Page 1

110 Series – 220V 60Hz/230V 50Hz

Ice and Water Dispensers

Order parts online

www.follettice.com

Installation, Operation and Service Manual

C/E110CT400A/W

Following installation, please forward this manual

C/E110CR400A/W

to the appropriate operations person.

801 Church Lane • Easton, PA 18040, USA

(610) 252-7301 • Fax (610) 250-0696 • www.follettice.com

C/E110FB400A/W

00109520R03

Page 2

Table of contents

Before you begin

Specifications

Field wiring

Installation

Installing freestanding dispensers

Installing countertop dispensers

™

Installing Satellite-fill

icemakers

Installing top mount icemakers

User information

Cleaning and sanitizing procedures

Service Information

Wiring diagram – lever models

Wiring diagram – SensorSAFE™ models

Dispenser troubleshooting

Troubleshooting SensorSAFE board and sensors

Disassembly and replacement instructions

Thermostat locations

Parts

Dispenser exterior

Dispense chute and splash panel areas – lever models

Electrical box – lever models

Dispense chute and splash panel areas – SensorSAFE models

Electrical box – SensorSAFE models

Wheel motor and drive system

Hopper components

Chilled water components

Solenoid dispense assembly

3

4

5

6

6

8

10

10

12

12

14

14

15

16

17

18

21

22

22

23

23

24

24

25

26

27

28

Follett Corporation

Equipment Return Policy

Follett equipment may be returned for credit under the following conditions:

1. The equipment is new and unused.

2. A return authorization number has been issued by customer service within 30 days after shipment.

3. Follett receives the equipment at the factory in Easton, PA within 30 days after issuance of the return authorization number.

4. The equipment must be returned in Follett packaging. If the packaging has been damaged or discarded, Follett will forward, at

the customer’s expense, new packaging.

Note: Return freight charges are the responsibility of the customer. If equipment is returned and is damaged because of

improper packaging, Follett Corporation will not be held responsible.

Credit will be issued when:

The equipment has been inspected by Follett and deemed suitable to be returned to stock.

Note: A 15% restocking charge will be deducted from the credit. If the cost to return the product to stock exceeds 15%, the

actual cost will be deducted.

2

Page 3

Welcome to Follett

Follett equipment enjoys a well-deserved reputation for excellent performance, long-term reliability and outstanding

after-the-sale support. To ensure that this equipment delivers that same degree of service, we ask that you review the

installation portion of this manual before beginning to install the unit. Our installation instructions are designed to help

you achieve a trouble-free installation. Should you have any questions or require technical help at any time, please call

our technical service group at (610) 252-7301.

Before you begin

After uncrating and removing all packing material, inspect the equipment for concealed shipping damage. If damage is

found, notify your shipper immediately and contact Follett Corporation for help in filing a claim, if necessary.

Check your paperwork to determine which model you have. Follett model numbers are designed to provide information

about the type and capacity of Follett equipment. Following is an explanation of model numbers:

C110CR400A

Condenser type – A = air-cooled, W = water-cooled

Icemaker capacity and refrigerant – 400 = 400 lbs (181kg)/day, R404A refrigerant

Icemaker location – R = Satellite-fill icemaker, T = integral icemaker in top of cabinet,

B = icemaker in base of freestanding units

Dispenser configuration – C = countertop, F = freestanding

Approximate storage capacity in lbs

Alternate voltage – C = 220V 60Hz, E = 230V 50Hz

!

Important cautions

• Do not tilt any unit further than 30° off vertical during uncrating or installation

• Dispenser bin area contains mechanical, moving parts. Keep hands and arms clear of this

area at all times. If access to this area is required, power to unit must be disconnected first.

• Follett recommends a Follett QC4-FL4S water filter system (item# 00130299) be installed in

the icemaker inlet water line

• Ice is slippery. Be sure counters and floors around dispenser are clean, dry and free of ice.

• Ice is food. Follow recommended cleaning instructions to maintain cleanliness of

delivered ice.

3

Page 4

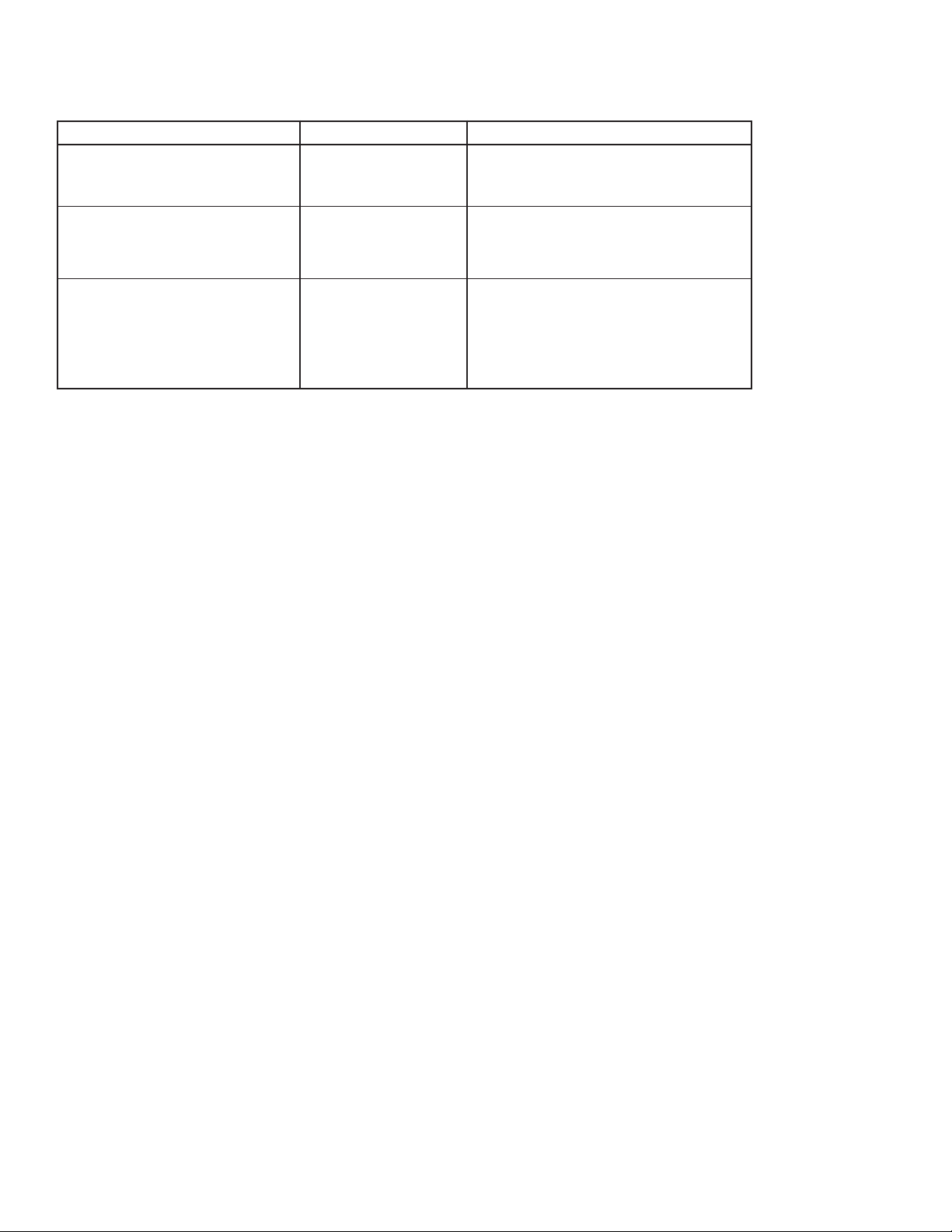

Specifications

Electrical

1. Models with Satellite-fill icemakers (C/E110CR400A/W)

Icemaker Dispenser

220V/60Hz/1 phase 5 amps 1.5 amps

230V/50Hz/1 phase 5 amps 1.5 amps

2. Freestanding models and models with integral icemakers (C/E110FB400A/W, C/E110CT400A/W)

Total system

220V/60Hz/1 phase 6.5 amps

230V/50Hz/1 phase 6.5 amps

3. Dispensers and Satellite-fill icemakers are supplied with 7-foot power cord

Ambient

Air temp 38°C/100° F max. 10°C/50°F min. (best performance below 27˚C/80˚F)

Water temp 32°C/90°F max. 4°C min./40°F (best performance below 21˚C/70˚F)

Water pressure 70 P.S.I. max. 10 P.S.I. min.

Plumbing

110CR with 110CT with 110FB with

Satellite-fill icemaker integral icemaker icemaker in base

Dispenser drain 3/4" FPT 3/4" FPT 3/4" FPT

Icemaker drain 3/4" MPT 3/4" MPT 3/4" MPT

Dispenser water inlet 3/8" FPT 3/8" FPT 3/8" FPT

Icemaker water inlet – 3/8" FPT –

Satellite-fill IM water inlet 3/8" OD push-in – –

Cond. inlet – w/c only 3/8" FPT 3/8" FPT 3/8" FPT

Cond. drain – w/c only 3/8" FPT 3/8" FPT 1/2" FPT

Note: Water shut-off recommended within 10 feet (3m) of dispenser. Drain to be hard piped and insulated, and maintain

slope of at least 1/4" per foot (6mm per 305mm run) of slope. All plumbing connections must be made in accordance with

local building codes.

Ventilation clearances

Countertop models with Satellite-fill icemaker (C/E110CR400A/W) – none. 775mm (12") at top advised for service.

Countertop models with integral icemaker (C/E110CT400A/W) – 153mm (6") at top. 153mm (6") each side advised

for service.

Freestanding models (C/E110FB400A/W) – 102mm (4") at rear. 305mm (12") at top advised for service.

4

Page 5

Field wiring for countertop dispensers with Satellite-fill icemakers

Model Electrical connection Current

C110FB400A/W cord provided 220V 60Hz, 6.5 amp

E110FB400A/W 230V 50Hz, 6.5 amp

C110CT400A/W cord provided 220V 60Hz, 6.5 amp

E110CT400A/W 230V 50Hz, 6.5 amp

C110CR400A/W cord provided 220V 60Hz

E110CR400A/W 230V 50Hz

dispenser: 1.5 amp

icemaker: 5.0 amp

5

Page 6

Installation procedures

Before you begin

• All dispensers must be installed level in both directions to ensure proper operation

• Required ventilation and recommended service clearances:

• Countertop models with Satellite-fill icemaker (C/E110CR400A/W) — none. 305mm (12") at top recommended for service.

• Countertop models with integral icemaker (C/E110CT400A/W) — 153mm (6") at top. 153mm (6") each side recommended

for service.

• Freestanding models (C/E110FB400A/W) — 102mm (4") at rear. 305mm (12") at top recommended for service.

• All countertop dispensers provide the option of taking utilities out the bottom or back of the dispenser. See counter

cutout (Fig. 2) for bottom exiting utilities on units with and without drain pans. For installations where utilities will exit through

back of dispenser, refer to back view drawings.

Installing freestanding dispensers

1. Carefully tip dispenser back to expose underside and block up in place.

Do not tilt unit further than 30° off vertical.

!

2. Remove legs from shipping box (taped to drain pan of dispenser) and screw into dispenser bottom, taking care to seat

legs securely against underside of dispenser.

3. Position dispenser in desired location and adjust legs to level in both directions.

4. Connect water supply to 3/8" FPT fitting on back of dispenser (Fig. 1A).

5. Remove 3/4" dispenser drain line plug from back of unit and discard. Connect separate drain lines to 3/4" FPT

dispenser drain fitting and 3/4" MPT icemaker drain fitting on back of dispenser (Fig. 1B and 1C.)

6. Run drain lines to wall or floor drain. Provide an air break between the drain lines and drain. If icemaker drain fitting is

below an intended wall drain, a condensate pump must be used.

7. If icemaker is water-cooled, connect water-cooled condenser supply line to 3/8" FPT condenser inlet fitting on back of

dispenser (Fig. 1D).

Note: Do not run condenser supply water through icemaker water filter system.

8. Connect condenser drain line to 3/8" FPT condenser outlet fitting on back of dispenser (Fig. 1E).

Important: Do not connect condenser drain line to any other drain lines.

9. Plug dispenser into 20 amp rated NEMA 5-20 wall socket.

10. Remove front cover of base section by removing two screws at bottom corners of cover. Allow cover to drop

approximately 5mm (3/8") and pull forward.

11. Turn on water supply and check that water level in float reservoir (when full) is within 6mm (1/4") of mark on side of

reservoir and that float moves freely. Check for leaks.

6

Page 7

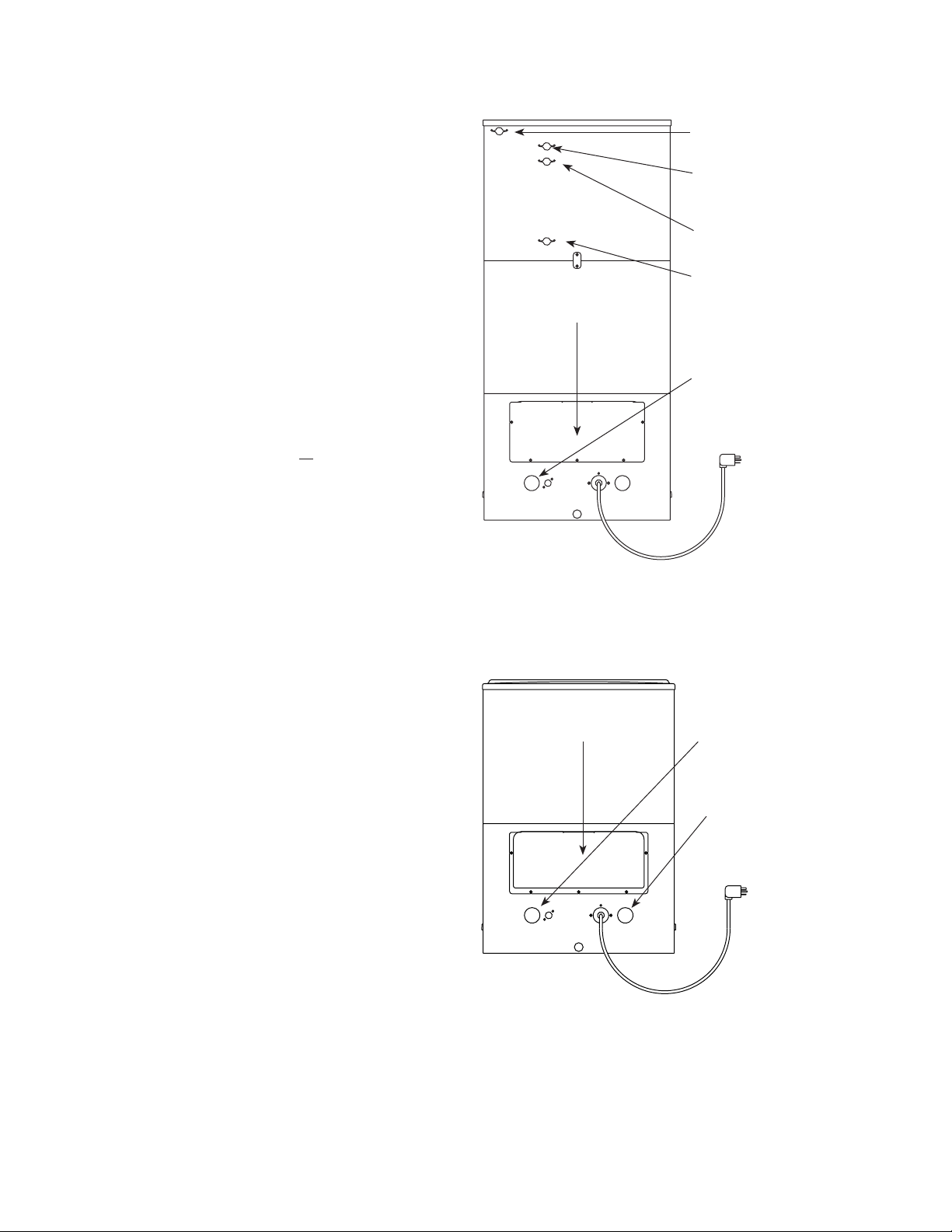

Fig. 1 – Rear connections, freestanding models

(B) 3/4” FPT drain

(A) 3/8" FPT

water inlet (A)

access panel

(D) 3/8" FPT

condenser inlet

location (water-

cooled only)

water inlet

(E) 3/8" FPT

condenser drain

location (water-

cooled only)

(C) 3/4" MPT

icemaker drain

location (aircooled only)

260mm

(10.25")

800mm

(31.5")

(C) 3/4" MPT

icemaker drain

location (water-

cooled only)

800mm

(31.5")

12. Verify that water sensor tabs are immersed in water in reservoir.

13. Remove top front cover by removing two screws at bottom corners of cover. Lift cover slightly and pull forward.

14. If dispenser is equipped with SensorSAFE, remove protective plastic coating from dispense sensor labels.

15. Turn on dispenser power and bin signal rocker switches. Check dispenser and icemaker operation.

16. Sanitize icemaker according to instructions in icemaker manual. Discard sanitized ice.

17. Turn off icemaker bin signal switch.

18. Remove dispenser hopper lid; clean and sanitize dispenser according to instructions.

19. Turn icemaker bin signal switch on and replace front covers, securing with screws.

7

Page 8

Installing countertop dispensers

Dispensers with top mount icemakers cannot be mounted on legs. They must be bolted to counter.

!

Use gloves when lifting icemaker to protect hands from sheet metal edges.

1. Position dispenser in desired location, mark

dispenser outline on counter and remove dispenser.

2. Drill four 5mm (3/8") holes in counter (Fig. 2) to

anchor dispenser to counter.

Follett countertop dispensers can have any or all

utilities run directly through counter or out rear of

dispenser. For dispensers with any utilities exiting

through counter, make counter cut-out as shown

in Fig. 2.

3. If ice transport tube will exit out rear of dispenser,

remove ice transport tube knock-out (Fig. 5G) from

rear of dispenser.

Note: Utility connections can be accessed through

front of dispenser by removing stainless steel splash

panel on front of dispenser, or by removing access

panel (Figs. 4, 5) on back of dispenser.

4. If any electric utilities or water line will be connected

through rear of dispenser, remove utility knock-out

(Fig. 5H) from rear of dispenser and install supplied

protective grommet.

5. If power is to be supplied through counter cut-out,

complete steps 6-9. If power is to be supplied through

rear of dispenser, proceed to step 10.

6. Temporarily remove rear access panel (Figs. 4, 5)

from rear of dispenser.

7. Loosen junction box mounting screws. Lift junction

box and power cord up until cord and mounting

screws clear notches on rear panel of dispenser.

Remove Phillips head screws from right side of

junction box.

8. Rotate junction box 90 degrees so that screw holes

on right side of junction box align with holes on rear

dispenser panel. Resecure junction box to dispenser

using Phillips head screws.

9. Place power cord inside dispenser and replace

access panel (Figs. 4 and 5) on rear of dispenser.

Note: For dispensers installed with utilities connected

through rear of dispenser, it may be easier to make

preliminary connections before dispenser is set in

place.

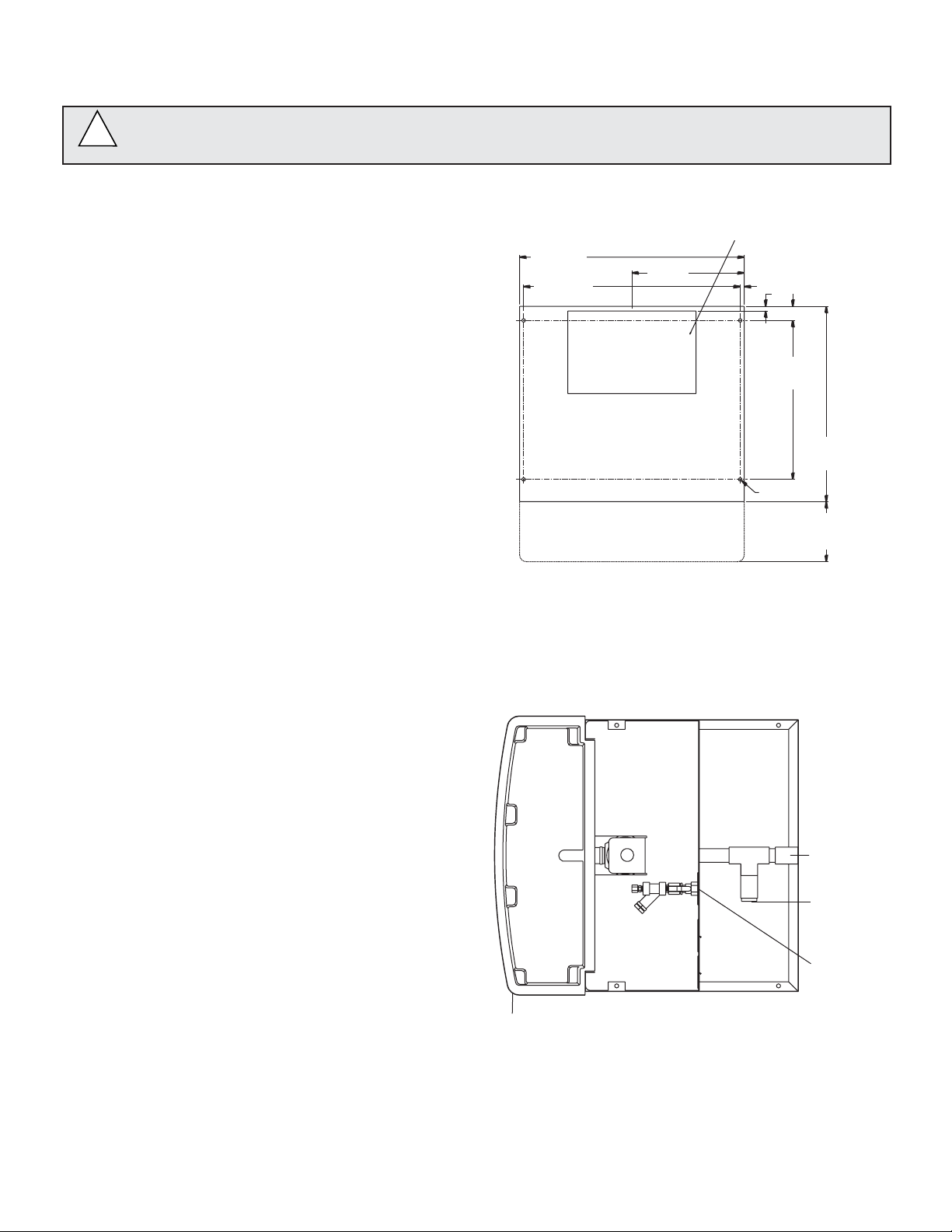

Fig. 2 – Counter cut-out, all models

622mm

(24.5")

603mm

(23.75")

227mm x 356mm (9" X 14")

311mm

(12.25")

CUT OUT

DRAIN PAN

13mm (.5")

13mm (.5")

41mm (1.625")

441mm

(17.375")

543mm

(21.375")

3/8"

167mm

(6.54")

Fig. 3 – Top view, dispenser plumbing connections

countertop and wall mount units with drain pan

(K) 3/4" FPT

dispenser drain

(L) alternate 3/4"

dispenser drain

location

(J) 3/8" FPT

water inlet

8

drain pan

Page 9

10. Apply a thick bead, approximately. 6mm (1/4")

diameter, of NSF listed silicone sealant (DowCorning RTV-732 or equivalent) 6mm (1/4") inside

marked outline of dispenser.

11. Carefully position dispenser on counter.

12. Remove four screws securing splash panel to front

of dispenser and gently lay splash panel on counter.

(Water line to solenoid valve can be disconnected

from water inlet valve by pushing on ring at end of

inlet fitting while pulling on tubing.)

13. Secure dispenser to counter with four 3/8" bolts

(supplied by others).

14. Smooth excess sealant around outside of dispenser.

15. Run water supply line from back of dispenser

through utility knock-out (Figs. 4, 5) or up through

counter cut-out. Connect water supply line to 3/8"

FPT, (Fig. 3J) fitting on utility flange at bottom of

dispenser.

16. Remove 3/4" drain connection plug from either fitting

at rear of dispenser, (Fig. 1K) or internal fitting, (Fig.

3L), as appropriate. Connect and run a dedicated

drain line to wall or floor drain. An air break should

be provided.

Fig. 4 – Rear connections, countertop models with

integral icemakers

(M) 3/8" FPT

icemaker water inlet

(R) 3/8" FPT condenser inlet

(water-cooled only)

(P) 3/8" FPT

condenser outlet

(water-cooled only)

(N) 3/4" MPT

icemaker drain

access panel

(H) utility knock-out

If dispenser is equipped with a top mount, water-

cooled icemaker complete steps 17 through 20.

If equipped with a top mount,

air-cooled icemaker proceed to step 21.

17. Connect icemaker water supply line to 3/8" FPT

water inlet, (Fig. 4M).

18. Connect icemaker drain line to 3/4 MPT drain

connection (Fig, 4N).

19. If icemaker is water-cooled, connect water-cooled

condenser supply line to 3/8" FPT condenser fitting

on back of dispenser (Fig. 4R).

Note: Do not run condenser supply water through

icemaker water filter system.

20. Connect condenser drain line to 3/8" FPT fitting on

back of dispenser (Fig. 4P).

Important: Do not connect condenser drain line to

any other drain lines.

21. Proceed with either Satellite-fill or top-mounted

icemaker connection instructions, as appropriate.

Fig. 5 – Rear connections, countertop models with

Satellite-fill icemakers

access panel

(H) utility knock-out

(G) ice transport tube knock-out

9

Page 10

Installing Satellite-fill icemakers

Models C/E110CR400A/W

See Icemaker Installation Manual (form #00124453) for critical installation instructions for Satellite-

!

1. Install Satellite-fill icemaker following instructions in icemaker manual.

2. Run uninsulated ice transport tube from dispenser through ice transport tube knock-out, (Fig. 5G) or through counter

opening to icemaker.

3. Insulate ice transport tube by sliding insulation over tube.

4. Adjust insulation to cover all exposed ice transport tubing including tubing inside dispenser cabinet.

5. Check that insulated ice transport tube runs continuously uphill (with no dips) from icemaker to dispenser.

6. Run bin signal wire from dispenser through utility knockout, (Fig. 5F) or counter cutout to the icemaker and connect

bin signal wire (two-conductor twist lock) to bin signal plug on icemaker.

7. Plug dispenser power cord into 20 amp rated NEMA 5-20 wall socket.

8. Turn on dispenser water supply and check for leaks. Replace splash panel.

9. Remove top front cover by removing two screws at bottom corners of cover. Lift cover slightly and pull forward. Turn on

power and bin signal rocker switches. Replace front cover and secure with screws. Test operation.

10. Clean and sanitize icemaker following instructions in icemaker manual. Discard sanitized ice.

11. Clean and sanitize dispenser hopper following instructions on page 13. Installation is complete.

fill icemakers. Failure to comply with these instructions will result in poor performance and void

warranty.

Fig. 6 – Ice transport tube and ice level control stat mounting for freestanding dispensers and countertop units

with Satellite-fill icemaker

ice level control stat

26mm

(1")

ice hose mounting bracket

5mm (3/16") ice tube hole

engaging pin

ice tube

Installing top mount icemakers

Models C/E110CT400A/W

Dispensers with top mount icemakers cannot be mounted on legs. They must be bolted to counter.

!

Use gloves when lifting icemaker to protect hands from sheet metal edges.

10

Page 11

1. Remove dispenser top front cover by removing two screws at bottom corners of cover, lifting cover slightly and pulling

forward.

2. Remove icemaker compartment top and side panels.

3. Remove icemaker hold-down bracket from front of icemaker compartment.

4. Lift icemaker onto dispenser top and slide icemaker completely into position, compressor end first. Front of icemaker

base must be flush with front of dispenser.

5. Reinstall hold down bracket on front of icemaker with power cord and bin signal cords in notch. Do not cut or pinch

cords.

6. Insert loose end of ice transport tube through bracket (on icemaker base) into hopper access hole. Be sure that transport

tube is secured under retainer on float reservoir bracket (Step 2, Fig. 7). Tighten transport tube clamp screw to secure ice

transport tube.

7. Connect plastic water supply line to fitting at top of float reservoir.

Fig. 7 – Ice transport tube

2

1

TIGHTEN

CLAMP

3

SCREW

8. Connect vinyl drain line from dispenser securely to drain line on icemaker.

9. Connect icemaker two-lead bin signal twist lock plug, and three-lead power twist-lock plug, to dispenser twist-lock

connectors.

10. On dispensers equipped with water-cooled icemakers, connect condenser water supply and drain lines to condenser

fittings on icemaker.

11. Turn on water supply and check that water level in float reservoir (when full) is within 1/4" (6mm) of mark on side of

reservoir and that float moves freely.

12. Verify that water sensor tabs are immersed in water in reservoir. Check for leaks. Replace splash panel.

13. Install appropriate plug on power cord and insert into wall socket.

14. If dispenser is equipped with SensorSAFE remove protective plastic coating form dispense sensor labels.

15. Clean and sanitize icemaker following instructions in icemaker manual.

16. Remove dispenser hopper access lid and clean and sanitize dispenser according to instructions on page 14.

17. Replace front cover and secure with screws. Installation is complete.

Fig. 8 – Ice transport tube and ice level control stat mounting for units with top-mounted icemakers

ice level control stat

19mm

(.75")

Hand bend cap tube

end to approximately.

45° as shown

45°

11

Page 12

User information

How the dispenser works

Follett’s 110 series automatic load ice and water dispensers receive ice from Follett’s 181kg (400 lb)/day icemaker located

in the dispenser base, in the cabinet top or in a remote location up to 6m (20 ft) away. Ice produced is stored in the bin

section of the dispenser. When dispensing is activated, the wheel motor is energized, causing the wheel to turn. This

moves ice to the dispense chute where it drops by gravity into the container held below the chute.

In Follett’s continuous icemaking process, water freezes to the inside walls of the stainless steel evaporator. A rotating

stainless steel auger carries the ice to the top of the evaporator where it is compressed and extruded through a nozzle on

the outlet port. The ice is then pushed through a tube to the dispenser bin. When the storage area is full, a bin thermostat

opens and shuts the icemaker off to avoid over-filling of the bin. The icemaker will restart after 20 minutes if the bin is

calling for ice.

How the SensorSAFE accessory works

Follett’s SensorSAFE accessory maximizes sanitation and minimizes the possibility of cross-contamination by eliminating

physical contact between the cup or container and dispenser. Sensors in the panel use reflected infrared light to detect

the presence of the container and send a signal to a control board which then activates the appropriate components for

ice or water dispensing.

The SensorSAFE package includes a cleaning switch under the left side of the front cover which temporarily shuts off

dispensing to allow cleaning of the panel and lenses. If the switch is not turned back on after cleaning, the dispenser

automatically resets after two minutes for normal operation.

SensorSAFE also includes a time limit safety feature which automatically stops ice dispensing after one minute of

continuous dispensing. Dispensing can be resumed by moving the container away from the dispenser and returning it to

the activation zone.

How the chilled water accessory works

Follett’s chilled water accessory uses ice from the dispenser’s storage hopper to chill incoming water supplied to the water

station. The water chiller assembly is located in the dispenser cabinet under the storage hopper. As ice is dispensed, it is

automatically fed into the water chiller assembly to chill the water coil inside the assembly.

Cleaning and sanitizing procedures

!

Solution A: Prepare cleaning solution (200 ppm of available chlorine content) of Ecolab Mikro-chlor Cleaner or equal

chlorinated detergent. Solution temperature must be 24˚C – 52˚C

( 75˚F – 125˚F).

Solution B: Prepare sanitizing solution (50 ppm of available chlorine content) of Ecolab Mikro-chlor Cleaner or equal

chlorinated detergent. Solution temperature must be 24˚C – 52˚C

( 75˚F – 125˚F).

Follett recommends the periodic cleaning schedule on page 13 to ensure the quality of ice provided. Use only

recommended cleaning solutions. Do not use solvents, abrasive cleaners, metal scrapers or sharp objects.

Recommended daily cleaning of drain pan

1. Remove all debris from drain pan.

2. Slowly pour 4L (1 gallon) hot water into drain pan to keep drain lines clear.

Always disconnect power before cleaning.

12

Page 13

Recommended weekly cleaning

1. Wash drain pan and grille with Solution A above. Rinse thoroughly.

2. Slowly pour solution of one cup (237ml/8 oz) household bleach mixed with 3.8L (1 gallon) hot water into drain pan to

help prevent algae growth in drain lines.

If dispenser is a SensorSAFE unit:

3. Deactivate dispenser by depressing and releasing clean switch located on left side of unit under top front cover.

4. Clean lens using soft cloth and mild, non-abrasive cleaner.

5. Reactivate dispenser by depressing and releasing clean switch a second time (dispenser automatically reactivates

after two minutes).

Recommended quarterly cleaning of dispenser hopper

Note: If icemaker and dispenser are cleaned and sanitized at the same time, icemaker should be completed first.

1. Remove ice from dispenser.

2. Working inside storage area, remove center thumbscrew from dispense wheel, tilt wheel up toward back to clear baffle

and lift wheel out.

3. Remove front cover, chute cover and clear plastic chute.

4. Wipe lid, wheel, baffle, inside of storage area and clear plastic chute with damp cloth wrung out in Solution A.

5. Rinse all above items with damp cloth rinsed and wrung out in clear water.

6. Wipe all bin surfaces with Solution A .

7. Rinse thoroughly with clear, potable water.

8. Wipe with Solution B to sanitize.

9. Reinstall dispense wheel and other components.

To avoid possible damage to motor assembly, use a damp cloth only. Do not allow water to run through

center hole in bottom of bin area.

!

If dispenser is equipped with chilled water accessory:

1. Remove four screws securing splash panel.

2. Disconnect 3/4" drain line from bottom of chilled water canister.

3. Loosen (do not remove) screw securing right bracket of chilled water canister to bottom of dispenser hopper.

4. Rotate canister clockwise to release front bracket, then slide canister to right to disengage left bracket.

5. Remove chilled water coil from canister and clean with cloth wrung out in Solution A.

6. Wipe inside of chilled water canister with cloth wrung out in Solution A.

7. Rinse all above items with damp cloth wrung out in clear water.

8. Sanitize all above items with damp cloth wrung out in Solution B. Do not rinse.

9. Reinstall chilled water coil into canister (rubber alignment grommet on coil tubing must be located outside chilled

water canister to hold coil securely against canister wall).

10. Reinstall chilled water assembly on dispenser and tighten screw securing right bracket.

11. Reconnect 3/4" drain line to chilled water canister.

12. Reinstall splash panel and top front cover.

13. Restore power and test operation.

Quarterly cleaning of icemaker system

Units with icemakers require icemaker cleaning at least every 3 months, and more often if local water

conditions dictate. Failure to clean icemaker will result in decreased performance and potential damage to

icemaker. Refer to Icemaker Operation and Service Manual for specific cleaning instructions.

13

Page 14

Service information

Wiring diagrams

How unit works — lever models

The dispense wheel motor and dispense solenoid are energized through the power and ice dispense switches. The water

solenoid valve is energized through the power and water dispense switches. The icemaker receives the bin signal through

the power switch, the normally closed bin thermostat and the icemaker switch. When the bin level thermostat is calling for

ice, a 115V bin signal is applied to the bin signal terminals on the icemaker circuit board.

thermostat, the contacts open, cutting the bin signal to the icemaker.

When ice builds up around the bin

4x4 JUNCTION BOX

BLACK

WHITE

GREEN

BLACK

ICE MACHINE

POWER

(220/230 VAC)

MAIN POWER

SWITCH

RD RD

T- ST AT

BLK

BLK

BLK

BIN SIGNAL

SWITCH

RED

PURPLE

ORANGE

RELAY #1

4

1

BLUE

7

TIMER

ORANGE

PUR

RED

GREEN/YELLOW

220V 60HZ

BROWN

230V 50HZ

BLUE

WHITE

WHITE

RLY

B

321

B

PUR

WHITE

A

#2

WHITE

WHITE

RLY

A

#1

WHITE

M

WHITE

S

WHITE

WTR

ICE MACHINE

BIN SIGNAL

(16 VDC)

BLACK

ORANGE

RELAY #2

1

4

7

RED

WHITE

14

Page 15

How unit works — SensorSAFE models

SensorSAFE models provide “touchless” ice and water dispensing. When a container is placed within the actuation

zone below the ice or water chute on SensorSAFE dispenser models, an infra-red signal reflects off the container and is

detected by the sensor. The sensor then sends a signal to the control board to activate the appropriate components to

dispense ice or water. LEDs on the board indicate when the board is receiving a signal from the sensors.

A safety, shut-off feature automatically shuts off dispensing after one minute of continuous activation. Dispensing can be

restarted by moving the container away and then returning it to the actuation zone.

Dispensing can be temporarily suspended for cleaning by depressing and releasing the clean switch, located under the

left side of the top front cover. Depressing and releasing the button a second time will return the dispenser to normal

operating state. If the clean switch is not depressed a second time, the dispenser will automatically resume normal

dispense operation (CLN LED goes out) after two minutes. An LED on the control board will light to indicate that the

dispensing has been suspended by activation of the clean switch.

4x4 JUNCTION BOX

T-S TAT

ICE

GND

PWR

NEUTRAL

GREEN

WTR

BIN SIGNAL

SWITCH

RD

CLN

WM

SOL

WTR

BLACK

WHITE

BLACK

MAIN POWER SWITCH

RED BLUE

GRN

BLACK

L1

ICE MACHINE

POWER

(220/230 VAC)

ORANGE

RELAY #1

YELLOW

YELLOW

PUR

4

1

ORANGE

A

TIMER

7

BLUE

321

RED

PUR

RLY

#2

B

BROWN

B

RLY

#1

M

S

WTR

GREEN/YELLOW

220V 60HZ

230V 50HZ

BLUE

WHITE

WHITE

WHITE

WHITE

WHITE

A

WHITE

CLEAN

SWITCH

WHITE

WHITE

WHITE

ICE MACHINE

BIN SIGNAL

(16 VDC)

BLACK

ORANGE

RELAY #2

1

4

RED

7

WHITE

15

Page 16

Dispenser troubleshooting

Disconnect power to dispenser and icemaker before putting hands or arms in storage area, or

attempting any repair or service to equipment.

!

Before calling for service:

• Check that there is ice in dispenser bin area • Check that all switches and circuit breakers are on

• Check that congealed cubes are not causing a jam • Check that all drains are clear

Symptom

1. Does not dispense

ice

2. Does not dispense

water

3. Water runs

continuously

4. Dispense

wheel rotates

continuously

5. Icemaker runs

continuously

Possible cause

a. Faulty dispense gate

b. Faulty dispense solenoid

c. Power switch off or faulty

d. Faulty dispense switch

e. Wheel motor malfunction

f. Drive chain off

g. Sprocket key missing

a. Dispense switch faulty

b. Faulty water solenoid

c. Solenoid plugged by debris

a. Dispense switch contacts burned shut

b. Debris preventing valve from closing

a. Dispense switch contacts burned shut

b. Faulty level fill timer

c. Faulty level fill relay

a. Faulty or incorrectly positioned bin

thermostat

Solution

a. Replace dispense gate

b. Replace dispense solenoid

c. Check switch; turn on or replace if faulty

d. Replace switch

e. Check motor and replace as required

f. Reinstall chain

g. Install key and tighten sprocket

a. Check switch and replace if faulty

b. Check solenoid and replace if faulty

c. Remove and clean valve

a. Check switch and replace if faulty

b. Remove and clean valve

a. Replace dispense switch

b. Replace level fill timer

c. Replace level fill relay

a. Check for proper positioning (middle of

adjustment range); if thermostat does not

open when ice is placed on capillary tube,

replace thermostat

6. Ice dispenses by

itself

b. Incorrect field wiring

a. Faulty dispense gate

b. Faulty dispense solenoid

c. Faulty dispense switch

b. Check that icemaker receives bin signal

from dispenser

a. Replace dispense gate

b. Replace dispense solenoid

c. Replace dispense switch

16

Page 17

Troubleshooting SensorSAFE board and sensors

Board guide

LEDs, when illuminated, indicate the following:

PWR (board power)

CLN (cleaning, no dispensing cycle)

ICE (ice dispensing activated)

WTR (water dispensing activated)

Problem: Does not dispense ice or water

Action

LED Status

PWR CLN ICE/WTR

Check LEDs on control

board

Place cup under drop

zone

OFF OFF OFF

ON ON OFF

ON OFF OFF

Terminals:

L1 (incoming power, hot)

L2 (neutral terminals)

WTR (power terminal for water solenoid)

SOL (power terminal for dispense gate

solenoid) not used

WM (power terminal for wheel motor)

CLN (terminals for clean cycle switch)

Solution

Check circuit breakers and power switch; restore

power or replace defective switch

Depress clean switch located under left side of front

cover to return board to normal operation

Troubleshoot appropriate lens/sensor and replace if

required (see Lens/Sensor Troubleshooting below)

ON OFF ON

Problem: Dispenses ice or water continuously

Action

LED Status

PWR CLN ICE/WTR

Check LEDs on control

board

ON OFF ON

ON OFF OFF

Verify power on appropriate output terminal

(WTR SOL or WM) on control board and replace

board if required; if board tests okay, troubleshoot

appropriate dispenser component

Solution

Troubleshoot appropriate lens/sensor and replace if

required (see Lens/sensor troubleshooting below)

If there is power on any output terminal (WTR, SOL

or WM) on control board, replace board

Remove lens protective cover; adjust funnel so water

doesn’t drip down lens or behind splash panel

17

Page 18

Lens/sensor troubleshooting

1. Turn dispenser power switch off.

2. Remove splash panel.

3. Disconnect wires from output terminal(s) (WTR, SOL, WM) on board.

4. Gently remove appropriate sensor/mounting block assembly from panel by moving block sideways until edge of block

clears retaining tab of panel.

5. Inspect lens and sensor assembly for foreign material and remove using non-abrasive cleaner.

6. Turn dispenser power on and test sensor by moving hands through activation area (no closer than1.9mm/3/16") in

front of sensor.

7. If LED on board turns on and off, sensor is working properly and dispenser may be reassembled. If LED does not

come on, switch sensor leads on board and retest. If the opposite LED comes on, board is defective and must be

replaced. If LED does not come on, sensor is defective and must be replaced.

Disassembly and replacement instructions

Dispense chute removal

1. Remove dispenser front cover.

2. Slide plastic dispense chute cover up and out to remove.

3. Pull out four white plastic fasteners and remove dispense chute.

Dispense wheel removal and installation

Note: Models with top mount icemakers require removal of icemaker before removing wheel.

1. Remove all ice from storage area of dispenser.

2. Remove center thumbnut from dispense wheel.

3. Remove thumbnuts holding baffle inside bin and remove baffle, remove 1/4" bar.

4. Tilt rear of wheel up and lift off motor drive shaft.

5. After reinstalling wheel, secure baffle loosely with thumbnuts, but do not

tighten.

6. Place a 1.6mm (1/16") spacer against wheel and allow baffle to drop

until it touches spacer.

7. Tighten thumbnuts and remove spacer.

dispenser

front

baffle

1.6 mm (1/16")

spacer

Drive bar removal

1. Remove dispense wheel from dispenser (see above).

2. Pull drive bar out of its channel in bottom of wheel.

side view wheel section

Wheel motor assembly removal

1. Shut water off; remove front cover.

2. Remove dispense wheel and dispense chute cover (see above).

3. Remove splash panel. Water line to solenoid valve can be disconnected from water inlet valve by pulling on ring at end

of inlet fitting. Disconnect wiring to splash panel.

4. Disconnect wires on motor.

5. Remove four bolts (7/16" socket) holding motor assembly to bottom of dispenser.

6. Remove motor assembly.

18

Page 19

Ice transport tube replacement

Top mount ice machines, model C/E110CT400A/W

!

Only use tubing supplied by Follett Corporation.

2

3

1

Ice transport tube replacement

Models C/E110FB400A/W, C/E110CR400A/W

Correct installation of ice transport tube is critical to Satellite-fill icemaker performance. Replacement

!

ice transport tubes for Satellite-fill icemakers must be insulated and run continuously from icemaker

to dispenser with no dips or bends with a radius of less than 153mm (6").

1. Remove top and rear access panel from dispenser (lower front panel in

freestanding unit).

2. Disconnect existing ice tube from engaging pin on transport tube bracket in ice

storage bin evaporator and pull down through dispenser chase.

3. Disconnect opposite end of tube from icemaker.

4. Run end of new ice transport tube with 5mm (3/16") hole through ice transport

tube knock-out, (Fig. 5G) in back of dispenser or through counter into bottom of

dispenser, being careful to avoid any bends with less than 153mm (6") radius.

5. Insert tube in internal chase in rear inside corner of dispenser (left side as you

face dispenser) and push up into storage area.

6. Push the 5mm (3/16") hole near end of tube into pin on ice tube bracket

(see drawing below).

Steps 7-8 for units with Satellite-fill icemakers only

7. Install supplied insulation to run of transport tube required for your site, leaving

approximately 51mm (2") of tube exposed at free end.

8. Check that insulated tube runs continuously uphill to dispenser with no dips.

TIGHTEN

CLAMP

SCREW

4

5mm (3/16")

dia. hole

Section A – A

26mm

(1")

AA

19

Page 20

All units

9. Slip supplied hose clamp onto tube and push tube onto exit port of evaporator.

Do not twist hose when securing to evaporator.

!

10. Fasten tube on port with hose clamp, being sure that clamp is positioned on evaporator side of nozzle flange.

11. Tighten clamp.

Only use tubing supplied by Follett Corporation.

ice level control stat

capillary tube

26mm

(1")

engaging pin

ice tube

ice hose mounting bracket

5mm (3/16") ice tube hole

20

Page 21

Thermostat locations

Thermostat locations – C/E110CT400A/W

ice deflector bracket assembly

rubber grommet

ice level control stat

control box assembly

ice level control stat

bin thermostat

control box assembly

hopper assembly

ice level

control stat

Hand bend

cap tube

end to approx.

45° as shown

.75"

(20mm)

45

Thermostat locations – C/E110CR400A/W, C/E110FB400A/W

ice mounting hose bracket

well nut

rubber grommet

knurled screw

ice level control stat

ice level

control stat

bin thermostat

control box assembly

hopper assembly

control box assembly

21

Page 22

Parts

Dispenser exterior

7

6

2

2

4

5

1

5

Part # Description Reference

502756 Cover, top front, 110 countertop (CT) 1

502703 Cover, top front, 110 countertop unit with Satellite-fill icemaker (CR) & freestanding (FB) 2

502704 Cover, lower section, 110 freestanding (FB) units 3

502681 Cover, dispense chute 4

501100 Knurled screws, front cover Not shown

502705 Drain pan 5

502706 Grille, drain pan Not shown

502779 Drain pan and base assembly (includes 502705 and 502706) Not shown

502709 Lid, icemaker, 110, countertop (CT) 6

502702 Lid, 110, countertop (CR) units with Satellite-fill icemakers & freestanding (FB) units 7

502088 Leg kit, for freestanding units – set of 4 Not shown

502298 Single leg, for freestanding units 8

500376 Strainer, water faucet and icemaker (models with integral icemaker) Not shown

502711 Drain tube assembly Not shown

00112854 Drain line adapter Not shown

502100 Mounting plate/fitting, water inlet Not shown

502433 Tee, water inlet Not shown

502222 Valve, water shut-off Not shown

502268 Fitting, drain and mounting plate (units with integral icemaker) Not shown

502716 Base stand assembly, countertop dispenser 9

502225 Assembly, water inlet, freestanding units (includes valve, tee and strainer) Not shown

502701 Drain fitting, brass, icemaker, freestanding units Not shown

00109728 Drain fitting, plastic, icemaker (includes screws) Not shown

502776 Cord, power, dispenser Not shown

502777 Cord & plug, female, bin signal, remote icemaker Not shown

502816 Cord & plug, female, bin signal, top mount icemaker Not shown

502817 Cord & plug, female, bin signal, freestanding Not shown

502359 Clean switch, SensorSAFE

502788 Cord & plug, icemaker power, top mount Not shown

502786 Cord & plug, female, icemaker power, freestanding Not shown

502805 Caster Not shown

5

9

3

8

Not shown

22

Page 23

Dispense chute and splash panel areas — lever models

4

13

2

7

10

8

1

14

12

11

6

5

16

9

15

3

Part # Description Reference

502057 Fastener, dispense chute bracket 1

502356 Tube, water station 2

502681 Cover, dispense chute 3

501829 Switch, dispense, ice, lever actuated (includes 501841) 4

502359 Switch, dispense, water, lever actuated (includes 501841) 5

502247 Bracket, chute (includes fasteners 502057) 6

502358 Lever, dispense 7

502248 Chute and funnel, ice 8

502249 Chute, water 9

502927 Solenoid assy, water (includes 502926, 502356, 502246, 502355

and 502262) 220V, 60Hz/230V, 50Hz 10

502355 Bracket, water solenoid and lever 11

502246 Fitting, inlet, 1/8" MPT x 1/4" comp 12

502262 Fitting, outlet, 1/8" MPT x 3/8" comp 13

502926 Solenoid valve, water, 220V, 60Hz/230V, 50 Hz 14

501841 Boot, dispense switch button (mounts on 501829 switch) 15

502079 Tubing, water station, thermoplastic, 1/4" OD (sold by the foot) Not shown

502789 Splash panel 16

Electrical box (front view) — lever models

Part # Description Reference

500514 Thermostat, bin level 1

501375 Level fill relay 2

502209 Switch, dispenser power 3

502209 Switch, icemaker bin signal 4

501375 Bin signal relay 5

501700 Level fill timer 6

23

1

2

1

LOAD

MADE IN USA

ADJUSTMENT

EXTERNAL

2 3

VOLTAGE

INPUT

5

3

6

4

Page 24

Dispense chute and splash panel areas – SensorSAFE™ models

321

10

8

3

15

12

13

11

9

1

14

7

2

5

4

6

Part # Description Reference

502057 Fastener, dispense chute bracket 1

502681 Cover, dispense chute (includes labels) 2

502248 Chute and funnel, ice 3

502249 Chute, water 4

502247 Bracket, chute (includes fasteners 502057) 5

502690 Lens, sensor 6

502710 Splash panel (includes 2 of 502690) 7

502927 Solenoid assy, water, 220V, 60Hz/230V, 50Hz

(incl. 502926, 502356, 502246, 502355, 502262) 8

502355 Bracket, water solenoid and lever 9

502356 Tube, water station 10

502246 Fitting, inlet, 1/8" MPT x 1/4" comp 11

502262 Fitting, outlet, 1/8" MPT x 3/8" comp 12

502926 Solenoid valve, water, 220V, 60Hz/230V, 50Hz 13

00122978 Sensor (includes 502690 and 203611) 14

203611 Ty-rap, sensor mounting 15

Electrical box (front view) SensorSAFE models

Part # Description Reference

500514 Thermostat, bin level 1

501375 Level fill relay 2

502209 Switch, dispenser power 3

502209 Switch, icemaker bin signal 4

501375 Bin signal relay 5

501700 Level fill timer 6

502915 SensorSAFE Board 7

24

1

2

5

6

3

7

4

Page 25

Wheel motor and drive system

3

8

7

4

6

1

Part # Description Reference

501699 Wheel motor, 220V, 60Hz/230V, 50Hz 1

501026 Washer, thrust 2

501607 Fan blade, wheel motor Not shown

501619 Drive shaft (includes threaded rod and nut, see #6, page 26) 3

502691 Chain, 54 link 4

502692 Sprocket, drive shaft, 35 teeth 5

501019 Sprocket, wheel motor, 10 teeth 6

501024 Bearing, drive shaft 7

500799 Connecting link, chain Not shown

500637 Key, driveshaft 8

502929 Dispenser drive assembly Includes all above

5

2

7

3

1

25

Page 26

4.5

Hopper components

Top view – top mounted unit

13

19

18

14

6

5

1

16

Top view – freestanding and Satellite-fill units

17

6

5

3

7

15

12

2

4.5

1

4

8

3

2

7

Ice tube bracket – side view –

freestanding & Satellite-fill units

Ice tube bracket – side view

– all top mounted units

11

Dispense wheel – bottom view all units

5

4

9

10

7

8

Part # Description Reference

501802 Baffle, ice 1

501493 Wheel, dispense (includes drive bar, rotating agitator, threaded bar & rod) 2

501494 Agitator, rotating 3

502712 Bracket, ice tube 4

501100 Screw 5

501612 Rod, threaded (includes knurled nut) 6

501617 Drive bar assembly (includes threaded rod and nut) 7

501616 Ice deflector/cap tube bracket (units with top mounted icemaker) 8

502698 Bracket, ice tube entry (units with top mounted icemaker) 9

502697 Ice transport tube assembly (units with top mounted icemakers) 10

501613 Screws, knurled 11

502723 Side panel, RH 12

502722 Side panel, LH 13

502714 Bracket, icemaker hold-down 14

501717 Cover, hopper access 15

502708 Cover, hopper 16

502709 Lid, Icemaker, 110CT 17

502824 Gasket, ice entry 18

00115196 Drain pan, hopper Not shown

26

Page 27

Ice transport tubing

Part # Description Reference

502522 Ice transport tube (Satellite-fill units) – 3.1m (10 ft) Not shown

502523 Ice transport tube (Satellite-fill units) – 6.1m (20 ft) Not shown

501176 Ice transport tube insulation (Satellite-fill units only) – sold by the foot Not shown

502327 Ice transport tube assembly (110 freestanding units) Not shown

502697 Ice transport tube assembly (110 top mount units) Not shown

Chilled water components

1

2

Part # Description Reference

502598 Coil, chilled water (includes two 502599) 1

502599 Fitting, water coil 2

502600 Brackets, chilled water canister, pair (includes screws) 3

502601 Canister, chilled water (includes 502600 and 502605) 4

502605 Elbow, drain 5

502602 Assembly, chilled water (includes reference #1 through 5 above)

502604 Tee, drain line Not shown

3

4

5

27

Page 28

Solenoid dispense assembly

1

Part # Description Reference #

501844 Solenoid, dispense, 220V, 60 Hz/230V, 50Hz 1

502040 Cotter pin 2

502039 Linkage, solenoid (includes 502054 grommet) 3

502042 Block, dispense gate 4

502054 Grommet 5

502045 Splash pan, gate assembly 6

502038 Shoulder screw and washer 7

501824 Spring, gate assembly 8

00128157 Gate assembly, 220V, 60 Hz/230V, 50Hz

(includes reference numbers 1 through 8 above)

2

8

3

7

4

5

6

801 Church Lane • Easton, PA 18040, USA

(610) 252-7301 • Fax (610) 250-0696 • www.follettice.com

00109520R03

02/07

Loading...

Loading...