Page 1

Ice Pro™ DB650, EDB650 Automatic

Ice Bagging and Dispensing System

Order parts online

www.follettice.com

Installation, Operation and Service Manual

Following installation, please forward this manual

to the appropriate operations person.

801 Church Lane • Easton, PA 18040, USA

Toll free (800) 523-9361 • (610) 252-7301

Fax (610) 250-0696 • www.follettice.com

220V 60Hz

models only

230V 50Hz

models only

00913509R02

Page 2

Contents

Welcome to Follett. . . . . . . . . . . . . . . . . . . . . 3

Before you begin . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Specications . . . . . . . . . . . . . . . . . . . . . . . . 4

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Plumbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Clearance and access information . . . . . . . . . . . . . 4

Ice type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Icemaker weight limit . . . . . . . . . . . . . . . . . . . . . . . 4

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Container sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Bag pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Dimensions and clearances . . . . . . . . . . . . . . . . . . 5

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Leveling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Utility connections . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Bag pin installation . . . . . . . . . . . . . . . . . . . . . . . . . 7

Foot pedal accessory . . . . . . . . . . . . . . . . . . . . . . . 7

Bag installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Adjusting drain pan . . . . . . . . . . . . . . . . . . . . . . . . . 9

Brush bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Sanitize . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Icemaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Filling other containers . . . . . . . . . . . . . . . . . . . . . .10

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

How the dispenser works . . . . . . . . . . . . . . . . . . . .11

Control functions . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Power switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Cleaning and sanitizing . . . . . . . . . . . . . . . . . . . . 13

DB650 wiring diagram, upper control box . . . . . . 14

DB650 wiring diagram, lower control box . . . . . . . 15

EDB650 wiring diagram, upper control box . . . . . 16

EDB650 wiring diagram, lower control box . . . . . 17

Before calling for service . . . . . . . . . . . . . . . . . . . 18

Replacement parts & accessories . . . . . . 19

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Upper chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Lower chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Lower chassis (cont.) . . . . . . . . . . . . . . . . . . . . . . 22

Dispense auger . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Electrical system, upper box . . . . . . . . . . . . . . . . . 24

Electrical system, lower box . . . . . . . . . . . . . . . . . 25

Follett Corporation

Equipment Return Policy

Follett equipment may be returned for credit under the following conditions:

1. The equipment is new and unused.

2. A return authorization number has been issued by customer service within 30 days after shipment.

3. Follett receives the equipment at the factory in Easton, PA within 30 days after issuance of the return authorization number.

4. The equipment must be returned in Follett packaging. If the packaging has been damaged or discarded, Follett will forward, at the customer’s

expense, new packaging.

Note: Return freight charges are the responsibility of the customer. If equipment is returned and is damaged because of improper packaging,

Follett Corporation will not be held responsible.

Credit will be issued when:

The equipment has been inspected by Follett and deemed suitable to be returned to stock.

Note: A 15% restocking charge will be deducted from the credit. If the cost to return the product to stock exceeds 15%, the actual cost will be

deducted.

2

Page 3

Welcome to Follett

Follett ice dispensers enjoy a well-deserved reputation for excellent performance, long-term reliability and

outstanding after-the-sale support. To ensure that this dispenser performs as intended, we ask that you take

a moment to review this manual before beginning the installation of the dispenser. Should you have any

questions or require technical help at any point, please call our technical service group, (800) 523-9361 or

(610) 252-7301.

Before you begin

After uncrating and removing all packing material, inspect the equipment for concealed shipping damage. If

damage is found, notify the shipper i mmediately and contact Follett Corporation so that we can help in the

ling of a claim, if necessary.

Check your paperwork to determine which model you have. Follett model numbers are designed to provide

information about the type and capacity of Follett ice dispensing equipment. Following is an explanation of the

different model numbers in the Ice Pro series.

DB650SA

SA = Semi-Automatic ice dispensing and bagging

650 – 650 lbs maximum bin capacity

DB – Dispensing bin - 220/60 Hz

EDB – Dispensing bin - 230/50 Hz

Important cautions

!

Storage area of dispenser contains mechanical, moving parts. Keep hands and arms clear of

this area at all times. If access to this area is required, power to unit must be disconnected rst.

Ice is slippery. Maintain counters and oors around dispenser in a clean and ice-free condition.

Ice is food. Follow recommended cleaning instructions to maintain cleanliness of delivered ice.

Should local codes require a hard-wired connection and/or shielded wiring, eliminate the cord(s)

and plug(s) and follow the appropriate wiring diagram.

Dispenser can accommodate most cube or cubelet ice up to 1" square. Crushed, ake, or nugget

ice cannot be used. Use of these ice types can jam dispenser and will void warranty. For

questions about ice compatibility, call Follett’s customer service group toll free at (800) 523-9361

or (610) 252-7301.

Always disconnect power before cleaning or servicing the dispenser.

This appliance is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they are supervised

or provided instruction concerning use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

3

Page 4

Specications

Electrical

DB650 – The Ice Pro DB650 dispenser requires a separate electrical circuit from the icemaker. Equipment

ground required. Standard electrical - 220V, 60Hz, 1 phase, maximum fuse – 5 amps, 15 amp circuit, NEMA

6-15 receptacle. The cord length is approximately 7' from right rear. A plug is provided.

EDB650 – The Ice Pro DB650 dispenser requires a separate electrical circuit from the icemaker.

Equipment ground required. Standard electrical - 230V, 50Hz, 1 phase, maximum fuse – 5 amps, 15 amp circuit,

max power - 3450 watts. The cord length is approximately 7' from right rear. A plug is not provided.

Plumbing

Drain 1" PVC FPT for bin drain – run to oor drain.

Note: Drains should be hard-piped and insulated. Maintain at least 1/4" per foot (1 cm per 48 cm run) slope

on drain line run. Do not tee into icemaker drain line.

Clearance and access information

Door entry

less than 34.5" (877 mm).

Service clearance

Ice type

Dispenser can accommodate most cube/cubelet ice up to 1" square as well as Follett Horizon™ Chewblet® ice.

Crushed, ake, or other manufacturers nugget ice cannot be used. Use of these ice can jam dispenser and will

void warranty. For questions about ice compatibility, call Follett’s technical service group toll free at

(800) 523-9361 or (610) 252-7301.

– Installation sites must have an unobstructed path to installation location with door openings no

– A minimum of 12" (305 mm) to right of unit is necessary for service.

Icemaker weight limit

Icemaker mounted directly on top of bin must not exceed 800 lbs (363 kg).

Environment

Intended for indoor use only - operating temperature range of 40 - 100 F (4 – 38 C). Not suitable for installation

in an area where a water jet could be used. (The dispenser should not be cleaned with a water jet or be

exposed to water jet used to clean surrounding areas) The dispenser has to be placed in a horizontal position.

The dispenser is only to be installed in locations where it can be overseen by trained personnel.

Container sizes

Unit acco mmodates bag sizes up to 20 lbs (9 kg) / 27.35" (695 mm) high.

Dispense chute compatible with carts and containers up to 28" (712 mm) high.

Bag pins

Bag pins may be adjusted to accommodate bag hole centers from 5" (127 mm) to 10" (254 mm).

4

Page 5

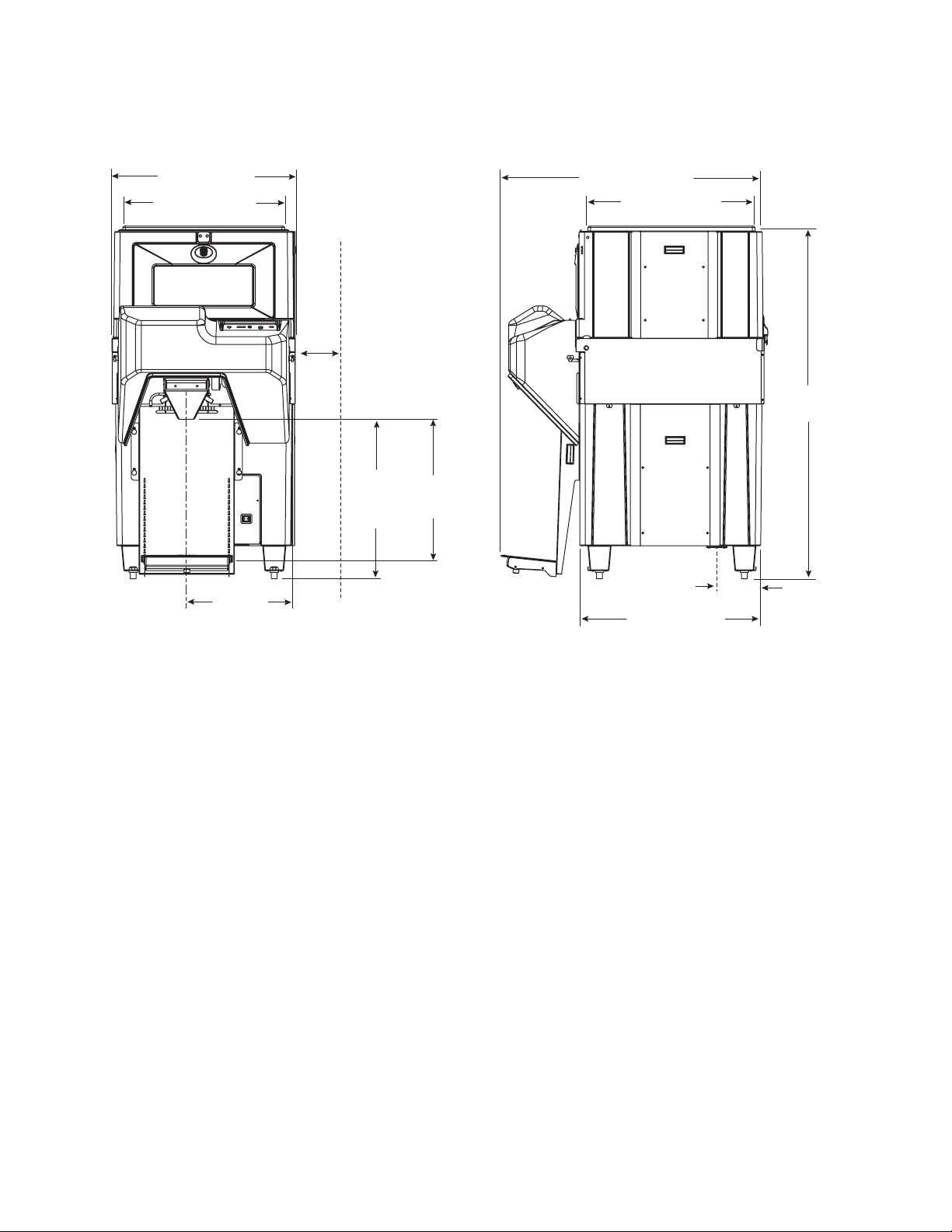

Dimensions and clearances

33.75" (858 mm)

29.75" (756 mm)

Front view

12" (305 mm)

Service

Clearance

28"

(712 mm)

max. cart

26"

(661 mm)

max. bag

48.25" (1226 mm)

30.75" (782 mm)

Side view

65

"

(1651 mm)

19.88"

(505 mm)

1" FPT drain

34.25"

(870 mm)

8.63"

(220 mm)

1" FPT drain

Notes

Follett Horizon icemakers and other icemakers less than 30" wide require a top that adds 2" to standard

unit height.

5

Page 6

Installation

Location

A minimum of 12" (305 mm) to the right of the unit must be available

for service clearance (see dimensions and clearances - page 5).

Allow access to front of unit for bagging operation and dispensing.

Leveling

Leveling the unit is important for the proper operation of any

top mounted icemaker. The dispenser is shipped with the legs in the

fully retracted position. Each leg may be adjusted independently by

turning clockwise to lower the leg or counterclockwise to raise the

leg. Do not remove legs; interference will occur with the bag stand

and dispense chute.

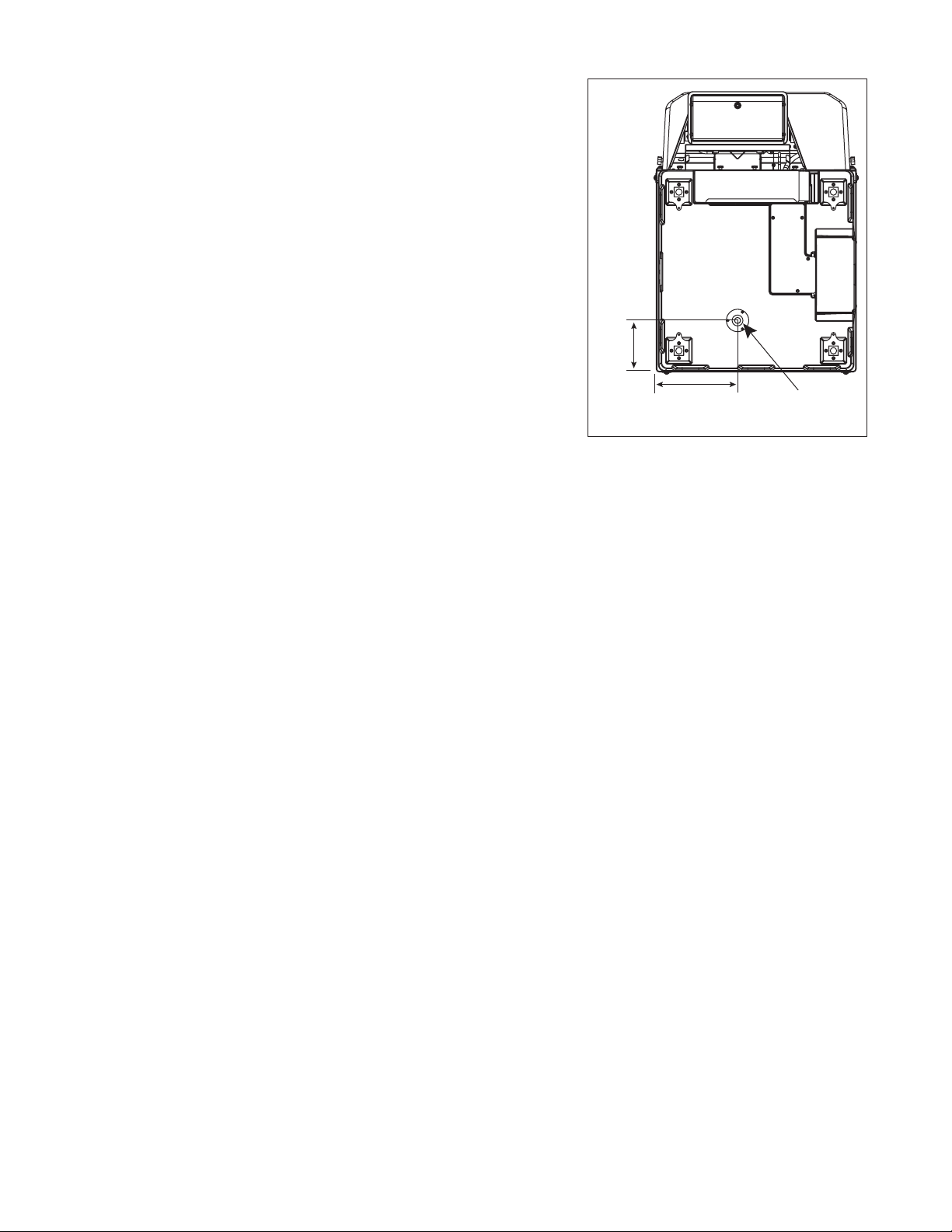

Fig. 1 Bottom view

8.25"

(210 mm)

Utility connections

Bin drain

Drain connection is made to the 1" FPT PVC tting (Fig. 1). Leave a

minimum of 1/4" per foot (1 cm per 46 cm run) slope on drain line run.

Insulate the entire run length to prevent condensation from forming on

outside of drain line.

Note: Avoid excessive tightening force when connecting to this tting.

Note: Do not apply excessive heat if any sweating of ttings is

necessary. Heat conduction through metal may melt threads in

plasticdrain.

Drain pan

The drain pan on the bag stand may be drilled out and plumbed

if desired. Use an 11/16" drill bit, a 3/4" FPT elbow and PVC glue.

Plumb with exible tubing to allow for height adjustment.

Electrical

Electrical connections to be in accordance with local and NEC

codes. Each dispenser and icemaker require separate circuits.

Equipment ground required.

Note: If the supply cord is damaged, it must be replaced by the

manufacturer, its service agent or similarly qualied persons in order to

avoid a safety hazard.

13.5"

(343 mm)

drain

DB650

220V, 60Hz, 1 phase. Max. fuse – 5 amps, 15 amp circuit.

Provide NEMA 6-15 receptacle within 7' of right rear corner. Cord

and plug provided.

EDB650

230V, 50Hz, 1 phase. Max. fuse – 5 amps, 15 amp circuit, max

power - 3450 watts. Provide means of connection within 7' of right

rear corner. Cord provided without plug.

6

Page 7

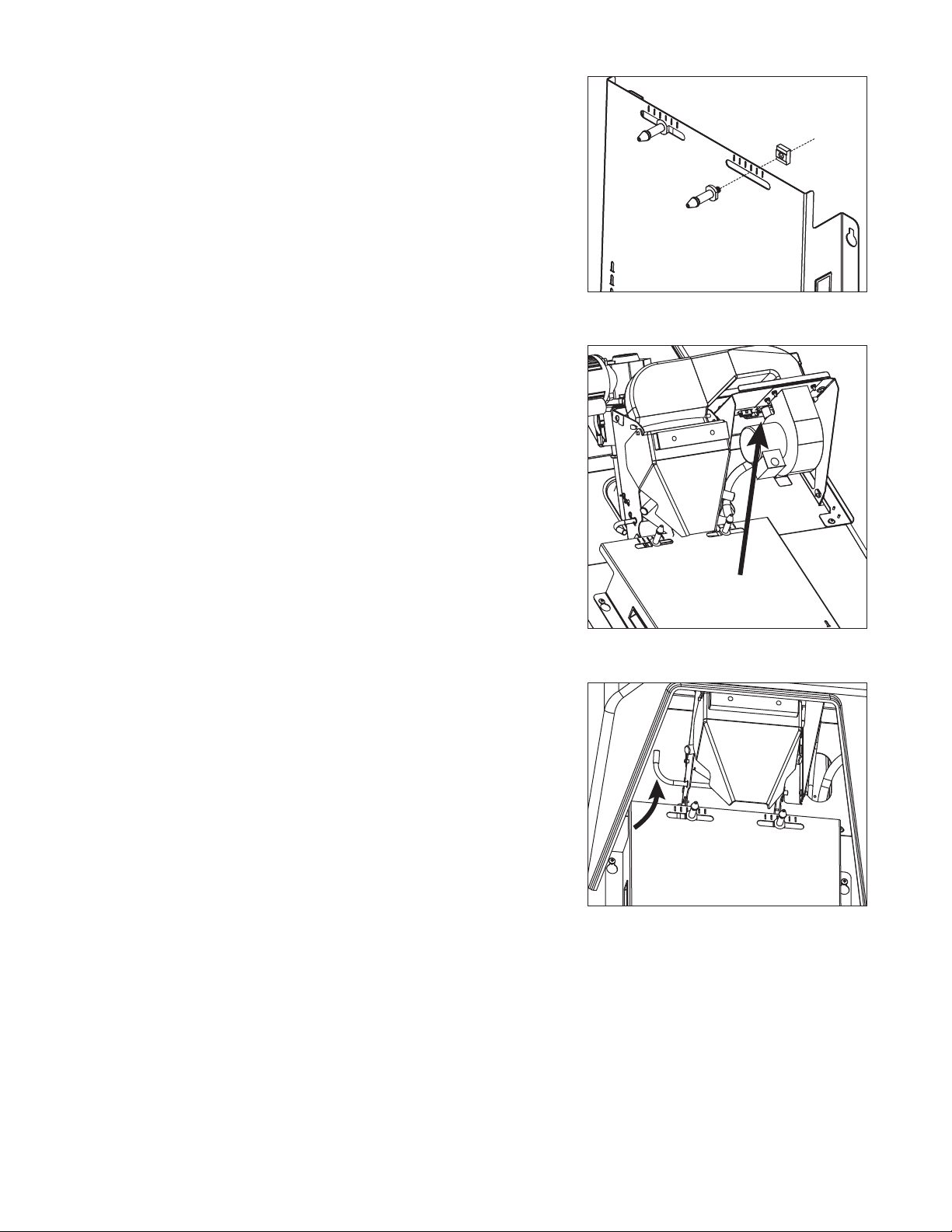

Bag pin installation

1. Position plastic bag pin nuts onto the rear slots of the bag stand

(Fig. 2).

2. Thread in and tighten bag pins.

Fig. 2

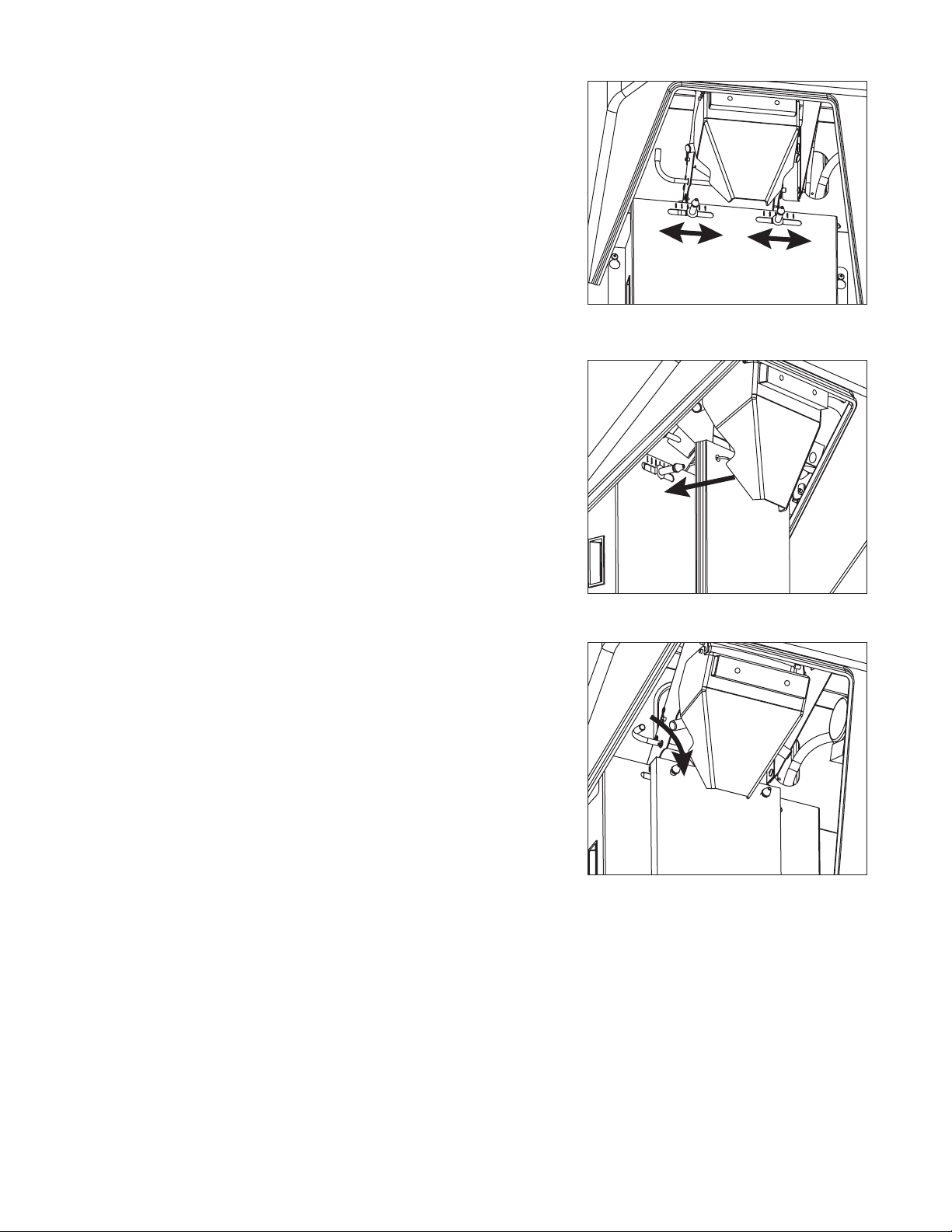

Foot pedal accessory

The optional foot pedal accessory allows dispensing of ice while

keeping your hands free. The pedal is placed on oor near bag

stand in front of the dispenser. It plugs into the 3-pin connector

located just under the control panel behind the blower motor

(Fig.3).

Bag installation

Note: Bag pins are designed to be used with bags mounted on wire

wickets. Do not install more than one wicket of bags at a time.

1. Move chute lever to up position (Fig. 4).

Fig. 3

Fig. 4

7

Page 8

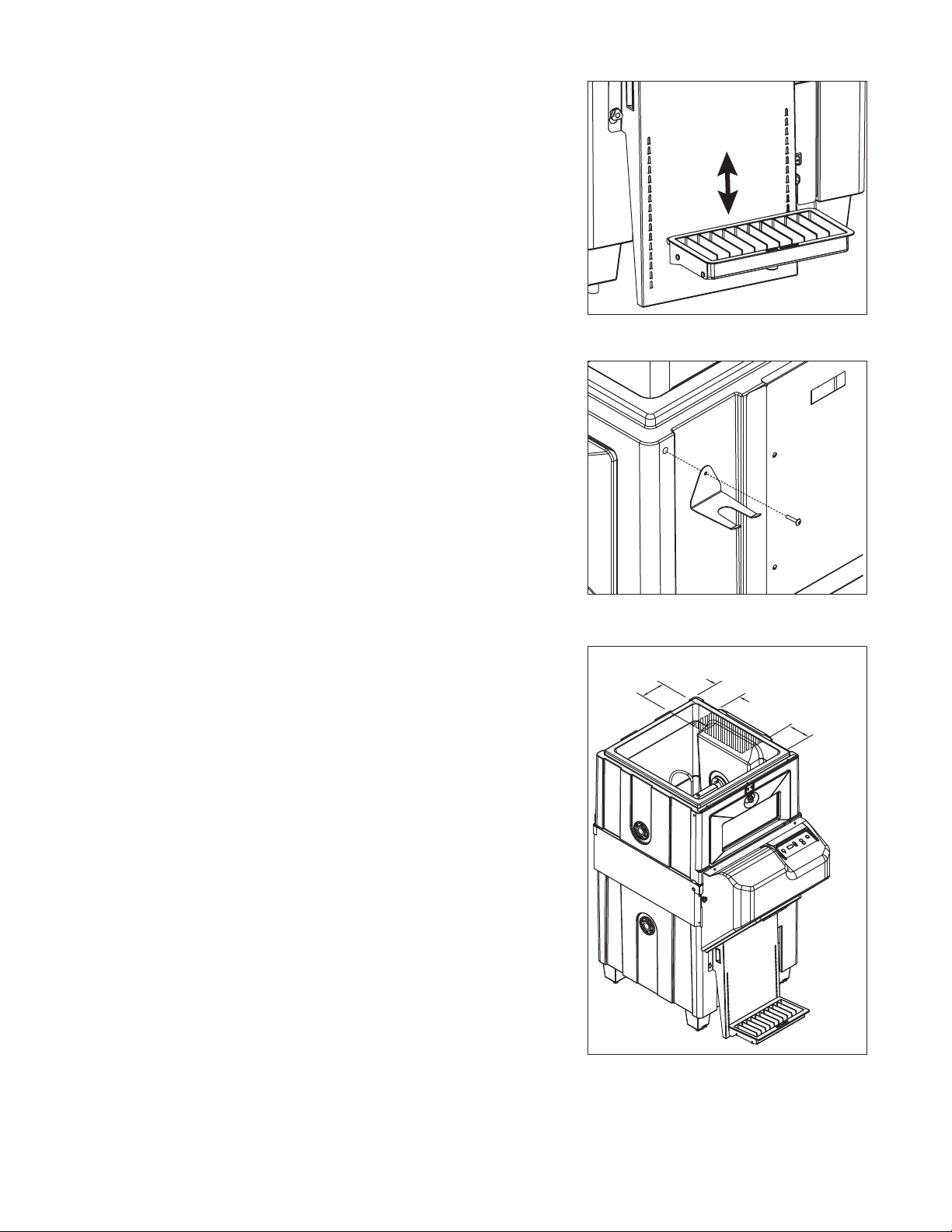

2. Adjust bag pin width to match that of the bag wicket

(Fig. 5). Center bag pins evenly.

Fig. 5

3. Remove rubber keepers from wicket and insert wicket wires

into bag pins. Transfer bags from wicket to bag pins. Slide 15

to 20 bags onto pins at a time until pins are full (Fig. 6).

4. Return chute lever to down position (Fig. 7). The

back of the chute holds bags to prevent more

than one opening at a time.

Fig. 6

Fig. 7

8

Page 9

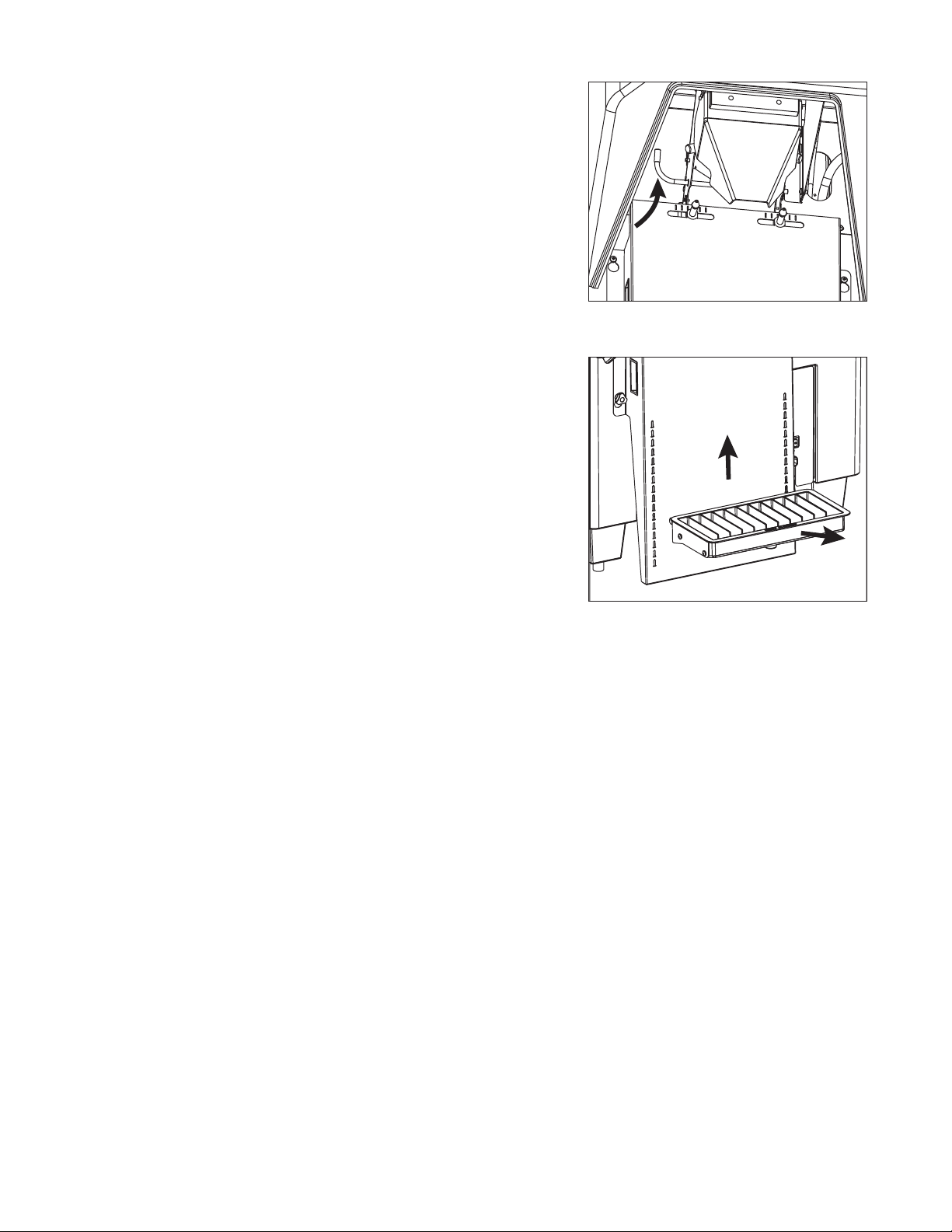

Adjusting drain pan

The drain pan may be raised or lowered to accommodate different

bag sizes and helps to support the bag while lling (Fig. 8). The

bottom of bags should rest on the tray when adjustment is correct.

1. Lift drain pan up and out of receiving slot on bag

stand base.

2. Insert drain pan in and down into desired receiving

slot on bag stand.

3. Marking the drain pan position makes future positioning easier.

Brush bracket

Mount the cleaning brush bracket to the top front left or right side

of the bin in one of the threaded inserts and hang cleaning brush

(Fig. 9).

Sanitize

Follow cleaning and sanitizing instructions before use - see

page13.

Fig. 8

Fig. 9

Icemaker

Follow icemaker manufacturer’s recommendations for installation.

Note: Icemaker mounted on top may not exceed 800 lbs (363kg).

Ensure that the drop zone of the ice does not fall onto the upper

right hand section of the bin (See shaded area in Fig. 10). Ice

falling from ice machine can hit this area of the bin and cause

damage to the icemaker.

Fig. 10

5.0"

(127 mm)

4.5"

(114 mm)

6.0"

(152 mm)

9

Page 10

Filling other containers

1. Ensure blower is off.

2. Move chute lever to up position (Fig. 11).

3. Adjust drain pan as needed.

4. Containers up to 28.75" (731 mm) tall may be

used by removing drip tray (Fig. 12).

Fig. 11

Fig. 12

10

Page 11

Operation

How the dispenser works

Follett’s Ice Pro bagging and dispensing system can operate in manual or semi-automatic ice dispensing and

bagging congurations. The Ice Pro dispenser features a blower to open bags for high volume, hands-free

dispensing, bag holder pins for use with wicketed bags, and a programmable dispense timer.

Ice is stored in the bin above the dispense auger. The upper and lower agitators break fused ice and direct it

into the auger for dispensing. When the timed or manual button is pressed, the dispense motor is activated.

This causes the auger assembly in the storage area to move ice to the dispense chute where it drops by

gravity into a bag or other container.

Window interlock switch

Prevents agitation and

dispensing when open

Window locks

Prevents unintended

access to ice

storage area

Agitators

Dispense auger

Easily removable

for cleaning

Upper and lower

agitators driven

by independent

gearmotors

Control panel

See detailed

description on

next page

Bag stand assembly

Drain pan may be removed to

empty water or to adjust for

bag height. Pan should support

bottom of bag. Bag stand

assembly may be removed to

ll other containertypes.

Blower motor

Opens bags for

automatic dispensing

Power switch

System ON/OFF

11

Page 12

Control functions

1. Open bag

Press to turn on blower.

Automatically blows

open one bag at a time

Press again to turn

blower off. Blower

automatically turns

off after 10 minutes.

1. Open bag 3. Dispense ice2. Adjust time

2. Adjust time

Press +/– to change

timed dispense duration

in seconds - maximum

time: 30 seconds

+

-

3. Dispense ice

Press Timed once to

dispense automatically.

Hold Manual to top off

bag or ll other containers

ManualTimed

STOP

Ice Pro

™

dispensing bin

Stop

Press to stop timed

dispense

Power switch

Note: Do not turn power OFF during normal operation. Turning power OFF disables periodic agitation

cycle which may lead to fused ice and damage to dispenser that may void warranty.

12

Page 13

Cleaning and sanitizing

Note: Do not clean with water jet.

Exterior care

A mild detergent cleaner may be used to clean the exterior plastic

sides of the bin. Stainless steel portions of the bin can be cleaned

with a stainless cleaner such as 3M Stainless Steel Cleaner &

Polish or equivalent.

Interior care

The interior should be cleaned and sanitized every six months,

or more often as conditions dictate, with the solutions A and B

shown below.

Solution A – Cleaning solution:

Combine 1 oz (30ml) bleach with 2 gal (7.6L) hot water

or useEcolab *Mikro-chlor sanitizer and mix for 200 ppm

availablechlorine.

Fig. 13

13.2

13.3

13.1

Solution B – Sanitizing solution:

Combine 1/4 oz (7ml) bleach with 2 gal (8L) hot water or

useEcolab Mikro-chlor sanitizer and mix for 50 ppm available

chlorine.

Cleaning brush

A long-handled cleaning brush should be used to access the

bottom of the Ice Pro bin.

Cleaning and sanitizing procedure

1. Remove all ice from bin

2. Disconnect power from icemaker and dispenser (Fig.13.1).

3. Remove ice storage window (Fig. 13.2).

4. Remove front cover by loosening side thumb screws and lifting

off of top guide pins (Fig. 13.3).

5. Detach gearmotor's two latches and set motor and attached

auger coupling aside. (Fig. 14.1).

6. Remove blower duct by loosening thumb screw rotating clip

and lifting up (Fig. 14.2).

7. Remove ice chute assembly (Fig. 14.3).

8. Pull out auger (Fig. 15.1).

9. Remove auger tube by unscrewing thumb screw on left side, lift

up on retaining clamp and pull tube out of bin. Note position of

locating slot on upper end for reinstallation (Fig. 15.2).

10. Remove drip tray from bag stand (Fig. 15.3).

11. Clean all components, inner bin storage surfaces and dispense

chute surfaces with a brush and cleaning solution A. Rinse

thoroughly with clean water.

12. Sanitize all components and bin storage surfaces with solution

B - do not rinse.

Fig. 14

14.1

14.2

14.3

Fig. 15

15.1

15.3

15.2

Drain line care

After cleaning and sanitizing procedure, and before relling bin with

ice, pour a solution of one cup (8oz / 237ml) bleach mixed with one

gallon (3.8L) hot water into drain to help prevent algae growth in the

drain lines.

*Mikro-chlor is a registered trademark of ECOLAB in the United States and other countries.

13

Page 14

DB650 wiring diagram, upper control box (220V, 60Hz)

14

Page 15

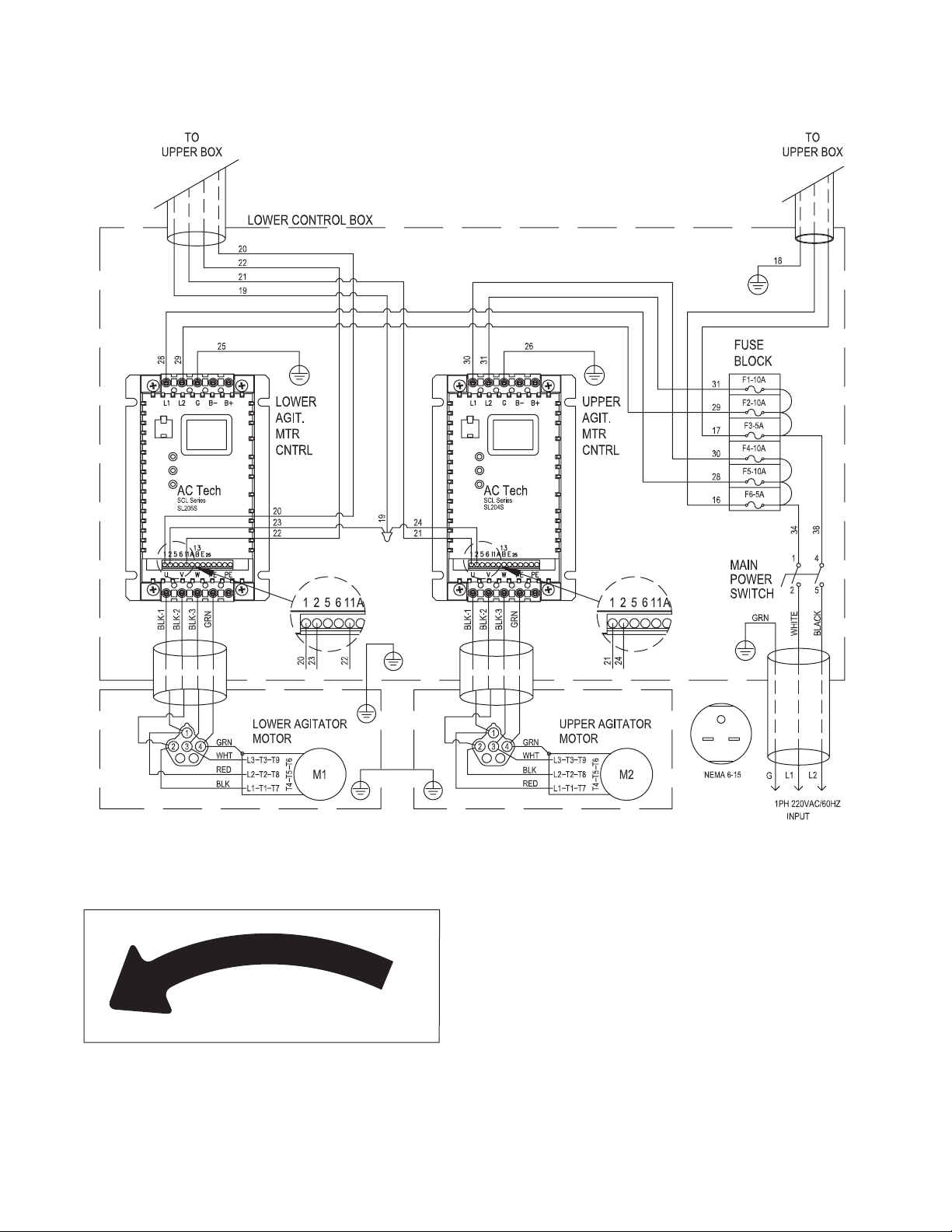

DB650 wiring diagram, lower control box (220V, 60Hz)

00938738R00

Drive rotation

Note: Both upper and lower agitator motors turn counter clockwise.

15

Page 16

EDB650 wiring diagram, upper control box (230V, 50Hz)

OPERATOR CONTROL PANEL

PB5

TIMED MODE

INCREASE

PB6

BAG OPEN

START/STOP

LED TIME DISPLAY

PB3 - TIMED MODE

START/STOP

BLOWER MOTOR

LED1

ON INDICATOR

OPERATOR CONTROL ENCLOSURE

04

03

J5

J6

FOOT

SWITCH

MOTOR

OVERLOAD (4AMP)

08

52

J20

PROG

PORT

J7

RS485

WINDOW

SW

J17

POWER

PB4

TIMED MODE

DECREASE

13

15

J11

J31

LOWER

1

AGIT

GROUND

J21

11

14

12

J10

J30

UPPER

N/C

AGIT

N/AUPRLWR

PB1

MANUAL

START/STOP

PB2 - TIMED MODE

STOP

13 15 14 12 52 09 05 06

J8

J29

J8

J9

N/C COM

J31

LOWER

AGIT

520905

J12

J13

AUGER

MOTOR

AUGER

J11

06

J14

J15

BLOWER

MOTOR

BLOWER

J30

UPPER

17

J2

220VAC

WINDOW

SWITCH

AGIT

16

J1

J9

J29

J10

N/C

N/C COM

J3

01

J4

02

J13

AUGER

MOTOR

J12

J14

J15

BLOWER

MOTOR

12

14

2 6431 5

19 BLK

20 RED

15

13

21 BLK

22 RED

08

BLK

09

10

2 5431

GRN

WHT

AUGER

MOTOR

(X) BLU

(V) RED

(U) BLK

05

06

07

03

04

2 431 2 31 21

BLK

WHT

BLOWER

GRN

M4M3

MOTOR

BLK

WHT

FOOT SWITCH

(OPTIONAL)

02

01

BLK

BLK

WINDOW

SWITCH

161718

16

Page 17

00938738R00

Drive rotation

12

14

15

13

08

09

10

05

06

07

02

01

161718

BLK

BLK

GRN

WHT

BLK

GRN

WHT

BLK

BLK

WHT

FOOT SWITCH

(OPTIONAL)

AUGER

MOTOR

BLOWER

MOTOR

WINDOW

SWITCH

M4M3

2 5431

2 6431 5

2 431 2 31 21

03

04

20 RED

19 BLK

22 RED

21 BLK

(U) BLK

(V) RED

(X) BLU

EDB650 wiring diagram, lower control box (230V, 50Hz)

LOWER AGITATOR

MOTOR CONTROL MOTOR CONTROL

U V W L1 L2

LOWER CONTROL ENCLOSURE

20

21

19

222220

F54SR

REACTOR

UPPER AGITATOR

30

31

A1

LINE

C2C1A2

56

57

U V W L1 L2

19

21

F55SR

REACTOR

C2C1A2

28

LINE

58

18

10A

F1

31

F2

29

F3

17

F4

30

F5

28

F6

16

29

A1

59

MAIN

POWER

10A

10A

10A

40

39

5A

36

35

5A

34

38

LINE

FILTER

60

61

4

1

2

5

BLK-1

BLK-2

2 3 4

GRN

BLK-3

1

LOWER AGITATOR

MOTOR

GRN

WHT

L3 T3 T9

RED

L2 T2 T8

BLK

L1 T1 T7

M1

T4 T5 T6

50

51

BLK-1

BLK-2

1

2 3 4

GRN

BLK-3

GRN

WHT

BLK

RED

Note: Both upper and lower agitator motors turn counter clockwise.

UPPER AGITATOR

MOTOR

L3 T3 T9

L2 T2 T8

L1 T1 T7

M2

T4 T5 T6

BRN

BLU

GRN

FERRITE

RINGS

BRN

BLU

GRN

L1

L2G

1PH 230VAC / 50HZ

17

Page 18

Before calling for service

1. Check that ice is in the dispenser and that fused cubes are not causing a jam.

2. Check that circuit breaker and switches are in ON position. Display will show time setting.

3. Check that window is on securely. If window is ajar, dispenser will not operate. Display shows three

dashes when window is ajar.

4. Check that the drain is clear.

Troubleshooting guide

Symptom Possible cause Solution

Ice does not dispense 1. No ice in bin. 1. Check operation of icemaker.

2. Dispense switch not

closing.

3. Auger motor not operating. 3A. Check for power to motor.

4. Agitator motors not

operating.

5. Auger motor & agitator

motors not operating.

6. Optional foot pedal

not operating.

Bags tear off pins

during lling

More than one bag

opens when blower is on

Bags won’t open 1. Blower switch not on. 1. Press OPEN BAG. Blower turns off after 10 minutes

1. Drip tray not adjusted

properly.

2. Poor quality bags. 2. Try bags from another supplier.

1. Stainless steel chute is not

resting against bags.

2. Bag pins not centered. 2. Adjust bag pins so bags are centered under chute.

2. Blower duct missing or out

of position.

3. No power to blower motor. 3A. Verify output LED lights on board.

4. Bag pins not centered. 4. Adjust bag pins so bags are centered under chute.

5. Wet bags. 5. Install new wicket of bags.

2A. Press manual dispense to check operation.

2B. Check LED's on board.

3B. Check LED's on board.

3C. Check fuses for 220 V. (EDB 230V)

3D. Check auger motor cable connection.

3E. Check auger motor connection to board.

3F. Check circuit breaker.

4A. Check for power at fuse block.

4B. Press manual dispense. Display on VFD (Variable

frequency drive – agitator motor controller) should

show numbers. Check for loose connections.

4C. Check for output from corresponding VFD.

5A. Check that window is in place. Display shows three

dashes when window is removed.

5B. Check interlock wires and connection.

6. Check for contact closure of switch inside foot pedal

enclosure.

1. Adjust drip tray to one notch above where bottom of

bag contacts platform.

1. Move chute lever to down position to position

stainless steel chute against bags.

without use.

2. Reinstall/re-position blower duct.

3B. Check for loose connections.

If problems persist after following this basic troubleshooting guide, call Follett’s technical

service department at (800) 523-9361 or (610) 252-7301.

18

Page 19

Replacement parts & accessories

Accessories

1 3

4

2

5 6

7 8

Reference # Description Part #

1 8 lb Bags, (case of 1000) 00116434

1 20 lb Bags, (case of 500) 00138370

2 Bostitch P-7 C-Ring Plier 00137711

Not Shown Aluminum Blunt End C Rings (box of 2500) 00137729

3 Foot Pedal Control Accessory 00115055

4 Follett Totes™ Ice Carrier 206950

5 Follett SmartCart™ 75 ice cart 00112771

6 Follett SmartCart™ 125 ice cart LSC125

7 Follett SmartCart 240™ ice cart 00122770

8 Ice Bin Paddle PB502871

Not Shown Cleaning Brush, DB650 (with bracket) 00924555

19

Page 20

9

Upper chassis

16

12

11

10

13

2

1

8

15

14

Reference # Description Part #

1 Cover, Upper Motor (with handle) 00924100

2 Guard, Drip Assy 00924118

3 Box, Upper Agitator Motor (with plates) 00924126

4 Catch, Upper Housing (one) 00924134

5 Brush Bracket 00924142

6 Motor, Upper Agitator (with cable) 00924209

7 Shaft, Upper Drive (with key) 00924217

8 Key, Upper Drive Shaft 00924225

9 Bolt, Upper Drive Shaft (with washer) 00924233

10 Agitator, Upper (with thrust washer) 00924308

11 Seal, Shaft, Upper Right Assy 00924316

12 Seal, Shaft, Upper Left Assy 00924324

13 Bearing, Upper Left (includes thrust washer) 00924332

14 Door, Bin Access (with latch and magnet) 00924506

15 Latch, Door Lock Assy 00924514

16 Plate, Door Strike (with hardware) 00924522

17 Sensor, Door Assy 00924530

18 Magnet, Door 00924548

17

18

4

3

5

7

6

20

Page 21

Lower chassis

11

12

10

4

8

Reference # Description Part #

1 Knobs, Front Cover (two) 00925008

2 Clip, Blower Duct (with knurled nut) 00925016

3 Drain, Bin Assy 00925057

4 Frame, Bag Stand (with bag pins and handles) 00925115

5 Cover, Lower Control Box 00925156

6 Cover, Lower Cable 00925164

7 Blower Motor (with cable) 00925248

8 Drain Pan 00925503

9 Bag Pin Set 00925511

10 Handles (two) 00925529

11 Blower Duct 00925545

12 Front Cover 00925552

1

2

7

9

6

5

3

21

Page 22

Lower chassis (cont.)

26

24

22

23

13

25

16

14

18

17

Reference # Description Part #

13 Cover, Lower Motor (with handle) 00925107

14 Box, Lower Agitator Motor (with plates) 00925123

15 Latch, Draw (one) 00925131

16 Plate, Guide (one) 00925149

17 Leg, Adjustable (one) 00925172

18 Motor, Lower Agitator (with cable) 00925206

19 Shaft, Lower Drive (with key) 00925214

20 Key, Lower Drive Shaft 00925222

21 Bolt, Lower Drive Shaft (with washer) 00925230

22 Agitator, Lower (with thrust washer) 00925305

23 Seal, Shaft, Lower Right Assy 00925313

24 Seal, Shaft, Lower Left Assy 00925321

25 Bearing, Lower Left (includes thrust washer) 00925339

26 Seal, Auger Tube Assy 00925537

15

20

19

21

22

Page 23

Dispense auger

6

9

10

7

8

3

5

1

14

11

4

1

13

2

12

Reference # Description Part #

1 Clamp, Auger Tube Assy (with knob) 00925024

2 Pivot, Rear Chute Assy 00925032

3 Pivot, Front Chute Assy 00925040

4 Knob, Auger Clamp 00925065

5 Chute, Rear Stainless 00925180

6 Motor, Auger (with cable) 00925255

7 Coupling, Auger Drive Assy 00925263

8 Auger, DB650 00925347

9 Mount, Auger Motor (with bolts) 00925354

10 Frame, Auger Tube (with latches) 00925362

11 Frame, Dispense 00925370

12 Chute, Front Clear 00925560

13 Tube, Auger Assy 00925578

14 Cradle, Auger Tube 00925586

23

Page 24

Electrical system, upper box

DB650 and EDB650

3

1

2

DB650 only

4 5

Reference # Description Part #

1 Control Panel (mounted on cover) 00924621

2 Circuit Board 00924639

3 Circuit Breaker 00924647

4 VFD Motor Controller, Lower Agitator, DB650 00925602

5 VFD Motor Controller, Upper Agitator, DB650 00924605

6 Fuse Block 00925610

7 Fuse, Kit (4 10-amp, 2 5-amp) 00925628

8 Switch, Rocker 00925636

Not shown Wiring Harness, Agitator Motor 00924613

76

8

24

Page 25

Electrical system, lower box

(EDB650 only)

1 1

6 6

Reference # Description Part #

1 VFD Motor Controller, Upper and Lower Agitator, EDB650 00925651

2 Fuse Block 00925610

3 Fuse, Kit (4 10-amp, 2 5-amp) 00925628

4 Filter, Line 00925677

5 Switch, Rocker 00925636

6 Reactor, Line 00925685

Not shown Wiring Harness, Agitator Motor 00924613

2

3

4

5

25

Page 26

262728

Page 27

Page 28

SmartCART and Totes are trademarks of Follett Corporation.

Chewblet is a registered trademark of Follett Corporation, registered in the US.

Follett reserves the right to change specications at any time without obligation. Certications may vary depending on country of origin.

801 Church Lane • Easton, PA 18040, USA

Toll free (800) 523-9361 • (610) 252-7301

Fax (610) 250-0696 • www.follettice.com

220V 60Hz

models only

230V 50Hz

models only

00913509R02

10/10

Loading...

Loading...