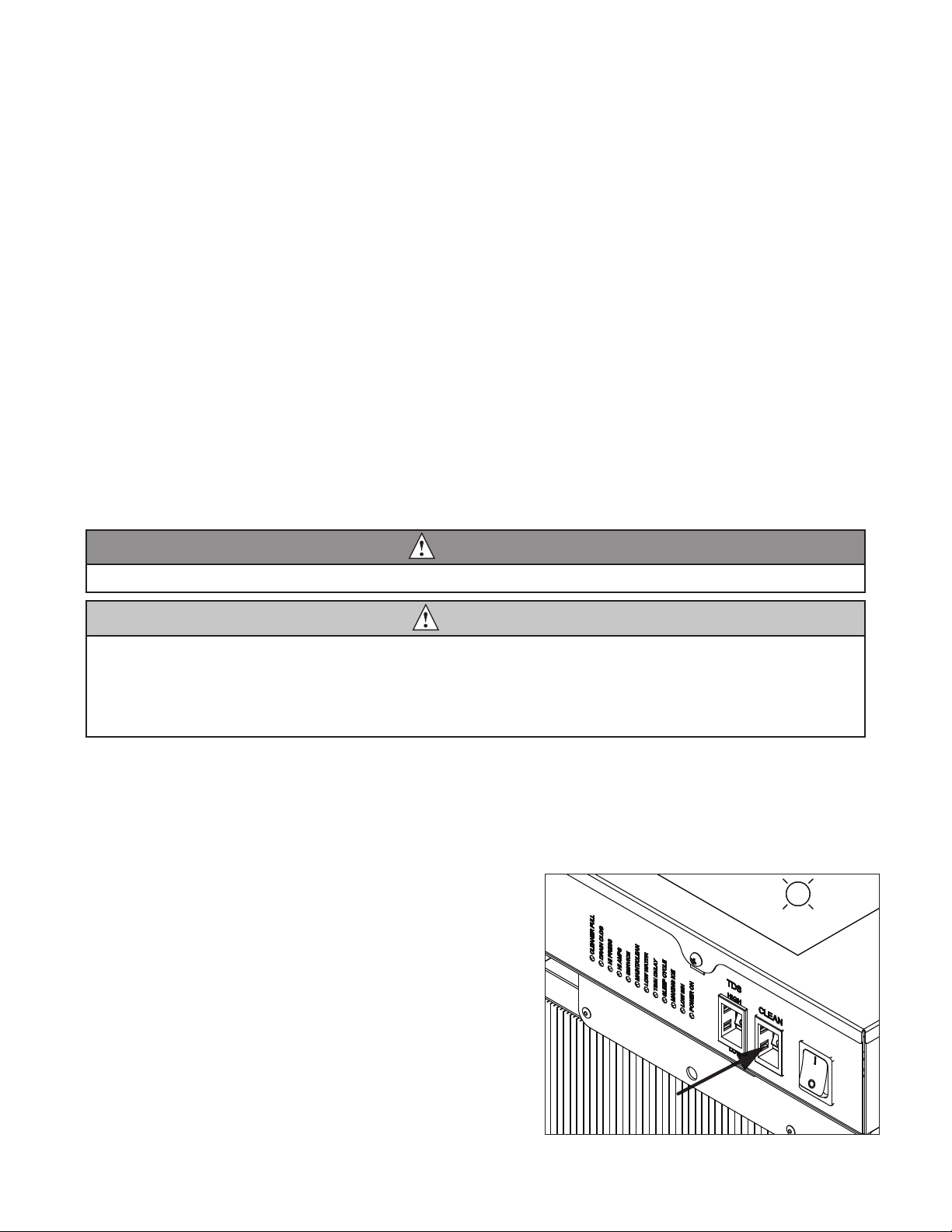

Fig. 1

1. Press the CLEAN button. The machine will drain. The

auger will run for a short time and then stop. Wait for

the LOW WATER light to come on.

LO WATER

HCC1010A/W, HCD1010A/W, HCC1410A/W, HCD1410A/W 7

Page 8

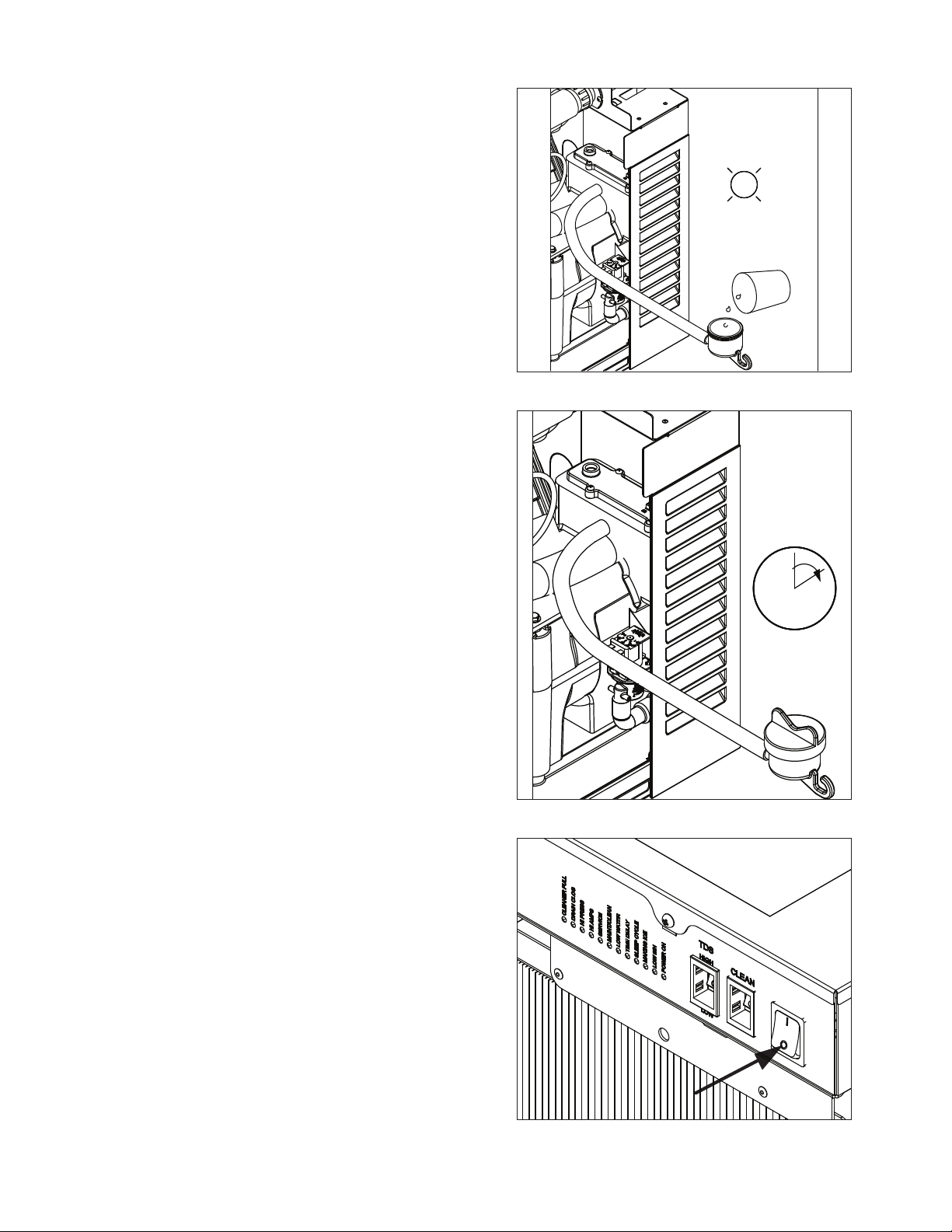

2. Follow the directions on the SafeCLEAN Plus

packaging to mix 1 gal. (3.8 L) of Follett SafeCLEAN

Plus solution. Use 100 F (38 C) water.

3. Using a 1 quart (1L) container, slowly ll cleaning cup

until CLEANER FULL light comes on. Do not overll.

4. Place one Sani-Sponge™ in remaining sanitizing and

cleaning solution and retain for Step 9.

Note: Do not use bleach to sanitize or clean the icemaker.

5. Replace cover on cleaner cup. Machine will clean,

then ush 3 times in approximately 15 minutes. Wait

until machine restarts.

Fig. 2

CLEANER FULL

Fig. 3

6. To clean/sanitize ice transport tube – Press power

switch OFF

15

Fig. 4

8 HCC1010A/W, HCD1010A/W, HCC1410A/W, HCD1410A/W

Page 9

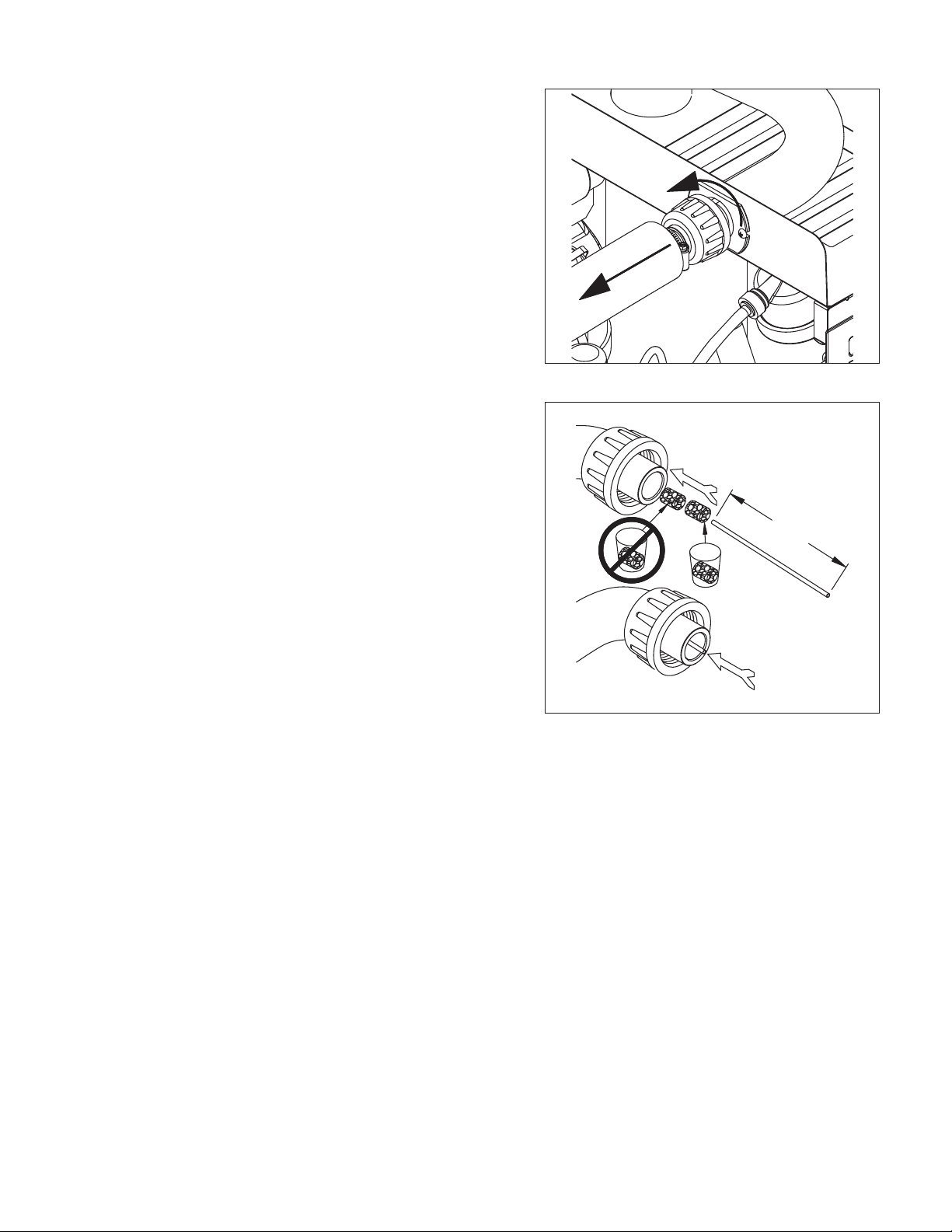

7. Disconnect coupling as shown.

8. Using disposable food service grade gloves, insert

dry Sani-Sponge.

9. Insert Sani-Sponge soaked in SafeClean Plus (from

Step 4).

10. Push both Sani-Sponges down ice transport tube

with supplied pusher tube.

Fig. 5

Fig. 6

1

16"

(407 mm)

2

3

HCC1010A/W, HCD1010A/W, HCC1410A/W, HCD1410A/W 9

Page 10

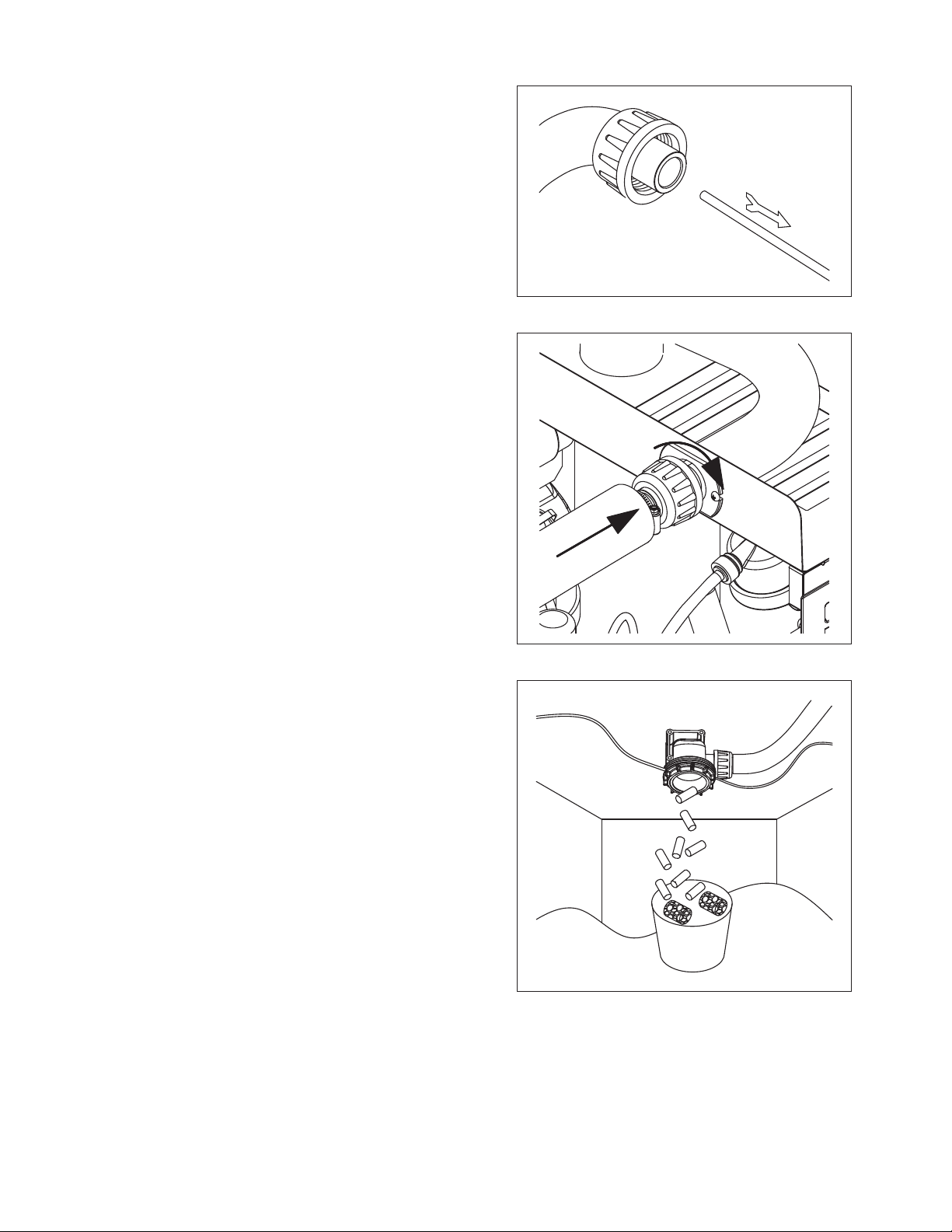

11. Remove and discard 16 inch (407 mm) pusher tube.

12. Reconnect coupling. Press power switch ON. Ice

pushes Sani-Sponges through ice transport tube.

Fig. 7

Fig. 8

13. Place a sanitary (2 gal. or larger) container in bin

or dispenser to collect Sani-Sponges and ice for 10

minutes.

14. Collect 5.5 lbs (3 kg) of ice from unit. Discard ice and

Sani-Sponges.

Fig. 9

10 HCC1010A/W, HCD1010A/W, HCC1410A/W, HCD1410A/W

Page 11

Service

Ice machine operation (all models)

Follett’s ice machine consists of ve distinct functional systems covered in detail as follows:

§ Water system

§ Electrical control system

§ Mechanical assembly

§ Refrigeration system

§ Bin full

The Horizon ice machine overview

The Follett Horizon ice machine uses a horizontal, cylindrical evaporator to freeze water on its inner surface. The

refrigeration cycle is continuous; there is no batch cycle. The evaporator is ooded with water and the level is

controlled by sensors in a reservoir. A rotating auger (17 RPM) continuously scrapes ice from the inner wall of the

evaporator. The auger moves harvested ice through the evaporator into an ice extrusion canal. The ice is forced

through a restrictive nozzle that squeezes out the water and creates the Chewblet. The continuous extrusion

process pushes the Chewblets through a transport tube into a dispenser or bin.

A solid state PC board controls and monitors the functionality of the ice machine. In addition to sequencing

electrical components, the board monitors various operational parameters. A full complement of indicator lights

allows visual status of the machine's operation. Additionally, the PC board controls the self-ushing feature of the

ice machine. The evaporator water is periodically drained and replenished to remove minerals and sediment.

A unique “bin full” detection system is incorporated in the Horizon ice machine. A switch located at the ice

discharge port of the machine detects the position of the transport tube. When the bin lls up with ice, the transport

tube moves out of the normal running position, and the switch turns the ice maker off. A domed housing at the end

of the transport tube contains the ice extrusion loads during shut down.

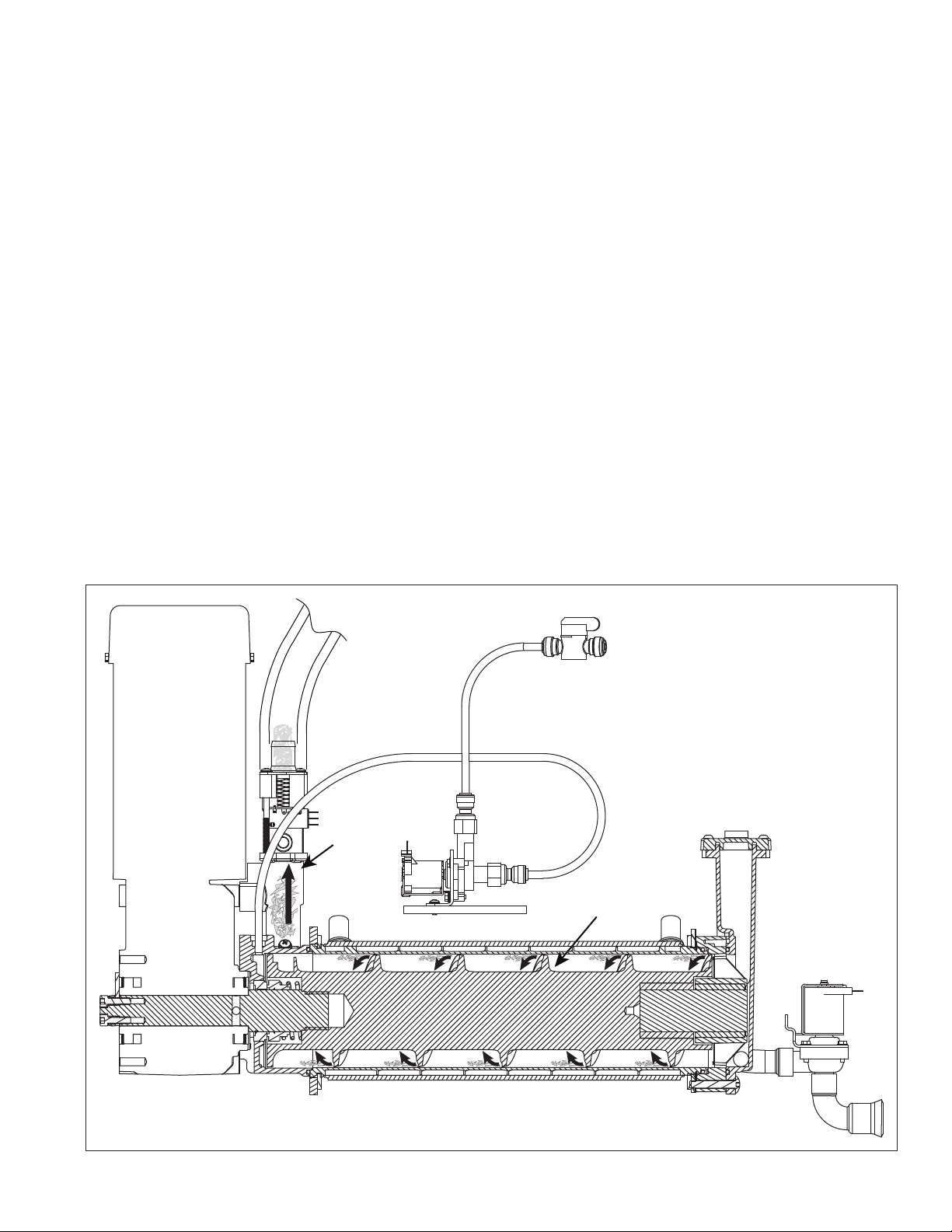

Harvest system diagram

Ice Transport Tube

Water Inlet

Compression

Nozzle

Auger

HCC1010A/W, HCD1010A/W, HCC1410A/W, HCD1410A/W 11

Page 12

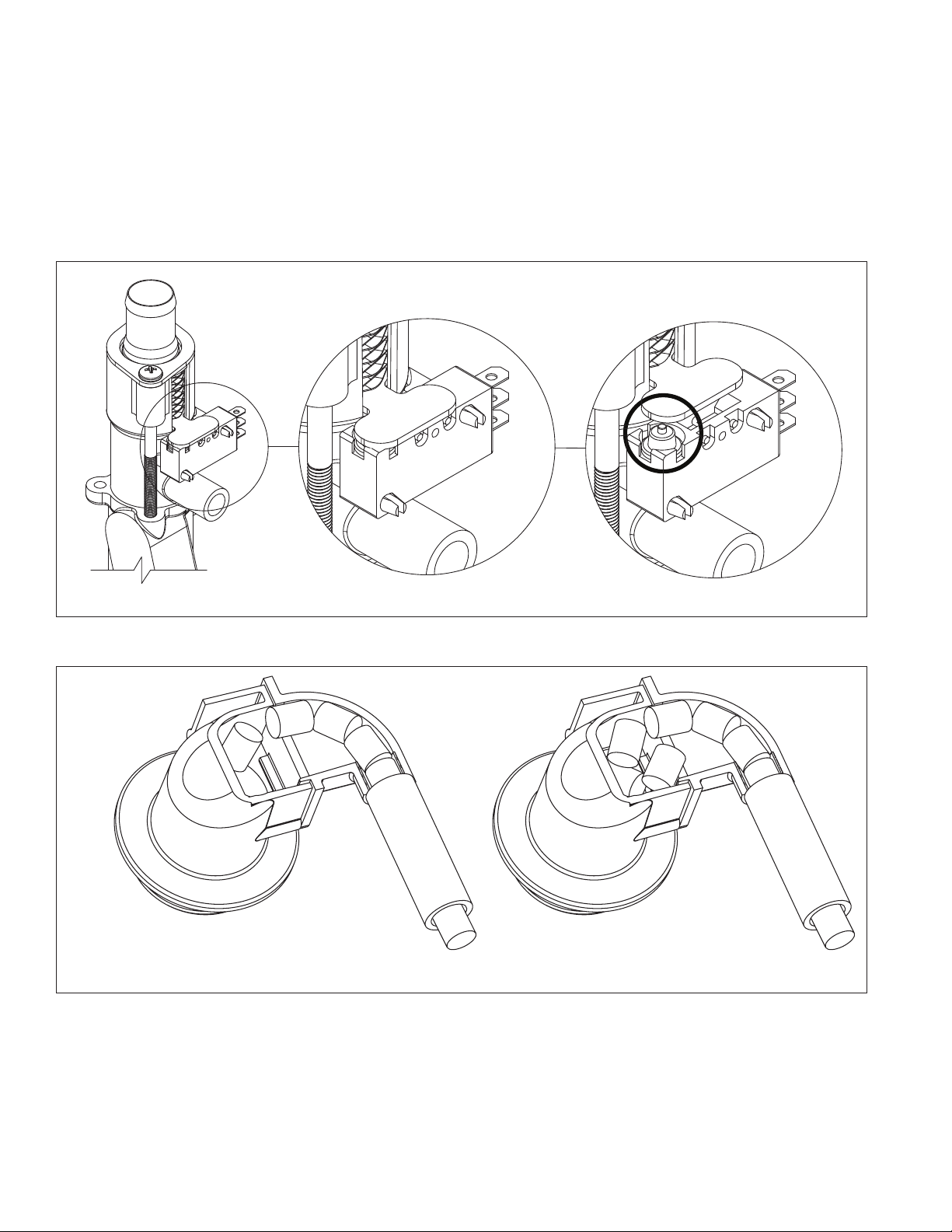

“Bin full” detection system

The Follett Horizon ice machine incorporates a unique “bin full” detection system that consists of the shuttle and

actuator. The shuttle incorporates a ag and switch. Referencing the gure below, the normal running position

of the ag is down, and the switch is closed. When the bin lls to the top and ice can no longer move through

the tube, the machine will force the shuttle ag up, opening the switch and shutting the machine off. The shuttle

actuator, located above the ice bin allows the ice to curl up within it when the bin is full. In this way, there are no

loads generated that would tend to lift off the lid of the bin.

Shuttle ag and sensor

Shuttle actuator

Running

Running Off

Off

12 HCC1010A/W, HCD1010A/W, HCC1410A/W, HCD1410A/W

Page 13

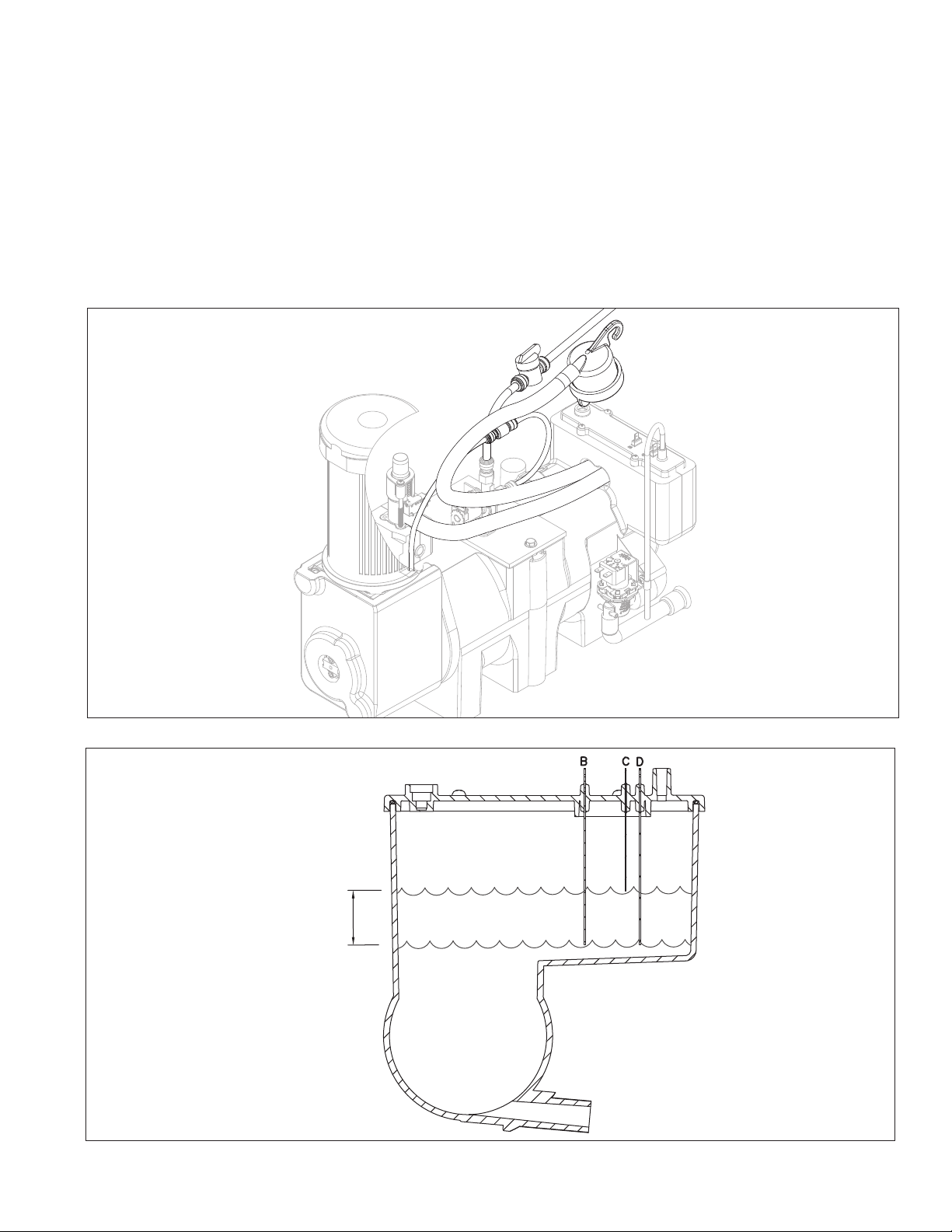

Water system

The water level in the evaporator is controlled by a feed solenoid and level detecting sensors. Referencing the

diagram below, water sensing probes extend down into the reservoir at the end of the evaporator assembly. The

system works via electrical conductivity as follows:

The probe labeled B is the common. When water is between any of the other probes and the common, the PC

board will sense the activation. During normal operation, the water level rises and falls between the Normal

High and Normal Low probes. As water is consumed to make ice, the level will fall until the Normal Low probe is

exposed, triggering the water feed solenoid on. Water will ll until the Normal High sensor is activated.

Note: The potable water total dissolved solids (TDS) content must be greater than 10 ppm for the water control

system to function properly. If using reverse osmosis water ltration system, ensure TDS level is greater than

10 ppm.

Water system diagram

Water level diagram

Common

Normal Hi

Normal Lo

Normal

Operating

Range

HCC1010A/W, HCD1010A/W, HCC1410A/W, HCD1410A/W 13

Page 14

Electrical system

FLASHINGON or OFF

Legend:

OFFON

ATTENTION!

To prevent circuit breaker/Hi-amp overload, wait 5 minutes before

restarting this unit. This allows the compressor to equalize and the

evaporator to thaw.

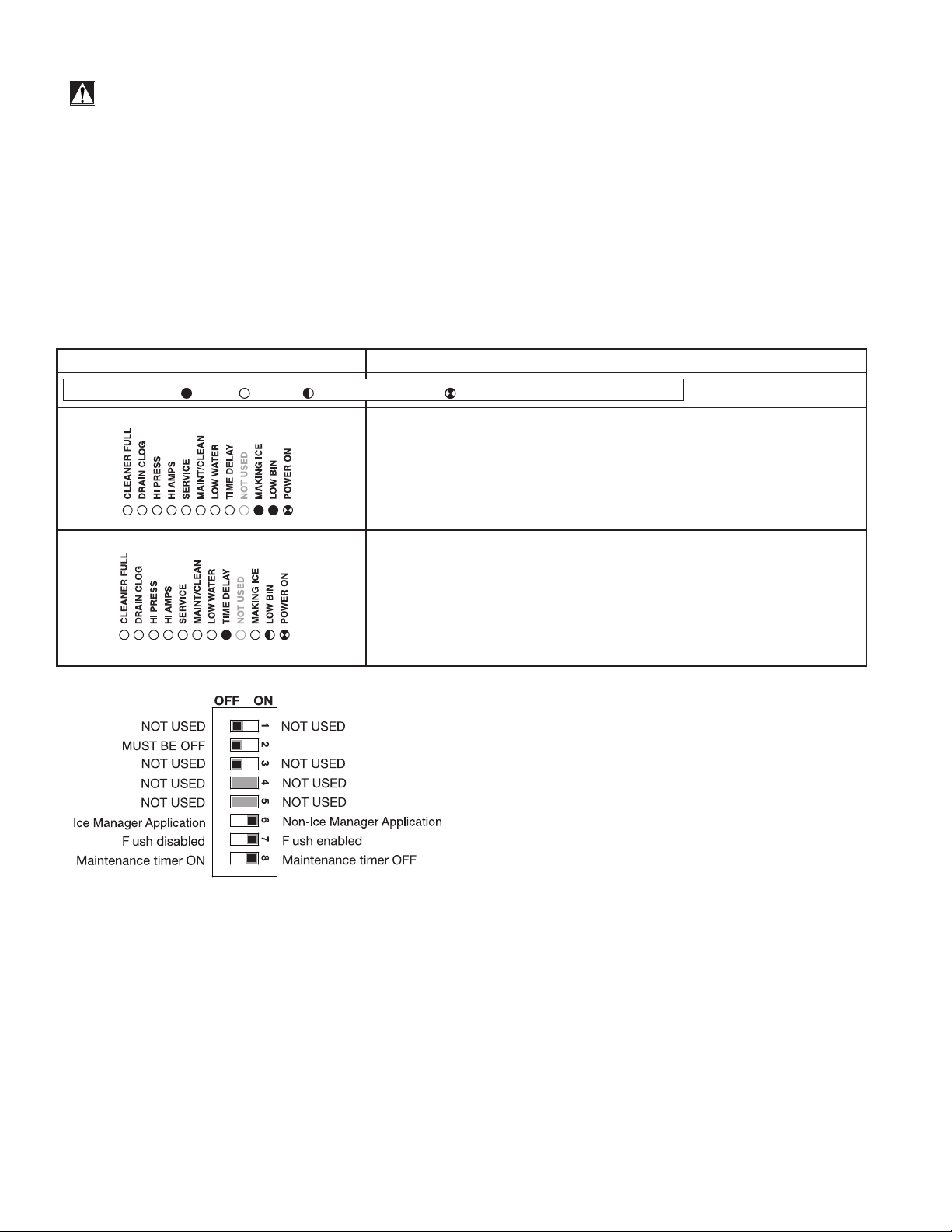

Normal control board operation

The PC board indicator lights provide all the information necessary to determine the machine's status. Green

indicator lights generally represent “go” or normal operation; Yellow indicators represent normal off conditions; Red

indicators generally represent alarm conditions.

A ashing green light labeled POWER indicates power to the machine. All other normal operation status indicators

are covered as follows:

Ice machine disposition Operating conditions

1. Ice machine is making ice.

.

2. Ice machine is not making ice.

DIP Switch Settings

1. Normal running.

2. Normal time delay. When the bin lls with ice, the LOW BIN

light goes out momentarily and the refrigeration and auger

drive systems immediately shut down. (Note: The fan motor

will continue to run for 10 minutes to cool condenser) The TIME

DELAY light comes on, initiating the time delay period. When the

time delay expires, the machine will restart provided that the LOW

BIN light is on.

14 HCC1010A/W, HCD1010A/W, HCC1410A/W, HCD1410A/W

Page 15

Error faults:

The Horizon PC board monitors various operating parameters including high pressure, auger gearmotor amperage

limits, clogged drain, and low water alarm conditions. There are three types of errors namely “soft” (time delay)

"hard" (reset), and “run”.

§ Soft errors will automatically reset after the 1 hour time delay or can be reset by cycling power.

§ Hard errors must be reset on the control board.

§ Run errors will give an indication of a problem, but will allow continuous normal operation.

Soft errors:

HI AMPS: The PC board monitors the amperage of the auger motor. Should the gear motor experience current

draw above the allowable limit, the machine will shut down and the TIME DELAY and HI AMP will be illuminated.

After the time delay the machine will restart and the TIME DELAY and HI AMP will clear.

LO WATER: During operation, the water level cycles between the normal low and normal high sensors. Should the

water be shut off to a running machine, a soft error will occur. The error sequence is as follows: During operation,

the water level falls to the normal low sensor, and when it does the water feed solenoid is energized. If water is not

detected at the normal low sensor within 10 seconds, a soft error will occur. The machine will shut down, but the

water feed solenoid will remain energized. Should water return, it will ll to the normal low sensor and the machine

will resume normal operation. The error will clear automatically.

HI PRESSURE: Should the refrigeration pressure rise above 425 psi, the machine will shut down and the TIME

DELAY and HIGH PRESSURE will be illuminated. After the time delay, and if the pressure has fallen back below

the reset point of 295 psi, the machine will restart and the TIME DELAY and HIGH PRESSURE will clear.

SERVICE: The water leak sensors, located in the chassis will detect the presence of water just below the top edge

of the chassis.

Hard error:

HI AMPS will light as a hard error if the gearmotor circuit is open (zero current draw). Press reset on the control

board to clear this error.

Run errors:

DRAIN CLOG: When the machine shuts down on a full bin and there has been 10 minutes of cumulative

compressor run time, the machine will purge before starting. During this purge, if water does not get below the low

probe in the reservoir within 20 seconds, the Drain Clog LED will light. The machine will continue to run but this is

an indication of a poorly draining machine and must be addressed.

Relay output indication:

Each relay on the board has an indicator light associated with its output. For example, when the relay for the water

feed solenoid is energized, the adjacent indicator light glows green.

Evaporator ushing sequence:

During operation, the purge solenoid will open in order to drain water. There are two drain settings to choose from:

High TDS or Low TDS. (There is a rocker switch behind the front cover of the machine.) The intent is to drain the

Total Dissolved Solids from the machine while it makes ice.

While ice is being made, the TDS of the water in the evaporator increases in TDS concentration. Without periodic

draining, the TDS levels will climb to very detrimental levels, levels that will cause scale to form and cause poor

machine operation. The Low TDS setting will allow the machine to operate for one hour before going through the

ushing sequence; the High TDS setting will allow the machine to run for 10 minutes before going through the

ushing sequence.

The ushing sequence toggles the purge and ll solenoids three times. That is, the purge solenoid will energize

until the water level drops below the low probe. The ll solenoid then energizes until water reaches the high probe,

and so on for 3 cycles.

Typically, High TDS might be considered levels above 200 PPM, but local experience and varying water chemistry

may compel a High TDS setting for best performance in even lower TDS levels.

Off cycle: During the off-cycle time delay, the machine checks for a cumulative 10 minutes of ice making time

since the last off-cycle ush. If the cumulative ice making time exceeds 10 minutes, the machine will open the

drain valve for 60 seconds to drain the evaporator in its entirety. It will then rell with water and begin making ice.

If the ice making time is less than 10 minutes, the machine will start and begin making ice without draining the

evaporator.

HCC1010A/W, HCD1010A/W, HCC1410A/W, HCD1410A/W 15

Page 16

Wiring diagram

16 HCC1010A/W, HCD1010A/W, HCC1410A/W, HCD1410A/W

Page 17

Compressor data

1010 1410

Compressor current draw at 208-230 VAC, 90 F/32.2 C

Locked rotor amps @ 208-230V 40.6A 90A

Compressor start winding (208-230 V) 2.74Ω 2.09Ω

Compressor run winding (208-230 V) 1.52Ω 0.73Ω

6.9A 12.1A

Gearmotor data

Gearmotor current 2.0A @ 208-230 V

Gearmotor torque-out (high amp) trip point: 2.8A @ 208-230 V

Locked rotor amps 20A @ 208-230 V

Resistance of windings

208-230 vac gearmotor (Brother):

Red to black: 12Ω

Blue to red: 12Ω

Blue to black: 24Ω

Fan motor data

Fan motor current 1.2A @ 208-230 V

Fan motor resistance 100Ω

HCC1010A/W, HCD1010A/W, HCC1410A/W, HCD1410A/W 17

Page 18

Mechanical System

Evaporator disassembly

1. Press CLEAN button to purge evaporator. Turn power

OFF when LO WATER lights.

2. Unscrew and disconnect transport tube from louvered

docking assembly.

3. Remove gearbox insulation..

Fig. 10

Fig. 11

4. Disconnect gear motor wires.

5. Remove screws (with 3/16" allen wrench) and auger

retaining fork:

Fig. 12

Fig. 13

18 HCC1010A/W, HCD1010A/W, HCC1410A/W, HCD1410A/W

Page 19

6. Remove gear motor bolts (9/16" wrench).

7. Remove gear motor and wipe auger shaft clean.

8. Remove main housing insulation and shuttle

insulation:

Fig. 14

WIPE

AUGER

SHAFT

Fig. 15

Fig. 16

9. Remove front feed water tube from push-in tting,

shuttle drain tube, and shuttle switch.

HCC1010A/W, HCD1010A/W, HCC1410A/W, HCD1410A/W 19

Page 20

10. Remove 3 screws (with 3/16" allen wrench) then

remove auger and main housing together.

Note: Auger is sharp - wear protective gloves.

11. Rotate auger to align opening in auger ange with

stream divider.

12. Pull out auger.:

Fig. 17

Fig. 18

Fig. 19

13. Remove and discard the ceramic mating ring and

shaft seal.

20 HCC1010A/W, HCD1010A/W, HCC1410A/W, HCD1410A/W

Page 21

Evaporator reassembly

14. Install ceramic mating ring and shaft seal.

Caution: Do not touch the sealed surface of either

part. Oil from bare skin will cause premature seal

failure.

15. Use liquid hand soap on the rubber part of the

ceramic seal when installing in main housing. Use

supplied cardboard disc to press into recess.

16. Apply liquid hand soap to raised area of auger

shaft and interior rubber portion of shaft seal before

installing seal.

1 7. Clean O ring groove. Lubricate O ring with petrol-gel

and reinstall.

18. Carefully install auger.

19. Rotate auger to position shown to clear main housing

stream divider.

Fig. 20

Cardboard

disc

Do NOT

touch!

Fig. 21

20. Install rear shuttle insulation (Fig. 22.1) and slide

main housing (Fig. 22.2) onto auger.

2 1. When installing new water seal, use screwdriver to

compress the spring (Fig. 22.3), which allows for

easier installation of the three screws.

Fig. 22

1

2

3

HCC1010A/W, HCD1010A/W, HCC1410A/W, HCD1410A/W 21

Page 22

22. Install shuttle switch.

§ Align holes with pins (Fig. 23.1) and depress switch

button (Fig. 23.2) to clear shuttle tab.

23. Install shuttle drain tube and front feed water tube

(Fig.24).

Fig. 23

Fig. 24

24. Install main housing insulation and shuttle insulation:

25. Apply a coat of petro gel to auger shaft.

Fig. 25

22 HCC1010A/W, HCD1010A/W, HCC1410A/W, HCD1410A/W

Page 23

26. Slide gear motor onto auger and install gear motor

bolts (9/16" wrench).

2 7. Connect gear motor wires.

Fig. 26

Fig. 27

28. Pry auger forward and rotate auger using 1/2" wrench

to align keyways.

29. Install key fully.

30. Pry shaft forward to install retainer fork.

Fig. 28

Fig. 29

HCC1010A/W, HCD1010A/W, HCC1410A/W, HCD1410A/W 23

Page 24

3 1. Rotate retainer fork to align screw holes.

32. Install screws to secure retainer fork.

33. Install gearbox insulation.

Fig. 30

Fig. 31

34. Connect transport tube to louvered docking assembly.

Fig. 32

24 HCC1010A/W, HCD1010A/W, HCC1410A/W, HCD1410A/W

Page 25

Reservoir/rear bushing disassembly

1. Press CLEAN button to purge

evaporator. Turn power OFF

when LO WATER lights.

Note: In many applications,

removing the gearmotor,

main housing, and

auger will allow for

the ice machine to be

pulled out further for

better access to rear

components.

2. Slide ice machine forward to

gain access.

3. Use Fig. 33 as disassembly

guide.

Note: Use petrogel when

installing/reinstalling

o-rings.

Fig. 33

Refrigeration system

1010 - Refrigerant pressure data

Air-cooled condensers (air) 60 F/16 C 70 F/21 C 80 F/27 C 90 F/32 C 100 F/38 C

Pressure (psig) discharge/suction 190/32 225/34 258/36 292/39 325/41

System Operating Pressures (Discharge/Suction) PSIG

Potable Water F/C

50/10 60/16 70/21 80/27 90/32

50/10 260/34 260/34 260/34 260/34 260/34 psig

60/16 260/34 260/34 260/34 260/34 260/34 psig

70/21 260/35 260/35 260/35 260/35 260/35 psig

80/27 273/36 284/36 285/36 285/36 285/36 psig

90/32 285/37 288/37 290/37 290/37 290/37 psig

Condenser Water F/C

Note: The water control valve is factory set to maintain 260 ± 15 PSIG discharge pressure on R404A @ 70 F/21 C

water, and 245 PSIG ± 15psi discharge pressure on R449A @ 70 F/21 C water.

HCC1010A/W, HCD1010A/W, HCC1410A/W, HCD1410A/W 25

Page 26

1410 - Refrigerant pressure data

Air-cooled condensers (air) 60 F/16 C 70 F/21 C 80 F/27 C 90 F/32 C 100 F/38 C

Pressure (psig) discharge/suction 235/27 275/30 315/32 355/35 395/37

System Operating Pressures (Discharge/Suction) PSIG

Potable Water F/C

50/10 60/16 70/21 80/27 90/32

50/10 290/32 290/32 290/32 290/33 290/33 psig

60/16 290/33 290/33 290/33 290/33 290/33 psig

70/21 290/33 290/33 290/33 290/33 290/33 psig

80/27 293/33 293/33 293/33 293/33 293/33 psig

90/32 295/34 295/34 295/34 295/34 295/34 psig

Condenser Water F/C

Note: The water control valve is factory set to maintain 260 ± 15 PSIG discharge pressure on R404A @ 70 F/21 C

water, and 245 PSIG ± 15psi discharge pressure on R449A @ 70 F/21 C water.

Refrigeration system diagram

26 HCC1010A/W, HCD1010A/W, HCC1410A/W, HCD1410A/W

Page 27

Refrigeration charge

All service on refrigeration systems must be performed in accordance with all federal, state and local laws. It is the

responsibility of the technician to ensure that these requirements are met. Recharging ice machine to other than

factory specications will void the warranty.

R404A ice machine charge specications

Model Charge Refrigerant type

HCC1010A (air-cooled) 33 oz (936 g) R404A

HCC1010W (water-cooled) 18 oz (510 g) R404A

HCC1410A (air-cooled) 35 oz (992 g) R404A

HCC1410W (water-cooled) 18 oz (510 g) R404A

HCC1010W Marine 15 oz (425 g) R449A

HCC1010W Marine 15 oz (425 g) R449A

Refrigerant replacement requirements

1. Non-contaminated refrigerant removed from any Follett refrigeration system can be recycled and returned to

the same system after completing repairs. Recycled refrigerant must be stored in a clean, approved storage

container. If additional refrigerant is required, virgin or reclaimed refrigerant that meets ARI standard 700-88

must be used.

2. In the event of system contamination (for example, a compressor burn out, refrigerant leak, presence of

non-condensibles or moisture), the system must be repaired, evacuated and recharged using virgin or

reclaimed refrigerant that meets ARI standard 700-88.

3. Follett Corporation does not approve of recovered refrigerants. Improper refrigeration servicing procedures

will void the factory warranty.

Evacuation

Evacuate the system to a level of 500 microns. When the 500 micron level is reached, close all valves. Allow the

system to sit for approximately 20 minutes. During this period the system pressure should not rise. If the system

pressure rises and stabilizes there is moisture in the system and further evacuation is needed. If the pressure

continues to rise check the system for leaks.

Ambients Minimum Maximum

1

Air temperature

Water temperature

1

Ambient air temperature is measured at the air-cooled condenser coil inlet.

2

Ambient water temperature is measured at the water feed valve inlet.

50 F/10 C 100 F/37.8 C

2

45 F/7 C 90 F/32.2 C

Ice capacity test

Ice machine production capacity can only be determined by weighing ice produced in a specic time period.

1. Replace all panels on ice machine.

2. Run ice machine for at least 15 minutes.

3. Weigh and record weight of container used to catch ice.

4. Catch ice for 15 or 20 minutes.

5. Weigh harvested ice and record total weight.

6. Subtract weight of container from total weight.

7. Convert fractions of pounds to decimal equivalents (ex. 6 lbs 8oz = 6.5 lbs).

8. Calculate production using following formula:

1440 min. x wt. of ice produced

Total test time in minutes

Production capacity/24 hr.

=

9. Calculated amount per 24 hours should be checked against rated capacity for same ambient and water

temperatures in Ice Production Tables.

HCC1010A/W, HCD1010A/W, HCC1410A/W, HCD1410A/W 27

Page 28

Troubleshooting

Please see “Service” section for a description of each function.

Ice machine disposition Possible causes Corrective action

Legend:

1. Ice machine is in running

condition but not making ice.

.

2. Machine in TIME DELAY without full

bin.

3. Ice machine is not making ice.

HI AMPS.

.

4. Ice machine is not making ice.

HI PRESSURE.

.

5. Ice machine is not making ice.

SERVICE.

OFFON

FLASHINGON or OFF

1. Defective compressor.

2. Defective start relay.

3. Defective start capacitor.

4. Defective run capacitor.

5. Defective main contactor.

6. No output from PC board.

1. Ice jamming due to improperly

installed transport tube causing a

false shuttle.

2. Shuttle stuck in up position.

3. Damaged or improperly installed

thermostat (open).

4. Transport tube backed-out of

coupling.

1. Poor water quality causing ice to jam

auger.

2. Damaged shuttle mechanism.

3. Intermittent drive output from

PC board. Evaporator will freeze

causing a HI AMPS error.

4. Gearmotor is unplugged.

1. High ambient temperatures

>100 F (38 C).

2. Poor ventilation or air recirculation.

3. Clogged condenser (air-cooled).

4. No water ow through condenser

(water-cooled).

5. Fan not working properly. No

air ow.

• Blocked fan blades

• No fan output from PC board

• Faulty fan motor

1. Internal water leak touching chassis

sensor.

1. Replace compressor.

2. Replace start relay.

3. Replace start capacitor.

4. Replace run capacitor.

5. Replace main contactor.

6. Replace PC board.

1. Correct transport tube routing.

2. Repair or replace shuttle

mechanism.

3. Replace or reposition thermostat.

4. Correct coupling installation.

1. Clean ice machine. Increase

ushing frequency. Position TDS

switch to High TDS setting.

2. Replace or repair shuttle

mechanism.

3. Replace PC board.

4. Plug in gearmotor.

1. Air condition area to below 100F

(38 C).

2. Reposition ice machine or properly

ventilate. Prevent ice machine

exhaust from recirculating.

3. Clean condenser grille (air-cooled).

4. Restore water ow to condenser.

5. Correct air ow.

• Remove any blockage from fan

blades

• Replace PC board

• Replace fan motor

1. Identify and repair leak. Clean/dry

chassis and sensors and restart

machine.

.

6. Drain clog.

.

1. Improper ow in drain system. 1. Correct/clean drain system.

28 HCC1010A/W, HCD1010A/W, HCC1410A/W, HCD1410A/W

Page 29

Ice machine disposition Possible causes Corrective action

Legend:

OFFON

7. Ice machine is making ice.

Excessive water in bin or

coming into bin from transport

tube.

8. Ice machine is not making ice.

Lo water.

9. Blinking Lo water, power, time

delay.

FLASHINGON or OFF

1. Failed water sensors. Processor

assumes there is no water when

there is water.

2. Blocked reservoir vent.

3. Defective water feed solenoid

valve. Stuck in open position.

1. Water supply is insufficient.

2. Low water pressure.

3. Defective water feed solenoid

valve. Stuck in closed position.

4. No water feed output from

PC board.

5. Plugged screen on inlet side of

ll solenoid.

6. Plugged check valve.

Machine did not see water

consumption while trying to make

ice.

1. Lack of refrigeration/low

refrigerant charge/leak.

2. Debris shorting reservoir probes.

1. Clean or replace water probe

assembly. Check wiring

connections.

2. Clean or replace vent tubes.

3. Replace water feed solenoid

valve.

1. Restore water supply and check

water lters. If evaporator was

completely empty the reset

button may have to be pressed

to restart the ice machine.

2. Ice machine will eventually start

when water reaches normal lo

level.

3. Replace water feed solenoid

valve.

4. Replace PC board.

5. Remove and clean screen.

6. Remove and clean.

1. Verify refrigerant pressures,

compressor running, sight glass

clear.

2. Clean probes and reservoir of

debris.

ATTENTION!

To prevent circuit breaker overload, wait 5 minutes before restarting

this unit. This allows the compressor to equalize and the evaporator

to thaw.

HCC1010A/W, HCD1010A/W, HCC1410A/W, HCD1410A/W 29

Page 30

Replacement parts

27

3

37

10

2

Evaporator assembly

2

1

2

5

4

31

7

8

29

17

11

9

20

17

31

15

31

12

10

3

14

13

2

21

31

32

17

31

16

31

25

24

13

19

33

36

31

6

18

17

17

13

22

31

26

28

28

23

30

35

34

30 HCC1010A/W, HCD1010A/W, HCC1410A/W, HCD1410A/W

Page 31

Reference # Description Part #

1 Tube, ice transport, insulated 01118181

2 Shuttle assembly 01118132

2 Shuttle assembly, IMDV 0111 8 140

3 Switch, shuttle 01006261

4 Compression nozzle 01278654

5 O-ring, shuttle 01164920

6 Screw, reservoir (10 pack)

01333830

7 Auger hardware (includes screws, key, retainer) 01118611

8 Key 01164938

9 Bolt, gearmotor mounting (2) (self-contained units), includes washers 01118629

10 Cartridge assembly, shuttle spring 01118033

10 Cartridge, shuttle spring, IMDV 01118041

11 Gearmotor, 220 V (includes capacitor) 01118025

12 Main housing, self-contained 01117969

13 O ring 01301720

14 Seal, auger shaft 01302249

15 Cup, sanitizer 01164995

16 Cap, sanitizer 01118637

Not shown Tubing, water, 3/8" OD 502719

Not shown Tubing, water, 1/4" OD 502079

17 Retainer kit, evaporator 01118652

18 Solenoid, water feed (220 V) 01301688

19 Reservoir lid and sensors (includes screws and o-ring) 0111810 8

20 Valve, shut-off, water 502921

21 Auger, 1010 self-contained (includes seal, key, and auger hardware) 01117928 (1010 only)

21 Auger, 1410 self-contained (includes seal, key, and auger hardware) 01117936 (1410 only)

22 Evaporator, 1010 01118066 (1010 only)

22 Evaporator, 1410 01118074 (1410 only)

23 Rear bushing housing and bushing (includes (1) o-ring) 01118082

24 Reservoir assembly, water (includes lid) 01118116

25 Tube, vent (17" required) 502079

26 Tube, sanitizer 01118660

27 Kit, MicroChewblet 01161843

28 Tube, shuttle drain, insulated 01118678

29 Insulation, gearbox, 220 V 01165240

30 Solenoid, purge, 220 V 01148733

31 Insulation kit, 1010 evaporator/reservoir 01302256 (1010 only)

31 Insulation kit, 1410 evaporator/reservoir 01302264 (1410 only)

32 Check valve 01122381

33 Tube, drain, reservoir, insulated 01118124

34 Tube, drain, 1010 01302272 (1010 only)

35 Tube, drain, 1410 01302280 (1410 only)

36 O-ring, reservoir lid 01302298

Not shown Kit, scale (includes reservoir, purge solenoid, drain tubes and tting) 01122654

37 O-ring, MicroChewblet 01161850

Not shown Drain kit (includes 2 ft. x 1" OD silicone tubing, 3/4" x 1" slip, 3/4" barb 3/4" FPT

01210350

(2), 3/4" barb x 3/4" FPT elbow)

HCC1010A/W, HCD1010A/W, HCC1410A/W, HCD1410A/W 31

Page 32

Air-cooled assembly

1410

2

3

7

4

5

6

6

3

1

8

1010

7

32 HCC1010A/W, HCD1010A/W, HCC1410A/W, HCD1410A/W

Page 33

Reference # Description Part #

1 Condenser 01118892

2 Fan motor assembly - 220 V/60 Hz 01117803

3 Cut-out, high pressure safety 01232941

4 Drier 01153683

5 Valve, expansion, thermal (includes insulation and (2) clamps) 01118942

6 Insulation, TXV (body and bulb) 502830

7 Compressor, 1010 - 220 V/60 Hz (includes start/run components and drier) 01117837 (1010 only)

7 Compressor, 1410 - 220 V/60 Hz (includes start/run components and drier) 01117845 (1410 only)

8 Base, ice machine 01117795

HCC1010A/W, HCD1010A/W, HCC1410A/W, HCD1410A/W 33

Page 34

Water-cooled assembly

15

10

9

12

17

1

3

2

5

4

13

7

11

4

8

16

14

13

6

7

34 HCC1010A/W, HCD1010A/W, HCC1410A/W, HCD1410A/W

Page 35

Reference # Description Part #

1 Electrical box support 01118934

2 Valve, water regulating 00131052

3 Union, water 01302827

4 Cut-out, high pressure safety 01302835

5 Drier 01153683

6 Valve, expansion, thermal (includes insulation and (2) clamps) 01118942

7 Insulation, TXV (body and bulb) 502830

8 Condenser, w/c, 1010/1410 01302843

9 Valve, shut-off, water 502222

10 Coupling 01305309

11 Ty-rap 01305309

12 Fitting, ared adapter 01302850

13 Compressor, 1010 - 220 V/60 Hz (includes start/run components and drier) 01117837 (1010 only)

13 Compressor, 1410 - 220 V/60 Hz (includes start/run components and drier) 01117845 (1410 only)

14 Base, ice machine 01117795

15 Elbow 01302868

16 Coupling, 3/8" double are 01302876

17 Tubes, condenser inlet and exit 01122373

HCC1010A/W, HCD1010A/W, HCC1410A/W, HCD1410A/W 35

Page 36

Electrical box

1

7

2

4

3

6

13

5

11

8

9

36 HCC1010A/W, HCD1010A/W, HCC1410A/W, HCD1410A/W

12

10

Page 37

Reference # Description Part #

1 Cover, electrical box, air/water-cooled 01118967

2 Board, control, 220 V (includes stand-offs) 01117 8 11

3 Stand-offs (set of 8) 00130906

4 Capacitor, compressor run - 220 V/60 Hz 01302892

5 Relay, compressor starting - 220 V/60 Hz, 1010 01302900 (1010 only)

5 Relay, compressor starting - 220 V/60 Hz, 1410 01302918 (1410 only)

6 Contactor - 220 V/60 Hz 01302926

7 Capacitor, compressor starting - 220 V/60 Hz, 1010 01302934 (1010 only)

7 Capacitor, compressor starting - 220 V/60 Hz, 1410 01302942 (1410 only)

8 Switch, evaporator clean 01165703

9 Switch, ice machine power 01165711

10 Cord, power, 220 V, 1010 01302959 (1010 only)

10 Cord, power, 220 V, 1410 01302967 (1410 only)

11 Switch, TDS 01165695

12 Circuit breaker, 4A 01302975

13 Cable, IMDV 01116 1 7 7

HCC1010A/W, HCD1010A/W, HCC1410A/W, HCD1410A/W 37

Page 38

Integration kit – top-mount and RIDE remote ice delivery

Top mount configuration

12

10

13

2

1

2

3

11

4

5

RIDE model configuration

6

1

7

8

14

12

14

11

3

10

2

4

5

6

9

2

7

8

38 HCC1010A/W, HCD1010A/W, HCC1410A/W, HCD1410A/W

Page 39

Reference # Description Part #

1 Shuttle actuator 00171322

2 Clamp 500377

3 Actuator elbow (includes 00167122 and 209100) 00171264

4 Screws 01303064

5 Gasket 01303072

6 Actuator body 00171272

7 Gasket, coupling 01303080

8 Ring, locking (includes 00126532) 00171371

9 Ice transport tube, 10' (3 m) 00171280

9 Ice transport tube, 20' (6 m) 00171298

10 Insulation, transport tube 501176

Not shown Insulated polywire ice transport tube, per foot 00174896

11 Insulation, elbow 01303098

12 Insulation, actuator 01303106

13 Ice transport tube, top mount, 30" (762 mm) 00171306

14 Extension-ll tube, 9" 01303114

14 Extension-ll tube, 4" 01303122

Not shown Integration kit, top mount, Harmony or Bin 00171389

Not shown Integration kit, RIDE model, Harmony or Bin, (includes 10' (3 m) of tube and

insulation)

Not shown Integration kit, drop in 00145334

Not shown Integration kit, Cornelius PR150 00144774

Not shown Integration kit, Vision (does not include ice tube) 00997171

Not shown Diverter plate (single agitator Cornelius dispensers and left-hand dispense chute on

dual-agitator Cornelius dispensers)

Not shown Diverter plate (right-hand dispense chute on dual-agitator dispensers) 00996207

Not shown SafeCLEAN Plus, case of 6 01149954

Not shown SafeCLEAN Plus, case of 24 01149962

Not shown Sani-Sponge kit 00132068

Not shown High-capacity lter system 01303148

Not shown Primary lter (1) 01333814

Not shown Primary lter (6) 00978973

Not shown Pre-lter (1) 01333822

Not shown Pre-lter (12) 00954305

Not shown IMSII or IMSIII sanitizer concentrate - 16 oz. 00979674

Not shown Sponge, sanitary, pack of 24 01075431

Not shown Kit, IMDV (included IMDV cartridge and communication cable) 01116 177

Not shown Tubing, silicone (per foot) 01303155

00171397

01303130

HCC1010A/W, HCD1010A/W, HCC1410A/W, HCD1410A/W 39

Page 40

Skins assembly

2

10

1

10

11

5

3

6

7

4

9

8

40 HCC1010A/W, HCD1010A/W, HCC1410A/W, HCD1410A/W

Page 41

Reference # Description Part #

1 Grille, front 01303163

2 Front cover, air-cooled, 1010/1410 01119007

2 Front cover, water-cooled, 1010/1410 01119023

Not shown Tubing, water, 3/8" OD 502719

3 Coupling (includes O-ring) 00171207

4 O-ring 01303171

5 Bulkhead tting 00171215

6 Catp, nut, ice hose 01303189

7 Hose clamp 500377

8 Plate, strain relief 00192070

9 Louvered docking assembly, 1010 (includes strain relief plate, bulkhead

tting)

9 Louvered docking station, 1410 (includes strain relief plate, bulkhead

tting)

10 Screw 01303197

11 Bulkhead connector kit 00171223

Not shown Gasket, front cover (inside), per foot (4 feet required) 00135574

Not shown Louver, intake/exhaust (25.75" W x 17.75" H) with gasket 01085448

Not shown Gasket, air intake (front cover, outside) (7 feet required) 01305317

Not shown Fitting, drain 00109728

01119 01 5 (1010 only)

01119031 (1410 only)

HCC1010A/W, HCD1010A/W, HCC1410A/W, HCD1410A/W 41

Page 42

Rejestracja gwarancji i ocena sprzętu

Dziękujemy za zakup urządzenia firmy Follett. Mamy nadzieję, że nasze urządzenia spełniają i przekraczają Państwa oczekiwania, gdyż

naszym celem jest dostarczenie klientom wysoce wartościowych produktów i usług, zasługujących na ich pełne uznanie.

Prosimy zapoznać się z załączoną instrukcją instalacji i obsługi. Istotne jest przeprowadzenie instalacji zgodnie z wymogami producenta, co

zapewni działanie urządzenia z maksymalną wydajnością.

Follett LLC nie będzie ponosić odpowiedzialności za szkody wtórne, wydatki, koszty podłączania lub odłączania lub jakiekolwiek straty

wynikające z wady urządzenia.

Aby uzyskać szczegółowe informacje na temat warunków gwarancji, prosimy odwiedzić naszą strone internetową www.follettice.com/

productwarranties.

Rejestracja gwarancji i ocena urządzenia to istotne czynności, ułatwiające nam utrzymanie aktualnych danych o miejscach instalacji naszych

urządzeń i o ich działaniu. Prosimy o zarejestrowanie gwarancji na nabyte urządzenie firmy Follett na naszej witrynie www.follettice.com/

support, gdzie należy wybrać Warranty Registration (Rejestracja gwarancji) i Equipment Evaluation (Ocena urządzenia). Jest to łatwe

i nieskomplikowane, prosimy o znalezienie na to paru minut jeszcze dzisiaj. Na formularzu jest również miejsce na przekazanie nam

komentarzy i informacji zwrotnych. Proszę podzielić się z nami swoimi wrażeniami, abyśmy mogli wykorzystać je w naszych ciągłych

dążeniach do usprawnień.

Jesteśmy dumni z naszych znakomitych urządzeń i staramy się usilnie wspierać je znakomitą obsługą klienta i wsparciem technicznym.

Chcielibyśmy wiedzieć, w jaki jeszcze sposób moglibyśmy Państwu pomóc. Z przyjemnością odpowiemy na Państwa pytania.

Registro de Garantía y Evaluación del Equipo

Gracias por haber elegido este producto Follett ®. Esperamos que nuestro equipo cumpla o supere sus expectativas porque es nuestro objetivo

ofrecer productos y servicios de gran valor que se ganen su plena confianza.

Le rogamos consulte el manual de instalación y de instrucciones adjunto, ya que es muy importante que la instalación se realice según las

especificaciones de fábrica para que el equipo funcione a su máxima eficiencia.

Follett LLC no se hace responsable de los daños indirectos, costos, gastos por conexión y desconexión o pérdidas por causa de defecto de la

máquina.

Si desea una información más completa sobre la garantía, visite nuestro sitio web www.follettice.com/productwarranties.

Las operaciones de registro de la garantía y evaluación del equipo son importantes para que podamos realizar un seguimiento de nuestro

equipo y registrar el rendimiento de la maquinaria. Por favor, registre las garantías del equipo Follett en nuestro sitio web www.follettice.

com/support y seleccione Registro de la Garantía y Evaluación del Equipo. Es muy sencillo, solo le llevará un momento realizar hoy mismo

el registro. En el formulario incluimos un espacio en blanco para sus comentarios y opiniones. Infórmenos sobre su experiencia para que

podamos incorporarla a nuestros continuos esfuerzos de mejora.

Nos enorgullecemos de producir un equipo excepcional y trabajamos duro para respaldarlo con un soporte técnico y un servicio de atención

al cliente de primera. Le rogamos nos indique qué más podemos hacer para ayudarle. Estaremos encantados de responder a sus dudas.

Enregistrement de la garantie et évaluation de l’équipement

Merci d’avoir acheté un équipement Follett®. Notre objectif étant d’offrir des produits et des services de grande valeur vous satisfaisant

pleinement, nous espérons que celui-ci satisfera, voire dépassera, vos attentes !

Veuillez consulter le manuel d’installation et d’exploitation. Il est important que l’installation soit réalisée conformément aux spécifications

de l’usine, de sorte que votre équipement fonctionne à son rendement maximum.

Follett LLC n’est pas responsable de tout dommage consécutif, de toute dépense, de tout frais de raccordement ou de déconnexion, ni de

toute perte liée à un défaut de la machine.

Pour lire la garantie dans son ensemble, visitez notre site Internet www.follettice.com/productwarranties.

L’enregistrement de la garantie et l’évaluation de l’équipement sont importants pour nous aider à suivre notre équipement et pour enregistrer

les performances de la machine. Nous vous demandons donc d’enregistrer la garantie de votre équipement Follett sur notre site Internet,

www.follettice.com/support, dans la section Warranty Registration and Equipment Evaluation. Cette opération est simple ; veuillez prendre

un moment pour la réaliser aujourd’hui.

Le formulaire contient également un espace pour nous faire parvenir vos commentaires et un retour d’informations. Veuillez nous faire part

de votre expérience pour que nous puissions prendre appui dessus pour poursuivre nos efforts constants d’amélioration.

Nous sommes fiers de produire des équipements exceptionnels et nous travaillons avec acharnement pour y associer une assistance à la

clientèle et technique exceptionnelle. N’hésitez pas à nous indiquer dans quelle mesure nous pouvons vous aider. Nous serions ravis de

répondre à vos questions.

Garantieregistrierung und Produktbeurteilung

Vielen Dank, dass Sie sich für ein Follett®-Produkt entschieden haben. Wir hoffen, dass unser Produkt Ihre Erwartungen erfüllen oder

sogar übertreffen wird, weil wir uns zum Ziel gesetzt haben, hochwertige Produkte und Leistungen anzubieten, die Ihre uneingeschränkte

Anerkennung verdienen werden!

Lesen Sie sich bitte die beiliegende Installations- und Betriebsanleitung durch. Es ist wichtig, dass die Installation entsprechend den

Werksangaben erfolgt, damit Ihr Produkt mit maximalem Wirkungsgrad arbeiten kann.

Follett LLC ist nicht für Folgeschäden, Ausgaben, Gebühren für Anschluss oder Abschaltung oder Verluste aufgrund eines Defekts der

Maschine haftbar.

Vollständige Garantieinformationen finden Sie auf unserer Website unter www.follettice.com/productwarranties.

42 HCC1010A/W, HCD1010A/W, HCC1410A/W, HCD1410A/W

Page 43

Garantieregistrierung und Produktbeurteilung sind wichtig, damit wir einen Überblick über unsere Produkte behalten und ihre Effizienz

bewerten können. Wir möchten Sie bitten, Garantien für Follett-Produkte auf unserer Website www.follettice.com/support zu registrieren und

den Punkt „Garantieregistrierung und Produktbeurteilung” zu wählen. Es ist ganz einfach. Nehmen Sie sich bitte einen Moment Zeit, um

die Registrierung heute vorzunehmen. Auf dem Formular ist auch Platz für Kommentare und Feedback vorhanden. Teilen Sie uns bitte Ihre

Erfahrungen mit unseren Produkten mit, damit wir sie für unsere fortlaufenden Produktverbesserungen verwenden können.

Wir sind stolz darauf, dass wir besondere Produkte herstellen, und wir bemühen uns, unsere Produkte mit besonderem Kundendienst zu

unterstützen. Lassen Sie uns bitte wissen, was wir noch für Sie tun können. Wir werden Ihre Fragen gerne beantworten.

Registrazione della garanzia e valutazione dell’attrezzatura

Grazie per aver acquistato un dispositivo Follett®. Ci auguriamo che il nostro prodotto soddisfi o superi le Sue aspettative, in quanto il

nostro obiettivo è quello di offrire prodotti e servizi di alta qualità che soddisfino pienamente le vostre esigenze!

La preghiamo di leggere attentamente il manuale per l’installazione e per l’uso allegato. È infatti importante che l’installazione sia effettuata

secondo le specifiche di fabbrica in modo tale che il dispositivo operi con la massima efficienza.

La Follett LLC non si assume alcuna responsabilità per danni conseguenti, spese, costi di collegamento o scollegamento o eventuali perdite

dovute ad un difetto della macchina.

Per visualizzare i dettagli completi relativi alla garanzia, recarsi alla pagina www.follettice.com/productwarranties.

La registrazione della garanzia e la valutazione dell’attrezzatura sono importanti per aiutarci a tenere traccia dei nostri dispositivi e a

registrare le prestazioni della macchina. Le chiediamo dunque di registrare le garanzie relative al dispositivo Follett sul nostro sito Web alla

pagina www.follettice.com/support scegliendo Registrazione della garanzia e Valutazione dell’attrezzatura. Farlo è semplice; dedichi pochi

minuti a registrare il prodotto oggi stesso. Sul modulo è inoltre previsto uno spazio in cui potrà fornirci i Suoi commenti e il Suo riscontro.

Ci faccia sapere della Sua esperienza in modo che possiamo farne tesoro per il nostro continuo miglioramento.

Siamo orgogliosi di produrre macchinari di ottima qualità e lavoriamo sodo per offrire un servizio di assistenza clienti e tecnico di qualità

altrettanto elevata. Ci faccia sapere come possiamo esserle di aiuto. Saremo lieti di rispondere a tutte le Sue domande.

Registo da garantia e avaliação do equipamento

Obrigado por ter adquirido equipamento Follett®. Fazemos votos de que o nosso equipamento cumpra ou exceda as suas expectativas, dado

que temos por objetivo fornecer produtos e serviços de elevado valor que mereçam a sua total satisfação!

Pedimos-lhe que leia o manual de instalação e operações em anexo. É importante que a instalação seja levada a cabo de acordo com as

especificações da fábrica, para que o seu equipamento funcione com a eficiência máxima.

A Follett LLC não assume a responsabilidade por quaisquer prejuízos indiretos, despesas, custos de ligação ou desligação ou quaisquer outras

perdas decorrentes de um defeito na máquina.

Para consultar os dados da garantia, visite o nosso website www.follettice.com/productwarranties.

O registo da garantia e a avaliação do equipamento são importantes para nos ajudar a estar a par do nosso equipamento e registar o

desempenho da máquina. Pedimos-lhe que registe as garantias de equipamento Follett no nosso website www.follettice.com/support, em

“Warranty Registration and Equipment Evaluation”. É muito simples; tire uns minutos para fazer o registo hoje mesmo. O formulário inclui

também espaço para os seus comentários e feedback. Conte-nos a sua experiência para que possamos usá-la nos nossos esforços contínuos de

melhoria.

Temos muito orgulho em produzir equipamento excecional e empenhamo-nos em proporcionar um apoio técnico e um apoio ao cliente

igualmente excecionais. Diga-nos o que mais podemos fazer para o ajudar. Teremos todo o prazer em responder às suas perguntas.

Registrering af garanti og evaluering af udstyr

Tak for dit køb af Follett ®-udstyr. Forhåbentlig synes du, at vores udstyr lever op til eller overstiger dine forventninger, for vores

målsætning er at levere produkter og serviceydelser af høj kvalitet, som du er fuldstændig tilfreds med!

Gennemlæs venligst den vedlagte installations- og driftsmanual. Det er vigtigt at installationen udføres i henhold til fabriksspecifikationerne,

så dit udstyr kan fungere med maksimal effektivitet.

Follett LLC hæfter ikke for følgeskader, udgifter, tilslutnings- eller frakoblingsomkostninger eller nogen form for tab, der skyldes en

maskindefekt.

Du kan læse de fulde oplysninger om garantien på vores website www.follettice.com/productwarranties.

Registrering af garantien og evaluering af udstyret er vigtigt for at hjælpe os med at følge op på vores udstyr og registrere maskinens

ydelse. Vi beder dig registrere garantier på Follett-udstyr på vores website www.follettice.com/support og vælge Warranty Registration and

Equipment Evaluation (Registrering af garanti og evaluering af udstyr). Det er nemt at gøre, så vi beder dig bruge et øjeblik på at registrere

dig i dag. Formularen har også plads til, at du kan give os kommentarer og feedback. Fortæl os om dine erfaringer, så vi kan bruge dem i

vores fortsatte bestræbelser på at forbedre os.

Vi sætter en ære i at fremstille udstyr i særklasse og arbejder hårdt på at kunne bakke udstyret op med fremragende kundeservice og teknisk

support. Fortæl os, hvad vi ellers kan gøre for at hjælpe dig. Vi svarer gerne på dine spørgsmål.

HCC1010A/W, HCD1010A/W, HCC1410A/W, HCD1410A/W 43

Page 44

Registratie van garanties en beoordeling van apparatuur

Gefeliciteerd met uw aankoop van Follett ®-apparatuur. We hopen dat onze apparatuur uw verwachtingen invult of zelfs overstijgt, omdat we

ernaar streven om hoogwaardige producten en diensten te leveren die u uitermate tevreden stellen!

Lees de bijgevoegde installatie- en bedieningshandleiding zorgvuldig door. Het is belangrijk dat de installatie uitgevoerd wordt volgens de

fabrieksspecificaties, zodat uw apparatuur zo efficiënt mogelijk werkt.

Follett LLC is niet aansprakelijk voor enige gevolgschade, uitgaven, montage- of demontagekosten of enige door een defect van de machine

geleden verliezen.

Bezoek onze website www.follettice.com/productwarranties voor alle garantiegegevens.

De registratie van garanties en de beoordeling van apparatuur is belangrijk voor ons om onze apparatuur te helpen traceren en de prestaties

van de machine te registreren. We verzoeken u dan ook om garanties van Follett-uitrusting te registreren op onze website www.follettice.

com/support en om “Warranty Registration” (Registratie van garanties) en “Equipment Evaluation” (Beoordeling van apparatuur) te kiezen.

Gelieve hier even tijd voor vrij te maken. Het is namelijk zeer eenvoudig. Er is op het formulier ook plaats om opmerkingen en feedback te

geven. Breng ons gerust op de hoogte over uw ervaring met onze apparatuur, zodat we ons kunnen blijven verbeteren.

We zijn trots op onze productie van uitstekende apparatuur en werken hard om dit bij te staan door een voortreffelijke klantendienst en

technische ondersteuning. Aarzel echter niet om enige andere bijstand te vragen. We zullen uw vragen met plezier beantwoorden.

Garantiregistrering och utvärdering av utrustning

Tack för att du köpt utrustning från Follett ®. Vi hoppas att du ska tycka att den uppfyller eller överträffar dina förväntningar, då vårt mål är

att leverera produkter och tjänster av högt värde som gör dig helt nöjd!

Studera medföljande installations- och bruksanvisning. Det är viktigt att installationen genomförs enligt fabrikens anvisningar så att din

utrustning arbetar med högsta effektivitet.

Follett LLC ansvarar inte för följdskador, kostnader, avgifter eller förluster som orsakats av fel på maskinen.

Fullständiga garantivillkor finns på vår hemsida www.follettice.com/productwarranties.

Garantiregistrering och utvärdering av utrustning är viktig för oss så att vi kan följa upp vär ultrustning och dess funktion. Vi vill att du

registrerar Folletts utrustningsgaranti på vår hemsida www.follettice.com/support, där du väljer Garantiregistrering och produktutvärdering.

Det är enkelt att göra, så ta dig tid en minut och registrera dig idag. Det finns också utrymme på blanketten för kommentarer och synpunkter.

Berätta för oss vad du tycker så att vi kan använda det i våra ansträngningar att alltid bli bättre.

Vi är stolta över att producera överlägsen utrustning och vi arbetar hårt med att stötta den med överlägset kundansvar och tekniskt stöd. Tala

om för oss vad vi kan göra mer för att hjälpa dig. Vi svarar gärna på dina frågor.

Warranty Registration and Equipment Evaluation

Thank you for purchasing Follett ® equipment. We hope you find that our equipment meets or exceeds your expectations, as our goal is to

deliver high value products and services that earn your complete satisfaction!

Please review the enclosed installation and operations manual. It is important that the installation be performed to factory specifications, so

your equipment operates to its maximum efficiency.

Follett LLC will not be liable for any consequential damages, expenses, connecting or disconnecting charges or any losses resulting from a

defect of the machine.

For full warranty details, visit our website www.follettice.com/productwarranties.

Warranty registration and equipment evaluation is important to help us keep track of our equipment and to record the machine’s performance.

We request that you register Follett equipment warranties on our website www.follettice.com/support and choose Warranty Registration and

Equipment Evaluation. It’s simple to do; please take a moment to register today. There is also space on the form to provide us with comments

and feedback. Please let us know about your experience so we can capture it for our continuous improvement efforts.

We pride ourselves on producing outstanding equipment and we work hard to back it up with outstanding customer and technical support.

Please let us know what else we can do to assist you. We would be happy to answer your questions.

Horizon, Harmony, Ice Manager, SafeCLEAN, Sani-Sponge and Vision are trademarks of Follett LLC.

Chewblet, RIDE and Follett are registered trademarks of Follett LLC, registered in the US.

801 Church Lane • Easton, PA 18040, USA

Toll free (877) 612-5086 • +1 (610) 252-7301

www.follettice.com

01096106R05

© Follett LLC 5/20

Loading...

Loading...