Page 1

K2 Power User Manual

Congratulations on purchasing a

product from the range, K2 Power.

We are happy you share our

passion, for the "the Spirit of

Sound". Designed using the latest

technology, these speakers continue Focals perfectionist beliefs,

developing products with high

power handling, and unrivalled

sound quality. To obtain the

best results from this product,

we recommend that you follow

carefully all the information

contained in this user’s manual.

If not followed correctly any fault

observed, may not be covered by

the guarantee.

Warning

Continued listening at high volume

levels above 110dB, are damage your

hearing durably

Listening above 130dB can damage

your hearing permently.

The Focal-JMlab guarantee

only applies if the enclosed

guarantee card is returned to

us within 10 days of purchase.

Features

Membrane K2 Power:

New CMKV sandwich composite,

including (Kevlar, foam, and structural

glass fibre). Three individual materials,

each with their own advantages, allow

the cone to be extremely rigid, with

continued low mass value, and

increased damping characteristics,

even when played loud. This ensures

improved power handling, with

detailed sound quality, low distortion

even at high volume levels.

Chassis made from Zamak:

Inherently rigid and non magnetic.

Voice coil wound on Kapton former:

Light-weight and highly durable

material ensures no deformation of

voice coil.

Butyl moulded rubber surround

suspension:

Long life characteristics, even in the

most extreme climates.

TN 52 with inverted tweeter dome:

Inverted dome formed from titanium

treated Tioxid 5 material. Producing

detailed high frequencies, acoustically

rich and dynamic. Controlled with

twin radius wave guides, for totally

controlled staging and directivity.

Crossover of high precision:

Precise level adjustment of tweeter

and medium available. High

quality audiophile components

used throughout. Large wire gauge

connections included.

Français page 9

Focal-JMlab® - BP 374 - 108, rue de l'Avenir - 42353 La Talaudière cedex - France - www.focal-fr.com

Due to constant technological advances, Focal reserves its right to modify specifications without notice. Images may not conform exactly to specific product.

Tel. (+33) 04 77 43 57 00 - Fax (+33) 04 77 43 57 04

Page 2

A B

C D

E

02

F

Page 3

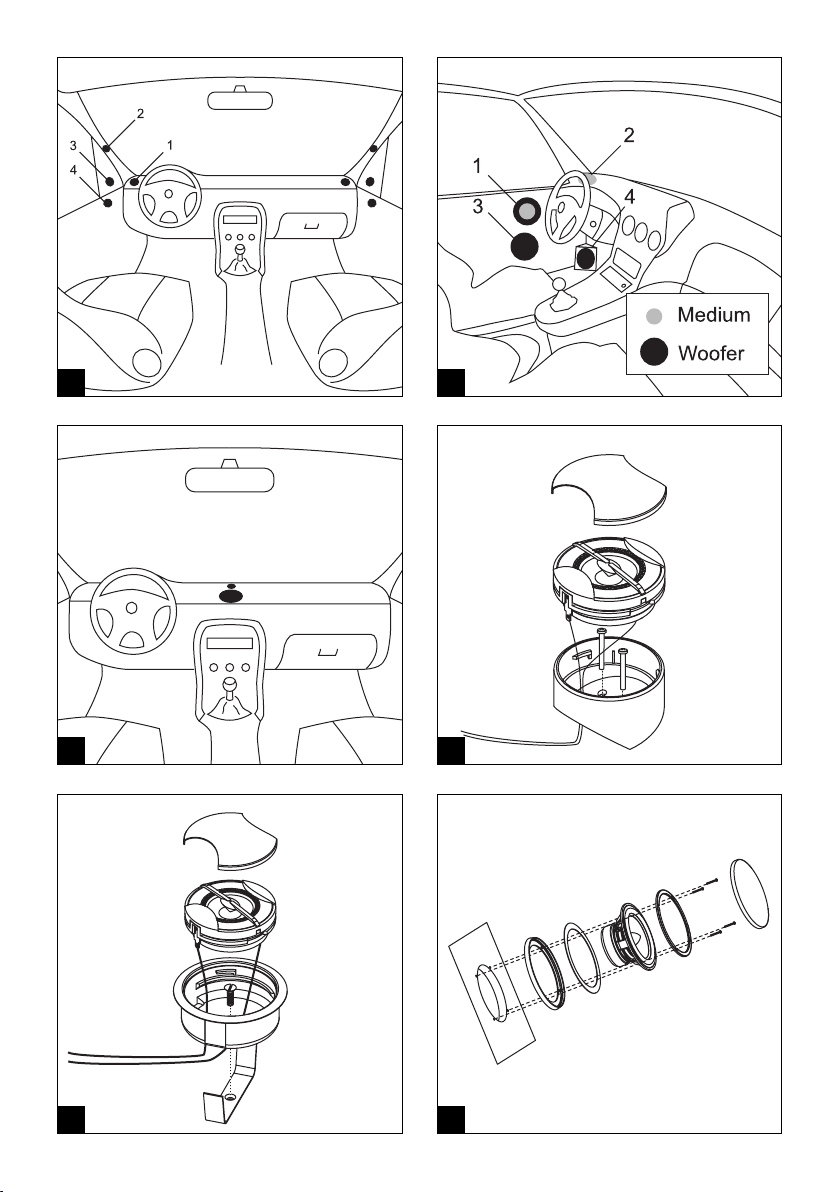

Installation and positioning

Tweeter

The TN52 tweeter has been designed

for flush mount or surface mount

positioning, using the two fixing kits

provided. The choice of install position

is extremely important to deliver

the best performance and maintain

integration into the system. This is a

major factor for high frequency SPL,

and the the stability of the acoustics,

stereophonic imaging, and overall

staging. Please check the drawing to

understand this further.

The standard recommendation for

ideal stereo imaging, is to ensure the

tweeters "left" and "right", are installed

in the same positions. Also they are

approximately at equal distance to the

driver (vice-versa for the passenger).

The various positions advised should

be verified and comparatives made,

for ideal positioning.

The tweeter should always be

positioned ahead of the normal

listening position. The main preferences are the outer positions of the

dash board (fig. A, 1), close to the

windshield (fig. A, 2). Normally easy

for installation. The location close

to the door mirror (fig. A, 3) is also

regarded as a good position, and

normally only requires a small amount

of install work. Lastly a position high in

the doors (fig. A, 4) is also acceptable

even if it is not considered the best for

optimised staging. It is imperative

to verify before any installation is

attempted, that enough space is

available (especially for flush-mount

applications). Also that there will be

no interference with security devices

air-bags, door latches etc.

Woofer-midrange

K2 Power woofer-midranges, positioned ideally high in the doors

(fig. B, 1), produce optimal midrange

frequencies, thus integrating better into

the rest of the system. The 100 KP Slim

thanks to its reduced depth feature

allows easy installation into the outer

positions of the dashboard (fig. B, 2).

If the woofer-mids are positioned

low in the doors (fig. B, 3), the loss

of midrange can be compensated by

adjusting the crossover (see section

"adjustment" page 15).

The woofer-mids from the K2 Power

range can also be placed low in

the "kick-panels" (fig. B, 4) of the

vehicle. This is to further optimise the

stereophonic imaging.

Centre Channel

Ideally suited for an audio video

installation using DVD multi channel

inputs (Dolby Digital, DTS etc), the

ultra compact midrange 100 KP

Slim, has obvious advantages. With

minimum depth dimension 39mm

(1.58"), due to its efficient neodymium

motor, the 100 KP is ideal for centre

channel applications, in normally

difficult locations such as the dash

board (fig. C).

Tweeter installation

Surface-mount

The flush-mounting fixing kit supplied

offers two possibilities for installing

the TN52 in an angle of 10°/30°.

This allows more flexibility for the

installation (fig. D).

Fix the assembly using the two screws

provided. Thread the cable from the

tweeter, through the back.

Then decide the defined angle and

lock in place on the support.

Flush-mount

(highly recommended)

Cut a perfectly round hole of 45mm

(1,77“) Push in the support and ensure

it remains flat on the surface. Ensure

it is locked in place with the screws

supplied. Thread the cable from the

tweeter, through the back. Then decide

the defined angle and lock in place

the tweeter on the support (fig. E).

Attention: It is not necessary to twist

lock the TN52 in place using a locking

tool (as for TN47).To do so, carefully

push and turn on the outer radius

wave guides, turning the tweeter until

it is locked in place.

03

Page 4

HG

I

J

04

Page 5

Installation and positioning

Woofer and woofer-midrange

recommendations

K2 Power woofers and woofermidranges have been designed for

a multitude of vehicles installations.

It is worth understanding the basic

requirements for installing such

products. These woofers and woofermidranges are capable of delivering

enormous amounts of energy, during

their positive/negative movement.

Therefore it is imperative that they

be fixed rigid to the desired location.

The fixing location should also

be strengthened where necessary.

Panels should be strengthened to

eliminate any unwanted vibrations.

Such vibrations will drastically reduce

the overall performance. These drive

units should be fixed and sealed to

the baffle or location panel. The use

of the foam gasket is advisable for

correct air sealing.

For added performance, and to better

reduce such unwanted vibrations

and other acoustical losses, we

recommend the use of "plain chant".

Easily positioned behind the woofer,

on the metal-work of the vehicle, Plain

Chant soaks-up vibrations as well as

acoustic reflections.

Always ensure before that enough

space is available for the magnet

assembly, that it doesn’t interfere with

safety mechanisms or general working

parts.

In the case of not using the grilles

supplied, it is important to ensure

the speakers will fit correctly. Ensuring

there is enough depth behind the

speaker has already been explained,

but enough thought must also be

given for the forward movement of the

cone and surround assembly.

Woofer and woofer-midrange

installation, simple steps (with grille)

Either cut the required hole or use the

correct hole of choice. Note correct

diameter (fig. F). Where necessary,

carefully push in the four fixing clips to

accept the fixing screws later.

Carefully place the fixing ring,

ensuring it lines-up with the holes or

fixing clip positions.

Fix the foam gasket to the back of the

drive unit chassis. Add a small amount

of glue where necessary, so it remains

in the correct position (line-up holes).

Lower the drive unit above the fixing

ring, so it remains in the correct

position (line-up holes).

Don’t forget to connect up the cable

to the connectors.

Now lower the drive unit and screw in

place, with the 4 screws provided.

Now add the grille and push in place.

Ensure the logo is straight.

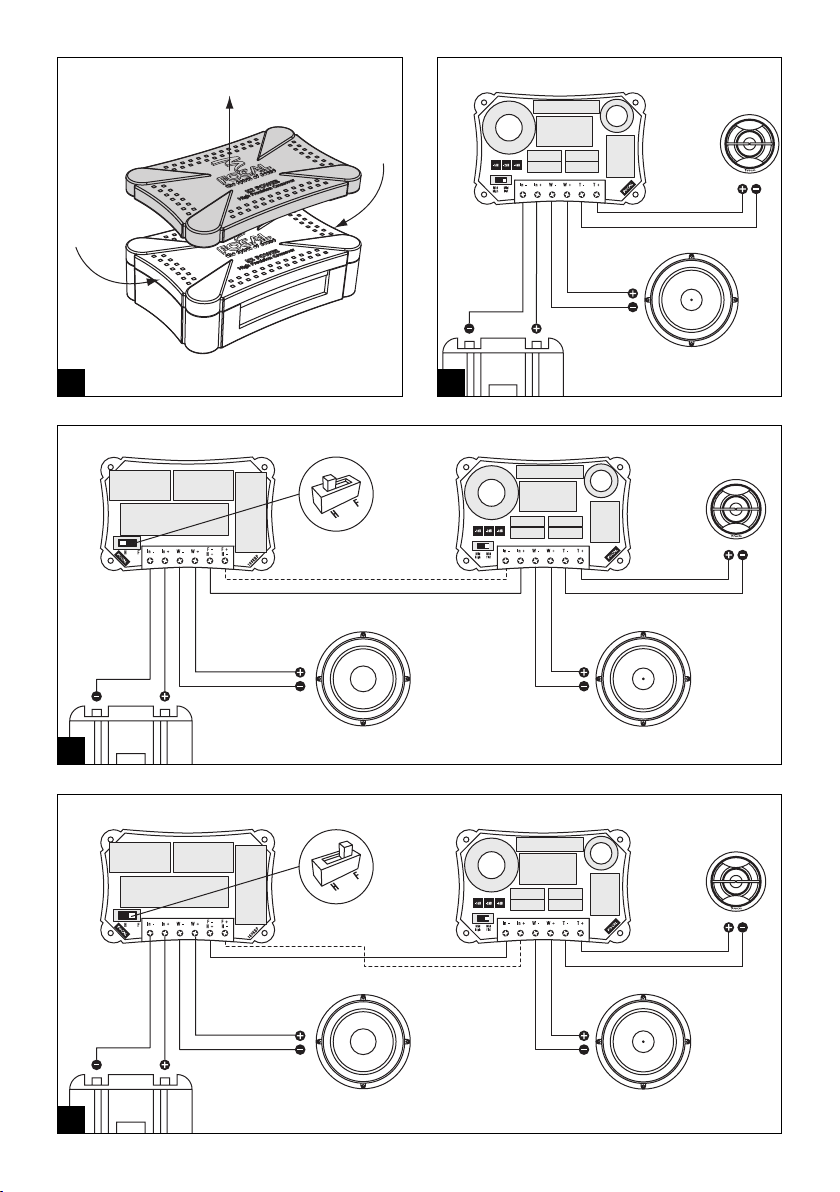

Crossover installation, simple steps

First before any work is started it is

necessary to remove the clear plastic

lid (fig. G).

Doing so enables access for

adjustment, and fixing the unit in

place.

Remove, by pushing gently on the two

shortest sides of the clear plastic lid.

Then pull off.

Never use a screwdriver to prise

off the lid, otherwise damage will

probably occur, not covered by the

warranty.

Once removed, fix in place with the

4 screws supplied. Ensure the length

of screw is suitable for the desired

location. Always ensure the crossover

is installed in a dry and vented area,

without risk of humidity.

2-Way kits connecting up, simple steps

Connect the output from the amplifier

into the input of the crossover "IN".

Connect the woofer to the output of

the crossover "W".

Connect the tweeter to the output of

the crossover "T" (fig. H).

Finally always ensure the tweeter

and woofer are connected in phase

correctly, thus polarities are respected

"+" to "+", and "-" to "-". If not done

correctly a "hole" or "peak", may

result, due to a shift in phase. This

will dramatically impair the overall

performance.

3-Way kits connecting up (165 K3P)

The 165 K3P uses two crossovers,

connected together. The exclusive

165 KBP low frequency cross-over,

has two configurations for filtering.

These being mode:

"High Pass" (fig. I, and K), for a true

3 way set-up, with separate bass mid

and high frequencies.

"Full" (fig. J, and L), for a 2+1 way

set-up, with 2x165mm in parallel, for

more dynamic fast bass.

Important (165K3P)

Depending on the preferred set-up,

the selector found in the 165KBP, must

be switched accordingly.

The mode "Full" (F),requires inverting

the connections, for input (fig. I, and J).

Doing this will ensure the overall

phase will remain correct. Because

this mode has a low impedance value

of approximately 2 ohms, verify if the

low loading is compatible for your

amplifier.

05

Page 6

LK

NM

O P

06

Page 7

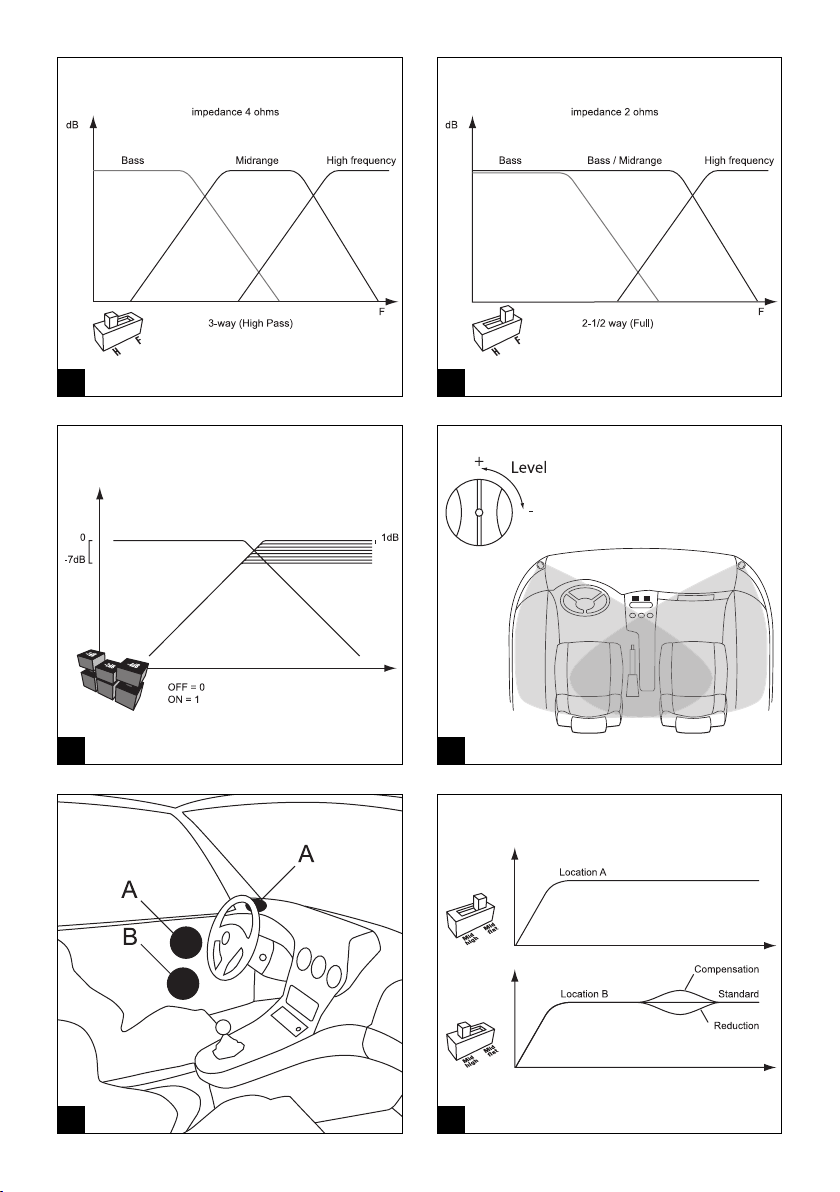

Fine tunning / set-up

Tweeter level adjustment

Adjustments to the tweeter level, can

be made at precise increments, using

the selector buttons found inside on

the PCB board of the crossover.

These are indicated as -1dB, -2dB and

-4dB. By pushing in one or several of

these selector buttons, allows various

reductions of level, from -7dB total by

1dB increments (fig. M).

Tweeter level adjustment table

-1dB -2dB -4dB Total

0000dB

1 0 0 -1dB

0 1 0 -2dB

1 1 0 -3dB

0 0 1 -4dB

1 0 1 -5dB

0 1 1 -6dB

1 1 1 -7dB

Midrange level adjustment

The crossover contains a specific

level adjustment for the midrange

frequencies.

Fitting the drive units high up in the

vehicle requires the mode " Mid flat "

to be used. Doing so will ensure the

overall response curve of the system

remains linear (fig. O, A and fig. P).

Fitting the drive units low in the

vehicle, especially in the bottom of the

door for example, requires the mode

"Mid High" to be used. Doing so will

ensure such normally directional

frequencies are not "masked" or lost

in the textiles of the vehicle (fig. O, B

and fig. P).

Staging level adjustment

The radiused-profiled wave-guides

on the exterior of the TN52 tweeter,

can control the directivity of the high

frequencies. Thereby, the acoustic

energy available can be controlled

by the orientation of this radiused

profile. This characteristic essentially

adds further benefit to the user, to

control the staging of the system, or

defining better the virtual acoustic

imaging of the sound produced.

By simply turning the tweeter and

changing the position of the radiused

profiles, will modify this staging

aspect (fig. N).

Running-in period

K2 Power drive units use the very

latest components. To ensure such

complex mechanical elements work

in harmony with each other, they

must be allowed to function correctly

in this environment. Such changes

in temperature and humidity are

regarded as very hostile. For K2 Power

speakers to benefit, a running-in

period must be used to ensure they

are prepared for this. We recommend

that once the system is ready for

listening the drive units should be

run-in with medium volume setting,

with music that has the full bandwidth

of frequencies (sub-bass through to

treble). This running-in period should

be used for a few weeks, to gain the

full potential. After which the excellent

performance of your K2 Power

products can be fully appreciated.

Information of other K2 Power

products

Focal-JMlab offer a range of subwoofers from the 13 KS (130mm/5")

to the impressive 46 KX4 (460mm/18")

Consult your dealer for futher

information.

Conditions of guarantee

All Focal loudspeakers are covered

by guarantee drawn up by the official

Focal distributor in your country.

Your distributor can provide all

details concerning the conditions of

guarantee. Guarantee cover extends

at least to that granted by the legal

guarantee in force in the country

where the original purchase invoice

was issued.

Your Focal-JMlab product was developed and manufactured with high-quality materials and components

which can be recycled and/or re-used. This symbol indicates that electrical and electronic equipment must be

disposed of separately from normal garbage at the end of its operational lifetime.Please dispose of this product

by bringing it to your local collection point or recycling centre for such equipment. This will help to protect the

environment in which we all live.

07

Page 8

specifications

Kit 100 KP 130 KP 165 KP 165 K2P 165 K3P

Maximum power

Nominal power

Sensitivity

Frequency response

Crossover

Nominal impedance

100W 140W 160W 200W 400W

50W 70W 80W 100W 200W

90dB 90dB 91dB 92.5dB 95.5dB

120 to

22 000Hz

3.5kHz to

12dB/oct

4 ohms 4 ohms 4 ohms 4 ohms 4 ohms (H)/2 ohms (F)

70 to

22 000Hz

3.5kHz to

12dB/oct

60 to

22 000Hz

3.8kHz to

18dB/oct

70 to

22 000Hz

3.8kHz to

18dB/oct

60 to 22 000Hz

200Hz/3.8 kHz to 18dB/oct

Resonant frequency (Fs)

DC resistance (Re)

Woofer/midrange

Resonant frequency (Fs)

DC resistance (Re)

Cut -out diameter

08

Mounting depth

Tweeter

Cone

Magnet

Cone

Voice coil

Magnet

Surround

Vas

Qes

Qms

Qts

Sd

Xmax

TN 52 TN 52 TN 52 TN 52 TN 52

Inverted Tioxid 5 Inverted Tioxid 5 Inverted Tioxid 5 Inverted Tioxid 5 Inverted Tioxid 5

Neodymium Neodymium Neodymium Neodymium Neodymium

1955Hz 1955Hz 1955Hz 1955Hz 1955Hz

5.8 ohms 5.8 ohms 5.8 ohms 5.8 ohms 5.8 ohms

4 K Slim 5 KP 6 KP 6 K2P 6 K2P 6 K3P

4” K2 sandwich

100mm

5” K2 sandwich

130mm

6” K2 sandwich

165mm

6” K2 sandwich

165mm

6” K2 sandwich

165mm

(medium)

6” K2 sandwich

165mm (woofer)

1“ - 25mm 1“ - 25mm 1“ - 25mm 1.6” - 40mm 1.6” - 40mm 1.6” - 40mm

Neodymium 3.4” - 85mm 3.4” - 85mm 4” - 100mm 4” - 100mm 4” - 100mm

Butyl Butyl Butyl Butyl Butyl Butyl

140Hz 88.6Hz 73Hz 69Hz 69Hz 68Hz

3.2 ohms 3.2 ohms 3.0 ohms 2.9 ohms 2.9 ohms 2.9 ohms

0.039Ft

1.13 litres

0.17Ft

4.93 litres

3

0.27Ft

7.71 litres

3

0.3Ft

8.64 litres

3

0.3Ft

8.64 litres

3

0.96 O.74 0.81 0.7 0.7 0.66

9.55 8.06 9.01 9.13 9.13 9.46

0.87 0.68 0.74 0.65 0.65 0.62

2

8.6in

2

55.4cm

3.8N/A 5.09N/A 5.09N/A 5.26N/A 5.26N/A 5.8N/A

Bl

13.42in

86.6cm

2

2

20.57in

132.7cm

2

2

20.57in

132.7cm

2

2

20.57in

132.7cm

2

2

0.1” - 2.5mm 0.1” - 2.5mm 0.2” - 5mm 0.18” - 4.5mm 0.18” - 4.5mm 0.18” - 4.5mm

3.67" - 93mm 4.53" - 115mm 5.60" - 142mm 5.60" - 142mm 5.60" - 142mm 5.60" - 142mm

1.54" - 39mm 2.41" - 61mm 2.80" - 71mm 3.03" - 77mm 3.03" - 77mm 3.03" - 77mm

0.27Ft

7.7 litres

20.57in

132.7cm

3

2

2

Page 9

Notice kits K2 Power

Nous vous remercions d’avoir

choisi les kits K2 Power et de

partager avec nous notre philosophie "the Spirit of Sound".

Ces haut-parleurs de haute

technicité intègrent les ultimes perfectionnements Focal en matière

de conception de haut-parleurs

pour l’obtention d’un son puissant

et de très haute qualité.

Afin d’exploiter toutes leurs performances, nous vous conseillons de

lire ce livret, puis de le conserver

avec précaution pour pouvoir vous

y référer ultérieurement.

Tout problème dû au non-respect

des règles d’utilisation peut entraîner l’invalidation de la garantie.

Avertissement

L’écoute prolongée à fort niveau

au-delà de 110 dB peut détériorer

durablement l’audition. Des écoutes

même brèves à plus de 130 dB

peuvent provoquer des lésions

auditives irrémédiables.

Pour validation de la garantie

Focal-JMlab, merci de nous

retourner la garantie jointe

dans les 10 jours.

Caractéristiques

Membrane K2 Power

Nouveau sandwich CKMV composite

Kevlar / mousse structurale / verre,

alliant très haute rigidité, légèreté

extrême et amortissement maximal

pour un son puissant et très détaillé,

sans distorsions même à fort niveau.

Châssis Zamak

Châssis rigide et amagnétique.

Bobine sur support Kapton

Très haute tenue en puissance sans

déformation de la bobine.

Suspension en butyle

Excellente fiabilité dans le temps.

Tweeter à dôme inversé TN 52

Dôme inversé en titane traité Tioxid 5

pour un son fin, doux, mais détaillé et

dynamique, amorce de pavillon pour

contrôler la directivité et optimiser la

scène sonore (staging).

Filtre haute précision

Réglage du niveau du tweeter et du

médium, composants de filtrage haute

définition, connexions massives.

Focal-JMlab® - BP 374 - 108, rue de l'Avenir - 42353 La Talaudière cedex - France - www.focal-fr.com

Dans un but d'évolution, Focal-JMlab se réserve le droit de modifier les spécifications techniques de ses produits sans préavis. Images non contractuelles. ©Focal-JMlab

Tél. (+33) 04 77 43 57 00 - Fax (+33) 04 77 37 65 87

09

Page 10

A B

C D

E

10

F

Page 11

implantation et montage

Placement tweeter

Le tweeter TN 52 est conçu pour

être monté en surface ou encastré

en affleurement, grâce aux deux kits

de fixation fournis. Le choix de l’implantation du tweeter, de la méthode

de montage encastré ou en surface,

mais aussi l’orientation du tweeter

ont une influence considérable sur

le rendu des hautes fréquences, la

stabilité de l’image stéréophonique

et le "staging".

La règle, incontournable en stéréo-phonie, est de chercher le

meilleur emplacement possible de

manière à ce que les tweeters droit

et gauche soient placés approximativement à égale distance du

conducteur (et vice-versa pour son

passager). L’emplacement idéal du

tweeter exigera de multiples écoutes

comparatives.

Le tweeter devra impérativement être

placé en avant du point d’écoute, de

préférence aux extrémités du tableau

de bord (fig. A, 1), ou mieux encore,

sur les montants de pare-brise

(fig. A, 2) moyennant transformation.

Le carter des rétroviseurs (fig. A, 3)

accepte généralement l’implantation

d’un tweeter moyennant une petite

transformation.

Un positionnement en haut des

portières (fig. A, 4) est acceptable,

même si il n’est pas optimal en termes

de "staging".

Il est impératif de vérifier la profondeur d’encastrement du tweeter

avant perçage, notamment en

encastrement.

Placement woofer / médium

Les haut-parleurs K2 Power pourront

être placés en haut des portières

pour une perception optimale des

fréquences médium (fig. B, 1),

ou, pour le 100 KP Slim aux

extrémités de la planche de bord

(fig. B, 2). Si les woofers sont fixés

au bas des portières (fig. B, 3), les

pertes dans le médium pourront être

avantageusement compensées par

un réglage approprié du filtre (voir

section "réglage fin" page 7).

Les woofers et les médiums K2

Power pourront également être

placés en "kicks panels" (fig. B, 4)

dans le but d’optimiser la perception

stéréophonique (staging).

Placement voie centrale

Dans le cadre d’une installation

multimédia avec utilisation d’une

source DVD multicanaux (Dolby

Digital, DTS), le médium ultra

compact 100 KP Slim pourra être

avantageusement utilisé en tant que

voie centrale (fig. C). Ses dimensions

réduites, notamment grâce à

l’uti-lisation d’un puissant aimant

néodyme très compact, permettront

d’envisager son installation sur le

sommet du tableau de bord ou sur la

console centrale du véhicule.

Montage tweeter

Montage en surface

Le kit de fixation pour le montage en

surface du TN 52 offre deux pans

pour choisir une inclinaison de 10° ou

30° et optimiser l’installation (fig. D).

Fixer le support au moyen de deux vis

fournies, faire passer les fils du tweeter

au travers du support, mettre en place

le tweeter puis le faire pivoter pour le

bloquer sur le support.

Montage encastré

(fortement recommandé)

Les meilleurs résultats sonores seront

obtenus pour un montage des

tweeters en encastrement.

Découper une ouverture de 45 mm

de diamètre. Insérer le support de

montage en affleurement avec sa

barrette de fixation maintenue par le

boulon (fourni). Bloquer la vis afin que

la barrette vienne pincer le support et

le maintienne fermement en haut de

porte ou sur la planche de bord. Faire

passer les fils du tweeter au travers du

support, mettre en place le tweeter

puis le faire pivoter pour le bloquer

sur le support (fig. E).

Attention : il ne faut en aucun cas

utiliser l’arceau central pour faire

pivoter le tweeter. Prendre uniquement

appui sur les lobes latéraux du

pavillon.

11

Page 12

HG

I

J

12

Page 13

implantation et montage

Installation woofer et médium

Recommandations importantes :

Les hauts-parleurs de la ligne K2

Power sont conçus, grâce à des

réglages adaptés et optimisés,

pour fonctionner au mieux de leurs

possibilités dans la plupart des

emplacements habituels.

Il convient cependant de ne pas

perdre à l’esprit que ces haut-parleurs

délivrent une énergie considérable qui

ne doit pas être diluée dans la structure

du véhicule, la faute à un support de

haut-parleur insuffisamment rigide.

Nous vous suggérons de fixer les

haut-parleurs K2 Power sur un support

très rigide, éventuellement renforcé

par du bois ou de la résine.

Les haut-parleurs devront y être

ensuite solidement fixés pour éviter les

vibrations parasites. L’étanchéité du

support doit être parfaite pour éviter

les fuites entre l’avant et l’arrière du

woofer, sous peine d’occasionner un

dysfonctionnement important.

Pour des écoutes optimales, nous

vous conseillons de coller un matériau

absorbant type plain chant directement sur la tôle intérieure de la

portière, juste derrière le haut-parleur,

pour amortir les vibrations.

Vérifier également que l’aimant

du woofer ne gênera pas certains

organes mécaniques du véhicule.

Si vous n’utilisez pas les grilles

fournies avec les kits K2 Power mais

celles d’origine par exemple, veillez à

ce que l’espace entre le haut-parleur

et la grille soit suffisant pour que la

membrane ne vienne pas percuter la

grille à fort volume.

Montage woofer et médium

Placer si nécessaire les 4 pattes de

fixations de vis fournies.

Mettre en place la couronne de

fixation de la grille (fig. F).

Fixer le joint circulaire sur la face

arrière du châssis du haut-parleur.

Mettre en place le woofer sur le

support de grille.

Pour les kits 165 K2P et 165 K3P

uniquement, placer la couronne de

rigidification en faisant coïncider les

trous de fixation.

Fixer solidement l’ensemble au moyen

des 4 vis fournies.

Mettre la grille de protection en

place.

Montage filtre

Pour accéder aux trous de fixation

du filtre mais aussi aux différents

réglages, retirer le capot translucide

en appuyant fermement sur les

deux extrémités de celui-ci et en le

soulevant. Ne pas utiliser d’outils

pour retirer le capot au risque de le

détériorer (fig. G).

Fixer solidement le filtre au moyen des

4 vis fournies sur un support adapté

dans le véhicule.

Les filtres doivent être montés dans

un endroit sec et aéré (de préférence

exempt de vibration).

Câblage kits 2 voies (100 KP Slim,

130 KP, 165 KP,165 K2P)

Brancher la sortie de l’amplificateur

sur les entrées "IN" du filtre.

Connecter le woofer sur l’entrée "W"

et le tweeter sur "T" (fig. H).

Attention : il est primordial de

respecter les polarités "+" et "-" pour

l’obtention d’un recoupement optimal

entre le woofer et le tweeter, sans

sensation de "trou" ou de "bosse" à

l’écoute.

Câblage kit 3 voies (165 K3P)

Le kit 165 K3P utilise 2 modules

de filtrage montés en cascade.

Le filtre grave 165 KBP peut être utilisé

selon deux types de configurations :

en mode "High Pass" (H) pour une

configuration 3 voies (fig. K), avec

grave, médium et aigu séparés, ou

en mode "Full" (F) en configuration

"2 voies et demie" (fig. L). Dans ce

cas, les deux haut-parleurs de 165 mm

fonctionnent en tandem dans le grave

pour des basses plus impactantes.

Pour commuter le mode de fonctionnement "Full" ou "High Pass",

positionner le sélecteur du filtre

165 KPB.

Le mode "Full" impose une inversion

de polarité pour l’interconnexion des

deux filtres (fig. I, J). Dans le cas

contraire, les boomers fonctionneront

en opposition de phase et les

graves vont s’annuler entre eux par

phénomène de compensation.

Attention : en mode 2 voies et demie,

l’impédance chute à 2 ohms. Vérifiez

si l’amplificateur utilisé est compatible

avec une telle charge.

13

Page 14

LK

NM

O P

14

Page 15

réglages fins

Réglage du tweeter

Le réglage du niveau du tweeter

s’effectue à l’intérieur du filtre, par

l’intermédiaire des 3 inverseurs

matriciels, qui commandent respectivement une atténuation de -1 dB,

-2 dB et -4 dB. Leur action peut être

cumulée pour atteindre une échelle

d’atténuation de -7 dB au total, par

pas de 1 dB (fig. M).

Tableau de réglage matriciel du

niveau du tweeter.

-1 dB -2 dB -4 dB Total

0 0 0 0 dB

1 0 0 -1 dB

0 1 0 -2 dB

1 1 0 -3 dB

0 0 1 -4 dB

1 0 1 -5 dB

0 1 1 -6 dB

1 1 1 -7 dB

Réglage du médium

Le filtre contient un réglage spécifique

de la voie médium qui optimise le

rendu en fonction de l’emplacement

choisi pour le woofer/médium.

Lorsque celui-ci est placé

suffisamment en hauteur (fig. O, A),

le mode "Mid flat" est préférable. Ce

mode correspond à une courbe de

réponse linéaire.

Lorsque le woofer/médium est placé

au bas des portières (fig. O, B) par

exemple, les fréquences du médium,

plus directives, sont atténuées, ce

qui risque de nuire à la richesse et

à la définition. Le mode "Mid High"

anticipe ces pertes grâce à une

compensation appropriée (fig. P).

Réglage du "staging"

Le profil des pièces de phases du

tweeter en "demi coque" permet

d’obtenir un contrôle précis de

la directivité du tweeter, donc de

l’énergie sonore totale délivrée, selon

l’orientation du pavillon du tweeter.

Cette caractéristique essentielle peut

être utilisée à profit pour optimiser

finement le "staging" (placement,

centrage et précision dans l’espace

des instruments).

La rotation du tweeter dans son support

devra être optimisé de manière à ce

qu’un auditeur perçoive d’avantage

de niveau du tweeter opposé que

celui lui faisant face (fig. N).

Période de rodage

Les haut-parleurs utilisés sur K2

Power sont des éléments mécaniques

complexes qui exigent une période

d’adaptation pour fonctionner au

mieux de leurs possibilités et s’adapter

aux conditions de température et

d’humidité de votre environnement.

Cette période de rodage varie selon

les conditions rencontrées et peut se

prolonger sur quelques semaines.

Pour accélérer cette opération, nous

vous conseillons de faire fonctionner

vos haut-parleurs une vingtaine

d’heures à niveau moyen, sur des

programmes musicaux riches en

grave. Une fois les caractéristiques des

haut-parleurs totalement stabilisées,

vous pourrez profiter intégralement

des performances de vos kits

K2 Power.

Configuration

La ligne K2 Power compte une

gamme de 5 subwoofers de 13 cm

(13 KS), 27 cm (27 KX), 33 cm (33

KX), 40 cm (40 KX) et 46 cm (46 KX 4)

dont les caractéristiques sont idéalement complémentaires avec celles

des kits K2 Power.

Consulter votre revendeur.

Conditions de garantie

En cas de problème, adressez-vous à

votre revendeur Focal.

La garantie pour la France sur tout

matériel Focal est de 1 an. En cas

de matériel défectueux, celui-ci

doit être expédié à vos frais, dans

son emballage d’origine auprès

du revendeur, lequel analysera le

matériel et déterminera la nature de la

panne. Si celui-ci est sous garantie, le

matériel vous sera rendu ou remplacé

en "franco de port". Dans le cas

contraire, un devis de réparation vous

sera proposé.

La garantie ne couvre pas les

dommages résultant d’une mauvaise

utilisation ou d’un branchement

incorrect (bobines mobiles brûlées par

exemple...).

En dehors de la France, le matériel

Focal est couvert par une garantie

dont les conditions sont fixées

localement par le distributeur officiel

Focal de chaque pays, en accord

avec les lois en vigueur sur le territoire

concerné.

Votre produit Focal-JMlab a été conçu et fabriqué avec des matériaux et composants de haute qualité,

susceptibles d’être recyclés et réutilisés. Ce symbole signifie que les appareils électriques et électroniques,

lorsqu’ils sont arrivés en fin de vie, doivent être éliminés séparément des ordures ménagères. Veuillez rapporter

cet appareil à la déchetterie communale ou à un centre de recyclage. Vous contribuez ainsi à la préservation

de l’environnement.

15

Page 16

caractéristiques

Kit 100 KP 130 KP 165 KP 165 K2P 165 K3P

Puissance maximale

Puissance nominale

Sensibilité

Réponse en fréquence

Fréquences de filtrage

Impédance nominale

100 W 140 W 160 W 200 W 400 W

50 W 70 W 80 W 100 W 200 W

90 dB 90 dB 91 dB 92,5 dB 95,5 dB

120 à

22 000 Hz

3,5 kHz à

12 dB/oct

4 ohms 4 ohms 4 ohms 4 ohms 4 ohms (H)/2 ohms (F)

70 à

22 000 Hz

3,5 kHz à

12 dB/oct

60 à

22 000 Hz

3,8 kHz à

18 dB/oct

70 à

22 000 Hz

3,8 kHz à

18 dB/oct

60 à

22 000 Hz

200 Hz/3,8 kHz à

18 dB/oct

Fréquence de résonance (Fs)

Résistance continue (Re)

Woofer/médium

Fréquence de résonance (Fs)

Résistance continue (Re)

Diamètre d'encastrement

Profondeur d'encastrement

16

Tweeter

Dôme

Aimant

Membrane

Bobine mobile

Aimant

Suspension

Vas

Qes

Qms

Qts

Xmax

TN 52 TN 52 TN 52 TN 52 TN 52

Inversé Tioxid 5 Inversé Tioxid 5 Inversé Tioxid 5 Inversé Tioxid 5 Inversé Tioxid 5

Néodyme Néodyme Néodyme Néodyme Néodyme

1955 Hz 1955 Hz 1955 Hz 1955 Hz 1955 Hz

5,8 ohms 5,8 ohms 5,8 ohms 5,8 ohms 5,8 ohms

4 K Slim 5 KP 6 KP 6 K2P 6 K2P 6 K3P

Sandwich K2

100 mm

25 mm 25 mm 25 mm 40 mm 40 mm 40 mm

Néodyme 85 mm 85 mm 100 mm 100 mm 100 mm

Butyle Butyle Butyle Butyle Butyle Butyle

140 Hz 88,6 Hz 73 Hz 69 Hz 69 Hz 68 Hz

3,2 ohms 3,2 ohms 3,0 ohms 2,9 ohms 2,9 ohms 2,9 ohms

1,13 litres 4,93 litres 7,71 litres 8,64 litres 8,64 litres 7,7 litres

0,96 O,74 0,81 0,7 0,7 0,66

9,55 8,06 9,01 9,13 9,13 9,46

0,87 0,68 0,74 0,65 0,65 0,62

55,4 cm

Sd

3,8 N/A 4,27 N/A 5,09 N/A 5,26 N/A 5,26 N/A 5,8 N/A

Bl

2,5 mm 2,5 mm 5 mm 4,5 mm 4,5 mm 4,5 mm

93 mm 115 mm 142 mm 142 mm 142 mm 142 mm

39 mm 61 mm 71 mm 77 mm 77 mm 77 mm

2

Sandwich K2

130 mm

86,6 cm

2

Sandwich K2

165 mm

132,7 cm

2

Sandwich K2

165 mm

132,7 cm

2

Sandwich K2

165 mm

(médium)

132,7 cm

2

Sandwich K2

165 mm

(woofer)

132,7 cm

2

Page 17

Su producto Focal-JMlab ha sido concebido y fabricado con materiales y componentes de alta

calidad, que pueden ser reciclados y reutilizados. Este símbolo signifi ca que los aparatos eléctricos

y electrónicos, al final de su vida útil, deberán ser separados de los residuos domésticos y reciclados.

Rogamos llevar este aparato al punto de recogida de su municipio o a un centro de reciclaje.

Por favor, contribuya Vd. también en la conservación del ambiente en que vivimos.

E

Deres Focal-JMlab-produkt er designet og fremstillet med materialer og komponenter af høj kvalitet,

som kan recycles og genbruges. Dette symbol betyder, at elektriske og elektroniske apparater skal

bortskaffes adskilt fra det almindelige husholdningsaffald, når de ikke længere bruges. Aflever dette

apparat på Deres lokale kommunale genbrugsstation eller på genbrugscentret. Hjælp med at passe på

det miljø, vi lever i.

DK

Ihr Focal-JMlab-Produkt wurde mit hochwertigen Materialien und Komponenten entworfen und

hergestellt, die recycelbar sind und wieder verwendet werden können. Dieses Symbol bedeutet, dass

elektrische und elektronische. Geräte am Ende ihrer Nutzungsdauer vom Hausmüll getrennt entsorgt

werden müssen. Bitte entsorgen Sie dieses Gerät bei Ihrer örtlichen kommunalen Sammelstelle oder

im Recycling Centre. Bitte helfen Sie mit, die Umwelt in der wir leben, zu erhalten.

D

Tämä Focal-JMlab-tuote on suunniteltu ja valmistettu korkealaatuisista materiaaleista ja

komponenteista, joita voidaan kierrättää ja käyttää uudelleen. Tämä symboli tarkoittaa, että

sähkölaitteet ja elektroniset laitteet tulee hävittää erillään kotitalousjätteestä, kun niitä ei enää käytetä.

Jätä tämä laite paikkakuntasi kunnalliseen keräyspisteeseen tai kierrätyskeskukseen. Auta meitä

säästämään luontoa, jossa elämme.

FIN

Il vostro prodotto Focal-JMlab è stato progettato e realizzato con materiali e componenti pregiati

che possono essere riciclati e riutilizzati. Questo simbolo signifi ca che gli apparecchi elettrici ed

elettronici devono essere smaltiti separatamente dai rifi uti domestici alla fine del loro utilizzo.

Vi preghiamo di smaltire questo apparecchio negli appositi punti di raccolta locali o nei centri preposti

al riciclaggio. Contribuite anche voi a tutelare l’ambiente nel quale viviamo.

I

Az Ön által vásárolt Focal-JMlab termék kiváló minőségű, újrahasznosítható és/vagy újra

felhasználható anyagok és komponensek felhasználásával készült. Ez a szimbólum azt jelzi, hogy

az elektromos és elektronikus készüléket a normális hulladéktól elkülönítetten kell kidobni, amikor

élettartama végére ért. A termék kidobásakor kérjük, vigye azt a helyi gyűjtőponthoz, vagy az

ilyen készülékek számára fenntartott újrahasznosító központba! Ezzel hozzájárulhat környezetünk

H

megóvásához, amelyben mindannyian élünk.

Uw Focal-JMlab-Product is ontworpen voor en gebouwd uit hoogwaardige materialen en componenten

die gerecycled kunnen worden en dus geschikt zijn voor hergebruik. Dit symbool betekent, dat

elektrische en elektronische apparatuur aan het einde van zijn levensduur gescheiden van het huisvuil

apart moet worden ingeleverd. Breng dit apparaat naar een van de plaatselijke verzamelpunten of naar

een kringloopwinkel. Help s.v.p. mee, het milieu waarin we leve te beschermen.

NL

SK

O seu produto Focal-Jmlab foi concebido e fabricado, utilizando materiais e componentes de alta

qualidade que, podem ser reciclados e reutilizados. Este símbolo significa que, no fim da sua vida

útil, equipamentos eléctricos e electrónicos devem ser eliminados separadamente dos resíduos sólidos

domésticos. Por favor, entregue este equipamento ao respectivo ecoponto local ou comunal ou ao

centro de reciclagem competente. Por favor, ajude-nos a preservar o meio ambiente em que vivemos.

P

17

Page 18

Produkt Focal-JMlab został zaprojektowany i wykonany z materiałów i elementów wysokiej jakości,

nadających się do recyklingu i ponownego wykorzystania. Symbol ten oznacza, że sprzęt elektryczny

i elektroniczny należy utylizować po zakończeniu użytkowania odrębnie od odpadów domowych.

Sprzęt należy utylizować w komunalnym punkcie zbiórki lub w punkcie recyklingu. Pomóżcie i Wy

chronić środowisko, w którym żyjemy.

PL

SLO

LT

GR

Focal-JMlabs produkter har konstruerats och tillverkats av högkvalitativa material och komponenter som

kan återvinnas och återanvändas. Symbolen innebär att uttjänade elektriska och elektroniska apparater

måste tas om hand separerat från hushållsavfallet. Lämna apparaten på kommunens insamlingsställen

eller återvinningscentraler. Hjälp oss att skydda vår miljö.

SE

CZ

LV

Teie Focal-JMlab toode on välja töötatud ning toodetud kõrgkvaliteetsest materjalist ning osades,

mida on võimalik ümber töödelda ning/või korduvkasutada. Antud märgis näitab, et elektri- ja

elektroonikaseadmeid peab nende kasutusaja lõppemisel kõrvaldama lahus muudest jäätmetest.

Palun viige toode kõrvaldamiseks teie kohalikku jäätmete kogumiskohta või antud seadme

ümbertöötamiskeskusesse. See aitab kaitsta meid ümbritsevat keskkonda.

SE

18

Page 19

Garantie France

Pour validation de la garantie Focal, merci de nous retourner cette page dans

les 10 jours, à l’adresse suivante :

Focal-JMlab

BP 374

108, rue de l’Avenir

42353 La Talaudière cedex - FRANCE

Modèle : N° de série :

Nom du revendeur : Ville :

Date de l’achat : Prix de l’achat :

Votre nom : Âge : Profession :

Votre adresse complète :

Votre adresse email :

Composition de votre installation (marque, modèle) :

Cassette : CD :

Système de navigation : Système multimédia :

DVD : Amplificateur :

Chargeur CD : Autres éléments :

Votre choix pour l’achat de ce modèle Focal s’est fait en fonction de :

Conseil du revendeur Conseil d’amis, relation

Visite d’exposition, salon Article de presse

Ecoute en auditorium Possède déjà Focal

Fiabilité / Qualité Catalogues

Réputation Matériel Français

Garantie Rapport qualité / prix

Esthétique / Finition Autre :

Son

En cas de renouvellement, quels étaient vos précédents haut-parleurs ?

Dîtes en quelques mots pourquoi vous avez choisi Focal...

Vos annotations éventuelles :

Nous garantissons la confidentialité de ces informations.

19

Page 20

International Guarantee

The Focal guarantee only applies if this page is returned to us within 10 days of

purchase, to the following address:

Focal-JMlab

BP 374

108, rue de l’Avenir

42353 La Talaudière cedex - FRANCE

Model: Serial number:

Name of dealer: Town:

Date of purchase: Purchase price:

Your name: Age: Occupation:

Your complete address:

Your email address:

Details of your installation (brand, model):

Cassette: CD:

Navigation: Multimedia center:

DVD: Amplifier:

CD-change: Other elements:

Your decision for purchasing this Focal model was made according to:

Dealer’s advice Friend’s advice

Visit to an exhibition, show Press article

Listening in auditorium Already own Focal products

Reliability / Quality Documentation

Reputation French produce

Guarantee Quality / Price ratio

Design / Finishes Other:

Sound

In case of purchase of new equipment, what where your former speakers ?

Explain in a few words why you choose Focal...

Further comments:

20

The information given on this page will remain confidential.

CODO1009

3544050001695

SCOS-060620/1

Loading...

Loading...