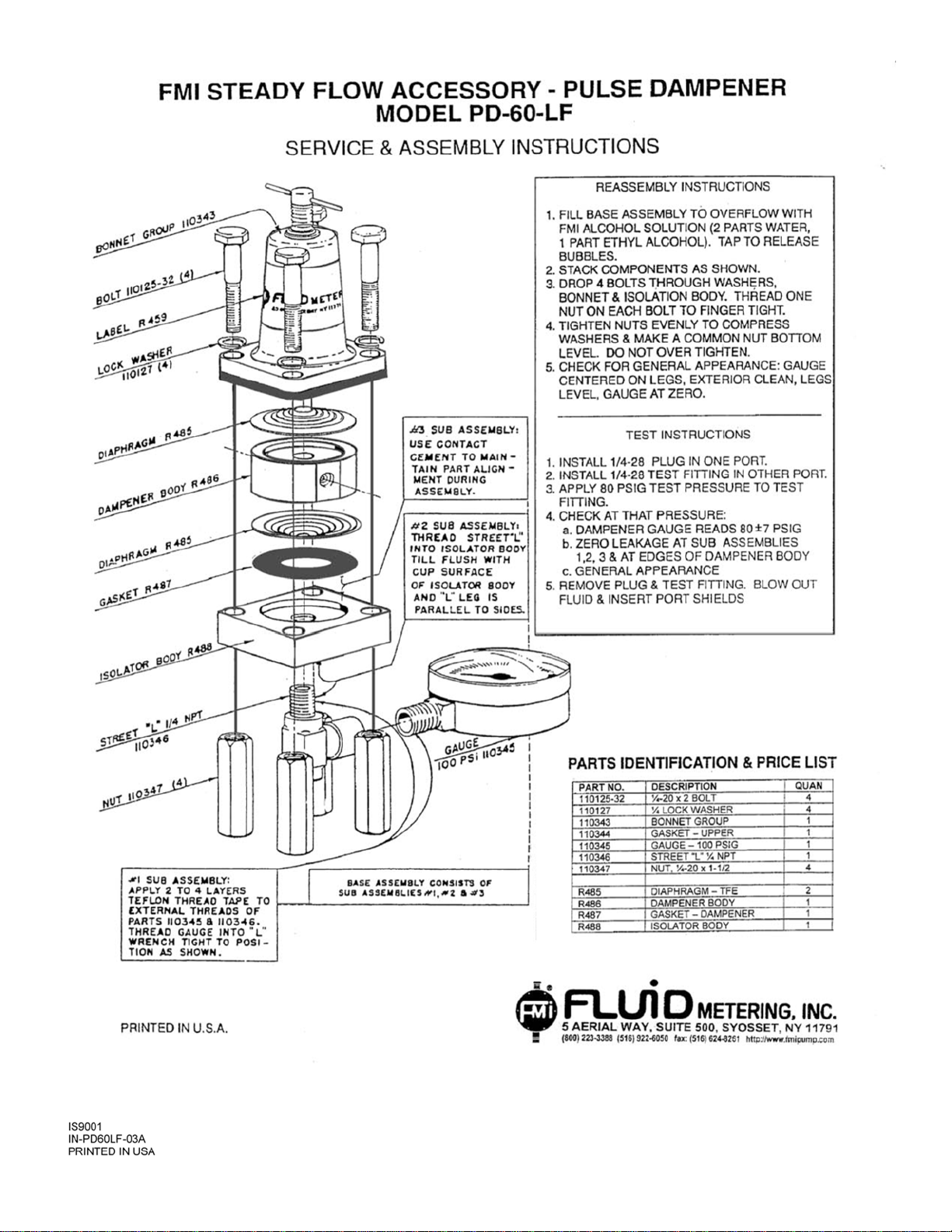

Page 1

FMI PULSE DAMPENER PD-60-LF

INSTALLATION & OPERATION INSTRUCTIONS

The FMI steady flow accessory is designed to effectively suppress

approximately 90% of the pulse magnitude generated by piston type

metering pumps operating at flow rates up to 50 ml/min and stroke

rates up to 150 per minute against head pressures of 10 to 65 psig.

It features low internal volume, isolated pressure gauge, corrosion

resistant wetted parts of type 316 stainless steel and TFE, flowthrough (self purging) design, excellent reduction of base line drift

and noise in feeding low-pressure liquid chromatographic systems,

all in a small (2.7” X 5” X 6” high), lightweight (1.6 pounds net) package arranged to accept standard ¼-28 tubing accessories.

1. CIRCUIT LOCATION: The FMI PD-60-LF Pulse Dampener is

designed for flow-through installation in the tubing line between a

pulse source (pump) and a system load (chromatography column, spray nozzle or other). Figure 1 illustrates a typical liquid

chromatography circuit employing the FMI PD-60-LF Pulse

Dampener.

2. CONNECTION: The FMI PD-60-LF Pulse Dampener is threaded

to accept standard (1/4-28 thread) fittings for small bore laboratory tubing. Care should be taken to avoid damage to the fine

threads in the Dampener Body when applying fittings. Fittings

should be screwed into the threaded holes of the Dampener

Body finger tight plus ¼ turn wrench tight.

3. PREPARATION: Before operating an FMI PD-60-LF Pulse

Dampener in a circuit application, it is advisable to flush interior

fluid passages of the dampener for a few minutes with system

fluid to remove fluid residues that may remain from earlier usage

or factory test.

4. TUNING: The FMI PD-60-LF Pulse Dampener is tuned to system operating conditions by turning the handle clockwise (down)

to stop position and, with the pump running, permitting the pressure to build up to a level of consistent sequential pulses as will

be noted in repeated fluctuation of the pressure gauge needle.

The handle is then turned slowly in the counterclockwise (up) direction until the gauge needle fluctuations suddenly diminish in

magnitude. At that point, pulse suppression is roughly adequate

for most system applications. Fine tuning for critical applications

may be accomplished by carefully turning the handle up and

down in small increments from that first point of pulse suppression until the point at which the smallest gauge needle fluctuation

is found: this is the optimum adjustment position for the specific

circuit hook-up involved.

5. STORAGE: When and FMI PD-60-LF Pulse Dampener is to be

stored, it is recommended that the control handle be turned

counterclockwise (up) until loose in its threads. This relieves

spring pressure on the diaphragms (the best storage condition)

and permits low pressure flush cleaning, which should be done

before storage.

IS9001

IN-PD60LF-03A

PRINTED IN USA

Page 2

Loading...

Loading...