Follett HCC1000AMS Installation Manual

Ice Manager™ Diverter Valve System

HCC1000AMS, HCC1400AMS, HCC1000WMS, HCC1400WMS,

HCD/HCF1000RMS, HCD/HCF1400RMS, HCD/HCF1650RMS,

HCD1000NMS, HCD1400NMS, HCD1650NMS

(See model number con gurator on page 2 for details.)

Order parts online

www.follettice.com

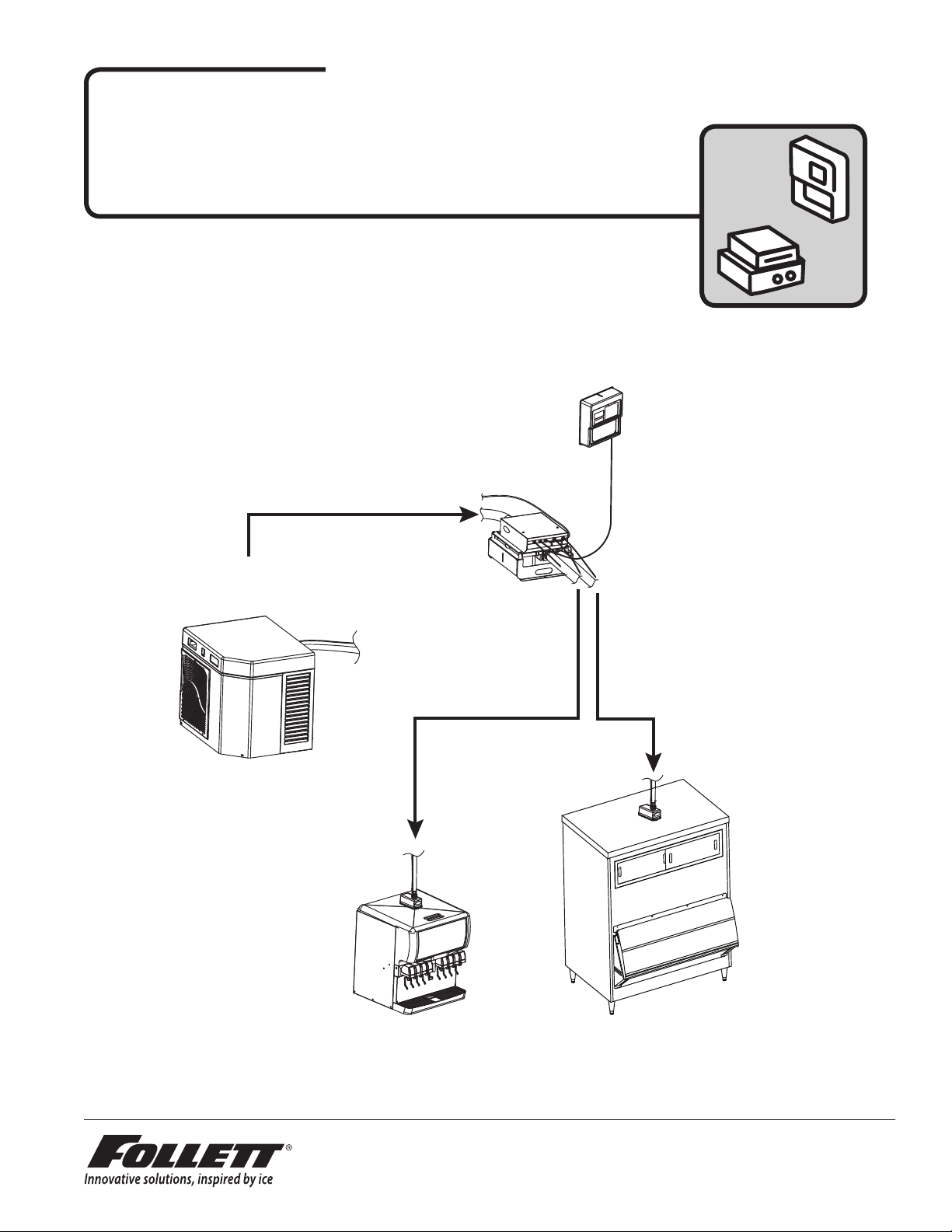

Ice Manager

Diverter Valve

Installation Instructions

Ice Manager

Control Panel

(1) Horizon

Chewblet® Ice Machine

(purchased separately)

™

(2) ice storage units

(purchased separately)

Any combination of bins or dispensers

Lane 2

Lane 1

801 Church Lane • Easton, PA 18040, USA

Toll free (877) 612-5086 • +1 (610) 252-7301

www.follettice.com

00169045R09

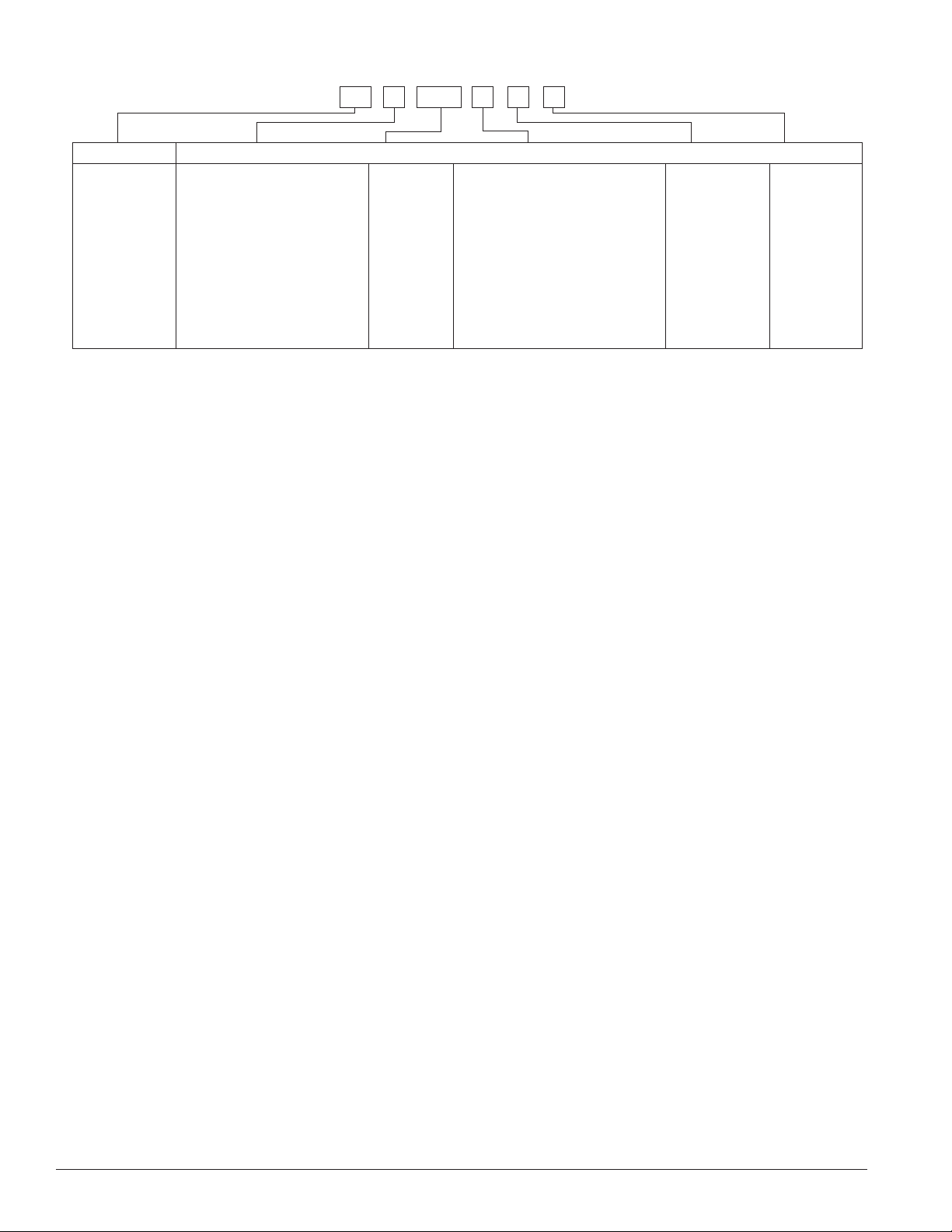

Chewblet® Ice Machine Model Number Configurations

A V SC 1000HC

Icemaker Voltage Series Condenser

MC Maestro

Chewblet

(400 Series)

HC Horizon

Chewblet

(1000, 1400,

1650 Series)

HM Horizon

Micro

Chewblet

C 208-230/60/1 (icemaking head)

Self-contained only.

D 115/60/1 (icemaking head)

Self-contained and remote.

If remote unit, high side is

208-230/60/1.

E 230/50/1 (icemaking head)

Self-contained only.

F 115/60/1 (icemaking head)

Remote only. High side is

208-230/60/3.

400 up to

454 lbs

(206kg)

1000 up to

1036 lbs

(471kg)

1400 up to

1450 lbs

(658kg)

1650 up to

1580 lbs

(717kg)

A Air-cooled, self-contained

W Water-cooled, self-contained

R Air-cooled, remote condensing unit

N Air-cooled, no condensing unit for

connection to parallel rack system

Application Configuration

V Vision™

H Harmony™

B Ice storage

bin

J Drop-in

M Ice Manager™

diverter valve

system

S RIDE™

(RIDE remote

ice delivery

equipment)

T Top-mount

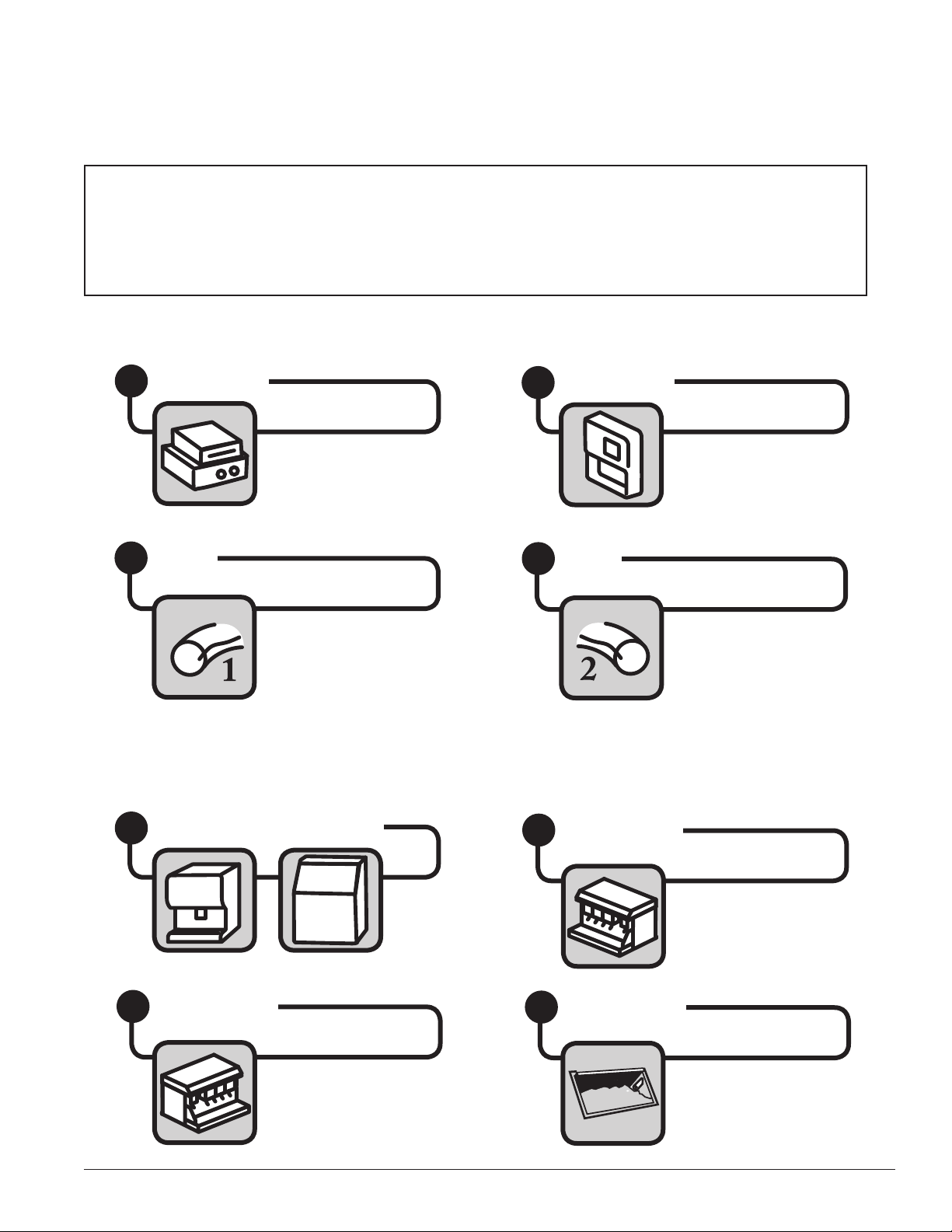

Special tools required

3.50" (88.9mm) hole saw: Required for ice and beverage dispensers manufactured by others or existing bins

2.50" (63.5mm) hole saw: Required for drop-in dispensers

1.75" (44.5mm) hole saw: Required for drop-in dispensers

2 Ice Manager Diverter Valve System Installation Instructions

300

155

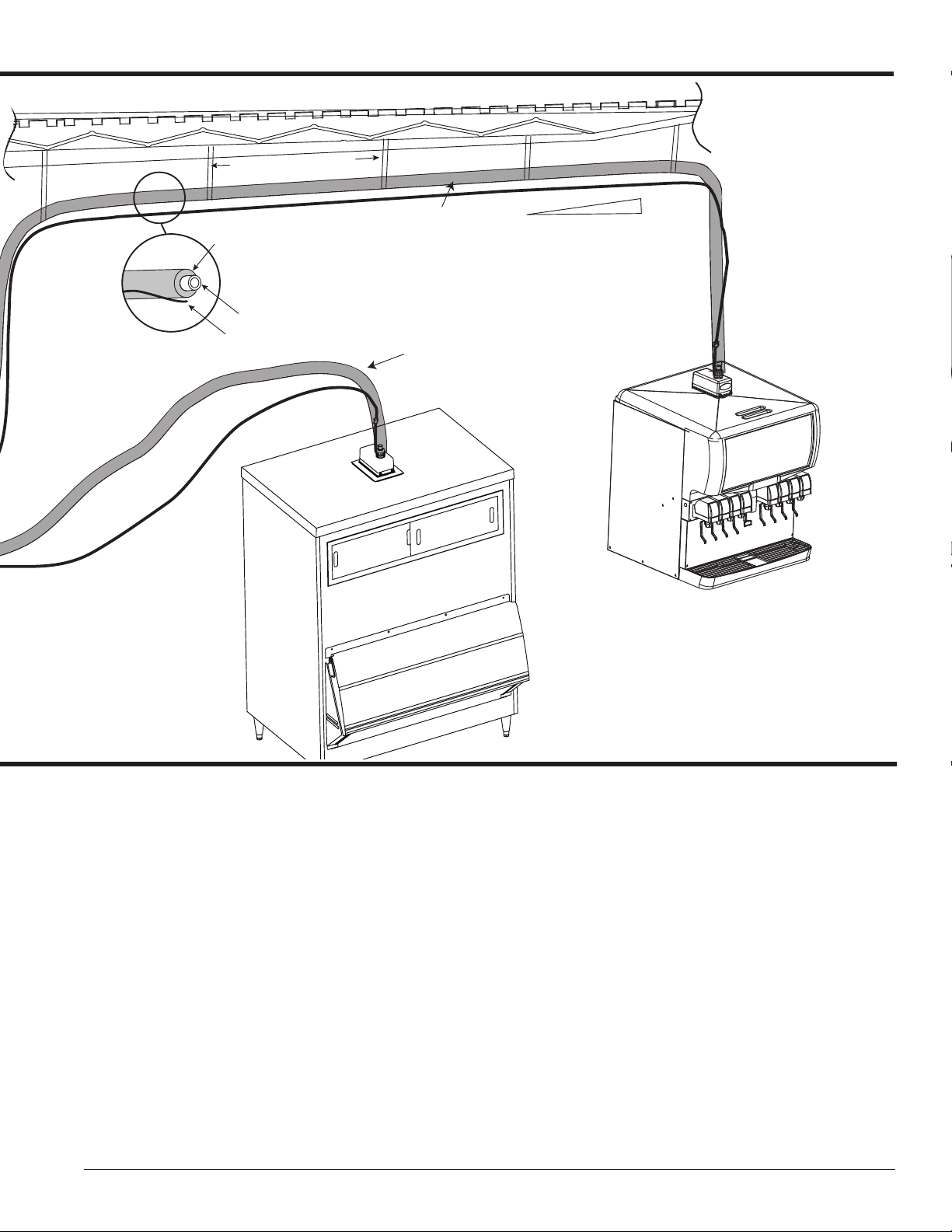

Ice Manager diverter valve system

The Ice Manager diverter valve system delivers ice to two ice storage units enabling a single ice

machine to meet demand for ice at two locations. The system’s sensors monitor ice levels in each

storage unit and automatically switch ice delivery to the appropriate location.

Carefully review system overview (pages 4 & 5) and be sure that you have a copy

of the Follett approved site survey before proceeding with installation steps.

After thorough review of the site survey, install Horizon ice machine and

dispenser/bin(s) using the installation guide provided with each unit.

Read and complete installation sections 1 through 4.

Diverter valve

1

Lane 1

3

ice transport tube & sensor cable

sections below that apply to your speci c application.

Ice & beverage dispenser/bin

5

Control panel

2

Lane 2

4

ice transport tube & sensor cable

Read and complete installation

Vision™ VU155

6

ice & beverage dispenser

Vision™ VU300

7

ice & beverage dispenser

Ice Manager Diverter Valve System Installation Instructions 3

Ice level

8

set points

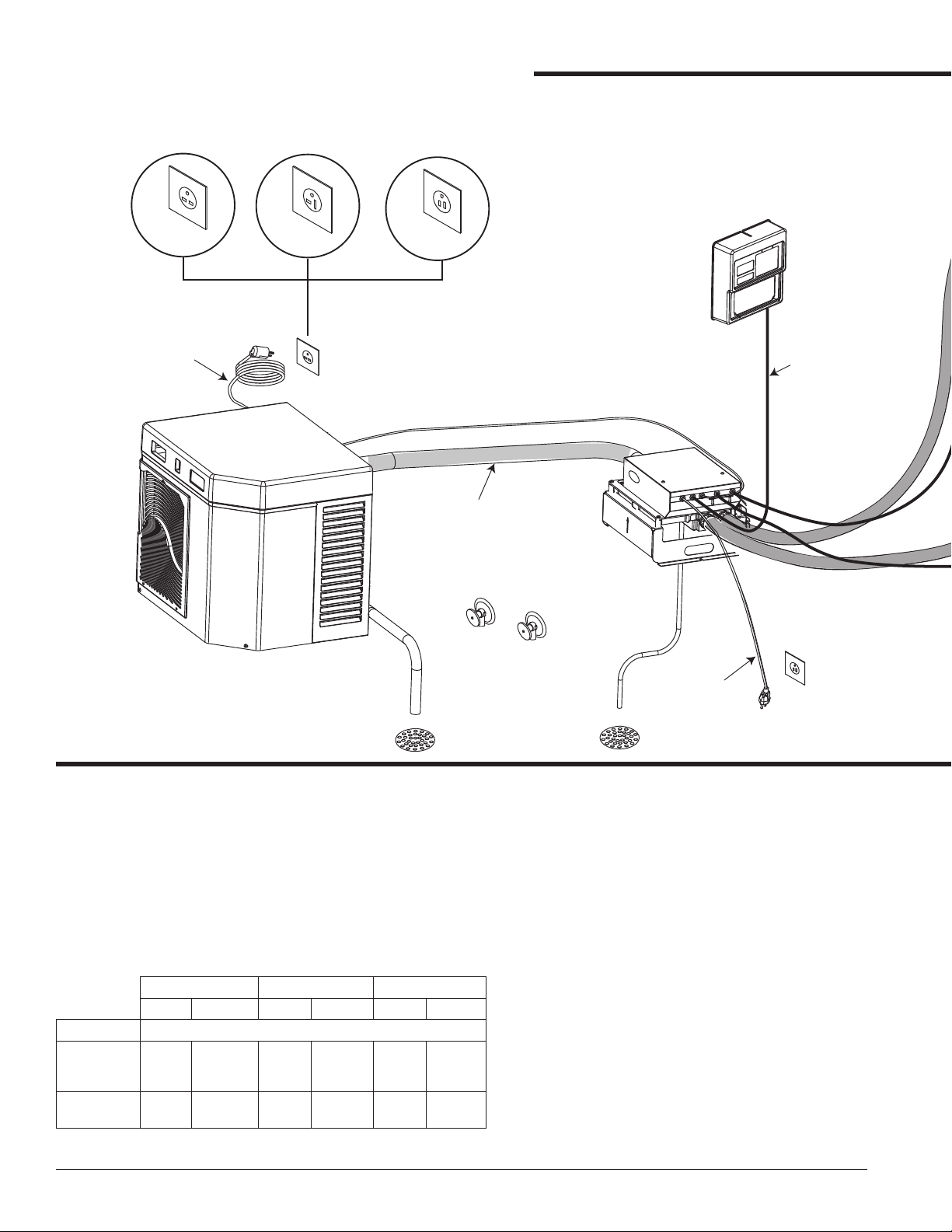

Ice Manager - Site preparation and system overview

1000N/R

1000A/W

1400A/W

1400N/R

1650N/R

CONTROL

PANEL

NEMA

6-15

6' (1.8m)

cord

NEMA

6-20

➊

NEMA

5-15

max. length of 10' (3m)

of cable and transport tube between

ice machine and diverter valve

➌

➍

DIVERTER

VALVE

max. length of 30' (9m)

of cable between

diverter valve

and operator

control panel

➋

ICE MACHINE

Electrical - ice machine ➊

• 1000 (A/W) 208-230/60/1, 11A, max. ice machine fuse 15A

• 1400 (A/W) 208-230/60/1, -5%/+10% under peak load. 16A,

max. ice machine fuse 20A

• 1000 (R/N)

Evap. 110/60/1, 6A; max. ice machine fuse 15A

• 1400 (R/N)

Evap. 115/60/1, 6A; max. fuse 15A

• 1650 (R/N)

Evap. 115/60/1, 6A; max. fuse 15A

Condenser (R models only)

1000R 1400R 1650R

Single 3-Phase Single 3-Phase Single 3-Phase

Electrical 208-230V, 60 Hz

Max Circuit

HVACR

Breaker Size

Min Circuit

Ampacity

15A 15A 30A 25A 50A 35A

10.7A 9.9A 20.0A 14.0A 29.9A 21.2A

8' (2.4m)

cord

NEMA

5-15

Electrical - Ice Manager ➋

• 115/60/1, 1.5 amps; max. fuse 15 amps

Drains

• Ice machine - 3/4" MPT - 3/4" FPT X SOC,

elbow provided, no vent required

• Ice Manager - 3/8" (9.5mm) barb - 15 ft. (4.6m)

3/8"(9.5mm) I.D. tubing provided

Potable water supply - ice machine ➌

• 10 - 70 psi (69 - 483kpa)

• 45 F to 90 F (7 C to 32 C)

• Follett recommends the use of an in-line water

lter (item# 00130286)

Condenser water supply for water-cooled

systems

• 10 psi min.; 150 psi max. (69kpa min.; 1034kpa

max.)

• 45 F to 90 F (7 C to 32 C)

• 1.5 gallons per minute (5.68 liters per minute)

➍

4 Ice Manager Diverter Valve System Installation Instructions

max. length of 2' (.6m)

between supports

➏

insulation

ice transport tube

sensor cable

max. length of 75' (23m)

of cable and transport tube between

diverter valve and ice storage unit

max. length of 75' (23m)

of cable and transport tube between

diverter valve and ice storage unit

1/4˝

1'

➎

Temperature and humidity requirements

• All components, including ice transport tube, must be

operated in ambient temperatures between 40 F and

20 F (5 C and 49 C)

• Relative humidity not to exceed 55%

Ice transport tube requirements

• Maximum vertical rise of 10' (3m) from ice machine to

highest elevation of tube

• Use one continuous piece of ice transport tube. Do not

splice.

• Horizontal run should be pitched so that melt water

drains back to diverter valve. Ice transport tube run

must have at least 1/4" per foot pitch (6.4mm/0.3m)

• Secure ice transport tube as needed to eliminate dips

and traps

➎

Ice transport tube and cable distance

requirements

• Ice machine to diverter valve - maximum run of

10' (3m)

• Diverter valve to operator control panel - maximum

run of 30' (9m)

• Diverter valve to ice receptacle - maximum run of

75' (23m)

• Distance between ice transport tube supports maximum of 2' (0.6m)

Operating temperature requirements

• Ice Manager diverter valve system components,

including ice transport tube must be operated in

ambient temperatures between 40 F and 120 F

(4.5 C and 49 C)

• Insulate all ice transport tube runs, making sure that

sensor cable runs outside of the insulation

➏

Ice Manager Diverter Valve System Installation Instructions 5

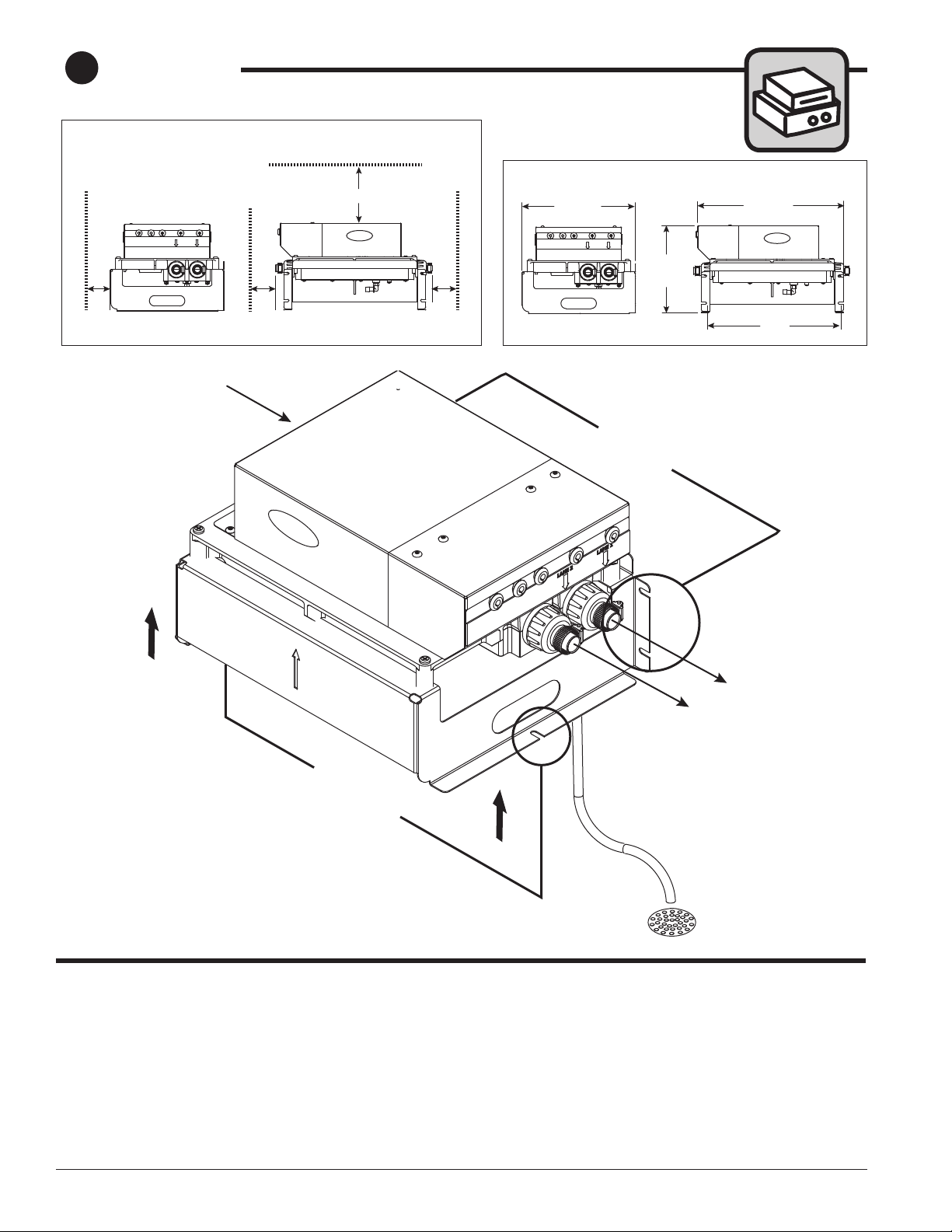

1

Diverter valve

Diverter Valve Required Clearances

LANE 2

LANE 1

6"

clearance

6"

clearance

ice “in”

from ice machine

➊

12" clearance

6"

clearance

Diverter Valve Dimensions

13.625"

346mm

LANE 2

LANE 1

10.375"

264mm

wall mount

(4 screws)

➌

17.468"

444mm

16"

407mm

➍

UP

floor mount

(2 screws)

➋

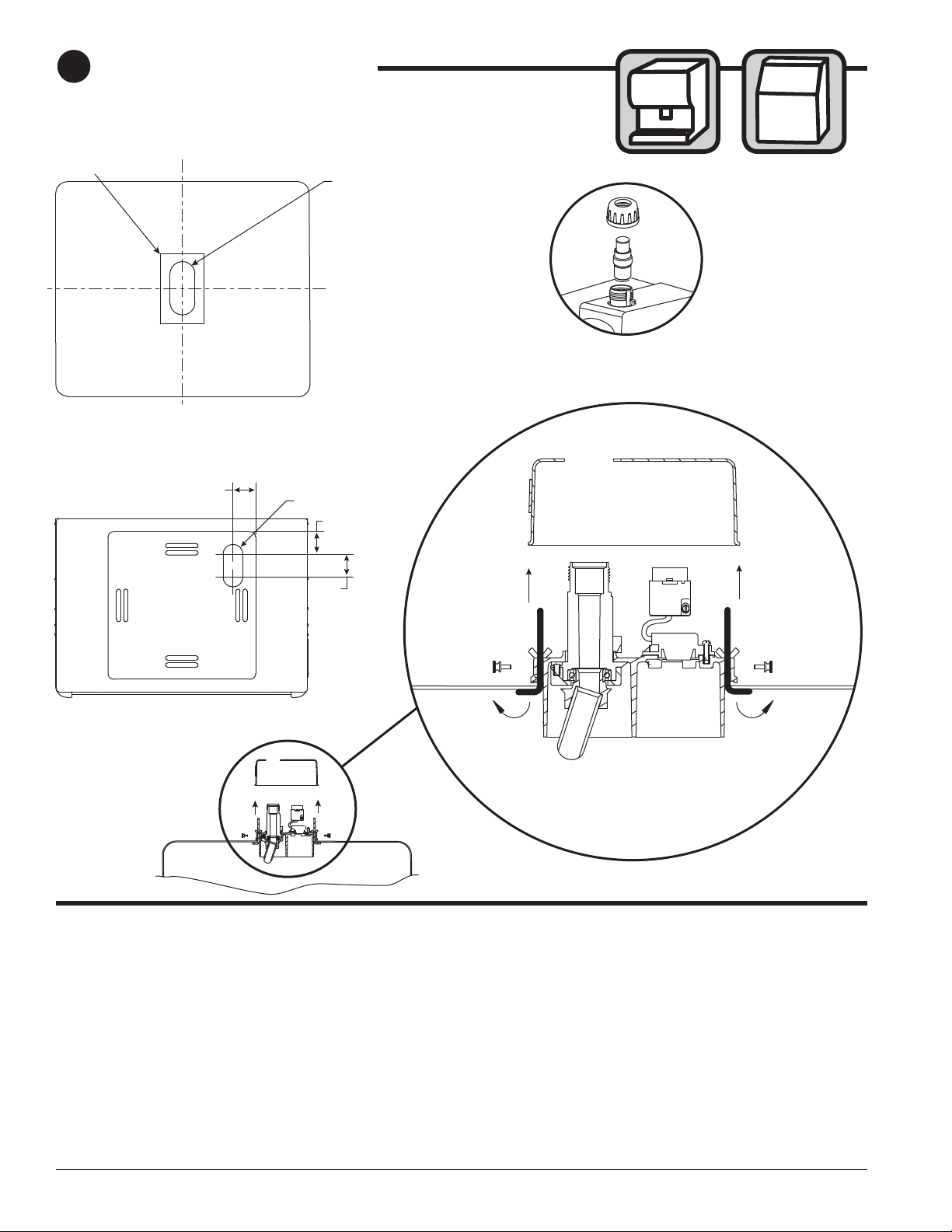

Mount diverter valve

• Minimum side clearances of 6" (153mm) required ➊

• Minimum top clearance of 12" (305mm) required

• Diverter valve bracket may be mounted on the oor

or on the wall ➌ using (4) anchors capable of

➋

supporting min. 40 lb (18kg)

• Diverter valve unit MUST face up

➍

➊

ice “out”

Lane 1

ice “out”

➎

Lane 2

➍

UP

drain

• Drain tube connects to tting on underside of

diverter valve

➎

6 Ice Manager Diverter Valve System Installation Instructions

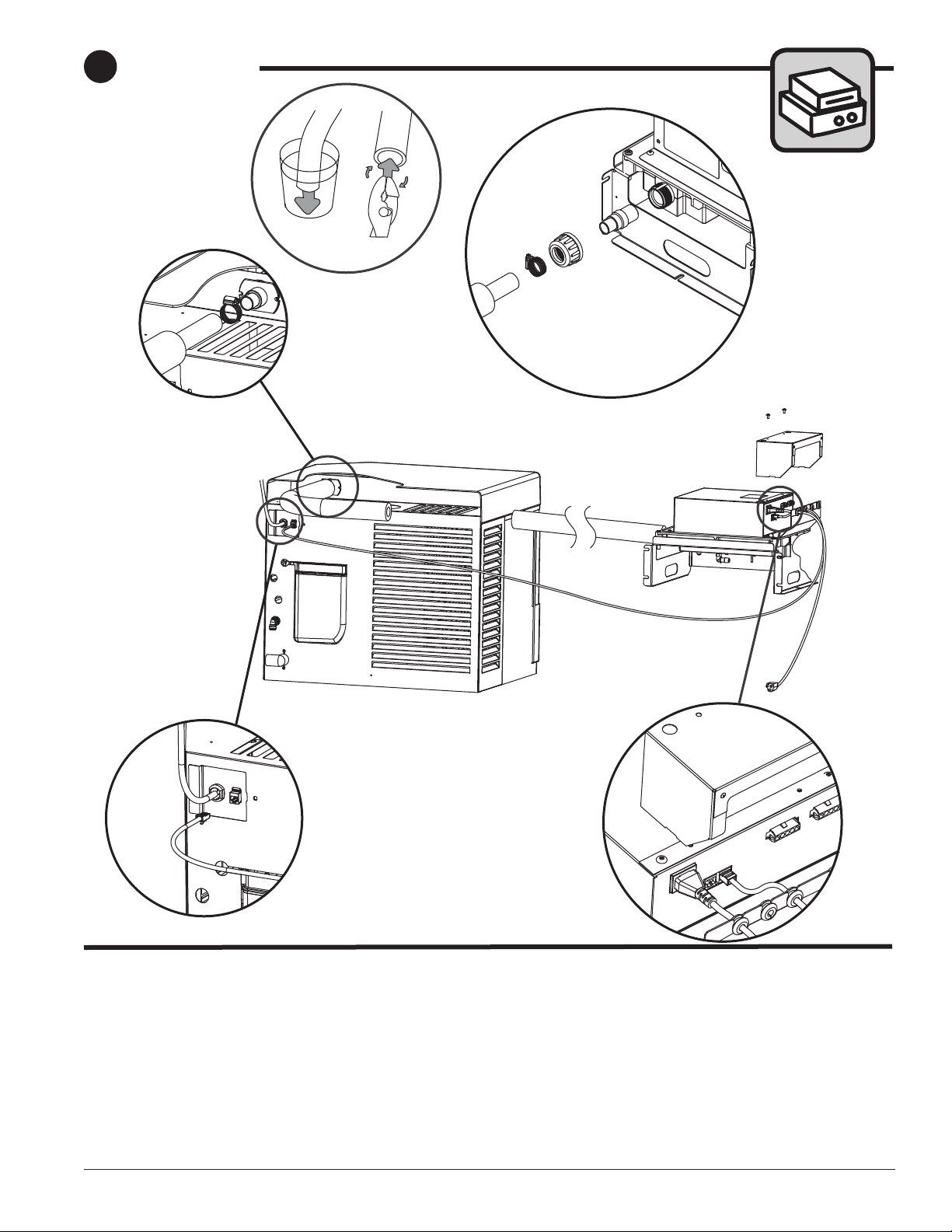

1

Diverter valve

Hot Water

160 F (71 C)

➏

➎

➌

10' (3m) max.

between

diverter valve

and ice machine

10' (3m) ice machine

cable (blue)

➎

➊

8' cord

➋

➍

➍

†

➊

† If Horizon ice machine is an existing unit install

using guidelines in “Site Preparation - Overview” on

➎

pages 4 & 5. Heat end of transport tube in cup of 160F

(71 C) hot water to soften and spread with pliers

before making connection to ease assembly and prevent

stainless coupler edge from cutting inner wall oftube.

Note: Ice transport tube run not to exceed 10' (3m).

applicable retro t kit before completing this portion of

installation (retro t instructions are included with retro t

kit).

➏

Connect diverter valve to ice machine

• Remove connection cover from diverter valve

• Connect blue ice machine cable to diverter valve ➋

Note: Control cable run not to exceed 10' (3m).

• Connect blue ice machine control cable to ice

machine ➌

• Connect power cord to diverter valve

• Run insulated ice transport tube to diverter valve

Ice Manager Diverter Valve System Installation Instructions 7

2

Control panel

30' (9m)

control

panel

cable

(gray)

➊

➎

wall mount

(2 screws)

➌

➋

➍

Mount control panel

• Remove cover from control panel

• Mount panel to wall ➋ using wall anchors if needed

➊

Connect control panel to diverter valve

• Connect gray control panel cable to control panel

• Connect gray control panel cable to diverter valve ➍

Note: Control panel cable run not to exceed 30' (9m).

• Replace control panel cover

➎

➌

8 Ice Manager Diverter Valve System Installation Instructions

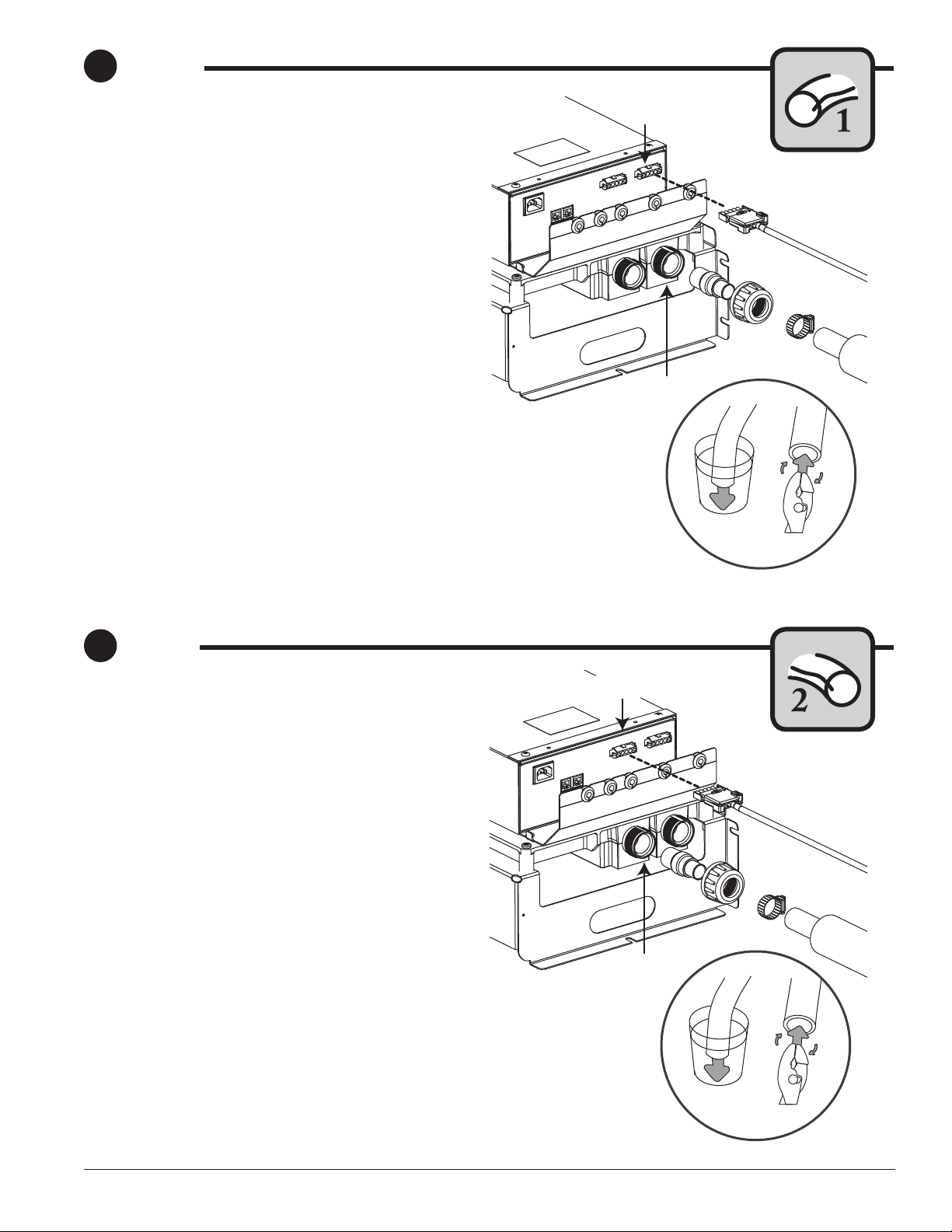

3

Lane 1

Ice transport tube and sensor cable

• Use the site survey to identify lane 1 dispenser

or bin

• Measure ice transport tube run and sensor cable run

from lane 1 dispenser/bin to diverter valve

• Verify that run lengths comply with requirements on

pages 4 & 5

• Insulate ice transport tube

• Secure insulated ice transport tube and sensor cable

as needed from dispenser/bin to diverter valve, being

certain to prevent dips and traps from forming.

See guidelines on pages 4 & 5.

• Pitch tube at least 1/4" per foot (6.4mm/0.3m). Tube

must drain towards diverter valve.

• Connect lane 1 sensor cable

transport tube ➋ to diverter valve

• Heat end of transport tube in cup of 160F (71 C)

hot water to soften and spread with pliers ➌ before

making connection to ease assembly

• Visually inspect inside of plastic coupling for burrs

and remove as needed

• Hand-tighten cap nut on the coupling at diverter

valve

and insulated ice

➊

LANE 1

LANE 1

Hot Water

160 F (71 C)

➊

➋

➌

4

Lane 2

Ice transport tube and sensor cable

• Use the site survey to identify lane 2 dispenser

or bin

• Measure ice transport tube run and sensor cable run

from lane 2 dispenser/bin to diverter valve

• Verify that run lengths comply with requirements on

pages 4 & 5

• Insulate ice transport tube

• Secure insulated ice transport tube and sensor cable

as needed from dispenser/bin to diverter valve, being

certain to prevent dips and traps from forming

• Pitch tube at least 1/4" per foot (6.4mm/0.3m). Tube

must drain towards diverter valve.

• Connect lane 2 sensor cable ➊ and insulated ice

transport tube ➋ to diverter valve

• Heat end of transport tube in cup of 160F (71 C)

hot water to soften and spread with pliers ➌ before

making connection to ease assembly

• Visually inspect inside of plastic coupling for burrs

and remove as needed

• Hand-tighten cap nut on the coupling at diverter

valve

LANE 2

LANE 2

➋

Hot Water

160 F (71 C)

➊

➌

Ice Manager Diverter Valve System Installation Instructions 9

5

Ice & beverage dispenser/bin

All other dispensers

C

template

L

front of dispenser or bin top

ED300 dispenser only

(102mm)

➊

4"

3-1/2"

(88.9mm) dia.

C

L

R1 3/4" (19mm)

4"

(102mm)

➋

4"

front of dispenser or bin top

front of

dispenser

or bin top

➍

(102mm)

➍

dispenser

or bin top

Prepare ice & beverage dispenser/bin top

• Locate center of ice & beverage dispenser (IBD)

top (all models except ED300)

• Using supplied template and 3.5" dia. hole saw, cut

top to template

Note: See drawing above for ED300 dispenser top

cut out.

➊

➌

front of

➌

back of

dispenser

or bin top

➎➎

Mount sensor distribution unit

• Unscrew cap nut and remove center assembly

• Loosen screws and remove cover

• Turn short arm of angle rods so unit can be lowered

into hole of IBD top

• Position unit into IBD top with tube at the front

• Turn angle rods to face outward

• Tighten wing nuts until arms of both rods press rmly

against underside of IBD top securing body of sensor

distribution unit

➌

➎

➋

➍

10 Ice Manager Diverter Valve System Installation Instructions

Loading...

Loading...