Focal NOVA UTOPIA Be User Manual

UTOPIA BERYLLIUM LINE

User manual

Français page 12

BP 374 - 108, rue de l'Avenir - 42353 La Talaudière cedex - France - Tel.: 00 33 4 77 43 57 00 - Fax: 00 33 4 77 37 65 87 - www.focal-fr.com

JMlab®, Utopia®, W®, Focus Ti me®, OPC®,, Focus Rin g®, Power Flower® and Structure "γ "® are trademarks of Focal-JMlab® - ©Focal-JMlab- SCOS-030722/6

2

User precautions

User manual Utopia Be line

Thank you for choosing the Utopia Be loudspeakers. We are pleased to share with you our philosophy : “the Spirit of

Sound”. These high-performance speakers feature the latest technical developments from Focal-JMlab in terms of

speaker design, whether it is for high fidelity or home theater systems. In order to make the most of these speakers and

enjoy the maximum of their performance, we advise you to read this user manual.

Special precautions regarding the Beryllium dome tweeter

In its solid form, Beryllium is harmless. However, due to its nature, certain special precautions should be observed to avoid exposure to

unnecessary risk.

- Under no circumstances should the Beryllium dome be subjected to any form of abrasive action. To ensure no accidental damage to

the tweeter dome it is advised to carefully replace the protection covers while not in use.

- In the unlikely case of damage to the dome, of any form, the supplied piece of adhesive tape should be immediately used to seal the

whole front surface of the tweeter. The protective cover should then be replaced and also taped securely in place. You should then

inform the dealer from whom you purchased the product so that the tweeter can be removed by a professional and returned to the

product distributor for replacement.

- If the dome is broken in any way giving rise to loose particles of Beryllium, these should be carefully collected with the use of an

adhesive tape and sealed in a zip-top bag to be returned with the tweeter.

For further information, please contact Focal-JMlab directly: beryllium@focal-fr.com

Breaking-in period

The drivers used in the Utopia Be line are made up of complex mechanical elements and require an adaptation period before they deliver

their full potential. They must get adapted to the temperature and humidity conditions of their environment. This breaking-in period

depends upon the encountered conditions and can last several weeks. In order to shorten this period, we advise you to let your speaker

operate for about twenty hours at medium level, playing stand music programs, but with a large amount of bass. Once the components of

the loudspeaker are completely stabilized, it is possible to enjoy the real performance of your speakers.

Magnetic disturbance

The Utopia Be line speakers generate a magnetic leakage that may interfere with other sensitive household appliances. It is strongly advised

not to place the speakers closer than 50cm to your TV screen. Frame geometry as well as colours can be severely distorted by a magnetic

field if the loudspeaker is placed too close to the cathode ray tube.

Generally, every sensitive element (audio tapes, video tapes, magnetic data storages, projector and CRTS overhead-projector) should not be

placed too close to non-shielded loudspeakers.

User precautions

All the products in the Utopia Be range are lacquered in order to offer a resistant cabinet surface and to make the upkeep easy.

We recommend the use of a dry cloth to dust your pair of loudspeakers. If the loudspeaker is stained, then use a damp cloth.

Never use any solvents, detergents, alcohol or corrosive products, scrappers or scouring powder to clean the surface of the loudspeaker.

Avoid placing the loudspeakers near a heat source.

3

Utopia Beryllium line

User manual Utopia Be line

Early in 1993, 13 years after its creation, Focal-JMlab

realized the need to launch a one-off, no compromise,

reference loudspeaker. After two years the Grande Utopia

was born initiating major technological innovations such

as the ”W “ sandwich cone, the Tioxid inverted dome

tweeter and the Focus Time system and Gamma.

It represented to us a high precision laboratory, which

would serve as the absolute reference for each Focal-JMlab

loudspeaker thereafter.

The first public demonstration of the Grande Utopia took

place in the spring of ’95. But what started as a

laboratory project quickly became the object of interest for

audiophiles the world over. The impact was so big that the

Grande Utopia gave birth to a full range of products

comprising all these technologies.

Innovation is the base value of Focal-JMlab. The new

Utopia Be range proves it. Building on the principles of

the original research started in 1993, we have introduced

the first dome made of pure Beryllium and the Focus ring

and Power Flower new magnet structures.

This manual contains a detailed presentation of the

patented technologies applied in the Utopia Beryllium

range. We are proud to present you with these technologies that form the base value of our dedication to sound

perfection and our philosophy: “the Spirit of Sound”.

The extreme precision offered by Utopia Beryllium

loudspeakers requires installation by a specialist; your

dealer has been selected for his skills in this field. The

weight of these loudspeakers also requires specialist

unpacking.

Beryllium tweeter p. 4

•

“Focus Ring

•

The “W

•

Focus Time p . 7

•

The “ϒ ” (gamma) front structure p . 8

•

OPC crossover p . 9

•

Technical specifications p. 10

•

International guarantee p. 24

•

™

” and “Power Flower™” p. 5

®

” cone p . 6

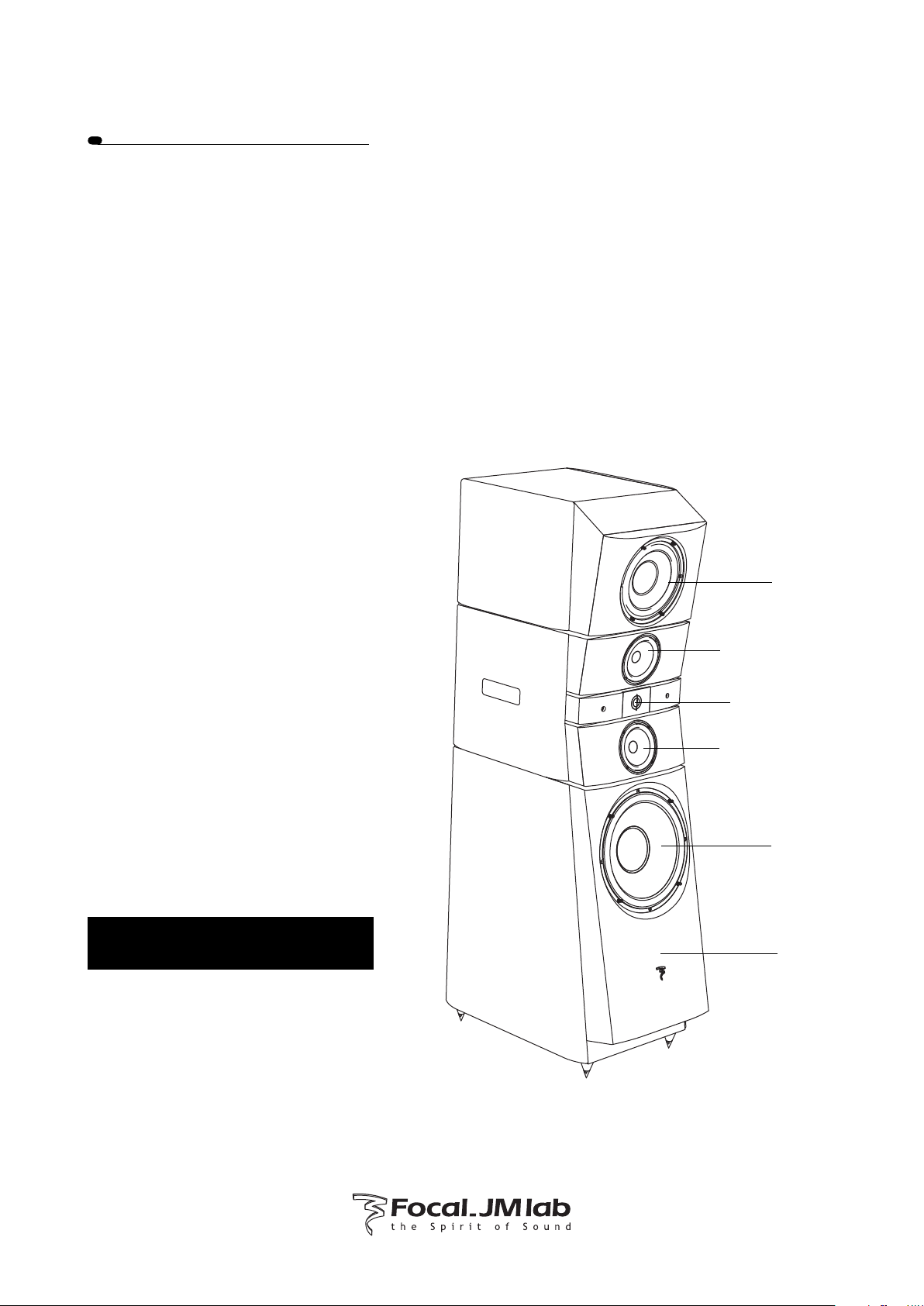

"W" Woofer

"Power Flower" magnet

"Power Flower" magnet

"W" Medium

Beryllium Tweeter

"Focus Ring" magnet

"W" Medium

"W" Woofer

The Focal-JMlab guarantee only applies if the

enclosed guarantee card is returned to us

within 10 days of purchase.

"ϒ " structure cabinet

Focus Time

4

Beryllium tweeter™

User manual Utopia Be line

The reversed dome tweeter is a hallmak of Focal-JMlab. As a result of more than twenty

years of development into a tweeter that could produce a high output, but without requiring high energy input and without increasing directivity. And now the company is ready

to make a major leap forward with the introduction of the pure Beryllium version.

The main advantage of the inverted dome tweeter or the “full” range tweeter...

The experience acquired over the last twenty years has allowed Focal-JMlab to push back the limits

of reversed dome technology and the work on the suspension, driver shape, adhesives and materials

have at each stage produced an improvement in linearity and bandwidth.

The research began by testing fibre domes, as a simple and less sensitive way to validate the

advantages of the reversed dome with regards to energy response. Then the company introduced

more rigid metal domes to extend the response in high frequencies, and with Titanium producing

the most impressive results it has proved to be the most relevant choice. Today to exceed these

limits and particularly to extend the response to nearly 40kHz, we need to move towards a

material even lighter and more rigid. Already competitors have moved to introduce super tweeters

to satisfy the extreme requirements of the new high-bandwidth sources. However, Focal-JMlab does

not believe the adoption of the super tweeter is to be a satisfactory solution.

First of all, the distance between the tweeters, for frequencies where the wavelength is of the order

of cm, poses serious problems of coherence. A filtering is imposed which destroys, by the losses and

distortion of phase, the benefits introduced by extending the frequency response. So it is advisable

to point out that simply extending the high frequency response is not an end in itself, as the ear is

most sensitive to transients. The improvement with regards to the impulse response is only

perceptible at a tweeter output far beyond the 20kHz, limit and to far beyond the perception of

human hearing. We should not forget that Focal-JMlab’s first objective was to design tweeters offe-

ring an optimum coupling, being able to integrate with the mid-range at sufficiently low

frequencies and before the output of the mid- range begins to tighten or beam. Thus the only

successful solution is, therefore, to produce a tweeter with an extended response that covers more

than five octaves from 1 000Hz to 40 000Hz.

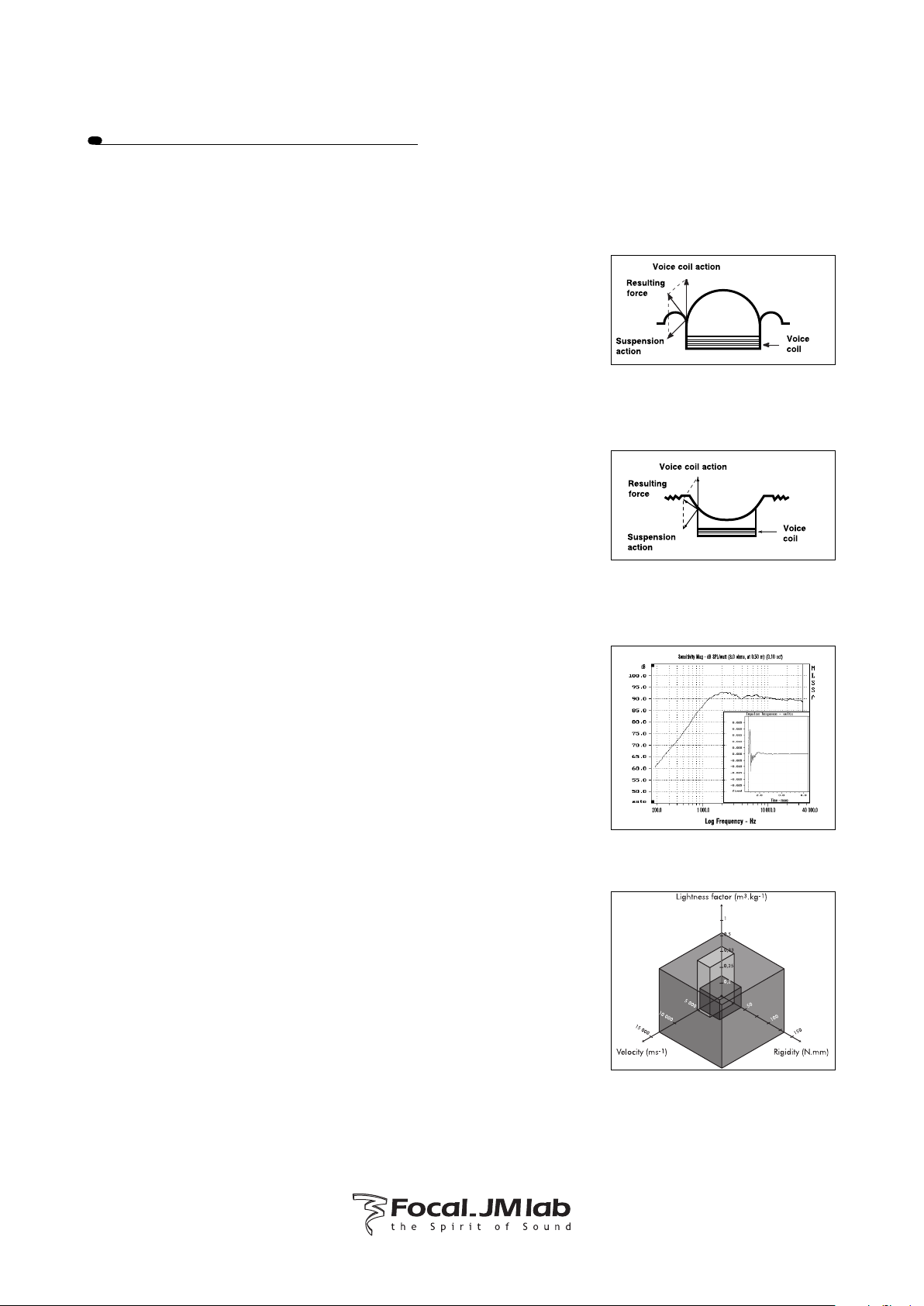

A standard dome tweeter has a poor mechanical coupling with the voice coil

attached to the outer diameter of the dome.

The result of the mechanical forces shows that considerable energy is lost into

the suspension where it is dissipated as heat.

Focal-JMlab inverted dome tweeter: The mechanical interface between the

voice coil and dome is optimal, the result of the forces tangential to the

dome. All of the energy is transmitted into the dome and radiated

as sound.

Beryllium - The ideal material for a dome.

An ideal dome must combine lightness, rigidity and damping. Currently, only one material offers

the possibility of a significant improvement. Beryllium’s density is 2.5 times lower than Titanium

and 1.5 times lower than Aluminium while its’ rigidity is 3 times higher than Titanium and 5 times

superior to Aluminium. Which means that for a dome of identical mass, a Beryllium version is 7

times more rigid than one made of Titanium or Aluminum - which have similar

rigidity for a given mass. Moreover, the velocity of sound in a Beryllium dome is 3 times faster

than a Titanium version and 2.5 times faster than Aluminum. However, the manufacturing of

Beryllium remains very difficult and its production has been limited to just three countries: the

United States, France and Russia. To date, Great Britain, Germany and Japan do not manufacture

pure Beryllium, rather using it in the form of an alloy. Beryllium is an excellent high-tech metal

- the only metal able to scratch glass - it is only used in strategic applications in the aeronautical and

military industries and consequently, its unique characteristics make it extraordinarily expensive,

much more than gold and nearly 100 times that of Titanium.

The only solution for Focal-JMlab - Control the manufactruing process.

The analysis of the mechanical characteristics inevitably leads to Beryllium’s choice as the ideal

material for a tweeter dome. However, a major problem exists because no company has been able

to manufacture such a dome. To arrive at a solution, required Focal-JMlab to conceive a process for

forming a pure Beryllium dome*. And after two years research and investment, the company now

posses a machine to carry out what was considered as utopia. Technological it is a world’s first and

certainly exceeds anything currently found in the audio field.

And the result is in line with the company’s hopes and expectations of an outstandingly detailed

loudspeaker which extends to nearly 40 kHz while maintaining a perfect impulse response.

* In the past certain manufacturers have attempted to use Beryllium for the construction of a direct radiating tweeter

dome. However, they have actually only used Beryllium as a surface coating on a dome structure leading to different

characteristics to anything achieved with pure Beryllium. .

The Beryllium tweeter offers a very extended response up to five octave

from 1,000Hz to 40,000Hz. The impulse response is ideal.

Comparaison beetween Beryllium, Titanium and Aluminum. Beryllium is

lighter and nearly five time more rigid.

5

Focus Ring™ and Power Flower

User manual Utopia Be line

™

Being hidden away magnetic circuits are seldom considered. However the energy

that they give is essential to the quality of reproduction. Focal-JMlab is always associated with investing in powerful arrays. And with the new Utopia line, the company wanted to apply its latest innovations.

“Focus Ring

An intense magnetic field is of the utmost importance for good tweeter performance and the TGU

conceived for large Utopia into 95 was a key point in the development of the Utopia line.

Selecting a magnet that combines high power with small dimensions narrows the choice of magnet

material to Neodymium. However the small dimensions required - and the need for a light coil

with a narrow air gap leads to intense heating of the magnet. A problem then occurs due to a

characteristic of Neodymium: its low “Curie Point”. The magnetisation saturation decreases as the

temperature rises and will cancel at a certain temperature, called the “Curie Point” (Tc). For a

ferrite, Tc is equal to 450 °C and, for a Neodymium Nd

Which means, should the magnet reach its Tc, the magnetic stru cture will loose its magnetism

bringing irreversible damage to its output and an audible loss of dynamics and definition. Since the

design of the TGU in 95, the evolution of the home cinema arena has imposed new constraints

with regards to power handling. In high fidelity musical performances very little energy is

demanded at high frequencies. However, with the special sound effects of home cinema new rules in

terms of power handling are created, with the subsequent effect on magnet temperatures.

Handling these new demands was a key rational in the design process of the new tweeter Beryllium

Utopia (TBe), which adopted a key new concept called “Focus Ring

pending. The material used in the magnet is Samarium-Cobalt Sm2Co17, which is more expensive

and slightly less powerful than Neodymium. However it offers a major advantage in that it pushes

the “Curie Point” (Tc) back to 825 °C, avoiding any chance of temperature related magnetic losses.

However to obtain a magnetic field of 2 Tesla, as in the TGU, doping of the magnetic circuit is

required by using a Neodymium ring to surround the Samarium magnet, thereby concentrating the

magnetic flux and reaching the target field. In addition, with the ring being mounted away from

the coil it is not affected by temperature increases and gives the tweeter exceptional stability

™

” - a patent for the magnetic circuit of the tweeter.

B magnet Tc is equal to 319 °C.

2Fe14

™

” - Focal-JMlab patent

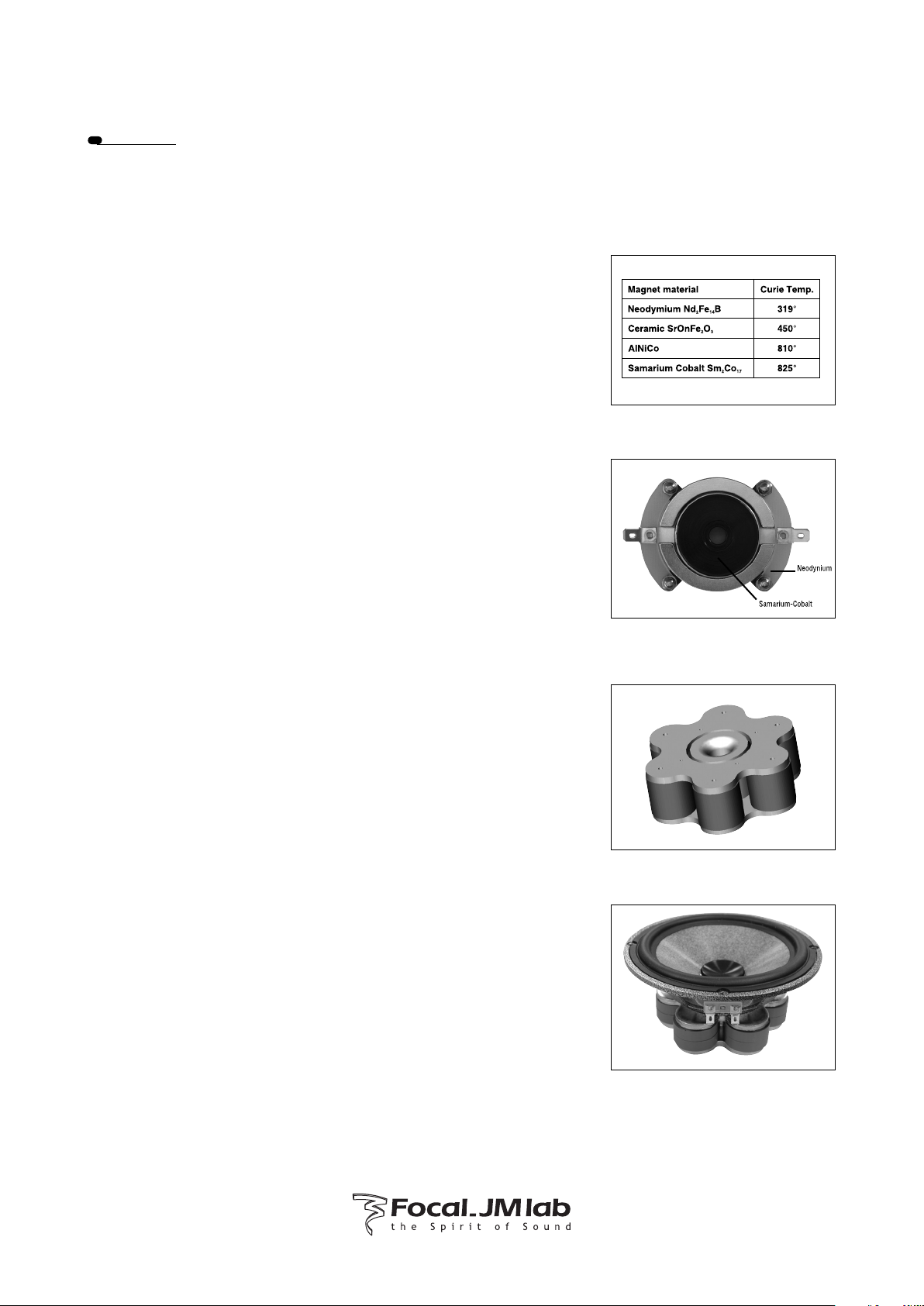

"Curie Point" of different magnets. Only Samarium-Cobalt and Alnico offer

a large safety area when temperature increases.

"Focus Ring™" : Neodynium ring concentrates the magnetic flux to 2T.

The central magnet uses Samarium-Cobalt to offer high stability with

temperature.

“Power Flower™” - a patent for a high precision mid-range

The new mid-range 165mm driver has also directly benefited from Focal-JMlab’s experience of

developing Cone “W” technology since 1995. A new membrane has been developed for use with a

new a 40mm coil and the optimisation of its rigidity has allowed a “single skin” cone to be formed,

which is perfectly controlled over a one octave range from 1 500-3 000Hz - essential to the setting

of the OPC filter. The phase plug is no longer effective and is replaced by a large aluminium focus

plug. Any risk of coloration is eliminated and directivity is optimal. The link with the tweeter can

be made seemless and the impusle response of the combined tweeter/mid-range is ideal.

This mechanical optimization of the drivers eliminates the source of various sonic problems and

in addition offers the guarantee of great manufacturing consistency. The magnetic circuit must

be of high precision with very low losses. But the utilisation of large pole parts generates a problem

of flatness. The bonding beetween pole piece and magnet is not consistent and generate magnetic

losses. The “multiferrites”, technology, first initiated by Focal-JMlab more than twenty years ago for

the company’s top woofer , also brings an unexpected solution to the mid range of the Beryllium

Utopia line. The new - patent pending - “Power Flower

ferrites laid out concentrically around the core. Bonding beetween pole piece and ferrites is very

accurate and cancel any variations due to small deviation in the flat surface. Moreover the polar

parts are machined in the shape of flower, whose petals match the shape of the ferrites, and to stop

magnetic escapes between the bottom and top of the field. Finally, this arrangement satisfies a

double requirement: high power output and perfect control of the magnetic discharge. Magnetic

loses in production are thus very small and in combination with the tight tolerances of the Cone

“W” manufacturing, the “Power Flower™”* design has given exceptional accuracy to the 165mm

mid range unit. The very small tolerances ensure a perfect reproduction of any performances,

particularly in the highly sensitive mid-range, guaranteeing the strict tonal balance of the speaker.

* The concept of “Power Flower

and offers two another advantages, an excellent cooling of the reel and a full back de compression.

™

” also offers two additional advantages of excellent coiling for the coil

™

”, uses seven powerful, but small diameter

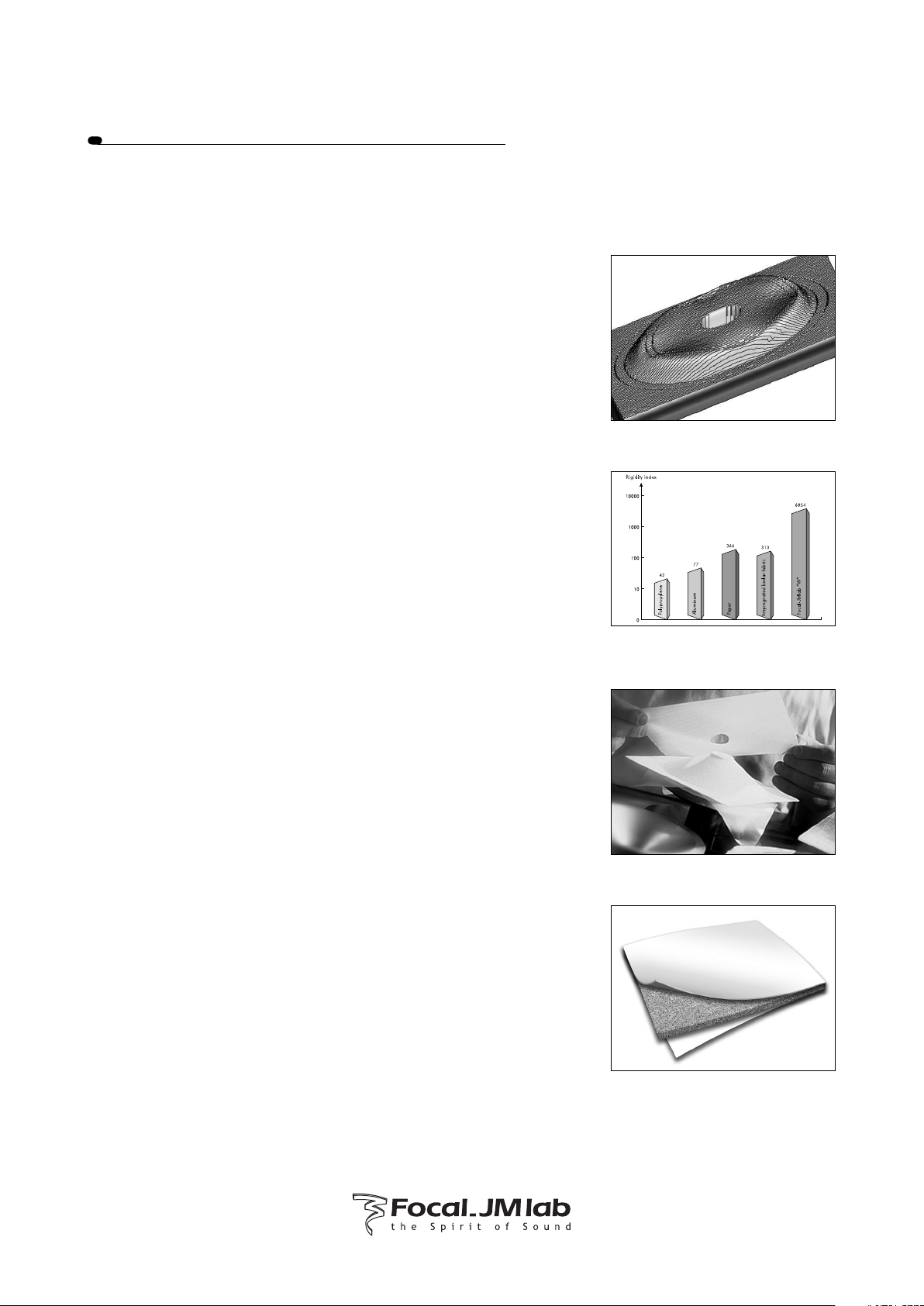

The shape optimisation and the use of multiferrites reduce consistently the

magnetic field losses.

The new mid-range “Power Flower™”. A great manufacturing consistency

provides an exceptionnal accuracy to this 165mm, guaranteeing the strict

tonal balance of the speaker.

6

The "W"™ cone

User manual Utopia Be line

For more than 15 years the composite cone sandwich technology is a Focal-JMlab

exclusivity. The “W” process, fi rst initiated in 1995 with the Grande Utopia,

provides now a true optimisation of the frequency response.

Properties of a drive unit membrane

Three parameters are of prime importance: mass, internal damping and stiffness.

• Stiffness allows the cone to behave as a piston over a wide range of frequencies,

especially important at bass frequencies for low distortion.

• Low mass delivers maximum acceleration on transients for the best reproduction of fine detail.

• Internal Damping damps out any ringing or vibrations in the cone structure that

would otherwise color the sound.

Materials

• Paper a light material, though not very rigid, but with reasonable internal damping.

Sound often suffers from a “cardboard” coloration.

• Polypropylene/Plastics a material relatively heavy, but with good internal damping properties.

Not especially stiff and the sound tends to lack detail and precision.

• A simple woven aramid fibres cone (not a sandwich type construction) uses a resin to seal the cone

and bring about the rigidity required, but this tends to lead to a dull plastiky coloration.

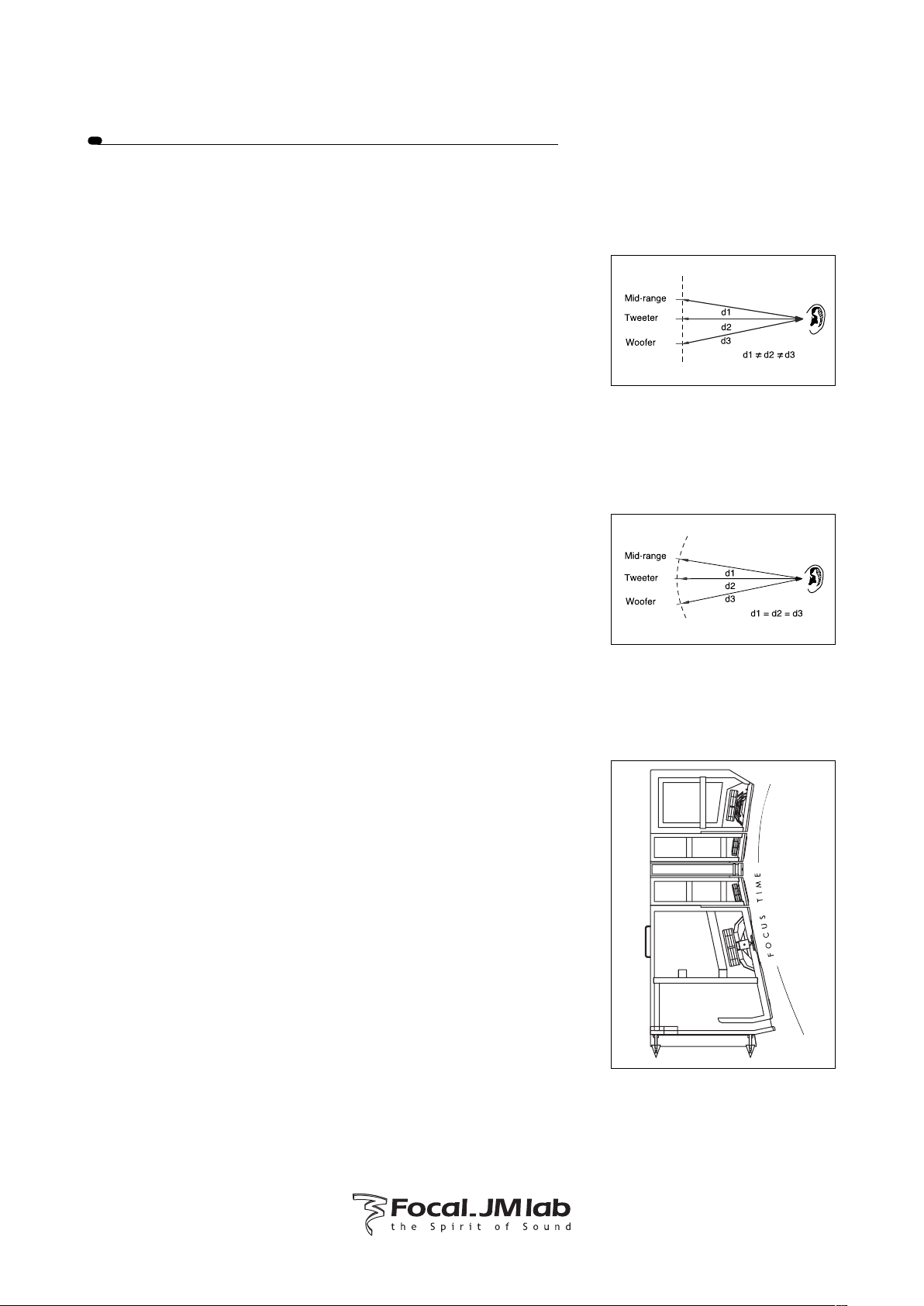

Analysis using laser interferometry allows the optimization of the “W” cones

in terms of rigidity/damping/mass.

The sandwich structure Focal-JMlab

During the mid 1980s, a new type of cone was developed and patented by Focal-JMlab which combined low mass, stiffness and high internal damping; the “Poly-K sandwich”.

Using woven aramid fibres tissue skins and a core of hollow microspheres of glass mixed with

a resin, this structure exhibited extremely high rigidity and low mass.

The damping could be controlled by the properties of the core.

Since this original construction, the process has been refined and developed to produce a new

generation of aramid fibres sandwich. The major advance in the construction of this cone is the use

of a special structural foam in place of the resin + microballs. This foam is used primarily in the

Aerospace industry; no other foam offers the same high ratio of stiffness/mass.

The name “W” is derived from Verre-Verre (Verre = Glass). The “W” cone uses two very fine

tissues of woven glass that are lighter and thinner than aramid fibres.

In addition, the molecular bond between the foam and the glass tissue is far superior to that of the

aramid fibres. This results in a cone structure which is mechanically more stable and with superior

stiffness. This construction allows us to further optimize the transmission speed of the sound wave

in the cone. This new construction process allows the amount of internal damping in the structure

to be very accurately controlled by varying the thickness of the foam: the thicker the foam,

the higher the damping factor.

The relationship between the thickness of the glass tissues and the foam core allows us to finely

optimize the cone structure depending on the particular application and the frequency area

to reproduce.

The “W” cone produces an extremely transparent and neutral sound free from coloration and

distortions normally associated with loudspeakers.

Its only limitation, the price; more than ten times the price of a quality paper cone.

Comparison of the index of rigidity in flexure (expressed in N.mm).

The performance of the “W” cones significantly betters that of other materials

for the same mass. In addition, internal damping is also superior.

The hand-made manufacturing of the "W" cone. Our industrial process is

patented.

The ‘W’ structure, a central core of foam covered by skins of glass tissue.

7

User manual Utopia Be line

Creating a special virtual source capable of delivering a coherent sound

without any loss of audio quality over space.

The scale of the audio spectrum to be reproduced imposes unavoidable physical constraints.

To appreciate this, you only need to consider the wavelengths to be produced.

The wavelength is expressed by:

Focus Time

™

v is the speed of sound in air (340m/s)

λ = v/f

f is the frequency of the signal to be reproduced

Therefore at 100Hz the wavelength

At 1,000Hz the wavelength

And at 10,000Hz the wavelength λ = 3.4cm

The only solution to achieve a faithful reproduction of the original signal is to divide up this

reproduction through the use of optimized loudspeakers, the diameters of which are related to the

frequencies that they are designed to reproduce in order to obtain constant directivity for the

frequencies concerned.

For the bass, due to obvious size restrictions it would be impractical to use diameters running into

meters. Fortunately, directivity is not critical in view of the large wavelength of frequencies in the

bass register. In the midrange and treble, directivity has a major influence however, so here multiple

drive units are needed.

However, although this multiplication of sources is ideal for faithfully reproducing each of the

frequency zones, it does pose a problem of coherence. The sound from each of the drive units must

reach the ear of the listener at the same time (chronological synchronicity). If the midrange, the

treble or the bass is received ahead of any of the other registers, there will naturally be an impression

that the sound is distorted. Faithfully reproducing the original audio signal dictates that all

frequencies must reach the listener at the same time, perfectly in sync.

The Focus Time principle

The alignment of several loudspeakers on a flat front baffle inevitably leads to a small degree of

audio distortion. The treble will be heard first, followed by the medium and the bass - this time

smearing is heard as a blurring of transients. Naturally, it is possible to experiment with the

respective positioning of the transducers in order to compensate for this effect. Nevertheless, it is

obvious that the tweeter that emits the shortest (and therefore the most direct) frequencies must be

placed on the axis of the listener’s ear (at the same height). This means that in order that the mid

and bass frequencies arrive at the same time as the treble, the drivers designed to reproduce these

frequencies must ideally be positioned in a semicircle, the center of which is located at the same

height as the listener’s ear. This is the principle of Focus Time, in which all frequencies are focused

upon the listener and take the same time to cover the distance separating the loudspeaker from the

listener whatever the register, be it bass, mid or treble.

λ = 3.4m

λ = 34cm

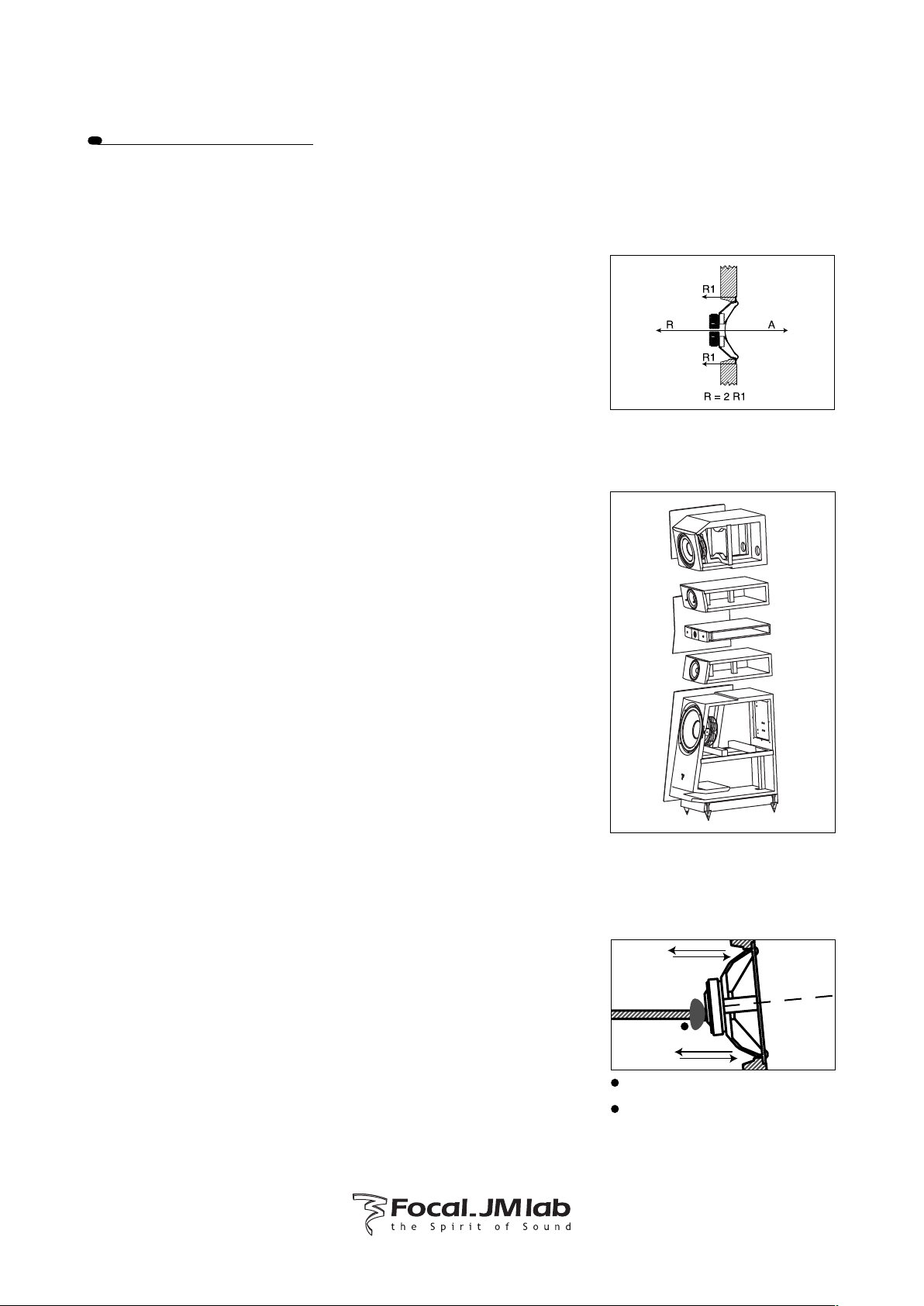

The various loudspeakers are aligned vertically on a traditional front panel.

The distance from the emissive center of each of these loudspeakers to the ear of

the listener is not identical.

The Focus Time structure: each of these loudspeakers is positioned in a

semicircle, taking the listener’s ear as its center.

Towards the ideal of the single point source

As mentioned previously, the theoretical ideal for localized sources inevitably runs up against physical

constraints. This is even more evident when you add the notion of the directivity of the transducers

(see OPC filter) and the notion of energy reproduction, for the bass, arising from the movement of

the membrane which increases progressively as the diameter decreases.

The Focus Time solution offers an intelligent response to all of these problems by reconciling

temporal coherence and enhanced dynamic range. The final sound image is characterized by

excellent stability regardless of the amplitude concerned.

This is the best possible solution to simultaneously reconcile the criteria of tone, dynamic range and

the sound image.

Cutaway view of the Grande Utopia, clearly showing the Focus Time profile.

8

The "γ " front structure

User manual Utopia Be line

The structure of the front baffle needs to reconcile inertia and damping properties in order

to guarantee the dynamic range and the absence of coloration in the bass.

A loudspeaker is a transducer. Its role involves causing molecules of air to vibrate under the influence

of a voice coil coupled with a membrane. A variation in electrical current mirroring the musical

message stimulates the voice coil, which (submerged in the magnetic field) moves “in rhythm” with

the musical signal. The electrical energy is converted into acoustic energy. This is the principle. In

reality however, in order for this conversion to be as faithful as possible to the original audio signal,

it is vital that the membrane moves in relation to a perfectly fixed reference. When the membrane

moves, the chassis must not budge, and its acceleration must be zero. It should

comprise a totally inert mechanical reference.

Inertia: it’s a mass thing!

The chassis of the loudspeaker is solidly attached to the front baffle of the speaker system, the baffle.

The mass ratio between the mobile assembly (voice coil plus membrane) and the frame (the chassis

plus the front panel) must be as high as possible. This is an application of the fundamental principle

of dynamic range: F = m ϒ .

The “ϒ ” (gamma) acceleration taken by the chassis subjected to the moving cone force “F” must

ideally be zero. Consequently, the mass “m” must be as high as possible: it must target infinity.

Thus, regardless of the material chosen to produce the front panel in terms of rigidity, it would be

a mistake to forget the mass. One could easily imagine that a highly dampened front panel would

be the solution to avoid spurious vibrations set up by the “kickback effect” but this would be at

the expense of dynamic output. Only a high mass can guarantee the transients. Damping can never

substitute for mass.

™

In response to the force stimulating A the cone, the front panel applies a

reactive force R of equal amplitude

Coupling between loudspeakers

The highest energy is in the lower register. The woofers induce vibrations in the front baffle which

will interact with the medium and high end drivers and will thus cause intermodulation distortion,

mainly in the high-end where the scale of displacement of the driver membrane is particularly low.

The faithful reproduction of small details will be masked.

The adopted ultimate solution consists in giving each driver its own individual enclosure, set in a

complex curve that is expensive to engineer but is guaranteed to give a total mechanical decoupling

of the drivers.

The Structural solution

The front baffle solution in the Utopia Beryllium introduces a very high inertia to allow the bass

driver to reproduce the transitory information of the low register with all its impact.

The baffle is a massive structure of 50mm thick MDF which gives the front face a very high mass.

For an indication of the scale of that mass, the Grande Utopia -Beryllium weighs 210 kg whereas

the original 95 version weighed 186 kg. The new version is free from any distorting vibration and

the report/ratio of mass - the moving element compared to the frame + box – of the new Utopia is

more than ten times superior to the traditional solutions using curved enclosures.

The “piston” function of woofers

The rear clearance profile provided in the 50mm thickness offers another decisive advantage.

Carefully calculated, it offers a genuine wave-guide for the back emission of the woofers. As such,

the membrane operates like a true “piston”, and is not hindered by waves reflected from inside the

housing which impact against it creating distortions through torsion and/or rolling effects. When

operating ideally, reproduction from the woofers is not affected by distortions arising from

mechanical constraints.

Enhanced listening quality

Every effort is made to remove the source of spurious vibrations and to provide an outstanding

dynamic output from the bass. The sound image is enhanced and the tone offers greater

differentiation due to the absence of the coloration from the cabinet. The midrange and treble registers are consequently better defined and more transparent as the micro-information is

transmitted without any “masking effect”.

Front panel with gamma structure, produced in solid medium density

fiberboard with a thickness of 50mm provides a mechanical reference.

The ultimate solution consists in using individual cabinet for each drive-units to

avoid any intermodulation beetween the drivers.

➋

1

1

The motor systems of the drive units are mechanically coupled to the

internal braces.

2

The optimized profile offers perfect guidance for the cone, which

functions as a true piston. This is not affected by turbulence from the

back wave.

Loading...

Loading...