Page 1

Annex G

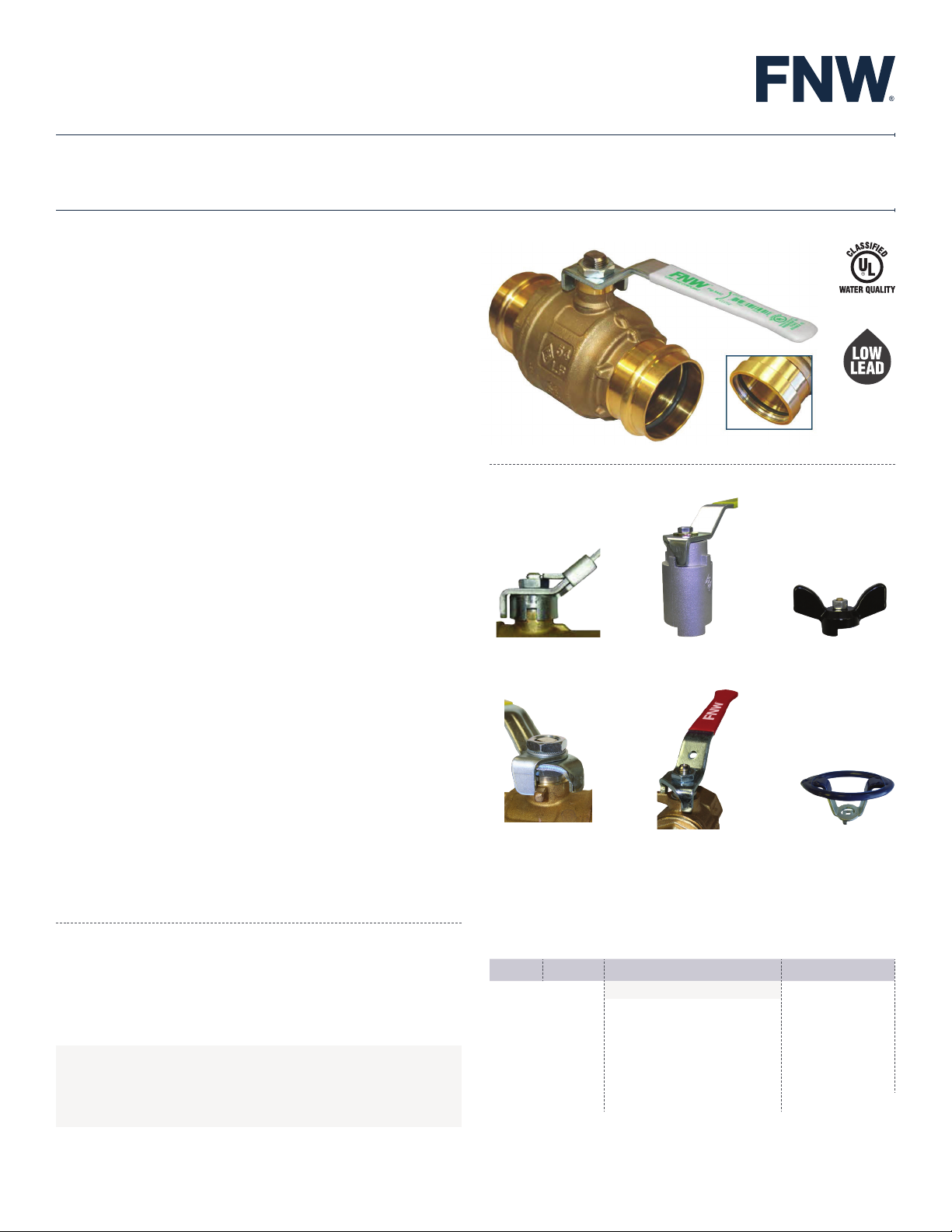

FIGURE X432

BRASS BODY BALL VALVES

LOWLEAD COMPLIANT 2PIECE* FULL PORT**

WATER SERVICE VALVE WITH PRESS ENDS

FEATURES

The FNW figure X432 press valve for water service is an

economical alternative to the more robust figure X430. The

valve allows quick installation on copper pipelines meeting

ASTM B88 standards. The structure of the valve, made in

dezincification-resistant brass, guarantees excellent corrosion

resistance particularly in the connection areas of the pipeline.

Drip fit O-rings ensure that an end connection will drip, indicating

an end was not pressed.

• Sizes: 1/2"–4" (2-1/2"–4" are XLC end connections‡)

• Full port**

• Press ends

• Drip fit O-rings (1/2"–2")

• No soldered-in end pieces

• Blowout-proof stem

• Dual O-ring non-adjustable packing

• Forged brass body and end cap

• 100% electronically tested in open and

closed position at 80 PSI

OPTIONS

ANSI/NSF61

2-1/2"–4" XLC Ends

PRODUCT SPECIFICATIONS

Standards

• Conforms to MSS SP-110†

• ANSI/NSF 61 Annex G Certified (UL)

(Annex G references NSF 372)

Service Limits

• Max. Working Pressure: 200 PSI (non-shock)

• Max. Temperature: 250°F (at max. pressure)

* Sizes 2-1/2"–4" use threaded-in O-ring and sealed XLC press end adapters

** Standard port is 4" valve

† The current specification SP-110 does not address the new technology of press

end connections; other than this exception, the valve meets the design criteria of

the specification

‡ XLC valves are for copper pipe or copper XLC fittings only and should not be used on

brass fittings or adapters

Note: Low Lead Compliant: Referring to laws defining “Lead Free” as wetted surface

of pipe, fittings and fixtures in potable water systems that have a weighted average

lead content ≤ 0.25% per the Safe Drinking Water Act (Sec. 1417) amended 1-4-2011 as

well as other state regulations.

NOT FOR USE AT OR BELOW GROUND LEVEL.

Locking Handle Kit

(1/2"–4")

Memory Stop Kit

(1/2"–2")

Stem Extension Kit

(1/2"–4")

Stainless Handle

(1/2"–2")

Tee Handle Kit

Oval Handle Kit

(1/2"–2")

ACCESSORY KIT CODES

FNW 420 Kit Size

Kit Type 1/2" = BD

Locking Handle Kit (LHK) 3/4"–1" = FG

Stem Extension (SE) 1-1/4"–1-1/2" = HJ

Tee Handle (THK) 2" = K

Oval Handle (OHK) 2-1/2"–3" = LM

Memory Stop (MSK) 4" = P

Stainless Handle (SSHK)

Note: The figure X432A uses the same accessories as the 420.

FNW.COM

©2019 FNW 0719 1389597

Page 2

FIGURE X432

BRASS BODY BALL VALVES

LOWLEAD COMPLIANT 2PIECE* FULL PORT**

WATER SERVICE VALVE WITH PRESS ENDS

REFERENCE CHART

Size ØP Q ØH L L1 L2 h R PN CWP Weight (Lbs)

1/2" 0.55 0.71 1.22 2.93 1.62 1.31 1.77 3.78 200 200 0.44

3/4" 0.75 0.91 1.46 3.37 1.85 1.52 2.22 4.76 200 200 0.72

1" 0.94 0.94 1.76 3.81 2.11 1.70 2.32 4.76 200 200 0.99

1-1/4" 1.19 1.02 2.11 4.17 2.24 1.93 2.85 5.94 200 200 1.55

1-1/2" 1.50 1.42 2.64 5.23 2.78 2.45 3.09 5.94 200 200 2.51

2" 1.95 1.57 3.39 6.27 3.29 2.98 3.70 6.30 200 200 4.19

2-1/2" 2.44 1.65 4.09 7.05 3.76 3.29 4.57 8.07 200 200 7.1 6

3" 2.99 1.91 4.96 8.27 4.45 3.82 4.98 8.07 200 200 10.76

4" 2.99 2.42 5.28 8.94 4.53 4.41 4.98 8.07 200 200 14.68

FIGURE NUMBER MATRIX

FNW X432 End Size

Configuration 1/2" = D 2" = K

1/2" to 2" = Blank 3/4" = F 2-1/2" = L

2-1/2" to 4" = AXLC 1" = G 3" = M

1-1/4" = H 4" = P

1-1/2" = J

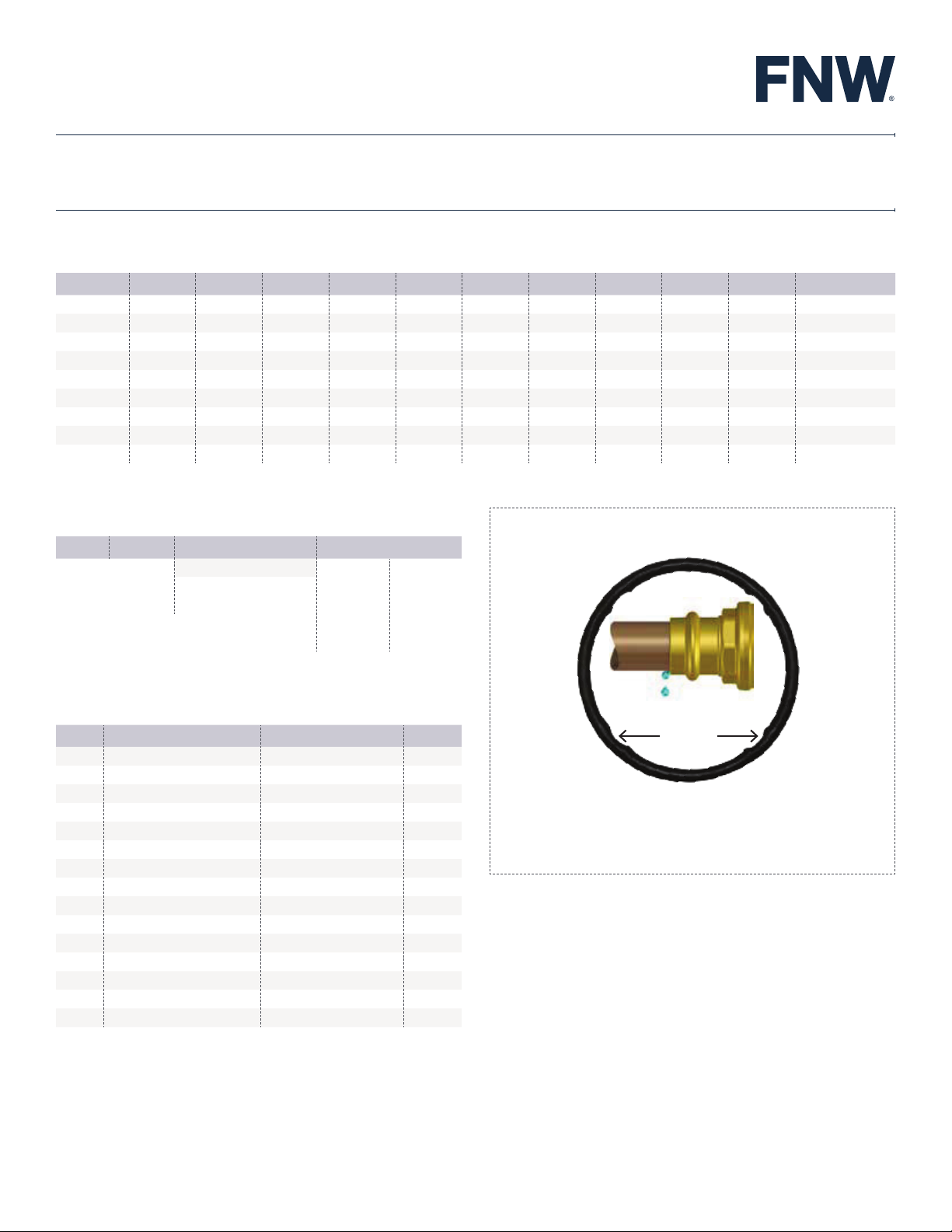

Drip Fit O-Rings

PART MATERIALS & QUANTITY

Ref # Description Material Qty

1 Body Brass CW 511L 1

2 End Connection Brass CW 510L 1

3 Ball Brass CW 510L 1

4 Seat PTFE 2

5 O-Ring EPDM 2

6 Compression Ring Steel 2

7 Packing Ring PTFE 2

8 O-Ring FKM 1

9 O-Ring NBR 1

10 Thrust Washer PTFE 1

11 Stem Brass CW 510L 1

12 Nut Steel CL 04 1

13 Handle Steel DD11 1

14 Ball Brass CW 510L 1

15 Ta g Paper 2

Dimpled

O-Ring

The drip fit O-rings ensure that an unpressed end will drip.

This is an added safety feature to ensure unpressed ends

are discovered and corrected.

FNW.COM

©2019 FNW 0719 1389597

Loading...

Loading...