Page 1

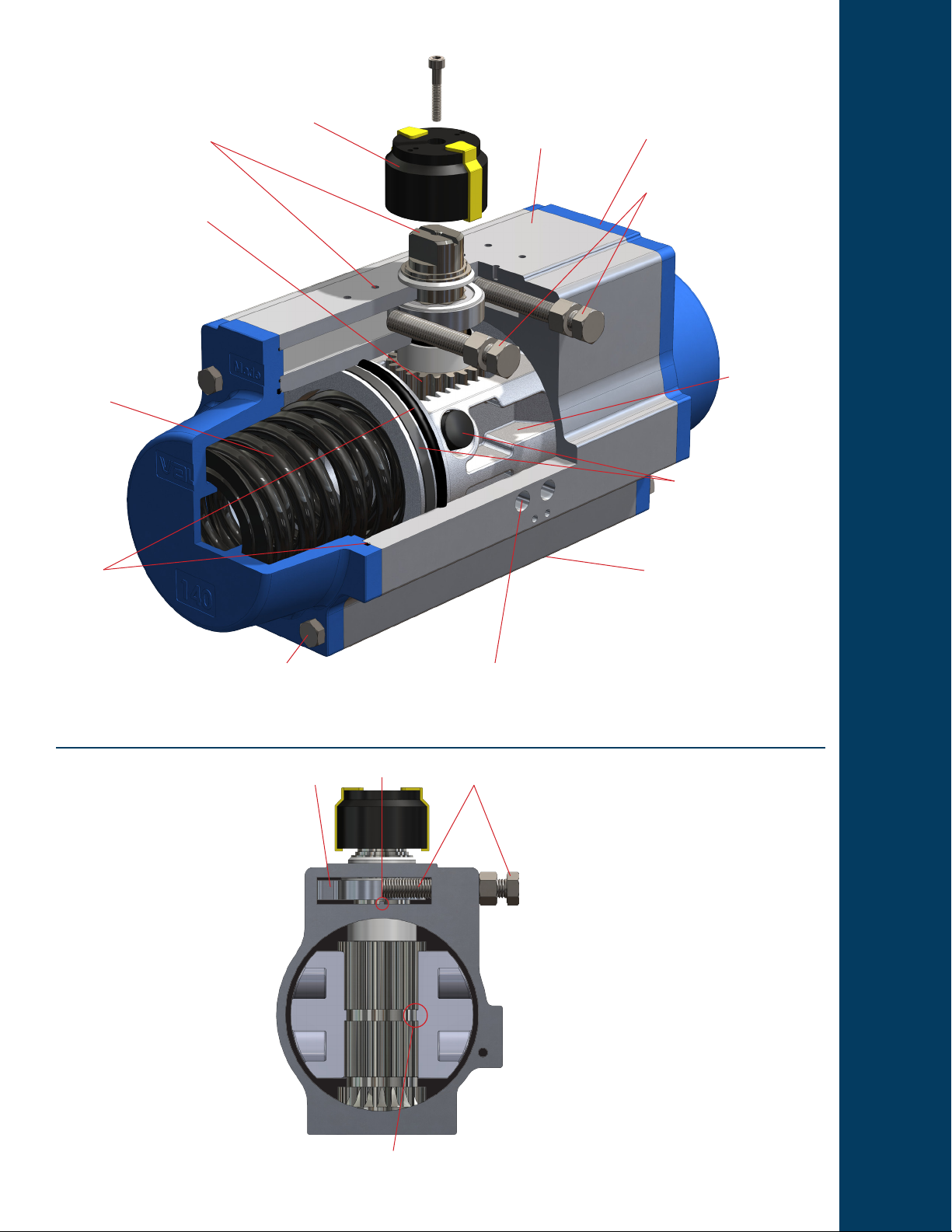

Figure RP

ACTUATORS

PNEUMATIC RACK & PINION

www.fnw.com

Page 2

TORQUE RANGES

The RP rack and pinion actuators are

available with output torques ranging

from 44 to 36,269 in-lbs depending on

air supply pressure and/or spring sets.

ACCESSORY MOUNTING

The accessory mounting pad meets

international NAMUR standards for

ease of directly attaching accessories

following the same standard.

ANTI BLOW-OUT PINION

The design of the pinion prevents

blow out by securing it with the piston

racks. The pinion is ground from

hardened steel and then nickel plated

for maximum corrosion and wear

resistance.

SPRINGS

For fail safe requirements,

reliable and high resistant

steel springs are included.

Springs are zinc phosphate

coated for corrosion

resistance.

SEALS

The standard

actuator is

supplied with NBR

seals at piston, pinion,

and end caps. Viton® is

available for high temperature

applications, and Silicon for low

temperature applications.

Standard Features

POSITION INDICATOR

High visibility position indicator with

snap on marks is easily converted to

indicate 3-way positions or can be

removed for other accessories.

END CAP SCREWS

End caps are secured with extra

length stainless steel screws for safe

disassembly.

ACTUATOR BODY

The body is a single piece extruded

aluminum housing with anodized

hard coat exterior nished to 45-50

microns. An optional nickel plated

exterior is available for added

corrosion resistance.

SOLENOID MOUNTING

Supply air connections follow the

international NAMUR standard for

direct mounting of like style solenoids

and is included on all sizes.

END CAPS

Ends caps are die cast aluminum with

polyester powder coating. Nickel

plated bodies also come with nickel

plated end cap. Double-acting

and spring-return actuators utilize

the same end caps, allowing quick

conversion by adding or removing

springs as needed.

TRAVEL STOPS

Each size actuator comes standard

with two travel stops for +/-5° of open

and close travel adjustment at

nominal positions of 0° and

90°. The stainless steel

adjustment screws and cam

are not located in the main

pressure containing

area of the body,

reducing the number

of possible leak

paths and necessary

seals.

PISTONS

Pistons are

constructed of die

cast aluminum and

designed for strength

and generous rack

engagement.

PISTON GUIDES

Piston guides, constructed from

POM materials, are designed with

a large contact area and long life.

The material offers low friction for self

lubrication.

VALVE MOUNTING

The valve mounting follows ISO 5211

for direct mounting to valves with the

same pattern. All output drive include

an 8-point female drive (except the

model 270 which has a single square

4-point female drive).

Travel Stops

The travel stop cam is located separate

from the pressure chamber of the

actuator. This design eliminates two

potential leak paths as well as the

associated seal components. The cam

is positively locked to the pinion and

easily installed during maintenance

via a guide in the cam chamber. The

cam chamber is a sealed compartment

that is protected from water and

dirt ingress, ensuring trouble free

operation.

Anti-Blowout Pinion

The RP actuators is designed with a

grooved pinion and a corresponding

at key cast in the piston rack. This

system creates an added mechanical

lock that prevents the pinion from

blowing out of the bottom of the

housing. In this design, lower pinion

clips and retainers that can wear out

are eliminated.

2

CAM STOP BOLT

GUIDE

PINION / PISTON GROOVE

Standard Materials

• Body - UNI 6060 Aluminum, Hard Anodized

(Optional Nickel Plating)

• End Caps - Die Cast Aluminum, Polyester

Powder Coated (Nickel plated with nickel plated

body)

• Pinion - Hardened Steel, Nickel Plated

• Pistons - Die Cast Aluminum

• Seals - NBR (Optional High Temperature Viton®

or Low Temperature Silicon)

• Guides/Spacers/Anti-Friction Rings - POM

(Acetal) (Model 270 uses PTFE and Graphite

Filled PTFE anti-friction rings)

• Travel Stops/Cam/End Cap Screws - Stainless

Steel

• Springs - Steel, Zinc Phosphate Coated (Spring

return models only)

• Position Indicator - Nylon

• Travel Stop Housing - GGG40 Ductile Iron

(Model 270 only)

• Upper Pinion Snap Ring - Steel, Nickel Plated

Page 3

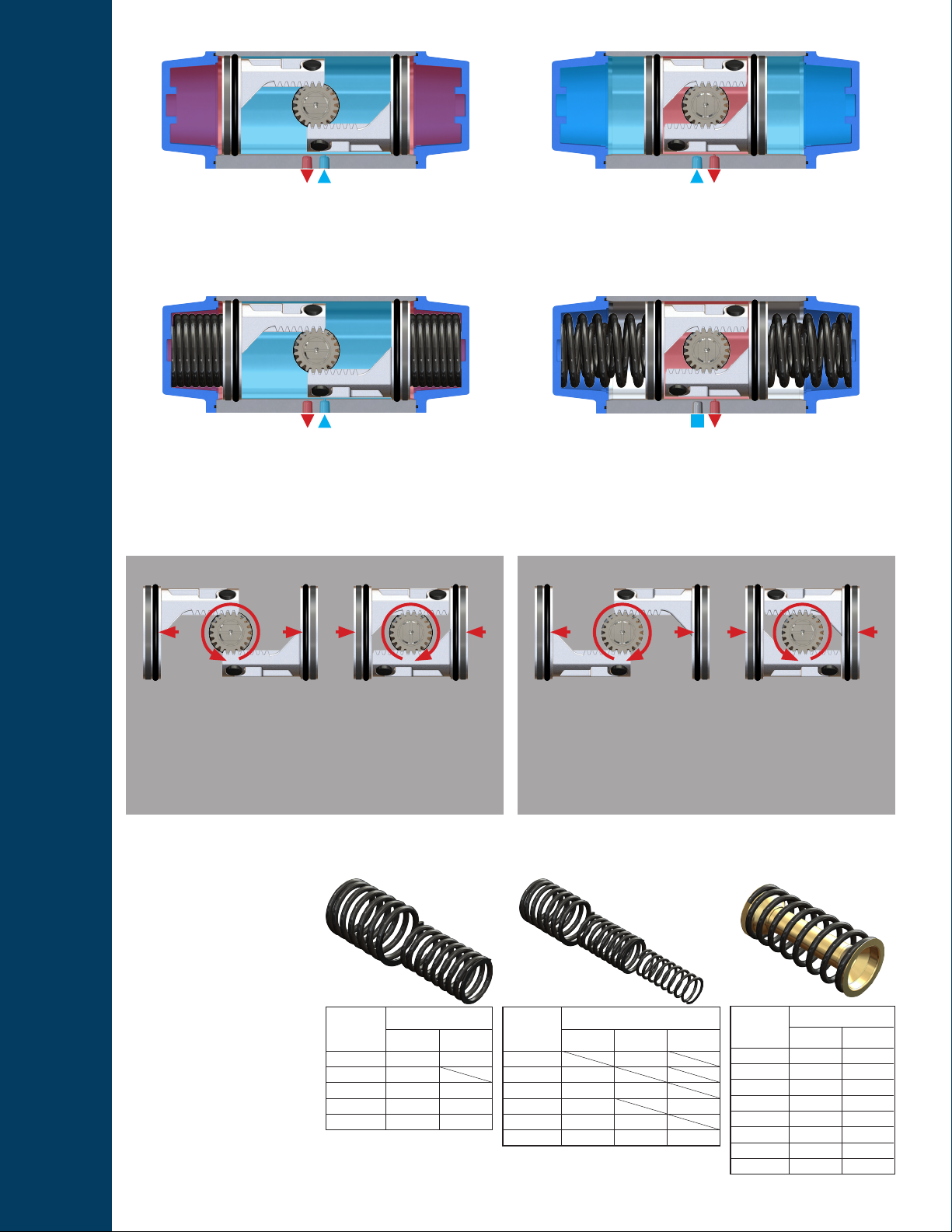

Standard Operation - Double Acting

AB AB

The RP rack and pinion actuator operates (turns) CCW by

supplying compressed air to port A. The pressure drives the

pistons outward, turning the drive pinion CCW. Air on the

outside of the pistons is exhausted out of port B.

Standard Operation - Spring Return

The RP rack and pinion actuator operates (turns) CW by

supplying compressed air to port B. The pressure drives the

pistons inward, turning the drive pinion CW. Air on the inside of

the pistons is exhausted out of port A.

AB

The RP rack and pinion actuator operates (turns) CCW by

supplying and holding compressed air at port A. The pressure

drives the pistons outward, turning the drive pinion CCW and

compressing the spring sets. Air on the outside of the pistons is

exhausted out of port B.

Reversible Operation

Standard Rotation Reversed Rotation

CWCCW

In the standard operation of the RP actuator, the output turns

CCW when the pistons are driven outwards. When the pistons

are driven inwards, the output turns CW. This is the typical

action of the majority of valves that open in the CCW direction,

and close in the CW direction.

Spring Return Spring Set Congurations

The RP rack and pinion

actuators are stocked with full

spring sets (spring set 05 for

models 52 to 140, spring set

06 for models 160 to 230, and

spring set 08 for the model

270).

Spring sets can be modied by

removal of springs, as indicated

in the spring set charts, to alter

the actuator’s torque curve as

shown on the torque charts.

Full spring sets provides the

maximum spring return torque

for a given size actuator, but

can be reduced for situations

where increased torque in the

air stroke is desired.

Spring

Set

01 1 1

02 2

03 1 2

04 2 1

05 2 2

Outer

Inner

Spring Quantity

Outer Inner

* Model 230 has maximum spring set of 06.

AB

The RP rack and pinion actuator operates (turns) CW by

releasing the compressed air at port A. This allows the spring

sets to decompress as they drive the pistons inward and the

pinion turns CW. Make-up air is drawn in through port B from

the atmosphere.

CCWCW

The RP actuator operation is eld reversible so the output turns

CW when the pistons are driven outwards, and CCW when they

are driven inwards. This conguration is used for spring return

actuators that require a mechanical fail in open position, or for

valves with reversed operation.

Models 160 to 200Models 52 to 140

Outer

Middle

Spring

Set

Spring Quantity

Outer Middle Inner

01 2

02 2

03 1 2

04 2 2

05 2 2

06 2 2 2

Inner

Models 230* & 270

Pre-tensioned

Spring

Set

Springs/Side

Side A Side B

01 2 3

02 3 3

03 3 4

04 4 4

05 4 5

06 5 5

07 5 6

08 6 6

Spring

3

Page 4

Weight (Pounds)

Model 52 63 75 85 100 115 125 140 160 180 200 230 270

Double Acting

Spring Return

2.47 3.66 6.13 8.60 12.13 19.51 23.81 35.94 47.95 63.93 81.57 128.97 182.26

2.87 4.34 7.47 10.58 15.43 25.24 31.04 47.40 65.04 87.96 121.25 156.53 221.06

Air Consumption Per Stroke (Cubic Inches)

Model 52 63 75 85 100 115 125 140 160 180 200 230 270

CCW (DA & SR)

CW (DA)

6.10 11.59 21.97 31.12 48.21 78.72 99.47 137.91 220.30 282.54 347.84 651.73 915.36

7.93 14.04 26.85 39.06 61.02 104.35 134.86 192.84 306.34 402.76 643.80 918.41 1,086.22

Stroke Speed (Seconds)*

Model 52 63 75 85 100 115 125 140 160 180 200 230 270

Double

CCW

Acting

Spring

CCW

Return

* Note: Stroke speeds listed are based on actuator alone (no valve) with 6 Bar (87 PSI) supply air pressure. Valve torques and ow characteristics of control accessories

will have an affect on overall stroke speed.

Temperature Ranges

Conguration Working Temperature

Standard

High Temp.

Low Temp.

High and low temperature congurations must be

specied separately.

0.07 0.11 0.18 0.36 0.38 0.60 0.80 1.13 1.43 1.99 3.08 4.15 6.16

0.05 0.10 0.15 0.25 0.34 0.54 0.70 0.94 1.25 1.80 2.41 3.80 5.47

CW

0.07 0.13 0.32 0.32 0.54 0.92 1.20 1.64 2.27 3.08 3.58 6.20 8.97

0.07 0.13 0.22 0.30 0.48 0.75 0.94 1.25 1.60 2.38 2.80 5.40 6.62

CW

Model Number Matrix

-4° to 185°F

(-20°C to 85°C)

-4° to 302°F

(-20°C to 150°C)

-40° to 185°F

(-40°C to 85°C)

52

63

75

85

100

115

125

SIZES

140

160

180

200

230

270

A = Anodized Aluminum

(with polyester powder coated end caps)

N = Nickel Plated

(with nickel plated end caps)

Actuators stocked standard for CCW rotation at supply port A, CW rotation at supply

port B. Standard spring return conguration is fail CW on loss of supply air. Spring

return actuators stocked with full (maximum) spring sets. When applications require

it, rotation, fail position, and spring sets can be modied, but must be specied

separately.

FNW RP 52 A DA

FINISH

DA = Double Acting

SR = Spring Return

ACTION

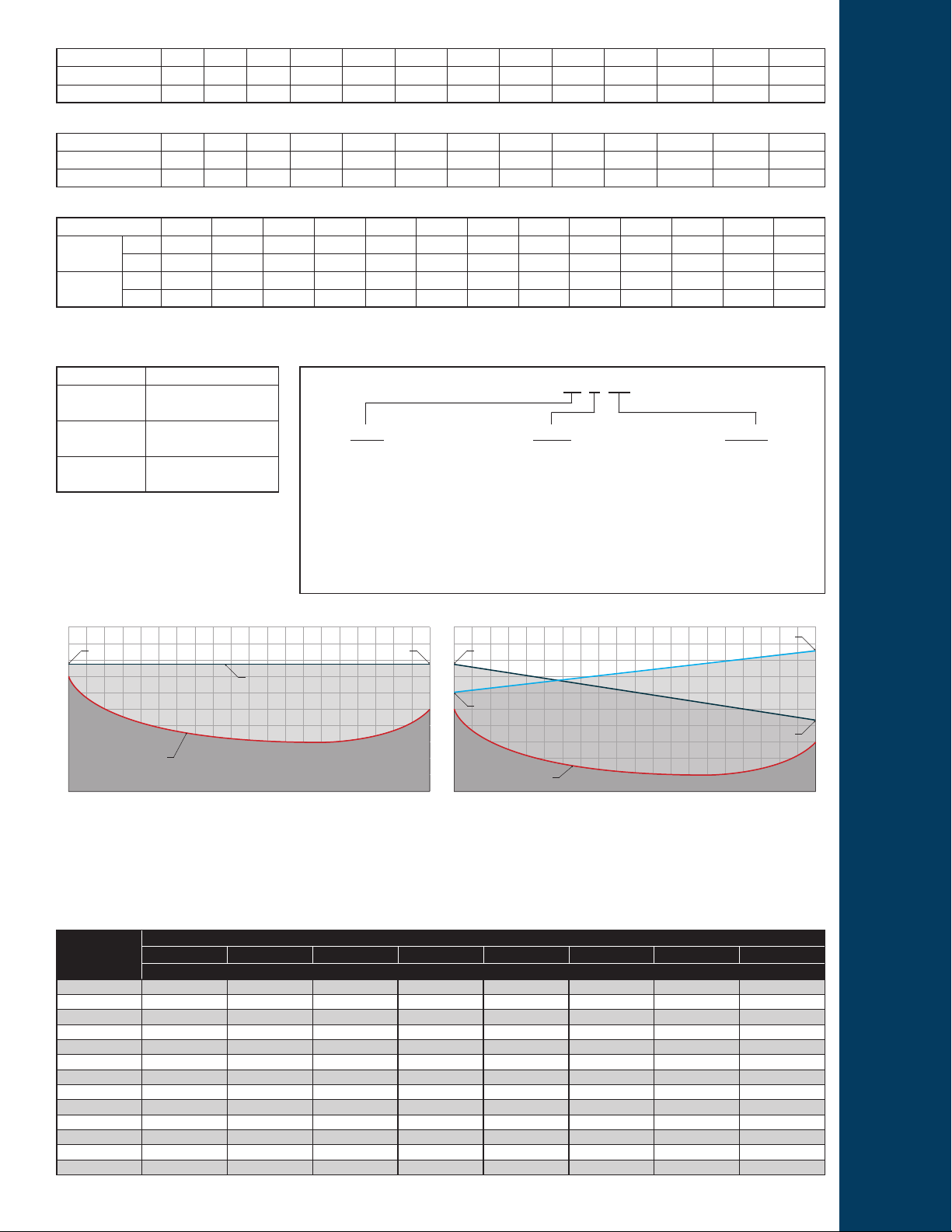

Double Acting Actuator Sizing

Air Stroke Start Air Stroke End

Actuator Torque Curve

TORQUE

Valve Torque Curve

0

The gure RP double acting rack and pinion actuator has a constant torque output.

This is represented by the horizontal line in the diagram. Sizing is simply a matter

of selecting the column for the amount of supply air pressure available for the

actuator, then choosing the actuator that has more torque than the highest torque

requirement of the valve plus a safety factor. Any amount of torque between the

valve and actuator’s torque curve is the safety factor and that percentage should be

chosen based on the type of valve and working conditions.

VALVE POSITION / DEGREES OF ROTATION

Safety Factor

90

Spring Return Actuator Sizing

Air Stroke Start

Actuator Spring Stroke Curve

Actuator Air Stroke Curve

Spring Stroke End

TORQUE

Safety Factor

Valve Torque Curve

0

The torque output of the gure RP spring return actuators is not constant,

but decreases during both the air stroke and spring stroke due to losses from

compression and decompression of springs. When sizing, care must be taken

to select an actuator whose end-of-air and end-of-spring stroke torque is greater

than the valve’s torque plus a safety factor. The RP has maximum spring strength

as standard, but lower spring sets can be obtained by removing the appropriate

springs.

VALVE POSITION / DEGREES OF ROTATION

Double Acting (Air-Air) Torque Chart

Air Supply Pressure (PSI)

Model

52 88 112 133 158 178 201 227 263

63 152 193 238 282 320 361 405 469

75 283 356 435 513 586 659 736 851

85 406 514 628 744 853 960 1,072 1,237

100 645 814 989 1,163 1,333 1,505 1,681 1,939

115 1,065 1,344 1,640 1,932 2,212 2,488 2,779 3,211

125 1,402 1,771 2,153 2,539 2,905 3,274 3,650 4,220

140 2,003 2,504 3,005 3,506 4,006 4,509 5,009 5,764

160 2,804 3,501 4,196 4,899 5,596 6,292 6,987 8,045

180 3,860 4,825 5,790 6,746 7,711 8,661 9,627 11,081

200 5,198 6,494 7,796 9,089 10,393 11,670 12,972 14,924

230 8,589 10,738 12,880 15,031 17,180 19,289 21,440 24,671

270 12,625 15,777 18,935 22,093 25,246 28,361 31,511 36,269

4

40 50 60 70 80 90 100 115

Air Stroke Torque Output (in-lbs)

Spring Stroke Start

Air Stroke End

90

Page 5

Model

52

63

75

85

100

115

125

140

160

180

200

230

270

Spring Return (Air-Spring) Torque Chart

Spring Stroke

Spring

Set

01 44 32 48 23 72 47 95 70

02 59 42 61 31 84 54 108 77

03 66 46 80 47 104 70 127 94 150 117

04 82 57 70 31 93 55 116 78 140 101 163 125

05 105 72 78 32 101 55 125 78 148 102 183 137

01 85 44 92 38 134 80 176 122

02 109 58 120 56 162 98 204 140

03 128 71 149 79 191 121 233 162 275 204

04 152 85 136 54 177 96 219 138 261 180 303 222

05 196 111 151 53 193 95 235 136 276 178 339 241

01 172 89 168 63 244 138 319 214

02 226 118 215 85 291 160 366 235

03 249 133 275 137 351 212 426 288 502 363

04 303 162 247 83 322 158 398 234 473 309 549 385

05 380 205 279 81 354 157 430 232 505 308 618 421

01 242 143 238 109 349 219 460 330

02 298 176 316 163 427 274 537 384

03 361 215 387 211 498 322 609 432 720 543

04 417 248 354 155 465 265 576 376 687 487 797 633

05 536 321 392 146 503 257 614 368 725 478 891 645

01 395 218 384 154 556 326 728 499

02 521 288 485 199 658 372 830 544

03 564 318 628 329 801 502 973 674 1,146 847

04 691 389 558 203 730 375 903 548 1,075 720 1,248 893

05 860 489 630 206 802 378 975 551 1,147 723 1,406 982

01 658 363 650 270 935 555 1,220 840

02 835 449 848 378 1,133 663 1,419 949

03 957 538 1,044 541 1,329 827 1,615 1,112 1,900 1,397

04 1,133 625 958 365 1,243 650 1,528 935 1,813 1,220 2,098 1,505

05 1,432 800 1,067 352 1,352 637 1,638 922 1,923 1,207 2,350 1,635

01 877 470 850 328 1,224 703 1,599 1,077

02 1,040 560 1,135 400 1,400 840 2,000 1,883

03 1,313 718 1,351 640 1,725 1,015 2,099 1,389 2,474 1,763

04 1,477 808 1,261 477 1,636 851 2,010 1,226 2,384 1,600 2,758 1,974

05 1,913 1,055 1,388 415 1,762 789 2,136 1,164 2,511 1,538 3,072 2,099

01 1,346 726 1,240 508 1,742 1,010 2,244 1,512

02 1,523 815 1,642 821 2,144 1,323 2,646 1,825

03 1,958 1,036 1,910 856 2,412 1,358 2,914 1,861 3,408 2,355

04 2,126 1,134 1,810 668 2,312 1,170 2,814 1,672 3,308 2,166 3,810 2,668

05 2,728 1,453 1,979 515 2,481 1,017 2,975 1,511 3,477 2,013 4,233 2,769

01 1,159 735 2,036 1,585 2,741 2,290

02 1,664 1,053 2,405 1,532 3,085 2,438

03 1,991 1,266 2,184 1,405 2,863 2,084 3,552 2,773

04 2,584 1,637 2,465 1,456 3,153 2,463 3,859 2,850

05 2,823 1,788 2,985 1,896 3,691 2,603 4,405 3,317

06 3,744 2,372 3,080 1,620 3,795 2,335 4,474 3,014 5,528 4,069

01 1,487 903 2,540 1,921 3,239 2,620

02 2,230 1,416 2,691 1,823 4,089 3,222

03 2,602 1,611 2,487 1,434 3,885 2,832 5,275 4,222

04 3,664 2,319 3,133 1,735 4,523 3,124 5,222 3,824

05 3,717 2,319 4,523 3,036 5,222 3,735 5,921 4,434

06 5,151 3,222 4,266 2,248 4,965 2,947 6,364 4,346 7,762 5,744

01 2,222 1,496 3,638 2,895 4,954 4,211

02 3,124 2,098 4,264 3,211 5,531 4,477

03 3,788 2,549 3,812 2,556 5,080 3,823 6,338 5,081

04 4,620 2,992 4,549 2,885 5,807 4,144 7,132 5,468

05 5,346 3,593 5,196 3,418 6,521 4,742 7,837 6,058

06 6,842 4,487 5,539 3,150 6,854 4,465 8,122 5,732 10,066 7,677

01 5,895 3,443 4,124 1,522 5,682 3,080 8,789 6,187

02 7,072 4,124 4,956 1,823 8,063 4,930

03 8,258 4,815 7,328 3,682 10,444 6,797

04 9,435 5,505 6,603 2,425 9,718 5,541 11,276 7,098

05 10,612 6,196 5,868 1,177 8,984 4,293 10,541 5,850 12,090 7,399

06 11,789 6,877 8,258 3,036 9,815 4,594 11,364 6,142 14,480 9,258 17,586 12,364

01 7,001 4,478 8,096 5,530 11,308 8,742 14,548 11,982

02 8,399 5,372 7,141 4,061 10,353 7,273 13,627 10,513

03 9,798 6,266 5,229 2,592 9,397 5,804 12,637 9,044 15,877 12,284

04 11,196 7,169 8,450 4,344 11,690 7,583 14,930 10,823 18,141 14,036

05 12,595 8,063 10,734 6,114 13,974 9,354 17,185 12,566 20,397 18,478

06 13,993 8,957 9,778 4,645 13,018 7,885 16,230 11,097 19,441 14,308

07 15,400 9,851 8,823 3,216 12,062 6,416 15,275 9,628 18,486 12,839 21,717 16,071

08 16,799 10,745 7,867 1,707 11,107 4,947 14,319 8,159 17,530 11,370 20,762 14,602 25,593 19,434

(in-lbs)

Start End Start End Start End Start End Start End Start End Start End Start End Start End

40 50 60 70 80 90 100 115

Air Supply Pressure (PSI)

Air Stroke Torque Output (in-lbs)

5

Page 6

Dimensional Drawing - Models 52 to 230

Standard Conguration

Connections: A = CCW Rotation, B = CW Rotation

Actuator shown in the CCW position as viewed from top

Drawing subject to change without notice

Model

Mtg

(ISO 5211)

CH A C D E F H øI J øK L1 L2 M N O P Q

R

(UNC 2B)S (UNC 2B)T (NPT)

52 F03/F05 0.43 5.55 1.18 1.61 3.21 0.79 0.35 0.83 0.31 0.47 3.15 1.18 0.47 1.04 1.97 1.42 10-24 1/4"-20 1/8"

63 F05/F07 0.55 6.46 1.40 1.77 3.66 0.79 0.43 0.98 0.31 0.59 3.15 1.18 0.63 1.08 2.76 1.97 1/4"-20 5/16"-18 1/8"

75 F05/F07 0.67 8.27 1.65 2.07 4.37 0.79 0.51 1.14 0.31 0.75 3.15 1.18 0.75 1.38 2.76 1.97 1/4"-20 5/16"-18 1/8"

85 F05/F07 0.67 9.47 1.87 2.30 4.92 0.79 0.59 1.38 0.31 0.87 3.15 1.18 0.75 1.65 2.76 1.97 1/4"-20 5/16"-18 1/8"

100 F07/F10 0.67 10.83 2.17 2.68 5.43 0.79 0.59 1.38 0.31 0.87 3.15 1.18 0.81 1.97 4.02 2.76 5/16"-18 3/8"-16 1/4"

115 F07/F10 0.87 13.11 2.52 2.87 6.39 1.18 0.87 1.93 0.55 1.26 5.12 1.18 0.95 1.97 4.02 2.76 5/16"-18 3/8"-16 1/4"

125 F07/F10 0.87 14.65 2.68 3.15 6.87 1.18 0.87 1.93 0.55 1.26 5.12 1.18 0.95 2.40 4.02 2.76 5/16"-18 3/8"-16 1/4"

140 F10/F12 1.06 17.13 3.01 3.44 7.76 1.18 0.94 1.93 0.63 1.38 5.12 1.18 1.14 2.80 4.92 4.02 3/8"-16 1/2"-13 1/4"

160 F10/F12 1.06 19.69 3.43 3.90 8.70 1.18 1.18 2.24 0.63 1.57 3.15 5.12 1.18 1.26 3.15 4.92 4.02 3/8"-16 1/2"-13 1/4"

180 F14 1.42 19.41 3.86 4.53 9.96 1.18 1.42 2.44 0.63 1.77 3.15 5.12 1.18 1.69 3.90 5.51 5/8"-11 1/4"

200 F14 1.42 22.78 4.25 4.29 10.94 1.18 1.42 2.64 0.63 1.97 3.15 5.12 1.18 1.46 3.07 5.51 5/8"-11 1/4"

230 F16 1.81 27.17 4.88 4.90 12.80 1.18 1.42 2.64 0.63 1.97 3.15 5.12 1.18 1.97 3.62 6.50 3/4"-10 1/4"

6

Page 7

Dimensional Drawing - Model 270

Standard Conguration

Connections: A = CCW Rotation, B = CW Rotation

Actuator shown in the CCW position as viewed from top

Drawing subject to change without notice

Model

Mtg

(ISO 5211)

CH A C D E F H øI J øK

270 F16 1.81 26.46 5.71 5.71 15.71 1.18 1.42 2.76 0.79 1.97

Model L1 L2 M N O P

S

(UNC 2B)T (NPT)

U V W Z

270 3.15 5.12 1.18 1.97 7.40 6.50 3/4"-10 1/4" 4.37 3.11 9.06 2.68

7

Page 8

Figure RP

ACTUATORS

DOC: FNWRP12 Ver. 7/2012

© 2012 - FNW. All rights reserved.

The FNW logo is a trademark of Ferguson Enterprises, Inc., PL Sourcing, PO Box 2778, Newport News, VA 23609

The contents of this publication are presented for information purposes only, and while effort has been made to ensure their accuracy, they are not to be construed as

warranties or guarantees, expressed or implied, regarding the products or services described herein or their use or applicability. All sales are governed by our terms and

conditions, which are available on request. We reserve the right to modify or improve the designs or specications of our products at any time without notice. Always

verify that you have the most recent product specications or other documentation prior to the installation of these products.

Loading...

Loading...