Page 1

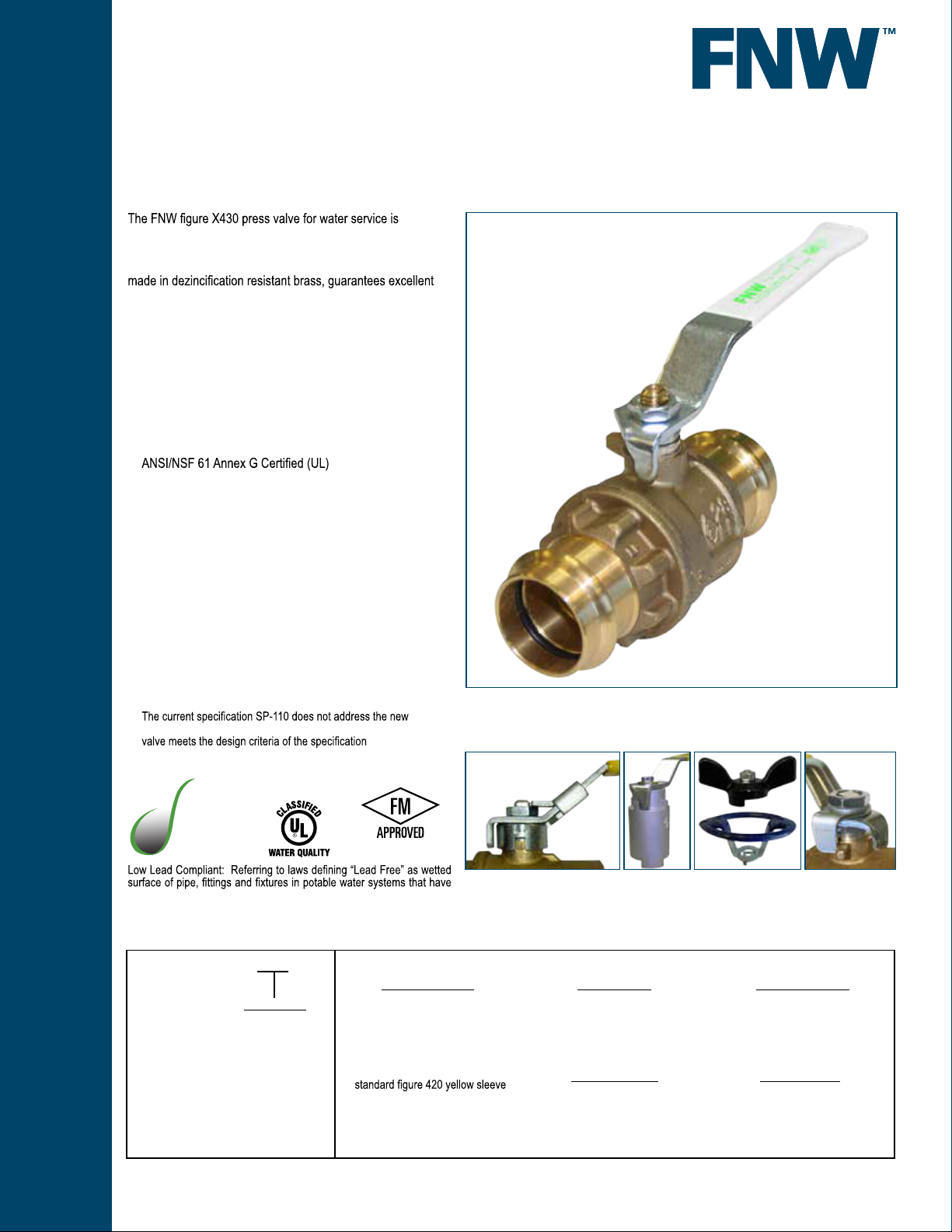

Figure X430

BRASS BODY BALL VALVES

LOW LEAD COMPLIANT 2 PC FULL PORT

WATER SERVICE VALVE w/PRESS ENDS

suggested for all applications where labor and time savings is

a must. The valve allows quick installation on copper pipelines

meeting ASTM B88 standards. The structure of the valve,

corrosion resistance particularly in the connection areas of the

pipeline.

will drip, indicating an end was not pressed.

Features:

*

Drip Fit o-rings ensure that an end connection

• 200 PSI Max. Working Pressure

• 250°F Max. Temperature at Max. Pressure

• Full Port

• Press Ends

• Conforms to MSS SP-110 *

•

(Annex G references NSF 372))

• True 2-Piece Design

• Drip Fit O-rings

• No Soldered-In End Pieces

• Blow-out Proof Stem

• Adjustable Packing

• Secondary O-Ring Stem Seal

• Forged Brass Body & End Cap

• 100% DZR Brass offering greater protection against

corrosion and cracking

• 100% Electronically Tested in Open and Closed Position at

80 PSI

• Uses The Same Handle Accessories As The Figure 420 Ball

Valve

• Sizes 1/2” to 2”

technology of press end connections. Other than this exception, the

OPTIONS

ANSI/NSF61

Annex G

LOW

LEAD

COMPLIANT

a weighted average lead content ≤ 0.25% per the Safe Drinking Water

Act (Sec. 1417) amended 1-4-2011 as well as other state regulations.

FNW X430 Size

SIZE CODE

1/2 = D

3/4 = F

1 = G

1-1/4 = H

1-1/2 = J

2 = K

Up to 2”

Figure Number Matrix

LOCKING LEVER*

1/2 = FNW420LHKBD

3/4 - 1 = FNW420LHKFG

1-1/4 - 1-1/2 = FNW420LHKHJ

2 = FNW420LHKK

* Note: Locking lever kits are of the

type.

www.fnw.com

Lock Lever

Stem Extension Tee or Oval Handle

Kit Codes (Order Separately)

EXTENSIONS

1/2 = FNW420SEBD

3/4 - 1 = FNW420SEFG

1-1/4 - 1-1/2 = FNW420SEHJ

2 = FNW420SEK

OVAL HANDLES

1/2 = FNW420OHKBCD

3/4 - 1 = FNW420OHKFG

1-1/4 - 1-1/2 = FNW420OHKHJ

2 = FNW420OHKK

Memory Stop

MEMORY STOPS

1/2 = FNW420MSKBD

3/4 - 1 = FNW420MSKFG

1-1/4 - 1-1/2 = FNW420MSKHJ

2 = FNW420MSKK

TEE HANDLES

1/2 = FNW420THKBD

3/4 - 1 = FNW420THKFG

Page 2

Figure X430

BRASS BODY BALL VALVES

LOW LEAD COMPLIANT 2 PC FULL PORT

WATER SERVICE VALVE w/PRESS ENDS

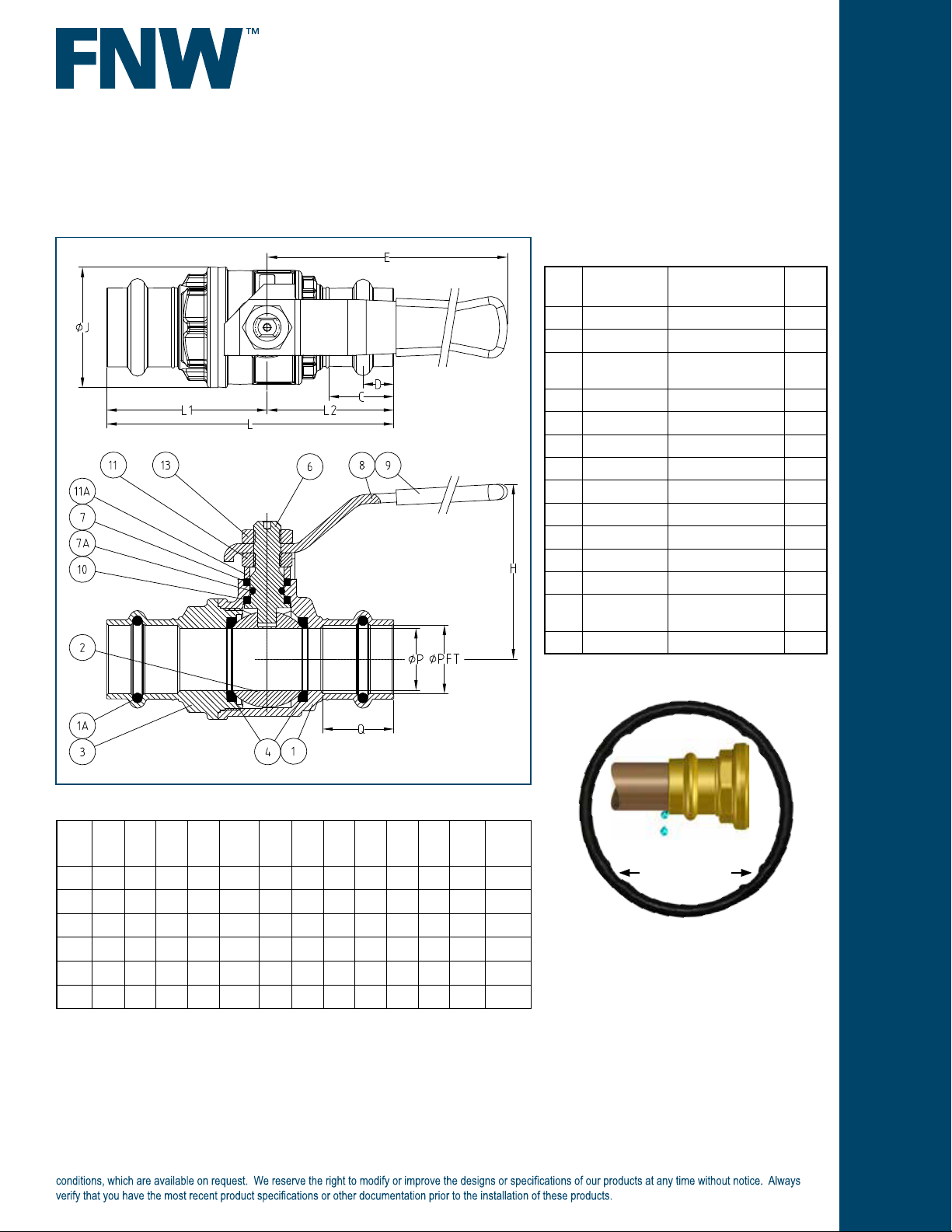

Standard Materials

Ref.

Description Material Qty

No.

1 Body Brass CW 511L 1

1A O-Ring EPDM (EP851)

2 Ball

3 End Cap Brass CW 511L 1

4 Seat PTFE 2

6 Stem Brass CW 510L 1

7 Stem Packing PTFE 1 Set

7A Stem O-Ring NBR 75 Shore A 1

8 Handle Steel DD11 1

9 Sleeve Vinyl 1

10 Thrust Washer PTFE 1

11 Gland Nut Steel CL 04 ZP 1

11A Packing Gland

13 Handle Nut Steel CL 04 ZP 1

Brass CW 510L

(Chrome-Plated)

Brass CW 614N UNI

12164

1

1

Drip Fit O-rings

Dimensions (Inches), Cv, & Weights

Size E H ØJ ØP ØPFT C D Q L L1 L2

1/2 3.86 1.89 1.30 0.59 0.63 0.67 0.31 0.71 3.13 1.71 1.42

3/4 4.80 2.28 1.54 0.79 0.88 0.83 0.39 0.91 3.66 2.05 1.61

1 4.80 2.44 1.93 0.98 1.13 0.83 0.39 0.94 4.13 2.32 1.81

1-1/4 6.02 3.07 2.32 1.26 1.38 0.83 0.39 1.02 4.41 2.44 1.97

1-1/2 6.02 3.35 2.87 1.57 1.63 1.02 0.49 1.42 5.63 2.91 2.72

2 6.38 3.80 3.39 1.95 2.13 1.18 0.57 1.57 6.48 3.39 3.09

DOC: FNWX430V10 Ver. rev-8/2017

© 2017 - FNW. All rights reserved.

The FNW logo is a registered trademark of Ferguson Enterprises, Inc., PL Sourcing, PO Box 2778, Newport News, VA 23609

The contents of this publication are presented for information purposes only, and while effort has been made to ensure their accuracy, they are not to be construed as

warranties or guarantees, expressed or implied, regarding the products or services described herein or their use or applicability. All sales are governed by our terms and

Wt.

Cv

(Lbs)

18 0.49

34 0.86

49 1.23

102 2.34

265 3.48

306 4.61

Dimpled O-ring

The Drip Fit o-rings ensure that an unpressed

end will drip. This is an added safety feature

to ensure unpressed ends are discovered and

corrected.

Loading...

Loading...