Page 1

"SCST-01" STEP MOTOR

CONTROL KIT

http://www.fmipump.com

OPERATION INSTRUCTIONS

New FMI Step Motor Control Kit “SCST-01”

Congratulations! Your FMI Step Motor Control Kit SCST-01 is a complete control

package designed specifically for FMI pumps with step motors. It’s small in size but big

in performance and provides a quick method to run your pump today.

Quick Start Instructions

Your controller is initially set to provide 320 strokes/minute or 150 strokes/minute.

Dispense and other speed settings are easily set by following the detailed instructions

on the following pages.

1. Connect harness J1 & J2 to appropriate connectors on board. The black and white

wires from J1 connect to the power supply. White (or black with white lettering) is the

positive lead while solid black is negative.

*Connect DIP Switch Assembly to Header J3 (Pin 1 to red stripe)

DO NOT TURN POWER ON

2. Connect motor wires to terminal block J1 according to the following chart:

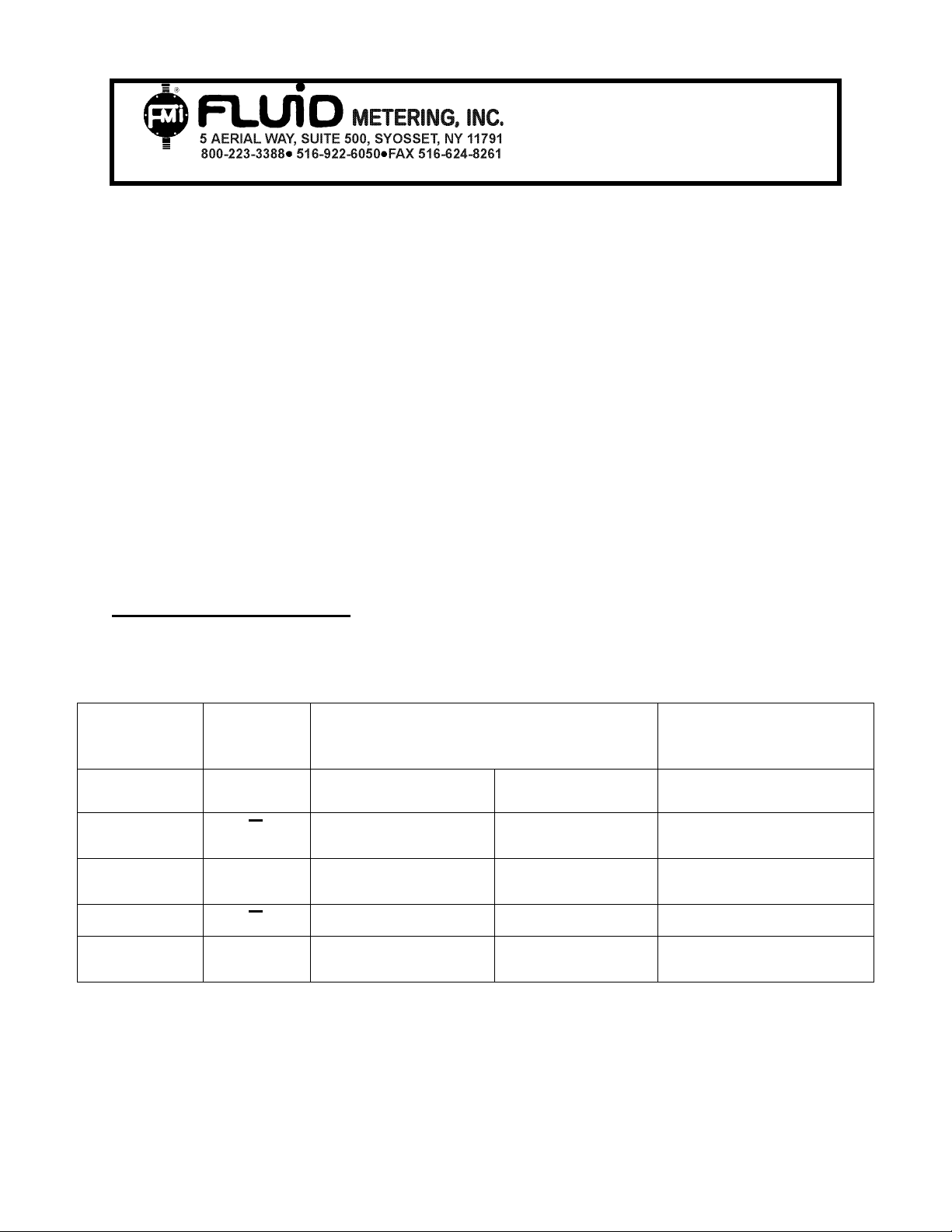

Table1.

Screw Terminal

Color

Motor Lead Color for Standard

STRH/STH/STQ/SQ pumps

Motor Phase Motor P/N 110746

(NEMA 23 Frame)

Motor P/N 110745

(NEMA 17 Frame)

STRH/STH/STQ/SQ

Duplex

Motor P/N 300615

(NEMA 23Frame)

Yellow A Yellow and Black Yellow Orange & White w/Black

Stripe

Red A Red and White Red Black & White w/Orange

Stripe

Brown B Blue and Orange Orange Yellow & White w/Red Stripe

Orange B Green and Brown Blue Red & White w/Yellow

Stripe

3. Connect pump sensor leads to J2 according to color i.e. Red to Red, etc.

4. Turn on power and pump will start running at factory setting. Note: See 4.1 page 6.

*Basic Boards use jumper pin connector shunts instead of DIP switch.

1.0 Description

IN-SCST-01-10 1

Page 2

"SCST-01" STEP MOTOR

http://www.fmipump.com

OPERATION INSTRUCTIONS

The SCST-01 is a self-contained step motor controller specifically designed for use with

Fluid Metering pumps. It contains its own step drivers and can be set to several run

modes utilizing either internal or external controls.

1.1 Features

• Pre-set Run Modes

• Multiple Control Methods: PLC, Relay, 0-5 VDC, or Manually by shunt

• Dispense, Run

• Sensor Enable/Disable

• Switchable Forward/Reverse of Motor Direction

2.0 Run Modes

The SCST-01 step motor controller can be used to drive any FMI stepper driven (STH,

STQ) pumps in any of the following modes.

2.1 Continuous (Constant Run) Mode

Your Kit comes factory set for 320 or 150 spm (strokes per minute). Speed is easily

adjustable using shunt connectors on Speed Header J3 (fig. 1) or DIP Switch Assembly.

Speed is adjustable using Pins (Switch) 1-7 and binary addition according to the

following chart and diagram or by 0-5 VDC input (Section 2.4).

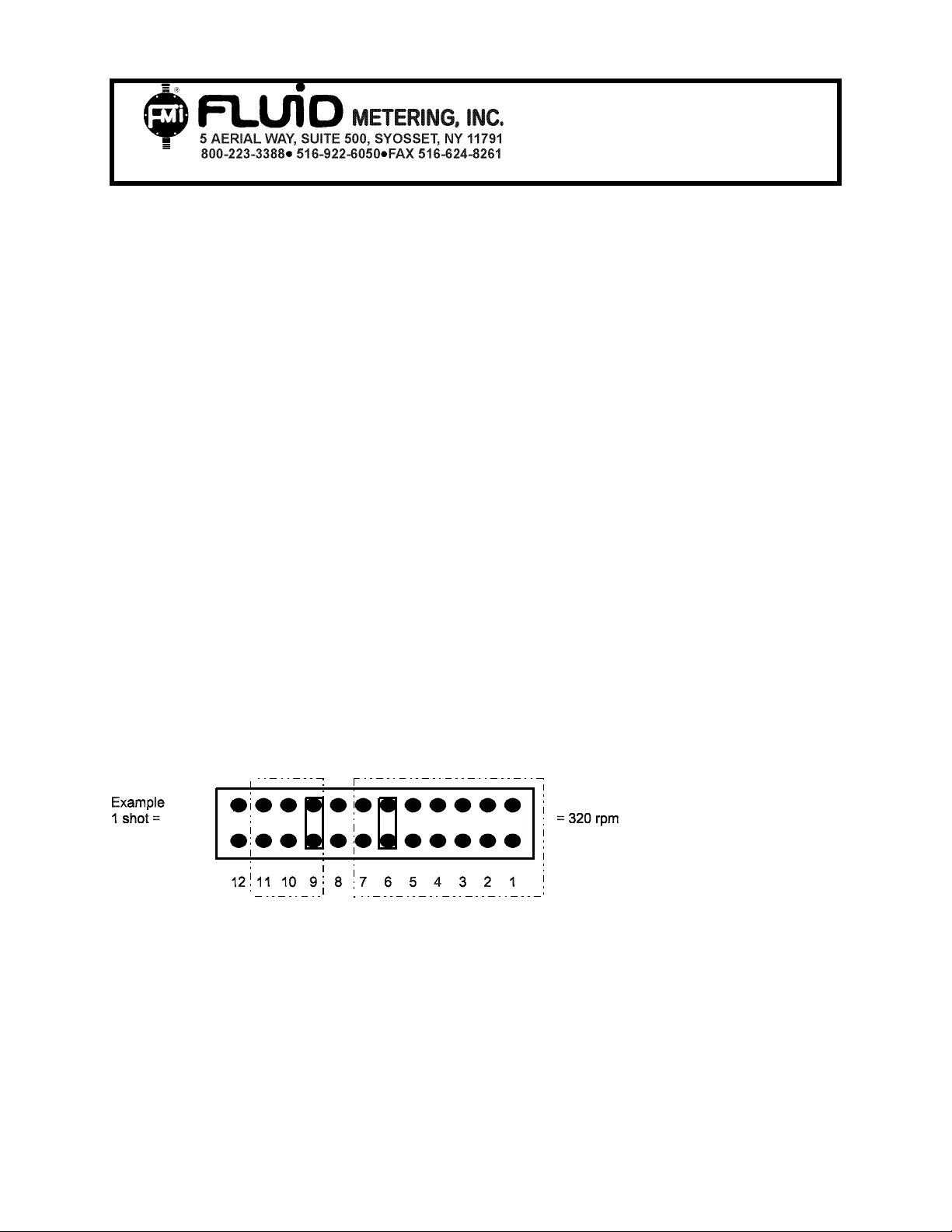

Figure 1

Switch

/ Pin Speed

SPEED HEADER - J3

Dispense Pins/ Switches

Speed or rpm Pins/ Switches

CONTROL KIT

1 =

2 =

3 =

4 =

5 =

6 =

7 =

10 rpm

20 rpm

40 rpm

80 rpm

160 rpm

320 rpm

640 rpm

2.2 Dispense Mode

The system will allow you to dispense from 1 to 7 shots per signal (momentary switch

closure on J2). The number of shots per signal is set by shunting pin/Switches sets 911 on Header J3.

Pin/Switch No.= # of shots Example

IN-SCST-01-10 2

Page 3

"SCST-01" STEP MOTOR

http://www.fmipump.com

OPERATION INSTRUCTIONS

Pin 9 = 1 Pin 9 + Pin 11 = 1 + 4 = 5 shots

Pin 10 = 2

Pin 11= 4

2.21 Actuation For Dispense

Dispense Actuation is handled by Pins 3 & 4 on the J2 Terminal Block by providing a

momentary contact (switch closure, PLC, Relay, Mechanical Timer) of the 2 yellow

wires. The minimum closure time that this input can see is 30 milliseconds (0.030 sec).

DO NOT APPLY ANY VOLTAGE to this input!

2.3 Timed/Count Dispense (Pin Shunt use only)

The pump will begin dispensing until both pins of pin set 9 on J3 are shorted together.

This will cause the pump to stop. Pin set 9 can be shorted by using any counter or

timer that can control a SPST type relay or switch closure. External counters can tap

pin 8 on J2 to sense the count pulse.

Typical wiring is as follow: With FMI Motors

CONTROL KIT

OPTICALLY ISOLATED

2

E

C

2N3904

B

1

4N35

6

5

4

J2 PIN 7

J2 PIN 8

DIRECTLY COUPLED

E

C

0.01mF

2N2222

* R

*R=10 k (for reference only, your specific

application "value" may need adjusting.

B

[SIGNAL IN]

[GROUND]

5 V DC

(J2 PIN 9)

[GROUND]

(J2 PIN 7)

(J2 PIN 8)

150 OHM

1 K OHM

2.4 External Control 0-5 VDC - Voltage Following Input

In order for the stepper controller board to recognize and accept a 0-5 VDC control input

all shunts on pins 1-7 (header J3) must be removed or Switched off. The board will not

respond to a voltage input if any of the speed select pins have a shunt across them.

Once the shunts on all pins are removed, a DC voltage signal may be applied to header

J2 pins 1 and 2 and a variation of that voltage will linearly vary the motor speed.

Maximum speed using a 0-5 VDC input signal is limited to 1200 rpm, depending on the

application. For duplex motor P/N 300615, the max speed is 150rpm.

3.0 Input Headers

The SCST-01 step motor controller has several different input/output header sections

for control and interface with the stepper motor. A diagram showing the placement of

these headers can be found in Figure 2.

A single 24VDC power supply delivering 1.25A (min) of current is required for

driving any of the standard Fluid Metering step motors (inputs 1 and 2 on Header

J1).

IN-SCST-01-10 3

Page 4

"SCST-01" STEP MOTOR

http://www.fmipump.com

OPERATION INSTRUCTIONS

3.1 POWER Header - J1

The POWER header section (J1) is used for input power and output to the stepper

motor phases. This is a 0.156” pitch 6 pin header connector which has the following

pinout:

Pin #

1. Power supply minus lead (V-) connection.

2. Power supply plus lead (V+) connection.

3. Connection to phase B of the stepper motor.

4. Connection to phase⎯B (B bar) of the stepper motor.

5. Connection to phase A of the stepper motor.

6. Connection to phase⎯A (A bar) of the stepper motor.

3.2 CONTROL Header - J2

The CONTROL header section (J2) is used for optical sensor connections, 0-5 VDC

controls and dispense controls. This is a 0.100” pitch 9 pin header connector. The

pinout for this header is as follows:

Pin #

1. 0-5 VDC Common

2. 0-5 VDC Signal Input

3. Start Pulse Common

4.* Start Pulse Signal Input (for dispense, controlled by momentary switch to

ground)*

Hall Effect sensor Opto Sensor 110569 Opto Sensor 300696

5. Emitter Cathode (black)

6.

7. Detector Ground

(green)

Emitter Anode (red)

Detector Ground (green)

/ Power Supply Ground

/ Power Supply Ground

8. Detector Signal (blue) Detector Signal (blue) Detector Signal (white)

9. Power +5 VDC (white) Power +5 VDC (white) Power +5 VDC (red)

NOTE: The colors listed for sensor leads are for the standard sensors supplied with FMI

pumps. Other sensors may have other lead color configurations.

*Note: DO NOT APPLY ANY VOLTAGE TO THIS INPUT!

CONTROL KIT

Detector Ground (black)

/ Power Supply

Ground

IN-SCST-01-10 4

Page 5

"SCST-01" STEP MOTOR

http://www.fmipump.com

OPERATION INSTRUCTIONS

3.3 SPEED Header - J3

The SPEED header section (J3) is used for speed settings, number of dispense

settings, and switching between stall detect (sensor) and non-sensor mode. This is a

dual row 0.100” pin header. Functions are actuated by means of connecting pins using

industry standard shunts or by DIP Switch Assembly. This header contains the controls

for speed settings, stall detect enable, and number of dispenses. The pinout for this

connector is as follows:

1. Speed - 10 rpm

2. Speed - 20 rpm

3. Speed - 40 rpm

4. Speed - 80 rpm

5. Speed - 160 rpm

6. Speed - 320 rpm

7. Speed - 640 rpm

8. Sensor detect on/off - The default (no shunt) is sensor enabled ( See page 1

item#4).

9. Dispense - 1 dispense

10. Dispense - 2 dispenses

11. Dispense - 4 dispenses

12. CW/CCW - The default (No Shunt) CW Rotation

13. Not Used.

These pins are set up as a binary system. This means that multiple pins shunted will

add their values together. For example, to set the motor to run at 500 rpm you must

shunt pin pairs Switches 6, 5, and 2 (320+160+20=500 rpm). The shunts can give a

maximum speed of 1270 rpm and 7 dispenses. (see page H1 item # 4) The controller

will run at constant speed until one of the dispense setting pairs are shunted.

The motor will then home itself to the proper starting point and begin the desired

number of dispenses upon connection of the Start Pulse Signal and the Start Pulse

Common pins (Header J2, pins 3 and 4) by means of a momentary switch.

3.4 Header – J4

This Header is for internal FMI use only. It has no function to control the Driver Board.

CONTROL KIT

IN-SCST-01-10 5

Page 6

"SCST-01" STEP MOTOR

http://www.fmipump.com

OPERATION INSTRUCTIONS

4.0 Features

4.1 Trim Pot

Factory set at (approx.) For motors P/N 110746, 300615 the trim pot is factory set at

1.75 amp/phase. The trimming potentiometer (see Figure 2 for approximate location) is

used to limit the amount of current used by the controller in driving the stepper motor.

Turning the potentiometer clockwise will provide more current to the motor, while turning

it counter-clockwise will reduce the current supplied.

Figure 2

CONTROL KIT

PHASE⎯A6

PHASE A 5

PHASE⎯B4

PHASE B 3

+ SUPPLY LEAD 2

−

SUPPLY LEAD 1

SENSOR POWER 9

SENSOR SIGNAL 8

SENSOR GROUND 7

SENSOR ANODE 6

SENSOR CATHODE 5

START SIGNAL 4

START COMMON 3

0-5 VDC INPUT 2

0-5 VDC COMMON 1

SPEED HEADER - J3

TRIM POT

Dispense Pins

Speed or rpm Pins

IMPORTANT

!

Additional heat sinking may be required when operating above 2.5 amps per phase.

Contact factory for additional information.

IN-SCST-01-10 6

Page 7

"SCST-01" STEP MOTOR

CONTROL KIT

http://www.fmipump.com

USE AMP METER 5 AMP FULL SCALE **

OPERATION INSTRUCTIONS

A

-

+

A

A

A

-

+

A

A

Nema 23 Frame (2.2 inch square)

FMI Part Number 110746

** Adjust motor current trim pot as required.

Do not exceed maximum motor rated current

of 3.5 Amps per phase.

Higher speed values can be achieved with

a 30 VDC 4 amp minimum power supply.

Pin # J1----POWER HEADER

Screw Terminal

Color

Yellow

6

5

4

3

B

B

Red

Brown

Orange

Motor

Phase

A

A

B

B

Nema 23 Frame (2.2 inch square)

FMI Part Number 300615

(DUPLEX DRIVE MAX SPEED 150 RPM)

** Adjust motor current trim pot as required.

Do not exceed maximum motor rated current

of 3.5 Amps per phase.

Higher speed values can be achieved with

a 30 VDC 4 amp minimum power supply.

Pin # J1----POWER HEADER

Screw Terminal

6

5

4

3

Color

Yellow

Red

Brown

Orange

Motor

Phase

A

A

B

B

Motor Lead

Connection

Yellow-Black

Red-White

Blue-Orange

Green-Brown

Motor Lead

Connection

ORG-WHT/BLK

BLK-WHT/ORG

YEL-WHT/RED

RED-WHT/YEL

B

B

A

-

+

A

A

Nema 17 Frame (1.7 inch square)

FMI Part Number 110745

** Adjust motor current trim pot as required.

Do not exceed maximum motor rated current

of 1.2 Amps per phase.

Pin # J1----POWER HEADER

Screw Terminal

Color

Yellow

6

5

4

3

B

B

Red

Brown

Orange

NOTE: Black no connection

White no connection

Motor

Phase

A

A

B

B

Motor Lead

Connection

Yellow

Red

Orange

Blue

IN-SCST-01-10 7

Loading...

Loading...