Page 1

IN-QC72/QC216-04

MOTOR ASSY

SE

1

INSTRUCTIONS

& PARTS LIST

DISPENSER

INSTALLATION & OPERATING TIPS

1. OPERATION - The QC has three

switches to control its functions:

a) An air-activated hand/foot switch

at the end of a 6’ long hose. This

switch starts and stops each operating cycle. It can be operated by hand,

foot, or other remote pressure means.

b) A mode switch in the up or dispense position. This switch permits

only one dispense or aspirate per

squeeze of the hand/foot switch. The

pump will make a complete uninterrupted dispense cycle once hand/

foot switch is squeezed and held and

will reset itself when released. The

down or pump position permits the

unit to operate continuously as a

pump. The hand/foot switch is inoperable in this mode.

c) A direction switch controls the

direction of fluid flow through the

pump head when the hand/foot switch

is squeezed, i.e., pushing the direction switch to the FWD or up position

will cause flow in that direction when

the hand/foot switch is squeezed.

Push switch down to the REV posi-

tion to reverse flow direction.* A center

“OFF” position on this switch provides

system off facility.

*Preferred pumping and dispensing direction

is from left to right when facing the pump head.

2. CAM ADJUSTMENT - Your QC

Dispenser hand/foot switch relates directly to a Cam Q502 actuated Limit

Switch Assembly Q501. This is timed

to the piston suction position. To adjust, loosen mounting Screws 11047710 on Terminal Strip 110476. Adjust

Limit Switch Assembly to Cam Q502

so that you get 2 clicks per revolution.

Tighten screws 110477-10 on Terminal Strip.

3. CALIBRATION - Hook-up inlet and

outlet tubing, set mode switch in down

(PUMP) position and clear the pump

of bubbles (see FMI Q431 instructions

and Parts Identification sheet, Sec.

12).

Calibration for specific shot volumes is

rather straightforward.

MODEL QC72/ QC216

a) Determine volume required per

shot.

b) Estimate approximate percentage

of maximum per shot flow for your

particular pump head, i.e., -3 or 1/2”

piston pump heads at 100% = 1.28

ml per shot, -2 or 3/8” piston pump

heads at 100% = 0.72 ml per shot, 1 or 1/4” piston pump heads at 100%

= 0.32 ml per shot and -0 or 1/8”

piston pumps at 100% = 0.08 ml per

shot.

c) When approximate setting is

made, pump 20 shots into a calibrated receiver (pipette, burette,

graduate), and divide the measured

volume by 20 to find the exact per

shot volume. If your volume is too

low, increase stroke volume by turning the STROKE LENGTH ADJUSTMENT KNOB Q464 counterclockwise. If too high, decrease by turning

clockwise. Repeat calibration check

as you fine-tune to your requirements.

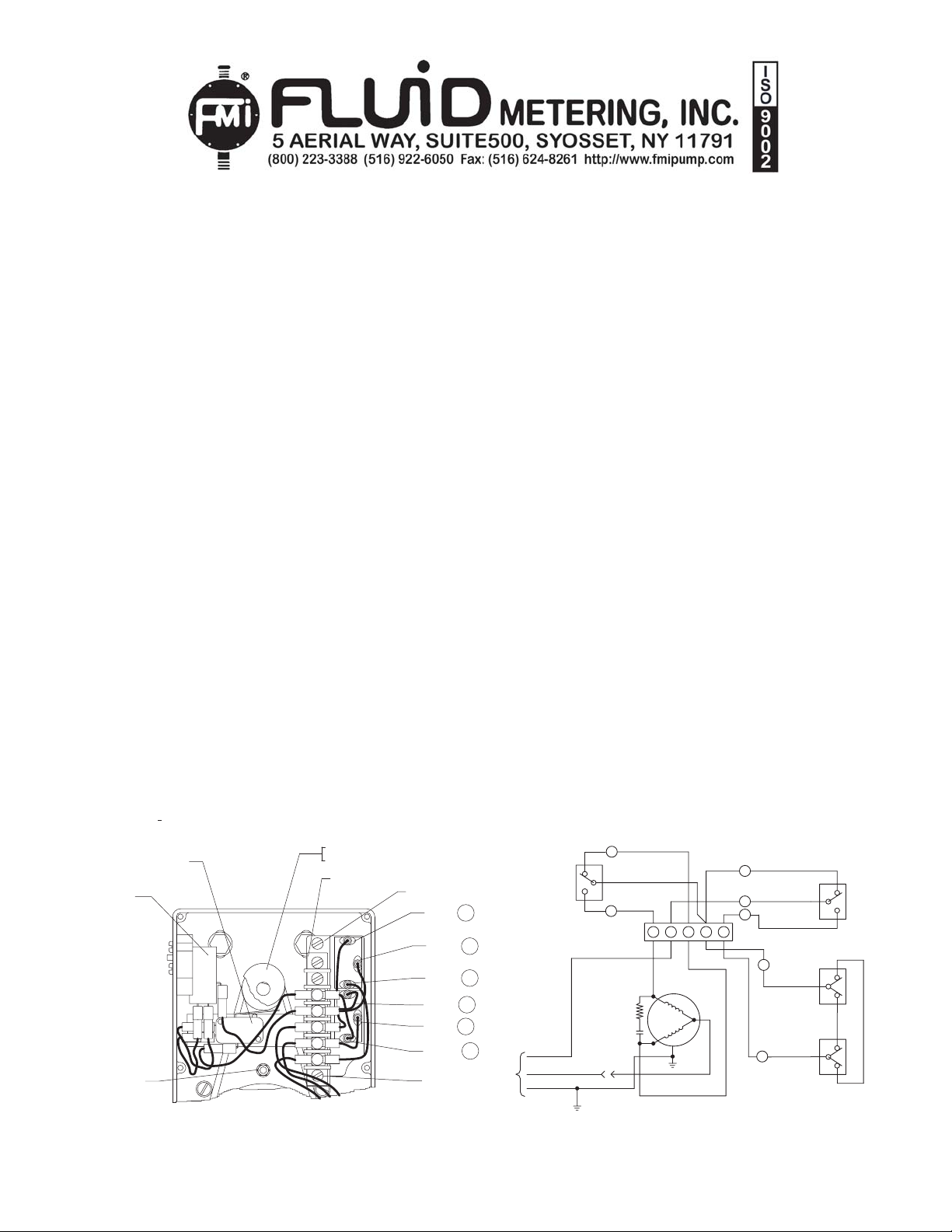

110529

10490-8

Q501

Q502

110671-4

110476

Q463

110392

DIRECTION

SWITCH

REV

OFF

FWD

(BLK) 3

BLK

(RED) 4

RED

GRN

WHT

WHT

N.O.

RED

A

B

B

WHT

ORG

A

WHT

Fig. 1Fig. 1

Fig. 1

Fig. 1Fig. 1

5

RED

RED

4

BLK

BLK

3

BLK

BRN

2

GRN

RED

1

(GRN) 1

(RED) 4

(BLK) 2

(WHT) 5

110477-10

INPUT

BRN

LT BLUE

GRN-YEL

GRN

Q644 BLK

3

Q642 RED

Q639 GRN

1

110476

R1

C1

(RED)

1

WHT

RED

(BLK)

Q468-_

Fig. 2Fig. 2

Fig. 2

Fig. 2Fig. 2

32 4 5

BLK

4

2

5

4

Q637 (WHT)

LIMIT SWITCH

5

Q643 RED

Q638 BLK

Q641 WHT

110529

AIR SWITCH

Q640 (RED)

COM

Q501

ASSY

COM

PUMP

110433

MODE

SWITCH

DISPEN

N.O.

N.C.

Q635

(ORG)

N.O.

N.C.

Q636 (WHT)

Page 2

IN-QC72/QC216-04

(2)

90-14(2)

1

1

P

T

R

A

A

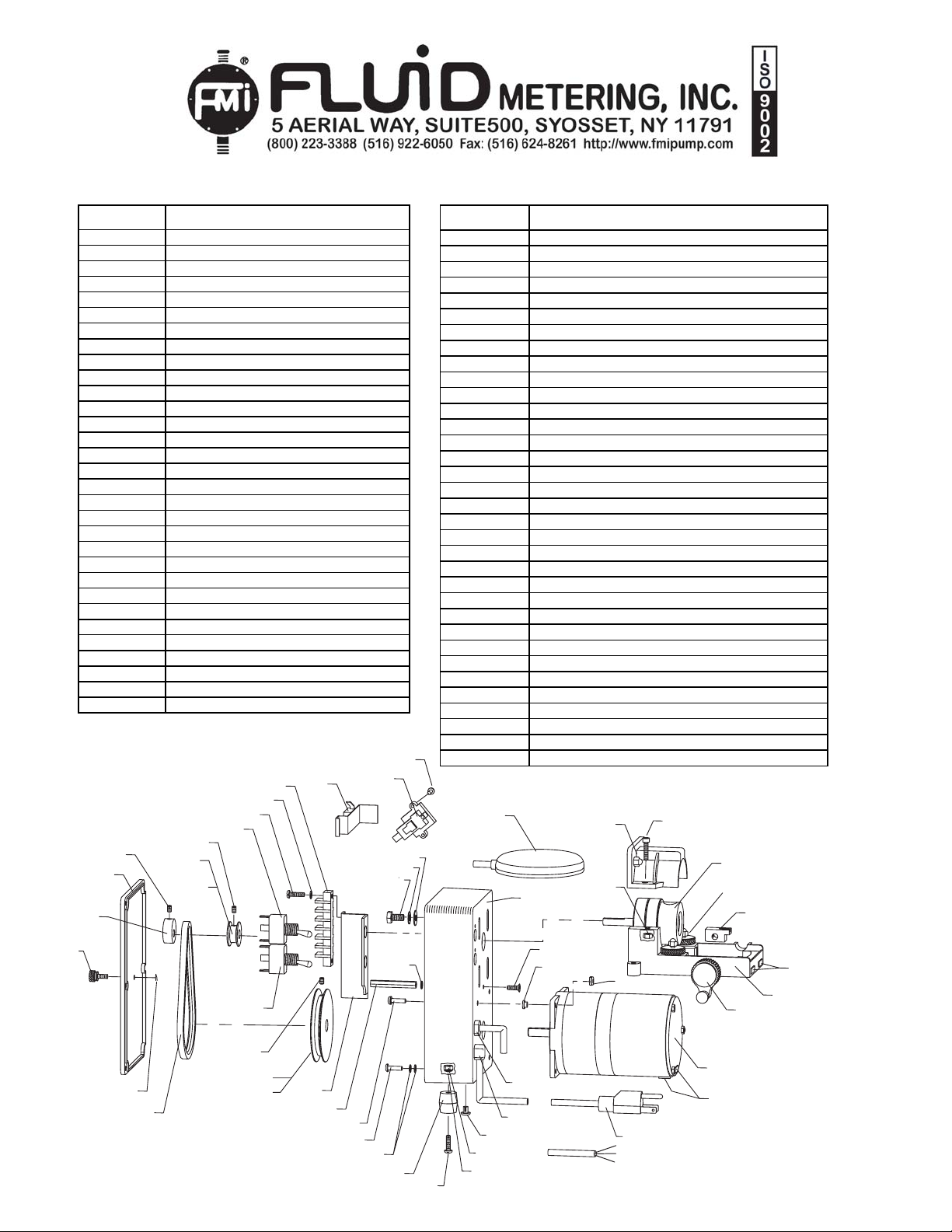

QC72/QC216 - PARTS PRICE LIST

PARTS NO. DESCRIPTION

Q424 SPINDLE ASSEMBLY

Q442-3 CASE ASSEMBLY

Q443-1 COV ER ASSEMBLY

Q448-2 PULLEY , 2” DIA., .313 I.D. 72S.PM

Q448-4 PULLEY , 2” DIA., .376 I.D. 72S.PM

Q448-1 PULLEY , 1” DIA., .313 I.D. 216 SPM

Q448-5 PULLEY , 3” DIA., .376 I.D. 216 SPM

Q454-3 FOLLOWER, FLOW CONTROL

Q456-1 POWER CORD ASSEMBLY 110 V OLT

Q456-2 POWER CORD ASSEMBLY 320 V OLT

Q463 BRACKET

Q468-1 MOTOR ASSEMBLY QC115 V AC 60HZ

Q468-2 MOTOR ASSEMBLY QC 230 V AC 50HZ

Q501 LIMIT SWITCH ASSEMBLY

Q502 CAM

Q616 RETAINER ASSEMBLY

Q635 JUMPER ASS’Y ORANGE (2-3/4” LG)

Q636 JUMPER ASS’Y WHITE ( 2-3/4” LG)

Q637 JUMPER ASS’Y WHITE ( 3-5/8” LG)

Q638 JUMPER ASS’Y BLA CK (2- 1/2” LG)

Q639 JUMPER ASS’Y GREEN (3-1/2” LG)

Q640 JUMPER ASS’Y RED ( 3-1/ 2 ” LG)

Q641 JUMPER ASS’Y WHITE ( 2-1/2” LG)

Q642 JUMPER ASS’Y RED (4” LG)

Q643 JUMPER ASS’Y RED ( 2-3/ 4 ” LG)

Q644 JUMPER ASS’Y BLA CK (3” LG)

110049 WASHER #8 INT. LOCK

110126 1/4 ID X 1/2 OD WASHER

110132-10 SCREW 8-32 X 5/8 PAN HEAD

110133 #8-32 X 11/32 D HEX NUT

110258 FOOT RUBBER

Fig. 3Fig. 3

Fig. 3

Fig. 3Fig. 3

Q501

110650-8(4)

110671-4

Q443-1

Q502

110288-2

Q448-1

(QC216)

Q448-2

110476

110479(2)

110477-10(2)

110392

(QC72)

10407(2)

110529

110126

110511(4)

PARTS NO. DESCRIPTION

110288-2 SET SCREW, #8-32 X 1/8” LONG

110288-4 SET SCREW, #8-32 X 1/4” LONG

110290-14 SCREW 8-32 X 7/8 SHD CA P

110295-1 LOCK NUT, #8-32

110388-1 BUSHING STRAIN RELIEF STR.

110388 BUSHING STRAIN RELIEF ANG.

110392 SWITCH-TOGGLE ( ON-OFF)

110405 REST PAD

110407 SCREW, SHEET METAL

110433 SWITCH-TOGGLE ( ON-OFF)

110436 EXTERNAL HAIR COTTER PIN

110437 THUMB SCREW, #8-32 X 13/32” LONG

110476 TERMINAL STRI

110477-10 SCREW, #6- 32 X 5/8” LG. PAN HEAD

110479 LOCK WASHER, #6 INT. TOOTH

110489-30 STANDOFF, #8-32 X 1-7/8” LONG

110490-8 SCREW, #8-32 X 1/2” 82° FLAT HEAD

110492 #1/4-20 NYLON CA P NU

110502 NYLON PLUG

110505 NYLON WA SHE

110506-12 SHC SCREW #10-32 X 3/4”

110511 WASHER, 1/4” INT. LOCK

110512 WASHER, 1/4” EXT. LOCK

110529

110531

110542-6 8-32 X 3/8” HD NYLON

110650-8 SCREW HEX HD 1/4-20 X 1/2” LONG

110655-12 SCREW PHP 8-32 X 3/4"

110671-4 SET SCREW,CP 8-32 X 1/4" DRI-LOC

110674 BELT “V”

110863-10 SCREW PHP 8-32 X 5/8" SEMS FLAT WACHER

110950 SCREW PHP 8-32 X 3/8"

200038 BASE ASSEMBLY

200051 SPEED K NO B A SSY

110531

IR SW ITCH

IR PENDANT

Q442-3

110492(2)

110451(2)

110506-12(2)

Q424

Q616

Q454-3

110542-6

110388-1

110388

110950

110505(4)

110295-1(4)

Q456-1 (115 VAC)

Q456-2 (230 VAC)

200051

Q468-1 (115 VAC)

Q468-2 (230 VAC)

110405(2)

110405

200038

10437

110433

110671-4

110436

110674

Q448-5 (QC216)

Q448-4 (QC72)

Q463

110489-30

110863-10 (3)

110655-12

110049

110049 (2)

110258(4)

110502

110133(2)

110049(2)

1102

Loading...

Loading...