Page 1

PDS-100

Programmable Dispensing System

INSTRUCTION MANUAL

OVERVIEW

The PDS-100 is a precision system capable of

dispensing or pumping fluids ranging from 5 uL per

dispense or 15 uL/min continuous (Single RH00LF) up

to 1536 mL/min (Dual Q3) into pressures ranging from

10 psi (Q3) to 100 psi (RH). The PDS-100 offers

single, dual (in phase, out of phase and independent)

pump head control. PDS-100 offers RS485

communications, which allows the user to control the

PDS-100 via a PC or PLC. Dry contact inputs offer an

easy method to start and stop the pumps through the

use of a simple switch. The PDS-100 also offers inputs

which provide control of the dispense rate via a 0 – 10

VDC, 0 –5 VDC or 4–20 mA input.

A simple easy to use local keypad provides the user

access to local control of the pump or pumps and a

vivid display to provide user-friendly menus for ease of

control.

IN-PDS100-13A

11/1/13 HW

Page 1 of 18

Page 2

Smooth Flow Operation

The PDS Smooth Flow product differs from the “Standard” PDS-100 in

that the dual pumps have each been precisely calibrated to provide

equal dispenses per revolution. The distinct difference found in the PDS

Smooth Flow is in the method by which the pumps are driven.

Proprietary programming provides a unique method of control in such a

way as to provide a virtually pulseless output when both pumps are

connected to a “Y” or “Tee” fitting.

Most of the controls and screens are the same for the Smooth Flow as

shown in the previous pages with the exception that the pumps are not

individually controllable. Instead the pumps are controlled as though

they are one.

Menus, for the most part, are the same except while in dispense or

continuous mode the word “Smooth” will appear at the top of the main

screen. In addition you will see the word “Smooth Drive” when power is

first applied to the unit.

Fuse Location

Power Switch

FEATURES:

“Set and Forget” approach

1-9999 dispenses (adjustable)

Table top/wall mount

Universal power supply with standard IEC line

cord

CSA/UL, CE, RoHS compliant

Learn mode/count to allow customer to command

the PDS-100 to “remember” desired dispense

cycles needed to fill to a desired volume.

Prime Mode

Purge/Reverse Mode

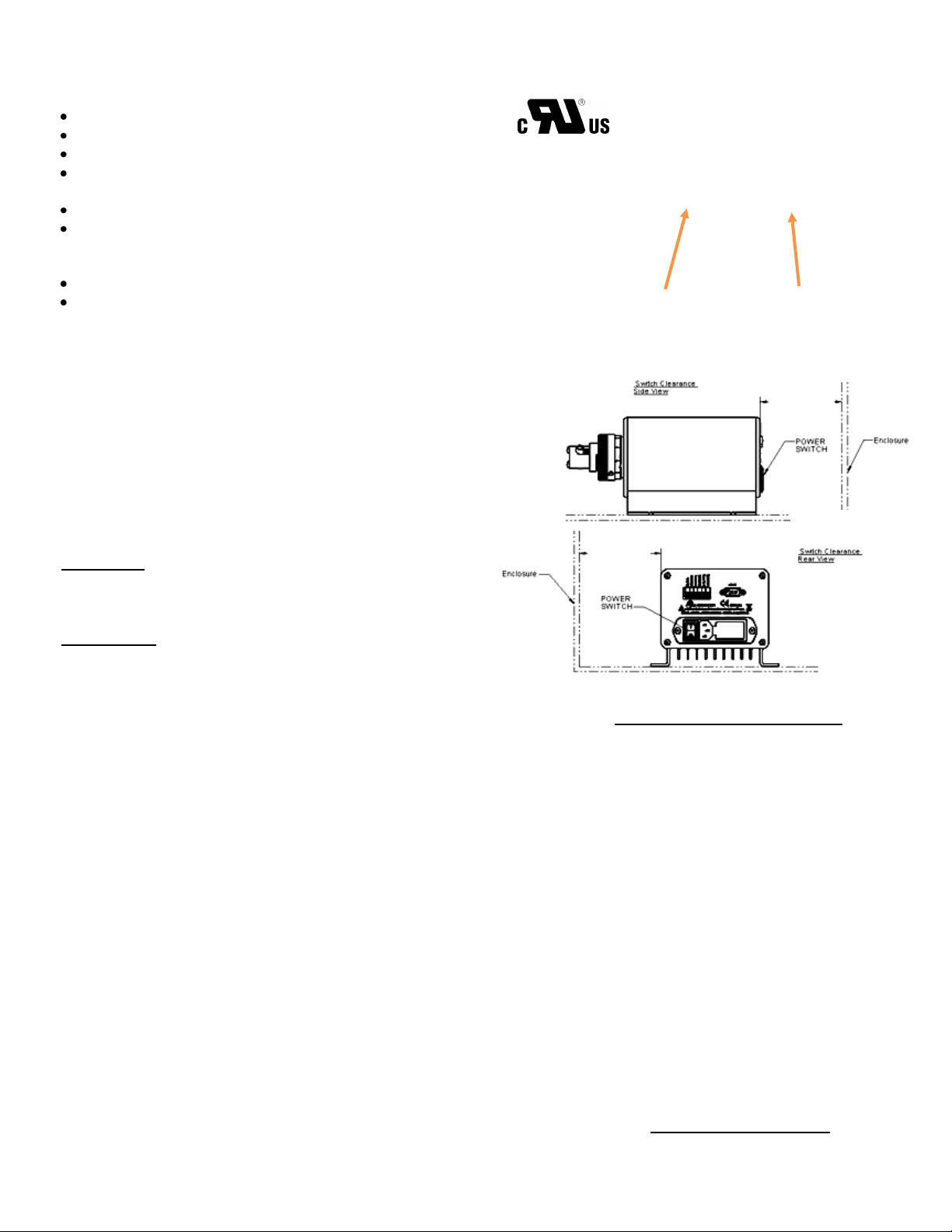

Table-top Mounting: The system is configured for table top

installation initially with rubber grommets slid into the mounting slots.

Before moving on to configuring the control module, make sure that

these rubber grommets are in place. There are no further installation

steps for table top use.

Wall-Mounting: For wall mounting, it is necessary to remove the

four rubber grommets from the control module before attempting to

mount. Each unit must be mounted in the correct orientation; with the

labels facing right side up, the control module will have the pumps at

the bottom. Wall mounting may require an appropriate mounting

board of at least 1/2”(12mm) thickness to straddle the studs of a

typical plasterboard wall. See Figure 3.

IMPORTANT When mounting PDS-100 in an enclosure it is

important to maintain a minimum clearance to provide adequate

space to reach the power switch. See figure 2.

Figure 1

PDS-100 Rear View

Figure 2

Minimum Power Switch Clearance

Figure 3

Required Mounting Pattern

Specifications

Supply Voltage: 100-240VAC +/- 10%, 50/60 Hz. Main Supply

Current: 0.6 to 0.25 Amps. Fuses: T250V-1A (time lag), 5x20mm, 2

required.

Physical: Dimensions: 5" H x 6 1/4" W x 12" (max) D; Weight: 7 lbs

Environment: For indoor use only. Humidity: 80% max for

temperatures up to 31°C, decreasing linearly to 50% relative humidity

at 40°C. Pollution degree, 2. Operating temperatures range from 5ºC

to 40ºC (41ºF to 104ºF).

4.0”

MINIMUM SIDE

CLEARANCE

REQUIRED

4.0”

MINIMUM REAR

CLEARANCE

REQUIRED

Switch Clearance

Rear View

IN-PDS100-13A

11/1/13 HW

Page 2 of 18

Page 3

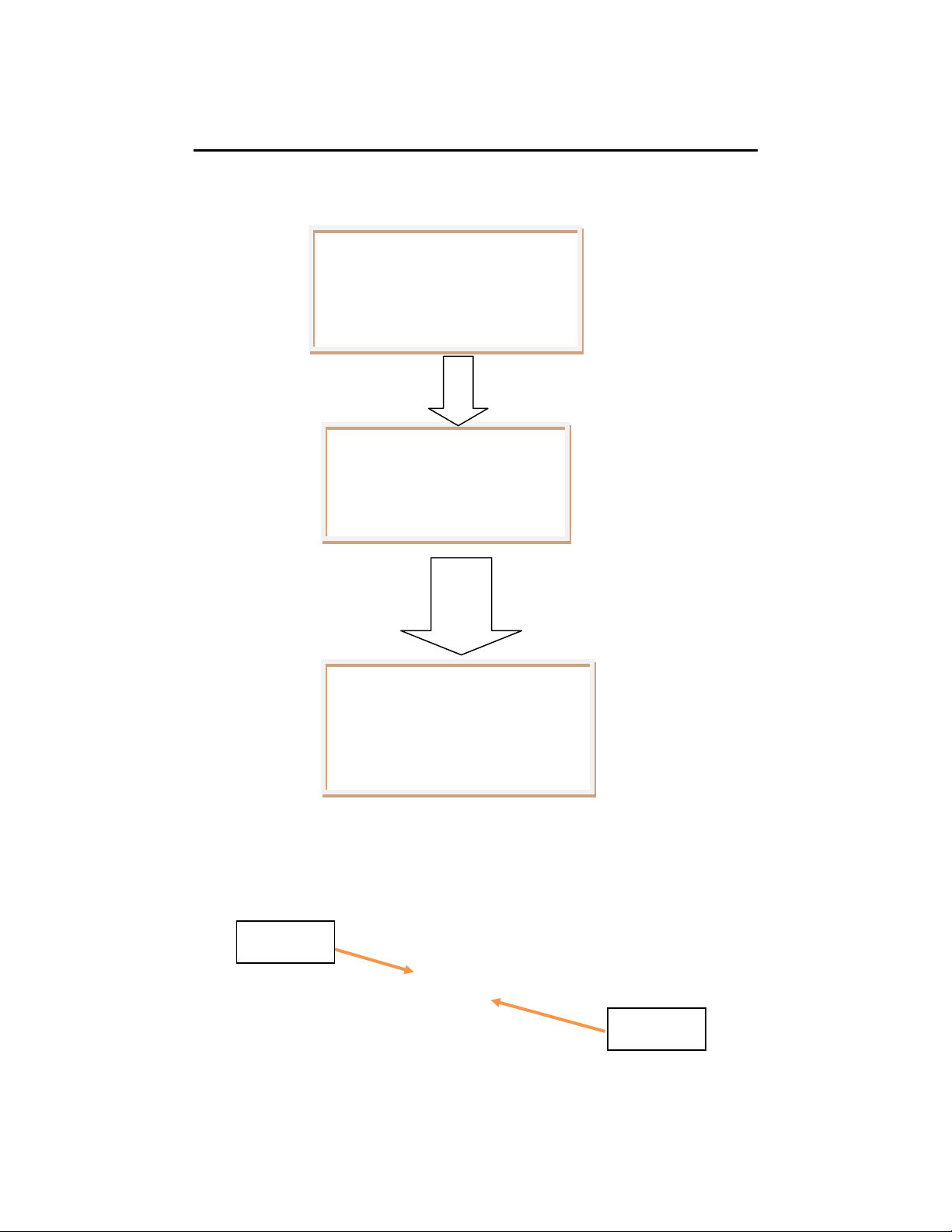

PDS-100

Duo Drive

Precision Dispenser

Software

Version

Pumps

home

Duo Mode

USE ARROWS TO SELECT

A = Dispense

B = Dispense

PRESS ‘ENTER’ TO ADJUST

Pump B

Pump A

IN-PDS100-13A

11/1/13 HW

Power Up Screens (two individually controlled pumps)

This is what will be seen on power up when the unit is configured for individually controlled

pumps (factory default). For Single pump configured system use “Pump A” screens only.

Figure 4

Pump A & Pump B Location

Page 3 of 18

Page 4

Setup A = Prime

‘ENTER’ FOR NEXT MENU

Speed = 200 rpm

Run = Start&Stop

USE ARROWS TO SELECT

Setup A = Purge

‘ENTER’ FOR NEXT MENU

Speed = 200 rpm

Run = Start&Stop

USE ARROWS TO SELECT

Setup A = Mode

‘ENTER’ FOR NEXT MENU

Mode = Dispense

Direction = CW

USE ARROWS TO SELECT

Setup A = Inputs

‘ENTER’ FOR NEXT MENU

Control = Keypad

Start = Keypad

USE ARROWS TO SELECT

Setup = RS485

‘ENTER’ FOR NEXT MENU

Interface = 2 Wire

Device Addr. = 5

USE ARROWS TO SELECT

IN-PDS100-13A

11/1/13 HW

Setup Screens (two individually controlled pumps)

Prime/Purge, Mode & Input Setup Screens

To select “Prime/Purge, Mode & Input Setup” screen wait for the pumps to home then press the

up up/down arrow to select desired pump (A or B: see figure 4) and then press the Setup

button. The following screens are available. Pressing enter will go to each screen.

Pressing the up or down arrow will select additional items.

***Factory default values shown***

Only appears if RS485 is selected

for Control mode and/or Start mode

on previous (Inputs) screen.

Page 4 of 18

Page 5

Setup Screens (two individually controlled pumps) cont’d:

Setup A = Prime

‘ENTER’ FOR NEXT MENU

Speed = 200 rpm

Run = Start&Stop

USE ARROWS TO SELECT

Setup A = Purge

‘ENTER’ FOR NEXT MENU

Speed = 200 rpm

Run = Start&Stop

USE ARROWS TO SELECT

IN-PDS100-13A

11/1/13 HW

Prime/Purge adjust and activation

Prime and Purge have the following available settings.

***Factory default values shown***

Speed (7 – 749 RPM for the STH & RH and 7 – 599 RPM for the STQ &

STQP)

Run

1. Run = “Start&Stop”. Start prime/purge via keypad “Run” and

stop prime/purge via “Stop”

2. Run = “Ext. Switch”. Start prime/purge via external switch.

Pump will continue to prime/purge until switch is released.

Switch A activates pump A and Switch B activates pump B.

3. Run – “Start&Hold”. Start prime/purge via keypad “Run”.

Prime/purge will continue until the Run button is released.

To adjust either the speed or run method simply press the up or down arrow

keys to go to the desired item and then press the enter key to select. To set the

speed press the up/down arrow keys until the desired speed is shown. Press

enter key to save. To set the desired run method press the up/down

arrow keys until the desired run method is shown. Press enter key to save. To

start the Prime/Purge process use the device chosen (Keypad run button or external

switch). To exit setup press the setup key and the motor(s) will automatically home

or press the enter key to go to the next setup screen.

Page 5 of 18

Page 6

Setup Screens (two individually controlled pumps) cont’d: Mode

Setup A = Mode

‘ENTER’ FOR NEXT MENU

Mode = Dispense

Direction = CW

USE ARROWS TO SELECT

IN-PDS100-13A

11/1/13 HW

and direction adjust

Mode has the following available settings for direction.

***Factory default values shown***

Mode

o Continuous (pump will run until a Stop command is given).

o Dispense (pump will run until a Stop command is given or the

programmed dispenses is reached)

Direction

o CW

o CCW

NOTE: When operating in dual pump mode, the direction will

change both pumps. Independent direction control is not available.

To adjust either the mode or direction simply press the up or down arrow keys

to go to the desired item and then press the enter key to select. To set the mode

press the up/down arrow keys until the desired mode is shown. Press the enter

key to save. To set the desired direction press the up/down arrow keys

until the desired direction is shown. Press the enter key to save. To exit setup

press the setup key and the motor(s) will automatically home or press the enter

key to go to the next setup screen.

Page 6 of 18

Page 7

Setup A = Inputs

‘ENTER’ FOR NEXT MENU

Control = Keypad

Start = Keypad

USE ARROWS TO SELECT

IN-PDS100-13A

11/1/13 HW

Setup Screens (two individually controlled pumps) cont’d:

Control and start method

Input has the following available settings for Input control type and start method.

***Factory default values shown***

Control (Speed). Speed can be adjusted prior to run command from

one of the following 5 options listed below:

o RS485

o 4-20 mA

o 0-10 V. (VDC)

o 0-5 V. (VDC)

o Keypad. The pump speed can be adjusted via the keypad

up/down arrow keys.

Start. The pumps can be activated (started) from one of the following 5

options listed below:

o RS485

o Analog (pump(s) will start when a voltage is applied to the

pump(s) Analog Input(s) based on Table 2, pg. 12.

o Power Up: The pumps will start to dispense/meter after power is

applied. Note: The pumps initially “home” prior to starting the

dispense/metering process. In dispense mode the pumps will

stop rotating once the desired dispense count is reached. The

keypad stop button can also activate a stop command.

o Switch. Momentary closure will activate a pump in dispense

mode. In continuous mode the pumps will only rotate while the

switch is closed. Upon switch removal the pumps will complete

rotating until “home” is reached.

To adjust either the control method or start method simply press the up or down

To set the control method press the up/down arrow keys until the desired

control method is shown. Press the enter key to save. To set the start method

press the up/down arrow keys until the desired start method is shown. Press

the enter key to save. To exit setup press the setup key and the motor(s) will

automatically home or press the enter key to go to next setup screen.

o Keypad. The pump will start when the keypad start key is

pressed and stop when the stop key is pressed.

arrow keys to go to the desired item and then press the enter key.

Page 7 of 18

Page 8

Setup = RS485

‘ENTER’ FOR NEXT MENU

Interface = 2 Wire

Device Addr. = 5

USE ARROWS TO SELECT

IN-PDS100-13A

11/1/13 HW

Setup Screens (two individually controlled pumps) cont’d

RS485 setup

RS485 has the following available settings for Interface & Device Address

***Factory default values shown***

Interface. 2 wire or 4 wire

Device Address. Up to 31 (address #1 to #31) units can be

independently addressed.

To adjust either the interface type or device address simply press the up or down

arrow keys to go to the desired item and then press the enter key. To set the

interface type press the up/down arrow keys until the desired control method is

shown. Press the enter key to save. To set the Device Address press the up/down

arrow keys until the desired address is shown. Press the enter key to

save. The address selected applies to both pumps in a dual pump system. To exit setup

press the setup key and the motor(s) will automatically home or press the enter

key to go to the next setup screen.

Page 8 of 18

Page 9

Duo Mode

USE ARROWS TO SELECT

A = Dispense

B = Dispense

PRESS ‘ENTER’ TO ADJUST

A=Dispense

USE ENTER WHEN FINISHED

Speed = 200 rpm

Strokes = 10

USE ARROWS TO ADJUST

A=Dispense

USE ENTER WHEN FINISHED

Speed = 200 rpm

Strokes = 10

USE ARROWS TO ADJUST

Duo Mode

USE ARROWS TO SELECT

A = Dispense

B = Dispense

PRESS ‘ENTER’ TO ADJUST

IN-PDS100-13A

11/1/13 HW

Main Screen (both pumps in dispense mode): Speed/Strokes

adjust via keypad

Press the up/down arrow keys then

the enter key to adjust the desired pump

Speed can be adjusted based on the control type selected from the Input Setup section in the

manual. By default the PDS-100 is configured for Keypad Control and Keypad Start.

To adjust the speed press the up arrow key and then press the enter key. Press the

up/down arrow keys to adjust and then press the enter key when finished to save.

To adjust the number of strokes press the down arrow and then press the enter key.

Press the up/down arrow keys to adjust and then press the enter key when

finished to save. Press the enter key one final time to go back to the main screen.

Page 9 of 18

Page 10

Main Screen (Pump A in continuous mode &

Duo Mode

USE ARROWS TO SELECT

A = Continuous

B = Dispense

PRESS ‘ENTER’ TO ADJUST

A = Continuous

USE ENTER WHEN FINISHED

Speed = 200 rpm

Control = Keypad

USE ARROWS TO ADJUST

Duo Mode

USE ARROWS TO SELECT

A = Continuous

B = Dispense

PRESS ‘ENTER’ TO ADJUST

A = Continuous

WAITING FOR START KEY

Analog = 200 rpm

Control = 0-5 v.

IN-PDS100-13A

11/1/13 HW

Pump B in Dispense mode): Speed adjust from external source

Press the up/down arrow keys

then press the enter key to adjust the

desired pump

To adjust the speed press the up/down arrow keys until the desired speed is set. Notice

how the speed immediately begins to adjust. To save press the enter key. The unit returns

to main screen

If the unit has been configured for other forms of speed control other then Keypad then the speed

can only be set by that type of control. For example, if the speed control is set for 0-5 V then the

following screen will be seen.

Page 10 of 18

Page 11

Analog Input Connector and Specifications

Signal

Description

Shield

Cable shield (terminate one end only)

Common

Ground

Switch A

Activates Prime, Purge and Start for Pump A

when connected to Common and configured as

such (TTL open collector or dry contact)

Switch B

Activates Prime, Purge and Start for Pump B

when connected to Common and configured as

such (TTL open collector or dry contact)

Analog A

Controls the speed of Pump A via an external

voltage or current when configured as such

Analog B

Controls the speed of Pump B via an external

voltage or current when configured as such

Analog/Switch Input

Terminal Strip

IN-PDS100-13A

11/1/13 HW

The PDS-100 incorporates a simple screwless (spring loaded) terminal strip (see figure 6) for

easy wire (22 to 14 AWG) connection to an external control source such as a PLC. It is

recommended that a DIN wire ferrule be used (See figure 5).

Figure 5

Wire Ferrule

Figure 6

Analog Pump Control Connector (Rear Panel)

Table 1

Analog/Switch Input Connector

Page 11 of 18

Page 12

Analog Input Connector and Specifications (cont’d)

RPM

4 - 20 (mA)

Input

resistance

490 ohms

(note 3,1,4)

0 - 5 (VDC)

(note 2,1)

0.5 - 10

(VDC)

(note 2,1)

Analog Input

Min

Max

Min

Max

Min

Max

Min

Max

4 - 20 mA

0 - 5 VDC

0 - 10 VDC

Standard H Pump

6

750

1.6 20 0.2 5 0.2 10

See Waveforms 1 to 9

Standard Q Pump

600

Standard STQP

Pump

700

IN-PDS100-13A

11/1/13 HW

Figure 7

Input Resistance Schematic (Analog input: 0 – 5 VDC or 0 – 10 VDC)

Table 2

Input Voltage/Current versus RPM

Note 1: Maximum current is reduced provided control method is set according to actual

input method (ie 0 – 5 VDC or 0 – 10 VDC). If desired control method is set for

“4–20mA” but a 0 – 5 VDC or 0 – 10 VDC is applied the maximum current will be

at its greatest.

Note 2: Absolute maximum input voltage is 10.8 VDC

Note 3: Absolute maximum current is 22 mA

When start/stop is controlled via the analog input the pump(s) will stop when the analog input

goes below the minimum voltage/current. The pumps will run when the minimum voltage/current

is reached and will run at the minimum speed.

Page 12 of 18

Page 13

RS485 Connector Pin, command set and specifications

Pin On DB9

Male

Connector

Signal

EIA/TIA-485 name

8

RXD0

A’

4

RXD1

B’

5

TXD1 B 9

TXD0 A 1

Common

C/C’

Pin On DB9

Male

Connector

Signal

EIA/TIA-485 name

5

D1

B | B’

9

D0

A | A'

1

Common

C | C’

RS485 DB9 Male

Connector

(2 wire)

(4 wire)

Important: For all industrial environments, it is recommended that an isolation /surge protection adapter

be used to protect the PDS-100 from external high voltages (for example: Aaxeon UTS-401B-SI.)

IN-PDS100-13A

11/1/13 HW

Figure 8

RS485 Control (Rear Panel)

Figure 9

RS485 Control (Rear Panel)

Table 3

RS485 DB9 pin out assignments

PDS-100 follows the guidelines per MODBUS over Serial Line protocol

Port Settings

Baud Rate 19,200

Stop Bits 1

Data Bits 8

Parity Even

Page 13 of 18

Page 14

RS485 Connector Pin, command set and specifications (cont’d)

DRIVE

CODE

Single (RH)

16384

Single (STH)

16385

Single (STQ)

16386

Single (STQP)

16387

Individual (RH)

49152

Individual (STH)

49153

Individual (STQ)

49154

Individual (STQP)

49155

In phase (RH)

49664

In phase (STH)

49665

In phase (STQ)

49666

In phase (STQP)

49667

Out of phase (RH)

50688

Out of phase (STH)

50689

Out of phase (STQ)

50690

Out of phase (STQP)

50691

Smooth (RH)

52736

Smooth (STH)

52737

Smooth (STQ)

52738

Smooth (STQP)

52739

Configuration Table

IN-PDS100-13A

11/1/13 HW

Note: PDS-100 accommodates up to 31 addressable units.

Command Mapping

Single bit read and write. Set bit to initiate action, PDS-100 will clear bit upon execution

Coil 0 = "start" > Pump A – (all configurations except individual – individual pump A only)

Coil 1 = "stop" > Pump A – (all configurations except individual – individual pump A only)

Coil 2 = “start-2" > Pump B – (individual configuration only)

Coil 3 = "stop-2" > Pump B – (individual configuration only)

Single bit status, read only

Input 0 = "busy" > Pump A – (all configurations except individual – individual pump A only)

Input 1 = "error” > Pump A – (all configurations except individual – individual pump A only)

Input 2 = "busy-2" > Pump B – (individual configuration only)

Input 3 = "error-2" > Pump B – (individual configuration only)

16 bit word read and write. Not allowed to change when pump is busy

Holding Register 0 = "rpm" > Pump A

Holding Register 1 = "stroke count" > Pump A

Holding Register 2 = "rpm-2" > Pump B

Holding Register 3 = "stroke count-2" > Pump B

16 bit word information read only

Input Register 0 = "configuration" *see configuration table

Input Register 1 = "operating mode" 0=continuous, 1=dispense

Input Register 2 = "operating mode-2" 0=continuous, 1=dispense

Input Register 3 = "error code" 0= no error, 1= error

Input Register 4 = "error code-2" 0= no error, 1= error

Input Register 5 = "minimum-speed"

Input Register 6 = "maximum-speed"

Page 14 of 18

Page 15

PDS-100

Configuration

Setup

Software

Version

Setup = Mode

‘ENTER’ FOR NEXT MENU

Pump = RH

Drive = Out Phase

USE ARROWS TO SELECT

IN-PDS100-13A

11/1/13 HW

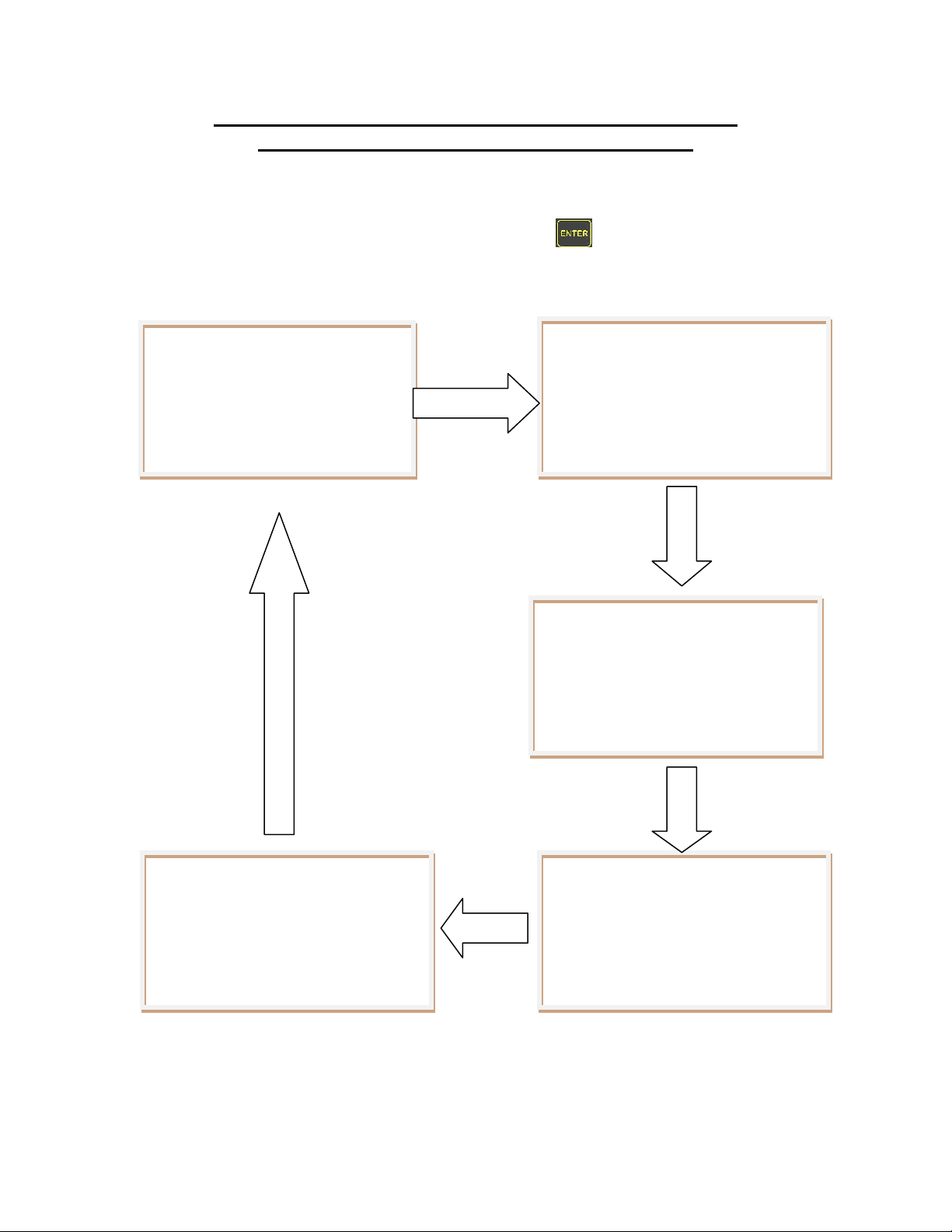

Configuration Modes Screens

(Appears when Up Arrow and setup Keys are held down while powering up unit)

The unit comes pre-configured as a Dual Individual system when purchased as a dual pump

system. To configure the dual pump system for “In Phase” operation or “Out Phase” operation

follow the procedure mentioned above to modify. If the unit supplied is a single pump system

there is no need to change the configuration.

Possible drive configurations types supported (configured by factory):

1. Single: Single pump.

* 2. Individual: Two pumps that can be controlled independently

3. In Phase: Two pumps that are in phase with each other.

4. Out of Phase: Two pumps that run 180 degrees out of phase for each other.

5. Smooth: Requires factory calibrated pump drive assembly. Not covered in this

manual.

* Default Setting

The following screens will be seen when entering the configuration mode. The configuration

mode can only be entered if the up arrow key and setup keys are held down while

powering on the unit. After configuration selection is made, power down and then restart the unit

for changes to take effect.

Page 15 of 18

Page 16

Table 4

Pump Operating Parameters

Waveform Graphs 1 - 9

Waveform #1

Waveform #2

IN-PDS100-13A

11/1/13 HW

Page 16 of 18

Page 17

Waveform #3

Waveform #4

Waveform #5

Waveform #6

IN-PDS100-13A

11/1/13 HW

Page 17 of 18

Page 18

Waveform #7

Waveform #8

Waveform #9

IN-PDS100-13A

11/1/13 HW

Page 18 of 18

Loading...

Loading...