Follett FZR5PL Service Manual

FZR Series

-30 C Undercounter Plasma Freezer

Order parts online

www.follettice.com

Installation, Operation and Service Manual

Serial numbers C83253 and above

Serial numbers below C83253 equipped with evaporator defrost heater retrot kit

Following installation, please forward this manual

to the appropriate operations person.

801 Church Lane • Easton, PA 18040, USA

Toll free (800) 523-9361 • (610) 252-7301

Fax (610) 250-0696 • www.follettice.com

00939132R00

Contents

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Series specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Electrical specications . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Refrigeration specications . . . . . . . . . . . . . . . . . . . . . . . 3

Installation specications . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installing legs – required . . . . . . . . . . . . . . . . . . . . . . . . . 4

Temperature surveillance module . . . . . . . . . . . . . . . . . . 4

Automated medication dispensing

and inventory systems interface. . . . . . . . . . . . . . . . . . . . 4

Reversing the door swing – optional . . . . . . . . . . . . . . . . 5

Controller operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

To display temperature cut-out. . . . . . . . . . . . . . . . . . . . . 6

To change temperature cut-out . . . . . . . . . . . . . . . . . . . . 6

Controller security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

To lock the controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

To unlock the controller . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Controller programming key - “hot key” . . . . . . . . . . . . . . 7

Programming freezer from a controller

programming key - “hot key” (download) . . . . . . . . . . . . . 7

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Temperature control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Defrosting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Interior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Exterior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Annual Cleaning and Inspection . . . . . . . . . . . . . . . . . . . 9

Removing drawers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Removing slides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Latch adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Door gasket replacement . . . . . . . . . . . . . . . . . . . . . . . . .10

Slide-out compressor tray . . . . . . . . . . . . . . . . . . . . . . . .10

Controller replacement . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Wiring diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Refrigeration system . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Checking refrigeration system pressures . . . . . . . . . . . . .12

Discharge and suction pressure table . . . . . . . . . . . . . . .12

Refrigeration system diagram . . . . . . . . . . . . . . . . . . . . .12

Freezer troubleshooting guide . . . . . . . . . . . . . . . . . . . . .13

Accessory Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Temperature surveillance module accessory . . . . . . . . .14

Temperature alarm accessory . . . . . . . . . . . . . . . . . . . . .14

Pedestal base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Stacking kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Replacement parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Evaporator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Condensing unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Hardware & electrical components . . . . . . . . . . . . . . . . .18

Follett Corporation Equipment Return Policy

Follett equipment may be returned for credit under the following conditions:

1. The equipment is new and unused.

2. A return authorization number has been issued by customer service within 30 days after shipment.

3. Follett receives the equipment at the factory in Easton, PA within 30 days after issuance of the return authorization number.

4. The equipment must be returned in Follett packaging. If the packaging has been damaged or discarded, Follett will forward, at the customer’s expense, new

packaging.

Note: Return freight charges are the responsibility of the customer. If equipment is returned and is damaged because of improper packaging, Follett Corporation

will not be held responsible.

Credit will be issued when: The equipment has been inspected by Follett and deemed suitable to be returned to stock.

Note: A 15% restocking charge will be deducted from the credit. If the cost to return the product to stock exceeds 15%, the actual cost will be deducted.

2 FZR PL Series 00939132R00

Welcome to Follett

Follett equipment enjoys a well-deserved reputation for excellent performance, long-term reliability and outstanding

after-the-sale support. To ensure that this product delivers that same degree of service, we ask that you take a moment

to review this manual before beginning the installation. Should you have any questions or require technical help at any

point, please call our technical service group at (800) 523-9361 or (610) 252-7301.

Before you begin

After uncrating and removing all packing material, inspect the equipment for concealed shipping damage. If damage

is found, notify the shipper immediately and contact Follett Corporation so that we can help in the ling of a claim, if

necessary.

Check your paperwork to determine which item number you have. Follett item numbers are designed to provide

information about the type of freezer you are receiving. Following is an explanation of the different item numbers.

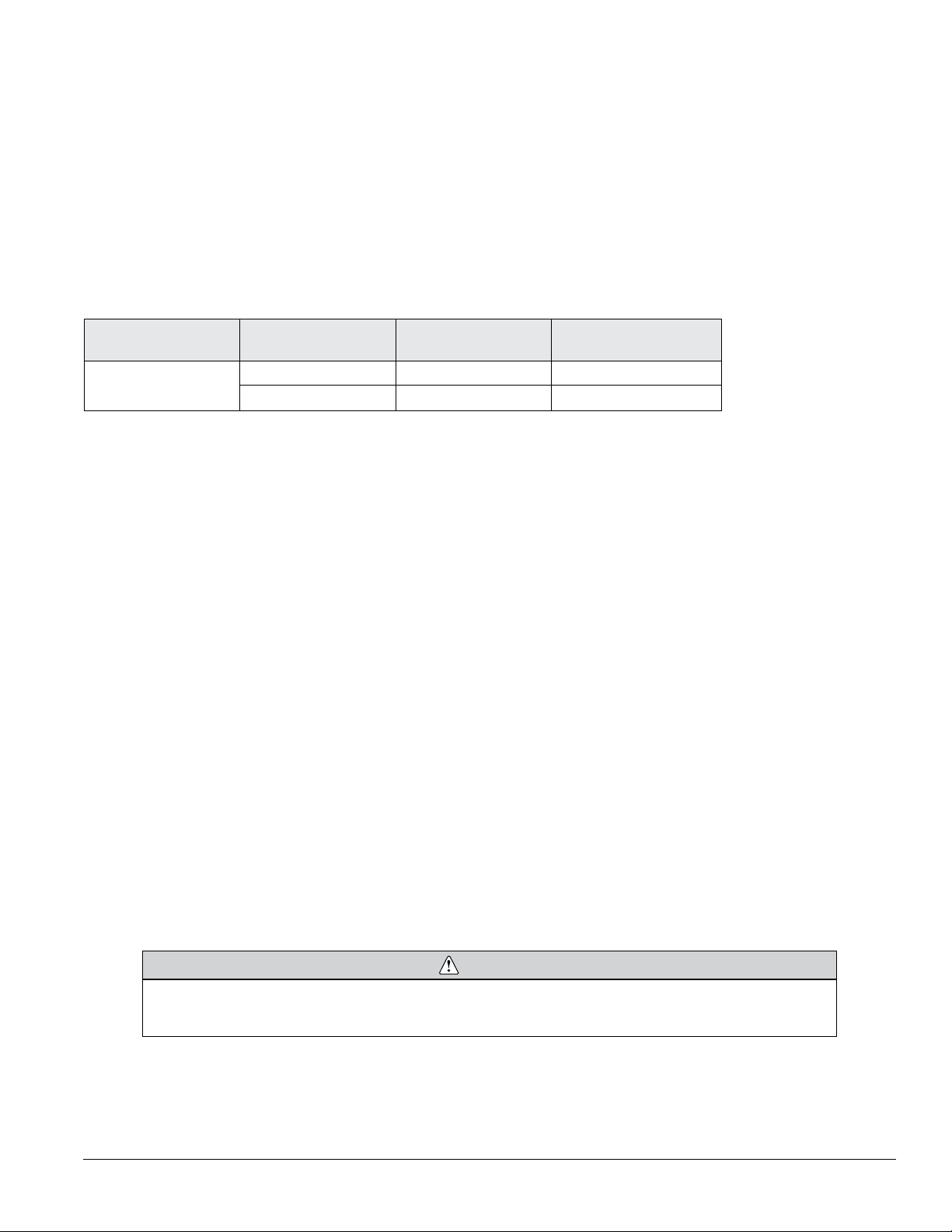

Model Number Item Number Stackable/Use with

Pedestal

FZR5PL FZR5PL-00STCR X X

FZR5PL-00ST00 X

Temperature

Surviellance Module

Specications

Series specications

FZR5-PL

34" (864mm) height ts below standard 36" (915mm) high counter

2 drawers - up to 40 (350ml) plasma cartons

Maximum drawer load - 35 lbs (16kg) each

Electrical specications

115V, 60Hz, 1 phase

Full load amps: 8.0

Minimum circuit ampacity: 15 amp

Maximum size of branch circuit overcurrent device: 15 amp

Refrigeration specications

Refrigerant – R404A

Charge size – 10 oz

Maximum design pressures: High side – 383 psi; Low side – 175 psi

Installation specications

Ambient temperature must not exceed 86 F (30 C). Relative humidity 60%.

The front louvered panel must be kept free of any cabinet trim or obstructions to ensure proper ventilation of the

refrigeration system.

CAUTION

• Equipment must be wired according to local NEC codes.

• Unplug equipment before servicing.

• Be sure to nd adequate storage for products prior to unplugging equipment.

FZR PL Series 00939132R00 Specications 3

Installation

Installing legs – required

Fig. 1

1. Remove legs from plastic bag packed inside freezer.

2. Tip freezer back and screw legs in all the way to stop (they will extend 1/8"

(3.175mm) below base of freezer).

3. Adjust legs as needed to level freezer in both directions. To access legs,

remove the lower front panel. Turn legs clockwise to extend legs.

Temperature surveillance module

Follett’s all-in-one temperature alarm and chart recording module (manufactured for Follett by Dickson) may be

included with your FZR5-PL. Please refer to the instructions packed with this module for set-up and operation

instructions.

A quick set-up guide has also been included (form# 00168609). This instruction sheet is also available in the

download section of the Follett website (www.follettice.com).

If equipped with temperature surveillance module, Follett’s monitoring bottle and temperature probe has already been

installed in the Follett FZR5-PL. Simply plug the loose end of the probe wire into the back of the freezer surveillance

module to complete the install.

A box of sixty (6) -50 to +50 7-day charts have also been included with this module. Replacement charts and pens

can be ordered by visiting www.follettice.com and choosing “order parts”.

Item# 00162099 – Box of sixty (60), -50 to +50 7-day replacement charts

Item# 00162081 – Box of six (6) replacement red pens

Charts with different temperature scales are also available directly from Dickson www.dicksondata.com.

Automated medication dispensing and inventory systems interface

(Pyxis*, Omnicell*, MedSelect*, etc.)

Follett refrigerators and freezers are compatible with most major automatic medication and inventory systems.

In some cases a Follett bracket accessory is required. Contact factory for further information.

*

Pyxis is a registered trademark of Cardinal Health in the United States and other countries.

Omnicell is a registered trademark of Omnicell, Inc. in the United States.

MedSelect is a registered trademark of AmerisourceBergen Technology Group, in the United States.

4 Installation FZR PL Series 00939132R00

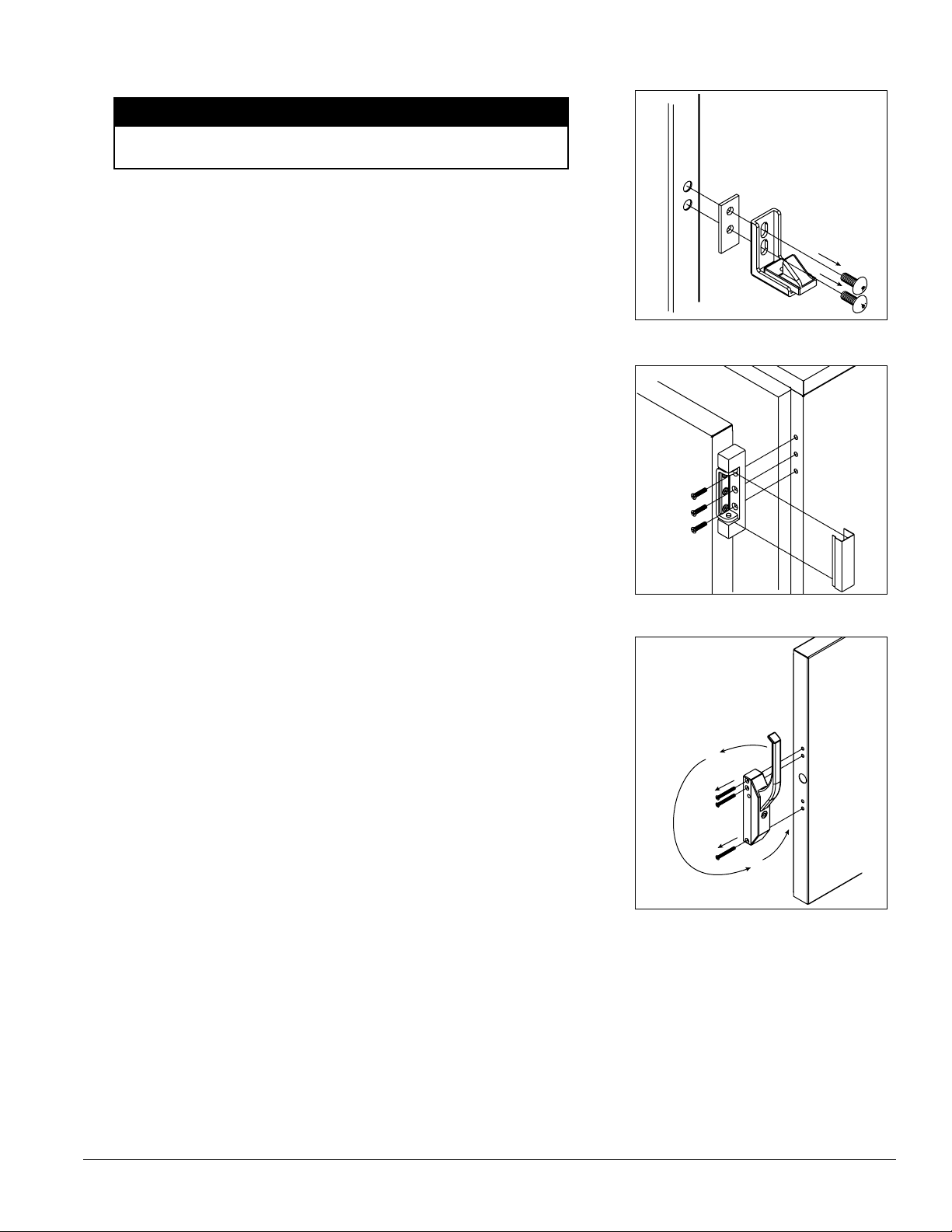

Reversing the door swing – optional

NOTICE

When reinstalling latch and hinge screws, 242 blue Loctite* MUST

be applied to screws. Torque screws to 25 in-lbs.

1. Remove screws and latch from refrigerator cabinet (Fig. 2.1).

2. Use at screwdriver to carefully remove (do not scratch) hinge

covers (Fig. 3.1).

3. Support door and remove screws attaching hinge to refrigerator cabinet

(Fig. 3.2).

4. Cover hinge screw holes with screw hole plugs removed from

opposite side.

5. Reverse door. Apply 242 blue Loctite to hinge screws and reinstall torqued

to 25 in-lbs.

6. Reinstall latch on opposite side.

Fig. 2

1

2

Fig. 3

2

1

7. Remove screws and handle from door (Fig. 4.1).

8. Rotate handle (Fig. 4.2).

9. Apply 242 blue Loctite to latch screws and reinstall torqued to 25 in-lbs.

Fig. 4

1

1

2

* Loctite is a registered trademark of Henkel Corporation in the United States and other countries.

FZR PL Series 00939132R00 Controller operation 5

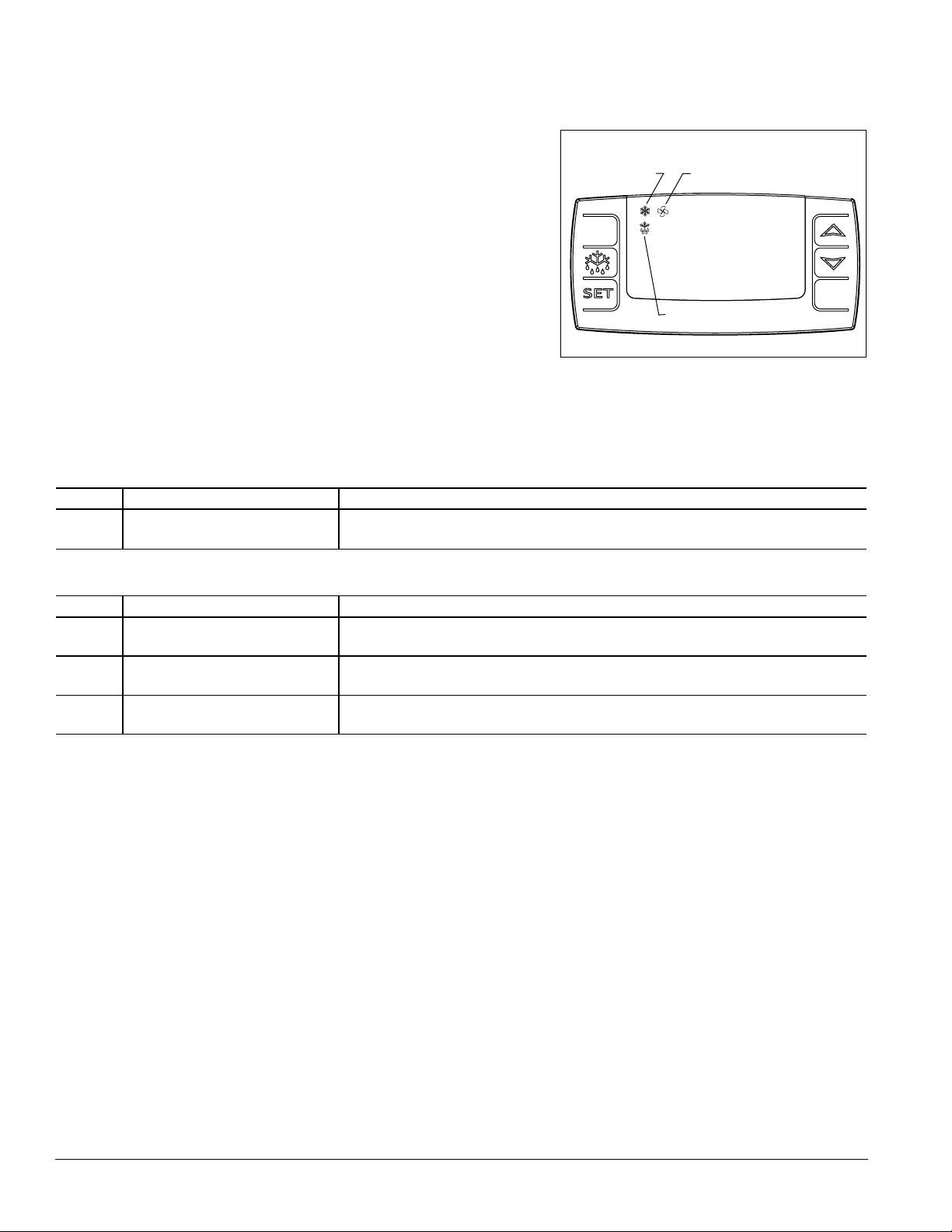

Controller operation

In normal operation the controller displays cabinet temperatures in

degrees C.

The controller is pre-programmed with a -35 C (-31 F) set point

which provides a compressor cut-in at -33 C (-27F) and cut-out at

-35 C (-31 F). The controller set point can be raised to -25 C

(-13 F) when a lower temperature is not desired. Follow instructions for

changing temperature cut-out below.

All set points have a 2 C differential. The 2 C differential means that with

a -35 C set point, for example, the compressor will turn off at -35 C (-31

F) and turn on when the cabinet reaches -33 C (-27 F).

This temperature may not reect the temperature of the blood products

in the freezer. The temperature of the blood products will be reected on

the recorder chart and the recorder’s digital temperature display. At times

there may be a difference between the two displayed temperatures.

Adjust the controller SET value to achieve your desired blood product

temperature as displayed on your chart recorder.

Fig. 7

refrigeration

system

energized

evaporator

fan

energized

- 35

defrost

To display temperature cut-out

STEP INPUT DISPLAY

1 Press and release SET Current cut-out temperature will display for approximately 5 seconds.

Display will return to current refrigerator temperature.

°C

To change temperature cut-out

STEP INPUT DISPLAY

1 Press and hold SET for 3

seconds

2 Press UP or DOWN arrows to

desired cut-out temperature

3 Press and release SET New cut-out temperature blinks three times, then current refrigerator

Current cut-out temperature displayed and °C will ash

New cut-out temperature displayed

temperature will display

6 Controller operation FZR PL Series 00939132R00

Loading...

Loading...