Page 1

!

!

!

IN-ST431-14

Before using any Fluid Metering, Inc. product read the following safety instructions

as well as specific product specifications and operating instructions.

STH/Q SET UP INSTRUCTIONS

FOR ADDITIONAL REFERENCES SEE H431 AND Q431

SAFETY INSTRUCTIONS

Warning!

xplosive atmosphere, corrosive air, wet environment or submerged in fluid.

e

Disconnect electrical power before checking pump for any problems.

Connect motor, speed controllers, or any other electrical devices

based on Fluid Metering Inc. specifications. Any unauthorized work

performed on the product by the purchaser or by third parties can

impair product functionality and thereby relieves Fluid Metering, Inc.

of all warranty claims or liability for any misuse that will cause

damage to product and/or injury to the individual.

Power cables and leads should not be bent, pulled or inserted by

excessive force. Otherwise there is a threat of electrical shock or fire.

Replace any inline fuses only with fuse rating as specified by Fluid

Metering, Inc.

When pump/drive is under operation, never point discharge tubing

into face or touch any rotating components of pump.

In a power down thermal overload cut-in condition, unplug or turn off

power to pump. Always allow a cool down period before restarting:

otherwise, injury or damage may occur.

For 30 seconds after power is removed from pump/drive: do not

touch any output terminals. Electrical shock may occur because of

residual voltage.

Fire, electrical shock or explosion may occur if used near combustibles

REQUIRED TOOLS:

1. Analytical Pan Balance

2. Hex Key Driver for Adjusting Stroke Length:

STH: 3/32" Hex Driver

STQ: 7/32" Hex Driver

3. A removable wicking thread lock (loctite 290)

Caution! Fire, electrical shock, injury and damage may

occur if not used in accordance with Fluid Metering, Inc.

specifications and operation instructions.

Do not put wet fingers into power outlet of unit.

Do not operate with wet hands.

Do not operate drive assemblies that require a hard mount

(to be bolted down) unless they are mounted per Fluid Metering, Inc.

specifications, if not injury may occur and/or damage to unit.

Do not touch any rotating pump or motor components: injury may

occur.

Do not run pump dry, unless designed for that service.

Running dry is harmful to the pump, and will cause excessive heating

due to internal friction.

Check pump rotation and inlet/outlet pump port orientation before

connecting power to pump. If not injury may occur.

When pulling out cords from outlets do not pull cord, grasp plug to

prevent plug damage or electrical shock.

Fluid Metering, Inc. Drive Motors become HOT and can cause

. DO NOT TOUCH!

a burn

2.0 GENERAL SET-UP

2.1 Setting Dispense Stroke Rate

Strokes Per Minute (spm): For fluids of 500cps

viscosity or less a stroke rate of 120-350 spm max is

ideal. For fluids with greater than 500cps a slower rate

is recommended.

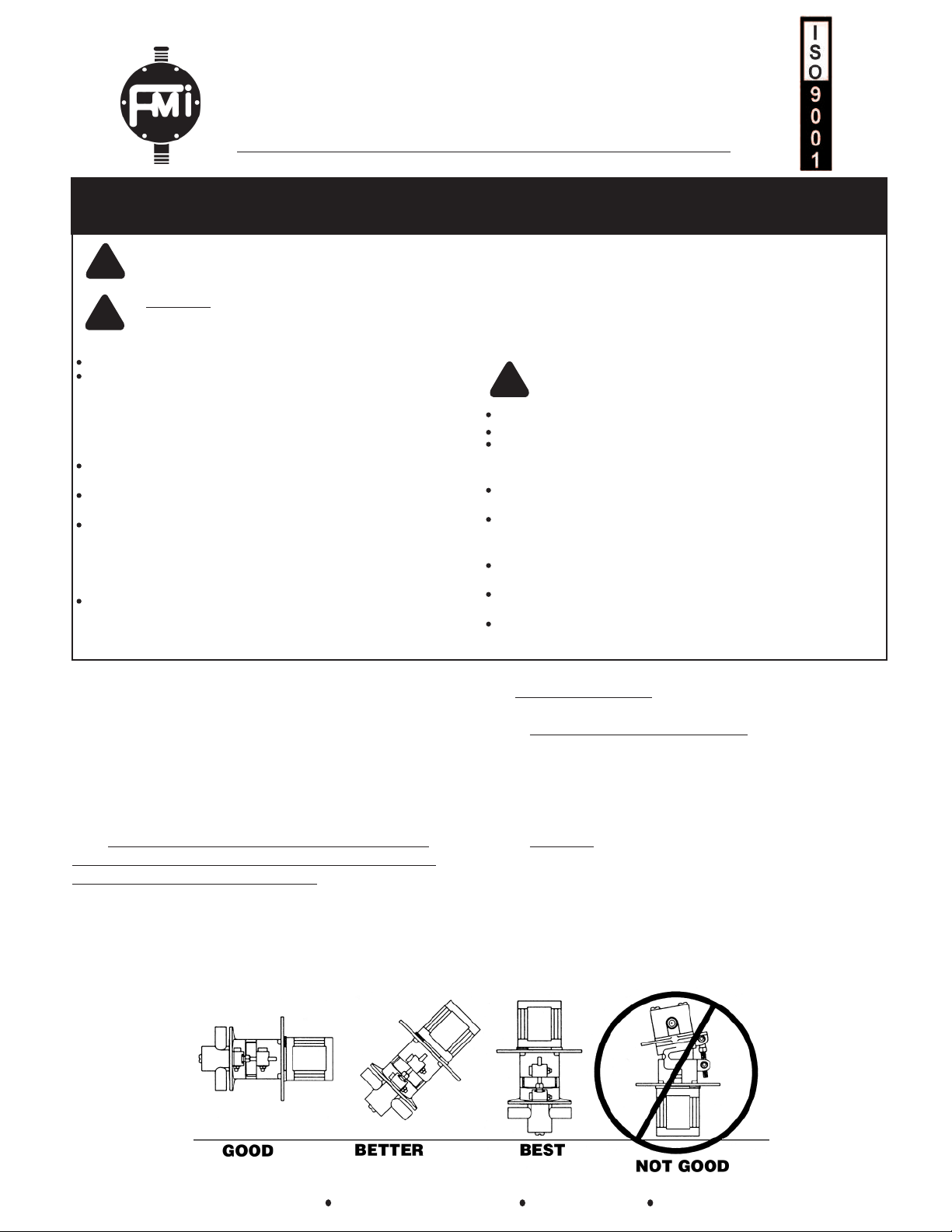

1.0 PUMP MOUNTING: For optimum pump performance it is recommended that your FMI pump

be mounted in a vertical position with the pump

head down in a 6:00 o'clock position and the motor

at 12:00 o'clock. This orientation will allow air bubbles that enter the pumping chamber to directly exit

through buoyancy assistance. Figure A

2.2 Fluidics:

Inlet (Suction) Tubing: To avoid cavitation use the

most resilient tubing possible with the largest

inside diameter (I.D.)

Outlet (Dispense) Tubing: For best dispense

performance use rigid Teflon tubing (to reduce

peristaltic action) with an equal or smaller I.D. than the

inlet (suction) tubing.

Figure A

www.fmipump.com pumps@fmipump.com 800-223-3388 516-922-6050

1

Page 2

IN-ST431-14

2.3 Step Motors:

MI ST pumps are supplied with a 17 or a 23

F

frame Motors.

For wiring diagram and detailed motor

specifications go to the literature section of our

ebsite at www.fluidmetering.com/literature.html

w

2.4 Rotational Sensor: FMI STH and

STQ standard pumps are supplied with an LED

rotational sensor. For wiring diagram and sensor

details see Figure G .

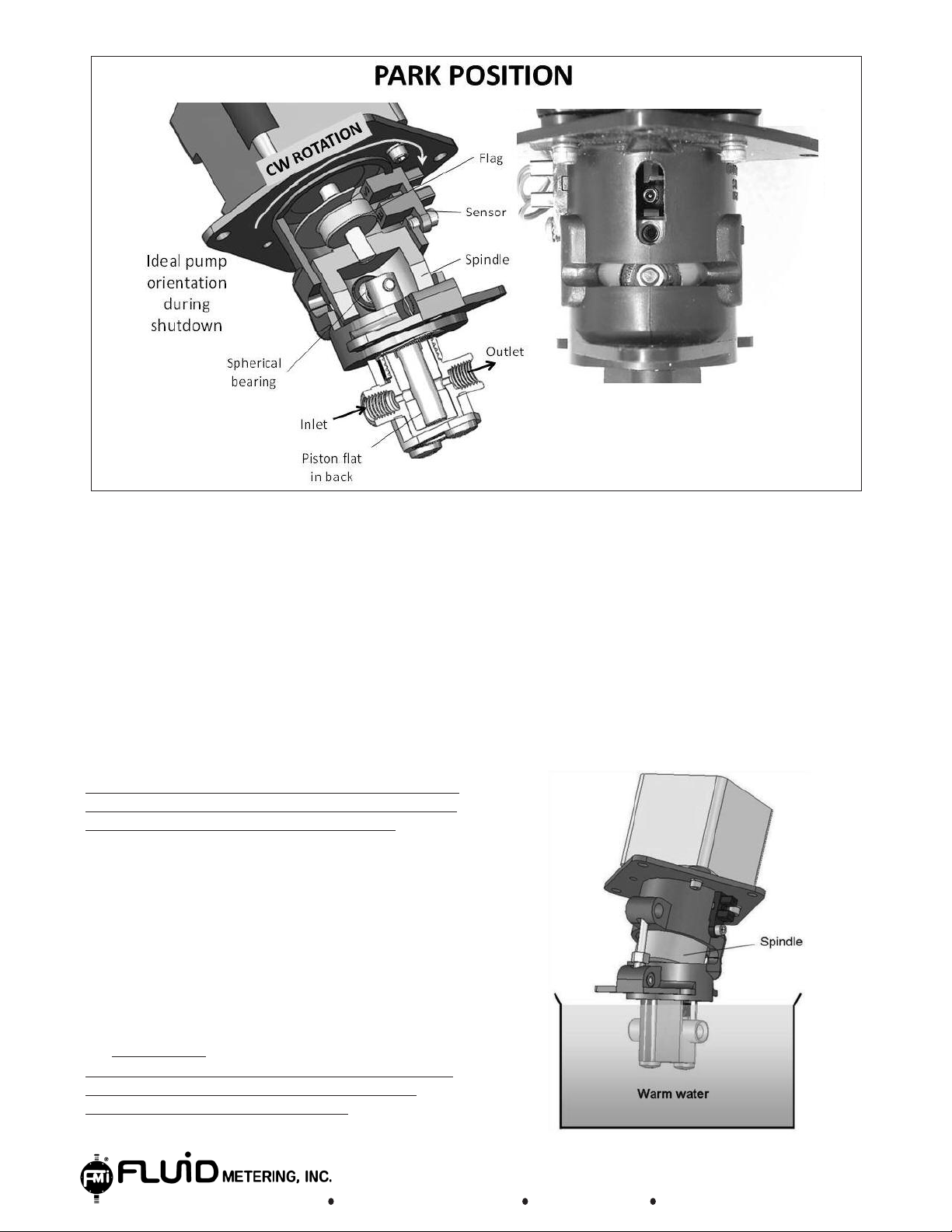

.6 Park Position:Preventive maintenance

2

steps in order to minimize the possibility of a

frozen pump or seize condition are as follows:

) Always completely flush out the pump with

a

water if it will be in an idle (non-operating mode)

for an extended period of time.

b) During shut down leave the pump’s fluid circuit

wet with flush water.

2.4.1 For sensor use with FMI SCST-01 Step

Motor Controller. See SCST-01 instructions.

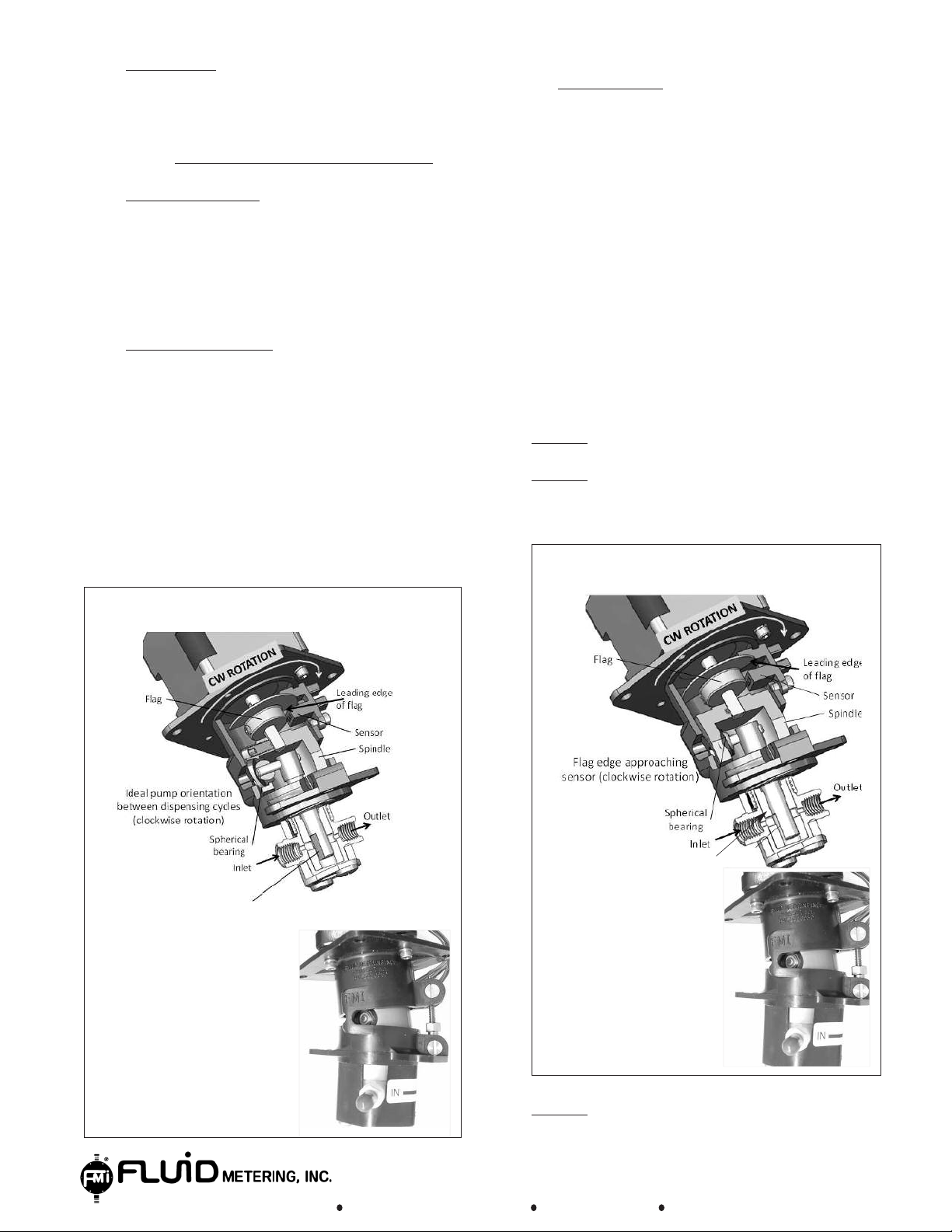

2.5 STH Pump Homing: Best dispensing

performance of the pump is obtained by proper set

up of the start/stop position of the piston relative

to the intake port of the pump housing.

Positioning of the piston flat so that it directly faces

the inlet port is termed “homing”.

The images below show the home position for a

pump which has been set up to turn clockwise.

In this case the inlet port is on the left.

If a particular application calls for the inlet port to

be on the right, the pump will be programmed to turn

counterclockwise and the figures bellow must be

reversed.

Home Position

c) The piston position should extend all the way

towards the bottom of the liner. This is known as

the PARK position.

Correct programming of pump motion to achieve

the PARK position involves the following sequence

(assuming clockwise rotation for operation).

Step #1

Step #2 While monitoring sensor signal, instruct

motor to turn clockwise while looking for the

leading edge of the flag (see figure 2 below).

The FMI pump stops (any location).

Flag Edge Approaching Sensor

Figure 1

www.fmipump.com pumps@fmipump.com 800-223-3388 516-922-6050

Piston flat facing

intel port

Piston flat approaching

alignment with intel port

Figure 2

Step #3 Next rotate Counter Clockwise 90 Degrees

the pump is now PARKED.

2

Page 3

IN-ST431-14

The design of FMI Pumps is unique throughout the

world. Having no valves and only one moving part,

“the piston” makes this design very special. No valves

means that our ceramic pistons and cylinders must

be matched to extremely close fits so that stroke to

stroke accuracy is maintained.

This precision fit requires some general maintenance

rules.

When a pump is allowed to sit idle and dry out, these

dried precipitate can form in the piston/cylinder clearance and cause a pump seizure condition. Upon system power up, this seizure can result in either no flow

or at worst a broken piston. So we recommend the

above procedure.

We do not live in a perfect world and accidents do

happen. If your pump seizes try the following procedures: With the pump in an instrument:

1) Cycle the pump in a back and forth motion (clock-

wise and counter clockwise rotation) at a slow speed

in a high torque mode.

2) Start and stop the pump in an effort to free system.

a) Soak the top portion of the pump (PUMP HEAD

ONLY) in a warm water bath for at least 20 minutes.

Then place your index finger and thumb around the

spindle assembly (gold coupling) and gently try to

rotate the assembly back and forth in an attempt to

loosen up the piston.

CAUTION:

Do not force the assembly free if it is

severely frozen as this could result in piston

breakage or pump damage.

3) If pump head is accessible try turning the drive

spindle back and forth with your index finger and

thumb.

2.7 Maintenance

With the Pump/Drive Assembly removed from the

instrument but not disassembled (WILL NOT

REQUIRE PUMP RECALIBRATION):

www.fmipump.com pumps@fmipump.com 800-223-3388 516-922-6050

3

Page 4

IN-ST431-14

CAUTIONŽƌŝĞŶƚ,ϰϬϱůĞƚƚĞƌŝŶŐ

as shown

H435 Cap

Screws(2)

Tighten to

9 in-lbs torque

With the Pump/Drive Assembly removed from the

nstrument and the piston/cylinder group removed

i

(MAY REQUIRE PUMP RECALIBRATION):

b) If the pump is severely frozen then the piston/cylin-

er group must be removed from the pump. Remove

d

the (2) screws that secure the H435 Cap to the pump

base assembly and carefully remove (twist, tilt & pull)

the piston/cylinder group from the pump base assembly.

d) Reassemble the piston/cylinder into the pump

base assembly (use FMI Instructions H431) page # 8

section # 22 for more details relative to installing the

piston/cylinder assembly.

c) Soak the piston/cylinder group in warm water for

20 minutes minimum. For quickest results use an

ultrasonic bath. Then try to loosen up the assembly by

hand - gently rotating the piston back and forth until

free.

CAUTION:

Do not pull piston out of cylinder or force the

piston as breakage or seal damage will occur.

www.fmipump.com pumps@fmipump.com 800-223-3388 516-922-6050

e) Reinstall H435 Cylinder Cap and apply a suitable

thread lock to the screws (Loctite # 425) and secure

screws (torque to 9 in-lbs).

f) Rotate the assembly to assure it moves smooth

and free. (If not see note #1 below).

g) Check the pump for proper calibration (If out of

specification see note #1 below).

Note#1:

Please return complete pump/drive unit to the factory for rework and

recalibration

4

Page 5

IN-ST431-14

3.0 CALIBRATION AND TESTING

3.1 Flush the system: clean with alcohol

or other suitable cleaning/wetting agent

before using the hydraulics and pump for the

irst time. Prime pump with fluids to assure

f

system is free of air bubbles.

3.2 Place pump in the standard

"home"

position with the piston-flat perpendicular to

the inlet port.The inlet port will be on the left

when the motor rotates clockwise (see

Figure B for the STH pump and Figure C for

the STQ pump).

3.3 Check the pump's dispense volume by

cycling the pump for one complete 360°

revolution (one complete rotation). Dispense onto

an analytical pan balance and observe the volume.

See Figure D. Readjust as necessary.

REMARK: When dispensing water-like solutions

assume 1 ml = 1 gram. A correction factor will

be required for other fluids

Note:

Calibration is Factory set and Should not be

Changed.

Figure D

an Balance

p

Figure B

Figure C

www.fmipump.com pumps@fmipump.com 800-223-3388 516-922-6050

5

Page 6

IN-ST431-14

3.4 Dispense Volume Values for FMI STH/STQ

umps:

P

MODEL

ML/REV

MIN

STH00 0.002

S

TH0

.005

0

STH1 0.010

ML/REV

MAX

0.025

.050

0

0.100

STQ0 0.008 0.080

STQ1 0.032 0.320

STQ2 0.072

STQ3 0.128

0.720

1.280

NOTE: To assure the best performance set the

pump displacement volume as large as possible.

FMI pumps are calibrated at the factory to the

maximum value. Both STH and STQ pumps can

be factory adjusted down to as little as 10% of the

rated flow.

3.5 Adjusting Dispense Volumes:

To fine adjust dispense volumes rotate the stroke

length adjustment s crew using the appropriate hex

driver (see Required Tools on page 1). To increase

the flow, turn the screw counter-clockwise.

To decrease the flow, turn the screw clockwise

3) Splashing can usually be avoided by

odifying dispense tip to larger I.D.and/or

m

decreasing dispense speed.

4) Hanging drop at dispense tip can be avoided

y:

b

a) Use of rigid discharge tubing

b) Small dispense tip

c) Increasing speed

5) High viscosity dispensing requires:

a) Large suction tubing

b) Pressurizing suction reservoir

6) Bubbles in discharge

a) Suction fitting leak

b) Cavitation

7) Need Help? Call, fax, or email us… We can

help solve almost any fluid control problem.

3.8 SPECIAL MOTORS AND CONTROLLERS

FMI offers a complete variety of stepper motors

and stepper motor controllers from simple quick

start control to complex application specific

stepper motor control. Our standard step motor

controllers are:

SCST General Purpose Stepper Motor Control for

quick start control of FMI STH and STQ pumps.

CCW=Increase, CW=Decrease.

CAUTION: DO NOT LOOSEN THE HEX LOCK

NUT WHEN ADJUSTING THE STROKE RATE.

IT IS SET AT THE FACTORY AND SHOULD NOT

BE TAMPERED WITH. See Figure E

3.6 Lock setting:

Once the pump is calibrated apply a drop of

removable wicking thread lock between the lower

pivot pin and the adjustment screw threads.

See Figure E.

3.7 Dispensing Hints:

1) Speed - Optimum results for fluids 500 cps or

less is between 120-350 rpm.

2) Cavitation: Use the largest suction tubing you

can to avoid cavitation.

ICST Intelligent Stepper Motor Controller

which includes an embedded microprocessor

for custom programming of FMI stepper motor

pumps to meet specific application operations.

IDS 2000 Industrial Dispenser/Pump which

includes the SCST and FMI pump head integrally

mounted in a rugged stainless steel enclosure.

www.fmipump.com pumps@fmipump.com 800-223-3388 516-922-6050

6

Page 7

IN-ST431-14

Vcc

Vcc

* NOT SUPPLIED WITH OPTICAL SENSORS

See suggested Rd values table below.

NOTE:FOR ADDITIONAL REFERENCES SEE H431 AND Q431

Rotational Sensor

Absolute Maximum Rating (TA=25ºC Unless otherwise noted)

Supply voltage, V (not to exceed 3 sec.).......................18 V

Input diode power dissipation....................................100 mW (1)

Output power dissipation............................................200 mW (2)

Total device power dissipation....................................300 mW (3)

Voltage at output lead (open collector output)............35 V

Diode foreword D.C Current............................................40 mA

Diode reverse D.C Voltage.............................................2 V

Note:

1. Derate linearly 2.22mW / ºC above 25ºC

2. Derate linearly 4.44mW / ºC above 25ºC

3. Derate linearly 6.66mW / ºC above 25ºC

Figure E

4. The optical switches are terminated with 24 inches

of 26 A.W.G.,UL 1492 wire on each terminal.

Insulation colors and function are as follows:

Red-Anode, Black-Cathode, White-Vcc, Blue-Output,

Green-Ground

5. Normal application would be used with light source blocked,

simulated by I

6. All parameters tested using pulse techniques.

7. Minimum supply voltage is 4.5 VDC

www.fmipump.com pumps@fmipump.com 800-223-3388 516-922-6050

F=0mA

Suggested RD Values

Vcc (VDC) RD (Ω)

5 180

12 470

15 620

Figure F

7

Loading...

Loading...